Abstract

Silicone hydrogels (SiHy), represent composite matrices composed of hydrophobic gas permeable silicone (Si) rich core and a surface enriched with hydrophilic polymer moieties. Their utilization in contact lens design requires number of SiHy properties (hydration, wettability, lubricity) to be optimized for the challenging conditions at the ocular surface. Typical limitations in literature are that (i) these properties are studied in isolation, monitoring only one parameter but not the rest of them, and (ii) measurements are performed with hydrated samples immediately after removal from storage solutions. Here we study the simultaneous evolution of critical material properties (evaporative loss of water, water contact angle, coefficient of friction) of different SiHy subjected to continuous blink-like desiccation/rehydration cycling. SiHy with wetting agents incorporated in their core (narafilcon A, senofilcon A) were particularly susceptible to extended desiccation. Stenfilcon A, a material with only 3% bulk Si content maintained its performance for 4 h of cycling, and delefilcon A (80% surface water content) resisted extended 8 h of desiccation/rehydration runs. Strong correlation exists between the evolution of SiHy wettability and lubricity at ≥4 h of blink-like cycling. Understanding the interplay between SiHy properties bears insights for knowledge based design of novel ophthalmic materials.

Keywords: Silicone hydrogels, wettability, coefficient of friction, desiccation, material properties, contact lens, water gradient

Introduction

Silicone hydrogels (SiHy) represent composite polymer materials composed of hydrophobic and highly gas permeable silicone (Si) rich core and a surface enriched with hydrophilic polymer moieties1 SiHy have found major field of application in the design of daily disposable contact lens (CL) used by millions of people today.2 Other implementations of SiHy include weekly disposable CL, drug delivery vehicles and tissue engineering implants.3

In order to ensure the visual acuity and the comfort of wear of the contact lens in vivo at the ocular surface, SiHy should be well optimized to maintain the stability of the 2–3 µm thin pre-lens tear film (PLTF) and to ensure the lubrication, i.e. the low coefficient of friction, between the eyelid wiper and the CL surface at blink.4 Fulfilling these functionalities have proven to be a challenging task due to the inherent stress exerted on the SiHy structure by the physiological conditions. Once fitted at the eye, CLs are continuously subjected to cycles of 6–40 s of desiccative exposure to air at interblink (open eye) and rapid rehydration (eye closing at blink). In the course of the day the accumulating desiccation stress modifies the sample structure and makes it possible for the hydrophobic silicone moieties to migrate from the core to the surface compromising the material properties of the SiHy which results in shortened PLTF breakup time (from 10–15 s to < 5 s) and lid wiper epitheliopathy (frictional wear of the lid margin).5,6

In an effort to maintain the surface properties of SiHy and to prevent or mitigate the effect of Si migration from the bulk to the surface of the material, various strategies have been implemented: from incorporation of wetting agents (polyvinylpyrrolidone, poloxamers etc.) in the SiHy core to the design of sophisticated CL surfaces with high water holding properties. The SiHy studied are chosen to present these distinct approaches7–9: narafilcon A (NarA), senofilcon A (SenA), stenfilcon A (StenA) and delefilcon A (DelA). NarA and SenA are SiHy materials with 48% and 38% water content, respectively, and no surface coating; polyvinylpyrrolidone based internal wetting agent is utilized instead. StenA (54% water content) implements the so called “smart chemistry” with just 4.4% silicone content, while DelA utilizes water gradient technology resulting in >80% water content at the CL surface.1

The laboratory studies of the material properties (water content, wettability, coefficient of friction) which might be crucial for the interaction of the contact lens with the tear film and with the cornea mostly share two major limitations. Firstly, the properties are typically accessed in isolation not accounting for the possible mutual relationship between them. However, the wettability of SiHy is essential for the integrity of the PLTF, which in turn can act as a lubricant minimizing the friction between the eyelid wiper and the CL surface. Thus although no previous studies are reported in this regard, it can be expected that wettability may influence SiHy lubricity.8,10,11 Secondly, the studies are commonly performed with fresh hydrated samples just removed from the blister solution, which neglects the alterations occurring in the CL due to accumulation of desiccation stress in the course of daily wear.8

Therefore, the aim of the current study is to probe simultaneously the changes that occur in the water content, the wettability and the coefficient of friction (CoF) of these four diverse silicone hydrogels in the course of blink-like desiccation (10 s)/rehydration (1 s) cycling and to analyze the relationship between these properties at a time scale matching the duration of extended daily wear of the CL (0 i.e. no air exposure at all, 1, 2, 4, 8, 12 and 16 h). Furthermore, the influence of frictional aging and sliding velocity on the tribological performance of SiHy is probed. While the effects of sliding velocity and frictional aging on the lubricity of CL was discussed before,12–14 to the best of our knowledge there is no previous systematic study on the effect of accumulation of desiccation stress, a major factor at the ocular surface, on the CoF of SiHy, neither on the relationship between the desiccation, wettability and CoF of SiHy. The wettability of the samples was assessed via sessile drop contact angle as explained in our previous study.9 The coefficient of friction was measured with pin-on-disk reciprocating microtribometer as it allows for implementation of broad range of sliding speeds, mucin coated (i.e. corneal like) glass countersurface and tear mimicking lubricant solution (an established model of the natural tears).4,12,15,16

Materials and methods

Materials

The SiHy samples used were obtained in the form of commercial contact lens: Senofilcon A– Acuvue®Oasys®1-Day (Johnsons&Johnson, Santa Ana, USA), Delefilcon A- Dailies Total 1 (Alcon, Fort Worth, USA), Stenfilcon A – My Day® (Cooper Vision, Lake Forest, USA), Narafilcon A - 1-Day Acuvue® TruEye ® (Johnsons&Johnson, Santa Ana, USA). The technical specifications of the SiHy are summarized in Table 1.

Table 1.

Summary of SiHy materials proprietary names and of some material properties of interest.

| Specifications |

USAN name |

||||

|---|---|---|---|---|---|

| Senofilcon A | Delefilcon A | Stenfilcon A | Narafilcon A | ||

| Surface treatment | None. Hydraluxe® internal wetting agent | Water gradient technology | Smart silicone chemistry (3% Si content) | None. PVP as internal wetting agent. | |

| Water content | 38% | 33% at core, >80% at surface | 54% | 48% | |

Note: Data provided by the manufacturers.

Prior measurements the contact lens were removed from blister and soaked/washed in phosphate buffered saline (PBS, pH 7.4) for 24 h in order to remove wetting agents from blister solution or agents that can be released from the lens core. The absence of desorbable wetting agents was accessed by monitoring of the surface tension of the washing solution.17

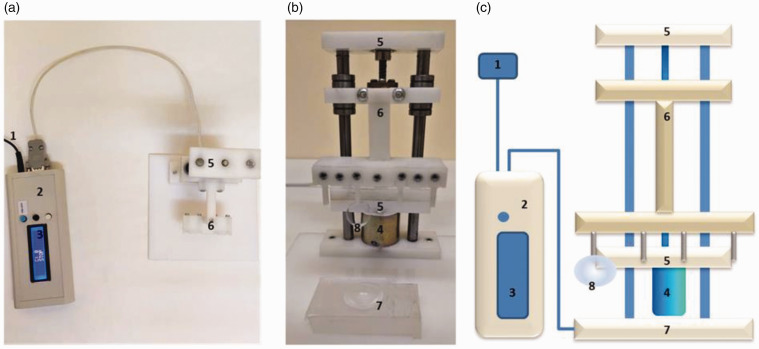

Then the SiHy were positioned on a dipping machine (Robotic Ltd., Sofia, Bulgaria) shown at Figure 1 and subjected to continuous automatic desiccation/rehydration cycling for 0 (no air exposure at all), 1, 2, 4, 8, 12 and 16 h as previously described.9,18 Each cycle consisted of 10 s air exposure of the CL and 1 s immersion in PBS buffer. This regime was chosen to emulate the natural blinking dynamics where interblink time (i.e., the period of time for which the eye is kept open) is reported to vary between 6 s (relaxed condition) to 40 s (when working on mobile phone/computer screen). For each time point 10 samples of each SiHy material were tested with each of the measurement protocols (see next points).

