Abstract

Multifilamentary Bi2Sr2CaCu2Ox (Bi-2212) wire made by the powder-in-tube technique is the only high temperature superconductor made in the round shape preferred by magnet builders. The critical current density (JC) of Bi-2212 round wire was improved significantly by the development of overpressure heat treatment in the past few years. Bi-2212 wire is commercially available in multiple architectures and kilometer-long pieces and a very promising conductor for very high field NMR and accelerator magnets. We studied the effects of precursor powder and heat treatment conditions on the superconducting properties and microstructure of recent Bi-2212 wires. Short samples of recent wire with optimized overpressure processing showed JC(4.2 K, 15 T) = 6640 A/mm2 and JC(4.2 K, 30 T) = 4670 A/mm2, which correspond to engineering critical current densities JE(4.2 K, 15 T) = 1320 A/mm2 and JE(4.2 K, 30 T) = 930 A/mm2.

Keywords: Superconductor, Bi-2212 wire, critical current density, superconducting magnet

I. Introduction

Bi-2212 round wire made by the powder-in-tube technique is a very promising conductor for very high field applications, such as general purpose research magnets, NMR magnets, and accelerator magnets that can reach fields beyond those achievable using Nb3Sn technology [1]–[9]. A key breakthrough for Bi-2212 conductor development is the use of overpressure heat treatment (OP-HT), which greatly increased the critical current density [1], [10]. Bruker OST is producing Bi-2212 wire in multiple architectures and kilometer piece lengths [7]. Bi-2212 solenoid magnets, racetrack and canted-cosine-theta (CCT) coils are being developed [4]–[6], [11]–[14], Shen et al. have recently demonstrated racetrack coils with critical current over 8 kA made of Bi-2212 Rutherford cable that was OP-HTed under 50 bar total pressure [14]. Conductor reinforcement and conductor-in-conduit-conductor (CICC) are also being developed [15]–[16].

One of the key components for manufacturing Bi-2212 wire is the precursor powder, which affects the wire performance significantly. Nexans in Germany was the only supplier of Bi-2212 powder for the past decade but they stopped Bi-2212 powder production when they moved their operation from Co-logne to Hannover in early 2015. Since then, the US Department of Energy has been supporting two US companies, nGimat and MetaMateria to make Bi-2212 powder. As we know, no magnet is ever better than its conductor and no Bi-2212 conductor will be better than its powder. The powder quality depends on its composition, phase assemblage, particle size and distribution, tap density, and content of carbon, hydrogen, and impurity elements. Both nGimat and MetaMateria have made significant progress in manufacturing Bi-2212 powder in the past three years. Bruker OST has produced many 2 kg and 10 kg Bi-2212 billets using the powders made by nGimat and MetaMateria. Here we report on the much-improved performance of Bi-2212 wires made with recent powders.

