Abstract

The objective of this study was to collect and interpret three-axis acceleration, temperature, and relative humidity data from six locations within commercial transport trailers shipping market-weight pigs. Transport was observed in Kansas (n = 15) and North Carolina (n = 20). Prior to loading, three-axis accelerometers were affixed to six locations on the trailers: top fore (TF), top center (TC), top aft (TA), bottom fore (BF), bottom center (BC), and bottom aft (BA) compartments. Data were post-processed to calculate root-mean-square (RMS) accelerations and vibration dose values (VDV) in the vertical direction and the horizontal plane. These values were compared with exposure action values (EAV) and exposure limit values (ELV), vibration levels deemed uncomfortable and potentially dangerous to humans. Additionally, RMS and VDV were compared among the trailer compartments. The vertical RMS accelerations for all compartments exceeded the EAV for loads measured in Kansas, and for the majority of the compartments measured in North Carolina. Many compartments, specifically the BA compartment from all trips, exceeded the vertical ELV. Regardless of where the data were collected, fewer compartments exceeded the EAV in the horizontal orientation. Only BA compartments exceeded the ELV in the horizontal orientation. There were Area × Level interactions for vertical and horizontal RMS and VDV (P < 0.01). The BF compartment had a greater vertical RMS value than the TF, TC, and BC (P < 0.02) compartments, but did not differ (P = 0.06) from the TA compartment. The vertical RMS of the TA compartment did not differ from the TF, TC, and BC compartments (P > 0.13). The BF compartment had a greater (P = 0.02) vertical VDV value than the TC location, but did not differ from the other locations (P > 0.16). All other locations did not differ in vertical VDV (P > 0.12). The BF compartment had greater horizontal RMS than the TC and TA compartments (P < 0.01), but did not differ from TF and BC compartments (P > 0.12). All other compartments did not differ in horizontal RMS (P > 0.34). All compartments, aside from the BA compartment, did not differ in horizontal VDV (P > 0.19). Vibration analyses indicated the BA compartment had the greatest vertical and horizontal vibrations and a large percentage of the compartments exceed the EAV and ELV, which indicated pigs may have experienced uncomfortable trips that could cause discomfort or fatigue.

Keywords: accelerations, environment, root-mean-squared, swine, transportation

Introduction

Transport loss is the term used to describe dead or nonambulatory animals found at the commercial abattoir following transport (Fitzgerald et al., 2009; Ritter et al., 2009). Nonambulatory animals include both injured and fatigued pigs. Fatigued pigs demonstrate no sign of disease, injury, or trauma; however, they refuse to walk (Ritter et al., 2005) and often display open-mouth breathing, skin discoloration, muscle tremors, and abnormal vocalizations (Anderson et al., 2002). Ritter et al. (2009) summarized 23 field trials encompassing the transport of over 6 million pigs and found over 29,000 of 46,000 pigs categorized under the transportation loss designation were nonambulatory. Ritter et al. (2005) reported greater than 50% of nonambulatory pigs at the packing plant were fatigued and approximately 0.3% of all pigs transported developed Fatigued Pig Syndrome. The term “Fatigued Pig Syndrome” was developed to loosely describe fatigue induced by transport. Thus, with over 125 million pigs being harvested in 2019 and utilizing the number reported by Ritter et al. (2005), 375,000 of pigs arriving at the commercial abattoir may have become fatigued during transport. Ritter et al. (2020) conducted a survey of packers responsible for almost 70% of the yearly harvest capacity and found the number of nonambulatory pigs increased to 0.63%. This would mean there were 787,500 nonambulatory pigs in the production chain in 2019.

Most reviews of the literature state animal welfare during transport became an issue a few decades ago, mainly due to consumer concerns (Nielsen et al., 2011; Schwartzkopf-Genswein et al., 2012; Miranda-de la Lama et al., 2014). Schwartzkopf-Genswein et al. (2012) noted the majority of work was conducted outside of North America where production systems, livestock breeds, and road conditions differ. Regardless of location, most reviews of the literature demonstrated transport welfare research focused on loading density, duration and distance, handling methods, seasonal temperature, and the relationship of these variables to stress, fatigue, and behavior (Speer et al., 2001; Swanson and Morrow-Tesch, 2001; Bench et al., 2008; Mitchell and Kettlewell, 2009; Nielsen et al., 2011; Schwartzkopf-Genswein et al., 2012; Miranda-de la Lama et al., 2014). While this body of literature has improved transportation welfare, scientists have largely ignored the impact the truck and trailer impart on welfare.

To date, most truck and trailer welfare research focused on the design and microenvironment of the trailer, with a balance of the research focused on atmosphere and trailer compartments’ temperature and humidity (Baker et al., 1996; Kettlewell et al., 2001; Kadim et al., 2006; Caulfield et al., 2014). Haley et al. (2008) found the incidence of dead pigs increased from 0.04% to 0.21% when trailer temperatures increased from 8.6 °C to greater than 30.5 °C. Averos et al. (2008) found mortality increased as average temperature increased and temperature was more important than other factors during the trip in determining mortality. Fitzgerald et al. (2009) reported transport losses increased as the temperature/humidity index rose. These studies indicate ambient temperature and humidity influenced transport loss, but few have examined variations within the trailer.

One stress factor not adequately explored is the effect trailer vibrations elicit on welfare, and more specifically, muscle fatigue. Hagbarth and Eklund (1966) reported a phenomenon called tonic vibration reflex in humans. This reflex is a muscle contraction that occurs without voluntary movement by the subject when vibration is applied indirectly or directly to the muscle. The International Organization for Standardization (ISO) 2631-1 provides health guidance zones for whole-body vibration exposure bounded below by an exposure action value (EAV) and above by an exposure limit value (ELV; ISO 2631-1, 1997). The standard indicates that vibration levels between the EAV and ELV may pose health risks, while vibration levels above the ELV are likely to cause health issues. While the standard itself does not describe the health problems associated with excessive vibration, Cvetanovic and Zlatkovic (2013) found that agricultural tractor operators may experience shortness of breath, nausea, or disturbed balance when exposed to vibration levels in excess of the EAV in the short term and “disorders in psychomotoric, physiological and psychological systems” in the long term. In poultry, Randall et al. (1996) concluded the frequency at which transporters vibrate may have an effect on welfare, but the exact effects were not explored. Peeters et al. (2008) found a “wild” driving style produced different longitudinal and lateral accelerations that affected pig heart-rate, salivary cortisol, and behavior, but no correlations were drawn between vibrations, muscle fatigue, and the nonambulatory condition. Therefore, the global hypothesis is vibration forces experienced by pigs during transportation contribute to the nonambulatory condition at harvest, mainly by catalyzing the onset of muscle fatigue. Before this hypothesis can be tested, the vibration profile of commercial transport trailers must be collected so further controlled type experiments can be conducted. Therefore, the objective of this study was to collect and quantify three-axis acceleration, temperature, and relative humidity profiles from six locations within commercial transport trailers shipping market weight pigs.

Materials and Methods

All procedures occurred prior and after pig transport; therefore, Institutional Animal Care and Use Committee approval was not required.

Raw data collection

Two commercial producers, located in Kansas (n = 16) and North Carolina (n = 20), agreed to have data collected on full loads of finished pigs. Additionally, data from three loads originating from the Kansas State University Swine Teaching and Research Center were collected. Data collected in Kansas were collected on pot-belly trailers over eight days from September 2018 to January 2019. Data collected in North Carolina were collected on straight-deck trailers over 6 days from December 2019 to February 2020.

