Highlights

-

•

Insights into the impact of COVID-19 outbreak on automobile and airline supply chain is provided.

-

•

Integrated time-to-recovery and financial impact analysis, empirical survey and semi-structured interviews were used.

-

•

Localized supply sources and industry 4.0 technologies identified as significant strategies by automobile industry.

-

•

Business continuity by defining operations at the airport and flights perceived significant strategy by airline industry.

-

•

Real-time information sharing and cooperation among supply chain stakeholders is critical.

Keywords: Covid-19, Supply chain resilience, Supply chain risk, Airline, Automobile, Financial impact

Abstract

There has been an increased interest among scholars to investigate supply chain resilience (SCRes) in manufacturing and service operations during emerging situations. Grounded in the SCRes theory, this study provides insights into the impact of the COVID-19 outbreak on the automobile and airline supply chain. Both the short and long-term response strategies adopted by the two supply chains are assessed, using a combination of qualitative and quantitative techniques in three distinct phases. In phase one, we use a sequential mixed-method for resilience evaluation, integrating Time-to-Recovery (TTR) and Financial Impact (FI) analysis. In phase two, we conduct an empirical survey involving 145 firms to evaluate the short-term SCRes response strategies. In the third phase, we conduct semi-structured interviews with supply chain executives both from the automobile and airline industries to understand the long-term SCRes response strategies. Our findings indicate that: (i) the automobile industry perceived that the best strategies to mitigate risks related to COVID-19, were to develop localized supply sources and use advanced industry 4.0 (I4.0) technologies. (ii) The airline industry on the other hand, perceived that the immediate need was to get ready for business continuity challenges posed by COVID-19, by defining their operations both at the airports and within the flights. (iii) Importantly, both the sectors perceived Big Data Analytics (BDA) to play a significant role by providing real-time information on various supply chain activities to overcome the challenges posed by COVID-19. (iv) Cooperation among supply chain stakeholders is perceived, as needed to overcome the challenges of the pandemic, and to accelerate the use of digital technologies.

1. Introduction

The ongoing Coronavirus disease (COVID-19), caused by the SARS-CoV-2 virus, was first identified in December 2019 in the Chinese city of Wuhan, and was declared a global pandemic by the World Health Organization (WHO) on March 11, 2020 (Lai et al., 2020). Since then, the pandemic has rapidly spread beyond China to almost every country on the globe. COVID-19 has affected millions of people, with several thousands of deaths in all states and territories around the world (WHO, 2020). Governments worldwide have increasingly undertaken an inhibition strategy to contend the outbreak, relying on widening social distancing, wearing masks, especially in public places and transport, along with various other measures in order to reverse the pandemic growth, and thereby manage the resilience of the healthcare systems. Notably, these measures in turn have often resulted in stricter border restrictions and complete nationwide lockdowns, and in the process thereby, causing a negative short-term impact on consumer spending, investments, and disruptions to international trade and global supply chains (Kumar and Managi, 2020).

Building supply chain resilience (SCRes) to COVID-19 has already attracted a great deal of attention from scholars today (Kumar and Managi, 2020; Ivanov and Dolgui, 2020). Several researchers and practitioners have been calling for an enhanced supply chain management, capable of dealing with the severe disruptions caused by the raging pandemic (Jacobsen, 2020). Large global supply chains, including the ones from the manufacturing sectors (i.e. automobile, electronics, pharmaceutical etc.) and service sectors (i.e. airline, retail suppliers, transportations etc.), have been substantially impacted because of their high dependence on China as a global supply chain partner over the past two decades. For instance, Wuhan, the focal point of the COVID-19 outbreak, is a major auto-component manufacturing hub that supplies essential components to global automobile manufacturers, such as Volkswagen, General Motors, Hyundai, and Toyota (Kumar and Managi, 2020; Sharma et al., 2020). Several suppliers based in the Wuhan car factory hub have already warned their global clients for its inability to deliver parts due to plant closures and other knock-on effects (LMC, 2020). Nevertheless, despite the ripple effect spreading worldwide, there exists little data-driven evidence to guide the global supply chains to become resilient against the disruptions caused by COVID-19, as it is relatively a new phenomenon; thus, the long-term impact remains uncertain (Yoo and Managi, 2020).

However, during black swan events, such as the COVID-19 outbreak, a clear understanding of the short and long-term implications and reasonable risk assessments are of paramount importance (Nakamura and Managi, 2020a). This would enable organizations establish suitable response and mitigation strategies (Kochan and Nowicki, 2019). So far, the amount of uncertainty and subjectivity associated with the impact of the current outbreak on the supply-chain, makes it difficult to fully ascertain the risk scenarios and develop effective response strategies thereof, particularly in the long-term (Kumar and Managi, 2020; Ivanov and Dolgui, 2020).

There is a timely motivation to investigate SCRes in both manufacturing and service supply chains in this uncertain situation. This study's primary purpose is to acquire in-depth insights into quantifying the current impact of the COVID-19 pandemic, and identify significant response strategies both in the short and long-term for developing resilient supply chains. Thus, this study is an effort towards assisting both manufacturing and service supply-chain practitioners in building SCRes to manage similar disruptions (i.e. COVID-19) by addressing two main research questions (RQs):

RQ1: What is the level of resilience of manufacturing and service supply chains against the COVID-19 outbreak?

RQ2: What are the short and long-term risk mitigation response strategies to manage COVID-19 disruptions in developing resilient supply chains?

In answering these RQs, we draw upon the SCRes theory perspective to guide the pursued research methodology. First, we evaluate SCRes of the selected supply chains against the COVID-19 outbreak, using an integrated Time to Recovery (TTR) and Financial Impact (FI) evaluation technique. Second, we explore the short-term response strategies adopted by the selected supply chain, using an empirical survey that includes 145 firms from the automobile and airline industry. Third, we discuss the long-term SCRes strategies to mitigate the COVID-19 disruptions, based on structured interviews with experts from the automobile and airline industry.

Our contribution is twofold: first, we advance literature on SCRes by proposing a conceptual framework for manufacturing and service supply chains. Our proposed framework incorporates the levels of SCRes, using an integrated evaluation technique, along with exploring and categorizing response strategies both in the short and long-term. Second, we provide empirical validation on how manufacturing and service supply chains respond to the impact of COVID-19. We believe that this would guide practitioners, policy-makers, along with other decision-makers in developing effective response strategies during and post-pandemic situations.

2. Theoretical background and literature review

2.1. Global manufacturing and services supply chain under COVID-19 outbreak

According to Ivanov and Dolgui (2020), the COVID-19 pandemic has been one of the most severe supply-chain disruptors in recent history, and is likely to weaken many organizations and supply-chains globally. In an attempt to contain the spread of the virus, most governments around the world responded by implementing human containment measures, border closures, and quarantines with varying degrees (Ivanov and Dolgui, 2020). This global response has severely impacted the global supply-chain operations (Ivanov and Dolgui, 2020). The National Association of Manufacturers (NAM) conducted a survey on its 558 US member companies on the impact of the COVID-19, and found that more than 78 percent of its members expected a severe financial impact due to the uncertainty caused by the pandemic on their businesses (NAM, 2020). Another study by PwC reports that 87 percent of cross-industry companies both in Mexico and the US are very concerned about the disastrous impact of the pandemic (PwC, 2020). Baldwin and Tomiura (2020) predict that the financial impact caused by COVID-19 on the manufacturing sector alone, would almost be threefold. They elaborate that the notable first is that the disease's concentration is primarily on the manufacturing heartland of the world (East Asia), and its spread to other industrial powerhouses in the US and European Union (EU) would thereby create direct and massive supply disruptions (in fact, this has already happened). Second, these immediate supply disruptions would cascade down to other manufacturing sectors in less-affected countries due to the supply-chain contagion effect. Third, the macroeconomic declines in aggregate demand, along with investment delays by companies, would undoubtedly generate demand disruptions.

While the extent and cost of this outbreak pandemic are still unrecognized, we do know that global supply-chains that link the world to China and other manufacturing hubs would be seriously disturbed (Nakamura and Managi, 2020b). Accordingly, both the vulnerability and complexity of supply-chains would spread and trigger the pandemic's effect even far from the pandemic's hotspots. China's large share in the global trade, and its integration into the global supply-chains, has magnified the economic spillovers to other less-affected countries. Even if the peak of the outbreak proves to be short-lived, with a gradual recovery in output and demand over the next few months, it would still exert a substantial drag on global growth in 2020 (OCED, 2020). Preliminary forecasts confirm that no business sector would be immune from the effect of the pandemic. Given the economic importance, sizeable demand and supply shocks would not be uniform through businesses and industries. The impact of COVID-19 on different business sectors would vary due to the differences in demand and supply patterns (Sharma et al., 2020). For instance, service companies that depend heavily on movement, such as travel, would be the first to be affected. In contrast, some others, such as retail, could observe a demand contraction, but would still be relatively self-contained. We thereby expect that the response strategies used to mitigate the supply chain risks caused by the ongoing pandemic would also be different.

