Abstract

Supply chain resilience (SCRes) and performance have become increasingly important in the wake of the recent supply chain disruptions caused by subsequent pandemics and crisis. Besides, the context of digitalization, integration, and globalization of the supply chain has raised an increasing awareness of advanced information processing techniques such as Artificial Intelligence (AI) in building SCRes and improving supply chain performance (SCP). The present study investigates the direct and indirect effects of AI, SCRes, and SCP under a context of dynamism and uncertainty of the supply chain. In doing so, we have conceptualized the use of AI in the supply chain on the organizational information processing theory (OIPT). The developed framework was evaluated using a structural equation modeling (SEM) approach. Survey data was collected from 279 firms representing different sizes, operating in various sectors, and countries. Our findings suggest that while AI has a direct impact on SCP in the short-term, it is recommended to exploit its information processing capabilities to build SCRes for long-lasting SCP. This study is among the first to provide empirical evidence on maximizing the benefits of AI capabilities to generate sustained SCP. The study could be further extended using a longitudinal investigation to explore more facets of the phenomenon.

Keywords: Supply chain performance, Artificial intelligence, Supply chain resilience, organizational information processing theory, Digital transformation

Introduction

The literature on big data analytics has demonstrated the use of predictive analytics for identifying the sources of supply chain disruptions resulting in improved supply chain resilience (SCRes) (Choi et al. 2018). Firms should develop analytical capabilities to enhance the SCRes by effectively utilizing the resident firm knowledge, thereby strengthening organizations’ existing information capabilities (Wong et al. 2020; Scholten et al. 2019). The studies have found a positive linkage between the business, information, engineering, and analytics to develop digitalization and supply chain risks. Emerging technologies such as Artificial Intelligence (AI), industry 4.0, additive manufacturing, and advanced product tracking applications hold significant potential for supply chain (SC) risk analytics, thereby improving SCRes (Ivanov et al. 2019). Blockchain, the other data-intensive technology, can help in mitigating the supply chain risks associated with the intermediaries' interventions, including hacking, compromised privacy, vulnerability to political turmoil, costly compliance with government rules and regulation, instability of financial institutions, and contractual disputes (Cui et al. 2019). A study to analyze the impact of data analytics capabilities on SCRes revealed that information planning, coordination, and control are the critical enablers of supply chain preparedness, alertness, and agility leading to SCRes (Mandal 2019). Organizations’ are needed to take a dynamic, innovative, and proactive approach in managing risks. Risks and disruptions should be opportunities to adapt and evolve in the face of hyper-connected networks, advanced cyber threats, highly competitive environments, and changing customer expectations to improve the supply chain performance (Butler 2018). The resilient organizations must use the technological advancements in automation, AI, and the Internet of Things to increase collaboration and cooperation, both vertically and horizontally, internally and externally (Butler 2018; Kamble et al. 2018).

The literature identifies AI as a pathbreaking analytics tool to enhance the supply chain performance (SCP) sphere (Grover et al. 2020). AI is related to statistical, self-learning, and predictive machine learning techniques to amplify human intelligence (Dubey et al. 2020). Grover et al. (2020) delineated AI as a facilitating factor presenting diverse solutions, providing prescriptive inputs in the decision-making process in the face of a complicated situation.

The proven potential of AI to underpin the decision-making process in supply chains triggers a profound reflection on how AI can be leveraged in pursuing the supply chain’s long-term performance and competitive advantage, i.e., innovation (Akter et al. 2020). While prior studies argued that process innovation strengthens SCRes under uncertainty, resulting in improved SCP (Akter et al. 2020; Kwak et al. 2018), developing AI-driven innovation is more advantageous as it may accelerate the decision process in identifying, prototyping, and testing novel solutions (Paschen et al. 2020). This decision process, at the heart of innovation, is what researchers refer to as design. The effect of AI-driven innovation on designing robust supply chains through information sharing, information processing, and system integration has long been regarded as a critical factor in SCRes building and SCP improvement (Wamba and Akter 2019).

The existing literature has demonstrated that AI algorithms have succeeded in promoting innovation to offer solutions leading to improved SCP (Dubey et al. 2020; Baryannis et al. 2019). Despite the significant potential of AI techniques to build SCRes, the extant literature lacks the focus on how the AI-driven innovation influences the SCRes, and to what extent the supply chain dynamism (SCD) and supply chain collaboration (SCC) affects this relationship.

In the present scenario, supply chains are becoming increasingly dynamic in changing business environments and technology. Continuous information is required for the supply chains operating in a dynamic environment as various internal and external threats continue to suppress their performance (Belhadi et al. 2019; Lee et al. 2016). Besides, Dubey et al. (2020) and Wamba et al. (2020) have recognized environmental dynamism as a critical factor to be investigated while dealing with performance-related issues. Hence, understanding the linkages between AI, SCRes, and SCP is highly relevant, and the relationships are expected to provide meaningful insights on how the AI capabilities need to be developed and deployed in the dynamic supply chains. The reviews by Baryannis et al. (2019) and Grover et al. (2020) identified that the literature on the predictive and learning capabilities of AI in supply-chain risk management is still in a nascent stage. To the best of our knowledge, this is the first study in the literature that empirically investigates the influence of AI on SCP through the mediating effect of SCRes.

The above research gaps have led us to investigate the following research questions in the present study.

RQ1: What are the direct, indirect, separate, and combined effects of AI capabilities and SCRes on SCP?.

RQ2: What is the effect of SCD on the interplay between AI, SCRes, and SCP?.

In addressing these RQs, we develop a research framework based on the theoretical underpinning of Organizational Information Processing Theory (OIPT). The framework is then analyzed using structural equation modeling (SEM) on the data collected from a sample of 279 manufacturing firms representing different manufacturing industries and located in different countries. Accordingly, the study makes the following novelties and relevant contributions. First, this study is among the first to advance the conceptual understanding of how AI-based information-processing innovation affects SCRes and how firms can create long-lasting SCP in front of disruptive and unexpected events through AI-based capabilities. Second, the study explains how developing AI-based information processing innovation could generate SCP and build SCRes through several components, thus contributing to the theory that aims at understanding how focal firms can maintain or improve SCP during disruptive events. Finally, the study paves the way for understanding the integration of AI capabilities in the different supply chain tiers to strengthen SCC and cope with SCD.

The rest of this paper is organized as follows. The second section provides details about the underpinning theories associated with the study's constructs. After that, the third section proposes the framework, along with the related hypotheses. The fourth section exhibits the research design and methodologies. The findings and outcomes of the study are presented in the fifth section. The sixth section discusses the contributions, implications, limitations, and future research agenda of the study. Finally, the seventh section concludes the paper.

The conceptual background of the study

Organizational information processing theory (OIPT)

The OIPT states that the firm’s information processing performance is an outcome of the firm's information processing needs and information processing capability. The uncertainties in the supply chains can affect the relationship between information processing capabilities and related outcomes (Wong et al. 2020; Chen et al. 2015). Therefore, it becomes essential for the supply chains to develop the capability to proactively engage in communication with stakeholders for improved visibility and traceability in SC operations. In the literature, the data analytics capability is conceptualized as an information processing capability based on OIPT while analyzing its impact on the supply chain performance (Kamble et al. 2020). Theoretically, organizations could either opt to rely on "mechanistic" organizational resources to reduce their dependency on information or enhance their information processing capabilities (Galbraith 1974). Organizations preferring the mechanistic models are required to schedule interdependent operations through the division of work and centralization of decisions (Srinivasan and Swink 2018). They tend to tackle issues and complexities called "exception scenarios" by using rules, hierarchy, targets, and goals. However, the high frequency of exception scenarios increase the mechanistic models' costs and reduce responsiveness (Peng et al. 2014). Alternatively, an organization could enhance its information-processing capability by developing lateral and vertical information systems (Srinivasan and Swink 2018). Vertical information systems allow data processing efficiently and intelligently to support resolving complexities through swift adjustment of plans with minimal resource involvement (Peng et al. 2014).

OIPT addresses the development of organizational capabilities to fill their information processing requirement (Wamba et al. 2020). Importantly, OIPT posits that organizations necessitate processing information under increasing uncertainty to sustain a certain performance level. Information processing capability to deal with risk, volatility, and dynamism is a highly required organizational capability (Srinivasan and Swink 2018; Peng et al. 2014). In this study, AI is conceptualized as an information-processing capability that should be inherently configured to alleviate its operational complexities and uncertainties. Furthermore, the OIPT advocates that the firms need to develop capacity buffers and have information processing capability to manage the supply chain disruptions (Srinivasan and Swink 2018).

