Abstract

Traditional foods are known as special products that do not have a specific production technology and are transferred traditionally from generation to generation. The most important feature that distinguishes Gelveri bread from the other bread is the use of sourdough technique and cooking in stone kilns. It is one of the traditional foods produced in Turkey for hundreds of years. We believe that standardization and commercialization of Gelveri bread will be challenging initiative to contribute to the local and national economy. Therefore, this study aimed to investigate the possibility of using infrared (IR) and ultraviolet-C technologies in the commercialization of traditional Gelveri bread production that abides by the sourdough technique. Traditionally Gelveri bread dough was prepared and cooked with the infrared oven designed for this study. Following the cooking step, some physicochemical and microbiological quality characteristics and shelf life of the Gelveri bread were investigated. The results indicated that the microbiological quality and shelf life were improved with the IR application without effecting the other quality parameters. On the other hand, a small decrease in pH was observed. As a result, it was concluded that if IR furnace integrated into the stone kilns, the quality of the bread might be standardized, and the sustainability of the traditional method will be ensured.

Keywords: Gelveri bread, Traditional foods, Infrared and ultraviolet-C applications, Microbial quality, Shelf life

Introduction

Because of its high content of carbohydrates, bread has been one of the basic foodstuffs that had great importance in the nutrition of all societies throughout the history and still continues to maintain its position today. Besides being an energy-supplying and satisfying foodstuff, it has been a well-accepted base and/or supplementary flavor when consumed with the other foods. According to the Turkish Food Codex Communiqué for Bread and Bread Varieties, bread is defined as: “is the product of added water, salt and yeast (Saccharomyces cerevisiae) when necessary, sugar and enzymes as a source of malt flour, vital gluten and the permitted other additives into the wheat flour; and kneading, shaping, fermentation and cooking of this mixture in accordance with the technique” (Elgün and Ertugay 1995; Kotancılar et al. 1995). Additionally, bread types are defined as, “in addition to the ingredients mentioned in the definition of bread, produced in accordance with the technique including the cereals and, if desired, condiments.” (Özkaya 1986; Boyacıoğlu 1993; Communique No: 2012/2). Therefore, the addition of any flavor to bread content is expressed as the bread variety. There have been many types of bread produced in the world due to some factors such as fermentation, formulation, shape and size, specific volume, shell properties and the characteristics of the bread structure (Elgün and Ertugay 1995; Demirkesen et al. 2010; Ertugay 2010).

In many countries, it is known that bread variety is very wide, and even in some countries, country-specific traditional bread is also produced (Erdem et al. 2017). Nowadays, the number of breads producing factories using high technology has increased, but some small enterprises produce different types of bread locally that revere the traditional bread variety (Karaağaoğlu et al. 2008; Albayrak and Gunes 2010; Beşirli 2010; Altuntaş and Gülçubuk 2014). Because of this situation and the richness in Turkey's ethnic diversity, traditional varieties of bread in Turkey are deemed plenty (Hatipoğlu et al. 2013; Kocatepe and Tırıl 2015; Gökmen et al. 2016).

Gelveri bread as an example is one of the traditional breads from Güzelyurt district of Aksaray Province in Turkey. Gelveri bread is a regional bread made by the sourdough method and the locally produced from wheat flour. Studies on Gelveri bread are limited to a few publications because a master-apprentice is necessary for production of the traditional bread which has been fulfilled by the residents in Güzelyurt themselves that only the aged skillful family members have this capacity (Acar 2016a, b, 2017; Gümüş etal. 2017; Erdem et al. 2017). In Gelveri bread production, stone kilns are used that constructed from special rocks, and it is one of the traditions that still maintained for centuries by the local people. The type of oven and properties of the flour used in the bread affects the quality parameters of the product (Koçan and Yapıcı 2012; Demir 2016; Uçar 2016; Zencir et al. 2018). There are 2 main features in the production of Gelveri bread:

Using the sour-dough method and

Baking in the traditional stone furnaces, kiln (Fig. 1).

Fig. 1.