Prior to loading, accelerometer collection devices were affixed to the under-side of the floor at six locations. Accelerometer collection devices consisted of a Pelican 1200 Protector Case (Pelican, Torrance, CA) with no padding, an Omars AC power supply (Wellmade, Shenzhen, China), and a myRIO accelerometer (National Instruments, Austin, TX). Holes were drilled through the bottom of the protective case and the AC power supply was attached to the case by using heavy-duty zip ties. Accelerometers were affixed to the power supply by double-sided Velcro strips that wrapped around the power supply and the accelerometer.

On pot-belly trailers, devices were placed at the approximate center of the top and bottom fore compartments (TF and BF, respectively), center of the middle compartments (TC and BC, respectively), approximately 15.24-cm off center to avoid the ramp for the top aft compartment (TA), and along the centerline and approximately 10.16 cm in front of the rear axle for the bottom aft compartment (BA). All collection devices were anchored to I-beams using four flatbed tarp straps (DC Cargo Mall, Lakewood, NJ). Straps were pulled tight to allow no movement of the devices. On split-deck trailers, trailers were split into thirds and sensors were affixed along the centerline of the top and bottom decks. Bottom deck collection devices were attached to the floor using tarp straps as described above. Top deck collection devices were modified due to the lack of I-beams for tarp strap attachment. The power supply and accelerometer were attached within a 50.8-cm red plastic lockable toolbox (Craftsman, Towson, MD) as described above. Boxes were attached to the floor using one, 5.08-cm wide, SmartStraps ratchet tie down strap (Winston Products, LLC, Solon, OH) and one, 3.18-cm wide, SmartStraps ratchet tie down strap (Winston Products, LLC). Straps were anchored to the vent holes of the side-wall panels, crossed at the box, and tightened until the boxes could not move in any direction. Figure 1 shows images of the two types of trailers and the approximate locations of the sensors.

Figure 1.

Locations of the sensors in the trailers used for the Kansas and North Carolina trips.

All devices were oriented in a manner that the x-axis collected vibrations in the direction of travel, the y-axis collected horizontal vibrations perpendicular to the direction of travel, and the z-axis collected the vertical vibrations. Since the vibration frequencies typically associated with human and animal discomfort typically lie below 50 Hz (Scott, 1994; ISO 2631-1, 1997; Perremans et al., 2001; Water et al., 2003), accelerometers were set to collect data at the relatively low rate of 100 Hz to conserve memory, and data were recorded on SanDisk Cruzer Fit 16 GB USB flash drives (Western Digital, San Jose, CA). Finally, temperature and relative humidity were recorded for the bottom deck by USB data loggers (Model OM-HL-SP-TH; Omega, Norwalk, CT) attached to the devices that recorded the upper-deck vibrations. Upper-deck temperature and humidity were recorded by hanging the data logger at the approximate location of the accelerometer devices, but out of the reach of the pigs.

Prior to movement, general information was collected including the time accelerometers were turned on and affixed, the trailer make, model, and year (confidential), the truck make, model, and year (confidential), tire pressure, and presence of an air suspension. At the farm, information including loading start and end time, ambient temperature, and number of pigs loaded was collected. Trip data collected included start time, major events (accelerations, decelerations, turns, bridges, train tracks, short stops, speed, etc.), road conditions, time at loading dock, unloading temperature, stop and start time of unloading, and total load weight. The 12 loads observed from the large Kansas producer originated from two locations approximately 16 km apart, but the remainder of the roads remained the same. Four loads originating from the Kansas State University Swine Teaching and Research Unit traveled the same route. In North Carolina, farms were spread over the eastern part of the state; therefore, routes varied. At unloading, the number of dead pigs per load were counted for all observed loads. The number of fatigued pigs per load were counted only for North Carolina and four loads in Kansas (data not analyzed due to small sample size). The remaining Kansas loads were not observed due to producer and abattoir biosecurity issues. Pigs displaying open-mouth breathing, red-splotchy skin, panting, laboring to move but not showing signs of injury, pigs moved with a sled, or pigs allowed to rest in the receiving alley were labeled as being fatigued. All load and pig data are presented in Table 1.

Table 1.

Commercial pig transport characteristic means and standard deviations of loads observed in Kansas and North Carolina

| Kansas1 | North Carolina2 | |||

|---|---|---|---|---|

| Mean | Standard deviation | Mean | Standard deviation | |

| Pig characteristics | ||||

| Pigs, #/load | 161 | 20 | 182 | 4 |

| Total load weight, kg | 20,913 | 863 | 24,353 | 862 |

| Average weight, kg | 125 | 4.5 | 134 | 4.1 |

| Dead3, % | 0.23 | 0.39 | 0.11 | 0.29 |

| Fatigued4, % | – | – | 0.39 | 0.91 |

| Temperature, °C | ||||

| Loading | 3.9 | −9.2 | 12.3 | −9.8 |

| Unloading | 5.7 | −9.1 | 13.5 | −9.6 |

| Time, min | ||||

| Loading | 44 | 24 | 43 | 8 |

| Trip | 186 | 33 | 110 | 22 |

| Unloading | 46 | 31 | 50 | 17 |

| Total | 276 | 39 | 203 | 31 |

1A total of 15 loads of pigs transported in pot-belly trailers were observed.

2A total of 20 loads of pigs transported in straight-deck trailers were observed.

3Included pigs found dead upon arrival or those pigs euthanized in the trailer.

4Pigs categorized as fatigued included those with open-mouth breathing, red-splotchy skin, panting, laboring to move but not showing signs of injury, pigs moved with a sled, or pigs allowed to rest in the receiving alley.

Vibration analysis

The vibration analyses presented here are primarily based on the techniques outlined in ISO 2631-1 and ISO 2631-5 technical standards for evaluating human exposure to whole-body vibrations (ISO 2631-1, 1997; ISO 2631-5, 2018), as there are no guidelines as how to analyze livestock data. Additionally, data were processed and averaged over the entire trip for each load. The former outlines general methods for evaluating whole-body vibrations, while the latter elaborates on methods for evaluating non-stationary whole-body vibrations. While the reference values in these standards are intended to model human comfort and health, the techniques themselves are used to quantify the vibration environment without reference to the species experiencing the vibration. All post-processing of the vibration data was performed using Matlab (MathWorks, Natick, MA). For all analyses, the raw acceleration data were first upsampled to 500 Hz using spline interpolation to ensure a uniform time step and no loss of detail while resampling.

The main quantity used to evaluate vibration exposure was the root-mean-squared (RMS) acceleration value , defined as

| (1) |

where N is the number of samples and aw is the frequency-weighted acceleration. The weights given in ISO 2631-1 were applied to the measured acceleration data by sequentially band-pass filtering the data using second-order, linear-phase Butterworth high- and low-pass filters with corner frequencies one-third octave outside of the target frequency band (ISO 2631-1, 1997). The filtered signals were multiplied by the weight for the corresponding pass band and summed to generate the frequency-weighted acceleration. The frequency-weighted acceleration was used to quantify the vibration transferred to the pigs rather than the physical vibrations in the environment.

The crest factor Cf was used to quantify the stationarity of the acceleration data and is defined as

| (2) |

When crest factors are greater than nine, additional metrics are required to quantify the vibration. The vibration dose value (VDV) quantifies the total amount of vibration experienced by an individual over the exposure time T. The VDV is given by

| (3) |

The frequency content of the acceleration data was analyzed by first splitting the un-weighted acceleration data into five-second intervals and calculating the power spectral density function (PSD) for each interval. The PSD function P for an acceleration signal a is calculated from

| (4) |

where fs is the sampling frequency and A is the Fourier transform of a. The PSD functions for six adjacent intervals were averaged to calculate the average PSD for a 30 s interval. The averaged PSD function for the 30 s interval has reduced noise and frequency resolution compared with a single PSD function taken over the raw data for the same interval. Repeating this process resulted in a series of PSD functions, each representing the average PSD of a non-overlapping 30 s interval. Note that unweighted acceleration data were used here to provide insight into the physical properties of the vibration environment rather than the perceived properties.

