Abstract

The COVID-19 pandemic attracts concerns globally and leads to an exponential increase in medical waste generation, and disposal of medical waste is an urgent need for preventing the epidemic spread. Emergency disposal scenarios of medical waste generated during the COVID-19 pandemic require a systematic assessment to quantify their potential environmental impacts. The environmental impacts and key factors of three movable disposal scenarios (i.e. incineration disposal vehicle, movable steam and microwave sterilization equipment both followed by co-incineration with municipal solid waste) were quantified via life cycle assessment approach. Furthermore, the environmental impacts of three movable disposal and two co-incineration scenarios were compared via life cycle assessment by expanding system boundaries. The results show that co-incineration with municipal solid waste has the lowest environmental impacts due to environmental benefits produced by power generation, while co-incineration with hazardous waste is the highest due to the high energy consumption. Energy consumption (i.e. kerosene, electricity and diesel) are the key factors for three movable disposal scenarios. For movable steam and microwave sterilization equipment followed by co-incineration with municipal solid waste, power generation from incinerating disinfected medical waste has significant beneficial environmental impacts due to avoided impacts of electricity consumption. The recommendations for improvement of the emergency disposal and management of medical waste during the COVID-19 pandemic globally and other serious epidemic in the future are provided.

Keywords: Medical Waste, COVID-19, Emergency Disposal Scenarios, Life Cycle Assessment, Movable Disposal Scenarios, Co-incineration

1. Introduction

The Coronavirus Disease 2019 (COVID-19) is spreading globally, especially in the United States, India, Brazil and Russia. Approximately 111 million people are reported to have contracted COVID-19 by February 22, 2021, and the amount is still growing at a rate of over 4 million per week. With the explosion of medical service demand, disposable protection products (e.g. masks, gloves, goggles, insulation garment and protective clothing) are rapidly consumed, which leads to an explosion of medical waste (MW) production globally (You et al., 2020, Yu et al., 2020). MW generated during the COVID-19 pandemic has a greater risk of infection than usual medical waste, and its amount far exceeds the existing disposal capacity in areas with serious epidemic (Klemeš et al., 2020, Saadat et al., 2020). Consequently, disposal of MW is a crucial component to prevent the epidemic spread (Peng et al., 2020, Saadat et al., 2020, Wang et al., 2020).

Usually, MW must be transported to central disposal facilities in China, but the explosion of MW causes tremendous pressure of disposal. For e.g., in Wuhan, the maximum amount of MW generated was above 240 t/d in February 2020, but there was only one centralized disposal center with a disposal capability of 50 t/d (Klemeš et al., 2020). In order to minimize the virus spread and alleviate the problem of inadequate disposal capacity of MW, Guidelines for Management and Technologies of Emergency Disposal of Medical Waste During the COVID-19 Pandemic (On Trial) was issued in China on January 28, 2020. Emergency disposal of MW refers to the timely, orderly, efficient, and harmless disposal of MW generated during the COVID-19 pandemic, and emergency disposal scenarios are the technological approaches for emergency disposal of MW. According to the Guidelines, emergency disposal scenarios (e.g. incineration disposal vehicle, steam sterilization cabin, movable microwave sterilization equipment, co-incineration with hazardous waste and co-incineration with municipal solid waste) have been allowed to adopt. Emergency disposal scenarios require a comprehensive assessment to understand their full environmental impacts.

Life cycle assessment (LCA) is an efficient method to analyze the environmental impacts of technology process, activity, or product during the whole life cycle for ecological design, technology and product improvement, policy establishment (Hellweg et al., 2014, ISO, 14044, 2006, ISO, 14040, 2006, Zhu et al., 2016). LCA has been employed to access MW disposal scenarios (Aung et al., 2019). The comparative LCA of incineration and steam autoclave sterilization with landfill for MW were reported, and results showed that incineration with energy recovery is better than steam autoclave sterilization (Zhao et al., 2009). Based on laboratory data, three MW disposal scenarios (i.e. microwave, autoclave and lime) followed by landfilling were evaluated, and it was confirmed that microwave disposal has the lowest environmental impact (Soares et al., 2013). Four systems of MW disposal in Korea (i.e. incineration, incineration with heat recovery, steam sterilization, and microwave disinfection) were compared, and results displayed that incineration with heat recovery is the best disposal scenario (Koo and Jeong, 2015). Hong studied the environmental and economic impacts of three MW disposal with pyrolysis, steam sterilization and chemical disinfection technologies, and found that steam sterilization has the highest environmental impacts due to high energy consumption (Hong et al., 2018). The life cycle impact of various plastic products including personal protection and healthcare during the COVID-19 pandemic epidemic was assessed, but the literature mainly focused on summary of previous studies and presentation of future research, directions and environmental policy recommendations about plastic waste management (Klemeš et al., 2020). Previous studies focused on performing LCA to evaluate conventional disposal scenarios based on normal MW production. At present, the centralized disposal facilities in China are generally large-scale equipment with difficulties on move and installation, lacking flexibility to adapt to the special disposal needs of massive highly infectious MW suddenly generated during the COVID-19 pandemic (Chen and Guo, 2020). Movable disposal facilities with convenient movement, installation, operation and energy supply can quickly eliminate or reduce the infection intensity of MW and dispose of MW on site, and they are suitable for emergency disposal of MW. According to Guidelines for Management and Technologies of Emergency Disposal of Medical Waste During the COVID-19 Pandemic (On Trial), hazardous waste incineration facilities and MSW incineration facilities are included in the emergency disposal resource list. Therefore, MW can be disposed of by the centralized hazardous waste incineration facilities, which have obtained a hazardous waste business license and the hazardous waste category covers infectious MW. In addition, the main technical requirements and the working conditions of the municipal solid waste (MSW) incinerator and the MW incinerator are similar, and there are already successful application cases of co-incineration of MW and MSW (Zhou et al., 2020). In 2018, the amount of MSW incinerated of 200 large and medium-sized cities nationwide exceeded 1.05 × 108 tonnes (Zhou et al., 2020). Based on the minimum 1% addition ratio, MSW incineration facilities can provide about 1.0 × 106 tonnes of MW disposal capacity. However, few studies focused on the environmental impacts of these emergency disposal scenarios. Consequently, this study aims to identify and analyze the key factors of the environmental impacts of three movable disposal scenarios by LCA, and further compare them with co-incineration scenarios via expanding system boundaries. The results could provide the practical reference for the emergency management of MW during the COVID-19 pandemic and other infectious diseases epidemic. The abbreviations of description are shown in Table 1 .

Table 1.

Abbreviation of description.

| Item | Abbreviation |

|---|---|

| Coronavirus disease 2019 | COVID-19 |

| Medical waste | MW |

| Municipal solid waste | MSW |

| Life cycle assessment | LCA |

| Life cycle inventory | LCI |

| Chinese life cycle database | CLCD |

| Primary energy demand | PED |

| Abiotic depletion potential | ADP |

| Global warming potential | GWP |

| Ozone depletion | ODP |

| Acidification potential | AP |

| Respiratory inorganics | RI |

| Photochemical ozone formation | POFP |

| Eutrophication potential | EP |

| Ecotoxicity-freshwater | ET |

| Human toxicity-cancer effects | HT-cancer |

| Human toxicity-non cancer effects | HT-non cancer |

| Ionizing radiation-human health effects | IRP |

| Land use | LU |

| Industrial water use | IWU |

| Chemical oxygen demand | COD |

| Energy conservation and emission reduction | ECER |

2. Methodology

2.1. Scenario setting and system boundary

During the COVID-19 pandemic, the capacity of conventional MW centralized disposal facilities is far from meeting current disposal need due to a tremendous amount of MW generated. In Wuhan, the total capacity of local MW disposal is significantly improved depend on emergency disposal facilities (Yang et al., 2021). As of April 10, 2020, only 30 t/d of the additional 215.6 t/d disposal capacity came from new centralized disposal facilities, with the rest from emergency disposal facilities (Table S1) (Zhang et al., 2020a). Hence, three movable disposal scenarios and two co-incineration scenarios were studied in this research.

