Abstract

The correlation between structure and function lies at the heart of materials science and engineering. Especially, modern functional materials usually contain inhomogeneities at an atomic level, endowing them with interesting properties regarding electrons, phonons, and magnetic moments. Over the past few decades, many of the key developments in functional materials have been driven by the rapid advances in short‐range crystallographic techniques. Among them, pair distribution function (PDF) technique, capable of utilizing the entire Bragg and diffuse scattering signals, stands out as a powerful tool for detecting local structure away from average. With the advent of synchrotron X‐rays, spallation neutrons, and advanced computing power, the PDF can quantitatively encode a local structure and in turn guide atomic‐scale engineering in the functional materials. Here, the PDF investigations in a range of functional materials are reviewed, including ferroelectrics/thermoelectrics, colossal magnetoresistance (CMR) magnets, high‐temperature superconductors (HTSC), quantum dots (QDs), nano‐catalysts, and energy storage materials, where the links between functions and structural inhomogeneities are prominent. For each application, a brief description of the structure‐function coupling will be given, followed by selected cases of PDF investigations. Before that, an overview of the theory, methodology, and unique power of the PDF method will be also presented.

Keywords: local structure, neutron scattering, novel functional materials, pair distribution function, structural characterization, synchrotron X‐ray

The pair distribution function (PDF) applications in a range of functional materials is reviewed. The outlines of principle, methodology, and unique powers of this technique have been firstly presented, followed by an introduction of its applications on selected functional material areas. Throughout this review, it has been attempted to emphasize the interplay between short‐range inhomogeneities and functionalities in novel functional materials.

1. Introduction

Modern functional materials usually possess orders compromised with disorders. Nowadays, technological advances depend increasingly on novel functional materials engineered with complex structures at atomic and nanoscale levels.[ 1 , 2 , 3 , 4 , 5 ] Typical examples are nano‐domains and domain walls that separate the coherent potentials (i.e., structure, electron, and spin) into fragments, which are the fundamental concept of interests in ferroelectrics, magnets, and superconductors.[ 6 , 7 , 8 ] In addition, nano‐sized or nanostructured materials, on account of large specific surface area and limited dimension, are recognized as pathways for desirable catalytic and semiconducting (i.e., quantum dots (QDs)) functionalities.[ 9 , 10 , 11 ] In the case of colossal magnetoresistance (CMR) magnets, the strong electron‐phonon coupling is mediated via a local Jahn‐Teller (J–T) distortion.[ 12 ] This distortion is embedded in the nanoscale regions of metallic and insolating domains, whose balance is the key enabler to drive the coincident metal–insulator (M–I) transition.[ 13 ] Furthermore, battery active materials are frequently engineered with defects and cation disorders for cathodes, or synthesized in nanoscale or amorphous phases for anodes.[ 14 , 15 ] An even more important fact is that the Li/Na insertion/extraction processes in the battery materials are actually inhomogeneous, so the key toward desired electrochemical performance lies in short‐range structural dynamics.[ 16 ]

To understand and design the functional materials in complex structures, it is crucial to gain knowledge of a short‐range structure deviated from the average. This is actually not a simple task since the conventional diffraction‐based crystallography on account of the Bragg's law is not developed for encoding aperiodic structures. Currently, the only methods of choice for probing short‐range structures include extended X‐ray absorption fine structure (EXAFS) and nuclear magnetic resonance (NMR), each of which owns their relative advantages.[ 17 , 18 ] Nevertheless, the spatial resolution limits of these techniques, such as ≈0.1 Å for the EXAFS, could be reached only for the first coordination shell around an atom, while the atomic interactions at greater distances cannot be distinguished with high accuracy.[ 19 , 20 ] On the other hand, the microscopic techniques, such as transmission electron microscopy (TEM) and atomic force microscopy (AFM), are capable of imaging the real‐space structure without the premise of long‐range ordering. However, the microscopic images are taken at a selected area, so it fails to give an accurate description if the structural complexity is heterogeneous over the materials. In such context, it is critical to provide statistical and precise descriptions of short‐range disorders embedding in the functional materials, for which the PDF method has demonstrated its success and wide applicability in the research area of functional materials.

The origin of the PDF method can be traced back in 1915 when the Debye scattering equation was first proposed,[ 21 ] but for a long time this method has not been widely used until the recent 20 years when the techniques of synchrotron X‐rays and intensely pulsed neutrons were rapidly developed.[ 22 ] These high‐energy and high‐flux beams allow for a greater reciprocal area to be detected (typically Q max > 25–30 Å−1, discussed later), enabling a high spatial resolution of ≈0.01 Å that covers most concerns of structural complexities. As a result, the PDF technique, as a highly complementary detector to conventional bulk probes, could surely act as a powerful booster to the functional materials community. Herein we review the PDF applications in a range of functional materials, where the structural complexity plays a critical role in their functionalities. First, we will give an overview of principle, methodology, and unique powers of the PDF techniques, followed by the PDF applications on the selected areas of functional materials. Throughout this review, we attempt to emphasize the interplay between short‐range inhomogeneity and various kinds of functionalities, which are bridged by the PDF method.

2. Principles and Methods

Diffraction‐based crystallography has long been the basis for encoding the crystalline structure of a material. When X‐rays, neutrons or electrons are incident into crystals with perfect lattice periodicity, elastic scattering occurs and results in geometrical shadows—homocentric rings for poly‐crystals or spot array for single‐crystal—at well‐defined positions predictable by the Bragg's law:

| (1) |

which paints a clear picture of the diffraction feature correlating incident (or reflection) angle θ, interlayer spacing d(hkl), and radiation wavelength λ. The fascination of this equation is the power that the description of all atoms has been simplified to a small repetitive unit cell based on translational symmetry. By calculating d‐spacings and further quantitative analysis such as Rietveld refinement,[ 23 ] an overview of average crystalline structure is provided, which is the key enabler for the revolution of materials science engineering over the past century.

The success of the Bragg's law relies critically on the assumption of perfect periodicity and long‐range lattice coherence. However, modern functional materials are usually engineered with defects and disorders, or synthesized in nanoscale or amorphous phases, in order to get desirable performance.[ 24 , 25 , 26 ] In principle, once a structure locally deviates from the periodicity, the elastically scattered phonons would result in diffuse signals lying beneath and between the diffraction signals (Figure 1a). In other word, these diffuse signals fingerprint the disorders. The traditional Bragg analysis deals with the diffraction and the diffuse signals separately. The structural information is extracted solely from the positions and shapes of the diffraction peaks, while the diffuse signals are subtracted as background. In this way, the translational symmetry of crystal structure is recovered to satisfy the Bragg's law, but meanwhile all the information regarding atomic disorders is abandoned. This problem could be even more prominent for nano‐crystalline without long‐range structural coherence.[ 27 ] Due to the finite size effect of a nano‐crystalline, a remarkable line‐broadening of diffraction peaks is generated (Figure 1b). The conventional crystallography analysis describes these broadened patterns with the Scherrer equation,[ 28 ] sometimes coupled with spherical harmonics for non‐hkl‐homogenous broadening‐shape.[ 29 ] Yet, difficulties and errors are frequently emerged when atomic positions are considered, so only average lattice parameters of nanoparticles can be given even by fine analysis.[ 30 ] Besides the finite size effect, nanoparticles also possess a high proportion of surface atoms, terminate with various hkl‐planes, and are highly disordered.[ 31 ] All the above features contradict the premise of the Bragg's law and challenge the determination of nanoscale structures. On the other hand, glasses, increasingly applied as novel functional materials, show no crystalline periodicity but are not totally random like gases.[ 32 ] For this non‐periodic family, the conventional diffraction‐based measurements only generate diffuse signal and provide no solution for structural determination. Actually, the structural description of glassy materials is still a great challenge in the fields of material science and solid‐state physics.

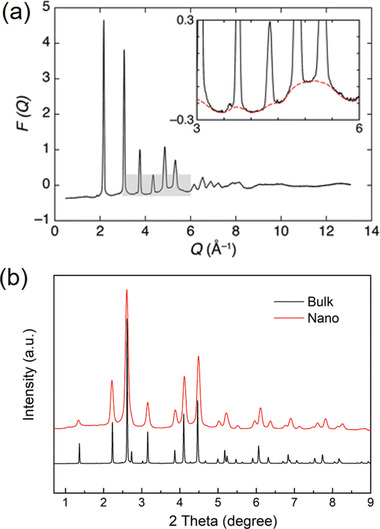

Figure 1.

a) Illustration of diffraction and diffuse scattering signals spreading over Q‐space. The F(Q) presented here was normalized from the diffraction of AgBr. The inset emphasizes the diffuse signals associated with structural disorders. Reproduced with permission.[ 19 ] Copyright 2011, Royal Society of Chemistry. b) Comparison of synchrotron XRD patterns of MnFe2O4 bulk and nanoparticles collected at 11‐ID‐C beamline (λ = 0.1173 Å).

By contrast, the PDF method makes use of the entire diffraction and diffuse scattering signals, that is, total scattering signals, from a sample, hence providing two distinct views of a material: average orders and local disorders. This is surely a significant step forward especially for describing disordered structures at various length levels. In this section, we will describe (Section 2.1) how the PDF analysis can be used to characterize complex structures with total scatterings, (Section 2.2) what kind of structural information can be achieved in different conditions, and (Section 2.3) what are the unique advantages of total scattering PDF over conventional crystallography techniques.

