Abstract

The article is an overview of various materials used in power hydraulics for basic hydraulic actuators components such as cylinders, cylinder caps, pistons, piston rods, glands, and sealing systems. The aim of this review is to systematize the state of the art in the field of materials and surface modification methods used in the production of actuators. The paper discusses the requirements for the elements of actuators and analyzes the existing literature in terms of appearing failures and damages. The most frequently applied materials used in power hydraulics are described, and various surface modifications of the discussed elements, which are aimed at improving the operating parameters of actuators, are presented. The most frequently used materials for actuators elements are iron alloys. However, due to rising ecological requirements, there is a tendency to looking for modern replacements to obtain the same or even better mechanical or tribological parameters. Sealing systems are manufactured mainly from thermoplastic or elastomeric polymers, which are characterized by low friction and ensure the best possible interaction of seals with the cooperating element. In the field of surface modification, among others, the issue of chromium plating of piston rods has been discussed, which, due, to the toxicity of hexavalent chromium, should be replaced by other methods of improving surface properties.

Keywords: structural materials, power hydraulics, hydraulic actuators, sealing system, coatings, surface modifications

1. Introduction

Hydraulic actuators are elements converting the energy of the working fluid into mechanical energy related to the reciprocating motion. The pressure of the working fluid acts on the piston and creates a force causing the piston assembly to move. As a result, the piston rod can perform useful work [1,2]. Hydraulic actuators are an executive element in power hydraulic systems. These structures have several advantages, which include the possibility of obtaining large working forces and low operating speeds [3].

The most general division of the actuators includes single-acting, double-acting, and rotary actuators [4]. A characteristic feature of single-acting actuators is the presence of one working chamber and the possibility of executive (active) movement only in one direction. The return movement can be carried out by an external force or a spring force. Double-acting actuators, in turn, are characterized by a working stroke in both directions.

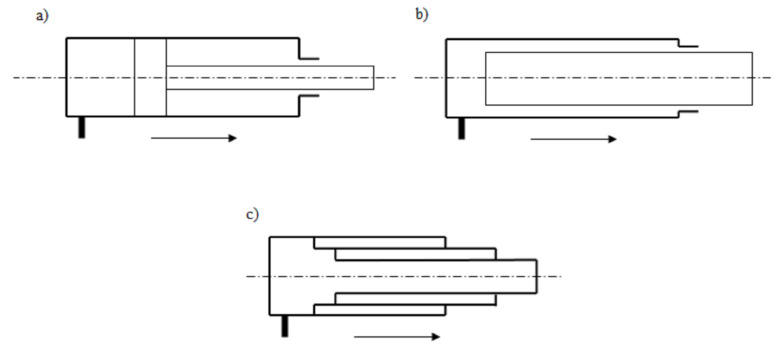

Single-acting actuators are divided into (Figure 1):

piston actuator;

plunger actuator;

telescopic actuator.

Figure 1.

Types of single-acting actuators: (a) piston, (b) plunger, (c) telescopic.

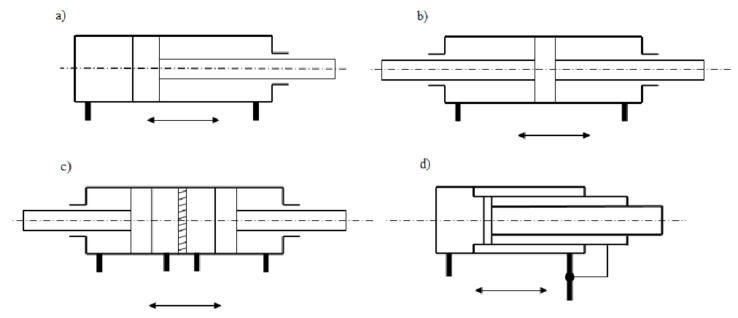

Double acting actuators are divided into (Figure 2):

piston actuator with one piston rod (with one-sided piston rod);

piston actuator with two-piston rods (with double-sided piston rod);

multi-piston actuator;

telescopic actuator.

Figure 2.

Types of double-acting actuators: (a) with one-sided piston rod, (b) two-sided piston rod, (c) multi-piston (double piston), (d) telescopic.

Piston actuators are the most common type of actuators. They are characterized by the fact that at the end of the piston rod on which the piston is mounted.

In a plunger actuator, there is the so-called plunger instead of the piston assembly. A telescopic actuator consists of a set of several pipes, extending one from the other—such an actuator allows obtaining large strokes.

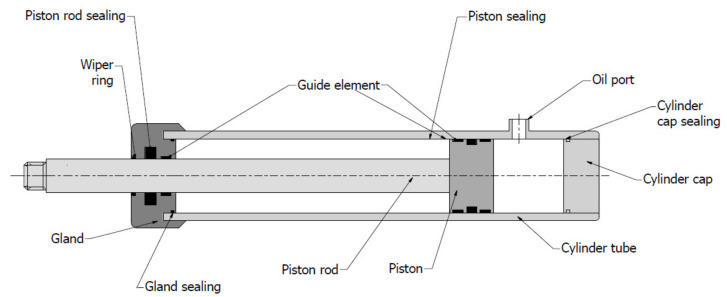

The construction of a hydraulic actuator is described on the example of the simplest piston actuator (Figure 3).

Figure 3.

Design of hydraulic piston actuator.

The casing of the actuator units is a cylinder tube. Inside the tube, there is a piston rod with a piston fixed at the end. On one side, the cylinder is closed by the end cap, and on the other side, there is a so-called actuator gland [5,6].

The cylinder cap can be assembled with a pipe using a welded connection—this is the most common way. Another method is to use a threaded cap. In the case of the latter solution, it is necessary to use a static seal to ensure adequate tightness here [4,5].

The piston rod is the component that transfers the load to the receiving element. The gland is usually attached to the cylinder pipe using a threaded connection, which is why sealing between the two components is also necessary here. The gland contains the entire sealing system for the piston rod. Most often there are one or two seals to prevent the working fluid from flowing outside and a wiper ring to prevent contamination from being transferred from outside to inside the cylinder. Such a sealing system contributes to increase the life of the cylinder [5,7,8,9].

There are also guide elements of the piston rod in the gland. They must be sufficiently lubricated with the working fluid of the hydraulic system. These elements absorb radial loads and hold the piston rod axially [10].

The piston is usually connected to the piston rod using a thread connection. In this case, the sealing element must also be located here. Guide elements mounted on the piston transmit side forces and ensure that the piston is centred in the cylinder [5,10]. In addition to the guides, there are also sealing rings that prevent the working fluid from moving between the chambers. The piston seal acts as a pressure barrier which, for example, keeps the piston rod in a specific position [11]. Piston seals can be single- or double-acting. The thickness of the acceptable lubricant film depends on the design of the actuator. Single-acting actuators require a small oil film; in double-acting actuators, the oil film can be slightly thicker [10].

Hydraulic actuators are used in many branches of industry, often requiring large working forces. They are used in construction and transportation equipment (excavators, forklifts, telescopic handlers, basket elevators, booms) [2,12,13]. Industries, where hydraulic cylinders are used, include mining, robotics, and aviation [6,14]. Therefore, manufacturers of actuators are outdoing each other in new material solutions and methods of improving the operational parameters of actuators.

