Abstract

The uncontrollable outbreak of the novel coronavirus (COVID-19) rapidly affected almost 230 countries across the world and territories since last year'2020 and its transmission mainly due to respiratory droplets. To fight and protect against micron dimension (~1.4 µm) corona virus the usage of disposable medical masks is one and only trivial option for patients, doctors, health employers and in fact mandatory for kids to senior citizens, as well as public places in a risky environment. Ordinary medical masks unable to self-sterilize in order to recycle for other appliances resulting further destroying impact of societies high economic and environmental costs. To minimize this global pandemic issue this proposal explores novel mechanism for further commercialization of surgical mask of photo-thermal and self-cleaning functionalization. Indeed, depositing few layer ultra-thin graphene coating onto low-melting temperature non-woven mask by tempering a dual mode laser induced mechanism. Incoming aqueous droplets are bounced off due the super-hydrophobic states were treated on the mask surface. Superficial hydrophobic surface yields an advanced safety towards approaching respiratory droplets. Due to the huge absorption coefficient capability of the sunrays activated laser-induced mask may rapidly boost temperature exceeds 85ºC under sunlight illumination, causes making the mask reusable after sunlight distillation. For SARS/coronavirus/ aerosolized bacteria, laser induced graphene mask is a recent breakthrough in superior antibacterial capacity. Furthermore, cost-effective and ultra-thin layered mask formulation recycled directly utilizes solar-driven desalination with remarkable self-exclusion performance for indelible usability. Featured review article, deals with remarkable achievements from forthcoming experimentation which may be inspired with layered mask designing by more progressive materials.

Keywords: Graphene, Nano/micro-porous, Sunlight sterilization, Reusable, Mask formulation

1. Introduction

Novel outbreak of coronavirus (COVID-19) diseases has vastly affected as well as transmitting in a rapid manner economic and human health worldwide. Amongst few sovereign states, a symbolic degradation of disease affection has been endorsed by utilizing medical masks principle as a filter to contain a virus, bacteria or any infectious agents [1], [2], [3], [4] from exhaled breath during sneezing. Recent investigation advised that a surgical mask could effectively prevent the transmission of infectious virus from symptomatic individuals [5,6]. However, the imprudent use and disposal of masks pose a high risk of secondary transmission and could imperil the safety response when tenacious pathogens are swelling on the masks [7]. Almost masks are designed for one time use, and the filtering layer uses polypropylene, a thermoplastic that takes last few decades to degrade in a landfill [8]. To mitigate the situation, there has been a proposal for the improvement of alternative materials to the melt-blown fabric and strategies to safely reuse masks [9]. The SARS/COVID could be deactivated at 55 °C in 15–20 min also reported by others Scientists group [10,11]. Additionally, in case of safety issues from environmental pollution and a shortage of material supply, as well as taking advantage of the broadband absorption properties of smart material graphene [12], [13], [14], that supposed to expose under sunlight sterilization is expected to achieve this temperature without requiring a temperature-controlled oven, water/ethanol distillation making disinfection of SARS/coronavirus (COVID-19) easier in areas where equipment and infrastructure lack.

The micro porous inorganic masks have always been considered as competent appliances against environmental threats, as well as protective equipment to preserve the respiratory system against the non-desirable air droplets and aerosols such as the viral or pollution particles. Therefore, the key challenge is to fabricate the filtration masks with higher efficiency to decrease the penetration percentage at the nastiest conditions. To accomplish this ideal concept, knowledge about the mechanisms of the penetration of the aerosols through the masks at different effective environmental surrounding is essential. We are currently passing in a time when COVID-19 pandemic is already causing the infection of more than 2.5 million people and more than 300,0000 deaths worldwide. In this circumstance to protect the population, an effective solution is individual containment; it is the use of a high-performance mask.

