Abstract

Wine is one of the most consumed beverages around the world. It is composed of alcohols, sugars, acids, minerals, proteins and other compounds, such as organic acids and volatile and phenolic compounds (also called polyphenols). Polyphenols have been shown to be highly related to both (i) wine quality (color, flavor, and taste) and (ii) health-promoting properties (antioxidant and cardioprotective among others). Polyphenols can be grouped into two big families: (i) Flavonoids, including anthocyanidins, flavonols, flavanols, hydrolysable and condensed tannins, flavanones, flavones and chalcones; and (ii) Non-flavonoids, including hydroxycinnamic acids, hydroxybenzoic acids, stilbenes, tyrosol and hydroxytyrosol. Each group affects in some way the different properties of wine to a greater or a lesser extent. For that reason, the phenolic composition can be managed to obtain singular wines with specific, desirable characteristics. The current review presents a summary of the ways in which the phenolic composition of wine can be modulated, including (a) invariable factors such as variety, field management or climatic conditions; (b) pre-fermentative strategies such as maceration, thermovinification and pulsed electric field; (c) fermentative strategies such as the use of different yeasts and bacteria; and (d) post-fermentative strategies such as maceration, fining agents and aging. Finally, the different extraction methods and analytical techniques used for polyphenol detection and quantification have been also reviewed.

Keywords: phenolic compounds, anthocyanidins, flavonols, flavanols, wine, quality, organoleptic properties, health benefits, extraction, winemaking technologies

1. Introduction

Wine is one of the oldest and most widespread alcoholic beverages consumed in the world. In 2019, the world wine consumption was 246 Mill. hL according to the latest data collected by the IOV (International Organization of Vine and wine) [1]. The United States, France, Italy, Germany and China are the main consumers, with an average of 120 million hectoliters consumed per year. The pleasure of tasting wine and the cultural tradition in some countries are some of the reasons that encourage consumers to drink it in preference to other alcoholic beverages.

Numerous researchers have proved that moderate consumption of wine is beneficial to health since it presents protective effects against neurological diseases, cancer, diabetes, and cardiovascular diseases [2,3]. In general, wine is composed of alcohol, sugars, acids, tannins, minerals, proteins, and other compounds, such as organic acids, volatile compounds, and phenolic compounds [4]. Polyphenols have been reported to have antioxidant, anti-aging, anti-inflammation, anti-obesity, cardioprotective, neuroprotective, antibacterial, antiviral, antifungal, antiproliferative, anti-inflammatory, anti-allergic, anti-hypertensive and antithrombotic properties, and positive effects on human microbiota composition and functionality [3,5,6,7]. However, the health effects of polyphenols depend on both the amount consumed and their bioavailability. In comparison with other alcohols, these healthy properties endow wine with added value, largely associated with polyphenols (mainly resveratrol). These bioactive properties of wine were clearly established in the conclusions of the so-called “French paradox”.

The “French paradox” concept was formulated in the 1980s by French epidemiologists [8], who compared the mortality rate from cardiovascular disease and the cholesterol level in different populations of the world. This correlation was positive in all the cities studied, except in Toulouse, which showed the same cholesterol levels as Glasgow but with a lower mortality rate from cardiovascular disease [8]. The discrepancy between the risk of cardiovascular disease (high blood cholesterol) and death as a result of it was called the “French paradox”. In 1992, the French authors Renauld and De Lorgeril explained this paradox by the consumption of the Mediterranean diet, with an abundance of vegetables, fruits, olive oil and especially red wine [9]. After an in-depth study of the variables that could contribute to this discrepancy, the researchers concluded that moderate wine consumption improved cardiovascular outcomes despite a high-fat diet [8,9,10].

Additionally, a study carried out in France and Denmark showed that the moderate consumption of wine caused a decrease in mortality (24–31%) from cardiovascular disease compared to the equivalent consumption of beer or spirits [11]. It has also been described that moderate wine consumption may ensure people a longer life expectancy than both those consuming wine in excess and those who drink none at all [12,13].

Consumer demands and the highly competitive market force wineries to produce high quality wines. The quality of a wine is determined by the interaction of physicochemical properties such as alcoholic strength, residual sugar content, density, total acidity, volatile acidity and sulfites together with sensory properties such as aroma, flavor, astringency, bitterness, color, turbidity, or unpleasant odors. These parameters depend on intrinsic factors such as the grape variety and extrinsic ones including soil, weather and winemaking techniques. The interaction of all of these factors determines a profile of compounds directly involved in the quality of the wines [14].

Phenolic compounds are a key factor in the quality of wines, especially red ones. A better understanding of their extreme complexity will allow us to consider their use as a quality criterion. The following sections present a review of the different polyphenols, highlighting their influence on the quality of the wine. To the best of the author’s knowledge, the most important factors that affect their content in grapes and wines and the most actual researcher about this topic are described. In addition, the extraction methods and the most frequently used analysis techniques for their determination in wines are also reviewed. Some of the advantages and disadvantages associated with both of them have been included with the aim of easing future researcher’s decisions for the polyphenol analysis. Conclusion includes some recommendations for the management of internal and external factors depending the type of wine to elaborate.

2. Polyphenols: Key Compounds for Wine Quality

Phenolic compounds are natural substances that are composed of one or more hydroxyl groups attached to one or more aromatic or benzene rings. Polyphenols can be found in many vegetables and fruits, including grapes, and therefore in must and wine. However, as discussed below (Section 3), their content is greatly influenced by the type of grape used, the technological practices to which grapes are exposed [4], the type of yeast used in the alcoholic fermentation, and the contact with solid parts of the grape during the maceration [15]. It is important to remember that red wines are exposed to all grape parts during the winemaking process. For this reason, their polyphenol concentration is higher (1–5 g/L) than in white wines (0.2–0.5 g/L), the contents of which are essentially originated from the pulp, as the types and proportions of polyphenols are different in the pulp, skin and seeds of grapes [5]. Rose wines present an intermediate polyphenol content, with values between those for red and white wines [15,16]. The polyphenols in wine determine many of its sensory properties such as appearance, color, astringency, bitterness, and flavor [17,18,19], and also its stability through subsequent oxidative processes (browning in white wines and oxidation in red wines).

It has been considered that polyphenol compounds have a significant influence on aroma compounds due to they are usually associated with volatile compounds through intermolecular interactions with important consequences on the loss of aroma [20,21,22]. It is for example the case of malvidin that can be bonded to acetosyringone, syringaldehyde, acetovanillone, vanillin, 3,5-dimethoxyphenol, and 4-ethylguaiaco. Or catechin, caffeic acid, and quercetin, which are commonly bonded to aroma compounds such as isobutyl methoxypyrazine, 3-mercaptohexanol, 3-mercaptohexanol acetate, and ethyl decanoate. However, a deep study about the influence of these unions in the aroma and sensory properties has not been carried out. In addition, they contribute to the health-promoting properties of wine mentioned in the previous section [23].

According to their chemical structure, polyphenols present remarkably diverse structures, from simple phenolic acids to high molecular mass polymeric forms such as hydrolysable and condensed tannins, respectively.

They are usually found in conjugated forms with sugar residues by β-glycosidic bonds (O-glycosylated) or by direct bonds of the sugar to a carbon atom of the aromatic ring (C-glycosides) [5,23]. Glucose is the main sugar in fruit skins, which is why many phenolic compounds are bonded to it. However, they can also be found bonded to galactose, rhamnose, xylose, arabinose, as well as glucuronide, galacturonic and other acids [23]. Another factor that could modify the phenolic compounds’ nature and that should be taken into account is malolactic fermentation. Malolactic fermentation is catalyzed by bacteria acid lactic that decarboxylates malic acid to lactic acid, which results in deacidification, which affects polyphenolic compounds in a different manner depending on their structure. It is, for example, the case of anthocyanins that turned into their colorless form during this process due to the changes in pH and the increment in acidity [24]. Or some glucosides can suffer hydrolysis reactions for this change in pH [25]. Moreover, malolactic fermentation provides microbiological stability and improves the final aroma balance by modifying fruit-derived aromas and producing aroma-active compounds [26,27,28].

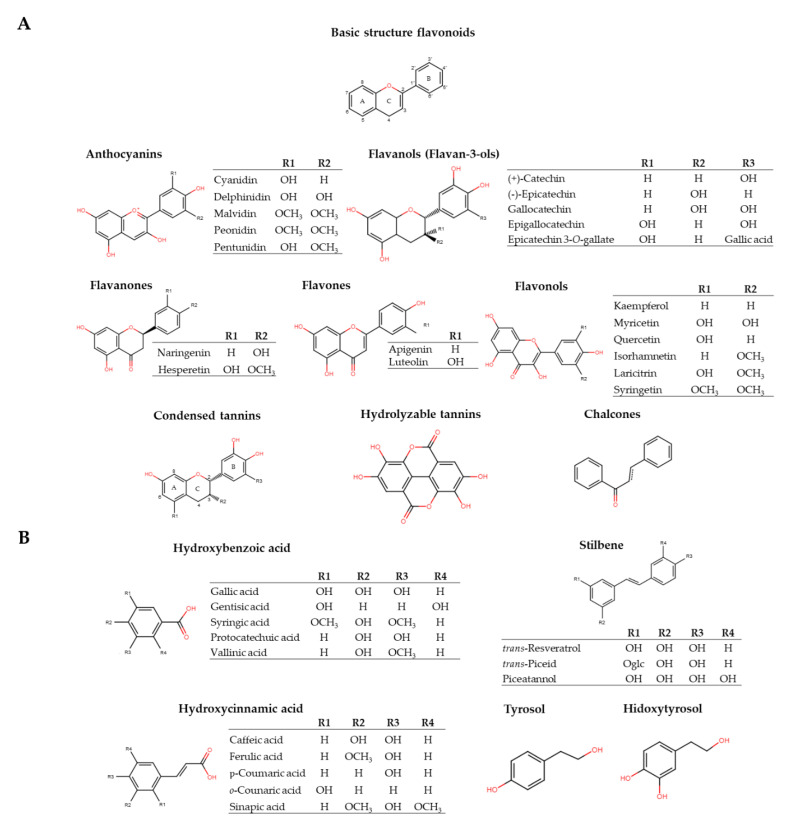

It is possible to distinguish an extensive family of phenolic compounds, which are grouped into flavonoids and non-flavonoids.