Several other theories come to support the assumptions of OIPT. For instance, the dynamic capability view (DCV) considers AI and data-driven systems as lower-order resources capabilities that create a ground for building higher-order capabilities such as supply chain collaboration, adaptation, and supply chain performance (Wamba et al. 2020). However, DCV left a gap in explaining the effect of a high scale disruption on the exploitation and the efficiency of lower-order capabilities. On the other hand, the contingency theory stipulates that organizations should develop a strategic fit between information processing capacity and information processing needs (Tushman and Nadler 1978). The view supports that SCRes can be positively associated with the supply chain performance when information processing capacity aligns with the scale of supply chain disruptions (Wong et al. 2020). Nonetheless, this theory fails to explain the inter-organizational information management capabilities within the supply chain network to underpin the development of operational capabilities such as supply chain collaboration and adaptation.

Our study seeks to fill the gaps and limitations of these theories by providing a holistic theoretical background built upon the OIPT to construct a solid investigation research framework for AI-driven innovation, SCRes, and SCP. The aim is to explore the performance impact of SCRes by putting forward SCD as contingent on exogenous factors and AI-driven innovation as low-order and inter-organizational capabilities along the supply chain.

Information processing capabilities of Artificial Intelligence (AI)

Artificial Intelligence (AI) is the ability of a system to acquire learnings by analyzing the external environment's data and using acquired learnings to adjust or make new plans against the environmental changes (Grover et al. 2020). This includes techniques and algorithms that enable us to learn from input data, with or without being informed about the eventual output forms (Baryannis et al. 2019; Rodríguez-Espíndola et al. 2020). The field of AI is not new in itself. However, it has witnessed alternating periods of significant rise and drastic slump since its first appearance in the 1950s (Baryannis et al. 2019). The growing computational capacities alongside the spread of big data and the broader application of AI in the area of operations, manufacturing, and supply chain management have driven renewed emphasis on this computational technology (Sharma et al. 2020). According to Haefner et al. (2021), information processing capabilities (IPC) of AI systems could be evaluated through three IPT levels, i.e., exploiting, expanding, and exploring. These levels indicate how likely AI systems are to replace and complement human decision-making. Through reviewing the literature of AI in the supply chain context, we summarize the most used techniques according to the IPT levels proposed by Haefner et al. (2021) as presented in Table 1.

Table 1.

Literature review of information processing capabilities of Artificial Intelligence for supply chain

| IPC levels | AI-driven IPC for supply chain | AI techniques | References |

|---|---|---|---|

| Level 1: exploiting |

Process much more massive amounts of information and knowledge Support supply chain problems detection Overcome cognitive information processing constraints |

Machine learning and big data | Priore et al. (2019), Cavalcante et al. (2019), Min et al. (2019), Choi et al. (2018) |

| Robust optimization | Baryannis et al. (2019), Choi et al. (2018) | ||

| fuzzy logic and programming | Leung et al. (2019), Baryannis et al. (2019) | ||

| Stochastic programming | Sabet et al. (2020), Baryannis et al. (2019) | ||

| Knowledge, representation Reasoning | Baryannis et al. (2019) | ||

| Level 2: expanding |

Generate new ideas within the supply chain innovation process Support supply chain problems analysis Strengthen the interaction between human and machine |

Network-based algorithms | Elhoone et al. (2020), Hosseini and Ivanov (2020), Baryannis et al. (2019), Bottani et al. (2019) |

| Rough set theory | Mehdizadeh (2020), Li et al. (2018), Shidpour et al. (2016) | ||

| Tree-based clustering | Zanjani et al. (2016), Thomassey (2010) | ||

| Level 3: exploring |

Explore new ways of identifying problems Explore new innovative solutions Prototype and evaluate the effectiveness of the innovation |

Agent-based systems | Muravev et al. (2020), Baryannis et al. (2019), Giannakis and Louis (2016) |

| Model Predictive Control | Belhadi et al. (2019), Nawaz et al. (2019), Zhang et al. (2019) | ||

| Robotic Process Automation | Schniederjans et al. (2020) | ||

| Computer vision | Grover et al. (2020), Dhamija and Bag (2020) |

First, exploiting techniques includes machine learning and big data (Cavalcante et al. 2019; Choi et al. 2018), robust optimization (Baryannis et al. 2019), fuzzy logic and programming (Leung et al. 2019), stochastic programming(Sabet et al. 2020) and knowledge, representation reasoning (Baryannis et al. 2019). Techniques at this level enable to overcome cognitive information processing constraints and deal with a more considerable amount of data while detecting patterns. Second, extension techniques allow generating new ideas in support of human-machine interaction during problem analysis. The methods at this level may include network-based algorithms (Elhoone et al. 2020; Hosseini andIvanov 2020), rough set theory(Mehdizadeh 2020), and tree-based clustering (Zanjani et al. 2016). Finally, exploring techniques involve more advanced AI algorithms such as agent-based systems (Baryannis et al. 2019), model predictive control (Belhadi et al. 2019), robotic process automation(Schniederjans et al. 2020) and computer vision (Dhamija and Bag 2020; Grover et al. 2020). These techniques revolutionize exploring problems and solutions and promoting fast prototyping and evaluation of innovative solutions.

Artificial intelligence-driven supply chain innovation (SCI)

According to Arlbjørn et al. (2011, p. 8), supply chain innovation (SCI) can be defined as a radical or progressive transformation in the supply chain technology, process, or network that could be implemented to improve new value creation for the stakeholder. SCI includes all activities aiming to deal with the environment's uncertainty through the generation of information processing and technology innovation to provide solutions for supply chain issues and identify new ways to improve processes (Kwak et al. 2018; Lee et al. 2011). Notably, supply chain innovation relies heavily on advanced technologies and processes alongside radical changes in product, service, or process that improve efficiency and enhance value delivery to the end customer (Akter et al. 2020; Hahn 2020 ). For instance, businesses are increasingly making use of AI techniques to overcome information processing constraints inherent to SCI, resulting in innovative paths of designing new products, solving supply chain issues and satisfying customers, and eventually, potentially establishing new ways to deal with uncertainty (Lee 2018). According to Haefner et al. (2021), AI techniques are prone to lead innovation processes by fasting forward new solutions for supply chain issues. This acceleration in innovation capacities stands to enable supply chain firms to create new profit streams more fastly and decrease costs in the process, thereby enhancing supply chain efficiency.

Further, embedding advanced AI techniques into supply chain innovation empowers innovation activities to be human-centric, creative, and effective in leveraging iterations (Verganti et al. 2020). However, there are various technology-driven innovations based on new digital technologies; significantly fewer studies have addressed AI-driven SCI, specifically how they are implemented and substitute prevailing current supply chain management practices (Beltagui et al. 2020). Overall, AI-driven innovation may benefit several aspects of supply chain management and attract attention to essential elements of the supply chain that received insufficient attention in the past, i.e., supply chain resilience and performance.

Supply chain resilience (SCRes)

Following the COVID-19 outbreak, supply chain resilience (SCRes) is at the forefront of the C-suite's agenda these days. SCRes is broadly concerned by the supply chain's ability to deal with instantaneous disruptive events (Jain et al. 2017), hence regaining the previous level or an even better performance level (Hendry et al. 2019). According to Scholten et al. (2019), SCRes is measured in all the three phases of a disruption: readiness (proactive, pre-disruption), response, and recovery (reactive, post-disruption). This definition has found the reasoning in past literature, which emphasizes the notion of an equilibrium state that should be regained after an unexpected disruptive event. However, the recent global disruption caused by the COVID-19 outbreak gives rise to the new concept of adaptive resilience, positing that there cannot be a state of equilibrium in complex and intertwined supply chains. Therefore, resilience should be seen as situational capability acquired through continuous learning and adaptations from a series of disruptions (Belhadi et al. 2020a, b). Ponomarov and Holcomb (2009) claimed that resilient supply chains are less sensitive to disturbances and are more absorptive of supply chain disruptions. SCRes enables the firms to ensure their products and services' continuous delivery to their customers (Namdar et al. 2018 ). At the same time, the literature on SCRes has expanded drastically in the aftermath of Christopher and Peck (2004). However, Datta (2017) and Dubey et al. (2020) have argued that research dealing with how supply chains develop resilience is still underdeveloped and needs to be updated with the increasing technological advancements and supply chain dynamism. This insufficiency affects, undoubtedly one of the most goals of supply chain management viz., supply chain performance, which is discussed in the following section.

Supply Chain Performance (SCP)

Supply Chain Performance (SCP) is, broadly, defined as the benefits derived from the efficiency and resilience of supply chain operations under a changing environment (Chowdhury et al. 2019; Jain et al. 2017). It reflects the extent to which the supply chain satisfies the end-customer needs in terms of product availability and on-time delivery while minimizing costs (Tarafdar andQrunfleh 2017). Past literature has widely demonstrated that SCP and its antecedents: SCRes and SCI are critical drivers of organizational and market performance. According to Khan et al. (2009), at the organizational level, SCP involves resource performance (efficiency), output performance (effectiveness), and flexibility performance (agility). Efficiency is the ability to create more value for the customers with less resource utilization; effectiveness is the ability to make the customer's value, such as quality, cost, and delay; agility is the ability to maintain value creation in a turbulent and uncertain environment. Previous studies on supply chain management have mainly adopted two different measures to evaluate SCP. The first measures are only related to costs, including inventory costs and operating costs (Chowdhury et al. 2019), whereas the second measures are combining costs and customer needs in terms of quality, availability, and responsiveness. Examples of this include lead-time, quality, stock out probability, and fill rate (Rodrigues and Carpinetti 2017).