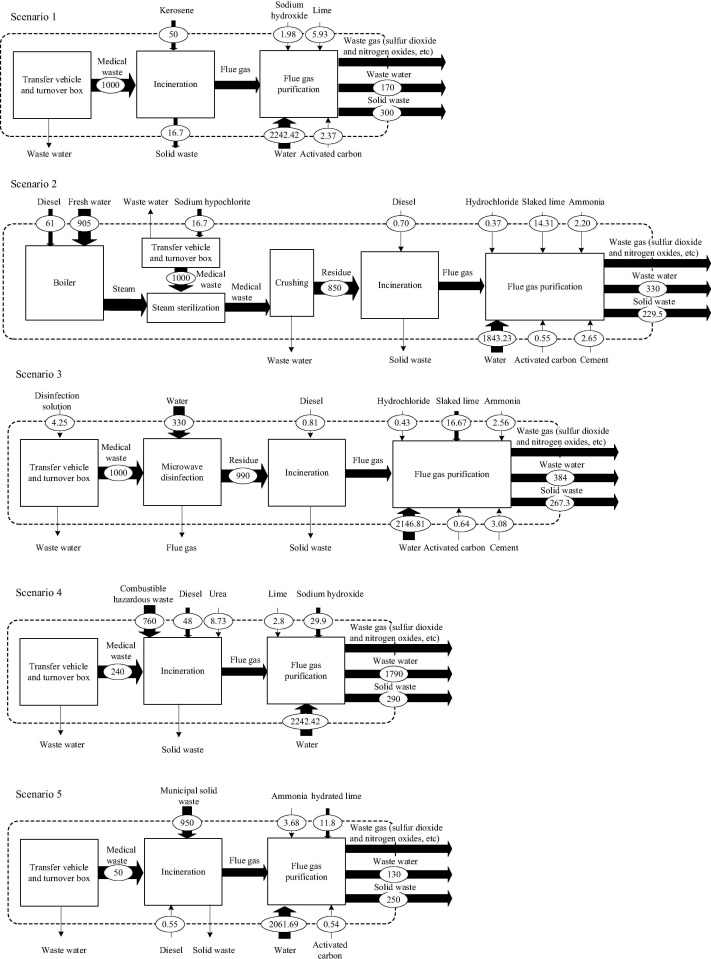

The common characteristics of the five emergency disposal scenarios are compared in Table S2. In scenario 1: MW is disposed of in incineration disposal vehicle which is a two-chamber thermal oxidation system with feed capacity of 4.8 t/d, and the flue gas is discharged safely after quenching, deacidification and dust removal. In scenario 2: MW is treated in movable steam sterilization cabin that is mainly composed of steam generation unit, crushing and packing unit, steam sterilization unit, waste gas treatment and waste water treatment unit. Disposal capacity of the cabin is 2.8 t/d and the operation area are only 50 m2. MW sterilized by steam sterilization is sent to MSW incineration facilities for co-incineration. In scenario 3: MW is treated in the movable microwave sterilization equipment which includes hydraulic lifting unit, material crushing unit, microwave sterilization unit and spiral discharge unit, and in which MW is sterilized by microwave irradiation and steam assisted heating (Chen et al., 2013). Disinfected MW residue after microwave sterilization is sent to MSW incineration facilities for disposal. In scenario 4: MW is disposed of with combustible hazardous waste in a rotary kiln, and compatibility of MW and hazardous waste needs to be noticed. Moreover, the mixture percentage of MW and hazardous waste for incineration is determined by the enterprise based on the comprehensive consideration of the local past production and the future production of MW and hazardous waste. Medical waste, industrial combustible hazardous waste, pesticide packaging waste and combustible hazardous waste in MSW account for 24.0 wt%, 51.0 wt%, 1.9 wt% and 23.1 wt% total mass of the mixed waste. In scenario 5: MW is disposed of in a grate incinerator for co-incineration with MSW and accounts for 5 wt% total mass of the mixed waste. The high plastic content in MW will increase the content of hydrogen chloride and dioxins in the flue gas, and the combustion of high calorific value MW may cause local overheating in the incinerator (Wang, 2013). Hence, MW can only account for up to 5 wt% (total mass of the mixed waste) for co-incineration with MSW (Zhou et al., 2020).

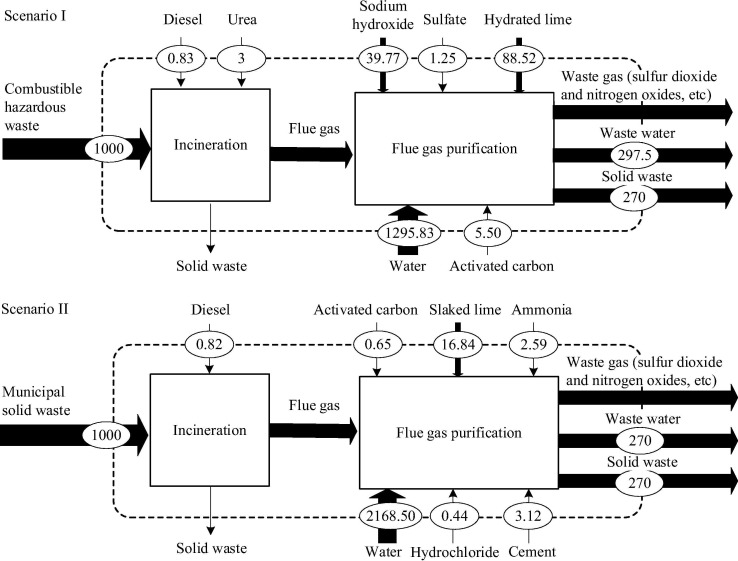

For scenarios 4 and 5, while disposing of MW, hazardous waste and MSW are also disposed of. If the functional unit is set to one tonne of MW disposal, environmental impacts of five scenarios are not comparable because that 3.17 tonnes hazardous waste in scenario 4 and 19 tonnes MSW in scenario 5 also are disposal of. System expansion aims to evaluate the overall impact of introducing new functions or products, and it benefits from its comprehensiveness (Meng and McKechnie, 2019). Consequently, two auxiliary scenarios are introduced for system expansion to determine the functional unit. In scenario I: Only hazardous waste is disposed of in a rotary kiln. In scenario II: Only MSW is disposed of in a grate incinerator. System expansion is employed by superposing the auxiliary scenarios on five disposal scenarios to compare the comprehensive environmental impact. This method is based on a clear identification of MW disposal as the primary function and all other functions as secondary. The five composite scenarios are as follows:

Scenario A: 1 tonne MW disposal in scenario 1, 3.17 tonnes hazardous waste disposal in scenario I and 19 tonnes MSW disposal in scenario II. Scenario B: 1 tonne MW disposal in scenario 2, 3.17 tonnes hazardous waste disposal in scenario I and 19 tonnes MSW disposal in scenario II. Scenario C: 1 tonne MW disposal in scenario 3, 3.17 tonnes hazardous waste disposal in scenario I and 19 tonnes MSW disposal in scenario II. Scenario D: 1 tonne MW disposal in scenario 4 and 19 tonnes MSW disposal in scenario II. Scenario E: 1 tonne MW disposal in scenario 5 and 3.17 tonnes hazardous waste disposal in scenario I.

Thus, the functional unit of composite scenarios is determined as 1 tonne MW disposal, 3.17 tonnes hazardous waste disposal and 19 tonnes MSW disposal. The system boundaries and the mass flows of five emergency disposal scenarios and two auxiliary scenarios are showed in Fig. 1, Fig. 2 , and Table 2, Table 3 display the detailed data.

Fig. 1.

System boundaries and mass flows of five emergency disposal scenarios (unit: kg).

Fig. 2.

System boundaries and mass flows of two auxiliary disposal scenarios (unit: kg).

Table 2.