To systematize the materials and surface modification methods used for hydraulic actuators elements, an extensive review of the existing literature has been made, which allowed for the preparation of a work presenting the current state of art in the field of hydraulic actuators manufacturing. This paper focuses on several of the most important elements of hydraulic actuators: pistons, piston rods, cylinders, glands, bottoms, and seals. The most common causes of failure of these parts are described, with particular emphasis on operational factors such as abrasive wear and material fatigue. Errors during the component manufacturing stage were also noted.

In the next part, the analysis of materials used for selected parts of hydraulic cylinders was performed. Material groups such as iron alloys, light metal alloys, composites, and polymers are discussed. For each of the discussed materials, the most important mechanical properties are presented, such as tensile strength, yield strength, hardness, impact energy, or elongation at break.

In this review article, a division of materials and methods has been applied according to their purpose (for cylinders, pistons, etc.) Such systematics can be helpful when there is a need to know the latest manufacturing technologies applied to a given hydraulic actuators’ components. For each actuator part, materials were selected into subgroups such as ferrous materials, light alloys, etc. During the review, items from recent years were selected to discuss the latest publications presenting modern materials and methods of surface modification. The database of available materials is constantly being expanded, so it is important that the knowledge presented is as up-to-date as possible.

2. Selection of the Appropriate Material and Its Influence on the Operation and Durability of the Hydraulic Actuator

Many factors have to be taken into account during designing a hydraulic actuator. The aim is not only that each element performs its functions as well as possible, but also that all elements work together in the best possible way. Both mechanical (e.g., strength) and operational (utility) factors must be considered.

Many articles have been written about research on failures of hydraulic cylinders. Thanks to a detailed analysis, conclusions can be drawn that will help to avoid failures in future projects and to ensure that the cylinders will work as long as possible without failures. Prevention of failures usually involves changes in the actuator design, both structural and material.

The selection of appropriate material should be carried out taking into account the shape of the designed part, both in terms of external dimensions and cell structure. The issue of choosing the appropriate material for pistons, piston rods, and cylinders has been briefly discussed in [15].

Generally speaking, the selected material and shape should be complementary with the method of producing the given object during the design [16]. Even the selection of the best material with a badly applied manufacturing method may not bring the expected final effect.

The working conditions of the part, the loads acting on it, and possible exposure to harmful substances should be considered. Financial outlays are an important issue. It is worth looking for cheaper solutions and improving the technology in such a way as to ensure minimization of costs while obtaining similar or even better mechanical and functional properties.

Nowadays, when selecting the material, great emphasis is also placed on ecology. Progressive pollution of the environment entails the necessity of actions limiting the so-called carbon footprint, defined most simply as the impact of a product or process on the climate [17]. Industrial production contributes to the emission of a huge amount of greenhouse gases into the atmosphere [18], so there is a need to look for the most environmentally friendly methods of manufacturing products.

Additionally, a tendency to reduce the weight of machine elements is observed. Less weight is usually associated with energy savings, increased efficiency, and reduced financial outlays [19,20,21,22]. Reducing the weight of an element by changing the material can be carried out, for example, by changing steel to light metals or plastics. However, the new material must meet the needed requirements for the designed part—it must not be too weak or, for example, not resistant to working conditions.

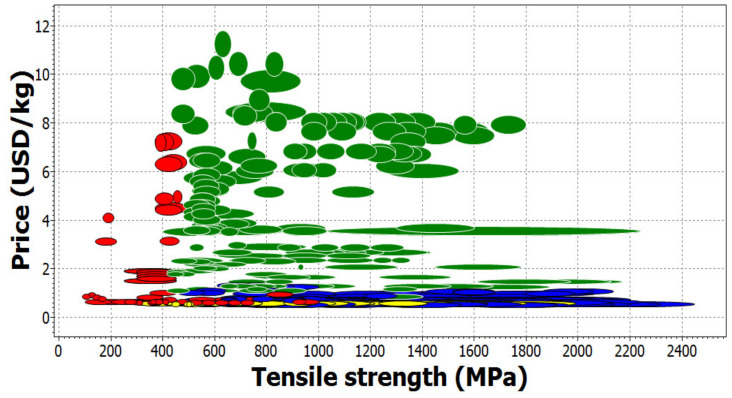

There are many tools for selecting materials. The optimum material is one that has the right values for the relevant parameters for the specific application. An interesting tool is the CES EduPack software, which allows analyzing materials and drawing material diagrams taking into account the values of various temperature, mechanical, and economic parameters. An example of such a material chart can be found in Figure 4. In this case, it is a graphical representation of different iron alloys in terms of selected parameters: tensile strength (horizontal axis) and price (vertical axis). In this case, stainless steel is marked in green and cast iron in red. Blue is responsible for low alloy steels and yellow for carbon steels. Each dot or oval represents a different material.

Figure 4.

Example of a material chart obtained in the CES EduPack software.

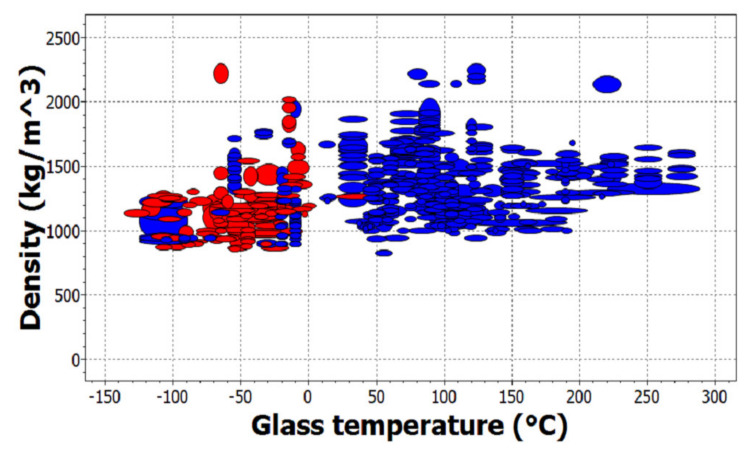

In Figure 5, there is another graphical representation of materials. The chart shows polymers in terms of density and glass temperature. Elastomers are marked in red and thermoplastic polymers are marked in blue.

Figure 5.

Example of a material chart obtained in the CES EduPack software.

The material properties can be modified by appropriate heat or heat-chemical treatment. Another way is to apply coatings required to meet several requirements, such as reduced friction, vibration damping, appropriate hardness, abrasion resistance, and good adhesion to the substrate [23].

3. Failures of Hydraulic Actuators

Failures of hydraulic actuators may result from various reasons. These reasons are either related to the actuator manufacturing process or operation. The literature extensively describes research on these breakdowns, and solutions were often proposed that could prevent similar defects in the future.

The most common causes of damage and failure of hydraulic actuators are three factors: abrasive wear, material fatigue, and friction [24].

Abrasive wear can lead to a risk of internal leakage and a decrease in the volume efficiency of the actuator [25]. Material fatigue (associated with the occurrence of variable loads) contributes to so-called fatigue cracking, hence the need to design the actuators in such a way as to ensure the highest possible resistance to this type of cracking [26].