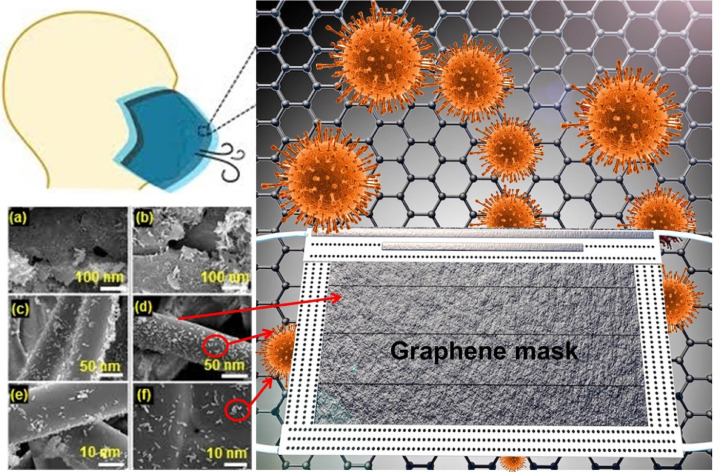

Removal of surgical masks can prohibit respiratory particulate matters from entering the lungs, that may assist to trim the risk factors are getting affected, alongside proper hygiene with hand sterilization methods [15], [16], [17], [18], [19], [20]. Nonetheless, some constraints of nominal standard mask ongoing usages for medical safety purpose. Firstly, the exteriors of surgical masks are hydrophobic, water droplets encompassing terrible viruses can remain on them [21,22]. Secondly, the mask has a low diffusing point; commonly lower than 130 °C to 140 °C, so those masks are highly demanding to reiterate them even with the sunlight sterilization techniques avoiding antibacterial coating from the graphene layered mask. Thirdly, the utilized masks are defined to recycle, due to capturing viruses/particulate matter might stay in their outlet areas of the mask. Transpires in a super hydrophobic state possess self-disinfecting can remarkably beneficial for biomedical appliances [23]. Hydrophobic surfaces with appropriate ultra-thin graphene nano-sheets, coating of structures can be super hydrophobic [24]. Several last decades, emerging super hydrophobic coatings with nanostructured surfaces developed rapidly [25,[26], [27], [28], [29], [30]]. Herein, we explore laser-induced graphene (LIG) materials further health protection capacity of anti-COVID sunlight sterilized long durable masks compared to that of ordinary surgical masks. It's kind of appreciable as well as essential for front line workers at a higher risk of infection; especially from antibacterial laser induced cum sunlight sterilized graphene mask improves the protection. The pristine exteriors of masks with polymer nano-fibers are soothing at the nanoscale ordering, beyond super hydrophobic features as comparison of antibacterial ability that utilized and illustrating different kinds of FE-SEM structures Fig. 1 (a-f) of laser-induced graphene [31], activated carbon fiber and melt-blown fabrics, integrity to cell structures from several substrates would surmount the restriction of smart material inventory masks schematically depicted in Fig. 1, as well as illustrated ultra-thin layers graphene fabricated anti-COVID virus protected mask efficiency [32].

Fig. 1.

Schematic diagram of laser induced graphene mask tools and mechanism of working principle for the protection of virus and illustration of the floating laser-induced graphene coated micro-porous layered sunlight sterilized mask (a-f) FE-SEM images of three kinds of mask materials showing various viability of E. coli to compare the antibacterial performance of laser-induced graphene, activated carbon fiber and melt-blown fabrics, integrity of cell structures. (Copyright © More et al.,2018 Vacuum, Elsevier).

As per current research inclination of unique interest, there is a hardly information concerning these super hydrophobic ingredients on sunlight sterilized medical masks firstly reporting to this review article. Indeed, precisely regulating the attention to a near-infrared laser beam, the super hydrophobic and super hydrophilic surfaces can be concurrently developed in the hostile section of the Polyimide. The culminating membrane controlled significant solar steam generation rates and could yield 1.3 kg/m2 purified water in an hour undertaken solar illumination [33]. The super hydrophilic amulets were also patterned on the super hydrophobic surfaces and could be utilized to capture sweat droplets on the human body [34]. Actively deposited laser-induced graphene via continuous wave (CW) forward to transfer (LIFT) exposed a super hydrophobic state with highly selective permeability oil and can manufacture as an oil recycling device, entirely mechanized robots [35]. By virtue of photo-thermal properties, laser-induced graphene can also be worn as antibacterial coatings. Considering to its admirable super-hydrophobic and photo-thermal pursuance, the laser-induced graphene is compatible with roll-to-roll assembly in which latest hygienic medical masks are utilized, due to the high processing temperatures of CW-LIFT and the low melting point of the polymer fibers, directly applying this laser-induced approach to non-woven masks are imposing [36].

Herein, dual-mode laser-induced graphene fabrication process has been developed for actively depositing onto commercial surgical masks as super-hydrophobic and photo-thermal porous glazing. The hygienic capability is enhanced graphene nanostructured coatings, with a static contact angle of over 140 °C accomplished. With this strong and super-hydrophobic resources, the water droplets can freely roll without appending on the mask surface. The surface temperature tolerance of the medical mask can quickly elevate to over 80 °C under solar illumination, which can effectively sterilize the particulate matters/virus as solar steam propagation rates were greater than 1.13 kg/m2/hour under the ferocity of the sunlight. Additionally, this mask can be advantageous for solar desalination after antivirus practice. The micro-pores within the mask [37,38] proven to have a better salt rejection carrying out as compared to polyimide-generated membranes that amplifies its long-term desalination capabilities.

