Highlights

-

•

NbSe2 micro/nanoparticles were achieved by ultrasonic-assisted exfoliation.

-

•

Prolonged ageing process modifies the morphology and chemical composition.

-

•

The excellent lubricating property with low friction coefficient and longer lifetime is obtained.

Keywords: NbSe2, Exfoliation, Ultrasonic-assisted, Ageing, Electrical contact

Abstract

2H-NbSe2 single crystal flake (ca. 2 × 2 × 0.5 mm in size) by chemical vapor transport is employed as the precursor for a top-down preparation of NbSe2 micro/nanoparticles by two kinds of processes, i.e. (1) mechanical exfoliation; (2) ultrasonic-assisted exfoliation in ethanol without ageing and with ageing for 210 days. NbSe2 micro/nanoparticles are applied on top of a Cu disk by a drop-casting process and the tribological property in sliding against a Cu pin under sliding electrical contact is investigated at room temperature. Mechanical exfoliation produces NbSe2 microplatets with typical sizes of 1 μm to 30 μ m with a thickness less than 2 μm. Ultrasonic-assisted exfoliation without aging facilitates the formation of NbSe2 micro/nanoplatets with sizes of 0.1 μm to 25 μm and nano-whiskers with 100 nm in diameter and 1 ~ 3 μm in length, but Nb2O5 and Se are also found on the basis of XPS results. Prolonged aging of the suspensions modifies the morphology by converting platets and whiskers into corrugated floccules (hybrid material), which are composed of Nb2O5, Se, NbSe2, and graphene. Notably, NbSe2 micro/nanoparticles by ultrasonic-assisted exfoliation without ageing exhibit an excellent lubricating property with low friction coefficient (0.3), mild wear, and longer wear lifetime (120 min) than that of mechanical exfoliated NbSe2 microplatets (10 min). The wear lifetime for the aged NbSe2 micro/nanoparticles can be as long as 504 min and are 4.2 times of the sample without aging, which can be a good solid lubricant for sliding electrical contact

1. Introduction

Metal-matrix self-lubricating composites (MMSC) containing metal chalcogenides (e.g. MoS2, NbSe2) as solid lubricant fabricated by powder metallurgy have been widely applied in sliding electrical contact (e.g. brush-slip) for many years [1], [2]. In most cases, MoS2 rather than NbSe2 is the main constitution of the composite due to its good lubricity. In specific, the excellent lubricity of MoS2 in various environments (e.g. vacuum) can be attributed to its excellent ability of transfer film-forming. However, the application of MoS2 is greatly limited by its poor electrical conductivity (0.118 S). In contrast, NbSe2 exhibits an excellent electrical conductivity (1.87 × 105 S) but a relatively poor lubricity due to its poor film-forming ability.

Recently, NbSe2 film (c.a. 1.5 μ m in thickness) by radio frequency magnetron sputtering shows good tribological property and good electrical conductivity [3]. This provides an alternative route for NbSe2 as solid lubricant coatings for electrical contact. Inspired by this result, NbSe2 coatings on electrically conducted metal (e.g. Cu and Cu alloys) either by mechanical exfoliation and transfer or by solution-based techniques (e.g. drop-casting, spraying) are also possible processes for protecting electrical contact from severe wear. There are some good examples for graphene as a protecting coating by mechanical exfoliation and transfer [4] and drop-casting [4], [5], [6] for electrical contact. This kind of coating has several advantages over MMSC containing graphene [7], [8], i.e. low consumption of solid lubricant, no risk of poor mechanical strength, and fast and efficient process; it also has much lower thickness than the sputtering film in reference [3] and therefore it produces much less wear debris. In principle, drop-casting is superior to mechanical exfoliation and transfer in considering the efficiency and reliability of the process. Until now, NbSe2 coating by solution-based techniques for electrical contact remains unstudied.

For solution-based process, NbSe2 as a solid loading in a volatile solvent should be prepared as precursor for drop-casting or spraying. NbSe2 nanoparticles, i.e. 2D nanoplates and 1D nanowires by a solution-based synthesis [9] and nanoplates and nanosheets by solid state synthesis [10], [11], [12] can be used for solution-based process. This is supported by the fact that ultrasonic-assisted preparation of nanoparticles of a variety of materials has come a long way [13], [14], [15], [16], [17], [18] in recent years and proves to be an efficient way for exfoliation of 2D materials [19] and layered materials [14], [16]. For ultrasonic-assisted preparation, its excellent ability to exfoliate 2D materials makes it possible for a top-down preparation of NbSe2 micro/nanoparticles or even few layers NbSe2 in organic solvent using single crystal NbSe2 flake as a precursor. As a matter of fact, NbSe2 nanotubes and nanofibers have been successfully prepared by chemical vapor transport (CVT) [20] and CVT large flake with a size of 10 mm is commercially available by HQ Graphene.

