Abstract

This study was performed to optimize the papaya pulp foaming process and determine the effect of drying conditions on the drying kinetics and the quality of the obtained powder. Thus, the one- factor-at-a-time experimental method, followed by 2 k full factorial design was implemented to determine the optimal conditions of the foaming process. The factors studied were egg white percentage (EW%), xanthan gum percentage (XG%), and whipping time (WT) which varied between 5–20%, 0–0.5%, and 5–20 min, respectively. The optimum conditions (EW% of 15%, XG% of 0.3% and WT of 15 min) for papaya foam expansion percentage (FE%) resulted in a foam with the highest FE% (275.64%) and desirability of 0.916. Foamed and non-foamed papaya pulp in thickness layers of 2-, 4- and 6-mm were dried at 60° and 80° C. Foaming papaya pulp reduced drying time at various layer thicknesses from 140–400 min to 60–160 min, and from 70–160 min to 30–100 min at 60° and 80° C, respectively. Foamed powder samples had the lowest dissolution times and hygroscopicity values; in addition, reconstituted solutions were lighter than non-foamed solutions. Ascorbic acid retention and total phenolic compound content was adversely affected by increased drying time. The obtained papaya powder was classified into six groups based on its quality parameters via hierarchical cluster analysis. In general, foam mat drying is a promising method for producing papaya pulp powder due to its high drying rates and better-quality product.

Keywords: Foam mat drying, Papaya pulp, Optimization, Hierarchical cluster analysis, Xanthan gum

Introduction

Dehydration is one of the oldest techniques used to preserve perishable fruit. Sagar and Suresh Kumar (2010) reported that more than 20% of the world’s perishable crop production is preserved by drying, which minimizes biological and chemical deteriorative reactions and consequently enhances food security. Fruit and vegetable drying methods and their influence on the quality of dried products have been reviewed (Zhang et al. 2017). Foam mat drying is the process in which liquid or semi-liquid foods are first transformed into stable foams by whipping them in the presence of a foaming agent and/or stabilizing agent. Then, the foams are dried in the form of a mat using various drying methods (Kadam et al. 2012). Foam mat drying has recently gained great attention as a new, effective drying technique because compared with other drying methods it is simple, inexpensive, less time-consuming, and results in high-quality dried products. In the light of these factors, several raw materials of plant origin have been foam dried, including banana (Thuwapanichayanan et al. 2008), tomato (Kadam et al. 2012), yacon juice (Franco et al. 2015), beetroot extract (Ng and Sulaiman 2018), and lime juice (Dehghannya et al. 2019).

Papaya (Carica papaya L.) fruits are grown in tropic and subtropics regions. They are rich in several phytochemical compounds such as polyphenols, carotenoids, ascorbic acid, etc. World production of papaya fruit reached 13,097,219 tons in 2017 (FAOSTAT 2019). Due to its high perishability and fast ripening cycle, papaya fruit losses in developing countries varied from 40 to 100% (Pandith and Srivastava 2018). In addition to being consumed fresh papaya fruits can be processed into several products such as nectar, jam, jelly, canned slices, and dried slabs. Moreover, papaya powder could be used to prepare nectar, and utilized as a flavouring agent for ice cream and fruited cereal products (Kandasamy et al. 2014; da Silva Júnior et al. 2018).

Several studies have been conducted to produce papaya pulp powder using foam mat drying (Kandasamy et al. 2012, 2014). However, these studies have not addressed the foaming process in much detail. In these studies, individual foaming agents were utilized separately, and the interactive effects of combining them or incorporating a foam stabilizer were ignored. Also, these studies ignored the interactive effects of foaming process parameters, and only implemented one-factor-at-a-time (OFAT) experimental design, which adversely affected the determination of optimal foaming process conditions. In addition, Pandith and Srivastava’s work (2018) on drying papaya pulp foam via induction heating did not mention the foaming and stabilizing agent concentrations used; futhermore, the foaming process itself was not studied.

Several materials have been used as stabilizer agents, such as methyl cellulose (Dehghannya et al. 2019), pectin (Ozcelik et al. 2019) and guar gum (Seerangurayar et al. 2018). Among these materials, xanthan gum showed unique characteristics. Mott et al. (1999) found that adding xanthan gum to whey protein isolate not only increased its foam stability 15-fold, but also enhanced its foaming expansion to values higher than that of egg white and whey protein isolate alone. These findings were confirmed through the work of Muthukumaran et al. (2008); and Xie and Hettiarachchy (1999). Thus, xanthan gum was selected, and its effects on papaya foam characteristics were studied.

The present work aimed to optimize papaya pulp foaming process conditions (xanthan gum%, egg white%, and whipping time) using response surface methodology (RSM). Conditions maximizing foam expansion percentage (FE%) were considered optimal. Furthermore, the influences of drying temperature and foamed and non-foamed papaya pulp layer thickness on the drying kinetics and the quality of dried powder were investigated. In addition, the ability to categorize the obtained powders based on their quality parameters using Hierarchical cluster analysis (HCA) was studied.

Materials and methods

Raw plant material

Solo variety papaya fruits (Carica papaya) were purchased in 2019 from a local market. The fully-ripened fruits were washed, hand peeled, and seeded. The pulp was blended with water by homogenization using a home mixer (Moulinex, France) and stored at −18 °C. Total soluble solids (TSS) and pH of the papaya pulp were 6.5 ± 0.058% and 4.36 ± 0.032, respectively.

Chemicals

Gallic acid, Folin-Ciocalteu reagent, 2,6-dichlorophenol indophenol indicator and ascorbic acid were purchased from Sigma Chemical Co., Ltd (St. Louis, MO, USA). Commercial xanthan gum was purchased from Shandong Fufeng Fermentation Co., Ltd (Qingdao, China).

Methods

Foam preparation

To obtain papaya pulp foam, fresh egg white and xanthan gum in proper proportions (5–20% and 0–0.5%, respectively) were whipped together for 2 min to form solid white foam using a hand mixer (Moulinex, France). Then, papaya pulp was added to the prepared foam and whipped for a specified time (5–20 min).

Experimental design for optimizing foaming process conditions

In the present work, two experimental designs were implemented in a sequential manner. During the first part, OFAT preliminary experiments were applied. During OFAT experiments one factor is changed while the other two factors remain constant. Whipping time (WT), egg white percentage (EW%) and xanthan gum percentage (XG%) were the factors studied, and varied from 5 to 20 min, 5 to 20% and 0 to 0.5% based on pulp weight, respectively. Based on OFAT results, the study variables producing the highest foam expansion percentage (FE%) were determined, and were used throughout the second part of the study.

