Abstract

Micromodels have been widely used to visualize surfactant flooding, which provides new insights into understanding pore-scale events during displacement. In this review, recent advances in micromodel studies of surfactant flooding are briefly summarized. The mechanisms of surfactant flooding as demonstrated by micromodel studies are presented, as well as pore-scale findings that cannot be captured by traditional coreflood methods.

1. Introduction

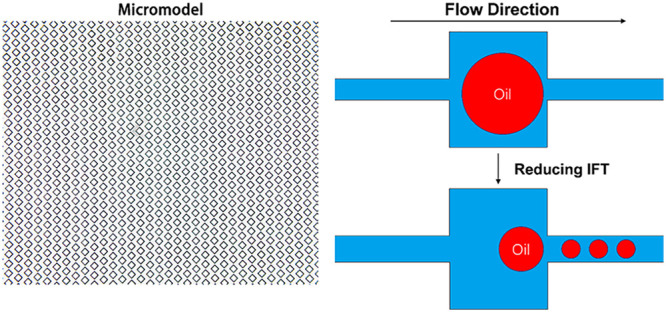

Oil recovery is a process in which the oil flows in porous media to production wells driven by the reservoir pressure or pressure exerted by the displacing fluids. Water is the most widely used displacing fluid due to its accessibility and low cost. Despite the benefits of waterflooding, the oil recovery of waterflooding is low, resulting in a large amount of residual oil in the reservoir. The residual oil is mainly trapped by capillary pressure and cannot be recovered by further water injection. The addition of surfactant into the injected water can effectively reduce the oil–water interfacial tension (IFT), thereby making the trapped oil ganglia mobilized by the injected water.1 Moreover, if the reservoir is oil-wet, the surfactant can change the wettability of the reservoir to water-wet so that the oil is released from the pore surface and can be recovered.2 Therefore, surfactant flooding is an effective method for enhanced oil recovery (EOR) and its effectiveness has been confirmed by many field tests.3

Typically, surfactant flooding is conducted in cores or sandpacks to study its efficiency in improving oil recovery.4 Although cores and sandpacks are good representatives of formations, the displacement cannot be visually observed, thus limiting the understanding of microscopic displacement mechanisms and phase distributions, which are important for optimizing surfactant flooding. Micromodels have been used for studying microscopic fluid flow in many applications.5,6 The use of a micromodel makes it possible to observe the displacement at pore scale; thus the displacement mechanism and pore-scale events can be obtained.

The study of two-phase displacements in micromodels can provide insights into understanding macroscopic displacement dynamics. The displacement pattern map developed by Lenormand et al.7 reveals the dependence of displacement patterns on capillary numbers and viscosity ratios by performing drainage in micromodels, which are widely used for the determination of displacement patterns. The subsequent micromodel study by Lenormand et al.8 extended the displacement pattern map to imbibition.

Many micromodel studies of surfactant flooding have been conducted with the aim of revealing the displacement characteristics and mechanisms of surfactant flooding, such as IFT reduction, wettability alteration, emulsification, etc.9−11 Some mechanisms of oil recovery by surfactant flooding have been verified by micromodel studies. Micromodel studies have also provided us with insights into surfactant flooding that have not been previously considered.

In this review, we focus on the recent advances in micromodel studies of surfactant flooding. The findings and mechanisms of surfactant flooding are summarized and discussed.