The ISO 2631-1 defines the axes of motion relative to the individual experiencing the vibration. In the present work, the axes are defined relative to the trailer and not relative to the pigs. In general, the z-axis of the trailer is coincident with the z-axis of the pigs. To account for horizontal motion, the motion in the x and y axes are combined according to ISO 2631-1 as

| (5) |

where η is a general bulk vibrational quantity (RMS or VDV). While ISO 2631-1 only applies this method to the RMS acceleration, this technique was applied to the VDV as well because the two quantities are analogous and no equivalent technique is given for the VDV. This equation represents the maximum vibration experienced for any possible orientation relative to the trailer.

Temperature and relative humidity data processing

After each day’s data collection, temperature and relative humidity data were downloaded using LogPro Software (Omega). Data were converted to a Microsoft Excel file and data from each trip was segmented into four periods. Loading consisted of the period from the beginning of loading until its completion (Load). The next period consisted of the first 30 min. after the completion of loading (Thirty). The third period consisted of the remainder of the trip until arrival at the abattoir (Trip). The unloading period was from arrival at the plant until completion of unloading (Unload). Data were analyzed as ambient temperatures recorded by the loggers and the change from the average of the reported atmosphere and relative humidity at loading and unloading.

Statistics

RMS and VDV data were analyzed as a randomized complete block design with a 2 × 3 factorial arrangement using truck load (trip) as the experimental unit. Fixed effects included Level (top or bottom) and Area (fore, center, or aft) and the random effect was state (Kansas or North Carolina). Temperature and humidity data were analyzed as a randomized complete block design with a 2 × 3 factorial arrangement with repeated measures. Fixed and random effects were the same as above in addition to time. Time served as the repeated measure, with Area × Level as subject, and compound symmetry as the covariance structure. All data were analyzed using the PROC MIXED procedure of SAS 9.4 (SAS Inst. Inc., Cary, NC) and pairwise comparisons between the least square means of the factor level comparisons were computed using the PDIFF option of the LSMEANS statement. Differences were considered significant at P < 0.05.

Results

Trip vibration analyses

Figure 2 shows RMS acceleration in the z-direction for each trip that took place in Kansas and North Carolina. Two shipments of pigs were transported in each of trips 12 through 15, but the two shipments were similar to each other, so only quantities from the first shipments of each trip are shown here for ease of visualization. Sensors on the top deck were not connected for trips 10 through 12. EAV (0.43 m/s2) and ELV (0.86 m/s2) published in ISO 2631-1 are also shown (ISO 2631-1, 1997). The reference values in ISO 2631-1 are based on an 8-h exposure duration, while a typical trip lasted only approximately 4 h. Levels of RMS exceeding the EAV are typically interpreted as uncomfortable and may cause long-term harm if the exposure duration exceeds the 8-h reference. Levels exceeding the ELV are very likely to cause long-term damage over the 8-h reference. All sensors from the Kansas data set and the majority of sensors from the North Carolina data set have an RMS acceleration exceeding the EAV. Many sensors, particularly the BA compartment of each trip, also exceed the ELV.

Figure 2.

Weighted RMS accelerations associated with the TF, BF, TC, BC, TA, and BA trailer compartments in the vertical (z) direction for (a) the Kansas trips and (b) the North Carolina trips. Each group of bars represents the RMS for all sensors for a given trip notated by truck (T), trip/session (S). The EAV and ELV from ISO 2631-1 are also shown. TF, top fore; BF, bottom fore; TC, top center; BC, bottom center; TA, top aft; BA, bottom aft.

Figure 3 shows the RMS acceleration in the combined x and y directions for each trip. The RMS accelerations in the horizontal plane are much smaller than those in the vertical direction. In fewer cases than the vertical direction, horizontal RMS accelerations exceed the EAV. Only the BA sensors have RMS accelerations that exceed the ELV. Hence, the weighted vibration in the horizontal plane is likely insignificant compared with the vertical weighted vibration.

Figure 3.

Weighted RMS accelerations associated with the TF, BF, TC, BC, TA, and BA trailer compartments in the combined x and y directions for (a) the Kansas trips and (b) the North Carolina trips. Each group of bars represents the RMS for all sensors for a given trip notated by truck (T), trip/session (S). The EAV and ELV from ISO 2631-1 are also shown. TF, top fore; BF, bottom fore; TC, top center; BC, bottom center; TA, top aft; BA, bottom aft.

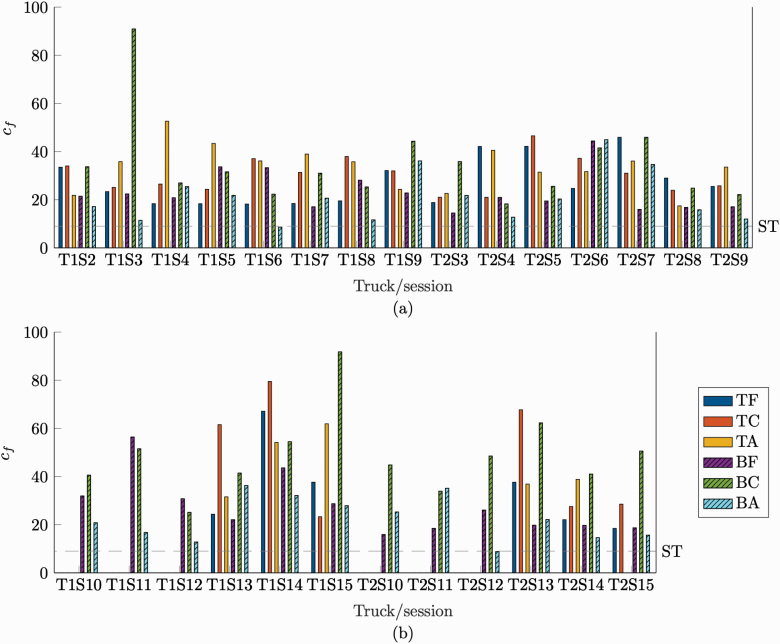

The crest factor is a metric that quantifies the steadiness or stationarity of a vibration signal. According to ISO 2631-1, for signals with a crest factor below approximately nine, the RMS acceleration is sufficient to describe the vibration for the purposes of predicting comfort and health for humans (ISO 2631-1, 1997). To date, this is the best threshold available to determine comfort and health of pigs, as no values are established. For crest factors greater than nine, additional metrics such as the VDV are required. Figure 4 shows the crest factor in the z direction for each trip. Also shown is the stationarity threshold (ST) of nine cited in ISO 2631-1. The vast majority of sensors among all the trips have a crest factor much greater than nine, so the vibration is typically far from stationary. Hence, it is important to examine the VDV in addition to the RMS acceleration to determine the effects of trailer vibrations on animal well-being. Note also that the crest factors associated with the BA sensors are often smaller than the crest factors in other trailer compartments, which implies that the BA compartment, despite having much larger RMS accelerations, may be viewed as somewhat more stationary than other compartments.

Figure 4.

Crest factors associated with the TF, BF, TC, BC, TA, and BA trailer compartments in the vertical (z) direction for (a) the Kansas trips and (b) the North Carolina trips. Each group of bars represents the crest factor for all sensors for a given trip notated by truck (T), trip/session (S). The threshold at which the RMS acceleration ceases to be a sufficient metric to describe the vibration (ST) from ISO 2631-1 is also shown. TF, top fore; BF, bottom fore; TC, top center; BC, bottom center; TA, top aft; BA, bottom aft.