2.2. Importance of automobile and airlines industries in the global supply chains

2.2.1. Impact of COVID-19 on the automobile industry

The automotive industry makes up the majority share in the manufacturing sector in a country's economy. It contributes positively to employment generation and is considered as a flagship bearer, and a useful barometer that measures the current wealth of the international economy (Kamble et al., 2020a; Gopal and Thakkar, 2016). For example, the UK's annual turnover of the automobile industry is over £82bn, adding a significant £18.6bn to the economy, while employing over 823,000 personnel across the wider automotive sector (Vine, 2020). Major automobile companies have been cutting jobs with decreasing sales, owed to the ongoing pandemic. Aston Martin Lagonda Global Holdings Plc for instance, announced the downsizing of its workforce by 20% (Philip, 2020). Government-imposed lockdown restrictions across the EU has forced the closure of several factories and showrooms since March 2020, as the potential car buyers have been locked at home. These closures have even forced vehicle distributors such as Lookers Plc to close down its 12 site operations and lay off 1500 employees. By and large, sales have declined by almost 89 percent in the UK as compared to the previous year in the same month (Philip, 2020).

The raging pandemic has brought the aspirations of major automobile companies' to a grinding halt. This includes the halt of $1.6 billion Mazda-Toyota joint-venture project, construction of multiple projects by Fiat Chrysler Automobiles in Detroit, and $740 million projects by Ford Motor Co. to renovate an old Detroit train station. Additionally, the manufacturing plants of General Motors have slowed due to the safety and lockdown protocols, such as temperature screening before entering the site, wearing medical-grade masks, and social distancing (Automotive News, 2020). According to Childerhouse et al. (2003), the auto industry has traditionally been playing an influential role, and providing lessons to some of the other sectors because of their accumulated experience in managing supply chain disruptions. Therefore, studying such a critical supply chain's response in managing disruptions caused by COVID-19, may offer an illustration to build resilience in the manufacturing supply chain at large.

2.2.2. Impact of COVID-19 on the airline industry

The airline industry on the other hand, has faced many threats throughout history, but none appear as severe as the one posed by the spread of COVID-19 (Amankwah-Amoah, 2020). Experts believe that the airline sector's recovery to normal levels would take at least six more years. The airline labor is bearing the major brunt with declining sales and looming uncertainty. This industry has witnessed a significant job loss of nearly 7–13 percent. Interestingly, there has been a higher impact in terms of job loss in larger airlines, while smaller airlines have faced lesser brunt (Sobieralski, 2020). According to an estimate by Bloomberg, about 400,000 airline workers have been fired, furloughed, or informed that they might lose their jobs due to the ongoing disruption. Almost all the major airlines such as British Airways, Deutsche Lufthansa AG, American Airlines, Delta Airlines, Emirates Airlines, and Qantas Airways Ltd have announced job cuts and unpaid leave regimes (Kotoky et al., 2020). Airlines today, have no other option than to minimize their flight operations due to border restrictions, fear of being infected, and to spend lengthy periods under quarantine. Further, the other dependent industries, such as the hotel and lodging sector, have seen a significant impact on the airline industry's job loss. According to the International Air Transport Association (IATA 2020a) there are 7.5 jobs lost for everyone in the aviation sector.

Further, according to Belobaba et al. (2015), the airlines industry generally attracts a great deal of attention from organizations that are directly involved in its supply chain, along with government policy-makers. The focus on the airline industry not only stems from its strong position on the international economy, but also from the impact it has on several other sectors, such as aircraft manufacturing, manufacturing of goods (air cargo), automobiles sales (alternate travel mode), and tourism (air travel) (Martin et al., 2020). Hence, studying the airline industry's mitigation strategies during the COVID-19 pandemic is indeed of great importance in building SCRes.

The information furnished thus far, characterizes both automobile and airline supply chains as complex and dynamic industries that are both capital and labor-intensive, and involve many dependent ancillaries. Disruption of these supply chains does put a significant portion of the global supply chain and economy under threat. A recent CRISIL (2020) report has identified gems and jewelry, steel, real estate, automobile, and airline industry to have a high impact on the COVID-19 pandemic due to their low resilience. In contrast, fertilizers, pharmaceuticals, food, FMCG, and telecom sectors are believed to have a low impact due to their high resilience (Martin et al., 2020). Hence, building SCRes in the automobile and airline sector is of particular interest, and is expected to provide valuable lessons to the other manufacturing and service supply chains coping with the ongoing disruptions. While the resilience of both the automobile and airline supply chains has attracted significant attention in recent times, extant literature lacks empirical investigations in building SCRes, and has not addressed global supply chain impact (Rose et al., 2017). The need to put forward the measures needed to sustain and strengthen both the manufacturing and service supply chains under the threat of COVID-19, acts as a timely motivation for the present study.

2.3. Supply chain resilience (SCRes) evaluation and strategies

Supply Chain Resilience (SCRes) refers to the supply chains' ability to prevent and absorb changes, and regain the initial performance level after an unexpected disturbance (Hendry et al., 2019). Much of the past work on SCRes relates to the quantification of resilience level before developing both response and recovery (Hosseini et al., 2019; Graveline and Grémont, 2017; Ivanov et al., 2017; Chowdhury and Quaddus, 2016). In the wake of a disruptive event, significant players in the supply chains shall predict, be prepared, and understand the extent of the impact of a disruption. They must devise strategies to respond quickly and reconfigure their resources to strengthen competencies and adapt to the consequent effects. Such reconfiguration and renewal of capability allow recovering from disruptions (Ivanov et al., 2017; Hernantes et al., 2017).

The evaluation of SCRes in literature have been primarily dominated by theoretical and modeling approaches. Our research review indicated that modeling and quantification approaches of SCRes could be categorized under two different categories. The first category encompasses models based on metrics that directly quantify SCRes. Hosseini et al. (2019) for instance, highlighted five evaluation metrics related to economic, vulnerability, recovery time, uncertainty, and resilience enhancement considerations. Other authors, such as Ojha et al. (2018), Torabi et al. (2015), and Schmitt and Singh (2012) used performance loss to measure supplier capacity and service performance. Ivanov et al. (2016) and Simchi-Levi et al. (2015) used recovery time to evaluate the impact of supply-chain disruptions. The second category of quantification models do not measure SCRes directly, but rather attempt to assess resilience strategies. For example, Yagi et al. (2020) evaluated supply chain vulnerability using a multi-input-output model for different mitigation strategies. Besides, Jabbarzadeh et al. (2018) measured supplier support and inventory levels as a resilience strategy to maintain disruption performance. Hosseini et al. (2020) evaluated SCRes by measuring supplier segregation, including geographically aggregated suppliers. However, despite the wide variety of theoretical studies, we note that most of them primarily emphasized upon the need for more empirical research on SCRes evaluation, especially during outbreaks and disruptive events.

Furthermore, past literature on SCRes has mainly focused on exploring the enablers, antecedents, practices, capabilities, and competencies required to build resilient supply chains without emphasizing upon strategies to manage the disruptions per se (Tukamuhabwa et al., 2017). According to Ivanov et al. (2017), these factors in some way, constitute strategies to build SCRes and incorporate concepts, such as enhancing supply chain agility, improving visibility, enhancing flexibility, redundancy, and collaboration among partners. This review enables us to identify various SCRes strategies that have been proposed in previous studies, and that are synthesized in Table 1 , being classified under two categories including proactive strategy and reactive strategy. Further, the categories have been segmented depending upon whether or not they are deployed before the occurrence of a disruptive event or in the aftermath (Hendry et al., 2019; Tukamuhabwa et al., 2017).

Table. 1.

Synthesis of proactive and reactive response strategies of SCRes.

| Supply chain risk mitigation strategies | Description | References | |

|---|---|---|---|

| Proactive strategies | Digital connectivity |

Digital technologies such as the Internet of things, blockchain technology, and digital twin are proving great potential to enhance supply chain resilience through high connectivity, accuracy, and transparency. | Ralston and Blackhurst (2020), Kamble et al. (2020a), HYPERLINK \l "bib23" Hofmann et al., (2019); Ivanov et al., (2019). |

| Supply chain automation |

Refers to systematizing physical and information workflow across the supply chain to improve processes. This implies utilizing technologies to minimize dependence on human between firms. | Ralston and Blackhurst (2020), HYPERLINK \l "bib78" Tan et al., (2019); Hofmann et al., (2019). | |

| Localization/ regionalization of sourcing |

Sourcing (and processing) are localized within the same region to meet the local demand and reduce supply chain integrations. Hence, the disruption risk could be contained within the area, as there is no spill-over of a risk incident from one region to another. | Kochan and Nowicki (2019), Iakovou et al., (2014). | |

| Integrated supply chain Risk Management | The focal firm must collaborate with all its supply chain partners (i.e., extended integration) for recovery. Therefore, the risk management efforts could be Rest on the focal firm, but more towards the whole supply chain perspective. | Zhu et al., (2017). | |

| Supply chain collaboration |

Firms at every tier of the supply chain should work closely together to meet shared objectives of foreseeing, predicting, and preventing potential threats in the supply chain. | Barrane et al., (2020), Kamble et al., (2020a), Kochan and Nowicki (2019); Tukamuhabwa et al., (2017) | |