2. IFT Reduction

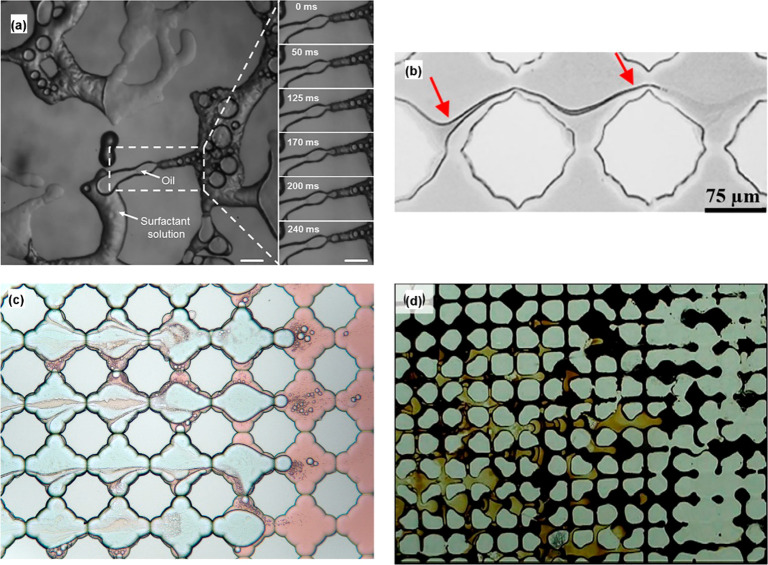

The reduction of oil/water IFT is considered to be the most important mechanism of surfactant flooding. The reduction of oil/water IFT by surfactants contributes to improve oil recovery in several ways. The reduction of IFT to low levels makes the trapped oil ganglia tend to be broken down into small oil droplets by snap-off at pore throats, which can much more easily pass through the pore throat and eventually be recovered (Figure 1a).12,13 Moreover, the produced large oil droplets can block the water path and divert water to the unswept oil zone, thus improving the sweep efficiency and oil recovery. The further reduction of IFT to ultralow levels significantly improves the oil recovery.14 Under the ultralow IFT, the trapped oil ganglia become extremely flexible and flow as rivulets with injected surfactant solutions (Figure 1b).15,16 Therefore, at favorable viscosity ratios, the ultralow IFT surfactant flooding can substantially improve oil recovery.

Figure 1.

(a) Generation of O/W emulsions by snap-off at the pore throat during low IFT surfactant flooding [Reprinted with permission from ref (12). Copyright 2020 Elsevier]. (b) Residual oil becomes extremely flexible and can be elongated during ultralow IFT surfactant flooding [Reprinted with permission from ref (15). Copyright 2017 American Chemical Society]. (c) Significant increase of apparent contact angle during ultralow IFT surfactant flooding in water-wet micromodels [Reprinted with permission from ref (18). Copyright 2020 Society of Petroleum Engineers]. (d) Formation of W/O emulsions during ultralow IFT surfactant flooding due to the significant increase in dynamic contact angle [Reprinted with permission from ref (19). Copyright 2012 Elsevier].

Due to the fractured nature of carbonate reservoirs, the imposed flow occurs mainly in fractures and is difficult to enter the matrix. The oil recovery in a fractured reservoir by surfactant flooding is mainly dependent on the imbibition of surfactant solution into matrix. Studies show that imbibition of surfactant solutions into vertically positioned micromodels at ultralow IFT is driven by gravity, and a large amount of oil in the matrix can be recovered after a few days. For the horizontally positioned micromodels, since the gravity and capillary forces are negligible, the imbibition rate and oil recovery are both much lower, and the oil recovery is attributed to the solubilization of oil by micelles.17

A significant difference between surfactant flooding at low IFT and ultralow IFT is that the emulsification takes completely different approaches. Whether W/O or O/W emulsions are formed in porous media mainly depends on the contact angle, and the nonwetting phase tends to be discontinuous resulting in the formation of droplets.12 The apparent contact angle during immiscible displacement in porous media is governed by the balance between capillary and viscous forces, and it increases with the increase of capillary number. For low IFT surfactant flooding in water-wet reservoirs, the capillary number is not high enough to significantly increase the advancing contact angle so that the oil remains the nonwetting phase, thus forming O/W emulsions (Figure 1a). For ultralow IFT surfactant flooding in water-wet reservoirs, the large capillary number makes the advancing contact angle greater than 90° (Figure 1c),18 resulting in the formation of W/O emulsions rather than O/W emulsions during the displacement (Figure 1d).19,20 The formation of viscous W/O emulsion during ultralow IFT surfactant flooding increases the pressure gradient and sweep efficiency, which effectively improve the heavy oil recovery.

