Abstract

This paper focuses on the production technology of late nineteenth-century tiles from the Ettehadieh House Complex in Tehran, Iran. It makes use of the opportunity to provide for the first time the results of chemical and microstructural analyses of late nineteenth-century tiles selected directly from context and with known provenance. The paper integrates the results of chemical study of the Ettehadieh tiles with other available technological information on nineteenth-century Persian tiles, including chemical analyses of signed tiles and samples of pigments, as well as the study of the treatise of a certain Persian potter, ‘Ali Mohammad Isfahani, to suggest processes of materials procurement and manufacture. These processes are used as evidence to discuss trade and technological interactions between Iran and Europe in the nineteenth century.

Keywords: Qajar Iran, Sèvres porcelain, Victorian England, Persian tiles, pigment chemistry, ceramics manufacture

Introduction

During the Qajar period (1785–1925) in Iran, contacts with Europe intensified and reached an unprecedented level, influencing the social, cultural and economic structures of the country. These challenges stimulated new directions in technology and art.1 Ceramics manufacture, too, was affected by this trend. European influences are clearly reflected in common representations on nineteenth-century Persian ceramics—vessels and more commonly tiles—which incorporated European motifs, Victorian rose garlands and vignettes, images of European-style architecture and European people, as well as European objects.2 For example, a Qajar tile now in the National Museum of Scotland,3 made in 1887, shows a hunting scene from the tale of Bahram Gur, the Sassanian King of Persia (r. 420–438 ce). Further behind is depicted a Persian girl watching Bahram, standing under an umbrella with binoculars in her hand.

From the technological point of view, nineteenth-century Persian ceramics represent an expanded colour palette compared with ceramics of the previous eras4 and reflect the use of a wider variety of pigments, raw materials, and relevant technologies. Much of our understanding of the manufacturing processes of nineteenth-century Persian ceramics comes from one master potter: ‘Ali Mohammad Isfahani. A native of Isfahan, ‘Ali Mohammad moved to the capital Tehran in the 1880s to carry on the manufacture of tiles. His workshop was located in the tilemakers’ quarter in south Tehran, outside the gate of Shah ‘Abd al-‘Azim, as the inscription on a tile dated 1884/1885 (1302 ah) and signed by him clearly states.5 Samples of his signed works are in the Shah ‘Abd al-‘Azim Shrine (Tehran), the Shaykh ‘Abd al-Nabi Nuri Mosque (Tehran), the Victoria and Albert Museum (London), and the National Museum of Scotland (Edinburgh), among others.6 During the second half of the nineteenth century, ‘Ali Mohammad's work significantly flourished and he became a household name among European residents and travellers in Tehran.7 His works particularly attracted interest by Major General Sir Robert Murdoch Smith (1835–1900),8 a Scottish engineer and the director of the Persian section of the Indo-European Telegraph Department from 1865. Smith also acted as agent in Iran for the Department of Science and Art at the South Kensington Museum (today the Victoria and Albert Museum, London) from 1873, and was later appointed director of the Edinburgh Museum of Science and Art (today the National Museum of Scotland, Edinburgh) in 1885.9 His acquisitions during his time in Iran were an invaluable contribution to the formation and enhancement of the Persian art collections at both these museums.10 Most relevant to the subject of this paper were the acquisition and commission of contemporary tileworks signed by ‘Ali Mohammad Isfahani, including a tile with a portrait of Murdoch Smith dated 1304 ah/1887,11 and a table top formed of glazed tiles dated 1887/1888 and ordered by ‘Colonel Robert Murdoch Smith’.12 In addition, Smith commissioned ‘Ali Mohammad to draft a description, explaining his methods of tile manufacture and raw materials. ‘Ali Mohammad's treatise On the manufacture of modern Kashi earthenware tiles and vases was translated from Persian to English by John Fargues, assistant superintendent of the English telegraph staff in Iran, and published in Edinburgh in 1888. However, unfortunately, the original Persian version is now lost. The translated text begins with:

The Master, Ustad Ali Mohamed, the inventor of that process, son of Ustad Mahdi, architect, native of Ispahan, and at this date, A.H. 1305, a celebrity in Islam, has allowed the humble scribe, Mirza Ali Mohamed, to write a pamphlet displaying the secret and describing the process of the art; and as the best deeds are those which award most profit to the doer, the writer has wished to explain how to procure the ingredients and requisites of the beautiful art, in order to acquire a good name amongst those who pursue it.13

Part I of the treatise on the so-called underglaze (Persian: zir la’ab) decorated tiles is in five chapters, and Part II on the manufacture of the so-called seven-colour (Persian: haft rang) tiles in two chapters. The chapters cover the procurement of ingredients and processes of the manufacture of bodies14 and glazes.15 Sporadic mentions of certain samples of ingredients occur in the text; on page 4, for instance, ‘Ali Mohammad stated after giving a recipe for ‘alkali-paint’: ‘We must send you a sample’. Samples of ‘Ali Mohammad's raw materials were sent to Edinburgh as part of Murdoch Smith's commission in 1887 and were shared between the Edinburgh Museum and the South Kensington Museum, London. The two sets of 23 samples were each labelled with the name in English, as well as in transliterated Persian, and a short description of what the material was used for was included (see appendix). Upon arrival in 1887, these samples were analysed for their chemical composition, and the results of these analyses were also included in the labels. The Edinburgh Museum disposed of its samples in 1947 but those sent to the Victoria and Albert Museum have been preserved until today.16

Over the past few years, ‘Ali Mohammad's signed and dated works in the western collections have been subject to non-destructive chemical analyses.17 Seventeen of his samples of raw materials used in the manufacture of underglaze decorated tiles were studied by Reiche and Voigt (2012) using a multi-analytical approach.18 The information given by Reiche and Voigt (2012) is gathered in the appendix (see table A1, right-hand column), where figure A1 is a photograph of the samples at the Victoria and Albert Museum, and table A1 shows the sample labels, descriptions, and the results of chemical analyses conducted in 1888, as well as those by Reiche and Voigt in 2012. The results of these analyses and their comparison with descriptions in ‘Ali Mohammad's treatise have provided valuable information on the science and technology of nineteenth-century ceramics in Iran.

Table A1.

Details of ‘Ali Mohammad Isfahani's samples and results of chemical analyses.

| Sample no. | Label description | Results of the analysis from 1888 | Results of the analysis from Reiche and Voigt (2012) |

|

|---|---|---|---|---|

| Major structural components | Minor and trace elements | |||

| 1 | Flint (Sang i Chekmak). One of the ingredients of the glaze. | The analysis shows this to be silica containing a trace of oxide of iron. | Quartz (99 SiO2) | Na, Cl, K, Ca, Pb, Sr, Fe |

| 2 | Pounded Flint (Sang i Chekmak kupideh). Ready for mixture with the potash to form the glaze. | This has the same composition as No. 1. | Quartz (93 3SiO2, 4SO3) | Na, Al, K, Ca, Pb, Fe |

| 3 | Flint and Potash Glaze (unpounded) (Reng i la'ab). Made by melting equal parts of flint and potash. | This contains of silicic acid, oxides of potassium and sodium, and traces of iron and magnesium. | 63 SiO2, 13 CaO, 12 Na2O, 5 MgO | K, Al, Cl, (Cr), Mn, Fe, Cu, Zn, Sr, Pb, (U) |

| 4 | Pounded Glaze (Reng i la'ab kupideh). Made by melting equal parts of flint and potash. And pounding the crystalline product. | This has the same composition as No. 3. | Quartz and glassy phase (73 SiO2, 15 Na2O, 5 CaO) | Mg, Al(?), S(?), Cl, K, Mn, Fe |

| 5 | Fire Clay (Gil i Booteh, lit. crucible clay). From Vartoon, a village near Ispahan. Used in making the paste of enamelled tiles. The paste consists of eight parts of powdered flint, one part of dry fire clay, and one of the flint and potash glaze mixed with a thin solution of fire clay). | This consists of silicic acid, oxides of aluminium and magnesium and atrace of oxide of iron. | Aluminosilicate and halite (71.50 SiO2, 18.82 Al2O3) | Na, Mg, Cl, K, Ca, Ti, Fe, Zn, Zr, Sn |

| 6 | Black Pencil – Stone (Siah Qalem Ma'adani). Used in drawing the designs and figures on the enamelled tiles and vases. It is ground to powder and mixed with grape treacle into a syrup which is applied with a hair pencil. | This consists of silicic acid and oxides of iron and magnesium. | Chromite (35 SiO2, 33 MgO, 12 Cr2O3, 11 Fe2O3) | Al, S(?), Cl, Ca, FeCr2O4, Ti, Pb, Mn, Ni, Cu, Zn, Sr |

| 7 | Tangar. A dissolvent similar to borax. Used in the preparation of the red and blue pigments. | This is sodium borate (i.e. borax). | Tincalconite (Na2B4O7.5H2O) (37 B2O3, 14 Na2O) | – |

| 8 | Borax (Booreh). From Yezd. Used in the preparation of the red and blue pigments. | This specimen is an impure one. It contains along with the oxides of sodium and boric acid, oxides of potassium and magnesium, carbonic and hydrochloric acid, and a trace of sulphuric acid. It is therefore an impure borax. | Tincalconite, halite | U |

| 9 | Red Pigment (Reng i Qermez. Zir reng) for the underglaze or enamelling process. It is made by dissolving 2 parts of gold and 1 of tin in aquafortis. Into the solution largely diluted with water is mixed some well pounded glass, which is left to form a sediment, to which, whenever the water is poured off is added some gold dross and tangar, and the whole well pounded. | Analysis shows this to consist of oxides of sodium, potassium, calcium, and iron; boric and silicic acids, and a trace of oxide of aluminium; it also contains a trace of gold, Tin could not be detected with certainty. | Major glass phase (75 SiO2, 8 Na2O, 8 CaO, 5 K2O, 1 B2O3) | Mn, Au, Cu, Mg, Al(?), P, S(?), Cl, Pb, Ti, Fe, Zn, As, Sn, U |

| 10 | Lapis Lazuli (Reng i Lagiverd). From the neighbourhood of Kashan. For the preparation of the blue pigment. Possibly this is cobalt and not lapis lazuli, as the Persian word “lagiverd” is usually translated. | The analysis shows that this is not the true lapis lazuli. It consists of oxides of cobalt, iron, calcium, aluminium, and magnesium, carbonic and silicic acids, and traces of oxides of zinc and potassium, and sulphuric acid. | Major glassy phase (3-69 CoO, 29-41 SiO2, 11-31 Fe2O3, 13-15 CaO, 7-13 Al2O3, 4-8 As2O5, 6 MgO) | Na, Cl, K, Ti, Cr, Mn, Cu, Zn, Sr, Zr, Sn, (U) |

| 11 | Fired Lapis Lazuli (Pink) (Lagiverd Surkh Atesh dadeh) | This has the same composition as No. 10. | Major glassy phase (39 SiO2, 20 CaO, 13 Fe2O3, 10 Al2O3, 3SO3, 2 K2O, 2 As2O3, 2 CoO) | Cl, Ti, Mn, Cu, CoO, Zn, Cr, Sr |