II. Experimental Detail

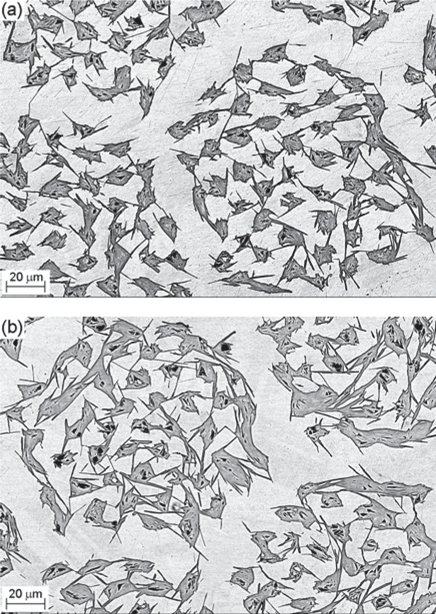

Both nGimat and MetaMateria make Bi-2212 powder with nearly the same overall composition as Nexans (Bi2.17Sr1.94Ca0.89Cu2Ox - called 521) [17], but each synthesizes it differently. MetaMateria uses chemical co-precipitation to form Bi-2212, and nGimat uses the nanospray combustion chemical vapor condensation (nCCVC) process. As we can see from Table I, the composition of nGimat LXB-52 and MetaMateria MM318 are very close to lot 87 powder from Nexans. In order to examine the particle size and phases using SEM, the powders were pressed into compacts that were sub-sequently cut and polished. SEM images of the two powders are shown in Fig. 1. A typical Bi-2212 grain size is about 1 to 2 μm for both powders, but nGimat LXB-52 contains about 3 vol% of alkaline earth cuprate (Sr, Ca)14Cu24Ox (AEC-14:24) with size up to 5 μm whereas MetaMateria MM318 has a small amount of CuO.

TABLE I.

Powder composition and Average filament size of densified wires

| Wire | Powder | Powder composition | Filament sizea (μm) |

|---|---|---|---|

| pmm170123 | nGimat LXB-52 | Bi2.10Sr1.90Ca0.86Cu2.0Ox | 11.2 |

| pmm171024 | MetaMateria MM318 | Bi2.17Sr1.95Ca0.90Cu2.03Ox | 12.8 |

| pmm151103b | Nexans lot 87 | Bi2.17Sr1.94Ca0.89Cu2.0Ox | 9.3 |

Filament diameters were calculated from optical images of cross sections of wires with densified powder (830°C/12h, 50 bar) like those shown in Fig. 2.

Wire pmm151103 was reported previously in reference 10.

Fig. 1.

SEM images of (a) nGimat powder LXB-52 and (b) MetaMateria powder MM318. The large black spots in image (a) are the alkaline earth cu-prate (Sr,Ca)14Cu 24Ox (AEC-14:24), whereas in (b) they are CuO.

Bi-2212 wires pmm170123 and pmm171024 (billet numbers) were fabricated by Bruker OST using nGimat powder LXB-52 and MetaMateria powder MM-318, respectively. The tap densities were 1.38 and 1.54 g/cm3 for nGimat powder LXB-52 and MetaMateria MM318, respectively. The Bi-2212 powder in the wire was always surrounded by pure silver but the outer sheath of the 55×18 stack was made with a Ag-Mg (0.2wt% Mg) alloy sheath. The wires were drawn into 400 m long 0.8 mm diameter piece lengths. Wire pmm170123 was made into a 17 strand Rutherford cable and used by Lawrence Berkeley National Laboratory to wind two racetrack coils that had record critical currents [14].

As shown previously [18], Bi-2212 wire is normally densified before the Bi-2212 powder melts in a standard OP-HT. To analyze the filament size and wire cross section area of densified wire, 9 cm long sections of wire, hermetically sealed on both ends, were heated at 830 °C for 12 h under 50 bar total pressure with an oxygen partial pressure (pO2) of 1 bar. The cross section area of the wire and densified powder were measured with an Olympus BX41M-LED microscope. Fig. 2 shows SEM images of the two wires after densification. The filling factor, defined as the ratio of the cross section area of Bi-2212 filaments to the total wire cross section area, for wires pmm170123 and pmm171024 after densification are 0.199 and 0.264, respectively. The filament size of wire pmm170123 (Fig. 2a) looks more uniform than that of pmm171024 (Fig. 2b). The engineering critical current density JE is defined as IC divided by the densified wire cross section area.

Fig. 2.

SEM images of the transverse cross sections of (a) wire pmm170123 (nGimat powder LXB-52) and (b) wire pmm171024 (MetaMate-ria powder MM318) after densification at 830°C/12h and 50 bar.

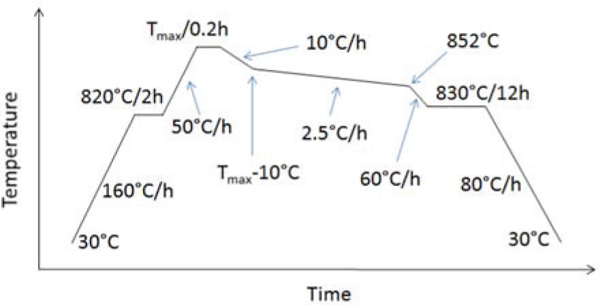

The OP-HT schedule used in this study is shown in Fig. 3, which is similar to the one reported previously [10], but Tmax was varied in the range 884 to 894 °C to optimize the heat treatment. Transverse cross-sections of fully-processed wires were dry polished using a series of SiC papers with decreasing grit sizes. Final polishing was conducted with a suspension of 50 nm alumina in ethanol using an automatic vibratory polisher (Buehler Vibromet). Microstructures were examined with a Zeiss 1540EsB scanning electron microscope (SEM).