2. Ultra-thin layered graphene nano-fibers synthesis mechanism

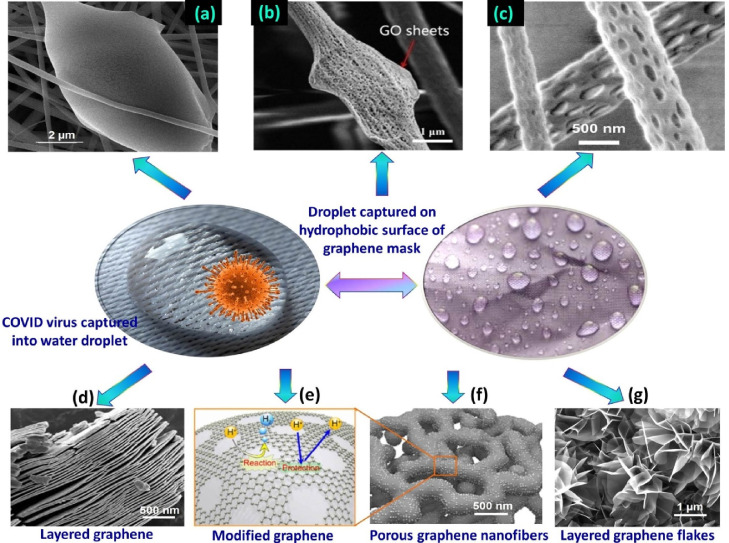

Two-dimensional (2D) graphene can be patterned by using stencils mask and oxygen plasma reactive-ion etching, and subsequent polymer-free direct transfer to flexible substrates. In conjunction with the recent evolution of additive and subtractive manufacturing techniques such as 3D printing and computer numerical control milling, we fabricated a simple and scalable graphene patterning technique using a stencil mask designed via laser cutter instrumentations. Unique approach to patterning graphene is based on a shadow mask technique that has been employed for contact metal deposition. The stencil masks are easily and rapidly manufactured for iterative rapid prototyping. Tremendous attention due to this unique tools and strategies of super-hydrophobic solar distillation anti-COVID solar mask formulation provides for fabricating ultra-thin nanofibers from a rich variety of micro-porous materials typical Field Emission Scanning Electron Microscopy (FE-SEM) also displayed in Fig. 2 (a) ultra-thin wide surface range of graphene nano-sheets, while the micro-porous structures of hydrophobic surface of graphene sheets mask captured by droplet as identified in Fig. 2(b). Infact, the porous structure obtained in Fig. 2(c), via traditional solvo-chemical assisted route of inorganic graphene fibers. Hence, few layered graphene tilt image as shown in Fig. 2(d). However, the modified grapheme depicted in Fig. 2(e), typical micro-porous graphene nano-fibers [38] investigated in Fig. 2(f), as well as layered graphene flakes [39] exhibited in Fig. 2(g). Indeed, those are also reusable, enabling cost-effective pattern replication.

Fig. 2.

Typical FE-SEM images of (a) ultra-thin wide surface range of graphene nano-sheets, (b) micro-porous structures of hydrophobic surface of graphene sheets mask captured by droplet, (c) porous structure obtained via traditional solvo-chemical assisted route of inorganic graphene fibers, (d) few layers graphene tilt image, (e) modified graphene, (f) micro-porous graphene nano-fibers, (Copyright © Clerk et.al., 2007, J. of Collide and Interface Science, Elsevier) and (g) layered graphene flakes, utilized for super-hydrophobic solar distillation anti-COVID solar mask formulation.(Copyright © Wang et.al., 2018, American Chemical Society).

3. Experimental attempts: utilized nanoparticles for mask formulation

3.1. Materials processing

The nanoparticle emulsion consisted of a mixture of 2 g/L silver nitrate, 1.5 g/L titanium dioxide, 2 g/L graphene oxide, 2 g/L MgO, 0.3 g CNTs/graphene etc., were purchased from Sigma Aldrich (Germany) absolutely 99.9% purity after tasted. The treated fabric elements were used to produce the advanced sunlight sterilized graphene layered mask.

3.2. Laser-induced graphene utilized functional mask formulation

In this experimental approach, modified polyimide film's assembly with medical masks were utilized directly after redeem without healing. It was investigated that our DMG Lasertec 50 laser system utilized for CW mode scribing of wavelength 1085 nm, power consumption 4 W, scan rate/second 300 mm, and spot identification 30 μm. The donor polyimide coated, ultra-thin film was converging by the laser beam. Simultaneously, the laser beam scanning via CW mode, synthesized graphene flakes deposited to the acceptor polyimide, alongside with a 1 mm spacer at the interval of donor and acceptor. Henceforth, layered graphene in the upper polyimide was further cumulated onto the medical mask during low temperature executed by pulse-LIFT by using spacer 1.0 mm, at a wavelength region 1085 nm with power consumption 0.5 W, employed 13 ns pulse width, at the maintaining speed 300 mm/second.

3.3. Graphene mask formulation techniques

‘Graphene’ is known for its anti-bacterial properties, so as early as last September,2020 before the outbreak of COVID-19 pandemic globally, producing outperforming masks based on laser-induced graphene already novel breakthroughs in our experimental laboratory. Throughout enormous efforts of our lab initiated laser-induced graphene with E. coli, and it achieved high anti-bacterial efficiency of about 82%. In comparison, the anti-bacterial efficiency of activated carbon fiber and melt-blown fabrics, both commonly-used materials in masks, were only 3% and 8% respectively. Experimental outcomes also showed that over 90% of the E. coli deposited on them remained alive even after 10 h, while most of the E. coli deposited on the graphene surface was dead after 8 h. Moreover, the laser-induced graphene exposed a superior anti-bacterial capacity of aerosolized bacteria. In order to achieve complete killing through airborne particles of bacteria, sunlight sterilization makes an important role, and higher concentration may be required for graphene coating masks.

