Abstract

Objective:

The aim of this study was to evaluate the cyclic fatigue, torsional behavior and bending resistance of EdgeTaper Platinum [ETP (tip 25, taper 0.06)], Flex Gold [FG (tip 25, taper 0.08)], Pro-T [PT (tip 25, taper 0.08)] and ProTaper Gold [PTG (tip 25, taper 0.08)] systems.

Methods:

Rotary instruments of ETP, PT, FG, and PTG were used (n=30). Cyclic fatigue tests were performed using an artificial stainless-steel canal with a 60o angle and a 5-mm radius of curvature at body temperature (35°±1°C). The time and number of cycles to fracture (NCF) was recorded. The torsional test evaluated the torque and angle of rotation to failure at 3 mm from the tip according to ISO 3630-1. The fractured surface of each fragment was observed by using scanning electron microscopy (SEM). The bending test evaluated the torque required to bend the instruments at an angular deflection of 60°. Data were analyzed using one-way ANOVA and Tukey tests, and the level of significance was set at 5%.

Results:

The ETP had highest time until fracture and NCF than all the groups (P<0.05). The PTG had the highest torsional strength, followed by FG (P<0.05). The ETP had the highest angular rotation, followed by PT and PTG (P<0.05). The FG showed the highest bending resistance, followed by the PTG (P<0.05).

Conclusion:

In conclusion, the ETP and PT exhibited higher cyclic fatigue resistance, higher angular deflection values and lower bending force than FG and PTG. The PTG instruments showed the highest torsional strength and the lowest cyclic fatigue resistance.

Keywords: Bending resistance, cyclic fatigue, nickel-titanium, torsional fatigue

HIGHLIGHTS.

Recently, several rotary systems were introduced presenting similar design, manufacturing process, and preparation techniques to other systems available on the market. However, these features do not ensure that they present similar mechanical properties and clinical performance.

The Edge Taper Platinum presented the highest cyclic fatigue resistance (time and number of cycles) and distortion angle to fracture.

The Protaper Gold presented the highest bending resistance and torsional strength to fracture.

INTRODUCTION

The introduction of nickel-titanium (NiTi) rotary instruments into endodontic practice provided many advantages such as faster preparation time and canal centering ability (1, 2). Despite these advantages, NiTi instruments appear to be vulnerable to separation by cyclic fatigue or torsional stress. A systematic review indicated that retained fragments do not significantly influence the healing of root canal treatments (3); however, the limited number and the poor quality of available studies for comparison reduced the power of this study. Therefore, Murad & Murray (4) states that there is insufficient evidence available to support or contribute to a change of current practice of fracture instrument removal, and well-conducted randomized controlled trials are necessary to provide sufficient evidence about this subject. To overcome instrument fracture possible drawbacks, improvements in the design of instruments and the use of new alloys with superior mechanical properties have been proposed (1, 2, 5).

The ProTaper Gold (Dentsply-Sirona, Baillagues, Switzerland) is the new generation of ProTaper Universal (Dentsply-Sirona, Baillagues, Switzerland), which use the same sequence and design but with different type of NiTi alloy (6). According to the manufacturer, this rotary system is manufactured by a complex heating-cooling proprietary treatment, resulting in a visible gold-coloured titanium oxide layer in the surface of the instrument (6). This treatment improves the mechanical proprieties of the instrument such as fatigue resistance, flexibility, cutting efficiency and canal centering ability (1, 5, 6). ProTaper Gold mechanical properties have been extensively reported (6-8) and when compared to its predecessor, this new system demonstrated superior results (8).

Recently, several rotary systems were introduced presenting similar design, manufacturing process and preparation technique to other systems available on the market. EdgeTaper Platinum (EdgeEndo, Albuquerque, NM, USA), Flex Gold (Easy Equipamentos Odontológicos, Belo Horizonte, MG, Brazil) and Pro-T (MK Life, Porto Alegre, RS, Brazil) are heat-treated NiTi rotary systems that are claimed to be similar in shape, manufacturing process, and to be used in the same way and the same technique such as ProTaper Gold instruments. These systems have the same number of instruments as the original ProTaper Gold system with a comparable designation as ProTaper Gold (eg. SX, S1, S2, F1, F2). Recently, such type of instruments were named as replica-like systems (9). Jamaleh et al. (8) reported that Edge Taper platinum presented greater flexibility and lower torsional resistance than ProTaper Gold. However, to date, despite the replica-like systems are being sold worldwide and used on a daily basis, there is a lack of scientific information on the mechanical properties of these new heat-treated rotary systems. Therefore, the present study aimed to evaluate the cyclic fatigue, torsional behavior and bending resistance of EdgeTaper Platinum, Pro-T and Flex Gold systems and compare the results with those obtained by ProTaper Gold. The null hypotheses tested were:

(i)There are no differences in the cyclic fatigue fracture resistance among the instruments;

(ii)There are no differences in the torsional behavior among the instruments;

(iii)There are no differences in the bending resistance among the instruments;

MATERIALS AND METHODS

Since no extracted teeth or patients were needed in this study, no ethics comitee approval was necessary. The sample calculation was performed based on previous studies (10-13) using G*Power v3.1 for Mac (Heinrich Heine, University of Düsseldorf, Düsseldorf, Germany) by selecting the ANOVA: Fixed effects, omnibus, one-way of the F test family. An alpha-type error of 0.05, a beta power of 0.95, and an effect size of 0.80 were used. A total of eight samples per group were indicated as the ideal size required for noting significant differences. Ten samples per group were used because an additional 20% was calculated to compensate for possible outlier values that might lead to sample loss.

Cyclic fatigue test

The cyclic fatigue test was performed using a custom-made device that simulated an artificial canal made of stainless steel, with a 60º angle of curvature and a 5-mm radius of curvature with a 0.40 mm diameter at the most apical portion, and a 0.06 mm taper, as previously described (10-13). The cyclic fatigue tests were performed at body temperature (35°±1°C) using a water bath, as previously described (11). The cyclic fatigue device was submerged in a plastic container filled with deionized water and an aquarium thermostat (Hopar, Guangdong, China) was submerged in the water a few minutes before starting the testing of each file to achieve the desired temperature (35°±1°C). During all tests, the temperature was measured by an aquarium digital thermometer.

A total of 10 instruments for each system were used, coupled to a VDW Silver Motor (VDW, Munich, Germany) connected to the cyclic fatigue device. Instruments were activated according the manufacturers recomendations, as follow: ETP (300 RPM and 3 N.cm), FG (500 RPM and 3 N.cm), PT (300 RPM e 2 N.cm) and PTG (300 RPM and 3 N.cm). The time to failure was recorded using a digital chronometer and video recording was made simultaneously to ensure the exact time of instrument fracture. The number of cycles to failure (NCF) was calculated using the following formula: time to failure (in seconds) X RPM/60.

Torsional fatigue test

The torsional tests were performed, based on ISO 3630-1 (1992) as previously reported (10, 13, 14). A total of 10 instruments of each rotary system were used. The test was performed to measure the maximum torque and angular rotation until instrument failure using a specific program (MicroTorque; Analógica, Belo Horizonte, MG, Brazil). The 3 mm of the instrument tips were clamped into a mandrel connected to a geared motor. The geared motor operated in clockwise rotation, at speed set to 2 RPM for all the groups.

Bending resistance test

This test was performed using a testing apparatus (Analógica, Belo Horizonte, MG, Brazil) built according to the pertinent specification ISO 3630-1, as previously reported (15). A total of 10 instruments of each group were used to evaluate the flexibility and the maximum torque demanded to bending the instruments at 60° in relation to its long axis.

Instruments were fixed at 5 mm from the tip perpendicular to the axis of the geared motor. The bending angle (60°) was measured and controlled by a resistive angular transducer connected to a process controller. The force (torque) demanded to bend the instruments was automatically measured by the load cell and recorded.

Metal mass volume and cross-section area analysis

A total of 10 instruments of each brand were scanned by Micro-CT (Skyscan 1174v2; Bruker-micro-CT, Kontich, Belgium) to evaluate the metal mass volume (mm3) and cross-section area of each instrument (mm2). The methodology used was previously described (16). The Micro-CT parameters used were 50 kV, 800 mA, 360° of rotation, an isotropic resolution of 14.1 μm, and 0.5 mm-thick aluminum filter. The images of each specimen were reconstructed into cross-section slices perpendicular to the long axis of the instruments with dedicated software (NRecon v. 1.6.3, Bruker-micro-CT), which enabled two and three-dimensional analysis. The three-dimensional evaluation measured the metal mass volume from the instrument tip until the 3rd and 5th mm from this initial point (Fig. 1a). Also, the two-dimensional analysis was based on reconstructed cross-section slices, which allowed a topographic view at 3 and 5 mm from the tip of the instruments (Fig. 1b). Then, the cross-section area (mm2) was measured at these levels.

Figure 1.