It is a good choice using a top-down preparation of NbSe2 micro/nanoparticles via. ultrasonic-assisted exfoliation of single crystal NbSe2 flake when considering the following three issues, i.e. (1) application of NbSe2 micro/nanoparticles to the working surface of electrical contact, (2) chemical modification of NbSe2 micro/nanoparticles, and (3) the surface topography effect on the tribological property. For issue 1, it should be noted that thin film approach with preapplied liquid lubricant on member of electrical contact has been widely used due to convenience and effectiveness. In specific, clean metal sample is coated with liquid lubricant by applying dilute lubricant solutions in a volatile carrier, e.g. 1,1,1-trichloroethane, ethanol [21]. Likewise, the as-received NbSe2 micro/nanoparticles in organic solvent (e.g. ethanol) can be feasibly applied to the member of electrical contact in similar processes (e.g. drop-casting). For issue 2, ultrasonic-assisted exfoliation of single crystal NbSe2 flake makes it possible for improved tribological property via. chemical modification of NbSe2 micro/nanoparticles in various ways (e.g. ageing, surfactant). For issue 3, from the viewpoint of tribology, both few layers NbSe2 and NbSe2 micro/nanoparticles are promising solid lubricant for electrical contact. The latter one (one-pot without centrifugation) is no doubt much more easily available than the former one and is more suitable for rough surfaces (e.g. abraded, surface textured). For example, few layer 2D materials are not engaged in sliding on a surface texture on a several tens of micrometer in size and this makes 2D material ineffective as a solid lubricant on such surface textures [22].

Herein, by using single crystal NbSe2 flake as precursor, NbSe2 micro/nanoparticles have been successfully synthesized by mechanical exfoliation and ultrasonic-assisted exfoliation in ethanol with or without ageing. The phase composition, surface chemistry, and morphology of NbSe2 micro/nanoparticles via. ultrasonic-assisted exfoliation without and with ageing of the suspensions are investigated in details. Furthermore, the lubricating property of NbSe2 micro/nanoparticles is performed and the wear mechanism is briefed.

2. Experimental

2.1. Materials

2.1.1. Single crystal 2H-NbSe2

Single crystal 2H-NbSe2 wafer with a purity of >99.995% prepared by chemical vapor transport is commercially available from HQ graphene Holland. It is the “mother” for NbSe2 micro/nanoparticles through exfoliation.

2.1.2. Mechanical exfoliation and ultrasonic-assisted exfoliation

A NbSe2 flake (ca. 2 × 2 × 0.5 mm in size) is carefully torn from the “mother” wafer for the following two kinds of exfoliation processes, i.e. (1) mechanical exfoliation by tape, and (2) ultrasonic-assisted exfoliation in organic solvent. Ethanol is selected in this study because it is also a good solvent commonly used in drop-casting process [4], [5], [6], [21].

Mechanical exfoliation of the NbSe2 flake is conducted using a specially designed tape in a standard way available from the supplier. No further treatment (e.g. sedimentation, centrifugation) is conducted for screening NbSe2 micro/nanoplatets of various sizes. Finally, NbSe2 micro/nanoplatets on tape are transferred onto Cu disk and ready for characterization and tribological property.

Ultrasonic-assisted exfoliation is conducted using neither a microtip nor a water–ice bath. As such, temperature rise of the suspension and thermal decomposition of NbSe2 are not intentionally avoided. A 0.57 mg/ml NbSe2 flake in ethanol (3 ml) is sealed in a centrifugal tube. Then the centrifugal tube is treated in a SYU4-180D ultrasonic bath using a power of 100 W successively for 10 h and is cooled down to room temperature. Finally, the suspensions are obtained without any further treatment (e.g. sedimentation, centrifugation). In addition, ageing of the suspensions up to 210 days is conducted at room temperature in lucifuge.

2.1.3. NbSe2 micro/nanoparticles on Cu by drop-casting

NbSe2 micro/nanoparticles for the tribological tests are deposited on a Cu disk by drop-casting process. The suspensions in section 2.1.2 are the precursor for drop-casting. A 60 μl suspension is applied for one side of a ϕ25 mm Cu disk. The surface of Cu disk is abraded using abrasive paper and ultrasonically cleaned before use. After complete evaporation of ethanol, NbSe2 micro/nanoparticles on a ϕ25 mm Cu disk is ready for tribological tests.

2.2. Tribological tests

Sliding electrical tests are conducted on an MFC4000 tribo-meter with a pin-on-disk configuration. A copper pin (3 mm in diameter and 15 mm in length with a hemispherical tip of 3 mm) sliding on a copper disk (25 mm in diameter and 3 mm in thickness) are used. Experimental details can be found elsewhere [21]. Test conditions are: 0.76 mm/s for sliding speed, 3 N for normal load, 20–25 °C for room temperature. The selection of sliding speed and normal load is based on the condition of severe adhesive wear occurred for unlubricated Cu-on-Cu contact. Under the same condition, the presence of NbSe2 micro/nanoparticles can greatly reduce adhesive wear.

2.3. Characterization

The worn surfaces of pin and disk are carefully examined and characterized. The morphology is observed using a ZEISS SIGMA field emission scanning electron microscopy (FESEM) with energy dispersive spectroscopy, and GZF2.0 transmission electron microscopy (TEM) of FEI Electron Optics. Raman (HR Evolution) is used to characterize NbSe2 micro/nanoparticles. XPS is used for determination of chemical states of selected elements of NbSe2 micro/nanoparticles on PHI 5000VersaProbe III.