LCI of disposal scenarios for 1 tonne waste.

| Item | Unit | Scenarios |

|||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | I | II | |||

| Raw materials | Electricity consumption | kWh | 43.4 | 134.27 | 374.40 | 159.02 | 64.29 | 198.00 | 79.45 |

| Generated energy | kWh | – | – | – | – | 449.89 | – | 444.96 | |

| Net energy generation | kWh | – | – | – | – | 385.60 | – | 365.51 | |

| Fresh water | kg | 2242.42 | 905 | 330 | 2242.42 | 2061.69 | 1295.83 | 2168.50 | |

| Transportation | t*km | 10.62 | 10.78 | 10.04 | 10.89 | 10.17 | 11.44 | 10.25 | |

| Sodium hydroxide | kg | 1.98 | – | – | 29.90 | 5.00E−02 | 39.77 | 4.00E−03 | |

| Activated carbon | kg | 2.37 | – | 0.13 | 1.20E−03 | 0.54 | 5.50 | 0.65 | |

| Hydrochloride | kg | – | – | – | – | 0.04 | – | 0.44 | |

| Sodium hypochlorite | kg | – | 16.7 | – | – | – | 2.50E−03 | 2.74E−03 | |

| Sulfate | kg | – | – | – | – | – | 1.25 | 4.00E−03 | |

| Urea | kg | – | – | – | 8.73 | – | 3 | – | |

| Ammonia | kg | – | – | – | – | 3.68 | – | 2.59 | |

| Hydrated lime | kg | – | – | – | – | 11.80 | 88.52 | 16.84 | |

| Lime | kg | 5.93 | – | – | 2.8 | – | – | – | |

| Natural gas | m3 | – | – | – | – | – | 22.50 | – | |

| Potland cement | kg | – | – | – | – | – | – | 3.12 | |

| Disinfection solution | kg | 0.99 | – | 4.25 | – | – | – | – | |

| Chlorine dioxide | kg | – | – | 0.02 | – | – | – | ||

| Kerosene | kg | 50 | – | – | – | – | – | – | |

| Diesel | kg | – | 61 | – | 48 | 0.55 | 0.83 | 0.82 | |

| Direct air emissions | Sulfur dioxide | kg | 0.05 | 0.51 | – | 1.80 | 0.11 | 1.23 | 0.26 |

| Nitrogen oxides | kg | 0.68 | 0.10 | – | 1.89 | 0.36 | 1.85 | 0.97 | |

| Particulate | kg | 0.16 | 9.26E−04 | – | 0.27 | 4.88E−05 | 0.36 | 0.19 | |

| Hydrogen fluoride | kg | 3.96E−03 | – | – | 0.02 | – | 0.02 | 0.19 | |

| Hydrogen chloride | kg | 3.96E−03 | – | – | 0.13 | – | 0.25 | – | |

| Hydrogen sulfide | kg | – | 4.63E−05 | 2.70E−05 | – | 2.69E−06 | 1.08E−03 | – | |

| Carbon monoxide | kg | – | – | – | 0.72 | – | 0.86 | – | |

| Volatile organic compound | kg | – | 0.02 | – | – | – | 0.11 | – | |

| Ammonia | kg | – | 4.07E−04 | 4.87E−03 | 0.08 | 2.02E−05 | 0.06 | – | |

| Mercury | kg | 2.37E−05 | – | – | 4.67E−04 | – | 5.00E−04 | – | |

| Cadmium | kg | 1.98E−05 | – | – | – | – | 6.25E−05 | – | |

| Lead | kg | 4.00E−03 | – | – | 4.47E−03 | – | 3.75E−04 | – | |

| Arsenic | kg | – | – | – | 4.67E−04 | – | 1.25E−05 | – | |

| Nickel | kg | 9.22E−04 | – | – | – | – | 5.00E−05 | – | |

| Dioxins | ug | 7.53 | – | – | 0.87 | – | 0.55 | 0.66 | |

| Waste water | Waste water | t | 0.17 | 0.33 | 0.384 | 1.79 | 0.13 | 0.2975 | 0.27 |

| Chemical oxygen demand | mg | 38461.54 | – | – | 89,300 | – | 29,750 | 15917.81 | |

| Suspended solids | mg | – | – | – | – | – | 17833.33 | 5315.07 | |

| Ammonia nitrogen | mg | 4395.6 | – | – | 8.93E + 03 | – | 2958.33 | 2136.99 | |

| Phosphorus | mg | – | – | – | – | – | 291.67 | – | |

| Lead | mg | – | – | – | – | – | 150 | – | |

| Mercury | mg | – | – | – | – | – | 58.33 | – | |

| Chromium | mg | – | – | – | – | – | 58.33 | – | |

| Arsenic | mg | – | – | – | – | – | 120.83 | – | |

| Solid waste | Sanitary landfill | t | 0.30 | – | – | 0.29 | 0.25 | 0.27 | 0.27 |

Table 3.

LCI of composite scenarios. Values are presented per functional unit.

| Item | Unit | Composite scenarios |

|||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | E | |||

| Raw materials | Electricity consumption | kWh | 2180.61 | 2339.01 | 2590.27 | 2172.65 | 1913.39 |

| Generated energy | kWh | 8454.22 | 8832.43 | 8894.73 | 8454.22 | 8997.81 | |

| Net energy generation | kWh | 6944.67 | 7255.35 | 7306.52 | 6944.67 | 7712.07 | |

| Fresh water | kg | 47551.79 | 48057.60 | 47786.19 | 50552.49 | 45341.50 | |

| Transportation | t*km | 241.58 | 250.44 | 251.14 | 240.11 | 239.75 | |

| Sodium hydroxide | kg | 128.13 | 126.15 | 126.15 | 124.76 | 127.07 | |

| Activated carbon | kg | 32.09 | 30.27 | 30.49 | 12.29 | 28.21 | |

| Hydrochloride | kg | 8.33 | 8.70 | 8.76 | 8.33 | 0.80 | |

| Sodium hypochlorite | kg | 0.06 | 16.76 | 0.06 | 0.05 | 0.01 | |

| Sulfate | kg | 4.05 | 4.05 | 4.05 | 0.08 | 3.97 | |

| Urea | kg | 9.51 | 9.51 | 9.51 | 36.42 | 9.51 | |

| Ammonia | kg | 49.14 | 51.34 | 51.70 | 49.14 | 73.53 | |

| Hydrated lime | kg | 600.57 | 614.89 | 617.25 | 319.98 | 516.62 | |

| Lime | kg | 5.93 | – | – | 11.68 | – | |

| Natural gas | m3 | 71.33 | 71.33 | 71.33 | – | 71.33 | |

| Potland cement | kg | 59.19 | 61.83 | 62.27 | 59.19 | – | |

| Disinfection solution | kg | 0.99 | – | 4.25 | – | – | |

| Chlorine dioxide | kg | – | – | – | 0.07 | – | |

| Kerosene | kg | 50 | – | – | – | – | |

| Diesel | kg | 18.26 | 79.96 | 19.07 | 215.78 | 13.56 | |

| Direct air emissions | Sulfur dioxide | kg | 8.87 | 9.56 | 9.08 | 12.42 | 6.13 |

| Nitrogen oxides | kg | 25.00 | 25.25 | 25.28 | 26.34 | 13.02 | |

| Particulate | kg | 4.98 | 4.98 | 5.01 | 4.81 | 1.13 | |

| Hydrogen fluoride | kg | 3.77 | 3.93 | 3.96 | 3.77 | 0.08 | |

| Hydrogen chloride | kg | 0.78 | 0.78 | 0.78 | 0.56 | 0.78 | |

| Hydrogen sulfide | kg | 3.43E−03 | 3.48E−03 | – | – | 3.49E−03 | |

| Carbon monoxide | kg | 2.73 | 2.73 | 2.73 | 3.00 | 2.73 | |

| Volatile organic compound | kg | 0.34 | 0.36 | 0.34 | – | 0.34 | |

| Ammonia | kg | 1.84E−01 | 0.18 | 0.19 | 0.33 | 0.18 | |

| Mercury | kg | 1.61E−03 | 1.59E−03 | 1.59E−03 | 1.95E−03 | 1.59E−03 | |

| Cadmium | kg | 2.18E−04 | 1.98E−04 | 1.98E−04 | – | 1.98E−04 | |

| Lead | kg | 5.18E−03 | 1.19E−03 | 1.19E−03 | 0.02 | 1.19E−03 | |

| Arsenic | kg | 3.96E−05 | 3.96E−05 | 3.96E−05 | 1.95E−03 | 3.96E−05 | |

| Nickel | kg | 1.08E−03 | 1.59E−04 | 1.59E−04 | – | 1.59E−04 | |

| Dioxins | ug | 21.77 | 14.81 | 14.90 | 16.11 | 1.75 | |

| Waste water | Waste water | t | 6.16 | 6.54 | 6.25 | 12.51 | 3.62 |

| Chemical oxygen demand | mg | 435207.40 | 410275.99 | 412504.49 | 674958.36 | 94307.50 | |

