Abstract

In this review, life cycle assessment (LCA) principles are coupled with circular economy (CE) in order to address LCA examples in the biomedical sector worldwide. The objectives were (1) to explore the application of LCA in the medical, pharmaceutical, and dental fields; (2) to describe the ways of biomedical waste management; (3) to emphasize on the problem of dental waste in private and public dental sectors; and (4) to propose ways of “green circulation” of the dental waste. A literature search was performed using the Google Scholar, PubMed, and Scopus search engines covering the period from January 2000 until May 2020, corresponding to articles investigating the LCA and circular economy principles and legislation for biomedical and dental waste, their management options, and modern ways of recycling. The results showed that incineration seems to be the best management way option involved despite the mentioned drawbacks in this technology. Different adopted models are well defined for the dental field based on the 3Rs’ module (reduce, reuse, recycle). Replacing disposable products with reusable ones seems to be a good way to tackle the problem of waste in medical and dental sectors. Interventions on the selection and better biomedical and dental waste management will ensure eco-medicine and eco-dentistry of the future. These new terms should be the new philosophies that will change the way these fields operate in the future for the benefit of the professionals/patients and the community.

Supplementary Information

The online version contains supplementary material available at 10.1007/s43615-020-00001-0.

Keywords: Circular economy, Life cycle assessment, Biomedical waste, Dental waste, Medical waste disposal, Public health and ecological risk

Introduction

Materials and resources in every sector of human activities are not endless. Even before the economic crisis of the beginnings of the twenty-first century, professionals and governments worldwide were discussing a circular rather than linear flow of material resources in every field of the economy. Boulding in 1966, suggested the shift from the “cowboy economy” (endless frontiers/resources and the ability to move on and abandon problems) to the “spaceship economy” where limited resources had to be reused and recycled as a prerequisite to sustainable life-support systems [1]. The concept has since been studied at a theoretical level and as part of environmental sustainability and economics [2]. Later on 21 May 1992, the circular economy (CE) concept was introduced in the European Economic Community (EEC) with the Council Regulation No. 1973/92. The concept introduced a reducing demand for natural resources and contributed to more sustainable patterns of production, consumption, and waste disposal. Further, the European Commission (EC) developed a vision of a “Resource Efficient Europe” as an important part of the “Europe 2020 Strategy” [3]. In 2011, the “Roadmap to a Resource Efficient Europe” was introduced which concluded that greater efficiency in the use of resources was critical and more than important, not just for environmental reasons but also for competitiveness, employment and resource security and development [4]. Later, it was highlighted that the CE should provide functional, safe, and high-quality products, which will be more efficient, affordable, last longer, and will be designed for reuse, repair, or high-quality recycling for the best of all people involved as well as the environment. Then, the philosophy of three R’s (reuse, repair, recycle) or “waste hierarchy” as it is called was incorporated in various ways in CE national legislations. This was made possible through sustainable services, new product models, digital solutions, and innovative resource analysis in order to guarantee less waste, innovative jobs, upgraded knowledge and skills, and, in the end, better quality of life up to 2030 [5].

So nowadays, EU politicians are almost keener in asking society to move to a circular economy plan. This means moving to a model that eliminates waste by design in a way that one industry’s waste is another industry’s raw material and vice versa. Generally, in nature, there is no actual waste, and everything is finally reused. To aid this transition, the Commission has put forward several legislative proposals. For example, the so-called Circular Economy Package, adopted on 2 December 2015, [6] intends to address the whole cycle of products. This includes production and consumption, to waste management and the market for secondary raw materials. It touches several policy areas: waste, packaging and packaging waste, landfill waste, and electronic waste.

Under this sensitive environmental and humanitarian scheme, the management of waste or its minimization from all human activities arises as a new point of study for professionals of all fields and governments. It is also a key component in a business’ ability to maintain ISO 14001 accreditation.

According to the World Health Organization (WHO), biomedical waste (BMW) constitutes one of the most important categories of waste that pose crucial potential risks to people and the environment [7, 8]. BMW is defined as “the generation of waste materials at healthcare institutions as well as medical research facilities, laboratories and private clinics” [9]. Chemicals, pharmaceuticals, medical instruments, needles, syringes, diagnostic samples, blood, and radioactive materials are included in this category [10–12]. It can be hazardous or non-hazardous and when derived from hospitals it is called hospital waste (HW). Non-hazardous or general healthcare waste (HCW) is the 75–90% of BMW. The remaining 10–25% includes the hazardous waste [13]. The WHO states that 85% of HW are non-hazardous, whereas 10% are infectious and 5% are non-infectious but they are included in hazardous wastes [9]. About 15 to 35% of HW is regulated as infectious waste [12]. Potential problems and risks of BMW generation have become increasingly apparent in recent years. Especially under COVID-19 pandemic schemes, extra protective equipment has been made obligatory by national health authorities augmenting the quantities of BMW and the need for proper disposal.

The truth is that even before the pandemic and over the decades, the growth of the medical and dental sector around the globe, combined with an increase in the use of disposable and single-use products, has contributed to a large amount of medical and dental waste generated. The management of these specific types of dental waste (DW) can be considered by many as a complicated holistic issue [14–17].

Furthermore, DW needs collaborative management that certainly can be organized further. New materials are constantly entering the dental market, with most of them having been already accused of hazardous emissions when burned or evaporated. So, it is obvious that even though dental units are considered a minor source of HCW, they do generate certain amounts, environmentally interesting according to their disposal components [17, 18]. Different kinds of DW generated are domestic/municipal types, infectious, toxic, pharmaceutical and chemical, and solid or liquid wastes. All these require a specific approach for collection, treatment, and disposal [19]. In dentistry, sustainability means that all previous mentioned waste must be handled in the most environmentally friendly way possible.

It is obvious that proper care to health is very important, but what is there to be done in the health industry in order to finally balance both human health and environmental health?

Despite the environmental and hygiene importance of the issue, no specific comparison exists in the relevant literature providing information on the quantities and qualities of HCW industry nor is there data on DW from public sectors contributing to the overall problem. Further, no comparison has been made on the methodologies of waste disposal existing in various countries. Thus, the aim of this nonsystematic review paper is to compare different categories of ΒΜW with DW and discuss the ways of management, bringing up-to-date examples on this environmentally sensitive part of the function of health and dental care public units.

Ways of Waste Management

There are certain ways of waste disposal worldwide: (1) The first and oldest method used ever was the landfill where waste materials were buried without any recovery actions. It still exists in many places around the world, including Greece. (2) Another method is the incineration where solid organic wastes are combusted. With this method, waste is converted into heat, steam, gas, and ash reducing the volume of solid waste by 80 to 95%. It is a practical method of disposal of certain hazardous waste (such as BMW) but it affects seriously the environment through the emission of gaseous pollutants. Particular concern has focused on some very persistent organic residues such as dioxins, furans, and polycyclic aromatic hydrocarbon (PAHs). (3) Recycling is also another option referring to the collection and reuse of waste materials such as empty beverage containers, paper, and aluminum according to the recycling programs of each country. Reprocessing into new products is usually carried out most of the times. (4) Finally, reuse refers to biological reprocessing such as composting and anaerobic digestion (AD) methods that decompose mainly organic materials. The combustion technology can be employed to burn any kind of waste combinations with low emissions. On the other hand, anaerobic digestion converts biomass into biogas, a mixture of CO2 and CH4, (by bacteria in the absence of oxygen) and compost. The biogas is partly utilized to heat the digestion reactors. The rest can be used to generate electricity and/or heat (e.g., with a gas engine). The production of a renewable energy carrier, the possibility of nutrient recycling, and reduction of waste volumes are advantages and environmental benefits of AD.

Other technologies applied for waste management include membrane separation technology that offers many advantages in its application, but with major drawbacks such as membrane clogging and delayed widespread application. Moreover, supercritical fluid extraction and subcritical water extraction are new environmentally clean technologies, used to isolate natural products from different raw materials, such as plants, food by-products, algae, and microalgae. When a fluid is forced to a pressure and temperature above its critical point, it becomes a supercritical fluid. Supercritical fluids have low viscosity and relatively high diffusivity and hence have better transport properties than liquids. These characteristics make them diffuse easily through solid materials and can therefore give faster extraction yields. In comparison, subcritical water extraction (SWE), is extraction using hot water under pressure. In general, although novel methods (bioremediation, biogas production, membrane technologies, supercritical and subcritical fluid extraction) appear to be promising and attractive alternatives, major drawbacks include high cost, for equipment and training, and are not yet applied in major business sectors [20–23].