3. Wettability Alteration

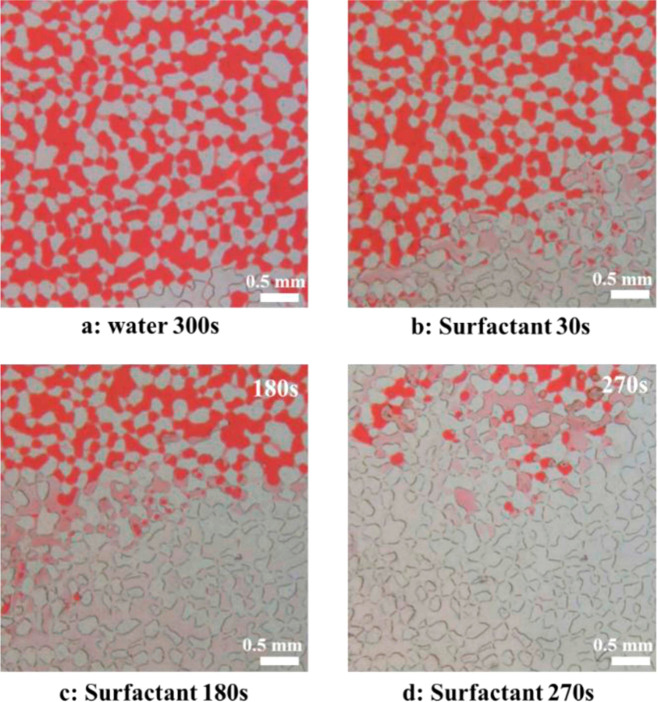

The surfactant-induced wettability alteration improves oil recovery in different aspects. In naturally fractured carbonate reservoirs, oil recovery from a tight matrix depends on spontaneous or forced imbibition, which is almost impossible if the matrix is strongly oil-wet at high IFT. The micromodel studies21−23 indicate that the water cannot be imbibed into an oil-wet micromodel, whereas the type I microemulsion-forming surfactant solution can be spontaneously imbibed into the micromodel (Figure 2). The higher concentration of surfactant has a stronger ability to alter the wettability of micromodel toward being water-wet, which leads to a higher imbibition rate. However, the displacement becomes less stable as the surfactant concentration increases, and this is owing to the development of fingers at higher imbibition rates.21 Therefore, both wettability alteration and invasion front stability should be considered to achieve a higher oil recovery. Micromodel study17 also shows that the reduction of IFT to ultralow levels can also effectively increase the imbibition rate under gravity. At ultralow IFTs, the capillary forces are dominated by gravity. Therefore, whether or not the wettability is altered has little effect on the imbibition rate.

Figure 2.

Water fails to effectively imbibe into the oil-wet micromodels after 300 s due to the hindrance by capillary forces. The type I microemulsion-forming surfactant solution can be spontaneously imbibed into the oil-wet micromodels because of the IFT reduction and wettability alteration [Reprinted with permission from ref (23). Copyright 2019 Elsevier].

The wettability alteration also contributes to the mobilization of residual oil, which plays an important role in EOR. In oil-wet reservoirs, the pore-scale displacement efficiency of waterflooding is low. The residual oil remains on pore surfaces and is difficult to remove because of the high detachment energy required. Surfactant can effectively change the wettability of micromodels from oil-wet to water-wet. The surfactant induced wettability alteration is time-dependent; with the change in wettability, the shape of residual oil changes from irregular to spherical (Figure 2c). After the wettability alteration is complete, the detachment energy is significantly reduced, thus making it easier to mobilize the residual oil. Moreover, the formation of microemulsions is competitive with the wettability alteration. As the salinity approaches the optimum value, the time required for wettability alteration is longer.24

Wettability is one of the most important factors determining oil–water displacement patterns in porous media. Experimental studies indicate that the displacement efficiency is low in strongly oil-wet micromodels, and the displacement efficiency is much higher in weakly water-wet or neutral micromodels.25 Oil recovery can be effectively improved by surfactant flooding if the wettability of micromodels can be changed immediately after contact with the surfactant solution. However, as illustrated in Section 2, the significant increase of apparent contact angle during ultralow IFT displacements makes micromodels show oil-wet behavior, regardless of their wettability. Therefore, wettability alteration has little effect on the displacement patterns at ultralow IFT. Wettability alteration can significantly affect the displacement patterns at low and high IFTs, where the apparent contact angle is similar to the static contact angle.