The stone kiln used for baking of traditional Gelveri Bread

The First step for the production of Gelveri bread is the preparation of dough in accordance with the traditional sourdough method. In this way, different types of bacteria and yeast proliferated in the dough act as a leavening agent and cooperate with the fermentation process. Therefore, due to the natural flora, the Gelveri bread has a strong flavor, suitable rising volume and dough structure with a long shelf life (Erdem et al. 2017). After the preparation of dough, the second step is the baking in the stone kilns that constructed traditionally.

In the traditional method, there is no homogenous moisture content or moisture standardization in the bread and oven stone systems require also mastery. Again, due to the lack of standardization in baking, the shelf life of the bread varies much but currently it is not long. Gelveri bread currently is not a commercial bread because it is prepared and baked once a week in the stone kilns by voluntary cooperation of the women living in Güzelyurt region (Demir 2016).

Recently, food applications of IR have become relatively popular especially in baking bread, biscuits, crackers, and cakes (Tuncel and Tuncel 2016). It has been reported that IR technology in the food industry is also being used from drying to sterilization (Özkoç 2010) and from cooking to microbial and enzyme inactivation purposes (Krishnamurthy et al 2008). Besides all, it can also be used to measure color, shell thickness, volume, textural and sensory properties of the different materials (Keskin et al. 2004; Shyu et al. 2008). On the other hand, UV-C is generally preferred to increase microbial quality in the food industry (Gökmen et al. 2019). It has also been used in cold sterilization of fruit juice, milk, drinking water and food packaging (Gökmen et al. 2015). The combined usage of UV and IR technology is reported in some spices and stuffed pasta (manti) production processes (Tuncel and Tuncel 2016; Gökmen et al. 2019), but there is no example for industrial usage of the combination of both techniques.

Therefore, in this study, the applicability of infrared (IR) drying technology and ultraviolet-C (UV-C) techniques were investigated as a standardization method in the Gelveri bread production. The aim is not to develop a new technology that will completely replace the traditional method but to integrate the new technology with the traditional one. Sourdough and stone kilns are the two specific parameters that make the traditional Gelveri bread. Hence, the sourdough was used in the same way, and IR furnace was also introduced instead of using a stone kiln alone. It was also among the purposes of this study to extend the shelf life and to help commercialization of the Gelveri bread.

Material and method

Material

Gelveri Bread, prepared and baked by traditional methods in Güzelyurt district of Aksaray Province, was used as a control sample. The raw materials for the production of the test samples of Gelveri bread were the mixture of 3 different wheat flour (all-purpose, bread and pastry flours mixed in 1/3 ratios), tape water, table salt and sourdough (as leavened). All these materials were supplied from the local bakery store that produces Gelveri Bread in accordance with the Turkish Standards Institution (TSE) standards.

Gelveri bread production

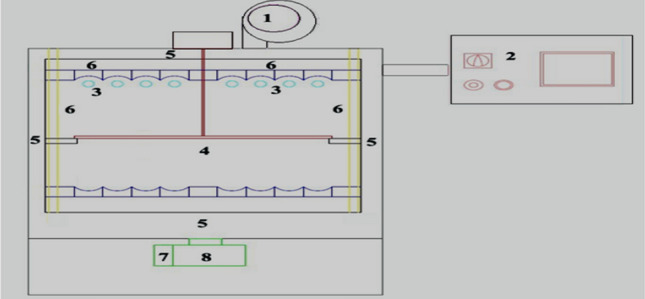

Traditional Gelveri bread production includes the following steps. After mixing and kneading the raw materials, the prepared dough was left to fermentation for overnight. Then, the fermented dough was allocated to the equally weighed lump of dough and shaped. Finally, the shaped dough pieces were cooked for 45 min with the infrared oven designed for this study. (Fig. 2).

Fig. 2.

The designed IR oven and its sections or components [1, the machine body; 2, heating plate; 3, lamps (IR and UV-C); 4, scales and tray; 5, suction fan; 6, calpe (cover); 7, vacuum indicator; 8, vacuum pump]. IR lamps: 500 W shortwave and bar type, 3 pieces (15 cm), UV lamps: 50 W short wavelength and rod type, 3 pieces (90 cm)

The trials were carried out as 5 pieces replicate (5 lumps of dough baked at the same time) with 3 parallel (as technical replicas), and finally, 15 bread were produced and analyzed for each case (trial). Then the samples of each trial were stored in plastic bags for 15 days at room temperature to observe the shelf life.