| 12 | Essence of Lapis Lazuli (Jowher i Lagiverd). | Analysis shows this to consist largely of sulphide of lead together with oxides of iron, magnesium, sodium. | Major glassy phase (33 SiO2, 20 CaO, 12 B2O3, 11 Na2O, 4 MgO, 7 Al2O3, 6 Fe2O3) | Co, P, S, Cl, K, Ti, Cr, Mn, Cu, Zn, Ga, As, Sr |

| 13 | Lapis Lazuli (Black) (Lagiverd Siah). | This has the same composition as No. 10. | Major glassy phase (42 SiO2, 17 Fe2O3, 10 Al2O3, 9 CaO, 6 MgO, 6 As2O5, 5 CoO) | Na, Cl, K, Ti, Cr, Mn, Cu, Zn, Sr |

| 14 | Violet Pigment (Reng i Banafsh), consisting of 3 parts of red and 1 of blue pigment. For underglaze process. | This statement is evidently incorrect, as analysis shows the pigment to consist largely of oxide of manganese, together with oxides of iron and magnesium, silicic acid, and a trace of oxide of potassium. | Glassy phase (57 MnO, 10 BaO, 9 Fe2O3, 5 SiO2) | Na, Mg, Al, S, K, Ca, Cu, Zn, As, Sr, (U) |

| 15 | Essence of Ochre (Jowher i Ukhra). From Khorassan. Used as a yellow pigment for the underglaze process. | This consists of oxides of uranium, sodium, and potassium, with silicic acid, and a small quantity of oxide of aluminium. | U | UO22− |

| 16 | Green Pigment (Reng i Sabz jowher i Ukhra). Consisting of a mixture of the yellow and blue pigments. For underglaze process. | This statement is evidently incorrect, as the pigment is found to contain oxide of chromium, together with oxides of sodium and potassium, and magnesium, and silicic acid. | Major glassy phase (49-96 SiO2, (23 PbO), 0-15 K2O, 0-6 CaO, 1-6 Cr2O3, 1-5 Na2O) | Mg, Al, S, Cl, Ti, (Mn), Fe, (Cu), (As) |

| 17 | Yellow Pigment (Reng i Zard). For the under-glaze process. | This consists largely of oxide of iron, together with oxide of aluminium, silicic acid, and a trace of oxide of magnesium. | Quartz, hematite (42 SiO2, 27 Fe2O3, 12 Al2O3, 9 SO3/PbO, 3 Na2O, 3 MgO) | P, K, Ca, Ti, V, Fe3+, Cr, Mn, Cu, Zn, Ge, As |

| 18 | White Glaze (Sefid Ab). Consisting of 3 parts of lead to 1 of tin mixed with pounded flint and potash glaze. For the seven-colour process. | This glaze consists largely of oxides of lead and tin, together with oxide of potassium and silicic acid, and a trace of oxide of magnesium. | Not analysed. | |

| 19 | Turquoise Pigment (Reng i Firouzi). For the seven-colour process. Prepared from copper. | This consists largely of silicic acid, together with oxides of copper and potassium, a small quantity of oxide of aluminium, and a trace of oxide of magnesium. | Not analysed. | |

| 20 | Yellow Pigment (Zard Haft Reng), consisting of 16 parts of lead to 1 of tin mixed with 4 of pounded stone. For the seven-colour process. This pigment, as Ali Muhammad says, will produce a colour like the face of a servant who has acted perfidiously. | This consists chiefly of lead and tin, together with […] and calcium, silicic acid and a trace of phosphoric acid. | Not analysed. | |

| 21 | Black Pigment (Meshki Haft Reng), consisting of 1 part of “Maghn” stone, 3 of glass, and 4 of flint potash glaze pounded together. For seven-colour process. When used a little liquid gum arabic and potash is added. | This pigment consists largely of oxides of manganese and iron, together with oxides of barium, calcium, sodium, potassium, and copper, silicic acid, carbonic acid, and a trace of phosphoric acid. | Not analysed. | |

| 22 | Blue Glaze (Lapis lazuli Lagiverd Haft reng), consisting of 1 part of raw lapis lazuli, 3 of glass, 4 of flint potash glaze, 1-16th of essence of lapis lazuli, and ½ of potash. For the seven-colour process. It is applied in liquid gum arabic. | This consists of oxides of sodium, potassium, iron, calcium, aluminium, cobalt and zinc, together with silicic acid, and a trace of phosphoric acid. No sulphide of lead (essence of lapis lazuli) was detected. | Not analysed. | |

| 23 | Green Pigment (Sabz Haft Reng), consisting of 1 part copper dross, 3 of vermilion, 6 of glass, 6 of flint, and 6 of flint potash glaze. For the seven-colour process. | This pigment consists of oxides of lead, copper and tin, silicic acid, and traces of oxides of iron, calcium and aluminium, and of […]. No vermilion was detected. | Not analysed. | |

Figure A1.

Samples of ‘Ali Mohammad Isfahani's pigments. Courtesy of the Victoria and Albert Museum, London; acc. no. 450A-1888. (Online version in colour.)

This paper focuses on the production technology of late nineteenth-century tiles from the Ettehadieh House Complex in Tehran, Iran. It makes use of the opportunity to provide for the first time the results of chemical and microstructural analyses of nineteenth century tiles selected directly from context and with known provenance. The paper combines the results of chemical study of the Ettehadieh tiles with those of ‘Ali Mohammad's signed tiles, his set of pigments, and descriptions in his treatise to suggest processes of materials procurement and manufacture. The paper uses these processes as evidence to suggest technological interactions and the role of trade between Iran and Europe in the nineteenth century.

The Ettehadieh Complex

The construction and development of the Ettehadieh House Complex in Tehran was closely linked to the cultural and economic transformations of its neighbourhood, now known as the Lalehzar district.19 Originally a royal garden during the reign of Fath ‘Ali Shah (1797–1834), located just outside the old city walls of Tehran, Lalehzar became one of the most sought-after neighbourhoods under the reign of Naser al-Din Shah (r. 1848–1896).20 During 1892 and 1896, large parts of the old Lalehzar Garden and adjacent areas were sold to court officials and aristocrats, who built private houses and gardens in this neighbourhood. The lands belonging to what has become known as the Ettehadieh House Complex were originally purchased by Amin al-Sultan (d. 1907),21 the last prime minister of Iran under Nasir al-Din Shah. The house was involved in many aspects of the political changes preceding and during the constitutional revolution of Iran (1905–1911); there are mentions in the literature of the political gatherings and meetings that took place in this house.22 For the purpose of this paper, however, no mention of architectural features or tilework is found in the literature.

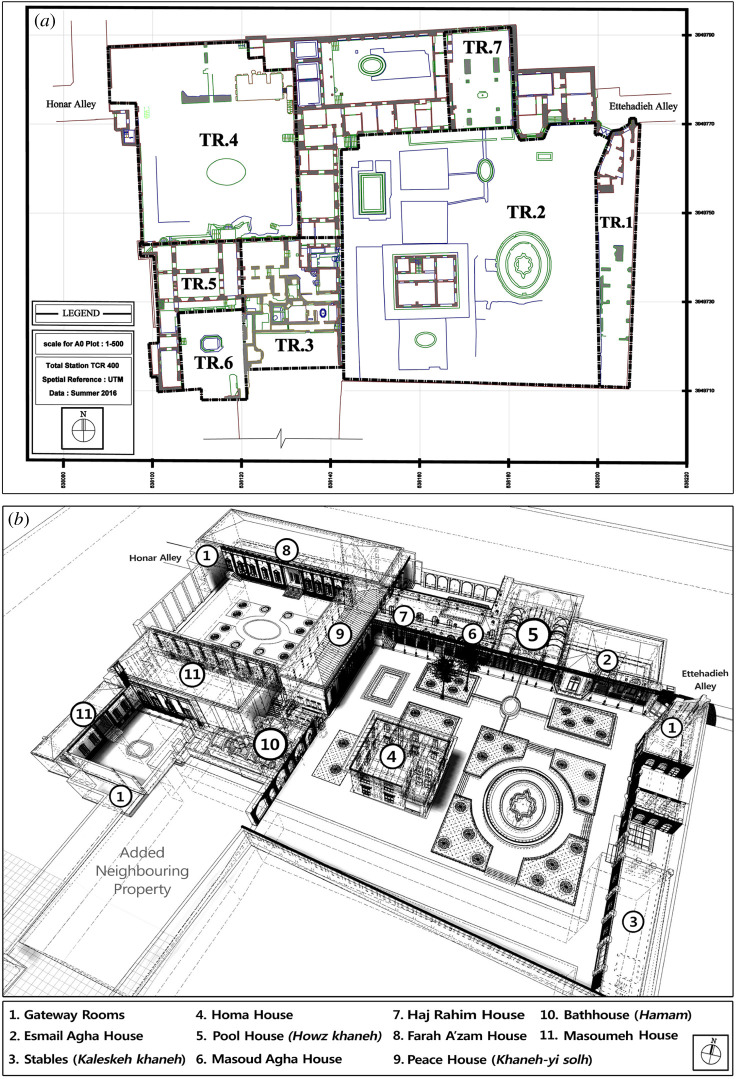

In 1916, almost nine years after the assassination of Amin al-Sultan, the lands were transferred to Haj Rahim Ettehadieh, the owner of the Ettehadieh factory, who had moved to Tehran from Tabriz.23 After the decease of Haj Rahim in 1934, the Ettehadieh Complex was distributed among his descendants, who took residence in its various buildings (see figure 1b). The properties were kept in the hold of the Ettehadieh family until they were purchased by Tehran's Mayor Bureau in October 2015.

Figure 1.

(a) Map of excavated trenches; (b) three-dimensional plan of the Ettehadieh House Complex as it stood between 1931 and 1951. (Online version in colour.)

The excavation and restoration project, organized by the Mayor Bureau and executed by the Pouyamehr Consulting Engineering Co., began on November 2015 with the two latter authors of this paper as experts and sixty labourers. The mission consisted of archaeologically supervised topsoil stripping by shovel cleaning and trowelling. The areas were then photographed, recorded, levelled and planned. The excavation began with Trenches 1 and 2 in the eastern and central area of the site (figure 1). Trench 3 in the west and southwestern area, Trench 4 in the northwestern area, Trenches 5 and 6 in the western area (figure 2a), and Trench 7 on the western side of the central area (figure 2b) were subsequently opened.

Figure 2.

Tiles from Ettehadieh; (a) remains of underglaze technique decorated tiles on the mortar layer, Trench 5; (b) remains of seven-colour technique decorated tiles, Trench 3. (Online version in colour.)