2.1. Total Scattering Conversion

The pair distribution function, that is, PDF, gives the weight probability of detecting any pair of atoms separated by a distance r—it establishes a distribution of interatomic distances in real space (Figure 2a,b). To begin with, a few forms of PDF expressions are required to be clarified. The first one is defined as atomic pair distribution function, g(r):[ 33 , 34 , 35 ]

| (2) |

where ρ(r) and ρ o are the local and average number densities of atoms, respectively, rij refers to the distance between the ith and jth atoms in the system containing N atoms, and δ is the Dirac delta function whose integral equals to one only when r = rij. This function of g(r) is the original definition of the PDF, but a reduced form, G(r), is more frequently used in practice:

| (3) |

which makes it accessible to be transformed from experimental total scattering data (discussed later). Another important form of PDF is the radius pair distribution function, R(r):[ 36 ]

| (4) |

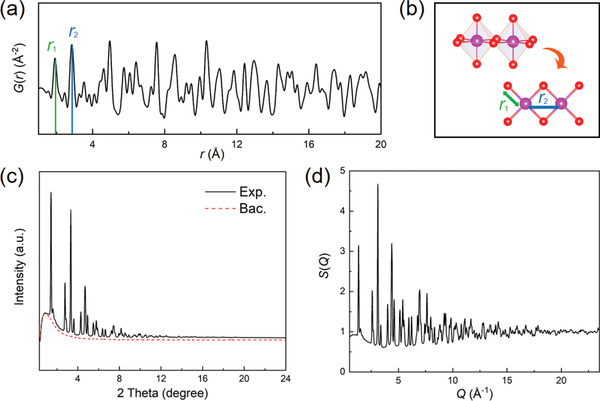

Figure 2.

a) The atomic distribution of Li‐rich cathode material (Li1.2Ni0.13Co0.13Mn0.54O2) deriving PDF G(r) pattern. b) The schematic diagram atomic distance responsible for the first two shells. c) The raw powder diffraction data collected from 11‐ID‐C beamline, APS. The underneath red dashed line is the measured background for deduction. d) The total scattering function S(Q) data of Li‐rich material (Q max = 23.5 Å−1).

This R(r) function enables a more clear physical picture to the PDF, since the exact number Nr of atoms in a spherical shell with a thickness dr can be given by:

| (5) |

where r can be interpreted as the radius of the spherical shell.

Experimentally, the PDF can be converted from powder diffraction measurements using X‐rays, neutrons or electrons, considering the diffraction and diffuse signals equally. However, the overall intensity recorded out of a sample is more complicated and composed of several components in terms of different scattering processes:[ 33 , 37 ]

| (6) |

where I e is the elastic (or coherent) scattering intensity, I ine is the inelastic (or incoherent) scattering intensity, I m is the multi‐scattering intensity, and I bac is the background intensity. The intensities of diffraction and diffuse belong to the elastic scattering category (i.e., I e), which are the focus of PDF analysis carrying structural information. The inelastic scattering, arising from either Compton scattering of X‐rays or nuclear spin scattering of neutrons, could be eliminated by sensitive detectors or mathematics.[ 37 , 38 ] Note that the background referred here is generated from the scattering “outside” the sample (i.e., sample holder, sample environment, optical system, and so on). Obviously, this is very different from the background in diffraction‐based crystallography, which contains diffuse scattering from the sample. The standard procedure for the background subtraction is to collect I bac just excluding the sample and deducting it from the raw data (Figure 2c). In addition, compared to X‐rays and neutrons, electrons show a more significant multi‐scattering effect due to their stronger interaction with atoms.[ 39 , 40 ] This results in an anomalous intensity of electron total scattering, hence extending electron diffraction to PDF is a great challenge.[ 41 , 42 ] Up to now, very few research works are based on electron PDF,[ 43 , 44 , 45 ] which will not be an overview in this paper.

The total scattering function, S(Q), can be calculated from the elastic scattering intensity I e(Q) involving both diffraction and diffuse:

| (7) |

where ci is the atomic concentration of the ith atom species and fi is the corresponding scattering factor for X‐rays or scattering length for neutrons. Here the variable Q is the amplitude of the momentum transfer Q, which can be defined by the difference between incident (ki) and scattered (ko) wave vectors for an elastic scattering:

| (8) |

| (9) |

Briefly speaking, Q is a more generalized description of the scattering angle θ, taking account of the wavelength λ of X‐rays or neutrons. Since the diffuse scattering signal, which carries wealthy information about local disorders, is dominant at a high scattering angle, it is of particular importance to measure the total scattering data over a wide Q range—a large area in reciprocal space—to sensitively probe the local structures against the average.[ 46 ] Nevertheless, as suggested by the Equation 9, the maximum Q, that is, Q max, that can be reached in experiments is limited by the wavelengths of applied X‐rays or neutrons. While the laboratory‐available Cu‐Kα (λ = 1.538 Å) X‐ray source only gives Q max ≈ 8 Å−1 and Mo‐Kα (λ = 0.708 Å) gives Q max ≈ 16 Å−1, the desirable Q max value for accurate PDF analysis is 25 ≈ 30 Å−1 or higher. As a result, high‐energy synchrotron X‐ray or spallation neutron sources are the first choices, if not necessarily, for high‐resolution total scattering measurements.[ 47 ] Apart from the limitation of wavelength λ, there are other factors, such as the detector boundaries and high‐Q noises, penalizing the Q max that should be paid attention to.

Figure 2d shows the S(Q) pattern calculated from synchrotron X‐ray diffraction data of Li‐rich cathode material (i.e., Li1.2Ni0.13Co0.13Mn0.54O2, Q max ≈ 23.5 Å−1). It appears different from the conventional powder diffraction shown in Figure 2b, not only because of the involvement of Q‐space; the total scattering function S(Q) has been divided by the square of atomic scattering factor <f(Q)>2 (Equation 7), which decreases at high‐Q region.[ 48 ] As a result, the weak peaks or oscillations at high‐Q, mainly induced from the diffuse scattering signal, are amplified in S(Q) and become as equally important as the sharp Bragg peaks at low‐Q. The pair distribution function, G(r), can be converted from this high‐Q‐amplified S(Q) through a sine Fourier transformation:

| (10) |

which presents a histogram of atomic distances, or “bond lengths”, in the real space. In many cases, the term Q[S(Q)‐1] is also referred as F(Q), which further highlights the importance of high‐Q data.[ 36 ] The power of this Fourier transform is to convert total scattering from reciprocal to real space, enabling a more intuitive view of the PDF data. Each PDF peak represents the probability of finding a pair of atoms between a given distance r. Obviously, the most straightforward way to analyze the local structure from PDF is to determine the peak positions in G(r), maybe coupled with a peak‐fitting process using a Lorentz or Gaussian function or their combination.[ 37 ] Following the peak‐shifting evolution appears to be more efficient and intuitive especially for the continuous data series. Also, the heterogeneities in bonding environments, which is very important in some optical and thermoelectric materials, could be evaluated from the widths of the related PDF peaks.[ 49 ] For a step forward, the coordination number between a pair of atoms could be estimated from the integrated area of the corresponding G(r) peak.[ 19 ] Nevertheless, this operation is hard to proceed in many cases, due to the merging of PDF peaks and the background, as well as the weighted contribution from different types of atoms. Hence, computational analysis of the G(r) is required for local structure details and will be discussed later.

Practically, the whole total scattering conversion process, including the correction and calculation of S(Q), and the subsequent Fourier transform of G(r), could be implemented by programs. The widely recognized programs for the X‐ray PDF conversion are the PDFgetX3[ 50 ] and recently developed xPDFsuite,[ 51 ] while the PDFgetN is the generally used program to process neutron PDF data.[ 52 ] At present, the programs are becoming increasingly automatic and user‐friendly to eliminate errors brought from the conversion. The most common error encountered in practice is the improper choice of the Q max value. Although the total scattering function S(Q) generally extends to a wide Q‐space, the Q max value employed in conversion is typically cut off below the experimental maximum to decrease the noises.[ 53 ] However, a low‐Q max conversion of S(Q) not only widens the G(r) peaks and reduces the real‐space resolution, but also produces strong ripples at a short distance (known as termination errors).[ 54 ] Keeping the balance of Q max is therefore important and requires a rich knowledge and experience in data analysis.

2.2. Computational Analysis

2.2.1. Real‐Space Rietveld Method

The real‐space Rietveld method is a powerful and widely used approach to offer a quantitative solution of the local structure from the G(r) pattern.[ 55 ] It is a full‐profile structural refinement similar to the well‐established Rietveld analysis in the diffraction‐based crystallography.[ 1 ] The major similarity lies in the fact that they both are based on a certain “small‐box” unit‐cell model with identical structural parameters (i.e., lattice constant, atomic coordinate, atomic occupancy, and anisotropic thermal ellipsoid). Also, they share analogical calculating algorithm. However, as mentioned, the conventional Rietveld method only refines the Bragg peaks and treats the diffusion signals as background arbitrarily, hence resulting in an average structure of a given model. By contrast, the real‐space PDF Rietveld refinement deals with the total scatterings (i.e., diffraction and diffusion), which contains the local disorders deviating from the average structure.

The popular programs to perform the real‐space Rietveld refinement include PDFgui and DiffPy‐CMI.[ 56 , 57 ] The structural model is built with a unit cell containing fraction‐coordinated atoms, and then the structure parameters are refined for the best G(r) description using a least‐square method. To extract the local structural information, a larger supercell is frequently used instead of the crystallographic unit cell.[ 58 , 59 ] It is also a common strategy to adopt structural models with lower symmetry in order to release more degrees of freedom for possible atomic disorders.[ 60 ] Furthermore, the G(r) pattern could be refined in separate Q‐space regions. While the refinement of G(r) at high‐Q region gives the long‐range average structure, the low‐Q refinement could provide insight into the local disorders in view of short‐range structure.[ 61 , 62 ] In this way, the departure of local structure from the average could be evaluated.