Figure 1.

Dipping device used for desiccation/rehydration cycling. A. Top view; B. Holder and adjustable container with PBS solution; C. Diagram of the device: 1 – power supply, 2 – controller, 3 – display, 4 – DC motor, 5 – fixed frame, 6 – moving lens holder, 7 – adjustable immersion bath, 8 – contact lens (up to four may be tested simultaneously). Small portion of the lens is gently attached to the holder and a desiccation/rehydration cycling program is selected via the controller. For the current study the lens is immersed in the bathing solution for 1 s and is kept in air for 10 s in each step of the cycling process.

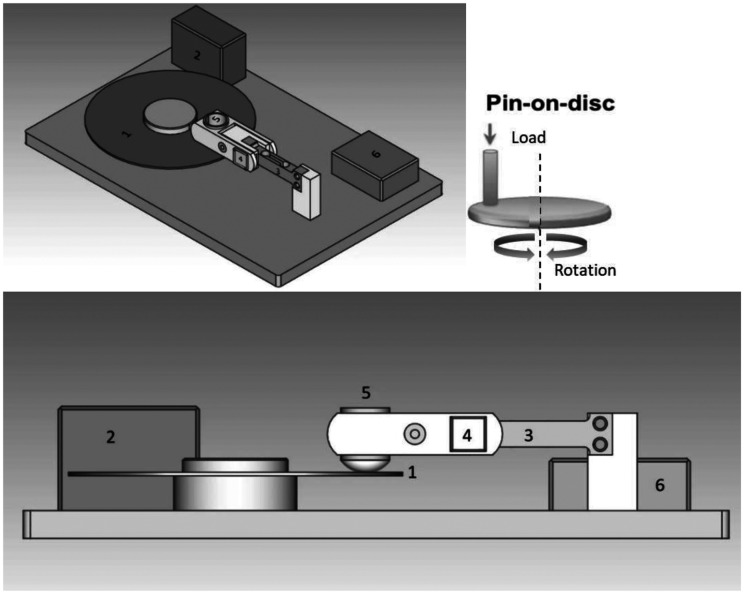

Pin-on-disk reciprocating microtribometry

Pin-on-disk reciprocating microtribometer (Robotic Ltd, Sofia, Bulgaria) allowing for registration of very low friction forces (0.01mN reproducibility) was used (Figure 2) for the study of the contact lens coefficient of friction in agreement with the approach described previously.19 The counter surface mounted on the rotary disk is mucin coated glass disk as described in Roba et al.12 to emulate the coating of the eyelid wiper surface. The friction coefficient (CoF) is defined as:

| (1) |

where FF friction force is between the CL surface and the countersurface and FN is the normal load.

Figure 2.

A CAD drawing of the pin-on-disk reciprocating microtribometer for the study of the contact lens coefficient of friction: 1 – tribometer disc; 2 – disc motor – controls speed and direction of the disc; 3 – friction force sensor – measure friction force between disc and lens; 4 – normal load sensor/actuator – creates and measures normal load applied to lens; 5 – lens holder; 6 – control electronics. In this setup the contact lens is attached to the holder (5). Thus the contact lens faces downwards and it is touched to rotary tribometer disc (1) that is covered with bovine submaxillary mucin treated glass. The mucin treated glass is wetted with thin film of lubricating fluid.

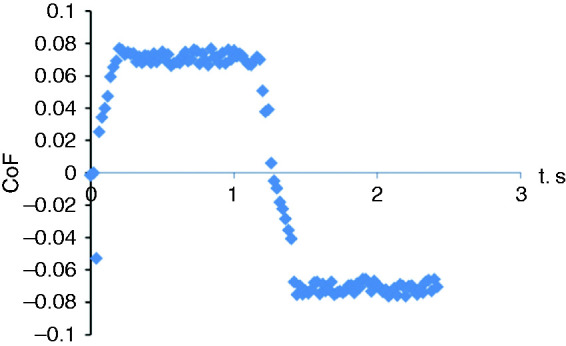

The pin-on-disc reciprocating microtribometer setup allows for multiple useful features. The stroke length is 1 cm which allows for accurate determination of the kinetic CoF (see Figure 3).

Figure 3.

Typical coefficient of friction transient obtained with the pin-on-disc reciprocating tribometer shown at Figure 2. The plateau values correspond to the kinetic coefficient of friction. The change of sign of the CoF values denotes the change in the direction of rotation, clockwise to counter clockwise, of the tribometer disk.

Stroke linear velocities that well encompass the physiologically relevant range of eyelid velocities were used here: (i) 0.1 mm/s which corresponds to eyelid velocity at small partial blinks) and (ii) 8 cm/s similar to the eyelid velocity at complete blink.13 The angular velocity of the tribometer disk is converted to linear velocity via equation (2)19:

| (2) |

where: is the linear velocity in m/s; r: Radius, in meter; RPM: Angular velocity, in RPM (Revolutions per Minute); 0.10472 comes from the ratio 2π/60 linking RPM to rad/s

The normal force applied to the CLs is 2 mN.12 Control experiments with normal loads in the range 0.25–5 mN did not change the trends in the CL behavior (data not shown). Similarly to linear reciprocating tribometry in the pin-on-disk setup the pressure exerted on the SiHy cannot be measured directly and can only be approximated by the Hertzian model which relates the pressure over the SiHy with its Young’s modulus.20 For the SiHy studied the modulus varies between 0.025 MPa (DelA)21 to 0.75 MPa (SenA).22 This yields pressures in the range of 0.23–5.79 kPa, which agrees with the range (0.3–7 kPa) of upper eyelid pressures over contact lens surface reported for the human eye.23–27

Five cycles, backward and forward, were recorded for each target time point (0, 1, 2, 4, 8, 12, and 16 hours) at stroke length 1 cm and stroke linear velocities of 0.1 mm/s and 8 cm/s. Generally after the third cycle stable stationary values were reached. Only data points obtained from the fifth cycle were subsequently analyzed. Two type of measurements were performed at each time point (0, 1, 2, 4, 8, 12 and 16 hours): (i) with CL immediately removed from the air cycling without frictional aging and (ii) with CL subjected to additional frictional aging of fifty cycles, backward and forward, prior the CoF to be measured. The aim of the condition (ii) is to study the effect of frictional aging of CL on CoF.

The lubricating solution deposited as thin layer over the glass disc counter surface is tear mimicking solution- phosphate buffered saline (TMS-PBS from Sigma-Aldrich) containing proteins originating from human serum (Precinorm U, Roche, Germany) (2.3–3.5 mg/ml) plus lysozyme (5 mg/ml) (the composition is given in the supplementary file).12,28

Determination of the loss of water content by SiHy

The loss of water content by SiHy in the course of dehydration/rehydration cycling was determined via high precision Sartorius gravimetric microbalance.29 All measurements are performed at room temperature and 60% relative humidity.