| Suspended solids | mg | 157517.97 | 162035.78 | 162779.89 | 100986.30 | 56531.67 | |

| Ammonia nitrogen | mg | 54376.26 | 51797.09 | 52096.27 | 77854.74 | 9377.92 | |

| Phosphorus | mg | 924.58 | 924.58 | 924.58 | – | 924.58 | |

| Lead | mg | 475.50 | 475.50 | 475.50 | – | 475.50 | |

| Mercury | mg | 184.92 | 184.92 | 184.92 | – | 184.92 | |

| Chromium | mg | 184.92 | 184.92 | 184.92 | – | 184.92 | |

| Arsenic | mg | 383.04 | 383.04 | 383.04 | – | 383.04 | |

| Solid waste | Sanitary landfill | t | 6.15 | 6.22 | 6.25 | 6.34 | 5.86 |

2.2. Life cycle inventory (LCI)

The life cycle inventory includes MW disposal but excludes upstream burdens associated with MW (Kosajan et al., 2020, Zhang et al., 2020b). The foreground data of raw materials and energy input in scenarios 1 were from Guangtong Automobile Group whose incineration disposal vehicles disposed of the MW of the cabin hospitals in Wuhan during the COVID-19 pandemic. Due to the absence of data in emissions of the vehicle, the data of emissions were collected from an enterprise which adopted incineration technology for MW disposal. The foreground data of raw materials and energy input in scenarios 2 were from Aerospace Shenhe (Beijing) Environmental Protection Co. Ltd whose movable steam sterilization cabin disposed of the MW of hospitals in Wuhan and Yichang City of Hubei Province during the COVID-19 pandemic. Due to the absence of data in emissions of the cabin, the data of emissions were collected from an enterprise which adopted steam sterilization technology for MW disposal in Ezhou City of Hubei Province. The foreground data in scenario 3 were collected from Henan Liying Environmental Protection Technology Co. Ltd whose movable microwave sterilization equipment treated the MW of hospitals in many cities of Hubei and Henan Province during the COVID-19 pandemic. The foreground data in scenarios 4 and 5 were from a hazardous waste disposal enterprise in Lishui City of Zhejiang Province, a MSW disposal enterprise in Putian City of Guangdong Province, respectively. The foreground data of two auxiliary scenarios I and II were from a hazardous waste disposal enterprise in Danyang City of Jiangsu Province, a MSW disposal enterprise in Xianyou County of Fujian Province, respectively. Detailed data are given in the Table 2, Table 3. The background data are from Chinese Life Cycle Database (CLCD) and ecoinvent database in the eFootprint platform (Jiao et al., 2019, Mi et al., 2019, Yue et al., 2015). Cut-off rule (1%) was applied and unobtainable raw materials weight less than 1% of the amount of waste input were ignored. Because this research considered only the differences in environmental impacts of MW disposal scenarios, it is assumed that the average distance of raw material transport is 10 km.

2.3. Life cycle impact assessment

This paper selected impact assessment methodologies embedded in the eFootprint platform. The eFootprint, an online platform for analyzing LCA data by Environmental Technology Co. Ltd., was adopted to carry out the LCA. This platform embedded with CLCD which is the high quality database for China’s local LCA assessment, and it has been used for previous studies (Jiao et al., 2019, Zhao et al., 2020). The 19 categories were considered, including Primary Energy Demand (PED), Abiotic Depletion Potential (ADP), Global Warming Potential (GWP), Ozone Depletion (ODP), Acidification Potential (AP), Respiratory Inorganics (RI), Photochemical Ozone Formation (POFP), Eutrophication Potential (EP), Ecotoxicity-Freshwater (ET), Human Toxicity-Cancer Effects (HT-cancer), Human Toxicity-Non Cancer Effects (HT-non cancer), Ionizing Radiation-Human Health Effects (IRP), Land Use (LU), CO2, Industrial Water Use (IWU), Chemical Oxygen Demand (COD), NH3-N, SO2, NOX. Environmental impacts of the indicators were characterized and normalized into a certain representation for evaluation.

The specific and quantified national ECER policy objective is not be unilaterally emphasized the advantages of certain aspects for avoiding transfer of environmental issues in different ECER policy objectives, and it was employed in this research (Fan et al., 2014). ECER evaluation index system includes seven indicators (i.e. PED, CO2, IWU, COD, NH3-N, SO2 and NOX) based on the nation's 13th Five-Year Plan and delegates comprehensive environmental impacts (Zhao et al., 2020). The calculation based on following formula.

| (1) |

where delegates the indicators chosen of a certain product or technique. is a comparable ECER policy target and is the national sum of the indicators in 2015.

3. Results

To identify key inventory data for the environmental impacts of MW disposal scenarios and compare the environmental impacts of emergency disposal scenarios, scenarios 1, 2, 3 and scenarios A, B, C, D, E were selected as reference flow, respectively.