Figure 5 shows the VDV for each trip that took place in Kansas and North Carolina, similar to Figure 2. Corresponding EAV and ELV values of 8.5 m/s1.75 and 17 m/s1.75, respectively, published in ISO 2631-5 are also shown (ISO 2631-5, 2018). Unlike the EAV and ELV values for RMS acceleration, the reference values for VDV evaluation may be compared to the measured VDV directly without explicit reference to exposure time. Similar to the results for RMS acceleration, all sensors from the Kansas data set and the majority of sensors from the North Carolina data set have a VDV in excess of the EAV. Many sensors also have a VDV exceeding the ELV. The VDV in the horizontal plane are significantly lower than those in the vertical direction, similar to the relationship between horizontal and vertical RMS values shown in Figures 2 and 3.

Figure 5.

Weighted VDVs associated with the TF, BF, TC, BC, TA, and BA trailer compartments in the vertical (z) direction for (a) the Kansas trips and (b) the North Carolina trips. Each group of bars represents the VDV for all sensors for a given trip notated by truck (T), trip/session (S). The EAV and ELV from ISO 2631-1 are also shown. TF, top fore; BF, bottom fore; TC, top center; BC, bottom center; TA, top aft; BA, bottom aft.

While the RMS acceleration and VDV can be valuable indicators of animal comfort based on their successful use in humans, neither measure provides a detailed description of the vibration environment from a physical perspective. A detailed physical description requires knowledge of the unweighted frequency spectra over the course of a typical trip. Figure 6 shows spectrograms for all sensors (rows) in the x, y, and z directions (columns) for truck 1 observed during session 2 (T1S2). The spectrograms are constructed from PSD functions calculated according to equation 4. Each PSD function is the average of 5-s PSD functions taken over a 30 s period. Frequencies from 0.2 to 50 Hz were analyzed. The upper frequency limit is half the original sampling frequency in accordance with the Nyquist sampling theorem. The lower limit is set by the reciprocal of the period over which the PSD is calculated. The frequency responses are typically more broadband for sensors on the bottom deck while frequency responses from the top deck typically reveal more discrete content. In particular, the BA sensors have much more broadband frequency content than sensors at other locations. For the Kansas trips using pot-bellied trailers, resonant frequencies existed in all directions at approximately 9.5, 18.5, and 28 Hz. An additional resonant frequency at 1.8 Hz also existed in the vertical direction, which likely corresponded to a bouncing motion of the trailer on its suspension. For the North Carolina trips using straight-deck trailers, resonant frequencies existed in all directions at approximately 10, 19, and 34 Hz. Much like the pot-belly trailers used in the Kansas trips, a resonant frequency at approximately 1.8 Hz also existed in the vertical direction only.

Figure 6.

Unweighted spectrograms for T1S2 at sensor positions (a–c) TF, (d–f) TC, (g–i) TA, (j–l) BF, (m–o) BC, and (p–r) BA. The columns represent sensor axes x, y, and z, respectively. The pink bars represent the time domain over which the RMS acceleration and VDV are calculated. TF, top fore; BF, bottom fore; TC, top center; BC, bottom center; TA, top aft; BA, bottom aft.

Trailer location vibration analyses

There were Area × Level interactions for z-axis RMS and VDV (P < 0.01; Figure 7). The BA compartment had a greater RMS value than all other locations (P < 0.01). The BF compartment had a greater RMS value than TF, TC, and BC (P < 0.02), but did not differ (P = 0.06) from the TA compartment. The RMS of the TA compartment did not differ from the TF, TC, and BC compartments (P > 0.13). The bottom deck of the trailer had a greater (P < 0.01) RMS value than the top deck. There was an Area main effect (P < 0.01), where the aft section of the trailer had a greater RMS value than the other two sections (P < 0.01) and the fore section of the trailer had a greater (P = 0.01) value than the center section.

Figure 7.

Effect of compartment location within the commercial pig transport trailer on z- and x, y-axis RMS and VDV.

The BA compartment had a greater z-axis VDV value than all other compartments (P < 0.01). The BF compartment had a greater (P = 0.02) VDV value than the TC compartment, but did not differ from the other compartments (P > 0.16). All other compartments did not differ in VDV value (P > 0.12). The bottom deck of the trailer had a greater (P < 0.01) VDV value than the top deck. There was an Area main effect (P < 0.01), where the aft section of the trailer had a greater VDV value than the other two sections (P < 0.01), but the front and middle sections did not differ (P = 0.15).

There were Area × Level interactions for x, y-axis RMS and VDV (P < 0.01). The BA compartment had a greater RMS than all other compartments of the trailer (P < 0.01). The BF compartment had greater RMS than the TC and TA compartments (P < 0.01), but did not differ from the TF and BC compartments (P > 0.12). All other compartments did not differ in RMS (P > 0.34). The bottom deck of the trailer had greater (P < 0.01) RMS than the top deck. There was an Area main effect (P < 0.01), where the aft section of the trailer had greater RMS than the other two sections (P < 0.01), which did not differ (P = 0.08) from each other.

The BA compartment had greater VDV than all other compartments (P < 0.01), but these compartments did not differ (P > 0.19). The bottom deck of the trailer had greater (P < 0.01) VDV than the top deck. There was an Area main effect (P < 0.01), where the aft section of the trailer had greater VDV than the other two sections (P < 0.01), which did not differ (P = 0.08) from each other.

Temperature and relative humidity analyses

There were no three-way and Area × Time interactions for all temperature and relative humidity measures (P > 0.43; Table 2). There were no Level × Time interactions for all measures (P > 0.07), except relative humidity change from atmosphere (P < 0.01). Humidity in the bottom deck was greater during loading compared with all other periods (P < 0.01). Humidity in the bottom deck at 30 min post loading was greater than the remaining time periods (P < 0.01), which did not differ from each other (P = 0.19). In the top deck, relative humidity did not differ between the time periods (P > 0.13).

Table 2.

Ambient and change from atmospheric temperature and relative humidity in six locations within pig transport trailers from loading to unloading1

| Top | Bottom | P-value | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fore | Center | Aft | Fore | Center | Aft | SEM | Area | Level | Time | Area*Level | Interactions2 | |