Determination of the water contact angles via the sessile drop technique

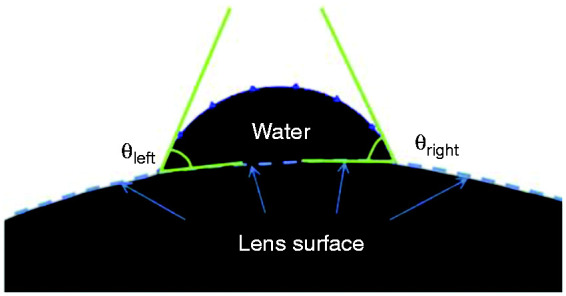

The sessile drop measurements (Figure 4) were performed with Contact Angle Meter with Rotatable Substrate Holder, Automated Dispenser & Temperature Control HO-IAD-CAM-01B (Holmarc Opto-mechatronics, Kochi, India) as described in detail in a previous study.9

Figure 4.

Measurement of water contact angle in sessile drop configuration (image taken from Reference 9).

Contact lens was fitted over ceramic substrate and positioned in glass chamber maintaining quiescent environment. The sessile drops were generated and manipulated by the automatic syringe. The contact angles were measured with HO-IAD-CAM-01B software utilizing the β-spline method,30 which allows to measure the contact angle between the drop and the curved surface of the contact lens.

Statistical analyses

Descriptive statistics, one- and two-factor repeated measures ANOVA and multiple pair-wise comparisons (Tukey-Kramer method) were performed with KyPlot 5 (KyensLab, Tokyo, Japan) and PAST 4.02 statistical packages.31,32

Results

Water loss of materials, wettability and implications to stability

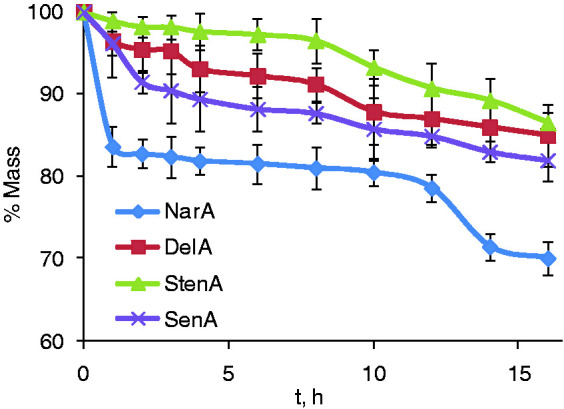

The data on the loss of mass by SiHy due to the evaporation of water in the course of desiccation rehydration cycling are summarized in Figure 5.

Figure 5.

Loss of mass by SiHy in the course of desiccation/rehydration cycling due to evaporation of water from the samples. For each data point n = 10 and whiskers represent standard deviations.

It can be seen that apart from NarA, rest of the SiHy materials showed similar water holding capabilities with more than 87% mass preserved even after 16 h of desiccation/rehydration cycling. The result is with stark contrast with the > 30% mass loss by SiHy when subjected to continuous 15 min desiccation reported earlier.29 This indicates that the brief 1–2 s rewetting in each blink-like cycle greatly facilitates the SiHy capabilities to maintain their bulk water content. The more rapid dehydration of NarA was reported previously29 and its biphasic kinetics indicates structural changes occurring in the material after 12 h of desiccation exposure, which aligns with ⁓2.5 increase of the CoF of NarA at this time point (see Figure 7 below).

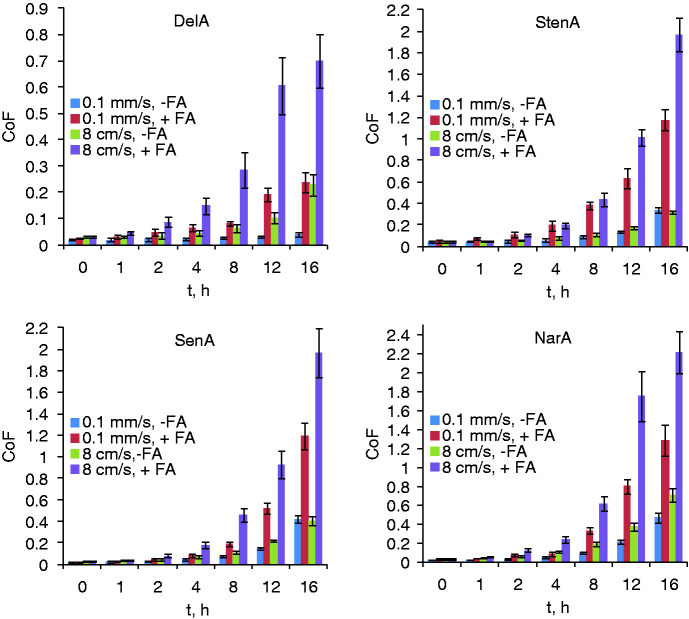

Figure 7.

Dependence of the coefficient of friction of SiHy on the duration of blink like desiccation/rehydration cycling at strike velocities of 0.1 mm/s and 8 cm/s without and with 50 cycles at frictional aging. For each data point n = 10 and whiskers represent standard deviations.

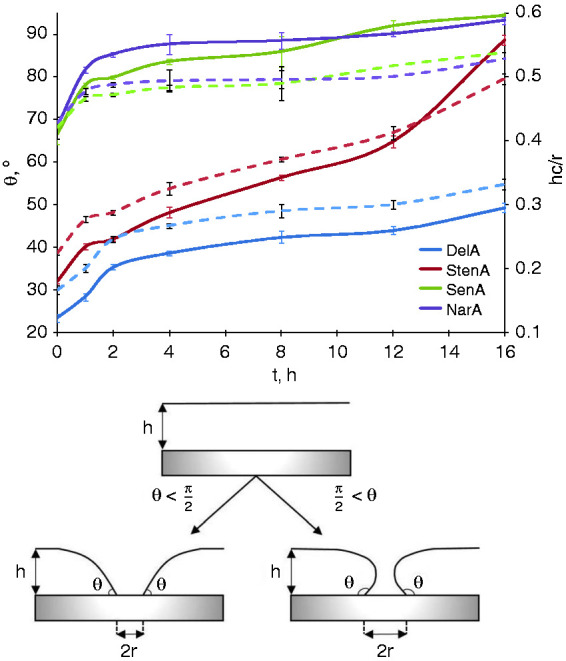

The changes of the sessile drops contact angle (data from Ref. 9) of the SiHy materials with the duration of the blink like desiccation/rehydration cycling are presented (solid line curves) at Figure 6 (the statistical analysis, is given in the supplementary file).

Figure 6.

Dependence of the water contact angle (solid curves) and of the critical film thickness/defect radius ratio (dashed lines; see the main text for details) of SiHy on the duration of desiccation/rehydration cycling. For each data point n = 10 and whiskers represent standard deviations. The lower panel depicts the model proposed by Sharma and Ruckenstein, 1989 on the relationship between wetting film stability and the macroscopic contact angle of contact lens (see main text for details).

As can be deduced from their very different composition, the materials alone (without supplementation with exogenous wetting agents) showed very different performance. NarA and SenA had contact angle (CA) of 66.7° (±2.43° SD) and 68.6° (±0.51°) prior desiccation exposure, and the CA grew steadily to 83.3° (±0.53°; SenA) and 87° (±2.39°; NarA). Then for both SiHy the contact angle increased gradually to 94.5°(±1.8°) for SenA and 93.3° (±1.9°) for NarA after 16 h of treatment. The advancing water CAs of DelA and StenA were significantly (p < 0.001) lower than the ones of NarA and SenA for the entire time scale of blink-like cycling. Furthermore in contrast to NarA and SenA which showed similar CA transients, the shape of θ(t) dependencies was very different between DelA and StenA. For fresh StenA samples the CA was 32.1°(±0.56°) and raised to 48.2°(±1.32°) at 4 h of cycling; then after 6 h of dehydration/rehydration cycling it started to raise steeply to reach 89° (±1.25°) at 16 h. The fresh DelA samples had 23.5° (±0.95°) CA which grew to 38.6 (±0.6)° at 4 h and then gradually raised to 49.3(±1.07)° after 16 h.