Research framework and hypotheses development

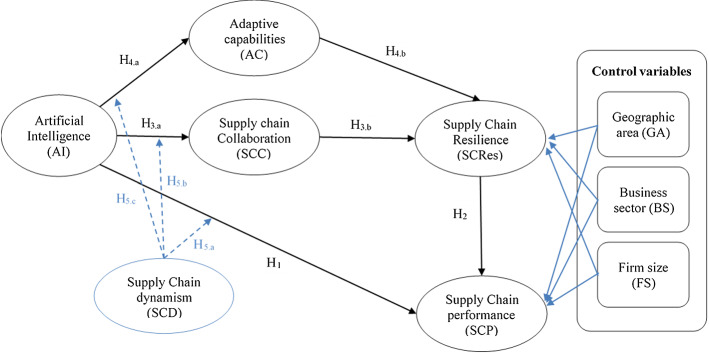

Data-driven supply chains collect a considerable amount of data from the customers and suppliers. However, this data has no value if no information is extracted from them, and no learning happens to the firm to understand and address the uncertainty linked to supply chain dynamism. AI, as an organizational information processing tool, not only helps in analyzing the rich data but also provides useful learning for the organization (Dubey et al. 2020; Belhadi et al. 2019). On the other hand, since the supply chain dynamism may create many uncertainties and disruptions to the supply chain operations, SCRes should be developed to alleviate the risks stemming from supply chain dynamism and maintain the high level of SCP (Dubey et al. 2020; Grover et al. 2020). Therefore, this paper aims to empirically test the interrelationships between AI and SCRes to achieve higher SCP on the theoretical underpinning of OIPT, as illustrated in Fig. 1.

Fig. 1.

The research framework

The effect of Artificial Intelligence on supply chain performance

Grover et al. (2020) argued that using AI techniques results in improved supply chains, product quality, design and development, and customer satisfaction. This enhances the operational performance of firms compared to human engagement. Moreover, Klumpp (2018) demonstrated that AI-driven SCI, such as self-driving systems, have great potential to positively stimulate the performance of logistics and transportation functions in the supply chain. Bottani et al. (2019) implemented an AI-based framework to support decision-making in wholesale distribution. Accordingly, the authors claimed the potential to decrease economic loss due to out-of-stock occurrences by more than 56%. Further, authors like Dubey et al. (2020) supported that AI arguably improves firms’ performance despite the ambiguity of how this performance could be enhanced through AI adoption.

Based on the OIPT perspective, we propose that AI's implementation enables supply chains to develop information-processing capabilities (Srinivasan and Swink 2018). It allows them to decrypt, interpret, and learn from convoluted information gathered from different sources to mitigate uncertainties surrounding demands, capacities, and supply availability (Grover et al. 2020). Otherwise, firms are constrained to keep a high level of inventories or rely on limited human capabilities to design a responsive supply chain, which in turn influences both profit margins and execution speed (Dubey et al. 2020). Altogether, such perspectives and evidence of the AI adoption can prospectively be translated into improved supply chain performance. Hence, we hypothesize that:

H1

AI has a significant and positive effect on supply chain performance (SCP).

Supply chain resilience and supply chain performance

Evidence from past studies proposed that building SCRes plays a central role in alleviating contingencies or maintaining the previous level of SCP (Chowdhury et al. 2019; Yu et al. 2019). According to Scholten et al. (2019), a resilient supply chain can hold a high level of agility (the ability to absorb changes caused by disruptions), responsiveness (the ability to respond purposefully and within an appropriate timeframe), and visibility (the ability to track and monitor the performance under uncertainty) towards customer needs to maintain high performance. Earlier, Carvalho et al. (2012) suggested that resilient strategies influence SCP and raised the issue of preserving SCP in times of crisis and disruption. Moreover, they proposed an integrated framework for developing SCRes and assessed its positive effect on SCP. Organizations that failed to build SCRes during the global financial crisis (Chowdhury et al. 2019) or Brexit (Hendry et al. 2019) were compelled to entirely or partially stop their operations during the disruption (Altay et al. 2018 ). Based on the arguments mentioned above, the literature trend points towards the positive effect of SCRes on SCP. Thus, we hypothesize that:

H2

SCRes has a significant and positive effect on SCP.

The mediating role of adaptive capacity and supply chain collaboration

The literature identifies that to compete in the global markets, the firms should have access to external knowledge and innovations. Open innovation-driven adaptive capacity is one of the key concepts that the firms can adopt to become competitive at the global level. The literature highlights adaptive capabilities and supply chain collaboration to be the most spread formative elements required to build SCRes (Scholten et al. 2019; Chowdhury et al. 2019; Jain et al. 2017). Therefore, our theoretical framework proposes to include these two factors as enablers of SCRes driven by AI capabilities.

According to Dovers and Handmer (1992), adaptive capabilities (AC) (e.g., stability, persistence, adaptability, and transformability) refer to the ability of the firm to accept the ineluctability of transformation and to deploy all the necessary resources for adjusting to new conditions and necessities. Previous studies such as Leitao (2009) supported that AI constitutes an efficient means of imitating adaptivity through learning from the external environment, thereby making complex systems more organized, highly reconfigurable, and adaptive. Further, Macías-Escrivá et al. (2013) concluded that AI techniques are among the facilitating means that underpin the advancement of new generations of adaptive systems. Hence, we propose that:

H3a

AI has a significant and positive effect on AC.

Similarly, authors such as Scholten et al. (2019) and Jain et al. (2017) argued that SCRes relies heavily on AC, which mitigates the impact of unexpected events through the proactive identification of strategies enabling the supply chain to adapt aftershock, regaining or even enhancing its initial situation. Li et al. (2020) consider adaptive planning and adaptive response are vital elements in building SCRes to pick up and recover from outbreaks under urban context. Further, Kochan and Nowicki (2018) supported the positive impact of AC on building SCRes through minimizing the likelihood of confronting non-routine events, withstand the propagation of shocks through holding control over organization and processes, and responding by proactive plans to absorb the shock and rebuild the robust state of the operations in the supply chain. This leads to the formulation of the following hypothesis:

H3b

AC mediates the relationship between AI and SCRes.

Jain et al. (2017) stated that supply chain collaboration (SCC) is the mechanism of several firms or partners coordinating and operating cooperatively to plan and perform supply chain operations. Despite the scarcity of studies addressing the relationship between AI and SCC, past literature positively links SCC to AI techniques. For instance, Rodríguez-Espíndola et al. (2020) and Baryannis et al. (2019) emphasized the potential of AI techniques to provide reliable and updated forecasts and near real-time visibility of inventories which resolve collaboration issues among stakeholders that arise from uncertain supply and demand. Hence, we can assume that:

H4a

AI has a significant and positive effect on SCC.

SCC has been widely considered as an antecedent to SCRes during disruptive events. Jain et al. (2017) asserted that collaborative partnerships enable efficient supply chain risk mitigation during disruptions. This finds support in the study of Dubey et al. (2020), which concludes that under complexity, collaboration among supply chain partners is vital in building SCRes by mitigating the risk of disruption through mutual trust, communication, sourcing decisions and information sharing. This improves response time and establishes new business opportunities. Further, Chowdhury et al. (2019) affirmed that the poor collaboration between supply chain partners, the integration of the whole supply chain might be negatively affected, thereby rendering the supply chain vulnerable and affecting the SCRes as well as the SCP. Hence, supply chain practitioners should create a favorable environment for healthy communication, effective collaboration, coordination, and mutual trust-based relationships between the supply chain partners to enhance the SCRes and positively influence the SCP. Therefore, we hypothesize that:

H4b

SCC mediates the relationship between AI and SCRes.

The moderating effect of supply chain dynamism

Yu et al. (2019) defined supply chain dynamism (SCD) using the rate of transformational change in the supply chain's products and processes. Supply chains are becoming increasingly dynamic in response to changing business environments and technology. Continuous information is required for the supply chains operating in a dynamic environment as various internal and external threats continue to suppress their performance (Lee et al. 2016). According to Zhou and Benton (2007), SCD can be evaluated through three main factors, i.e., the revenue captured from new products, the level of innovation for products, and the pace of innovation of processes. Authors like Dubey et al. (2020), Yu et al. (2019) and Jain et al. (2017) supported that a deep understanding of the extent of SCD is an essential element for the firms to develop more resilient approaches and improved SCP. OIPT supports the influence of supply chain dynamism on information sharing and supply chain practice. Supply chain dynamism impacts information sharing practices and the inter-organizational relationships positively, improving the supply chain performance (Lee et al. 2016). In another study, the supply chain dynamism was found to positively impact the supply chain disruption orientation and supply chain resilience (Yu et al. 2019). The study identifies supply chain dynamism as an antecedent to supply chain resilience, influencing the firm's financial performance. The supply chain dynamism was found to moderate the relationship between supply chain integration and supply chain performance. According to Zhou and Benton (2007), SCD affects how information processing capabilities help reduce the uncertainty associated with external and internal environments. Therefore, we rely on this evidence to assume that:

H5.a, b, c

SCD has a positive moderating effect on the relationship between (a) AI and SCP, (b) AI and SCC, and (c) AI and AC.