Fig. 3.

Schematic heat treatment schedule for 50 bar OP-HT.

Critical currents of fully-processed wires were measured using the four-probe transport method with a 1 μV/cm criterion at 4.2 K in a magnetic field of up to 31.2 T applied perpendicular to the wire axis. The overall wire critical current density JE was calculated using the densified whole wire cross section. JC values reported here use the densified cross-section of the filaments after the 830°C/12h densification as the area.

Magnetization measurements were performed in an Oxford vibrating sample magnetometer (VSM) at 20 K in a swept field from −2 T to 14 T. Samples were cut to 5 mm in length and oriented with their axes orthogonal to the field direction.

III. Results

Fig. 4 shows IC(4.2 K) and n value as a function of applied field for wire pmm170123 and pmm171024. IC(4.2 K, 5 T) is 888 A for wire pmm170123 (LXB-52) and 712 A for pmm171024 (MM-318). Both Ic values of both wires are much higher than that of previous wires with the same diameter of 0.8 mm made with Nexans powder (IC(4.2 K, 5 T) of about 500 A). The n values are in the range of 25 to 30 for pmm170123 and 20 to 25 for pmm171024.

Fig. 4.

IC(4.2 K) and n values as a function of applied field for wires pmm170123 (nGimat LXB-52) and pmm171024 (MetaMateria MM318).

Fig. 5 shows JE(4.2 K) and JC(4.2 K) as a function of the applied field for wires pmm170123 and pmm171024. For comparison JE and JC data are shown for wire pmm151103 with a diameter of 1.0 mm and filling factor of 0.20 that was made with Nexans lot 87, which was the best Nexans powder lot [10]. JE values of wires pmm170123 and pmm171024 are much higher than that of wire pmm151103. JE(4.2 K, 5 T) is 1810 A/mm2 for pmm170123 and 1456 A/mm2 for pmm171024. Fig. 5 also shows JC(4.2 K, 15 T) =6640 A/mm2, JC(4.2 K, 30 T) = 4670 A/mm2, JE(4.2 K, 15 T) = 1320 A/mm2 and JE(4.2 K, 30 T) = 930 A/mm2 for pmm170123.

Fig. 5.

Comparison of wires pmm170123 (nGimat LXB-52), pmm171024 (MetaMateria MM318) and pmm151103 (Nexans lot 87). (a) JE(4.2 K) and (b) JC(4.2 K) as a function of applied field. The data of wire pmm151102 is taken from reference 10.

Fig. 6 shows SEM images of the fully-heat-treated high JC pmm171023 and pmm171024 samples. The prominent features of the microstructure of the high JC pmm170123 sample are that the filament size looks uniform after the full OP-HT and the connections between the filaments formed through Bi-2212 grains touching rather through merging in the melt. Samples of pmm171024 (MM318) showed some filaments merged together.

Fig. 6.

SEM images of the transverse cross sections of fully heat treated wires. (a) pmm170123 (nGimat LXB-52) with IC(4.2 K, 5 T) = 914 A and JC(4.2 K, 5 T) = 9530 A/mm2, and (b) pmm171024 (MetaMateria MM318) with IC(4.2 K, 5 T) = 712 A and JC(4.2 K, 5 T) = 5470 A/mm2.