In the eye PLTF is not in quiescent environment. Instead, it is constantly subjected to perturbations due to eyelid movements, invasion by dust/cosmetic particles, and formation of hydrophobic nonwetting spots at the SiHy surface (due to silicone migration, lipid deposition or other) etc. These perturbations may open transient holes of micrometric size in it, which may either (i) enclose, i.e. the PLTF heals and remains stable or (ii) expand and result in dewetting of the SiHy and destabilization of the PLTF. The relationship between the PLTF thickness and stability, the hole radius and the macroscopic CA of the SiHy was given by the detailed theoretical model of Sharma and Ruckenstein33,34:

| (3) |

Here hc is the critical thickness below which the wetting film is no longer unconditionally stable and becomes susceptible to rupture if a hole, a dry spot, with radius r, is formed on the SiHy surface. As lower is the hc/r ratio as more stable is the PLTF (i.e. it will not rupture even at low aqueous thickness) and vice versa as higher is the hc/r ratio as more unstable the PLTF will become. The data are presented with dashed lines on the upper panel of Figure 6. It can be seen that for low CA, the hc/r ratio is < 0.4, i.e. even thin (compared to the size of the defect) PLTF should remain stable. This means that for a nonwetting spot of 3–4 micrometer radius (as typically observed at the early stages of SiHy desiccation damage35), for any aqueous film thickness ≥1.6 µm the wetting film will remain unconditionally stable. With the increase of hc/r either due to inherently higher CA or due to compromised wettability because of extended air exposure time, the situation changes. For hc/r ratio of ≥0.5 the PLTF will become susceptible to rupture for h < 2 µm. This means that at the physiological PLTF thickness of 2–2.5 micrometers dewetting becomes energetically favorable. Such prediction agrees very well with the PLTF instability observed on CL contaminated via lipid deposition.

Coefficients of friction and correlations with wettability

The dependence of the coefficient of friction on air exposure time with and without frictional aging at 0.1 mm/s and 8 cm/s sliding speed is presented at Figure 7. As previously reported it can be seen that the application of frictional aging shifted the coefficients of friction (CoF) to higher values.12,14,36 At both sliding speeds the CoF of SiHy prior exposure to desiccation (t = 0 h) were in the range 0.016– 0.04, which agrees well with previous studies.12,13 The accumulation of desiccation stress, particularly at t > 4 h, increased the friction coefficient in agreement with a previous report, and at t > 8 h the CoF of all SiHy raised by orders of magnitude, and when frictional aging via 50 reciprocating cycles was applied, it reached values >1 (at 0.1 mm/s) and >1.9 (at 8 cm/s) for all samples except DT. This is in concordance with previous reports that in case of dehydration of SiHy surface the CoF rises steeply, >10 times the values observed immediately after the removal of contact lens from the blister pack.37 The increase of sliding speed resulted in increase of the CoF values compared to the ones observed at 0.1 mm/s, which agrees with previous studies.12,14,36 Comparing the different SiHy materials between each other reveals that within the first two hours after exposure to blink-like cycling the difference between the CoF of the different materials were small to medium, i.e. Cohen’s d in the range of 0.2–0.5, albeit statistically significant (ANOVA and Tukey-Kramer post-hoc pairwise comparisons at each time point are presented in the supplementary file).

For example at 0.1 mm/s at t = 0 h (i.e. no exposure to desiccation) the CoF in absence of frictional aging were 0.0163(±0.002) for SenA, 0.0187(±0.0017) for DelA, 0.0202(±0.0016) for NarA and 0.0407(±0.01) for StenA, and when frictional aging was applied the CoF values were 0.0186(±0.0023) for SenA, 0.0238(±0.007) for DelA, 0.0315(±0.0043) for NarA and 0.0473(±0.0098) for StenA. With the accumulation of desiccation stress DelA showed highest lubricity and significantly lower CoF compared to the rest of the specimen (particularly at t ≥ 4 h) and even after 16 h of desiccation-rehydration cycling, both without and with frictional aging, DelA maintained CoF lower than 0.039(±0.0096) (at 0.1 mm/s) and 0.69(±0.17) (at 8 cm/s plus frictional aging). For the rest of the SiHy the CoF increased steeply at ≥ 4 h of desiccation/rehydration cycling and the relative ranking of the materials varied between time points and depending on whether frictional aging was applied. This observation agrees with the previously reported sensitivity and variability of microtribometric estimations.13,38 (ANOVA and Tukey-Kramer post-hoc pairwise comparisons at each time point and combination of conditions are presented in the online supplementary material).

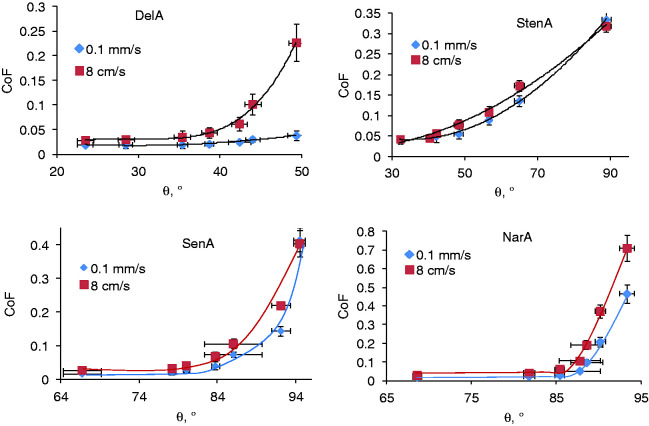

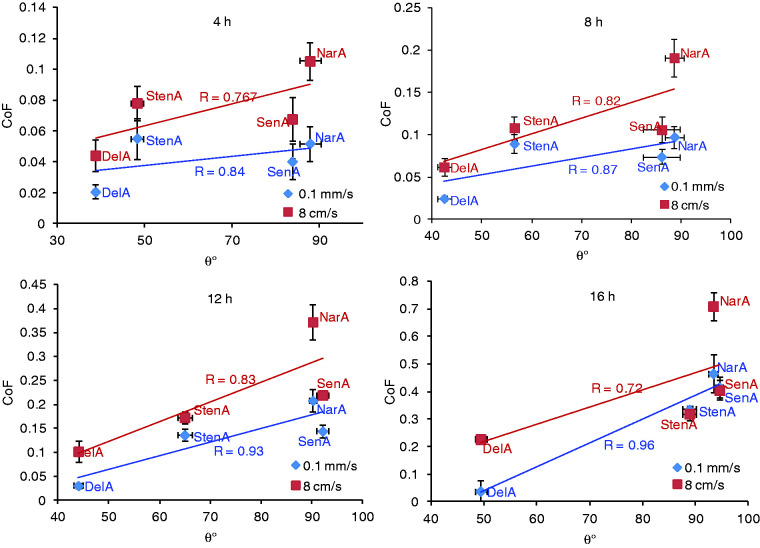

The dependences of CoF on the water contact angles (CA) of the samples (both properties observed after identical duration of hydration/dehydration cycling) are shown at Figure 8 for each of the individual SiHy. Only CoF obtained without frictional aging are analyzed, as such pretreatment was not used in the CL wettability results shown at Figure 6 (it was found that frictional aging resulted in too scattered values of CA).

Figure 8.

