Abstract

We report on a recent workshop dedicated to additive manufacturing (AM) of ceramics that was held at the National Institute of Standards and Technology (NIST) in November 2019. This two-day all-invited meeting brought together experts from industry, government agencies and academia to review the state of the field and identify the most pressing applied materials research and metrology issues which, if addressed, could accelerate the incorporation of AM methods into commercial ceramic manufacturing. Besides the AM technologies, the discussions included consideration of the necessary post-processing steps. We highlight some of the successes and challenges for the adoption of ceramics AM on an industrial scale, as viewed by the workshop participants. We also propose actions for the ceramic community to facilitate the wider commercialization of these fabrication methods.

1. Introduction

After several decades of development, global markets 1 for additive manufacturing (AM) of polymers and metals have each attained an annual multibillion-dollar level, with these technologies showing every indication of becoming mainstream. By comparison, the market for ceramics AM is an order of magnitude smaller, although most economic models predict a ten-fold growth over the next decade.1 The positive perspective is reflected in the steep increase in the numbers of research publications and patent applications, and by representation at trade exhibitions. The increasing availability of low-cost table-top printers suitable for ceramics and of dedicated companies providing services in ceramics AM offer greater accessibility of these technologies. Multiple cases of integrating ceramics AM into products already exist, as can be exemplified by the robocasting2 of lattice filters for metal-casting applications, catalyst supports, various on-demand ceramic components, dental implants, and casting cores and molds. Nevertheless, despite many demonstrations, there are few “industrialization stories.” In many ways, ceramics AM efforts are fragmented, and realistic, far-reaching applications with the potential to drive AM technologies into the mainstream of ceramic manufacturing remain to be determined. Several review articles discussing various aspects of ceramics AM have been published previously. 3–6

In November 2019, NIST hosted a workshop “Materials Research and Measurement Needs for Ceramics Additive Manufacturing” to identify the most promising broad-impact applications of ceramics AM and the associated materials measurement needs. Here, we summarize the main points and recommendations discussed at this meeting. The goal of our paper is not to provide another review of materials research in ceramics AM, but rather to highlight the materials measurement needs, including research, that must be addressed to overcome barriers for the incorporation of these technologies in commercial applications. Actions identified as critically needed for the industrialization of ceramics AM encompass the development of the fundamental understanding and predictive models of the material transformations during the entire build process – from feedstock through the green body to the final post-processed part, and metrological developments, including databases and benchmark structures & tests that are required to standardize and certify AM-built parts. Such an undertaking will require the involvement and close cooperation of both the basic-science and engineering parts of the ceramic community, as well as suitably focused proposal calls from the scientific funding agencies, all of which this report hopes to stimulate.

2. Objectives and description of the workshop

The workshop reviewed the opportunities and challenges for ceramics AM in key market sectors with discussions focused on formulating the materials research directions to bridge the knowledge gaps that presently hinder the broader deployment of ceramics AM technologies. The program also included discussions of the lessons learned from work in metals AM and in polymers AM, as well as the prospects for AM of hybrid ceramic/metal and ceramic/polymer materials or gradient-microstructure ceramics. One emphasis lay in seeking potential cross-cutting research efforts to address ceramics AM measurement needs across a range of application areas. The workshop was attended by ≈ 60 participants from both the USA and elsewhere, representing early industrial adopters of ceramics AM, AM-equipment manufacturers, government agencies, and academia. Details of the technical program are provided in the Supporting Information.

The participants were asked to address the following three questions:

What is the state-of-art, and what are the most promising and practical opportunities for growth in ceramics AM technologies (feedstock, processing, post-processing)?

What is the critical research (both fundamental and applied) that still needs to be undertaken, including measurement and modeling needs, and standards?

How can the collective expertise and facilities of different institutions be leveraged to realize answers to these questions?

The presentations provided insightful illustrations of many aspects associated with realizing ceramics AM commercial application. Here, we present highlights of the presentations and discussions that most directly addressed the questions above.

3. Overview of the field

The primary AM technologies considered for ceramics include material extrusion, material jetting, binder jetting, sheet lamination, vat photopolymerization, powder bed fusion, and direct energy deposition – the same techniques that apply to metals and polymers.8 Table 1 summarizes the selected characteristics of these methods and their current penetration of ceramic markets. All the processes, but the last two, produce green, porous parts that remain to be densified. Thus far, only such green-part-printing technologies have found commercial use. The choice of the most appropriate method depends on the application, and for now, no overall winner can be named.

Table 1.

Ceramics AM processing techniques, their characteristics, and current commercial applications. (Based on material supplied by Cathleen Hoel, GE Global Research.)

| AM Technique | Advantages | Disadvantages | Application Industries |

|---|---|---|---|

| Materials extrusion: {slurry in cartridge, includes DIW*, fused deposition modeling (FDM), fused filament formation (FFF)} | fast and cheap, low waste, material agnostic, enclosed structures acceptable | rough surface, stresses in debinding and sintering | art & design, technical, medical, electronics, composites, construction/cement |

| Material jetting: includes NanoParticle Jetting (XJet, Rehovot, Israel) | soluble support material for any non-closed design, smooth surfaces, high resolution, material agnostic, multiple materials possible | requires cleanout of support material, particle size < 1 μm | technical ceramics, medical |

| Binder jetting: | no supports needed for printing, material agnostic, porous green body for fast debinding | excess powder cleanup, particle size > 5 μm, may require supports for sintering, weak green body, some roughness | sand casting molds, medical, niche-technical, fast prototyping |

| Sheet lamination: (laminated object manufacturing, LOM) | fast and material agnostic, can do closed surfaces | geometry limitations, low lamellar adhesion, rough surfaces, nonrecyclable waste, low resolution | technical ceramics, composites, heat exchangers |

| Vat polymerization: {includes stereolithography (SLA), digital light processing (DLP), & lithography-based manufacturing (LCM)} | smooth surfaces, high resolution, can use pre-ceramics, complex geometries possible | slow and expensive, no strong UV absorbing materials, particles cause light scattering, more complex rheology than for polymers AM | technical ceramics, cores & molds, medical |

| Powder bed fusion: {includes selective laser melting (SLM)} | strong as-printed product, no debinding or sintering, complex geometries possible | slow, some roughness, residual porosity, high temperature powder bed, excess powder cleanup, cracking due to stresses | art & design, optics, lighting, medical |

| Directed energy deposition: | less heat and waste compared to SLM, enclosed structures, curved surfaces OK, no de-binding or sintering | high temperature gradients, strong cooling requirements, rough surfaces, limited geometries | art & design, optics, lighting |

Cost reduction is vital for driving broader adoption of ceramics AM. Significant expenditures include capital costs associated with both the AM machines (low throughput) and the equipment for quality inspection, such as time-consuming X-ray computer tomography (XCT), plus the cost of labor involved in frequently tedious post-processing of AM-built parts. Indeed, the need to develop and optimize appropriate post-processing steps has emerged as one of the more critical challenges that needs to be overcome if ceramics AM is to be more widely adopted.

AM technologies are most easily introduced for rapid prototyping and demonstrations, as well as for the manufacturing of auxiliary parts to support manufacturing operations. Near-net shaping is a crucial factor for the commercial viability of ceramic components because their machining is both expensive and time-consuming. Therefore, on-demand services in ceramics AM attract customers who are testing new designs and do not want yet to invest in tooling for conventional processing, and those for whom the complexity of designs and the work required to manufacture new parts using traditional methods would involve long lead times. AM offers “tool-free” fabrication, automated operation, and parallel production of multiple small parts. Design flaws can be discovered early, without much investment that would be required with other methods. Advanced Computer Numerical Control (CNC) methods of machining can compete with ceramics AM in cost- and time-effective on-demand near-net shaping, but not for complex parts like heat exchangers.9

More challenging approaches to the adoption of AM involve using these technologies to upgrade existing parts (i.e., manufacture replacements) or, ultimately, design new products. The latter path offers the most significant performance rewards but also is the most difficult to implement; in this case, the demonstration of substantial design benefits is a requirement. One significant issue is in identifying products where ceramics could provide a superior and cost-effective alternative to metals and polymers, even before the additional advantages and disadvantages of AM are considered. However, in some cases, the adoption of AM methods could facilitate the use of ceramic components by eliminating the time-consuming and expensive machining and grinding steps required for conventional ceramics. A key feature of the development of ceramic components is that design of products and fabrication of ceramics are frequently performed by separate entities, which can even belong to different organizations. Therefore, one side has to reach out to the other, a step not generally required for metals or polymers. Below we summarize examples of current and envisioned applications of ceramics AM in key industrial sectors and conclude with our discussion of research and measurement needs, including those pertaining to post-processing that must be addressed for commercialization of these technologies.