In the second part, 2 k full factorial design (FFD) was implemented to reach maximum FE%, where k equals the number of studied factors, which was 3 in the present study. The actual and coded levels of studied factors WT (X1, 10 and 15 min), EW% (X2, 10 and 15%), and XG% (X3, 0.3 and 0.4%) are outlined in Table 1.

Table 1.

Matrix of 23 FFD, the observed and predicted values of foam expansion percentage, ANOVA analysis and statistical parameters of first order model

| Run | Whipping Time (min) (X1) | White egg (%) (X2) | Xanthan gum (%) (X3) | Foam expansion percentage | |

|---|---|---|---|---|---|

| Observed | Predicted | ||||

| 1 | 10 (−1) | 10 (−1) | 0.3 (−1) | 236.36cd ± 2.48 | 234.63 |

| 2 | 15 (+1) | 10 (−1) | 0.3 (−1) | 221.43d ± 3.97 | 223.17 |

| 3 | 10 (−1) | 15 (+1) | 0.3 (−1) | 271.90ab ± 0.00 | 273.64 |

| 4 | 15 (+1) | 15 (+1) | 0.3 (−1) | 280.16a ± 7.14 | 278.42 |

| 5 | 10 (−1) | 10 (−1) | 0.4 (+1) | 252.89bc ± 2.48 | 254.63 |

| 6 | 15 (+1) | 10 (−1) | 0.4 (+1) | 253.97bc ± 3.17 | 252.23 |

| 7 | 10 (−1) | 15 (+1) | 0.4 (+1) | 258.68b ± 3.31 | 256.94 |

| 8 | 15 (+1) | 15 (+1) | 0.4 (+1) | 269.05ab ± 3.97 | 270.78 |

| ANOVA analysis and statistical parameters of first order model | ||||||||

|---|---|---|---|---|---|---|---|---|

| SS | df | MS | F | p | Effect estimate | Std. Err | Reg. Coeff | |

| Constant | 5055.522 | 6 | 842.587 | 29.46624 | 0.000000 | 254.7488 | 1.336860 | 22.2944 |

| X1 | 2.689 | 1 | 2.689 | 0.0940 | 0.766088 | 0.8199 | 2.673721 | −13.2166 |

| X2 | 3415.416 | 1 | 3415.416 | 119.4405 | 0.000002 | 29.2208 | 2.673721 | 23.3635 |

| X3 | 195.185 | 1 | 195.185 | 6.8258 | 0.028149 | 6.9854 | 2.673721 | 681.4902 |

| X1X2 | 168.663 | 1 | 168.663 | 5.8983 | 0.038067 | 6.4935 | 2.673721 | 0.5195 |

| X1X3 | 96.799 | 1 | 96.799 | 3.3852 | 0.098931 | 4.9193 | 2.673721 | 19.6773 |

| X2X3 | 1176.770 | 1 | 1176.770 | 41.1528 | 0.000123 | −17.1520 | 2.673721 | −68.6082 |

| Residual | 257.356 | 9 | 28.595 | |||||

| Lack of fit | 28.92768 | 1 | 28.92768 | 1.013103 | 0.3436 | |||

| Pure error | 228.4283 | 8 | 28.55354 | |||||

| Total SS | 5312.878 | 15 | ||||||

| R2 | 0.95156 | |||||||

| Adjusted R2 | 0. 91,927 | |||||||

| Mean | 254.75 | |||||||

| Std. Dev | 5.3478967 | |||||||

| C.V. % | 2.0993 | |||||||

Values are expressed as means ± standard deviations

Different letters in the same column show significant differences at p < 0.05

The experimental data were fitted using the first-order polynomial model (1).

| 1 |

where, YFE% is the response (FE%); Xi, Xj are coded factors; and b0, bi and bij are regression coefficients for model intercept, linear and interactive effects, respectively. ANOVA analysis was conducted to determine statistical significance of the generated model and identify the effects of studied factors. The goodness-of-fit of the generated model was checked by R2, CV% values and the significance of the lack of fit. Statistica software version 12 (StatSoft, Inc., USA) was used to implement FFD and data analysis.

Papaya foam characteristics

Foam expansion percentage (FE%)

The papaya FE % was determined using Eq. (2), as outlined by Ng and Sulaiman (2018):

| 2 |

where, VF represents the final volume (cm3) of foamed papaya pulp, and VI is the initial volume (cm3) of papaya pulp incorporating foaming and stabilizing agents.

Foam stability

Papaya foam stability was determined according to Marinova et al. (2009). The foam was put in a graded cylinder and left for 3 h at room temperature. The volume of papaya foam was observed and recorded every 30 min. Foam stability was calculated using Eq. (3):

| 3 |

where, Vt and V0 are foam volume (cm3) at time t and initial foam volume (cm3), respectively.

Drying

According to Thuwapanichayanan et al. (2008) and Kandasamy et al. (2014), non-foamed and optimally foamed papaya pulp were dried in a forced air oven (Shel-Lab, USA) at two different temperatures (60° and 80 °C) and three different layer thicknesses (2-, 4- and 6-mm). The drying air velocity was 3 m/s which was measured using a hot wire thermo-anemometer (EXTECH, Taiwan). Foamed and non-foamed papaya pulp were spread in aluminium foil trays to specified thicknesses based on their density and tray area. The reduction in the trays’ weights containing different samples was recorded every 5, 10 and 20 min for drying time intervals varied between 0–30, 30–120 and above 120 min, respectively until reaching constant weight. The dried foamed samples were scraped off using a spatula, while the non-foamed samples were easily separated from the drying trays in the form of dried layers (Fig. 3). Then, they were pulverized using a bench top analytical mill (Cole-Parmer, USA), and stored at room temperature in glass bottles inside a desiccator for further analysis.