Compared to other computing techniques, the real‐space Rietveld analysis is the simplest method of choice that provides a first‐step glimpse of the local structure. Here we highlight the advantages of this method from the following aspects. First, the structural model extracted from the PDF refinement could be compared directly with that generated from the reciprocal‐space Bragg analysis, so these two approaches are complementary. This is usually the first stage in determining whether there is any short‐range disorder beyond the average structure. Second, the applied small‐box unit‐cell model, compared with the “big‐box” modeling discussed later, could be constructed easily, and the physical interpretations from the model are straightforward and visual. Moreover, some of the structural parameters, such as the atomic thermal factors and their ellipsoid anisotropies, that related heavily to the local structure are considered to be more precisely determined from the real‐space than reciprocal space analysis.[ 33 ] As a consequence, the real‐space Rietveld method is widely accepted and applied in analyzing PDF and will be increasingly important in studying novel functional materials that tend to be more disordered.

2.2.2. Reverse Monte Carlo (RMC) Simulation

The real‐space Rietveld method is incapable of recognizing unknown structures, as it depends on a certain unit cell with specific crystallographic symmetry. Also, it is impossible to simply describe a highly disordered structure, such as heterogeneous gradient systems or amorphous phases, with a repeating small‐box unit. For these situations, an alternative solution to analyze PDF without the small‐box and symmetric constraints is necessarily required for encoding the complex structures. The reverse Monte Carlo (RMC) technique is developed based on an opposite philosophy to the Rietveld—it puts a large ensemble of atoms (hundreds to thousands) into a 3D big‐box configuration and randomly arranges them to search for a good fit of the experimental G(r) data.[ 63 , 64 , 65 ] The purpose here is to create a sufficiently large space for describing disorders and local structural correlations within the initial model. Clearly, the scheme of RMC modeling is pellucid, and is attractive to not only amorphous materials (i.e., silicon, metallic glasses, and so on),[ 66 , 67 , 68 , 69 ] but also crystals with significant disorders in structure, site occupancy, electrons, spin, and atomic thermal vibrations.[ 70 , 71 , 72 , 73 ] A few examples of the RMC modeling are shown in Figure 3 .

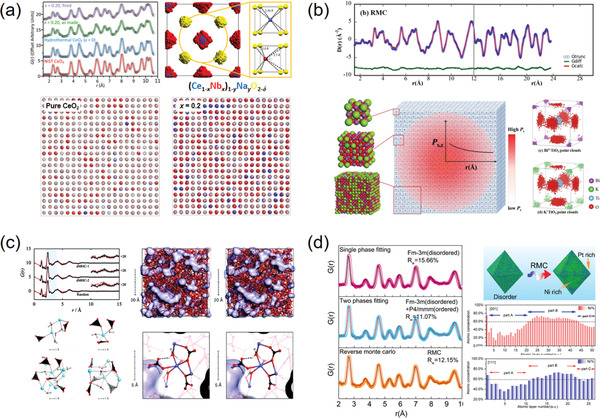

Figure 3.

a) RMC models and simulations of neutron total scattering from Nb‐doped CeO2. A 10 × 10 × 10 supercell was built as the initial model and the fitting result of atomic displacements was conformed into a single fluorite unit cell. Reproduced with permission.[ 71 ] Copyright 2018, American Chemical Society. b) RMC fitting results of synchrotron X‐ray total scattering data for Bi0.5K0.5TiO3 ferroelectric perovskite using a 12 × 12 × 12 supercell. The atomic displacement distributions were folded into the P4mm unit cells. Reproduced with permission.[ 72 ] Copyright 2017, American Chemical Society. c) RMC models and simulation results of X‐ray total scattering data for a clear view of the nanoporous channels and short‐ and medium‐range orders in the amorphous hydrated calcium carbonate. Reproduced with permission.[ 69 ] Copyright 2010, American Chemical Society. d) RMC fitting results of synchrotron X‐ray PDF for determining the component segregations in a single Pt41Ni59 alloy nanoparticle. Reproduced with permission.[ 73 ] Copyright 2017, American Chemical Society.

The original RMC code was developed for extracting the atomic structures of liquids and net‐work glasses from the diffuse signals, which has given birth to several RMC programs like DISCUS and RMC++.[ 74 , 75 ] For a further step, the program RMCProfile has extended the RMC technique approaching to the disordered crystalline materials, implemented by fitting a separate profile of Bragg diffraction, that is, F(Q), along with the G(r) function.[ 76 ] For a typical procedure, the big‐box configuration is constructed with the periodic conditions, and the atoms in the box are allowed to move randomly in order to produce a structural model consistent with the experimental data. To avoid unphysical solutions, it is critical to impose constraints (e.g., bond lengths, bond angles, coordination numbers, and so on) into the RMC refinements as appropriate.[ 77 ] Note that the final target of the RMC simulation is to search for rules from the random (a structure output at random is meaningless to the crystallography!). For the crystalline materials, this is usually accomplished by folding all the atomic displacements into their crystallographic unit cells to map the “atomic clouds” (Figure 3a,b).[ 71 , 72 ] In the cases of amorphous materials, the ligand environments within near r distances could be also summarized from the simulated structural models (Figure 3c).[ 69 ]

At present, the combination of total scattering and RMC modeling has been recognized its power and applied extensively in the fields of amorphous materials and disordered crystalline materials. However, the importance of RMC in studying nano‐materials might be undervalued. In fact, the RMC method has been manifested as capable of modeling a nanoparticle with tens to a hundred thousand closely‐packed atoms in a larger box, where each nanoparticle is isolated properly considering the periodic conditions (Figure 3d).[ 73 ] In this way, the surface‐to‐bulk inhomogeneities (i.e., surface reconstructions, segregations of elements and phases, and so on) in dimension‐limited systems could be simulated. Recently, some algorithmic progress has been made to correct the errors brought from removing the periodic boundary condition when the low‐dimensional box is built.[ 78 ] As this correction will be made available via the RMCProfile program, the RMC method would play a more important role in clarifying the inhomogeneities in low‐dimensional nano‐systems.

2.2.3. DFT/Molecular Dynamics Coupling

The RMC simulation has enabled a pathway to encoding the highly disordered materials with a 3D atomic configuration. However, it is always a great challenge to properly build the starting models. For the amorphous and non‐periodic materials, especially, this big box is actually more like a “black box” with unknown structure, which contains a large ensemble of atoms arranging randomly regardless of energetics and thermodynamics. Even if the model is constrained with given bonding environments, it is insufficient, complex, and may enroll errors, raising a question as to whether the RMC method could be extended to widespread researches of disordered materials.

In such a context, ab initio theoretical techniques, such as density functional theory (DFT), molecular dynamics (MD), and their combination (DF‐MD), have been frequently used to predict the feasible structure of the starting model. For example, the heterogeneous structure of SiO containing an amorphous Si‐SiO2 hybrid could be revealed by the X‐ray total scattering coupling RMC, where MD simulations were applied to reduce the total energy of the starting model.[ 79 ] Analogously, the DFT‐relaxed geometric models of La‐ and Mn‐substituted BiFeO3, compared to the models constrained only by crystallographic symmetry, were demonstrated more successfully in the descriptions of G(r) patterns.[ 80 ] Furthermore, by coupling DF‐MD with RMC, the total scattering data of amorphous Sb‐Te‐based alloy and also hydrated SnO2 surface could be reproduced with efficiency.[ 81 , 82 ] One common practical application of this strategy is to construct and optimize the 3D models of metallic nanoparticles such as Au‐, Pt‐, and Pd‐based nanoalloys, normally with MD corrected by the Sutton–Chen potential.[ 83 , 84 , 85 ] For all the above cases, the processes of the theoretical prediction and RMC modeling are isolated, which means the empirical constraints are still required during the RMC reconstruction. To minimize the uncertainty of RMC modeling, a DFT‐RMC iterative process has been developed, in which the atomic model could be constrained and relaxed by DFT throughout the data‐driven modeling.[ 86 ] Using this method, the final structure of amorphous kaolinite that is both experimentally reasonable and energetically feasible could be accessible.[ 87 ]

Undoubtedly, both RMC and ab initio computational techniques are extremely powerful but meanwhile inevitably labor intensive. As a result, these methods are cautioned to be applied at the very beginning of the PDF analysis, particularly in the cases of materials with known average structures. The small‐box Rietveld approach should be the first‐step method of choice, if the guidance of G(r) peak shifting is not clear or sufficient enough to get structural information. Nevertheless, as the today's functional materials are increasingly embedded with disorders, the RMC‐based total scattering techniques will surely play a more important role in unraveling the structural origins of properties and related functionalities.

2.3. Power of PDF Methods

2.3.1. Defects and Local Disorders

Lattice defects, such as point defects, dislocations, grain boundaries, and so on, strongly affect the intrinsic properties of materials through a sudden perturbation of crystallographic coherence. Modern functional materials are usually engineered with defects, as they could act as a regulator for acquiring desired performance.[ 88 , 89 , 90 ] In general, the crystal structure within a defective area is heavily distorted, and may be reconstructed into domains or defect clusters for a lowered total systematic energy.[ 91 ] Nevertheless, a full and accurate description of this defective structure is experimentally difficult and still awaited for many functionalized systems. The conventional diffraction‐based crystallography gives only long‐range average structure and is cautioned for probing defective structures, because the weak diffuse signals generated from defects and local disorders are disregarded. The recent development of atomic‐resolved STEM technique has enabled an approach to visualizing the defects and related disorders,[ 92 ] yet it only provides the structural information within a selective area, and a statistical result regarding the defective structure is still needed.