Glazed tile samples

The tile samples were of two types: underglaze (zir la'ab) and seven-colour (haft rang)24 (figure 3). The underglaze technique involved the direct application of coloured glazes onto the tile surface. The painted surface was then covered with a colourless transparent glaze and fired in the kiln. The seven-colour technique, on the other hand, was an overglaze decoration in which the tile surface was first covered with an opaque white glaze and fired. The tile was then painted with different coloured glazes and subsequently fired for the second time. Eight samples of underglaze decorated tiles (ETH3–10) and three samples of seven-colour on-glaze decorated tiles (ETH1, 2, 11) have been examined in this study (figure 4; table 1). The tiles were sampled only from areas of previous damage, which sometimes meant that not all of the colours from each tile could be sampled. The electronic supplementary material (S1) includes additional photographs of tiles from the Ettehadieh House Complex. A group of monochrome tiles decorated with the seven-colour technique were also found at the site but none was sampled for laboratory analysis.

Figure 3.

Schematic diagram of different bodies and different glaze layers of underglaze and seven-colour decorated tiles.

Figure 4.

Photographs of selected tile samples. (Online version in colour.)

Table 1.

List of tile samples from Ettehadieh, Tehran and their corresponding trench numbers.

| Sample | Technique | Trench | Context |

|---|---|---|---|

| ETH1 | Seven-colour | 3 | 3002 |

| ETH2 | Seven-colour | 1 | 1002 |

| ETH3 | Underglaze | 2 | 2012 |

| ETH4 | Underglaze | 7 | 7004 |

| ETH5 | Underglaze | 7 | 7004 |

| ETH6 | Underglaze | 4 | 4007 |

| ETH7 | Underglaze | 7 | 7004 |

| ETH8 | Underglaze | 7 | 7004 |

| ETH9 | Underglaze | 2 | 2012 |

| ETH10 | Underglaze | 3 | 3023 |

| ETH11 | Seven-colour (blue and white) | 7 | 7004 |

It is important, if possible, to suggest a dating for the tiles. With the exception of tiles from Trenches 3, 5 and 7, which had remained in situ, the majority of tiles found at the site had been removed from the walls and floors and were stored in piles. It was thereby impossible to determine whether the tileworks were performed under Amin al-Sultan, or later under Haj Rahim Ettehadieh. Similarly, the areas in Trench 3 appeared to have gone through different phases of development and it was difficult to establish a dating for the tileworks.25 For Trenches 5 and 7, however, the excavated tiles of both the underglaze and seven-colour techniques appeared to belong to the earliest phases of the development of the building and were most likely performed some time between 1892 and Amin al-Sultan's death in 1907.

Experimental and analytical procedure

Prior to chemical analysis, selected tiles were examined on site using a 100-LED portable ultraviolet (UV) torch run on a 9 V battery, shone from a distance of about 1–1.5 m. Small fragments of tiles (ca 1–2 cm across) were sampled and mounted in resin. Polished cross-sections through the glaze into the body were then prepared and carbon-coated for scanning electron microscope–energy dispersive spectroscopy (SEM-EDS) measurements at the Research Laboratory for Archaeology and the History of Art (RLAHA), Oxford. A JEOL SEM (JSM-5910) with Oxford Instruments EDS (INCA 200 system) operated at 20 kV and with 120 s measuring time was used in backscattered electron mode (BSE), which reveals contrast as a result of variations in atomic numbers. Count rate on metallic cobalt was around 3000 cps. EDS measurements were performed on areas of up to approximately 1 mm × 1.2 mm for bodies and 0.8 mm × 0.8 mm for glazes. A minimum of three readings was reported for area and spot analyses. Detection limits for SnO2 and PbO were about 0.5%, and for P2O5 and As2O3 around 0.2%. For all other oxides, values <0.1% were unreliable and were regarded as below detection limits.

Results and Discussion

Bodies

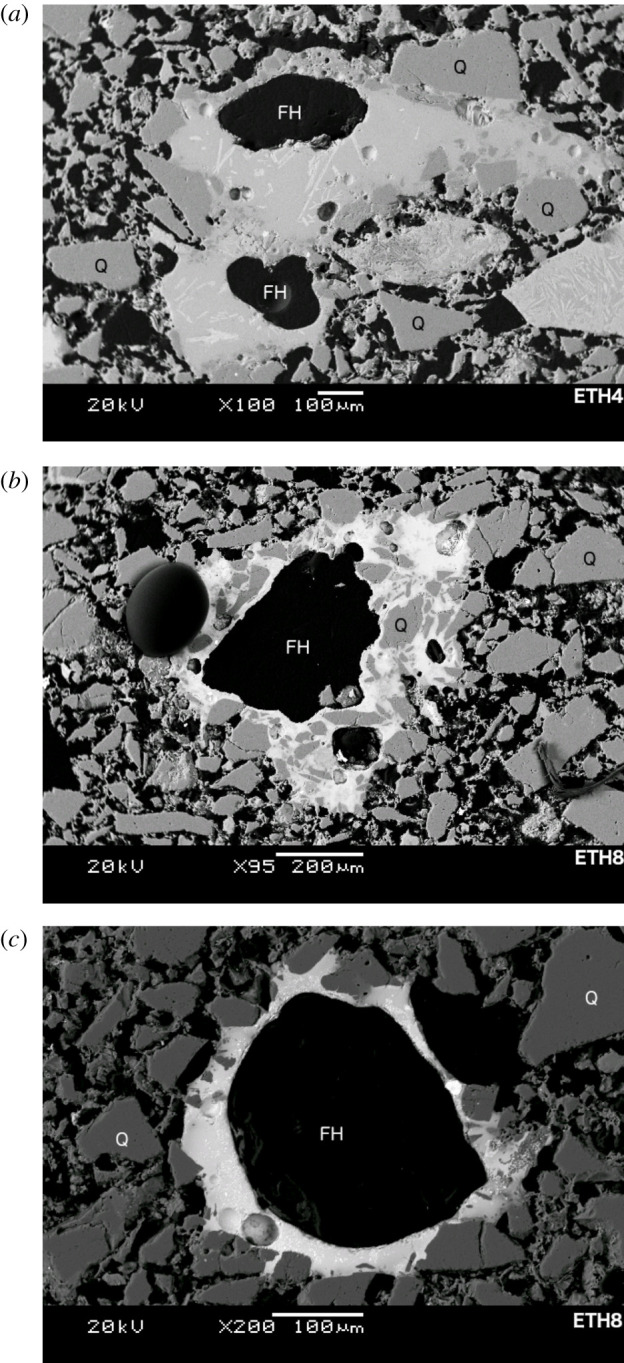

It is evident from SEM microstructural images (figure 5) and EDS chemical compositions (table 2) that there are significant differences between the bodies of underglaze and seven-colour decorated tiles. Bodies of underglaze tiles are of the stonepaste26 type, primarily made of quartz (ca 85% SiO2) with small amounts of glassy frit27 fragments and clay (figure 5a). The majority of frit fragments were fused into the body during firing, leaving pore spaces in the fabric. In some cases, relics of fused frit glass had remained around the vesicles and were analysed to characterize the composition of the frit (table 2). The frit in the ETH4 body were lime alkali composition (14% CaO, 12.1% Na2O + K2O) and had developed secondary needle-like crystals of wollastonite (calcium silicate; CaSiO3) during firing (figure 6a). In the ETH8 body, two types of frit were identified: a lead–alkali composition (10% PbO, 5.2% Na2O + K2O) (figure 6b), and a high lead composition (30% PbO) containing tin oxide crystals (19.4% SnO2; figure 6c). The bodies of seven-colour decorated tiles, on the other hand, were essentially clay-based; some sand grains were also added to the clay mixture, but no frit fragments were identified (figure 5b and table 2).

Table 3.

Energy dispersive spectroscopy analysis of frit fragments in the stonepaste bodies of ETH4 and 8 (wt%; obtained by averaging three area measurements; normalized to 100%).

| Sample no. | Na2O | MgO | Al2O3 | SiO2 | K2O | CaO | FeO | SnO2 | PbO |

|---|---|---|---|---|---|---|---|---|---|

| ETH4 | 9.5 | 3.3 | 1.9 | 66.8 | 2.6 | 14.3 | 0.9 | bd | 0.7 |

| ETH8—frit type I | 3.6 | 2.8 | 3.1 | 69.9 | 1.9 | 7.2 | 1.5 | bd | 10.0 |

| ETH8—frit type II | 2.3 | 0.6 | 2.5 | 37.9 | 2.1 | 1.4 | 9.2 | 19.4 | 24.6 |

Figure 5.

Backscattered scanning electron micrographs of (a) the clay-based body of the seven-colour decorated tile ETH2; (b) the stonepaste body of the underglaze-decorated tile ETH3. During the firing process, the glass diffused into the body, leaving holes (FH), often with concave boundaries, surrounded by a vitrified halo. Q: quartz/sand grains; FH: frit hole; BDY: body; GLZ: glaze.

Table 2.

Energy dispersive spectroscopy analysis of bodies (wt%; obtained by averaging three to five area measurements for each sample; normalized to 100%).

| Sample no. | Decoration technique | Na2O | MgO | Al2O3 | SiO2 | SO3 | K2O | CaO | FeO |

|---|---|---|---|---|---|---|---|---|---|

| ETH1 | Seven-colour | 2.6 | 3.4 | 13.9 | 59.9 | 0.8 | 3.3 | 11.6 | 4.5 |

| ETH2 | Seven-colour | 3.2 | 3.3 | 13.2 | 59.3 | 0.8 | 3.8 | 11.5 | 4.9 |

| ETH11 | Seven-colour | 2.3 | 3.4 | 13.4 | 58.6 | 0.7 | 3.0 | 13.8 | 4.8 |

| ETH3 | Underglaze | 2.0 | 0.9 | 3.6 | 87.9 | 0.4 | 1.4 | 3.2 | 0.6 |

| ETH4 | Underglaze | 2.1 | 0.7 | 3.7 | 88.2 | 0.8 | 1.3 | 2.6 | 0.6 |

| ETH5 | Underglaze | 2.0 | 0.7 | 3.9 | 83.3 | 0.6 | 1.2 | 7.6 | 0.6 |

| ETH6 | Underglaze | 1.3 | 0.7 | 3.2 | 89.3 | 0.5 | 1.1 | 3.5 | 0.6 |

| ETH7 | Underglaze | 1.3 | 1.0 | 5.3 | 81.4 | 0.7 | 1.6 | 7.5 | 1.1 |

| ETH8 | Underglaze | 1.2 | 0.5 | 3.8 | 89.9 | 0.7 | 0.9 | 2.0 | 0.9 |

| ETH9 | Underglaze | 1.6 | 0.7 | 4.1 | 87.9 | 0.7 | 1.5 | 2.7 | 0.8 |

| ETH10 | Underglaze | 1.6 | 0.6 | 5.7 | 88.3 | 0.6 | 1.0 | 1.7 | 0.6 |

Figure 6.