| Social supply chain focus |

Focus on humanitarian and social performance all across the supply chain is of great need to mitigate the risk of disruption at all levels. | Kamble et al., (2020b), Kamble et al., (2020a), HYPERLINK \l "bib80" Tukamuhabwa et al., (2017); Iakovou et al., (2014) | |

| Human capabilities |

Refers to the capabilities of the human concerning analysis of enormous information, monitoring, and controlling critical supply chain points. | Tukamuhabwa et al., (2017),Blackhurst et al., (2005). | |

| Reactive strategies | Lifeline maintenance |

Transportation system and lifeline during disruption should be maintained, as loss of the lifeline and transport systems would affect the entire supply chain of the manufacturing sector | Graveline and Grémont (2017), HYPERLINK \l "bib37" Ivanov et al., (2016); Haraguchi and Lall (2015) |

| BDA-driven and real-time information system | Supply chain information systems use Big Data Analytics (BDA) capabilities to collect, process, and extract meaningful insights from real-time data across the overall supply chain to support suitable and timely decision-making. | Kamble and Gunasekaran (2020), Belhadi et al., (2019) | |

| Virtual marketplaces | Refers to the development of digital marketplace for delivering the products and services. | Sharifi et al., (2006), Kamble et al., (2020a) | |

| Supply chain simulation |

Simulation is a proven way to support multi-criteria decision making while tackling uncertainty and complexity related to supply chains | Ivanov and Dolgui (2020), HYPERLINK \l "bib23" Hofmann et al., (2019); Kamble et al., (2018) | |

| Supply chain collaboration |

Firms at every tier of the supply chain should work closely together to meet shared objectives of recovery and help each other to mitigate disruption impact | Barrane et al., (2020), Villena and Gioia (2018); Zhu et al., (2017) | |

| Inventories and reserve capacity |

Supply chains use inventory and reserve capacity to mitigate the negative effects caused by the disruption. | Lücker et al., (2019), Simchi-Levi et al., (2015). | |

| Business continuity plans |

Business continuity planning is of the utmost importance to create processes and systems of prevention and recovery to deal with potential disruption in the supply chain. | Hernantes et al., (2017), Zsidisin et al., (2005) | |

| Decision-making proximity |

Decision-maker should be close to every node in the supply chain to collect accurate data and make the right decisions | Zsidisin et al., (2005) | |

Proactive strategies are primarily technology-driven strategies that rely on developing technical infrastructures, such as digital connectivity and supply chain automation to avoid future disruptions (Ralston and Blackhurst, 2020; Tan et al., 2019; Hofmann et al., 2019). Iakovou et al. (2014) highlighted localization and regionalization of sourcing, while Zhu et al. (2017) talked about integrated approaches for supply chain risk management. Other authors have proposed social-related strategies with social supply chain focus (Iakovou et al., 2014) and human capabilities (Blackhurst et al., 2005).

Reactive strategies mainly rely on a real-time information system, and are based on data-driven decision-making (Kamble and Gunasekaran, 2020; Belhadi et al., 2019; Belhadi et al., 2018), creating virtual marketplaces (Sharifi et al., 2006) and using supply chain simulation (Hofmann et al., 2019). Besides, extant literature emphasized other concurrent strategies (first and swift responses during or in the instant aftermath of a disruption), such as transportation and lifeline maintenance (Graveline and Grémont, 2017; Ivanov et al., 2016; Haraguchi and Lall, 2015), inventories and reserve capacity (Lücker et al., 2019; Simchi-Levi et al., 2015), business continuity plans (Hernantes et al., 2017; Zsidisin et al., 2005) along with decision-making proximity (Zsidisin et al., 2005). A few strategies, such as developing digital capabilities and supply chain collaboration can be both proactive and reactive, depending on the time and purpose of its use.

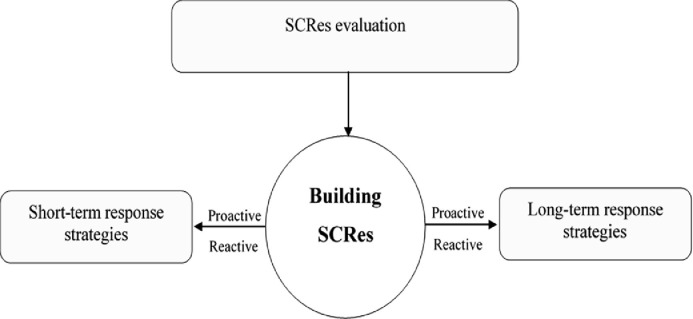

Based on the discussions above, a conceptual framework is proposed, to explore resilient supply chain strategies that include evaluation of the impact that COVID-19 has caused on the global supply chains, and analyze the short and long-term response strategies that have been adopted to manage the risks. This framework constitutes the initial research framework for this study, as illustrated in Fig. 1 .

Fig. 1.

Conceptual research framework.

The evaluation of the SCRes of the selected industries to COVID-19 paves the way for a deep understanding of the disruption characteristics, which is the first step in building SCRes, as proposed by Hosseini et al. Invalid source specified. along with Graveline and Grémont Invalid source specified.. Moreover, the use of SCRes theory is based on proactive and reactive strategies, which focus on when, why, and at which level in the supply chain, a strategy should be deployed. Importantly, the COVID-19 pandemic could last for a long time, and would undoubtedly constitute a new supply-chain management model. Therefore, building SCRes in both short and long-term is of utmost importance.

3. Research methods

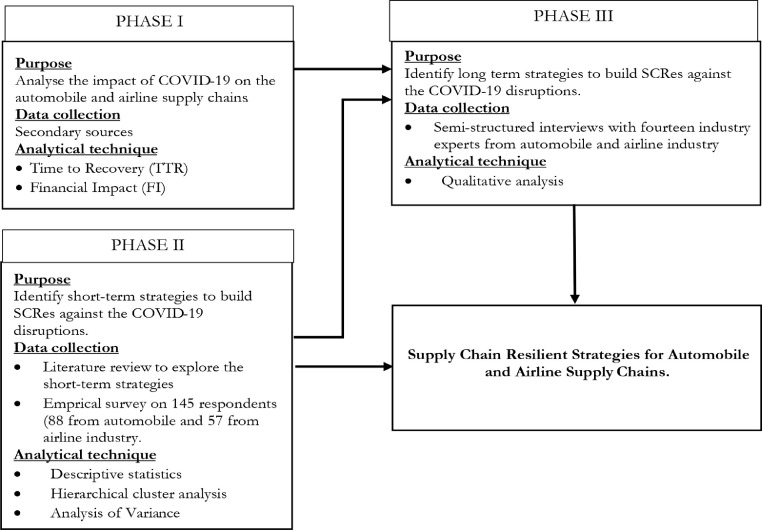

We employed a mixed-method approach, using a combination of both qualitative and quantitative methodologies, as shown in Fig. 2 (Venkatesh et al., 2013; Golicic and Davis, 2012). Notably, using a mixed-method approach presents an excellent opportunity to advance the literature by providing a profound understanding of a complex phenomenon (Golicic and Davis, 2012). Besides, it gives the ability to address an exploratory and confirmatory issue within the same study, along with a better methodological triangulation (Venkatesh et al., 2013).

Fig. 2.

Mixed method approach adopted in this study.

In order to achieve our objectives, we used a three-phase design (Fig. 2). In phase 1, we undertook a quantitative resilience evaluation based on secondary data. Herein, the objective was to evaluate the impact of the ongoing pandemic on two supply chains, i.e. automobiles and airlines. In phase II, we conducted an empirical survey to identify significant short-term strategies that have been adopted by the industries selected (i.e. airlines and automobiles) to overcome supply chain disruptions caused by the pandemic. Herein, the supply chain risk mitigation strategies that were identified from literature, were used to develop the measurement items of our questionnaire (see table 1). In the third phase, we conducted a qualitative study, using semi-structured questionnaire. Herein, the interviews were conducted with supply chain practitioners to discuss long-term recovery strategies. Further, the interviews were conducted using an online platform, (e.g. Skype, Zoom, and Google Meet) in groups of 3–4 experts, as they were based at different locations, while we were compelled to maintain social distancing norms laid by the governing bodies. It is important to note in here that the mixed-method approach did ensure the exploratory power of quantitative research, the generalizability of a survey, and the richness and profoundness of in-depth interviews. In fact, a quantitative analysis of this genre, lays the basic foundation, and acts as a starting point when a phenomenon of interest is fuzzy and uncertain (Golicic and Davis, 2012). Thus, quantitative research enables an initial inductive, and a detailed understanding of the extent by which the current pandemic has been affecting some of the most crucial supply chains. Post the survey, adopting a semi-structured interview method, does provide deeper insights into the results obtained, and in the process, opens up interesting perspectives on the topic. The details of the research design adopted in Phase I, II, and III are elaborated under Section 3.1, 3.2, and 3.3.

3.1. Research design: phase i

Phase I of the study evaluated the resilience of the selected supply chains against the disruptions caused by the pandemic. We used quantitative data collected from secondary sources, such as research databases, research papers, and published reports. SCRes was evaluated using a combined Time-to-recover (TTR) and Financial impact (FI) analysis. The summary of sector-wise data and critical sources for conducting the TTR-FI evaluation is presented in Table 2 .