Dependence of coefficients of friction of SiHy at sliding speed of 0.1 mm/s and 8 cm/s on the water contact angles of the specimen. For each data point n = 10 and whiskers represent standard deviations. The points from left to right correspond to 0, 1, 2, 4, 8, 12 and 16 h of blink like desiccation/rehydration cycling. The solid lines correspond to the fits (R2 ≥ 0.95) of the exponential growth equation CoF= Ao + A.exp(θ/C). Refer to the main text for details.

It can be seen that at both sliding speeds, 0.1 mm/s and 8 cm/s, the increase of contact angle is accompanied by increase in the CoF which becomes steeper after 4 hours of blink-like cycling. As the CoF(CA)- dependencies are not linear the magnitude and the statistical significance of the correlation was probed using the non-parametric Kendall’s tau (τ) rank correlation coefficient.39 For all SiHy at slow (0.1 mm/s) and fast (8 cm/s) sliding speed τ > 0.7 (p < 0.05) which denotes strong and significant correlation between CoF and CA for all specimen.

In order to further quantify the relationship between the CoF and the wettability of the SiHy, the data on Figure 8 were processed with exponential growth equation (4) which provided best fit of the curves:

| (4) |

Here: Ao is offset; A is a pre-exponential term defining the “weight” of the exponent; C is a constant characterizing the growth rate of the exponent (the lower is C, the higher is the power of the exponent and the steeper the value of the exponent grows). The data are summarized in Table 2.

Table 2.

Numerical values of the coefficient Ao, A and C in the exponential growth equation (equation (4)) used to fit the data at Figure 8.

| SiHy sample | Sliding speed | Ao | A | C (°) | p-Value |

|---|---|---|---|---|---|

| Delefilcon A | 0.1 mm/s | 1.7*10−2 | 2.5*10−6 | 7.3 | 0.023 |

| 8 cm/s | 2.6.10−2 | 5.8*10−2 | 9.3 | 0.029 | |

| Stenfilcon A | 0.1 mm/s | 5*10−3 | 1.4*10−2 | 28.7 | 0.025 |

| 8 cm/s | 3*10−2 | 7.9*10−3 | 23.8 | 0.014 | |

| Senofilcon A | 0.1 mm/s | 6*10−5 | 3.3*10−21 | 3.2 | 0.048 |

| 8 cm/s | 3.2*10−3 | 9.3*10−20 | 4.8 | 0.039 | |

| Narafilcon A | 0.1 mm/s | 1*10−3 | 2.7*10−14 | 3.2 | 0.038 |

| 8 cm/s | 0.8*10−3 | 4.17*10−12 | 3.6 | 0.04 |

Note: For all cases the curve fitting procedure is with R2 ≥ 0.95 (p-values are given in the table). The standard deviations in of the parameters were less than 5% of the values.

It can be seen that for DelA, SenA, and NarA the values of the pre-exponential term A was very low, while for StenA the high value of the constant C (28.7) suppressed the growth of the exponent at the starting data points. All this suggests that for all SiHy the impact of wettability in the first few hours after exposure to air is low, but it grew steeply afterwards.

This pattern was confirmed when the correlation between the CoF and the CA was probed across the different types of SiHy at the individual time points (Figure 9). Here, at denoted moments after the start of desiccation/rehydration cycling, the positions are shown of the different SiHy specimens in the CoF(CA) coordinates plane.

Figure 9.

Dependence of coefficients of friction of SiHy at sliding speed of 0.1 mm/s and 8 cm/s on the water contact angles of the specimen for the individual time points. For each data point n = 10 and whiskers represent standard deviations. The type of the material is denoted in a label next to the data points. The value of the correlation coefficients between CA and CoF at t ≥ 4 is denoted on the charts (data at t ≤ 2 h are in Supplementary file).

It can be clearly seen that with the aging of SiHy at ≥4 h of blink-like dehydration/rehydration cycling significant and strong correlation was found between CA and CoF of the CL despite of the different composition and structure of the samples.

A crude simplified relationship between the CoF of CL and the mean thickness of the lubricating film (hf) between the CL and the countersurface was proposed by equation (5)40:

| (5) |

where and

Here: E is the elastic modulus of the eye-form made of silicone rubber and considered to be a semi- infinite solid (2.6 Mpa; υ - Poisson’s ratio (0.5) ; R- radius of curvature (7.8 mm); FF and FN- friction force and normal load respectively; η - viscosity of the lubricating solution (∼1 mPa s at 8 cm/s); Umax is the strike velocity.

Although the values of hf obtained by the simplified equation (5) should be considered as rough indicative estimates, they still provide useful insights to the changes that develop in the tribological system in the course of blink-like desiccation/rehydration cycling. At coefficients of friction in the range of 0.01–0.1 the mean thickness of the lubricating film is within 245 to 60 nm, in agreement with the assumptions of elastohydrodynamic lubrication. When the ratio of FF to FN increases i.e. when CoF raises to 0.2–0.4 the hf is within the limits of 12–5 nm (i.e. transition to boundary lubrication state occurs). At further raise of CoF, the values of mean hf become too low to allow for continuous lubricating film between the CL and the countersurface, which means that dry patches can occur at certain points between SiHy and the mucin coated glass surface. As can be seen by above only DelA was able to maintain CoF < 0.5 for extended (t > 8 h) blink-like cycling, while for the rest of the SiHy values in the range 0.8–1.5 were observed. Although the analysis by equation (5) is only approximate it agrees well with the different structure of pre-lens tear film over SiHy surfaces with different wettability.41,42 Indeed, it can be expected that surfaces with high CA might not be able to sustain continuous structure of the pre-lens tear film especially at extended dehydration/rehydration cycling, which in turn might result in increased friction during blink.

Discussion

The time evolution of SiHy water content, wettability and lubricity was studied in the course of blink-like desiccation/rehydration cycling. The loss of water content was not a strong predictor for the SiHy performance, which suggests that it is not the bulk hydration but the surface structure and the inherent differences in polymer matrices that have most pronounced impact on the SiHy performance in agreement with previous studies.1,37,43 However, significant correlations were observed between the water contact angle (a measure of wettability) and the coefficient of friction (a measure of lubricity) of the SiHy in the course of desiccation/rehydration treatment.

The increased exposure to air, i.e. the prolonged duration of blink-like desiccation/rehydration cycling, results in impaired lubricity of SiHy both at 0.1 mm/s and 8 cm/s sliding speed, without and with frictional aging pretreatment. Although to the best of our knowledge there are no previous studies of the effect of air exposure on the CoF of SiHy, the results agree well with the reported desiccation-induced decrease of SiHy wettability9 and with the data on detrimental effect of dryness on the surface structure (increase in roughness and in number of surface austerities responsible for the stronger cohesion with the countersurface) and composition (migration of Si moieties from the core to the air-exposed surface of the material) of the CL.35,44 The raise in the CoF for most of the time points with the increase of sliding speed (from 0.1 mm/s to 8 cm/s) and with the application of frictional pretreatment as well agree with previous reports.12–14

