Abstract

The present study evaluated the effect of supercritical fluid extraction (SFE) assisted by cold pressing (SFEAP) on the overall yield, extraction kinetics, composition of baru seed oil and manufacturing cost (COM). The best extraction conditions were determined in extraction assays combining different pressures (150–350 bar) and temperatures (35 and 45 °C). The extraction yield by SFEAP (28.6 g oil/100 g baru seed) was approximately 31% higher than that obtained by SFE (21.9 g oil/100 g baru seed), according to the kinetic study with the best extraction conditions (350 bar and 45 °C). The extraction yield observed under this condition allowed us to obtain a lower COM for both techniques (SFE was US$ 118.32/kg baru oil and SFEAP was US$ 87.03/kg baru oil) compared to lower pressures and temperatures. The oil obtained under all extraction conditions was rich in unsaturated fatty acids and other bioactive compounds. The extraction of baru seed oil by SFEAP resulted in a higher yield and lower manufacturing cost than SFE.

Keywords: Economic evaluation, Supercritical fluid extraction assisted by pressing, Baru seed oil, Supercritical CO2

Economic evaluation; Supercritical fluid extraction assisted by pressing; baru seed oil; supercritical CO2.

1. Introduction

The baru (Dipteryx alata) is native to the Brazilian savannah; its seeds are consumed roasted and used as ingredients in the typical gastronomy in several states of Brazil. Baru seeds have high lipid and protein contents of high nutritional qualities (Sousa et al., 2011; Fernandes et al., 2010). In traditional medicine, baru is used to treat various diseases, such as cholesterol, diabetes, gastritis, osteoporosis, and sexual impotence (Ribeiro et al., 2017). Recently, it has been reported that baru seed consumption contributes to the reduction of cholesterol in slightly hypercholesterolemic people (Bento et al., 2014).

Several studies have focused on the extraction and identification of the bioactive compounds present in baru seeds to better use their nutraceutical potential. For this purpose, discontinuous and continuous mechanical pressure was used to extract the oil, obtaining yields of 7.9 % and 25 %, respectively (Marques et al., 2015). The yield obtained in the continuous pressing process was higher than that obtained by discontinuous mechanical pressure (Marques et al., 2015) and SFE (Santos et al., 2016). Nonetheless, in the oil obtained, no terpenes were detected. These are the compounds with the major biological activities present in baru seeds. Therefore, the continuous pressing process negatively affects the composition of the oil due to the temperature increase resulting from friction (Marques et al., 2015). This behavior was different in the oil obtained by hydraulic pressing, in which the presence of mono- and sesquiterpenes was observed but with a lower overall yield (Marques et al., 2015). On the other hand, SFE has been successfully applied for oil extraction of added value nutraceutical from Vitis vinífera L. (Coelho et al., 2018), Eucommia ulmoides Oliv (Zhang et al., 2018), Hylocereus polyrhizus (Abdullah et al., 2018), Citrullus lanatus var. Colocynthoideis (Karrar et al., 2019), Dracocephalum kotscthyi Boiss (D. kotschyi) (Sodeifian et al., 2017), Plukenetia volubilis L. (Triana-Maldonado et al., 2017), the pulp Caryocar brasiliense (Johner et al., 2018b) and Persea americana (Abaide et al., 2017; Corzzini et al., 2017). SFE was applied in the extraction of baru seed oil using supercritical carbon dioxide as the extraction solvent, obtaining the highest yields at 40 °C (22.6 %) and 50 °C (22.8 %) at 35 MPa (Santos et al., 2016). These results were obtained using a solvent flow rate of 11.46 g/min and solvent mass/feed mass ratio (S/F, g/g) of 458.4, both used as scaling factors (Duba and Fiori, 2019). In the literature, lower values are used for scaling projects (Prado et al., 2011), and it is known that these factors influence technical and economic viability; therefore, it is necessary to optimize SFE processes at a laboratory scale seeking to obtain the lowest flow rate and S/F possible. The reduction in particle size leads to an increase in the overall extraction yield. Nevertheless, an excessive reduction (such as 0.5 mm as used by Santos et al. (2016)) could cause fluidization and agglomeration problems due to the flow rate of the solvent, producing channels in the extraction bed (Valle, 2015; Valle et al., 2014).

Alternatively, organic solvents could be used as cosolvents in supercritical extraction to improve the extraction yield of baru oil, as was done in the extraction of quinoa oil (Wejnerowska and Ciaciuch, 2018). Nevertheless, it is not attractive for the present study because it affects the extraction selectivity and negatively affects the oil phytochemical profile. Then, the use of cosolvents was not considered because this study aimed to obtain an oil rich in terpenic compounds, which are low polarity compounds such as supercritical CO2 (Park et al., 2007). An extraction method was recently developed, combining two extraction methods, SFE and cold pressing, called supercritical fluid extraction assisted by pressing (SFEAP) (Johner et al., 2018b). The SFEAP method, compared to SFE, proved to be more efficient in extracting pequi oil (C. brasiliense). In that study, the pressure was applied through a piston connected to the extractor; the pressure was generated by applying two torques (40 Nm and 70 Nm). The authors concluded that the lowest torque efficiently increased the extraction yield (Johner et al., 2018b). Similar studies were carried out with fennel (Foeniculum vulgare) (Hatami et al., 2018) and clove buds (Syzygium aromaticum) (Hatami et al., 2019). In both, an increase in the extraction yield was observed with the SFEAP method with a torque of 40 N.m. The implementation of cold pressing in the SFE process increases the extraction yield and, consequently, decreases the cost. The technique's cost/benefit is also attractive due to the time gain considering that the SFEAP method requires less time (Hatami et al., 2019). For these considerations, the present study aimed to evaluate the interaction between the cold pressing process's extraction pressure and extraction with supercritical CO2 (sc-CO2) on the extraction yield and composition of baru seed oil. Additionally, both extraction processes (SFE and SFEAP) were evaluated economically.

2. Materials and methods

2.1. Sample obtention

A total of 8.4 kg of baru fruit was collected from the soil under trees in the city of Pontal do Araguaia, MT, Brazil. The fruits were then bagged and transported to the Supercritical Technology Laboratory (LASEFI) in Campinas, SP, Brazil.

2.2. Sample preparation

Baru fruits were selected, washed with drinking water, and left to dry at room temperature (20 °C for one day). After drying, the fruits were peeled and pulped manually with the aid of a stainless steel knife, obtaining the endocarp containing the seeds. The seeds were removed by cutting the endocarp using a hand-held metal saw and a bench blade. The seeds were stored at freezing temperature (-20 °C) and protected from light until the extraction experiments were carried out. For the extraction, the baru seeds were previously submitted to grinding using a Mixer (Walita Philips Mix, 400 W, Brazil) for 80 s. The average particle diameter was determined using a sieve shaker (Bertel, N. 1868, Caieiras, Brazil), according to the equation proposed by the American National Standard Institute (ANSI-ASAE, 1998).

2.3. SFE extractions

The extractions were performed on equipment assembled and validated at LASEFI (Johner and Meireles, 2016). In the extraction assays, 10 g of ground baru seeds was used. With an average particle size of 1.8 mm, loaded in a 0.1 L extraction vessel, the vessel's volume not occupied by the sample was completed with glass beads. The extractions were carried out using a static time of 5 min and combining pressures of 150, 200, 250, 300, and 350 bar, with two temperatures of 35 and 45 °C, making a total of 10 extractions, with two repetitions in each assay. The extractions were performed for 17 min (S/F ~ 12), and the yields obtained were used to determine the best extraction pressure and temperature. These conditions were used for the kinetic study until complete extraction. Carbon dioxide was used as the extraction solvent at 99% purity (White Martins, Campinas, Brazil). The extraction yield (y,%) was calculated with Eq. (1), where moil is the mass of the extracted oil and mraw-material is the mass of the raw material used for extraction.

| (1) |

2.4. SFEAP extractions

The SFEAP method was performed in the same equipment as SFE, to which a cold-pressing system was attached. The extraction process was performed according to the methodology described by Johner et al. (2018b). Ten grams of ground baru seeds were placed in a 0.1 L extraction vessel, and then the sample was compressed with the piston of the cold-pressing system by applying a torque of 40 Nm with the aid of a torque wrench (Sata, ST96303SC, Sorocaba, Brazil). After pressing, the pressing system was disassembled, and the extraction vessel was assembled (Johner et al., 2018b). The best extraction conditions were determined following the same steps and conditions described in section 2.3.

