Abstract

Abstract

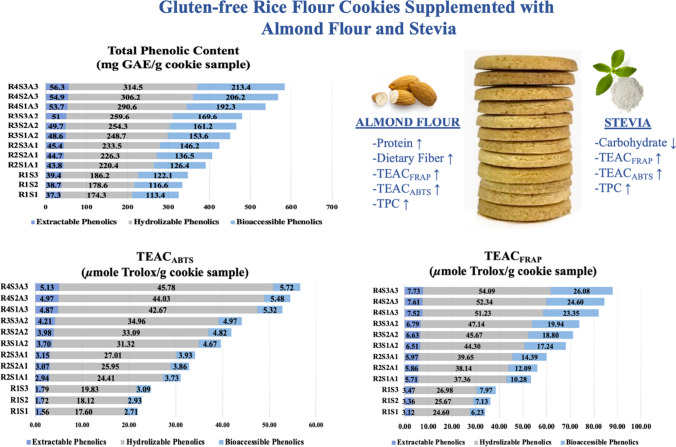

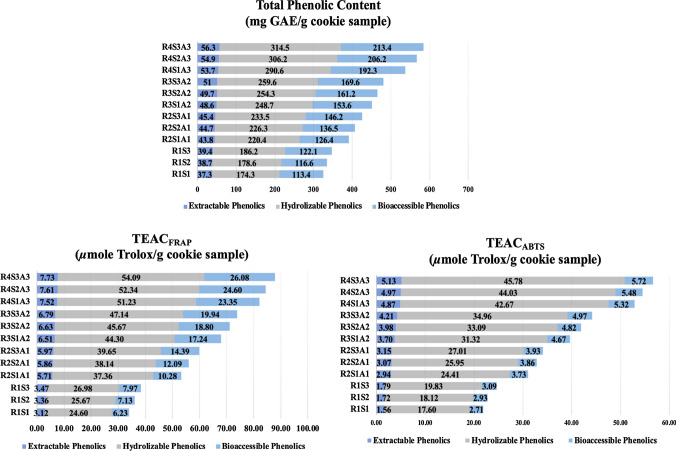

The gluten-free cookies were produced by replacing rice flour (RF) and sucrose content with almond flour (AF) and stevia. Supplementation of AF caused to decrease the moisture content of the gluten-free cookies; while ash, total protein, total fat and total dietary fiber content increased. Regarding of total phenolics; extractable, hydrolyzable and bioaccessible fractions of gluten-free cookie samples that were produced with 30% of AF supplementation, were increased by 43.69–73% compared with the control group that was prepared with 100% RF (p ≤ 0.01). Gluten was detected in the cookies with neither RF nor AF. No cross-contamination was detected during the production, too. Quality characteristics of the gluten-free cookies reached the acceptable level while AF and stevia contents were increased. Protein and dietary fiber contents of the cookie with AF and stevia were enriched to 82 and 96%, while the total carbohydrate amount decreased 19% (p ≤ 0.01). The contents of TEACABTS and TEACFRAP of gluten-free cookies with AF and stevia were 5.72 ± 0.07 and 26.08 ± 0.49 µmol Trolox/g and higher than the control (100% RF + sucrose). It has found that physicochemical, nutrition and sensorial properties of gluten-free cookies that were produced with AF + stevia supplementation provided to produce more acceptable products.

Graphic abstract

Electronic supplementary material

The online version of this article (10.1007/s13197-020-04608-x) contains supplementary material, which is available to authorized users.

Keywords: Cookie, Celiac, Gluten-free, Rice flour, Almond flour, Stevia

Introduction

Gluten is a food component available in some cereals. When some people consumed the foods containing gluten, they are faced with significant health problems, e.g. celiac disease. Celiac disease (CD) is one of the most common disorders associated with food consumption. Due to new ingredients explored and rapidly changing eating habits, the number of people that have been suffered from these health problems is getting increased. However, scientific studies and consumer awareness that were focused on the disorders, intensify day by day. CD has been considered as a global health problem among the most common chronic and autoimmune diseases in recent years (Rubin and Crowe 2020).

Due to CD, protein fractions (glutenin and gliadin) cause inflammation in the upper small intestine and this leads to the destruction of the surface epithelium and flattening of the villi occurs (Green and Cellier 2007). Because of this, foods cannot be absorbed and digested, properly. Therefore, it has been defined that it is a chronic and inflammatory intestine disease triggered by gluten consumption, and continue lifelong. For this reason, the people with CD have to consume gluten-free foods during life-time (Theethira and Dennis 2015). Thus, the consumption of gluten-free foods has great importance for those patients. On the other side, gluten proteins play a key role in the quality of bakery products, as they are responsible for water absorption capacity, viscosity, and flexibility of the dough production (Wieser 2007). Eventually, the development of gluten-free products is unavoidable for bakery producers if the consumption demands of CD patients are considered.

A cookie is one of the most consumed bakery products with attractive palatability in society. It has been preferred as a snack that is cheap, satisfactory food and it has a high nutritional quality according to ingredients added. Rice, bran, starches (potatoes, rice, corn, etc.), buckwheat, tambourine, sorghum, millet, and soy can be used as an alternative ingredient in the production of gluten-free cookie instead of wheat flour (Demirceken 2011). However; rice flour, cornflour, and starches are the ingredients that have been commonly used in the production of gluten-free cookies, their glycemic index (GI) tends to increase depending on their starch-based composition. Therefore, their consumption is risky for the patient suffering from metabolic disorders, e.g. obesity and diabetes. In many studies, it has been aimed to use alternative ingredients to eliminate negative properties of gluten-free cookies, increase their nutritional quality, improve their functional properties and develop sensory properties (Di Cairano et al. 2018). Rice flour is an important and functional ingredient to compose a good dough quality in the production. Therefore, some gluten-free additives are needed to develop in order to produce new cookies that can be consumed by CD patients (Demirceken 2011, Sakač et al. 2015, Di Cairano et al. 2018).

Almond (Prunus amygdalus) contain 35–40% fat, 20–25% protein, 10–15% carbohydrate, and 15–18% total dietary fiber can be used as an alternative gluten-free ingredient. It is a rich nut regarding protein, monounsaturated fatty acids, especially oleic acid (18:1 × 9), tocopherols, dietary fiber, minerals (Ca, P, Cu, Mg, etc.) vitamin E and phytochemicals (phytosterols and polyphenols). Almond has a higher content of phenolic compounds than other nuts such as hazelnut, peanut, cashew, peanut, and macadamia nuts (Takemoto et al. 2001). In addition to its rich nutritional value, almond is a healthy ingredient for bakery applications due to its high dietary fiber content and taste. It was found that almond has a cholesterol-lowering effect. It helps to enrich protein content, amino acid profile, and dietary fiber composition when it is used and ingredient (Mukuddem-Petersen et al. 2005).

Stevia (Stevia rebaudiana Bertoni) is a plant-based natural (100%) and non-toxic sweetener that has been used in food product development in recent years. It has no energy value thus, no effect to change the level of the blood sugar comparing to sucrose. It is 250–300 times sweeter than sucrose. Stevia has been recommended to people with diabetes and obesity, because of its beneficial properties for human health (Panpatil and Polasa 2008).