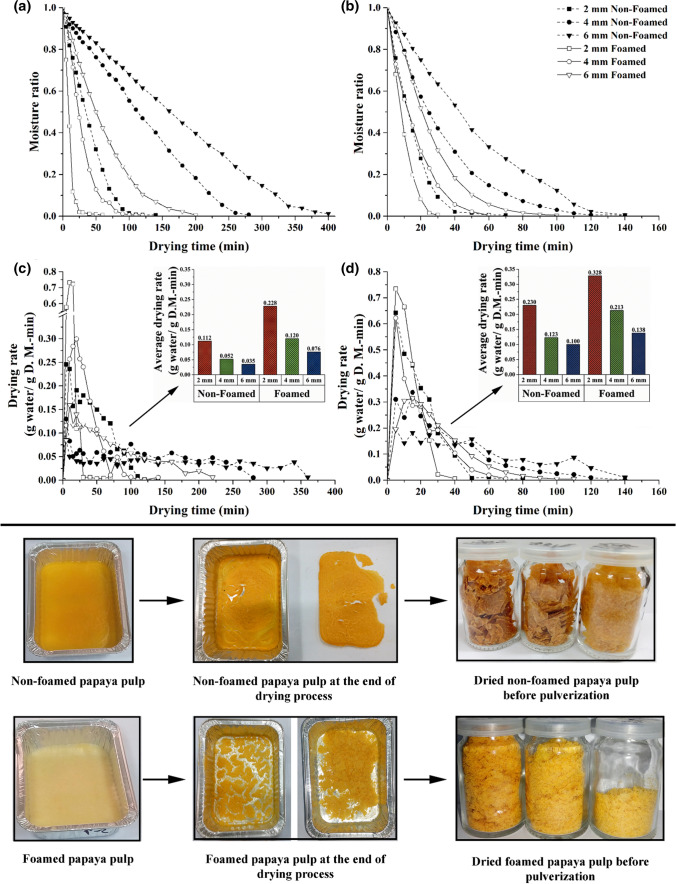

Fig. 3.

Variation in foamed and non-foamed papaya pulp moisture ratio and drying rates with time at drying temperature of 60 °C (a and c) and 80 °C (b and d). Average drying rates at different layer thickness and drying temperature of 60 °C (c) and 80 °C (d). Typical images of non-foamed and foamed papaya pulp as well as their images at the end of the drying process and before pulverization

Drying kinetics

Moisture ratio (MR) and drying rate

Moisture ratio was calculated using Eq. (4):

| 4 |

where, M0 (kg water/kg DM) is the initial moisture content of foamed and non-foamed papaya pulp as determined by AOAC (2005), and Mt (kg water/kg DM) is the moisture content at any time t.

Drying rate (g water/g D.M.-min) was calculated using Eq. (5):

| 5 |

where, is the moisture content at time t + Δt (min). Drying curves and drying rate curves were plotted using moisture ratio values and drying rate values against drying time, respectively (Dehghannya et al. 2018).

Quality of dried foams

Colour of reconstituted papaya solution (1 powder:10 water w/w) was determined using a colorimeter (Minolta, model CR400, Japan) in terms of L*, a* and b* which represent lightness, redness/greenness and yellowness/blueness, respectively.

Total carotenoid content of dried samples was determined by the Rodriguez-Amaya method (2001) and expressed as µg/100 g DM.

Ascorbic acid content of dried samples was determined according to AOAC (2005) using 2,6-dichlorophenol indophenol indicator, and expressed as mg/100 g DM.

Total phenolic content (TPC) of dried samples was determined using the Folin-Ciocalteu method as described by Abd El-Salam and Morsy (2019) and expressed as mg Gallic acid equivalents (GAE)/100 g DM.

Hygroscopicity of dried samples was determined according to the methodology proposed by Ng and Sulaiman (2018). Dried powders were placed in open petri dishes that were placed inside desiccators containing a saturated solution of NaCl. The desiccators were stored at room temperature for 7 days. The increase in sample weight due to water absorption after 7 days was determined, and the hygroscopicity of dried samples was expressed as g absorbed moisture/100 g powder.

Dissolution time of dried powder was determined according to Ozdikicierler et al. (2014) with some modification. One gm of powder was dissolved in 10 ml distilled water at 25 °C with continuous magnetic stirring (Medline Scientific, Model MS 300, UK). The time necessary for the reconstitution of the powders was estimated by stopwatch.

Statistical analysis

One-way ANOVA followed by a Tukey test was implemented to determine the effect of various drying conditions on the quality parameters of the obtained papaya powder. Then, the powder quality evaluation data were subjected to hierarchical cluster analysis (HCA) using the unweighted pair-group average method. XLSTAT 2014.5.03 software (Addinsoft, USA) was used to implement one-way ANOVA and HCA.

Results and discussion

Preliminary OFAT experiments

Foams are thermodynamically unstable and tend to continuously collapse due to their high interfacial energy. Thus, several studies have been conducted to enhance foam stability using various substances (Hardy and Jideani 2017). Among these substances, protein-anionic polysaccharides showed better stabilization properties than protein alone (Xie and Hettiarachchy 1999). Therefore, in the present work xanthan gum was used as an anionic polysaccharide to enhance the stability of papaya pulp foam. Throughout all experiments, incorporating xanthan gum during preparation was found to result in a highly stable foam. In terms of evaluating foam stability, foam volume remained unchanged for times greater than the 3-h specified time. In some experimental trials, the foam volume was unchanged for times greater than 10 h. This increase in foam stability could be related to the improvement effect of the polysaccharide stabilizer (xanthan gum) on the interfacial Lamellae strength (Azizpour et al. 2014). Moreover, Pasban et al. (2013) explained the stabilizing effect of xanthan gum in terms of lowering the forces exerted by the liquid, which consequently reduces the drainage phenomena. Thus, the effects of foaming process factors on the foam properties are restricted to its effect on FE% only.

The ability of food matrices to form foams is highly dependent on their composition, especially protein content and its associated functional properties. The addition of foaming agents to some food matrices is mandatory for foam formation, while this addition is not needed for others. In the present study, papaya pulp exhibited no ability to form foam without foaming agents.

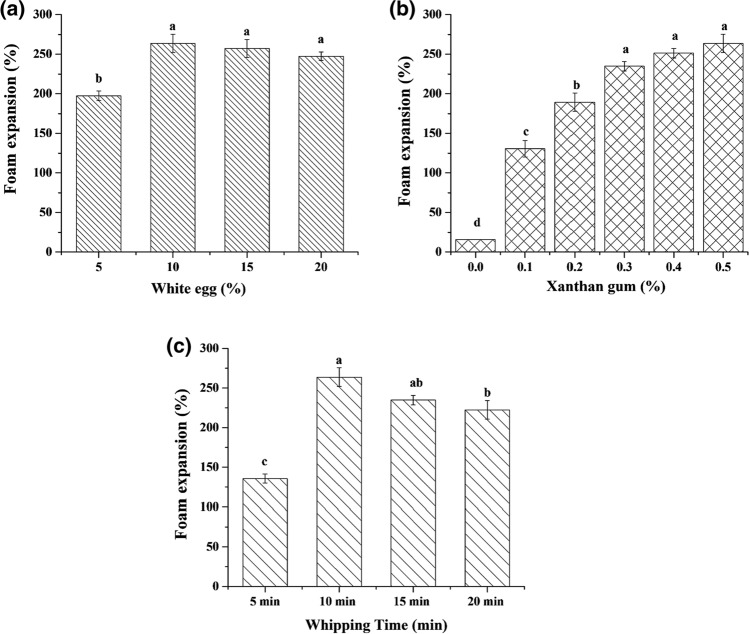

Effect of egg white percentage (EW%) on foam expansion percentage (FE%)

The effect of EW% (5–20%) on papaya pulp FE% was investigated at 0.5% xanthan gum and WT of 10 min. Data illustrated in Fig. 1a show that the highest FE% was observed at EW% of 10%, and beyond this level further increase in EW% had an insignificant (p > 0.05) effect on FE%. This increment in foam expansion may be due to the enhancement in the interaction between protein and papaya pulp at 10%, which increased the incorporated air volume and consequential foam expansion (Chandrasekar et al. 2015). These results are consistent with those reported by Kandasamy et al. (2014), where they found that the ability of papaya pulp to form foam was low at an EW% of 5%.