Table. 2.

Summary of the quantitative data sources.

| Type of Data | Sector | Sources of data |

|---|---|---|

| Production forecast | Automobile | (IHS Markit, 2020); GlobalData Analysis; (KPMG, 2020); (Roland Berger, 2020) |

| Production forecast | Airline | (IATA 2020a); (ICAO, 2020) |

| Employment impact | Automobile | (ILO, 2020a); (ILO, 2020b) |

| Production impact | Automobile | (ACEA, 2020); (McKinsey, 2020); company's announcements |

| Tourism impact | Airline | (UNWTO, 2020) |

| Cargo impact | Airline | (IATA, 2020b) |

3.1.1. Analysis techniques

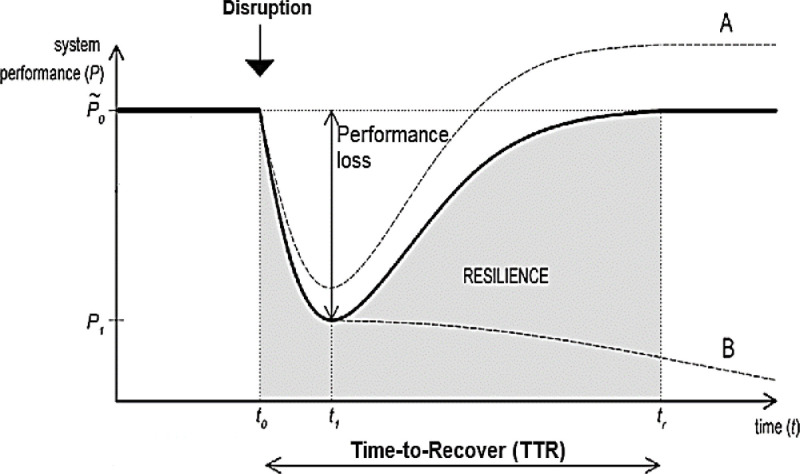

TTR has been found to be suitable, as it is a quantitative resilience measurement that is in line with the SCRes theory, as discussed in Section 2.3. SCRes can be evaluated when a supply chain network needs to restore its pre-disruption state of operation post a disruption per se (Ivanov et al., 2017). Besides TTR, we also used FI to assess SCRes, and to evaluate the loss of capacity during the recovery period (Ivanov et al., 2016; Simchi-Levi et al., 2015). Notably, the higher the capacity loss due to an interruption, the less resilient is a supply chain against disruptions (Tan et al., 2019). Fig. 3 illustrates the typical profile of a supply-chain disruption and TTR.

Fig. 3.

A typical profile of supply-chain disruption and Time to Recovery.

Let us suppose that P(t) marks a supply chain's performance. The permanent level of P(t) is. Notably, the starting point of the disruption is where the performance of the supply chain starts decreasing, until it reaches a minimum level, before it resumes its rise in order to achieve its original level at whereby the supply-chain effectively recovers its permanent performance. TTR is thereby calculated using Eq. (1).

| (1) |

The performance loss is calculated using Eq. (2) as the area between P(t) and permanent performance and the actual performance P(t).

| (2) |

In a highly uncertain context, TTR is generally estimated through a panel of scenarios ranging from the most optimistic one (curve (A) in Fig. 3) to the most conservative situation (curve (B) in Fig. 3). This scenario panel is then compared with the basic scenario (BS) for which there is no disruption, and therefore, no risk mitigation action is undertaken by the concerned (Iakovou et al., 2014).

In supply-chain literature, TTR has been widely used to measure both the resilience of the supply-chain network and the magnitude of disruption (Schmitt and Singh, 2012). For instance, Ojha et al. (2018) proposed a Bayesian scenario analysis to calculate TTR of supply-chain disruption. Earlier, Iakovou et al. (2014) have analyzed multiple scenarios to offer a risk mitigation strategy for emergency sourcing of humanitarian supply-chains.

The Financial impact (FI) of disruption is considered another essential SCRes measure (Tan et al., 2019). FI may be quantified using total induced cost under different aspects, such as profit, revenue, sales, transportation, and inventory costs (Tan et al., 2019; Sawik, 2019). From our literature review, one could argue that outbreaks do impact supply-chain risks that may be categorized into two,—viz. direct effects (i.e. pertaining to property damage) and indirect effects (i.e. relating to business interruptions) (Rose, 2004). In fact, Haraguchi and Lall (2015) divided the outbreak into direct and indirect, along with tangible and intangible. This categorization seems more relevant, since both tangible and intangible effects represent an outbreak's significant ripple effects on the areas affected (Santos et al., 2012). Notably, FI over a duration t can be calculated using Eq. (3).

| (3) |

Where Cd(t) stands for costs of direct impacts, and Ci(t) represents the costs of the indirect effects.

We choose to focus on TTR in order to measure the resilience of the studied supply-chains against the impacts of the COVID-19 pandemic on the larger supply networks. For this, we used hypothetical planning to estimate TTR for both optimistic (V-shaped) and conservative (U-shaped) scenarios. Moreover, we relied on FI to quantify exceptional losses that may have been caused by the pandemic on its operating profits.

3.2. Research design: phase ii

3.2.1. Instrument development, sampling, and data collection

The main focus in the second phase was to investigate the adoption of short-term SCRes strategies by the industries studied, i.e. automobiles and airlines. We gathered data using a questionnaire survey, since it enabled us to collect more information from key informants within a short duration (Belhadi et al., 2020), considering the current crisis. Firms operating in different tiers of both the automobile and airline supply chains were our target. The firms’ database was acquired from different regional databases such as the European Association of Aerospace Industries (AECMA), European Automobile Manufacturers Association (ACEA), China Association of Automobile Manufacturers (CAAM), and Association for Operations Management (APICS). For the survey, we approached 382 automobile and airline practitioners that included operations executives, managing directors, vice-presidents, and general managers of firms at different tiers of the supply chain. These participants were thought to be the most qualified and competent personnel involved in decisions concerning the design and implementation of SCRes response strategies.

The survey instrument was developed (see Appendix 1) based on the SCRes response strategies identified from literature review and validation from a panel of experts, comprising five academicians from supply chain management along with four industry practitioners. Moreover, the survey instrument was administered through e-mail, accompanied by a cover letter, explaining the study's objective and the potential use of the findings, assuring thereby a strict warranty of data confidentiality. The data collection phase was covered in two slots, spread over four weeks, and three e-mail reminders. Finally, we received a total of 145 filled response sheet to our questionnaire, with a response rate of 38%. Eighty-eight respondents (60%) represented the automobile sector, while the remaining 57 (40%) the airline sector. Table 3 summarizes the profile of the selected respondents.

Table. 3.

Summary of the general information of the respondent companies.

| Frequency | Percentage |

| Supply-chain sector | ||

|---|---|---|

| Automobile | 88 | 60.68% |

| Airline | 57 | 39.32% |

| Total | 145 | 100% |

| Supply chain tier | ||

|---|---|---|

| Suppliers | 74 | 51% |

| Focal firm | 55 | 38% |

| Distribution and retailing partners | 16 | 11.% |

| Total | 145 | 100% |

| Firm size (Automobile sector) | ||

|---|---|---|

| Multinational enterprises | 32 | 36% |

| Medium sized enterprises | 22 | 25% |

| Small-sized enterprises | 23 | 26% |

| Micro-sized enterprises | 11 | 13% |

| Total | 88 | 100% |

| Firm size (Airline sector) | ||

|---|---|---|

| Domestic Airline | 19 | 33 |

| International Airline | 38 | 67 |

| Total | 57 | 100% |

| Location | ||

|---|---|---|

| Europe | 24 | 30% |

| Asia | 18 | 22% |

| Africa | 39 | 48% |

| Total | 81 | 100% |

Before conducting further analysis, we conducted a power analysis, using a power calculator (G∗Power 3.1) following Cohen's recommendation (Cohen, 1988). Invalid source specified.. The results showed that the minimum number required for statistical analysis was 51 responses, indicating thereby that our sample size was adequate.

3.2.2. Analysis techniques

To extract meaningful insights from the data collected, we first employed descriptive analysis (e.g. mean, standard deviation, t-test, and ANOVA) to rank and identify the SCRes strategies. These results guided us to identify the firms' critical strategies in response to the COVID-19 pandemic. Then, we used the hierarchical clustering technique to segment the responding firms according to their SCRes strategies. Further, we performed a one-way independent Analysis of Variance (ANOVA) to check the group differences within the clusters identified, establish validity and consistency of the selected strategies.