2.5. Extraction kinetics and modeling

The best extraction conditions (pressure and temperature) determined in sections 2.3 and 2.4 were used to obtain the baru oil extraction kinetics by SFE and SFEAP. The extraction kinetics were constructed by plotting the accumulated extraction yield (g) versus the extraction time (min). Approximately 10 g of ground baru seeds was used for extraction, and during the extraction period, 14 extract samples were collected sequentially at different times (approximately 1, 2, 4, 7, 10, 15, 21, 29, 39, 54, 76, 103, 139 and 185 min).

The spline model was used for the mathematical modeling of extraction kinetics by SFE and SFEAP. The spline model typically describes three regions or extraction periods. A period of constant extraction speed (CER) in which the extraction is controlled by convection. A period of decrease in extraction speed (FER) in which extraction occurs by convection and diffusion, and finally, a period controlled by diffusion (DC) (Jesus et al., 2013; Meireles, 2008). The spline model is shown in Eqs. (2), (3), and (4).

| (2) |

| (3) |

| (4) |

where mExt is the mass of extract (g oil baru seeds); a1, a2 and a3 are the slope coefficients (first-order terms) of CER, FER and DC straight lines, respectively (g/min); tCER is the time interval of the CER period (min); and tFER is the end of the FER period (min).

The fit quality of the experimental data to the spline model was evaluated considering the objective function defined as the absolute average relative deviation (AARD) referred to as the accumulated mass extract expressed by Eq. (5) (Santos et al., 2016):

| (5) |

AARD is the average absolute relative deviation (%), n is the number of data points, and xi, exp and xi, and cal refer to the experimental and calculated yields for data i, respectively.

2.6. Extracts analysis

Qualitative analysis of baru oil by thin-layer chromatography (TLC) was performed for the qualitative identification of volatile compounds. Silica gel plates (Macherey-Nagel, DC-Fertigfolien Alugram®, Xtra SIL G, 20 × 20 cm, Germany) were used as a stationary phase. The mobile phase was the same as Santana and Meireles (2016) used to quantify phenolic and volatile compounds. The mobile phase was composed of chloroform, ethanol, and glacial acetic acid (95:05:01 v/v, respectively). The detection of volatile compounds was carried out by spraying the vanillin-sulfuric acid developer on the plate at the concentration described by Pirrung (2017). The images of the revealed TLC plates were measured using ImageJ software, as described by Johner and Meireles (2016).

Baru oil extracted with the best extraction conditions in both methods, SFE and SFEAP, was analyzed to determine its composition in fatty acids. The oil was esterified to obtain fatty acid methyl esters (FAMEs) with approximately 0.5 g of oil, 10 mL of methanol, and two drops of H2SO4 at reflux for 2 h (Hartman, 1973). FAMEs were extracted with hexane and injected into the organic phase in an Agilent 6890 gas chromatograph. The chromatograph was equipped with a Stabilxax column (30 m × 0.25 mm; 0.25 μL) and a flame ionization detector (FID). Helium was used as a carrier gas, and the temperature was programmed as follows: 45 °C for 2 min, 5 °C/min up to 50 °C, 30 °C/min up to 250 °C, isotherm for 10 min. The injector and detector temperatures were adjusted to 250 °C. The identification of fatty acids was carried out by comparing the retention times of FAMEs obtained from baru oils with a FAME standard (Supelco, C8–C24 p/n CRM18918, USA) analyzed under the same chromatographic conditions. Fatty acids were quantified by calculating each FAME's peak area percentages, reporting as a relative percentage (%).

2.7. Process simulation model

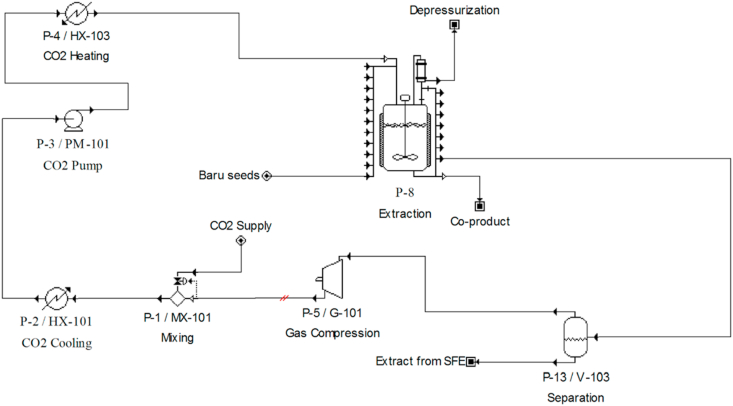

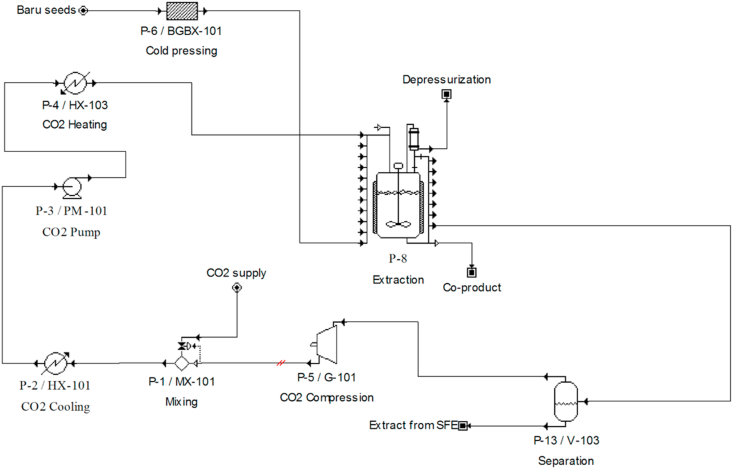

The SFE and SFEAP process simulations were performed using SuperPro Designer 8.5® software (Intelligen Inc., Scotch Plains, NJ, USA). Figure 1 shows the flowsheet used for the simulation of the SFE process. The process consisted of a CO2 replacement inlet, a cooler, a pump, and a heater. Initially, ground baru seeds are loaded into the extractor. Then, CO2 is cooled (-4 °C) using P2/HX-101 and pressurized (150–350 bar) using P-3/PM-101. CO2 is heated (35–45 °C) by P-4/HX-103 and enters P-8. Once the temperature and pressure are reached, extraction is performed. The solvent and the extract were recovered using a separation vessel P-13/V-103 (50 °C and 90 bar). The sc-CO2 is reused through P-5/G-101 (20 °C and 60 bar). For the SFEAP process (Figure 2), the raw material is cold-pressed in P-6/BGBX-101 before entering the extractor. Then, the pressed raw material is loaded into the extractor, and the process is conducted as described previously for the SFE process.

Figure 1.

Flowsheet of the SFE process, designed by SuperPro Designer 8.5® software: CO2 is cooled (-4 °C) using P2/HX-101 and pressurized (150–350 bar) using P-3/PM-101. CO2 is heated (35–45 °C) by P-4/HX-103 and enters P-8. The solvent and the extract were recovered using a separation vessel P-13/V-103 (50 °C and 90 bar). The sc-CO2 is reused through P-5/G-101 (20 °C and 60 bar).

Figure 2.

Flowsheet of the SFEAP process, designed by SuperPro Designer 8.5® software. CO2 is cooled (-4 °C) using P2/HX-101 and pressurized (150–350 bar) using P-3/PM-101. CO2 is heated (35–45 °C) by P-4/HX-103 and enters P-8. The solvent and the extract were recovered using a separation vessel P-13/V-103 (50 °C and 90 bar). The sc-CO2 is reused through P-5/G-101 (20 °C and 60 bar).

2.8. Economic evaluation

The value of each piece of equipment used in the SFE and SFEAP processes was estimated using direct quotation values reported by Johner et al. (2018c) (see Table 1). An extraction facility with one extraction vessel of 40 L was considered. This volume was chosen based on our experience in the development of homemade SFE equipment. To determine the equipment cost at the required capacity, Eq. (6) was used. This equation corresponds to the power law of capacity (Smith, 2005).

| (6) |

Table 1.