3. Results and discussion

3.1. Mechanically exfoliated NbSe2 microplatets

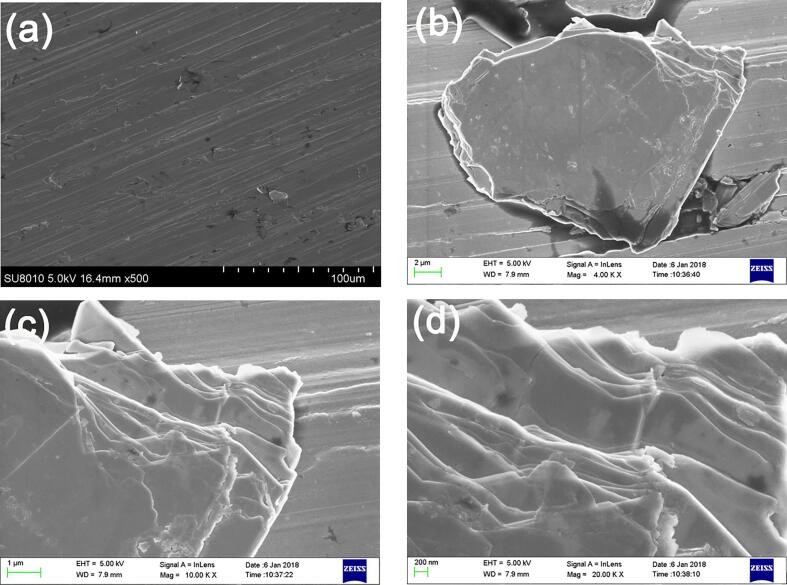

Mechanical exfoliation of 2H-NbSe2 flake produces NbSe2 microplatets of various sizes (typical size of 1 μm to 30 μ m with a thickness less than 2 μ m) and it takes at least 10 times to transfer adequate amount of NbSe2 microplatets onto Cu disk for the tribological tests, see Fig. 1a. The individual microplatet is a layered crystal with irregular edge (Fig. 1b). Raman spectrum in Fig. S1 justify the microplatets as NbSe2 by 230 cm−1 for Se-Se (A1g) and 237 cm−1 for Nb-Se (E12g). Unlike XRD pattern of 2H-NbSe2 flake (Fig. S2a), XRD pattern suggest the presence of only (0 0 2) plane for sample by mechanical exfoliation, which is similar to those of ultrasonic-assisted exfoliation without ageing and after ageing for 15 days (Fig. S2b). Evidences for delamination and cleavage are presented in Fig. 1c and Fig. 1d, respectively. No corrugation on the edge of microplatet is observed.

Fig. 1.

FESEM micrographs of (a) mechanically exfoliated NbSe2 microplatets transferred to Cu disk (one time transfer); (b) an individual microplatet, (c,d) the edge of an individual microplatet in (b).

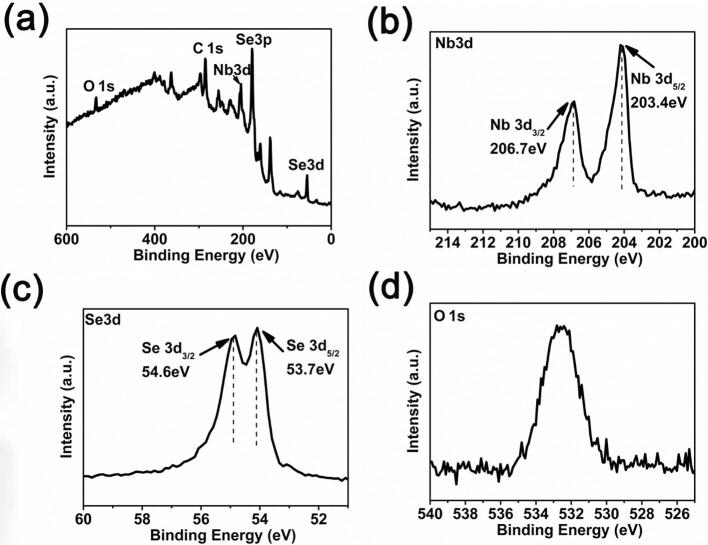

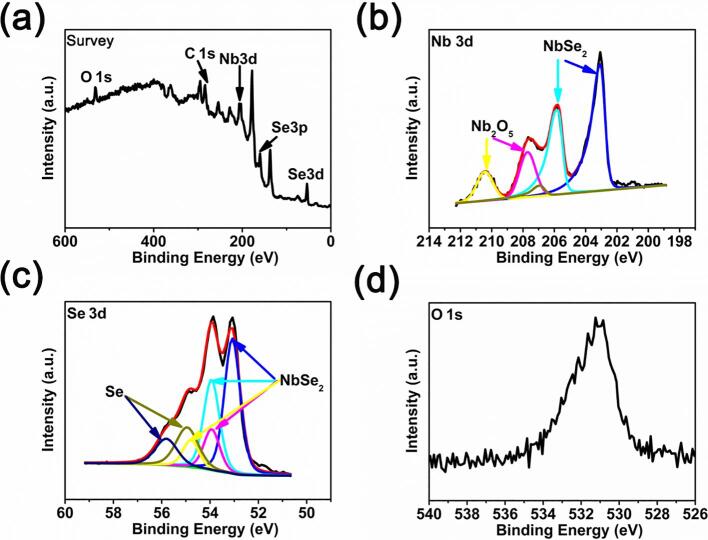

XPS spectra in Fig. 2 show that very mild oxidation on the surface of mechanically exfoliated NbSe2 microplatets and the naturally occurred oxide can be readily removed by Ar+ ion sputtering for 12 s. The presence of N1s at 400 eV in Fig. 1a is attributed by the carrying gas used in chemical vapor transport process.

Fig. 2.

XPS spectra of (a) survey, (b) Nb3d, (c) Se3d, (d) O1s after being sputtered for 12 s using Ar+ ion.