Chemical analysis

Moisture content (%) of the samples was determined gravimetrically by drying at 100 ± 2 ºC until to get constant weight.

pH of the samples was determined with the aid of a pre-calibrated pH meter (Inolab-pH 7110, GER). For this purpose, 10 g of bread was homogenized with 90 mL of distilled water and then the pH values were measured (Elgün and Ertugay 1995).

Microbiological analysis

For microbiological analysis, 20 g of each bread sample was weighed and homogenized in 100 ml with the sterile isotonic solution (% 0.9 NaCl). After preparation of the appropriate dilutions, they were inoculated on Potato Dextrose Agar (PDA) for total yeast and molds and Plate Count Agar (PCA) for total mesophilic aerobes. After incubation at 30–35 °C either for 16–18 h for bacteria or 5 days for mold and yeast, the formed colonies were counted. Inoculation procedures were repeated at the beginning, first week and second week of the storage periods.

Sensory analysis

Sensory analysis was performed by using the interview form (Table 1). For this purpose, interviews were arranged in a face to face set-up with different occupational groups residing in Güzelyurt (a totally 10 people consisted of hostel operators, academic and administrative staff of the university, security officers, restaurant owners, and chefs). The panelists were especially chosen from that the people who were accustomed to the taste of Gelveri bread and living in Guzelyurt region (Table 1).

Table 1.

Interview form used for the determination of sensorial preferences of the Gelveri breads produced

| Determination of differences between the Gelveri bread baking with traditional and infrared oven methods |

|---|

| Date of Interview:……………….. |

| 2. Birth Date:……………… |

| 3. Profession:……………………… |

| 4. Can you see the difference in appearance and shape, and if so, what are those? |

| 5. Would you rate it in terms of volume of the bread? |

| 6. Would you rate it in terms of aroma, taste, and odor? |

| 7. Would you rate it in terms of baking condition? |

| 8. Would you rate it in terms of bread-inside structure? |

| 9. Is there any other information you would like to add? |

Statistical analysis

The difference between the samples of the trials and the storage times were evaluated by using the JMP 12.0 statistical analysis program in a confidence interval of 95% (Sall et al. 2012).

Results and discussion

In this study, it is aimed to increase microbial quality and to preserve the physicochemical and sensory properties of traditionally produced Gelveri bread by using infrared (IR) oven which is designed by this research group instead of the stone oven. The results showed that while the microbial quality increased with IR application, the overall quality of the bread is mostly retained too.

Physicochemical analysis

There was no statistically significant differences (p > 0.05) between the samples in terms of their initial and storage-related moisture contents, IR and control groups (Table 2). On the other hand, the pH values of the IR treated samples were lower than those of the traditional samples (controls) (Table 3).

Table 2.

Moisture contents (%) of the Gelvery breads produced with traditional oven and IR application

| Time of process | Traditional method | IR method |

|---|---|---|

| 1st day | % 60.70 Aa | % 58.50 Aa |

| 7th day | % 60.00 Aa | % 56.50 Aa |

| 14th day | % 59.00 Aa | % 61.50 Aa |

The capital letters in the same row are the comparison of cooking methods. There was no statistically significant differences between the same capital letters in the same row (p > 0.05). Lowercase letters in the same column are the comparison of storage time. Again, there was no statistically significant differences between the same lowercase letters in the same column (p > 0.05)

Table 3.

pH values of the Gelvery breads produced in this study

| Storage time | Traditional method | Infrared method |

|---|---|---|

| 1st day | 7.14 Aa | 5.97 Ba |

| 7th day | 7.09 Aa | 5.79 Ba |

| 14th day | 7.14 Aa | 5.65 Ba |

The capital letters in the same row are the comparison of cooking methods. There was no statistically significant differences between the same capital letters in the same row (p < 0.05). The lowercase letters in the same column are the comparison of storage time. Again, there was no statistically significant differences between the same lowercase letters in the same column (p > 0.05)

Microbiological analysis results

The total number of yeast-mold and bacteria was examined in the bread samples. The results showed that although there was some colony formation in the control group, there was no growth (total bacteria, yeast, and mold) in the IR applied samples (test group) both initially and during storage (Table 4). On the first day of incubation, there were only 2 different colonies on the APC agar plates of control breads. This could be due to the environment of the stone-oven and the duration of the cooking. After a week, besides high number of bacteria colony formation, the mold growth was also started on the control samples (Table 4). Therefore, it is concluded that applying the IR technology on the cooking process might be better for the microbial quality of the Gelveri breads compared to the traditional method.