Further, we incorporate three control variables in our statistical analyses, which impact the exogenous constructs in the theoretical framework. First, the firm size (FS) by using the annual turnover (Wamba et al. 2020; Dubey et al. 2020), second, the business sector (BS) (Dubey et al. 2020) and third, the geographical area (GA).

Research methodology

Instrument development

A cross-sectional study design was used to collect the data through a survey-based instrument. In compliance with Malhotra and Grover's (1998) recommendations, established measures from the literature were adopted with minor modifications in the wording of the items according to the study's context and pre-test results. The measurement items were developed using a five-point Likert scale with extreme points ranging from 1 = strongly disagree to 5 = strongly agree.

Further, the subjective measures related to SCP commonly used in supply chain research have been adopted. The questionnaire has been pre-tested for face-validity by requesting nine supply chain experts from different industries to fill the survey in the researcher's presence to uncover any shortcomings. Next, the experts were asked to provide general feedback on the structure and relevance of the measures used to evaluate the constructs. The measurement items used for the constructs and their literature sources are shown in "Appendix". All the constructs were deployed as reflective constructs.

Sampling design and data collection

The research's empirical context is international supply chains engaged in digital transformation involving the deployment of AI techniques. The unit of analysis used in this study was the focal firm from which one key respondent has been contacted to provide his perception of the study's constructs. Accordingly, the instrument was designed for a single respondent. Besides, 1128 potential respondents (including managers and senior executives) were identified from digitalized firms located in North Africa, South Europe, and Southern Asia. Special attention has been paid to the key respondents' involvement in AI implementation in the supply chain. After that, the survey has been administered to the key respondents via e-mail. A questionnaire along with a covering letter explaining the aim of the study and future use of data collected and a strict guarantee of data confidentiality. Through two waves of data collection over four weeks and after three e-mail reminders, we obtained 279 complete and usable responses, giving an effective response rate of 24.73%. This response rate is entirely adequate in keeping with surveys' usual response rate in prior studies (Belhadi et al. 2020a, b; Dubey et al. 2020). The profiles of the responding firms are summarized in Table 2.

Table 2.

Profiles of the responding firms

| Parameters | Details | Frequency | Percentage (%) |

|---|---|---|---|

| Profile of respondents | |||

| Gender | Male | 171 | 61.29 |

| Female | 108 | 38.71 | |

| Department profile | General manager | 60 | 21.51 |

| Unit head | 54 | 19.35 | |

| Supply chain exuctive/manager | 27 | 9.68 | |

| Operations executive/manager | 58 | 20.79 | |

| Sales executive/ manager | 80 | 28.67 | |

| Managerial experience | Between 3–5 years | 43 | 15.41 |

| 5–10 years | 74 | 26.52 | |

| 10–15 years | 80 | 28.67 | |

| Above 15 years | 82 | 29.39 | |

| Profile of companies | |||

| Firm size (FS) | Annual turnover < €10 M | 38 | 13.62 |

| Annual turnover between €10 M €100 M | 78 | 27.96 | |

| Annual turnover between €100 M €1 B | 96 | 34.41 | |

| Annual turnover > €1 B | 67 | 24.01 | |

| Business sector (BS) | Fast-moving consumer goods | 61 | 21.86 |

| Chemical products | 57 | 16.85 | |

| Automobile | 53 | 15.41 | |

| Electric/Electronic | 38 | 13.62 | |

| Mining products | 38 | 13.62 | |

| Pharmaceuticals | 33 | 9.68 | |

| Geographic area (GA) | Morocco | 125 | 44.80 |

| France | 79 | 28.32 | |

| India | 75 | 26.88 | |

| Total | 279 | 100 | |

To overcome the issue related to biasedness in the survey-based approach, we tested the non-response bias according to the procedure suggested by Armstrong and Overton (1977) by comparing the responses of early respondents (first 25%), late respondents (last 25%), and a sample of non-respondents. The results showed that for all items, p > 0.3, suggesting the non-existence of a statistically significant difference between the early, late, and non-respondents. Moreover, there was no significant difference between respondents and non-respondents regarding control variables (FS, BS, and GA). Hence, we can conclude that non-response bias is not a critical issue in the present study.

Data analysis and results

Structural equation modeling (SEM) includes statistical procedures for measurement testing, functional, predictive, and causal hypotheses (Jin et al. 2020). SEM is a suitable approach for examining interrelationships between one or more independent variables and one or more dependent variables since the method includes a set of regression analyses (Jin et al. 2020; Dubey et al. 2020). Furthermore, SEM is appropriate when the dependent variable for one regression analysis could become an independent variable of another. Besides, SEM allows the computation of measurement error variance in both exogenous and endogenous variables, which meets this study's need. Therefore, we proposed to use SEM to test our hypothesis using Maximum Likelihood Estimation (MLE) (Cudeck 1989) as recommended by Jin et al. (2020). All the SEM computations were performed on IBM SPSS ver. 26.

Measurement validation

To evaluate the construct validity and unidimensionality, we carried out a confirmatory factor analysis (CFA) using IBM SPSS v22 and the maximum likelihood procedures (Hair et al. 2009). Table 3 depicts the results of descriptive statistics, factor loadings, and t-values of the items. The standardized factor loadings for all the items were observed above the minimum threshold value of 0.5, suggesting construct validity (Hair et al. 2009). Further, the evaluation of fit indices were found to be satisfactory (χ²/df = 1.31, GFI = 0.957, CFI = 0.982, CR = 0.923, RMSEA = 0.093).

Table 3.

Descriptive analysis of measurement scales

| Items | Mean | SD | Standardized loadings | t-values |

|---|---|---|---|---|

| AI_1 | 3.78 | 1.15 | 0.871 | 14.8 |

| AI_2 | 4.43 | 1.27 | 0.766 | 11.32 |

| AI_3 | 4.46 | 0.59 | 0.887 | 11.15 |

| AI_4 | 4.2 | 1.52 | 0.813 | 11.8 |

| AI_5 | 4.59 | 1.83 | 0.834 | 11.79 |

| AC_1 | 4.06 | 1.8 | 0.719 | 12.97 |

| AC_2 | 4.48 | 2.03 | 0.808 | 13.37 |

| AC_3 | 2.68 | 0.78 | 0.863 | 13.43 |

| SCC_1 | 2.54 | 1.47 | 0.885 | 11.78 |

| SCC_2 | 2.81 | 1.51 | 0.702 | 12.8 |

| SCC_3 | 3.3 | 2.05 | 0.801 | 13.24 |

| SCC_4 | 3.02 | 1.9 | 0.698 | 14.25 |

| SCRes_1 | 3.92 | 2.06 | 0.702 | 13.84 |

| SCRes_2 | 2.53 | 1.26 | 0.709 | 13.45 |

| SCRes_3 | 2.84 | 1.7 | 0.935 | 14.39 |

| SCRes_4 | 2.71 | 0.54 | 0.794 | 13.84 |

| SCRes_5 | 2.57 | 2.08 | 0.931 | 14.52 |

| SCP_1 | 3.54 | 1.78 | 0.751 | 11.26 |

| SCP_2 | 4.23 | 0.61 | 0.907 | 12.6 |

| SCP_3 | 3.67 | 1 | 0.721 | 11.87 |

| SCP_4 | 3.53 | 0.53 | 0.706 | 11.09 |

| SCP_5 | 4.63 | 2.09 | 0.967 | 11.86 |

| SCD_1 | 2.78 | 1.5 | 0.925 | 13.84 |

| SCD_2 | 3.77 | 1 | 0.746 | 13.85 |

| SCD_3 | 4.43 | 1.65 | 0.701 | 13.87 |

| SCD_4 | 3.96 | 1.06 | 0.724 | 11.96 |

AI Artificial Intelligence, AC adaptive capabilities, SCC supply chain coordination, SCRes supply chain resilience, SCP supply chain performance, SCD supply chain dynamism

The convergent and discriminant validity of the constructs was established based on Hair et al.'s (2009) recommendations. Accordingly, we examine the Cronbach's alpha (α), Composite Scale Reliability (CSR), and Average Variance Extracted (AVE) for the first-order constructs, as presented in Table 4. The results illustrate that α coefficients and CSR values were above the minimum threshold value of 0.7, and AVE values exceeded the threshold of 0.5, indicating that all the constructs were reliable and valid construct. The discriminant validity of constructs was ensured by comparing the inter-construct correlations with AVE scores' square root as suggested by Fornell and Larcker (1981).