Backscattered scanning electron micrographs of partially fused frit (glass) fragments in the stonepaste bodies of the (a) ETH4 tile, of lime–alkali composition showing (light grey) needle-like wollastonite crystals (up to 200 µm in length); (b) ETH8 tile, of lead–alkali composition, embedding partially fused quartz grains; (c) ETH8 tile, of high-lead composition, showing scatters of (white) tin oxide crystals. Q: quartz grains; FH: frit hole; BDY: body; GLZ: glaze.

SEM-EDS observations of bodies are in accordance with the processes explained by ‘Ali Mohammad Isfahani. For the bodies of underglaze decorated wares, he provided the recipe: eight parts of powdered flintstones (chekhmaq), one part of dry white clay (gil-i bootah; lit. crucible clay), and one part of a burnt mixture of flint with ashes (kali) of glasswort (shoora-i-biabani) plants. The three mixed together produce a paste that is rolled up and flattened and then moulded to shape the bricks. After drying, the bricks were thinly coated with a slurry—28 made of one part of flint, one-eighth of white clay, and some water—and then left to dry.29

For the bodies of seven-colour tiles, Isfahani suggested using potters's clay (khak-i russ) mixed with a little sand (masseh) or ashes. The paste was then ‘placed in a wooden mould and left to dry for twenty-four hours’.30

Glaze

Underlying white opaque glaze (for seven-colour decorated tiles)

Figure 3 shows that the surface of the seven-colour decorated tiles was directly covered with opaque white glazes; further coloured glaze decorations were applied on top of this opaque glaze. EDS analysis (table 4) showed that the composition of the opaque white base glazes was lead—alkali containing 17.9–24.3 wt% PbO, 6.5–11.6 wt% Na2O + K2O, 7–8.9 wt% CaO + MgO. The glazes were opacified by scatters of tin oxide crystals and contained 6.7–9.9 wt% SnO2.

Table 4.

Energy dispersive spectroscopy analysis of glazes of seven-colour decorated tiles (wt%; obtained by averaging three to five area measurements for each sample; normalized to 100%).

| Glaze colour | Sample | Na2O | MgO | Al2O3 | SiO2 | P2O5 | K2O | CaO | Cr2O3 | MnO | FeO | CoO | CuO | As2O3 | SnO2 | Sb2O3 | Au2O3 | PbO | UO3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pink | ETH1 | 4.4 | 2.0 | 2.2 | 45.1 | bd | 2.1 | 5.4 | bd | bd | 0.8 | bd | bd | bd | 10.8 | bd | 2.3 | 24.9 | bd |

| Turquoise | ETH1 | 13.6 | bd | 3.7 | 72.0 | bd | 4.9 | 0.8 | bd | bd | 0.4 | bd | 3.5 | bd | bd | bd | bd | 1.1 | bd |

| Green | ETH2 | 5.3 | 0.2 | 1.6 | 38.8 | 0.3 | 2.0 | 1.1 | bd | bd | 0.4 | bd | 1.4 | bd | 7.0 | bd | bd | 42.1 | bd |

| Black line | ETH1 | 14.8 | bd | 2.9 | 69.2 | bd | 4.9 | 1.7 | bd | 3.7 | 0.9 | bd | bd | bd | bd | bd | bd | 1.9 | bd |

| Yellow | ETH1 | 0.5 | bd | 0.7 | 22.7 | 0.3 | 0.1 | 0.0 | bd | bd | 0.0 | bd | bd | bd | 11.0 | bd | bd | 64.7 | bd |

| Blue/cerulean | ETH1 | 11.9 | 0.8 | 2.6 | 65.4 | bd | 3.6 | 3.2 | bd | bd | 0.6 | 1.2 | bd | bd | bd | bd | bd | 10.7 | bd |

| Blue/cerulean | ETH11 | 12.0 | 0.9 | 2.5 | 66.7 | bd | 4.2 | 3.8 | bd | bd | 1.4 | 1.0 | bd | 0.2 | bd | bd | bd | 7.4 | bd |

| Base white glaze | ETH1 | 4.3 | 2.0 | 2.2 | 48.4 | bd | 2.2 | 5.9 | bd | bd | 0.8 | bd | bd | bd | 9.9 | bd | bd | 24.3 | bd |

| Base white glaze | ETH2 | 5.0 | 2.4 | 1.8 | 53.1 | bd | 3.0 | 6.4 | bd | bd | 0.7 | bd | bd | bd | 9.6 | bd | bd | 17.9 | bd |

| Base white glaze | ETH11 | 8.9 | 2.2 | 1.9 | 52.1 | bd | 2.7 | 4.8 | bd | bd | 0.7 | bd | bd | bd | 6.7 | bd | bd | 20.1 | bd |

bd: below detection.

Isfahani described the preparation process of the white opaque glaze under ‘How to Make Colours Special to the ‘Seven-Colours Process’ for Bricks and Vases’:

Bray as before, three parts of lead and one of tin, add to them six parts of that glass-like paint, before mentioned, put all in a vessel of water with a little clear gum arabic. With this paint the brick uniformly, place it in the kiln—using only half the previous degree of heat31 for this the ‘seven-colours process’. On removing the brick from the kiln it will be found to be white—the effect of the above drug.32

Overlying transparent glaze (for underglaze decorated tiles)

As shown in figure 3, a layer of transparent glaze was used to coat over the coloured glaze decorations in underglaze decorated tiles. Chemical analysis of the top transparent glazes (table 5) indicated that they varied in composition from essentially alkali33 to alkali–lead composition containing 14.8–16.3 wt% Na2O + K2O, 9.7–12.1 wt% CaO + MgO, and between 0.5 and 2.6 wt% PbO. For the transparent glaze, for which Isfahani used the term ‘alkali-paint’ (rang-i-kolai),34 alkali ashes were mixed with pounded flint stones, fired, and then ground to produce the alkali–paint powder.

Table 5.

Energy dispersive spectroscopy analysis of glazes of underglaze decorated tiles (wt%; obtained by averaging three to five area measurements for each sample; normalized to 100%).

| Glaze colour | Sample | Na2O | MgO | Al2O3 | SiO2 | P2O5 | K2O | CaO | Cr2O3 | MnO | FeO | CoO | CuO | As2O3 | SnO2 | Sb2O3 | Au2O3 | PbO | UO3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Top transparent glaze | ETH3 | 11.1 | 2.9 | 1.6 | 71.4 | bd | 3.8 | 6.7 | bd | 0.3 | 0.6 | bd | bd | bd | bd | bd | bd | 1.6 | bd |

| Top transparent glaze | ETH4 | 13.5 | 3.8 | 1.5 | 69.6 | bd | 2.4 | 8.3 | bd | 0.3 | 0.5 | bd | bd | bd | bd | bd | bd | bd | bd |

| Top transparent glaze | ETH5 | 12.9 | 3.5 | 1.4 | 70.1 | bd | 3.0 | 8.2 | bd | 0.3 | 0.5 | bd | bd | bd | bd | bd | bd | bd | bd |

| Top transparent glaze | ETH7 | 13.3 | 3.3 | 1.7 | 70.0 | bd | 3.0 | 6.7 | bd | 0.2 | 0.6 | bd | bd | bd | bd | bd | bd | 1.2 | bd |

| Top transparent glaze | ETH8 | 12.7 | 3.7 | 1.4 | 68.6 | bd | 2.2 | 8.0 | bd | 0.3 | 0.5 | bd | bd | bd | bd | bd | bd | 2.6 | bd |

| Top transparent glaze | ETH9 | 14.2 | 3.7 | 1.3 | 69.6 | bd | 2.5 | 7.7 | bd | bd | 0.5 | bd | bd | bd | bd | bd | bd | 0.5 | bd |

| Top transparent glaze | ETH10 | 13.2 | 2.9 | 1.6 | 70.9 | bd | 2.8 | 7.0 | bd | 0.2 | 0.6 | bd | bd | bd | bd | bd | bd | 0.7 | bd |

| Pink | ETH8 | 2.3 | 0.6 | 2.4 | 44.7 | bd | 2.1 | 1.4 | bd | bd | 8.6 | bd | bd | bd | 14.4 | bd | bd | 23.5 | bd |

| Blue | ETH3 | 9.9 | 1.3 | 3.3 | 75.8 | bd | 2.4 | 2.4 | 0.7 | 0.7 | 1.1 | 0.4 | bd | bd | bd | bd | bd | 1.8 | bd |

| Blue | ETH6 | 10.3 | 2.0 | 2.2 | 75.8 | bd | 3.1 | 4.7 | bd | bd | 0.6 | bd | bd | bd | bd | bd | bd | 1.2 | bd |

| Blue | ETH10 | 9.9 | 1.9 | 4.3 | 75.7 | bd | 2.7 | 3.4 | bd | bd | 1.5 | 0.2 | bd | 0.4 | bd | bd | bd | bd | bd |

| Violet | ETH10 | 7.6 | 1.1 | 2.9 | 79.6 | bd | 2.4 | 3.8 | bd | 0.7 | 0.7 | bd | bd | bd | bd | bd | bd | 1.3 | bd |

| Yellow | ETH3 | 5.7 | 0.9 | 2.5 | 79.2 | bd | 0.1 | 2.3 | 0.1 | 0.1 | 0.1 | 0.6 | bd | bd | bd | bd | bd | bd | 8.4 |

| Yellow | ETH4 | 4.7 | 0.7 | 1.7 | 81.0 | bd | 1.6 | 2.6 | bd | bd | 0.4 | bd | bd | bd | 0.8 | bd | bd | 2.2 | 4.4 |

| Yellow | ETH5 | 11.0 | 2.5 | 1.5 | 64.4 | bd | 2.6 | 6.2 | bd | 0.1 | 0.5 | bd | bd | bd | bd | 3.7 | bd | 3.2 | 4.2 |

| Yellow | ETH9 | 5.0 | 1.0 | 2.0 | 81.2 | bd | 1.6 | 2.5 | bd | bd | 0.5 | 0.5 | bd | bd | 0.5 | bd | bd | 1.5 | 3.8 |

| Yellow | ETH10 | 10.3 | 2.0 | 3.7 | 70.6 | bd | 2.6 | 4.7 | bd | 0.3 | 0.8 | bd | bd | bd | bd | bd | bd | bd | 4.9 |

| Green | ETH3 | 5.9 | 1.3 | 3.0 | 81.4 | bd | 2.3 | 2.7 | 1.3 | 0.1 | 0.5 | bd | 0.3 | bd | bd | bd | bd | 0.5 | 0.7 |

| Black | ETH3 | 6.6 | 2.5 | 4.1 | 73.3 | bd | 2.5 | 2.5 | 3.7 | 2.6 | 2.0 | bd | 0.2 | bd | bd | bd | bd | bd | bd |

| Black | ETH4 | 7.3 | 2.5 | 3.5 | 75.9 | bd | 2.2 | 3.0 | 2.9 | 0.6 | 2.2 | bd | bd | bd | bd | bd | bd | bd | bd |

| Black | ETH5 | 11.0 | 5.4 | 4.0 | 58.7 | bd | 2.2 | 7.3 | 7.1 | 1.4 | 2.7 | bd | 0.2 | bd | bd | bd | bd | bd | bd |

| Black | ETH7 | 9.5 | 4.5 | 3.8 | 65.7 | bd | 2.9 | 3.0 | 6.3 | 0.3 | 3.0 | bd | bd | bd | 0.5 | bd | bd | 0.5 | bd |

| Black | ETH8 | 9.7 | 3.6 | 3.9 | 65.4 | 0.3 | 2.5 | 3.7 | 5.7 | 0.3 | 2.5 | bd | bd | bd | 0.5 | bd | bd | 1.9 | bd |

| Black | ETH9 | 10.1 | 3.5 | 2.7 | 66.1 | bd | 2.4 | 5.9 | 4.3 | 1.0 | 1.8 | bd | bd | bd | bd | bd | bd | 2.1 | bd |

| Black | ETH10 | 8.4 | 7.6 | 6.1 | 57.8 | bd | 2.3 | 3.5 | 9.3 | 0.4 | 4.4 | bd | bd | bd | bd | bd | bd | bd | 0.2 |

| Brown | ETH6 | 9.9 | 2.0 | 2.2 | 74.3 | bd | 3.0 | 4.4 | bd | bd | 3.8 | bd | bd | bd | bd | bd | bd | 0.5 | bd |

bd: below detection.