With the consideration of both diffraction and diffuse signals, the PDF technique is one of the few available pathways toward local disorders and defects. For a typical example, CeO2 has conventionally been thought to own a cubic fluorite structure (Fm‐3m) even under a highly defective condition, but this idea has recently been challenged by neutron PDF investigations, which showed that the existence of oxygen vacancies could induce a tetragonal (P42/nmc) structure and drive a reversible tetragonal‐to‐cubic phase transition in a temperature range of −25 ≈ 75 °C (Figure 4a).[ 60 ] In another case, the monoclinic‐to‐cubic phase transition occurred in La2Mo2O9 oxygen‐ion conductor was demonstrated to be driven by the dynamical distribution of oxygen defects, evidenced by neutron PDF analysis.[ 93 ] Additionally, the impact of anion vacancies on the local structure of Fe‐based oxyfluoride electrode material was also investigated by X‐ray total scattering combined with DFT.[ 94 ] The results demonstrated that the formation of oxygen vacancies is coupled with a spontaneous rearrangement of the local structure, hence triggering a remarkable enhancement in electronic transport and Li insertion processes during battery reactions. Furthermore, the unique power of PDF method in probing cation/anion defects and the derived local distortions has been manifested in a variety of functional materials such as UO2 nuclear fuel,[ 95 ] defect‐rich thermoelectric Eu2ZnSb2‐xBix,[ 96 ] high‐entropy alloys,[ 97 ] and so on.

Figure 4.

a) The small‐box neutron PDF refinements of nanosized ceria, revealing a tetragonal phase and a tetragonal‐to‐cubic phase transition induced by oxygen vacancies. Reproduced under the terms of CC‐BY Creative Commons Attribution 4.0 International License.[ 60 ] Copyright 2018, The Authors, published by Springer Nature. b) The X‐ray PDF refinements of Cs2SnI6 and (CH(NH2)2)2SnI6 with 3 × 3 × 3 supercell structure models. In these models, the rigid octahedral units were randomly rotated with a maximum rotating angle θ max. Reproduced with permission.[ 104 ] Copyright 2017, American Chemical Society. c) The X‐ray PDF refinements of CsPbBr3 nanocrystals with a PbBr6‐octahedron tilted structure model. The tilted domains are joint with twin boundaries. Reproduced with permission.[ 105 ] Copyright 2017, American Chemical Society.

On the other hand, the stacking faults, capable of shaping band structures and gap energies, play an important role in the performance of semiconductors, catalysts, and optical materials.[ 98 ] This special type of planar defect could be also determined by fine analysis of total scattering. By refining the G(r) pattern with a DFT‐relaxed stacking model, the stacking faults could be clearly identified within the nanodomains of γ‐Al2O3 matrix, providing a new insight into its catalytic functionality.[ 99 ] In addition, the strain‐driven stacking faults in CdSe/CdS core‐shell nanorods could be also probed by X‐ray PDF along with STEM experiments.[ 100 ] Recently, an R‐space PDF analytical method has been developed, dedicated to encoding the stacking faults in close‐packed metals, which would be helpful to the researches of metallic nanoalloys.[ 101 ]

In practice, the small‐box Rietveld‐like refinement is an efficient way to reconstruct the defective structure from total scattering data. In order to depict this disordered structure, the applied unit cell model is often built in a lowered symmetry, so that the roles of defects could be concluded as local distortions.[ 60 , 102 , 103 ] Meanwhile, a coupling strategy is to construct a larger supercell, instead of the smaller crystallographic one, to tolerate more inhomogeneity in the whole system. As shown in Figure 4b, the X‐ray PDF modeling of vacancy‐ordered A 2SnI6, where A = Cs+ and CH(NH2)2 +, were carried out by constructing 3 × 3 × 3 supercells, where random rotations of rigid octahedral units were introduced with a maximum rotating angle θ max. The results of PDF modeling revealed that the replacement of Cs+ with CH(NH2)2 + in A‐site of perovskite A 2SnI6 could induce a more disordered structure with a larger θ max value, holding implications for the electron‐phonon interactions and related optoelectronic applications.[ 104 ] Another way of probing the defect‐induced local disorders from PDF analysis is to separately refine the low‐r and high‐r regions in the G(r) pattern. The low‐r region is more sensitive to the defects and local disorders, as it enrolls a greater proportion of diffuse signals compared to the high‐r region. Using this method, the nanotwin structures in CsPbX3 (X = Cl, Br, I) nanocrystals was able to be clarified.[ 105 ] It was shown that low‐r pattern could be refined with PbX6 octahedron‐tilted orthorhombic subdomains, while the high‐r pattern could be matched with the tetragonal phase (Figure 4c). These tilted subdomains are hinged through the network of twin boundaries. Lastly, a more realistic picture of a defective structure could be drawn by the big‐box RMC analysis of total scattering. The distribution of defects and also the reconstructed coordination around defects could be statistically mapped by the RMC method.[ 106 , 107 ]

2.3.2. Nanomaterials

The finite‐size effects have enabled nano‐sized materials with peculiar chemical and physical features, and endowed functional nanodevices with great potentials.[ 31 ] In the past few decades, tremendous research and development efforts have been devoted to miniaturize the devices for potable capability and novel functionality. The success of these efforts depends on a robust understanding of nanomaterial structures especially at atomic scales. As mentioned above, the conventional diffraction‐based techniques provide only lattice constants and an average symmetry of nanocrystallines, while the atomic structural details, such as coordinations of atoms, surface reconstructions, anisotropic thermal ellipsoids, and so on, would be hidden behind the broadened and overlapped Bragg peaks at the high‐Q region. Moreover, the materials in nanoscale are usually heterogeneous in compositions and phases, which introduces additional complexities into the nanostructures.

The commonly used methods for probing nanostructures include EXAFS and PDF. Among them, the EXAFS technique is capable of probing the coordination environments around one certain atom. Currently, many of the current works adopt the EXAFS method to study nanomaterials, taking advantage of its elemental sensitivity. Especially, the polarization‐dependent X‐ray spectroscopy technique is capable of probing the orientational effects on surfaces, which is also a feasible approach to detect the local structure of nanomaterials.[ 108 , 109 ] However, as mentioned above, the high spatial resolution of the EXAFS (≈0.1 Å) could be achievable only for the first coordination shell, while the atomic interactions at greater distances cannot be determined with high accuracy. This hinders the wide applicability of the EXAFS method. On the other hand, the PDF method has been widely applied and demonstrated to be brilliantly successful in probing the structures of nanomaterials. This could be attributed to its advantageous feature for describing finite‐size nanocrystals—it summarizes the entire nanoscale system from the nearest‐neighbor bonds up to the furthest‐distance atom pairs.[ 110 ] In view of this, the confined size of a nanoscale material can be estimated from the termination of G(r) fluctuation.[ 111 ] One straightforward motivation for studying nanomaterials with PDF is to obtain reliable atomic coordinations for the G(r) refinements, so that the averaged atomic structures, such as bond lengths and bond angles, could be extracted for further investigation. In this respect, the structure clarification of ferrihydrite is a classic example. Although the ferrihydrite is ubiquitous in nature and widely applied as an industrial sorbent, there has been no consensus regarding its crystal structure for a long time, because this mineral exists in the form of a nanocrystalline (<10 nm in general). By means of real‐space PDF modeling, the atomic structure of ferrihydrite was uncovered for the first time.[ 112 ] This structure adopts a single hexagonal P63 mc phase, consisting of 20% tetragonal‐ and 80% octahedral‐coordinated Fe(III) ions (Figure 5a), which breaks the typically believed multiphase structure model for ferrihydrite. Later, the aging structure of ferrihydrite, as well as its relation to the magnetic structure was also revealed by X‐ray PDF analysis.[ 113 ] In a recent case, the structure of nano‐sized MoO2, which is known to differ from the bulk distorted rutile phase, was initially determined by the small‐box refinements of X‐ray PDF data.[ 114 ] For the nanoparticles larger than 40 nm, the overall rutile structure could be retained, while the ultrafine nanoparticles (<5 nm) could be described with either Magnéli or De Wolff structural model with rich defects. This size‐induced structural change could offer a possible explanation of the better electrochemical performance of nanoscale MoO2 anodes for Li‐ion batteries. These examples illustrate the strength of PDF in probing nanostructures, and most of them are performed with Rietveld‐like refinements. It is worth noting that this PDF Rietveld method should not be just regarded as a diffraction refinement in real space, as it enlists diffuse signals that are sensitive to the short‐range coherence, such as surface structures, heterogeneous nanoregions, and so on. With this in mind, the atomic structures of nanomaterials extracted from diffraction should be cautiously used for further analysis, even in the case that the well‐defined Bragg peaks are generated.

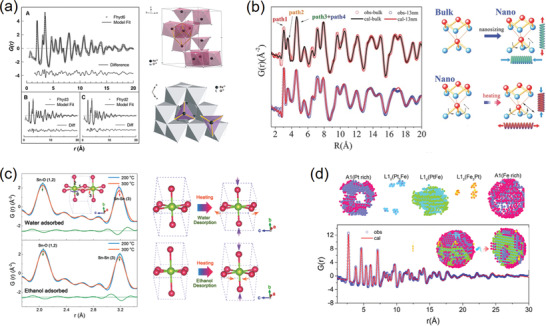

Figure 5.

a) The polyhedral‐interconnected unit cell of ferrihydrite mineral resulted from the small‐box PDF refinements. Reproduced with permission.[ 112 ] Copyright 2007, American Association for the Advancement of Science. b) The surface structural change upon nanosizing and heating in 13 nm Bi particles extracted from the PDF real‐space refinements. Reproduced under the terms of CC‐BY Creative Commons Attribution 4.0 International License.[ 115 ] Copyright 2016, The Authors. Published by Wiley‐VCH. c) The surface structural evolutions upon water and ethanol desorption upon heating achieved from the PDF refinements. Reproduced with permission.[ 119 ] Copyright 2018, Wiley‐VCH. d) The 3D diagram of the phase segregation in 3.5 nm PtFe alloy particles stripped from the PDF‐RMC simulated model. Reproduced with permission.[ 123 ] Copyright 2018, American Chemical Society.