Table 4.

Construct correlations and discriminant validity results

| α | CR | AVE | AI | AC | SCC | SCRes | SCP | SCD | |

|---|---|---|---|---|---|---|---|---|---|

| AI | 0.882 | 0.968 | 0.683 | (0.826) | |||||

| AC | 0.89 | 0.896 | 0.675 | 0.363 | (0.806) | ||||

| SCC | 0.851 | 0.839 | 0.806 | 0.377 | 0.33 | (0.894) | |||

| SCRes | 0.954 | 0.886 | 0.972 | 0.218 | 0.188 | 0.298 | (0.985) | ||

| SCP | 0.897 | 0.795 | 0.707 | 0.498 | 0.69 | 0.074 | 0.234 | (0.84) | |

| SCD | 0.935 | 0.873 | 0.883 | 0.202 | 0.76 | 0.301 | 0.315 | 0.283 | (0.94) |

AI Artificial Intelligence, AC adaptive capabilities, SCC supply chain coordination, SCRes supply chain resilience, SCP supply chain performance, SCD supply chain dynamism

Bold and between brackets values are square roots of AVE

Common method bias

The common method bias (CMB) is usually related to using key respondents for data collection in a cross-sectional survey design since they use the same method to provide data (Dubey et al. 2020; Srinivasan and Swink 2018). According to Podsakoff et al. (2003), CMB could also result from the tendency of key respondents to answer questions in a specific way that could be dictated by the survey's instructions. Therefore, the measures could potentially share a certain amount of common method variation (CMV). Hence, to mitigate CMB's potential impact, we used the split survey method by collecting AC, SCC, and SCD in a separate questionnaire. Further, we carried out several CMB measurements. First, we performed Harman's single-factor test that was performed to examine CMV. The outcomes show that the total variance extracted by factor analysis is 35.84%, which is less than the threshold of 50% (Podsakoff et al. 2003), indicating that CMB is not a significant issue. Second, we carried out the marker variable technique (Lindell andWhitney 2001), which proposes to assess CMV through integrating an item, which does not have a tie with the primary constructs to the measurement model. Importantly, no significant differences were detected, suggesting that CMB has no substantial impact on the study results.

According to Guide Jr and Ketokivi (2015), causality is a critical issue that should be verified before hypothesis testing. In doing so, we computed the Non-linear Bivariate Causality Direction Ratio (NLBCDR), and we found that NLBCDR = 0.863, which is well above the threshold of 0.7, signifying the absence of causality effect.

After confirming the data's underlying statistical significance, convergent, and discriminant validity of the constructs, the research framework's hypothesis was tested for statistical validation.

Hypothesis results

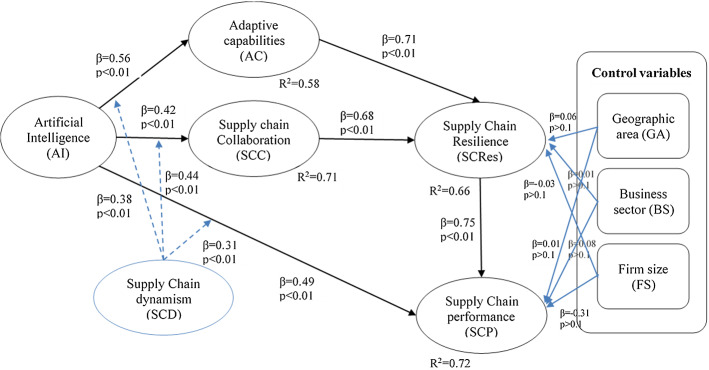

The significant paths and the associated standardized coefficients in the structural model are presented in Fig. 2. The values of standardized path coefficients and p-values shown in Table 5 explain a significant variance for the endogenous constructs. Notably, the explained variance (R²) of our framework on AC is R² = 0.58, SCC is R² = 0.71, SCRes is R² = 0.66, and SCP is 0.72 (Table 5).

Fig. 2.

Final research framework

Table 5.

Summary of structural estimates

| Hypothesis | Model link | Path coefficient | p value | Result |

|---|---|---|---|---|

| H1 | AI → SCP | 0.49 | < 0.01 | Supported |

| H2 | SCRes → SCP | 0.66 | < 0.01 | Supported |

| H3.a | AI → AC | 0.56 | < 0.01 | Supported |

| H3.b | AC → SCRes | 0.71 | < 0.01 | Supported |

| H4.a | AI → SCC | 0.42 | < 0.01 | Supported |

| H4.b | SCC → SCRes | 0.68 | < 0.01 | Supported |

| H5.a | AI*SCD → SCP | 0.31 | < 0.01 | Supported |

| H5.b | AI*SCD → SCC | 0.44 | < 0.01 | Supported |

| H5.c | AI*SCD → AC | 0.38 | < 0.01 | Supported |

| Effect of control variables | FS → SCRes | -0.03 | > 0.1 | Not supported |

| FS → SCP | -0.31 | > 0.1 | Not supported | |

| BS → SCRes | 0.01 | > 0.1 | Not supported | |

| BS → SCP | 0.08 | > 0.1 | Not supported | |

| GA → SCRes | 0.06 | > 0.1 | Not supported | |

| GA → SCP | 0.01 | > 0.1 | Not supported |

AI Artificial Intelligence, AC adaptive capabilities, SCC supply chain coordination, SCRes supply chain resilience, SCP supply chain performance, SCD supply chain dynamism, FS firm size, BS business sector, GA geographic area

The links AI→SCP (β = 0.49; p < 0.01) and SCRes→SCP (β = 0.66; p < 0.01) are positively related. Based on path coefficients and associated p-values, we put forward that H1 and H2 are supported. Besides, the combined paths for mediation effect of AC and SCC on the path linking AI and SCRes, (AI→AC (β = 0.56; p < 0.01), AC→SCRes (β = 0.71; p < 0.01) and AI→SCC (β = 0.42; p < 0.01), SCC→SCRes (β = 0.68; p < 0.01)) are found to be positively linked which supports the hypotheses H3.a, H3.b, H4.a, and H4.b. Further, the hypotheses H5.a, H5.b, and H5.c for the moderation effect of SCD on the links joining AI and SCP (β = 0.31; p < 0.01), AI and SCC (β = 0.44; p < 0.01) and AI and AC (β = 0.38; p < 0.01) were found to be supported.

Control variables

Regarding the effect of control variables, firm size did not show a significant influence on SCRes (β = − 0.03; p > 0.1) and SCP (β = − 0.31; p > 0.1). This finds support in several studies (e.g., Ali et al. 2017; Kamalahmadi and Parast 2016), which argued that large companies' antecedents of resilience and performance are also applicable to small businesses. The effect of the business sector on SCRes (β = 0.08; p > 0.1) and SCP (β = 0.08; p > 0.1) is also found to be insignificant. In addition, geographic area does not influence significantly SCRes (β = 0.06; p > 0.1) and SCP (β = 0.01; p > 0.1). Previous studies have found corroborating results (e.g. Wamba et al. 2020; Dubey et al. 2020), which have used similar variables without finding any significance effect.

Discussions and implications

The present research examined a theoretically developed structural framework linking the Artificial Intelligence (AI) capabilities, Supply Chain Performance (SCP), and Supply chain Resilience (SCRes) under the effect of Adaptive Capabilities (AC), Supply Chain Collaboration (SCC), and Supply Chain Dynamism (SCD). Grounded in OIPT, our findings postulate that Supply Chain during disruptive and unexpected events could maintain or even enhance the supply chain performance through information processing and adaptation capabilities provided by AI techniques. Despite its scarcity, the past literature has indicated a relationship between AI and SCP (Dubey et al. 2020; Grover et al. 2020; Baryannis et al. 2019). Srinivasan and Swink (2018) found that information-processing capabilities are the key to maintaining the organization's performance. Our study attempts to empirically assess the relationship between AI-driven information processing capabilities and innovation, resilience, and organizational performance at the supply chain level under the condition of high uncertainty dictated by the dynamic environment. Accordingly, our findings support the previous claims that AI-driven innovations have a high potential to allow firms within a highly dynamic environment to enhance or at least maintain the current SCP level. This is possible due to AI’s potential to learn from data to adapt the decision-making, pomote supply chain innovation and respond quickly during disruptive events (Grover et al. 2020; Akter et al. 2020). Besides, we have found a strong link between SCRes and SCP. This suggests that firms that can develop strong readiness in the pre-disruption, efficient response during the disruption, and swift recovery in the post-disruption are more likely to maintain long-lasting SCP (Chowdhury et al. 2019; Datta 2017). Therefore, it is judicious to think of a more sustained way to gain superior SCP through AI over time, i.e., by developing SCRes through enhancing readiness and recovery capabilities besides response mechanisms (Chowdhury et al. 2019).