- Flavonoids: flavonoids are made up a C15 (C6-C3-C6) type structure (benzene) linked by a 3-carbon chain cyclized through oxygen (Figure 1a). This carbon skeleton and the multiple radicals bonded to it are responsible for the chemical diversity of this family [4]. All the flavonoids found in grapes and wine have a hydroxyl group in position 5 and 7 of the A ring [29]. The antioxidant action of flavonoids depends mainly on their ability to reduce free radicals and chelate metals (Cu and Zn), preventing the catalytic reactions of free radicals [30]. This family comprises anthocyanidins, flavanols, flavonols, flavanones, flavones, chalcones and tannins (condensed tannins and hidrolysable tannins).

-

○Anthocyanidins are natural, water-soluble pigments responsible for the red color of grapes and red wines. Anthocyanin pigments are mainly composed of aglycones (anthocyanidins) bonded sugar (anthocyanins) (Figure 1a). Five anthocyanidins have been identified in both grapes and wine: delphinin, cyanidin, petunidin, peonidin and malvidin. The color of the anthocyanin changes depending on the pH, the concentration of sulfur dioxide, and the copigments present in the wine. At a low pH (less than 4), all anthocyanidins are in the flavan (red) cation form. When the pH increases, the intensity of color increases, from colorless to violet or blue in alkaline or neutral solutions [24]. The anthocyanin concentration can range between 90 and 400 mg/L [29], to concentrations above 700 mg/L in aged red wine, whereas in white wine they are absent [5]. When anthocyanidins interact with other phenolic compounds in wine, a phenomenon known as co-pigmentation occurs, which usually stabilizes the anthocyanidins, and therefore the color [31].

-

○Flavanols (flavan-3-ols) are found in monomeric form (catechin and epicatechin) and in their polymeric form (proanthocyanidins, also called condensed or non-hydrolysable tannins). The following flavan-3-ols are the main ones found in the skin and seed of grapes: (+) catechin, (−) epicatechin, epigallocatechin and epicatechin 3-O-gallate (Figure 1a) [32,33]. Flavanols are responsible for the stabilization of both the color and sensory characteristics (mainly astringency and bitterness) of wines [34]. The concentration range detected in young white wine is from 15 to 25 mg/L, and from 4 to 120 mg/L in young red wine [5,35].

-

○Flavonols [4,5] are yellow pigments found in the skin of grapes characterized by a double bond between C2 and C3 and by the presence of a hydroxyl group in position 1 (Figure 1a). They are usually present in glycosidic forms, linked to a sugar (glucose or rhamnose), but others such as galactose, arabinose, xylose or glucuronic acid may also be involved. The main flavonols described in grapes and wine are myricetin, quercetin, laricitrin, kaempferol, isorhamnetin and syringetin [36]. Flavonols are present in both white and red wines. In white wines the proportion that affects the color is exceedingly small, while in red wines the yellow color is masked by the purplish red of the anthocyanidins [37]. Furthermore, the flavonoid color can change from white to yellow and they consequently play an important role in the color stabilization of young red wines, through the copigmentation interaction with anthocyanidins [38]. In addition, they have an important role in the sensory perception of astringency and bitterness [24]. In red wine, the maximum content described is 60 mg/L [29,39].

-

○Condensed tannins are the result of the condensation of flavanols (flavan-3-ols) (Figure 1a). Epicatechin is the most abundant condensed tannin in grapes and wine, followed by catechin. B-type proanthocyanidins, and in particular dimers B1, B2 and B4 or trimer procyanidin C1, are mainly located in grape skins and seeds [40]. These tannins increase during the aging of the wine and can form insoluble polymers [41], increasing astringency with tannin concentration. Natural condensed tannins can be found at concentrations levels from 1.2 to 3.3 g/L [42,43].

- ○

-

○Flavones are characterized by the presence of a double bond between carbons C2 and C3 and by the absence of a hydroxyl group in the C3 position. Isoflavones are isomers of flavones, displaying the aromatic ring B in the C3 position [4]. Flavones can be present in wine in levels ranging from 0.2 to 1 mg/L [44,45].

- ○

-

○Hydrolysable tannins are high molecular weight molecules, composed mainly of esters of gallic acid (gallotannins) and ellagic (ellagitannins) bonded to glucose or other sugars (Figure 1a). They are more susceptible to hydrolysis than condensed tannins induced by pH changes, enzymatic or non-enzymatic processes [46]. The hydrolysable tannins are not found in Vitis vinifera, only in grapes of the muscadine subgenus and in wines aging in barrels and are thus proposed in the literature as a marker of maturity. The final content of hydrolysable tannins can vary widely, from 0.4 to 50 mg/L [43,47,48].

-

○

- Non-flavonoids form an extensive family within polyphenols, generally having a simpler structure than that of flavonoids. They are mainly composed of phenolic acids (hydroxybenzoic acids and hydroxycinnamic), and stilbenes [4,5]. These groups can reach a concentration range from 60 to 566 mg/L in red wine [46].

-

○Hydroxybenzoic acids have a C6-C1 structure derived from benzoic acid (Figure 1b). The most abundant are p-hydroxybenzoic, gallic, vanillic, gentisic, syringic, salicylic, and protocatechuic acids [49]. The total amount of hydroxybenzoic acids in red wine is expected to range from undetectable to 218 mg/L [46]. Gallic acid is considered the most important phenolic acid in red wine with a concentration of around 70 mg/L, while levels can reach 10 mg/L in white wine [29]. It stands out for being the precursor of all hydrolysable tannins.

-

○Hydroxycinnamic acids have a C6-C3 structure, are very abundant, diverse and all come from cinnamic acid (Figure 1b). The main examples are caffeic, coumaric, sinapic and ferulic acids, essentially conjugated with tartaric acid esters or diesters [50]. Hydroxycinnamic acids are the third most abundant group of polyphenols in grapes and the predominant group in must and white wine. They are easily oxidizable and are associated with wine browning processes. They also are precursors of volatile phenolic compounds [51]. The average amount of hydroxycinnamic acids quantified is about 100 and 30 mg/L in red and white wines, respectively [5] although some authors have found higher concentrations: 130 mg/L in white wines and 60 mg/L in red wines [29].

-

○Stilbenes are bioactive compounds consisting of two aromatic rings linked by ethyl positions (Figure 1b). The main sources of stilbenes in the human diet are grapes and their derivatives: juice and wine [52]. The main stilbenes described in Vitis vinifera wines are trans-piceid and trans-resveratrol, with hopeaphenol, ampelosin A, isohopeaphenol, piceatannol, pallidol, ɛ-viniferin, miyabenol C, r-viniferin, r2-viniferin also being detected [53,54,55,56]. They are found naturally in wine, but at low concentrations (0–5 mg/L) [6]. However, when grapes are exposed to biotic or abiotic stress, the levels of resveratrol (the most studied compound), its glycoside called piceid, and its dimeric and trimeric forms (e.g., pallidol, viniferins) may range from negligible up to more than 100 mg/L [5]. Recently, some stilbenes have been quantified by UPLC-MS/MS, trans-piceid being the most abundant in white wine (average of 155 μg/L), and cis- and trans-piceids and hopeaphenol in red wine (average of 3.73 and 3.16 mg/L, respectively) (mean 1.55 mg/L) [57].

- ○

-

○Hydroxytyrosol (HT) (3,4-dihidroxifeniletanol) is a phenyl ethyl alcohol, mainly responsible for the antioxidant properties of olive oil (Figure 1b). In 2011, it was accepted as protective compound against oxidative damage [58]. It is found naturally in red wine at concentrations between 1.98 and 3.89 mg/L [6,59]. It seems to be synthesized during alcoholic fermentation by yeasts [60].

-

○

Figure 1.

(a) Structure of the flavonoid compounds in wine; (b) Structure of the non-flavonoid compounds in wine. (Own elaboration).

All the above polyphenols largely define the quality of wine, due to their contribution to its sensory properties: color, taste, mouthfeel, flavor, astringency, and bitterness [4,61]. The present review examines the many factors influencing the polyphenol concentration in wine, and the different extraction and analytical techniques employed for their quantification.

3. External Factors and Polyphenol Content

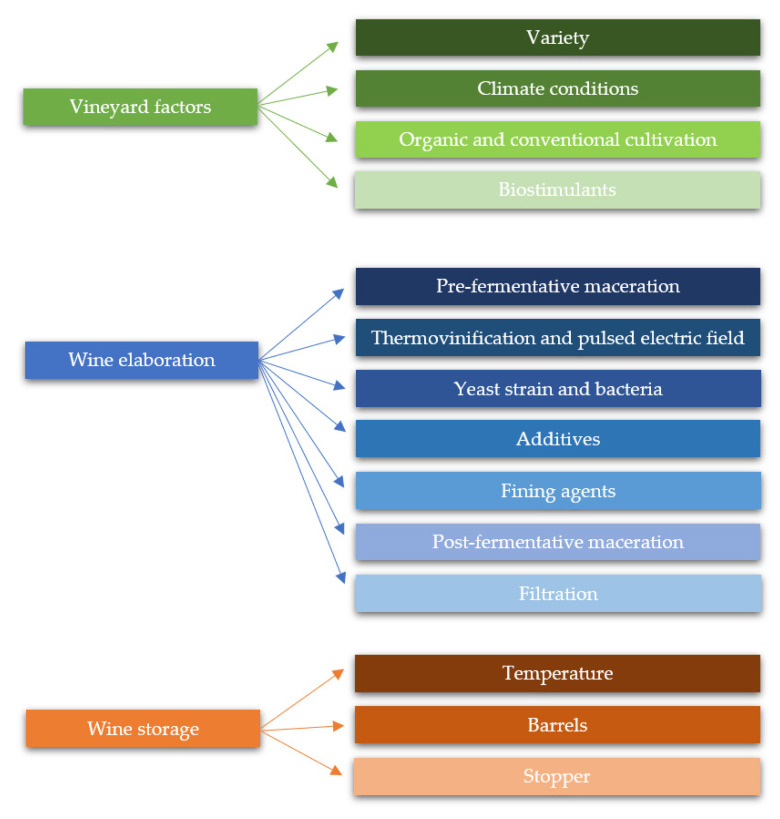

As previously mentioned, the phenolic content of wine has a decisive influence on its organoleptic properties, and therefore on its quality. Many internal and external factors have proved to significantly affect to the concentration of phenolic compounds. Some of these variables have been studied by researchers with the aim of controlling and/or modulating the phenolic concentration and the organoleptic properties associated with them in wine. It is possible to distinguish three decisive levels in which phenolic compounds may be modulated: (i) vineyard; (ii) winemaking; and (iii) wine storage. Below, an in-depth study of these levels and their influence on phenolic content is performed. A summary diagram can be found in Figure 2.