3.2. Ultrasonic-assisted exfoliation

3.2.1. Without ageing

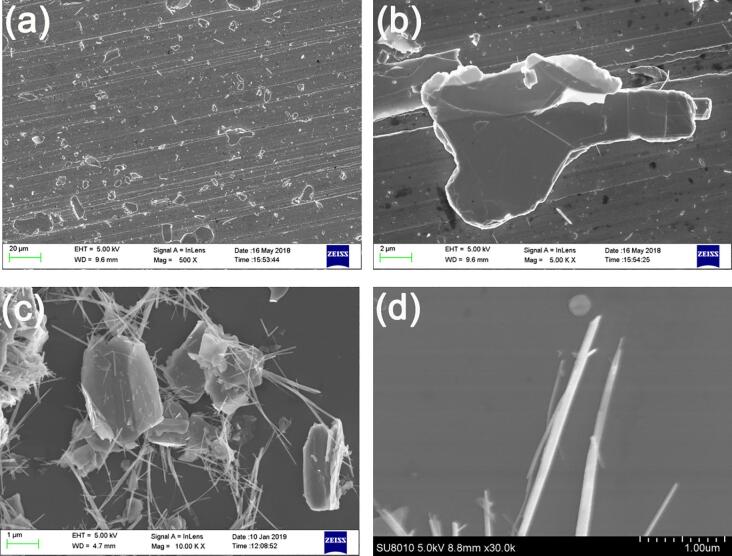

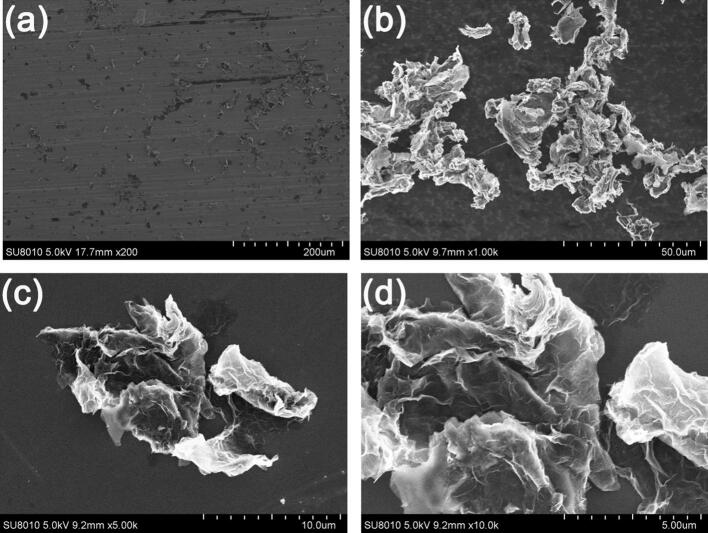

Ultrasonic-assisted exfoliation of 2H-NbSe2 flake produces micro/nanoparticles in two kinds of morphologies, i.e. (1) micro/nanoplatets and (2) nanowhiskers. By using as-received NbSe2-ethanol suspensions after ultrasonic treatment, the drop-casting process enables a homogeneous distribution of micro/nanoplatets and nanowhiskers on Cu disk, see Fig. 3a. The particle sizes of micro/nanoplatets range from 0.1 μm to 25 μm with a thickness less than 1 μm (Fig. 3b), which is smaller than that of mechanical exfoliated ones (Fig. 1b). No corrugation on the edge of micro/nanoplatets is observed. Agglomeration of micro/nanoplatets and nanowhiskers can be observed, see Fig. 3c. The average diameter of nanowhiskers is ca. 100 nm and the length is from 1 to 3 μm, see Fig. 3b and 3d.

Fig. 3.

FESEM micrographs of (a) ultrasonic-assisted exfoliated NbSe2 microparticles transferred to Cu disk; (b) an individual microplatet with cracks on the surface, (c) agglomerated micro/nanoplatets and nanowhiskers, (d) nanowhiskers.

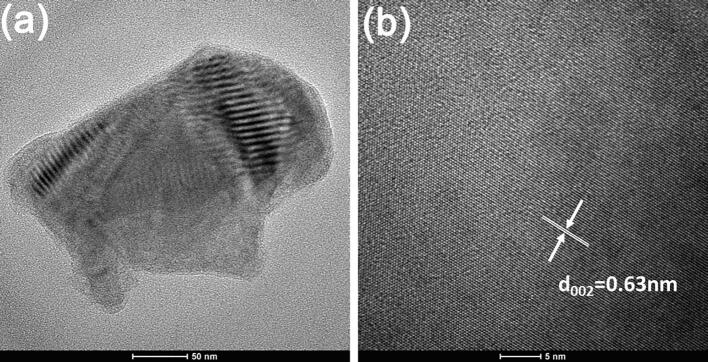

TEM micrograph and HRTEM image in Fig. 4 show that nanoplatets (Fig. 4a-b) and nanowhiskers are single crystal NbSe2 based on unit cell parameters in Fig. S2, which is also evident by Raman spectrum similar to in Fig. S1 and EDS in Fig. S3.

Fig. 4.

(a) TEM micrograph and (b) HRTEM image of an individual NbSe2 microplatet.

XPS spectra in Fig. 5 show the presence of Nb2O5 and Se for ultrasonic-assisted exfoliated NbSe2 micro/nanoparticles. Nb2O5 and Se are the products of chemical reaction between NbSe2 micro/nanoparticles and ethanol. Nb2O5 can be removed by Ar+ ion sputtering for 60 s, see Fig. S4.

Fig. 5.

XPS spectra of (a) survey, (b) Nb3d, (c) Se3d, (d) O1s for ultrasonic-assisted exfoliated NbSe2 micro/nanoparticles.