4. Application-specific challenges

Aerospace

One of the prime interests in this field is to use AM for fabricating ceramic matrix composites (CMCs), which offer significant performance advantages over superalloys, but with much lower density.10For space applications, the focus is on SiC-based CMCs for use in engine components (combustion liners, shrouds/vanes in mixer nozzles).11 Conventional manufacturing approaches are all based on the infiltration of a preform: chemical vapor infiltration (CVI), polymer infiltration pyrolysis, melt infiltration, and hybrid methods that combine these processes.10–12 Such methods are generally slow and involve multiple steps plus extensive post-processing. AM would be simpler and enable custom and complex geometries, including sharp transitions of section dimensions, as well as the fabrication of hybrid and multifunctional composites. Additionally, the AM route can require fewer steps with shorter production times, thereby cutting the cost. The challenges are in the integration of fiber reinforcements, achieving fully dense matrices, and in the optimization of processing and properties.10

The methods evaluated for the SiC-based CMCs are laminated object manufacturing (LOM),13 binder jetting,14,15 and direct ink writing (DIW).16 LOM is viable for producing continuous-fiber reinforced composites after modifications of the commercial machines. The development of CMC prepregs (reinforcement materials pre-impregnated with either a thermoplastic or thermoset resin) is a critical step, which includes the optimization of laser cutting parameters. Silicon infiltration of LOM-produced prepregs yields a dense matrix but damages uncoated fibers; therefore, fiber coating is necessary to prevent their reaction with silicon and for creating weak fiber/matrix interfaces to improve fracture toughness.13 Binder jetting allows for using tailored binders and chopped fiber reinforcements. Silicon-melt infiltration can provide full densification even for high SiC-fiber loadings (up to 65 % by volume).15 Mechanical properties of the AM-built SiC CMC coupons still trail those resulting from conventional processing. Nevertheless, AM of actual turbine-engine parts has been demonstrated (e.g., first stage nozzle and high-pressure turbine nozzle segments).15 Laminated object manufacturing (LOM) offers continuous-fiber reinforced CMCs while the binder jetting method enables short-fiber reinforced SiC-based ceramics. See Figure 1. DIW of CMCs also exhibits some promise. A significant need exists for modeling efforts to assist in the design of materials and in processing optimization, as is the case for metals AM.

Figure 1.

AM-built 20 % vol. SiC fiber CMC turbine engine components.10

Courtesy: Mike Halbig, NASA Glenn Research Center, Cleveland, OH.

The military aircraft industry is exploring AM to improve capability, readiness, and affordability. Already ceramics AM supports casting of metal alloys to produce cores & molds, enabling significant savings of time and cost. Such tools are consumed in the casting process. In this connection, ceramics AM is used to mold legacy parts and make new airfoils with improved cooling-channel designs that cannot be manufactured otherwise. This application area is of sufficient importance that we cover it separately in a later section on investment castings.

Ceramics AM is also seen as a disruptive technology for use in extreme environments. It could satisfy unmet demands for high-temperature materials, e.g., ultra-high temperature ceramics (UHTCs), and complex geometries. However, affordable and scalable AM routes to tough and damage tolerant ceramics are lacking. As indicated above, the requirement is to obtain fiber-reinforced composites or materials with multiscale (nano to macro) internal architectures and novel compositions, structures, and properties. One attractive area for the early adoption of ceramics AM is in low-cost engines for small drones, which can benefit from any increased performance. In these applications, higher risks of component failures have relatively insignificant implications and can be treated as a testbed for prototyping and accelerated design iterations.

Several types of AM technology are being explored for military aircraft applications, including stereolithography (SLA), digital light processing (DLP), DIW, aerosol jet printing (AJP), and powder bed fusion. Significant research is focused on approaches that utilize preceramic polymer precursors (PCP).17 Examples include monomer resins, which under UV light undergo direct conversion to ceramics via pyrolysis without a separate debinding step, yielding high final densities even for compositions that are otherwise difficult to sinter (SiC, Si3N4).18 With this approach, CMCs can be readily produced by incorporating the reinforcement particles or whiskers as suspensions in the resin, which are then pyrolyzed into a fully dense composite. See Figure 2. PCPs provide an extended shelf-life, permit control of molecular weight and rheology during processing, can achieve the rapid curability appropriate for ceramics AM (especially using AJP or DIW), and, being modular, enable tailoring of the chemistry.19 PCPs with different metal cross-linkers are under development to provide compositional flexibility (e.g., polymers based on siloxane or carbosilane and ZnCl2, TiCl4 or YCl3 metal components).19 The cross-linked preceramic precursors are viscoelastic, yielding AM-built materials that are more densely cross-linked, can be shaped, and retain their shapes without support structures. These properties permit DIW processing, especially UV-assisted DIW of ceramic fiber composites. Despite the advantages offered by the preceramic-resin technologies, several challenges remain to be addressed. The final product strength, being controlled by the presence and nature of defects, still exhibits significant variability. In general, for structural applications, reduced variability is preferable to higher mean strength. Additional research is required to extend the strength and toughness of resin-derived AM products to higher temperatures, e.g., 1200 °C to 1300 °C for these materials to surpass alumina. Also, more work is needed to tailor resin chemistry to prevent shrinkage. Low oxygen resins show promise in this regard. Another direction for optimizing the properties of AM CMCs is the development of methods for aligning filler particles that have anisotropic shapes with large aspect ratios (i.e., chopped fibers, whiskers, platelets). For example, an external magnetic field has been used successfully to align such particulates in polymer matrices.20

Figure 2.

UV-DIW parts & their conversion to dense ceramic components via pyrolysis.

Courtesy: Matt Dickerson, Air Force Research Laboratory, Wright-Patterson AFB, OH.

Selective laser melting (SLM) appears attractive for depositing UHTC coatings onto complex shapes. In such parts, careful control of differential cooling is essential because it results in different grain sizes throughout the AM-built material.21 Interesting examples to date include UHTC ZrC/W composite nozzles manufactured by reactive molding injection (MI).22 Moving towards interface coatings (e.g., metal alloys to ceramic thermal-barrier coatings) will be an important development for the future, especially for engine and turbine applications.

Biomedical

Ceramics are attractive for medical engineering because they are bioinert, non-allergenic, exhibit low thermal and no electrical conductivity, produce no artifacts for XCT (in the medical context) or Magnetic Resonance Imaging (MRI), are easy to sterilize, and possess high mechanical strength and wear resistance. AM could enable patient-specific solutions, including resorbable and permanent implants, dental implants, crowns, and bridges, medical device components, and surgical tools. The bone itself can be considered an advanced ceramic-based composite which, in principle, can be generated via AM. Demonstrations suggest that such AM-printed artificial bones are highly osteoregenerative and even capable of serving as carriers for liquid biologics.23

The current focus in biomedical applications is on new structures, not new materials. AM is envisioned to reduce the complexity of surgeries, improve biological response to implants, and lower cost relative to conventionally manufactured titanium and polyetheretherketone (PEEK) because there is less machining. A challenge for the health industry is to validate ceramic parts produced by AM. Indeed, for any biomaterial to be clinically acceptable, see Figure 3, several profile requirements must be met: cytocompatibility, biocompatibility, functionality, surgical friendliness, manufacturability, cost-effectiveness, and regulatory acceptance.24

Figure 3.

Printed ceramic biomedical implants (ZrO2, Si3N4).

Courtesy: Shawn Allan, Lithoz America, Troy, NY.

Principal barriers for wider use of additive technologies in bio-ceramics include a requirement for clinicians to be engaged at all stages of the fabrication; the relatively slow turnaround (at present, next-day implants are impossible); the need for standards and protocols to qualify and validate AM-built parts; and the requirement for every part to be inspected. A significant effort is needed in the development and adaptation of standards, which should build on cooperation with the International Standards Organization (ISO) and the Federal Drug Administration (FDA), and in manufacturing validation in general. For example, even a universal definition of bio-inks for use in DIW is missing (e.g., do bio-inks necessarily incorporate cells?).

For parts inspection, questions exist about the use and interpretation of XCT which has become a standard tool in AM. Among specific issues are types of defects that can be revealed in ceramics, approaches/protocols for using XCT to compare parts produced by AM vis-à-vis other forming technologies, and criteria for validating such characteristics as critical flaw size and shape. For effective validation, AM developers and users need to have metrological guidance and standards, as well as better integration of ceramics, AM, and medical-device designs, including active engagement of clinicians in the development and validation of AM-built ceramic products.