It can be seen that the dependence of the contact lens CoF on the water CA follows complex time-dependent pattern. At less than 4 h of blink like cycling there is no correlation between CA and CoF. This result agrees with previous finding showing wide variability of the CoF and CA of SiHy freshly removed from blister solutions.45 However, at t ≥ 4 h there is significant and very strong correlation between the two properties. This suggests that with aging of the sample, the SiHy wettability may become a major factor for the lubricity of the specimen. This can be anticipated, indeed, as the high wettability is determinative for the capability of the SiHy to maintain continuous lubricant film over its surface.9 That is the reason why Delefilcon A showed much higher capability to maintain low CoF at t ≥ 4 h compared to the rest of the SiHy, in agreement with its propensity to maintain low CA even after extended exposure to air. The result also agrees with the excellent lubricity of DelA obtained via the inclined plane method.43 That is related with the very structure of DelA. Because of the implementation of water gradient technology DelA displays >80% water at the outer CL surface42 allowing it to better sustain the impact of long term desiccation compared to the rest of the SiHy studied. The latter was well illustrated by a recent study using X-ray photoelectron spectroscopy to probe the Si content in the outermost 3 nm of SiHy exposed to dryness.46 It was found that the Si surface concentration of narafilcon A and senofilcon A was 8.5% and 12.8%, respectively. In contrast, the outermost region of delefilcon A contained merely 0.5% Si. The performance of NarA and SenA can be explained with the limited ability of the internal wetting agents (PVP based) to protect the CL surface as compared to surface coatings. It is interesting that in spite of the “smart chemistry” technology, the limited loss of bulk water (confirmed also in our measurements) in the course of air exposure 47 and the very low (3%) bulk percentage of silicon, the X-ray photoelectron spectroscopy showed that the surface content of Si of the desiccated StenA sample was as high as 10.2%.46 Such behavior agrees with the hypothesis that in StenA, the hydrophobic silicone material phase separates on a small length scale and in the course of desiccation these Si enriched domains appear at the CL surface as hydrophobic nonwettable spots.46 It can be seen that, indeed, when considering wettability compared to NarA and SenA samples, StenA was closer in performance to the water gradient DelA for the first couple of hours. However, later on the water contact angle started to increase and reached values similar to the traditional SiHy, NarA and SenA, which rely on internal wetting agents. Thus it highlights that in lack of surface modifications and/or instillation of wetting agents the low bulk Si content may not guarantee distinct performance of the SiHy surface, as especially at extended wear, the desiccation may “extract” Si moieties from the bulk to the surface of the SiHy. It is important to note that the superior in vitro wettability of DelA against the rest of the SiHy studied, was recently confirmed in in vivo quantification of contact lens wettability under low humidity conditions48 where “delefilcon A performed better than stenfilcon A and narafilcon A after 6 hrs of wear including 3 hrs intensive visual tasks under challenging environmental conditions”. The DelA superior lubricity and wettability in the course of extended desiccation/rehydration cycling in vitro also aligned with the clinical observation that in population of symptomatic CL wearers, delefilcon A lenses showed superior subjective ratings for comfort, dryness, quality of vision, comfort daily wear time, and better lens surface attributes including fewer surface deposits and superior wettability than did narafilcon A lenses after 2 weeks of wear.49

The result agrees well with the relatively high CoF of stenfilcon A even after shorter exposure to dryness (t < 4 h). Thus the importance of true coating for the long term control of SiHy surface properties is emphasized as compared to implementation of (internal) wetting agents and to alterations of bulk Si content. The very low CoF of SenA at the initial time points (t < 4 h) can be explained with the softness (low modulus) of the material which results in its high lubricity if not exposed to desiccation.12

The fact that CA alone might not be the main determinant of the CoF of SiHy at t ≤ 4 h is also manifested by the CoF dependence on the water CA for each individual material. The low value of the exponential power (the high value of C) and/or of the pre-exponential term A reveal that for shorter (<4 h) periods of desiccation/rehydration cycling there is only moderate impact of CA on CoF, while at t ≥ 4 h the influence of CA steeply increases. Probably the fresh, less desiccation stressed, materials have compensatory mechanism which neutralizes the impact of the diminished wettability. It might be related with the smoother surface of fresh hydrated SiHy while materials affected by dryness reveal higher number of surface austerities which cannot compensate the lack of continuous lubricating film across poorly wettable SiHy surfaces.25,34 This is well manifested by the very different pattern of the tear film at the surface of SiHy with low and high wettability reported in literature.41,42 Wettable CL maintain stable PLTF for ≥ 15 s in open eye across the entire CL with small size of the breakup spots, while for materials with low wettability the pre-lens tear film usually breaks up for less than 10 s and the breakup spots rapidly expand in area and cover large parts of the CL surface. Indeed tapping mode atomic force microscopy data reveal that SiHy manifest significant surface roughness that is further modified by exposure to desiccation and in the course of CL wear. For example when freshly removed from blister senofilcon A displays mean square surface roughness of 4.70 ± 0.005 nm.50 DelA immediately after removal from blister shows mean square roughness of 14.2 ± 5.5 nm.51 Direct comparison between the values should be taken with caution as different experimental protocols were implemented in the studies. Yet, the higher roughness of DelA might be attributed to the more porous “water gradient” surface. However it should be noted that in the course of daily wear DelA surface roughness decreased to 10.9 ± 4.0 nm probably due to partial loss of surface hydration. In contrast for SiHy without surface coating like SenA, StenA and NarA it is found that surface roughness increases 2–2.5 times in the course of wear.35 Water contact angle reports for both, changes in the roughness and in the chemical heterogeneity of the SiHy surfaces.10,33,34 As roughness is known to emphasize the inherent wettability of a material, the CA increase when roughness grows can be explained solely by the enrichment of the CL surface with hydrophobic Si spots.52,53

Many other factors can contribute to the modification of SiHy surface and to its tribological performance in vivo: lipid and protein deposits, inter- and intra-individual variability, the state of the corneal and conjuctival epithelium etc.1–4 These factors can also mutually interfere with each other and alleviate or synergistically facilitate their effects. Therefore in order to see whether the factors that determine the CoF of SiHy and also the actual correlation between the in vitro properties and the clinical performance of the materials, the in vitro results should be collated with the CoF values of the worn contact lenses and with the corresponding data on the PLTF stability and the patient comfort. Such studies can identify key material properties that are readily accessible in vitro and can serve as an early stage predictor for the physiological “in eye” performance of the silicone hydrogels. In vitro frictional study of contact lenses is an increasing area of interest, especially because the TFOS contact lens materials, design, and care subcommittee highlighted its relationship to discomfort.10 However it should be also kept in mind that the coefficient of friction is a “system property”, i.e. it is not determined solely by the SiHy characteristics but is also strongly dependent on the measurement technique and protocol (choice of countersurface, lubrication fluid etc.) which has caused significant discrepancies between the values reported in literature.13 Pin-on-disk reciprocating microtribometer was suggested as a convenient tool to measure CL coefficient of friction in what appears to be the first publication on the topic but remained almost unexplored since then.19 It was chosen here as apart from allowing the implementation of various countersurfaces and lubrication fluids, it also allows for implementation of physiologically relevant sliding speeds.4,12,15,16 Range of other techniques has been used previously like inclined plane, linear reciprocating tribometry, atomic force microscopy etc. each having its own advantages and limitations.4,12,15,16,43 Inclined plane43 offers a particularly simple and convenient approach, which however does not allow precise control of the sliding speed between the CL and the countersurface, while AFM and linear reciprocating tribometry typically require slow sliding speeds (0.1 mm/s) and short stroke length (1 mm), which may not allow for pure kinetic friction regime to be established.13 Recently measurement of the friction against corneal tissue was proposed, which aims for maximum physiological relevance of the system, but might not be convenient for rapid testing of multiple SiHy at the early stages of material design.54

The current study reveals that all the material properties (water content, wettability, and lubricity) of SiHy were influenced by the blink-like desiccation rehydration cycling. It is seen that significant correlation exists between the CA and the CoF of the SiHy especially at ≥4 h of desiccation/rehydration treatment. This suggests that it might be clinically important to maintain the wettability of the SiHy for extended periods of time to ensure the ocular health and comfort of the wearer. In view of the possible relationship between patient comfort and SiHy material properties (lubricity, wettability etc.), and the relationship between the SiHy structure and properties in the course of blink-like cycling, different strategies can be recommended for ensuring optimal performance of SiHy at the ocular surface. The implementation of water gradient technology as in Delefilcon A may ensure extended durability of wettability and lubricity. These materials are new approach in CL design and full picture of their clinical performance will become available in the years to come. Other SiHy materials (narafilcon A, senofilcon A, stenfilcon A) might be enhanced via supplementation with rewetting solution or eyedrops with wetting agents (hyaluronic acid, poloxamers, tetronics, polyvinylpyrrolidone, mucomimetic polymers etc.10). Such approach offers the possibility for development of specific compositions, which are optimized for the particular silicone hydrogel, so that to ensure optimal interplay between the wettability and lubricity of the material.55,56