3.2.2. With ageing

Short time ageing (e.g. 15 days) doesn’t obviously modify the morphology of NbSe2 micro/nanoparticles (Fig. 6) and XRD pattern (Fig. S2b) while prolonged ageing (e.g. 210 days) greatly modifies the morphology of NbSe2 micro/nanoparticles (Fig. 7) as well as the chemical composition by chemical interaction between NbSe2 micro/nanoparticles and ethanol (Fig. 8, Fig. S2c, Fig. S5). (0 0 2) plane of NbSe2 micro/nanoparticles after ageing for 210 days almost disappears in Fig. S2c. Elements C and O can also be found on NbSe2 micro/nanoparticles in Fig. S5. The drop-casting process enables a homogeneous distribution of micro/nanoparticles on the surface of Cu disk, see Fig. 7a. Most of the micro/nanoparticles are corrugated floccules (ca. 98%) with only a few nanowhisker (Fig. 7b) and a few micro/nanoplatets (Fig. 7b) are observed. Agglomeration of floccules can be seen in Fig. 7b and 7c. The morphology of corrugated floccules in Fig. 7d is similar to that of graphene nanoplatets.

Fig. 6.

FESEM micrograph of ultrasonic-assisted exfoliated NbSe2 micro/nanoparticles after ageing for 15 days.

Fig. 7.

FESEM micrographs of (a) ultrasonic-assisted exfoliated NbSe2 micro/nanoparticles after ageing for 210 days and then deposited on a Cu disk by drop-casting, (b) floccules with a few nanowhisker and micro/nanoplatets, (c) agglomerated floccules, (d) corrugated floccules.

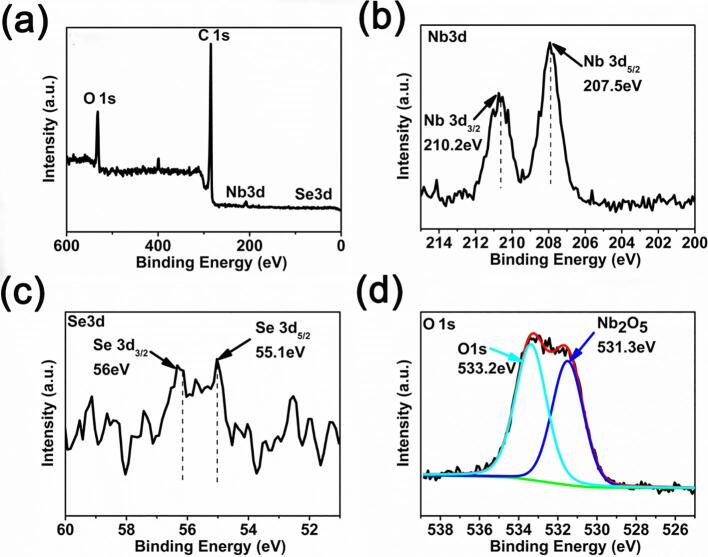

Fig. 8.

XPS spectra of (a) survey, (b) Nb3d, (c) Se3d, (d) O1s for ultrasonic-assisted exfoliated NbSe2 micro/nanoparticles after ageing for 210 days.

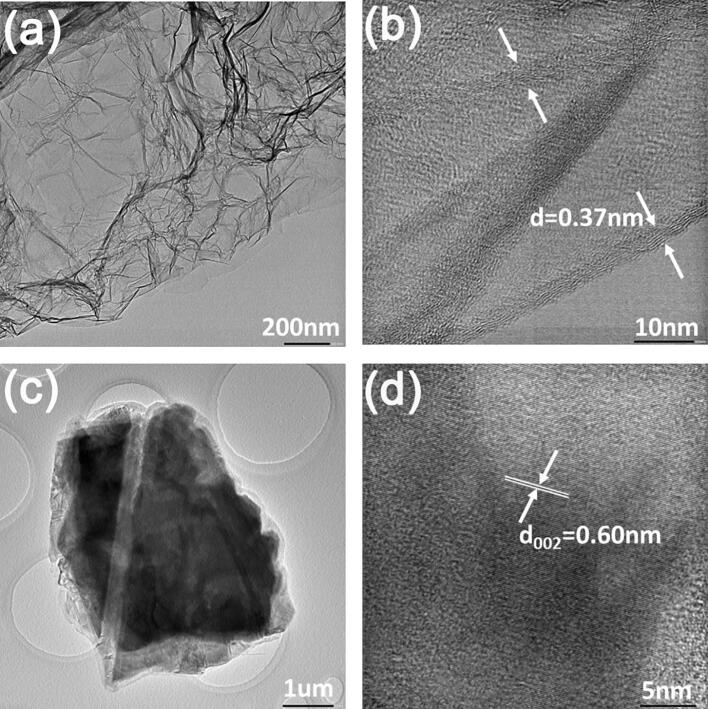

Chemical interaction between NbSe2 and ethanol is significant as evident by presence of Nb2O5, Se, and NbSe2 after ageing for 15 days. After ageing for 210 days, the peaks of Nb3d for NbSe2 vanishes and peaks of Nb3d for Nb2O5 dominates (Fig. 8a). This implies that NbSe2 will be totally consumed with prolonged time. HRTEM image suggests that corrugated floccules be composed of amorphous Nb2O5 and graphene (Fig. 9a-b) while NbSe2 micro/nanoplatets are composed of crystalline NbSe2 (Fig. 9c-d).

Fig. 9.

(a) TEM micrograph and (b) HRTEM image of floccules. (c) TEM micrograph and (d) HRTEM image of NbSe2 nanoplatets.