Failures caused by fatigue are also investigated in [2]. During the fatigue failure analysis, it is necessary to locate the places where the stress concentration in the actuator is high and may negatively affect the strength. Usually, such concentration occurs in places of geometric discontinuities [27].

It is also worth mentioning the issue of uniformity of working movements in the actuator. It is important because it affects the accuracy of piston rod positioning, the uniformity of the contact force, and the safety of the user of the hydraulic actuator. The uniformity of piston movement is related to the type of sealing and piston rod guiding elements, piston rod load, and wear of the actuator elements. Non-coaxial load influences the change in the uniformity of piston movement [14,28].

The work [29] discusses a case of damage to a hydraulic actuator caused by design errors of the hydraulic system and operator’s errors during manual control of the machine operation.

Another cause of problems with the actuator are vibrations and oscillatory movements. The article [30] proposes a solution in the form of vibration reduction using rotary viscous dampers.

Corrosion of cylinders, pistons, and piston rods can be a significant problem. As a result, it is necessary to apply corrosion-resistant materials on the actuator elements and/or to apply an appropriate anti-corrosion coating [31].

In the article [23], it has been noted that corrosion and tribological extortion entails the risk of unfavourable structural changes in the material used for the actuator, which leads to a deterioration in its functional properties and, consequently, to system failure.

3.1. Failures of Cylinders

Failures of hydraulic cylinders can result from many factors. Most often it is material stress caused by high pressure, loss of stability, corrosion, and fatigue cracking [3,12,26].

The fact of high pressures in a hydraulic system should be taken into account during the cylinder design process. Cylinders under the influence of pressure may suffer from deformation manifested by e.g., change of diameter [32]. A pipe exposed to high pressures may swell. The solution is to select appropriately thick walls, which will prevent deformation and thus reduce the risk of seal failure and loss of tightness. Welding joint failures also often occur in high-pressure cylinders. The material of pipes working in such conditions is required to have a high yield strength, good weldability, and right impact capabilities [33].

Cylinders can be subject to axial and radial forces and fretting vibrations. That results in abrasive wear on the pipe surface [34]. It can significantly accelerate corrosive wear.

Fatigue cracking can occur in the cylinders due to stress concentration at welding joints, e.g., at oil connections [26,35]. This leads to oil leakage near the working fluid ports. The article [35] proposes the introduction of a washer made of heat-resistant material or glue to fill the gap between the cylinder surface and the oil inlet. By protecting the gap against oil ingress, the propagation of fatigue cracks in the joint can be prevented.

3.2. Failures of Piston Rods and Pistons

Piston rods are those elements of hydraulic actuators which most often fail [36]. This is because these components are often exposed to an aggressive environment and compressive cyclic loads [37].

Because the piston rod slides out of the cylinder, it is highly exposed to external factors. Temperature changes, precipitation, dirt, and dust often cause damage to its surface, which leads to failures that can be dangerous for people working nearby [13].

The forces in the piston rod should be applied axially, but sometimes lateral forces may also occur, which is not beneficial for the piston rod operation. This can occur either intentionally or accidentally. The piston rod is subjected to quite high tensile or compressive stress. In the case of single-acting actuators, the piston rod is only subjected to compressive stress, so only buckling is considered in the strength calculation. This is different for double-acting cylinders. Here, there are both compressive and tensile stresses, so fatigue strength must also be taken into account in the strength calculations [1,38].

In an element as important as the piston rod, the correct choice of surface modification is crucial. The article [39] analyzes the piston rod failure related to its fracture. The results showed that the crack could have been the result of improperly selected heat treatment, which led, among others, to susceptibility to stress corrosion cracking (SCC) and low toughness of the piston rod material.

In [40], the piston rod failure related to the crack that appeared in the centre of the welding joint and then propagated further was described. The results showed that the carbides formed during the nitriding process contributed to the brittleness of the joint. This phenomenon resulted from the coexistence of two factors: the use of unsuitable welding material and subsequent nitriding of the piston rod.

The issue of cracking was also examined in works [37,41], where it was noticed that the segregation of copper and nickel in the material of the piston rod can cause cracking resulting from improperly performed heat treatment.

Another piston rod failure was described in the article [42]. Here, the destruction resulted from fatigue related to the stress concentration at the rounding point on the piston rod (so-called “fillet”). Fatigue life reduction was also featured in the article [43]. In this case, the stress concentration caused the change of the thread used to connect the piston rod with the piston to a smaller pitch thread. During operation, the piston rod is also exposed to abrasive wear [44].

The piston and piston rod together form a unit, so the materials used to make the pistons and piston rods should have similar hardness and high impact strength [33]. The piston is much less likely to fail than the piston rod, which is a result of different operating conditions. Scratches or pits appear most often on the piston surface and they disturb the degree of geometric accuracy and may contribute to the loss of tightness. In [45], it was noted that the critical point may be the piston edges.

3.3. Failures of End Caps and Glands

The end cap and the gland are not among the most loaded elements of the actuator, but there are a few things to consider during designing them.

If the cylinder cap is welded—a crack may occur at the joint. The situation of that failure is described in the article [2]. In this case, the welding joint is fatigued, mainly due to cyclical loads. On the other hand, in the case of the ends connected to the cylinder by means of a thread, the problem may be caused by leakage of working fluid. In such cases, it is necessary to use a static seal at this point.

The gland is usually fastened with a thread. In this case, also it is usually necessary to use a seal here to prevent working fluid from leaking from the actuator chamber. It is worth mentioning that in the case of higher pressures, screwing the gland is not recommended due to the risk of swelling of the cylinder pipe and the possibility of loosening of the threaded connection [33]. In such cases, e.g., structural modifications of the existing threaded connection are made.

The article [46] describes the failure of the hydraulic actuator gland in aviation related to leakage. It was shown that the pressure bolts broke during the machine start-up test. It was related to material fatigue. Measures are proposed here to increase the fatigue strength of these bolts, such as modifications to the way the bolts are manufactured.

3.4. Failures of Sealing Systems

Sealing systems are often a critical element of hydraulic cylinders [47]. The main mechanisms responsible for seal failures are swelling, thermal degradation, deformation, and wear associated with contact with the other surface [48]. Destruction of seals leads to loss of tightness and, as a result, to leakage of working fluid.

Seals are exposed to many negative external factors such as high temperature, radial loads, aggressive environment, and harmful substances. During designing the seals, it is necessary to take into account the pressure range of the fluid in the system and possible pressure peaks, the temperature range, the speed of the piston rod, the condition of the cooperating surface, and the type of working fluid. All these factors affect the durability of the sealing system and the performance of the entire hydraulic system [10,49,50].

The basic requirements for the dynamic sealing system in cylinders are of course low friction coefficients and leaks close to zero [51]. The issue of friction is related to the performance of seals and their durability [52]. Seals must be designed with materials of appropriate module and hardness [10]. The design of the seal should ensure appropriate resistance to friction and corrosion, easy assembly/disassembly and a possibility to work in a wide temperature range [6]. There should be a small layer of working fluid on the piston rod seal. The lubricating film reduces friction, which contributes to increasing the life of the seals. Another advantage is the prevention of corrosion on the piston rod surface [5,10,48,53].