For nanocrystals, the PDF analysis averages the structures from the external surface (or interface) to the internal core. Since the core atoms in the nanocrystals theoretically possess nearly the same coordination environments with those in the bulk, it is rational to speculate that the difference between the nano and bulk structures given by PDF is derived from the surface reconstructions. As a result, the PDF technique could act as a surface detector of nanomaterials when comparing and extracting the bulk structure out of it. For example, the surface distortions in Bi nanoparticles and the related thermal behaviors were successfully determined using X‐ray PDF analysis.[ 115 ] By comparing the PDF‐derived structures of bulk and nanoparticles, the bond lengths and bond angles on the corrugated layer surface are revealed to change remarkably, which affects the bending acoustic waves and induces an uniaxial negative thermal expansion (NTE) in the nanosized bismuth (Figure 5b). Likewise, the local octahedral distortions near the twin boundaries of SnO2 nanowires could be also determined by the PDF analysis.[ 116 ]

On the other hand, the surface of a nanoparticle is rich in dangling bonds that make it easy to adsorb small molecules (i.e., H2O, ethanol, and so on). This has led to a variety of important applications such as TiO2 photocatalysts and SnO2 gas sensors, where knowledge of surface structural changes upon adsorption is a fundamental issue.[ 117 ] In this respect, the PDF method enables a feasible solution, which could be realized by comparing the surface structures with and without adsorbates from the PDF analysis. For example, the surface structures of anatase‐phase TiO2 nanoparticles upon water adsorption were clarified by the X‐ray PDF refinements.[ 118 ] It is found that the dissociative adsorption of water, which is the first step of photocatalytic water splitting, takes place mainly on highly‐active {001} facets, leading to a significant modification of the Ti—O—Ti bonding environment. Such a (hkl)‐dependent change in the surface structure is demonstrated to greatly impact the thermal expansion behavior of TiO2 nanoparticles. For the SnO2 ethanol gas sensors, the sensing sensitivity drops largely from a fundamental study to real‐life application, which is a result of the ambient interference especially the humidity. However, understanding this phenomenon is challenging and intricate, as it involves the adsorptions of water, ethanol, and their mixture on the surface. The X‐ray PDF analysis provides a new insight into the cross‐sensitivity of SnO2 ethanol sensor to humidity, indicating that the performance of ethanol sensors is strongly coupled with the surface structures upon adsorptions.[ 119 ] During the sensing process, the SnO2 surface is adsorbed with water and ethanol simultaneously, so their independent effect could not be achieved simply from the PDF data of clean SnO2. In this case, the adsorbed nanoparticles were heated for the desorptions of water and ethanol at distinct temperatures, and thus the relative roles of water and ethanol could be deduced from the thermal lattice evolutions (Figure 5c).

Moreover, nanosized materials frequently undergo segregations of strains, phases or chemical compositions, which could be driven from either the surface effects or the synthetic processes.[ 120 , 121 ] These heterogeneous nanodomains are proven to be very important to functional properties such as magnetic response and catalytic activity, yet depicting a clear picture of the segregations has always been a great challenge.[ 122 ] The PDF coupled with RMC technique is one of the few available approaches toward segregated domains in nanomaterials. For example, the local strains and the related A1‐L10‐L12 phase segregations in PtFe nanoalloys are deciphered with PDF‐RMC modeling.[ 123 ] From the disassembly of the simulated structure, the surface of the prepared PtFe nanoparticle shows a disordered A1 phase, while the core lattice exhibits mainly a Pt/Fe stacking L10 structure (Figure 5d). The stretching strains induced from the lattice mismatch between these two phases could affect the overall magnetic property and thermal behavior of the PtFe nanoalloys. In the case of PdAu nanoparticles, the RMC modeling was carried out to investigate the compositional and structural heterogeneity.[ 124 ] The RMC‐simulated results indicate an enrichment of Pd on the surface, which is synthetically directed by prior binding of the Pd‐containing peptide. Thus, the PDF‐RMC simulation has enabled an opportunity for the rational design of the surface chemistry, structure, and strains in bimetallic nanoalloys for a desirable catalytic activity.

2.3.3. Amorphous or Glassy Solids

An amorphous solid is a condensed matter that lacks the long‐range order. It is sometimes synonymous with the terms of “glass” or “glassy solid”, but is strictly a glass that should undergo a glass transition.[ 125 ] The classic amorphous solids include metallic glasses, polymers, vitreous silica, porous carbon, etc., and any amorphous precursor before crystallization. For a long time, amorphous materials were rarely employed as functional materials as they are complex and unpredictable. However, a clear trend is emerging today, placing the amorphous materials at the forefront of research in broad areas covering catalysts, sensors, superconductors, energy storage devices, and so on.[ 124 , 125 , 126 , 127 , 128 ] In principle, the structures of the amorphous materials are nonperiodic yet not totally random—they are composed of interconnected unit clusters that could be similar with their crystalline phases.[ 129 ] Clearly, the conventional diffraction‐based crystallography provides no solution for such complex structures, and it is also not wise to specify all the atomic positions in an amorphous system from microscopic techniques, even though the resolution is sufficiently high enough to reach an atomic scale.

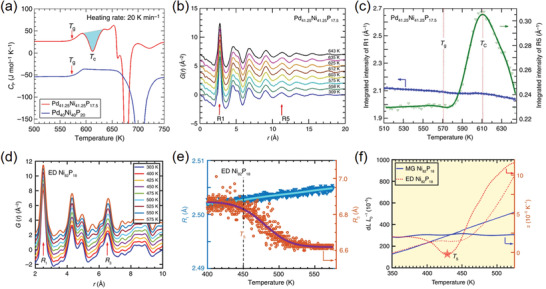

In fact, the total scattering technique is initially developed for tackling this “amorphous problem”. Since the unit clusters possess certain coordination environments, they could produce sharp peaks within the short r‐distance of the G(r) patterns. As a result, many efforts have been devoted to reproduce the local structures of amorphous solids from the PDF peak positions, where the first several shells could represent the neighbor bonding and global packing of the unit clusters, respectively.[ 130 , 131 ] As a typical example, metallic glasses are amorphous metals (usually alloys) that exhibit unique properties with respect to their crystalline counterparts. However, there exists a long‐standing mystery in a number of metallic glasses, whose differential scanning calorimetry (DSC) curves show an anomalous exothermal peak between the glass and crystallization temperatures (Figure 6a). This indicates an unknown amorphous phase transition during the heating process. To address this issue, Lan et al. carried out a series of PDF measurements on Pd41.25Ni41.25P17.5 alloy, in order to gain atomistic insights into the structural evolutions at different temperatures (Figure 6b).[ 132 ] The results reveal a hidden amorphous phase in this alloy, and therefore the anomaly in the DSC curve is resulted from a polyamorphous phase transition at the corresponding temperature. This phase transition could be regarded as the rearrangement of the local clusters in the medium range (up to ≈18 Å), which is fingerprinted by integrated G(r) intensity from the first (R1) to the fifth (R5) shells (Figure 6c). In addition, it has recently been found that this medium‐range packing could be engineered with electrodeposition (ED).[ 133 ] The PDF patterns of the ED Ni82P18 alloy could visualize both short‐range and medium‐range shells from the first (R1) and the third (R3) peaks, providing key evidence of this medium‐range engineering (Figure 6d). Remarkably, it has been shown that the nearest R1 expands while the R3 contracts upon heating, giving rise to an anomalous thermal expansion behavior in the ED alloy (Figure 6e,f). This suggests that engineering the packing arrangements of unit clusters could pave a feasible way to tailor a thermal expansion property in metallic glasses. Additionally, a variety of mechanical processes in metallic glasses, such as elastic deformation,[ 134 ] high‐pressure torsion,[ 142 ] and so on, could be encoded by following the peak evolutions in the G(r) pattern series.

Figure 6.

a) The DSC anomaly in Pd41.25Ni41.25P17.5 at T C ≈612 K, while no anomaly could be observed in Pd40Ni40P20. b) Reduced G(r) patterns collected from the Pd41.25Ni41.25P17.5 alloy at different temperatures. c) Integrated intensity of from the R1 to R5 shells in the G(r) patterns. Reproduced under the terms of CC‐BY Creative Commons Attribution 4.0 International License.[ 132 ] Copyright 2017, The Authors. Published by Springer Nature. d) Reduced G(r) patterns collected from ED Ni82P18 alloy at various temperatures. e) The temperature‐dependent peak positions in the variable‐temperature G(r) patterns of the ED Ni82P18 alloy. f) Anomalous thermal expansion behavior in the ED Ni82P18 alloy, in comparison with the metallic glass (MG) Ni82P18 alloy with normal positive thermal expansion behavior. Reproduced under the terms of CC‐BY Creative Commons Attribution 4.0 International License.[ 133 ] Copyright 2019, The Authors. Published by Springer Nature.

The clarification of amorphous‐to‐crystalline dynamics is another important application of PDF in this area. For example, the crystallizing process of amorphous zeolites was investigated by identifying the first few shells in the G(r) patterns.[ 135 ] The results reveal a clear picture of the local structural evolution during the induction period of crystalline, which involves a condensation process of aluminosilicate units and a subsequent construction of a large‐ring structure. In another case, the nucleation of layered titanates, which are the precursors of anatase or rutile TiO2 in wet‐chemical synthesis, was studied by in situ X‐ray PDF analysis during the hydrothermal reaction.[ 136 ] These intermediate layers present lepidocrocite‐type structure along the ab plane, so the generated G(r) patterns could be described well with a small‐box nanosheet model. The PDF results show that the lepidocrocite‐layered titanates are formed directly in the alkaline solution with cluster sizes <0.7 nm, while the subsequent thermal treatment connects these pre‐structures into periodic 2D layers. For the reverse procedure, the amorphization of monoclinic Nb2O5 under high pressure could be also illuminated by PDF measurements.[ 137 ] By following the peak evolutions at variable pressures, the amorphization is revealed to be closely related to the breakdown of long‐range polyhedral chains, whereas the local unit blocks of edge‐sharing NbO6 octahedra and pentagonal bipyramids could be maintained during this procedure.