3.3. Exfoliation mode

As mentioned in section 2.1.2, the NbSe2 flake has ca. 2 × 2 × 0.5 mm in size, which means the flake is approximately composed of 60,000 to 80,000 layers. Mechanical exfoliation enables cleavage and delamination on 2H-NbSe2 flake and its fragments. NbSe2 microplatets in Fig. 1a has a thickness of ca. 2μ m (ca. 3000 layers) due to delamination along the basal plane and a plane size of 20 μm due to cleavage vertical to the basal plane (Fig. 1b, 3b).

The thickness of NbSe2 micro/nanoplatets is less than 1 μm, suggesting approximate 1500 layers. As a matter of fact, NbSe2 particles in ethanol suspension has a diversity of particle sizes, ranging from few-layer NbSe2 to micro/nanoplatets. Since the suspension is not centrifugated, the proportion of few-layer NbSe2 to micro/nanoplatets can not be determined.

Exfoliation mechanism under ball milling of NbSe2 powder suggests that nanosheet, nanobelt, nanorod, and nanoparticles by shear and plastic deformation be observed [23]. Cavitation-induced bubbles collapse and produce high temperature and high pressure which has impact on the delamination and cleavage of NbSe2 flake and its fragments. Fresh surface by delamination and cleavage are prone to chemical reaction with organic solvent. And this makes ageing a useful route to chemically modify the particles in the suspensions. Such a chemical modification may be accelerated by ageing at higher temperature and deserves further investigation.

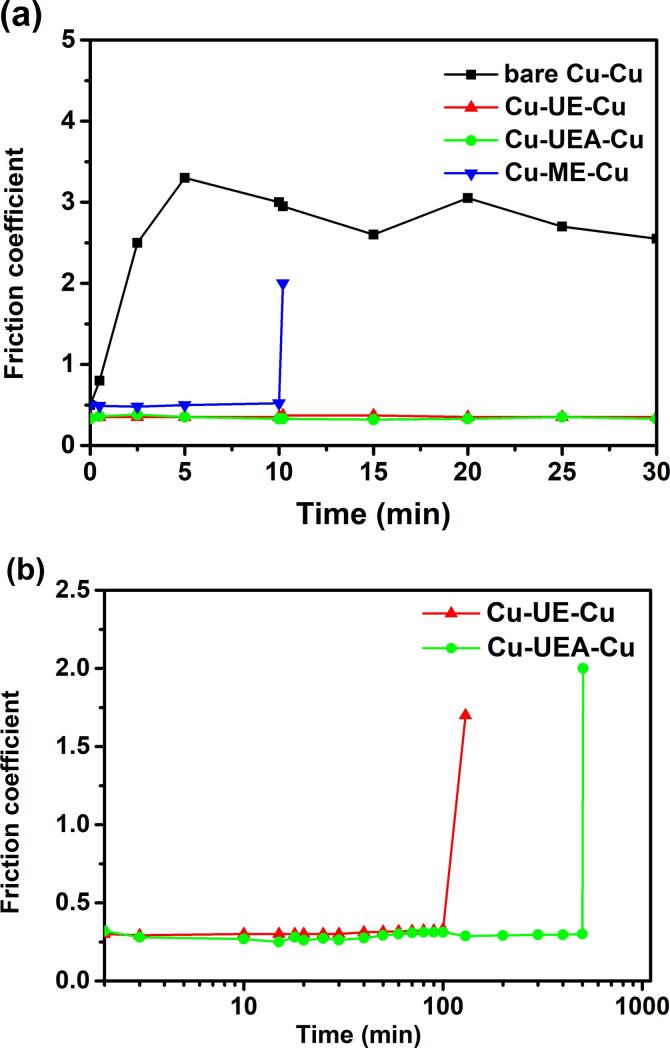

3.4. Tribological property

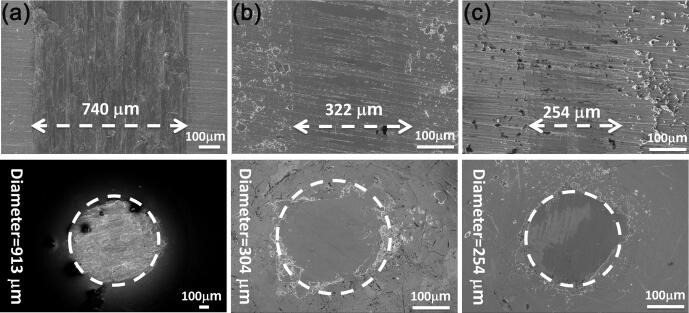

Friction coefficient for unlubricated Cu-on-Cu contact is as high as 3.0 at steady stage (Fig. 10a), and severe adhesive wear and severe plastic flow on both Cu pin and Cu disk are observed (Fig. 11a). This is observed and explained by Antler [24]. In the presence of mechanically exfoliated NbSe2 micro/particles, friction coefficient is stable at ca. 0.5 for 10 min before tribological failure (a sudden increase in friction coefficient in Fig. 10a). NbSe2 micro/nanoparticles by ultrasonic-assisted exfoliation allow friction coefficient as low as ca. 0.3 and much longer wear lifetime, i.e. 120 min for one without ageing and 504 min for one with ageing, see Fig. 10b.

Fig. 10.

Frictional traces of (a) unlubricated Cu-on-Cu contact, mechanically exfoliated NbSe2 micro/particles. (b) NbSe2 micro/nanoparticles by ultrasonic-assisted exfoliation without and with ageing. ME: mechanically exfoliated; UE: ultrasonic-assisted exfoliation without ageing; UEA: ultrasonic-assisted exfoliation with ageing.

Fig. 11.