4. Microemulsion Formation and Effects of Microemulsions on Oil Recovery

Microemulsions are thermodynamically stable mixtures of oil, water, and surfactant that form spontaneously during ultralow IFT surfactant flooding.26 The formation of microemulsions during surfactant flooding will change the displacement dynamics. Meanwhile, the phase behavior of oil/water/surfactant system is usually determined under static and equilibrium conditions, and it needs to be revealed whether the microemulsions formed under flow conditions are similar to those formed under static conditions.

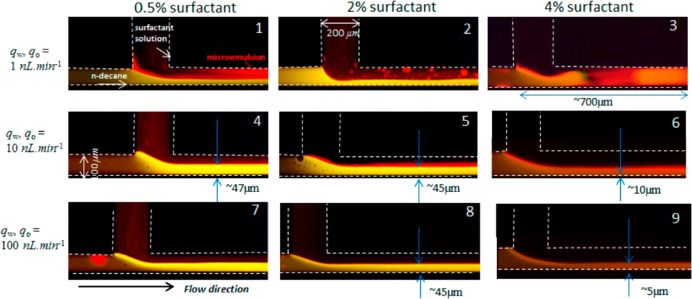

Experimental study6 by coinjecting surfactant solution and oil into a micromodel with a T-junction shows that the microemulsions forms at the oil/surfactant solution interface (Figure 3). The formation of microemulsions is limited by diffusion. The surfactant solution and oil are gradually solubilized into the microemulsions, and the volume of microemulsion increases as the surfactant solution and oil flow from upstream to downstream. The formation of microemulsions during flow changes the flow patterns, and how the flow pattern is affected by microemulsions depends on the salinity and capillary numbers. During surfactant flooding, there is a lag in the formation of microemulsions, which are mainly formed from residual oil.27,28 More microemulsions are formed as the displacement continues, leading to the formation of microemulsions bank, which can significantly change the displacement patterns in which the injected surfactant solution can become discontinuous. The type and solubilization ratio of microemulsions are typically determined by static phase behavior tests. The micromodel studies indicate that the microemulsions formed under dynamic conditions in micromodels are locally equilibrated, and the oil–water ratio of the microemulsions varies spatially due to changes in the surfactant solution composition during the displacement.15

Figure 3.

Flow dynamics and microemulsions formation at oil-surfactant solution interface at different flow rates and surfactant concentrations [Reprinted with permission from ref (6). Copyright 2016 American Chemical Society].

The formation of microemulsions plays an important role in the recovery of residual oil.24 For ultralow IFT surfactant flooding at unfavorable viscosity ratios, there is still a lot of unswept oil and trapped oil ganglia that can be recovered. The residual oil transforms into microemulsions when in continuous contact with a fresh surfactant solution. Although the IFT between surfactant solution and oil is ultralow, the IFT between surfactant solution and type III microemulsions can be even lower due to the nonequilibrium between the microemulsion and the surfactant solution. For a type I microemulsion-forming surfactant solution, the oil/surfactant solution IFT is higher than that of a type III microemulsion-forming surfactant solution. Type I microemulsions have an external phase of water and are therefore miscible with the injected surfactant solution as shown in Figure 2, making the residual oil completely solubilized. Therefore, more residual oil can be recovered by the formation of microemulsions during surfactant flooding. In addition, it has been observed that the microemulsions formed during surfactant flooding can destabilize into W/O emulsions, thereby blocking water channels and diverting water flow.10

5. Conclusions

We briefly reviewed recent advances in micromodel studies of surfactant flooding. The mechanisms of surfactant flooding and the displacement dynamics have been directly visualized by many studies. The reduction of IFT to low levels facilitates the transport and recovery of oil droplets, and the flow paths can be changed by blockage of pore throats by O/W emulsions. Oil recovery is significantly improved at ultralow IFT because the residual oil is more easily to be mobilized. Moreover, the dynamic contact angle increases as the IFT decreases, resulting in the formation of an O/W emulsions at low IFT while the emulsions formed at ultralow IFT become W/O. Forming either O/W emulsions or W/O emulsions has been shown to improve sweep efficiency. The wettability alteration by surfactants promotes the imbibition in the initially oil-wet micromodels. During surfactant flooding, more trapped oil droplets are mobilized due to wettability alteration. The formation of microemulsions during surfactant flooding can change the displacement patterns and increase the oil recovery by solubilizing the residual oil.