Figure 2.

Summary diagram about the external factors selected to be studied and their influence on phenolic compounds in grape, must, and wine.

3.1. Vineyard Factors

The phenolic concentration of grapes is influenced by multiple factors. First, by the genetic factor, which implies that some varieties naturally produce higher concentrations of phenolic compounds than others. On the other hand, there are other factors related to vineyard management that have a direct effect on the phenolic compound concentration in grapes. Below, some of these factors, such as the climate conditions or terroir, biostimulants and early harvest, have been reviewed.

3.1.1. Variety

Grape (Vitis vinifera L.) has proved to be one of the most abundant fruits worldwide with a high concentration of phenolic compounds. However, several authors have proved that the phenolic compound profile can change significantly according to the variety, genetics being one of the main factors to consider when wanting to achieve a high concentration of these compounds. In fact, the composition and content of the phenolic compounds may be used as markers to determine the variety of an unknown sample. This is, for example, the case of Vitis Vinifera hybrid Regent, which exhibits a high concentration of anthocyanin diglucosides, whereas most Vitis Vinifera varieties show a high content of anthocyanin monoglucosides [62,63]. Or varieties such as Tempranillo, which presents elevated malvidin content in comparison with other Vitis Vinifera varieties, a fact that could be easily used for the determination of this variety [64,65]. In general, red grapes exhibit a higher concentration of phenolic compounds than white grapes. However, a deeper study makes it possible to determine the specific profile of the different varieties.

Brezoiu et al. [66] studied the phenolic composition of two different red grape varieties (Feteasca Negra and Cabernet Sauvignon) by the solid-liquid extraction and HPLC-DAD methodology. The results are shown in Table 1. In this case, the number of phenolic compounds identified in grape extracts and their relative concentrations were considerably higher in the Cabernet Sauvignon variety. González de Peredo et al. [67] analyzed twelve varieties of Vitis vinifera grapes, quantifying the concentration of phenolic compounds by UHPLC (ultra-high pressure liquid chromatography). The results are shown in Table 1. As expected, the concentration of the 17 phenolic compounds (caffeic acid, caftaric acid, catechin, ECGc, epicatechin, gallic acid, kaempferol, myricetin, trans-piceid, procyanidin A2, procyanidin B1, procyanidin B2, protocatechuic acid, quercetin 3-O-galactoside, quercetin 3-O-glucoside, quercetin 3-O-rhamnoside, trans-resveratrol) was lower in the white grape varieties (Albariño, Chardonnay, and Gewurtztraminer) than in the red ones (Cabernet Sauvignon, Graciano, Malbec, Mencía, and Merlot). In contrast, white grapes exhibited a high degree of hydroxycinnamoyltartaric acids such as caftaric acid.

Table 1.

Concentration of phenolic compounds (mg/g) quantified in grape varieties analyzed under different conditions. * fw: fresh weight; dw: dry weight; ** ECGc: Epigallocatechin gallate; -: this compound has not been analyzed during this research.

| Variety | Albariño | Chardonnay | Gewurtztraminer | Cabernet Sauvignon | Graciano | Malbec | Mencía | Merlot | Syrah (Bahia) | Syrah (Pernambrusco) | Cabernet Sauvignon | Feteasca Negra | |||

| Compounds/Reference | González de Peredo et al. [67] (mg/g fw *) | de Oliveira et al. [70] (mg/g fw *) | Brezoiu et al. [66] (mg/g fw *) | ||||||||||||

| Caffeic acid | 0.001 | 0.001 | 0.001 | 0.005 | 0.006 | 0.001 | 0.002 | 0.001 | - | - | - | - | |||

| Caftaric acid | 0.357 | 0.443 | 0.267 | 0.406 | 0.161 | 0.426 | 0.482 | 0.249 | - | - | - | - | |||

| Catechin | 0.02 | 0.014 | 0.087 | 0.026 | 0.033 | 0.02 | 0.022 | 0.047 | - | - | 0.184 | - | |||

| Cyanidin 3-O-glucoside | - | - | - | - | - | - | - | - | 0.001 | 0.001 | - | - | |||

| Delphinidin 3-O-coumarylglucoside | - | - | - | - | - | - | - | - | 0.001 | - | - | - | |||

| Delphinidin 3-O-glucoside | - | - | - | - | - | - | - | - | 0.002 | - | - | - | |||

| ECGc ** | 0.016 | - | 0.107 | 0.015 | 0.153 | 0.168 | 0.051 | 0.137 | - | - | - | - | |||

| Epicatechin | 0.008 | 0.008 | 0.009 | 0.009 | 0.008 | 0.008 | 0.008 | 0.07 | - | - | 2.666 | 2.27 | |||

| Gallic acid | 0.006 | 0.002 | 0.003 | 0.008 | 0.003 | 0.007 | 0.004 | 0.005 | - | - | 1.171 | 1.069 | |||

| Isorhamenetin 3-O-Glucoside | - | - | - | - | - | - | - | - | - | - | - | - | |||

| Kaempferol | 0.192 | 0.191 | 0.193 | 0.193 | 0.214 | 0.194 | 0.198 | 0.189 | - | - | - | - | |||

| Myrcetin | - | - | - | - | - | - | - | - | - | - | 0.172 | 0.055 | |||

| Peonidin 3-O-acetylglucoside | - | - | - | - | - | - | - | - | - | 0.001 | - | - | |||

| Peonidin 3-O-coumarylglucoside | - | - | - | - | - | - | - | - | 0.001 | 0.001 | - | - | |||

| Peonidin 3-O-glucoside | - | - | - | - | - | - | - | - | 0.004 | - | - | - | |||

| Petunidin 3-O-coumarylglucoside | - | - | - | - | - | - | - | - | - | 0.001 | - | - | |||

| Petunidin 3-O-glucoside | - | - | - | - | - | - | - | - | 0.003 | 0.001 | - | - | |||

| trans-Piceid | 0.048 | 0.006 | 0.012 | 0.017 | 0.017 | 0.014 | 0.03 | 0.017 | - | - | - | - | |||

| Procyanidin A2 | 0.07 | 0.001 | 0.004 | 0.083 | 0.228 | 0.016 | 0.118 | 0.012 | - | - | - | - | |||

| Procyanidin B1 | 0.271 | 0.136 | 0.134 | 0.365 | 0.494 | 0.207 | 0.397 | 0.496 | - | - | - | - | |||

| Procyaidin B2 | 0.035 | 0.013 | 0.019 | 0.03 | 0.056 | 0.016 | 0.047 | 0.059 | - | - | - | - | |||

| Protocatechuic acid | 0.003 | - | 0.001 | 0.001 | 0.004 | 0.003 | 0.001 | 0.002 | - | - | 0.451 | 0.489 | |||

| Quercetin 3-O-galactoside | 0.006 | 0.002 | 0.007 | 0.011 | 0.018 | 0.019 | 0.013 | 0.008 | - | - | - | - | |||

| Quercetin 3-O-Glucoside | 0.004 | 0.002 | 0.006 | 0.005 | 0.012 | 0.016 | 0.008 | 0.003 | - | - | - | - | |||

| Quercetin 3-rhamnoside | - | - | - | - | - | - | 0.002 | - | - | - | - | - | |||

| Rutin | - | - | - | - | - | - | - | - | - | - | 0.532 | - | |||

| Syringic acid | - | - | - | - | - | - | - | - | - | - | 2.031 | 1.917 | |||

| trans-Resveratrol | - | - | - | - | 0.003 | 0.001 | - | - | 0.004 | 0.006 | 0.033 | 0.049 | |||

| Vanillic acid | - | - | - | - | - | - | - | - | - | - | 0.368 | 1.088 | |||

| Variety | Cabernet Sauvignon | Jaen Tinto | Palomino Negro | Tempranillo | Tintilla de Rota | Cabernet Sauvignon | Canaiolo Nero | Colorino del Valdarno | Flogia Tonda | Merlot | Montepulciano | Sangiovese | Cabernet Sauvignon | Carmènéere | |

| Compounds/Reference | Guerrero et al. [52] (mg/g fw *) | Iacopini et al. [68] (mg/g dw *) | Obreque-Slier et al. [69] (mg/g dw *) | ||||||||||||

| Caftaric acid | 0.009 | 0.014 | 0.014 | 0.010 | 0.019 | - | - | - | - | - | - | - | 0.008 | 0.008 | |

| Catechin | 0.004 | 0.003 | 0.003 | 0.006 | 0.002 | 1.418 | 1.407 | 1.244 | 0.674 | 1.388 | 2.057 | 0.969 | 0.051 | 0.031 | |

| trans-Coutaric acid | 0.006 | 0.010 | 0.009 | 0.007 | 0.012 | - | - | - | - | - | - | - | - | - | |

| Cyanidin 3-O-glucoside | - | 0.007 | 0.037 | 0.015 | 0.036 | - | - | - | - | - | - | - | - | - | |

| Cyanidin-3-p-coumaroylglucoside | - | - | 0.019 | - | 0.014 | ||||||||||

| Delphinidin 3-O-acetylglucoside | 0.021 | - | 0.018 | 0.01 | - | - | - | - | - | - | - | - | - | - | |

| Delphinidin 3-O-glucoside | 0.046 | 0.028 | 0.197 | 0.107 | 0.098 | - | - | - | - | - | - | - | - | - | |

| Epicatechin | - | 0.001 | - | 0.002 | - | 1.276 | 2.057 | 0.89 | 0.472 | 1.318 | 1.646 | 1.068 | - | - | |

| Gallic acid | - | - | - | - | - | - | - | - | - | - | - | - | 0.033 | 0.034 | |

| Isorhamenetin 3-O-Glucoside | 0.027 | 0.013 | - | - | 0.031 | - | - | - | - | - | - | - | 0.125 | 0.226 | |

| Kaemperol 3-O-Galactoside | - | - | - | - | - | - | - | - | - | - | - | - | 0.083 | 0.124 | |

| Kaemperol 3-O-Glucoside | 0.036 | 0.021 | 0.018 | 0.029 | 0.032 | - | - | - | - | - | - | - | 0.313 | 0.399 | |

| Malvidin 3-O-acetylglucoside | 0.552 | 0.137 | 0.067 | 0.049 | 0.153 | - | - | - | - | - | - | - | 0.004 | 0.003 | |

| Malvidin-3-caffeoylglucoside | 0.062 | 0.038 | 0.042 | - | 0.056 | - | - | - | - | - | - | - | - | - | |

| Malvidin 3-O-coumarylglucoside | - | - | - | - | - | - | - | - | - | - | - | - | 0.002 | 0.003 | |