Conclusions

The coefficient of friction was studied of a diverse range of SiHy materials, utilizing internal wetting agents (Senofilcon A and Narafilcon A), “smart” low Si content chemistry (Stenfilcon A) or water gradient technology resulting in 80% water content at the CL surface (Delefilcon A) and the impact of air-exposure time, frictional aging and sliding velocity on the tribological performance of SiHy was probed. It was found that the increase in the duration of the desiccation/rehydration cycling, the increase in the sliding speed velocity between the countersurface and the SiHy surface and the application of frictional aging pretreatment resulted in rise of the materials CoF. At ≥4 h desiccation/rehydration cycling CL wettability had major impact on the CoF of the specimen. This is manifested by the capability of Delefilcon A to maintain low (<0.5) coefficient of friction even after extended air exposure while the tribological performance of the rest of the SiHy deteriorated (CoF > 1 at 8 h of blink like cycling).

Supplemental Material

Supplemental material, sj-pdf-1-jba-10.1177_0885328220967526 for Relationships between the material properties of silicone hydrogels: Desiccation, wettability and lubricity by Petar Borisov Eftimov, Norihiko Yokoi, Nikola Peev, Yasen Paunski and Georgi Asenov Georgiev in Journal of Biomaterials Applications

Footnotes

Declaration of conflicting interests: The author(s) declared the following potential conflicts of interest with respect to the research, authorship, and/or publication of this article: The sources of support had no involvement in study design, collection, analysis, and interpretation of data, writing of the report and the submission of the report for publication. The authors had full access to all of the data in this study and take complete responsibility for the integrity of the data and the accuracy of the data analysis.

Funding: The author(s) disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: The study is supported by grant P-22–804/06.04.2020 of the Bulgarian Ministry of Science and Education (to P. B. Eftimov) and by Alcon Japan (Collaborative research grant, 2019).

ORCID iD: Georgi Asenov Georgiev https://orcid.org/0000-0002-7774-9314

Supplemental material: Supplemental material for this article is available online.

References

- 1.Musgrave CSA, Fang F. Contact lens materials: a materials science perspective. Materials (Basel) 2019; 12: 261. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Efron N. Contact lens practice. 3d ed. Amsterdam: Elsevier, 2017. [Google Scholar]

- 3.Aswathy SH, Narendrakumar U, Manjubala I. Commercial hydrogels for biomedical applications. Heliyon 2020; 6: e03719-e. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Mann A, Panaser A, Tighe B. Biotribology measurement of in vitro and ex vivo contact lenses. Cont Lens Anterior Eye 2013; 36: e27. [Google Scholar]

- 5.Efron N, Brennan NA, Morgan PB, et al. Lid wiper epitheliopathy. Prog Retin Eye Res 2016; 53: 140–174. [DOI] [PubMed] [Google Scholar]

- 6.Fonn D. Targeting contact lens induced dryness and discomfort: what properties will make lenses more comfortable. Optom Vis Sci 2007; 84: 279–285. [DOI] [PubMed] [Google Scholar]

- 7.Mann A, Tighe B. Contact lens interactions with the tear film. Exp Eye Res 2013; 117: 88–98. [DOI] [PubMed] [Google Scholar]

- 8.Vidal-Rohr M, Wolffsohn JS, Davies LN, et al. Effect of contact lens surface properties on comfort, tear stability and ocular physiology. Cont Lens Anterior Eye 2018; 41: 117–121. [DOI] [PubMed] [Google Scholar]

- 9.Eftimov P, Yokoi N, Peev N, et al. Impact of air exposure time on the water contact angles of daily disposable silicone hydrogels. Int J Mol Sci 2019; 20: 1313. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Jones L, Brennan NA, González-Méijome J, et al. The TFOS international workshop on contact lens discomfort: report of the contact lens materials, design, and care subcommittee. Invest Ophthalmol Vis Sci 2013; 54: TFOS37–TFOS70. [DOI] [PubMed] [Google Scholar]

- 11. Coles CML and Brennan NA. Coefficient of friction and soft contact lens comfort. Optom Vis Sci. 2012;88:e-abstract 125603. https://www.aaopt.org/detail/knowledge-base-article/coefficient-friction-and-soft-contact-lens-comfort.

- 12.Roba M, Duncan EG, Hill GA, et al. Friction measurements on contact lenses in their operating environment. Tribol Lett 2011; 44: 387–397. [Google Scholar]

- 13.Mann A, Tighe BJ. Ocular biotribology and the contact lens: surface interactions and ocular response. In: Chirila TV. (ed.) Biomaterials and regenerative medicine in ophthalmology. 2nd ed. UK: Woodhead Publishing, 2016, pp.45–74. https://www.sciencedirect.com/science/article/pii/B9780081001479000031 [Google Scholar]

- 14.Rennie AC, Dickrell PL, Sawyer WG. Friction coefficient of soft contact lenses: measurements and modeling. Tribol Lett 2005; 18: 499–504. [Google Scholar]

- 15.Pult H, Tosatti SG, Spencer ND, et al. Spontaneous blinking from a tribological viewpoint. Ocul Surf 2015; 13: 236–249. [DOI] [PubMed] [Google Scholar]

- 16.Sterner O, Aeschlimann R, Zurcher S, et al. Friction measurements on contact lenses in a physiologically relevant environment: effect of testing conditions on friction. Invest Ophthalmol Vis Sci 2016; 57: 5383–5392. [DOI] [PubMed] [Google Scholar]

- 17.Read ML, Morgan PB, Kelly JM, et al. Dynamic contact angle analysis of silicone hydrogel contact lenses. J Biomater Appl 2011; 26: 85–99. [DOI] [PubMed] [Google Scholar]

- 18.Lorentz H, Heynen M, Khan W, et al. The impact of intermittent air exposure on lipid deposition. Optom Vis Sci 2012; 89: 1574–1581. [DOI] [PubMed] [Google Scholar]

- 19. Nairn JA and Jiang T. Measurement of the friction and lubricity properties of contact lenses. In: Proceedings of ANTEC 1995; May 7–11, 1995 in Boston. http://www.cof.orst.edu/cof/wse/faculty/Nairn/papers/contacts.pdf.