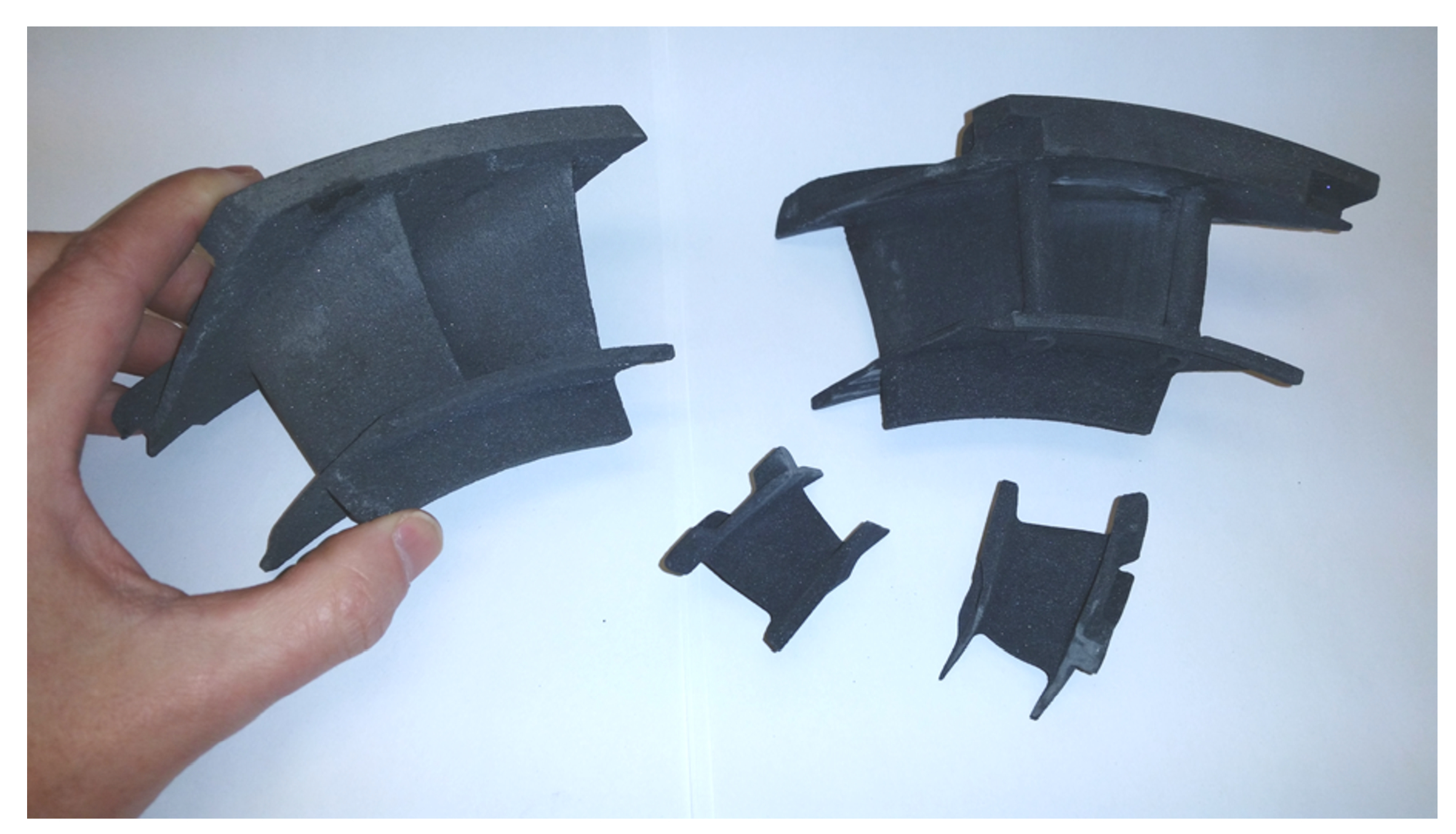

Ceramic Armor

Finding disruptive materials to improve armor efficiency becomes increasingly challenging, especially for protecting the individual soldier, see Figure 4. Therefore, new processing technologies are sought. Natural biological composites, which commonly incorporate simple base materials in complex hierarchical structures, exhibit mechanical properties superior to those of individual components.25,26 Ceramics AM offers potential for implementing bioinspired multiscale designs to generate armor materials with an optimal combination of properties (density, microstructure, menchanical strength, and fracture toughness). However, the ability to realize this potential remains to be demonstrated, for which more research, together with the development of more extensive modeling capabilities will be required.

Figure 4.

Ceramic armor body-wear.

Courtesy: Lionel Vargaz-Gonzales, US Army Research Laboratory, Aberdeen, MD.

Binder jetting, DIW, and SLA have all been considered for AM of armor composites. As in many other potential ceramics AM applications, none of these methods are optimal. Binder jetting is easy to implement and scalable but provides relatively low fill densities (30 % to 35 % by volume), rough surfaces, and is limited in terms of its resolution and ability to co-process several materials.27 DIW works for a wide choice of materials, allows for suspensions with high solid loadings, offers a multi-material capability, and is readily scalable. However, it requires careful control of suspension rheology, has limited resolution, and printed parts suffer from shrinkage and warping defects.28 SLA enables high resolution and surface fidelity, but materials of interest exhibit refractive indexes too high in the UV-A range; additionally, this method has limitations on the solid loadings and the abilities to co-process distinct materials.29

Successes have been achieved using a customized DIW printer with an in-line mixing capability.30 This printer features a feed system that provides precise control over the material input ratio into the printing head; the latter also incorporates an in-line helical auger tool to convey and mix independent suspensions. Thus far, a 0.8 mm nozzle has been used. A significant emphasis is on the development of printable ceramic inks. The goal is to obtain pseudoplastic suspensions by matching their yield stress and flow curves to get predictable conveyance and mixing properties; additionally, there is a desire to have rheological characteristics that are independent of powder type.30 Issues exist with printing sharp corners, and work is in progress to optimize the process strategy. Another challenge is to achieve a tailorable texture within the printed layer using shear alignment.

Some of the challenges encountered with multi-component DIW include the lack of metrology for quantifying the mixing efficiency and the need to determine the optimal auger design to achieve adequate mixing of specific inks. Despite DIW-printed alumina parts featuring density, hardness, and microstructure on par with those of standard ceramic armor materials, like Cerashield CAP 3 (CoorsTek Inc., Golden, CO)* 99.5 % Al2O3, their projectile depth of penetration remains unsatisfactorily high.31 This problem in performance under dynamic strain conditions has been attributed to high densities of defects which originate from the printing process, such as slurry bubbles trapped both within and between the layers. Given that high strain-rate events activate the entire defect population, minimizing defect concentrations and size distributions is imperative. Better control of feedstock (particle size distributions, agglomeration in slurries) is one direction for achieving this goal. A metrology gap cited in this context is the lack of a direct method for measuring agglomeration at the solid loadings of interest. Other sources of defects include shrinkage, warping, and print-derived defects. A challenge is to develop an approach for balancing high yield stress, printability, and shape retention of feedstock suspensions with the reduction of print-induced defects. On the metrology side, there is a need for the metrics to describe warping and shrinkage.

Energy

In this area, opportunities exist for both structural (heat exchangers, engine membranes, turbines) and functional (batteries, fuel cells, catalysts) ceramics. The interest falls into several categories summarized in Table 2. A number of these applications are discussed in more detail in other sections. For example, AM requirements for CMCs, including the use of CVI in packed preforms, overlap closely with those faced in the aerospace sector. For structural components, ceramics can be introduced into metal-alloy parts directly during AM builds, as has been accomplished using in situ laser nitridation of Ti-based alloys to generate wear- and corrosion-resistant TiN coatings.32 Successful demonstrations of such hybrid processes for functional energy applications can be exemplified by the stop-n-go approach, wherein the direct-energy-deposition build of a metal part designed to operate in extreme environments is interrupted to embed ceramic sensors (e.g., made from Pb(Zr,Ti)O3).33 (Some more information onceramics AM for sensors is provided in the next section.) Also overlapping with the aerospace sector is the significant application of ceramics AM in molds, scaffolds and castings in connection with turbine engine design. Indeed, land-based gas turbines play a major role in modern energy (electricity) supply, and the ceramics AM issues associated with the turbine components are similar to those discussed for the aerospace field. See Figure 5. Ceramics AM is discussed more specifically with regard to investment castings below, as applicable to land-based gas turbines as it is to aerospace jet engines.

