Main Text

The coronavirus disease 2019 (COVID-19) epidemic has become a global public health emergency over last months. As of September 14th, over 28,000,000 confirmed cases and 917,000 deaths have been reported from all over the world.1 Its large-scale outbreak and pandemic cause an extreme shortage of personal protective equipment (PPE) and medical supplies such as face masks, testing kits, nasopharyngeal swabs, and medical ventilators in the early stage, which consequently leads to the collapse of local medical systems.2 It turns out that measures like lockdown and travel bans are the most effective strategies in response to an epidemic at an early stage with insufficient knowledge.3 However, those physical isolation measures will inevitably result in work stoppages and have a great impact on industrial production. The supply of raw materials and components, and the production and transportation of final products are greatly restricted under a global supply chain.4 This further aggravates the shortage of anti-epidemic supplies and so the vicious cycle begins.

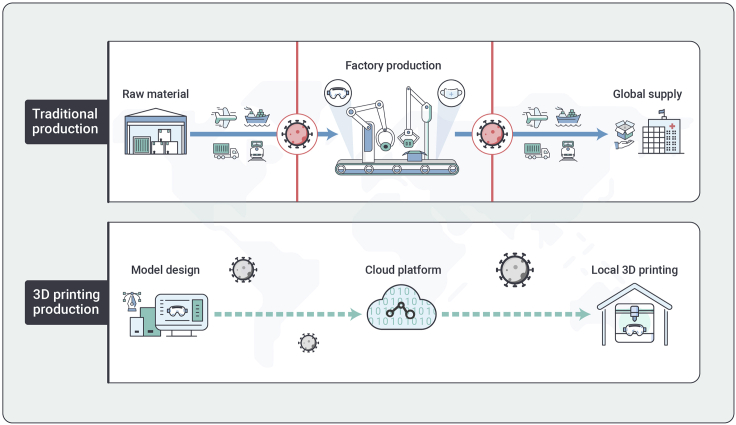

3D printing technology provides an opportunity to break the vicious cycle (Figure 1). Over the past few months, 3D printing communities, including companies and individuals around the world, made the most of their manufacturing skills and capabilities to fight against the global outbreak of COVID-19. 3D-printed anti-epidemic supplies, including medical goggles, face masks, nasopharyngeal swabs, valves for medical ventilators, shells of handheld body temperature monitors, and breathing masks have been rapidly fabricated and put into use.5 3D models of COVID-19-infected lungs of critically ill patients were developed to guide the diagnosis and treatment.6

Figure 1.

Comparison between 3D Printing Production and Traditional Production in Rapid Response to Public Health Emergencies

3D printing technology has demonstrated some special capabilities and its potential in rapid response to a public health emergency. The first one is its unprecedentedly rapid progress from design to production. For example, 3D printing took only a few days from design to final production with a daily production capacity over hundreds.7

Another important capability of 3D printing is decentralized manufacturing. Sharing digital models through the Internet enables 3D printing communities from all over the world to participate, quickly forming a 3D manufacturing international Internet of things (IoT), breaking geographical restrictions, and achieving local production. Meanwhile, the cloud manufacturing platform allows network collaborative production to further improve the production efficiency. For example, a digital model of custom-designed face masks was developed and freely shared online,8 and many similar digital models of PPE are available online now.

Furthermore, 3D printing is a manufacturing mode with a high degree of freedom and very low threshold. Although it cannot substitute for traditional industrial manufacturing, a certain proportion of 3D printing in the manufacturing industry can easily mobilize non-medical manufacturers and individuals. Affected by the COVID-19 epidemic, many factories around the world have stopped production. Airbus, Volkswagen, Mercedes-Benz, and numerous other companies evolved a cross-border cooperation through an international network called Mobility goes Additive (MGA). They have recently switched their main production facility to producing PPE such as goggles and face shields to support medical staff in fighting against COVID-19.

At the same time, we must be aware that many problems and challenges remain in this field. First of all, unlike industrial manufacturing, production by 3D printing in an emergency normally lacks proper quality assurance/quality control (QA/QC). Even with the same digital model, different printing materials, printers, and printing parameters may lead to different performance of products. This may cause serious problems regarding testing kits and medical devices, which need high precision and reliability. As an example, to cope with the shortage of medical resources, the US Food and Drug Administration (FDA) has granted emergency use authorization (EUA) to a 3D printing manufacturer, Formlabs, for the first time to allow them 3D print adapters for medical ventilators.4 The toxicity of 3D printing materials is another potential issue related to the production's QA/QC, because some printing materials have been proved to be toxic.9 Hence, the publisher of a 3D printing model bears the responsibility for the validity of the model, and sufficient product testing by manufacturers or users before clinic use is necessary. In this case, the model publisher, manufacturer, and user should clarify the responsibilities for the potential undesirable consequences caused by using 3D-printed products. For this purpose, it is necessary to set up a screening system to examine relevant models before their upload and clinic use. Meanwhile, the screening should provide standards and guidelines for 3D manufacturing and model sharing. Authorities like FDA can play a very important role in this regard.