3.1. Results of scenarios 1, 2, 3

3.1.1. Characterization analysis

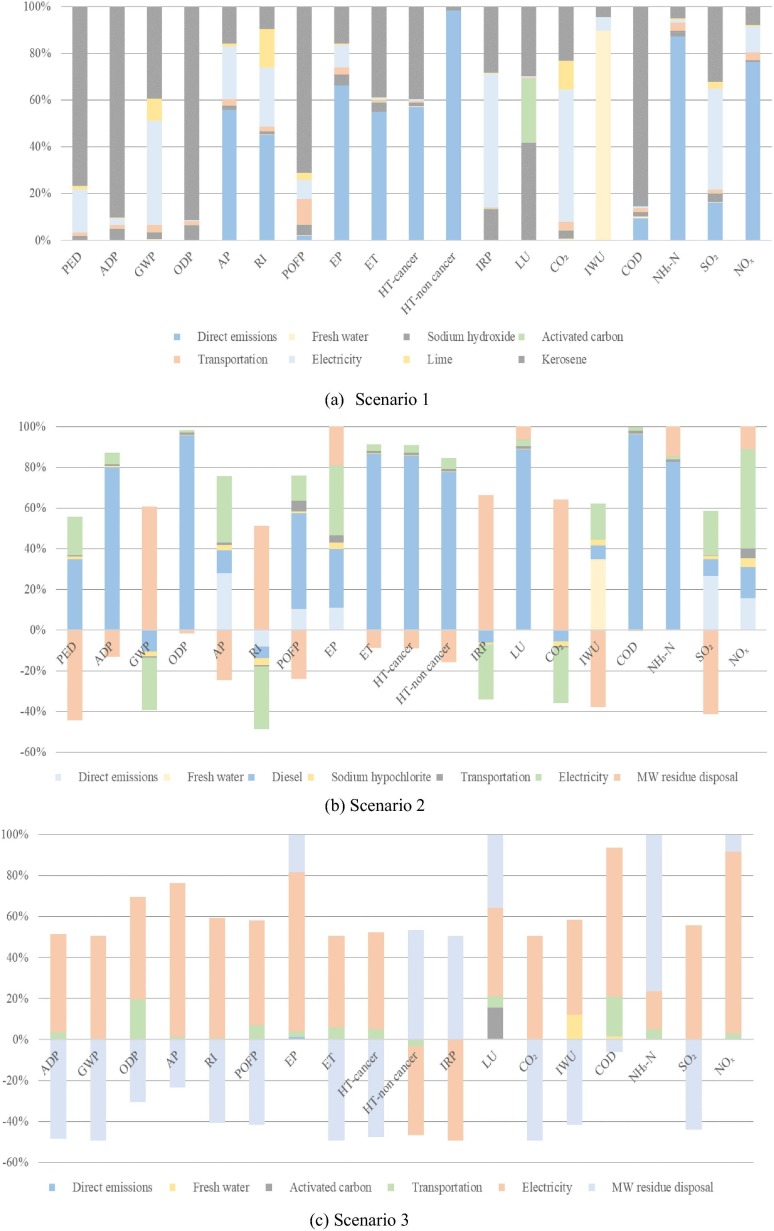

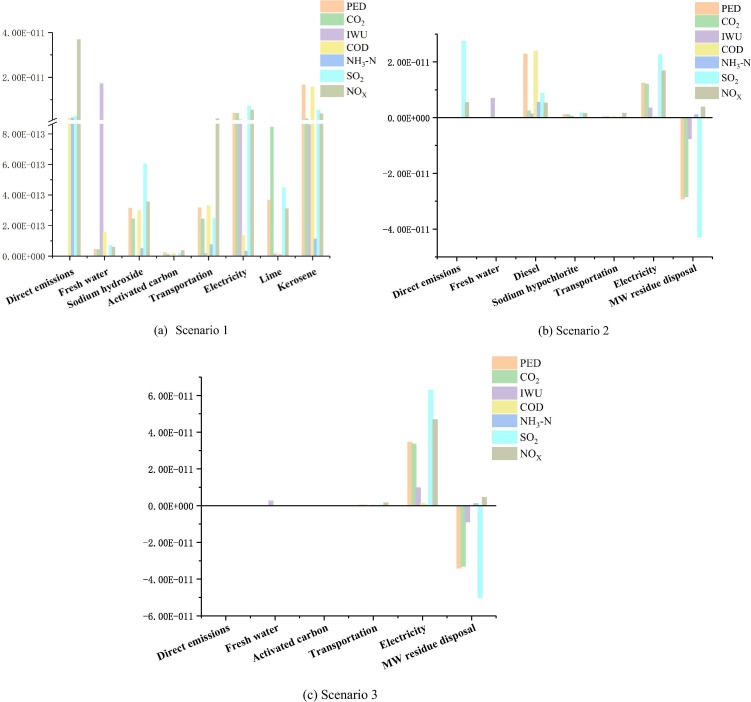

Characterization results of scenarios 1, 2, 3 are shown in the Supplemental Information and Fig. 3 . In scenario 1, direct emissions, electricity and kerosene are the main contributors to most categories. Direct emissions during MW incineration process include acidic gases (e.g. SO2) and particulate matters which make great contributions to AP and RI. Electricity is a major contributor of PED, GWP, AP, RI, IRP, CO2 SO2 and NOX. Incineration requires consumption of kerosene as fuel to provide high-temperature conditions. The mining, transportation and incineration of kerosene have a significant impact on the environment, so kerosene has a significant negative impact on most categories except for HT-non cancer, IWU and NH3-N. The electricity and diesel consumption are also the main contributors of pyrolysis incineration scenario (Hong et al., 2018). In scenario 2, the most energy consumption is the boiler in the steam generation system, which consumes diesel to produce high temperature steam for sterilization. The life cycle process of diesel from resource extraction to combustion has a significant negative impact on the environment. Hence, diesel contributes significantly to all the categories. The diesel consumed by the boiler in steam sterilization is also a major contributor of most categories in the reference (Koo and Jeong, 2015, Hong et al., 2018). Electricity consumption also has a significant negative impact on PED, GWP, AP, RI, IRP, CO2 and SO2. The negative values of MW residue disposal in most of the categories because electricity generation has significant beneficial impacts on environment. In scenario 3, the most energy consumed is electricity for microwave sterilization. Coal fired power generation lead to resource depletion and environmental pollution, so electricity consumption is a major contributor of most categories. The use of electricity in microwave scenario also has significant negative environmental impacts in the literature (Soares et al., 2013). Moreover, MW residue incineration power generation has significant positive impacts on the most categories due to avoided environmental impacts of electricity consumption, so the values of MW residue disposal in most of the categories are negative.

Fig. 3.

Effect of each material and energy consumption on the indicators of environmental impact.

3.1.2. Normalization analysis

Normalization analysis is favorable to dig the environmental impact of certain technologies for integral environment in region and the normalized factors are determined with the statistical survey (London, 2016, Xue et al., 2015). According to the policy targets for energy conservation and emission reduction of the 13th Five-Year Plan, PED, CO2, IWU, COD, NH3-N, SO2 and NOX were selected for normalization analysis. The normalization results of scenarios 1, 2, 3 are presented in the Supplemental Information and Fig. 4 .

Fig. 4.

Normalized environmental impacts.

For scenario 1, direct emissions contribute the most to NH3-N, NOX and the values are one to several orders of magnitude higher than the other material and energy consumption. Electricity is the biggest contributor for CO2, SO2 and the second biggest contributor for PED, IWU and NOX. Kerosene contributes the most to the results of PED, COD and the second most significant impacts on CO2, SO2 and NH3-N. Sodium hydroxide, fresh water and activated carbon have relatively slight contributions. For scenario 2, diesel has the most significant negative impacts on most categories except for CO2 and IWU. Direct emissions are the largest contributor for SO2, and electricity is the secondary important contributor to PED, CO2, IWU, and NOX. Electricity generation of MW residue incineration has significant beneficial impacts on PED, CO2, IWU, and SO2. Fresh water and sodium hydroxide contribute slightly. For scenario 3, electricity has the largest negative impacts on all the categories except for COD and NH3-N. Meanwhile, due to electricity generation, MW residue disposal has significant positive impacts on PED, CO2, IWU, and SO2. Fig. S1 displays that three scenarios all have significant impacts on NOX and SO2. The value of PED from scenario 1 is much higher than scenarios 2 and 3 because scenario 1 consumes massive diesel and electricity generated by MW residue incineration of scenarios 2 and 3 have significant beneficial impacts. Scenario 3 has higher impacts on CO2 than scenario 2 due to higher electricity consumption. Scenario 1 has higher impacts on IWU than scenarios 2 and 3 due to higher fresh water consumption. The value of COD from scenario 2 is higher than scenarios 1 and 3 due to massive diesel consumption. Scenario 2 has lower impacts on NOX than scenarios 1 and 3 because direct emissions of scenario 1 have a significant impact on NOX and massive electricity consumption of scenario 3 contributes significantly to NOx.

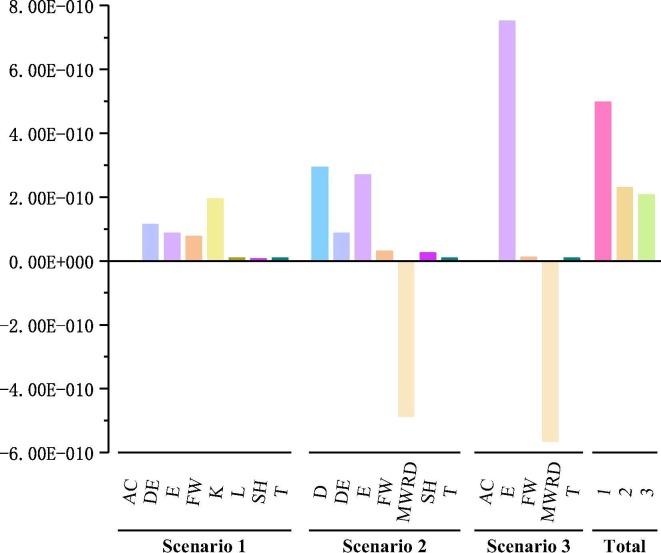

3.1.3. Energy Conservation and Emission Reduction (ECER) assessment

The ECER assessment results of scenarios 1, 2, 3 are shown in the Supplemental Information and Fig. 5 . In scenario 1, the rankings of ECER results are kerosene, direct emissions, electricity, fresh water, transportation, lime, sodium hydroxide and activated carbon. Direct emissions account for 23.0% to ECER indicator due to massive SO2 and NOX produced during incineration. In scenario 2, the ranks of results are diesel, electricity, direct emissions, fresh water, sodium hydroxide and transportation. Diesel and electricity contribute 2.93E−10, 2.70E−10 respectively and MW residue disposal counteracts 4.85E−10. In scenario 3, the rankings of ECER results are electricity, fresh water, transportation and activated carbon. Electricity contributes 7.52E−10, and MW residue disposal counteracts 5.65E−10. Kerosene and direct emissions contribute 39.0% and 23.0% to ECER indicator in scenario 1. Diesel and electricity contribute 128.0% and 117.7% of the indicator, MW residue disposal counteracts 211.7% in scenario 2. The ECER indicators of scenarios 1, 2 and 3 are 4.97E−10, 2.29E−10 and −2.88E−10. ECER indicator of scenario 1 is 2.17 times that of scenario 2 and 2.40 times that of scenario 3.