Nonetheless, there is an insufficient understanding of how AI-driven information processing capabilities and innovations could help supply chains develop resilience, including readiness, response, and recovery from the disruptive event, thereby gaining long-term supply chain performance. This gap that has been mentioned in several studies (Wamba and Akter 2019; Akter et al. 2020), stems from the tendency in the literature to treat AI as a technological toolbox directly used to enhance SCRes metrics rather than to build organizational capability towards innovation (Trabucchi andBuganza 2019). Authors such as Scholten et al. (2019) and Chowdhury et al. (2019) underlined that AC and SCC are among the most potent organizational enablers to build SCRes. Therefore, we attempted to fill the gap above by studying the effect of AI-based innovation in developing those enablers, thereby creating SCRes under a dynamic environment. The results support that developing AI-based innovation is positively and significantly related to enhancing both AC and SCC. This provides empirical evidence to past studies (e.g. Baryannis et al. 2019; Wamba andAkter 2019; Macías-Escrivá et al. 2013; Leitao 2009) regarding the ability of AI-driven adaptive capabilities to build SCRes alongside those who postulate that AI enhances visibility and real-time coordination (Rodríguez-Espíndola et al. 2020; Baryannis et al. 2019), resulting in reinforcement of supply chain collaboration and building of SCRes.

Firms developing AI-based Information processing capabilities such as self-adaptive algorithms, prediction, and learning techniques are witnessing their adaptive skills enhanced in the pre-disruption era due to predictive and forecasting capabilities (Baryannis et al. 2019). Besides, they could develop collaboration mechanisms with their partners through sharing real-time forecasts of inventories and production capacities and informing them of the risk of upcoming events (Rodríguez-Espíndola et al. 2020). Those firms can swiftly adapt their strategies during disruptive event and collaborate with their suppliers and customers through AI-driven and shared decision-making (Dubey et al. 2020). Further, AI-driven SCI enables firms to rapidly recover in the post-disruption via adaptive algorithms and AI-enabled collaboration among supply chain partners (Baryannis et al. 2019).

Further, we have found a positive effect of the SCD on the links between AI and SCP, AC, and SCC. The findings are in line with the studies conducted by Wamba et al. (2020), and Dubey et al. (2020). The supply chain's dynamic environment has a beneficial effect in developing organizational capabilities, including information processing capabilities, adaptive capabilities, and supply chain collaboration mechanisms. However, they stated that this relationship might be nonlinear, and a negative effect could appear in a highly uncertain and turbulent environment. Altogether, these complex and nuanced effects provide meaningful implications, advancing theory and practice in this emerging research area.

Theoretical implications

The achievement of high and long-lasting supply chain performance relies heavily on the focal firm's ability to benefit from its information processing capabilities to operate within a dynamic supply chain and build resilience against disruptive and unexpected events. According to the OIPT, AI, which embodies statistical-based, prediction, and self-learning algorithms, enables the firm to develop information-processing capabilities. These capabilities could either directly improve SCP related metrics or create a sustained SCP through building SCRes under moderate dynamism and uncertainty of the environment. While several past studies such as Akter et al. (2020), Grover et al. (2020) or Baryannis et al. (2019), relied on literature review or qualitative research to postulate the relationship between AI-driven innovations, SCRes, and SCP, our study is among the earlier one to understand how AI-based information-processing systems affect SCRes empirically. This constitutes a significant conceptual contribution to the research of how firms can create long-lasting SCP through AI-based capabilities while confronting disruptive and unexpected events. Accordingly, the first theoretical contribution of the research is in studying the complex relationships between AI, SCRes, and SCP, thereby giving insight on how AI could lead directly or indirectly to SCP through the mediating effect of SCRes and the moderating effect of SCD. Second, past studies such as Grover et al. (2020), Dubey et al. (2020) and Srinivasan and Swink (2018) focus on the direct effect of AI-based information processing in building SCRes and enhancing SCP. This study explains how developing AI-based innovations could generate SCP and create SCRes indirectly through SCC and AC. The study also expands the extant literature that mainly concentrates on intelligent systems and antecedents of SCRes and their combined impact on the overall SCP, thus contributing to the theory that aims to fully understand how focal firms can maintain and improve SCP during disruptive events. Finally, our study advances OIPT by empirically demonstrating that AI innovations could promote the organizational concepts, i.e., AC and SCC, which are highly needed to build SCRes against disruptive events and dynamic environment.

Implications for practitioners

The findings of this study present several implications for managerial practice concerning supply chain management. First, supply chain managers should develop AI capabilities for enhancing their SCP metrics. Second, to deal with uncertainties and unexpected events, managers could maintain or even improve SCP in a sustained way through the development of SCRes. In doing so, they should recognize the role of developing AI-based information processing capabilities to develop AC and SCC among the supply chain partners, which leads to the creation of long-lasting SCP under dynamism and uncertainty. Knowledge acquisition, assimilation, transformation, and knowledge exploitation are found to be the indicators of the adaptive capability of a firm (Cooper and Molla 2017; Pradana et al. 2019). Developing adaptive capacity, both in firms and in supply chains, are also integral to responding to dynamic markets and customer needs. The findings imply that the adaptive capacity is found to influence the utilization of big data and predictive analytics on sustainable supply chain innovation, urging the researchers to develop research models for sustainable supply chain innovation applications (Hazen et al. 2016). The firms that can recognize and acquire external knowledge develop environmental competencies and capable of assimilating, transforming, exploiting the knowledge and develop environmental capabilities, resulting in better performance (Dzhengiz and Niesten 2020).

Even though the focal firm develops the AI capabilities for building SCRes, those capabilities might not be used to its full potential unless all the supply chain partners that include the lower tier suppliers respond by implementing a data-driven supply chain. The majority of the suppliers at the lower tiers of the supply chain may not have access to the skilled resources and technological sophistication needed for developing AI capabilities or may possess inconsistent data or incompatible interface standards. The cooperation and value of information sharing amongst the supply chain partners are highly critical to mitigating the risks (Li et al. 2020). The level of collaboration between the supply chain partners contributes to supply chain resilience, benefiting supply chain operations in risk management (Yen and Zeng 2011). However, a high level of supply chain uncertainty does not always lead to a high degree of collaboration with the supply chain partners but is mainly driven by organizational culture having external orientation (Mamillo 2015). In another study, it was pointed out that the collaboration between buyers and suppliers does not directly lead to supply chain resilience but rather enables the antecedents to SCRes (Scholten et al. 2019). The integration of AI capabilities in the different tiers of the supply chain is critical for SCC and AC to develop SCRes. Besides, the supply chain's high dynamism needs careful consideration since it is assumed to play an inverse effect on the relationship between AI-driven SCI, SCRes, and SCP. High turbulence may affect the reliability of data and information shared that feed AI algorithms, thus generating unreliable contingencies and poor decision-making.

Conclusions, limitations, and future research possibilities

The purpose of this study was to investigate the effect of AI-based systems in enhancing, directly and indirectly, SCP during the influence of dynamism and uncertainty. In doing so, the study was based on a conceptual framework grounded in OIPT, including SCRes and its antecedent's AC and SCC. The framework was then empirically evaluated using data gathered from 279 firms of different sizes, located in many countries across Africa, Europe, and Asia, and operating in many business sectors. The findings provide empirical evidence supporting the proposed framework, which demonstrates that AI information processing capabilities significantly influence SCP directly by enhancing related metrics or creating a long-lasting SCP through SCRes building. Notably, the development of a sustained SCP requires the firms to develop AI capabilities to enhance SCRes through its main enablers AC and SCC under the dynamism and uncertainty of the supply chain environment.

The many consecutive outbreaks and supply chain disruptions highlight the increased need to exploit the information-processing capabilities to manage the global supply chain risks that include business continuity, essential commodity, and food security. The present study has made a substantial contribution by emphasizing the benefits AI-driven innovations can provide by creating long-lasting SCP. Besides, this paper contributes to the lack of literature in the field of AI.

Although we have taken the necessary precautions during all stages of the design and execution of this research, the study is subject to few limitations usually associated with most survey designs. Therefore, we suggest that scholars and practitioners evaluate the study's outcomes and implications in light of these limitations. First, the theoretical framework and the constructs used in the study are influenced by OIPT. As with any theory-grounded research, the measure used to test the hypotheses may not provide comprehensive coverage of all the theoretical issues associated with AI and SCRes. Thus, future research is recommended to explore more relationships and phenomena using mixed qualitative and quantitative methodologies to get deeper insights. Second, the findings represent a cross-sectional snapshot in time, amplified by the current COVID-19 outbreak requirement. Hence, more in-depth longitudinal studies are required to confirm the interrelationships between AI, SCRes, and SCP during the post-COVID-19 era. Third, despite the heterogeneity of sectors used in this study, all firms are operating in the manufacturing industry. Generalization of this study's findings will require similar investigations to be performed in services sectors such as travel, transportation, and healthcare.