In [54], it was noted that the friction force and sensitivity to load variation is related to the type and shape of the seal used. It was also found that friction may negatively impact the accuracy of position adjustment.

Apart from friction, the wear of piston rod seals often results from oil contamination, which is not without influence on the life of the entire system [55].

The piston seal separates two chambers of different pressure. If the seal expands too much under the influence of temperature and presses too hard against the inner surface of the pipe—the lubricant may be completely removed, causing the seal to wear. Therefore, the seals used for large diameter and high-pressure pistons should be reinforced with different materials. The use of fabric can reduce thermal expansion and compensate for the excessive pressure of the seal on the sliding surface of the hydraulic cylinder. Additionally, it is important that the piston seal should be symmetrical to the transverse axis of the piston, otherwise a loss of tightness could occur when the piston is loaded [32].

The article [50] examines the behaviour of seals on chromium plated piston rods. The tests showed that the seal material and the condition of the piston rod surface have a key influence on friction and wear of the seals. The issue of friction can only be neglected if the hydraulic power of the actuator is sufficiently high. For more demanding applications with the necessary high positioning and control accuracy, tribology cannot be neglected.

The article [56] confirms that the material used for the seals and the pressure conditions in the chambers influence the dynamic friction conditions.

The research described in [57,58] showed that tribological issues and tightness of the system are influenced by the roughness of cooperating surfaces.

The high roughness of the sliding surface causes a thick lubricating film. The edges of the seals wear out quickly as they come into contact with the roughness peaks. Too small roughness in turn makes the film thin, so the friction forces are much higher [5].

The article [59] discusses the influence of anisotropic surface roughness on friction at the contact between the two elements. Anisotropic roughness is created during the machining of a part. It was shown that the friction force decreases if the cylinder surface is grooved perpendicularly to the direction of motion.

The stick-slip phenomenon occurring at low sliding speeds is also important. It consists of causing vibrations by changing the friction force. In the article [60], it is noted that the phenomenon was related to the transfer of carbon monoxide from carbon steel to the sealing surfaces. This leads to noise and accelerates the wear of sealing elements.

Problems with seals such as extrusion and cracking often result from excessive pressure [33]. In the article [61], it is noted that high pressure in the actuator system used in aviation can cause the formation of thicker fluid layers and thus more effective lubrication.

It is noted that the design of the wiper ring has a major impact on the control of leaks from the actuator gland [9]. It seems obvious that double lip scraper rings can cause less leakage than single lip ones. Unfortunately, however, double lip wipers, due to their design, can cause the wiper ring or seal ring to be ejected from the groove.

Sealing failures can lead to dangerous failure of the entire hydraulic system, so it is important to regularly check the condition of the seal and replace worn seals [48].

4. Materials and Surface Modifications Used for Hydraulic Actuator Elements

4.1. Cylinders

4.1.1. Materials Used for Cylinders

A variety of different materials are used for the cylinders, from metal materials to composites and polymers. Most often, the cylinders are made of steel or aluminum. At pressures lower than 10 MPa, cast iron cylinders are used. At pressures higher than 20 MPa, they are made of seamless steel pipe. For pressures above 20 MPa, the pipes are made of steel or forged steel [6].

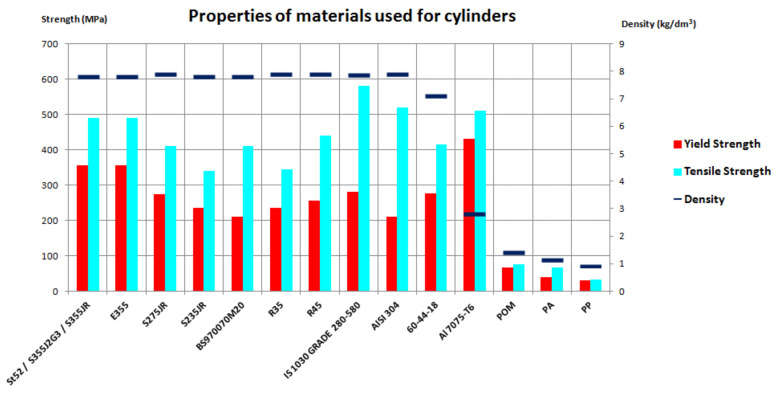

The properties of the discussed metals and polymer materials are described in Table 1 and Table 2. The basic data is also presented graphically in Figure 6. The chart clearly shows the difference in the density of steel and polymer materials.

Table 1.

Basic properties of the materials used for cylinders.

| Material | Density (kg/dm3) | Minimum Yield Strength (MPa) | Minimum Tensile Strength (MPa) | Maximum Carbon Content (%) | Description |

|---|---|---|---|---|---|

| St52/S355J2G3/S355JR | 7.8 | 355 | 490 | 0.2 | low-carbon structural steel |

| E355 | 0.22 | low-carbon quality steel | |||

| S275JR | 7.9 | 275 | 410 | 0.21 | low-carbon structural steel |

| S235JR | 7.8 | 235 | 340 | 0.2 | low-carbon structural steel |

| BS970070M20 | 7.8 | 210 | 410 | 0.24 | low-carbon structural steel |

| R35 | 7.9 | 235 | 345 | 0.16 | low-carbon structural steel for pipes |

| R45 | 7.9 | 255 | 440 | 0.22 | low-carbon structural steel for pipes |

| IS 1030 GRADE 280-580 | 7.85 | 280 | 580 | 0.25 | non-alloy steel, general purpose |

| AISI 304 | 7.9 | 210 | 520 | 0.08 | austenitic stainless steel |

| 60-40-18 | 7.1 | 276 | 414 | 3.4–3.8 | spheroidal cast iron |

| Al 7075-T6 | 2.8 | 430 * | 510 | – | Al-Zn alloy |

| POM | 1.41 | 67–69 | 67–85 | – | polyoxymethylene |

| PA | 1.13 | 40 | 67 | – | polyamide |

| PP | 0.92 | 30 | 32 | – | polypropylene |

* For aluminium alloy, instead of the yield strength Re, the conventional yield strength Rp0.2 is given.

Table 2.

Additional properties of the materials used for cylinders.

| Material | Average Hardness | Impact Energy (J) | Elongation at Break (%) |

|---|---|---|---|

| St52/S355J2G3/S355JR | 180 HB | 27 (−20 °C) | 22 |

| E355 | |||

| S275JR | 160 HB | 27 (20 °C) | 22 |

| S235JR | 140 HB | 27 (20 °C) | 26 |

| BS970070M20 | 140 HB | 24 (10 °C) | 21 |

| R35 | 112 HB | 27 (0 °C) | 24 |

| R45 | 142 HB | 22 (20 °C) | 22 |

| IS 1030 GRADE 280-580 | 220 HB | 22 (20 °C) | 18 |

| AISI 304 | 215 HB | 60 (−196 °C) | 45 |

| 60-40-18 | 160 HB | 12 (−20 °C) | 18 |

| Al 7075-T6 | 150 HB | 17 (23 °C) | 10 |

| POM | 81 (Shore D) | - | 30 |

| PA | 76–82 (Shore D) | - | 20–200 |

| PP | 70–83 (Shore D) | - | 150–600 |

Figure 6.