FESEM micrographs of worn surfaces of Cu disk (upper) and Cu pin (lower) in presence of NbSe2 microparticles by (a) mechanical exfoliation, (b) ultrasonic-assisted exfoliation without ageing, (c) by ultrasonic-assisted exfoliation with ageing.

Typical characteristics of worn surface of “lubrication in good condition” are observed for NbSe2 micro/nanoparticles by ultrasonic-assisted exfoliation without ageing. These characteristics are: (1) lubricant film and original scratches on worn surface of Cu disk (upper micrograph in Fig. 11b) and (2) burnished surface on worn surface of Cu pin (lower micrograph in Fig. 11b). The same characteristics are also observed for NbSe2 micro/nanoparticles by ultrasonic-assisted exfoliation with ageing (Fig. 11c). The original parallel scratches are produced by abrading the Cu disk before drop-casting process. The preserved scratches indicates very mild wear on the Cu disk and the scratches act as the “reservoir” by trapping NbSe2 micro/nanoparticles (upper micrograph in Fig. 11b). It is very important because the amount of solid lubricant on the tribo-interface determines the wear lifetime of coatings of this kind. In other words, once NbSe2 on the worn surface is exhausted, tribological failure occurs.

The results of this work are compared with the previous work in Table 1. It should be pointed out that the friction coefficient reported in this study is the highest in Table 1. The friction coefficient of bare Cu-on-Cu contact is as high as 3, which is much higher than the reported values in references [1], [7], [8]. Friction coefficient of Cu-on-Cu contact in presence of NbSe2 micro/nanoparticles is merely one tenth of the friction coefficient of Cu-on-Cu contact in absence of NbSe2 micro/nanoparticles. In addition, NbSe2 micro/nanoparticles can also be used as a solid lubricant for running-in procedure of a brush/slip assembly.

Table 1.

Comparison on tribological property of NbSe2 as solid lubricant with previous literature reports.

| Material and process | Friction coefficient | Wear rate or wear regime | Refs. |

|---|---|---|---|

| NbSe2 coating (1.4 and 1.6 μm in thickness) with a Ti intermediate layer by radio frequency magnetron sputtering | <0.1 | 10−15 m3N−1m−1 | [8] |

| Ag-NbSe2 composite by powder metallurgy | 0.2 | 10−14 m3N−1m−1 | [1] |

| Cu-NbSe2 composite by powder metallurgy | 0.15–0.20 | N/A | [7] |

| NbSe2 micro/nanoplatets (8% coverage on the worn surface) by drop-casting | 0.3 | Mild wear, 10−15 m3N−1m−1 before worn out | This study |

4. Conclusions

A top-down preparation of NbSe2 micro/nanoparticles by mechanical exfoliation and ultrasonic-assisted exfoliation in ethanol without and with ageing. Ultrasonic-assisted exfoliation produces NbSe2 micro/nanoplatets and nano-whiskers, as well as Nb2O5 and Se. Prolonged ageing of the suspensions modifies the morphology by converting platets and whiskers into corrugated floccules, which are composed of Nb2O5, Se, and graphene. NbSe2 micro/nanoparticles by ultrasonic-assisted exfoliation allow sliding with low friction coefficient (0.30), mild wear (wear too low to measure). The wear lifetimes in presence of NbSe2 micro/nanoparticles (120 min for the in-aged one and 504 min for the aged one) are much longer that of mechanical exfoliation (10 min). The profound advantages in easy deposition on Cu substrate, good tribological property promise NbSe2 micro/nanoparticles to be good solid lubricant for sliding electrical contact. NbSe2 micro/nanoparticles can also be used as solid lubricant for running-in procedure of a brush/slip assembly.

CRediT authorship contribution statement

Rong Qu: Methodology, Investigation, Data curation. Xiaoqin Wen: Investigation, Data curation, Writing - original draft. Yamei Zhao: Formal analysis, Investigation. Tingmei Wang: Methodology, Validation. Ruiqing Yao: Writing - review & editing. Jinjun Lu: Supervision.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work is supported by Natural Science Foundation of China (51775434), Hundred Talent of Shaanxi Province, and opening project of State Key Laboratory of Solid Lubrication (LSL16-02).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.ultsonch.2021.105491.

Appendix A. Supplementary data

The following are the Supplementary data to this article:

References

- 1.European Space Tribology Laboratory. Space tribology handbook. AEA Technology, 2002.

- 2.Tang H., Cao K., Wu Q., Li C., Yang X., Yan X. Synthesis and tribological properties of copper matrix solid self-lubricant composites reinforced with NbSe2 nanoparticles. Cryst. Res. Technol. 2011;46:195–200. [Google Scholar]

- 3.Liu J., Sui X., Zhang S., Xu S., Hao J. The effect of Ti transition layer on lubrication-conduction properties of NbSe2 films. Tribology (in Chinese) 2018;38:635–644. [Google Scholar]

- 4.Berman D., Erdemir A., Sumant A.V. Graphene: a new emerging lubricant. Mater. Today. 2014;17:31–42. [Google Scholar]

- 5.Mao F., Wiklund U., Andersson A.M., Jansson U. Graphene as a lubricant on Ag for electrical contact applications. J. Mater. Sci. 2015;50:6518–6525. [Google Scholar]

- 6.Berman D., Erdemir A., Sumant A.V. Graphene as a protective coating and superior lubricant for electrical contacts. Appl. Phys. Lett. 2014;105(23):231907. [Google Scholar]