IV. Discussion

The wires made with recent nGimat and MetaMateria pow-ders showed much improved performance than Nexans powder even through the compositions of the new powders are very close to Nexans’ standard composition 521. As shown in Fig. 2, a typical characteristic of nGimat powder LXB-52 is that it contains about 3 vol% of AEC-14:24 and the particle size of the AEC-14:24 up to 5 μm. As shown in Table I, there is a slight composition difference between nGimat LXB-52 and Nexans lot 87, i.e., the Bi ratio ( Bi : Bi +Sr +Ca +Cu) of nGimat LXB-52 is lower than that of Nexans powder lot 87, 0.306 vs. 0.310. This reduced Bi ratio could result in the existence of the extra AEC-14:24 particles. A recent powder (not reported here) made by nGimat with intentionally increased Bi ratio indeed showed reduced amount of AEC-14:24 particles, but lower JC. The reduced Bi ratio in LXB-52 also means an extra amount of Sr-Ca-Cu in the powder, resulting in the formation of AEC-14:24. So far, we believe this extra amount of Sr-Ca-Cu is beneficial to the wire performance. Further analysis and testing are in progress.

The size of the AEC-14:24 particles in nGimat powder LXB-52 is about half of the Bi-2212 filament diameter (shown in Table I), which could reduce the longitudinal uniformity of the filament during the later stages of wire drawing. The large AEC particles can also cause composition inhomogeneity along the filaments. Thus, if the AEC particles are smaller and more uniformly distributed in the powder, we believe the JC performance could be further improved.

The transverse cross section microstructure of the record high JC pmm170123 sample showed more uniform filament size, compared to the microstructure shown previously [1], [10], [19]–[20] and its n values of 25 to 30 are much higher than that of other 0.8 mm wires [19]–[20]. Both the micro-structure and n value show that the filaments of pmm170123 are quite uniform longitudinally, a characteristic of better JC [21]. Fig. 7 shows the normalized JC(B) curves for the three wires and they almost overlap each other, indicating that the improved JC resulted from improved connectivity. We also measured the Kramer irreversibility field at 20 K. As shown in Fig. 8, all the three wires showed HK (20 K) of about 9.0 T, further confirming the improved performance is not a result of improved flux pinning. A more detailed JC(B) behavior analysis will be reported by Brown et al. [22].

Fig. 7.

Normalized JC(4.2 K)/JC(4.2 K, 15 T) as a function of applied field for wires pmm170123 (nGimat LXB-52), pmm171024 (MetaMateria MM318 and pmm151103 (Nexans lot 87).

Fig. 8.

Kramer function Δm1/2B1/4 measured at 20 K as a function of applied field for wires pmm170123 (nGimat LXB-52), pmm171024 (MetaMateria MM318) and pmm151103 (Nexans lot 87). The dashed lines are drawn by fitting the linear sections of the Kramer plots, and the irreversibility (HK) is defined by the linear extrapolations to the field axis.

V. Conclusion

We studied two recent Bi-2212 wires made from nGimat and MetaMateria powders. Both nGimat and MetaMateria are producing good Bi2212 powder. New record JE and JC values have been achieved with nGimat powder LXB-52, JE(4.2 K, 15 T) = 1320 A/mm2 and JC(4.2 K, 15 T) = 6640 A/mm2, values which show a 60% increase over Nexans powder.

Acknowledgment

We are grateful to discussions with A. Xu of nGimat, Y. Kim and E. S. Bosque of the NHMFL, and technical help form D. V. Abraimov, J. J. Jaroszynski, V. S. Griffin and W. L. Starch of the NHMFL.

The work is supported by the US DOE Office of High Energy Physics under grant number DE-SC0010421, by the National Institute of General Medical Sciences of the NIH under Award Number R21GM111302, and by the NHMFL, which is supported by NSF under Award Numbers DMR-1157490 and DMR-1644779, and by the State of Florida, and is amplified by the U.S. Magnet Development Program (MDP)