- 20.Chaudhri MM, Yoffe EH. The area of contact between a small sphere and a flat surface. Philos Mag A 1981; 44: 667–675. [Google Scholar]

- 21.Thekveli S, Qiu Y, Kapoor Y, et al. Structure–property relationship of delefilcon a lenses. Cont Lens Anterior Eye 2012; 35: e14. [Google Scholar]

- 22.Ozkan J, Willcox MD. The effect of lens modulus on insertion comfort with silicone hydrogel lenses. Invest Ophthalmol Vis Sci 2011; 52: 6515. [Google Scholar]

- 23.Seo J, Byun WY, Alisafaei F, et al. Multiscale reverse engineering of the human ocular surface. Nat Med 2019; 25: 1310–1318. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Sakai E, Shiraishi A, Yamaguchi M, et al. Blepharo-tensiometer: new eyelid pressure measurement system using tactile pressure sensor. Eye Cont Lens 2012; 38: 326–330. [DOI] [PubMed] [Google Scholar]

- 25.Yamamoto Y, Shiraishi A, Sakane Y, et al. Involvement of eyelid pressure in Lid-Wiper epitheliopathy. Curr Eye Res 2016; 41: 171–178. [DOI] [PubMed] [Google Scholar]

- 26.Shaw AJ, Collins MJ, Davis BA, et al. Eyelid pressure and contact with the ocular surface. Invest Ophthalmol Vis Sci 2010; 51: 1911–1917. [DOI] [PubMed] [Google Scholar]

- 27.Shaw AJ. Eyelid pressure on the cornea. Australia: Queensland University of Technology, 2009. [Google Scholar]

- 28.Wilson T, Aeschlimann R, Tosatti S, et al. Coefficient of friction of human corneal tissue. Cornea 2015; 34: 1179–1185. [DOI] [PubMed] [Google Scholar]

- 29.Jones L, May C, Nazar L, et al. In vitro evaluation of the dehydration characteristics of silicone hydrogel and conventional hydrogel contact lens materials. Cont Lens Anterior Eye 2002; 25: 147–156. [DOI] [PubMed] [Google Scholar]

- 30.Stalder AF, Kulik G, Sage D, et al. A snake-based approach to accurate determination of both contact points and contact angles. Coll Surf A 2006; 286: 92–103. [Google Scholar]

- 31.Yoshioka K. KyPlot – a user-oriented tool for statistical data analysis and visualization. Comput Stat 2002; 17: 425–437. [Google Scholar]

- 32.Hammer Ø, Harper DAT, Ryan PD. Past: paleontological statistics software package for education and data analysis. Palaeontol Electron 2001; 22: 9. [Google Scholar]

- 33.Eli Ruckenstein GB. Wetting theory. Boca Raton: CRC Press, 2019. [Google Scholar]

- 34.Sharma A, Ruckenstein E. Dewetting of solids by the formation of holes in macroscopic liquid films. J Colloid Interface Sci 1989; 133: 358–368. [Google Scholar]

- 35.Lira M, Santos L, Azeredo J, et al. Comparative study of silicone-hydrogel contact lenses surfaces before and after wear using atomic force microscopy. J Biomed Mater Res Part B Appl Biomater 2008; 85: 361–367. [DOI] [PubMed] [Google Scholar]

- 36.Zhou B, Li Y, Randall NX, et al. A study of the frictional properties of senofilcon-A contact lenses. J Mech Beh Biomed Mater 2011; 4: 1336–1342. [DOI] [PubMed] [Google Scholar]

- 37.Paar A. Influence of relative humidity on the curing behavior of silicone based adhesives. Austria: Anton Paar; 2016. [Google Scholar]

- 38. Subbaraman LN and Jones LW. Measuring friction and lubricity of soft contact lenses: a review. Contact Lens Spectr. 2013; 28: 28–33.

- 39.Ratner BD. Correlation, materials properties, statistics and biomaterials science. In: Buddy D, Ratner ASH, Frederick J, et al. (eds) Biomaterials science: an introduction to materials in medicine. 3rd ed. Cambridge, MA: Academic Press, 2013, pp.1354–1361. [Google Scholar]

- 40.Medley JB, Ngai V. Biotribology of contact lenses. In: Wang QJ, Chung Y-W. (eds) Encyclopedia of tribology. Boston, MA: Springer US, 2013, pp.213–217. [Google Scholar]

- 41.Craig JP, Willcox MDP, Argüeso P, et al. The TFOS international workshop on contact lens discomfort: report of the contact lens interactions with the tear film subcommittee. Invest Ophthalmol Vis Sci 2013; 54: TFOS123–TFOS56. [DOI] [PubMed] [Google Scholar]

- 42.Szczesna-Iskander DH. Comparison of tear film surface quality measured in vivo on water gradient silicone hydrogel and hydrogel contact lenses. Eye Cont Lens 2014; 40: 23–27. [DOI] [PubMed] [Google Scholar]

- 43.Tucker RC, Quinter B, Patel D, et al. Qualitative and quantitative lubricity of experimental contact lenses. Invest Ophthalmol Vis Sci 2012; 53: 6093. https://iovs.arvojournals.org/article.aspx?articleid=235979222879411 [Google Scholar]

- 44.Santos L, Rodrigues D, Lira M, et al. Bacterial adhesion to worn silicone hydrogel contact lenses. Optom Vis Sci 2008; 85: 520–525. [DOI] [PubMed] [Google Scholar]

- 45. Giles T. In vitro contact angle and coefficient of friction profiles for daily disposable contact lenses. Acta ophthalmologica. 2008; 86: 0–0. https://onlinelibrary.wiley.com/doi/abs/10.1111/j.1755-3768.2008.567.x.

- 46.Rex J, Knowles T, Zhao X, et al. Elemental composition at silicone hydrogel contact lens surfaces. Eye Cont Lens 2018; 44: S221–S226. [DOI] [PubMed] [Google Scholar]

- 47.Schafer JM, Steffen R, Vaz T, et al. Comparing on eye dehydration and corneal staining of three daily disposable contact lenses in a low humidity environment. Cont Lens Anterior Eye 2012; 35: e12. [Google Scholar]

- 48. Nick J, Schwarz S, Jarvinen S, et al. Performance of Daily Disposable Contact Lenses in Symptomatic Wearers. JCLRS [Internet]. 2020 Feb.5 [cited 2020 Oct.15]; 4: e1–e11. https://jclrs.org/index.php/JCLRS/article/view/35.

- 49.Nick J, Schwarz S, Jarvinen S, et al. Performance of daily disposable contact lenses in symptomatic wearers. JCLRS 2020; 4. [Google Scholar]

- 50.Giraldez MJ, Serra C, Lira M, et al. Soft contact lens surface profile by atomic force microscopy. Optom Vis Sci 2010; 87: E475–E481. [DOI] [PubMed] [Google Scholar]

- 51.Joseph Hook D, Phillip Lusignan C, Aneta Wygladacz K, et al. Development and preliminary evaluation of a system to rapidly measure coefficient of friction on soft contact lenses. Int J Ophthalmol Vis Sci 2019; 4: 88–96. [Google Scholar]

- 52.Yanez-Soto B, Leonard BC, Raghunathan VK, et al. Effect of stratification on surface properties of corneal epithelial cells. Invest Ophthalmol Vis Sci 2015; 56: 8340–8348. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Rupp F, Gittens RA, Scheideler L, et al. A review on the wettability of dental implant surfaces I: theoretical and experimental aspects. Acta Biomater 2014; 10: 2894–2906. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Samsom M, Chan A, Iwabuchi Y, et al. In vitro friction testing of contact lenses and human ocular tissues: effect of proteoglycan 4 (PRG4). Tribol Int 2015; 89: 27–33. [Google Scholar]

- 55.Weeks A, Boone A, Luensmann D, et al. The effects of hyaluronic acid incorporated as a wetting agent on lysozyme denaturation in model contact lens materials. J Biomater Appl 2013; 28: 323–333. [DOI] [PubMed] [Google Scholar]

- 56.Weeks A, Luensmann D, Boone A, et al. Hyaluronic acid as an internal wetting agent in model DMAA/TRIS contact lenses. J Biomater Appl 2012; 27: 423–432. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplemental material, sj-pdf-1-jba-10.1177_0885328220967526 for Relationships between the material properties of silicone hydrogels: Desiccation, wettability and lubricity by Petar Borisov Eftimov, Norihiko Yokoi, Nikola Peev, Yasen Paunski and Georgi Asenov Georgiev in Journal of Biomaterials Applications