Fig. 1.

Effect of egg white percentage (a), xanthan gum percentage (b) and whipping time (min) (c) on the papaya pulp foam expansion percentage

Effect of xanthan gum percentage (XG%) on foam expansion percentage (FE%)

Changes in FE% with different XG% (0–0.5%) were investigated at 10% EW% and 10 min WT. Data in Fig. 1b show that increasing XG% from 0.1 to 0.3% significantly (p < 0.05) increased FE% from 130.58 ± 10.52 to 234.71 ± 5.84%, while further increase in XG% had insignificant (p > 0.05) influence on FE%. Xie and Hettiarachchy (1999) found that increasing the proportion of xanthan gum to soy protein isolate from 1:10 to 1:1 increased the foam capacity of the mixture. They also found that further increase in the proportion from 1:1 to 3:1 had no significant effect on foam capacity.

Effect of whipping time (WT) on foam expansion percentage (FE%)

To investigate the effect of WT on FE%, various WTs (5–20 min) were used. EW% and XG% were kept constant at 10% and 0.5%, respectively. Increasing WT from 5 to 10 min increased FE% from 135.34 ± 5.84 to 263.64 ± 11.68; FE% decreased thereafter as WT increased (Fig. 1c). A similar trend was observed during foaming of egg white and whey protein isolate (Mott et al. 1999). This decrease in FE% with high whipping times could be related to foam collapse due to overbeating (Kandasamy et al. 2012).

Full factorial design (FFD) and optimization of foam expansion percentage (FE%)

Based on the results of preliminary OFAT experiments, 10 and 15 min WT, 10 and 15% EW%, and 0.3 and 0.4% XG% were selected for FFD. Actual and predicted values of FE% are outlined in Table 1.

Fitting the model

The FE% values varied significantly at different runs. The highest FE% value was observed at run 4 (15 min WT, 15% EW% and 0.3% XG%). The experimental data were fitted using Eq. (1), and the obtained model is outlined below (Eq. 6):

| 6 |

The goodness-of-fit of the obtained model to represent the FE% variability was evaluated using multiple regression analysis and analysis of variance (ANOVA) as shown in Table 1. All regression coefficients were significant (p ≤ 0.0380) except the regression coefficient of X1 and X1X3. The values of R2 and adjusted R2 were 0.95156 and 0.91927, respectively. The lack of fit was insignificant, and the model’s coefficient of variation (CV%) was 2.0993. All of the preceding statistical data indicates the adequacy of the mathematical model to predict the experimental data (Abd El-Salam and Morsy 2019).

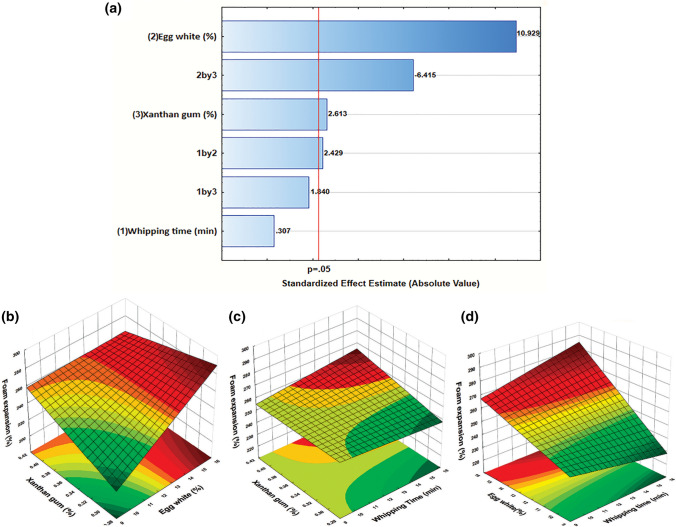

Effect of process variables on foam expansion % (FE%)

Data in Table 1 reveal that FE% was greatly affected by EW% followed by the interaction between EW% and the XG%; however, the effect of WT and its interaction with XG% was insignificant. These findings were corroborated by a Pareto chart (Fig. 2a), which was generated to elucidate the significance of standardized effects of factors and their combinations.

Fig. 2.

Response surface plots and Pareto chart showing the influence of studied factors and its interactions on the foam expansion percentage

The interactive effects of studied factors (WT, EW% and XG%) on FE% were illustrated using 3D plots (Fig. 2) which were drawn using Eq. 6. Figure 2b shows that the highest FE% was observed at higher EW% levels and lower XG% levels, while the lowest FE% was observed at lower levels of both EW% and XG%. Increasing XG% at higher EW% had an adverse effect on FE%. These observations are consistent with the data shown in Fig. 2a, where the standardized interactive effect of EW% and XG% was significant and negative. This decrease in foam expansion could be ascribed to increased fluid viscosity at higher XG levels, which reduce the incorporated air volume and consequently decrease the foam volume (Dabestani and Yeganehzad 2019).

Figure 2c shows that the highest FE% was observed at higher levels of both WT and XG%, whereas the lowest foam expansion was observed at higher WT levels and the lowest XG% level. In addition, it should be noted that the change in slope of the surface plot for WT specifically is very low. These decreases in plot slope represent the insignificant effects of both WT and the interactive effect of WT and XG% (Fig. 2a). The effect of XG% on FE%, on the contrary, was significant and positive; the interactive effect of WT and XG% was also positive, and led to the greatest foam expansion at high levels of the investigated factors.

Figure 2d shows that the highest FE% was observed at higher levels of EW% and WT. This observation could be attributed to significant effects of both EW% and its interaction with WT (Fig. 2a) which shows obviously in the surface plot’s slope.