The basic cost for equipment composing the SFE and SFEAP plants.

| na | Unit base cost (US$) 0.1 Lb | Number required | Total base cost (US$) | |

|---|---|---|---|---|

| Jacketed extraction vessel | 0.82 | $300.00 | 1 | $40,814.00 |

| Air-driven pump (booster) | 0.55 | $800.00 | 1 | $21,589.00 |

| Cooler | 0.59 | $1,360.00 | 1 | $46,640.00 |

| Heater | 0.59 | $430.00 | 1 | $14,746.00 |

| Separation vessel | 0.49 | $600.00 | 1 | $11,302.00 |

| Manometer | 0.60 | $70.00 | 2 | $5,098.00 |

| Blocking valve | 0.60 | $60.00 | 2 | $4,369.00 |

| Micrometering valve | 0.60 | $130.00 | 1 | $4,733.00 |

| Safety valve | 0.60 | $280.00 | 1 | $10,195.00 |

| Flowmeter | 0.60 | $90.00 | 1 | $3,277.00 |

| Temperature controller | 0.60 | $180.00 | 1 | $6,554.00 |

| CO2 compressor | 0.46 | $1,200.00 | 1 | $18,886.00 |

| Piping, connectors, mixers, splitters, and crossheads | 0.60 | $250.00 | 1 | $9,103.00 |

| Structural material for supporting the equipment |

0.60 |

$150.00 |

1 |

$5,462.00 |

| TotalCost forSFE | - | - | - | $202,767.00 |

| Pressing system | 0.60 | $290.00 | 1 | $10,559.00 |

| TotalCost forSFEAP | - | - | - | $213,327.00 |

n constant depending on equipment type (El-Halwagi, 2012; Peters et al., 2003).

Based on Johner et al. (2018c).

Eq. (6) has been used by several authors to estimate the cost of several types of equipment used to calculate the COM of Genipa americana extracts (Náthia-Neves et al., 2019), Carludovica palmata, Ruiz & Pav (Galviz-Quezada et al., 2019) and cupuassu extracts (Cavalcanti et al., 2016).where C1 is the equipment cost with capacity Q1, C2 is the known base cost for the equipment with capacity Q2, and n is the equipment-type constant. Values of n were collected from El-Halwagi (2012) and Peters et al. (2003). In this study, the cost of manufacturing (COM) was estimated according to the method proposed by Turton et al. (2012) (Eq. 7). The three main components (direct costs, fixed costs, and general expenses) were estimated in terms of the following five major costs: fixed capital of investment (FCI), cost of raw material (CRM), cost of operational labor (COL), cost of utilities (CUT), and cost of waste treatment (CWT).

| COM = 0.304 × FCI +2.73 × COL +1.23 × (CUT + CWT + CRM) | (7) |

FCI is associated with expenses involved in implementing the extraction plant, extractors, equipment, and auxiliary equipment. CRM includes the costs of the preprocessing of the baru seeds for extraction (cleaning, breaking the hard shell, selecting nuts, and milling) and the costs of CO2. COL is related to the number and wage of the operators of the extraction unit and auxiliary equipment. In this work, two operators were considered to be sufficient based on our experience. CUT considers the energy used in the solvent cycle for generating steam, refrigerating the materials, and using electricity. In this work, CWT is considered to be zero because the coproduct generated from the extraction process is harmless and clean. Thus, it would potentially be used as a raw material in another process, for instance, the baru flour that can be used in the formulation of special diet products.

For scale-up, it was assumed that the process yields and extract composition obtained in the laboratory scale unit would also be obtained at the industrial scale under the same processing conditions. An industrial extractor of 40 L was considered. The SFE and SFEAP processes were designed to operate for 7920 h year−1 (e.g., three daily shifts for 330 d year−1). The amount of raw material to be extracted was calculated based on the extractor size and the S/F ratio used for the extractions. The CO2 loss during the process was presumed to be 2 %, which was the loss from a separator (flash tank) that was calculated by the simulator. Initially, the baru seed purchasing cost was assumed to be US$20 kg−1 (Mercadolivre, São Paulo, Brazil). Table 2 provides the data used to estimate COM.

Table 2.

Input economic parameters used for simulating the COM of Baru oil obtained from Baru seeds by SFE and SFEAP; the scale of 40 L.

| Values | |

|---|---|

|

Direct Fixed Capital (DFC) | |

| SFE extraction planta | US$382,859.00 |

| SFEAP extraction planta | US$400,014.00 |

| Insuranced | 1.5% DFC |

| Local taxesd | 2.5% DFC |

| Factory expensed |

5.5% DFC |

|

Fixed capital investment (FCI) | |

| SFE extraction plantb | US$202,767.00 |

| SFEAP extraction plantb | US$213,327.00 |

| Depreciation ratec | US$ 10%/year |

| Annual maintenance ratec |

6%/year |

|

Cost of operational labor (COL) | |

| Waged | US$ 16.80/h |

| Number of workers per shift |

2.00 |

|

Cost of raw material (CRM) | |

| Baru seedse | US$ 20.00/kg |

| Pre-processing Baru seedsd | US$ 40.00/t |

| Industrial CO2d |

US$ 2.70/kg |

|

Cost of utilities (CUT) | |

| Electricityd | US$ 0.50/kWh |

| Water (for cooling and cleaning)d | US$ 1.06/t |

| Glycol solutiond | US$ 15.00/t |

SuperPro Designer.

Estimated cost using Eq. (1).

Based on Peters et al. (2003).

based on Johner et al. (2018c).

Direct quotation.

2.9. Sensitivity study

A sensitivity study allows establishing a project's profitability based on project indices and its behavior under different scenarios. The sensitivity study was performed considering that the SFE extract selling price is US$ 533.00 kg−1 (Terra Flor, Alto Paraíso de Goiás, Brazil). A sensitivity study is typically conducted using the following project indices: gross margin (GM), return on investment (ROI), payback time (PT), internal rate of return (IRR) and net present value (NPV). The GM is calculated as the percentage of a company's total sales revenue minus its cost of goods sold divided by the total sales revenue. Thus, it is the proportion of each dollar of revenue that the company retains as gross profit (Dimian, 2003). In other words, this parameter is an indicator that allows evaluating the short-term benefits of a specific activity. The ROI is the annual profit generated by a unit of invested capital; then, the more desirable the project is, the higher the ROI. This parameter is a performance measurement used to evaluate the efficiency of an investment. For example, ROI values between 10 % and 15 % are used to accept or cancel a project (El-Halwagi, 2012). PT represents the length of time necessary to recover the cost of an investment. Although the PT's accepted value depends on the type of company and its investors, it is generally accepted that the shorter the payback time is, the faster the initial investment is recovered. The NPV is the difference between cash inflow and cash outflow over a specific period and represents that the remaining “surplus” for the investor is the gain on the initial investment. According to Terry et al. (1992), a project should be considered feasible if the NPV of a project is positive after assuming a discount interest of 7%.

2.10. Statistical analysis

The effect of temperature, pressure, and the extraction method (SFE and SFEAP) on the overall extraction performance was evaluated by analysis of variance (ANOVA) at a significance level of 0.05, considering a full factorial randomized design. The mathematical modeling of the extraction kinetics using Eqs. (2), (3), (4), and (5), was performed using the genetic algorithm (GA) with MATLAB software (MathWorks, version R12).

3. Results and discussion

3.1. Baru fruit and seed characteristics

The production of barú fruits occurs between March and August (Isa, 2009). According to a biometric study of the fruits and seeds, carried out by Zuffo et al. (2014), it was observed that the fruits had a weight between 27.5 and 34.7 g, longitudinal size between 53.7 to 59.5 mm and width between 28.8 to 31.6 mm, on the other hand, the seeds had a weight between 1.2 to 1.3 g, longitudinal size between 22.3 to 25.91 mm and width between 7.2 to 8.9 mm. The seeds present 3.5% moisture, 29.9% protein, 41.9% total lipids, 12.25% carbohydrates and 9.2% total fiber (Sousa et al., 2011). A similar composition was observed by Vera et al. (2009).