- 7.Kinloch I.A., Suhr J., Lou J., Young R.J., Ajayan P.M. Composites with carbon nanotubes and graphene: an outlook. Science. 2018;362:547–553. doi: 10.1126/science.aat7439. [DOI] [PubMed] [Google Scholar]

- 8.Nieto A., Bisht A., Lahiri D., Zhang C., Agarwal A. Graphene reinforced metal and ceramic matrix composites: a review. Int. Mater. Rev. 2017;62(5):241–302. [Google Scholar]

- 9.Sekar P., Greyson E.C., Barton J.E., Odom T.W. Synthesis of nanoscale NbSe2 materials from molecular precursors. J. Am. Chem. Soc. 2005;127(7):2054–2055. doi: 10.1021/ja0428006. [DOI] [PubMed] [Google Scholar]

- 10.Zhang X., Zhang D.u., Tang H., Ji X., Zhang Y.i., Tang G., Li C. Facile synthesis and characterization of hexagonal NbSe2 nanoplates. Mater. Res. Bull. 2014;53:96–101. [Google Scholar]

- 11.Tang G., Zhang J., Liu C., Tang H., Li C. Facile synthesis of single-crystal NbSe2 ultrathin nanosheets via a pressureless sintered process. Mater. Lett. 2014;124:289–292. [Google Scholar]

- 12.Tang H., Li C., Yang X., Mo C., Cao K., Yan F. Synthesis and tribological properties of NbSe3 nanofibers and NbSe2 microsheets. Cryst. Res. Technol. 2011;46:400–404. [Google Scholar]

- 13.Dinari M., Haghighi A. Ultrasound-assisted synthesis of nanocomposites based on aromatic polyamide and modified ZnO nanoparticle for removal of toxic Cr(VI) from water. Ultrason. Sonochem. 2018;41:75–84. doi: 10.1016/j.ultsonch.2017.09.023. [DOI] [PubMed] [Google Scholar]

- 14.Dinari M., Mallakpour S. Ultrasound-assisted one-pot preparation of organo-modified nano-sized layered double hydroxide and its nanocomposites with polyvinylpyrrolidone. J. Polym. Res. 2014;21:350. [Google Scholar]

- 15.Soltani R., Dinari M., Mohammadnezhad G. Ultrasonic-assisted synthesis of novel nanocomposite of poly(vinyl alcohol) and amino-modified MCM-41: A green adsorbent for Cd(II) removal. Ultrason. Sonochem. 2018;40:533–542. doi: 10.1016/j.ultsonch.2017.07.045. [DOI] [PubMed] [Google Scholar]

- 16.Soltani R., Shahvar A., Dinari M., Saraji M. Environmentally-friendly and ultrasonic-assisted preparation of two-dimensional ultrathin Ni/Co-NO3 layered double hydroxide nanosheet for micro solid-phase extraction of phenolic acids from fruit juices. Ultrason. Sonochem. 2018;40:395–401. doi: 10.1016/j.ultsonch.2017.07.031. [DOI] [PubMed] [Google Scholar]

- 17.Mohammadnezhad G., Abad S., Soltani R., Dinari M. Study on thermal, mechanical and adsorption properties of amine-functionalized MCM-41/PMMA and MCM-41/PS nanocomposites prepared by ultrasonic irradiation. Ultrason. Sonochem. 2017;39:765–773. doi: 10.1016/j.ultsonch.2017.06.001. [DOI] [PubMed] [Google Scholar]

- 18.Afshari M., Dinari M., Momeni M. Ultrasonic irradiation preparation of graphitic-C3N4/polyaniline nanocomposites as counter electrodes for dye-sensitized solar cells. Ultrason. Sonochem. 2018;42:631–639. doi: 10.1016/j.ultsonch.2017.12.023. [DOI] [PubMed] [Google Scholar]

- 19.Cunningham G., Lotya M., Cucinotta C.S., Sanvito S., Bergin S.D., Menzel R., Shaffer M.S.P., Coleman J.N. Solvent exfoliation of transition metal dichalcogenides: dispersibility of exfoliated nanosheets varies only weakly between compounds. ACS Nano. 2012;6:3468–3480. doi: 10.1021/nn300503e. [DOI] [PubMed] [Google Scholar]

- 20.Tsuneta T., Toshima T., Inagaki K., Shibayama T., Tanda S., Uji S., Ahlskog M., Hakonen P., Paalanen M. Formation of metallic NbSe2 nanotubes and nanofibers. Curr. Appl. Phys. 2003;3(6):473–476. [Google Scholar]

- 21.Ding Z., Wen X., Qu R., Fu Y., Yao R., Lu J. Robust lubricious and low corrosive imidazolium hexafluorophosphate lubricant on multi-arc ion plating Ag-Cu/Ti film under sliding electrical contact. Tribol. Int. 2020;151:106451. [Google Scholar]

- 22.Shi Z., Shum P., Wasy A., Zhou Z., Li L. Tribological performance of few layer graphene on textured M2 steel surfaces. Surf. Coating Technol. 2016;296:164–170. [Google Scholar]

- 23.Ibrahem M.A., Huang W.-C., Lan T.-W., Boopathi K.M., Hsiao Y.-C., Chen C.-H., Budiawan W., Chen Y.-Y., Chang C.-S., Li L.-J., Tsai C.-H., Chu C.W. Controlled mechanical cleavage of bulk niobium diselenide to nanoscaled sheet, rod, and particle structures for Pt-free dye-sensitized solar cells. J. Mater. Chem. A. 2014;2(29):11382–11390. [Google Scholar]

- 24.Antler M. Processes of metal transfer and wear. Wear. 1964;7(2):181–203. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.