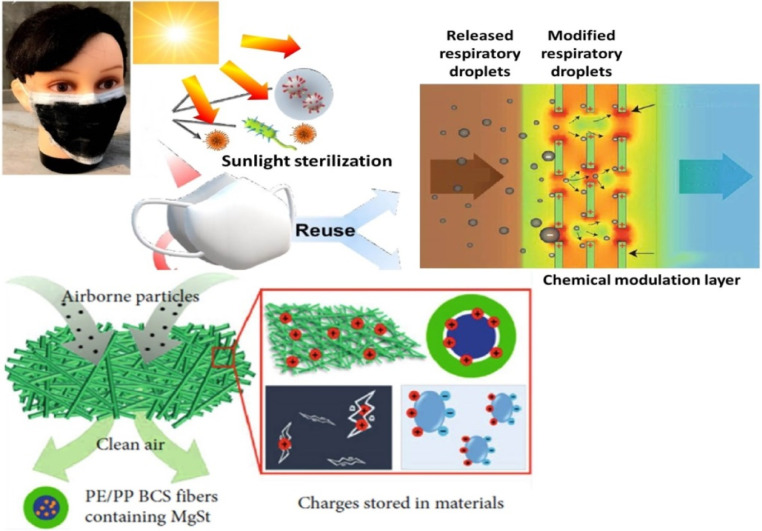

Diagrammatically analyzed Fig. 3 , shown that the optical image of the laser-induced sunlight sterilized reusable graphene mask tools for the chemical modulation layer of the air filtration mechanism [39], as well as magnesium stearate as the charge enhancer as well as air-moisture induced electricity from gradient graphene. Tolerance of inorganic materials is an essential attribute of antimicrobial agents utilized in the hospital environment. In this study, it was found that the presence of electronically activated charged carbon materials had a slight inactivation effect on the anti-microbial effect of the nanoparticles.

Fig. 3.

Optical image of the laser-induced sunlight sterilized reusable graphene mask, schematics of the chemical modulation layer of the air filtration mechanism, an electret filter consists of carbon charged particles attributes as ultra-thin layered surface matrix and magnesium stearate as the charge enhancer as well as air-moisture induced electricity from gradient graphene.(Copyright © Ming Hui Chua et al. 2020, Exclusive Licensee Science and Technology Review Publishing House).

The achievements might be related to the damage of bacterial cell membranes by graphene's sharp edge of honeycomb nanostructures. The bacteria may be killed by dehydration induced by the hydrophobic (water-repelling) characteristics of graphene. It was well known to all as well declared by the World Health Organization (WHO) is that COVID-19 virus would lose its transmission of virulent at high temperatures. So, our experimental attempts to test if the graphene's photo-thermal effect (producing heat after absorbing light) can enhance the anti-bacterial effect. The results revealed that the anti-bacterial efficiency of the graphene material could be improved to 99.998% within 15–20 min under sunlight sterilization, while activated carbon fiber and melt-blown fabrics only showed an efficiency of 60% and 90% respectively. The inorganic porous microstructure laser-induced optimized graphene masks as depicted in Fig. 3. The transferred carbon on the surface of the pristine white mask thus appeared black color as shown in cartoon graphics. So, we may anticipate that the laser-induced graphene masks are reusable as employed “Green synthesis” cost-effective production just one and a half minutes, an area of 100 cm² can be converted graphene as the outer or inner layer of the mask.

The unique attempts firstly report on the anti-microbial effect of ultra-thin graphene-coated sunlight sterilized and chemically modulated layer masks are promisingly effective against E. coli and S. aureus, and those bacteria attached to the surface of nanoparticle-treated masks were killed completely. Effective inhibition of micro-organisms present on layered graphene masks are utilized as the combination of anti-microbial agents may be of value in preventing the emergence of resistant bacterial strains, as well as for protection of front-line healthcare workers exposed to infectious agents.

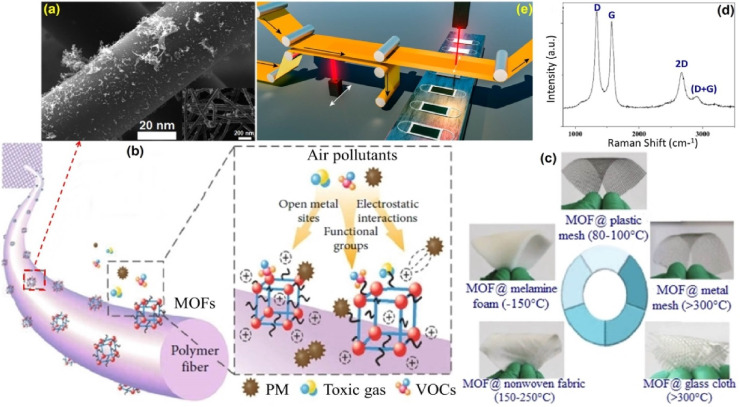

Typical field-emission scanning electron microscopy (FE-SEM), explores the microstructures of the smooth surface of microfibers coated materials were investigated, as exhibited in Fig. 4 (a). While nanowires investigated overall the fiber surfaces, with typical morphologies were constantly diffused in the range from 100 nm to a few micro-meters orders [Inset of Fig. 4(a)].

Fig. 4.

(a). Typical FE-SEM image of the graphene-coated, ultra-thin non-woven nanofibers within the surgical mask (resolution scale bar 20 nm), (b) schematic illustration of the surface of metal organic frameworks/graphene nanofibres, (c) roll-to-roll hot-pressing tools and mechanism on MOF-filters based flexible graphene fibers production for the prevention of virus/particulate matters/pollutants (Inset), (d) Raman spectram of the ultra-thin layered graphene-coated mask alignment, and (e) advanced-generation laser induced graphene production schemes are adaptable with a roll-to-roll illustration. (Copyright © Ming Hui Chua et al. 2020, Exclusive Licensee Science and Technology Review Publishing House).

Henceforth, metal-organic frameworks (MOFs) based filter are an excellent class of porous crystalline materials that are composed of transition-metal cations and coordinately bonded multidentate inorganic linkers. Indeed, tunable porous structures, rich functionalities, high porosity as well as efficient thermal stability with the MOFs hold great promise for important applications as filtration materials [40]. While embedded in polymer fibrous membranes are helping to form MOF crystals helps to grow as a light powder form, which firstly explored in the interactions between MOFs and particulate pollutants.