Overall, among the different technologies available for the treatment of biowaste, AD is the one recognized to pursue a global recovery of the materials with good agronomic properties [24–26]. Environmental benefits could also be derived due to the production of mineral fertilizers such as nitrogen, potassium, and phosphorous [27, 28]. Both Antonopoulos et al. [29], and Lundin et al. [30] reported avoidance of global warming, acidification, and resource depletion when AD is implemented for the management of BW. Ahamed et al. [31] found that AD is favored when BW has an oil content < 5% for bio-diesel production. By using a similar approach, Cremaito et al. [32] reported the positive role of AD in integrated waste management systems, for decreasing the whole environmental impact.

On the other hand, among the currently available industrial technologies, wet and dry processes, working with a total solid (TS) concentration ≤ 10% and 10% TS ≤ 20%, respectively, are credited with higher process stability and higher biogas and methane production compared to solid anaerobic digestion batch (SADB) operating with 20% TS ≤ 35% [33]. In addition, food industry waste can be used to obtain polymeric materials in the CE module. Valuable biocomposites for many uses, such as food packaging, biomedical devices and for cosmetic purposes could be produced by polymer compounds. In this context, the blending of chitosan and gelatin to formulate films has been extensively studied due to the great biocompatibility and nontoxic, biodegradable nature of the resulting materials [34, 35].

Biowaste, Biomedical Waste, and Ways of Management

The Green Paper of the European Commission (2008) [21] defines the biowaste (BW) as “Biodegradable garden and park waste, food and kitchen waste from households, restaurants, caterers and retail premises, and comparable waste from food processing plants. It does not include forestry or agricultural residues, manure, sewage sludge, or other biodegradable waste such as natural textiles, paper or processed wood.” So, solid waste can be classified into different types depending on their source: (a) Household waste commonly classified as municipal waste, (b) industrial waste that can be either hazardous or non-hazardous, and (c) biomedical waste or hospital/clinical waste which can be either infectious or non-infectious waste. Another classification for biomedical waste is defined as (1) “hazardous” when the waste itself or the material or substances it contains are harmful to humans and/or the environment and (2) “offensive” waste, which primarily contains waste that is considered unpleasant due to its appearance and smell, for instance incontinence waste [22] (Figure S1).

Healthcare waste or biomedical waste is generated during the diagnosis, treatment, or immunization of human beings or animals or in research activities in these fields. Mastorakis et al. [36] defined “Biomedical waste as any solid and/or liquid waste including its container and any intermediate product, which is generated during the diagnosis, treatment or immunization of human beings or animals or in research pertaining there to or in the production or testing thereof.”

BMW is composed of human anatomical waste; microbiological and biotechnological waste; sharps such as syringes, needles, scalpels, broken glass; discarded medicines and drugs; liquid wastes (blood, body fluid solutions, inorganic salts, etc.); and solid waste such as dressings, bandages, plaster casts, chemical waste, incinerator ash generated from hospitals and research centers. It can be hazardous or non-hazardous, and moreover, it can be infectious/risk or non-infectious/non-risk. Examples of hazardous waste include discarded blood, sharps, unwanted microbiological cultures and stocks, identifiable body parts, other human or animal tissue, used bandages and dressings, discarded gloves, other medical supplies that may have been in contact with blood, saliva, and body fluids, and laboratory waste. Waste sharps include potentially contaminated used (and unused discarded) needles, scalpels, lancets, and other devices capable of penetrating skin. Common generators (or producers) of biomedical waste include hospitals, health clinics, nursing homes, medical research laboratories, offices of physicians, dentists, and veterinarians, home healthcare, and funeral homes. In healthcare facilities (i.e., hospitals, clinics, doctors’ offices, veterinary hospitals, and clinical laboratories), waste with these characteristics may alternatively be called medical or clinical waste (MW). Finally, it can be solid or liquid medical waste. Liquid waste may be divided into (a) liquid reagents/chemicals discarded and (b) the cleaning and washing water channeled into the drain. Non-hazardous waste disposed of in the hazardous/clinical waste stream can often be 50–90% [37].

As it is well understood, a proper waste management system should be required to dispose this hazardous BMW. Several methods have been employed including incineration, steam sterilization, microwave sanitation, chemical disinfection, dry heat disinfection, and superheated steam disinfection. The most used technology so far for the treatment of BMW is incineration [38]. In Figure S2, not only incineration is depicted but also other methodologies according to the categorization of biodegradable versus non-biodegradable. The incineration process destroys pathogens and reduces waste volume by 90% and weight by 75%. Incineration usually involves the combustion of mingled solid waste with the presence of air or enough oxygen. Temperature of incinerator is more than 850 °C and the waste is converted into carbon dioxide and water. The incineration of hospital wastes not only releases toxic acid gases (CO, CO2, NO2, SO2, etc.), dioxides, into the environment but also leaves a solid material called ash as residue including bottom ash and fly ash which increases the levels of heavy metals, inorganic salts, and organic compounds [39, 40]. For example, higher concentration of heavy metals and dioxins such as polychlorinated dibenzodioxin (PCDDs) and polychlorinated dibenzofurans (PCDFs) was observed in medical waste incinerator ash [41]. Also, Zhao et al. [42] investigated the levels of polycyclic aromatic hydrocarbons (PAHs) in different types of hospital waste incinerator ashes and found mean PAH levels in the range from 4.16 to 198.92 mg kg−1 while the mean concentration of carcinogenic PAHs ranged from 0.74 to 96.77 mg kg−1. Also mentioned elsewhere, the incineration plants seem to be the main source of environmental damage due to the formation of dioxins and mercury [40]. Furthermore, the disposal of BMW ash in landfill may lead to contamination of groundwater due to metals presence in the leachate [40].

The limited space and the high cost for land disposal were serious but not the only reasons for the development of recycling technologies. But certainly, such factors led to the reuse of the previous mentioned ash in different systems for the last almost two decades. This means that there was a successful utilization of biomedical waste ash in agriculture as fertilizer and in the construction sector in order to minimize leaching of the previous mentioned hazardous components [40].

Generally, for BMW with a significant impact on health and environment due to the hazardous, infectious, and toxic materials it contains, incineration seems to be the best technology to reduce the volume of this hazardous waste as proposed by many authors. Currently, several process equipment including autoclaves, hydroclaves, pyrolysis reactors, and incineration chambers have been used for the treatment of healthcare waste. Microwave energy is another alternative option for the direct delivery of energy to microwave-absorbing materials, which allows the volumetric heating of samples. This technology raises minimal concerns regarding air, water, and solid residues. To further reduce the carbon footprint, segregation between contaminated and non-contaminated waste and the subsequent inactivation of contaminated parts might also be a good step in this direction (Tables 1 and 2).

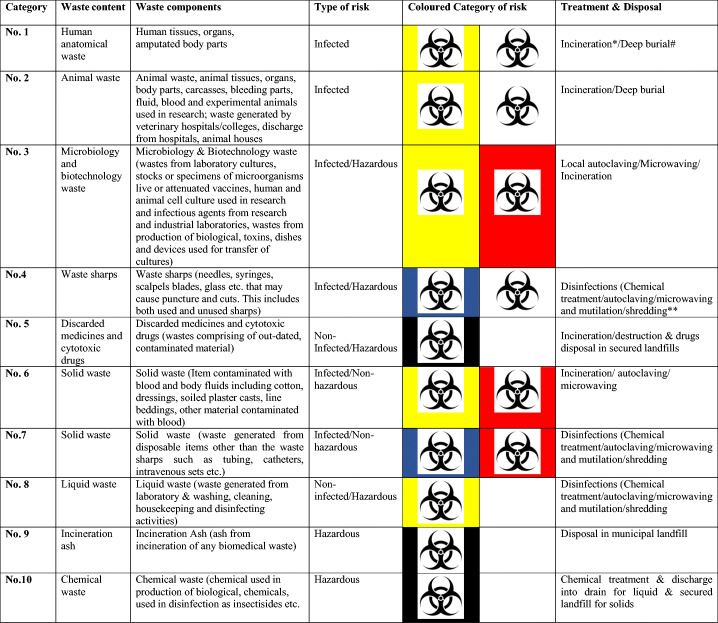

Table 1.