| Malvidin 3-O-glucoside | 0.665 | 0.425 | 0.508 | 0.292 | 1.207 | - | - | - | - | - | - | - | 0.006 | 0.016 | |

| Malvidin-3-p-coumaroylglucoside (cis) | 0.018 | 0.011 | 0.078 | 0.059 | 0.021 | - | - | - | - | - | - | - | - | - | |

| Malvidin-3-p-coumaroylglucoside (trans) | 0.22 | 0.144 | 0.222 | 0.22 | 0.427 | - | - | - | - | - | - | - | - | - | |

| Myrcetin | - | - | - | - | - | - | - | - | - | - | - | - | 0.104 | 0.151 | |

| Myricetin-3-O-glucuronide | 0.05 | 0.052 | 0.06 | 0.032 | 0.131 | - | - | - | - | - | - | - | - | - | |

| Myricetin-3-O-glucoside | 0.098 | 0.056 | 0.059 | 0.178 | 0.079 | - | - | - | - | - | - | - | - | - | |

| Peonidin 3-O-acetylglucoside | 0.029 | 0.015 | 0.016 | - | 0.043 | - | - | - | - | - | - | - | - | - | |

| Peonidin 3-O-glucoside | 0.043 | 0.043 | 0.096 | 0.03 | 0.437 | - | - | - | - | - | - | - | - | - | |

| Petunidin 3-O-acetylglucoside | 0.026 | - | 0.027 | 0.015 | - | - | - | - | - | - | - | - | - | - | |

| Petunidin 3-O-glucoside | 0.051 | 0.042 | 0.179 | 0.091 | 0.119 | - | - | - | - | - | - | - | - | - | |

| Petunidin-3-p-coumaroylglucoside | 0.021 | 0.016 | 0.067 | 0.056 | 0.029 | - | - | - | - | - | - | - | - | - | |

| Procyaidin B3 | - | - | - | - | - | - | - | - | - | - | - | - | 0.037 | 0.035 | |

| Quercetin | - | - | - | - | - | 0.006 | - | 0.005 | 0.003 | 0.007 | 0.008 | 0.011 | - | - | |

| Quercetin 3-O-Galactoside | - | - | - | - | - | - | - | - | - | - | - | - | 0.19 | 0.181 | |

| Quercetin 3-O-Glucoside | 0.07 | 0.032 | 0.041 | 0.115 | 0.103 | - | - | - | - | - | - | - | 1.095 | 1.812 | |

| Quercetin-3-O-rutinoside | 0.069 | 0.035 | 0.043 | 0.133 | 0.100 | - | - | - | - | - | - | - | - | - | |

| Rutin | - | - | - | - | - | 0.886 | 0.413 | 0.403 | 0.604 | 0.899 | 0.532 | 1.491 | - | - | |

| Syringetin-3-O-glucoside | 0.067 | 0.023 | - | - | 0.062 | - | - | - | - | - | - | - | - | ||

| Syringic acid | - | - | - | - | - | - | - | - | - | - | - | - | 0.015 | 0.031 | |

| trans-Caftaric acid | 0.001 | 0.001 | 0.001 | 0.001 | 0.002 | - | - | - | - | - | - | - | - | - | |

| trans-Coutaric acid | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | - | - | - | - | - | - | - | - | - | |

| trans-Resveratrol | - | - | - | - | - | 0.255 | 0.028 | 0.164 | 0.013 | 0.105 | 0.109 | 0.007 | - | - | |

| Vanillic acid | - | - | - | - | - | - | - | - | - | - | - | - | 0.073 | 0.075 | |

Iacopini et al. [68] quantified phenolic compounds in seven varieties (Sangiovese, Merlot, Cabernet Sauvignon, Canaiolo Nero, Colorino del Valdarno, Foglia Tonda, and Montepulciano) cultivated in the Experimental Institute of Viticulture in Arezzo (Italy). Five phenolic compounds (catechin, epicatechin, resveratrol, rutin, and quercetin) were quantified by comparison of retention times with pure standards. The results can be found in Table 1. Montepulciano exhibited the highest catechin concentration and Canaiolo was the variety with the highest value of epicatechin, whereas Foglia Tonda showed the lowest content of catechin, epicatechin and quercetin. Cabernet Sauvignon manifested the highest values of resveratrol and Sangiovese showed the highest concentration of quercetin and rutin, and the lowest content of resveratrol. Finally, Colorino exhibited the lowest concentration of rutin.

Obreque-Slier et al. [69] analyzed two Carménère and Cabernet Sauvignon varieties from Chile with the aim of calculating their phenolic compound concentrations. A total of 15 phenolic compounds (caftaric acid, catechin, gallic acid, isorhamnetin 3-O-glucoside, kaempferol 3-O-galactoside, kaempferol 3-O-glucoside, malvidin 3-O-acetylglucoside, malvidin 3-O-coumarylglucoside, malvidin 3-O-glucoside, myricetin, procyanidin B3, quercetin 3-O-galactoside, quercetin 3-O-glucoside, syringic acid, vanillic acid) were identified but slight differences were observed in the content between both varieties, as shown in Table 1. Guerrero et al. [52] quantified 25 phenolic compounds (trans-caftaric acid, catechin, trans-coutaric acid, cyanidin 3-O-glucoside, cyanidin-3-p-coumaroylglucoside, delphinidin 3-O-acetylglucoside, delphinidin 3-O-glucoside, epicatechin, isorhamnetin 3-O-glucoside, kaempferol 3-O-glucoside, malvidin 3-O-acetylglucoside, malvidin-3-caffeoylglucoside, malvidin 3-O-glucoside, cis-malvidin-3-p-coumaroylglucoside, trans-malvidin-3-p-coumaroylglucoside, myricetin-3-O-glucuronide, myricetin-3-O-glucoside, peonidin 3-O-acetylglucoside, peonidin 3-O-glucoside, petunidin 3-O-acetylglucoside, petunidin-3-p-coumaroylglucoside, petunidin-3-O-glucoside, quercetin-3-O-rutinoside, syringetin-3-O-glucoside) from three autochthonous red grape varieties (Jaen Tinto, Palomino Negro, and Tintilla de Rota), one international variety (Cabernet Sauvignon) and one Spanish variety (Tempranillo). All of them were grown in a warm climate (Table 1). Tintilla de Rota exhibited the highest phenolic compound concentration followed by Cabernet Sauvignon.

A comparison of the concentrations in each variety cannot be made since they were not cultivated under the same conditions and the extraction and analysis methodologies used were different.

3.1.2. Climate Conditions

Terroir was defined by Seguin in 1988 [71] as an interactive ecosystem which includes climate, soil and the vine (rootstock and cultivar). Some authors [72] have included human factors as well, like viticultural and ecological practices. As observed in Table 1, the phenolic composition of Cabernet Sauvignon varies depending on the different origins. Brezoiu et al. [66] chose Romania from the black sea zone as the location for their research. The climate of this zone could be characterized as continental, which means mild winters with average temperatures of −1 °C and frequent snowfall. On the other hand, summer is quite warm with temperatures of around 26 °C, and this is the rainiest season of the year, with storms that can cause floods. González de Peredo et al. [67] selected different varieties with multiple countries of origin but all grown in Alcalá de Henares (Spain). In this zone, the summers are very hot, dry, and cloudless and the winters are long, cold, and partly cloudy. The temperatures can vary from 1 °C to 33 °C. Iacopini et al. [68] performed their research in Arezzo (Italy), which is characterized by hot and cloudless summers and long, cold and cloudy winters. The temperatures vary from 0 °C to 31 °C. Lastly, Obreque-Slier et al. [69] evaluated the phenolic content of the Cabernet Sauvignon variety from Maule Valley (Chile). This region presents a Mediterranean climate with temperatures between 7 °C in winter and 30 °C in the summer months. Snowfall is not usual in this zone but rain is, with an average amount of 735 mm per year.

The results observed in Table 1 exhibited a higher concentration of phenolic compounds in varieties grown in a climate of long winters with low temperatures and possible snowfall. In this case, the average phenolic compounds obtained from the Cabernet Sauvignon variety was 1.35 mg/g grape from those grown in Italy, while respective concentrations of 0.82, 0.17, and 0.11 were found in the grapes from Turkey, Chile and Spain. As an example, the concentration of catechin in the Cabernet Sauvignon grapes was 0.184 mg/g grape in those from Turkey, 0.026 mg/g in those from Spain, 1.418 mg/g in those from Italy, and 0.051 in those from Chile. However, a total comparison could not be performed as only one variety was analyzed from each different origin.

Different researchers have evaluated the effect of some climate parameters on the phenolic concentration in grapes. Van Leeuwen et al. [73] evaluated the influence of climate conditions, soil and cultivar on grape composition. To this end, three Vitis vinifera varieties were selected (Merlot, Cabernet Sauvignon, and Cabernet Franc) and cultivated in vineyards located in the Bordeaux region with three kinds of soils (gravelly soil, heavy clay, and sandy soil) and over three years. The climate conditions of the three years were measured by a weather station located in the same vineyard. The climate exhibited the most influential effect on the grape composition followed by soil and cultivar. The results proved that vine water availability is a decisive parameter for the phenolic compound concentration, even more than temperature and sunshine hours. In fact, a negative water balance from flowering to harvest combined with soils with water deficits resulted in earlier shoot-growth slackening, a reduced berry size and thus a high phenolic compound concentration, which increased grape quality. These results were in accordance with the observed by Ratiu et al. [74] who evaluated the influence of different climatic conditions on secondary metabolites such as phenolic compounds. They proved that conditions with low temperatures and deficiency of water facilitate the production of the phenolic compounds and especially the anthocyanin accumulation. These authors also observed that soils with nutrient stress or rich in sucrose (which induces osmotic stress) have an important influence on the synthesis of phenolic compounds.

De Oliveira et al. [70] evaluated the influence of climate conditions on the composition of Syrah grapes (Table 1). To this end, the Syrah variety grown in two zones from Brazil was selected. The first zone, Pernambuco, is characterized by latitudes 8 and 9° parallels at 350 m asl (above sea level) and with soils classified as red-yellow argisols and a semi-arid tropical climate. The second zone was Morro du Chapéu in the Chapada Diamantina region at the 11° parallel, at 1.100 m asl. The soils were classified as red-yellow deep latosols with a pH around 4.8, and the climate is classified as tropical with rain distributed throughout the year. The Syrah grapes cultivated in the Diamantina region showed a higher concentration of most of the phenolic compounds, evidence that, in the case of Brazil, a tropical climate and latosols present in soils promote a higher production of these compounds.