It was considered that, the particulate pollutants can be apprehended by the MOF based filters via three techniques: (i) graphene interacting with the functional groups on MOFs and/or polymers, (ii) binding to the open metal sites on MOFs, and (iii) inter-molecular electrostatic interactions with MOF nanocrystals as illustrated in Fig. 4(b). Due to the unbalanced metal ions and defects on the surface, MOFs can offer positive charge to polarize the particulate matter (PM) surface, leading to enrich electrostatic adsorption of PM pollutants, seems tiny particles with high efficiency while maintaining air permeability. Accordingly achieve high removal efficiency, thick layers of densely packed micro-fibers are needed and air permeability is therefore sacrificed. Recently, a variety of novel membrane filters have been developed for PM purification with enhanced performance and attractive characteristics such as nano-fiber diameters, higher specific surface area, low air resistance, and transparency, while being light and having functionalized active surfaces to capture particles more efficiently by electrostatic forces or chemical bond interactions. Experimentally inspired by the promising outcomes, the same group further employed a roll-to-roll hot-pressing methodology for mass production of MOF-based filters on various commercially available graphene like stretchable substrates, e.g., metal mesh, glass cloth, plastic mesh, melamine foam and non-woven fabric [41] as investigated in Fig. 4(c). So, finally we may predict that the fabricated MOF based graphene mask demonstrated a brilliant performance for the particulate matter removal activate under certain range of temperatures 80°−300 °C as well as sunlight rays sterilization.

Furthermore, phonon vibration modes were investigated via Raman spectroscopy to confirm the chemical compositions are presented into the prepare nano-flakes, as illustrated in Fig. 4(d), two significant graphene peaks. It's novel mechanism of graphene mask really beneficial for indelible usability without apparent efficiency loss by employing tap water or ethanol spray (sanitizer), which is quite promising for application in residential anti-COVID controlling via cost-effective sunlight sterilization process.

4. Results and discussions

Furthermore, elaborate experimental roadmap of the polyimide film is the primary designed and laser-induced graphene from the bottom to the top polyimide thin-film layers by using a CW mode laser. Hence, the relocated graphene is lifted to the second laser adopting a pulse mode, which further transfers the fabricated ultra-thin layered graphene onto the mask exteriors. The actual momentum of the photons is exploited as kinetic energy to transfer the graphene due to applied 10 ns pulse [42]. However, the layered graphene can be laminated onto the medical mask without damaging its surfaces at sufficiently low temperature. Inspired by the promising research outcomes, the same group further employed a roll-to-roll hot-pressing tools and techniques for mass production of metal organic frameworks (MOF)-based filters on various commercially available flexible substrates based filter for virus, particulate matters or air pollutants as explored in the Fig 4(a) FE-SEM image of the graphene-coated, ultra-thin non-woven nanofibers within the surgical mask (resolution scale bar 20 nm), while Fig 4(b) depicted the schematic illustration of the surface of metal organic frameworks/graphene nanofibres [39]. However, the roll-to-roll hot-pressing tools and mechanism on MOF-filters based flexible graphene fibers as shown in Fig 4(c) production for the prevention of virus/particulate matters/pollutants (Inset of Fig. 4(c)). Raman spectrum of the ultra-thin layered graphene-coated mask alignment explored in Fig. 4(d). However, the top-generation laser-induced scheme is also compatible with a roll-to-roll system may be readily integrated within the existing ordinary mask yielding elongation lines, as schematically displayed to Fig. 4(e).

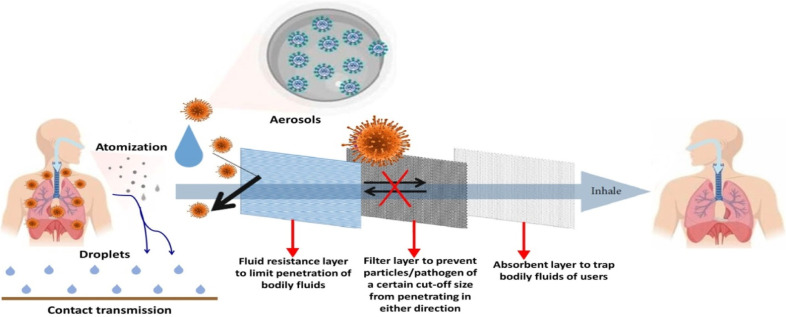

5. Exclusive performance of commercialize 3-layed graphene mask

Typically 3-layered graphene mask is made up of non-woven fabric with each layer having specific functions. This cost-effective graphene mask further elucidated the supplementation of the airborne transmission to the CORONA virus (COVID-19) epidemic by analyzing the direction and extenuation during this pandemic globally considering the virus transmission passages as show in Fig. 5 . Reusable and sunlight sterilized layered graphene mask covering forbids both airborne transmission by hindering atomization and inhalation of virus-bearing aerosols and direct communication by preventing viral shedding or droplets. The outermost layer (typically blue) is waterproof and helps to repel fluids such as mucosalivary droplets [39]. The middle piece is the filter, which prevents particles or pathogens above a certain size from penetrating in either direction. The innermost layer is made of absorbent materials to trap mucosalivary droplets from the user. This layer also absorbs the moisture from exhaled air, thus improving comfort. Together, these 3-layers effectively protect both the user and the surrounding people by limiting the penetration of particles and pathogens in both directions. As suggested by its name, non-woven fabric does not contain intertwining strands and is made by bonding a mass of fibers together using heat, chemical, or mechanical means. 'Felt' is one of the most common examples of non-woven fabric. Although non-woven fabric is mechanically weaker than its counterpart, it is cheap and fast to manufacture. Therefore, it is an ideal material of the surgical mask. The two most common methods of making non-woven fabric for surgical mask are spun bond and melt-blown. Meanwhile, the technical emergence of incorporating functional graphene nanosheets designed optical image of the laser-induced and sunlight sterilized reusable graphene mask internal working principle as displayed in Fig. 5.