Representative images of Micro-CT analyses of metal mass volume and cross-sectional area. The metal mass volume since the instrument tip until the 3 and 5 mm from this initial point (a). The cross-section area was measured using the cross-section slices at 3 and 5 mm from the tip of the instrument (b)

SEM evaluation

After the cyclic and torsional test, the instruments were assessed by SEM evaluation (JEOL, JSM-TLLOA, Tokyo, Japan) to determine the topographic features of the fragments. The instruments were cleaned in an ultrasonic cleaning device (Gnatus, Ribeirão Preto, São Paulo, Brazil) in distilled water during 3 minutes before SEM evaluation. All the fractured surfaces of the instruments were examined at 100x and 1000 x magnification after the cyclic fatigue test. In addition, the fractured surface of the instruments submitted to the torsional test was examined at 200x and 1000x magnification in the center of the surface.

Statistical analysis

The data normality was performed with the Shapiro-Wilk test, showing that the data were normally distributed. The One-way analysis of variance (ANOVA) and Turkey tests were used for multiple and individual comparisons. The level of significance was set at 5%.

RESULTS

Table 1 shows the results of the cyclic fatigue test and torsional resistance data of the tested instruments. The ETP had the highest time until fracture and NCF, followed by the PT (P<0.05). The FG and PTG had a similar time until fracture (P<0.05), however, the FG had a significantly higher NCF (P<0.05).

TABLE 1.

Mean values of time (in seconds), number of cycles (NCF), Torque (N.cm) and angular rotation (°) of instruments tested

| Instruments | Cyclic fatigue | Torsional fatigue | ||||||

|---|---|---|---|---|---|---|---|---|

| Time (seconds) | Cycles (NCF) | Torque (N.cm) | Angles (°) | |||||

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| ETP 25.06 | 290.5a | 12.27 | 1453a | 61.34 | 1.08a | 0.09 | 625.3a | 79.22 |

| PT 25.08 | 261.5b | 14.52 | 1307b | 72.61 | 0.95b | 0.06 | 572.0b | 24.47 |

| PTG 25.08 | 145.2c | 8.55 | 732c | 42.76 | 1.52c | 0.07 | 444.1c | 25.86 |

| FG 25.08 | 146.5c | 6.83 | 1210d | 56.96 | 1.29d | 0.07 | 399.4d | 6.34 |

SD: Standard deviation. Different superscript letters in the same column indicate statistical differences among groups (P<0.05)

In terms of the torsional test, the PTG showed the highest torsional strength when compared to all groups, followed by FG and ETP (P<0.05). The PT had the lowest torsional strength (P<0.05). Concerning to the angular rotation, the ETP had the highest angular rotation, followed by PT and PTG (P<0.05). The FG had the lowest angular values (P<0.05).

Table 2 shows the results of bending moment of the tested instruments. The FG showed the highest bending resistance, followed by the PTG (P<0.05). There was no significantly difference between ETP and PT (P>0.05). The FG showed the highest bending resistance, followed by the PTG (P<0.05). There was no significantly difference between ETP and PT (P>0.05).

TABLE 2.

Mean values of Torque (N.cm) at bending moment of the tested instruments

| Instruments | Bending moment (N.cm) | |

| Mean | SD | |

| ETP 25.06 | 1.25a | 0.07 |

| PT 25.08 | 1.18a | 0.08 |

| PTG 25.08 | 1.43b | 0.09 |

| FG 25.08 | 1.63c | 0.08 |

SD: Standard deviation. Different superscript letters in the same column indicate statistical differences among groups (P<0.05)

Table 3 shows the results of two (cross-section area–mm2) and three-dimensional (metal mass volume-mm3) analysis of the instruments. The ETP had the smallest metal mass volume along with the 3 mm of the tip of the instruments, followed by PT, PTG, and FG (P<0.05). There was no significant difference between ETP and PT along with the 5 mm (P>0.05). In terms of the cross-section area, there was a significant difference among the instruments at 3 and 5 mm from the instrument’s tip (P<0.05). The ETP had the smallest metal mass volume along with the 3 and 5 mm of the instrument’s tip, followed by PT, PTG, and FG (P<0.05).

TABLE 3.