From the consumer point of view; in addition to nutritional properties, foods can also be preferred to consume due to their health benefits such as antioxidant capacity. During the consumption and digestion of foods, various complex reactions, and processes that include some physicochemical and physiological mechanisms occur (McClements et al. 2008). Due to these complex reactions, it is not possible to digest every part of the food or food component completely. Antioxidants and phenolics are the compounds that can also be affected by these complex digestion processes and therefore, are not fully absorbed and benefitted by the human body. There are two basic terms to define and evaluate absorption capability and readiness to absorption for food components: bioavailability and bioaccessibility. Bioavailability is the amount of ingested component that passes to systemic circulation unchanged while, bioaccessibility is the amount of food component that is released from the food matrix in the intestine and available to absorb and pass to the systemic circulation (Bermúdez-Soto et al. 2007, Porrini and Riso 2008). Bioaccessible contents of the foods are determined by the mimic intestinal digestion procedure that includes extraction and determination of total phenolic content and antioxidant capacity (Apak et al. 2008; Bouayed et al. 2012).

In this research, rice and almond flour-based gluten-free cookies were produced according to the pre-described formulations for patients with celiac and no-celiac patients with gluten sensitivity.

Materials and methods

Materials

RF (Ege Glutensiz, Istanbul, Turkey), AF (Guzel Gida, Istanbul, Turkey), high fructose corn syrup (Cargill Inc. Minnesota, USA), NaHCO3 (Sigma-Aldrich Corp. Missouri, USA) and NH4HCO3 (Sigma-Aldrich Corp. Missouri, USA) was used for gluten-free cookie production. All the other ingredients purchased from a local market from Bursa, Turkey.

Methods

Cookie production

In the gluten-free cookie production, almond flour (AF) was replaced with rice flour (RF) at different ratios (0, 10, 20 and 30%) in order to increase its nutritional composition and sensorial properties. The sucrose content of gluten-free cookies was also replaced with stevia that was used in different ratios (0, 25 and 50%) in order to produce carbohydrate-reduced and gluten-free cookies. The sweetness equivalent principle was considered to adjust added stevia amount instead of sucrose. Gluten-free cookie samples were analyzed in terms of physicochemical, mechanical, textural, nutritional and sensorial properties. The cookie formulations were given in Table 1. Wire-cut cookie procedure was carried out in cookie production specified by AACCI (1995) (Method No: 10.54). Considering that stevia is 200 times sweeter than sucrose (Kulthe et al. 2014); every 8 g of sucrose replaced with 0.04 g stevia powder (8 g/200 = 0.04 g).

Table 1.

Cookie formulations

| Sample | RF:AF (g) | Stevia (g) | Sucrose (g) | Brown Sugar (g) | HFCS (g) | SMP (g) | Salt (g) | NaHCO3 (g) | NH4HCO3 (g) | Shortening (g) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RF | AF | ||||||||||

| R1S1 | 100 | 0 | 0 | 32 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R1S2 | 100 | 0 | 0.04 | 24 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R1S3 | 100 | 0 | 0.08 | 16 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R2S1A1 | 90 | 10 | 0 | 32 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R2S2A1 | 90 | 10 | 0.04 | 24 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R2S3A1 | 90 | 10 | 0.08 | 16 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R3S1A2 | 80 | 20 | 0 | 32 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R3S2A2 | 80 | 20 | 0.04 | 24 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R3S3A2 | 80 | 20 | 0.08 | 16 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R4S1A3 | 70 | 30 | 0 | 32 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R4S2A3 | 70 | 30 | 0.04 | 24 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

| R4S3A3 | 70 | 30 | 0.08 | 16 | 10 | 1.5 | 1.0 | 1.25 | 1.0 | 0.5 | 40 |

R1S1:100% rice flour, 0% stevia; R1S2: 100% rice flour, 25% stevia; R1S3: 100% rice flour, 50% stevia; R2S1A1: 90% rice flour, 10% almond flour, 0% stevia; R2S2A1: 90% rice flour, 10% almond flour, 25% stevia; R2S3A1: 90% rice flour, 10% almond flour, 50% stevia; R3S1A2: 80% rice flour, 20% almond flour, 0% stevia; R3S2A2: 80% rice flour, 20% almond flour, 25% stevia; R3S3A2: 80% rice flour, 20% almond flour, 50% stevia; R4S1A3: 70% rice flour, 30% almond flour, 0% stevia; R4S2A3: 70% rice flour, 30% almond flour, 25% stevia; R4S3A3: 70% rice flour, 30% almond flour, 50% stevia

RF rice flour, AF almond flour, HFCS high fructose corn syrup, SMP skimmed milk powder

Cookies were baked in a convection oven (Inoksan FKE 006, TR) at 170 ± 2 °C for 8 min. After baking, cookies were cooled down at room temperature for 30 min. Physical analyzes such as size measurements, color measurements, texture analysis, and sensorial evaluation were performed 2 h after baking. Then the cookie samples were grounded (Delonghi Kg 49, Italy) and kept in the freezer (− 18 °C) in the sealed bags.

Physico-chemical analysis

Analyses of moisture, ash, protein and fat according to AOAC (1990), dietary fiber with AACC (2000), gluten with AOAC (2015), and total carbohydrates with FAO (2003) were performed. The diameter and thickness of the cookies were measured by caliper and the spread ratio of cookies was determined by the ratio of diameter to thickness for each cookie sample. The color characteristics (Minolta CM-3600d, Osaka, Japan) of the cookies were evaluated in terms of L, a, b values. The hardness of the cookies was evaluated by TA. Texture analyzer (TX2, Stable Micro Systems Ltd., Surrey, UK) equipped with HDP/3BP knife set and HDP/90 heavy-duty platforms. The maximum force required for breaking the cookies was determined in Newton (N).

Antioxidant capacity and phenolic content

Antioxidant capacity (AC) and total phenolic content (TPC) of gluten-free cookie samples analyzed in terms of extractable, hydrolyzable, bioaccessible fractions of phenolics (Bouayed et al. 2012, Vitali et al. 2009). AC was determined with ABTS (2,2-azinobis-[3-ethylbenzothiazoline-6-sulphoni-cacid]) as mentioned by Apak et al. (2008). Ferric Reducing Antioxidant Power Assay (FRAP) was conducted according to Benzie and Strain (1996). The absorbance of the extracts was measured by a spectrophotometer (Jenway 6405 UV/Vis, Mettler Toledo, Milano, Italy), a calibration curve of y = 1978.3x − 4.7115 (R2 = 0.999) was obtained for TEACABTS, a calibration curve of y = 23.343x + 0.0193 (R2 = 0.998) was obtained for TEACFRAP in-between range of 0.02–0.08 µmol Trolox and the results were expressed as µmol Trolox equivalent (TE)/g sample. TPC was evaluated by the Folin-Ciocalteu method according to the procedures of Apak et al. (2008). The absorbance of the extracts was determined spectrophotometrically and a gallic acid calibration curve of y = 0.0026x + 0.0626 (R2 = 0.998) utilized for calculation. The results were expressed as mg gallic acid equivalents (GAE)/100 g. The bioaccessibility rate of phenolics and antioxidant compounds was calculated according to Anson et al. (2009).

Sensorial analysis

Sensory analysis was performed with the participation of 32 (untrained) panelists aged between 22 and 35. Based on the nine-point hedonic scale, cookies were evaluated in terms of color, odor, mouthfeel, taste, overall acceptability. The cookies were scored 5 and over, considered as a consumable gluten-free product.

Statistical evaluation

Data obtained from cookie analyzes were evaluated statistically by using variance analysis with JMP IN 7.0.0 (Statistical Discovery from SAS 2005. Institute Inc.). The LSD test (Least Significant Differences) was used to determine the statistical difference between the mean values obtained.