Biomedical waste (BMW) categories and their segregation, collection, treatment processing and disposal options

Table 2.

Shows representative research methodologies on biomedical waste disposal activities (BW)

| References | Category of waste & Treatment Parameters |

Methodology | Results/Uses in the medical sector |

|---|---|---|---|

|

Soliman and Ahmed (2007) [43] |

Biomedical waste-Incineration Recycling industry. Open burning or dumping in the backyard |

A WHO questionnaire was used | 60% of the intensive care units studied are considered high risk departments, followed by 40% of operating rooms, laboratories and healthcare units as they do not segregate any items of biomedical waste. Departments that segregate sharps use puncture resistant containers. |

| Tudor et al. (2008) [44] |

Hazardous and non-hazardous medical waste Ιmproved waste segregation, sending packaging back to the suppliers, use of biodegradable or reusable nappies and greater streamlining of procurement with product/service usage. Recycling of hazardous clinical waste. |

A four-bin system has been implemented comprising of an orange bag waste stream (to be treated using alternatives to incineration such as the use of hot oil); a domestic waste bag stream; a ‘Tiger bag’ stream (low-risk clinical waste e.g. swabs and dressings); and a yellow bag waste steam (for high-risk clinical waste) that is incinerated. | The findings from Cardiff and Vale NHS Trust and the Cornwall NHS Trust suggest that development and implementation of the systems should first be grounded in incorporating information on waste generation and monitoring, as well as staff training and awareness for the employees. The systems should employ both quantitative (e.g. questionnaires and waste bin analyses), as well as qualitative (e.g. interviews) mechanisms. |

|

Marinkovic et al. (2008) [45] |

Hazardous medical waste-Local landfilling with or without pretreatment. Incineration. Sorting, treatment. Thermal treatment. | Integrated approach to medical waste management. Reduction by sorting and separating, pretreatment on site, safe transportation, final treatment and sanitary disposal. | Small incinerators may be a more economical solution for a country like Croatia. Prior to any decision on the location of a landfill and type or installation of a new technology, a human health risk assessment study should be conducted. |

| Zhao et al. (2009b) [46] | Medical waste-Hazardous waste incineration (HWI) and steam autoclave sterilization with sanitary landfill (AL) as a type of non-incineration technology. The functional unit is the disposal of 1 ton of medical waste. | Implementation of the ISO 14040 standard. Data on steam autoclave sterilization were obtained from an on-site operations report. Inventory models were used for HWI, sanitary landfill, and residues landfill. The ecoinvent database was used. |

HWI with 30% energy recovery efficiency has the lowest environmental impacts for all impact categories, except freshwater ecotoxicity. Non-incineration treatments have an approximately sevenfold higher impact than incineration treatments with respect to eutrophication due to the difference in N element transformations. |

| Manga et al. (2011) [47] | Healthcare waste-Disposal in open dumps in combination with municipal solid wastes or in incinerators which are often poorly designed | Interviews and structured questionnaires were used to collect data on waste practices from key hospital staff and stakeholders. | Average waste generation rate estimated at 44.9 kg/day equivalent to over 16 tonnes/annum comprising 49%, 16% and 14% of general, infectious and sharps, respectively for a health facility in Buea, Cameroon. Reducing the waste quantities being incinerated results in less potential for persistent organic pollutants (POPs) and greenhouse gases |

| Chen et al. (2012) [48] |

Medical waste-Incineration (rotary kiln or fixed bed). Chemical and thermal dynamics characteristics of the waste determine the size and operating condition of the incineration facility |

Different types of dust precipitation and absorption towers will be used for flue gas purification to ensure the stability and efficiency of the medical waste incineration. | The incineration technology can achieve environmentally sound disposal, reduction and recycling of the waste, but it has also its limitation; for example, the flue gas generated from the incineration process will cause environmental pollution. |

| Antonopoulos et al. (2013) [29] | Biowaste- AD-Landfilling, aerobic and anaerobic biological treatment, incineration and recycling | Avoided global warming, acidification and resource depletion when AD is implemented for the management of bio-waste. | |

| Kumari et al. (2013) [8] | Biomedical waste- Autoclaving, shredding and incineration | Different categories-colour coding for waste segregation |

Cost of incineration could be minimized by segregation which reduces to 8e10% of the total waste. Step-by-step approach for establishing Biomedical waste management (BMWM) System in tertiary level hospital. |

| Ahamed et al. (2016) [31] | Biowaste- AD | Comparison with biodiesel production | AD is favored when bio-waste has an oil content <5%. |

| Zimmermann (2017) [49] | Biomedical waste- Microwave | The waste should be preferably inactivated either directly at the place where it is generated, or biohazardous waste should be transported only in closed systems. | Microwave technologies allow a validated inactivation of biohazardous materials. |

| McPherson et al. (2019) [50] |

Biomedical waste Disposable (DSC) to reusable sharps containers (RSC); Reprocessing of RSC; Biological DSC (autoclaving); Chemo/pharma DSC (incineration); Water supply; Wastewater; Heated water. Recycling of RSC parts; landfilled DSC polymer (post autoclaving); landfilled DSC ash (post incineration); landfilled end-of-life RSC. |

Using a ``cradle to grave” life cycle GHG tool the annual GHG emissions of CO2, CH4 and N2O expressed in metric tons of carbon dioxide equivalents (MTCO2eq) for each container system was calculated. |

Converting to RSC, a large University Health system reduced its annual GHG by 162.4 MTCO2eq. Annually it eliminated 50.2 tons of plastic DSC and 8.1 tons of cardboard from the sharps waste stream. Of the plastic eliminated, 31.8 tones were diverted from landfill and 18.4 from incineration. |

| Khan et al. (2019) [51] |

Biomedical waste-Autoclaving/microwave treatment. Incineration of human/animal body tissue or treated by pyrolysis or autoclaved and landfilled. Unused hazardous pharmaceuticals and their containers should be returned to the manufacturer |

Waste reduction strategies and segregation were applied. Brief training sessions by doctors to staff members and waste handler to educate them about the importance of healthcare waste management. |

Prion-infected sharps must be incinerated under high pressure after a chemical treatment or treated by pyrolysis Facilities in Asian countries extensively lack proper waste segregation, collection, safe storage, transportation, and disposal. Landfilling is often confused with open dumping, causing environmental damage. Outdated incineration plants need to be replaced with autoclaving, steam sterilisation, and comparatively reasonable new practice of pyrolysis to avoid the emission of toxic gases. |

| Tunesi et al. (2016) [52] | Healthcare waste-Recycling and segregation | The sampling methodology adopted the weighing of wastes by type of group and subgroup for seven consecutive days. | Non-dangerous wastes represented around 93.3%, including infectious wastes with low potential risks, while dangerous was represented by high infectious risk (1.4%), chemicals (2.4%) and sharps (2.9%). |

| Ansari et al. (2019) [53] | Hospital solid waste-Incineration, landfill, microwave, steam sterilization technologies, and chemical disinfection. | Hospital solid waste generation rate (HSWGR), hospital solid waste composition (HSWC), gross domestic product (GDP) per capita, and environmental performance index (EPI). | Results showed that the highest and lowest reported HSWGR (in national average level) belonged to Ethiopia (6.03) and India (0.24) kg bed −1 day −1, respectively. |

| Wajs et al. (2019) [54] |

Medical Waste- Incineration by thermal treatment. Temperature of the flue gas is at least 850 °C for the non-infectious waste, and at least 1100°C for the waste with the infectious properties. |

The incineration plant must contain at least one auxiliary burner. The flue gas generated during the process should be removed to the atmosphere, after its purification. |