Chart of basic properties of the materials used for the cylinders.

One of the most popular cylinder steels is steel St 52 [26,27,35]. It is steel belonging to the grade of low-carbon structural steel. It is characterized by good weldability, machinability, and does not require special treatment for both processes. This material in the context of this application is also described in the article [62]; however, there is a designation according to European standards: S355J2G3. Similar material is also described in [22], where it appears as S355JR. The latter two types of steel differ only permanently in the temperature of the impact test, as indicated by the mark at the letter “J.” Another equivalent of this steel, also used for cylinder tubes, is E355 [2]. It is quality steel, often used for tubular elements.

Cylinders are also made of S275 JR [20,63] and S235 JR [21]. Both have slightly lower yield strength than S355 (Table 1).

Cylinders made of another low-carbon steel are mentioned in [45]: BS970070M20. This material is also available under a different designation: C22E. This steel was selected for testing in this article because of its appropriate yield strength and tensile strength. Moreover, its advantage is low price. Other materials used for cylinders are unalloyed steels with a special purpose: R35 or R45 [64]. Cylinders can also be made of IS 1030 GRADE 280-580 [65] or AISI 304 stainless steel [21]. The latter, however, is used for special applications or those working in difficult conditions.

In the article [66], an analysis of a selection of suitable material for the cylinder pipe was carried out. After establishing requirements such as corrosion resistance, high strength, low density, good machinability, and low cost, the most optimal material was selected: spheroidal cast iron 60-40-18. It is a good choice in hydraulic systems with relatively low working pressures. Moreover, the use of cast iron allows avoiding noise caused by excessive vibrations, as this material, like any cast iron, has the ability to dampen them [67].

Apart from ferrous materials, the tendency to reduce mass determines the use of light metal alloys, e.g., aluminum, for cylinders. In [68], AlZnMgCu cylinders are mentioned—this is a group of aluminium alloys, in which zinc is the dominant additive. To this group belongs the material Al 7075-T6, which was described in many articles.

In [21], the steel materials were compared with Al 7075-T6 and a composite material consisting of 40% epoxy resin and 60% carbon fibers. Comparing the cylinder made of structural steel and this composite material, the mass was reduced by as much as 96% while maintaining appropriate mechanical properties. Unfortunately, the price of the composite cylinder is even several times higher than for the other materials tested. A good solution seems to be the use of aluminum, which reduces the weight of the cylinder by 91% compared to steel, and in economic terms, it more than doubles the price of the cylinder.

In [22], it was noted that the change of material from structural steel to Al 7075-T6 resulted in a significant reduction of the cylinder weight, which had a positive impact on the degree of the ecology of the hydraulic system as well as on its power demand. In [63], similar tests were carried out, but here the Al 7075-T6 aluminium pipe was wrapped in a composite consisting of epoxy resin and carbon fibers with the same proportions as in [21]. Such a solution was chosen to avoid damage caused by seals slipping on the inner surface of the pipe. A similar construction was also discussed in works [19,20].

In [69], the pipe is made from a thin S355 steel insert on the inside and is wrapped with CFRP (Carbon Fiber Reinforced Polymer) on the outside. The use of the insert was to provide the sealing system with appropriate tribological working conditions. This approach reduced the weight of the cylinder by several dozen percent. CFRP material has high strength, is resistant to corrosion and fatigue. Additionally, it has a low density. As the name suggests, it consists of carbon fibers embedded in a polymer resin, in which the carbon fibers act as a strengthening material and the polymer resin acts as a matrix holding the fibers [70]. The article [71,72] also discusses the application of CFRP to hydraulic cylinders. The paper [71] points out that the application of the composite for the cylinder pipe will allow for significantly reducing the weight; however, it will bring additional tribological problems in the piston-cylinder contact, hence the need to find a suitable method of manufacturing such cylinders. In the article [72], it was noted that in some situations steel inserts in a polymer tube may be damaged due to critical stress caused by the difference in mechanical properties of the metal and CFRP. The article notes the necessity of stiffening the structure. The application of nanostructured epoxy resin gelcoat made of Al2O3 nanoparticles inside a multilayer CFRP cylinder was proposed as a method. The inner surface of such a cylinder proved to be very durable.

The article [73,74] present prototypes of cylinders made of POM (polyoxymethylene) plastic. Such an approach was explained by many advantages of this type of materials: reduction of weight, an increase of vibration damping, and thus reduction of noise and nuisance to the environment. POM plastic shows adequate mechanical strength and heat resistance. Plastics can provide better tribological properties and resistance to aggressive environments.

In [75], the use of polyamide (PA) and polypropylene (PP), of which prototype hydraulic cylinders are made, is described. PA is a polymer with good mechanical properties and abrasion resistance, but can, unfortunately, absorb water. In turn, PP is a material characterized by chemical inertia and very good fatigue strength [76].

4.1.2. Surface Modifications of Cylinder

The inner surfaces of the cylinders are ground and honed to achieve a smooth surface. However, sometimes machining proves to be insufficient. The performance of most steels used for hydraulic cylinders is improved by additional surface modification.

In [64], the technology of production of hydraulic cylinders is described, which is a combination of machining and forming (burnishing). Burnishing can be carried out with simultaneous rolling of the sleeve or after the manufacturing process. It enables to skip the honing stage. Burnishing allows obtaining high smoothness of the surface layer and additionally strengthens it. The surface becomes more resistant to abrasive wear and fatigue. The pressing process is also economical as it can be carried out simultaneously with other processes.

The properties of the steel used for cylinders, such as hardness, can also be improved by carburizing [45]. After the carburizing process, hardening is carried out, which directly leads to increased resistance. The surface layer of the steel becomes wear-resistant and retains its mechanical properties at the same time [77].

For special applications, the inner surface of the cylinder can be chrome plated—this is the case with telescopic cylinders, for example. Such a coating makes it possible to give it abrasion resistance. Its other properties and the reasons for the gradual abandonment of this technique are described in more detail in Section 4.3.2.

In [24], the application of n-Al2O3/Ni–Co nanocomposite coatings on hydraulic cylinders by brush plating was mentioned to increase their resistance to wear.

Hydraulic cylinders can also be coated with zinc or tin coatings on the outside. The main role of such coatings is to give protection against corrosion. This is especially important for cylinders working outside and exposed to adverse weather conditions.

In [78], the application of DLC (Diamond-Like Carbon) coatings on hydraulic actuator tubes is also mentioned. These coatings are resistant to harmful substances, characterized by low friction coefficient and high hardness as well as resistance to wear and corrosion.

4.2. Pistons

The pistons are usually made of steel or cast iron [4]. It must be a high-quality material to allow for the longest possible trouble-free operation.

In [79], spheroidal cast iron 65-45-12 for piston application is mentioned. It is a good alternative to carbon steel. The graphite content facilitates processing. Furthermore, ductile iron is lighter than steel.