Typically, the PDF data collected from an amorphous system is difficult to be analyzed computationally. The barrier lies in the fact that it is impossible to describe a glassy solid with a repeating small‐box unit. With regard to this, the large‐box RMC simulation could be the only method of choice to feedback an amorphous structural model from the PDF data. The first RMC modeling of amorphous SiO2 was performed in 1990,[ 138 ] and since then the algorithm has been optimized significantly, capable of combining MD and DFT, and triggered the RMC studies in a variety of amorphous systems such as metallic glasses,[ 139 ] hydrated complexes,[ 69 ] SiOx,[ 79 ] amorphous MOFs,[ 140 ] porous carbon,[ 141 ] and so on. Despite the above success, nonetheless, this method is frequently questioned as to whether the PDF data itself can carry such a huge information about every random atomic position in an amorphous system, and whether the retrieved chemical or topological results are model‐independent. These, up to now, are still open questions, but doubts maybe gradually eliminate by more exposure of successful cases and further improvements in RMC algorithms.

3. Applications in Functional Materials

In this section, we will review the PDF‐related applications in functional materials, placing emphasis on how the structural inhomogeneities play roles in their functionalities, and how the PDF method promotes the developments of these materials. For each application, we will begin with a brief introduction of the links between functions and structural, electronic or magnetic inhomogeneities, followed by selected cases of PDF investigations and possible operando PDF measurements applied in temperature, electric and magnetic fields.

3.1. Ferroelectrics/Thermoelectrics

3.1.1. Ferroelectrics

A ferroelectric material is identified by the occurrence of spontaneous polarization (PS) that is switchable in response to an external electric field.[ 143 ] This unique feature has enabled it to be functionalized and widely applied in piezoelectric transducers, non‐volatile memories, fatigue‐free capacitors and so on.[ 144 , 145 , 146 ] Theoretically, the properties of ferroelectricity are presented only in crystalline materials with asymmetric groups, where the positive charge center, typically in MO6 (M = metal) octahedra, is slightly displaced away from its axis‐symmetric position.[ 147 ] As a result, one central topic in the research field of ferroelectrics is the crystallography‐polarization coupling, which is also critically challenging due to its complex structural concepts including off‐center distortions, different‐orientated domains, polar nanoregions (PNRs) and so on. In addition, modern ferroelectric materials are usually made of nanomaterials or engineered with dopants and solid solutions, which also introduce structural complexities. With this regard, the PDF method could play an important role in studying the ferroelectric materials and related physics.

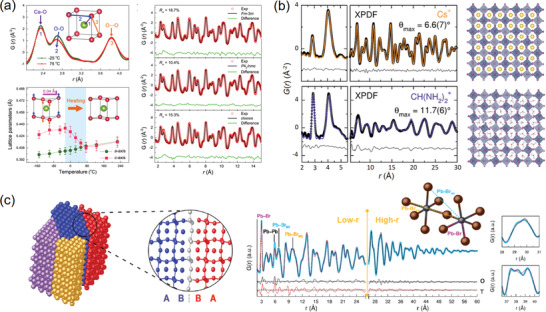

The classic family of ferroelectrics is the perovskite‐type (ABO3) oxides, such as PbTiO3 (PT), BaTiO3 (BT), Pb(Mg1/3Nb2/3)O3, BiFeO3, (K,Na)NbO3, etc., and their composites.[ 148 ] They usually exhibit an enhanced piezoelectric response at the morphotropic phase boundary (MPB)—a region separating two phases in the compositional phase diagram, where the structure abruptly changes and the electromechanical coupling is maximized.[ 149 ] Consequently, the structures of piezoelectric materials are practically complex, heterogeneous and very difficult to be clarified, for which the PDF method is frequently used to probe the structures near the piezoelectric MPB. For example, as one typical piezoelectric material, PbZr1‐xTixO3 (PZT) was conventionally regarded to show a tetragonal‐to‐rhombohedral transition across the MPB. However, this phase transition is forbidden by the symmetric continuity, and is considered to be mediated with a monoclinic phase. To clarify this intermediate monoclinic structure, neutron PDF coupled with RMC modeling was carried out to study both short‐ and long‐range structures at MPB.[ 150 ] It is revealed that there are two types of monoclinic phase coexisting in both long‐ and short‐range structures and being separated by an additional phase boundary, which is inspiring for the wide piezoelectric applications (Figure 7a). In addition, the PDF analysis could be also utilized to map the microscopic polarizations (i.e., cation off‐center displacements) in the ferroelectric structure of MPB. By means of the RMC modeling of neutron total scattering, comprehensive pictures of the cation off‐center shifts in a series of ferroelectric compounds could be depicted with varying compositions (Figure 7b).[ 151 , 152 , 153 ] These results provide visual correlations of the local atomic displacements as well as the dynamical coupling between A‐ and B‐site cations, which promote the uncover of structure‐property relationships in ferroelectrics near MPB.

Figure 7.

a) The phase diagram of PZT speculated from PDF‐RMC modeling. The crossover between the two intermediate monoclinic phases is marked by a dashed line. Reproduced with permission.[ 150 ] Copyright 2014, Springer Nature. b) The stereographs of the direction of polar displacements extracted from the RMC simulation of neutron PDF data. The polar direction associated with the perovskite structure is also presented. Reproduced with permission.[ 152 ] Copyright 2017 by the American Physics Society. c) The contour plots of in situ PDF patterns for different compositions and temperatures. Reproduced with permission.[ 168 ] Copyright 2018 by the American Physics Society.

Relaxor ferroelectrics are a special class of ferroelectrics with disordered structure and peculiar properties.[ 154 ] One distinguishable feature of the relaxor ferroelectrics is the existence of polar nanoregions (PNRs), that is, nanoscale clusters with randomly orientated dipole moments (polarizations), which affect the local structures and dielectric properties significantly.[ 155 ] Due to the obvious structural inhomogeneity, clarifying the roles of PNRs played in properties of relaxor ferroelectrics has always been a challenging task. By employing neutron PDF analysis, Jeong et al. reported the temperature evolutions of local polarizations and PNRs in a classic relaxor ferroelectric Pb(Mg1/3Nb2/3)O3 (PMN).[ 156 ] The PDF results show that PNRs exhibit a medium‐range (≈5–50 Å) rhombohedral order, and the temperature‐dependent volume fraction of the PNRs has been also estimated. Especially, the PNRs were observed to freeze into a spin‐glass state at low temperature (T < ≈200 K), which couples with other PDF‐derived local structure evidence to explain the relaxor behaviors. Analogously, the structure of Pb(Zn1/3Nb2/3)O3 (PZN) can be described with a mixture of rhombohedral PNRs in a medium‐range order, as revealed by the PDF‐RMC simulations.[ 157 ] Yet, the PNRs in PZN own a larger size (≈150 Å) compared to those in PMN, which explains the local correlations and the relaxor behaviors of PZN well. In addition, the short‐range structure correlations, as well as their temperature dependence, in relaxor ferroelectric SrxBa1‐ xNb2O6 (SBN) were investigated by neutron PDF analysis.[ 58 ] It is revealed that the heavily distorted structure is induced by Sr and Ba vacancies, which introduce local strains to tilt the Nb‐O6 octahedra and thereby affect the polarizations and relaxor behavior in the material. Apart from the above, the PDF method has been also applied to study the local structural correlations and PNRs in a variety of relaxor ferroelectrics such as BaZrxTi1‐ xO3,[ 158 , 159 ] 0.75PMN‐0.25PT,[ 160 ] Bi0.5K0.5TiO3,[ 161 ] and so on.

Nano‐ferroelectrics, such as nano‐BaTiO3, are of fundamental interests, as they often show different crystallographic phases and cation off‐center behaviors, as well as unique ferroelectric property compared to the bulk materials. The origin of these features comes mainly from the finite‐size effects that reduce the lattice coherence of the nanoscale systems.[ 162 ] As a result, the PDF method has been frequently used to study the ferroelectric nanostructures and the related ferroelectric properties. Taking the nano‐BaTiO3 as an example, the room‐temperature structure of BaTiO3 nanoparticles was proven to be different from the bulk BaTiO3 by neutron PDF analysis.[ 163 ] It is suggested that the average lattice of nanosized BaTiO3 appears to be metrically cubic at room temperature, while locally the Ti atoms exhibit a tetragonal‐like off‐center displacement. Additionally, the size‐dependent trends of this Ti off‐center displacement and the related local distortions have been built by X‐ray PDF analysis, indicating that the loss of long‐range coherence is responsible for the cubic symmetry in nanosized BaTiO3.[ 164 ] Afterwards, Rabuffetti et al. examined the local structural evolution of sub‐10 nm BaTiO3 nanocrystals upon the synthetic sol‐gel process by X‐ray PDF analysis.[ 165 ] The results confirm the long‐range cubic symmetry and the local off‐centering of Ti atoms in nanosized BaTiO3. Also, the polarization in nano‐BaTiO3 is demonstrated to be comparable to that in bulk BaTiO3, but the coherent length of the local Ti off‐centering displacement is only ≈16 Å. This suggests that the polarization performance could be achieved in nano‐BaTiO3 if the ferroelectric coupling could be increased. Lately, the structures of BaTi1‐ xFexO3 (x = 0, 0.1, 0.2, 0.3) nanocrystals were systematically studied by X‐ray PDF analysis, and it was revealed that the c‐axis of tetragonal P4mm lattice expands with x increasing.[ 166 ] All these results illustrate that it is of particular importance to consider diffuse signals to elucidate real ferroelectric nanostructures, where the PDF method becomes necessary in many cases.