Fig. 5.

ECER indicator for each materials, energy consumption and total in scenarios 1, 2 and 3 (AC: activated carbon; DE: direct emissions; E: electricity; FW: fresh water; K: kerosene; L: lime; SH: sodium hydroxide; T: transportation; D: diesel; MWRD: medical waste residue disposal).

3.1.4. Sensitivity analysis

A 5% variation about each material and energy consumption of scenarios 1, 2 and 3 were conducted for sensitivity analysis (Wei et al., 2015). Sensitivity analysis results of scenarios 1, 2 and 3 are given in the Supplemental Information and Fig. S2. For scenario 1, direct emissions contribute significantly to NH3-N, SO2 and NOX, and the changes of normalized results are 9.56E−14, 1.34E−13 and 1.84E−12. A 5% variation of kerosene leads to significant changes to PED and COD. Direct emissions and kerosene result in the ECER indicator variation 5.72E−12 and 9.70E−12 respectively. For scenario 2, diesel and electricity result in significant changes on most categories and 1.9%, 5.9% variation of ECER indicator respectively. MW residue disposal counteracts 2.42E−11 of ECER indicator. Electricity has an important impact on most categories. For scenario 3, electricity leads to significant changes to PED, CO2, SO2 and NOX (i.e. 1.73E−12, 1.68E−12, 3.14E−12 and 2.34E−12). MW residue disposal counteracts significant changes which are 1.70E−12, 1.65E−12, 2.50E−12 and 2.82E−11 for PED, CO2, SO2 and ECER indicator. Therefore, the priority should be assigned to direct emissions and kerosene for scenario 1, diesel and electricity for scenario 2, electricity for scenario 3.

3.2. Results of scenarios A, B, C, D and E

3.2.1. Characterization analysis

Characterization results of scenarios A, B, C, D and E are given in the Supplemental Information. Compared with other scenarios, scenario D consumes massive diesel because that scenario 4 (co-incineration with hazardous waste) requires consumption of diesel as fuel. Diesel has a significant impact on most categories, so scenario D has the highest environment impacts among scenarios A-E. Electricity generation of co-incineration with MSW in scenario E has significant environmental benefits due to avoided impacts of electricity consumption, and scenario E has the lowest environment impacts on most categories. The difference in values of ADP, AP and POFP in scenarios A-E is relatively big. The value of ADP from scenario D is approximately seven times as much as scenario E because scenario D consumes much more diesel. The value of AP from scenario D is twice that of scenarios A-C due to acidic gases produced during incineration. The value of POFP from scenario D is much higher than the other scenarios, and direct emissions, electricity, sodium hydroxide and diesel are main contributors to POFP of scenario D. Moreover, the values of ADP, AP and POFP in scenario E is lower than the other scenarios, because electricity generated by MW residue incineration has significant beneficial environmental impacts.

3.2.2. Normalization analysis and ECER assessment

Normalization results of scenarios A, B, C, D and E are presented in the Supplemental Information and Fig. S3. The primary environmental issues of five scenarios are IWU, NOX, and the issues of PED, CO2 and SO2 get alleviated. Compared with the other categories, there is no obvious influence for COD and NH3-N. Normalization results of five scenarios on PED, CO2 and SO2 are negative due to power generation of auxiliary scenario II in composite scenarios. There are large differences on COD between five scenarios. The COD value of scenario D is 5.67 times as much as scenario E due to massive diesel consumed by scenario D. In addition, scenario E has the smallest impact on NOX whose value is unique negative in the five scenarios. The value of NOX from scenario D is highest, and direct emissions, electricity have significant impacts on NOX. Fig. S4 shows that the ranks of ECER results are scenarios D, A, B, C, E. The environmental impact of scenario D is much higher than the other scenarios. ECER result of scenario E is the smallest value which is −7.53E−09. The differences between scenario A, B and C are small, and the ECER results of scenario A, B and C are −3.88E−09, −4.14E−09 and −4.17E−09.

4. Discussion

According to the results, kerosene, direct emissions during incineration and electricity of incineration disposal vehicle are the main contributors to the integrated impacts index, accounting for 39.0%, 23.0% and 17.5%. Kerosene and electricity are the main contributors to CO2, and NOX emission from incineration is relatively large. In addition, Koo compared MW conventional centralized incineration and incineration with heat recovery by LCA, and found the environmental impacts of the latter are relatively low (Koo and Jeong, 2015). Consequently, energy recovery is the option of reducing the environmental impact for incineration disposal vehicle. For steam sterilization cabin, diesel and electricity contribute 128.0% and 117.7%, and power generation from infection residue counteracts 211.7% to the integrated impacts index. Diesel contributes significantly to PED and COD, and electricity is the main contributor to CO2, SO2, and NOX. Disinfection residual after steam sterilization is sent to incineration power generation, which produces environmental benefits compared with landfill. Hong reported that electricity consumed by conventional steam sterilization is 774.97 kWh per tonne MW disposal (Hong et al., 2018), which is much higher than electricity consumption of movable steam sterilization cabin. Overall, the environmental impacts of movable steam sterilization cabin are much lower. For movable microwave sterilization equipment, electricity is the most significant contributor, which is consistent with the literature reports of conventional microwave disposal (Soares et al., 2013). PED, CO2, SO2, and NOX are the main impact categories caused by electricity. Incineration power generation of disinfected residue counteracts 273.0% to the integrated impacts index, which can alleviate some of environmental impacts. Furthermore, results of LCA by expanding system boundaries reveal that the environmental impacts of co-incineration with hazardous waste are the highest among the five emergency disposal scenarios. The ADP, AP, POFP, ET, IWU, COD and NH3-N of scenario D are much higher than the other scenarios due to the high energy consumption and lack of energy recovery. The integrated impacts index of co-incineration with MSW is the lowest, and the values of ADP, AP, POFP, EP, COD, NH3-N and NOX are much lower than the other scenarios because that electricity generation counteracts some environmental impacts.

4.1. Life cycle management of medical waste

According to Guidelines for Management and Technologies of Emergency Disposal of MW During the COVID-19 Pandemic (On Trial), the overall objectives of emergency MW disposal are timely, orderly, efficient and harmless. Timely and orderly disposal is achieved through effective organizational management, efficient and harmless disposal mainly relies on disposal techniques. Consequently, meticulous management covering all the stages of the full life circle of MW including collection, classification, packaging identification, transportation and disposal shall be strengthened during the COVID-19 pandemic (Chen and Guo, 2020).

Medical institutions generating MW are the direct responsible departments that shall collect and classify MW in a timely manner to provide prerequisites for the use of different disposal technologies. Each MW packaging bag and sharp box shall be tied and affixed with a label. For infectious MW generated during the COVID-19 pandemic, characters such as “COVID-19” or “NCP” shall appear in the special note of labels. In addition, package size of MW shall meet the requirements of transportation and disposal equipment. Medical institutions shall set up a special area for temporary storage of MW, and timely inform the disposal institutions to pick up. The temporary storage time within the medical institutions cannot exceed 24 h in principle. In addition, eco-environmental departments shall strengthen the information exchange with medical institutions, especially designated hospitals, fever clinics and quarantine points. The accurate data of MW generation shall be collected to arrangement the transfer and disposal.