Mean values of metal mass volume (mm3) and cross-section area (μm) at 3 and 5 mm from the tips of the instruments tested

| Instruments | Metal mass volume (mm3) | Cross-section area (μm2) | ||||||

|---|---|---|---|---|---|---|---|---|

| 3 mm | 5 mm | 3 mm | 5 mm | |||||

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| ETP 25.06 | 0.1298a | 0.002 | 0.3767a | 0.025 | 74.35a | 0.073 | 135.5a | 0.079 |

| PT 25.08 | 0.1574b | 0.004 | 0.3680a | 0.005 | 79.77b | 0.148 | 140.4b | 0.058 |

| PTG 25.08 | 0.1898c | 0.002 | 0.4321c | 0.006 | 99.69c | 0.139 | 183.1c | 0.326 |

| FG 25.08 | 0.1994d | 0.008 | 0.4874d | 0.005 | 107.0d | 0.019 | 193.4d | 0.471 |

SD: Standard deviation. Different superscript letters in the same column indicate statistical differences among groups (P<0.05)

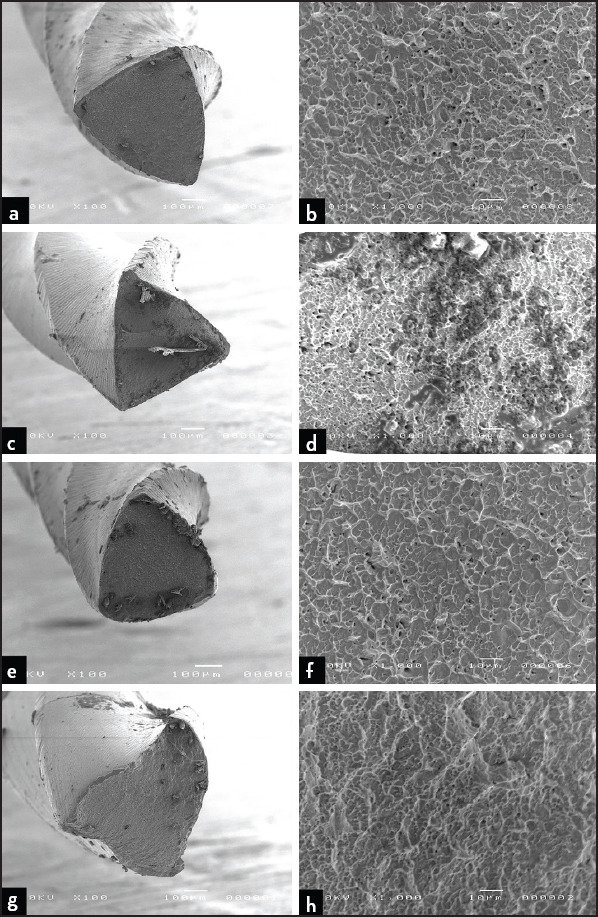

The SEM evaluation of the fractured surface revealed similar and typical features of cyclic and torsional behavior. The cyclic fatigue test caused a crack initiation area and microscopic dimples (Fig. 2). The torsional test generated concentric abrasion marks, with a dimpled surface with micro-voids at the center (Fig. 3).

Figure 2.

SEM images of fractured surfaces of separated fragments of Edge Taper Platinum (a, b), Pro-T (c, d), ProTaper Gold (e, f) and FlexGold (g, h) instruments after cyclic fatigue testing. The images show numerous dimples, a feature of ductile fracture

Figure 3.

SEM images of fractured surfaces of separated fragments of Edge Taper Platinum (a, b), Pro-T (c, d), ProTaper Gold (e, f) and FlexGold (g, h) instruments after torsional test, with the circular box indicating the concentric abrasion mark at 100X magnification ; the right column shows the concentric abrasion mark at 1000x magnification, the skewed dimples near the center of rotation are typical features of torsional failure

DISCUSSION

The aim of the present study was to evaluate the mechanical properties of three thermally treated NiTi rotary instruments, ETP, PT and FG and compare the results with those obtained by PTG instruments. In this study, the methodology used to evaluate cyclic fatigue was already validated and used in previously published articles in peer-reviewed journals (10-13). It is important to emphasize that there are no specifications or international standards for the evaluation of cyclic fatigue resistance in NiTi instruments. According to Plotino et al. (17), the artificial canal should reproduce the instrument size and taper to ensure that different NiTi instruments may follow the repeatable canal trajectory in terms of radius and angle of curvature. However, this is not possible in the current study because the tested instrument presents different tapers. Therefore, to standardize the testing conditions, the same tapered artificial canal was used for all the groups (0.40 mm diameter at the most apical portion, and a 0.06 mm taper). It is important to emphasize that, although the simulated canal was not specifically developed for each tested instruments, all instruments fitted in the simulated canal. Another methodological point that needs to be addressed is related to the temperature used during the cyclic fatigue tests. In the present study, these tests were performed at 35°±1°C to mimic clinical conditions and the body temperature (1, 8, 11).