Contributor Information

J. Jiang, Applied Superconductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University.

G. Bradford, Applied Super-conductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University

S. I. Hossain, Applied Super-conductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University

M. Brown, Applied Super-conductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University

J. Cooper, Applied Super-conductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University

E. Miller, Applied Super-conductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University

Y. Huang, Bruker OST, Carteret, NJ 07008, USA

H. Miao, Bruker OST, Carteret, NJ 07008, USA

J. A. Parrell, Bruker OST, Carteret, NJ 07008, USA

M. White, nGimat LLC, 2436 Over Dr. Lexington, KY 40511, USA

A. Hunt, nGimat LLC, 2436 Over Dr. Lexington, KY 40511, USA

S. Sengupta, MetaMateria, 870 Kaderly Dr, Columbus, OH 43228, USA

R. Revur, MetaMateria, 870 Kaderly Dr, Columbus, OH 43228, USA

T. Shen, Lawrence Berkeley National Laboratory, Berkeley, CA, 94720, USA.

F. Kametani, Applied Super-conductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University

U. P. Trociewitz, Applied Super-conductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University

E. E. Hellstrom, Applied Super-conductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University.

D. C. Larbalestier, Applied Super-conductivity Center, National High Magnetic Laboratory, Tallahassee, FL 32310, USA and also with Florida State University.

References

- [1].Larbalestier DC, Jiang J, Trociewitz UP, Kametani F, Scheuer-lein C, Dalban-Canassy M, Matras M, Chen P, Craig NC, Lee PJ, and Hellstrom EE, “Isotropic round-wire multifilament cuprate super-conductor for generation of magnetic fields above 30 T,” Nat. Mater, vol. 13, pp. 375–81, 2014. [DOI] [PubMed] [Google Scholar]

- [2].Hasegawa T, et al., “Improvement of superconducting properties of Bi-2212 round wire and primary test results of large capacity Rutherford cable,” IEEE Trans. Appl. Supercond vol. 11, pp. 3034–3037, 2001. [Google Scholar]

- [3].Weijers HW, Trociewitz UP, Marken K, Meinesz M, Miao H, and Schwartz J, “The generation of 25.05 T using a 5.11 T Bi2Sr2CaCu2Ox superconducting insert magnet,” Supercond. Sci. Technol, vol. 17, pp. 636–644, 2004. [Google Scholar]

- [4].Miao H, Marken KR, Meinesz M, Czabaj B and Hong S, “Development of Round Multifilament Bi-2212/Ag Wires for High Field Mag-net Applications,” IEEE Trans. Appl. Supercond vol. 15, pp. 2554–2557, 2005. [Google Scholar]

- [5].Godeke A, Acosta P, Cheng D, Dietderich DR, Mentink MGT, Prestemon SO, Sabbi GL, Meinesz M, Hong S, Huang Y, Miao H and Parrell J, “Wind-and-react Bi-2212 coil development for accelerator ma-gnets,” Supercond. Sci. Technol vol. 23, 034022, 2010. [Google Scholar]

- [6].Dalban-Canassy M, Myers DA, Trociewitz UP, Jiang J, Hell-strom EE, Viouchkov Y, and Larbalestier DC, “A study of the local varia-tion of the critical current in Ag-alloy clad, round wire Bi2Sr2CaCu2O8+x multi-layer solenoids,” Supercond. Sci. Technol, vol. 25, 115015, 2012. [Google Scholar]

- [7].Huang Y, Miao H, Hong S, and Parrell JA, “Bi-2212 round wire development for high field applications,” IEEE Trans. Appl. Supercond, vol. 24, no. 3, Jun, 2014, Art. no. 6400205. [Google Scholar]

- [8].Chen P, Trociewitz UP, Lu J, Bosque ES, Jiang J, Hellstrom HE, and Larbalestier DC, “Experimental Study of Potential Heat Treatment Issues of Large Bi-2212 Coils,” IEEE Trans. Appl. Supercond, vol. 27, no.4, June 2017, Art. no. 4601405. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [9].Chen P, Trociewitz UP, Davis DS, Bosque ES, Hilton DK, Kim Y, Abraimov DV, Starch WL, Jiang J, Hellstrom EE and Larbalestier DC, “Development of a persistent superconducting joint be-tween Bi-2212/Ag alloy multifilamentary round wires,” Supercond. Sci. and Technol, vol. 30, no. 2, Dec. 2017, Art. no. 025020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [10].Jiang J, Francis A, Alicea R, Matras M, Kametani F, Trociewitz UP, Hellstrom H and Larbalestier DC, “Effects of filament size on criti-cal current density in overpressure processed Bi-2212 round wire”, IEEE Trans. Appl. Supercond, vol. 27, no. 4, June 2017, Art. 6400104. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [11].Godeke A et al. , “Bi-2212 Canted-Cosine-Theta coils for high-field ac-celerator magnets,” IEEE Trans. Appl. Supercond, vol. 25, no. 3, Jun. 2015, Art. no. 4002404. [Google Scholar]