Results and discussion

The results obtained for chemical properties of RF, AF and cookie samples are given in Table 2. AF was come to the forefront with higher in content of dietary fiber (9.79 ± 0.13%), protein (23.63 ± 0.23%) and fat (57.29 ± 1.23%) than RF with content of dietary fiber (3.02 ± 0.11%), protein (6.71 ± 0.14%) and fat (0.57 ± 0.01%). On the other hand, the moisture content of AF (4.82 ± 0.54%) was lower than the RF (12.04 ± 0.23%). Similar results were observed in previous studies. Sacchetti et al. (2004) determined the content of dietary fiber, ash, fat, protein and moisture belongs to RF respectively as 0.20, 0.60, 1.00, 9.00, 14.00%, while De Pilli et al. (2008) determined the content of ash, moisture, protein, fat belongs to AF respectively as 3.32, 4.67, 22.24, 58.7%. Partial differences have probably arisen from variation between flour varieties, environment and growth conditions and the production methods.

Table 2.

Chemical composition of flour and cookie samples

| Sample | Moisture (%) | Ash (%) | Crude protein (%) | Crude fat (%) | Total dietary fibre (%) | Carbohyrate (%) | Gluten presence (mg/g) |

|---|---|---|---|---|---|---|---|

| RF | 12.04 ± 0.23B | 0.41 ± 0.02B | 6.71 ± 0.14B | 0.57 ± 0.01B | 3.02 ± 0.11B | 80.27 ± 0.17A | nd |

| AF | 4.82 ± 0.54A | 3.54 ± 0.45A | 23.63 ± 0.23A | 57.29 ± 1.23A | 9.79 ± 0.13A | 10.72 ± 0.21B | nd |

| R1S1 | 5.98 ± 0.01a | 1.07 ± 0.01j | 4.47 ± 0.10a | 24.73 ± 0.76h | 0.85 ± 0.01a | 63.75 ± 0.19b | nd |

| R1S2 | 5.95 ± 0.04b | 1.11 ± 0.01ı | 4.71 ± 0.11a,b | 24.26 ± 0.75i | 0.97 ± 0.03b | 63.97 ± 0.11b | nd |

| R1S3 | 5.94 ± 0.03b | 1.13 ± 0.00h | 5.05 ± 0.12b | 22.93 ± 0.71j | 1.01 ± 0.02b | 64.95 ± 0.20a | nd |

| R2S1A1 | 5.93 ± 0.01b | 1.18 ± 0.01g | 5.51 ± 0.13c | 29.32 ± 0.91e | 1.10 ± 0.01c | 58.06 ± 0.17e | nd |

| R2S2A1 | 5.91 ± 0.06c | 1.21 ± 0.02f | 5.68 ± 0.13c,d | 27.77 ± 0.73f | 1.16 ± 0.01d | 59.43 ± 0.10d | nd |

| R2S3A1 | 5.86 ± 0.04d | 1.25 ± 0.00e | 5.79 ± 0.13d | 26.84 ± 0.60g | 1.21 ± 0.03e | 60.26 ± 0.13c | nd |

| R3S1A2 | 5.85 ± 0.01d | 1.29 ± 0.00e | 6.16 ± 0.14e | 35.71 ± 1.11g | 1.30 ± 0.02f | 50.99 ± 0.21i | nd |

| R3S2A2 | 5.83 ± 0.02e,f | 1.31 ± 0.00d | 6.62 ± 0.15f | 32.21 ± 1.00c | 1.38 ± 0.02g | 54.03 ± 0.15g | nd |

| R3S3A2 | 5.82 ± 0.01f | 1.34 ± 0.01c | 7.02 ± 0.16g | 30.36 ± 0.94d | 1.46 ± 0.03h | 55.46 ± 0.12f | nd |

| R4S1A3 | 5.84 ± 0.19e | 1.38 ± 0.00b | 7.43 ± 0.17h | 37.64 ± 1.17a | 1.49 ± 0.05h | 47.71 ± 0.15j | nd |

| R4S2A3 | 5.83 ± 0.01f | 1.44 ± 0.01a | 7.60 ± 0.17h,i | 34.17 ± 1.06b | 1.57 ± 0.02i | 50.96 ± 0.10i | nd |

| R4S3A3 | 5.82 ± 0.06f | 1.46 ± 0.01a | 8.18 ± 0.19ı | 33.14 ± 1.03b | 1.67 ± 0.03j | 51.40 ± 0.01h | nd |

Mean values ± standard deviation with different superscript (Upper case for flour samples; lower case for cookie samples) the same colon are significantly different (p ≤ 0.01)

Detection limit of the Elisa Test for gluten determination:4.69 ppm; nd.: no detection

R1S1:100% rice flour, 0% stevia; R1S2: 100% rice flour, 25% stevia; R1S3: 100% rice flour, 50% stevia; R2S1A1: 90% rice flour, 10% almond flour, 0% stevia; R2S2A1: 90% rice flour, 10% almond flour, 25% stevia; R2S3A1: 90% rice flour, 10% almond flour, 50% stevia; R3S1A2: 80% rice flour, 20% almond flour, 0% stevia; R3S2A2: 80% rice flour, 20% almond flour, 25% stevia; R3S3A2: 80% rice flour, 20% almond flour, 50% stevia; R4S1A3: 70% rice flour, 30% almond flour, 0% stevia; R4S2A3: 70% rice flour, 30% almond flour, 25% stevia; R4S3A3: 70% rice flour, 30% almond flour, 50% stevia

RF rice flour, AF almond flour

Physicochemical and nutritional characteristics of cookies

Moisture and ash content

Moisture content has an important effect on the crunchiness and mechanical strength (crumbliness) of the cookies (Hoseney 1994). As the AF ratio increased in cookie formulation, moisture content of cookies (5.82–5.93%) were decreased significantly compared to control group with 100% RF (5.94–5.97%). AF has a higher total dietary fiber compared to RF. It is thought that dietary fiber absorbs water during kneading, reduces the amount of free water remaining in the system without being absorbed and it helps to reduce the moisture content of the final product. The lower moisture content of AF has an influence over reducing the moisture of cookies. It was also observed that as the stevia amount was increased, moisture content was decreased significantly in the cookies (p ≤ 0.01). The lower moisture content at the final product is important for providing a longer shelf life and an expected crunchy structure.

The richer ash content of AF (3.54 ± 0.45%) provided an increase in the ash amount of the AF cookies significantly (1.18–1.46%) (p ≤ 0.01), and probably provided the richer mineral content. Ahmed et al. (2014), similarly, reported in their study about cookies with tiger nut, as the amount of nut content was increased, ash and mineral content of cookie samples were increased correspondingly. Also, the replacement of sucrose with stevia provided an increase in the ash amount of the cookies as well (p ≤ 0.01).

Protein

The significant increase in the amount of protein content of the cookie samples can be attributed to the higher protein content of the AF (23.63%) than the RF (6.71%) (p ≤ 0.01). Stevia substitution affected the %protein amounts of cookies the same as the study of Kulthe et al. (2014). They associated the increase of the protein content with the replacement of the stevia in the formulation. By reducing the amount of the sucrose in the formulations (replacement with 8 g sucrose to 0.04 g stevia), the dough amount decreases and the ratio of the protein increases in the dough. Sakač et al. (2015) evaluated the gluten-free rice and buckwheat cookies and determined the protein amount of cookies respectively 4.40, 4.48, 4.60, 4.90 g/100 g in control (100% RF), 10%, 20%, 30% buckwheat flour (BWF) replaced cookie samples. The protein content of the control sample (4.40 g/100 g) was in accordance with our control sample (4.47 g/100 g) but AF provided a greater increase in the protein content of gluten-free cookies than the BWF and the protein amount of AF cookies ranged between 5.51 and 8.18 g/100 g.