3.3. Research design: phase iii

3.3.1. Case selection and data collection

In the third phase, we aimed to understand the complex and emerging phenomenon of SCRes against the pandemic in the selected supply chains (i.e. automobiles and airlines). We adopted a multiple case study design approach to generate theories, and gain relevant insights into SCRes strategies against the pandemic, both in the short and long-term. Discussion within this phase were primarily based upon contextually embedded data, gathered through semi-structured interviews with a few industry practitioners both from the automobile and airlines sectors. In total, fourteen practitioners (i.e. 7 each from the automobile and airline sector respectively) participated in discussing the long-term recovery strategies. These practitioners were selected from both personal and professional networks. We assured them of complete confidentiality and anonymity, and thus, their names along with the company details have been withheld. Nevertheless, we coded them, using appropriate pseudonyms. Importantly, the interviews/discussions were conducted remotely using online platforms, following the protocol presented in Appendix 2, and guaranteed adequate coverage of the interview questions and procedures of research ethics. The interviews were semi-structured, enabling the interviewee thereby to express and provide supplement information freely. Each meeting lasted for about 45 min to an hour, and was conducted from March 16 to May 10, 2020. The details of the industry experts selected for this phase of the study are presented in table 4 .

Table. 4.

Profile of selected industry experts.

| Code | Location | Business sector | Position | Years of experience | Date of the interview |

|---|---|---|---|---|---|

| Aut1 | Germany | Automobile | Logistics manager | 11 | March 16, 2020 |

| Aut2 | US | Automobile | Operations manager | 13 | March 23, 2020 |

| Air1 | France | Airlines | Customer relationship executive | 9 | March 24, 2020 |

| Aut3 | Korea | Automobile | Supply-chain Manager | 9 | March 27, 2020 |

| Air2 | Morocco | Airlines | Operations executives | 13 | March 28, 2020 |

| Air3 | US | Airlines | Strategy and Marketing manager | 12 | March 28, 2020 |

| Aut4 | Germany | Automobile | Operations Manager | 14 | March 30, 2020 |

| Aut5 | Morocco | Automobile | Procurement manager | 7 | March 31, 2020 |

| Air4 | Spain | Airlines | Strategy manager | 15 | April 1, 2020 |

| Aut6 | Spain | Automobile | Supply-chain executive | 10 | April 1, 2020 |

| Aut7 | France | Automobile | Supply-chain Manager | 9 | April 3, 2020 |

| Air5 | Morocco | Airlines | Manager- airport operations | 8 | May 8, 2020 |

| Air6 | Germany | Airlines | Manager- flight operations | 12 | May 9, 2020 |

| Air7 | France | Airlines | Risk Management Officer | 17 | May 10, 2020 |

3.3.2. Coding and analysis techniques

The starting point in the analysis process was the writing up case histories for each interview with the interviewees' permission to ensure data reliability and internal validity. The following steps began with the interviews' open coding, assorting sentences, quotes, or paragraphs inductively into categories and codes (Strauss and Corbin, 1990). Further, we conducted a step of axial coding to yield more abstracts, as well as remove and combine codes (Strauss and Corbin, 1990). At this stage, we attempted to connect our inductive codes to the established constructs gathered from extant literature (section 2.3), such as SCRes readiness against COVID-19 outbreak through the evaluation of the impact, SCRes response, or SCRes recovery, in coherence with our aim of theoretical extension.

4. Analysis and findings

The research framework presented in Fig. 2, steered the procedure for analysis for achieving the stated research objectives. This section evaluates SCRes of the selected supply chains (i.e. automobile and airlines) against the COVID-19 outbreak. Herein, we investigate the immediate strategies and operating modes within these supply chains based upon their response to the disruption caused by the pandemic. Finally, we explore the perspectives of a long-term strategy to address post-COVID-19-related challenges.

4.1. Results of quantitative evaluation of SCRes

4.1.1. Evaluation of SCRes of the automobile sector to COVID-19 outbreak

TTR is the time needed for a supply chain to regain its usual level of performance (Tan et al., 2019), while FI is the total of performance loss (direct and indirect) during a disruption (Hosseini et al., 2019). TTR and the consequent FI of the automobile supply chain are mainly dependent upon the spread of COVID-19 in each region, affecting thereby the shutdown duration. Moreover, owing to the pandemic, the demand slowdown could be attributed to the market's recession, even after factories reopen. Although the evolution of the coronavirus spread seems to have stabilized before reaching an exponential growth phase, there are controversial viewpoints among specialists on how the pandemic will be contained in future.. Consequently, we considered two scenarios for evaluating the pandemic. We identified two factors in assessing the economic impact, namely car production and sales that reflect the supply and demand, respectively.

Recognizing the early signs that manufacturing is beginning to pick up again in China (ILO, 2020b), we considered a V-shaped scenario that assumes a relatively fast recovery by late Q2 (June 2020). Based on studies of LCM AutomotiveInvalid source specified. and Roland BergerInvalid source specified., we assume a sharp drop of 65 to 75% (compared to baseline) in car production, and 10 to 25% in car sales during Q2 before showing some recovery in Q3. By early Q4 2020, carmakers would ramp up their production to minimize the effect, while car sales would return to the baseline situation. The total recovery of the automotive sector is expected by early Q1 2021. On the other hand, the second scenario considered, called ‘U-shaped’, assumes a prolonged contraction until late Q3. According to LCM AutomotiveInvalid source specified. and Roland BergerInvalid source specified., this scenario hypothesizes that no ramp-up in car production is possible until Q1 2021. The details of the assumptions for the evolution of the two factors during 2020, according to the considered scenarios, are shown in Table 5 .

Table. 5.

Assumptions of the evolution of car production and sales according to the considered scenarios.

| Month | Baseline (Pre-COVID-19 forecast) | V‐shaped scenario | U-shaped scenario | |||

|---|---|---|---|---|---|---|

| Car production reduction | Car sales reduction | Car production reduction | Car sales reduction | Car production reduction | Car sales reduction | |

| Q1 2020 | Q1 2019 results of top companies | Q1 2019 results of top companies | actual | Q1 2020 results of top companies | actual | Q1 2020 results of top companies |

| Q2 2020 |

0% |

Q2 2019 results of top companies | 35 to 45 percentage points lower than Baseline | 10 to 25 percentage points lower than Baseline | 65 to 75 percentage points lower than Baseline | 25 percentage points lower than Baseline |

| Q3 2020 |

0% |

Q3 2019 results of top companies | 5 to 10 percentage points lower than Baseline | 10 percentage points lower than Baseline | 65 to 75 percentage points lower than Baseline | 25 percentage points lower than Baseline |

| Q4 2020 | 0% | Q4 2019 results of top companies | 10 to 30 percentage points higher than Baseline | Baseline | 35 to 45 percentage points lower than Baseline | 25 percentage points lower than Baseline |

| Q1 2021 |

0% |

Q1 2020 results of top companies | Baseline | Baseline | 10 to 30 percentage points lower than Baseline | 10 percentage points lower than Baseline |

Source: press release.

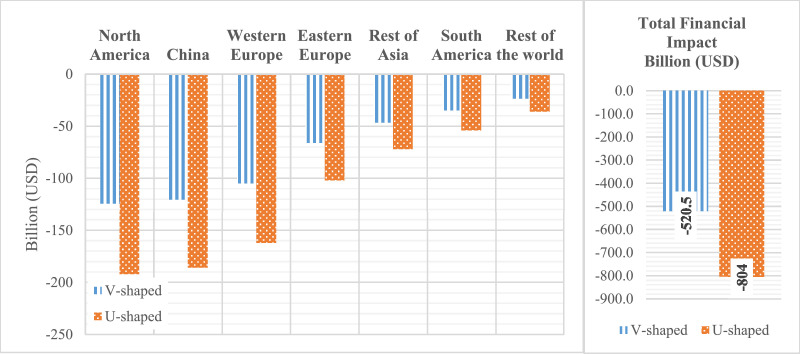

Preliminary estimations based on data from LCM AutomotiveInvalid source specified. and Roland BergerInvalid source specified. and Global Data indicate that the automotive sector would reduce its production by a proportion varying from 16.78% (V-shaped scenario) to 20.97% (U-shaped scenario). Reduction in sales would range from 13.4 million units to 20.7 million units. Furthermore, the estimated loss in potential revenue varies from $520.5 billion to $804, as presented in Appendix 3.

In both scenarios, we considered a delayed economic restart both in Europe and the US, caused by the growing propagation and different reaction to the pandemic that would effectively delay the full resumption in both Europe and the US, despite the projected recovery from China. According to a study of KPMG Invalid source specified., this delay primarily may be caused by market vulnerabilities (e.g. trade tensions, declining sales) that are likely to persist even after a full Chinese recovery, given the tight inventories (fewer than six weeks) and complex supply-chains. Although South America and the Rest of the world were a week or two behind other markets in both outbreaks and aggressive responses, they are likely to resume their full production simultaneously with both US and Europe due to the close link between them (see Fig. 4 ).

Fig. 4.

The financial impact of COVID-19 outbreak on the automobile sector by region between January 2020 and March 2021Data Source: LCM AutomotiveInvalid source specified. and Roland BergerInvalid source specified.Source: GlobalData Analysis; Expert Interviews; Press Articles; Company Announcements.