A mobile medical waste incinerator was proposed in Poland. The novelty is a waste feeder into the combustion chamber, adapted to a mobile unit. Usage of the three-stage flue gas cleaning system. |

| Zamparas et al. (2019) [55] |

Healthcare waste-Pretreatment with sodium hypochlorite substitutes. Hazardous Waste and purely infectious liquids from hospital laboratories after pre-treatment can be discharged into the drainage. |

The Analytic Hierarchy Process (AHP) methodology was applied under pair wise comparison matrices in two stages | The AHP methodology yielded good results. Model was based on #3Rs module. |

| Mohseni-Bandpei et al. (2019) [56] |

Healthcare waste-Pyrolysis Reaction temperature (300-700°C), residence time (100-190s) and waste particle size (1-3 cm). |

Health-care waste was pyrolyzed using a continuous tubular fast pyrolysis reactor. Response surface methodology (RSM) and central composite design (CCD) were applied. | The PAHs were characterized in significant concentrations in pyrolytic oil (121-29440 mg/lit) and char (223-1610 mg/kg) products. Fast pyrolysis of hazardous health-care waste, as thermal treatment method, would influence the formation and destruction of PAHs and their fraction to a different extent. |

| Li et al. (2019) [57] | Waste water involving pharmaceuticals and personal care products (PPCPs)-Ozonation, granular activated carbon adsorption and reverse osmosis | The environmental and human health impacts of the three scenarios-processes were assessed using LCIA with the TRACI 2.1 characterization method, which was developed by the U.S. Environmental Protection Agency. US Etox model was used. | Electricity consumption was the main contributor to the impact categories of acidification, global warming, ozone depletion, and smog air in scenarios. Reverse osmosis appeared to have the greatest environmental burden due to the high energy and material consumption during the treatment process. |

| Kythavone and Chaiyat (2020) [58] |

Medical waste-Incineration Three outputs from the incinerator-exhaust gas, ash and combustion heat-are generated from the burning process. Exhaust gas is sent to a treatment loop via a hot air blower and an absorber. |

Very small organic Rankine cycle (VSORC) combined with a municipal solid waste incinerator (MSWI). A life cycle assessment (LCA) of eighteen midpoint and three endpoint levels under the ReCiPe method was performed by using the SimaPro database. | The VSORC-MSWI unit can process cleaned infectious medical waste in the form of refuse-derived fuel type 3 (RDF-3). In the LCA results, all the midpoint impact categories are considerably driven using steel. |

| Di Maria et al. (2020) [33] |

Biowaste-AD Biogas upgrading was assumed to be performed by pressure swing adsorption technology (PSA). |

The following impact indicators were adopted: Global Warming (GWP at 100 years); Photochemical Ozone Formation (POF); Fresh Water Eutrophication (FWE); Mineral, fossil and renewable Resource Depletion (RD). | Increase of global warming (kg CO2 eq), freshwater eutrophication (kg Peq) and human health (DALY) of about 300%. |

| Alam and Mosharraf (2020) [59] |

Healthcare waste Recycling, open burning, composting, land filling. The functional unit is defined as to the disposal of the entire HCW (18.5 tons/day) generated in CCC. |

Internal storage (temporal), partial segregation (irregular), on-campus open burning, on-side transport, unlicensed trade, unlawful disposal, discharge to CCC dustbins, off-side transport, dumping, manual segregation (dumpsite), open burning at the dumpsite, unlicensed recycling, composting and dumping. Also, disinfection (steam autoclave sterilization), incineration with energy recovery and sanitary landfill. | Open burning and incineration of healthcare waste contributes to the global warming and human toxicity potential. Disposal of healthcare waste by dumping (landfilling) mainly contributed to the freshwater aquatic ecotoxicity and terrestrial ecotoxicity potential. |

| Saeidi-Mobarakeh et al (2020) [60] |

Hazardous medical waste (including infectious, chemical and sharp, and pathological waste types). Substantial amount of waste is disposed of directly without any previous treatment. Potential landfilling. |

The robust optimization approach employed a method of reformulation of the bi-level model into Mixed-Integer Linear Programming (MILP) formulation. After that, the obtained formulation was reduced to a single-level constrained optimization problem using the Karush-Kuhn-Tucker (KKT) conditions. |

Bi-level and robust optimization model for decision-making in the hazardous waste management context were evaluated. |

Pharmaceutical/Medical/Dental Types of Waste

Pharmaceutical/Medical Waste

Pharmaceutical packaging waste has been continuously increasing over the years due to the increase in the number of its applications in everyday life. Globally, the pharmaceutical packaging market grew from 47.8 billion USD in 2010 [61] to 71.0 billion USD in 2018 [62]. Moreover, it is projected that the pharmaceutical packaging market will reach 111.9 billion USD by 2026 following a compound annual growth rate (CAGR) of 8.75%. Waste pharmaceutical blisters (WPBs) are one of the major segments of pharmaceutical waste packaging [63, 64] and consist of an average of 80–85 wt% of plastic films and 10–20 wt % of aluminum foils [65]. They are mainly disposed of by incineration and landfilling in municipal solid waste. Incineration of plastics may cause the release of hazardous gases such as dioxins, hydrogen chloride, and nitrous oxide, with consequent environmental impacts [65–67]. That is why the sustainability of WPB recycling along with sustainability in the whole pharmaceutical industry sector has become an environmental, social, and economic concern almost everywhere [68–70].

Separation of aluminum from plastic laminates through exfoliation has also been studied using different solvents such as organic solvents, acid solutions, basic solutions, and water. The hydrometallurgical separation of aluminum from polyvinyl chloride (PVC) has been investigated by dissolving the aluminum from WPBs using hydrochloric acid and sodium hydroxide as lixiviants [65]. Zhang et al. [71] investigated the separation of aluminum–plastic laminates in Tetra Pak® using a mixed organic solvent system of benzene–ethyl alcohol–water as separation chemicals. Another separation approach for waste packaging is the application of switchable hydrophilicity solvents that are separated from the extracted product by changing their polarity, upon the addition and removal of CO2. Others applied N,N-dimethylcyclohexylamine (DMCHA) to separate polymer and aluminum layers from packaging materials [67, 72].

Further, electrohydraulic fragmentation (EHF) or high-voltage pulse crushing, or shockwave technology is an emerging liberation technique, where shockwaves are generated between electrodes using a high-voltage pulse generator, propagating waves in a liquid medium. The shockwaves pass through the solid (the target material placed in the liquid medium) spherically breaking it down into small fragments from the mechanical weak points or interface of metal and nonmetals. EHF is recently investigated for the separation of aluminum from the polymer in WPBs in order to make Al available for direct recycling at a secondary Al facility [73]. It was then reported that the investigated fractions of WPBs consisted of approximately 10–12 wt% of aluminum, with the clear majority of waste blister mass in the polymer fractions (88–90 wt%), which consisted of two overlapping layers [73].

To add more, van Leeuwen et al. [74], presented the creation of the Energy & Raw Materials Factory (ERMF) of the Dutch Water Authorities, known as the Resource Factory. Resources like cellulose, bioplastics, phosphate, alginate-like exopolymers from aerobic granular sludge (bio-ALE), and biomass can be recovered from municipal wastewater. Also, cellulose can be recycled from toilet paper. The recovered cellulose can be used in road construction, but further markets still must be developed. Bioplastics are formed using a complicated process during which volatile fatty acids (VFAs) are firstly produced and these VFAs are later fed to microbes which form the wanted building blocks for bioplastics. This can be considered as a form of up-cycling. Phosphate can be recovered as, e.g., struvite (MgNH4PO4·6H2O). In this way, phosphorus becomes available again since the recovered struvite can be applied as fertilizer. The extraction of bio-ALE from aerobic granular sludge can be considered as up-cycling since a more valuable product is produced from waste. At the end, the organic waste stream can be digested into biogas (energy). Bio-ALE is an alginate-like polymer of sugars and proteins and can be used in agriculture and horticulture, the paper industry, medical, and construction industries. Application in the Netherlands show that the concept of the ERMF is viable and adds to the creation of CE [74]. For the moment, these technologies are not adequate for full-scale use worldwide. It should finally be mentioned that the value of a resource in the CE is determined by the degree to which a recovered resource means an up-cycling of the original resource, and so far, this is not the case in these entities.