Fat

The higher fat content of AF (54.53%) provided a significant increase in the fat amount of the rice-based AF gluten-free cookies (p ≤ 0.01). While the control group of cookies with 100% RF were ranged between 22.93 and 24.73 g/100 g, AF cookies were changed between 26.84 and 37.64 g/100 g. Sakač et al. (2015) also determined the fat content of gluten-free RF cookies between 19.60 and 19.9 g/100 g. The shortening amount of the formulation and the high fat content of AF were probable reasons for higher fat content in our gluten-free cookies.

Almonds are one of the recommended foods for human diet owing to their high-fat content (45–55%), and the ratio of monounsaturated and polyunsaturated fatty acids (46–76%) in this fat content (Lapsley and Huang 2004). According to FDA, a daily intake of 11 g almond, meets the required daily amount of low saturated fat and cholesterol amount that should be consumed (Lapsley and Huang 2004). In many publications, AF has been reported to have beneficial effects on human health, such as regulating the blood lipid profile and preventing the risks of cardiovascular diseases, especially owing to the amount of monounsaturated oleic acid and polyunsaturated linoleic acid (Kamil and Chen 2012). In this context, enrichment of cookies with AF, resulted in the improvement of the nutritional potential belongs to the gluten-free cookie formulation.

Dietary fiber

The noticeable dietary fiber content of the AF (9.79 ± 0.13%) was led to improve in dietary fiber content in rice-based gluten-free AF cookies (1.10–1.67%). Stevia replacement in cookie formulation also had an adjuvant effect on dietary fiber content in the final product. According to the EU Regulation (EC No: 1924/2006), the food containing at least 6% dietary fiber content is defined as “food with high dietary fiber source”, and almond is complying with the definition. By the inclusion of AF into the gluten-free cookie formulation, total dietary fiber content (R4S1A3 sample; 1.49 ± 0.05%) was nearly doubled (R1S1 sample; 0.85 ± 0.01%) in cookies. Dhingra et al. (2012) indicated that fiber-rich flours have great potential for improving the nutritional value and food properties. The dietary fiber might change the solubility, viscosity and hydration in bakery products; in terms of health properties they help to stimulate the intestinal process, slowing glucose absorption, decreasing total cholesterol and LDL, promoting the short-chain fatty acid production.

Gluten

According to the results of immunological gluten determination with ELISA gliadin allergen test kit, no gluten was detected in RF nor AF (LOD: 4.69 ppm, Table 2). These results are important in terms of determining that the RF and AF used in production did not contain gluten and they were suitable for the cookie production for celiac patients. Mostly, the immunological gluten determination is not performed within the studies about gluten-free food production; this is an important deficiency in terms of revealing cross-contamination of gluten during the production. As an exceptional study, Sarabhai et al. (2015) applied the Elisa test for gluten-free RF and gliadin content was determined as 2.1 ppm. As a result of the ELISA test, there was also no cross-contamination in our gluten-free cookie production (Detection limit: 4.69 ppm, Table 2). For gluten-sensitive individuals, less than 10 mg daily intake of gluten is determined as a critical level. For the international restrictions; in Spain, Italy, England, Canada, and USA, the gluten limit is 20 ppm, while in Argentina 10 ppm; 3 ppm in Australia, New Zealand and Chile (Bascunan et al. 2017). As a result of the gluten analysis, it was confirmed that the right raw materials were selected and produced correctly in production.

Carbohydrate

For the purpose of obtaining more nutritious gluten-free cookies, the sucrose content of the formulation was replaced with the stevia partially in sweetness equivalent. By the increasing level of AF replacement, the carbohydrate content of gluten-free cookies were decreased significantly (p ≤ 0.01, Table 2). Not only the lower carbohydrate value of AF (10.72 ± 0.21%) in regard to RF (80.27 ± 0.17%) but also the stevia replacement was associated with the reduced carbohydrate content of cookies. Comparing the R1S1 sample (63.75 ± 0.19%) with the R4S1A3 sample (47.71 ± 0.15%), there was an approximately 25% decrease in carbohydrate level. When the stevia replacement is evaluated, the carbohydrate amount of cookies was increased by the increasing replacement amounts; this arose from decreasing the amount of dough because of the weight difference of sucrose and stevia (8 g sucrose vs. 0.04 gr stevia) same in protein and fat content of cookies. Similar results were also obtained by the study of Kulthe et al. (2014), the decrease was observed in the carbohydrate amount of cookies by the defatted soy flour and the stevia leaves powder replacement. Di Cairano et al. (2018) evaluated the gluten-free biscuits in terms of ingredients and their challenges in gluten-free bakery products. The necessity of decreasing the glycemic index of starchy gluten-free products was emphasized. Also, increasing the protein and dietary fiber content by replacing with the carbohydrate in formulations was also advised. Being associated with the quantity of carbohydrate amount, GI is considered as glycemic load. For this purpose, inserting the AF and stevia into the gluten-free cookie formulation helped to produce carbohydrate reduced; protein, dietary fiber, phenolic content enriched gluten-free cookie production.

Phenols, antioxidant capacity and bioaccessibility

TPC of gluten-free cookies were evaluated in terms of extractable, hydrolysable and in-vitro bioaccessible phenolic fractions. Results of analysis are given in Fig. 1. AF added gluten-free cookie samples were determined to have higher TPC than the control group of cookie samples (100% RF samples). There were 43%, 69%, 73% increases respectively in extractable, hydrolysable, bioaccessible fractions in 30% AF cookie samples comparing to the control group of 100% RF samples. Increasing levels of stevia replacement also provided enrichment of the TPC in cookie samples significantly (Fig. 1, p ≤ 0.01). According to % bioaccessibility of phenolics which determined by the calculation of Anson et al. (2009), outstanding raises were observed as 54.12%, 52.42%, 54.60%, 57.55% respectively in R1S2, R2S2A1, R3S2A2, R4S2A3 samples with stevia replacement.

Fig.1.

Total phenolic content and antioxidant capacity results of cookies. R1S1:100% rice flour, 0% stevia; R1S2: 100% rice flour, 25% stevia; R1S3: 100% rice flour, 50% stevia; R2S1A1: 90% rice flour, 10% almond flour, 0% stevia; R2S2A1: 90% rice flour, 10% almond flour, 25% stevia; R2S3A1: 90% rice flour, 10% almond flour, 50% stevia; R3S1A2: 80% rice flour, 20% almond flour, 0% stevia; R3S2A2: 80% rice flour, 20% almond flour, 25% stevia; R3S3A2: 80% rice flour, 20% almond flour, 50% stevia; R4S1A3: 70% rice flour, 30% almond flour, 0% stevia; R4S2A3: 70% rice flour, 30% almond flour, 25% stevia; R4S3A3: 70% rice flour, 30% almond flour, 50% stevia

TEACABTS and TEACFRAP results are also seen in Fig. 1. The bioaccessible fractions for TEACABTS ranged between 2.71 ± 0.02 and 3.09 ± 0.02 µmol Trolox/g sample for 100% RF cookies, TEACFRAP ranged between 3.73 ± 0.04 and 5.72 ± 0.07 µmol Trolox/g sample for the AF containing gluten-free cookies. AF replacement was found more effective in promoting the antioxidant capacity than the stevia replacement according to AC and TPC results. FRAP and ABTS antioxidant capacity assays both have the same reaction mechanism (ET based AC assays) but they have different pH, redox potentials, chemical sensitivity for the different reactive components (Apak et al. 2008). The gluten-free cookies exhibited higher AC results in TEACFRAP than TEACABTS. Antoniewska et al. (2019) associated the antioxidant potential of cookies with polyphenol content and also the compounds forming during the Maillard reactions. Mainly melanoidins were determined to be able to scavenge ABTS and peroxyl radicals in bakery products (Michalska et al. 2008).