The existing micromodel studies of surfactant flooding mainly focused on revealing the pore-scale mechanisms of oil recovery. However, due to the complex phase behaviors of surfactant–water–oil system, the surfactant concentration (oil/water IFT) can vary spatially during the displacement. Therefore, how the displacement dynamics are affected is not fully understood. The goal of conducting pore-scale study is to provide new insights and guidelines for field applications. But how the pore-scale events affect core-scale and field-scale displacement parameters, such as relative permeability, has not been extensively studied and need to be investigated in depth in the future.

Acknowledgments

Weipeng Yang and Jun Lu acknowledge the McDougall School of Petroleum Engineering at The University of Tulsa for the support of this research.

Biographies

Weipeng Yang is a Ph.D. degree candidate in petroleum engineering in the McDougall School of Petroleum Engineering at the University of Tulsa. His research interests include enhanced oil recovery (EOR), multiphase flow in porous media, and groundwater remediation. Yang holds a bachelor’s degree in chemical engineering from China University of Mining and Technology, China, and a master’s degree in petroleum engineering from China University of Petroleum (Huadong).

Jun Lu is an assistant professor in the McDougall School of Petroleum Engineering at the University of Tulsa. His research interests include enhanced oil recovery (EOR), reservoir engineering, reservoir simulation, flow assurance and groundwater modeling and remediation. He holds a Ph.D. degree in petroleum engineering from the University of Texas at Austin.

Bing Wei is a professor in the Petroleum Engineering School at Southwest Petroleum University, where Wei is the director of Complex Reservoir EOR Research center. His research focuses on unconventional reservoirs EOR including phase behaviors, multiphase flow in porous media, nanofluid, mobility control, etc. Wei holds a Ph.D. degree in Chemical Engineering from University of New Brunswick.

Haiyang Yu is currently a professor in the Department of Petroleum Engineering at China University of Petroleum, Beijing. His research interests include unconventional oil and gas development, CO2/carbonated water injection characterization and simulation, enhanced oil recovery by gas injection, and reservoir simulation. He holds a B.S. degree from Dalian University of Technology, and a master’s degree from Tsinghua University, majoring in thermal engineering. After that, he got a Ph.D. degree in petroleum engineering from the University of Texas at Austin.

Tianbo Liang is currently an associate professor in the Unconventional Petroleum Research Institute at China University of Petroleum at Beijing. His research interests include formation damage, reservoir stimulation, and CEOR in the unconventional reservoirs. He holds a bachelor’s degree in materials science from Tsinghua University; a master’s degree in materials science from the University of California at Davis; and a Ph.D. degree in petroleum engineering from the University of Texas at Austin.

The authors declare no competing financial interest.

References

- Hirasaki G. J.; Miller C. A.; Puerto M. Recent Advances in Surfactant EOR.. SPE J. 2011, 16 (04), 889–907. 10.2118/115386-PA. [DOI] [Google Scholar]

- Kamal M. S.; Hussein I. A.; Sultan A. S. Review on Surfactant Flooding: Phase Behavior, Retention, IFT, and Field Applications. Energy Fuels 2017, 31 (8), 7701–7720. 10.1021/acs.energyfuels.7b00353. [DOI] [Google Scholar]

- Pursley S. A.; Healy R. N.; Sandvik E. I. A Field Test of Surfactant Flooding, Loudon, Illinois. JPT, J. Pet. Technol. 1973, 25 (07), 793–802. 10.2118/3805-PA. [DOI] [Google Scholar]