| Ambient | ||||||||||||

| Temperature, °C | 2.78 | <0.01 | <0.01 | <0.01 | 0.13 | >0.83 | ||||||

| Load | 10.45 | 10.27 | 8.13 | 14.42 | 12.04 | 11.89 | ||||||

| Thirty | 14.95 | 14.03 | 11.02 | 18.65 | 15.62 | 14.04 | ||||||

| Trip | 14.31 | 12.55 | 12.17 | 17.60 | 13.20 | 14.52 | ||||||

| Unload | 14.63 | 14.26 | 11.97 | 18.57 | 15.05 | 16.25 | ||||||

| Relative humidity, % | 3.08 | <0.01 | <0.01 | <0.01 | 0.08 | >0.07 | ||||||

| Load | 71.14 | 70.35 | 62.68 | 70.90 | 70.32 | 66.46 | ||||||

| Thirty | 71.46 | 69.96 | 62.21 | 64.49 | 63.80 | 64.35 | ||||||

| Trip | 67.69 | 65.30 | 60.67 | 54.42 | 59.29 | 58.55 | ||||||

| Unload | 70.35 | 67.88 | 62.80 | 60.45 | 62.25 | 58.15 | ||||||

| Change from atmosphere | ||||||||||||

| Temperature, °C | 2.04 | <0.01 | <0.01 | <0.01 | <0.01 | >0.43 | ||||||

| Load | 2.04 | 2.03 | 1.96 | 5.72 | 3.67 | 2.83 | ||||||

| Thirty | 6.53 | 5.79 | 4.84 | 9.95 | 6.51 | 5.26 | ||||||

| Trip | 6.44 | 4.31 | 3.97 | 8.77 | 4.83 | 5.64 | ||||||

| Unload | 6.76 | 6.02 | 5.79 | 9.87 | 6.68 | 7.33 | ||||||

| Relative humidity, % | 5.44 | 0.15 | <0.01 | <0.01 | 0.21 | >0.85 | ||||||

| Load | 10.29 | 8.99 | 7.79 | 13.45 | 11.16 | 6.95 | ||||||

| Thirty | 10.48 | 8.60 | 9.26 | 7.04 | 5.39 | 4.79 | ||||||

| Trip | 8.02 | 3.94 | 7.80 | −0.82 | 0.13 | −1.22 | ||||||

| Unload | 7.44 | 6.51 | 7.91 | 3.01 | 3.09 | −1.50 | ||||||

1Ambient values consisted of temperature and relative humidity recorded by USB data loggers once loading began through the end of unloading. Change from atmosphere values consisted of ambient values minus the average of the reported atmospheric temperature and humidity recorded during loading and unloading. “Load” consists of the period from the beginning of loading until its completion, “Thirty” is the first 30 min after the completion of loading, “Trip” is the remainder of the trip until arrival at the abattoir, and “Unload” is the period from arrival at the plant until the completion of unloading.

2Smallest P-values for the Area*Level*Time, Area*Time, Level*Time interactions. There was a Level*Time interaction (P < 0.01) for change from atmosphere relative humidity.

There were no Area × Level interactions for all measures (P > 0.08), except temperature change from atmosphere (P < 0.01). The TF compartment had a greater (P = 0.02) temperature change than the TA compartment. The TC compartment did not differ in temperature change compared with the other two areas (P > 0.11). The BF compartment had a greater temperature change that the other two compartments (P < 0.01), which did not differ (P = 0.75) from each other.

There were Area and Level main effects for all measures (P < 0.01), except no Area main effect (P = 0.15) for relative humidity change from atmosphere. The bottom deck had greater (P < 0.01) ambient temperature than the top deck, but had less (P < 0.01) ambient relative humidity. The fore section had greater ambient temperature than the other sections (P < 0.01), which did not differ (P > 0.20). The fore and center sections had greater ambient relative humidity than the aft section (P < 0.01), but did not differ (P = 0.96) from each other. The fore section had a greater (P = 0.05) relative humidity change from atmosphere than the aft section, while the center did not differ from either area (P > 0.20).

There were Time main effects for all measures (P < 0.01). Ambient temperatures at Load were less than all other periods (P < 0.01), which did not differ from each other (P > 0.17). Load ambient relative humidity was greater than Trip and Unload relative humidity (P < 0.01), but Load relative humidity did not differ (P = 0.10) from Thirty relative humidity. Thirty ambient relative humidity was greater (P < 0.01) than Trip relative humidity, but did not differ (P = 0.06) from Unload. Trip and Unload ambient relative humidity did not differ (P = 0.26). Load temperature change from atmosphere was less than all other periods (P < 0.01). Thirty temperature change from atmosphere did not differ from the other periods (P > 0.06), but Trip change was less (P < 0.01) than the Unload change. Relative humidity change from atmosphere was greater at Load and Thirty compared to the other periods (P < 0.01), but did not differ (P = 0.09) from each other. Trip and Unload relative humidity change from atmosphere did not differ (P = 0.26).

Discussion

The term “Fatigued Pig Syndrome” was developed to loosely describe fatigue induced by transport (Ritter et al., 2005). Hamilton et al. (2004) reported a strong correlation (r = 0.81) between nonambulatory and dead pigs. Therefore, it can be hypothesized that fatigued pigs have a good probability of dying before harvest. The economic loss due to transport losses is quite large. Ritter et al. (2009) estimated transport losses cost the swine industry approximately $46 million in 2006. This is a substantial increase from the $8 million figure estimated by Speer et al. (2001) for dead pigs. New data from Ritter et al. (2020) estimated nonambulatory and dead pigs cost the industry $37 and $52 million, annually; almost a doubling of the yearly losses reported in 2009. Aside from the economic concerns, dead and nonambulatory pigs reduce the ability of the pork industry to contribute to food security. Using data published by Ritter et al. (2009), dead and nonambulatory pigs resulted in the equivalent loss of 164 million 0.11 kg meals. Therefore, the most recent results reported by Ritter et al. (2020) figure to a loss of 336 million meals, which reduces the ability of American agriculture to feed a rapidly growing population. To understand contributors to transport losses, numerous studies have examined factors such as handling, environmental conditions, stocking density, and driving style. To date, scientists have mainly ignored the effect trailer vibrations may have on creating transport losses. Before this question can be explored, characterizing the three-axis vibration profiles of commercial pig transport trailers must be conducted.

Data from producers operating in two vastly different geographic locations of the country were collected for the current study. Because locations and production methods were different, data were not analyzed between the two locations; however, summary statistics were generated for the loads observed at each location (Table 1). On average, loading and unloading atmospheric temperatures differed by 8.4 and 7.8 °C, with Kansas trips having the colder temperatures. While both locations had similar loading and unloading times, Kansas trips after load-out to the commercial abattoir were on average 76 min longer, which resulted in much longer total trip times. Kansas trips had more variability in the time measurements, primarily because of the long transfer method to load the pigs and long wait times before unloading pigs at the abattoir for the four loads originating from Kansas State University. On average, Kanas loads transported less pigs which were lighter, which resulted in lighter total load weights. In Kansas, 0.23% of the pigs delivered were categorized as dead, while 0.11% of the pigs were dead upon arrival in North Carolina. North Carolina values were below the industry values reported by Ritter et al. (2020) who reported dead pigs ranged between 0.22% and 0.24%, but the Kansas loads met the industry average. In North Carolina 0.39% of the pigs transported displayed signs of being fatigued, which is less than the reported nonambulatory pig range of 0.66% and 0.70% (Ritter et al., 2020). Overall, while atmospheric temperatures were warmer than anticipated, loads of pigs observed are typical of what is currently shipping in these two parts of the country.

As mentioned earlier, there are no comfort or injury threshold values established for livestock species; therefore, ISO standards are the best values currently available. While these values are correlated to human comfort and injury, Gebresenbet et al. (2011) used the same thresholds in their study. In the current study, values would indicate vibrations in the trailer environment could contribute to pig transport losses. In the vertical direction, RMS acceleration and VDV almost always exceeded the EAV, and the ELV for RMS acceleration and VDV were frequently exceeded. Values in excess of the EAV and ELV reference values reported in ISO 2631-1 and ISO 2631-5 are likely to cause discomfort. ISO 2631-1 includes a list of approximate comfort levels and the associated RMS acceleration values, reproduced in Table 3 (ISO 2631-1, 1997). The RMS acceleration EAV and ELV values of 0.43 and 0.86 m/s2 correspond to comfort levels of “a little uncomfortable” and “uncomfortable”, respectively. These comfort values are based on the likely reactions of human passengers on public transport, such as city busses (Sekuli´c et al., 2013). Gebresenbet et al. (2011) found vibration values along the three-axis cattle experienced during transportation in Europe were above the European Union’s EVA and the lateral vibrated near the ELV. The total comfort level of a trip may be diminished by other environmental factors such as trip duration, temperature, posture (seated or standing), acoustic noise, or cramped conditions (ISO 2631-1, 1997). While not measured in the current study, it could be expected the pigs were likely less comfortable than the reference values predicted due to other environmental factors such as cramped conditions, temperatures, road noise, and the texture of the floors on which the animals stand.