3.2. Oil extraction

ANOVA showed that the temperature, pressure, and extraction method individually had a significant effect (p-value <0.001) on the extraction yield, as observed in the extraction isotherms (Figure 3A). In the same way, the interaction between temperature - pressure and temperature - extraction method showed a significant effect (p-value < 0.02 and p-value < 0.001, respectively). This was different in the interaction between the extraction method and pressure, showing a p-value > 0.05, in the same way, in the interaction between the three variables (p-value > 0.05). These results may be influenced by the highest standard deviation observed in the extraction isotherms of the SFEAP method. This variation in the standard deviation is because, in the SFEAP process, there are losses of extract and raw material, specifically in the disassembly of the mechanical press after mechanical cold pressing. The losses of extract and raw material are because these adhere to the inaccessible spaces of the press piston. These losses could be reduced if the mechanical pressing and supercritical extraction processes were executed online, with which it could avoid such losses.

Figure 3.

Extraction yield of Baru seed oil with sc-CO2 at different pressures (150–350 bar). (A) and densities (740.05–952.25 kg m−3) (B), with (SFEAP) and without pressing (SFE) at 35 and 45 °C. The CO2 flow rate was 7 g/min, and the S/F ratio was 12.

The highest and lowest yields obtained after 17 min of extraction by SFE were 8.3 g oil/100 g baru seed (350 bar and 45 °C) and 1.9 g oil/100 g baru seed (150 bar and 45 °C), while via SFEAP, they were 12.9 g oil/100 g baru seed (350 bar and 45 °C) and 4.1 g oil/100 g baru seed (150 bar and 35 °C), respectively. The extraction isotherm of SFEAP at 45 °C showed the highest extraction yields compared to the same technique at 35 °C and for SFE at the two temperatures studied (Figure 3A). The effect on baru oil extraction yield, observed under different extraction conditions, is because temperature and pressure affect the properties of sc-CO2 (Figure 3B), changing its density in the extraction bed (Cornelio-Santiago et al., 2017; Gustinelli et al., 2018; Rai et al., 2018). Overall, the SFEAP technique obtained higher yields in all pressure and temperature conditions than SFE, and the major extraction yield found for baru seeds using SFEAP was 55 % higher than the best result found by SFE at 350 bar and 45 °C. This condition was chosen as the best condition for the kinetic study.

3.3. Kinetic and spline model

The extraction kinetics with the best extraction conditions (350 bar and 45 °C) with SFEAP (29 g oil/100 g baru seed) showed a higher final extraction yield than SFE (22 g oil/100 g baru seed) after approximately 185 min (Figure 4). The extraction yield by SFEAP was 27% higher than that reported by Santos et al. (2016); these results are promising for industrial applications. At 39 min of extraction with the SFEAP technique, an extraction yield similar to that obtained at 185 min of extraction with SFE was obtained using the same pressure and temperature conditions. The higher yield observed in the extraction with SFEAP concerning SFE (Figure 4) can be explained by the effect produced by applying mechanical pressure, which led to a greater release of the oily extract contained in the particles of baru seeds. This produced a greater saturation of the solvent in the static time (5 min), which led to a greater extraction in less process time. Similar observations were noted by Johner et al. (2018b) and Hatami et al. (2018) in the extraction of pulp Caryocar brasiliense and seeds Foeniculum vulgare, respectively.

Figure 4.

Kinetics of baru seed oil extraction by supercritical CO2 at 350 bar and 45 °C, with (SFEAP) and without pressing (SFE).

The mathematical model of the extraction kinetics for both the SFE and SFEAP techniques, using the spline model, allowed us to observe three extraction periods, CER, FER and DC. The kinetic parameters of the spline model for the SFE technique were tCER = 32.94 min, tFER = 59.43 min, a1 = 0.0539 g/min, a2 = 0.0116 g/min and a3 = 0.0017 g/min. ARRD (%) = 4.7 %. The kinetic parameters of the spline model for the SFEAP technique were tCER = 14.94 min, tFER = 44.44 min, a1 = 0.0844 g/min, a2 = 0.0453 g/min and a3 = 0.0031 g/min. ARRD (%) = 5.11 %. The yield in the CER period for the SFEAP technique (12.61 g oil/100 g baru seeds) was lower than that of the SFE technique (17.75 g oil/100 g baru seeds). In the FER period, the yield obtained by SFEAP (25.97 g oil/100 g baru seeds) was higher than that obtained by SFE (20.83 g oil/100 g baru seeds). The modeling of the extraction kinetics by SFE reported by Santos et al. (2016) showed, for the same raw material, two extraction periods according to the spline model. For the CER period (tCER = 11.46 min), they reported a 20.11% mass yield, with a mass transfer rate (mCER) of 0.61 g/min. These differences from our study are probably due to the smaller particle size (0.508 mm) and higher CO2 flow (11.46 g/min) used by these authors; it is known that a greater decrease in particle size and a higher CO2 flow increase the extraction yield (Johner et al, 2018a, 2018c). However, it is recommended for industrial purposes to use particular sizes equal to or greater than 1 mm to avoid fluidization and channeling problems of the extraction bed (Valle et al., 2014; Valle, 2015).

The yield in the FER period (44.44 min) obtained by SFEAP (25.97 g oil/100 g baru seeds) was higher than the total yield (22.8 g oil/100 g raw material) obtained in 120 min of extraction by Santos et al. (2016). In our study, extraction by SFEAP turned out to be more efficient than extraction by SFE, observing a higher yield in the FER period and, thus, for the total extraction time. This can be explained by observing that higher mass transfer rates were obtained for the three extraction periods. The mechanical pressure used in the SFEAP technique allows a greater release of the substrate, which leads to saturation of the extraction bed before supercritical extraction, allowing a higher extraction yield (Hatami et al., 2018; Johner et al., 2018b).

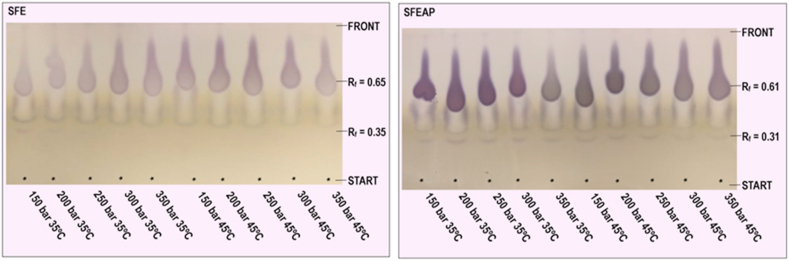

3.4. TLC

The baru oil extracts obtained under different conditions (pressure, temperature and extraction technique (SFE and SFEAP)) have similar phytochemical profiles (Figure 5), showing two spots on both chromatoplates, SFE (Rf, 1 = 0.35 and Rf, 2 = 0.65) and SFEAP (Rf, 1 = 0.31 y Rf, 2 = 0.61). The extracts obtained via SFEAP indicated an Rf of 0.31 compounds that were only indicated in SFE 150 bar and 35 °C. The purple spots on the chromatoplate indicate the presence of terpenoids (Tirimanna, 1973; Wagner et al., 1984). This coloration is produced by derivatization with the chromogenic reagent vanillin + sulfuric acid (Santana and Meireles, 2016; Spangenberg et al., 2011). Under the best extraction conditions (35 MPa and 45 °C) for both techniques (SFE and SFEAP), SFEAP showed two spots on the chromatoplate, and SFE showed only one (Figure 5), which allows us to infer that the SFEAP technique improved the composition of bioactive compounds.

Figure 5.

Images of the chromatoplates obtained from Baru oils obtained by SFE and SFEAP visualized under visible light after post derivatization with vanillin-sulfuric acid. Mobile phase: chloroform:ethanol:glacial acetic acid (95:05:01 v/v, respectively).