Fernández-Marín et al. [75] evaluated the effect of variety and terroir on stilbene concentration. The authors analyzed four different red grape varieties (Syrah, Merlot, Cabernet Sauvignon, and Pinot Noir) from four different Andalusian zones (Jerez, Cabra, Cadiar, and Ronda). The results showed that the terroir effect was stronger than the variety on stilbene concentration and that the Cabra terroir produced the highest stilbene content.

Ramos and Martínez de Toda [76] studied the influence of climate conditions and soil composition on the phenolic content in Tempranillo grapes. The study was carried out in La Rioja (Spain) in three different zones: two in La Rioja Alta with an Atlantic influence, and one in La Rioja Oriental with a Mediterranean influence. The three zones exhibited different soil compositions (clay, sand, silt and coarse elements were selected for the evaluation). In addition, the trial was carried out from 2008 to 2018, ensuring significant differences in climate conditions. The results showed a higher concentration of phenolic compounds in climate conditions with high temperatures and an important water deficit, in agreement with Van Leeuwen et al. [73,77].

In agreement with these results, many authors [78,79,80] have confirmed that high temperatures and a water deficit as a consequence of permeable soils which enhance this situation result in a lower development of the vine, leading to a higher concentration of phenolic compounds in the grapes. In addition, Del-Castillo-Alonso et al. [81] have recently proved that a supplement of ultraviolet radiation via a mechanical method increases the phenolic concentration of grape skins and consequently of the wine produced.

Furthermore, there are climate events that could directly affect the composition of grapes such as heatwaves, characterized by an important increase in temperatures with a low humidity grade. These are unpredictable episodes that can last from a day to several weeks. The drastic change of temperatures and the high values reached have an important impact on agriculture, including viticulture, with decisive desiccation of the plants and fruits and with significant changes in their composition, which could generate irreversible damage. For this reason, it is very important to evaluate the influence of heatwaves on grape compositions to predict their effect on the wine. Gouot et al. [82] evaluated the influence of heatwaves on the phenolic compositions of grapes. The authors exposed grapes to three different temperatures (ambient, high, and very high) under experimental conditions for varied periods of time (from 3 to 39 h). In the case of the high temperature, an increase in anthocyanins, flavanols and tannins was detected after just 18 h of exposure. Anthocyanins were the most affected polyphenol compounds, increasing from 0.2 mg/g to 17.1 mg/g in just 18 h. Tannins were measured in the seeds too, but no significant difference was observed at different temperatures or time of exposure, likely due to the protection conceded by the pulp and skin. It was concluded that the maximum temperature reached was a more influential factor than the exposure time. In fact, temperatures around 43 °C to 46 °C led to an increase in compounds such as anthocyanins, flavonols or tannins in just 18 h. However, temperatures higher than 53 °C resulted in a decisive degradation of compounds without any significant influence of the time of exposure. The authors suggested that in the event that a vineyard suffered a heatwave with temperatures higher than 53 °C, an early harvest would be a good decision. Nevertheless, this research should be performed in a vineyard to establish a definitive conclusion.

3.1.3. Organic and Conventional Cultivation

During the last few years, the concern of consumers by the chemicals present on the food products has increased notoriously. For this reason, there are multiple vineyards that support organic viticulture practices. Organic agriculture is characterized by not using pesticides during the cultivation [83], which suppose that vineyards suffer more fungal infections and thereby producing higher levels of secondary metabolites for their defense.

Dani et al. [84] evaluated the influence of organic and traditional cultivate on varieties Bordo and Niagara from Vitis Labrusca. Phenolic compounds were quantified on grape juices. The results proved that organic juices exhibited a higher total polyphenol content compared to juices from conventional grapes. It is for example the case of Bordo variety that exhibited concentrations of 290.26 and 109.71 mg/L of the measured anthocyanins in organic and conventional grape juices, respectively. In the case of catechins, the conventional grape exhibited concentrations of 2.06 mg/L and 2.13 mg/L for catechin and epicatechin whereas the organic grapes showed contents of 33.89 and 2.72 mg/L for catechin and epicatechin. For the procyanidins (B1-B4) the conventional cultivation showed a concentration of 15.77 mg/L and the organic one a concentration of 20.52 mg/L. In the case of Niagara variety, the conventional cultivation displayed 7.39 and 5.95 mg/L for catechin and epicatechin whereas the organic cultivation showed concentrations of 0.90 and 1.81 mg/L, respectively. Conventional cultivation showed concentrations of procyanidins (B1-B4) of 24.35 mg/L and 27.12 mg/L for organic cultivation.

Angelica De Pascali et al. [85] evaluated the use of conventional and organic practices as well on Apulia Negroamaro variety. The results were in consonance with the previously observed, a significant increment of phenolic compounds was detected when organic cultivation was used. J.Olejar [86] suggested the use of weedmat undervine treatment instead of herbicides treatment on the vineyard and evaluated its influence on phenolic composition grapes. The grapes from conventional cultivation exposed a total phenolic content of 1.82 mg/L whereas the organic cultivation showed contents of 1.98 and 2.03 mg/L for black weedmat and white weedmat, respectively.

Other authors [87,88,89,90,91] have evaluated the influence of organic practices on grape composition and the results have proved a promotion on the production of phenolic compounds but, it was observed as well that its influence is highly related to the variety.

3.1.4. Biostimulants

Plant biostimulants are defined at European level as “products stimulating plant nutrition processes independently of the product’s nutrient content, with the aim of improving the crop quality traits among other characteristics of the plant” [92]. Biostimulants have been widely used in vineyards with the aim of promoting the production of some compounds in grape such as phenolic compounds. Martínez-Gil et al. and Pardo-García et al. used different concentrations of an aqueous oak extract on Verdejo, Petit Verdot, and Monastrell grapes varieties [93,94,95]. The extract was diluted with water to one in four parts and applied (i) once, on the seventh day post-veraison (25%-1 treatment) and (ii) four times (7, 11, 15, and 18 days post-veraison (25%—four treatments). Lastly, the undiluted extract was tested once on the seventh day post-veraison (100%—one treatment). A total of 16 plants were selected in the same row, with other rows with untreated plants between the different applications. A total of 300 mL of the corresponding formulation were sprayed onto the leaves of each plant. The treatments were carried out at 20 °C and the winemaking process was performed under traditional conditions. The results showed that the phenolic compounds were correctly assimilated by the grapes and transmitted into their wines with positive effects on their final quality. Table 2 shows the phenolic compound concentrations detected in the Monastrell wine after the oak extract treatment. The treatment significantly increased the total content of hydroxycinnamic acids and hydroxycinnamoyltartaric acids in the wines. These compounds were more abundant in the treated wines than in the control, especially after malolactic fermentation. On the other hand, after 6 months of malolactic fermentation, a decrease in trans-caftaric and trans-coutaric acids was observed and an increase in trans-caffeic and p-coumaric acids, with the greatest content found in the grapes following the 25%—1 and 25%—4 treatments. These results support the idea that wine from treatments with more oak extract are more resistant to oxidation. In addition, total hydroxybenzoic acids increased as well with aging, with gallic acid being the most abundant compound. Regarding stilbenes, the oak treatment led to an increase in the content of trans-resveratrol and trans-piceid in the wine. In the case of the anthocyanins, the acylated anthocyanins content was significantly higher when 100%—1 treatment was applied compared with the control, but they were found to decrease in all the wines over time. No effect of the oak extract treatment on the concentration of vitisins A and B was detected. However, significant differences in the main flavanol concentrations ((+)-catechin and (−)-epicatechin) were perceived among the treated wines and the control. The 100%—1 treated wines exhibited the highest content of total phenolic compounds and the wines from the 25%—1 treatment the lowest. Furthermore, a relationship was found between the oak extract treatment and the increase in flavanols in general.

Table 2.

Pardo-García et al. and Cebrián et al.; Concentration of phenolic compounds in wines (mg/L) from Monastrell, Airén and Cencibel varieties after grapevine/wine treatment with oak extracts. * 100%: one treatment with oak extract on seventh day post-veraison; ** BAF: Before alcoholic fermentation, AAF: after alcoholic fermentation, AMF: after malolactic fermentation; Portu et al.: Concentration of phenolic compounds in wines (mg/L)/grapes (mg/kg) from Garnacha and Tempranillo varieties after grapevine treatment with phenylalanine (Phe), methyl jasmonate (MeJ), chitosan (Ch), and yeast extracts (YE); n.d.: not detected; -: this compound has not been analyzed during this research.

| Variety | Monastrell | Airén | Cencibel | |||||||||||

| Reference | Pardo-García et al. [93] | Cebrián et al. [98] | ||||||||||||

| Compound(mg/L)/Treatment | Oak extract | Control BAF ** | Chips BAF ** | Granule BAF ** | Control AAF ** | Chips AAF ** | Granule AAF ** | Control BAF ** | Chips BAF ** | Granule BAF ** | Control AMF ** | Chips AMF ** | Granule AMF ** | |

| Control | 100% * | |||||||||||||

| trans-Caffeic acid | 0.74 | 1.68 | 2.815 | 2.51 | 2.69 | 3.49 | 3.93 | 3.48 | 0.36 | 0.44 | 0.33 | 0.35 | 0.50 | 0.78 |

| trans-Caftaric acid | 17.9 | 25.1 | 7.61 | 6.12 | 8.31 | 6.18 | 4.85 | 5.68 | 43.85 | 46.12 | 45.84 | 43.55 | 44.24 | 45.25 |

| (+)-Catechin | 29.3 | 49.3 | 9.50 | 9.59 | 12.21 | 7.25 | 9.99 | 11.50 | 22.13 | 25.37 | 20.55 | 18.05 | 18.83 | 21.70 |

| p-Coumaric acid | 0.68 | 2.79 | - | - | - | - | - | - | - | - | - | - | - | - |

| trans-Coutaric acid | 5.34 | 10.6 | 3.87 | 3.76 | 3.68 | 3.65 | 3.06 | 2.93 | 23.71 | 24.70 | 24.85 | 21.57 | 21.22 | 20.69 |

| Cyanidin 3-(6-p-coumaroyl)-glucoside | 1.33 | 0.85 | - | - | - | - | - | - | - | - | - | - | - | - |

| Cyanidin 3-O-glucoside | 0.87 | 0.82 | - | - | - | - | - | - | - | - | - | - | - | - |

| Delphinidin 3-O-glucoside | 11.2 | 11.3 | - | - | - | - | - | - | - | - | - | - | - | - |