Optimization of foam expansion and model validation

The desirability function was implemented to maximize FE%. The factor levels to obtain optimum FE% were 15 min WT, 15% EW%, and 0.3% XG% with FE% of 275.64% and desirability of 0.916. The preceding optimal conditions are identical to the foaming conditions of run 4, which resulted in foam expansion of 280.16 ± 7.14%. The absolute error between predicted and experimental values was 1.63, which indicates the suitability of the mathematical model to predict response.

Drying curves

The effects of layer thickness and drying temperature on the drying characteristics of non-foamed and optimally foamed papaya pulp were illustrated in Fig. 3a-d. The moisture ratio of both foamed and non-foamed papaya pulp was decreased with extended drying time. At the same drying temperature, reducing layer thickness from 6 to 2-mm decreased the drying time (Fig. 3a and b). Similarly, increasing drying temperature at the same layer thickness decreased drying time. Data in Fig. 3a and b reveal that foaming papaya pulp and drying at 60 °C effectively reduced drying time from 140 to 60 min, 280 to 120 min and 400 to 160 min at layer thickness of 2-, 4- and 6-mm, respectively. Similarly, at a drying temperature of 80 °C, drying times were reduced for the same layer thicknesses from 70 to 30 min, 140 to 60 min and 160 to 100 min, respectively. The drying times obtained were lower than those previously recorded by Kandasamy et al. (2014) for foam mat drying of papaya pulp under similar drying conditions. These decreases might be explained by the fact that in the present study, the amount of gas incorporated in the foam was obviously high, which resulted in decreased film thickness and improvement of the vaporization process.

Except for drying rate curves of 2-mm non-foamed papaya pulp and 2- and 4-mm foamed papaya pulp at 80 °C (Fig. 3d), all drying rate curves show two distinct drying rate periods. The constant rate period is limited to 20 min for foamed papaya pulp, with extended times for non-foamed pulps. The falling rate period is the only (or predominant) drying rate period at which the drying process occurred, especially at higher temperature and lower thickness. Several foamed biological materials have exhibited similar drying characteristics, including lime juice (Dehghannya et al. 2018) and raspberry puree (Ozcelik et al. 2019). Data in Figs. 3c and 3d indicate that the drying rates increased with increasing drying temperature and decreasing layer thickness. For both foamed and non-foamed papaya pulp, increasing layer thickness from 2- to 6-mm decreased the average drying rate by close to 68% at 60° and 57% at 80 °C, respectively. Dehghannya et al. (2018) found that increasing the thickness of foamed lime juice from 4- to 6- mm decreased the average drying rate by 33.33% at 50 °C. Also, data in Fig. 3c and d reveal that at 60 °C, the average drying rates of foamed papaya pulp is twice that of non-foamed pulps at the same layer thickness, while at 80 °C, they are 138–173% of the average drying rates of non-foamed papaya pulp. In particular, as the internal thermal resistance of the foamed material reduces by an order of magnitude, the drying rate of the foamed samples increases. These high drying rates of foamed papaya pulp improve the drying process in terms of energy conservation and drying costs.

Typical images of non-foamed and foamed papaya pulp, as well as images from the end of the drying process and before pulverization, are shown in Fig. 3. At the end of the drying process, it was observed that non-foamed papaya pulp applied in small layer thickness dried in a hard layer like a gelatine sheet. However, the layer hardness decreased with increasing layer thickness, resulting in a hard leather-like texture.

Quality of papaya powder

Consumer acceptance of reconstituted papaya solution is highly dependent on the powder’s quality attributes, which are influenced by drying conditions. The effects of the layer thicknesses and drying temperatures on the quality attributes of non-foamed and foamed mat dried papaya powder and its reconstituted solution are outlined in Table 2. Each obtained powder was identified by the layer thickness (2-, 4- or 6-mm) followed by foaming status (FM and NFM mean foamed and non-foamed, respectively) and drying temperature (60° or 80° C). For instance, 2-mm-FM-60 is foamed papaya powder that dried to 2-mm at 60 °C, whereas 2-mm-NFM-60 is non-foamed papaya powder obtained under the same drying conditions.

Table 2.

Effect of the thickness and drying temperature on the quality characteristics of non-foamed and foamed mat dried papaya powder and its reconstituted papaya solution

| Sample | Color of reconstituted papaya solution | Hygroscopicity (g/100 g) | Ascorbic acid (mg/ 100 g DM | Total carotenoids (μg/100 g DM) | TPC (mg GAE/ 100 g DM) |

Dissolution time (S) | ||

|---|---|---|---|---|---|---|---|---|

| L* | b* | a* | ||||||

| 2-mm-FM-60 | 40.74ab ± 0.18 | 24.65def ± 1.54 | −1.53b−e ± 0.29 | 21.01e ± 0.66 | 83.44e ± 3.08 | 10.93e ± 1.03 | 454.52 cd ± 2.11 | 50.00 h ± 7.81 |

| 4-mm-FM-60 | 40.54ab ± 1.04 | 28.23ab ± 0.96 | −1.20a ± 0.10 | 22.40de ± 1.08 | 96.58 cd ± 4.35 | 45.42b ± 0.81 | 451.50 cd ± 8.39 | 64.00gh ± 4.36 |

| 6-mm-FM-60 | 39.49abc ± 0.51 | 26.34bcd ± 1.14 | −1.71ef ± 0.15 | 21.41e ± 0.91 | 68.03f ± 3.16 | 29.41d ± 0.23 | 394.63e ± 2.11 | 106.33 g ± 12.06 |

| 2-mm-FM-80 | 41.27a ± 1.34 | 26.85bcd ± 1.00 | −1.68def ± 0.07 | 20.93e ± 0.42 | 89.49de ± 5.91 | 9.76e ± 0.39 | 450.42 cd ± 8.42 | 50.00 h ± 5.57 |

| 4-mm-FM-80 | 41.65a ± 1.61 | 29.79a ± 0.94 | −1.22ab ± 0.02 | 21.14e ± 0.41 | 79.13e ± 3.49 | 43.85b ± 2.15 | 443.40d ± 8.76 | 53.33 h ± 3.79 |

| 6-mm-FM-80 | 38.45bcd ± 0.23 | 27.16bc ± 0.29 | −1.95f ± 0.03 | 22.13de ± 0.93 | 83.44e ± 3.08 | 56.40a ± 1.13 | 456.03 cd ± 8.76 | 90.00gh ± 10.00 |

| 2-mm-NFM-60 | 40.20ab ± 1.00 | 24.59def ± 0.13 | −1.44a−e ± 0.02 | 25.40abc ± 0.72 | 86.72de ± 5.00 | 41.92b ± 0.96 | 607.53a ± 1.24 | 955.00c ± 18.03 |