3.5. Fatty acid composition

The fatty acid profile and composition of baru oil obtained under the best extraction conditions (35 MPa and 45 °C) for both techniques (SFE and SFEAP) were similar (Table 3). A similar effect was observed for the fatty acid profile of Caryocar brasiliense oil obtained by both techniques (Johner et al., 2018b). The fatty acid composition of baru oil observed in the present study was similar to that reported by Santos et al. (2016). Baru oil contained 5 saturated fatty acids (C16:0, C18:0, C20:0, C22:0 and C24:0), 3 monounsaturated fatty acids (C18:1, C20:1 and C22:1) and a polyunsaturated fatty acid (C18:2). The content of monounsaturated fatty acids (MUFAs) was larger than the contents of polyunsaturated (PUFA) and saturated (SFA) fatty acids. An important concentration of MUFAs and PUFAs is noteworthy, especially linoleic fatty acids (omega 6), which, on average, showed a concentration of 26.5%. This polyunsaturated fatty acid is not synthesizable by humans. Therefore, it must be supplied through the foods that contain them. Its consumption is of great importance due to specific functions in which it participates: regulating monocyte immunomodulation related to atherosclerosis (Subash-Babu and Alshatwi, 2018), in combination with other PUFAs it has an anti-inflammatory effect (Melo et al., 2017), it has a cardioprotective effect (Chattipakorn et al., 2009), regulating metabolic syndrome in adults (Mirmiran et al., 2012) and other effects on human health.

Table 3.

Fatty acid composition (%) of Baru oil obtained by SFE (350 bar and 45 °C) and SFEAP (350 bar and 45 °C).

| Fatty acid | SFE (350 bar–45 °C) | SFEAP (350 bar–45 °C) |

|---|---|---|

| Palmitic acid (C16:0) | 7.6 (±0.1) | 7.3 (±0.1) |

| Stearic acid (C18:0) | 5.7 (±0.1) | 5.7 (±0.1) |

| Oleic acid (C18:1) | 50 (±1) | 49 (±1) |

| Linoleic acid (C18:2) | 27 (±1) | 26 (±1) |

| Arachidic acid (C20:0) | 1.4 (±0.1) | 1.4 (±0.1) |

| cis-11-Eicosenoic acid (C20:1) | 2.9 (±0.1) | 2.9 (±0.1) |

| Docosanoic acid (C22:0) | 3.0 (±0.1) | 3.6 (±0.1) |

| Erucic acid (C22:1) | 0.30 (±0.01) | 0.38 (±0.01) |

| Lignoceric acid (C24:0) | 2.6 (±0.1) | 3.5 (±0.1) |

| SFA | 20.3 (±0.5) | 21.5 (±0.5) |

| MUFA | 53 (±1) | 52 (±1) |

| PUFA | 27 (±1) | 26 (±1) |

3.6. Economic evaluation

Initially, the COM was determined for different process conditions for both processes. Processes with an S/F of 12 and pressures between 150 and 350 bar and temperatures of 35 and 45 °C were tested to compare the extraction process based on the COM. As can be observed in Table 4, for both extraction processes, the COM decreased as the pressure increased at the same temperature. Similar behavior was observed when the temperature increased. The combination of higher temperatures and pressures enhanced the performance of the process, and the yield increased. As the COM is calculated as the relation between the annual operating cost (CMR + FCI + COL + CUT) and the annual production rate, in this case, as the annual operating cost is almost constant for all process conditions (Table 4), the higher the yield is, the higher the productivity and therefore the lower the COM. A higher yield was obtained for both extraction processes when the process was conducted at 45 °C and 350 bar. Under these process conditions, COMs of US$ 260.33 kg−1 baru oil and US$ 167.77 kg−1 baru oil were determined for SFE and SFEAP, respectively. These COMs are consistent with the literature. For example, under optimized conditions, the SFE COMs were US$ 125.41 kg−1 and US$ 178.8 kg−1 for the production of oleoresin from malagueta peppers (Aguiar et al., 2018) and turmeric (Carvalho et al., 2015).

Table 4.

COM composition and project indices of the SFE and SFEAP processes. The system capacity and the Baru seeds purchasing cost were 40 L and US$ 20 kg−1, respectively.

| Pressure (bar) | Temperature (°C) | COM (US$/kg) | CRM (%) | COL (%) | FCI (%) | CUT (%) | GM (%) | ROI (%) | PT (years) | IRR (%) | NPV (US$ x 106) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SFE process | |||||||||||

| 150 | 35 | 1123.57 | 95.67 | 1.9 | 1.23 | 1.19 | -110.8 | -347.74 | N/A | N/A | -26.68 |

| 200 | 35 | 681.97 | 95.61 | 1.9 | 1.23 | 1.26 | -27.95 | -142.73 | N/A | N/A | -11.43 |

| 250 | 35 | 428.47 | 95.54 | 1.9 | 1.23 | 1.33 | 19.61 | 100.86 | 0.99 | 81.17 | 6.77 |

| 300 | 35 | 333.66 | 95.48 | 1.9 | 1.23 | 1.39 | 37.4 | 242.58 | 0.41 | 161.02 | 17.34 |

| 350 | 35 | 287.63 | 95.42 | 1.9 | 1.23 | 1.46 | 46.04 | 345.13 | 0.29 | 205.86 | 24.99 |

| 150 | 45 | 1628.96 | 95.61 | 1.9 | 1.23 | 1.26 | -205.62 | -446.1 | N/A | N/A | -34.03 |

| 200 | 45 | 684.17 | 95.54 | 1.9 | 1.23 | 1.33 | -28.36 | -144.45 | N/A | N/A | -11.56 |

| 250 | 45 | 438.14 | 95.48 | 1.9 | 1.23 | 1.4 | 17.8 | 89.89 | 1.11 | 73.67 | 59.56 |

| 300 | 45 | 314.69 | 95.41 | 1.9 | 1.23 | 1.46 | 40.86 | 281.23 | 0.36 | 178.83 | 20.23 |

| 350 |

45 |

260.33 |

95.35 |

1.9 |

1.23 |

1.53 |

51.16 |

423.15 |

0.24 |

235.39 |

30.83 |

| SFEAP process | |||||||||||

| 150 | 35 | 518.05 | 96.25 | 1.53 | 1.02 | 1.2 | 2.8 | 15.15 | 6.6 | 11.95 | 0.44 |

| 200 | 35 | 378.05 | 96.18 | 1.53 | 1.02 | 1.27 | 29.07 | 178.59 | 0.56 | 133.05 | 15.05 |

| 250 | 35 | 340.69 | 96.12 | 1.53 | 1.02 | 1.33 | 36.08 | 244.96 | 0.41 | 168.83 | 20.97 |

| 300 | 35 | 297.24 | 96.05 | 1.53 | 1.02 | 1.4 | 44.23 | 343.14 | 0.29 | 214.14 | 29.73 |

| 350 | 35 | 261.36 | 95.99 | 1.53 | 1.02 | 1.47 | 50.96 | 448.89 | 0.22 | 256.02 | 39.18 |

| 150 | 45 | 415.13 | 96.18 | 1.53 | 1.02 | 1.27 | 22.11 | 124.56 | 0.8 | 99.77 | 10.24 |

| 200 | 45 | 318.7 | 96.11 | 1.53 | 1.02 | 1.34 | 40.21 | 291.28 | 0.34 | 191.02 | 25.10 |

| 250 | 45 | 290.67 | 96.05 | 1.53 | 1.02 | 1.4 | 45.47 | 360.55 | 0.28 | 221.33 | 31.29 |

| 300 | 45 | 205.37 | 95.98 | 1.53 | 1.02 | 1.47 | 61.47 | 687.56 | 0.15 | 334.3 | 60.47 |

| 350 | 45 | 167.77 | 95.92 | 1.52 | 1.02 | 1.54 | 68.52 | 937.44 | 0.11 | 401.33 | 82.79 |

When both processes are compared, the SFEAP′ COM is lower than the SFE′ COM, as shown in Table 4: for the best process conditions (45 °C and 350 bar), the SFEAP′ COM is almost 35 % lower than the SFE’ COM. Generally, the SFEAP process has better performance using a slightly longer extraction time. The SFEAP process lasts only 10 min longer than the SFE process because the SFEAP includes cold pressing in its process. The application of cold pressing in the SFEAP process is fast and straightforward and allows us to increase productivity. As mentioned before, the annual operational cost is almost constant; it is possible to diminish the COM by increasing the extraction yield. Table 4 shows the COM components, and as can be observed, all COM components are similar for both extraction processes.

Moreover, the CMR is the component that has a major contribution to the COM, as has been repeatedly shown in the literature (Johner et al., 2018c; Viganó et al., 2017; Zabot et al., 2018). In this work, the raw material's high price significantly impacted the COM, being responsible for up to 96% of the COM. The raw material (baru seeds) used for the extraction is expensive when compared with other works. For example, the price of the baru seeds used initially (US$ 20 kg−1) is larger than that of passion fruit rinds (US$ 2.7 kg−1) (Viganó et al., 2017), cupuassu seed byproducts (US$ 2.7 kg−1) (Cavalcanti et al., 2016), Capsicum pepper (Aguiar et al., 2018) or even the raw material cost is considered zero if it is a coproduct (Guindani et al., 2016).