| (−)-Epicatechin | 12.4 | 31.2 | 15.21 | 16.09 | 32.41 | 13.03 | 15.62 | 35.56 | 132.16 | 155.51 | 129.25 | 65.40 | 64.64 | 83.37 |

| Gallic acid | 22.3 | 45.8 | 5.65 | 7.24 | 8.18 | 6.55 | 7.18 | 8.49 | 16.42 | 17.52 | 17.93 | 18.84 | 16.08 | 19.15 |

| Malvidin 3-O-glucoside | 148 | 111 | - | - | - | - | - | - | - | - | - | - | - | - |

| Malvidin 3-(6-p-coumaroyl)-glucoside | 17.5 | 15.1 | - | - | - | - | - | - | - | - | - | - | - | - |

| Malvidin 3-O-(6-acetyl)-glucoside | 12.2 | 10.8 | - | - | - | - | - | - | - | - | - | - | - | - |

| Myricetin 3-O-galactoside | 4.6 | 3.9 | - | - | - | - | - | - | - | - | - | - | - | - |

| Myricetin 3-O-glucuronide + myricetin 3-O-glucoside | 24.5 | 10.4 | - | - | - | - | - | - | - | - | - | - | - | - |

| Peonidin 3-O-(6-acetyl)-glucoside | 1.02 | 0.79 | - | - | - | - | - | - | - | - | - | - | - | - |

| Peonidin 3-(6-p-coumaroyl)-glucoside | 3.76 | 2.88 | - | - | - | - | - | - | - | - | - | - | - | - |

| Peonidin 3-O-glucoside | 6.2 | 4.4 | - | - | - | - | - | - | - | - | - | - | - | - |

| Petunidin 3-O-glucoside | 26.8 | 21.4 | - | - | - | - | - | - | - | - | - | - | - | - |

| Procyanidin B2 | - | - | n.d. | n.d. | n.d. | 3.67 | 3.14 | 3.98 | 1.96 | 1.22 | 1.41 | 1.78 | 0.74 | 1.38 |

| Quercetin | 14.5 | 23 | 1.24 | 1.12 | 1.29 | 2.06 | 1.08 | n.d. | 1.87 | 1.43 | 1.15 | 1.17 | 1.27 | 1.07 |

| Quercetin 3-O-glucoside | 4.69 | 3.38 | - | - | - | - | - | - | - | - | - | - | - | - |

| Quercetin 3-O-glucoronide | - | - | 2.76 | 2.33 | 2.12 | 2.52 | 1.95 | 2.41 | 4.03 | 4.08 | 3.64 | 4.19 | 3.75 | 2.60 |

| trans-Resveratrol | 0.15 | 0.4 | 0.36 | 0.84 | 3.93 | 0.36 | 1.00 | 3.94 | 0.78 | 0.88 | 1.62 | 0.64 | 0.87 | 1.86 |

| Syringetin 3-O-glucoside | 3.94 | 3.65 | - | - | - | - | - | - | - | - | - | - | - | - |

| Syringic acid | 7.2 | 7.9 | - | - | - | - | - | - | - | - | - | - | - | - |

| Vanillic acid | 2.98 | 2.04 | n.d. | 0.19 | 0.27 | n.d. | n.d. | n.d. | 1.67 | 1.67 | 1.76 | 2.06 | 1.67 | 1.90 |

| Variety | Garnacha | Tempranillo | ||||||||||||

| Reference | Portu et al. [103,105] | |||||||||||||

| Compound (mg/L)/treatment | Control | Phe | MeJ | Phe + MeJ | Control | MeJ | CHT | YE | Control | MeJ | CHT | YE | ||

| Grape berries (mg/kg) | Wines (mg/L) | |||||||||||||

| trans-Caffeic acid | - | - | - | - | n.d. | n.d. | n.d. | n.d. | 4.48 | 4.75 | 4.61 | 4.59 | ||

| trans-Caftaric acid | 87.19 | 98.7 | 116.08 | 100.53 | 28.53 | 33.72 | 30.73 | 26.07 | 43.43 | 38.46 | 41.34 | 35.18 | ||

| (+)-Catechin | 123.13 | 105.51 | 108.45 | 112.49 | 27.48 | 29.94 | 24.65 | 24.76 | 12.35 | 12.13 | 11.57 | 10.38 | ||

| p-Coumaric acid | - | - | - | - | n.d. | n.d. | n.d. | n.d. | 1.48 | 1.54 | 1.37 | 1.22 | ||

| trans-Coutaric acid | 18.82 | 24.91 | 29.41 | 24.55 | 35.55 | 37.35 | 35.54 | 33.34 | 32.69 | 29.51 | 32.75 | 25.16 | ||

| Cyanidin 3-(6-p-coumaroyl)-glucoside | 2.72 | 2.77 | 3.34 | 2.91 | 10.4 | 13.25 | 10.31 | 11.96 | 1.84 | 2.36 | 1.94 | 1.83 | ||

| Cyanidin 3-O-glucoside | 6.58 | 5.73 | 15.12 | 8.04 | 34.16 | 56.4 | 37.22 | 50.1 | 1.84 | 2.7 | 1.96 | 1.81 | ||

| Delphinidin 3-O-glucoside | 24.74 | 29.66 | 58.12 | 36.58 | 261.6 | 319.98 | 264.77 | 312.3 | 36.17 | 48.79 | 39.59 | 38.5 | ||

| (−)-Epicatechin | 59.02 | 44.72 | 37.92 | 45.31 | 17.36 | 18.48 | 16.08 | 18.28 | 5.9 | 6.93 | 5.14 | 5.39 | ||

| Gallic acid | 14.65 | 18.89 | 19.3 | 16.23 | 9.21 | 9.98 | 8.5 | 8.35 | 11.71 | 11.11 | 11.82 | 10.82 | ||

| Malvidin 3-O-glucoside | 384.58 | 430.53 | 525.75 | 474.32 | 541.57 | 577.92 | 535.57 | 618.94 | 280.43 | 310.57 | 286.58 | 315.54 | ||

| Malvidin 3-(6-p-coumaroyl)-glucoside | 3.1 | 3.03 | 3.03 | 3.15 | 73.24 | 96.75 | 68.01 | 95.24 | 9.03 | 10.06 | 9.65 | 9.39 | ||

| Malvidin 3-O-(6-acetyl)-glucoside | 11.91 | 13.34 | 14.1 | 13.08 | 35.36 | 33.68 | 33.46 | 36.89 | 16.88 | 17.07 | 16.56 | 18.43 | ||

| Myricetin 3-O-galactoside | 0.42 | 0.45 | 0.74 | 0.57 | 7.4 | 7.12 | 6.3 | 7.28 | 1.54 | 1.57 | 1.28 | 1.42 | ||

| Myricetin 3-O-glucuronide + myricetin 3-O-glucoside | 5.18 | 5.84 | 6.82 | 6.03 | 7.98 | 8.44 | 6.76 | 8.24 | 2.12 | 1.85 | 1.57 | 1.68 | ||

| Peonidin 3-O-(6-acetyl)-glucoside | 11.36 | 11.29 | 14.03 | 12.04 | 3.29 | 3.87 | 3.44 | 3.92 | 1.05 | 1.23 | 1.08 | 1.07 | ||

| Peonidin 3-(6-p-coumaroyl)-glucoside | 3.02 | 2.9 | 3.28 | 3.01 | 23.17 | 25.63 | 22.33 | 24.95 | 5.94 | 7.39 | 6.63 | 6.29 | ||

| Peonidin 3-O-glucoside | 51.97 | 43.02 | 88.67 | 60.19 | 71.25 | 101.24 | 72.86 | 93.25 | 8.93 | 14.37 | 10.16 | 9.5 | ||

| Petunidin 3-O-glucoside | 30.3 | 35.68 | 60.97 | 43.01 | 190.18 | 225.35 | 190.02 | 222.11 | 55.47 | 69.72 | 59.3 | 62.21 | ||

| Procyanidin B2 | 27.33 | 22.26 | 20.37 | 21.13 | 5.19 | 6.61 | 5.09 | 5.5 | 3.63 | 4.34 | 3.63 | 3.05 | ||

| Quercetin 3-O-glucoside | 17.23 | 16.75 | 30.61 | 28.29 | 23.71 | 30.99 | 20.11 | 29.72 | n.d. | n.d. | n.d. | n.d. | ||

| Quercetin 3-O-glucoronide | 9.53 | 16.01 | 22.54 | 22.49 | 17.42 | 21.29 | 14.86 | 21.1 | 4.95 | 4.34 | 3.29 | 3.85 | ||

| trans-Resveratrol | 3.53 | 3.26 | 6.8 | 6.55 | 0.13 | 0.37 | 0.32 | 0.39 | 0.32 | 0.27 | 0.32 | 0.25 | ||

| Syringetin 3-O-glucoside | 0.53 | 0.49 | 0.69 | 0.71 | 4.81 | 4.89 | 4.32 | 4.69 | 2.16 | 2.16 | 1.89 | 2.1 | ||

| Syringic acid | 3.93 | 2.65 | 4.2 | 4.47 | - | - | - | - | - | - | - | - | ||

| Vanillic acid | 3.79 | 2.85 | 3.3 | 4.27 | - | - | - | - | - | - | - | - | ||

Sánchez-Gómez et al. [96,97] used aqueous extracts from Moscatel grapevine shoots as a biostimulant on Airén white grapevines. A positive influence of the grapevine shoot extract was detected, with a significant increase in volatile and phenolic compounds, especially phenolic acids. The resulting wines exhibited a characteristic fruity and floral aroma and there was a significant contribution of toasty and spicy notes. Cebrián et al. [98] added two Vitis vinifera vine-shoots (Airén and Cencibel) in two formats (chip and granule) at a concentration of 12 g/L during winemaking. The results (Table 2) show that the content of phenolic compounds increased when vine-shoots were used. In the case of the Airén wine, the phenolic content was higher when granules were used instead of chips due to the higher contact surface, especially before alcoholic fermentation. In the case of the Cencibel wine, when vine-shoots were added before alcoholic fermentation, an increase in its phenolic concentration was observed when chips were used, whereas a decrease in content was detected when granules were employed. On the other hand, when vine-shoots were added after alcoholic fermentation, no significant differences were observed with chips, but a significant increase was observed when granules were used.