| 4-mm-NFM-60 | 36.26cd ± 0.25 | 22.41f ± 0.29 | −1.51a−e ± 0.06 | 24.41bc ± 0.23 | 66.25f ± 3.06 | 42.18b ± 0.98 | 495.15bc ± 12.26 | 1127.00b ± 18.08 |

| 6-mm-NFM-60 | 36.20cd ± 0.28 | 23.40ef ± 0.95 | −1.54cde ± 0.09 | 23.53 cd ± 0.61 | 66.31f ± 3.78 | 35.39c ± 2.24 | 520.86b ± 14.19 | 1320.66a ± 40.00 |

| 2-mm-NFM-80 | 40.49ab ± 0.52 | 24.56def ± 0.23 | −1.23abc ± 0.03 | 26.69a ± 0.20 | 100.41bc ± 1.97 | 35.14c ± 0.85 | 646.25a ± 12.76 | 592.33f ± 7.51 |

| 4-mm-NFM-80 | 39.93ab ± 1.25 | 25.25cde ± 0.57 | −1.26abc ± 0.06 | 25.55ab ± 0.23 | 136.37a ± 1.14 | 45.62b ± 3.49 | 642.02a ± 41.65 | 789.00e ± 15.00 |

| 6-mm-NFM-80 | 37.35cd ± 0.17 | 23.04ef ± 0.13 | −1.38a−d ± 0.05 | 25.68ab ± 0.42 | 110.44b ± 1.13 | 33.70 cd ± 0.70 | 639.02a ± 21.60 | 873.33d ± 10.41 |

Values are expressed as means ± standard deviations

Different letters in the same column show significant differences at p < 0.05

Reconstituted papaya solution colour

Data in Table 2 reveal that the colour parameters of reconstituted foamed and non-foamed mat dried solutions varied significantly (p < 0.05) under different drying conditions. L* values of reconstituted foamed papaya solution were generally higher than those of reconstituted non-foamed papaya solution, especially at layer thicknesses of 4- and 6-mm. The darkness (low L* values) of reconstituted non-foamed papaya solution might be a result of browning reactions that occurred at higher temperature for long times (Shaari et al. 2018). Also, it should be noted that at the same layer thickness, lightness (L*) and yellowness (b*) values were higher at a drying temperature of 80 °C than at 60 °C. Salahi et al. (2017) found that increasing drying temperature at the same layer thickness increased L* values of cantaloupe pulp foam. They attributed the decrement in lightness (L*) values associated with low drying temperature to lengthier drying time.

Powder hygroscopicity

Data in Table 2 show that at various layer thicknesses and drying temperatures, hygroscopicity values of non-foamed dried powders were higher than those of foamed ones. These results are consistent with those of Ng and Sulaiman (2018) who found that hygroscopicity values of non-foamed dried beetroot extract powder were higher than those of foamed ones.

Ascorbic acid content

Ascorbic acid content varied significantly between 66.25 ± 3.06 and 136.37 ± 1.14 (mg/100 g DM). Kandasamy et al. (2014) found that ascorbic acid content of foam-mat dried papaya powder ranged between 76–152 mg/100 g. Samples of 6-mm-FM-60, 4-mm-NFM-60 and 6-mm-NFM-60 exhibited the most significant reduction in ascorbic acid content. This reduction could be ascribed to the heat labile nature of ascorbic acid, which was found to be more highly influenced by drying time than drying temperature. The ascorbic acid content of the samples dried at 80 °C (short drying time) were generally higher than those dried at 60 °C (long drying time). Qadri and Srivastava (2014) found that ascorbic acid content of foamed tomato pulp was more sensitive to change in drying time than change in temperature. In addition, data in Table 2 show that ascorbic acid content of foamed samples was generally higher than or equal to that of non-foamed samples at 60 °C, whereas at 80 °C, the ascorbic acid content of foamed samples was lower than that of non-foamed ones. These variations in ascorbic acid content could be ascribed to the dilution effect of foaming and stabilizer agents, as well as to drying conditions that affect drying time and consequently ascorbic acid retention.

Total carotenoid content

Among various samples, the 6-mm-FM-80 sample showed the highest retention of total carotenoids (56.40 ± 0.88 μg/100 g DM). For foamed papaya pulp, it should be noted that decreasing foam thickness had a significant (p < 0.05) adverse effect on the retention of total carotenoids. Carotenoids are susceptible to oxidation and thermal degradation due to their unsaturated chemical structure (Stefanovich and Karel 1982). Thus, increasing exposure time of carotenoids to air at high temperature increases their deterioration reactions, especially at a low foam thickness. However, this phenomenon was not prevalent during drying of non-foamed papaya pulp, because of the low exposure area of carotenoids to air. In addition, increasing drying temperature at all layer thicknesses generally decreased the retention of total carotenoids.

Total phenolic content

TPC of various foamed samples varied insignificantly, except for 6-mm-FM-60, which had the lowest significant TPC (394.63 ± 6.88). Similarly, 4-mm-NFM-60 and 6-mm-NFM-60 exhibited significant decrement in TPC, while non-foamed samples varied insignificantly. This decrement in TPC content could be attributed to prolonged drying times. The destructive effect of the drying process on several phenolic components might be promoted at long drying times, especially when combined with high drying temperature (Garau et al. 2007). Also, data in Table 2 reveal that TPC of non-foamed papaya powder was higher than TPC of foamed powders under different drying conditions. It seems possible that these reductions in foamed powder TPC are due to the dilution of phenolic content by foaming and stabilizer agents (Seerangurayar et al. 2018).

Dissolution time

The dissolution time test is used to assess the ability to complete reconstitution of powder in water. Short dissolution time means better powder quality (Ozdikicierler et al. 2014). Results in Table 2 show that the dissolution time of foamed papaya powders (50 ± 7.81—106.33 ± 10 S) was significantly (p < 0.05) less than that of the non-foamed papaya powders (592.33 ± 7.51 to 1320.66 ± 40 S). This decrement in dissolution time may be due to the high specific surface area of foam-mat dried powder, which is influenced by the high stability of foams during drying (Salahi et al. 2017). The results in Table 2 also indicate that the dissolution time of various samples decreased as drying temperature increased and layer thickness decreased. Salahi et al. (2017) related these reductions in dissolution time to the porosity of dried material, which increased at high evaporation rates.