Table 4.

Microbiological analysis results of Gelvery breads baked with different methods

| Time/process | Traditional method | Infrared method | ||

|---|---|---|---|---|

| Total bacteria | Yeast and mold count | Total bacteria | Total yeast and mold | |

| 1st day | < 10 cfu/g | < 10 cfu/g | No growth | No growth |

| 7th day | UC | UC | No growth | No growth |

| 14th day | UC | UC | No growth | No growth |

UC, Uncountable; No growth, No colony was detected

Sensory analysis

In the sensory analysis, it was observed that the IR baked samples were different from the traditional ones in terms of softness and aroma profile. Again, it was expressed by the panelists that the bread baked in the IR oven was harder in texture and sourer in taste compare to the bread baked in the traditional stone oven.

In the commercialization studies of the local food products, there might always have some problems in maintaining the quality and standardization of the product. Taking this into consideration, it is aimed to use infrared technology within the scope of the new generation food technology which would shed light on the commercialization of Gelveri bread baked in traditional furnaces by traditional methods. Therefore, the feasibility of the infrared oven method as an alternative to the traditional stone method was investigated in the cooking process of Gelveri Bread.

Although there was not much difference in the physicochemical features of the products obtained in both processes, the sensory quality decrease was observed with the IR application. For instance, bread surface was harder and pH value was lower in IR applied brads than those of the traditional counterparts. The reason for hardness is might be due to the baking time (45 min) in the IR oven which was longer than that of the traditional ovens (10 min). Although the cooking time with IR seems to be longer, but when the whole process was considered, the time needed for the preparation of traditional oven before the baking (approximately 30 min) and plus 10 min for cooking is a total of 40 min.

The reason for the sour taste found by the panelists might be due to the lower pH value of the IR samples compared to the traditional ones. It should also be taken into account that the panelists were from the same local region who got used to the taste of traditional Gelveri bread. Another reason might that the bread produced with sourdough is not a habit of consuming our people except for local people (Yiğit and Doğan 2010; Acar 2016a, b, Akgün 2007; Bircan et al. 2017). Besides, baking bread with traditional methods requires mastery, especially in old-style furnaces. However, this method can easily be standardized with IR technology.

In previous studies, it was determined that according to the results of microbiological analysis in IR applied bread samples, microbiological deterioration time was longer (Wade 1987; Ertekin 2013; Gökmen et al. 2019) which might be due to the lower pH value and drier crust, bread surface. In the result, it could be stated that the use of IR technology in the Gelveri bread production might extend the shelf life of the product (Table 4).

Conclusion

While traditional foods show the cultural values and lifestyle of the local people, the commercialization of such products in the global market may end up their recognition and dissemination which also contributes to both the local and national economy of the people. Since the traditional production method of Gelveri bread is not very suitable for the commercialization or at least meet the demand, different production processes need to be developed. It is important to abide by the traditional methods at this stage. One of the most important features in the traditional Gelveri bread production is the use of sourdough technique, while the other criteria is an old fashion stone oven. In this research, the sourdough technique was preserved while IR technology was used in place of stone kilns. If IR furnace integrated into the stone kilns and the complete process carried out as traditional, the traditional method will also be adhered to completely. Hence, the quality of the bread will be standardized, and the sustainability of the traditional method will be secured. As a result, the microbiological quality and shelf life of the bread were increased with the IR integration with the traditional furnace. Therefore, it might be concluded that the integrated system of IR with the kiln might be a suitable technique for the commercialization of traditional Gelveri bread production.