Table 3.

Approximate comfort levels and corresponding RMS accelerations1

| , m/s2 | Comfort Level |

|---|---|

| <0.315 | Not uncomfortable |

| 0.315–0.63 | A little uncomfortable |

| 0.5–1.0 | Fairly uncomfortable |

| 0.8–16 | Uncomfortable |

| 1.25–2.5 | Very uncomfortable |

| >2.0 | Extremely uncomfortable |

1Values taken from ISO 2631-1 (ISO 2631-1, 1997).

The resonant frequencies observed in the spectrograms of Figure 6 roughly agree with the fundamental frequencies of poultry transport trailers (Scott, 1994). Furthermore, Scott (1994) stated the viscera of broiler chickens exhibit resonance at approximately 10 Hz, which corresponded to the trailer’s second resonant frequency. This resonance caused added strain on the skeletal muscles as they compensate for the extreme motion of the organs. Perremans et al. (2001) vibrated pigs with body weights between 20 and 25 kg at frequencies of 2, 4, 8, and 18 Hz for 2-h intervals at a RMS magnitude of 1 or 3 m/s2. The pigs spent less time lying down during all vibration trials than under control conditions, but the time spent lying was 10 times shorter at 8 Hz and 18 times shorter at 18 Hz compared with exposures at 2 and 4 Hz. Both the pot-bellied and straight deck trailers studied here have resonant frequencies at approximately 8 and 18 Hz, suggesting pigs may be bothered by the trailers’ vibration environments. Furthermore, based on the frequency weights used to generate the frequency-weighted acceleration from ISO 2631-1, frequencies between approximately 0.5 and 10 Hz are the most important to predicting human discomfort due to vertical vibrations. Water et al. (2003) found calves become more stressed when subjected to vibrations at 2 Hz than at 12 Hz. Hence, it is possible that the resonance at approximately 1.8 Hz has a significant effect on fatigue in pigs. The most important frequencies for predicting human discomfort due to horizontal vibrations lie between 0.5 and 2 Hz. Because the first resonant peak at approximately 1.8 Hz has only a small component in the horizontal plane, resulting in small horizontal RMS accelerations, it is unlikely that horizontal vibration is an important factor for predicting fatigue.

One of the main objectives of this study was to determine if different compartments of the trailer possessed divergent vibration and environmental profiles. Randall (1992) hypothesized livestock experience different and greater vibration patterns than drivers because the trailer is not designed to minimize vibrations. The BA z- and x, y-axis RMS accelerations were on average 166% and 165% greater than the other compartments, respectively. Similar to RMS results, BA z- and x, y-axis VDV values were on average 152% and 181% greater than the other compartments, respectively. The BA compartment is directly above the rear axle, which may indicate transfer of vibrations from the road to the trailer are most pronounced in that location. The effect of the tires directly transferring vibrations from the road to the trailer can also be seen where BF z-axis RMS and VDV and x, y-axis RMS are greater than several other compartments. To date, there are few studies examining vibration profiles in commercial livestock trailers, with a majority of the studies conducted outside the United States. In contrast to the current study, Aradom and Gebresenbet (2013) reported the floor closest to the chassis had less vertical and lateral vibrations and more horizontal vibrations than floor 3 of a 3-deck transport trailer. The difference between this study and the current study could lie in differences in trailer designs and possibly the materials used in the construction of the trailers. The current study observed aluminum trailers, while Aradom and Gebresenbet (2013) observed trailers with steel alloy construction. In agreement with the current study, Stevens and Camp (1979) and Singh (1991) reported the rear compartment above the axle produced the most vibrations. While Peeters et al. (2008) did not compare the different compartments within the trailer, the authors reported that as driving patterns became more “wild”, longitudinal and lateral forces increased, pig heart rate and cortisol values increased (increase in stress), and pigs stood more. Overall, the data of the current study suggest the bottom deck compartments over the tires experience more vibrations than the remainder of the trailer.

In contrast to trailer vibration research, one of the most studied factors contributing to transport losses is environmental conditions during transportation. Within this area of study, numerous studies demonstrated season strongly influences trailer temperature. Fitzgerald et al. (2009) concluded there were more transport losses at Midwest United States commercial abattoirs, including dead, fatigued, and injured pigs during the hotter months of the year (June–July) compared with cooler months (November–December). In a foundational study, Smith and Allen (1976) found little effect of humidity on losses in England, but losses greatly increased when temperatures were above 18 °C. Also observing the English production system, Warriss and Brown (1994) reported transport losses exponentially increased when temperatures were above 15 to 17 °C. Ritter et al. (2007) and Ritter and Ellis (2008) found the incidence of nonambulatory pigs increased in the winter months compared with the spring and summer. For the current study, the majority of the observed trips occurred during the winter months (December through February); however, the majority of the trips experienced warmer temperatures than anticipated or desired.

In the current study, ambient temperature at loading was approximately 3.4 °C lower at loading than the rest of the trip. Relative humidity was 5.1% greater through the first 30 min of the trip compared with the remaining time pigs were in the trailer. When considering changes from atmosphere, loading temperature was also 3.4 °C lower than the rest of the trip, and relative humidity was 5.5% greater through the first 30 min of the trip compared with the remaining observed time. Overall, a time pattern can be seen where temperatures rose and humidity fell during the first 30 min of the trip, both fell during the remainder of the trip to the abattoir, and they rose while unloading occurred. This could indicate air movement in the trailer is responsible for the temperature and humidity fall during the majority of movement, but both climb once the truck stops major movement at the abattoir. Mitchell and Kettlewell (2009) reported a similar increase/decrease/increase in pig produced heat and moisture when they were transported and experienced stationary periods in European transport trailers. McGlone et al. (2014) reported in cold weather (<10 °C), temperature and relative humidity increased 0.1 °C and 0.13% to 0.22%, respectively, per minute during loading. Lewis et al. (2010) found a fully loaded stationary trailer increased in temperature 1.5 °C every 15 min. Xiong et al. (2018) reported a rise in temperature after loading pigs is more apparent in cold, rather than hot weather. These studies and the current study’s results indicate movement and ventilation are key to maintaining a comfortable environment for pigs during transport.

Aside from trailer movement and atmospheric temperature, compartment and deck within the trailer could play a major role on pig well-being. Throughout the entire trip, the bottom deck of trailers observed in the current study were 2.8 °C greater in temperature and ambient relative humidity and relative humidity change from atmosphere were reduced by 3.6% and 3.8%, respectively. The fore compartment of the trailer was 2.5 °C greater in temperature compared with the other areas of the trailer and the fore and center of the trailer was 4.3% more humid than the aft. The only significant difference in compartments lied in temperature change from atmosphere, where the BF compartment had a 3.6 °C greater temperature rise than the other compartments. Ritter and Ellis (2008) reported pot belly trailers were hotter than flat-deck trailers due to differences in perforation patterns of the sidewalls. Brown et al. (2011) also reported intra-trailer temperature variation of pot belly trucks, with greater temperatures recorded in the front compartments of the middle and bottom decks. McGlone et al. (2014) found compartment temperature and humidity were dependent on bedding level. Because bedding was only used on the Kansas State University loads, bedding was most likely not a factor in this study. Xiong et al. (2018) reported change in temperature from atmosphere and temperature/humidity index were not affected during hotter weather, but in cold and very cold weather, change in temperature was on average 3.3 °C greater in the fore compartments of the trailer compared with center and aft compartments. The authors hypothesized circulating air was entering the trailer from the aft and accumulating in the fore and Seedorf and Schmidt (2017) demonstrated the front compartment of a 3-deck European pig transport trailer caused a suction event which pulled air from the rear to the front of the trailer. Observations from this study indicated the fore compartments, especially the BF, may have had greater temperatures because ventilation was always blocked at the front of the trailer in cold weather, thus preventing air suction, the truck also provided some level of protection from air movement, and the truck also generates some heat which may accumulate in the fore compartments. Overall, while temperature and relative humidity most likely did not affect pigs in the current study, these factors could be major influencers of well-being in the summer.