- Bryan J. L.; Kantzas A. Enhanced Heavy-Oil Recovery by Alkali-Surfactant Flooding. SPE Ann. Tech. Conf. Exhib. 2007, 10.2118/110738-MS. [DOI] [Google Scholar]

- Bartels W.-B.-B.; Mahani H.; Berg S.; Menezes R.; van der Hoeven J. A.; Fadili A. Oil Configuration Under High-Salinity and Low-Salinity Conditions at Pore Scale: A Parametric Investigation by Use of a Single-Channel Micromodel. SPE J. 2017, 22 (05), 1362–1373. 10.2118/181386-PA. [DOI] [Google Scholar]

- Unsal E.; Broens M.; Armstrong R. T. Pore Scale Dynamics of Microemulsion Formation. Langmuir 2016, 32 (28), 7096–7108. 10.1021/acs.langmuir.6b00821. [DOI] [PubMed] [Google Scholar]

- Lenormand R.; Touboul E.; Zarcone C. Numerical Models and Experiments on Immiscible Displacements in Porous Media. J. Fluid Mech. 1988, 189, 165–187. 10.1017/S0022112088000953. [DOI] [Google Scholar]

- Lenormand R. Liquids in Porous Media. J. Phys.: Condens. Matter 1990, 2 (S), SA79–SA88. 10.1088/0953-8984/2/S/008. [DOI] [Google Scholar]

- Shang X.; Bai Y.; Sun J.; Dong C. Performance and Displacement Mechanism of a Surfactant/Compound Alkaline Flooding System for Enhanced Oil Recovery. Colloids Surf., A 2019, 580, 123679. 10.1016/j.colsurfa.2019.123679. [DOI] [Google Scholar]

- Yu F.; Jiang H.; Fan Z.; Xu F.; Su H.; Li J. Formation and Flow Behaviors of in Situ Emulsions in Heavy Oil Reservoirs. Energy Fuels 2019, 33 (7), 5961–5970. 10.1021/acs.energyfuels.9b00154. [DOI] [Google Scholar]

- Pei H.; Zhang G.; Ge J.; Jiang P.; Zhang J.; Zhong Y. Study of Polymer-Enhanced Emulsion Flooding to Improve Viscous Oil Recovery in Waterflooded Heavy Oil Reservoirs. Colloids Surf., A 2017, 529, 409–416. 10.1016/j.colsurfa.2017.06.039. [DOI] [Google Scholar]

- Zhao X.; Feng Y.; Liao G.; Liu W. Visualizing In-Situ Emulsification in Porous Media during Surfactant Flooding: A Microfluidic Study. J. Colloid Interface Sci. 2020, 578, 629–640. 10.1016/j.jcis.2020.06.019. [DOI] [PubMed] [Google Scholar]

- Ezeh C. G.; Chen C.-Y.; Papadopoulos K. D. Mobilization of N-Hexadecane in Porous Media Using Food Grade Amphiphiles. Colloids Surf., A 2018, 558, 123–129. 10.1016/j.colsurfa.2018.08.061. [DOI] [Google Scholar]

- Yun W.; Chang S.; Cogswell D. A.; Eichmann S. L.; Gizzatov A.; Thomas G.; Al-Hazza N.; Abdel-Fattah A.; Wang W. Toward Reservoir-on-a-Chip: Rapid Performance Evaluation of Enhanced Oil Recovery Surfactants for Carbonate Reservoirs Using a Calcite-Coated Micromodel. Sci. Rep. 2020, 10 (1), 782. 10.1038/s41598-020-57485-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tagavifar M.; Xu K.; Jang S. H.; Balhoff M. T.; Pope G. A. Spontaneous and Flow-Driven Interfacial Phase Change: Dynamics of Microemulsion Formation at the Pore Scale. Langmuir 2017, 33 (45), 13077–13086. 10.1021/acs.langmuir.7b02856. [DOI] [PubMed] [Google Scholar]