The pistons of hydraulic cylinders can be made of C35 or C45 steel [6]. These are unalloyed steels that are very easy to heat treat, but difficult to weld. Other steels are S275 JR [63], S 355 JR [22], and BS970070M20 [45]. These are structural steels already mentioned in the hydraulic cylinders. Stainless steels are used for pistons (e.g., in special purpose cylinders) [80].

Apart from ferrous materials, light metals such as Al 7075-T6 [63,69] are also used in the context of this application.

Currently, research is being conducted on the application of composite and polymer materials in pistons. The article [73] proposes a piston from POM.

Pistons are rarely subject to surface modifications. Sometimes it is possible to improve their surface parameters by applying DLC coatings [78].

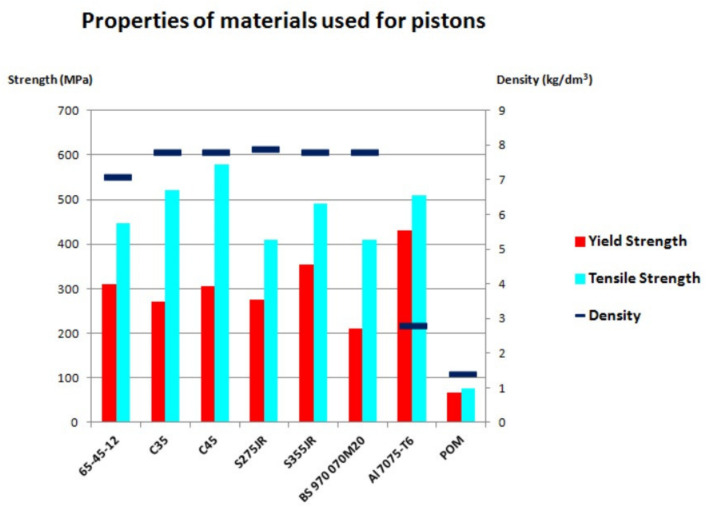

The properties of the discussed materials are described in Table 3 and Table 4. The basic data is also presented graphically in Figure 7.

Table 3.

Basic properties of the materials used for pistons.

| Material | Density (kg/dm3) | Minimum Yield Strength (MPa) | Minimum Tensile Strength (MPa) | Maximum Carbon Content (%) | Description |

|---|---|---|---|---|---|

| 65-45-12 | 7.1 | 310 | 448 | 3.50–3.90 | spheroidal cast iron |

| C35 | 7.8 | 270 | 520 | 0.32–0.39 | medium-carbon structural steel |

| C45 | 7.8 | 305 | 580 | 0.42–0.5 | medium-carbon structural steel |

| S275JR | 7.9 | 275 | 410 | 0.21 | low-carbon structural steel |

| S355JR | 7.8 | 355 | 490 | 0.2 | low-carbon structural steel |

| BS970070M20 | 7.8 | 210 | 410 | 0.24 | low-carbon structural steel |

| Al 7075-T6 | 2.8 | 430 * | 510 | – | Al-Zn alloy |

| POM | 1.41 | 67–69 | 67–85 | – | polyoxymethylene |

* For aluminium alloy, instead of the yield strength Re, the conventional yield strength Rp0.2 is given.

Table 4.

Additional properties of the materials used for pistons.

| Material | Average Hardness | Impact Energy (J) | Elongation at Break (%) |

|---|---|---|---|

| 65-45-12 | 131–220 HB | 14 (23 °C) | 12 |

| C35 | 160 HB | 23 (23 °C) | 17 |

| C45 | 200 HB | 25 (23 °C) | 14 |

| S275JR | 160 HB | 27 (20 °C) | 22 |

| S355JR | 165 HB | 27 (20 °C) | 22 |

| BS970070M20 | 140 HB | 24 (10 °C) | 21 |

| Al 7075-T6 | 150 HB | 17 (23 °C) | 10 |

| POM | 81 (Shore D) | – | 30 |

Figure 7.

Chart of properties of the materials used for the pistons.

4.3. Piston Rods

4.3.1. Materials Used for Piston Rods

The piston rod, as a quite demanding element, must be made of good quality material with appropriate parameters. Both unalloyed and alloyed and even stainless steel are used for the piston rod.

In [21], S235 JR steel is used for the piston rod. In [63], steel with a slightly higher yield point was selected: S275 JR. In [81], the use of other structural steel was described: S355J0. Its other designation is 18G2A.

Many papers discussed piston rods made of steel C45 [43,44,82,83]. In [6], apart from the mentioned steel, C35 is also used, and if the influence of vibrations is high, even C55 or 40Cr. In [84], piston rods made of the equivalent steel 40Cr, 40X are used. In [1,38], C45E is used.

The steel commonly used for the piston rod can also be 40HM (42CrMo4) [42,69,81]. Other materials are 20MnV6 [85], 19MnVS6, 38MnVS6 [1], or 30CrNiMo8 [70]. BS970070M20 [45] and similar BS970070M55 (other designation: C55E) [40] are also applied.

For more demanding applications, stainless steel is used. These are 17-4PH [41], AISI 304 [21], and AISI 410 [39]. The latter belongs to the group of martensitic steels, which are mechanically durable and at the same time resistant to corrosion. Their resistance depends strictly on chromium and carbon content and processing conditions. Unfortunately, these materials belong to the group of soft steels [86].

Apart from steel, piston rods can be made of aluminium alloys [68]. In [20,21,63], the piston rod is made of Al 7075-T6. In [73,74], the piston rod is made of POM. Another material, still in the testing phase, is a composite of epoxy resin and carbon fibers [21].

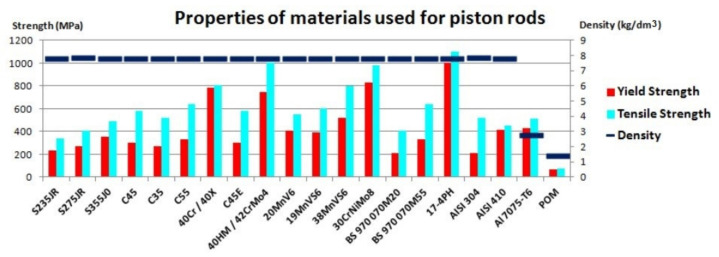

The properties of the discussed materials are described in Table 5 and Table 6. The basic data is also presented graphically in Figure 8.

Table 5.