Other biostimulants have also been used to improve the phenolic composition of wines. Pardo-García et al. [99,100] studied the use of eugenol, guaiacol and the combination of both in foliar applications on Monastrell grapevines. All the treatments increased the concentration of phenolic compounds in the wines, but the combination of both compounds (eugenol + guaiacol) significantly increased the concentrations of anthocyanins and stilbenes. Brillante et al. and Dinis et al. [101,102] suggested the use of kaolin (a particle film technology) as a biostimulant in the vineyard, the results presenting an increase in the phenolic compounds content and the resulting wines being considered more attractive and appreciated by the tasters. The total flavonoids quantified were 2.205 mg/L for the control sample and 2.830 mg/L for the vineyards treated with kaolin. Furthermore, the anthocyanins quantified were 0.75 mg/L in the control samples and 0.97 mg/L for the treated samples. In addition, Brillante suggested the use of pinolene (a film-forming antitranspirant) in the vineyard as a biostimulant, but a decrease in phenolic compounds, especially anthocyanins, was observed, and the final wine was less appreciated by the tasters. Lastly, methyl jasmonate, chitosan and yeast extract have been evaluated as biostimulant treatments in vineyards. Portu et al. [65,103] evaluated the use of the three treatments on Tempranillo and Graciano varieties. The results are shown in Table 2. Methyl jasmonate and yeast extract had a significant impact on the concentration of phenolic compounds, especially anthocyanins and stilbenes. However, the chitosan treatment did not have a significant effect on phenolic compounds. In contrast, other authors have attributed to chitosan important biostimulant properties [104]. Portu et al. [105] also researched the treatment of Garnacha grapevines with methyl jasmonate combined with phenylalanine. However, the phenolic content was not improved after the treatment in comparison with the control sample (Table 2). The result was similar when the treatment was repeated with only phenylalanine. Nevertheless, Ali Andi et al. [106] also performed research based on the use of methyl jasmonate and phenylalanine in Vitis vinifera L. cv. Shahani variety under different external light conditions. The results showed that the combination of both compounds under darkness growth conditions produced the highest production of total phenolic compounds, flavonoids and stilbenes, even higher than when methyl jasmonate was applied under light conditions. Other authors have suggested the use of benzothiadiazole as a biostimulant with good results in the production of phenolic compounds in grapes [107,108,109]. It has been tested in multiple varieties such as Monastrell, Merlot and Cabernet Sauvignon, with similar results to those obtained with methyl jasmonate, these two biostimulants being the most extensively recommended by many authors. Fernandez-Marin et al. [110] also evaluated the use of three different preharvest treatments: benzothiadiazole, methyl jasmonate, and chitosan on stilbene concentrations in the Syrah variety. After harvesting, these treatments were combined with UVC treatment. The results showed that benzothiadiazole significantly increased the trans-resveratrol concentration in grapes, but this appears to be linked to a ripening delay. When these treatments were combined, only the methyl jasmonate combined with UVC treatment was successful in increasing the stilbene content of the grapes.

In conclusion, it is important to remark that many of these results are influenced by the variety of study and by the climatic conditions, very influential variables in the foliar treatment with biostimulants. Biostimulants obtained from plants, such as vine-shoots or oak extracts, have proved to be a useful tool for increasing the concentration of phenolic compounds in grapes and wines. Other biostimulants such as eugenol, guaiacol, methyl jasmonate, chitosan, or benzothiadiazole have been evaluated as biostimulants in winemaking, all of them demonstrating an increase in phenolic compound concentrations.

3.2. Wine Elaboration

There are a variety of factors that could influence the phenolic compound content in grapes. During winemaking, it is possible to distinguish the internal and external agents that have an impact on phenolic compound development. Three stages have been defined during the winemaking process: (i) pre-fermentative, (ii) fermentative, and (iii) post-fermentative. Pre-fermentative maceration and thermovinification are strategies that have been selected for study in the pre-fermentative stage; yeast strain and additives were the variables studied during the fermentative process; and lastly, fining agents, filtration and post-fermentative maceration have been studied for the post-fermentative stage.

3.2.1. Pre-Fermentative Maceration

Pre-fermentative maceration is the period during red and rose winemaking in which the solid parts of the grapes are in contact with the must before alcoholic fermentation takes place. This process is of vital importance because interesting compounds are transferred from the grape skins into the must, increasing their concentration in the wine. First, the grapes are crushed ensuring the breakdown of the vacuole and cell membranes [111]. Then, the enzymatic activity of the pectinase, protease and polysaccharides added during the maceration process ensure the cell wall degradation [112]. Finally, the contact of solid parts with the must promotes the extraction of compounds, including phenolic compounds.

Multiple factors affect the maceration process, the temperature being one of the most important. Maceration has to be carried out under low temperatures to prevent yeast growth and thus the start of the fermentation process since some phenolic compounds are better extracted in the absence of ethanol. This process is known as cold maceration and some authors have recommended that it takes place at temperatures around 4–8 °C [113]. Many authors have reported a significant increase in phenolic compounds in the must when cold maceration was performed in a vast range of grape cultivars [114,115,116,117,118]. Gómez-Miguez et al. [119] noticed a higher extraction of anthocyanins than other phenolic compounds, associated with the high solubility of anthocyanins in aqueous medium, the better protection of the anthocyanins at lower temperatures and lower levels of tannins [120]. Hydroxycinnamic acids and flavonols exhibited a similar growth rate to anthocyanins but flavonols showed a slower process, associated with their lower solubility in aqueous medium. Furthermore, an increase in catechin, epicatechin and tannin concentrations was also observed when the maceration process was extended. Nevertheless, after a certain time the extraction rates slowed down indicating a possible saturation of the aqueous medium [121]. Lastly, a decrease was observed in the concentration of phenolic compounds a certain time after the maceration finished, related to the stabilization of the increased compounds. For this reason, the use of additives or enzymes treatments that could ensure a successful maceration process has been recommended [122,123,124,125].

As previously mentioned, grape skins, especially in red varieties, are rich in phenolic compounds such as anthocyanins and tannins. However, some authors have shown that less than 50% of these compounds are transferred to wine during winemaking [126]. This phenomenon is closely related to the limited permeability of cell walls and cytoplasmatic membranes [127,128]. For this reason, numerous pre-fermentative techniques have focused on weakening the cell barriers and increasing the polyphenol content in wines in recent years.

Carbonic maceration is the process whereby the grapes undergo maceration under anaerobic conditions [129,130]. Grapes (without destemming or crushing) are placed in tanks and subjected to a carbon dioxide atmosphere. In these conditions, intracellular fermentation takes place inside the grapes and starts the production of alcohol and the degradation of malic acid. In addition, volatile compounds are formed and phenolic compounds are diffused from the skin to the pulp [131]. At a certain moment, the grape skin is broken and its juice is transferred and mixed with the other juices, which are fermented by yeasts. It is important to remark that the internal fermentation of the grapes and the alcoholic fermentation of the must occur simultaneously. After the alcoholic fermentation, must is removed and the grapes are pressed. The two musts undergo alcoholic fermentation mixed together or separately. Finally, they are subjected to malolactic fermentation. González-Arenzana et al. [132] analysed a total of 84 wines from D.O.Ca. Rioja of the Tempranillo Vitis vinifera variety of the same vintage (2017). Forty of these wines had been elaborated by carbonic maceration and forty four were elaborated by the traditional methodology. No significant differences were appreciated in their physical-chemical composition or microbial load. However, the wines made by carbonic fermentation presented a higher content of phenolic compounds. Even if the anthocyanin concentration of the carbonic maceration wines was similar to those of the wines elaborated by traditional methodologies, the concentrations of vitisins A and B were considerably increased by carbonic maceration. The authors recommended the use this alternative maceration to the traditional methodology in order to increase the phenolic compound concentration in wine.

It is common for enzymes to be added during pre-fermentative maceration. Pectolytic enzymes are exogenous preparations of pectinases, hemicellulases and cellulases added during the fermentation process that attack the grape cell walls allowing the release of intracellular pigments [133]. For this reason, an increase in the phenolic compound concentration was expected. In fact, some authors have shown a significant rise in the anthocyanin content when pectolytic enzymes were added [134,135]. However, other authors have found the opposite effect [136], a fact highly related to the enzymatic preparation and maturity of the grape.

3.2.2. Thermovinification and Pulsed Electric Field

Thermovinification is a pre-fermentative methodology that makes it possible to disrupt the cell structure when temperatures higher than 70 °C are used for a short period of time (30–40 min) and followed by a cooling process before the alcoholic fermentation. This process involves water soluble phenolic compounds coming out from the cells [137]. El Darra et al. [134] performed a research study where Cabernet Sauvignon grapes underwent a thermovinification process at 70 °C for 30 min before cooling until 20 °C. The musts were analyzed by HPLC-DAD, and the phenolic compounds, mainly anthocyanins and flavonols, were quantified. The results showed that the content of anthocyanins was not statistically different after the thermovinification process but that the content of total phenolic compounds and total flavonols were statistically higher when thermovinification was applied. Geffroy et al. [138] studied the influence of temperature and heating time on the phenolic content of Vitis Vinifera L. Carignan. To this end, grapes were exposed to temperature levels of 50 °C and 75 °C and two heating times (30 min and 180 min). The results showed that the heating temperature had a significant impact on the extraction of phenolic compounds, and a thermal degradation of anthocyanins was detected when the temperatures exceeded the 75 °C. It was also observed that the reduction in the heating temperature could be compensated for by extending the heating time. Thus, the musts obtained from grapes heated at 50 °C for 180 min had a similar level of phenolic compounds as those treated at 75 °C for 30 min.

Pulsed electric field is a non-thermal treatment inducing pores in cell membranes, thus achieving the breakdown potential, increasing their permeability and enhance the exchange of intercellular compounds [139,140]. Samples are exposed to a high-intensity electric field (5–10 kV/cm) for short durations (30 min). This technology has been tested on multiple Vitis Vinifera varieties such as Cabernet Sauvignon, which was selected by El Darra et al. [134] to evaluate its use. The results indicated that the use of this technology at a moderate intensity during cold maceration significantly increased the concentration of phenolic compounds, especially anthocyanins, in comparison with when this treatment was used during alcoholic fermentation. An increase in the tannin concentration in wine was also found when pulsed electric field treatment was used on the second or fourth day of cold maceration. Saldaña et al. [141] also evaluated this technique for extracting polyphenols from Grenache, Syrah and Tempranillo grapes. The results showed that the treatment increased the extraction of polyphenols by more than 40% in the Syrah and Grenache varieties but lowered it (24%) in Tempranillo grapes. The greatest effect was observed at the highest electric field strength and applying longer pulses. Other authors [134,142,143,144] have evaluated the use of the pulsed electric field methodology, in every case observing a rise in the phenolic compound content of the must and wine.