4.1.2. Evaluation of SCRes of the airline's sector to COVID-19 disruption

To evaluate TTR for the airlines' segment, we worked with different scenarios due to the uncertainty in the situation and fast-changing characteristics. We based our analysis from data collected and explored by ICAO Invalid source specified. and IATA Invalid source specified., using a baseline scenario alongside two possibilities. Here again, the first scenario is called ‘V-shaped’, whereby we assume a relatively fast recovery Q3 of 2020. The second scenario, called ‘U-shaped’, hypothesizes an extended recession until early 2021. In line with ICAO Invalid source specified., we considered two factors for calculating FI of COVID-19 on the airlines’ sector, namely, passenger capacity (i.e. related to supply) and passenger load (i.e. connected to demand). Table 6 summarizes the assumptions of the evolution of the two factors according to each scenario.

Table. 6.

Assumptions of the evolution of passenger capacity and passenger load in each scenario.

| Month | Baseline | V‐shaped scenario | U-shaped scenario | |||

|---|---|---|---|---|---|---|

| Passenger capacity | Passenger load | Passenger capacity | Passenger load | Passenger capacity | Passenger load | |

| Q1 2020 | January 2019 results of top companies | January 2019 results of top companies | actual | January 2019 results of top companies | actual | January 2019 results of top companies |

| Q2 2020 |

100% |

March 2019 results of top companies | actual | 15 to 25 percentage points lower than Baseline | actual | 25 percentage points lower than Baseline |

| Q3 2020 |

100% |

January 2019 results of top companies | airlines' schedules filed in early April minus 1 to 4 percentage points | 15 percentage points lower than Baseline | airlines' schedules filed in early April minus 1 to 4 percentage points | 25 percentage points lower than Baseline |

| Q4 2020 |

100% |

January 2019 results of top companies | 65 to 75 percentage points lower than Baseline | 10 percentage points lower than Baseline | 80 to 90 percentage points lower than Baseline | 25 percentage points lower than Baseline |

| Q1 2021 |

100% |

January 2019 results of top companies | 35 to 45 percentage points lower than Baseline | 10 percentage points lower than Baseline | 80 to 90 percentage points lower than Baseline | 25 percentage points lower than Baseline |

Sources: ICAO Invalid source specified.; IATA Invalid source specified.

According to the initial estimates, the impact of scheduled international passenger traffic during 2020 compared to the baseline is shown in Appendix 4. Notably, the overall passenger capacity reduction varies from 42% (V-shaped scenario) to 56% (U-shaped scenario). Moreover, the general decrease in passenger load varies from 2037 million (V-shaped scenario) to 3046 million (U-shaped scenario). The most significant impact is observed in Europe and North America, followed by Asia/Pacific and the Middle East.

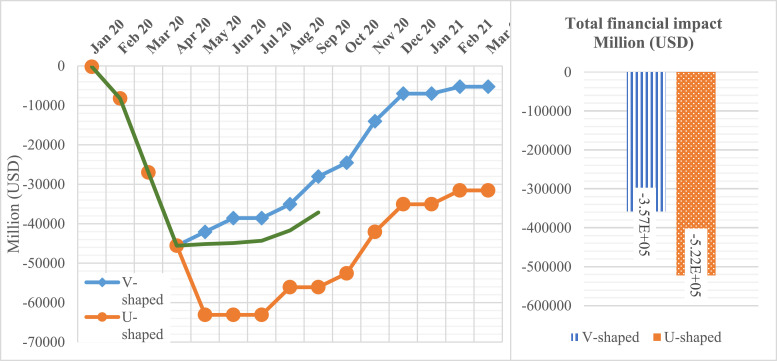

The monthly global financial impact illustrated in Fig. 5 depicts the difference between the two scenarios. Notably, the total FI is estimated to vary between $357 billion (V-shaped scenario) and $522 billion (U-shaped scenario) between January 2020 and March 2021.

Fig. 5.

The financial impact of Covid-19 outbreak on the airline sector between January 2020 and March 2021. Data Sources: ICAO (2020); IATA (Industry Statistics, 2020).

The evaluation of SCRes of both automobile and airline sectors to the COVID-19 outbreak has thereby demonstrated a high level of vulnerability that these supply chains present to disruption. The preliminary results indicate an extended TTR and a high FI, requiring an urgent response strategy to swiftly face the current challenges, and thus deal with the problems of the post-COVID-19 era.

4.2. Results of short-term response strategies

To investigate the short-term response strategies, the results of the questionnaire-based survey administered to 145 firms operating in different tiers of automobile and airline supply chains were used. The purpose was to link the short-term strategies adopted by supply chains, and to categorize the firms according to their performance in dealing with the COVID-19 disruption.

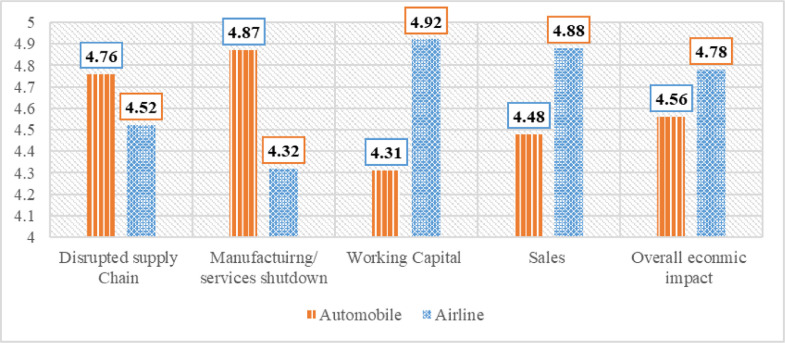

4.2.1. Impact of COVID-19 on the responding firms

First, the respondents were asked to identify the extent of the COVID-19 outbreak's impact on their performance on five predefined performance metrics. As shown in Fig. 6 , they agreed that COVID-19 did have a significant effect on both the automobile and airline sectors. The results show that the mean values for all the performance metrics are above 4.00, indicating thereby that the pandemic has hugely disrupted the supply chains of both these sectors. Besides, the automobile sector has a high impact on supply chain disruptions and manufacturing shutdowns, as compared to the airline sector. However, the airline sector scores high mean values on a shortage of working capital, sales, and overall impact, as opposed to the automobile sector.

Fig. 6.

Impact of COVID-19 on automobile and airline sector.

4.2.2. Adoption of short-term response strategies for automobile and airline SCRes building

The identified proactive and reactive SCRes response strategies have been sent to the responding companies to evaluate their levels of adoption of each strategy. To compare the adoption of strategies in each sector, we used a two-sample t-test to assess the equality of means. The mean values, standard deviations, and the results of the t-test (at sig. value of 0.05) are presented in table 7 .

Table. 7.

Adoption of SCRes response strategies in automobile and airlines sectors.

| Response Strategies | Automobile | Airline | t-value | Sig.value | ||

|---|---|---|---|---|---|---|

| Mean | Std.Deviation | Mean | Std.Deviation | |||

| BDA-driven and real-time information system | 4.20 | 0.41 | 4.00 | 0.67 | .93 | .36 |

| Supply chain automation | 3.80 | 0.56 | 3.20 | 0.42 | 2.88 | .01 |

| Localization/ regional eco-system | 4.50 | 0.53 | 2.80 | 0.68 | 6.69 | .00 |

| Lifeline maintenance | 3.20 | 0.41 | 2.50 | 0.53 | 3.71 | .00 |

| Industry 4.0 technologies | 4.33 | 0.72 | 1.70 | 0.67 | 9.15 | .00 |

| Integrated supply chain risk management | 3.53 | 0.52 | 2.60 | 0.70 | 3.84 | .00 |

| Virtual marketplaces | 3.27 | 0.46 | 3.70 | 0.48 | -2.27 | .03 |

| Supply chain simulation | 2.53 | 0.64 | 2.20 | 0.79 | 1.16 | .26 |

| Supply chain collaboration | 2.40 | 0.51 | 2.30 | 0.48 | .49 | .63 |

| Social supply chain focus | 3.80 | 0.41 | 3.70 | 0.48 | .55 | .59 |

| Inventories and reserve capacity | 2.47 | 0.52 | 2.70 | 0.48 | -1.13 | .27 |

| Business continuity plans | 3.27 | 0.70 | 4.20 | 0.92 | -2.88 | .01 |

| Human capabilities | 2.80 | 0.56 | 2.80 | 0.42 | .00 | 1.00 |

| Decision making proximity | 2.53 | 0.52 | 2.60 | 0.52 | -0.32 | .75 |

Table 7 shows that localization/ regionalization of sourcing (mean value = 4.50), use of BDA-driven and real-time information system (mean value= 4.20), digital connectivity (mean value = 4.33), supply chain automation (mean value = 3.80), social supply chain focus (mean value = 3.80) and integrated supply chain risk management were the most preferred response strategies by the automobile industry to overcome COVID-19 disruption. On the other hand, business continuity plans (mean value =4.20), BDA-driven and real-time information system (mean value=4), virtual marketplaces (mean value= 3.70), and social supply chain focus (mean value=3.70) were found to be the most preferred response strategy by the practitioners in the airline industry. The response strategies viz., supply chain automation, localization or regionalization of sourcing, lifeline maintenance, digital connectivity, and integrated supply chain risk management were perceived with significant differences by the practitioners from the automobile industry, thereby giving more importance to the automobile firms. However, the response strategies, such as focusing on business continuity plans and creating secure virtual marketplaces, were found to attract more attention by the airline firms. The use of a BDA-driven and real-time information system, supply chain collaboration, developing social supply chain focus, consuming inventories and reserve capacity were perceived without any significant differences.