Acknowledgements

Any information that would reveal author(s) identity should be placed here, as JFST follows a double blind review process, at the time of initial submission and revision(s): Gelveri bread, Traditional foods, Infrared and ultraviolet-C applications, Microbial quality, Shelf life

Abbreviations

- IR

İNfrared

- uv

Ultraviolet

- cfu

Colony forming unit

- UC

Uncountable, too many

- calpe

Cover

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Acar Y. Gastronomi turizmi kapsamında Aksaray ili Güzelyurt (Gelveri) yöresel mutfağının unutulmaya yüz tutmuş tatlarının değerlendirilmesi. JOTAGS. 2016;4:81–86. doi: 10.21325/jotags.2016.8. [DOI] [Google Scholar]

- Acar Y. Aksaray İli Güzelyurt İlçesi (Gelveri) Potansiyelinin Ekomüzecilik Kapsamında SWOT Analizi ile Değerlendirilmesi. Çatalhöyük Uluslararası Turizm ve Sosyal Araştırmalar Dergisi. 2016;1:321–330. [Google Scholar]

- Acar DY. Requirements for the pres güzelyurt. Int J Curr Res Key. 2017;9:49588–49592. [Google Scholar]

- Akgün FB. Ekşi hamur tozu eldesi ve ekmek üretiminde kullanılabilme olanakları. Denizli: Pamukkale Üniversitesi Fen Bilimleri Enstitüsü Yüksek Lisans Tezi; 2007. [Google Scholar]

- Albayrak M, Gunes E. Traditional foods: Interaction between local and global foods in Turkey. Afr J Bus Manag. 2010;4:555–561. [Google Scholar]

- Altuntaş A, Gülçubuk B. Yerel kalkınmada yaygınlaşan bir araç olarak geleneksel gıdalar ve geleneksel gıda mevzuatının yaygınlaştırılabilirliği. GOP Üniv Ziraat Fak Derg. 2014;31:73–81. [Google Scholar]

- Beşirli H. Yemek, kültür ve kimlik. Milli Folklor. 2010;22:159–169. [Google Scholar]

- Bircan D, Güray CT, Bostan K. Farklı Yöntemlerle Ekşitilmiş Hamurlardan Ekmek Yapımı Üzerine Çalışmalar. Aydın Gastron. 2017;1:1–8. [Google Scholar]

- Boyacıoğlu H. Ekmeğin bayatlaması, tanımı, teoriler, tayin yöntemleri ve yavaşlatma yolları. Unlu Mamuller Dünyası. 1993;2:15–18. [Google Scholar]

- Demir G (2016) Traditional sample of solidarity and charity: Imece. In: Proceedings of the12th international conference of ASECU, vol 1, pp 165–171

- Demirkesen I, Mert B, Sumnu G, Sahin S. Rheological properties of gluten-free bread formulations. J Food Eng. 2010;96:295–303. doi: 10.1016/j.jfoodeng.2009.08.004. [DOI] [Google Scholar]

- Elgün A, Ertugay, Z (1995) Tahıl İşleme Teknolojisi. Atatürk Üniversitesi Ziraat Fakültesi Yayınları, Yayın No: 718 Ankara

- Erdem N, Işık N, Gökmen S. Aksaray İli Güzelyurt İlçesi'nin Geleneksel Bir Gıdası Gelveri Ekmeği. JOTAG. 2017;1:534–545. doi: 10.21325/jotags.2017.164. [DOI] [Google Scholar]

- Ertekin C. İnfrared kurutucu ile kerevizin kurutulması. Tralleis. 2013;2:16–25. [Google Scholar]

- Ertugay Z. Buğday, un ve ekmek arasındaki kalite ilişkileri. J Fac Agric. 2010;13:165–176. [Google Scholar]

- Gökmen S, Aydın MF, Kocabaş A, Sayaslan A, Yetim H, Çağlar A. A study on quality criteria of commercial stuffed pasta (mantı), as traditional food. IFRJ. 2015;22:2018–2024. [Google Scholar]

- Gökmen S, Sayaslan A, Çağlar A. Mantıda Farklı Kurutma Yöntemlerinin Hidroksimetil Furfural (HMF) Oluşumu ve Duyusal Kalite Üzerine Etkileri. Cumhuriyet Üniversitesi Fen-Edebiyat Fakültesi Fen Bilimleri Dergisi. 2016;37:176–186. [Google Scholar]

- Gökmen S, Kocabaş A, Savran I, Sayaslan A, Aydin MF, Yetim H. Effect of infrared, ultraviolet-C radiations and vacuum drying on certain chemical and microbial characteristics of stuffed pasta (Manti) JAS. 2019;25:100–107. [Google Scholar]