Glaze pigments

Colour in ceramic glazes is provided by certain metallic oxides known as ‘pigments’, which are usually fritted with a mixture of silica and fluxes (i.e. alkalis, borax or lead), or with pre-prepared glass, to produce glaze colourants. Various types of pigment were used in the glazes of the underglaze and seven-colour decorated tiles from Ettehadieh.

Black

The black pigment was mainly used to paint the outlines of designs and figures, details of facial features and hair, as well as borders of the tiles. Two different types of black pigment were used in the underglaze and seven-colour decorated tiles. For seven-colour tiles, the black decorations appeared more dark brown in tint. SEM examination of the ETH1 tile showed that the pigment had completely dissolved in the glaze and no relic particles of the pigments were identified in the photomicrographs. EDS measurements indicated increased concentrations of manganese and iron oxides in the black glaze area (3.7 wt% MnO, 0.9 wt% FeO; table 4).

For underglaze tiles, EDS measurements of the black glaze of ETH3, 4, 5, 7, 8, 9 and 10 showed significant amounts of chromium oxide (2.9–9.3 wt% Cr2O3) and elevated concentrations of magnesium oxide (2.5–7.6 wt% MgO) and iron oxide (1.8–4.4 wt% FeO), as well as manganese oxide (0.3–2.6 wt% MnO) (table 5). EDS spot analysis of the undissolved crystals in the black glaze of ETH4, 5, 9 and 10 identified spinel-type solid solution crystals of magnesium–iron chromite with the formula (Mg,Fe)Cr2O4; the composition of the crystals varied in the range 51.7–54.8 wt% Cr2O3, 17.4–22.2 wt% MgO, 13.6–18.4 wt% Al2O3, 4.6–9.2 wt% FeO (figure 7).

Figure 7.

Backscattered scanning electron micrograph of the black glaze; underglaze decorated tile ETH4, showing air bubbles and chromite crystals (white) near the body–glaze interaction layer. BDY: body; GLZ: glaze.

Isfahani described two different black pigments in his treatise. For the seven-colour tiles, the pigment maghn was fritted and used as the black colourant.35 For underglaze decorated tiles, the two pigments siah-qalam-i-ma'dani (lit. black pencil mineral) and maghn were mixed in the ratio of 10 : 1.36 We have been fortunate to have samples of both as part of the Victoria and Albert Museum set of Isfahani's pigments analysed by Reiche and Voigt (2012).37 The siah-qalam pigment sample (appendix, sample no. 6) showed high concentrations of chromium, magnesium and iron oxides, and the maghn pigment (appendix, sample no. 21) showed elevated concentrations of manganese oxides. The results of chemical analyses of the pigments therefore confirmed the observations on the Ettehadieh tiles that the maghn pigment was used in the seven-colour decorated tiles and that a mixture of siah-qalam and maghn was used in the underglaze decorated tiles.

The history of the use of manganese and chromite oxides as dark brown (manganese) or black (chromite) pigments in ceramic glazes predates the nineteenth century by far. Manganese oxide, in its mineral form, pyrolusite, was used as brown pigment on ceramics as early as the seventh millennium bc, 38 and was subsequently widely used in Islamic39 and European40 glazed ceramics. In medieval Islamic treatises, the pigment is usually referred to as maghnīsīyā;41 Isfahani's ‘maghn’ might have been derived from this term.

Chromite has also been prevalently used in Islamic glazed ceramics since at least the medieval period. Evidence of its use is available from chemical analysis as well as scientific texts.42

Green

Two different types of green pigment were used in the underglaze and seven-colour decorated tiles. In the seven-colour decorated tile ETH2, the green pigment is copper-based and the glaze is lead-based and opacified by scatters of tin oxide crystals, containing 1.4 wt% CuO, 42.1 wt% PbO and 7 wt% SnO2 (table 4).43

For the green glaze on underglaze decorated tiles, EDS measurements on the ETH3 sample detected 1.3 wt% Cr2O3 (table 5). Unlike the black pigment, the chromium in the green pigment is not associated with high contents of magnesium and iron oxides which would be expected with chromite, the natural form of chromium oxide. Rather, as suggested by Troalen and colleagues (2009), the chromium oxide in the green pigment seems to be associated with a refining process of chromite that was developed in France in the early nineteenth century.44 The composition of the sample of the green pigment from the set of Isfahani's raw materials (appendix, sample no. 16) corresponds with that of the ETH3 green glaze. Chemical analysis of the pigment sample confirms elevated concentrations of chromium oxide with negligible amounts of magnesium and iron oxides.45 The description on the label ‘consisting of a mixture of the yellow and blue pigments’ is misleading and incorrect, and does not conform with the results of chemical analysis of the pigment sample. The absence of any description on the underglaze green pigment in Isfahani's treatise leaves us with no further clue as to the preparation of the pigment.

Pink/red

The pigment used in the manufacture of pink glazes includes gold, as well as tin oxide and lead oxide. EDS analysis of the pink glaze on the seven-colour tile ETH1 detected 2.3 wt% Au2O3, 10.8 wt% SnO2 and 24.9 wt% PbO (table 4). Similarly, EDS measurements on the pink glaze of underglaze decorated tile ETH8 detected high contents of tin oxide and lead oxide (14.4 wt% SnO2, 23.5 wt% PbO); however, no gold was detected (i.e. the levels were below the detection limit; see table 5). SEM photomicrographs showed even layers of pink glaze but gold particles were not visible. Tin oxide particles were observed in the underglaze pink glaze of ETH8 but not on the seven-colour tile ETH1.

Previous chemical analysis of Isfahani's sample of red pigment identified traces of gold (appendix, sample no. 9), thus confirming our observations of Ettehadieh tiles. Isfahani's description of the pink pigment reads:

Put half a miscal46 of gold in aqua-fortis (tizab), dissolve a quarter of a miscal of tin (gal) in about a bowl (kasseh) of aqua-fortis, then pour the two solutions into an earthenware vessel containing 5 maunds of water; the water will turn red (qermez), verging to black, mix with it 32 miscals of crystal glass, well pounded to the fineness of collyrium (surma); it will then throw up a red froth, which will subside; pour away the water which is at the top, put 4 miscals of dross of gold (murdeh sang-i-tela) with the deposit—(to melt gold one uses lead and water; when the melted gold is removed, the refuse, leaf, water, and dross of gold, is the murdeh sang-i-tela meant here)—add also 2 miscals of “tangar” (a dissolvent similar to borax), bray the whole well, and with a hair-pencil you may paint with this “deva” any part of your sketch which you wish to come out red.47

Gold-containing pigments used in the manufacture of red glass and glazes, so-called ruby glazes, or ‘purple of Cassius’,48 developed in Europe in the late seventeenth century following the discovery by Johann Kunckel of the pink preparation of gold colloids precipitated from an aqueous solution and stabilized with tin. By the early eighteenth century, the pink pigment was being used in the decoration of European porcelain, and from Europe its use spread to China, where it was used in the characteristic pink glaze of Famille Rose porcelain during the Qing dynasty.49 In Iran, the pink/red pigment was used in the decoration of ceramics and in enamels on metalwork and jewellery from at least the mid-eighteenth century. During the Zand period (1751–1794) in Shiraz, the pink decoration became the characteristic feature of architectural tileworks.50

Blue

The blue glaze pigments contained cobalt and elevated amounts of iron and arsenic. The blue glazes of seven-colour decorated tiles ETH1 and ETH11 contained 1–1.2 wt% CoO, 0.6–1.4 wt% FeO and 0.2 wt% As2O3 (table 4). For the underglaze decorated tiles ETH3, ETH6 and ETH10, the blue glazes contained 0.2–0.4 wt% CoO, 0.6–1.5 wt% FeO and 0.4 wt% As2O3 (table 5). For both seven-colour and underglaze decorated tiles, the blue pigments were completely dissolved in the glaze matrix and no undissolved relic particles of the primary cobalt minerals remained (figure 8). Nevertheless, the compositions of the blue glaze pigments were diagnostic enough to suggest a possible source for the cobalt ore. The compositions of the pigments were closely comparable to that of cobalt ore from a historic cobalt mine in Iran, located in the village of Qamsar in Kashan, which had been widely referred to in Islamic and Chinese accounts and European travelogues.51 In a former survey of the Kashan mine,52 the cobalt mineral was identified to contain arsenic (and sulfur); the ore was associated with high iron impurities, embedded in calcium rocks. In his treatise, Isfahani53 explicitly indicated that the blue pigment was produced from a mixture of lajvard-khak and the essence of lajvard procured from Kashan, thereby supporting the above hypothesis. Analyses of the samples of the Isfahani blue pigments further verified the results; samples 10, 11 and 13 consisted mostly of oxides of cobalt, iron and calcium (see appendix). It should be noted that in historical Persian technical texts, the term lajvard was used for both cobalt and lapis lazuli. The English translation of lajvard into lapis lazuli on ‘Ali Mohammad's sample labels as well as in his treatise is therefore somewhat misleading as the term in fact refers to cobalt compounds.

Figure 8.

Backscattered scanning electron micrograph of the blue glaze on the seven-colour decorated tile ETH11, showing double glaze layer with inner glaze containing a scatter of tin oxide particles (white) and air bubbles, and outer glaze containing air bubbles. BDY: body; GLZ: glaze.

To this cobalt mixture was added half the quantity of Yezd borax (booreh-i-Yezd) and tangar from Khorasan and the resulting mixture was heated in an earthenware vessel in the kiln.54 Analyses of the samples of Yezd borax (appendix, sample no. 8) and tangar (appendix, sample no. 7) showed that they both consisted of borax.55 The reason for the addition of borax to the cobalt extract is perhaps attributed to its strong fluxing power, resulting in complete dissolution of the cobalt-bearing crystals in the glaze during firing, which in turn produces the blue colour. Although boron was not detected by EDS owing to its low atomic number, SEM photomicrographs confirmed that the cobalt phases were in complete dissolution and no relics of the minerals had remained in the glaze.