Except for movable disposal facilities that can dispose MW on site, the transportation of MW is a key link for co-incineration and centralized disposal facilities. The transfer routes shall be determined in advance, the areas of dense population shall be avoided, and leakage and diffusion of MW shall be avoided. Special vehicles shall be arranged to transport the infectious MW generated during the COVID-19 pandemic, instead of mixed loading with other MW. In addition, transfer vehicles temporarily modified can be used to increase transfer capacity, but must be fully sealed, with anti-seepage, corrosion resistance, and equipped with a sterilization and disinfection system.

Disinfection is the key to preventing secondary infection of MW and shall be strengthened in all the stages of the full life circle. MW isolation areas need setting special isolation marks, and it is necessary that a special person disinfects the walls, floors, surfaces, etc. When the carrying work is finished, the carrying tools shall be cleaned and disinfected. Moreover, health protection of related personnel shall be strengthened in the process of MW collection, storage, transportation and disposal.

Conventional centralized disposal facilities and movable disposal facilities shall give priority to disposal of infectious MW during the COVID-19 pandemic, and other noninfectious MW (e.g. pathological waste, injury waste and pharmaceutical waste) may be diverted to the hazardous waste incinerator, MSW incinerator and industrial furnace for disposal. There are difficulties on moving and installing because that the centralized disposal facilities are large-scale equipment. In contrast, movable disposal facilities with the characteristics of convenient movement, installation and operation are easy to realize timely on-site disposal of MW for eliminating the infective risk of MW temporary storage and transfer. Incineration disposal vehicle is powered by electricity, and the disposal location shall be chosen properly to keep away from drinking water conservation area, densely populated areas and other environmentally sensitive areas. Movable steam sterilization cabin is powered by diesel engine without external power supply, especially is suitable for cabin hospital. Movable microwave sterilization equipment generates no acid gas, dioxin and waste water. Disinfection residue after steam and microwave sterilization is sent to the nearest MSW incineration facilities for power generation. Movable disposal facilities could be further used in some small and remote medical institutions (e.g. community hospitals, urban outpatient clinics and rural clinics) after being used as temporary facilities during the COVID-19 epidemic. In addition, it is suggested to issue technical standards and guidelines for movable disposal facilities as well as technical selection principles for facilities with different disposal scales on the premise of technical applicability, cost-effectiveness, international compliance. When amount of infectious MW exceeds disposal capacity of the centralized and movable facilities, co-incineration facilities shall be reformed completely for adapting infectious MW to reduce the infectious risk. For co-incineration with hazardous waste, feeding facilities should be reformed and disinfection of MW should be strengthened. Compatibility of MW and hazardous waste should be noticed to ensure the safe and stable operation. For co-incineration with MSW, grate incinerator is suitable for MW disposal. A special transportation route, temporary storage area and separate feed port ought to be set up for MW, and batch feeding allows unbroken MW to be introduced into the incinerator. Amount of MW generated, space requirements, existing facilities nearby, economic impact shall also be considered for the choice of emergency disposal scenarios. In addition, the automation level of disposal facilities, shall be improved to reduce direct contact between people and MW.

4.2. Recommendations for emergency management of medical waste

Cities with severe epidemic shall survey MW emergency disposal capacity including movable disposal facilities, hazardous waste incinerators, MSW incinerators and industrial furnaces, etc. Furthermore, cities with insufficient capacity of MW disposal may establish an interregional emergency disposal coordination mechanism with nearby cities with spare MW disposal capacity. For remote counties and towns in some cities with large areas, MW shall be transported to the close disposal facilities in neighboring cities rather than centralized disposal facilities in these cities for a long distance, which can reduce infection risk and cost of long-distance transportation. In the future, MW disposal institutions in nearby areas shall formulate an emergency disposal preparedness to determine the reception plan, cost settlement method and optimize the vehicle route for ensuring MW disposal efficiency in an emergency.

A set of emergency management procedures of MW at the national and regional levels shall be formulated for improvement of emergency disposal system. According to the Work plan for Comprehensive Waste Management in Medical Institutions issued in China on February 24, 2020, at least one centralized MW disposal facility shall be built in each prefecture-level or above city by the end of 2020. By the end of June 2022, regional facilities for the collection, transfer or disposal of MW will be set up taking into account geographical location and population, so that every county (city) will have a system for the collection, transfer and disposal of MW. MW disposal facilities are often ignored in urban infrastructure construction system in China due to their small disposal volume, small number of facilities and relatively remote disposal location. At present, construction of sewage and MSW disposal facilities have been included in the special plan of urban infrastructure construction, but MW disposal facilities are not separately included in the special plan. Consequently, when constructing urban infrastructures, systematic thinking shall be strengthened for emphasizing MW disposal facilities. When building or renovating centralized disposal facilities, future changes in the amount of MW and the redundancy of disposal capacity should be considered to determine the scale of facilities. Hazardous waste incinerator, MSW incinerator and industrial furnace can be considered for the normalization facilities of collaborative MW disposal. In addition, emergency operation teams and expert teams for an emergency shall be established, and enterprise suppliers shall be determined in advance to ensure that the experienced operation teams can rush to the site in the first time (Sun et al., 2020).

5. Conclusions

The environmental impacts of three movable medical waste disposal equipment were evaluated by life cycle assessment method, and the environmental impacts of three movable disposal and two co-incineration scenarios were compared with life cycle assessment by expanding system boundaries. The results reveal that co-incineration with MSW has the lowest environmental impacts due to power generation, and co-incineration with hazardous waste has the highest environmental impacts. For incineration disposal vehicle, direct emissions, electricity and kerosene have significant impacts on the environment. For movable steam sterilization cabin and microwave sterilization equipment followed by co-incineration with municipal solid waste, energy consumption are the main contributors to most environment categories, and incinerating disinfected medical waste has significant positive environmental impacts due to electricity generation.

Three movable disposal scenarios can eliminate the risk of infection from the accumulation and transfer of infectious medical waste during COVID-19 pandemic and they are supposed to be distributed and adjusted according to equipment disposal capacity and regional distribution of medical waste. It is not proposed that co-incineration facilities dispose of infectious medical waste due to the infection risk from disposal. However, when infectious medical waste amount exceeds disposal capacity of the centralized and movable facilities, co-incineration facilities should be reformed completely to adapt to infectious medical waste and reduce the infection risk. Amount of medical waste generated, space requirements, existing facilities nearby, and economic impact should be considered for the choice of emergency disposal scenarios. The medical waste disposal is a common and extremely crucial task faced by all the countries during the COVID-19 epidemic and a long time thereafter. These emergency disposal scenarios and coordination mechanisms not only are suitable for China but also might provide the valuable reference for the emergency management of medical waste globally.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This research was funded by Tianjin Science and Technology Major Project and Engineering number 18ZXSZSF0012, National Natural Science Foundation of China under grant under the project number NSFC51908400, Tianjin Science Foundation under the project number 18JCYBJC24100, National key research development program number 2017YFC0703100 and Innovation team building plan of Tianjin colleges and universities number TD13-5003.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.wasman.2021.03.034.

Appendix A. Supplementary material

The following are the Supplementary data to this article:

References

- Aung T.S., Luan S., Xu Q. Application of multi-criteria-decision approach for the analysis of medical waste management systems in Myanmar. J. Clean. Prod. 2019;222:733–745. doi: 10.1016/j.jclepro.2019.03.049. [DOI] [Google Scholar]

- Chen Y., Ding Q., Yang X., Peng Z., Xu D., Feng Q. Application countermeasures of non-incineration technologies for medical waste treatment in China. Waste Manage. Res. 2013;31:1237–1244. doi: 10.1177/0734242X13507314. [DOI] [PubMed] [Google Scholar]

- Chen, Y., Guo, C., 2020. Handbook of Emergency Disposal and Management of Medical Waste in China. http://bcrc.tsinghua.edu.cn/col/1256347643949/index.html (Accessed 2 November 2020).