Basic properties of the materials used for piston rods.

| Material | Density (kg/dm3) | Minimum Yield Strength (MPa) | Minimum Tensile Strength (MPa) | Maximum Carbon Content (%) | Description |

|---|---|---|---|---|---|

| S235JR | 7.8 | 235 | 340 | 0.2 | low-carbon structural steel |

| S275JR | 7.9 | 275 | 410 | 0.21 | low-carbon structural steel |

| S355J0 | 7.8 | 355 | 490 | 0.2 | low-carbon structural steel |

| C45 | 7.8 | 305 | 580 | 0.42–0.5 | medium-carbon structural steel |

| C35 | 7.8 | 270 | 520 | 0.32–0.39 | medium-carbon structural steel |

| C55 | 7.8 | 330 | 640 | 0.5–0.6 | medium-carbon structural steel |

| 40Cr/40X | 7.8 | 785 | 810 | 0.37–0.44 | alloy steel |

| C45E | 7.8 | 305 | 580 | 0.42–0.5 | medium-carbon structural steel |

| 40HM/ 42CrMo4 |

7.8 | 750 * | 1000 | 0.38–0.45 | alloy steel |

| 20MnV6 | 7.8 | 410 | 550 | 0.22 | low-alloy structural steel |

| 19MnVS6 | 7.8 | 390 | 600 | 0.15–0.22 | non-alloy special steel |

| 38MnVS6 | 7.8 | 520 | 800 | 0.34–0.41 | alloy steel |

| 30CrNiMo8 | 7.8 | 830 | 980 | 0.26–0.34 | alloy structural steel |

| BS970070M20 | 7.8 | 210 | 410 | 0.24 | low-carbon structural steel |

| BS970070M55 | 7.8 | 330 | 640 | 0.52–0.6 | medium-carbon structural steel |

| 17-4PH | 7.8 | 1000 | 1100 | 0.07 | martensitic stainless steel |

| AISI 304 | 7.9 | 210 | 520 | 0.08 | austenitic stainless steel |

| AISI 410 | 7.8 | 415 | 450 | 0.15 | martensitic stainless steel |

| Al 7075-T6 | 2.8 | 430 * | 510 | – | Al-Zn alloy |

| POM | 1.41 | 67–69 | 67–85 | – | poly-oxymethylene |

* For aluminium alloy and 42CrMo4 steel, instead of the yield strength Re, the conventional yield strength Rp0.2 is given.

Table 6.

Additional properties of the materials used for piston rods.

| Material | Average Hardness | Impact Energy (J) | Elongation at Break (%) |

|---|---|---|---|

| S235JR | 140 HB | 27 (20 °C) | 26 |

| S275JR | 160 HB | 27 (20 °C) | 22 |

| S355J0 | 165 HB | 27 (0 °C) | 18 |

| C45 | 200 HB | 25 (23 °C) | 14 |

| C35 | 160 HB | 23 (23 °C) | 17 |

| C55 | 225 HB | 25 (23 °C) | 15 |

| 40Cr/40X | 200 HB | 47 (23 °C) | 9 |

| C45E | 207 HB | 25 (23 °C) | 16 |

| 40HM/ 42CrMo4 |

218 HB | 30 (23 °C) | 10 |

| 20MnV6 | 220 HB | 27 (−20 °C) | 19 |

| 19MnVS6 | 255 HB | 24 (23 °C) | 16 |

| 38MnVS6 | 275 HB | 20 (20 °C) | 12 |

| 30CrNiMo8 | 250 HB | 30 (23 °C) | 13 |

| BS970070M20 | 140 HB | 24 (10 °C) | 21 |

| BS970070M55 | 220 HB | 25 (23 °C) | 12 |

| 17-4PH | 305 HB | 42 (23 °C) | 16 |

| AISI 304 | 215 HB | 60 (−196 °C) | 45 |

| AISI 410 | 217 HB | 30 (23 °C) | 20 |

| Al 7075-T6 | 150 HB | 17 (23 °C) | 10 |

| POM | 81 (Shore D) | – | 30 |

Figure 8.

Chart of properties of the materials used for the piston rods.

4.3.2. Surface Modifications of Piston Rods

The surface of the piston rod is modified very often by heat- and heat-chemical treatment or by coating.

In [40,87], quenching and tempering was proposed as a treatment for the piston rod. Improvement is a process of combining hardening and high tempering. Its aim is to achieve high impact strength and ductility with appropriate hardness and strength values [88].

In [89], there is talk about induction hardening of the hydraulic cylinder piston rod. This method allows increasing surface resistance to damage. In [41], the precipitation hardening was proposed to improve the surface parameters of the piston rods and obtain high strength of the layer.

Among the coatings, a definitely basic modification is hard chromium plating [4,9,38,50,84,90]. Such a coating is applied electrolytically in a bath [91]. The action of direct current causes the deposition of metal ions of the coating on the steel surface.

Chromium plating allows obtaining a coating resistant to wear and corrosion, even in aggressive environments. The hard chrome layers are characterized by high hardness and low friction. However, the accuracy of application is important, as there is a risk of micro-cracks weakening the properties of coatings [92]. The solution may be to apply a layer of nickel under the chromium layer, which additionally improves the corrosion resistance [38].

Unfortunately, chromium coatings have their disadvantages. Already during the coating process, there is a risk of chrome poisoning by the process personnel. This metal is toxic and may cause respiratory damage, asthma, or cancer [93]. The process absorbs large amounts of energy and generates dangerous waste, which is difficult to utilize [94]. In many countries, it is recommended to abandon hexavalent chromium coatings by standards introducing limits for this element or completely banning its use in some applications [95,96,97]. Hence, there is a need to find alternatives to this method of surface modification.

The issue of alternative surface modifications is described in detail in the article [95]. The main method is the use of one of the varieties of thermal spraying—HVOF (High Velocity Oxygen Fuel) process, which can give corrosion and wear resistance even better than galvanic chromium plating. This method is based on the fact that the particles of the applied material are raised in a gas stream with a speed several times higher than the speed of sound. Such high speed allows limiting unfavourable changes in the chemical composition of these particles. Accelerated particles affect the surface of the substrate and result in a coating [77,98]. This method can be used to obtain homogeneous coatings with low porosity, good adhesion to the substrate, and high strength. The process is more efficient than galvanic chromium plating and does not produce so much waste. However, the cost may be even twice as high as for electrolytic chromium plating [94,95,97,99].

Examples of coatings used on piston rods produced by HVOF and giving similar features as electrolytic chrome plating are: WC-10Co-4Cr, Cr3C2–NiCr, and WC/Co/Cr [95].

Another alternative is APS (Atmospheric Plasma Spraying). The process allows obtaining coatings of similar structure and porosity to HVOF. It consists of melting the material for the coating in electric arc plasma [77]. In the case of plasma spraying, it is possible to combine materials in one layer and control the parameters of the coating relatively precisely. Plasma spraying has the advantage over HVOF that it can also be used for internal surfaces, such as cylinders. Coatings that can be applied to the piston rod using the APS method are, e.g., Cr2O3–SiO2–TiO2 [95].

HVOF coating as an alternative to chromium plating is also given in [83]. The possibility of applying Fe/TiC coatings produced with HVOF to the piston rods was investigated, and its properties were compared with hard chromium coatings applied electrolytically and with WC/CoCr coatings applied with HVAF (High Velocity Air Fuel) process. Studies have shown that Fe/TiC coatings showed similar anti-wear and anti-corrosion properties as the reference coatings, but their application was much more economical. The method of thermal spraying for modification of the piston rod surface was also mentioned in [87].

In [100], it was noted that the application of protective layers melted from cored wires (CW) under the flux layer is more ecological and economical than galvanic chromium plating. The article examines different layers embedded in the mentioned technology, differing in phase structure. It was shown that with an increase in the percentage of ferrite in the structure, the corrosion resistance of the austenitic matrix increases. Among the investigated coatings, the most resistant to corrosion turned out to be the core wire coating with an only ferritic matrix structure.