- Gümüş D, Uray G, Gümüş KS. Sosyo-Ekonomik Kalkınmada Sanat Eserleri: Aksaray İli Güzelyurt (Gelveri) İlçesinde Mimarî Yapılarda Görülen Bitkisel Figürlü Taş Bezemeler ve Anlamları. J Int Soc Res. 2017;10:371–380. doi: 10.17719/jisr.20175334126. [DOI] [Google Scholar]

- Hatipoğlu A, Zengin B, Batman O, Şengül S. Yöresel yemeklerin, kırsal turizm işletmeleri mönülerinde kullanım düzeyleri: Gelveri Örneği. IJSES. 2013;1:6–11. [Google Scholar]

- Karaağaoğlu N, Karabudak E, Yavuz S, Yüksek O, Dinçer D, Tosunbayraktar G, Eren FH. Çeşitli ekmeklerin protein, yağ, nem, kül, karbonhidrat ve enerji değerleri. J Food. 2008;33:19–25. [Google Scholar]

- Keskin SO, Sumnu G, Sahin S. Bread baking in halogen lamp–microwave combination oven. Food Res Int. 2004;37:489–495. doi: 10.1016/j.foodres.2003.10.001. [DOI] [Google Scholar]

- Kocatepe D, Tırıl A. Sağlıklı beslenme ve geleneksel gıdalar (Healthy nutrition and traditional foods) JOTAG. 2015;3:55–63. [Google Scholar]

- Koçan D, Yapıcı Y. Güzelyurt’un Geleneksel Gelveri Ekmeği III. Geleneksel Gıdalar Sempozyumu Bildiriler. 2012;2:375–376. [Google Scholar]

- Kotancılar G, Çelik İ, Ertugay Z. Ekmeğin besin değeri ve beslenmedeki önemi. Atatürk Üniversitesi Ziraat Fakültesi Dergisi. 1995;26:431–441. [Google Scholar]

- Krishnamurthy K, Khurana HK, Soojin J, Irudayaraj J, Demirci A. Infrared heating in food processing: an overview. CRFSFS. 2008;7:2–13. [Google Scholar]

- Özkaya H. Buğday, un ve ekmeğin besin değeri ve ekmeğin zenginleştirilmesi. J Food. 1986;11:10–15. [Google Scholar]

- Özkoç SÖ. Kızılötesi ve Kızılötesi-Kombinasyon Isıtma Teknolojilerinin Gıda İşleme Uygulamalarında Kullanımı. J Food. 2010;3:211–218. [Google Scholar]

- Sall J, Lehman A, Stephens ML, Creighton L. JMP start statistics: a guide to statistics and data analysis using JMP Sas Institute. Biometrics. 2012;1:1319. [Google Scholar]

- Shyu YS, Sung WC, Chang MH, Hwang JY. Effect of far-infrared oven on the qualities of bakery products. JCST. 2008;6:105–118. [Google Scholar]

- Tuncel NY, Tuncel NB. Kızılötesi Teknolojisi ve Gıda İşlemedeki Kullanımı. Acad Food J. 2016;14:196–203. [Google Scholar]

- Uçar H. Geleneksel Bayburt Evlerinin Tasarım Programında Yer Alan Mekânlar. Atatürk Üniversitesi Sosyal Bilimler Enstitüsü Dergisi. 2016;22:2213–2236. [Google Scholar]

- Wade P. Biscuit baking by near-infrared radiation. J Food Eng. 1987;6:165–175. doi: 10.1016/0260-8774(87)90022-7. [DOI] [Google Scholar]

- Yiğit AH, Doğan İS. Ağrı ilindeki ekmek fırınlarının bazı özelliklerinin değerlendirilmesi üzerine bir anket çalışması. Yüzüncü Yıl Üniversitesi Tarım Bilimleri Dergisi. 2010;2:75–87. [Google Scholar]

- Zencir E, Özoğul T, Göde MÖ, Ekincek S. Hazırlanarak Yiyecek İçecek İşletmelerinde Yöresel Yemeklerin Ön Standart Tarifeleri. JOTAG. 2018;6:387–441. doi: 10.21325/jotags.2018.220. [DOI] [Google Scholar]