Fig. 5.

Internal geometrical studies and working principle of layered musk formulation and inhalation mechanism further effectively protected from SARS/COVID-19 virus, pathogens etc.

6. Conclusions, outlook and future prospects

Summering as a whole, couple-mode laser-induced mechanism for supplemental dispersing few-layer graphene on sunlight sensitized cost-effective advanced generation surgical mask is sighted, comparable to low capacity commercial surgical masks are insufficient to destroy the contained bacteria on the surface. As a consequence over the 90% of bacteria remain prolifeative even after 8–10 h. Additionally, these low impact surgical masks might not be reliable to contain the global pandemic or even the epidemic when a highly transmissive coronavirus and fatal disease breaks out. Simultaneously, the anti-COVID filtration properties of this sunlight sterilized laser induced graphene layered masks are immensely reliant on the commercial utilization. Admitting significant antibacterial coating performance already proven of photo-thermal and super hydrophobicity CW-LIFT graphene across particulate matter, E. coli, virus protection. Meanwhile, more advanced mechanism with super hydrophobic and photo-thermal techniques are likely to expose for derivates into next generation temperature-sensitize novel designing mask formulation, the expansion to nanofibers on the electrical shielded masks by spray coating on the super-hydrophobic pristine masks.

Hence, the progress on typical research is critically desired to assess the transformation, transmission, and dispersion of virus-bearing aerosols from human atomization under different environmental conditions. So far, the related impacts on virus infectivity by the moderation of sunlight sterilized reusable graphene mask. Although it's equally important to understand human atomization of airborne viruses. It is also essential to evaluate the attainment of cost-effective anti-COVID graphene mask to quantify the efficiency to filtrate airborne viruses relevant to human atomization and inhalation. Our novel implementations of anti-COVID graphene mask formulation that definitely will prevent highly virulent corona virus through airborne transmission route. More exclusive moderation of these mechanisms may also require an interdisciplinary effort.

In contrast with latest technique, the intrinsic and photothermally enhanced antibacterial activity of our laser induced graphene materials to improve the safety from infectious viral, which can ensure the protection of the masks. The dangerous SARS/COVID-19 viruses were proclaimed to deactivate at increased temperature, which can be attained by laser-induced graphene mask under several minutes in sun rays. In spite of that, future laboratory and clinical assessment of infectious species in a broader ambience will bring more wisdom. As well as we may anticipate that our concerns on the viability of infectious agents and investigated proposed novel tool will be beneficial for the society amongst a disease outbreak. Henceforth, this high surface recycled graphene-layered mask supporting solar illumination can be disinfected surface viruses of the mask, as well as also it can perform as solar steam propagation devices via salt-rejection excellence for long-lasting durability. Also, it can be predicted the sophisticated pursuance will be carried out from future attempts, that can be influenced by this implemented discoveries in the next generation healthcare mask formulation by leading-edge materials.

Compliance with Ethical Standards

Funding

There is no such funded scheme for this work

Research involving human participation and/or animals

None.

Informed consent

None.

Ethical approval

None.

Contribution

Kaushik Pal, performed hand on synthesis and experiments, with review data analysis, manuscript writing; George Z. Kyzas, investigated conceptualization of the work with details spectroscopic illustrations; Samo Kralj, investigated experimental methodology and formal analysis; Fernando Gomes de Souza Jr., was responsible for draft review and editing as well as visualization of graphical demonstrations.

Declaration of Competing Interest

There is no conflict of interest amongst the author or any financial interest for publication.

Acknowledgements

The author Dr. Kaushik Pal is grateful to his associate colleagues and Doctoral/Postdoctoral research scholars, Directors at the Federal University of Rio de Janeiro, Brazil. Especially, Dr. Pal, owing to his sincere thanks to all scientific operators in Greece also gratefully acknowledged for providing excellence of the research conceptualization as well as extensiv spectroscopic analysis.

References

- 1.Bowles J., Hjort J., Melvin T., Werker E. Ebola, jobs and economic activity in Liberia. J. Epidemiol. Community Health. 2016;70:271–277. doi: 10.1136/jech-2015-205959. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Sohrabi C., Alsafi Z., O’Neill N., Khan M., Kerwan A., Al-Jabir A., Iosifidis C., Agha R. World health organization declares global emergency: a review of the 2019 Novel Coronavirus (COVID-19) Int. J. Surg. 2020;76:71–76. doi: 10.1016/j.ijsu.2020.02.034. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Coibion O., Gorodnichenko Y., Weber M. Labor markets during the COVID-19 crisis: a preliminary view. SSRN J. 2020 doi: 10.2139/ssrn.3574736. [DOI] [Google Scholar]

- 4.McKibbin W.J., Fernando R. The global macroeconomic impacts of COVID-19: seven scenarios. SSRN J. 2020 doi: 10.2139/ssrn.3547729. [DOI] [Google Scholar]