Table 2.

Energy applications of current interest. (Based on material supplied by Beth Armstrong, Oak Ridge National Laboratory.)

| Applications | Technology | Materials |

|---|---|---|

| Sustainable Nuclear and Fusion Energy Development | Binder Jetting/CVI, selective laser sintering (SLS) | Composites: SiC/SiC SiOC/SiC |

| Energy Generation, Conversion and Storage | DIW | SOFC, Li-ion/solid-state battery materials |

| Sensors | FDM | Pb(Zr,Ti)O3, PbMg1/3Nb2/3O3-PbTiO3 |

| Energy-related Industrial Processes | Binder Jet/DLP, Binder Jet/CVI/SLS/FDM | Shape-memory ceramics, oxides/non-oxides for gears, turbines, blades, molds |

Figure 5.

(lef) Particle-reinforced SiOC nozzle as printed from preceramic polymer. (middle) after pyrolysis; (right) during testing.13

Courtesy: HRL Laboratories, LLC., Malibu, CA

For energy-storage applications, AM has been used to fabricate ultralight-weight lattices and hierarchical structures of materials with large surface areas, like graphene aerogels, that display properties attractive for supercapacitor electrodes.34,35 Methods considered for printing such lattice structures include projection microstereolithography (a photochemical and optical technique),36,37 DIW (utilizing unique fluid flow and gelling properties),38,39 and electrophoretic deposition (transport of nanoparticles enabled by an electric field).40 As indicated in Table 2, various Li-ion and solid-state battery materials, and also complete solid oxide fuel cells (SOFCs) have been successfully fabricated using ceramics AM methods. While promising, it is not yet clear when AM-processing for such devices will become commercially competitive with respect to more conventional manufacturing processes.

Electronics

For application in electronics, the interest is in using AM to fabricate multi-material architectures for radiofrequency (RF) components (e.g., antennas), metamaterials, ceramic microelectronic packaging, sensors, etc.41 See Figure 6. Ceramic-particle jetting, as implemented by XJet (Rehovot, Israel), is capable of printing zirconia with dielectric properties (after sintering) suitable for electromagnetic applications.42 The power of AM is in its ability to produce zirconia parts with textured anti-reflective surfaces (e.g., moth-eye-like), which makes these structures attractive for use in high-temperature missile and rocket radomes that are required to protect expensive antennas and electronics from both natural and operational conditions.43,44 Other applications of this technology include ceramic substrates for transmission lines and antennas, coded apertures for X-ray imaging, passive beam-forming lenses using spatially graded properties, and photonic crystals. Photonic crystals can be produced by printing metamaterial structures with periodic dielectric constant variation.45 Primary usages include low-dielectric-loss dielectric-resonance cavities, waveguides, and sensors. The commercial systems for particle jetting can print parts on an industrial scale. While, at present, the choice of ceramic materials is limited to zirconia, alumina (which would be easier to work with for radomes) and stainless steel are expected to become available soon. Indeed, the ability to accommodate a broader range of feedstock materials would provide particle-jetting technology with much greater flexibility. The removal of the support materials after the initial build remains a challenge and needs to be addressed.

Figure 6.

AM-printed ceramic RF devices.

Courtesy Mark Mirotznik, University of Delaware, Newark, DE.

Ceramics offer advantages over polymers for AM-fabricated RF components, including a wider range of dielectric constants, lower losses, less damage from binder burnout during metallization, and enhanced functionality.46 Unlike polymers, which are commonly deposited using extrusion-based printers, ceramics are printed from slurries. This means that sagging of printed parts can be an issue, leading to poor dimensional control; additionally, post-build sintering is required to densify the part. In this context, ultralow temperature (ULT) ceramics provide several advantages: low sintering temperature, high density, compatibility with metal inks, very low dielectric loss even at microwave frequencies, and temperature-stable resonance frequencies. However, slurry and nozzle geometry remain challenges, and nanoscale feedstock powders are still required. For proof of concept, various blends of Bi2O3 – MoO3 have been investigated.46–48 These materials have been studied extensively for their application in low-temperature-cofired-ceramic (LTCC) technologies, where a low ceramic sintering temperature (≈ 900 °C) permits co-firing with highly conductive metals such as silver or gold to form a multilayer composite component having the desired RF and microwave performance characteristics. A slurry-based 3D printing process using selective laser burnout (SLB) of Bi2Mo2O9 could achieve satisfactory microstructures, high dielectric constants, and low losses. Using this method, a 3D-printed structure of Bi2Mo2O9 with floating Ag electrodes has been successfully fabricated.49

Another potential application of ceramics AM is in microelectronic packaging, where current scale limitations are limiting the miniaturization of 3D designs, causing technological bottlenecks. One needs to be able to machine features smaller than 10 μm. Micro digital light processing (μDLP) methods show potential for achieving the product resolution needed to address this issue, and are becoming commercially available.29 Uniform arrays of interconnects with < 10 μm diameter and smooth surfaces have been fabricated using μDLP. Moreover, 3D printing of sub-μm ceramic features using two-photon lithography with UV curable pre-ceramic resin has been demonstrated.50 Printing speeds remain too slow, but a record 7 GPa loading strength has been achieved.50

Ceramic tooling for investment casting

Direct printing of ceramic molds for investment casting is already a game-changer for industry because it reduces cost and lead time by 70 %, enabling efficient fabrication of parts in small quantities.51 This area represents the most significant commercial success of ceramics AM to date. See Figure 7. Typical casting tools include cores, molds, and filters. The traditional investment casting process, including the creation of a ceramic mold, involves at least ten steps. These can be reduced to four if AM-build tools are used.

Figure 7.

Ceramics AM for sacrificial casting cores creating the cooling geometry in turbine blades

(Sources: left – Siemens, https://new.siemens.com/global/en/products/energy/power-generation/gas-turbines/sgt-a05-ae.html#!/; right – Courtesy: Tom Wasley, MTC, Coventry, UK.)

A primary driver for rapid precision casting is the need to maintain a diverse and aging aircraft fleet. Spare parts are required usually in small volumes and, therefore, the non-recurring engineering and tooling costs associated with investment castings are significant. Metal AM, which could address this problem, is not ready yet. Ceramics AM of the casting toolsets using, e.g., vat photopolymerization, provides a viable solution.52 Several issues, however, need to be resolved. Binder burnout creates internal pressure that can compromise structural integrity, causing microcracks. The availability of tools for modeling polymer oxidation to predict internal forces would help with mitigating these issues. Likewise, modeling capabilities are needed to predict shrinkage and distortions of ceramic parts during post-build sintering. The anisotropy of printed parts requires dedicated studies to identify primary variables that lead to anisotropic properties of AM products.

Emerging sintering techniques for post-processing

The workshop clarified that virtually all ceramic AM-built parts require at least some post-processing, and optimization of the post-processing step is as critical as that of the respective AM process itself. Heat treatments to relieve stress may also be important because residual stresses readily result in cracking and/or warping of the product, or in the appearance of other defects. Post-processing commonly involves clean-up, de-binding of any support materials, and product densification. Clean-up of printed parts and/or machines can be both costly and time-consuming (depending on the AM process and type of the product) but normally does not introduce defects. The de-binding step, however, which is required for many but not all ceramics AM processes, can be a primary source of defects and associated failures. Sintering of a green-body AM build presents perhaps the most ubiquitous challenge for delivering the desired shape and (full) density without introducing defects and part failures. The recently developed energy-efficient flash- and cold-sintering technologies provide candidate solutions to this problem. In both cases, the aim is to produce densification under conditions less extreme than required for conventional ceramic sintering processes.

In flash sintering, densification occurs as green part is subjected to a direct electric field applied via customized electrodes at a specific temperature.53–56 At some combination of field and temperature, a sudden increase in the electrical (ionic) conductivity takes place in the ceramic. See Figure 8. This ‘flash even’ leads to the rapid densification with a reduction in both the required sintering temperature and in the sintering time, hence also decreasing energy consumption and cost. Flash sintering affords an ability to tune certain material properties, and sometimes, the ability to densify an AM product without common sintering issues. However, for this method to work, the AM product must be capable of densifying at modest temperatures, and not degrade under the strong thermal gradients that can be involved. Potential examples are low-temperature coatings, some multilayered materials (including CMCs), graded structures, and geopolymers. Flash sintering can be contactless which eliminates high mechanical or thermal stress at the contact point that could create defects or crack failures, but sometimes generates high dislocation densities. Clearly, there are significant challenges and opportunities here for future materials research in academia and elsewhere to elucidate how flash sintering phenomena can be integrated into ceramics AM processes to optimize densification.