- Fan H., Wang H., Xie A., Hou P. Life cycle energy conservation and emission reduction targets assessment of refined copper industry (in Chinese) Asian J. Ecotoxicol. 2014;9:737–743. [Google Scholar]

- Hellweg S., Mila I Canals L. Emerging approaches, challenges and opportunities in life cycle assessment. Science. 2014;344:1109–1113. doi: 10.1126/science.1248361. [DOI] [PubMed] [Google Scholar]

- Hong J., Zhan S., Yu Z., Hong J., Qi C. Life-cycle environmental and economic assessment of medical waste treatment. J. Clean Prod. 2018;174:65–73. doi: 10.1016/j.jclepro.2017.10.206. [DOI] [Google Scholar]

- ISO, 14044, 2006. Environmental management Life cycle assessment Requirements and guidelines. https://www.iso.org/standard/38498.html (Accessed 2 November 2020).

- ISO, 14040, 2006. Environmental Management-life Cycle Assessment Principles and Framework. http://www.iso.org/iso/home/store/catalogue_tc/catalogue_detail.htm?csnumber=37456 (Accessed 2 November 2020).

- Jiao J., Li J., Bai Y. Uncertainty analysis in the life cycle assessment of cassava ethanol in China. J. Clean. Prod. 2019;206:438–451. doi: 10.1016/j.jclepro.2018.09.199. [DOI] [Google Scholar]

- Klemeš J.J., Fan Y.V., Tan R.R., Jiang P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew. Sustain. Energy Rev. 2020;127:109883. doi: 10.1016/j.rser.2020.109883. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Koo J., Jeong S. Sustainability and shared smart and mutual - green growth (SSaM-GG) in Korean medical waste management. Waste Manage. Res. 2015;33:410–418. doi: 10.1177/0734242X15574561. [DOI] [PubMed] [Google Scholar]

- Kosajan V., Wen Z., Fei F., Doh Dinga C., Wang Z., Zhan J. The feasibility analysis of cement kiln as an MSW treatment infrastructure: From a life cycle environmental impact perspective. J. Clean. Prod. 2020;267:122113. doi: 10.1016/j.jclepro.2020.122113. [DOI] [Google Scholar]

- London, B., 2016. BP statistical review of world energy June 2016.

- Meng F., McKechnie J. Challenges in quantifying greenhouse gas impacts of waste-based biofuels in EU and US biofuel policies: Case study of butanol and ethanol production from municipal solid waste. Environ. Sci. Technol. 2019;53:12141–12149. doi: 10.1021/acs.est.9b04286. [DOI] [PubMed] [Google Scholar]

- Mi Z., Kunliang L., Feng P. IEEE; 2019. Whole Life Cycle Comprehensive Environment Impact Assessment of Hydraulic Power Chuck; pp. 35–39. [Google Scholar]

- Peng J., Wu X., Wang R., Li C., Zhang Q., Wei D. Medical waste management practice during the 2019–2020 novel coronavirus pandemic: Experience in a general hospital. Am. J. Infect. Control. 2020 doi: 10.1016/j.ajic.2020.05.035. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Soares S.R., Finotti A.R., Prudêncio Da Silva V., Alvarenga R.A.F. Applications of life cycle assessment and cost analysis in health care waste management. Waste Manage. 2013;33:175–183. doi: 10.1016/j.wasman.2012.09.021. [DOI] [PubMed] [Google Scholar]

- Saadat S., Rawtani D., Hussain C.M. Environmental perspective of COVID-19. Sci. Total Environ. 2020;728 doi: 10.1016/j.scitotenv.2020.138870. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sun N., Liu F., Zhang Y., Ding Z. Thoughts and Suggestions on Reinforcing the Weakness of Medical Waste Collection and Disposal Facilities in China (in Chinese) Environ. Pro Sci. 2020;46:120–126. [Google Scholar]

- Wang, W., 2013. Advantage and disadvantage of waste incinerator burning domestic waste with medical waste: Taking Shanghai Yuqiao domestic waste incineration plant as an example (in Chinese). Environ. Sanitat. Eng. 21, 18-20.

- Wang J., Shen J., Ye D., Yan X., Zhang Y., Yang W., Li X., Wang J., Zhang L., Pan L. Disinfection technology of hospital wastes and wastewater: Suggestions for disinfection strategy during coronavirus Disease 2019 (COVID-19) pandemic in China. Environ. Pollut. 2020;262:114665. doi: 10.1016/j.envpol.2020.114665. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wei W., Larrey-Lassalle P., Faure T., Dumoulin N., Roux P., Mathias J. How to conduct a proper sensitivity analysis in life cycle assessment: taking into account correlations within LCI data and interactions within the LCA calculation model. Environ. Sci. Technol. 2015;49:377–385. doi: 10.1021/es502128k. [DOI] [PubMed] [Google Scholar]

- Xue M., Kendall A., Xu Z., Schoenung J.M. Waste management of printed wiring boards: A life cycle assessment of the metals recycling chain from liberation through refining. Environ. Sci. Technol. 2015;49:940–947. doi: 10.1021/es504750q. [DOI] [PubMed] [Google Scholar]

- Yang L., Yu X., Wu X., Wang J., Yan X., Jiang S., Chen Z. Emergency response to the explosive growth of health care wastes during COVID-19 pandemic in Wuhan, China. Resour. Conserv. Recycl. 2021;164:105074. doi: 10.1016/j.resconrec.2020.105074. [DOI] [PMC free article] [PubMed] [Google Scholar]

- You S., Sonne C., Ok Y.S. COVID-19's unsustainable waste management. Science. 2020;368:1431–1438. doi: 10.1126/science.abc7778. [DOI] [PubMed] [Google Scholar]

- Yu H., Sun X., Solvang W.D., Zhao X. Reverse logistics network design for effective management of medical waste in epidemic outbreaks: Insights from the Coronavirus Disease 2019 (COVID-19) Outbreak in Wuhan (China) Int. J. Environ. Res. Pub. Health. 2020;17:1770. doi: 10.3390/ijerph17051770. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yue Y., Wang T., Liang S., Yang J., Hou P., Qu S., Zhou J., Jia X., Wang H., Xu M. Life cycle assessment of high speed rail in China. Transp. Res. Part D: Transp. Environ. 2015;41:367–376. doi: 10.1016/j.trd.2015.10.005. [DOI] [Google Scholar]

- Zhang Z., Cheng L., Wang X., Lu R., Wei C., Lei M. Construction of medical waste emergency disposal system in China (in Chinese) Res. Environ. Sci. 2020;33:1683–1690. doi: 10.13198/j.issn.1001-6929.2020.05.49. [DOI] [Google Scholar]

- Zhang N., Wang H., Gallagher J., Song Q., Tam V.W.Y., Duan H. A dynamic analysis of the global warming potential associated with air conditioning at a city scale: an empirical study in Shenzhen, China. Environ. Impact Asses. 2020;81:106354. doi: 10.1016/j.eiar.2019.106354. [DOI] [Google Scholar]

- Zhao H., Liu F., Liu H., Wang L., Zhang R., Hao Y. Comparative life cycle assessment of two ceramsite production technologies for reusing municipal solid waste incinerator fly ash in China. Waste Manage. 2020;113:447–455. doi: 10.1016/j.wasman.2020.06.016. [DOI] [PubMed] [Google Scholar]

- Zhao W., van der Voet E., Huppes G., Zhang Y. Comparative life cycle assessments of incineration and non-incineration treatments for medical waste. Int. J. Life Cycle Ass. 2009;14:114–121. doi: 10.1007/s11367-008-0049-1. [DOI] [Google Scholar]

- Zhou Q., Xu Y., Wang F., Cai H., Yang Y., Wang X., Huang Q. Current situation and risk prevention and control of emergency process of medical waste by MSW incineration facility (in Chinese) Environ. Sanitat. Eng. 2020;28:23–26. doi: 10.19841/j.cnki.hjwsgc.2020.02.005. [DOI] [Google Scholar]

- Zhu Y., Romain C., Williams C.K. Sustainable polymers from renewable resources. Nature. 2016;540:354–362. doi: 10.1038/nature21001. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.