Wojdyło et al. [126] performed a comparative research study of different pre-fermentative maceration processes. The authors selected the Vitis vinifera Dornfelder variety cultivated in Poland. Four different treatments were examined. One of them was the traditional process used as a control. For the other three, samples were macerated in a first trial. After that, one of them was subjected to microwave extraction for eight minutes at 1200 W and 80 °C. Another was heated at the same temperature, but any extra treatment was carried out corresponding to the thermomaceration. Finally, in the last trial, a pectinolytic enzyme was added at a dose of 0.05 mg/L for 1 h at 50 °C. After this time, the must was heated until 65 °C for 2 min to denature the enzyme. All the samples after pre-treatment were cooled in an ice bath prior to adding yeast and starting the fermentation process. The authors detected a significant influence of the pre-treatment on the phenolic compound composition in the must/wine. In this case, the samples pre-treated with microwaves exhibited the highest phenolic compound concentration (43.44 mg/mL), followed by the enzyme treatment (34.07 mg/mL). No significant differences were found in the musts (before starting fermentation) of all the pre-treatment maceration samples and the control, but the content of phenolic compounds was slightly higher in the must after thermomaceration (29.79 mg/mL) than in the control sample (28.95 mg/mL).

3.2.3. Yeast Strain and Bacteria

Phenolic compound content is usually modified through enzymatic reactions or the metabolic activities of yeast [145]. For example, β-glucosidase is responsible for the hydrolysis of glycosidic linkages. Furthermore, yeast may react with anthocyanins to form pyranoanthocyanins such as vitisins [146], but a high hydroxycinnamate decarboxylase activity is required for effective production [147]. Lastly, it has been reported that anthocyanins are usually adsorbed on the yeast cell wall, which could be of great importance in grape varieties with a lower anthocyanin content [148].

Although Saccharomyces cerevisiae yeast is commonly used with good results [149], during the last few years other Saccharomyces and non-Saccharomyces species have been evaluated [150]. To this end, non-Saccharomyces strains, that exhibited a positive hydroxycinnamate decarboxylase activity, such as Torulaspora delbrekii, Pichia guilliermondii or Schizosaccharomyces pombe have been used to start alcoholic fermentation [146,151,152].

Topić Božič et al. [153] evaluated the use of 95 different Saccharomyces and non-Saccharomyces strains on the alcoholic fermentation of the Pinot Noir variety. The hydroxycinnamate decarboxylase activity of the selected strains varied from 0.0% to 91.1%, ensuring the heterogeneity of the group. All the non-Saccharomyces strains except P. manshurica M49 produced higher concentrations of vinylphenolic pyranoanthocyanins than the Saccharomyces strains. In fact, the Pichia guilliermondii ZIM624 and Wickerhamomyces anomalus S138 strains showed the highest production of vinylphenolic pyranoanthocyanins, with 40.2 and 38.5 mg/L, respectively. In addition, the authors observed for the first time pyranoanthocyanin formation by the S. paradoxus strain.

Minnaar et al. [154] evaluated the use of mixed cultures of yeast + malolactic bacteria such as Saccharomyces + O. oeni/Lb. plantarum and Saccharomyces + non-Saccharomyces + O. oeni/Lb. plantarum in Syrah grape must during alcoholic fermentation. The authors included a fermentation by S. cerevisiae as a reference. The results showed that the phenolic content of wines elaborated with mixed strains was 1 or 3 times higher than the wines elaborated with Saccharomyces. Hence, the authors proposed the mixed culture of S. cerevisiae and malolactic bacteria to improve the phenolic content of Syrah wines. In addition, no negative effects of mixed cultures on the vinification process were detected. Many authors have evaluated the influence of yeast strain on the phenolic composition and organoleptic properties of wines after alcoholic fermentation. All of them have concluded that a clear correlation exists, a specific study for each variety being required. In addition, the results suggest the possibility of using non-Saccharomyces or mixed cultures as feasible strategies for increasing the phenolic composition of final wines.

3.2.4. Additives

Additives are chemical or natural substances that are added during the winemaking process with multiple functions. It is for example the case of sulphur dioxide (SO2), which has antioxidant and antimicrobial properties and is the most used preservative in the wine industry. It has proved to inhibit polyphenol oxidase activity during winemaking [155], preventing the oxidation of phenolics and, therefore, the loss of the polyphenols in the wine. However, several human health risks have been associated with the consumption of SO2, including dermatitis, urticaria, angioedema, diarrhea, abdominal pain, bronchoconstriction, or anaphylaxis [156]. In fact, the maximum SO2 concentration in wine authorized by the International Organization of Vine and Wine (IOV) was 200 mg/L for white and rosé wines, and 150 mg/L for red wines [157].

The IOV described in the resolution IOV-OENO 439 in 2012 [157] the additives with different purposes it allows to be used in wines. In the case of sweeteners, dextrose, fructose, invert sugar and other derivates of sugar are allowed with the aim of balancing the gustatory properties of a wine. To increase the alcoholic content or dilute another additive, ethyl alcohol or wine distillate are recommended. In addition, additives such as lactic acid, malic acid, tartaric acid, and citric acid are the only additives allowed by the IOV to reduce the pH of wine and to modify its gustatory properties. On the other hand, when the acidity of the wine should to be increased to achieve the quality properties required for this product, the IOV suggests the use of neutral potassium tartrate, potassium acid carbonate or calcium carbonate.

The caramel or other food coloring have been accepted to increase the yellow/red tone of wines. Lastly, when dissolving coloring or sweetener substances, adjusting the content of a final product or reducing the number of salts is required, the OIV recommend the use of water (under OMS characteristics).

3.2.5. Fining Agents

Fining agents are chemical or natural compounds with a positive or negative charge that bond with proteins, tannins, and phenolic compounds which are in suspension in wine causing a cloud aspect [158]. For this reason, fining agents are commonly used to clarify and enhance wine stability. Moreover, the modulation of tannins and phenolic composition can eliminate intense flavors and soften sensory properties such as bitterness or astringency [159,160].

Chemical fining agents have been extensively used by multiple authors, for example polyvinylpolypyrrolidone (PVPP), which is commonly used as it has polyphenol binding affinities. Gil et al. [159] evaluated the use of this compound as a fining agent in two blends of rosé varieties: Grenache Noir and Merlot (70/30 and 50/50). Four concentrations of PVPP were evaluated, from 20 g/hl to 80 g/hl (maximum legal dose). The results (Table 3) exhibited a significant decrease in polyphenol contents, especially flavonols, flavanols (especially dimers and trimmers), and anthocyanins (especially anthocyanin coumaroyl derivatives), which is associated with a strong preference to be adsorbed by PVPP.

Table 3.

Total phenolic concentration (mg/L) in wines from different varieties treated with chemical, animal and plant fining agents. Percentage of reduction has been included. PVPP: polyvinylpolypyrrolidone.

| Reference | Wine | Treatments | Total Phenolic Content (mg/L) | Reduction (%) |

|---|---|---|---|---|

| Gil et al. [159] | Rosé A | Control | 156 | - |

| PVPP 20 g/hL | 134 | 14 | ||

| PVPP 40 g/hL | 125 | 20 | ||

| PVPP 60 g/hL | 120 | 23 | ||

| PVPP 80 g/hL | 114 | 27 | ||

| Rosé B | Control | 182 | - | |

| PVPP 20 g/hL | 149 | 18 | ||

| PVPP 40 g/hL | 135 | 26 | ||

| PVPP 60 g/hL | 129 | 29 | ||

| PVPP 80 g/hL | 127 | 30 | ||

| Río Segade et al. [164] | Primitivo | Control | 4577 | - |

| Gelatin_Low | 4237 | 7 | ||

| Gelatin_High | 3030 | 34 | ||

| Pea_1_Low | 4198 | 8 | ||

| Pea_1_High | 4204 | 8 | ||

| Pea_2_Low | 4519 | 1 | ||

| Pea_2_High | 4489 | 2 | ||

| Potato_1_Low | 4337 | 5 | ||

| Potato_1_High | 4539 | 1 | ||

| Potato_2_Low | 4554 | 1 | ||

| Potato_2_High | 4386 | 4 | ||

| Montepulciano | Control | 4770 | - | |

| Gelatin_Low | 4261 | 11 | ||

| Gelatin_High | 3880 | 19 | ||

| Pea_1_Low | 4446 | 7 | ||

| Pea_1_High | 4320 | 9 | ||

| Pea_2_Low | 4566 | 4 | ||

| Pea_2_High | 4484 | 6 | ||

| Potato_1_Low | 4222 | 11 | ||

| Potato_1_High | 4272 | 10 | ||

| Potato_2_Low | 4701 | 1 | ||

| Potato_2_High | 4524 | 5 | ||

| Syrah | Control | 4753 | - | |

| Gelatin_Low | 4578 | 4 | ||

| Gelatin_High | 4199 | 12 | ||

| Pea_1_Low | 4512 | 5 | ||

| Pea_1_High | 4538 | 5 | ||

| Pea_2_Low | 4531 | 5 | ||

| Pea_2_High | 4276 | 10 | ||

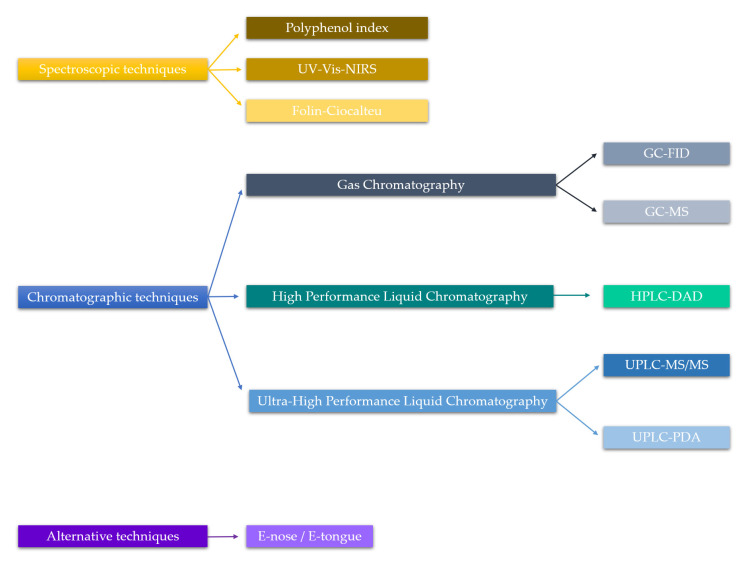

| Potato_1_Low | 4427 | 7 | ||