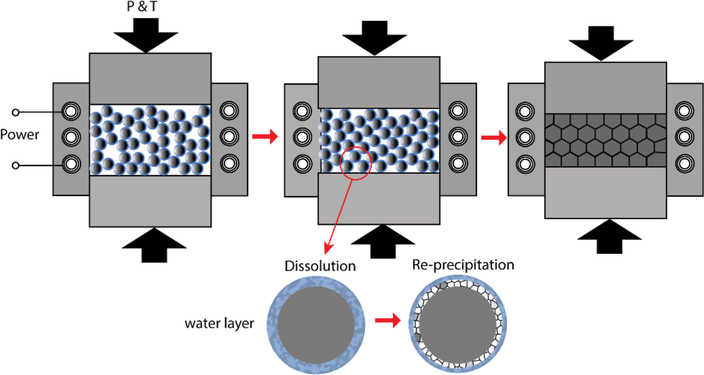

Figure 8.

A schematic drawing of a common flash-sintering setup with a dog-bone-shaped sample. Local heating is achieved by applying an electric field to the sample.

Developed largely in academia, cold sintering is realized by adding a small quantity of water (or other solvent) to ceramic powder, so that densification occurs through the partial dissolution of solid particles in transient aqueous phase, followed by re-precipitation.57–60 See Figure 9. The process requires some pressure (typically less than 200 MPa) and heating, typically to less than 300 °C – much lower than used in conventional sintering. The possibility of incorporating this technology into ceramics AM of suitable feedstock materials (initially, oxides, but other ceramics now possible) is being researched. Cold sintering enables co-processing of ceramics with metals and polymers, which makes it attractive for parts that incorporate several types of materials, especially when a layered configuration is appropriate. A major challenge will be to interface the uniaxial compression geometry of cold sintering with the more complex geometries found generally in ceramics AM applications; however, the technique can be more readily applicable to composites, including those combining ceramics with polymers or metals, where AM is used to realize complex controlled architectures.

Figure 9.

Schematic of aqueous or fluid-mediated cold sintering process (temperature (T) < 300 °C pressure (P) < 200 MPa pressure).

Most recently, after this workshop, a new densification technique called ultrafast high-temperature sintering (UHS) has been reported.61 In this method, a part to be sintered is sandwiched between two carbon tapes through which electric current is passed, providing rapid (seconds) heating up to temperatures as high as 3000 °C. The process is performed in an inert atmosphere. UHS has been demonstrated to achieve densities greater than 95 % while yielding uniform compositions and favorable microstructures for a broad range of ceramics that can be difficult to densify with the same results using conventional approaches. Importantly, it is readily applicable to complex-shape AM-built parts with several examples of UHS-sintered 3D-printed samples provided already in the original publication. The mechanisms that operate during UHS remain currently uncertain but undoubtfully will be a subject of research in the immediate future.

Research & Measurement Needs

To date, few clear indications have emerged as to which methods will dominate ceramics AM in the long term. Some of the needs specific for individual technologies and applications are described in the preceding sections. Here, we concentrate on the universal measurement and materials research challenges that apply to the entire field. Comprehensive standardized characterization of feedstock materials is one high priority issue. Particle morphologies, chemical purity, and rheology of suspensions are examples of characteristics that determine the quality of AM-build ceramic parts but often remain uncertain. At the same time, clearly defined specifications for feedstocks are unavailable which compounds the problem. Likewise, the applicability of existing standards for the characterization of dry powders and particle suspensions to the ceramic AM feedstock has not been verified yet. Many details of commercial raw materials remain proprietary which creates a strong need for an openly accessible database of feedstock characteristics (including metadata). Recycling poses another issue and metrology is required to determine the reusability of feedstock material. In principle, ceramics AM, in common with all additive manufacturing, offers strong opportunities for the development of a sustainable circular economy. In this connection, advantage should be taken of the current rapid development of rheology based materials research of slurries and fluid mixes. This would greatly benefit all the ceramics AM methods where fluid inks or composite suspensions are involved (DIW, vat polymerization, etc.). Realtime rheological studies of concentrated colloidal suspensions while subjected to oscillatory shear, coupled with in situ characterization of the evolution of particle morphologies using X-ray and neutron small-angle scattering, can provide major insights into the physics and chemistry of the suspension, allowing various rheological properties to be optimized directly. Recently developed measurement capabilities at the NIST Center for Neutron Research (NCNR), and elsewhere, could present some significant opportunities for advances in this area. 62,63 Such studies would be particularly relevant for materials research focused on optimizing ceramic “inks” for DIW.

The palette of commercial feedstock materials for ceramic AM remains limited and must be extended. Many technologically promising functional ceramics, like some materials for solid-state batteries or RF components, are unavailable for AM. For several application sectors, new feedstock options will need to be developed for enabling AM to produce multi-material (e.g., combinations of metals, polymers, and ceramics) and composite products. The development of raw materials must be tied to the details of the given AM technology, including the post-processing steps involved, to facilitate fabrication of defect-free, net-shape parts having controlled densities and microstructures.

Like feedstock, AM processes implemented in commercial equipment are frequently proprietary. This complicates understanding of the variability often encountered even among parts produced using nominally identical conditions. The same problem exists in metals AM, where it has been addressed by developing standard test structures to enable meaningful comparisons of different methods and machines. Ceramics AM would benefit from similar standards both for green parts and final post-processed products. Questions remain whether such test structures could adopt the design employed for metals AM or if new ceramics-specific artifacts must be developed. Meanwhile, much fundamental research is still needed to elucidate the thermodynamics of the many AM processes of current interest, including how the different component materials in composite systems will interact with each other during AM-relevant transformation processes, as well as during any post-processing.

Measurement standards and test structures are also required to characterize the properties and performance of AM-build parts adequately. For example, standard procedures for the determination of mechanical properties in ceramics, like three-point flexure of rectangular bars, may not be representative of the complex shapes with variable cross-sectional dimensions produced by AM. However, the applicability of standards devised for conventional ceramics to the characterization of ceramic AM products must be critically assessed before the exact needs for any new measurement protocols can be established. The mechanical properties of AM-produced complex-shaped green parts need to be investigated from a fundamental viewpoint to determine the true effects of densification and shrinkage. It is unlikely that characterization of relatively simple test cubes (the current practice) will suffice. A curated property database for ceramic AM products, which would include all the metadata from feedstock to build & post-processing steps to characterization methods, besides its overall value for the field, could provide a useful basis for such an assessment. The possibility of establishing a standardized development protocol for each of the various AM technologies could be considered, based on one or several success stories that use each technology. Such an approach could save on development time as well as costs. In this connection, it will be important to work with the appropriate committees of standards organizations such as ASTM International and the ISO. As an example, a benchmarking effort in AM of both metals and polymers, the so-called "AM-bench" project, is already being used to populate databases for these material areas.64

The main post-processing steps, such as debinding and sintering, remain understudied. Better characterization of the fundamental physical and chemical phenomena that underlie the various debinding processes, preferably in situ, would help to optimize their duration and minimize the associated formation of cracks. The binder fraction within ceramics AM feedstock materials must frequently be significantly higher than found in conventional ceramic processing and may represent ≈ 50 % of the feedstock solid-powder volume.65 Methods for detecting cracks during the debinding are also highly desired. The densification of parts with complex shapes requires dedicated studies as the optimal conditions are likely to differ from those employed for conventionally manufactured parts.

Because most commercially viable AM approaches generate green parts, for many applications the post-build sintering is critical for AM to provide the required part performance at acceptable cost. The emerging flash sintering and, possibly, cold sintering technologies are attractive for this purpose. Cold sintering has the appeal of co-processing ceramics with metals or polymers. Further studies and development of these methods in the context of applying them to complex-shape green parts are required for their integration with AM. Much fundamental research is still needed to elucidate both phenomena sufficiently for their incorporation into commercial-scale ceramics AM technologies.

Quality control, which today is typically performed via XCT, is widely regarded as a bottleneck because of its cost and slow speed. The field would benefit from the availability of defect standards and best XCT practices that would target the types of defects (porosity, bubbles, microcracks, etc.) typically encountered in AM-built parts. The development of cost- and time-effective non-destructive techniques is highly desired and would significantly reduce the barrier for commercialization of ceramics AM.