The static cyclic fatigue model was used in a laboratory-controlled environment, as described by previous studies (10-13). In this method, the instruments are mounted in a stabilized handpiece and rotate freely in an artificial canal with predefined features and under specific conditions until instruments fracture. This method reduces some biases, increasing the validity and reproducibility of the method, which allows a better understanding of the resistance of the behaviour of instruments. Therefore, it is questionable a recent editorial stating that the results of cyclic fatigue are useless for the clinicians (18), especially under the justification that such information must be provided by the manufacturer. Additionally, an extensive discussion in the endodontic literature is moved regarding the use of a dynamic cyclic fatigue test. This methodology induces less localized mechanical stress, increasing the time and number of cycles to fatigue (19-21). On the other hand, it is essencial to emphasize that static methods can provide better information on the impact of different design features of the instruments or NiTi alloy (22).

The dynamic models also have some disadvantages that should also be considered. Depending on the design of the tube or artificial groove, torsional stress can be created, which could compromise to distinguish the type of fatigue occurred, as previously pointed out by Dederich & Zakariasen (23) and reinforced in a recent critical appraisal of Hülsmann et al. (18). This critical appraisal stated that “standardization of the axial motion of the instrument without any lateral movement inducing torsional loads is complicated” and that “a lateral motion during the rotating instrument could also induce a second bending point at the beginning of the tube or artificial groove modifying the results of the dynamic test” (18). Therefore, this study used the static test because the dynamic analysis seems to be a more sensitive method and could create other variables beyond the type of the instrument.

The first results of the present study demonstrated significant differences in the cyclic fatigue resistance among the instruments. Therefore, the first null hypothesis was rejected. These results corroborate with several previously published studies that showed that the instrument’s features (cross-sectional design, core diameter, taper) and thermal treatment of the NiTi affect the mechanical properties of the instruments (1, 5, 24, 25). Although ETP, PT, and FG are claimed to be similar to the PTG system, these instruments have different design and surface finish, as demonstrated in the present study. Moreover, the manufacturers supply no specific information regarding the applied thermal treatment. The type of NiTi used during the manufacturing process has an influence on the mechanical properties of NiTi engine-driven instruments (1, 4, 24-26). The thermal treatments improve the flexibility of the NiTi, modifying the martensitic/austenitic transformation (5). A higher percentage of the martensitic phase in the NiTi alloy promoted more flexibility and higher cyclic fatigue resistance (1, 5, 26). In addition, the martensitic phase transformation could favor a different dissipation of the energy required for crack formation and/or propagation during the cyclic fatigue test (1, 5, 24). Therefore, it is plausible to assume that possible differences in the NiTi alloy might be related to the present results. Probably the thermal treatments of the ETP and PT instruments may induce a different arrangement of the crystal structure and a more signifincat percentage of martensite phase on the NiTi alloy at body temperature, explaining our results.

The ETP outperformed all tested instruments in the cyclic fatigue test. Although all tested instruments have a similar tip diameter (0.25 mm), ETP was the only one with a different taper (0.06), while the others have 0.08. Previous studies reported that instruments with lower taper tend to present greater flexibility and higher cyclic fatigue resistance (1, 5, 24, 27). Probably, the lower taper of ETP might also contribute to its performance on the cyclic fatigue resistance test. Also, despite the fact that PT and FG instruments have the same taper of PTG instruments, the results of this study showed that PTG presented the lowest NCF. Therefore, other variables should be considered (rotational speed and type of thermal treatment). Previous studies reported that higher rotational speed increases the cyclic fatigue stress due to inducing more compressive and tensile stresses in the NiTi instruments (28). In this study, all the instruments were used following the manufacturer’s instructions (PTG, PT, and ETP were used at 300 RPM, while FG at 500 RPM). Therefore, it is important to emphasize that FG instruments were submitted to more significant cyclic fatigue stress than the other groups, which probably affect the lifetime of these instruments and the results of this group.

The methodology used in the torsional test was also reported and validated in previous studies (10, 13, 14). The results of the torsional fatigue test also pointed out to clear differences among the tested instruments. Therefore, the second null hypothesis was also rejected. The maximum torsional strength of PTG was higher than the other tested instruments (P<0.05). Clinically, this might implicate in a lower chance of breakage when the tip of the instrument binds to the canal. In contrast, PT showed a lower value of torsional strength (P<0.05). It is important to emphasize that all means values of torque to fracture were lower than those indicated by the manufacturers. Regarding the angle to fracture, ETP required a higher angle while FG required the lower one. The differences in this outcome could be influenced by differences in the NiTi thermal treatment, as previously described. Also, taper values of the instruments and cross-sectional design have a key role effect on the metal mass volume, affecting the torsional resistance (1, 24, 26, 27). This is an interesting result, and clinicians should use such information when selecting the maximum torque for an instrument, varying the indication proposed by the manufacturer. Also, such type of information can be used for manufacturers to review the recommended protocols for the tested instruments, modifying their torque recommendations.