Appendix: measurement constructs used in the study

| Constructs | Source | Items |

|---|---|---|

| Artificial Intelligence (AI) | Dubey et al. (2020) |

AI_1. We possess the infrastructure and skilled resources to apply AI information processing system AI_2. We use AI techniques to forecast and predict environmental behavior AI_3. We develop statistical, self-learning, and prediction using AI techniques AI_4. We use AI techniques at all level of the supply chain AI_5. We use AI outcomes in a shared way to inform supply chain decision-making |

| Supply Chain Resilience (SCRes) | Yu et al. (2019), Altay et al. (2018 ) |

SCRes_1. Our firm's supply chain is well prepared to face constraints of supply chain disruptions SCRes_2.Our firm's supply chain can rapidly plan and execute contingency plans during disruptions SCRes_3. Our firm's supply chain can adequately respond to unexpected disruptions by quickly restoring its product flow SCRes_4. Our firm's supply chain can swiftly return to its original state after being disrupted SCRes_5. Our firm's supply chain can gain a superior state compared to its original state after being disrupted |

| Supply Chain Performance (SCP) | Srinivasan and Swink (2018) |

SCP_1. Order fill rate (% complete, error-free orders shipped on time) SCP_2. On-time delivery SCP_3. Order fulfillment lead time (speed) SCP_4. Product unit cost |

| Adaptive Capabilities (AC) | Tarafdar and Qrunfleh (2017), Srinivasan and Swink (2018) |

AC_1. We can rapidly adjust capacity to accelerate or decelerate production in response to external changes AC_2. We can meet particular customer specification AC_3. We can swiftly introduce large numbers of product improvements/variation |

| Supply Chain Collaboration (SCC) | Dubey et al. (2020), Yu et al. (2019), Srinivasan and Swink (2018) |

SCC_1. We continuously share our resources (i.e., data, information, knowledge, and infrastructure) with our suppliers, partners …etc. SCC_2. We cooperate tightly with our partners to define and implement response strategies SCC_3. We share our risks and benefits |

| Supply Chain dynamism (SCD) | Dubey et al. (2020), Yu et al. (2019) |

SCD_1. Operating processes become outdated at a high rate SCD_2. Customers' requirements change at a high rate SCD_3. Unexpected and disruptive events (i.e. shocks, outbreaks, disruptive technologies) occur at a high rate SCD_4. Competitors' capabilities change at a high rate |

Footnotes

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Amine Belhadi, Email: Belhadi.amine@outlook.com.

Venkatesh Mani, Email: m.venkatesh@montpellier-bs.com.

Sachin S. Kamble, Email: Sachin.kamble@edhec.edu

Syed Abdul Rehman Khan, Email: Sarehman_cscp@yahoo.com.

Surabhi Verma, Email: suv@sam.sdu.dk.

References

- Akter S, Michael K, Uddin MR, McCarthy G, Rahman M. Transforming business using digital innovations: The application of AI, blockchain, cloud and data analytics. Annals of Operations Research. 2020 doi: 10.1007/s10479-020-03620-w. [DOI] [Google Scholar]

- Ali A, Mahfouz A, Arisha A. Analysing supply chain resilience: integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Management. 2017;22(1):16–39. doi: 10.1108/SCM-06-2016-0197. [DOI] [Google Scholar]

- Altay N, Gunasekaran A, Dubey R, Childe SJ. Agility and resilience as antecedents of supply chain performance under moderating effects of organizational culture within the humanitarian setting: A dynamic capability view. Production Planning & Control. 2018;29(14):1158–1174. doi: 10.1080/09537287.2018.1542174. [DOI] [Google Scholar]

- Arlbjørn JS, Haas Hd, Munksgaard KB. Exploring supply chain innovation. Logistics Research. 2011;3:3–18. doi: 10.1007/s12159-010-0044-3. [DOI] [Google Scholar]

- Armstrong JS, Overton TS. Estimating non-response bias in mail surveys. Journal of marketing research. 1977;14(3):396–402. doi: 10.1177/002224377701400320. [DOI] [Google Scholar]

- Baryannis G, Validi S, Dani S, Antoniou G. Supply chain risk management and artificial intelligence: State of the art and future research directions. International Journal of Production Research. 2019;57(7):2179–2202. doi: 10.1080/00207543.2018.1530476. [DOI] [Google Scholar]

- Belhadi A, Kamble S, Jabbour CJ, Gunasekaran A, Ndubisi NO, Venkatesh M. Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technological Forecasting and Social Change. 2020 doi: 10.1016/j.techfore.2020.120447. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Belhadi A, Kamble SS, Zkik K, Cherrafi A, Touriki FE. The integrated effect of Big Data Analytics, Lean Six Sigma and Green Manufacturing on the environmental performance of manufacturing companies: The case of North Africa. Journal of Cleaner Production. 2020;252:119903. doi: 10.1016/j.jclepro.2019.119903. [DOI] [Google Scholar]

- Belhadi A, Zkik K, Cherrafi A, Yusof SM, Elfezazi S. Understanding big data analytics for manufacturing processes: Insights from literature review and multiple case studies. Computers & Industrial Engineering. 2019;137:106099. doi: 10.1016/j.cie.2019.106099. [DOI] [Google Scholar]

- Beltagui A, Kunz N, Gold S. The role of 3D printing and open design on adoption of socially sustainable supply chain innovation. International Journal of Production Economics. 2020;221:107462. doi: 10.1016/j.ijpe.2019.07.035. [DOI] [Google Scholar]

- Bottani E, Centobelli P, Gallo M, Kaviani MA, Jain V, Murino T. Modelling wholesale distribution operations: an artificial intelligence framework. Industrial Management & Data Systems. 2019;119(4):698–718. doi: 10.1108/IMDS-04-2018-0164. [DOI] [Google Scholar]

- Butler C. Five steps to organisational resilience: Being adaptive and flexible during both normal operations and times of disruption. Journal of Business Continuity & Emergency Planning. 2018;12(2):103–112. [PubMed] [Google Scholar]

- Carvalho H, Azevedo SG, Cruz-Machado V. Agile and resilient approaches to supply chain management: influence on performance and competitiveness. Logistics research. 2012;4(1–2):49–62. doi: 10.1007/s12159-012-0064-2. [DOI] [Google Scholar]

- Cavalcante IM, Frazzon EM, Forcellini FA, Ivanov D. A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. International Journal of Information Management. 2019;49:86–97. doi: 10.1016/j.ijinfomgt.2019.03.004. [DOI] [Google Scholar]

- Chen DQ, Preston DS, Swink M. How the use of big data analytics affects value creation in supply chain management. Journal of Management Information Systems. 2015;32(4):4–39. doi: 10.1080/07421222.2015.1138364. [DOI] [Google Scholar]

- Choi T-M, Wallace SW, Wang Y. Big data analytics in operations management. Production and Operations Management. 2018;27(10):1868–1883. doi: 10.1111/poms.12838. [DOI] [Google Scholar]

- Chowdhury M, Quaddus M, Agarwal R. Supply chain resilience for performance: Role of relational practices and network complexities. Supply Chain Management: An International Journal. 2019;24(5):659–676. doi: 10.1108/SCM-09-2018-0332. [DOI] [Google Scholar]

- Christopher M, Peck H. Building the resilient supply chain. International Journal of Logistics Management. 2004;15(2):1–13. [Google Scholar]

- Cooper V, Molla A. Information systems absorptive capacity for environmentally driven IS-enabled transformation. Information Systems Journal. 2017;24(7):379–425. doi: 10.1111/isj.12109. [DOI] [Google Scholar]

- Cudeck R. Analysis of correlation matrices using covariance structure models. Psychological Bulletin. 1989;105(2):317–327. doi: 10.1037/0033-2909.105.2.317. [DOI] [Google Scholar]

- Cui, Y., Idota, H., & Ota, M. (2019). Improving supply chain resilience with implementation of new system architecture. In IEEE (Ed.), Social Implications of Technology (SIT) and Information Management (SITIM), (pp. 1–6).

- Datta P. Supply network resilience: A systematic literature review and future research. The International Journal of Logistics Management. 2017;28(4):1387–1424. doi: 10.1108/IJLM-03-2016-0064. [DOI] [Google Scholar]

- Dhamija, P., & Bag, S. (2020). Role of artificial intelligence in operations environment: a review and bibliometric analysis. The TQM Journal, 32(4), 869–896.