Plastic can either be “synthetic” or “biobased.” Synthetic plastics are derived from crude oil, natural gas, or coal. While biobased plastics come from renewable products such as carbohydrates, starch, vegetable fats and oils, bacteria, and other biological substances. Most of the plastic in use today is synthetic because of the ease of manufacturing methods involved in the processing of crude oil. The strength, flexibility, and light weight of traditional oil-derived plastics make them ideal materials for many applications, including packaging, medical devices, building, and transportation. Examples of synthetic plastics are the following: polyethylene terephthalate (PET), polyvinyl chloride (PVC), high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP), polystyrene (PS), and other plastics including acrylic, polycarbonates, polylactic acid (PLA), fibers, and nylon. Most produced synthetic plastics are single-use plastics, which, coupled with a throw-away culture, leads to the accumulation of plastic waste and pollution, as well as the loss of valuable resources. The growing demand for limited oil reserves is driving a need for newer plastics from renewable resources such as waste biomass or animal waste products from the industry. Narancic and O’Connor [75] discussed the advances and possibilities in the biotransformation and biodegradation of oil-based plastics. They reviewed biobased and biodegradable polymers and highlighted the importance of end-of-life management of biodegradables. Biobased polymers (bioplastics) are partly or completely made of biomass-derived raw materials. However, the biobased origin does not reflect the opinion that biobased plastic is also biodegradable. One hundred percent biobased polyethylene (bio-PE) and biobased polyethylene terephthalate (bio-PET) are not fully biodegradable [76, 77]. Biodegradable plastics such as thermoplastic starch (TPS), PLA, and polyhydroxyalkanoate (PHA) can be derived from renewable resources and are thus biobased and biodegradable plastics. However, there are also other biodegradables derived from fossil carbon, e.g., polycaprolactone (PCL) and polybutylene adipate terephthalate (PBAT) [77].

Chen and Tsai [78] evaluated the operational problems and risks of BMW by means of a failure mode and effects analysis (FMEA). In this case, the BMW life cycle was divided into seven processes: production, classification, packaging, sterilization, weighing, storage, and transportation. Twenty main failure modes were identified in these phases and risks were assessed based on their risk priority numbers. The highest proportion of the risk priority number score (27.7%) was due to failure modes in the production phase. The highest risk priority number score in the packaging phase (high severity rating) was attributed to the failure mode “sharp articles not placed in solid containers.” The sterilization process had the lowest priority risk number in the treatment of infectious and non-infectious BMW and failure modes in the sterilization phase were mainly attributed to human factors (operators).

Additionally, in the Republic of Korea, the economic growth, environmental protection, science technology, art, social justice, and mutual voluntarism were applied to medical waste management [79]. Four systems were evaluated: incineration, incineration with heat recovery, steam sterilization, and microwave disinfection. Results showed that incineration with heat recovery is the best solution for BMW. However, when heat recovery is impossible, incineration without heat recovery becomes the next best alternative. That is the reason that 95% of BMW within the Republic of Korea is currently treated by both incineration and incineration with heat recovery.

In Pakistan, a life cycle assessment (LCA) was applied for the estimation of different impacts of current and alternative hospital solid waste (HSW) treatment practices [80]. Two of the scenarios used, referred either to incineration or direct landfilling of HSW. The third scenario included the use of pyrolysis and chemical disinfection of waste derived from both public and private hospitals. It was interesting to report that public hospitals produced a larger amount of HSW (74%) compared to private ones (24%). The researchers reported that poor regulations and absence of clear obligations for the collection, disposal, and management of waste are the main obstacles in order to implement good practices. The current established practices of the first two scenarios turned out to be the worst for all aspects such as human toxicity, freshwater eco-toxicity, marine aquatic eco-toxicity, terrestrial eco-toxicity, acidification potential, climate change, eutrophication, and photochemical oxidation. In particular, the largest impact of all was recorded for human toxicity generated by incineration as mentioned before. The third scenario (alternative up-to-date practices) would generate lower impacts. It is important to mention that the highest value was recorded for marine aquatic eco-toxicity in relation to pyrolysis. It was then suggested that applying the third scenario, it would be possible to recover plastics, paper, and sharps. Moreover, they concluded that energy could be recovered from the pyrolysis process.

From the above, it seems that the establishment of rules to manage HSW and healthcare waste (HCW), which include waste from all private and public health sectors and not only in a solid form, is a great challenge. Regulatory agencies must ensure the safety of waste management alternatives for two very different profiles of generators: (a) hospitals, and (b) small sectors, such as clinics, small private offices, and pharmacies for two different profiles of HCW generators. Soares et al. [81] evaluated three management scenarios for small sector HCW generators. Each scenario consisted of a disinfection technique which included (a) microwave, (b) autoclave, and (c) lime. The disinfection technique was followed by landfilling and transportation was also included. Using an LCA and cost analysis, the decision-making tools aimed to determine the technique with the best environmental performance. This consisted of evaluating the eco-efficiency of each scenario. Based on the LCA, microwaving had the lowest environmental impact (12.64 Pt) followed by autoclaving (48.46 Pt). The cost analyses indicated values of US$ 0.12 kg−1 for the waste treated with microwaves. As a result of this study, the microwave disinfection presented the best eco-efficiency performance among those studied.

Additionally, Sanchez et al. [82] assessed the environmental and economic impacts of reusable and disposable blood pressure cuffs. Out-patient clinic and ambulatory procedure rooms and 5-day in-patient regular ward and intensive care unit (ICU) healthcare encounters were used. Environmental modeling using LCA was employed to estimate greenhouse gas (GHG) emissions and other environmental impacts. Cuff, cleaning, and packaging materials were identified and weighed directly. Both per-encounter and per-day low-level disinfection scenarios were performed. Life cycle costs were determined with hospital data, including procurement, labor (time-motion observations), and waste disposal. It was found out that for all use and cleaning scenarios, the reusable cuff was environmentally preferable in terms of GHG emissions and other impact categories and in some cases by a factor of 40. Disposable cuffs are slightly lower cost in the in-patient setting where reusable BP cuffs are shared among patients and therefore require frequent cleaning. However, reusable cuffs are also more economical in the in-patient settings when patients have dedicated personal equipment (i.e., stays with them during their entire healthcare encounter).

Another issue of plastic pollution is single-use plastics for food beverages in hospitals that have attracted much attention in terms of elimination and mitigation measures in the health sector. Leissner and Ryan-Fogarty [83] examined single-use food packaging plastic waste in Irish maternity hospital settings, through a case study of ready-to-use infant formula bottles. A quantitative and qualitative assessment of single-use plastics arising from infant feeding bottles was presented. Quantitative examination revealed a high variability in materials used for bottles, teats, and associated packaging, thus creating difficulties in standardizing labeling and identifying appropriate waste treatment options. Quantitative calculations revealed the extent of plastic waste generated by this single-use product. Possible mitigation options included demand reduction for single-use bottles in the first place, alternative solutions to eliminate single-use bottles, opportunities for manufacturers to address product design, and impetus for policy makers to act on coherent labeling systems for materials and improved overall waste management.

To add more, a government study in the UK confirmed medical waste containers are among the top 20 items that account for more than 70% of the supply chain footprint. To reduce the footprint, it was suggested that manufacturers should report footprints of their products, reductions in quantity purchased, and sourcing of low carbon alternatives [84].

Overall, nο specific guidelines are published for recycling and disposal of BMW in public health, although the need for reduction, reuse, and recycle of these wastes is discussed. In general, it seems there is a certain level of confusion at hospital and household sectors as to the best waste management method. The need for targeted collaborative research utilizing sectoral best practice, waste hierarchy, and CE principles is prioritized.