4.2.3. Categorization of automobile firms according to their short-term response strategies

The responding firms were segmented according to their response strategies into three groups; they include ‘well-prepared’, ‘partially prepared’, and ‘ill-prepared’. Hierarchical cluster analysis was applied to study the response strategies' mean values using squared Euclidean distance between these variables. Ward's method was applied to optimize the minimum variances among clusters. Comparisons of mean values and standard deviations were conducted among these groups. Table 8 provides a summary of the results of the cluster analysis for the automobile sector. Herein, three clusters have been identified, with 40% of the respondents (35 companies) being classified under ‘well prepared’. These companies have high mean values for all response strategies, representing thereby a high degree of adoption of these practices. As depicted in Table 8, the mean values of response strategies varied from 3.54 to 4.92. Importantly, for the well-prepared firms, localization and regional ecosystem, big-data analytics-driven and real-time information system, industry 4.0 technologies, supply chain focus, and integrated supply chain risk management approaches have been found to be the most commonly applied response strategies with mean values of 4.92, 4.83, 4.82, 4.23 and 4.03, respectively, indicating a substantial level of adoption. The second cluster represented the partially prepared firms that constitute 45% of the sample (39 companies). As presented in Table 8, the mean values ranged from 1.96 to 4.39, with the highest preference being for developing local/regional ecosystems, adopting industry 4.0 technologies, and big data analytics for real-time information sharing. The third cluster, viz., ‘ill-prepared’ firms, representing 16% of the sample (14 respondents). They have been identified being on the lower end of the scale, as they had not adopted any supporting practices to develop response strategies. Hence, these firms had low mean scores varying from 1.23 to 3.46, as compared to the well prepared and ill-prepared firms.

Table. 8.

Short-term SCRes response strategies cluster analysis for the automobile sector.

| Response Strategies | Well prepared companies (n = 35) | Partially prepared companies (n = 39) | Ill-prepared companies (n = 14) | |||

|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | |

| BDA-driven and real time information system | 4.83 | 0.79 | 3.9 | 1.2 | 3.19 | 1.39 |

| Supply chain automation | 4.28 | 0.64 | 3.71 | 0.51 | 2.62 | 0.66 |

| Local/ regional ecosystem | 4.92 | 0.57 | 4.39 | 1.33 | 3.46 | 1.12 |

| Lifeline maintenance | 3.98 | 0.61 | 2.95 | 1.28 | 1.78 | 0.88 |

| Digital connectivity | 4.82 | 0.83 | 4.13 | 0.72 | 3.39 | 0.88 |

| Integrated supply chain Risk Management | 4.03 | 0.71 | 3.21 | 0.53 | 2.95 | 0.9 |

| Virtual marketplaces | 3.86 | 0.99 | 3.24 | 0.67 | 1.65 | 1.47 |

| Supply chain simulation | 3.57 | 0.93 | 1.97 | 0.59 | 1.33 | 0.72 |

| Supply chain collaboration | 3.46 | 1.1 | 1.81 | 0.8 | 1.23 | 1.14 |

| Social supply chain focus | 4.23 | 0.66 | 3.65 | 1.39 | 2.92 | 1.1 |

| Inventories and reserve capacity | 3.49 | 0.81 | 1.96 | 0.57 | 1.23 | 0.87 |

| Business continuity plans | 3.95 | 0.69 | 3.05 | 0.64 | 1.98 | 1.38 |

| Human capabilities | 3.54 | 0.98 | 2.58 | 1.09 | 1.37 | 1.43 |

| Decision making proximity | 3.57 | 0.64 | 1.97 | 1.28 | 1.33 | 0.84 |

Interestingly, one of the relevant issues that caught our attention, and was worth investigating is whether there was any significant difference among these three clusters concerning the perceived impact of COVID-19 outbreak. Therefore, we conducted a one-way independent analysis of variance (ANOVA) test to evaluate the clusters' validity and consistency with different mean values of the perceived impact. The ANOVA scores revealed an F-value of 125.48 (p = 0.01), suggesting thereby that these clusters were significantly different from each other.

4.2.4. Categorization of airlines firms according to their short-term response strategies

The above analysis to form the clusters was performed for the airline sector. The investigation revealed three groups which were again named as ‘well prepared’, ‘partially prepared’, and ‘ill-prepared’. Table 9 provides a summary of the results of the cluster analysis for the airline sector. The first cluster was identified with 36% of the respondents (21 firms) being classified as ‘well prepared’. They had high mean values for almost all the response strategies, representing thereby a high degree of adoption of these practices. As depicted in Table 9, the mean values of response strategies varied from 2.32 to 4.93. Further, for these ‘well-prepared’ firms, the business continuity plan, big-data analytics, real-time information system, social supply chain focus, and virtual marketplace, have been found to be the most commonly applied response strategies with mean values of 4.93 4.60, 4.45, and 4.43, respectively, indicating thereby a substantial level of adoption. The second cluster represented the partially prepared firms constituting 42% of the sample (24 firms). As presented in Table 9, again, the same strategies were preferred, including a business continuity plan with a mean value of 3.99, followed by big-data analytics and real-time information systems, social supply chain focus, and virtual marketplace with somewhat lower mean values as compared with the well-prepared firms. For the third cluster, viz., ill-prepared firms included 22% of the sample (12 respondents). They were at the lower end of the scale, and rated the response strategies with low mean values ranging from 1.09 to 3.19. Herein, it was observed that the use of industry 4.0 technologies was the least preferred strategy.

Table. 9.

Short-term SCRes response strategies cluster analysis for airlines sector.

| Short-term SCRes response strategies | Well prepared companies (n = 21) | Partially prepared companies (n = 24) | Ill-prepared companies (n = 12) | |||

|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | |

| BDA-driven and real time information system | 4.6 |

0.87 |

3.92 |

1.31 |

3.19 |

1.22 |

| Supply chain automation | 3.68 | 0.54 | 3.2 | 0.98 | 2.4 | 0.78 |

| Local/ regional ecosystem | 3.88 |

0.68 |

2.47 |

1.19 |

1.67 |

1.34 |

| Lifeline maintenance | 3.34 | 0.54 | 2.34 | 1.45 | 1.45 | 0.98 |

| Industry 4.0 technologies | 2.32 | 0.92 | 1.49 | 0.87 | 1.09 | 0.79 |

| Integrated supply chain risk management | 3.62 |

0.81 |

2.32 |

0.89 |

1.46 |

1.19 |

| Virtual marketplaces | 4.43 | 1.01 | 3.64 | 0.76 | 2.63 | 1.33 |

| Supply chain simulation | 3.36 | 0.98 | 1.76 | 0.59 | 1.15 | 0.86 |

| Supply chain collaboration | 3.56 |

1.12 |

1.84 |

0.87 |

1.1 |

1.24 |

| Social supply chain focus | 4.45 | 0.73 | 3.72 | 1.31 | 2.45 | 1.28 |

| Inventories and reserve capacity | 3.49 |

0.93 |

2.75 |

0.87 |

1.32 |

0.95 |

| Business continuity plans | 4.93 | 0.75 | 3.99 | 0.96 | 3.41 | 1.48 |

| Human capabilities | 3.44 | 1.21 | 2.9 | 1.27 | 1.56 | 1.23 |

| Decision making proximity | 3.48 |

0.87 |

2.28 |

1.09 |

1.76 |

0.89 |

The ANOVA revealed an F-value of 168.34 (p = 0.001), suggesting that these clusters were significantly different from each other.

4.3. Results of long-term strategies to SCRes building

The findings from interviews suggest that a significant stage in long-term SCRes building involves developing capabilities to evaluate and raise awareness of potential threats among the supply chain. Hence, this section starts with a discussion of how firms could develop such skills. Several interlocutors have emphasized the need for strengthening reactive SCRes strategies to accelerate recovery from the COVID-19 outbreak. Herein, we note that firms should develop proactive SCRes to prevent the impact of potential disruption and maintain business profitability thereof. Table 10 summarizes the critical constructs, building empirical evidence thereby from the discussion on the three subsections below.

Table. 10.