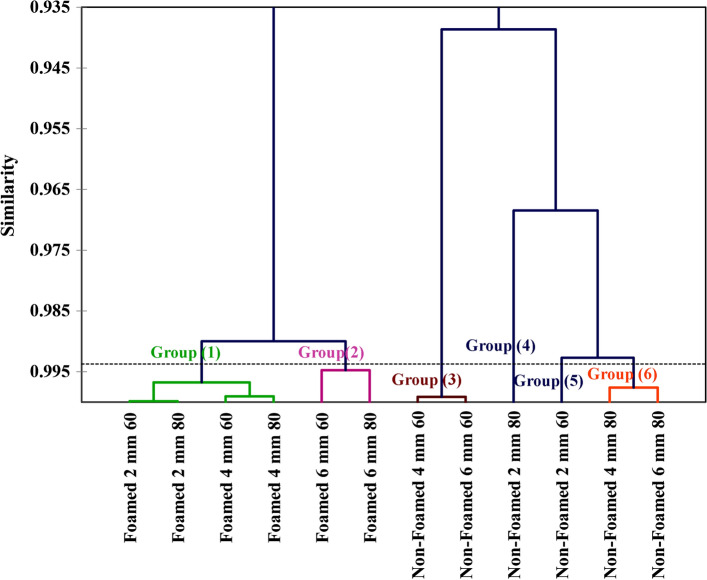

Hierarchical cluster analysis (HCA)

HCA was successfully utilized to differentiate between various food types based on chemical composition (da Silva Torres et al. 2006). Thus, HCA was implemented to determine the association degree between foamed and non-foamed papaya powders’ quality parameters, and to classify them into various clusters. Six discernible clusters were observed in the dendrogram (Fig. 4), which was generated with the results of the HCA. The first group (1) consists of 2-mm-FM-60, 2-mm-FM-80, 4-mm-FM-60 and 4-mm-FM-80, which had the lowest dissolution time and highest lightness (L*) values (Table 2). The second group (2) is comprised of 6-mm-FM-60 and 6-mm-FM-80. This group had higher dissolution time and lower lightness (L*) values than the first group. The third cluster (3) is composed of 4-mm-NFM-60 and 6-mm-NFM-60, which had unique characteristics; this cluster had the lowest lightness (L*), yellowness, ascorbic acid content values, and highest dissolution values. The fourth and fifth clusters (4 and 5) include 2-mm-NFM-80 and 2-mm-NFM-60, respectively. The last cluster (6) includes 4-mm-NFM-80 and 6-mm-NFM-80. This cluster retained the highest content of ascorbic acid and total polyphenols and had higher hygroscopicity values.

Fig. 4.

Dendrogram of HCA for various foamed and non-foamed papaya powder obtained under different drying conditions using unweighted pair-group average method

Conclusion

The present work shows the capability of producing papaya pulp powder using the foam mat drying method, wherein foaming process optimization and the effects of drying temperature (60 ° and 80 °C) and layer thickness (2-, 4-, and 6-mm) on drying kinetics and powder quality compared to non-foamed papaya pulp were studied. The optimum conditions for foaming papaya pulp using egg white and xanthan gum at different WT was successfully achieved through implementation of OFAT experimental design and 2K FFD in sequential order. Through OFAT experiments, XG not only improved the stability of the foam, but also enhanced its extension percentage. The first order model fitted experimental data well; the optimal conditions for foaming papaya pulp were EW% of 15%, XG% of 0.3% and WT of 15 min. At various drying conditions, the foamed papaya pulp had the lowest drying times and highest drying rates. The average drying rates of foamed papaya pulp were reached 1.38–2 times those of non-foamed ones. The dissolution time and hygroscopicity values of foamed powders were significantly lower than those of non-foamed ones. On the other hand, the reconstituted non-foamed solutions exhibited more darkness (low L* values). The retention of ascorbic acid and total phenolic compounds was significantly (p < 0.05) decreased as drying time increased. HCA successfully classified the obtained powder into six groups according to their quality parameters. Taken together, these findings suggest that superior quality papaya pulp powder can be achieved via the foam mat drying method.

Compliance with ethical standards

Conflicts of interest

The authors declare no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Abd El-Salam EA, Morsy NFS (2019) Optimization of the extraction of polyphenols and antioxidant activity from Malva parviflora L. leaves using Box-Behnken design. Prep Biochem Biotechnol, pp 1–8. 10.1080/10826068.2019.1633667 [DOI] [PubMed]

- AOAC (2005) Official methods of Analysis of the Association of Analytical Chemists International, 18th edn, Gaithersburg, USA

- Azizpour M, Mohebbi M, Hossein Haddad Khodaparast M, Varidi M. Optimization of foaming parameters and investigating the effects of drying temperature on the foam-mat drying of shrimp (Penaeus indicus) Dry Technol. 2014;32:374–384. doi: 10.1080/07373937.2013.794829. [DOI] [Google Scholar]

- Chandrasekar V, Gabriela JS, Kannan K, Sangamithra A. Effect of foaming agent concentration and drying temperature on physiochemical and antimicrobial properties of foam mat dried powder. Asian J Dairy Food Res. 2015;34:39. doi: 10.5958/0976-0563.2015.00008.1. [DOI] [Google Scholar]

- da Silva Torres EAF, Garbelotti ML, Moita Neto JM. The application of hierarchical clusters analysis to the study of the composition of foods. Food Chem. 2006;99:622–629. doi: 10.1016/j.foodchem.2005.08.032. [DOI] [Google Scholar]

- da Silva V, Júnior E, Lins de Melo L, Batista de Medeiros RA, et al. Influence of ultrasound and vacuum assisted drying on papaya quality parameters. Lwt. 2018;97:317–322. doi: 10.1016/j.lwt.2018.07.017. [DOI] [Google Scholar]

- Dabestani M, Yeganehzad S. Effect of Persian gum and Xanthan gum on foaming properties and stability of pasteurized fresh egg white foam. Food Hydrocolloids. 2019;87:550–560. doi: 10.1016/j.foodhyd.2018.08.030. [DOI] [Google Scholar]

- Dehghannya J, Pourahmad M, Ghanbarzadeh B, Ghaffari H. Influence of foam thickness on production of lime juice powder during foam-mat drying: experimental and numerical investigation. Powder Technol. 2018;328:470–484. doi: 10.1016/j.powtec.2018.01.034. [DOI] [Google Scholar]

- Dehghannya J, Pourahmad M, Ghanbarzadeh B, Ghaffari H. Heat and mass transfer enhancement during foam-mat drying process of lime juice: impact of convective hot air temperature. Int J Therm Sci. 2019;135:30–43. doi: 10.1016/j.ijthermalsci.2018.07.023. [DOI] [Google Scholar]

- FAOSTAT (2019) FAOSTAT. Available at: https://fao.org/faostat/en/#data/QC/visualize. Accessed 15 July 2019

- Franco TS, Perussello CA, Ellendersen LDSN, Masson ML. Foam mat drying of yacon juice: experimental analysis and computer simulation. J Food Eng. 2015;158:48–57. doi: 10.1016/j.jfoodeng.2015.02.030. [DOI] [Google Scholar]