Turquoise

The turquoise pigment was used only on seven-colour decorated tiles from Ettehadieh. EDS analysis of the turquoise glaze on the ETH1 tile identified elevated concentrations of copper oxide (3.5 wt% CuO; table 4), which corresponds to Isfahani's sample of turquoise pigment for the seven-colour process (appendix, sample no. 19). The copper pigment has entirely dissolved in the glaze and no traces of the primary pigment remain.

Violet

The violet pigment was used only on underglaze decorated tiles. The violet glaze on the ETH10 sample contained elevated amounts of manganese and iron oxides (0.7 wt% MnO and 0.7 wt% FeO; table 5) and the pigment has completely dissolved in the glaze so that the coloured glaze layer is not distinguishable from the top transparent glaze. Isfahani prescribed using pounded maghn stone for the iris–violet paint.56 Analysis of the sample of violet pigment similarly detected oxides of manganese, iron and magnesium (appendix, sample no. 14).

Yellow

Different types of yellow pigment were used in the seven-colour and underglaze decorated tiles. The yellow pigment used in the seven-colour decorated tiles is of the lead–tin oxide (lead stannate) type. Lead–tin oxide yellow pigment was used during the Byzantine period in glass, and subsequently in ceramic glazes in Egypt, the Levant and Mesopotamia since at least the eighth century.57 Lead–tin oxide yellow glazes continued to be used in Safavid Persian and Indian Mughul seven-colour tiles.58 The application of lead–tin oxide yellow on nineteenth-century Qajar tiles therefore suggests continuation of an established tradition.59 EDS analysis of the yellow glaze of the ETH1 tile detected elevated amounts of lead oxide and tin oxide corresponding to the yellow pigment (64.7 wt% PbO and 11 wt% SnO2; table 4). SEM photomicrographs showed lead–tin oxide crystals scattered throughout the yellow glaze layer (figure 9a). The key ingredient in the manufacture of lead–tin oxide yellow glazes was the so-called calx—a fine powder formed from a mixture of tin and lead that has been calcined (oxidized). In his treatise, Isfahani described the preparation of the lead–tin yellow for seven-colour decorated tiles as follows:

If you want a yellow colour, take sixteen parts of lead and one of tin, melt them together, take the froth (kurk) and heat it; when it begins to melt, add a quarter of its quantity of well-brayed stone, and mix thoroughly. Bricks or vases painted with this preparation and heated, come out of the kiln a yellow colour, like a servant who has acted perfidiously, and who, as is well known, turns yellow. With an iron ladle (sikh), skimmer-like, you must take out that yellow colour when melting, bray it, mix it with solution of gum Arabic (la’āb-i-katira), and apply it to bricks and vases. This requires one half the heat of other colours.60

Figure 9.

Backscattered scanning electron micrograph of yellow glazes: (a) seven-colour decorated tile ETH1, showing double glaze layer with inner glaze containing a scatter of tin oxide particles (white) and air bubbles, and outer glaze containing lead–tin oxide (lead stannate) particles (white); (b) underglaze decorated tile ETH3, showing double glaze layer with inner glaze containing uranium clouds, and outer glaze containing air bubbles. BDY: body; GLZ: glaze.

Chemical analysis from 1888 of the sample of yellow pigment correspondingly showed elevated amounts of lead and tin oxide. However, there is one clear difference in the lead-to-tin ratios (Pb/Sn) between Isfahani's recipe and the results of the analysis of the yellow glaze of the ETH1 tile from Ettehadieh. The Pb/Sn ratio as analysed on the ETH1 yellow glaze is ca 6.8 (see table 5), whereas that suggested by Isfahani is ca 16. In fact, the Pb/Sn ratio of 16 is not very common among yellow glazes of the seven-colour tiles of either Persian or Indian origin, the ratios tending to average around 7.61 The inconsistency might be due to an error in writing or translation of Isfahani's text; further analysis of nineteenth-century Persian tiles will be required to confirm this.

For the underglaze decorated tiles, on the other hand, two different yellow pigments were used. One type was identified on the tile ETH6. The glaze was more brown in tint and contained elevated amounts of iron oxide (3.8 wt% FeO; see table 5). The iron-based pigment had completely dissolved in the glaze and remnants of primary pigments were not detected.

Another type of yellow decoration was identified on the underglaze decorated tiles ETH3, 4, 5, 9 and 10, which showed significant amounts of uranium, ranging between 3.8 and 8.4 wt% UO3 (table 5). Uranium phases were primarily dissolved in the glaze (figure 9b); a few uranium grains were identified containing nearly 82 wt% UO3 (figure 9b, table 5). For visual analysis of the areas of tiles affected by the uranium yellow glaze, photographs of tiles were taken while a UV torch was shone upon the surface.62 The uranium-containing glazes emitted UV fluorescence and therefore it was possible to snapshot a map of uranium glazes in tile hand specimens. Figure 10 shows photographs of tiles under UV light.

Figure 10.

Tiles under ultraviolet light. The areas with uranium emit a bright yellow fluorescence. (Online version in colour.)

Both the uranium- and iron-based yellow pigments used for underglaze-decorated tiles were described by Isfahani in his treatise and samples 15 and 17 corresponding to both types were included in the set of samples (see appendix). Sample no. 15 was labelled ‘Essence of Ochre (Jowher-i-Ukhra), from Khorasan’, but chemical analysis indicated that the pigment consisted mainly of oxides of uranium, and that no iron oxide was present. Isfahani's description of the pigment read: ‘For yellow colour, men of the craft procure from Khorasan a kind of clay called ukhrā (ochre). They extract the essence of the refined part of it, which when pounded becomes yellow paint.63 Sample no. 17 was labelled a mere ‘Yellow pigment’, and chemical analysis suggested that the pigment was mainly made of a clay that was rich in iron. Isfahani's description read: ‘Another kind of yellow colour is procurable at the alchemists (meshshaq)’.64

Based on chemical analyses of the two pigments and consideration of the possible sources for the uranium- and iron-based pigments, it appeared that the labels for the samples 15 and 17 of yellow pigments were most likely interchanged; i.e. sample no. 17 contained the iron-based yellow pigment that was procured from the ochre clays of Khorasan, and sample no. 15 contained the uranium yellow pigment that was purchased from the alchemist (see appendix). Ochre (Persian ukhra) occurs as well-known iron-rich clay deposits that contain the natural mineral limonite (hydrated iron oxide), which is responsible for their yellow colour. Sources of ochre clay are found widely in Khorasan province, Iran, and the use of ochre as iron-based yellow pigment in nineteenth-century ceramic glaze-making is highly plausible. The use of uranium pigment in Iran, on the other hand, was unprecedented before the Qajar period and its occurrence thereafter must have been a result of increasing connections with the West during this period. Uranium was widely used as a colourant in glass and glazes in Europe from the 1830s and it is plausible to assume that the pigment was most likely imported to Iran from Europe.65

Conclusion

The results of chemical analysis of Ettehadieh tiles match almost perfectly with those of ‘Ali Mohammad's pigments and signed tiles, and his descriptions of materials and processes in his treatise. On the basis of the technological features, therefore, it is seen that the tileworks of the Ettehadieh House were produced using materials and manufacturing processes similar to those employed by ‘Ali Mohammad's workshop.66 Despite these technological similarities, however, it is difficult to establish whether the tiles from Ettehadieh were produced in ‘Ali Mohammad's workshop; other tilemaking workshops were also active in Tehran at that time and might have used similar materials and manufacturing processes. The construction and development of the Ettehadieh House must have begun during or perhaps slightly after the 1892 to 1896 period, when the lands in the Lalehzar district were being sold. This period must have fallen somewhat to the end of ‘Ali Mohammad's period of activity as indicated by his signed tiles; the latest known signed works by him are the tiles at the Nezam Mafi Mosque in Tehran, dated Rajab 1310 ah/January–February 1893. It appears from other sources, however, that Ali Mohammad's workshop must have been active for longer. As pointed out by Voigt (2002), the German archaeologist Friedrich Sarre (1865–1945)67 visited ‘Ali Mohammad's workshop in Tehran in 1898 and purchased twenty-five tiles.68

‘Ali Mohammad is perhaps the most well-known tilemaker of nineteenth-century Tehran, but there were also others who produced similar works. Among them were tilemakers signing Mahdi Kashi, Sadegh Kashi and Mostafa on tiles at the Gulistan Palace, ‘Ali Asqar on tiles at the Esma'il Shrine, Mohammad Yousef Khan Nuri and Ustad ‘Ali Akbar Kashani on tiles at the Taher Shrine, and Ostad Mohammad Gholi Shirazi on tiles at the Shaykh Abd Al-Hussayn Mosque.69 Apart from their signatures, however, very little is known about these tilemakers and their workshops. A photograph taken by Antoin Sevruguin70 of a tilemaking workshop in Tehran, ca 1880–1930, shows tilemakers in practice and provides compelling visual evidence of the types of tileworks produced;71 however, no further details of the exact location and date of the photograph are available. In his rigorous study of traditional crafts in Qajar Iran, Willem Floor pointed out a clear increase in the number of ceramic workers in Tehran between 1870 and 1920: ‘In 1920, there were 13 tilemakers’ (kashipazi) shops, employing 10 masters (ostads), 17 workers (kargars), and 7 boys (padus)’.72 The increased demand and interest in architectural tileworks in the second half of the nineteenth century seem to have been linked to Nasir al-Din Shah's ambitious reconstruction programme73 to transform Tehran into a modern capital city. The expansion of the city walls and the transformation of the old Lalehzar Garden was at the centre of these developments. Many of the buildings commissioned in Lalehzar by Qajar aristocrats and courtiers were decorated in a mixture of traditional Persian and contemporary European styles, which was very much a reflection of the patrons’ tastes. Extensive traditional polychrome tilework was to be found alongside carved or moulded stucco ornamentation (Persian gach kari) and spectacular mirrorwork (Persian ayneh kari).