TPC and AC results were in accordance with the physico-chemical analysis results, by the increase in AF and stevia amounts, the recipes were enriched in nutritional potential. The hydrolysable fractions were higher than extractable and bioaccessible fractions according to all three antioxidant assays. Depending on the H2SO4-ethanol extraction, higher temperature (85 °C) and longer timer (20 h), the extraction procedure possibly helped for releasing the more phenolic content. Vitali et al. (2009), also found that the ratio of the releasing extractable and hydrolysable fractions of bakery products was affected by the baking process. Bouayed et al. (2011) indicated that the lower bioaccessible phenolic fraction content compared to the total of the extractable and hydrolysable fractions might be the reason for uncompleted degradation or releasing after the in-vitro gastrointestinal digestion. Bioaccessibility of food may also change depending on several factors such as nature of the compound, food matrix, molecular linkage properties, interaction with other compounds, the amount of the compound, intestinal conditions and their absorption (Porrini and Riso 2008).

Giuberti et al. (2018) produced gluten-free RF cookies with alfalfa seed (Medicago sativa L.) flour and evaluated the nutritional properties of cookies by TPC and AC analysis. AF incorporated rice-based gluten-free cookies in our study had higher TPC results (37.3–56.3 mg GAE/g cookie sample) than these gluten-free alfalfa seed incorporated RF gluten-free cookies (22.9 to 112.9 mg GAE/100 g).

Žilić et al. (2016) determined the TPC of anthocyanin-rich corn flour cookies between 192.9 and 251.2 mg GAE/100 g and Jan et al. (2016) determined the TPC of raw and germinated Chenopodium album flour gluten-free cookies as 323.0 and 671.0 mg GAE/100 g. Sakač et al. (2015) also determined the AC of gluten-free rice and buckwheat cookies in terms of DPPH assay and Fe+2 chelating activity as IC50. In DPPH assay, 30% BWF replacement rice-based gluten-free cookies were determined to increase by 60% of the AC. Fe+2 chelating activity had higher antioxidant potential like our TEACFRAP results and provided four times more AC in 30% BWF replaced gluten-free cookies. They also expressed that, the studies about gluten-free cookies generally concentrated on sensorial and physicochemical properties without any functional analysis such as antioxidant activity. The studies which have been conducted in recent years have not yet filled the gap about the gluten-free studies.

The higher TPC and AC content of rice-based gluten-free AF cookies in our study can be attributed to the rich content of protein, monounsaturated fatty acids, tocopherols, dietary fiber, minerals, vitamin E and phytochemicals (Takemoto et al. 2001) of AF. Fatty acid profile and dietary fiber contents of AF were especially responsible for the higher bioaccessible phenolic fractions. Cassady et al. (2009) indicated that the fat content of almond nuts are determined to be effective on the energy balance of human. The dietary fiber content and its impact on decreasing the free fatty acid absorption provide strong satiety properties for humans. Phytochemicals to be presented in almonds and other nuts have bioactive properties on health such as antiproliferative, antiviral, antioxidant, anti-inflammatory and hypocholesterolaemia (Bolling et al. 2010). Because of the rich content and dietary inclusion, nuts are found to be recommended for cardiovascular disease prevention and treatment (Lorenzon dos Santos et al. 2020).

Dimensions of cookies

There are three basic quality criteria for cookies. These are: “Size (as diameter, thickness, and spread ratio)”, “texture” and “color”. Baking performances of the rice-based gluten-free cookies are given in Table 3. The desirable quality of the cookie has been associated with a larger diameter and lower thickness values (Giuberti et al. 2018). There was a significant increase in diameters of cookies by the increasing amount of the AF amount and it was changed between 0.82 and 0.98 cm (p ≤ 0.01).

Table 3.

Physical properties of cookies

| R1S1Sample | Thickness (cm) | Diameter (cm) | Spread ratio | Hardness (N) | L* | a* | b* |

|---|---|---|---|---|---|---|---|

| R1S1 | 0.81 ± 0.02g | 6.00 ± 0.01a | 7.41 ± 0.02f | 57.65 ± 1.92a | 48.74 ± 0.64a | 6.95 ± 0.61f | 23.09 ± 0.05a |

| R1S2 | 0.83 ± 0.03e,f | 5.77 ± 0.04d | 6.95 ± 0.03h | 57.58 ± 1.56d | 50.16 ± 0.98b | 6.53 ± 0.56e | 23.38 ± 0.13a |

| R1S3 | 0.86 ± 0.03c | 5.69 ± 0.03g | 6.62 ± 0.04j | 57.51 ± 3.55g | 50.96 ± 0.74c | 5.95 ± 0.13d | 23.57 ± 0.14a |

| R2S1A1 | 0.82 ± 0.02f,g | 5.90 ± 0.07b | 7.19 ± 0.11d | 57.70 ± 3.21b | 49.98 ± 0.69b | 6.59 ± 0.34e | 23.99 ± 0.13b |

| R2S2A1 | 0.85 ± 0.01c,d | 5.75 ± 0.06e | 6.77 ± 0.04g | 57.63 ± 3.50e | 51.03 ± 0.49c | 5.21 ± 0.03c | 24.19 ± 0.08b |

| R2S3A1 | 0.88 ± 0.01b | 5.67 ± 0.01h | 6.44 ± 0.06ı | 57.54 ± 0.87h | 51.58 ± 1.81c | 4.71 ± 0.64b | 24.47 ± 0.09b |

| R3S1A2 | 0.83 ± 0.04e,f | 5.89 ± 0.08c | 7.09 ± 0.03c | 57.78 ± 0.28b | 52.36 ± 0.73d | 5.38 ± 0.23c | 25.09 ± 0.43c |

| R3S2A2 | 0.85 ± 0.03c,d | 5.72 ± 0.02f | 6.73 ± 0.05e | 57.68 ± 3.44f | 52.50 ± 0.40d | 5.11 ± 0.47c | 25.30 ± 0.32c,d |

| R3S3A2 | 0.97 ± 0.04d,e | 5.65 ± 0.04ı | 5.82 ± 0.08h | 57.59 ± 3.10ı | 52.74 ± 0.63d | 4.17 ± 0.13a | 25.72 ± 0.15d |

| R4S1A3 | 0.84 ± 0.03d,e | 5.85 ± 0.04d | 6.96 ± 0.04b | 57.83 ± 1.09c | 53.36 ± 0.95e | 4.82 ± 0.25b | 25.49 ± 0.43c |

| R4S2A3 | 0.86 ± 0.04d | 5.70 ± 0.01g | 6.63 ± 0.07d | 57.71 ± 4.05g | 53.60 ± 0.27e | 4.77 ± 0.34b | 25.81 ± 0.24d |

| R4S3A3 | 0.98 ± 0.03a | 5.57 ± 0.02j | 5.68 ± 0.04a | 57.63 ± 1.51e | 53.82 ± 0.77e | 3.94 ± 0.03a | 26.03 ± 0.17e |