A major overarching problem that hinders the development of ceramics AM is the nearly complete lack of modeling efforts, although some promising published results of modeling and simulations have emerged recently.66–69 The community envisions modeling to benefit almost every aspect of the AM process, from the selection of feedstock characteristics and build parameters to the optimization of debinding and sintering schedules per a specific product. Development of computational approaches and software tools, which would enable predictive simulations of a complete workflow even for a few selected AM methods, like SLA or DIW, is perceived as a high priority. Given the diversity and complexity of processes involved in ceramics AM, addressing this goal will require interdisciplinary efforts, focused on each of the physical processes mentioned above. Eventually, the modeling methodology and the software tools should be accessible by industry.

Concluding Summary & Outcome

Ceramics AM is remarkably diverse as the choice of best processes and feedstock varies with applications. As a result, this field is more fragmented than AM of polymers or metals. Nevertheless, besides prototyping and art & design applications, two significant industrial areas exist where ceramics AM is already making a measurable economic impact: customized complex biomedical /dental implants and ceramic tooling for casting of metal-alloy turbine-engine and related components with highly tuned geometries. Despite their diversity, all ceramics AM technologies share similar measurement needs for standardized characterization, modeling, and curated databases. Below we use the input from the workshop discussions to propose several paths forward. Many of these will only be successful if there are integrated collaborative efforts involving industry, government agencies, and academia. Hence, we submit that progress along these paths would be greatly accelerated through appropriately focused proposal calls from the research funding agencies.

Develop and demonstrate the computational capability to simulate and validate all processing steps associated with any of the AM processes. If a university or government laboratory could use such a capability to achieve a predictive understanding of even one AM process, generating openly available results and model simulations, it would provide a reference case from which future work could build.

Research the fundamental physical and chemical phenomena governing the thermodynamics of ceramics AM feedstock materials, together with the kinetics associated with their application in complete ceramics AM processing all the way to final parts.

Work with groups of interested stakeholders in multiple application areas to develop databases for feedstock properties, AM build processes, as-built green-body material properties, de-binding and sintering/densification characteristics & final-product properties. Government agencies (such as NIST in the USA) could provide unbiased curation services for such databases. However, actual input would need to come from stakeholders in the field. The first step should involve the evaluation of the already available resources.

Develop best-practice standards and certification protocols in connection with specific AM methods and application areas. Following precedents in conventional manufacturing, this will require groups of invested government agencies, industry, and university researchers to engage with relevant committees of standards organizations such as ASTM International and ISO. As with databases, an assessment of existing standards and protocols for their applicability to ceramics AM processes and products is required before the need for new standards can be determined. In this connection, the most relevant committees for additive manufacturing have been ASTM Committee F42 on Additive Manufacturing and ISO/TC261 Additive Manufacturing. Nowadays, these two committees have merged and operate as one, developing standards for AM across all materials classes.

For well-defined niche commercial applications, define possible round-robin studies, followed by NIST Standard Reference Material (SRM) (or similar) development in connection with specific ceramics AM fabrication routes. (For a NIST SRM, a 5-year viability commercial case would need to be established before proceeding.)

Establish ambitious research and development efforts to elucidate the post-build processing steps, especially pyrolysis of preceramic resins, or (when pyrolysis is not used) the emerging flash-sintering and cold-sintering technologies. In this connection, we note recently published reviews that have specifically included how post-processing steps should be integrated in the overall AM build.70,71

As the next step, forming working groups and collaborative task forces focused on the evaluation of databases, standards, and best practices is warranted. Likewise, it could be of significant importance to hold biennial or triennial scientific and technical meetings dedicated to ceramics AM. These gatherings would review the global state-of-the art, together with national and international research directions for moving the ceramics AM field forward.

Supplementary Material

Acknowledgements

We acknowledge Cathleen Hoel of GE Global Research, Niskayuna, NY, for providing much of the material for Table 1, and Beth Armstrong of Oak Ridge National Laboratory, Oak Ridge, TN, for providing much of the material for Table 2. We also thank the following for providing or identifying suitable figures: Mike Halbig, NASA Glenn Research Center, Cleveland, OH, for Figure 1; Matt Dickerson, Air Force Research Laboratory, Wright-Patterson AFB, OH, for Figure 2; Shawn Allan, Lithoz America, Troy, NY, for Figure 3; Lionel Vargaz-Gonzales, US Army Research Laboratory, Aberdeen, MD, for Figure 4; Kayleigh Porter and Tobias Schaedler HRL Laboratories LLC, Malibu, CA, for Figure 5; Mark Mirotznik, University of Delaware, Newark, DE, for Figure 6; Tom Wasley, MTC, Coventry, UK, and Anand Kulkarni, Siemens Corporation, Charlotte, NC, for Figure 7. Finally, we wish to thank all contributors to the NIST Workshop on Materials Research and Measurement Needs for Ceramics Additive Manufacturing, held on NIST’s Gaithersburg, MD, campus in November 2019. Without them this paper would not have been possible. Their names are listed in the Workshop Agenda that comprises the Supporting Information.

List of Abbreviations

- AJP

aerosol jet printing

- AM

additive manufacturing

- CMC

ceramic matrix composite

- CNC

Computer Numerical Control

- CVI

chemical vapor infiltration

- DIW

direct ink writing

- DLP

digital light processing

- FDA

Federal Drug Administration

- FDM

fused deposition modeling

- FFF

fused filament formation

- ISO

International Standards Organization

- LCM

lithography-based manufacturing

- LOM

laminated object manufacturing

- LTCC

low-temperature-cofired-ceramic

- μDLP

micro digital light processing

- MI

molding injection

- MRI

Magnetic Resonance Imaging

- NIST

National Institute of Standards and Technology

- PCP

preceramic polymer precursor

- PEEK

polyetheretherketone

- RF

radio frequency

- SLA

stereolithography

- SLB

selective laser burnout

- SLM

selective laser melting

- SLS

selective laser sintering

- SOFC

solid oxide fuel cell

- SRM

standard reference material

- UHTC

ultra-high temperature ceramic

- ULT

ultralow temperature

- UV-A

ultraviolet A

- XCT

X-ray computertomography

Footnotes

Any mention of commercial products is for information only; it does not imply recommendation or endorsement by NIST.

References

- 1.Dunham S. The ceramic AM market roadmap. Presentation at Ceramics Expo, Cleveland, OH, 2018; SmarTech reports commercially available at: www.smartechpublishing.com. [Google Scholar]

- 2.Cesarano J. A review of robocasting technology. Mater. Res. Soc. Proc. 1999; 542:133–139 [Google Scholar]

- 3.Travitzky N, Bonet A, Dermeik B, Fey T, Filbert-Demut I, Schlier L, Schlordt T, Greil P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014;16(6):729–754. [Google Scholar]

- 4.Gao W, Zhang YB, Ramanujan D, Ramani K, Chen Y, Williams CB, Wang CCL, Shin YC, Zhang S, Zavattieri PD. The status, challenges, and future of additive manufacturing in engineering. Computer-Aided Des. 2015;69:65–89. [Google Scholar]

- 5.Zocca A, Colombo P, Gomes CM, Gunster J. Additive manufacturing of ceramics: issues, potentialities, and opportunities. J. Am. Ceram. Soc. 2015;98(7):1983–2001. [Google Scholar]

- 6.Deckers J, Vleugels J, Kruth J-P. Additive manufacturing of ceramics: a review. J. Ceram. Sci. Tech. 2014;5(4):245–260. Deckers J, Vleugels, Kruth J-P. Additive manufacturing of ceramics: a review. J. Ceram. Sci. Tech. 2014;5(4):245–260. [Google Scholar]

- 7.Ruiz-Morales JC, Tarancón A, Canales-Vázquez J, Méndez-Ramos J, Hernández-Afonso L, Acosta-Mora P, Rueda JRM, Fernandez-Gonzales R. Three dimensional printing of components and functional devices for energy and environmental applications. Energy Environ Sci. 2017;10(4):846–859. [Google Scholar]

- 8.Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B Eng. 2018;143(December 2017):172–196. [Google Scholar]

- 9.Nafis OZ, Nafrizuan MY, Munira MA, Kartina J. Review on CNC-rapid prototyping. IOP Conf Ser Mater Sci Eng. 2012;36(1) art. no. 12032. [Google Scholar]

- 10.Zhang Q. Research on ceramic matrix composites (CMC) for aerospace applications. Adv Mater Res. 2011;284–286:324–329. [Google Scholar]

- 11.Zhu D. Aerospace Ceramic Materials: Thermal, Environmental Barrier Coatings and SiC/SiC Ceramic Matrix Composites For Turbine Engine Applications. NASA/Tm-2018–219884. 2018.