In this kind of process, the COM is strongly dependent on the cost of raw material, and thus, this component has an important contribution to the COM of the extract. Thus, to diminish the COM of the product, it is important to obtain baru at a lower cost, making it possible to improve the baru production chain. In this context, five different scenarios were tested considering lower prices for the baru seeds. Figure 6 shows the influence of the raw material price on the COM for the two studied processes. The behavior of the COM is similar in both extraction processes. As expected, the lower the raw material cost, the lower the COM obtained. For example, under the best process conditions, when the raw material price decreased from US$ 20 kg−1 to US$ 10 kg−1, COM decreased from US$ 260.33 kg−1 baru oil to US$ 140.31 kg−1 baru oil (SFE) and from US$ 167.77 kg−1 baru oil to US$ 89.96 kg−1 baru oil (SFEAP). This is almost two times smaller than the COMs obtained using the original raw material cost.

Figure 6.

Influence of extraction time and baru seed purchasing cost on the COM for SFE and SFEAP processes. (A): Lines black refer to SFE and lines red to SFEAP. (B): Gray columns refer to SFE and blue columns to SFEAP.

On the other hand, as shown in Figure 6A, the COM was higher for both extraction processes at the beginning of the extraction. This behavior can be explained by the fact that at short extraction times, it is possible that raw material still retains a considerable amount of Baru oil. On the other hand, when the COM of baru oil is expressed as a function of processing time (Figure 6A), the COMs of SFEAP are lower than the COMs of SFE for all extraction times. Moreover, although tFER is a good parameter for making an initial COM estimate (Turton et al., 2012), according to the economic analysis, for both extraction processes, the lowest production cost was achieved after a processing time of approximately 75 min (Figure 6A). At this extraction time, the COMs obtained were US$ 118,32 kg−1 baru oil and US$ 87,03 kg−1 baru oil for SFE and SFEAP, respectively.

3.7. Sensitivity study

When both processes are compared, it is observed in Table 4 that when temperature and pressure increased, the project indices (GM, ROI, PT, IRR, and NPV) improved. As mentioned before, the higher the yield, the lower the COM, and therefore, the more feasible the process is. However, for the SFE process, only when the process is performed using pressures above 250 bar will the process be economically feasible, and the economic parameters of the sensitivity study become positive. On the other hand, for the SFEAP process, the process is feasible for all the extraction conditions tested. Thus, the SFEAP process is economically more feasible than the SFE process. Under the lower COM conditions (45 °C/350 bar), the GM of the SFEAP is 25% higher than the GM of the SFE, which means that the company would retain up to US$ 0.69 from each dollar generated instead of US$ 0.51. The same behavior was observed in the other project indices. For example, although the PT for both processes is quite attractive, in the SFEAP process, the initial investment is recovered in 50% less time. On the other hand, the SFEAP process has ROI, IRR, and NPV values 2.2, 1.7, and 2.7 higher than those of the SFE process; thus, although both processes have acceptable and attractive project index values, the SFEAP is the more desirable project.

As stated before, the CWT was considered zero; however, due to the coproduct characteristics, such as its protein content, it could be considered revenue. Therefore, if the coproduct can be sold, the project will be more feasible. In that context, the coproduct selling price ranged between US$ 5 kg−1 and US$ 15 kg−1. Figure 7 shows the effect of the coproduct selling price on the project indices. As shown in Figure 7, the SFEAP process's behavior is better than that of the SFE process for all project indices. For example, for GM, it is clear that the higher the selling price of the coproduct is, the lower the GM. In this case, if the company sells the coproduct using the lower selling price (US$ 5 kg−1), the GM is 56.78 % and 70.88 % for the SFE and SFEAP processes, respectively. On the other hand, when the higher selling price is used, the GM for the SFE process is 64.86 % and 74.64 % for the SFEAP process. For both processes, according to the GM, the project is quite attractive because the company would retain at least US$ 0.56 or US$ 0.64 from each dollar generated if the coproduct is sold using the lower price.

Figure 7.

Influence of the coproduct selling price on the SFE and SFEAP processes' project indices. a) to e): Black lines refer to SFE and green lines to SFEAP.

Similar behavior was observed for ROI, IRR, and NPV. For example, the higher the coproduct selling price is, the higher the ROI (Figure 7c). Both processes showed excellent behavior regarding the ROI because generally, a minimum value of 15% is assumed to accept a project. In this work, although the coproduct was sold using the less expensive price, ROIs of 529% and 1047% were found for the SFE and SFEAP processes, respectively. On the other hand, the higher a project's IRR is, the more desirable the project; again, although both processes have positive and attractive IRR values, the SFEAP process has better profitability. As shown in Figure 7d, all IRR values in the SFEAP are higher than those in the SFE process, and as the coproduct selling price increases, the IRR increases. For example, when the process was simulated using a coproduct selling price of US$ 5 kg−1, the IRR of the SFEAP is almost 50% higher than the IRR of the SFE process.

Similarly, Figure 7e shows that the higher the coproduct selling price is, the higher the gain on the initial investment for both processes. In this case, the NPV, after assuming a discount interest of 7 % of the SFEAP, is 2.4 times higher than the NPV of the SFE process using the lower coproduct selling price. An increase in the coproduct selling price allows for obtaining a more desirable project. For example, in the SFEAP process, when the coproduct selling price increased from US$ 5 kg−1 to US$ 15 kg−1, the NPV increased from US$ 92,652,528 to US$ 112,362,955, which represents 21% more earnings. Contrary to the other project indices, a decrease in the PT was observed when the coproduct selling price increased (Figure 7b). When the coproduct selling price increases, the company generates more revenues, and thus, the length of time necessary to recover the initial investment is shorter. Although the PT is quite acceptable in all scenarios tested in the SFEAP process, the initial investment is recovered almost half of the time. For example, when a higher coproduct selling cost is used, the initial investment is recovered 63 % faster in the SFEAP process than in the SFE process.

In summary, according to the results obtained after the simulations of the different scenarios, it was possible to observe that the project indices are acceptable, and the extraction of baru oil is economically feasible. CRW represents the major contribution to COM; therefore, the raw material cost is a critical factor in the extraction of baru oil. On the other hand, selling the coproduct increases the process's profitability, as shown after the simulation of different sensitivity study scenarios.

4. Conclusions

Overall, the SFEAP technique obtained higher yields in all pressure and temperature conditions when compared to SFE. Under the best extraction conditions (350 bar and 45 °C), the oil yield of baru seeds using SFEAP (29 g oil/100 g baru seeds) was 31.8% higher than the best result found for the SFE (22 g oil/100 g baru seeds) technique after approximately 185 min of extraction. The extraction kinetics of SFE and SFEAP were adequately modeled by the spline model, observing three extraction periods (CER, FER, DC), with a higher mass transfer rate in the periods of SFEAP extraction compared to SFE. The SFEAP resulted in a promising industrial application technique due to the higher extraction yield and the lower CO2 flow (7 g/min) used in this study compared to that reported in the literature. The manufacturing cost decreased when the extraction pressure and temperature increased due to the higher oil yield resulting from the increase in pressure and temperature. The most attractive COM was observed in the extraction process at 350 bar and 45 °C for both techniques, SFE and SFEAP. The lowest estimated COM values for the SFE and SFEAP were US$ 118.32/kg baru oil and US$ 87.03/kg baru oil, respectively, when the CRM was US$ 10.0/kg baru seeds. Therefore, the SFEAP process is more economically viable than the SFE, with more attractive project indices. The baru oil obtained by the two techniques was rich in unsaturated fatty acids and bioactive compounds. Both techniques were economically viable for the oil extraction process from baru seeds, but further studies are necessary to fully use the seed on an industrial scale.

Declarations

Author contribution statement

Larry Oscar Chañi-Paucar: Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

J. Felipe Osorio-Tobón: Analyzed and interpreted the data; Wrote the paper.

Júlio C. F. Johner: Performed the experiments; Analyzed and interpreted the data.