Mean values ± standard deviation with different superscript in the same colon are significantly different (p ≤ 0.01)

R1S1:100% rice flour, 0% stevia; R1S2: 100% rice flour, 25% stevia; R1S3: 100% rice flour, 50% stevia; R2S1A1: 90% rice flour, 10% almond flour, 0% stevia; R2S2A1: 90% rice flour, 10% almond flour, 25% stevia; R2S3A1: 90% rice flour, 10% almond flour, 50% stevia; R3S1A2: 80% rice flour, 20% almond flour, 0% stevia; R3S2A2: 80% rice flour, 20% almond flour, 25% stevia; R3S3A2: 80% rice flour, 20% almond flour, 50% stevia; R4S1A3: 70% rice flour, 30% almond flour, 0% stevia; R4S2A3: 70% rice flour, 30% almond flour, 25% stevia; R4S3A3: 70% rice flour, 30% almond flour, 50% stevia

Spread ratio

The spread ratio is one of the quality criteria for cookies and expected to show higher values (Giuberti et al. 2018). The effect of change in diameter and thickness was also observed in the spread ratio values, an increasing amount of AF resulted in an inversely correlated decrease in the spread ratio significantly (p ≤ 0.01, Table 3). Higher dietary fiber and protein content of the AF (compared with RF) was probably responsible for the decrease in spread ratio of the gluten-free cookie samples. Becker et al. (2014), evaluated the spread ratio of gluten-free cookies with buriti endocarp flour. They determined that the spread ratio increased by a higher amount of the buriti endocarp flour and this was progressed by the competition of the constituents for the water present in the dough. Therefore, dietary fiber from buriti endocarp flour may reduce the spread ratio of gluten-free cookie samples. It is thought that dietary fiber-rich AF reduced the amount of the free water remaining without the absorption and this may cause an increase in the viscosity and decrease in the spread ratio.

Textural aspects

The textural properties vary depending on the fat and flour properties in the cookie formulation. Shortening and soft wheat flour usage in production ensure the crunchy texture of the desired characteristics of the cookies. The crunchiness is one of the main factors, affecting the quality and textural properties (Hoseney 1994). The AF addition increased the hardness of the cookies significantly compared to the control group of 100% RF samples (p ≤ 0.01, Table 3). The highest breaking force value (57.83 N) was determined in the R4S1A3 sample and the lowest value (57.51 N) was determined in the control group (R1S3). Similarly, de Oliveira Pineli et al. (2015) determined that the addition of baru almond flour increased the hardness of the cookies and they reported that protein and fiber contents are more effective on the texture of starch and lipid. A similar relationship between dietary fiber content and hardness of cookies was evaluated per Ajila et al. (2008) by trying different mango peel levels in cookie samples. Occurring mechanical changes were associated with the increase in dietary fiber, fat and phenolic content, with a decrease in carbohydrate content of samples. The findings of our study are in the same line with the literature, the higher dietary fiber content of AF provided the increase in the hardness of cookie texture.

Color

Color is one of the important quality parameters that provide the charming for the cookies. The properties of flour and starch used in cookie production, have a remarkable effect on color formation. Also, the Maillard reaction that occurs during the cooking process is another effective factor in the color of final products in the bakery (Giuberti et al. 2018). Color properties of gluten-free RF-based cookies are given in Table 3. According to Garcia-Serna et al. (2014), sugar substitution with stevia was affected the cookie color parameters. Non-enzymatic browning reactions during cooking are found to be responsible for the weak color development. AF and stevia had a complex effect on the color development of the cookie, generally, both, provided an increase in L and b values and decreased in a value, and had the lighter color compared with RF-sucrose cookies.

Sensorial properties

Generally, nutritious and healthy food products even if their sensory properties are insufficient, they are consumed by people. Consumers could ignore the sensorial satisfaction and accept some negative sensory changes in a healthier diet (Sabbe et al. 2009). Gluten-free bakery products are also characterized by weaker sensorial properties. They could not provide the expectations, because of the harder structure, darker color, unpleasant view and dry-sandy feeling remaining in the mouth. When the overall acceptance scores were evaluated, AF-cookie scores were significantly higher than the RF-cookie scores (p ≤ 0.01, Table 4). AF-cookies were found acceptable by panelists, due to getting 5 and higher points. Also, the score of cookies with stevia replacement was significantly lower than the control group of cookies (p ≤ 0.01).

Table 4.

Sensorial evaluation of cookies

| Sample | Color | Odor | Crispness | Mouthfeel | Taste | Overall acceptability |

|---|---|---|---|---|---|---|

| R1S1 | 4.9 ± 1.64h | 4.7 ± 1.60h | 4.3 ± 1.64h | 4.8 ± 1.98g | 4.4 ± 1.95g | 4.5 ± 1.71h |

| R1S2 | 4.7 ± 1.84ı | 4.2 ± 1.76ı | 4.1 ± 1.64ı | 4.1 ± 1.98h | 4.1 ± 1.80h | 4.4 ± 1.50ı |

| R1S3 | 4.2 ± 1.86j | 4.2 ± 1.57ı | 3.4 ± 1.92j | 3.9 ± 1.89ı | 4.0 ± 1.80ı | 4.0 ± 1.50j |

| R2S1A1 | 5.4 ± 1.54e | 5.3 ± 1.63f | 5.5 ± 1.98e | 5.4 ± 1.55e | 4.7 ± 1.93e | 5.4 ± 1.80f |

| R2S2A1 | 5.4 ± 1.83e | 5.3 ± 1.58f | 5.4 ± 1.61f | 5.4 ± 1.98e | 4.6 ± 1.95f | 5.3 ± 1.69g |

| R2S3A1 | 5.2 ± 1.30g | 5.0 ± 1.46g | 5.1 ± 2.06g | 5.3 ± 1.80f | 4.6 ± 1.72f | 5.3 ± 1.62g |

| R3S1A2 | 5.8 ± 1.75d | 5.6 ± 1.38d | 5.8 ± 1.41d | 5.5 ± 1.65d | 5.9 ± 1.68e | 5.7 ± 1.60d |

| R3S2A2 | 5.8 ± 1.78d | 5.6 ± 1.50d | 5.8 ± 1.84d | 5.4 ± 1.80e | 5.7 ± 1.79d | 5.7 ± 1.75d |

| R3S3A2 | 5.3 ± 1.61f | 5. 4 ± 1.61e | 5.4 ± 1.69f | 5.4 ± 1.68e | 5.7 ± 2.27d | 5.6 ± 1.93e |

| R4S1A3 | 6.5 ± 1.61a | 6.0 ± 1.61a | 6.3 ± 1.77a | 5.9 ± 1.71a | 6.2 ± 1.99a | 6.0 ± 1.90a |

| R4S2A3 | 6.2 ± 1.72 b | 5.9 ± 1.73b | 6.2 ± 2.05b | 5.8 ± 1.59b | 6.0 ± 2.14b | 5.8 ± 1.91c |

| R4S3A3 | 6.1 ± 1.59 c | 5.7 ± 1.66c | 6.0 ± 1.43c | 5.6 ± 1.82c | 6.0 ± 1.82b | 5.9 ± 1.79b |

9-point hedonic scale with 9-like extremely, 8-like very much, 7-like moderately, 6-like slightly, 5-neither like or dislike, 4-dislike slightly, 3-dislike moderately, 2-dislike very much, and 1-dislike extremely was used

Mean values ± standard deviation with different superscript in the same colon are significantly different (p ≤ 0.01)

R1S1:100% rice flour, 0% stevia; R1S2: 100% rice flour, 25% stevia; R1S3: 100% rice flour, 50% stevia; R2S1A1: 90% rice flour, 10% almond flour, 0% stevia; R2S2A1: 90% rice flour, 10% almond flour, 25% stevia; R2S3A1: 90% rice flour, 10% almond flour, 50% stevia; R3S1A2: 80% rice flour, 20% almond flour, 0% stevia; R3S2A2: 80% rice flour, 20% almond flour, 25% stevia; R3S3A2: 80% rice flour, 20% almond flour, 50% stevia; R4S1A3: 70% rice flour, 30% almond flour, 0% stevia; R4S2A3: 70% rice flour, 30% almond flour, 25% stevia; R4S3A3: 70% rice flour, 30% almond flour, 50% stevia

Conclusion

Gluten-free cookie formulation was produced by using RF and sucrose; RF was replaced with AF 0, 10, 20, 30% ratio and sucrose was replaced with stevia 0, 25 and 50% ratio for new carbohydrate-reduced gluten-free cookie formulation.