In recent years, in situ electric‐field PDF technique has been developed to provide insights into the dynamical correlations of atomic structure in novel ferroelectric materials. For example, lead‐free piezoceramics have received much attentions for replacing PZT because they are environmental friendly.[ 142,167 ] Benefitting from in situ neutron PDF analysis, the stabilization mechanism of PNRs in one of the most general lead‐free piezoceramics, Ba(ZrxTi1‐ x)O3 (BZT), was clearly revealed (Figure 7c).[ 168 ] With a proper stoichiometry, the rotation of the local polarization could be sufficiently retarded, hence enabling an enhanced dipole correlation within the PNRs. In another example, the short‐range correlations in (1‐x)Ba(Zr0.2Ti0.8)O3‐x(Ba0.7Ca0.3)TiO3 (BZT‐xBCT), a lead‐free relaxor ferroelectrics, were clarified with in situ X‐ray PDF studies.[ 169 ] The PDF analysis indicates nonlinear lattice strains over all the compositions, which deviates from the typical piezoelectric behavior. Moreover, the in situ PDF technique has also been employed to investigate the field‐induced structural responses in some other representative ferroelectrics, such as SrTiO3,[ 170 ] (KxNa1‐x)0.5Bi0.5TiO3,[ 170 , 171 ] 0.7PMN‐0.3PT,[ 172 ] and so on.

3.1.2. Thermoelectrics

Thermoelectric materials are solid‐state energy convertors that enable a direct and reversible conversion between heat and electricity.[ 173 ] These materials are of great potential to be used for waste heat recovery, refrigeration, and as greenhouse‐gas eliminator, hence providing a feasible pathway to the sustainable energy solution.[ 174 , 175 , 176 ] The efficiency of a thermoelectric material depends on its dimensionless figure of merit (zT), defined as:[ 177 ]

| (11) |

where S stands for the Seebeck coefficient (or thermopower), σ is the electrical conductivity, κ is the thermal conductivity, and T is the absolute temperature. Accordingly, the focus of this research field is to optimize the thermoelectric materials for a large Seebeck coefficient, a high electrical conductivity, and a low thermal conductivity, which are conflicting properties in bulk crystals.[ 178 ] On the contrary, nanostructured or heterostructured materials with complexity in multi‐scale levels are theoretically predicted to exhibit high zTs without compromise.[ 179 ] For example, the nanoscale materials with confined dimensionality (e.g., nanocrystals, nanowires, films, and so on) are demonstrated to possess an increased Seebeck coefficient and meanwhile a reduced thermal conductivity.[ 180 , 181 ] On the other hand, the materials with defects, disorders or heterostructures allow for decoupling of the electrical conductivity with Seebeck coefficient, hence leading to a high zT.[ 182 ] As a result, the high‐efficient thermoelectric materials are usually complex in structures, synthesized in nanoscale, or engineered with heterostructures, defects or local disorders,[ 183 ] while PDF analysis is often needed to clarify these complex structures that correlate the thermoelectric performance.

The strategy of defect (intrinsic defects or extrinsic dopants) engineering is a very common approach toward high‐zT thermoelectric materials. The defects could modify the band structure of a semiconductor for an optimized carrier concentration, which hence enhances the electrical conductivity and also facilitates the scattering of phonons for a suppressed thermal conductivity κ.[ 184 ] For example, the effects of strains on defect‐enabled phonon scattering were examined in thermoelectric SnSe and its alloys.[ 185 ] By means of PDF analysis, the bonding environments of different SnSe‐based alloys were clearly determined, indicating that the strain fields could make a strong impact on the local disorders and also the thermal conductivity. Similarly, the local structure of thermoelectric Cu2/3CrS2 possessing 1/3 Cu+ vacancies was investigated by X‐ray PDF analysis.[ 186 ] It was demonstrated that a monoclinic phase with modulated CrS6‐octahedral distortions was newly formed, which would impact the zT value.

For doped systems, in particular, the Eu2+‐substituted defective BaTiO3 (i.e., Ba1‐ xEuxTiO3‐ δ) nano‐powders were proven to show an enhanced thermoelectric performance. With the help of small‐box PDF refinements, the local structures of these substituted materials were found to adopt a disordered Amm2 phase within r < 20 Å range, while the long‐range structure is identical to the cubic perovskite BaTiO3.[ 187 ] This unique local structure, induced by Eu2+ substitution and oxygen defects, enables a remarkably enhanced electrical conductivity of the material, although the parameters of S and σ go slightly against the overall performance. In another case, the impacts of doping‐derived distortions on the promoted phonon scattering and suppressed thermal conductivity were investigated in Sn1‐ xGexTe series.[ 188 ] The X‐ray PDF analysis shows that the global cubic structure of Sn1‐ xGexTe presents a local rhombohedral distortion accompanied with Ge alloying, which is fingerprinted by a local chain‐like Ge off‐centering. This local structural change could effectively scatter acoustic phonons, giving rise to a low κ and an improved thermoelectric performance. Besides, the structural complexity in Yb21Mn4Sb18 thermoelectric system was probed by neutron PDF measurements.[ 189 ] The small‐box refinement results indicated a distorted structure with anisotropic atomic displacements, which is consistent with a new Zintl phase that is first discovered in the Yb‐Mn‐Sb system.

The anharmonicity of interatomic potential well, measured by thermal expansion property macroscopically and Grüneisen parameter γ microscopically,[ 148 ] is a fundamental to suppress the thermal conductivity. This is realized by limiting the phonon lifetime for a reduced κ.[ 190 ] A strong anharmonicity could be achieved from weak or heterogeneous bonding environments, as well as heavy or lone‐pair atoms. For example, the n‐type rock‐salt AgPbBiSe3 was found to exhibit a low κ. The X‐ray PDF results reveal an obvious bonding heterogeneity existing in the lattice, which could be originated from the lone‐pair 6s 2 electrons of Pb and Bi atoms.[ 191 ] This induces strong anharmonicity that greatly enhances the phonon‐phonon scattering, which is responsible for the reduced thermal conductivity. In another n‐type thermoelectric AgBiS2, the κ value could almost approach to it theoretical minimum. Analogously, the lone‐pair electrons of Bi atoms were found to play a critical role to this phenomenon, which leads to local structural distortions along the [011] direction and thereby a strong lattice anharmonicity, as revealed by the X‐ray PDF analysis.[ 192 ]

As mentioned, high zT values are expected in nanoscale or low‐dimensional thermoelectric materials. The underlaid mechanism is the quantum size effect that could reduce the mean free path of phonon scattering.[ 193 ] The PDF method is frequently used to probe the nanostructures and clarify the related fundamentals. For example, Soriano et al. combined thermoelectric PbTe and Sb2Te3 into solid solutions (i.e., PbmSb2 nTem +3 n), and found that these compounds are stable only when they are nanocrystals.[ 194 ] The PDF analysis suggests that the local structure of PbmSb2 nTem +3 n is distorted relative to the rock‐salt cubic phase, which provides key clues for understanding the thermodynamic limits of nanoscale systems. In a separate study focusing on thermoelectric Li1‐ xSn2+ xAs2, the PDF analysis was carried out to probe the phase segregation at a nanoscale level.[ 195 ] It is indicated that the low thermal conductivity in Li1‐ xSn2+ xAs2 could be attributed to the nano‐inclusions and abundant boundaries associated with Sn4As3 and SnAs nanodomains, resulting in a hierarchical superstructure that scatters the heat‐carry phonons. In addition, similar nanophase segregation was also found in PbTe1‐ xSx compounds.[ 196 ] The small‐box Rietveld PDF refinements show that the system includes nanoscale PbTe‐rich and PbTe‐poor regions, which plays an important role in producing enhanced zT in this material.

In some cases, the thermoelectric materials may present amorphous state at the beginning or during the thermal processes, where PDF method is essential for studying these materials. For example, carbonized polydopamine (cPDA) was found to have potential for thermoelectric applications, so clarifying the atomic structure and its thermal evolutions of cPDA are highly desirable. By fitting the neutron PDF patterns with a graphite structure model, the short‐range atom correlations were characterized at the small r‐distance region.[ 197 ] Although the structure of cPDA is mainly amorphous, a short‐range ordering was revealed within a nanoscale region of ≈0.6 nm. Also, a graphite‐like local structure was observed to emerge in cPDA by increasing the temperature of heating treatment. As an opposite example, the X‐ray PDF was measured in thermoelectric Mg3Sb1.475Bi0.475Te0.05 to exclude the possible amorphous‐Bi formation during the heat cycling.[ 198 ] It is revealed that a crystalline Bi impurity, instead of Bi amorphous phase, appears upon cooling from 725 K, which is conducive to paint a clear picture of the thermal stability in this material.

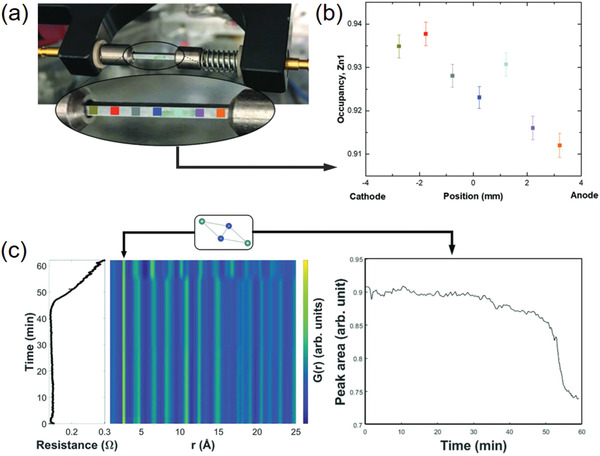

Very recently, inspiring progress has been made in developing synchrotron‐based in situ PDF technique dedicated for studying thermoelectric materials. Figure 8 shows the in situ setup that is capable of collecting X‐ray PDF data with real‐time detection of electrical resistance on pallets subjected to electrical current.[ 199 ] With this method, the in situ PDF investigation of β‐Zn4Sb3 thermoelectric material was carried out at different current densities, and both zinc‐ion migrations and related decomposition reaction were evaluated. Based on its principles, this in situ PDF setup could also be potentially used for studying ferro‐/piezo‐electric materials and solid‐state battery electrolytes.