Conclusion

Data from the current study provided one of the first comprehensive simultaneous evaluations of environmental and vibration profiles associated with different compartments of two types of commercial pig trailers transporting finished pigs on roadways within the United States. While atmospheric temperatures during data collection were warmer than expected, data indicated the bottom deck, especially the BF compartment, possessed greater temperatures than the remainder of the trailer. Vibration data indicated vertical vibrations were greater than horizontal vibrations. The BA compartment had much larger vibrations than other compartments and the BF had the next greatest vibrations. This would indicate compartments located above the wheels of the truck and trailer could be a major source of vibration and a possible area of the trailer that can be improved. The exact effect of vibrations detected in the current study on pig welfare, specifically muscle fatigue, are hard to quantify, but using EAV and ELV thresholds as guidance suggests vibrations in most of the truck may be enough to be considered uncomfortable and possibly affect muscle function or fatigue rate. These vibration profiles and their effect on muscle fatigue need to be explored further.

Acknowledgments

This work was supported by Animal Health and Production and Animal Products: Animal Well-Being grant no. 2018-67015-30090/project accession no. 1020292 from the USDA National Institute of Food and Agriculture. We would like to thank Doug Schaefer of Schaefer Trucking, LLC. and Smith Mackey of Mackey Family Transport for allowing data collection to occur on their trailers; Jimmy Pollock of J. C. Howard Farms, LLC. for allowing data to be collected on loads of pigs; Jason McAlister of Triumph Foods for allowing data collection at the commercial abattoir; and Matt Ritter of Provimi North America for assistance in locating cooperating producers.

Glossary

Abbreviations

- EAV

exposure action value

- ELV

exposure limit value

- PSD

power spectral density

- RMS

root-mean-squared

- ST

stationary threshold

- VDV

vibration dose value

Conflict of interest statement

The authors declare no real or perceived conflicts of interest.

Literature Cited

- Anderson, D. B., D. J. Ivers, M. E. Benjamin, H. W. Gonyou, D. J. Jones, K. D. Miller, R. K. Mcguffey, T. A. Armstrong, D. H. Mowrey, L. F. Richardson, . et al. 2002. Physiological responses of market hogs to different handling practices. Kansas City (MO): Proc Am. Assoc. Swine Vet; p. 399–400. [Google Scholar]

- Aradom, S., and G. Gebresenbet. . 2013. Vibration on animal transport vehicles and related animal behaviours with special focus on pigs. J. Agri. Sci. Tech. A 3:231–245. [Google Scholar]

- Averós, X., T. G. Knowles, S. N. Brown, P. D. Warriss, and L. F. Gosálvez. . 2008. Factors affecting the mortality of pigs being transported to slaughter. Vet. Rec. 163:386–390. doi: 10.1136/vr.163.13.386 [DOI] [PubMed] [Google Scholar]

- Baker, C., S. Dalley, X. Yang, P. J. Kettlewell, and R. Hoxey. . 1996. An investigation of the aerodynamic and ventilation characteristics of poultry transport vehicles: part 2, wind 558 tunnel experiments. J. Agri. Eng. Res. 65:97–113. doi: 10.1006/jaer.1996.0083 [DOI] [Google Scholar]

- Bench, C., A. L. Schaefer, and L. Faucitano. . 2008. The welfare of pigs during transport. In: Faucitano, L. and A. L. Schaefer, editors, The welfare of pigs—from birth to slaughter. Wageningen: Wageningen, Academic Publishing. p. 161–195. [Google Scholar]

- Brown, J. A., T. S. Samarakone, T. Crowe, R. Bergeron, T. M. Widowski, J. A. A. Correa, L. Faucitano, S. Torrey, and H. W. Gonyou. . 2011. Temperature and humidity conditions in trucks transporting pigs in two seasons in eastern and western Canada. Trans. ASABE. 565 54:2311–2318. doi: 10.13031/2013.40650 [DOI] [Google Scholar]

- Caulfield, M. P., H. Cambridge, S. F. Foster, and P. D. McGreevy. . 2014. Heat stress: a major contributor to poor animal welfare associated with long-haul live export voyages. Vet. J. 199:223–228. doi: 10.1016/j.tvjl.2013.09.018 [DOI] [PubMed] [Google Scholar]

- Cvetanovic, B., and D. Zlatkovic. . 2013. Evaluation of whole-body vibration risk in agricultural tractor drivers. Bulgarian J. Ag. Sci. 19:1155–1160. [Google Scholar]

- Fitzgerald, R. F., K. J. Stalder, J. Matthews, C. M. S. Kaster, and A. K. Johnson. . 2009. Factors associated with fatigue, injured, and dead pig frequency during transport and 573 lairage at a commercial abattoir. J. Anim. Sci. 87:1156–1166. doi: 10.2527/jas.2008-1270 [DOI] [PubMed] [Google Scholar]

- Gebresenbet, G., S. Aradom, F. S. Bulitta, and E. Hjerpe. . 2011. Vibration levels and frequencies on vehicle and animals during transport. Biosys. Eng. 110:10–19. doi: 10.1016/j.biosystemseng.2011.05.007 [DOI] [Google Scholar]

- Hagbarth, K. E., and G. Eklund. . 1966. Tonic vibration reflexes (TVR) in spasticity. Brain Res. 2:201–203. doi: 10.1016/0006-8993(66)90029-1 [DOI] [PubMed] [Google Scholar]

- Haley, C., C. E. Dewey, T. Widowski, and R. Friendship. . 2008. Association between in-transit loss, internal trailer temperature, and distance traveled by Ontario market hogs. Can. J. Vet. Res. 72:385–389. [PMC free article] [PubMed] [Google Scholar]

- Hamilton, D. N., M. Ellis, T. M. Bertol, and K. D. Miller. . 2004. Effects of handling intensity and live weight on blood acid-base status in finishing pigs. J. Anim. Sci. 82:2405–2409. doi: 10.2527/2004.8282405x [DOI] [PubMed] [Google Scholar]

- ISO 2631-1, 1997. 1997. Mechanical vibration and shock—evaluation of human exposure to whole-body vibration—part 1: general requirements. Geneva: Standard. International Organization for Standardization. [Google Scholar]

- ISO 2631-5, 2018. 2018. Mechanical vibration and shock—evaluation of human exposure to whole-body vibration—part 5: method for evaluation of vibration containing multiple shocks. Geneva: Standard. International Organization for Standardization. [Google Scholar]

- Kadim, I. T., O. Mahgoub, A. Al-Kindi, W. Al-Marzooqi, and N. M. Al-Saqri. . 2006. Effects of transportation at high ambient temperatures on physiological responses, carcass and meat quality characteristics of three breeds of Omani goats. Meat Sci. 73:626–634. doi: 10.1016/j.meatsci.2006.03.003 [DOI] [PubMed] [Google Scholar]