- Dovers SR, Handmer JW. Uncertainty, sustainability and change. Global Environmental Change. 1992;2(4):262–276. doi: 10.1016/0959-3780(92)90044-8. [DOI] [Google Scholar]

- Dubey R, Gunasekaran A, Childe SJ, Bryde DJ, Giannakis M, Foropon C, et al. Big data analytics and artificial intelligence pathway to operational performance under the effects of entrepreneurial orientation and environmental dynamism: A study of manufacturing organisations. International Journal of Production Economics. 2020;226:107599. doi: 10.1016/j.ijpe.2019.107599. [DOI] [Google Scholar]

- Dzhengiz T, Niesten E. Competences for environmental sustainability: A systematic review on the impact of absorptive capacity and capabilities. Journal of Business Ethics. 2020;162(4):881–906. doi: 10.1007/s10551-019-04360-z. [DOI] [Google Scholar]

- Elhoone H, Zhang T, Anwar M, Desai S. Cyber-based design for additive manufacturing using artificial neural networks for Industry 4.0. International Journal of Production Research. 2020;58(9):2841–2861. doi: 10.1080/00207543.2019.1671627. [DOI] [Google Scholar]

- Fornell C, Larcker DF. Structural equation models with unobservable variables and measurement error: Algebra and statistics. Journal of Marketing Research. 1981;18(3):382–388. doi: 10.1177/002224378101800313. [DOI] [Google Scholar]

- Galbraith JR. Organization design: An information processing view. Interfaces. 1974;4(3):28–36. doi: 10.1287/inte.4.3.28. [DOI] [Google Scholar]

- Giannakis M, Louis M. A multi-agent based system with big data processing for enhanced supply chain agility. Journal of Enterprise Information Management. 2016;29(5):706–727. doi: 10.1108/JEIM-06-2015-0050. [DOI] [Google Scholar]

- Grover, P., Kar, A. K., & Dwivedi, Y. K. (2020). Understanding artificial intelligence adoption in operations management: insights from the review of academic literature and social media discussions. Annals of Operations Research. 10.1007/s10479-020-03683-9.

- Guide VD, Jr., Ketokivi M. Notes from the editors: Redefining some methodological criteria for the journal. Journal of Operations Management. 2015;37(1):v-viii. doi: 10.1016/S0272-6963(15)00056-X. [DOI] [Google Scholar]

- Haefner N, Wincent J, Parida V, Gassmann O. Artificial intelligence and innovation management: A review, framework, and research agenda. Technological Forecasting & Social Change. 2021 doi: 10.1016/j.techfore.2020.120392. [DOI] [Google Scholar]

- Hahn GJ. Industry 4.0: A supply chain innovation perspective. International Journal of Production Research. 2020;58(5):1425–1441. doi: 10.1080/00207543.2019.1641642. [DOI] [Google Scholar]

- Hair JF, Black WC, Babin BJ, Anderson RE. Multivariate data analysis. 7. London: Pearson; 2009. [Google Scholar]

- Hazen BT, Skipper JB, Ezell JD, Boone CA. Big data and predictive analytics for supply chain sustainability: A theory-driven research agenda. Computers & Industrial Engineering. 2016;101:592–598. doi: 10.1016/j.cie.2016.06.030. [DOI] [Google Scholar]

- Hendry LC, Stevenson M, MacBryde J, Ball P, Sayed M, Liu L. Local food supply chain resilience to constitutional change: The Brexit effect. International Journal of Operations & Production Management. 2019;39(3):429–453. doi: 10.1108/IJOPM-03-2018-0184. [DOI] [Google Scholar]

- Hosseini S, Ivanov D. Bayesian networks for supply chain risk, resilience and ripple effect analysis: A literature review. Expert Systems with Applications. 2020;161:113649. doi: 10.1016/j.eswa.2020.113649. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ivanov D, Dolgui A, Sokolov B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. International Journal of Production Research. 2019;57(3):829–846. doi: 10.1080/00207543.2018.1488086. [DOI] [Google Scholar]

- Jain V, Kumar S, Soni U, Chandra C. Supply chain resilience: model development and empirical analysis. International Journal of Production Research. 2017;55(22):6779–6800. doi: 10.1080/00207543.2017.1349947. [DOI] [Google Scholar]

- Jin S, Vegelius J, Yang-Wallentin F. A marginal maximum likelihood approach for extended quadratic structural equation modeling with ordinal data. Structural Equation Modeling: A Multidisciplinary Journal. 2020;27:864–873. doi: 10.1080/10705511.2020.1712552. [DOI] [Google Scholar]

- Kamalahmadi M, Parast MM. A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. International Journal of Production Economics. 2016;171:116–133. doi: 10.1016/j.ijpe.2015.10.023. [DOI] [Google Scholar]

- Kamble SS, Gunasekaran A, Gawankar SA. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Safety and Environmental Protection. 2018;117:408–425. doi: 10.1016/j.psep.2018.05.009. [DOI] [Google Scholar]

- Kamble SS, Gunasekaran A, Gawankar SA. Achieving sustainable performance in a data-driven agriculture supply chain: A review for research and applications. International Journal of Production Economics. 2020;219:179–194. doi: 10.1016/j.ijpe.2019.05.022. [DOI] [Google Scholar]

- Khan A, Bakkappa B, Metri BA, Sahay BS. Impact of agile supply chains' delivery practices on firms' performance: Cluster analysis and validation. Supply Chain Management: An International Journal. 2009;14(1):41–48. doi: 10.1108/13598540910927296. [DOI] [Google Scholar]

- Klumpp M. Automation and artificial intelligence in business logistics systems: Human reactions and collaboration requirements. International Journal of Logistics Research and Applications. 2018;21(3):224–242. doi: 10.1080/13675567.2017.1384451. [DOI] [Google Scholar]

- Kochan CG, Nowicki DR. Supply chain resilience: A systematic literature review and typological framework. International Journal of Physical Distribution & Logistics Management. 2018;48(8):842–865. doi: 10.1108/IJPDLM-02-2017-0099. [DOI] [Google Scholar]

- Kwak D-W, Seo Y-J, Mason R. Investigating the relationship between supply chain innovation, risk management capabilities and competitive advantage in global supply chains. International Journal of Operations & Production Management. 2018;38(1):2–21. doi: 10.1108/IJOPM-06-2015-0390. [DOI] [Google Scholar]

- Lee HL. Big data and the innovation cycle. Production and Operations Management. 2018;27(9):1642–1646. doi: 10.1111/poms.12845. [DOI] [Google Scholar]

- Lee H-Y, Seo Y-J, Dinwoodie J. Supply chain integration and logistics performance: The role of supply chain dynamism. The International Journal of Logistics Management. 2016;27(3):668–685. doi: 10.1108/IJLM-06-2015-0100. [DOI] [Google Scholar]

- Lee SM, Lee D, Schniederjans MJ. Supply chain innovation and organizational performance in the healthcare industry. International Journal of Operations & Production Management. 2011;31(11):1193–1214. doi: 10.1108/01443571111178493. [DOI] [Google Scholar]

- Leitao P. Holonic rationale and bio-inspiration on design of complex emergent and evolvable systems. In: Hameurlain A, Küng J, Wagner R, editors. Transactions on large-scale data- and knowledge-centered systems. Berlin: Springer; 2009. pp. 243–266. [Google Scholar]

- Leung KH, Luk CC, Choy KL, Lam HY, Lee CK. A B2B flexible pricing decision support system for managing the request for quotation process under e-commerce business environment. International Journal of Production Research. 2019;57(20):6528–6551. doi: 10.1080/00207543.2019.1566674. [DOI] [Google Scholar]

- Li G, Kou C, Wang Y, Yang H. System dynamics modelling for improving urban resilience in Beijing, China. Resources, Conservation and Recycling. 2020;161:104954. doi: 10.1016/j.resconrec.2020.104954. [DOI] [Google Scholar]

- Li J, Fang H, Song W. Sustainability evaluation via variable precision rough set approach: A photovoltaic module supplier case study. Journal of Cleaner Production. 2018;192:751–765. doi: 10.1016/j.jclepro.2018.04.248. [DOI] [Google Scholar]

- Lindell MK, Whitney DJ. Accounting for common method variance in cross-sectional research designs. Journal of applied psychology. 2001;86(1):114. doi: 10.1037/0021-9010.86.1.114. [DOI] [PubMed] [Google Scholar]

- Macías-Escrivá FD, Haber R, Toro R, Hernandez V. Self-adaptive systems: A survey of current approaches, research challenges and applications. Expert Systems with Applications. 2013;40(18):7267–7279. doi: 10.1016/j.eswa.2013.07.033. [DOI] [Google Scholar]

- Malhotra MK, Grover V. An assessment of survey research in POM: from constructs to theory. Journal of operations management. 1998;16(4):407–425. doi: 10.1016/S0272-6963(98)00021-7. [DOI] [Google Scholar]

- Mamillo D. Supply chain collaboration under uncertainty in the Albanian beer market. Management Dynamics in the Knowledge Economy. 2015;3(1):99–117. [Google Scholar]

- Mandal S. The influence of big data analytics management capabilities on supply chain preparedness, alertness and agility. Information Technology & People. 2019;32(2):297–318. doi: 10.1108/ITP-11-2017-0386. [DOI] [Google Scholar]