- 5.Leung N.H.L., Chu D.K.W., Shiu E.Y.C., Chan K.-.H., McDevitt J.J., Hau B.J.P., Yen H.-.L., Li Y., Ip D.K.M., Peiris J.S.M., Seto W.H., Leung G.M., Milton D.K., Cowling B.J. Respiratory virus shedding in exhaled breath and efficacy of face masks. Nat. Med. 2020;26:676–680. doi: 10.1038/s41591-020-0843-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Eikenberry S.E., Mancuso M., Iboi E., Phan T., Eikenberry K., Kuang Y., Kostelich E., Gumel A.B.M. To mask or not to mask: modeling the potential for face mask use by the general public to curtail the COVID-19 Pandemic. Infect. Dis. Model. 2020;5:293–308. doi: 10.1016/j.idm.2020.04.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Feng S., Shen C., Xia N., Song W., Fan M., Cowling B.J. Rational use of face masks in the COVID-19 Pandemic. Lancet Respir. Med. 2020;8:434–436. doi: 10.1016/S2213-2600(20)30134-X. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Canopoli L., Coulon F., Wagland S.T. Degradation of excavated polyethylene and polypropylene waste from landfill. Sci. Total Environ. 2020;698 doi: 10.1016/j.scitotenv.2019.134125. [DOI] [PubMed] [Google Scholar]

- 9.Dargaville T., Spann K., Celina M. Opinion to address the personal protective equipment shortage in the global community during the COVID-19 outbreak. Polym. Degrad. Stab. 2020;176 doi: 10.1016/j.polymdegradstab.2020.109162. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Yang P., Wang X. COVID-19: a new challenge for human beings. Cell. Mol. Immunol. 2020;17:555–557. doi: 10.1038/s41423-020-0407-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Zhou P., Yang X.-.L., Wang X.-.G., Hu B., Zhang L., Zhang W., Si H.-.R., Zhu Y., Li B., Huang C.-.L., Chen H.-.D., Chen J., Luo Y., Guo H., Jiang R.-.D., Liu M.-.Q., Chen Y., Shen X.-.R., Wang X., Zheng X.-.S., et al. A pneumonia outbreak associated with a new coronavirus of probable bat origin. Nature. 2020;579:270–273. doi: 10.1038/s41586-020-2012-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Zhong H., Zhu Z., Lin J., Cheung C.F., Lu V.L., Yan F., Chan C.-.Y., Li G. Reusable and recyclable graphene masks with outstanding superhydrophobic and photothermal performances. ACS Nano. 2020;14:6213–6221. doi: 10.1021/acsnano.0c02250. [DOI] [PubMed] [Google Scholar]

- 13.Zhang P., Liu F., Liao Q., Yao H., Geng H., Cheng H., Li C., Qu L. A Microstructured graphene/poly(N-Isopropylacrylamide) membrane for intelligent solar water evaporation. Angew. Chem., Int. 2018;57:16343–16347. doi: 10.1002/anie.201810345. Ed. [DOI] [PubMed] [Google Scholar]

- 14.Ren H., Tang M., Guan B., Wang K., Yang J., Wang F., Wang M., Shan J., Chen Z., Wei D., Peng H., Liu Z. Hierarchical graphene foam for efficient omnidirectional solar−thermal energy conversion. Adv. Mater. 2017;29 doi: 10.1002/adma.201702590. [DOI] [PubMed] [Google Scholar]

- 15.Leung C.C., Lam T.H., Cheng K.K.Mass. Masking in the COVID-19 Epidemic: people need guidance. Lancet. 2020;395:945. doi: 10.1016/S0140-6736(20)30520-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Addi R.A., Benksim A., Cherkaoui M. Easybreath Decathlon Mask: an Efficient Personal Protective Equipment (PPE) against COVID-19 in Africa. J. Clin. Exp. Invest. 2020;11:em00738. [Google Scholar]

- 17.Makison Booth C., Clayton M., Crook B., Gawn J.M. Effectiveness of surgical masks against influenza bioaerosols. J. Hosp. Infect. 2013;84:22–26. doi: 10.1016/j.jhin.2013.02.007. [DOI] [PubMed] [Google Scholar]

- 18.MacIntyre C.R., Chughtai A.A. Facemasks for the prevention of infection in healthcare and community settings. BMJ. 2015;350 doi: 10.1136/bmj.h694. No. h694. [DOI] [PubMed] [Google Scholar]

- 19.Leung N.H.L., Chu D.K.W., Shiu E.Y.C., Chan K.-.H., McDevitt J.J., Hau B.J.P., Yen H.-.L., Li Y., Ip D.K.M., Peiris J.S.M., Seto W.-.H., Leung G.M., Milton D.K., Cowling B.J. Respiratory virus shedding in exhaled breath and efficacy of face masks. Nat. Med. 2020 doi: 10.1038/s41591-020-0843-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Booth C.M., Clayton M., Crook B., Gawn J. Effectiveness of surgical masks against influenza bioaerosols. J. Hosp. Infect. 2013;84:22–26. doi: 10.1016/j.jhin.2013.02.007. [DOI] [PubMed] [Google Scholar]

- 21.Shen H., Leonas K. Study of repellent finish of filtration ability of surgical face masks. Int. Nonwovens J. 2005 os-14. [Google Scholar]