Dental Waste

Composition of Dental Waste

Dental waste (DW) consists of different categories of items and materials to dispose (Figure S3). Basically, DW consists of paper, plastics, and cardboard that can be collected and disposed of with municipal solid waste that contains domestic-type, general waste [17, 85, 86], or recycled materials if cleaned. Latex and nitrile gloves, sharps with visible traces of blood or other human body fluids, and discarded dental materials or equipment that have been exposed to blood and its derivatives [17, 87, 88] are considered infectious wastes. Infectious waste is classified as hazardous BMW as mentioned before [86, 89–91]. Blood-soaked/dripping gauzes are also BMW and part of DW. They should be enclosed in a yellow biomedical waste bag covered with a double bag, labeled with a biohazard symbol, and refrigerated onsite for more than 4 days [92]. Dental practices produce also certain amounts of metals and chemical compounds with health hazards to people and the environment. Dental amalgam, fixer solutions, and chemical disinfectants [93, 94] are the common sources of such hazardous waste at dental clinics. Dental amalgam is a solid restorative material used in dental restorations for almost 200 years [95]. Amalgam consists of mercury and silver for more than 70% w/w and because of this, it is regulated as a hazardous waste. These metals can accumulate in the food chain and impose adverse health risks [96]. In January 2013, in Japan, delegates from over 140 countries after 3 years of negotiations finally signed the Minamata convention on Mercury. This is a new multilateral environmental agreement that addresses specific human activities which are contributing to widespread mercury pollution [97]. The treaty aimed to curb the significant health and environmental impacts of mercury pollution and included provisions addressing mining, export and import, storage, and waste management of products containing mercury. Importantly, a provision heavily negotiated in the treaty, addressed the use of dental fillings using mercury amalgam. Interesting to be reported is the directive 146163/12, which suggests that “dangerous chemical residues and waste with high content of mercury or cadmium should be placed separately into special resistant waterproof containers. Every container should be noticeably labeled according to content and different dangerous chemical waste should never be blended. Broken mercury column pressure indicators, impaired lead chest sand, damaged medical equipment should be all collected separately according to manufacturer’s directions.” The Hellenic Dental Association also highlights the fact that the waste of dental amalgam into the drainage or together with the domestic waste is an unacceptable and irresponsible action that puts the public health in danger [95].

Other hazardous waste streams typically found in dental practices are fixer and developer solutions from X-ray processing units. Wastes from conventional radiography can be broadly categorized as solid wastes and effluents. The solid waste components associated with conventional radiography are the film box made of cardboard, vinyl wrap, black paper, lead foil, film, end boards, used lead aprons, lead boxes, and packaging components of processing solutions [92, 98]. The liquid waste products that are discharged into a body of water and are associated with radiography, consist of unused/used developer solution, used fixer solution, wash water, and developer tank cleaning solutions. Wastes having a silver concentration of 5.0 parts per million (ppm) or more are considered hazardous due to their toxicity content. Wastes that typically contain silver in concentrations greater than 5 ppm include (a) fixer (a solution normally used for the processing of dental radiographs), (b) rinse waters following fixer baths, and (c) solutions from cleaning developer tanks [99]. Silver is another heavy metal that can enter the water system via improper disposal of dental office waste. Of course, dental offices generate a very low amount of silver waste relative to other photographic processing facilities. According to published data, a batch-replenished processing of 450 size 2 dental films and eight 35-mm film strips, each 250 mm long, yields 830 mL of used fixer solution with a silver concentration of 10.90 g/L. Silver concentrations in used fixer solutions generally range from 8 to 12 g/L [88]. An additional by-product of traditional radiography is the lead shields contained in each film packet. Although the lead shields themselves are relatively small, the cumulative waste produced can be measurable. Reduction of lead waste could be evaluated by the replacement of the procedure with digital radiography which is in favor of use the past 10 years.

Except of the previously mentioned metals, dental study molds contain gypsum which, when landfilled with biodegradable waste, can produce hydrogen sulfide (H2S) gas. Hydrogen sulfide gas is highly toxic and malodorous. Also, gypsum has been banned from normal landfilling processes (containing biodegradable waste) and must be diverted to a separate cell for high sulfate waste [100].

To add further, various impression materials containing polyvinysiloxane and polyethers are of great concern, because they are extremely stable, and the disintegration time is extremely long exceeding up to 20 years. Unfortunately, their future substitutes by means of 3D printing materials produce large amounts of breath hazardous emissions, requiring special infrastructure in order to minimize the volatile compounds emitted indoors, during their preparation. It is reported that more than one million kilograms of polyvinyl siloxane is used per year for dental purposes and more than 1.7 million liters of sodium alginate is used for relevant purposes in the EU [101].

Finally, there are other chemicals, disinfectants, and sterilizing agents in the dental setting needed to be discussed here. It is reported that halogenated sterilants have a detrimental effect on environment while ignitable sterilants should not be poured down the drain as they have potency to explode. HCHO sterilants should also not be disposed down a drain. Pouring sterilants into a septic system, may significantly disrupt the bacteria which normally breakdown wastes [102, 103].

Disinfectants are also widely used in healthcare settings to prevent cross contamination, outbreak of diseases, and hospital-acquired infections. Yet, the biocidal active substances that are so effective at disinfecting products, surfaces, and skin also pose a variety of potential hazards to human health and the environment. Recent studies indicate that biocidal active substances pose potential occupational health hazards and environmental threats and can even contribute to the spread of antimicrobial resistance (AMR) which is a global threat. The most reported occupational hazards related to the use of disinfectants are acute illnesses, respiratory issues and chronic obstructive pulmonary disease (COPD), skin problems, eye irritation, migraine, or other neurologic symptoms [104, 105]. Some disinfectant ingredients are also allergens and have been identified as CMR (carcinogenic, mutagenic, and repro-toxic) [106] or endocrine disrupting [100, 107]. In terms of environmental impact, certain disinfectants have adverse effects on the aquatic systems due to high aquatic toxicity and/or low biodegradability [108]. Substituting these pollutants in the healthcare sector is therefore important to reduce the sector’s environmental burden on sewage treatment plants and surface waters [109].

Finally, there are metallic or plastic cutting dental burs that can be reused or used once and then disposed. A comparative LCA was carried out by Unger and Landis [110] to evaluate the disparities in environmental impacts of such disposable and reusable dental burs. The functional unit was defined as one reusable dental bur, where the maximum instances reused was 30 (or in the case of a disposable, the equivalent functional unit would be 30 disposable dental burs). Reusable burs had 40% less of an environmental impact than burs used on a disposable basis when ultrasonic and autoclave were loaded optimally. When these treatments were loaded to approximately two-third capacity, four environmental impact categories (ozone depletion, smog, respiratory effects, eco-toxicity) favored reusable burs and four impact categories (acidification, eutrophication, carcinogenics, and non-carcinogenics) the environmentally favored disposables. As reported elsewhere, single-use products are not less expensive and do not necessarily benefit the environment from the waste management perspectives [110].

Quantity of Dental Waste

Suitable management options can be achieved by the identification of the quantity and composition of dental waste [111]. Hence, many studies on dental waste have been reported in different countries [112–115]. Most of them have concentrated on waste composition. Kizlary et al. [85] reported that dental waste consisted of approx. 94.7% infectious waste, 2.0% non-infectious waste, and 3.3% domestic-type waste by weight. Ozbek and Sanin [112] also reported on dental solid waste (rubber gloves and paper) in eight clinics of a dental school. Eighty percent of total dental waste is infectious waste (including blood-contaminated paper towels, saliva-contaminated paper towels, saliva-contaminated cotton, extracted teeth (some of them having restorations with materials such as the dental amalgam or composite resins materials), blood-contaminated gauze, inseparable components, nylon and latex gloves, tongue blades, saliva ejector, and blood-contaminated cotton). Koolivand et al. [116] described that the domestic, potentially infectious, toxic, and chemical and pharmaceutical wastes constituted 35.46, 34.24, 11.83, and 5.56% of total waste, respectively. In a province of Greece, it was also reported a mean daily production in a private unit of 30.4 ± 48.7 g/day/unit for domestic, for the potentially infectious 336.9 ± 264.5 g/day/unit, and for the toxic 13.4 ± 13.7 g/day/unit [17].

Regarding the real quantity of waste, Nabizadeh et al. [111] reported that production per capita of dental waste in general and specialist dentist offices in Iran were 48.72 and 65.87 g/day/patient, respectively. It seems that the generation rate of dental waste possibly depends on cultural, economic, national legislative, and learned dental procedures. Also, the variety of dental materials used is an important factor for the difference in the quantity, quality and rhythm of waste production. Comparing the previous mentioned results in Iran, with other countries such as Greece, it should be mentioned that there are differences as follows: (a) production per capita of 51.2 ± 19.1 g/day/person for the dentists trained in Greece, (b) 64.0±21.7 g/day/person for those trained in Turkey, and (c) 54.3±46.8 g/day/person for those trained in other countries [17].