- 12.Han D, Mei H, Xiao S, Dassios KG, Cheng L. A review on the processing technologies of carbon nanotube/silicon carbide composites. J Eur Ceram Soc. 2018;38(11):3695–3708. [Google Scholar]

- 13.Klosterman D, Chartoff R, Graves G, Osborne N, Priore B. Interfacial characteristics of composites fabricated by laminated object manufacturing. Composites Part A Appl Sci Manuf. 1998;29(9–10):1165–1174. [Google Scholar]

- 14.Lv X, Ye F, Cheng L, Fan S, Liu Y. Fabrication of SiC whisker-reinforced SiC ceramic matrix composites based on 3D printing and chemical vapor infiltration technology. J Eur Ceram Soc. 2019;39(11):3380–3386. [Google Scholar]

- 15.Halbig MC, Grady JE, Singh M, Ramsey J, Patterson C, Santelle T. A Fully Nonmetallic Gas Turbine Engine Enabled by Additive Manufacturing Part III: Additive Manufacturing and Characterization of Ceramic Composites. NASA/TM-2015–218892. 2015.

- 16.Franchin G, Maden HS, Wahl L, Baliello A, Pasetto M, Colombo P. Optimization and characterization of preceramic inks for Direct Ink Writing of Ceramic Matrix Composite structures. Materials (Basel). 2018;11(4):1–14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Colombo P, Mera G, Riedel R, Sorarù GD. Polymer-derived ceramics: 40 Years of research and innovation in advanced ceramics. J Am Ceram Soc. 2010;93(7):1805–1837. [Google Scholar]

- 18.Eckel ZC, Zhou C, Martin JH, Jacobsen AJ, Carter WB, Schaedler TA. Additive manufacturing of polymer-derived ceramics. Science 2016;351(6268):58–62. [DOI] [PubMed] [Google Scholar]

- 19.Baldwin LA, Rueschhoff LM, Deneault JR, Cissel KS, Nikolaev P, Cinibulk MK, Koerner H, Dalton MJ, Dickerson MB. Synthesis of a Two-Component Carbosilane System for the Advanced Manufacturing of Polymer-Derived Ceramics. Chem Mater. 2018;30(21):7527–7534. [Google Scholar]

- 20.Kokkinis D, Schaffner M, Studart AR. Designing bioinspired composite reinforcement architectures via 3D magnetic printing. Nature Comm, 2015;6:8641. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.King D, Middendorf J, Cissel K, Key T, Carney C. Selective laser melting for the preparation of an ultra-high temperature ceramic coating. Ceram Int. 2019;45(2):2466–2473. [Google Scholar]

- 22.Lipke DW, Zhang Y, Liu Y, Church BC, Sandhage KH. Near net-shape/net-dimension ZrC/W-based composites with complex geometries via rapid prototyping and Displacive Compensation of Porosity. J Eur Ceram Soc. 2010;30(11):2265–2277. [Google Scholar]

- 23.Jakus AE, Rutz AL, Jordan SW, Kannan A, Mitchell SM, Yun C, Koube KD, Yoo SC, Whiteley HE, Richter CP, Galiano RD, Hsu WK, Stock SR, Hsu EL, Shah RN. Hyperelastic “bone”: A highly versatile, growth factor-free, osteoregenerative, scalable, and surgically friendly biomaterial. Sci Transl Med. 2016;8(358):1–16. [DOI] [PubMed] [Google Scholar]

- 24.Jakus AE, Rutz AL, Shah RN. Advancing the field of 3D biomaterial printing. Biomed Mater. 2016;11(1) art.no.014102. [DOI] [PubMed] [Google Scholar]

- 25.Arola D, Murcia S, Stossel M, Pahuja R, Linley T, Devaraj A, Ramulu M, Ossa EA, Wang J. The limiting layer of fish scales: Structure and properties. Acta Biomater. 2018;67:319–330. [DOI] [PubMed] [Google Scholar]

- 26.Meyers MA, Lin AYM, Chen PY, Muyco J. Mechanical strength of abalone nacre: Role of the soft organic layer. J Mech Behav Biomed Mater. 2008;1(1):76–85. [DOI] [PubMed] [Google Scholar]

- 27.Karandikar P, Watkins M, McCormick A, Givens B, Aghajanian M. Additive manufacturing (3D printing) of ceramics: microstructure, properties, and product examples. In: Proceedings of the 41st International Conference on Advanced Ceramics and Composites. Daytona Beach, Florida; 2017. p. 175–187. [Google Scholar]

- 28.Costakis WJ, Rueschhoff LM, Diaz-Cano AI, Youngblood JP, Trice RW. Additive manufacturing of boron carbide via continuous filament direct ink writing of aqueous ceramic suspensions. J Eur Ceram Soc. 2016;36(14):3249–3256. [Google Scholar]

- 29.Chen Z, Li Z, Li J, Liu C, Lao C, Fu Y, et al. 3D printing of ceramics: A review. J Eur Ceram Soc. 2019;39(4):661–687. [Google Scholar]

- 30.Pelz J, Ku N, Meyers M. Additive Manufacturing Utilizing a Novel In - Line Mixing System for Design of Functionally Graded Ceramic Composites. Aberdeen Proving Ground, MD; 2019. [Google Scholar]

- 31.Jones TL, Vargas-Gonzalez L, Scott B, Goodman B, Becker B. An In-Depth Analysis of Competing 3D Printed Methods for the Mobile Manufacturing of Body Armor at the Point of Need. Aberdeen Proving Ground, MD; 2019. [Google Scholar]

- 32.Morton PA, Taylor HC, Murr LE, Delgado OG, Terrazas CA, Wicker RB. In situ selective laser gas nitriding for composite TiN/Ti-6Al-4V fabrication via laser powder bed fusion. J Mater Sci Technol. 2020; in press. [Google Scholar]

- 33.Hossain MS, Gonzalez JA, Hernandez RM, Shuvo MAI, Mireles J, Choudhuri A, Lin YR, Wicker RB. Fabrication of smart parts using powder bed fusion additive manufacturing technology. Addit Manuf. 2016;10:58–66. [Google Scholar]

- 34.Zhu C, Han TYJ, Duoss EB, Golobic AM, Kuntz JD, Spadaccini CM, Worsley MA. Highly compressible 3D periodic graphene aerogel microlattices. Nature Commun. 2015;6:1–8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Zheng X, Lee H, Weisgraber TH, Shusteff M, DeOtte J, Duoss EB, Kuntz JD, Bienner MM, Ge Q, Jackson JA, Kucheyev SO, Fang NX, Spadaccini CM. Ultralight, ultrastiff mechanical metamaterials. Science. 2014;344(6190):1373–1377. [DOI] [PubMed] [Google Scholar]

- 36.Hensleigh RM, Cui HC, Oakdale JS, Ye JCC, Campbell PG, Duoss EB, Spadaccini CM, Zheng XY, Worsley MA. Additive manufacturing of complex micro-architected graphene aerogels. Mater Horizons. 2018;5(6):1035–1041. [Google Scholar]

- 37.Yao B, Chandrasekaran S, Zhang J, Xiao W, Qian F, Zhu C, Duoss EB, Spadaccinin CM, Worsley MA, Li Y. Efficient 3D Printed Pseudocapacitive Electrodes with Ultrahigh MnO2 Loading. Joule. 2019. February 20;3(2):459–470. [Google Scholar]

- 38.Nguyen DT, Meyers C, Yee TD, Dudukovic NA, Destino JF, Zhu C, Duoss EB, Baumann TF, Suratwala T, Smay JE, Dylla-Spears R. 3D-Printed Transparent Glass. Adv Mater. 2017;29(26):1–5. [DOI] [PubMed] [Google Scholar]

- 39.Dudukovic N, Wong L, Nguyen D, Destino J, Yee T, Ryerson F, Suratwala T, Duoss EB, Dylla-Spears R. Predicting Nanoparticle Suspension Viscoelasticity for Multimaterial 3D Printing of Silica– Titania Glass. ACS Appl Nano Mater. 2018. July 17;1(8):4038–4044. [Google Scholar]

- 40.Pascall AJ, Qian F, Wang G, Worsley MA, Li Y, Kuntz JD. Light-directed electrophoretic deposition: Anew additive manufacturing technique for arbitrarily patterned 3D composites. Adv Mater. 2014;26(14):2252–2256. [DOI] [PubMed] [Google Scholar]