- [12].Fajardo LG, Brouwer L, Caspi S, Gourlay S, Prestemon S, and Shen T, “Designs and prospects of Bi-2212 Canted-Cosine-Theta magnets to increase the magnetic field of accelerator dipoles beyond 15 T,” vol. 28, no. 4, June 2018, Art. no. 4008305. [Google Scholar]

- [13].Zhang K, Higley H, Ye L, Gourlay S, Prestemon S, Shen T, Bosque E, English Ch., Jiang J, Kim Y, Lu J, Trociewitz U, Hell-strom E and Larbalestier D, “Tripled critical current in racetrack coils made of Bi-2212 Rutherford cables with overpressure processing and leakage control”, Supercond. Sci. Technol vol. 31, no. 10, 2018, Art. no. 105009. [Google Scholar]

- [14].Shen T et al., “Stable, predictable operation of racetrack coils made of high-temperature superconducting Bi-2212 Rutherford cable at the very high wire current density of more than 1000 A/mm2,” arXiv:1808.02864.

- [15].Otto A, “Transposed high current cables made with strong, rectangular Bi2212 superconductor wire”, The 13th European Conference on Applied Superconductivity (EUCAS 2017), Geneva, Switzerland, Sept. 2017. [Google Scholar]

- [16].Qin J, et al. , Manufacture and test of Bi-2212 Cable-in-Conduit Conductor, IEEE Trans. Appl. Supercond, vol. 27, no. 4, June 2017, Art. 4801205. [Google Scholar]

- [17].Miao H, Marken KR, Meinesz M, Czabaj B, Hong S, Rikel MO, and Bock J, “Studies of precursor composition effect on Jc in BiǦ 2212/Ag wires and tapes,” AIP Conference Proceedings vol.824, pp.673–782, April 2006. [Google Scholar]

- [18].Matras MR, Jiang J, Larbalestier DC and Hellstrom EE, “Under-standing the densification process of Bi2Sr2CaCu2Ox round wires with overpressure processing and its effect on critical current density”, to appear in Supercond. Sci. Technol vol. 29, no. 10, 2016, Art. no. 105005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [19].Jiang J, Starch WL, Hannion M, Kametani F, Trociewitz UP, Hellstrom EE and Larbalestier D C DC, “Doubled critical current density in Bi-2212 round wires by reduction of the residual bubble density,” Supercond. Sci. Technol vol. 24, 2011, Art. no. 082001 [Google Scholar]

- [20].Jiang J, Miao H, Huang Y, Hong S, Parrell JA, Scheuerlein C, Di Michiel M, Ghosh AK, Trociewitz UP, Hellstrom EE, and Larbalestier DC, “Reduction of gas bubbles and improved critical current density in Bi-2212 round wire by swaging”, IEEE Trans. Appl. Super-cond vol. 24, no. 3, Jun. 2014, Art. no. 6400205. [Google Scholar]

- [21].Warnes WH and Larbalestier DC, “Critical current distributions in superconducting composites,” Cryogenics, vol. 26, pp. 643–653, 1986. [Google Scholar]

- [22].Brown MD, Jiang J, Tarantini C, Abraimov A, Bradford G, Jaro-szynski J, Hellstrom EE, Larbalestier DC, “Prediction of the JC(B) behavior of Bi-2212 wires at high field,” Applied Superconductivity Conference, Oct. 28 - Nov. 2, 2018, Seattle, WA. Submitted to IEEE Trans. Appl. Supercond [Google Scholar]