The curious amalgam of traditional Persian and modern European influences appears to have gone far deeper than mere ‘appearance’. The results of chemical and microstructural analyses of tiles from the Ettehadieh Complex indicated that beside the use of pigments known to have been used in earlier Persian ceramics technology—such as manganese brown, manganese purple, chromite black, cobalt blue, copper green and copper turquoise—new pigments were introduced from Europe, i.e. uranium yellow, chromium green, and gold-based pink.74 One possible means of introduction of these pigments into traditional Persian ceramic production was through the establishment of a modern educational institution that subsequently became known as Dar al-Fonun (House of Techniques).75 Founded in Tehran in 1851 (1268 ah) by Nasir al-Din Shah's first premier, Mirza Taqi Khan Amir Kabir,76 the main purpose of the establishment of Dar al-Fonun was to bring European instructors to Iran to teach various fields, including medicine, pharmacy, military sciences, engineering and mining. In 1852, the Majma’ al-Sanayi’ School77 was also founded for the education of arts and handicrafts. Nasir al-Din Shah himself took great interest in the activities of these institutions; he encouraged European experts to take part in practical projects outside their college duties, sponsored sending students abroad to study Western science, and commissioned translation of European technical texts. For ceramics technology, one Persian manuscript is illuminating: Risala dar tafsil-i sakhtan-i chini (‘A treatise on porcelain manufacture’) in the collection of the Sipahsalar Library, Tehran78 dating from the reign of Nasir al-Din Shah.79 The Persian text is a translation of Traité des arts céramiques ou des poteries: considérées dans leur histoire, leur pratique et leur théorie (Treatise on ceramic arts or potteries: considerations of their history, their practice and their theory) by Alexandre Brongniart (1770–1847),80 a French geologist, naturalist, chemist and ceramics scientist, and director of the Musée National de Céramique, Sèvres. Published in Paris in 1844, the book was at the cutting edge of the science and technology of porcelain manufacture. The patronage of its translation by the Qajar court is a clear manifestation of their fascination for fine porcelain. The quality, materials, and production technology of contemporary Persian earthenware tiles were perhaps far from those of desired European porcelain; nevertheless, the text of the Risala dar tafsil-i sakhtan-i chini manuscript is not entirely irrelevant to nineteenth century tileworks. On folio 36a of Risala, there is a mention of chromium oxide (oksid-e krom) used for green glazes. Uranium oxide (oksid-e uran) is mentioned in the same folia as the pigment to achieve light yellow. Gold-based pink pigment is mentioned as ‘red of Cassius’ (sorkh-e kassius) on folio 36a and its different processes of preparation using tin and aqua regia (tizab) are discussed at length on folio 38a. Alongside, there are mentions of cobalt blue, manganese black, manganese purple, and copper green, among others. How exactly the tilemakers were exposed to this information is unclear. Recent research by Carey (2017) and her cited evidence have revealed that the Sèvres Museum took an active interest in ceramic production in Iran during the mid-nineteenth century and undertook chemical experiments on samples of raw materials used in Persian ceramic production.81 Henri-Victor Regnault (1810–1878),82 who was appointed director of the Sèvres Porcelain Factory in 1852, five years after the death of Alexandre Brongniart, commissioned Emile Duhousset (1823–1911), a French army officer in Tehran between 1858 and 1861, to conduct much extensive fieldwork and research on ceramics production in Iran. The Sèvres Museum was also in correspondence regarding Persian ceramics with Domenico Fochetti, the first professor of chemistry and pharmacy at Dar al-Fonun. There is, however, no further evidence to suggest how exactly the relationship between Sèvres and Dar al-Fonun might have facilitated the Persian translation of the Traité des arts céramiques. In discussing nineteenth-century ceramics by ‘Ali Mohammad and other potters with products of similar type, Watson (2006, p. 340) referred to them as ‘Art school production’, and argued: ‘It is the product of individuals chosen and trained specifically in particular educational establishments, with a clear agenda set from on high for both the final product and for its market’.

Besides being a widespread mode of decoration in Tehran's ambitious building programme by the Shah, Persian tileworks were also in increased demand by the European residents and travellers in Iran, who saw them as examples of quality contemporary craft. The acquisitions by the Sèvres Museum and the Victoria and Albert Museum further attest to this heightened interest. Murdoch Smith reported to the South Kensington Museum in 1884:

I have ordered some wall tiles to be made at Isfahan by a clever young potter there, who, for the last few years has been making experiments in imitation of the tiles in the old Safavian buildings in that city. Some specimens of his last productions which I saw recently struck me as highly artistic, the designs are original, only the paste, the glaze and the general style of the old examples being imitated.83

It was not only the artistic quality of the tileworks that Europeans took an interest in. Incidents of lead poisoning were on the rise in Europe, but it was not until the Industrial Revolution in the nineteenth century that a thorough understanding of the problem and its association with the use of lead was recognized.84 Research on industrial lead exposure expanded significantly in the second half of the nineteenth and early twentieth centuries, primarily in search for alternative recipes and materials to prevent lead poisoning. In the ceramics industry, lead poisoning was a severe issue owing to the common use of lead as the main flux85 in European ceramic glazes. In 1904, William Furnival published his Leadless decorative tiles, faience and mosaic in an effort to suggest the replacement of lead with alternative formulations in ceramic glazes. The treatise is dedicated to: ‘Manufacturers of Decorative Tiles and Faience throughout the world who desire to protect their operatives from Lead Poisoning, and to all who are interested in the highest welfare of the Ceramic Industry, this volume is most respectfully addressed’. The book has a special focus on alkali-fluxed ceramic glazes from the Near East and Islamic lands, among others, as valid substitutes for lead-fluxed glazes. In the third chapter of the book, Rise of the modern industry in decorative tiles, Furnival has included a full copy of ‘Ali Mohammad's treatise,86 and added as a final comment: ‘Words such as “maghn”, “ukhra”, “kela” have a peculiarly familiar sound’.87 Whether or not ‘Ali Mohammad's recipes had any direct influence on the twentieth-century transition from lead to alkali glazes in Britain remains unknown. However, Furnival's inclusion of ‘Ali Mohammad's text and the comment on etymological similarities of technical terms (maghn for manganese, ukhra for ochre, and kela for alkali) speaks of an undeniable interest in nineteenth-century Persian ceramic technology, which itself had been longing for European-influenced modernization.

Supplementary Material

Acknowledgements

We would like to thank Professor Michael Tite and three anonymous reviewers for their constructive suggestions on an earlier version of this manuscript. We are also grateful to Dr Moya Carey and Dr Mariam Rosser-Owen for permission and help to study and photograph samples of ‘Ali Mohammad Isfahani's pigments at the Victoria and Albert Museum, to the Research Laboratory for Archaeology and the History of Art, Oxford and Dr Chris Doherty for help with chemical analysis, and to the Tehran Mayor's Office and Dr Yasser Ja'fari for their support of the excavation project at Ettehadieh. Moujan Matin would like to acknowledge funding from the British Institute of Persian Studies, UK, and the Social Sciences and Humanities Research Council of Canada (SSHRC grant 756-2019-0502).

Footnotes

See, e.g., G. Fellinger, L'empire des roses: chefs d'oeuvre de l'art persan du XIXe siècle (Snoeck, Gand; Musée de Louvre-Lens, Lens, 2018); J. Scarce, ‘Art in Iran x.1 Art and Architecture of the Qajar Period’, Encyclopaedia Iranica (online edn), vol. II, fasc. 6, pp. 627–637 (accessed online 20 January 2020).

F. Voigt, ‘Falkenreiter und Liebespaar: Das Bild im keramischen Architekturdekor Irans zur Zeit der Qadscharen’, Baessler Arch. Beitr. Völkerkunde 55, 43–101 (2007); see also M. R. Riazi, Kashikariha-yi Ghajaar (Yasaavoli, Tehran, 2016) [in Persian].

Acc. no. A.1888.105.

See, e.g., J. Scarce, ‘Ali Mohammed Isfahani, tilemaker of Tehran’, Oriental Art 22, 278–288 (1976).

Victoria and Albert Museum; acc. no. 512-1889. Available online at: https://collections.vam.ac.uk/item/O113632/tile-isfahani-ali-muhammad/.

Scarce, op. cit. (note 4), Table I.

See, e.g., tiles by ‘Ali Mohammad commissioned by Alfred Lemaire (1842–1907), a French music teacher at Dar al-Fonun and chief music master of the Iranian government (Victoria and Albert Museum, acc. nos 512-1889; 522:1 to 10-1889). For a list of Europeans who purchased tiles, see L. Troalen et al., ‘To acquire a good name: specimens of 19th-century Persian tile-making from the Tehran workshop of the master potter Ali Muhammad Isfahani’, in Sources and serendipity: testimonies of artists' practice (ed. Erma Hermens and Joyce H. Townsend), p. 125, footnote 5 (Archetype, London, 2009).

G. Stronach, ‘Smith, Sir Robert Murdoch (1835–1900)’, Oxford dictionary of national biography (online edn: doi:10.1093/ref:odnb/25896) (Oxford University Press, 2014).

See, e.g., J. Scarce, ‘Travels with telegraphs and tiles in Persia: from the private papers of Major-General Sir Murdoch Smith’, Art Archaeol. Res. Pap. (June 1973), pp. 70–81; J. Scarce, ‘Persian art through the eyes of Major-General Murdoch Smith KCMG’, in The enterprising Scot, Scottish adventure and achievement (ed. J. Calder), pp. 131–138 (Royal Museum of Scotland, Edinburgh, 1986).

M. Carey, Persian art: collecting the arts of Iran for the V&A, chs 2, 4 and 5 (V&A Publishing, London, 2017).

National Museum of Scotland, acc. no. V.2019.63.

Victoria and Albert Museum, acc. no. 559: 1 to 9-1888.

‘Ali Mohammad Isfahani, On the manufacture of modern Kashi earthenware tiles and vases in imitation of the ancient (trans. John Fargues) (Museum of Science and Art, Edinburgh, 1888), p. 1.

Clay or other mixtures (see note 26) from which the piece is made. The term is used as opposed to any additional parts of a ceramic piece such as glaze.

Glaze is a thin layer of glass coating applied to ceramic bodies; see M. Matin, ‘Glazes, slips, and paints’, The encyclopaedia of archaeological sciences (online edn: doi:10.1002/9781119188230.sa) (Wiley–Blackwell, Chichester, 2019).

Victoria and Albert Museum, acc. no. 450A-1888. Available online at: http://collections.vam.ac.uk/item/O438476/pigments-framed-together-isfahani-ali-muhammad/.

Troalen et al., op. cit. (note 7), pp. 119–127; I. Reiche et al., ‘Development of a non-destructive method for underglaze painted tiles—demonstrated by the analysis of Persian objects from the nineteenth century’, Analyt. Bioanalyt. Chem. 393, 1025–1041 (2009); I. Reiche and F. Voigt, ‘Technology of production: the master potter Ali Muhammad Isfahani: insights into the production of decorative underglaze painted tiles in 19th century Iran’, in Analytical archaeometry (ed. Howell Edwards and Peter Vandenabeele), pp. 502–531 (Royal Society of Chemistry, Cambridge, 2012).

Namely, ultraviolet fluorescence, visible light reflectance spectroscopy, scanning electron microscopy–energy-dispersive X-ray fluorescence, micro-particle-induced X-ray emission, and Raman spectroscopy.

See, e.g., M. Habibi and Z. Ahari, ‘Lalehzar—a promenade, from garden to avenue’, Honar-ha-yi Ziba 34, 5–15 (2008) [in Persian]; M. Mirzaei, ‘Bagh-hayi Lalehzar’, Jostarha-yi Shahrsazi 32 (2010), pp. 84–89 [in Persian]; J. Lewisohn, ‘The rise and fall of Lalehzar, cultural centre of Tehran in the mid-twentieth century’, Tehran Project 1, UC Irvine, pp. 1–38 (2015).