The bending resistance test concerns the flexibility of the instrument and was previously described (15). The results of the bending resistance test also demonstrated statistically significant differences among the instruments (P<0.05). Therefore, the third null hypothesis was rejected. Such as the other tested outcomes, these results are also related to possible differences in the instrument’s design and NiTi alloy special heat-treatment provided by the manufacturers. The bending test also demonstrated the greater flexibility of the ETP and PT in comparison with FG and PTG. In a clinical scenario, an instrument with lower flexibility can be responsible for more anatomical deviations when compared to more flexible instruments (29). Future studies should evaluate root canal preparation by using microcomputed tomography technology to understand the behavior of such replica-like instruments.

The metal mass volume is directly affected by instrument features (core diameter, cross-section, and taper), modifying their flexibility (1, 24, 27). Therefore, this study evaluated the metal mass volume (mm3) and cross-section area (µm) using Micro-CT, which allowed two and three-dimensional analyses of the instruments (16). Then, the metal mass volume (mm3) of the first 3 mm was measured as well as the 5 first mm of all instruments. Also, using the reconstructed cross-section slices, the cross-section area was measured at 3 and 5 mm from the tip of the instruments. The results of this study demonstrated that there was a significant difference among the instruments regarding the metal mass volume and cross-sectional area (P<0.05). The ETP had the smallest metal mass volume along with the 3 mm of the tip of the instruments, followed by PT, PTG, and FG (P<0.05). There was no significant difference between ETP and PT, along with the 5 mm (P>0.05). In terms of the cross-section area, ETP had the smallest cross-section area at 3 and 5 mm from the tip of the instruments than the other groups (P<0.05). Therefore, these results corroborate with the mechanical tests, showing that the metal mass volume and design features (taper, core diameter) are strongly correlated, explaining our findings.

The SEM analysis showed the typical fractographic features of cyclic fatigue and torsional fractures, with a similar appearance among the brands. After the cyclic fatigue test, numerous dimples spread on the fractured surface. After the torsional test, the fragments demonstrated the typical features of shear failure, including concentric abrasion marks and fibrous microscopic dimples at the center of rotation (11-13, 15).

CONCLUSION

In conclusion, the ETP and PT exhibited higher cyclic fatigue resistance, greater distortion angle values and lower bending force than FG and PTG. The PTG instruments showed the highest torsional strength and the lowest cyclic fatigue resistance.

Footnotes

Conflict of Interest: The authors deny any conflict of interest related to this study.

Ethics Committee Approval: Since no extracted teeth or patiens were nedeed in this study, no ethics comitee aproval was necessary.

Peer-review: Externally peer-reviewed.

Financial Disclosure: This work was supported by FAPESP/BRAZIL (grant no. 2014/25520-0).

Authorship contributions: Concept – M.P.A., M.A.H.D., R.R.V.; Design – E.J.N.L.S., P.A.A.S.; Supervision – M.A.H.D., R.R.V.; Funding - This work was supported by FAPESP/BRAZIL (grant no.2014/25520-0); Materials - P.H.S.C., R.R.V.; Data collection &/or processing – M.P.A., M.A.H.D., E.J.N.L.S.; Analysis and/or interpretation – M.P.A., P.A.A.S., E.J.N.L.S.; Literature search – P.H.S.C., M.P.A.; Writing – M.P.A., E.J.N.L.S., P.A.A.S.; Critical Review – M.A.H.D., R.R.V.

REFERENCES

- 1.Gavini G, Santos MD, Caldeira CL, Machado MEL, Freire LG, Iglecias EF, et al. Nickel-titanium instruments in endodontics:a concise review of the state of the art. Braz Oral Res. 2018;32(suppl 1):e67. doi: 10.1590/1807-3107bor-2018.vol32.0067. [DOI] [PubMed] [Google Scholar]

- 2.Staffoli S, Grande NM, Plotino G, Özyürek T, Gündoğar M, Fortunato L, et al. Influence of environmental temperature, heat-treatment and design on the cyclic fatigue resistance of three generations of a single-file nickel-titanium rotary instrument. Odontology. 2019;107(3):301–7. doi: 10.1007/s10266-018-0399-5. [DOI] [PubMed] [Google Scholar]