- 22.Majchrzycka K., Okrasa M., Szulc J., Jachowicz A., Gutarowska B. Survival of microorganisms on nonwovens used for the construction of filtering facepiece respirators. Int. J. Environ. Res. Public Health. 2019;16:1154. doi: 10.3390/ijerph16071154. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Tian X., Verho T., Ras R.H. Moving superhydrophobic surfaces toward real-world applications. Science. 2016;352:142–143. doi: 10.1126/science.aaf2073. [DOI] [PubMed] [Google Scholar]

- 24.Lafuma A., Quéré D. Superhydrophobic states. Nat. Mater. 2003;2:457–460. doi: 10.1038/nmat924. [DOI] [PubMed] [Google Scholar]

- 25.Liu M., Wang S., Jiang L. Nature-inspired super wettability systems. Nat. Rev. Mater. 2017;2:17036. [Google Scholar]

- 26.Lin Z., Wang Z., Zhang X., et al. Superhydrophobic, photo-sterilize, and reusable mask based on graphene nanosheet-embedded carbon (GNEC) film. Nano Res. 2021;14:1110–1115. doi: 10.1007/s12274-020-3158-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Seo G., Lee G., Kim M.J., Baek S.-.H., Choi M., Ku K.B., Lee C.-.S., Jun S., Park D., Kim H.G., Kim S.-J., Lee J.-O., Kim B.T., Park E.C., Kim S.I. ACS Nano. 2020;14(4):5135–5142. doi: 10.1021/acsnano.0c02823. [DOI] [PubMed] [Google Scholar]

- 28.Sharma A., Sharma N., Kumari A., Lee H.-J., Kim T.Y., Tripathi K.M. Appl. Mater. Today. March 2020;18 [Google Scholar]

- 29.Al-Qatatsheh A., Morsi Y., Zavabeti A., Zolfagharian A., Salim N., Kouzani A.Z., Mosadegh B., Gharaie S. Sensors. 2020;20(16):4484. doi: 10.3390/s20164484. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Pal K., Aljabali A.A.A, Kralj S., Thomas S., Gomes de Souza F. Chemosphere. 2021;263 doi: 10.1016/j.chemosphere.2020.128104. [DOI] [PubMed] [Google Scholar]

- 31.Hiragonda C.B., Kshirsagara A.S., Dhapteb V.V., Khannaa T., Joshia P., Morea P.V. Vacuum. 2018;156:475–482. [Google Scholar]

- 32.Self-Reporting and Photothermally Enhanced Rapid Bacterial Killing on a Laser-Induced Graphene Mask, ACS Nano 2020, 14, 9, 12045–12053. [DOI] [PubMed]

- 33.Li G., Law W.-C., Chan K.C. Floating, highly efficient, and scalable graphene membranes for seawater desalination using solar energy. Green Chem. 2018;20:3689–3695. [Google Scholar]

- 34.Li G., Mo X., Law W.-.C., Chan K.C. Wearable fluid capture devices for electrochemical sensing of sweat. ACS Appl. Mater. Interfaces. 2019;11:238–243. doi: 10.1021/acsami.8b17419. [DOI] [PubMed] [Google Scholar]

- 35.Li G., Mo X., Wang Y., Chan C.-Y., Chan K.C. All 3Dprinted superhydrophobic/oleophilic membrane for robotic oil recycling. Adv. Mater. Interfaces. 2019;6 [Google Scholar]

- 36.Li G., Mo X., Law W.-C., Chan K.C. 3D printed graphene/nickel electrodes for high areal capacitance electrochemical storage. J. Mater. Chem. A. 2019;7:4055–4062. [Google Scholar]

- 37.Ni G., Zandavi S.H., Javid S.M., Boriskina S.V., Cooper T.A., Chen G. A salt-rejecting floating solar still for low-cost desalination. Energy Environ. Sci. 2018;11:1510–1519. [Google Scholar]

- 38.Wu Y., Clark R.L. Controllable porous polymer particles generated by electrospraying. J. Colloid Interface Sci. 2007;310:529–535. doi: 10.1016/j.jcis.2007.02.023. [DOI] [PubMed] [Google Scholar]

- 39.Chua M.H., Cheng W., Goh S.S., Kong J., Li B., Lim J.Y.C., Mao L., Wang S., Xue K., Yang L., Ye E., Zhang K., Cheong W.C.D., Tan B.H., Li Z., Tan B.H., Lo X.J. Face masks in the new COVID-19 normal: materials, testing, and perspectives. Research. 2020;2020 doi: 10.34133/2020/7286735. Article ID: 7286735, 40 pgsDOI: 10.34133/2020/7286735. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Qiu S., Xue M., Zhu G. Metal–organic framework membranes: from synthesis to separation application. Chem. Soc. Rev. 2014;43(16):6116–6140. doi: 10.1039/c4cs00159a. [DOI] [PubMed] [Google Scholar]

- 41.Chen Y., Zhang S., Cao S., et al. Roll-to-roll production of metal-organic framework coatings for particulate matter removal. Adv. Mater. 2017;29(15) doi: 10.1002/adma.201606221. article ID 1606221. [DOI] [PubMed] [Google Scholar]

- 42.Visser C.W., Pohl R., Sun C., Römer G.-W., Huis in ’t Veld B., Lohse D. Toward 3D printing of pure metals by laser-induced forward transfer. Adv. Mater. 2015;27:4087–4092. doi: 10.1002/adma.201501058. [DOI] [PubMed] [Google Scholar]