Management Aspects of Dental Waste

Generally, there is no effective activity for waste minimization, separation, reuse, and recycling in dental settings worldwide. In Iran [116], the management of sharps, potentially infectious, and other hazardous dental wastes was not carried out properly, and these items were collected and disposed along with domestic waste. These findings agreed well with other studies where dental waste of 35.7% of dental centers is disposed into municipal solid waste without segregation and disinfection [114]. In Brazil, it was also reported that the waste management activities were confirmed as poor and unsuitable and far from the philosophy of CE [114].

According to WHO and CE regulations, all health units should consider ways of waste management [117]. In this road, a larger healthcare facility should aim to establish a formal waste management plan. This plan should contain combined knowledge and decisions for all involved in the production, handling and treatment of wastes. A senior person at a healthcare facility should be chosen and made responsible for preparing the plan, collecting ideas from others, and, once agreed, promoting the way healthcare waste should be managed to medical and ancillary staff. At a smaller health center, the local plan would be a shorter description of the waste management arrangements that should be put in place in each medical area, as well as identifying who is responsible for good practices in each department, where the waste will go, and how it should be disposed of after it has been removed by a cleaner or porter. As such, for example, the Dental School, National and Kapodistrian University of Athens, which is a public sector, has an organized infection control committee consisted of four (4) academic persons which collaborates with auxiliary personnel (5 university employees) for the collection and disposal of the DW of the school. They come in terms with the local authorities and the recycling company for the disposal of the hazardous waste. Finally, they guarantee the sanitary chain within the dental school. In an early article of Tzoutzas et al. [118], it is mentioned that dental clinics of the Dental School of the National and Kapodistrian University of Athens produced daily large quantities of solid and liquid wastes. Until 2003, the typical practice performed by the dental personnel, i.e., dentists, dental chairside assistants, and the janitors was to dump most of dental solid wastes into household disposal cans and landfills, without any separation, sterilization, or even disinfection process. Used sharps (needles, scalpels, and burs) separated and stored in labeled yellow plastic boxes and instrument were also deposited in the municipal disposal areas. The law proposed a mandatory management scheme, describing the appropriate mode for collecting and handling the hazardous and infected medical wastes, commissioning either incineration or heat disinfection (sterilization) system. This law has been followed for the past 5 years at the Dental School and a university contract is in issue with a relevant disposal company.

In the after COVID-19 era, the necessity of such committees in all private and public health units nationwide and worldwide will excel. There should be clear delineation of responsibilities and funding that takes place chiefly at the planning stage. Planning should cover six objectives [119]: (1) develop the legal and regulatory framework for healthcare waste management, (2) rationalize the waste management practices within the healthcare facility, (3) develop specific financial investment and operational resources dedicated to waste management, (4) launch capacity building and training measures, (5) set up a monitoring plan, and (6) reduce the pollution associated with waste management. Climate change is a significant global health threat requiring concerted action to reduce greenhouse gas emissions. Duane et al. [120] provided the first systematic attempt to quantify the carbon emissions of a national dental service. Carbon accounting combined a top–down approach using input–output analysis for indirect emissions (procurement) and a process analysis (bottom–up) approach for direct emissions (building energy, travel, waste, and water). Energy and water consumption were based on meter readings, waste-related emissions from collection contracts and travel from staff and patient questionnaires. Dental companies were approached for carbon footprint data on their products. The carbon footprint for the service was 1798.9 tones CO2 eq per annum. Travel was the greatest source (45.1%), followed by procurement (35.9%) and building energy (18.3%). Perhaps counter-intuitively older clinics had lower footprints than newer clinics as they are less energy intensive. Extrapolating the data suggests that Scotland’s NHS dental service annually generates 0.16 mega tones (Mt) CO2 eq (4%) of the total Scottish NHS carbon footprint.

To mention another case, in Greece for example, in the pre-COVID-19 era, the Dental School of Athens, produced daily approximately 700 L of waste. This waste was either hazardous or infected solid waste, containing paper, plastic, latex, various metals, glass, and remnants of dental materials. Heat sterilization was the most cost-effective method for handling infected solid waste, but it was necessary to create protocols for the safe collecting, separating, and sealing in proper colored bags in order to prevent human contact with them. So the Committee for Infectious Control of the School came up a with a strict protocol for the disposal of a large variety of dental materials used, such as composite and acrylic polymerics, metals, latex, nitrile, and vinyl as well as packaging materials such as paper, glass, various plastics, polystyrene, polypropylene, and cellulose (Figure S4). Before the COVID-19 pandemic, in only one academic semester, almost 100 packaging (boxes 20 × 20 × 30 cm with dental packaging materials) were collected, of a gross weight 151.1 kg and net weight of 129.32 kg (Figure S5). The materials collected were mainly polypropylene, polystyrene, polyethylene, and paper. After COVID-19 national legislation guidelines, all COVID-19-related waste should be treated, preferably onsite and then safely disposed. Due to the donning and undonning requirements related to the COVID-19 and the additional materials used for semi-critical surfaces covering, the quantity of daily produced disposals has been tremendously increased (almost tripled). For that reason, new, special construction, color coded, and relatively labeled large disposal bins of 120 L capacity have been additionally installed inside every clinic for the easier collection and disposal of the DW of the School.

From the economic part of the equation, during the COVID-19 pandemic challenge, professionals worldwide are doubted to fulfill the prerequisites for amalgam separators, ventilators, and sanitary options for addressing the pandemic. These guidelines are estimated to almost triple the disposal waste costs. Unfortunately, if no cheap bio-eco-recyclable materials are used in the dental field soon, a lot of dental units across Europe and globally will not be able to be in legal eco-function.

Overall, the lack of comprehensive data on quantities of dental waste reduces the ability to effectively manage environmental emissions. Consideration needs to be given also to the impact of patient travel, staff travel, and new clinic construction/renovation on the carbon footprint. It is at least a promising step nowadays that medical suppliers are encouraged to provide LCA for dental products in order to imply CE regulations.

Legislation on Dental Waste

All clinical waste handling and disposal procedures must comply with certain regulations. In the UK, these regulations are the Environmental Protection Act 1990 (including the Duty of Care Regulations), the Controlled Waste Regulations 2012, the Hazardous Waste Directive 2011, and the Carriage of Dangerous Goods Regulations. In the EU, the Communication of 28 January 2005 from the Commission to the European Parliament and the Council entitled “Community Strategy Concerning Mercury,” as reviewed on 7 December 2010 (“the Strategy”), aimed at minimizing and, where feasible, ultimately eliminating global anthropogenic mercury releases to air, water, and land [19]. In the past 10 years, significant progress has been achieved in the EU in the field of mercury management following the adoption of the Strategy and of a wide range of measures concerning mercury emissions, supply, demand and use, and the management of mercury surplus and stocks.

The EU Regulation 2017/852 reports six (6) main points: (1) Since 1 January 2019, dental amalgam shall only be used in pre-dosed encapsulated form. The use of mercury in bulk form by dental practitioners shall be prohibited. (2) Since 1 July 2018, dental amalgam is not to be used for dental treatment of deciduous teeth of children under 15 years and of pregnant or breastfeeding women, except when deemed strictly necessary by the dental practitioner based on the specific medical needs of the patient. (3) Since 1 July 2019, each Member State must have set out a national plan concerning the measures it intends to implement to phase down the use of dental amalgam. Member States must have already organized their national plans publicly available on the internet and shall have them transmitted to the Commission within 1 month of their adoption. (4) Since 1 January 2019, operators of dental facilities in which dental amalgam is used or dental amalgam fillings or teeth containing such fillings are removed shall ensure that their facilities are equipped with amalgam separators for the retention and collection of amalgam particles, including those contained in used water. Such operators shall ensure that (a) amalgam separators are put into service (since 1 January 2018) and provide a retention level of at least 95% of amalgam particles and (b) from 1 January 2021, all amalgam separators in use should provide the retention level specified in point (a). Amalgam separators shall be maintained in accordance with the manufacturer’s instructions to ensure the highest practicable level of retention. (5) Capsules and amalgam separators complying with European standards, or with other national or international standards that provide an equivalent level of quality and retention, shall be presumed to satisfy the requirements set out in points (1) and (4). (6) Dental practitioners shall ensure that their amalgam waste, including amalgam residues, particles and fillings, and teeth, or parts thereof, contaminated by dental amalgam, is handled and collected by an authorized waste management establishment or undertaking.