- Kettlewell, P. J., C. J. Hampson, N. R. Green, and N. J. Teer. . 2001. Heat and moisture generation of livestock during transportation. In Livestock Environment VI: Proceedings of the 6th International Symposium, Louisville, KY. p. 519–526. doi: 10.13031/2013.7112 [DOI] [Google Scholar]

- Lewis, C. R. G., N. Krebs, L. E. Hulbert, and J. J. McGlone. . 2010. Use of a putative maternal pheromone during transport and the effect of trailer temperatures on pig losses and welfare. Anim. Prod. Sci. 50:916–924. doi: 10.1071/AN09147 [DOI] [Google Scholar]

- McGlone, J., A. Johnson, A. Sapkota, and R. Kephart. . 2014. Temperature and relative humidity inside trailers during finishing pig loading and transport in cold and mild weather. Animals (Basel). 4:583–598. doi: 10.3390/ani4040583 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Miranda-de la Lama, G. C., M. Villarroel, and G. A. Mar´ıa. . 2014. Livestock transport from the perspective of the pre-slaughter logistic chain: a review. Meat Sci. 98:9–20. doi: 10.1016/j.meatsci.2014.04.005 [DOI] [PubMed] [Google Scholar]

- Mitchell, M. A., and P. J. Kettlewell. . 2009. Welfare of poultry during transport—a review. Proceedings of 8th Poultry Welfare Symposium, Cervia, Italy. p. 90–100. [Google Scholar]

- Nielsen, B. L., L. Dybkjær, and M. S. Herskin. . 2011. Road transport of farm animals: effects of journey duration on animal welfare. Animal 5:415–427. doi: 10.1017/S1751731110001989 [DOI] [PubMed] [Google Scholar]

- Peeters, E., K. Deprez, F. Beckers, J. De Baerdemaeker, A. E. Aubert, and R. Geers. . 2008. Effect of driver and driving style on the stress responses of pigs during a short journey by trailer. Anim. Welfare. 17:189–196. [Google Scholar]

- Perremans, S., J. M. Randall, G. Rombouts, E. Decuypere, and R. Geers. . 2001. Effect of whole-body vibration in the vertical axis on cortisol and adrenocorticotropic hormone levels in piglets. J. Anim. Sci. 79:975–981. doi: 10.2527/2001.794975x [DOI] [PubMed] [Google Scholar]

- Randall, J. M. 1992. Human subjective response to lorry vibration: implications for farm animal transport. J. Agri. Eng. Res. 52:295–307. doi: 10.1016/0021-8634(92)80068-4 [DOI] [Google Scholar]

- Randall, J. M., M. T. Cove, and R. P. White. . 1996. Resonant frequencies of broiler chickens. Animal Science. 62:369–374. doi: 10.1017/S1357729800014697 [DOI] [Google Scholar]

- Ritter, M., and M. Ellis. . 2008. Effect of season and trailer design on transport losses in market weight pigs. Presentation at the Livestock Transport Conference, Kansas City, MO, USA, 620. [accessed 16 June 2016]. http://www.meatami.com/ht/a/GetDocumentAction/i/11139. [Google Scholar]

- Ritter, M., M. Ellis, M. Benjamin, E. Berg, P. DuBois, J. Marchant-Forde, A. Green, P. Matzat, P. Mormede, T. Moyer, . et al. 2005. The fatigued pig syndrome. J. Anim. Sci. 83(Suppl. 1):258. (Abstr.) [Google Scholar]

- Ritter, M., M. Ellis, N. Berry, S. Curtis, L. Anil, E. Berg, M. Benjamin, D. Butler, C. Dewey, B. Driessen, . et al. 2009. Review: transport losses in market weight pigs: I. A review of definitions, incidence, and economic impact. Prof. Anim. Sci. 25:404–414. doi: 10.15232/S1080-7446(15)30735-X [DOI] [Google Scholar]

- Ritter, M. J., M. Ellis, C. R. Bertelsen, R. Bowman, J. Brinkmann, J. M. Dedecker, K. K. Keffaber, C. M. Murphy, B. A. Peterson, J. M. Schlipf, . et al. 2007. Effects of distance moved during loading and floor space on the trailer during transport on losses of market weight pigs on arrival at the packing plant. J. Anim. Sci. 85:3454–3461. doi: 10.2527/jas.2007-0232 [DOI] [PubMed] [Google Scholar]

- Ritter, M. J., C. L. Yoder, C. L. Jones, S. N. Carr, and M. S. Calvo-Lorenzo. . 2020. Transport losses in market weight pigs: II. U.S. incidence and economic impact. Transl. Anim. Sci. 4:txaa041. doi: 10.1093/tas/txaa041 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schwartzkopf-Genswein, K. S., L. Faucitano, S. Dadgar, P. Shand, L. A. González, and T. G. Crowe. . 2012. Road transport of cattle, swine and poultry in North America and its impact on animal welfare, carcass and meat quality: a review. Meat Sci. 92:227–243. doi: 10.1016/j.meatsci.2012.04.010 [DOI] [PubMed] [Google Scholar]

- Scott, G. B. 1994. Effects of short-term whole body vibration on animals with particular reference to poultry. World’s Poultry Sci. J. 50:25–38. doi: 10.1079/WPS19940003 [DOI] [Google Scholar]

- Seedorf, J., and R. G. Schmidt. . 2017. The simulated air flow pattern around a moving animal transport vehicle as the basis for a prospective biosecurity risk assessment. Heliyon 3:e00358. doi: 10.1016/j.heliyon.2017.e00358 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sekuli´c, D., V. Dedovi´c, S. Rusov, S. Salini´c, and A. Obradovi´c. . 2013. Analysis of vibration effects on the comfort of intercity bus users by oscillatory model with ten degrees of freedom. Appl. Math. Mod. 37:8629–8644. doi: 10.1016/j.apm.2013.03.060 [DOI] [Google Scholar]

- Singh, S. P. 1991. Vibration levels in commercial truck shipments. ASAE Meeting Presentation 1–12, Albuquerque, NM. [Google Scholar]

- Smith, L. P., and W. M. Allen. . 1976. A study of the weather conditions related to the death of pigs during and after their transportation in England. Agric. Meteorol. 16:115–124. doi: 10.1016/0002-1571(76)90072-8 [DOI] [Google Scholar]

- Speer, N. C., G. Slack, and E. Troyer. . 2001. Economic factors associated with livestock transportation. J. Anim. Sci. 79(E. Suppl.):E166–E170. doi: 10.2527/jas2001.79E-SupplE166x [DOI] [Google Scholar]

- Stevens, D. G., and T. H. Camp. . 1979. Vibration in a livestock vehicle. ASAE Meeting Presentation, 1–10, New Orleans, LA. [Google Scholar]

- Swanson, J. C., and J. Morrow-Tesch. . 2001. Cattle transport: historical, research, and future perspectives. J. Anim. Sci. 79:E102–E109. doi: 10.2527/jas2001.79E-SupplE102x [DOI] [Google Scholar]

- Warriss, P. D., and S. N. Brown. . 1994. A survey of mortality in slaughter pigs during transport and lairage. Vet. Rec. 134:513–515. doi: 10.1136/vr.134.20.513 [DOI] [PubMed] [Google Scholar]

- Van De Water, G., T. Heylen, K. Swinnen, and R. Geers. . 2003. The impact of vertical vibrations on the welfare of calves. Dtsch. Tierarztl. Wochenschr. 110:111–114. [PubMed] [Google Scholar]

- Xiong, Y., R. S. Gates, and A. R. Green-Miller. . 2018. Factors affecting trailer thermal environment experienced by market pigs transported in the US. Animals. 8:4–20. doi: 10.3390/ani8110203 [DOI] [PMC free article] [PubMed] [Google Scholar]