- Schumi B.; Clemens T.; Wegner J.; Ganzer L.; Kaiser A.; Hincapie R. E.; Leitenmüller V. Alkali Co-Solvent Polymer Flooding of High TAN Number Oil: Using Phase Experiments, Micro-Models and Corefloods for Injection Agent Selection. SPE Eur. featured at 81st EAGE Conf. Exhib. 2019, 1. 10.2118/195504-MS. [DOI] [Google Scholar]

- Mejia L.; Tagavifar M.; Xu K.; Mejia M.; Du Y.; Balhoff M. Surfactant Flooding in Oil-Wet Micromodels with High Permeability Fractures. Fuel 2019, 241, 1117–1128. 10.1016/j.fuel.2018.12.076. [DOI] [Google Scholar]

- Yang W.; Fu C.; Du Y.; Xu K.; Balhoff M. T.; Weston J.; Lu J. Dynamic Contact Angle Reformulates Pore-Scale Fluid-Fluid Displacement at Ultralow Interfacial Tension. SPE J. 2020, 1–12. 10.2118/204459-PA. [DOI] [Google Scholar]

- Dong M.; Liu Q.; Li A. Displacement Mechanisms of Enhanced Heavy Oil Recovery by Alkaline Flooding in a Micromodel. Particuology 2012, 10 (3), 298–305. 10.1016/j.partic.2011.09.008. [DOI] [Google Scholar]

- Li K.; Jing X.; Qu D.; Pu W.; Wei B. Pore-Level Investigations on the Oil Displacement Mechanisms of a Viscoelastic Surfactant in Porous Media. J. Pet. Sci. Eng. 2019, 173, 748–757. 10.1016/j.petrol.2018.09.086. [DOI] [Google Scholar]

- Yuan S.; Liang T.; Zhou F.; Liang X.; Yu F.; Li J. A Microfluidic Study of Wettability Alteration Rate on Enhanced Oil Recovery in Oil-Wet Porous Media. Abu Dhabi Int. Pet. Exhib. Conf. 2019, 10.2118/197715-MS. [DOI] [Google Scholar]

- Liang X.; Zhou F.; Liang T.; Su H.; Yuan S.; Li Y. Impacts of Pore Structure and Wettability on Distribution of Residual Fossil Hydrogen Energy after Imbibition. Int. J. Hydrogen Energy 2020, 45 (29), 14779–14789. 10.1016/j.ijhydene.2020.03.208. [DOI] [Google Scholar]

- Yu F.; Jiang H.; Xu F.; Fan Z.; Su H.; Li J. New Insights into Flow Physics in the EOR Process Based on 2.5D Reservoir Micromodels. J. Pet. Sci. Eng. 2019, 181, 106214. 10.1016/j.petrol.2019.106214. [DOI] [Google Scholar]

- Yu F.; Jiang H.; Ma M.; Xu F.; Su H.; Jia J. Visualization the Surfactant Imbibition at Pore Scale by Using of Fractured Micromodels. SPE Improved Oil Recov. Conf. 2020, 10.2118/200349-MS. [DOI] [Google Scholar]

- Zhao B.; MacMinn C. W.; Juanes R. Wettability Control on Multiphase Flow in Patterned Microfluidics. Proc. Natl. Acad. Sci. U. S. A. 2016, 113 (37), 10251–10256. 10.1073/pnas.1603387113. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Healy R. N.; Reed R. L.; Stenmark D. G. Multiphase Microemulsion Systems. SPEJ, Soc. Pet. Eng. J. 1976, 16 (03), 147–160. 10.2118/5565-PA. [DOI] [Google Scholar]

- Xu K.; Liang T.; Zhu P.; Qi P.; Lu J.; Huh C.; Balhoff M. A 2.5-D Glass Micromodel for Investigation of Multi-Phase Flow in Porous Media. Lab Chip 2017, 17 (4), 640–646. 10.1039/C6LC01476C. [DOI] [PubMed] [Google Scholar]

- Liang T.; Xu K.; Lu J.; Nguyen Q.; DiCarlo D. Evaluating the Performance of Surfactants in Enhancing Flowback and Permeability after Hydraulic Fracturing through a Microfluidic Model. SPE J. 1900, 25 (01), 268–287. 10.2118/199346-PA. [DOI] [Google Scholar]