- 3.Panitvisai P, Parunnit P, Sathorn C, Messer HH. Impact of a retained instrument on treatment outcome:a systematic review and meta-analysis. J Endod. 2010;36(5):775–80. doi: 10.1016/j.joen.2009.12.029. [DOI] [PubMed] [Google Scholar]

- 4.Murad M, Murray C. Impact of retained separated endodontic instruments during root canal treatment on clinical outcomes remains uncertain. J Evid Based Dent Pract. 2011;11(2):87–8. doi: 10.1016/j.jebdp.2011.03.005. [DOI] [PubMed] [Google Scholar]

- 5.Zupanc J, Vahdat-Pajouh N, Schäfer E. New thermomechanically treated NiTi alloys - a review. Int Endod J. 2018;51(10):1088–103. doi: 10.1111/iej.12924. [DOI] [PubMed] [Google Scholar]

- 6.Plotino G, Grande NM, MercadéBellido M, Testarelli L, Gambarini G. Influence of temperature on cyclic fatigue resistance of ProTaper Gold and ProTaper universal rotary files. J Endod. 2017;43(2):200–2. doi: 10.1016/j.joen.2016.10.014. [DOI] [PubMed] [Google Scholar]

- 7.Keskin C, Inan U, Guler DH, Kalyoncuoğlu E. Cyclic fatigue resistance of XP-Endo Shaper K3XF, and ProTaper Gold Nickel-titanium instruments. J Endod. 2018;44(7):1164–7. doi: 10.1016/j.joen.2018.04.005. [DOI] [PubMed] [Google Scholar]

- 8.Jamleh A, Alghaihab A, Alfadley A, Alfawaz H, Alqedairi A, Alfouzan K. Cyclic fatigue and torsional failure of EdgeTaper Platinum endodontic files at simulated body temperature. J Endod. 2019;45(5):611–4. doi: 10.1016/j.joen.2019.02.008. [DOI] [PubMed] [Google Scholar]

- 9.Martins JNR, Nogueira Leal Silva EJ, Marques D, Ginjeira A, Braz Fernandes FM, Deus G, et al. Influence of kinematics on the cyclic fatigue resistance of replica-like and original brand rotary instruments. J Endod. 2020 May; doi: 10.1016/j.joen.2020.05.001. [Epub ahead of print] doi:10.1016/j.joen.2020.05.001. [DOI] [PubMed] [Google Scholar]

- 10.Alcalde MP, Duarte MAH, Bramante CM, de Vasconselos BC, Tanomaru-Filho M, Guerreiro-Tanomaru JM, et al. Cyclic fatigue and torsional strength of three different thermally treated reciprocating nickel-titanium instruments. Clin Oral Investig. 2018;22(4):1865–71. doi: 10.1007/s00784-017-2295-8. [DOI] [PubMed] [Google Scholar]

- 11.Klymus ME, Alcalde MP, Vivan RR, Só MVR, de Vasconselos BC, Duarte MAH. Effect of temperature on the cyclic fatigue resistance of thermally treated reciprocating instruments. Clin Oral Investig. 2019;23(7):3047–52. doi: 10.1007/s00784-018-2718-1. [DOI] [PubMed] [Google Scholar]

- 12.Marks Duarte P, Barcellos da Silva P, Alcalde MP, Vivan RR, Rosa RAD, Duarte MAH, et al. Canal transportation, centering ability, and cyclic fatigue promoted by twisted file adaptive and navigator EVO instruments at different motions. J Endod. 2018;44(9):1425–9. doi: 10.1016/j.joen.2018.06.002. [DOI] [PubMed] [Google Scholar]

- 13.Alcalde MP, Tanomaru-Filho M, Bramante CM, Duarte MAH, Guerreiro-Tanomaru JM, Camilo-Pinto J, et al. Cyclic and torsional fatigue resistance of reciprocating single files manufactured by different nickel-titanium alloys. J Endod. 2017;43(7):1186–91. doi: 10.1016/j.joen.2017.03.008. [DOI] [PubMed] [Google Scholar]

- 14.Alcalde MP, Duarte MAH, Bramante CM, Tanomaru-Filho M, Vasconcelos BC, Só MVR, Vivan RR. Torsional fatigue resistance of pathfinding instruments manufactured from several nickel-titanium alloys. Int Endod J. 2018;51(6):697–704. doi: 10.1111/iej.12879. [DOI] [PubMed] [Google Scholar]