Second, 3D printing should occupy a certain proportion of industrial production and form a complementary relationship with other production modes. In recent years, the 3D printing industry has been developed rapidly all over the world. According to the estimates, the United States has the largest amount of 3D printers in the world (422,000 units in 2019), while the 3D printing industry of China is expected to have an output value of $7.68 billion and to occupy one-third of the global market by 2020.10 Despite this, the proportion of 3D printing in the industrial system is still small. Compared with other modes of production, a 3D printer can be used to manufacture completely different products with strong versatility and almost no startup time. In order to make better use of this feature, it is necessary to develop versatile 3D printers, make the printing process more intelligent, improve printing performance, develop more biocompatible materials, reserve more models in peacetime, and develop user-friendly software library just like a smart-phone app store. In this way, the 3D printer will become a common household/community appliance to realize local production and local service in the near future, and more ordinary people will be able to easily design, obtain, and print the digital models.

Third, intellectual property protection is another issue 3D printing has encountered. On the one hand, all commercial products are protected by copyrights and patents, and reproduction of them may risk violation of the law. In an existing case, after a hospital in Italy ran out of ventilator valves in treating COVID-19 patients but did not get replenishment in time, a local startup company helped them with 3D-printed replica parts at much lower costs. They saved dozens of lives but are facing the risk of being sued by the original manufacturer. 3D printing or waiting for replenishment is not a hard choice when saving lives during an emergency. However, we do need proper criteria or laws to determine under what circumstances the reproduction of commercial products by 3D printing is acceptable without legal authorization from the owners of the rights. These criteria should include, but not be limited to, emergencies, lack of conditions or time to obtain authorization, non-profit, and restricted use of the digital models. On the other hand, the intellectual property protection for digital models is weak at present. Once published online, the threshold from digital model to real object is very low due to the gradual popularization of 3D printers, and people with ulterior motives can exploit this. In this respect, we should improve and strengthen the protection of the copyright of digital files.

This was the first time that 3D printing demonstrated its great potential in the rapid response to a public health emergency. With the cost reduction and development of versatile printers with high performance and more printable materials, as well as enhanced QA/QC, complementary with other production modes, and improved intellectual property protection strategies in an emergency, 3D printing technology will play a more important role in rapid response to not only public health emergencies but also other emergency issues, such as accidents in traffic, construction, and earthquakes.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (91743203, 21825403, and 21677153) and The Thousand Talents Plan for Young Professionals, China. We also acknowledge the support of the Sanming Project of Medicine in Shenzhen (No. SZSM201811070).

References

- 1.World Health Organization Coronavirus disease 2019 (COVID-19) weekly epidemiological update. https://www.who.int/docs/default-source/coronaviruse/situation-reports/20200914-weekly-epi-update-5.pdf?sfvrsn=cf929d04_2

- 2.Ranney M.L., Griffeth V., Jha A.K. Critical supply shortages - the need for ventilators and personal protective equipment during the Covid-19 pandemic. N. Engl. J. Med. 2020;382:3. doi: 10.1056/NEJMp2006141. [DOI] [PubMed] [Google Scholar]

- 3.Chen S.M., Yang J.T., Yang W.Z., et al. COVID-19 control in China during mass population movements at New Year. Lancet. 2020;395:764–766. doi: 10.1016/S0140-6736(20)30421-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Manero A., Smith P., Koontz A., et al. Leveraging 3D printing capacity in times of crisis: recommendations for COVID-19 distributed manufacturing for medical equipment rapid response. Int. J. Environ. Res. Public Health. 2020;17:4634–4651. doi: 10.3390/ijerph17134634. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Ishack S., Lipner S.R. Applications of 3D printing technology to address COVID-19-related supply shortages. Am. J. Med. 2020;133:E385–E387. doi: 10.1016/j.amjmed.2020.04.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Larraneta E., Dominguez-Robles J., Lamprou D.A. Additive manufacturing can assist in the fight against COVID-19 and other pandemics and impact on the global supply chain. 3D Print. Addit. Manuf. 2020;7:100–103. doi: 10.1089/3dp.2020.0106. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Zastrow M. Open science takes on COVID-19. Nature. 2020;581:109–110. doi: 10.1038/d41586-020-01246-3. [DOI] [PubMed] [Google Scholar]

- 8.Swennen G.R.J., Pottel L., Haers P.E. Custom-made 3D-printed face masks in case of pandemic crisis situations with a lack of commercially available FFP2/3 masks. Int. J. Oral Maxillofac. Surg. 2020;49:673–677. doi: 10.1016/j.ijom.2020.03.015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Oskui S.M., Diamante G., Liao C.Y., et al. Assessing and reducing the toxicity of 3D-printed parts. Environ. Sci. Technol. Lett. 2016;3:1–6. [Google Scholar]

- 10.https://3d.ultimaker.com/Sentiment-index?elqTrackId=07b79c02d7b0442bb44f57455e0de8e8&elq=00000000000000000000000000000000&elqaid=599&elqat=2&elqCampaignId=