The fourth king of the Qajar dynasty (1794–1025). He was the first Iranian monarch to formally meet Europe and wrote travelogues about his experience. For urban development of Tehran under Naser al-Din Shah, see J. D. Gurney, ‘The transformation of Tehran in the later nineteenth-century’, in Téhéran: capitale bicentenaire (ed. C. Adle and B. Hourcade), pp. 51–71 (Institut Français de Recherche en Iran, Paris/Tehran, 1992).

J. Calmard, ‘Atabak-E ‘Azam, Amin-Al-Soltan’, in Encyclopaedia Iranica (online edn), vol. II, fasc. 8, pp. 878–890 (accessed online 20 January 2020).

For a review of the history of the history of the Ettehadieh Complex, see M. Gholamnejad and A. Nemati Abkenar, Gozarish-i marimat va kavosh-i majmo'e-i tarikhi Ettehadieh, forthcoming [in Persian]. See also, H. Karimian et al., ‘kashf-i bana-yi mowsum bi ‘khana-yi solh’ dar kavosh majmo-yi tarikhi ettehadieh: ravayat-i bastanshenasana az dargiriha-yi vaqe'e-yi 14 azar 1330 Tehran’, Jostarha-yi Tarikhi, 9(2), 49–79 (2018/2019) [in Persian].

See, e.g., M. E. Nezam-Mafi, ‘Merchants and government, tobacco and trade: the case of Kordestan, 1333 ah/1919 ad’, Iranian Stud. 20(1), 1–15 (1987).

The ‘seven-colour’ technique here refers to overglaze polychrome glazed tiles and should not be confused with twelfth-century Persian Mina'i wares; see, Abu'l Qasim Kashani, Arāyis al-Jawāhir va Nafāyis al-Atāyib (ed. I. Afshar) (Intishārāt-i al-Maie, Tehran, 2006) [in Persian].

Gholamnejad and Nemati Abkenar, op. cit. (note 22).

A translation of the Persian term sangīneh first used by Wulff (1966); also referred to as ‘fritware’ in art historical literature. Stonepaste is an artificial ceramic body made mainly of quartz sand with small amounts of white clay and frit fragments (see note 27). Stonepaste bodies were distinguished for their whiteness and fineness and almost replaced clay-based ceramic bodies in Egypt, Syria and Iran from the twelfth century onwards. H. E. Wulff, The traditional crafts of Persia (MIT Press, Cambridge, MA and London, 1966), p. 166; see also R. B. Mason and M. S. Tite, ‘The beginnings of Islamic stonepaste technology’, Archaeometry 36, 77–91 (1994); R. B. Mason and G. A. Bailey, Tamerlane's tableware; a new approach to the chinoiserie ceramics of fifteenth- and sixteenth-century Iran (Mazda Publishers, Costa Mesa, CA, 1996); O. Watson, Ceramics from Islamic lands (Thames & Hudson, London, 2004), pp. 289–326.

Granulated glass fragments. Glasses are quenched from the molten state to form granulated glass, and subsequently ground.

Nevertheless, slip/slurry coating was not identified in SEM photomicrographs.

Isfahani, op. cit. (note 13), p. 3.

Isfahani, op. cit. (note 13), p. 8.

This implies that the body had been biscuit fired before applying the glaze, and therefore, three firings were used in total.

Isfahani, op. cit. (note 13), p. 9.

The tradition of alkaline glazing goes back to the beginning of ceramic glazes and glass in the fourth millennium bc in Mesopotamia and continued until the medieval and late Islamic period. The alkalis used in glaze manufacture came from ashes produced by burning salt-loving desert plants that are rich in soda, potassium, magnesium and calcium.

Isfahani, op. cit. (note 13), p. 3.

Isfahani, op. cit. (note 13), p. 9.

Isfahani, op. cit. (note 13), p. 6.

Reiche and Voigt, op. cit. (note 17).

E. Chalmin, C. Vignaud, H. Salomon, F. Farges, J. Susini and M. Menu, ‘Minerals discovered in paleolithic black pigments by transmission electron microscopy and micro-X-ray absorption near-edge structure’, Appl. Phys. A 83, 213–218 (2006).

See, e.g., M. Matin et al., ‘On the origins of tin-opacified ceramic glazes: new evidence from early Islamic Egypt, the Levant, Mesopotamia, Iran, and Central Asia’, J. Archaeol. Sci. 97, 57, Fig. 9 (2018).

See, e.g., J. Molera et al., ‘Manganese brown decorations in 10th to 18th century Spanish tin glazed ceramics’, Appl. Clay Sci. 82, 86–90 (2013).

See, e.g., M. Matin, ‘The technology of medieval Islamic ceramics, the study of two Persian manuscripts’, appendix, in O. Watson, Ceramics of Iran; Islamic pottery in the Sarikhani Collection (Yale University Press, Princeton, 2020).

For examples of chemical analysis, see E. Pernicka and H. Malissa, ‘Examination of Islamic glazes with the electron microprobe’, in Proceedings of the Sixteenth International Symposium on Archaeometry and Archaeological Prospection (ed. E. A. Salter and J. O. Tate), pp. 96–112 (National Museum of Antiquities of Scotland, Edinburgh, 1980); R. B. Mason et al., ‘Advances in polychrome ceramics in the Islamic world of the 12th century AD’, Archaeometry 43, 191–209 (2001); I. C. Freestone et al., ‘Scientific analysis of glazed tile from the Seljuq Palace of Kubad-Abad, Lake Beysehir, Turkey’, in Scientific research on historic Asian ceramics; Proceedings of the Fourth Forbes Symposium at the Freer Gallery of Art (ed. B. McCarthy, E. S. Chase, L. A. Cort, J. G. Douglas and P. Jett) (Archetype, London, 2009). For scientific texts see, Matin, op. cit. (note 41). For early use of chromite on Near Eastern ceramics, see A. Steinberg and D. C. Kamilli, ‘Paint and paste studies of selected Halaf sherds from Mesopotamia, in P. M. Rice, Pots and potters: current approaches in ceramic technology (Institute of Archaeology, University of California, Los Angeles, 1984).

The glaze most probably corresponds to Isfahani's sample no. 23 (see appendix); however, this pigment sample was not subject to recent chemical analysis; see Reiche and Voigt, op. cit. (note 17).

N. Eastaugh and V. Walsh, The pigment compendium: optical microscopy of historic pigments, p. 102 (Butterworth–Heinemann, Oxford, 2004).

In a study of Iznik pottery from Ottoman Turkey, Tite detected chromite in the blue and green glazes. The presence of chromite in the green and blue glazes was associated with elevated concentrations of copper and cobalt oxide as the main pigments. He discussed that when cobalt and copper were present in the glaze or in the adjacent glazes, they were preferentially absorbed by chromite and replaced magnesium and iron in the chromite lattice. This, however, could not have been the case for the nineteenth-century tiles studied here as no significant amounts of copper were detected in the green glaze and pigment. See M. S. Tite, ‘Iznik pottery: an investigation of the methods of production’, Archaeometry 31, 126 (1989); see also Pernicka and Malissa, op. cit. (note 42).

One miscal is ca 2.9 g.

Isfahani, op. cit. (note 13), p. 4.

L. B. Hunt, ‘The true story of Purple of Cassius; the birth of gold-based glass and enamel colours’, Gold Bull. 9, 134–139 (1976); W. Vogel, Glass chemistry (Springer-Verlag, Berlin, 1992), vol. 3, ch. 9.5.

W. D. Kingery and P. B. Vandiver, ‘The eighteenth century change in technology and style from the Famille-Vert Palette to the Famille-Rose Palette', in Ceramics and civilization II: technology and style (ed. W. D. Kingery), pp. 363–382 (American Ceramic Society, Columbus, OH, 1986); P. Colomban, L. Arberet, B. Kιrmιzι, ‘On-site Raman analysis of 17th and 18th century Limoges enamels: implications on the European cobalt sources and the technological relationship between Limoges and Chinese enamels’, Ceramics Int. 43, 10158–10165 (2017); H. Duan, X. Zhang, B. Kang, G. Wang, L. Qu, Y. Lei, ‘Non-destructive analysis and deterioration study of a decorated Famille Rose porcelain bowl of Qianlong Reign from the Forbidden City’, Stud. Conserv. 64(6), 311–322 (2019).

See, e.g., G. Degeorge and Y. Porter, The art of the Islamic tile, pp. 164–175 (Flammarion, Paris, 2002).

M. Matin and A. M. Pollard, ‘Historical accounts of cobalt ore processing from the Kashan mine, Iran’, Iran 53(1), 171–183 (2015); Q. Wang, ‘Study on blue pigment applied on blue-and-white porcelain’, Wenwu (Cultural Relics) 8, 59–64 (1982); J. C. Y. Watt, ‘Notes on the use of cobalt in later Chinese ceramics’, Ars Orientalis 11, 69–80 (1979).

M. Matin and A. M. Pollard, ‘From ore to pigment: a description of the minerals and an experimental study of cobalt ore processing from the Kāshān Mine, Iran’, Archaeometry 59(4), 731–746 (2017).

Isfahani, op. cit. (note 13), pp. 6–7.

For laboratory replication of this process, see Matin and Pollard, op. cit. (note 52).

Matin and Pollard, op. cit. (note 51).

Isfahani, op. cit. (note 13), p. 7.

Matin et al., op. cit. (note 39); M. S. Tite et al., ‘Revisiting the beginnings of tin-opacified Islamic glazes’, J. Archaeol. Sci. 57, 80–91 (2015).

M. S. Gill et al., ‘Tradition and indigeneity in Mughal architectural glazed tiles’, J. Archaeol. Sci. 49, 546–555 (2014); P. Holakooei et al., ‘Haft rang or cuerda seca? Spectroscopic approaches to the study of overglaze polychrome tiles from seventeenth century Persia’, J. Archaeol. Sci. 41, 447–460 (2014); S. Gulzar et al., ‘Characterization of 17th century Mughal tile glazes from Shahdara Complex, Lahore–Pakistan’, J. Cult. Heritage 14, 174–179 (2013).

M. Matin, ‘Tin-based opacifiers in archaeological glass and ceramic glazes: a review and new perspectives’, Archaeol. Anthropol. Sci. 11, 1155–1167 (2019).

Isfahani, op. cit. (note 13), p. 7

Matin, op. cit. (note 59), Fig. 4.

This technique was previously used by Reiche et al., op. cit. (note 17) for non-destructive analysis of nineteenth-century underglaze decorated tiles.

Isfahani, op. cit. (note 13), p. 7.

Ibid.

It is not entirely unlikely that the uranium pigment was in fact procured from ochre deposits in Iran, perhaps present in the form of the mineral uranopilite (uranium ochre), as suggested by Reiche and colleagues. Evidence to support this, however, is currently limited and there is not much information regarding sources of uranium-bearing ochre in Khorasan; see Reiche et al., op. cit. (note 17).