AF replacement was found to have richer in terms of ash, protein, fat and dietary fiber contents while the moisture content was lower. According to physical measurements, thickness and hardness were increased while the diameter and spread ratio were decreased in samples (p ≤ 0.01). AF and stevia had a complex effect on the color development, generally, both increased the L and b values and decreased in the a value, and the lighter color than the control group of cookies was obtained in AF-stevia cookies (p ≤ 0.01). There was no gluten content (ELISA gliadin allergen, R-Biopharm AG Darmstadt, Germany) determined in RF, AF nor gluten-free cookie samples. This is indicating the preferring suitable ingredients and completing the gluten-free production without cross-contamination of gluten.

In terms of TPC of cookie samples, 43%, 69%, 73% increases were observed respectively in extractable, hydrolyzable, bioaccessible fractions in 30% AF samples comparing to the control group (100% RF samples). TEACABTS values of the bioaccessible fractions were ranged between 2.71 ± 0.02 and 3.09 ± 0.02 µmol Trolox/g sample for the control group, TEACFRAP values were ranged between 3.73 ± 0.04 and 5.72 ± 0.07 µmol Trolox/g sample for the AF cookies. The highest results were presented in the R4S3A3 sample with 30% AF and 50% stevia replacement.

The high glycemic index of the starchy structure has been an important problem in gluten-free products. Including the AF and stevia into the gluten-free cookie formulation; protein, dietary fiber, phenolic compound contents were enriched and the carbohydrate amount was reduced in produced gluten-free cookies. Besides the nutritional enrichment, AF-stevia gluten-free cookies were provided the quality characteristics and found acceptable according to sensorial evaluation. AF and stevia are determined to be good ingredients for gluten-free cookie production within the context of this study.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC (2000) AACC method 30-25-crude fat in wheat, corn, and soy flour, feed, and mixed feeds. In: Approved Methods of the American Association of Cereal Chemists, 10th edn. St. Paul, MN

- AACCI . Approved methods of American Association of Cereal Chemists International. St. Paul: AACCI; 1995. [Google Scholar]

- Ahmed ZS, Abozed SS, Negm MS. Nutritional value and sensory profile of gluten-free tiger nut enriched biscuit. World J Dairy Food Sci. 2014;9(2):127–134. doi: 10.5829/idosi.wjdfs.2014.9.2.1136. [DOI] [Google Scholar]

- Ajila CM, Leelavathi KUJS, Rao UP. Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J Cereal Sci. 2008;48(2):319–326. doi: 10.1016/j.jcs.2007.10.001. [DOI] [Google Scholar]

- Anson NM, Selinheimo E, Havenaar R, et al. Bioprocessing of wheat bran improves in vitro bioaccessibility and colonic metabolism of phenolic compounds. J Agric Food Chem. 2009;57:6148–6155. doi: 10.1021/jf900492h. [DOI] [PubMed] [Google Scholar]

- Antoniewska A, Rutkowska J, Pineda MM. Antioxidative, sensory and volatile profiles of cookies enriched with freeze-dried Japanese quince (Chaenomeles japonica) fruits. Food Chem. 2019;286:376–387. doi: 10.1016/j.foodchem.2019.02.029. [DOI] [PubMed] [Google Scholar]

- AOAC . Official methods of analysis of Association of Official Analytical Chemists. Washington: AOAC; 1990. [Google Scholar]

- AOAC . Official methods of analysis of Association of Official Analytical Chemists. Washington, USA: AOAC; 2015. [Google Scholar]

- Apak R, Guclu K, Ozyurek M, et al. Mechanism of antioxidant capacity assays and the CUPRAC (cupric ion reducing antioxidant capacity) assay. Microchim Acta. 2008;160:413–419. doi: 10.1007/s00604-007-0777-0. [DOI] [Google Scholar]

- Bascunan KA, Vespa MC, Araya M. Celiac disease: understanding the gluten-free diet. Eur J Nutr. 2017;56(2):449–459. doi: 10.1007/s00394-016-1238-5. [DOI] [PubMed] [Google Scholar]

- Becker FS, Damiani C, de Melo AAM, Borges PRS, Boas EVDBV. Incorporation of buriti endocarp flour in gluten-free whole cookies as potential source of dietary fiber. Plant Food Hum Nutr. 2014;69(4):344–350. doi: 10.1007/s11130-014-0440-y. [DOI] [PubMed] [Google Scholar]

- Benzie IFF, Strain JJ. The ferric reducing ability of plasma (FRAP) as a measure of antioxidant power: the FRAP assay. Anal Biochem. 1996;239:70–76. doi: 10.1006/abio19960292. [DOI] [PubMed] [Google Scholar]

- Bermúdez-Soto MA, Tomás-Barberán FA, García-Conesa MT. Stability of polyphenols in chokeberry (Aronia melanocarpa) subjected to in vitro gastric and pancreatic digestion. Food Chem. 2007;102:865–874. doi: 10.1016/j.foodchem.2006.06.025. [DOI] [Google Scholar]

- Bolling BW, McKay DL, Blumberg JB. The phytochemical composition and antioxidant actions of tree nuts. Asia Pac J Clin Nutr. 2010;19(1):117. [PMC free article] [PubMed] [Google Scholar]

- Bouayed J, Deußer H, Hoffmann L, et al. Bioaccessible and dialysable polyphenols in selected apple varieties following in vitro digestion vs. their native patterns. Food Chem. 2012;131:1466–1472. doi: 10.1016/jfoodchem201110030. [DOI] [Google Scholar]

- Cassady BA, Hollis JH, Fulford AD, Considine RV, Mattes RD. Mastication of almonds: effects of lipid bioaccessibility, appetite, and hormone response. Am J Clin Nutr. 2009;89(3):794–800. doi: 10.3945/ajcn.2008.26669. [DOI] [PubMed] [Google Scholar]

- de Oliveira Pineli LDL, de Carvalho MV, de Aguiar LA, de Oliveira GT, Celestino SMC, Botelho RBA, Chiarello MD. Use of baru (Brazilian almond) waste from physical extraction of oil to produce flour and cookies. LWT-Food Sci Technol. 2015;60(1):50–55. doi: 10.1007/s11130-014-0460-7. [DOI] [PubMed] [Google Scholar]

- De Pilli T, Jouppila K, Ikonen J, Kansikas J, Derossi A, Severini C. Study on formation of starch-lipid complexes during extrusion-cooking of almond flour. J Food Eng. 2008;87(4):495–504. doi: 10.1016/j.jfoodeng.2007.12.028. [DOI] [Google Scholar]