- Franco TS, Perussello CA, Ellendersen LN, Masson ML. Effects of foam mat drying on physicochemical and microstructural properties of yacon juice powder. LWT Food Sci Technol. 2016;66:503–513. doi: 10.1016/j.lwt.2015.11.009. [DOI] [Google Scholar]

- Garau MC, Simal S, Rosselló C, Femenia A. Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chem. 2007;104:1014–1024. doi: 10.1016/j.foodchem.2007.01.009. [DOI] [Google Scholar]

- Hardy Z, Jideani VA. Foam-mat drying technology: a review. Crit Rev Food Sci Nutr. 2017;57:2560–2572. doi: 10.1080/10408398.2015.1020359. [DOI] [PubMed] [Google Scholar]

- Kadam DM, Wilson RA, Kaur S, Manisha Influence of foam mat drying on quality of tomato powder. Int J Food Prop. 2012;15:211–220. doi: 10.1080/10942911003763701. [DOI] [Google Scholar]

- Kandasamy P, Varadharaju N, Kalemullah S, Maladhi D. Optimization of process parameters for foam-mat drying of papaya pulp. J Food Sci Technol. 2014;51:2526–2534. doi: 10.1007/s13197-012-0812-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kandasamy P, Varadharaju N, Kalemullah S, Moitra R. Preparation of papaya powder under foam-mat drying technique using egg albumin as foaming agent. Int J BiocResource Stress Manag. 2012;3:324–331. [Google Scholar]

- Marinova KG, Basheva ES, Nenova B, et al. Physico-chemical factors controlling the foamability and foam stability of milk proteins: sodium caseinate and whey protein concentrates. Food Hydrocoll. 2009;23:1864–1876. doi: 10.1016/j.foodhyd.2009.03.003. [DOI] [Google Scholar]

- Mott CL, Hettiarachchy NS, Qi M. Effect of xanthan gum on enhancing the foaming properties of whey protein isolate. JAOCS. 1999;76:1383–1386. doi: 10.1007/s11746-999-0154-8. [DOI] [Google Scholar]

- Muthukumaran A, Ratti C, Raghavan V. Foam-mat freeze drying of egg white and mathematical modeling. Part I optimization of egg white foam stabilit. Drying Technol. 2008;26(4):508–512. doi: 10.1080/07373930801929581. [DOI] [Google Scholar]

- Ng ML, Sulaiman R. Development of beetroot (Beta vulgaris) powder using foam mat drying. LWT Food Sci Technol. 2018;88:80–86. doi: 10.1016/j.lwt.2017.08.032. [DOI] [Google Scholar]

- Ozcelik M, Ambros S, Heigl A, et al. Impact of hydrocolloid addition and microwave processing condition on drying behavior of foamed raspberry puree. J Food Eng. 2019;240:83–91. doi: 10.1016/j.jfoodeng.2018.07.001. [DOI] [Google Scholar]

- Ozdikicierler O, Dirim SN, Pazir F. The effects of spray drying process parameters on the characteristic process indices and rheological powder properties of microencapsulated plant (Gypsophila) extract powder. Powder Technol. 2014;253:474–480. doi: 10.1016/j.powtec.2013.12.004. [DOI] [Google Scholar]

- Pandith JA, Srivastava AK. Induction heating assisted foam mat drying of papaya pulp: drying kinetics, drying modeling, and effects on quality attributes. Agric Eng Int CIGR J. 2018;20:206–215. [Google Scholar]

- Pasban A, Mohebbi M, Pourazarang H, Varidi M. Effects of endemic hydrocolloids and xanthan gum on foaming properties of white button mushroom puree studied by cluster analysis: a comparative study. J Taibah Univ Sci. 2013;8:31–38. doi: 10.1016/j.jtusci.2013.09.004. [DOI] [Google Scholar]

- Qadri OS, Srivastava AK. Effect of microwave power on foam-mat drying of tomato pulp. Agric Eng Int CIGR J. 2014;16(3):238–244. [Google Scholar]

- Rodriguez-Amaya DB. A guide to carotenoid analysis in foods. 1. USA: ILSI Press; 2001. [Google Scholar]

- Sagar VR, Suresh Kumar P. Recent advances in drying and dehydration of fruits and vegetables:a review. J Food Sci Technol. 2010;47:15–26. doi: 10.1007/s13197-010-0010-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Salahi MR, Mohebbi M, Taghizadeh M. Development of cantaloupe (Cucumis melo) pulp powder using foam-mat drying method: effects of drying conditions on microstructural of mat and physicochemical properties of powder. Dry Technol. 2017;35:1897–1908. doi: 10.1080/07373937.2017.1291518. [DOI] [Google Scholar]

- Schuck P, Dolivet A, Jeantet R. Analytical methods for food and dairy powders. 1. West Sussex: Wiley; 2012. [Google Scholar]

- Seerangurayar T, Manickavasagan A, Al-Ismaili AM, Al-Mulla YA. Effect of carrier agents on physicochemical properties of foam-mat freeze-dried date powder. Dry Technol. 2018;36:1292–1303. doi: 10.1080/07373937.2017.1400557. [DOI] [Google Scholar]

- Shaari NA, Sulaiman R, Rahman RA, Bakar J. Production of pineapple fruit (Ananas comosus) powder using foam mat drying: effect of whipping time and egg albumen concentration. J Food Process Preserv. 2018;42:1–10. doi: 10.1111/jfpp.13467. [DOI] [Google Scholar]

- Stefanovich AF, Karel M. Kinetics of beta-carotene degradation at temperatures typical of air drying of foods. J Food Process Preserv. 1982;6:227–242. doi: 10.1111/j.1745-4549.1982.tb00655.x. [DOI] [Google Scholar]

- Thuwapanichayanan R, Prachayawarakorn S, Soponronnarit S. Modeling of diffusion with shrinkage and quality investigation of banana foam mat drying. Dry Technol. 2008;26:1326–1333. doi: 10.1080/07373930802330979. [DOI] [Google Scholar]

- Xie YR, Hettiarachchy NS. Effect of xanthan gum on enhancing the foaming properties of soy protein isolate. JAOCS. 1999;76:1383–1386. doi: 10.1007/s11746-999-0154-8. [DOI] [Google Scholar]

- Zhang M, Chen H, Mujumdar AS, et al. Recent developments in high-quality drying of vegetables, fruits, and aquatic products. Crit Rev Food Sci Nutr. 2017;57:1239–1255. doi: 10.1080/10408398.2014.979280. [DOI] [PubMed] [Google Scholar]