- 41.Saracho-Pantoja IO, Montejo-Garai JR, Ruiz-Cruz JA, Rebollar JM. Additive Manufacturing of 3D Printed Microwave Passive Components. In: You KY, editor. Emerging Microwave Technologies in Industrial, Agricultural, Medical and Food Processing. IntechOpen; 2018. [Google Scholar]

- 42.Oh Y, Bharambe V, Mummareddy B, Martin J, McKnight J, Abraham MA, Walker JM, Rogers K, Connor B, Cortes P, MacDonald E, Adams JJ. Microwave dielectric properties of zirconia fabricated using NanoParticle Jetting™. Addit Manuf. 2019;27(March):586–594. [Google Scholar]

- 43.Roper DA, Good BL, McCauley R, Yarlagadda S, Smith J, Good A, Pa P, Morotznik MS. Additive manufacturing of graded dielectrics. Smart Mater Struct. 2014;23(4) art. no. 045029. [Google Scholar]

- 44.Pa P, Mirotznik MS, McCauley R, Yarlagadda S, Duncan K. Integrating metamaterials within a structural composite using additive manufacturing methods. IEEE Trans Antennas Propag. 2013;61(5):2411–2417. [Google Scholar]

- 45.Maldovan M, Thomas EL. Diamond-structured photonic crystals. Nat Mater. 2004;3:593–600. [DOI] [PubMed] [Google Scholar]

- 46.Zhou D, Wang H, Pang LX, Randall CA, Yao X. Bi 2O 3-MoO 3 Binary system: An alternative ultralow sintering temperature microwave dielectric. J Am Ceram Soc. 2009;92(10):2242–2246. [Google Scholar]

- 47.Zhou D, Guo D, Li WB, Pang LX, Yao X, Wang DW, Reaney IM. Novel temperature stable high-: ϵ r microwave dielectrics in the Bi2O3-TiO2-V2O5 system. J Mater ChemC. 2016;4(23):5357–5362. [Google Scholar]

- 48.Zhou D, Pang LX, Wang DW, Li C, Jin BB, Reaney IM. High permittivity and low loss microwave dielectrics suitable for 5G resonators and low temperature co-fired ceramic architecture. J Mater Chem C. 2017;5(38):10094–10098. [Google Scholar]

- 49.Gheisari R, Chamberlain H, Chi-Tangyie G, Zhang SY, Goulas A, Lee CK, Whittaker T, Wang DW, Ketharam A, Ghosh A, Vaidhyanathan B, Whittow W, Cadman D, Vardaxoglou YC, Reaney IM. Multi-Material Additive Manufacturing of Low Sintering Temperature Bi2Mo2O9 Ceramics with Ag Floating Electrodes by Selective Laser Burn-Out. Virtual Phys Prototyp. 2020; in press.

- 50.Bauer J, Crook C, GuellIzard A, Eckel ZC, Ruvalcaba N, Schaedler TA, et al. Additive Manufacturing of Ductile, Ultrastrong Polymer-Derived Nanoceramics. Matter. 2019;1:1–10. [Google Scholar]

- 51.Xu W, Lu Z, Tian G, Miao K, Li D, Zhu W, Wang F, Zhang H, Wang Y, Song Y. Fabrication of singlecrystal superalloy hollow blade based on integral ceramic mold. J Mater Process Technol. 2019;271(May 2018):615–622. [Google Scholar]

- 52.Wang L, Liu X, Wang G, Tang W, Li S, Duan W, Dou R. Partially stabilized zirconia moulds fabricated by stereolithographic additive manufacturing via digital light processing. Mater Sci Eng A. 2020;770(August2019):art. no. 138537. [Google Scholar]

- 53.Biesuz M, Sglavo VM. Flash sintering of ceramics. J Eur Ceram Soc. 2019;39(2–3):115–143. [Google Scholar]

- 54.Chaim R, Chevallier G, Weibel A, Estournes C. Grain growth during spark plasma and flash sintering of ceramic nanoparticles: a review. J. Mater. Sci. 2018;53(5):3087–3105. [Google Scholar]

- 55.Becker MZ, Shomrat N, Tsur Y. Recent advances in mechanism research and methods for electric-field-assisted sintering of ceramic. Adv. Mater. 2018;30(41) art. no. 1706369. [DOI] [PubMed] [Google Scholar]

- 56.Luo J. The scientific questions and technological opportunities of flash sintering: from a case study of ZnO to other ceramics. Scripta Mater. 2018;146:260–266. [Google Scholar]

- 57.Maria JP, Kang X, Floyd RD, Dickey EC, Guo H, Guo J, Baker A, Funihashi S, Randall CA. Cold sintering: Current status and prospects. J Mater Res. 2017;32(17):3205–3218. [Google Scholar]

- 58.Guo J, Floyd R, Lowum S, Maria J-P, deBeauvoir TH, Seo J-H, Randall CA. Cold sintering: progress, challenges and future opportunities. Annu. Rev. Mater. Res. 2019;49:275–295. [Google Scholar]

- 59.Guo H, Baker A, Guo J, Randall CA. Cold sintering process: a novel technique for low-temperature ceramic processing of ferroelectrics. J. Am. Ceram. Soc. 2016;99(11):3489–3507. [Google Scholar]

- 60.Ivakin YD, Smirnov AV, Tarasovskii VP, Rybal’chenko VV, Vasin AA, Kholodkova AA, Kormilitsin MN. Cold sintering of ZnO ceramic in water medium: test demonstration. Glass Ceram. 2019;76(5–6): 210–215. [Google Scholar]

- 61.Wang C, Weiwei P, Bai Q,Cui H, Hensleigh R, Wang R, Brozena AH, Xu Z, Dai J, Pei Y, Zheng C, G. Pastel, Gao J, Wang X, Wang H, Zhao J-C, Yang B, Zheng X(R), Luo J, Mo Y, Dunn B, Hu L. A general method to synthesize and sinter bulk ceramics in seconds. Science, 2020; 368: 521–526 [DOI] [PubMed] [Google Scholar]

- 62.Bharati A, Hudson SD, Weigandt KM. Poiseuille and extensional flow small-angle scattering for developing structure-rheology relationships in soft matter systems. Current Opinion in Coll. Interf. Sci. 2019;42: 137–146. [Google Scholar]

- 63.Shan LY, Xie R, Wagner NJ, He HS, Liu Y. Microstructure of neat and SBS modified asphalt binder by small-angle neutron scattering. Fuel. 2019:253: 1589–1596. [Google Scholar]

- 64.Levine LE, Lane B, Heigel J, Stoudt M, Phan T, Ricker R, Strantza M, Hill M, Zhang F, Seppala J, Garboczi E, Bain E, Cole D, Allen AJ, Fox J, Campbell C. Outcomes and conclusions from the 2018 AM-bench measurements, challenge problems, modeling submissions, and conference. Integrating Materials and Manufacturing Innovation. 2020: in press.

- 65.Gonzalez-Gutierrez J, Cano S, Schuschnigg S, Kukla C, Sapkota J, Holzer C. Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: a review and future perspectives. Materials. 2018;11: art. no. 840. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 66.Jimenez EM, Ding D, Su L, Joshi AR, Singh A, Reeja-Jayana B, Beuth J. Parametric analysis to quantify process input influence on the printed densities of binder jetted alumina ceramics. Additive Manufacturing. 2019;30: art. no. 100864. [Google Scholar]

- 67.Chavez LA, Ibave P, Wilburn B, Alexander IVDA, Stewart C, Wicker R, Lin Y. The influence of printing parameters, post-processing, and testing conditions on the properties of binder jetting additive manufactured functional ceramics. Ceramics. 2020;3: 65–77. [Google Scholar]

- 68.Lorenz M, Dietemann B, Wahl L, Bierwisch C, Kraft T, Kruggel-Emden H, Travitzky N. Influence of platelet content on the fabrication of colloidal gels for robocasting: experimental analysis and numerical simulation. J. Euro. Ceram. Soc. 2020; 40:811–825. [Google Scholar]

- 69.Renteria A, Fontes H, Diaz JA, Regis JE, Chavez LA, Tseng T-L, Liu Y, Lin Y. Optimization of 3D printing parameters for BaTiO3 piezoelectric ceramics through design of experiments. Mater. Express. 2019;6: art. no. 085706. [Google Scholar]

- 70.Bandyopadhyay A, Heer B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. Rep. 2018;129:1–16. [Google Scholar]

- 71.Chen AN, Wu JM, Liu K, Chen JY, Xiao H, Chen P, Li CH, Shi YS. High-performance ceramic parts with complex shape prepared by selective laser sintering: a review. Adv. Appl. Ceram. 2018;117(2):100–117. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.