- 15.Nakagawa RK, Alves JL, Buono VT, Bahia MG. Flexibility and torsional behaviour of rotary nickel-titanium PathFile RaCe ISO 10. Scout RaCe and stainless steel K-File hand instruments. Int Endod J. 2014;47(3):290–7. doi: 10.1111/iej.12146. [DOI] [PubMed] [Google Scholar]

- 16.Vivan RR, Alcalde MP, Candeiro G, Gavini G, Caldeira CL, Duarte MAH. Torsional fatigue strength of reciprocating and rotary pathfinding instruments manufactured from different NiTi alloys. Braz Oral Res. 2019;33:e097. doi: 10.1590/1807-3107bor-2019.vol33.0097. [DOI] [PubMed] [Google Scholar]

- 17.Plotino G, Grande NM, Cordaro M, Testarelli L, Gambarini G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J Endod. 2009;35(11):1469–76. doi: 10.1016/j.joen.2009.06.015. [DOI] [PubMed] [Google Scholar]

- 18.Hülsmann M, Donnermeyer D, Schäfer E. A critical appraisal of studies on cyclic fatigue resistance of engine-driven endodontic instruments. Int Endod J. 2019;52(10):1427–45. doi: 10.1111/iej.13182. [DOI] [PubMed] [Google Scholar]

- 19.Pedullà E, Lizio A, Scibilia M, Grande NM, Plotino G, Boninelli S, et al. Cyclic fatigue resistance of two nickel-titanium rotary instruments in interrupted rotation. Int Endod J. 2017;50(2):194–201. doi: 10.1111/iej.12609. [DOI] [PubMed] [Google Scholar]

- 20.Keleş A, Eymirli A, Uyanık O, Nagas E. Influence of static and dynamic cyclic fatigue tests on the lifespan of four reciprocating systems at different temperatures. Int Endod J. 2019;52(6):880–6. doi: 10.1111/iej.13073. [DOI] [PubMed] [Google Scholar]

- 21.De-Deus G, Leal Vieira VT, Nogueira da Silva EJ, Lopes H, Elias CN, Moreira EJ. Bending resistance and dynamic and static cyclic fatigue life of Reciproc and WaveOne large instruments. J Endod. 2014;40(4):575–9. doi: 10.1016/j.joen.2013.10.013. [DOI] [PubMed] [Google Scholar]

- 22.Saber S, Fawzy AS. Effect of thermal treatment on the flexural resistance of mechanically pre-fatigued NiTi rotary endodontic files. ENDO –Endodontic Practice Today. 2011;5(2):145–50. [Google Scholar]

- 23.Dederich DN, Zakariasen KL. The effects of cyclical axial motion on rotary endodontic instrument fatigue. Oral Surg Oral Med Oral Pathol. 1986;61(2):192–6. doi: 10.1016/0030-4220(86)90186-6. [DOI] [PubMed] [Google Scholar]

- 24.Shen Y, Zhou HM, Zheng YF, Peng B, Haapasalo M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J Endod. 2013;39(2):163–72. doi: 10.1016/j.joen.2012.11.005. [DOI] [PubMed] [Google Scholar]

- 25.Fukumori Y, Nishijyo M, Tokita D, Miyara K, Ebihara A, Okiji T. Comparative analysis of mechanical properties of differently tapered nickeltitanium endodontic rotary instruments. Dent Mater J. 2018;37(4):667–74. doi: 10.4012/dmj.2017-312. [DOI] [PubMed] [Google Scholar]

- 26.Kaval ME, Capar ID, Ertas H. Evaluation of the cyclic fatigue and torsional resistance of novel nickel-titanium rotary files with various alloy properties. J Endod. 2016;42(12):1840–3. doi: 10.1016/j.joen.2016.07.015. [DOI] [PubMed] [Google Scholar]

- 27.Baek SH, Lee CJ, Versluis A, Kim BM, Lee W, Kim HC. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J Endod. 2011;37(9):1283–6. doi: 10.1016/j.joen.2011.05.032. [DOI] [PubMed] [Google Scholar]

- 28.Lopes HP, Ferreira AA, Elias CN, Moreira EJ, de Oliveira JC, Siqueira JF Jr. Influence of rotational speed on the cyclic fatigue of rotary nickel-titanium endodontic instruments. J Endod. 2009;35(7):1013–6. doi: 10.1016/j.joen.2009.04.003. [DOI] [PubMed] [Google Scholar]

- 29.Burklein S, Schafer E. Critical evaluation of root canal transportation by instrumentation. Endod Topics. 2013;1(29):110–24. [Google Scholar]