Maria Angela A. Meireles: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) (Finance Code 001), Prograna Nacional de Innovación Agraria (PNIA) – Perú (CONTRATO No. 192-2018-INIA-PNIA-PASANTÍA), and CNPq (302423/2015–0).

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare the following conflict of interests: Maria Angela A. Meireles is an Associate Editor for the Food Science and Nutrition section.

Additional information

No additional information is available for this paper.

References

- Abaide E.R., Zabot G.L., Tres M.V., Martins R.F., Fagundez J.L., Nunes L.F., Druzian S., Soares J.F., Dal Prá V., Silva J.R.F., Kuhn R.C., Mazutti M.A. Yield, composition, and antioxidant activity of avocado pulp oil extracted by pressurized fluids. Food Bioprod. Process. 2017;102:289–298. [Google Scholar]

- Abdullah A., Gani S.S.A., Mokhtar N.F.M., Hin T.Y.Y., Haiyee Z.A., Mustafa S. Supercritical carbon dioxide extraction of red pitaya (Hylocereus polyrhizus) seeds: response surface optimization, fatty acid composition and physicochemical properties. Malays. Appl. Biol. 2018;47:39–46. [Google Scholar]

- Aguiar A.C. de, Osorio-Tobón J.F., Silva L.P.S., Barbero G.F., Martínez J. Economic analysis of oleoresin production from malagueta peppers (Capsicum frutescens) by supercritical fluid extraction. J. Supercrit. Fluids. 2018;133:86–93. [Google Scholar]

- ANSI-ASAE . ASAE STANDARDS; USA: 1998. Method of determining and expressing particle size of chopped forage materials by screening; pp. 562–564. [Google Scholar]

- Bento A.P.N., Cominetti C., Simões Filho A., Naves M.M.V. Baru almond improves lipid profile in mildly hypercholesterolemic subjects: a randomized, controlled, crossover study. Nutr. Metabol. Cardiovasc. Dis. 2014;24:1330–1336. doi: 10.1016/j.numecd.2014.07.002. [DOI] [PubMed] [Google Scholar]

- Carvalho P.I.N., Osorio-Tobón J.F., Rostagno M.A., Petenate A.J., Meireles M.A.A. Techno-economic evaluation of the extraction of turmeric (Curcuma longa L.) oil and ar-turmerone using supercritical carbon dioxide. J. Supercrit. Fluids. 2015;105:44–54. [Google Scholar]

- Cavalcanti R.N., Albuquerque C.L.C., Meireles M.A.A. Processing Supercritical CO2 extraction of cupuassu butter from defatted seed residue: experimental data, mathematical modeling and cost of manufacturing. Food Bioprod. Process. 2016;97:48–62. [Google Scholar]

- Chattipakorn N., Settakorn J., Petsophonsakul P., Suwannahoi P., Mahakranukrauh P., Srichairatanakool S., Chattipakorn S.C. Cardiac mortality is associated with low levels of omega-3 and omega-6 fatty acids in the heart of cadavers with a history of coronary heart disease. Nutr. Res. 2009;29:696–704. doi: 10.1016/j.nutres.2009.09.011. [DOI] [PubMed] [Google Scholar]

- Coelho J.P., Filipe R.M., Robalo M.P., Stateva R.P. Recovering value from organic waste materials: supercritical fluid extraction of oil from industrial grape seeds. J. Supercrit. Fluids. 2018;141:68–77. [Google Scholar]

- Cornelio-Santiago H.P., Gonçalves C.B., de Oliveira N.A., de Oliveira A.L. Supercritical CO2 extraction of oil from green coffee beans: solubility, triacylglycerol composition, thermophysical properties and thermodynamic modelling. J. Supercrit. Fluids. 2017;128:386–394. [Google Scholar]

- Corzzini S.C.S., Barros H.D.F.Q., Grimaldi R., Cabral F.A. Extraction of edible avocado oil using supercritical CO2 and a CO2/ethanol mixture as solvents. J. Food Eng. 2017;194:40–45. [Google Scholar]

- Dimian M. Chapter 15 Economic evaluation of projects. Comput. Aided Chem. Eng. 2003;13:571–604. [Google Scholar]

- Duba K., Fiori L. Supercritical CO2 extraction of grape seeds oil: scale-up and economic analysis. Int. J. Food Sci. Technol. 2019;54:1306–1312. [Google Scholar]

- El-Halwagi M.M. Overview of process economics. In: El-Halwagi M.M., editor. Sustainable Design through Process Integration. Butterworth-Heinemann; USA: 2012. pp. 15–61. [Google Scholar]

- Fernandes D.C., Freitas J.B., Czeder L.P., Naves M.M.V. Nutritional composition and protein value of the baru (Dipteryx alata Vog.) almond from the Brazilian Savanna. J. Sci. Food Agric. 2010;90:1650–1655. doi: 10.1002/jsfa.3997. [DOI] [PubMed] [Google Scholar]

- Galviz-Quezada A., Ochoa-Aristizábal A.M., Arias Zabala M.E., Ochoa S., Osorio-Tobón J.F. Valorización of irica (Carludovica palmata, Ruiz & Pav.) infructescence by ultrasound-assisted extraction: an economic evaluation. Food Bioprod. Process. 2019;118:91–102. [Google Scholar]

- Guindani C., Podestá R., Block J.M., Rossi M.J., Mezzomo N., Ferreira S.R.S. Valorization of chia (Salvia hispanica) seed cake by means of supercritical fluid extraction. J. Supercrit. Fluids. 2016;112:67–75. [Google Scholar]

- Gustinelli G., Eliasson L., Svelander C., Alminger M., Ahrné L. Supercritical CO2 extraction of bilberry (Vaccinium myrtillus L.) seed oil: fatty acid composition and antioxidant activity. J. Supercrit. Fluids. 2018;135:91–97. [Google Scholar]

- Hartman L.R.C. Rapid preparation of fatty acid methyl esters from lipids. Lab. Pract. 1973;22:475–476. [PubMed] [Google Scholar]

- Hatami T., Johner J.C.F., Meireles M.A.A. Extraction and fractionation of fennel using supercritical fluid extraction assisted by cold pressing. Ind. Crop. Prod. 2018;123:661–666. [Google Scholar]

- Hatami T., Johner J.C.F., Zabot G.L., Meireles M.A.A. Supercritical fluid extraction assisted by cold pressing from clove buds: extraction performance, volatile oil composition, and economic evaluation. J. Supercrit. Fluids. 2019;144:39–47. [Google Scholar]

- Isa - Instituto Socioambiental . Plante as Árvores Do Xingu e Araguaia: Guia de Identificação. Instituto Socioambiental; São Paulo: 2009. Baru; p. 304. [Google Scholar]

- Jesus S.P., Calheiros M.N., Hense H., Meireles M.A.A. A simplified model to describe the kinetic behavior of supercritical fluid extraction from a rice bran oil byproduct. Food Publ. Health. 2013;3:215–222. [Google Scholar]

- Johner J.C.F., Hatami T., Carvalho P.I.N., Meireles M.A.A. Impact of grinding procedure on the yield and quality of the extract from clove buds using supercritical fluid extraction. Open Food Sci. J. 2018;10:1–7. [Google Scholar]

- Johner J.C.F., Hatami T., Meireles M.A.A. Developing a supercritical fluid extraction method assisted by cold pressing for extraction of pequi (Caryocar brasiliense) J. Supercrit. Fluids. 2018;137:34–39. [Google Scholar]

- Johner J.C.F., Hatami T., Zabot G.L., Meireles M.A.A. Kinetic behavior and economic evaluation of supercritical fluid extraction of oil from pequi (Caryocar brasiliense) for various grinding times and solvent flow rates. J. Supercrit. Fluids. 2018;140:188–195. [Google Scholar]

- Johner J.C.F., Meireles M.A. de A. Construction of a supercritical fluid extraction (SFE) equipment: validation using annatto and fennel and extract analysis by thin layer chromatography coupled to image. Food Sci. Technol. 2016;36:210–247. [Google Scholar]

- Karrar E., Sheth S., Wei W., Wang X. Supercritical CO2 extraction of gurum (Citrullus lanatus var. Colocynthoide) seed oil and its properties comparison with conventional methods. J. Food Process. Eng. 2019 [Google Scholar]