Figure 8.

a) The photo of experimental setup for in situ PDF measurements, installed at P02.1 beamline, DESY. The sample is loaded on the pathway of X‐ray beam between two electrodes. b) The refined Zn occupancy at different positions colored in (a). c) The contour plot of the collected in situ PDF patterns along with the change of electrical resistance. The integration of the PDF at ≈2.7 Å, associated with the Zn occupancy, is also performed. Reproduced under the terms of CC‐BY Creative Commons Attribution 4.0 International License.[ 199 ] Copyright 2020, The Authors. Published by International Union of Crystallography.

3.2. Colossal Magnetoresistive Manganites

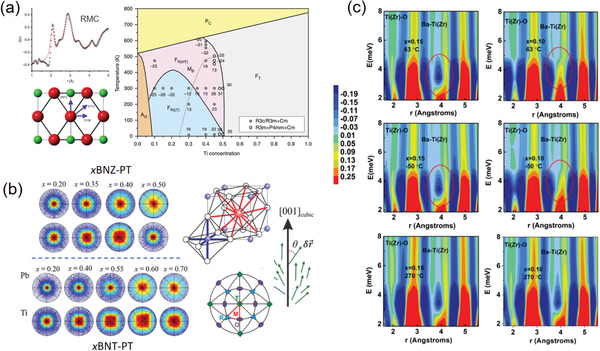

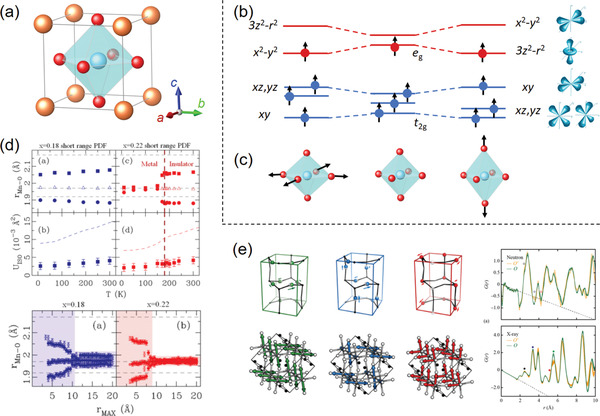

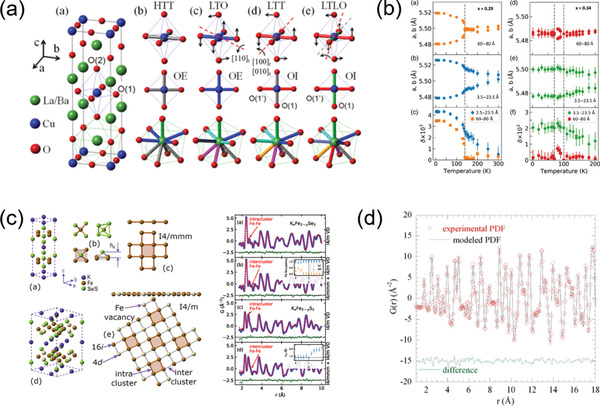

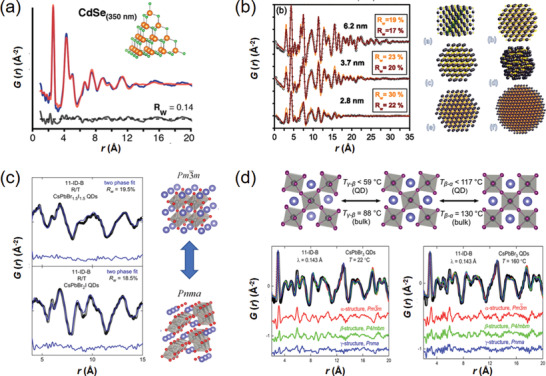

The term of CMR refers to a large drop of resistance in a magnetic material driven by application of a magnetic field near the Curie temperature (T C), in which the material would undergo a M–I transition accompanied with the intrinsic ferromagnetic‐to‐paramagnetic (F–P) transition.[ 200 , 201 , 202 ] The growth of research interest in this area comes from the prospective usage of disk read‐and‐write heads, whose performance is expected to exceed that of the giant magnetoresistance (GMR) devices that are composed of transition‐metal (TM) multilayer hybrids.[ 203 ] Mostly, the CMR effect is observed in mixed‐valent manganite (Mn3+‐Mn4+) perovskite, R 1‐ xAxMnO3, where R is a trivalent lanthanide metal (e.g., La, Pr, Nd) and A is a divalent cation (e.g., Ca, Sr, Ba, Pb). In these materials, the mixed Mn3+‐Mn4+ ions occupy the central sites of the vertex‐sharing MnO6 octahedra in the near‐cubic units (Figure 9a). It is now well established that at the heart of the CMR physics lies a strong electron‐phonon coupling mediated via a J–T distortion of the Mn3+ ions. On account of the crystal field, the five‐fold degeneracy of 3d orbitals is partially lifted into three lower‐lying t 2g levels and two higher‐lying e g levels. For the Mn3+O6 octahedra, the central Mn sites present a high‐spin electronic configuration, wherein the occupied e g level shows a marked tendency to lower its energy by octahedral distortion (Figure 9b).[ 204 ] This J–T distortion is regarded as the key enabler to localize the e g charge carriers when T > T C, and competitively these carriers could be released by the ferromagnetic exchange interactions of Mn spins at T C.[ 205 ] Such a competition between the localization and delocalization of charge barriers drives the coincident M–I transition, whose balance induces complex local structures in the CMR manganites. Apart from the CMR effect, the cooperative J–T distortion also leads to some unique phenomena such as orbital and charge ordering,[ 206 ] phase segregations,[ 207 ] etc., introducing additional lattice complexity in the materials.

Figure 9.

a) The near‐cubic unit cell of the R 1‐ xAxMnO3 perovskite. b) The schematic diagram of the five‐fold degenerated Mn3+‐3d orbital levels with distinct crystal‐field splittings. c) The typical octahedral Jahn–Teller distortions coupled with e g occupied orbitals. d) The results of neutron PDF refinements for La1‐ xCaxMnO3 (x = 0.18 and 0.22) samples at variable r‐distances to reveal the correlation length of the J–T distortion. Reproduced with permission.[ 212 ] Copyright 2016 by the American Physics Society. e) The representative orbital‐correlated models for small‐box PDF refinements and the corresponding X‐ray and neutron PDF patterns. Reproduced with permission.[ 213 ] Copyright 2017 by the American Physics Society.

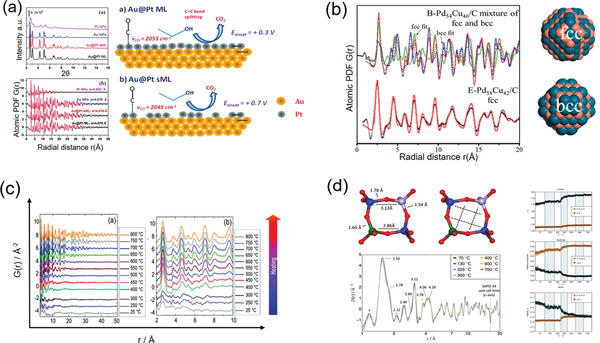

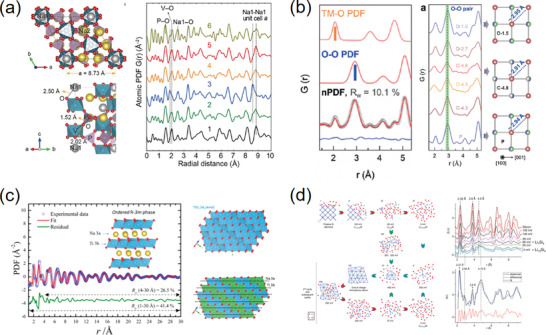

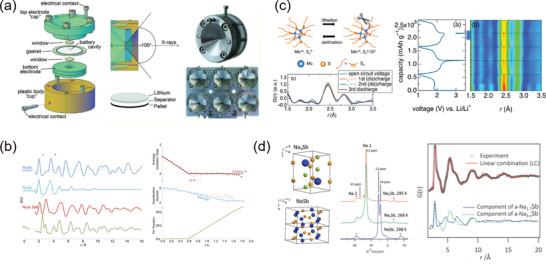

The most general octahedral J–T distortions are the elongation along z‐axis coupled with 3z 2‐r 2 orbital or along x‐ and y‐axis (in‐plane) coupled with x 2–y 2 orbital (Figure 9c).[ 208 ] A quantitative probe of these distortions is a key step toward understanding the related CMR physics. With this regard, the PDF method enables a straightforward way to distinguish the J–T distortion with the first Mn‐O peak being split into two components. This has triggered a lot of PDF investigations on the CMR manganites with temperature and doping leveling out across the M–I transition boundary.[ 209 , 210 , 211 ] For example, Shatnawi et al. conducted a comprehensive study on the local J–T evolutions in the La1‐ xCaxMnO3 (x = 0.18 and 0.22) compounds across their M–I transition.[ 212 ] A two‐phase structural model was applied to describe the neutron PDF patterns, and the refinements were carried out at variable r‐distances for revealing the correlation length of the J–T distortion (Figure 9d). The results show that the J–T distortion suddenly vanishes as soon as the temperature or doping level goes into the metallic phase region. Additionally, the two‐phase modeling provides no evidence of a phase coexistence away from T C, which disagrees the previously assumed percolative scenario for the M–I transition based on nanoscale phase separation. Recently, Thygesen et al. tracked the orbital order/disorder transition that couples the J–T distortions in LaMnO3, implemented by combining X‐ray and neutron PDF analysis at variable temperatures.[ 213 ] Different orbital‐correlated models were tested for small‐box PDF refinements, and a three‐state Potts (3SP) model was revealed to describe the G(r) patterns best (Figure 9e). The results show that a discontinuous local structural change emerges between the ordered and disordered states, which differs from the conventional order/disorder descriptions.