In the USA, EPA [121] promulgated pretreatment standards in 2017 to reduce discharges of mercury from dental offices into publicly owned treatment works. The Dental Office Category regulation is codified at 40 CFR Part 441. EPA expects that compliance with this final rule will annually reduce the discharge of mercury by 5.1 tons as well as 5.3 tons of other metals found in DW [121].

In Greece, the DW guidelines have been handed to dentists by the Hellenic Dental Association [122], which under EU legislation is forcing each dental unit all over the country to have a contract with a local disposal company. Almost 13 years ago, a great number of dentists did not seem to incorporate the law [123], something that has not change radically nowadays.

Discussion

The European Council has held since 2014, a public orientation debate, on a legislative proposal amending six directives addressing the management of various types of waste (11598/14). The aim of this proposal is to improve waste management in the European Union, with a view to protect the quality of the environment and ensuring prudent and rational use of natural resources. More specifically, it reviews the legally binding targets contained in Directives 2008/98/EC on Waste, 94/62/EC on Packaging and Packaging Waste, and 1999/31/EC on the Landfill of Waste, with a view to improving resource efficiency in line with the Resource Efficiency Roadmap (14632/11) and the 7th Environment Action Programme [24]. Other proposed measures include harmonization of definitions and calculation methods, simplification of reporting requirements, setting minimum operating conditions for Extended Producer Responsibility, and the setting up of an early-warning system to monitor target compliance. The proposal forms part of the Commission’s Circular Economy Package (presented in July 2014), which also comprises a Communication on “Towards a Circular Economy: a Zero Waste Programme for Europe” (11592/1/14 REV 1) and a Communication on “Resource Efficiency Opportunities in the Building Sector” (11609/14). The Ministers’ discussion was based on three questions prepared by the Presidency (14060/1/14 REV 1) and last December 2017, a new Directive on Waste was under construction [24]. There it was mentioned that the establishments and undertakings referred to in Article 23(1), the producers of hazardous waste, and the establishments and undertakings which collect or transport hazardous waste on a professional basis, or act as dealers and brokers of hazardous waste, should keep a chronological record of (a) the quantity, nature, and origin of that waste and the quantity of products and materials resulting from preparing for reuse, recycling, or other recovery operations and (b) where relevant, the destination, frequency of collection, mode of transport, and treatment method foreseen in respect of the waste [24]. Recently, in December 2019, the European Commission published a Roadmap based on the scheduled Circular Economy Policy of the EU, aiming to speed up the transition, from the linear economy to a sustainable products policy, since EU market for secondary raw materials remains to be further developed [6].

The Dental profession in Europe, as expressed by the Council of European Dentists (CED), states that a clarification is needed describing who should make the data available to the competent authorities through the electronic registry or registries—the establishments and undertakings which collect or transport hazardous waste on a professional basis, or act as dealers and brokers of hazardous waste. Generally, it seems that the dental waste management in modern dental private or public settings is the new entity of educational and administrative management that will flourish the next decade asking from professionals to improvise or take advantage of extra funding from companies or national dental associations.

The future dental waste philosophy would be the three R’s philosophy (reduce, reuse, recycle). So, from this day on, effective measures must be applied, such as reducing, reusing, and recycling (3Rs) or recovering energy mainly from plastic wastes from dental packaging.

To ensure the future proper management of solid waste, Thailand has established the National 3R Strategy and the National Master Plan for Waste Management (2016–2021). Furthermore, Thailand also launched a “Plastic Debris Management Plan 2017–2021,” which comprises promotion and introduction of eco-packaging design and eco-friendly plastic substitution, development of the material flow for plastic containers and packaging inventory, implementation of the 3Rs strategy for plastic debris management, and the promotion of education for relevant stakeholders in the field of plastics and its alternative materials [124]. Moreover, more effective plastic waste management can be created by implementation of legislation or revision of the laws to improve the efficiency and reduce the amount of plastic waste, such as imposing plastic bag fees, strengthening the 3Rs measures, and encouraging the implementation of CE in plastic value chains.

In Japan, there are several laws/legislations for plastic waste management. The Packaging Waste Management Law, which was enforced in 1997, established a shared consumer responsibility approach for separating waste for collection, municipalities responsible for its collection, and industries responsible for recycling the collected materials. The Containers and Packaging Recycling Law in 2006, mentioned objectives such as the discharge of waste by consumers, separate collection of containers and packaging by municipalities, and recycling of containers and packaging by businesses that manufacture and use them. This resulted in the effective use of 62% of plastic waste as resources [125].

Waste packaging that accounts for 33% of garbage is obvious that needs to be reduced. Many manufacturers are already cutting down on the amount of packaging for their products or making more of the packaging reusable or recyclable.

In this environmentally friendly way, many high-tech innovations in dentistry help reduce waste, like oral cancer diagnostics that create less waste than oral cancer rinse screenings. Further actions could involve purchasing often-used items in bulk (like prophy paste, gloves, masks, cotton squares, alcohol, antiseptics), requesting supply companies to combine orders in a way to cut down on shipping boxes, setting printers for double-sided printing, implementing digital technology for imaging, digital impressions, cancer screening, charting, marketing, branding, and using steam sterilization eliminating the use of hazardous chemicals. Also, by reusing dental equipment and materials, the need to transport it “away,” the need to store it as trash, and the need to create a new item are eliminated. Single-use infection control items are the biggest source of trash in the dental office, sending billions of pieces of paper and plastic trash into the environment every year [126]. Paper and plastic pouches for sterilization, plastic chair barriers, plastic tray covers, and plastic head rest covers are tossed by the hundreds every week in the typical dental practice. Much of this plastic waste can be reduced by switching to cloth infection control and sterilization, which has been used in high-end hospital operating rooms for decades. By switching to reusable, a typical single-dentist practice can divert as much as 4,680 paper and plastic autoclave bags annually [127]. By transitioning from the two-ply paper, one-ply plastic patient bibs to reusable ones, a practice can divert as much as 40,800 pieces of paper and 20,400 pieces of plastic from landfill each year [3, 4, 127]. Other plastic, single-use items can be replaced with stainless-steel ones that can be sterilized and reused for years, like impression trays. So it could be suggested turning to cloth sterilization bags and patient barriers, wearing cloth lab coats instead of paper ones, using a reusable face shield, reusing lab and shipping boxes, switching to stainless steel impression trays, suction tips, providing glass or ceramic “rinse & swish” cups, and using washable dishes and cutlery in the staff break room. Finally, recycling should be carried out more sufficiently in dental waste generators. Eighty-five percent of the water bottles only in the USA are not recycled every year, and most of the dental settings worldwide due to the time consumed do not recycle the paper and plastic packages of dental materials, a lot of waste would have been eliminated. Recycling in the dental units would consist of participating in an instrument recycling program, using a sharps disposal service that recycles them into building materials, recycling copy paper and choosing a medical shredding service that recycles the shredded paper, and providing recycling bins for staff break room waste. A good idea of recycling could be the use of aluminum foil as barriers instead of plastic. Aluminum foil is 100% recyclable. Recycling aluminum saves about 95% of the energy that would be needed to make new aluminum [127].

Alternatively, to the previous suggestions, dentistry could benefit extensively if new biodegradable plastic-like products will evolve. Compostable/biodegradable bags have been developed and might be an option for barriers in the dental office. There are several alternatives to the regular plastic bag used as barriers. Compostable bags or toothbrushes are made from corn, potato, and soy starches which can break down in a natural environment in a matter of weeks. Other plastic bags are made with chemical additives that allow the bag to break down into smaller pieces faster with the use of UV light exposure and high temperatures. There are also new forms of textiles for medical/dental scrubs that can be autoclaved and reused in order to minimize the volume of wastes for both private and public dental sectors [22].