Summary of the constructs generated from the interviews.

| Long-term SCRes response strategies | Supporting quotes | References |

| (a) SCRes evaluation and awareness | ||

| Digital driven data analysis capabilities | "…Through the data analysis we performed, we found that it would be better to maintain the plants running and build inventory, absorbing fixed costs, and preparing for the post-COVID-19″ [Aut7] | Aut1, Aut2, Aut4, Aut7, Air2, Air3, Air7 |

| "… Data analysis is critical for the new world… we are learning a lot from our weaknesses during the COVID-19 outbreak … I think we should be able to detect the disruption before it occurs … This is for what data collection and analysis is helpful" [Air7] | ||

| Human awareness | "…We are talking about the devastating impact of COVID-19 on our employees every day…. Everybody should be aware of that to help us implementing resilient strategies" [Air3] | Aut1, Aut3, Aut4, Aut7, Air1, Air2, Air6 |

| (b). SCRes reactive strategies | ||

| Lifeline and transportation system | "…The current situation is putting us into a huge uncertainty… one thing is certain – air cargo is critical for delivering lifesaving drugs and medical equipment and supporting global supply-chains. Firms and governments should support the air cargo and remove all the restrictions to support the global air cargo network" [Air4] | Aut2, Aut3, Aut5, Aut6, Air1, Air2, Air4, Air7 |

| Emerging technologies | "Simulation and big data analytics outputs enhanced transparency and facilitated the quick buy-in and commitment of everybody to the selected decision… We decided to keep the air cargo running even though the fall of demand" [Air4] | Aut1, Aut2, Aut4, Aut7, Air2, Air7 |

| "We should have our employees able to take advantage of technologies to take swift decisions…" [Aut1] | ||

| Supply chain collaboration | "I think before a disruption; we should have built strong relationships with key suppliers at every supply chain tiers… we need to collaborate with everyone and share common goals" [Aut6]. | Aut1, Aut3, Aut5, Aut6, Aut7, Air2, Air5 |

| "We are interconnected within the supply chain, and our fate is part of our suppliers' and costumers' fate… we should learn to work together" [Aut7] | ||

| (c). SCRes proactive strategies | ||

| Digital transformation | "… One of our major weaknesses during the outbreak is the lack of real-time visibility across our supply chain. We are losing a great opportunity to support critical business decisions… It is vital to accelerate digital transformation … because many of the capabilities it offers could have greatly reduced the impact of this crisis on us all" [Aut5] | Aut1, Aut2, Aut4, Aut7, Air1, Air2, Air3, Air7 |

| "…All the members of the steering committee now believe that our digital infrastructure needs strengthening to mitigate the impact of COVID-19″ [Air1] | ||

| "… Soon, digital workflows and automation should no longer be goals; they should be requirements…" [Air3] | ||

| Integrated risk management | "It is vital to implement global risk assessments into our supplier relationship management strategy and develop long-term business continuity plans" [Air2] | Aut1, Aut4, Air2, Air3, Air5, Air6 |

| "Maintaining a traditional approach to risk management is no longer an option… Therefore, we need a more holistic approach to hazard identification and risk management because systemic risks are complex and non-linear" [Air6] | ||

| Corporate Social Responsibility | "The pandemic is teaching us a lesson that firms and ecosystems are interconnected in terms of the impact and decisions; therefore we should be conscientious of this interconnection and develop an early focus on social components" [Aut3] | Aut1, Aut3, Aut6, Air1 |

4.3.1. Capabilities for SCRes evaluation and awareness

The capabilities identified by the interviewers as necessary to enable supply chains to detect and evaluate disruptive events are:

-

(1)

Digital driven data analysis capabilities,

-

(2)

Human awareness.

The evidence of these capabilities is given in part (a) of Table 10. According to many interviewees (Aut1, Aut2, Aut4, Aut7, Air2, Air3, and Air7), the COVID-19 pandemic and its impact on the global supply chains have compelled organizations to realize the operational advantages of using digital techniques to make more informed decisions and manage the disruption thereof. Big Data Analytics has proven to be a remarkable support to some of the firms in increasing information processing and streamlining their supplier selection process, both before and during the disruption (Belhadi et al., 2019; Roßmann et al., 2018), enhancing thereby their predictive capabilities against potential disruptions. However, a few other experts (Aut1, Aut3, Aut4, Aut7, Air1, Air2, and Air6) emphasized upon the tremendous role of human capabilities and awareness in anticipating disruption. Finally, a joint development of digital and social capabilities to sense potential disruption and systematically evaluate SCRes is clearly highlighted by many interviewees (Aut1, Aut7, and Air2).

4.3.2. Long-term SCRes reactive response strategies

The long-term SCRes reactive strategies highlighted by the interviewees include:

-

(1)

Lifeline and transportation system,

-

(2)

Emerging technologies,

-

(3)

Supply chain collaboration.

Evidence of these strategies is provided in part (b) of Table 10. Importantly, many interviewees (Aut6, Air1, Air2, Air4, and Air7) called for an urgent need for both governments and firms to coordinate effectively among one another in order to ensure that air cargo begins functioning normally, as suggested by the International Air Transport Association (IATA, 2020b). Second, firms should ensure the use of emerging technologies during disruptions, in order to enable them to recover quickly from after-shocks of such disruptions. The impact of the interplay of different digital technologies on reducing TTR vis a vis the intensity of the ripple effect in supply chains, has already been proven in literature (Ivanov et al., 2017). Finally, a few interviewees (Aut1, Aut3, Aut5, Aut6, Aut7, Air2, and Air5) emphasized upon the necessity of supply chains to learn to work together, and share their goals and information in order to develop robust coordinated strategies, fostering thereby faster recovery.

4.3.3. Long-term proactive SCRes proactive response strategies

The SCRes proactive strategies emphasized by the interviewees in the long-term are:

-

(1)

Digital transformation,

-

(2)

Integrated risk management,

-

(3)

Corporate Social Responsibility.

The evidence from the interviews is given in part (c) of Table 10. Accordingly, many interviewees (Aut1, Aut2, Aut4, Aut7, Air1, Air2, Air3, and Air7) attested that firms in both manufacturing and service supply chains should promote their digital transformation and SCRes capabilities against future disruptions. Other interviewees, such as Aut1, Aut4, Air2, Air3, Air5, and Air6 highlighted the challenges of adapting traditional risk management approaches involving only top-tier suppliers in the post-COVID-19 era. This would make businesses oblivious and vulnerable to disruptions and shocks, hitting their ‘invisible’ lower-tier suppliers. The COVID-19 outbreak has highlighted the need to involve all supply-chain nodes in creating an integrated approach to supply-chain risk management. Finally, many experts, such as Aut1, Aut3, Aut6, and Air1 called for adopting more holistic approaches that merge supply-chain resilience and Corporate Social Responsibility (CSR) practices to protect employment and employees in the workplace. Notably, manufacturing and service supply-chain actors should learn from the disastrous social effect generated by the ongoing pandemic that has disrupted millions of lives around the world, causing tremendous human and economic losses. These actors should thereby look to develop more socially-oriented strategies in the future. Besides, customers, investors, governments, and other key stakeholders should ultimately judge firms on their level of humanitarian and socially responsible attitude in the future.

5. Discussion and implications from the study

5.1. Decision-making framework for the practitioners

Finally, we draw the practitioners' implications by summarizing the key lessons learned from the findings, and providing a decision-making framework to plan the SCRes strategy to overcome the impact of COVID-19.

RQ1: What is the level of resilience of manufacturing and service supply chains against the COVID-19 outbreak?

The analysis of TTR and FI of both automobile and airline supply chains demonstrated a significant impact of the COVID-19 outbreak through a TTR that might exceed one year, and several hundreds of millions of dollars as FI in each sector, leading to many social impacts, such as job losses and increase in poverty. Further, the analysis showed that both the manufacturing and service sectors are not immune to the COVID-19 effect. This could be explained by the unexpected drop in demand, along with global movement restrictions of products and services in an attempt to curb the spread of the virus (Katafuchi et al., 2020). Moreover, the findings suggest that the global supply chains (both in manufacturing and service sectors) are likely to be vulnerable to such a substantial unexpected disruption, albeit with some differences. For instance, the service sectors, such as airlines, which have been particularly greatly affected with a sharp negative demand shock in the initial months of the global outbreak, are likely to witness U-shaped disruption with an extended TTR and a high FI. On the other hand, the manufacturing supply chains have great potential to have a V-shaped scenario with moderate effect in the long-term. It is noteworthy that some particular industries of first-necessity products such as food and medicines, which have experienced a sharp rise in demand in the short-term, are not related to our analysis.

While generalizing the findings to the other sectors, it is implied that the hardest-hit sectors would probably see the fastest and the most robust recovery, as unexpressed demand is released in line with a recovery in sentiment and production resumptions. However, the manufacturing sector's recovery would largely depend on the firms' ability to quickly re-mobilize their complex multi-country supply chains, depending on how best they can map them as well as manage the risks. COVID-19 has exposed the structural flaws in the firms' approach towards global manufacturing and sourcing to a great extent. Based on our analysis, we assume that manufacturing firms would in all likelihood reshape their global business landscape.

We also learn that the manufacturing and service industry's level of supply chain resilience, would depend on how they have digitalized their supply chain operations. COVID-19 has put immense pressure on these firms for digital transformation to mitigate disruptions in the supply chains. The significant short and long-term strategies identified from our interactions with industry practitioners to mitigate supply chain disruptions are discussed below.

RQ2: How could global manufacturing and service supply chains respond to the COVID-19 disruption in the short- and long-term run?

Both the qualitative and quantitative study of the SCRes response strategies adopted by the selected supply chains to mitigate the effect of the global outbreak both in the short and long-term has led to developing a generalized and integrated decision-making framework for developing SCRes (Fig. 7 ).

Fig. 7.

An integrated decision-making framework for SCRes in manufacturing and service supply chains.