- Demirceken FG. Gluten enteropathy: a classic history and current developments. Curr Gastroenterol. 2011;15(1):58–72. [Google Scholar]

- Dhingra D, Michael M, Rajput H, Patil RT. Dietary fiber in foods: a review. J Food Sci Technol. 2012;49(3):255–266. doi: 10.1007/s13197-011-0365-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Di Cairano M, Galgano F, Tolve R, Caruso MC, Condelli N. Focus on gluten free biscuits: ingredients and issues. Trends Food Sci Technol. 2018;81:203–212. doi: 10.1016/j.tifs.2018.09.006. [DOI] [Google Scholar]

- FAO, Food and Agriculture Organization (2003) Food energy—methods of analysis and conversion factors. Report of a technical workshop. FAO Food and Nutrition Paper No. 77, Rome

- Garcia-Serna E, Martinez-Saez N, Mesias M, Morales FJ, del Castillo MD. Use of coffee silverskin and stevia to improve the formulation of biscuits. Pol J Food Nutr Sci. 2014;64(4):243–251. doi: 10.2478/pjfns-2013-0024. [DOI] [Google Scholar]

- Giuberti G, Rocchetti G, Sigolo S, Fortunati P, Lucini L, Gallo A. Exploitation of alfalfa seed (Medicago sativa L.) flour into gluten-free rice cookies: nutritional, antioxidant and quality characteristics. Food Chem. 2018;239:679–687. doi: 10.1016/j.foodchem.2017.07.004. [DOI] [PubMed] [Google Scholar]

- Green PH, Cellier C. Celiac disease. N Engl J Med. 2007;357(17):1731–1743. doi: 10.1056/NEJMra071600. [DOI] [PubMed] [Google Scholar]

- Hoseney RC. Principles of cereal science and technology. St. Paul: American Association of Cereal Chemists. Inc.; 1994. p. 170. [Google Scholar]

- Jan R, Saxena DC, Singh S. Physico-chemical, textural, sensory and antioxidant characteristics of gluten-free cookies made from raw and germinated Chenopodium (Chenopodium album) flour. LWT-Food Sci Technol. 2016;71:281–287. doi: 10.1016/j.lwt.2016.04.001. [DOI] [Google Scholar]

- Kamil A, Chen CYO. Health benefits of almonds beyond cholesterol reduction. J Agric Food Chem. 2012;60(27):6694–6702. doi: 10.1021/jf2044795. [DOI] [PubMed] [Google Scholar]

- Kulthe AA, Pawar VD, Kotecha PM, Chavan UD, Bansode VV. Development of high protein and low-calorie cookies. J Food Sci Technol. 2014;51(1):153–157. doi: 10.1007/s13197-011-0465-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lapsley KG, Huang G. Health benefits of almonds. Cereal Food World. 2004;49(1):6. [Google Scholar]

- Lorenzon dos Santos J, Quadros ASD, Weschenfelder C, Garofallo SB, Marcadenti A. Oxidative stress biomarkers, nut-related antioxidants, and cardiovascular disease. Nutrients. 2020;12(3):682. doi: 10.3390/nu12030682. [DOI] [PMC free article] [PubMed] [Google Scholar]

- McClements DJ, Decker EA, Park Y, Weiss J. Designing food structure to control stability, digestion, release and absorption of lipophilic food components. Food Biophys. 2008;3(2):219–228. doi: 10.1007/s11483-008-9070-y. [DOI] [Google Scholar]

- Michalska A, Amigo-Benavent M, Zielinski H, del Castillo MD. Effect of bread making on formation of Maillard reaction products contributing to the overall antioxidant activity of rye bread. J Cereal Sci. 2008;48(1):123–132. doi: 10.1016/j.jcs.2007.08.012. [DOI] [Google Scholar]

- Mukuddem-Petersen J, Oosthuizen W, Jerling JC. A systematic review of the effects of nuts on blood lipid profiles in humans. J Nutr. 2005;135(9):2082–2089. doi: 10.1093/jn/135.9.2082. [DOI] [PubMed] [Google Scholar]

- Panpatil VV, Polasa K. Assessment of stevia (Stevia rebaudiana)-natural sweetener: a review. J Food Sci Technol. 2008;45(6):467. [Google Scholar]

- Porrini M, Riso P. Factors influencing the bioavailability of antioxidants in foods: a critical appraisal. Nutr Metab Cardiovas. 2008;18:647–650. doi: 10.1016/j.numecd.2008.08.004. [DOI] [PubMed] [Google Scholar]

- Rubin JE, Crowe SE. Celiac disease. Ann Intern Med. 2020;172(1):ITC1–ITC16. doi: 10.7326/AITC202001070. [DOI] [PubMed] [Google Scholar]

- Sabbe S, Verbeke W, Deliza R, Matta V, Van Damme P. Effect of a health claim and personal characteristics on consumer acceptance of fruit juices with different concentrations of açaí (Euterpe oleracea Mart.) Appetite. 2009;53(1):84–92. doi: 10.1016/j.appet.2009.05.014. [DOI] [PubMed] [Google Scholar]

- Sacchetti G, Pinnavaia GG, Guidolin E, Dalla Rosa M. Effects of extrusion temperature and feed composition on the functional, physical and sensory properties of chestnut and rice flour-based snack-like products. Food Res Int. 2004;37(5):527–534. doi: 10.1016/j.foodres.2003.11.009. [DOI] [Google Scholar]

- Sakač M, Pestorić M, Mišan A, Nedeljković N, Jambrec D, Jovanov P, Mandić A. Antioxidant capacity, mineral content and sensory properties of gluten-free rice and buckwheat cookies. Food Technol Biotechnol. 2015;53(1):38–47. doi: 10.17113/ftb.53.01.15.3633. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sarabhai S, Indrani D, Vijaykrishnaraj M, Kumar VA, Prabhasankar P. Effect of protein concentrates, emulsifiers on textural and sensory characteristics of gluten free cookies and its immunochemical validation. J Food Sci Technol. 2015;52(6):3763–3772. doi: 10.1007/s13197-014-1432-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Takemoto E, Okada IA, Garbelotti ML, Tavares M, Aued-Pimentel S. Composição química da semente e do óleo de baru (Dipteryx alata Vog.) nativo do Município de Pirenópolis, Estado de Goiás. Revista do Instituto Adolfo Lutz. 2001;60(2):113–117. [Google Scholar]

- Theethira TG, Dennis M. Celiac disease and the gluten-free diet: consequences and recommendations for improvement. Dig Dis. 2015;33(2):175–182. doi: 10.1159/000369504. [DOI] [PubMed] [Google Scholar]

- Vitali D, Vedrina Dragojevic I, Sebecic B. Effects of incorporation of integral raw materials and dietary fiber on the selected nutritional and functional properties of biscuits. Food Chem. 2009;114:1462–1469. doi: 10.1016/j.foodchem.2008.11.032. [DOI] [Google Scholar]

- Wieser H. Chemistry of gluten proteins. Food Microbiol. 2007;24(2):115–119. doi: 10.1016/j.fm.2006.07.004. [DOI] [PubMed] [Google Scholar]

- Žilić S, Kocadagli T, Vančetović J, Gokmen V. Effects of baking conditions and dough formulations on phenolic compound stability, antioxidant capacity and color of cookies made from anthocyanin-rich corn flour. LWT-Food Sci Technol. 2016;65:597–603. doi: 10.1016/j.lwt.2015.08.057. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.