- Marques F.G., Neto J.R.D.O., Cunha L.C., Paula J.R. De, Bara M.T.F. Identification of terpenes and phytosterols in Dipteryx alata (baru) oil seeds obtained through pressing. Rev. Bras. Farmacogn. 2015;25:522–525. [Google Scholar]

- Meireles M.A.A. Extraction of bioactive compounds from Latin American plants. In: Martinez J., editor. Supercritical Fluid Extraction of Nutraceuticals and Bioactive Compounds. CRC Press – Taylor & Francis Group; USA: 2008. pp. 243–274. [Google Scholar]

- Melo R.B., de Barros Silva P.G., Oriá R.B., Melo, J.U. de S., da Silva Martins C., Cunha A.M., Vasconcelos P.R.L. Anti-inflammatory effect of a fatty acid mixture with high ω-9:ω-6 ratio and low ω-6:ω-3 ratio on rats submitted to dental extraction. Arch. Oral Biol. 2017;74:63–68. doi: 10.1016/j.archoralbio.2016.11.009. [DOI] [PubMed] [Google Scholar]

- Mirmiran P., Hosseinpour-Niazi S., Naderi Z., Bahadoran Z., Sadeghi M., Azizi F. Association between interaction and ratio of ω-3 and ω-6 polyunsaturated fatty acid and the metabolic syndrome in adults. Nutrition. 2012;28:856–863. doi: 10.1016/j.nut.2011.11.031. [DOI] [PubMed] [Google Scholar]

- Náthia-Neves G., Vardanega R., Meireles M.A.A. Extraction of natural blue colorant from Genipa americana L. using green technologies: techno-economic evaluation. Food Bioprod. Process. 2019;114:132–143. [Google Scholar]

- Park H.S., Lee H.J., Shin M.H., Lee K.W., Lee H., Kim Y.S., Kim K.O., Kim K.H. Effects of cosolvents on the decaffeination of green tea by supercritical carbon dioxide. Food Chem. 2007;105:1011–1017. [Google Scholar]

- Peters M., Timmerhaus K., Ronald W. fifth ed. McGraw-Hill Education; New York: 2003. Plant Design and Economics for Chemical Engineers. [Google Scholar]

- Pirrung M. ELSEVIER. Academic Press; 2017. Handbook of Synthetic Organic Chemistry; p. 290. [Google Scholar]

- Prado J.M., Prado G.H.C., Meireles M.A.A. Scale-up study of supercritical fluid extraction process for clove and sugarcane residue. J. Supercrit. Fluids. 2011;56:231–237. [Google Scholar]

- Rai A., Mohanty B., Bhargava R. Optimization of parameters for supercritical extraction of watermelon seed oil. Separ. Sci. Technol. 2018;53:671–682. [Google Scholar]

- Ribeiro R.V., Bieski I.G.C., Balogun S.O., Martins, D.T. de O. Ethnobotanical study of medicinal plants used by ribeirinhos in the north Araguaia microregion, mato grosso, Brazil. J. Ethnopharmacol. 2017;205:69–102. doi: 10.1016/j.jep.2017.04.023. [DOI] [PubMed] [Google Scholar]

- Santana Á.L., Meireles M.A.A. Thin-layer chromatography profiles of non-commercial turmeric (Curcuma longa L.) products obtained via partial hydrothermal hydrolysis. Food Publ. Health. 2016;6:15–25. [Google Scholar]

- Santos P., Aguiar, A.C. de, Viganó J., Boeing J.S., Visentainer J.V., Martínez J. Supercritical CO2 extraction of cumbaru oil (Dipteryx alata Vogel) assisted by ultrasound: global yield, kinetics and fatty acid composition. J. Supercrit. Fluids. 2016;107:75–83. [Google Scholar]

- Smith R. John Wiley & Sons, Ltd; 2005. Chemical Process Design and Integration. [Google Scholar]

- Sodeifian G., Sajadian S.A., Saadati Ardestani N. Supercritical fluid extraction of omega-3 from Dracocephalum kotschyi seed oil: process optimization and oil properties. J. Supercrit. Fluids. 2017;119:139–149. [Google Scholar]

- Sousa A.G.O., Fernandes D.C., Alves A.M., de Freitas J.B., Naves M.M.V. Nutritional quality and protein value of exotic almonds and nut from the Brazilian Savanna compared to peanut. Food Res. Int. 2011;44:2319–2325. [Google Scholar]

- Spangenberg B., Poole C.F., Weins C. Springer-Verlag Berlin Heidelberg; New York: 2011. Quantitative Thin-Layer Chromatography: A Practical Survey. [Google Scholar]

- Subash-Babu P., Alshatwi A.A. Effects of increasing ratios of dietary omega-6/omega-3 fatty acids on human monocyte immunomodulation linked with atherosclerosis. J. Funct. Foods. 2018;41:258–267. [Google Scholar]

- Terry R.E., Branting R.A., Whitman D.L. A critical review of project analysis techniques. In: Parsaei H.R., Sullivan W.G., Hanley T.R., editors. Economic and Financial Justification of Advanced Manufacturing Technologies. Elsevier; 1992. pp. 103–118. [Google Scholar]

- Tirimanna A.S.L. A qualitative study of the essential oil of manufactured black tea by thin layer chromatography. Mikrochim. Acta. 1973;61:9–14. [Google Scholar]

- Triana-Maldonado D.M., Torijano-Gutiérrez S.A., Giraldo-Estrada C. Supercritical CO2 extraction of oil and omega-3 concentrate from Sacha inchi (Plukenetia volubilis L.) from Antioquia, Colombia. Grasas Aceites. 2017;68 [Google Scholar]

- Turton R., Bailie R.C., Whiting W.B., Shaeiwitz J.A., Bhattacharyya D. Prentice-hall International Series in Engineering. fourth ed. Prentice Hall; Upper Saddle Rive: 2012. Analysis, synthesis, and design of chemical processes. [Google Scholar]

- Valle J.M. Del. Extraction of natural compounds using supercritical CO2: going from the laboratory to the industrial application. J. Supercrit. Fluids. 2015;96:180–199. [Google Scholar]

- Valle J.M. Del, Núñez G.A., Aravena R.I. Supercritical CO2 oilseed extraction in multi-vessel plants. 1. Minimization of operational cost. J. Supercrit. Fluids. 2014;92:197–207. [Google Scholar]

- Vera R., Soares Junior M.S., Naves R.V., E.R.B. de Souza, Fernandes E.P., Caliari M., Leandro W.M. Características químicas de amêndoas de barueiros (Dipteryx alata Vog.) de ocorrência natural no cerrado do estado de Goiás. Brasil. Rev. Bras. Frutic. 2009;31:112–118. [Google Scholar]

- Viganó J., Zabot G.L., Martínez J. Supercritical fluid and pressurized liquid extractions of phytonutrients from passion fruit by-products: economic evaluation of sequential multi-stage and single-stage processes. J. Supercrit. Fluids. 2017;122:88–98. [Google Scholar]

- Wagner H., Bladt S., Zgainski E.M. first ed. Springer-Verlag Berlin Heidelberg; New York: 1984. Plant Drug Analysis. [Google Scholar]

- Wejnerowska G., Ciaciuch A. Optimisation of oil extraction from Quinoa seeds with supercritical carbon dioxide with co-solvents. Czech J. Food Sci. 2018;36:81–87. [Google Scholar]

- Zabot G.L., Moraes M.N., Meireles M.A.A. Processing Process integration for producing tocotrienols-rich oil and bixin-rich extract from annatto seeds: a techno-economic approach. Food Bioprod. Process. 2018;109:122–138. [Google Scholar]

- Zhang Z.S., Liu Y.L., Che L.M. Optimization of supercritical carbon dioxide extraction of Eucommia ulmoides seed oil and quality evaluation of the oil. J. Oleo Sci. 2018;67:255–263. doi: 10.5650/jos.ess17153. [DOI] [PubMed] [Google Scholar]

- Zuffo A.M., Andrade F.R., Júnior M.Z. Caracterização biométrica de frutos e sementes de baru (Dipteryx alata Vog.) na região leste de Mato Grosso, Brasil. Rev. Ciências Agrárias. 2014;37:463–471. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.