In [50], the application of CVD (Chemical Vapour Deposition) and PVD (Physical Vapour Deposition) coatings, laser coating, and thermal spraying were indicated as an alternative to chromium plating. Surface treatment technologies are also proposed as a combination of gas nitrocarbonation, plasma nitrocarbonation, and oxidation. This provides a layer that protects against corrosion and wear and has tribological parameters. Nitrided piston rods were also mentioned in [81].

In [101], it was proposed to apply a nanostructured tungsten carbide coating deposited with CVD on metal elements in contact with seals in order to minimize possible leaks, among others in actuators. Such a coating allows obtaining high resistance to abrasion and corrosion and general protection of surface roughness parameters of the substrate. All this has a positive effect on the durability of seals. It has been noted that this coating can also be a very good alternative to hard chrome coatings.

In [24], as an alternative to chromium coatings on the piston rod, a n-Al2O3/Ni–Co nanocomposite coating produced in the process of brush plating was proposed. This method belongs to galvanic methods. It can be used to repair damages in chromium plated piston rods. Such a coating gives much higher wear resistance and is tribologically similar to hard chromium coatings.

In [44], the method of repairing piston rods that have been corroded by powder welding (Plasma-Powder Surfacing) with a Fe–C–Cr–V coating is described. Conventional arc welding (AS, Arc Surfacing) could not be applied due to the risk of deformation of a relatively small diameter bar. Corrosion-resistant material, chrome-vanadium cast iron 315Kh19F3 grade was used as a padding weld.

In [25], the application of DLC coatings for hydraulic actuator components, which are covered by the concept of sliding motion, was examined. An example of such an element is the piston rod. In [78], the application of DLC coatings for the piston rod of a hydraulic cylinder used in construction machines was mentioned. It was related to very good parameters of these coatings in terms of resistance to wear and aggressive environment [23].

In [102], the DLC coating was compared with TiN coating. Both are characterized by high mechanical strength. TiN has better wear resistance, but DLC has better tribology and corrosion resistance.

4.4. End Caps and Glands

Glands and end caps of hydraulic actuators are described and tested relatively rarely. Both of these elements are indirectly responsible for the tightness of the actuator, so great care must also be taken to manufacture them.

The caps are often made of the same material as the cylinder. This can be low carbon steel S355 [69], S355 JR [2], or S275 JR [63]. In [20,63], Al 7075-T6 alloy is additionally proposed for this element.

In the work [65], IS 1030 GRADE 280-580 was used for the cylinder cap. In [45], BS970070M20 was proposed. The article [4] also mentions the cast iron caps. Quite a modern and still being tested material is POM [73,74]—such elements are used for cylinders made of plastic.

As far as the gland is concerned, it can be made of steel or aluminum. The gland made of S275 JR steel is described in [63]. In industry, these parts are also made of C45, 42CRMo4, AISI 304, or G25 cast iron.

Aluminum Al 7075-T6 for glands was used in [20,63,69]. In [73], the application of POM type plastic is mentioned.

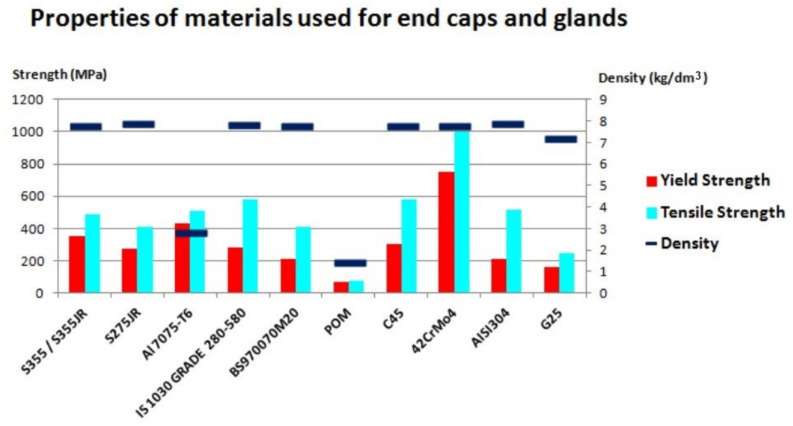

When it comes to surface treatment, glands can sometimes be modified with chromium-containing coatings, which protect the elements against corrosion [95]. Table 7 and Table 8 contain properties of materials used for the end caps and glands. The basic data is also presented graphically in Figure 9.

Table 7.

Basic properties of the discussed materials used for bottoms and glands.

| Material | Density (kg/dm3) | Minimum Yield Strength (MPa) | Minimum Tensile Strength (MPa) | Maximum Carbon Content (%) | Description |

|---|---|---|---|---|---|

| S355/S355JR | 7.8 | 355 | 490 | 0.2 | low-carbon structural steel |

| S275JR | 7.9 | 275 | 410 | 0.21 | low-carbon structural steel |

| Al 7075-T6 | 2.8 | 430 * | 510 | – | Al-Zn alloy |

| IS 1030 GRADE 280-580 | 7.85 | 280 | 580 | 0.25 | non-alloy steel |

| BS970070M20 | 7.8 | 210 | 410 | 0.24 | low-carbon structural steel |

| POM | 1.41 | 67–69 | 67–85 | – | poly-oxymethylene |

| C45 | 7.8 | 305 | 580 | 0.42–0.5 | medium-carbon structural steel |

| 42CrMo4 | 7.8 | 750 * | 1000 | 0.38–0.45 | alloy steel |

| AISI304 | 7.9 | 210 | 520 | 0.08 | austenitic stainless steel |

| G25 | 7.2 | 165 | 250 | 3.2–3.5 | grey cast iron |

* For aluminium alloy and 42CrMo4 steel, instead of the yield strength Re, the conventional yield strength Rp0.2 is given.

Table 8.

Additional properties of the materials used for bottoms and glands.

| Material | Average Hardness | Impact Energy (J) | Elongation at Break (%) |

|---|---|---|---|

| S355/S355JR | 165 HB | 27 (20 °C) | 22 |

| S275JR | 160 HB | 27 (20 °C) | 22 |

| Al 7075-T6 | 150 HB | 17 (23 °C) | 10 |

| IS 1030 GRADE 280-580 | 220 HB | 22 (20 °C) | 18 |

| BS970070M20 | 140 HB | 24 (10 °C) | 21 |

| POM | 81 (Shore D) | – | 30 |

| C45 | 200 HB | 25 (23 °C) | 14 |

| 42CrMo4 | 218 HB | 30 (23 °C) | 10 |

| AISI 304 | 215 HB | 60 (−196 °C) | 45 |

| G25 | 215 HB | 12 (−20 °C) | 0.5 |

Figure 9.

Chart of properties of the materials used for the end caps and glands.

4.5. Seals

The most general division of seals includes static and dynamic seals. Static seals occur mainly between the screwed-in bottom or gland and the cylinder pipe [11]. Additionally, the design solution may require the use of seals between the piston and the piston rod. When selecting a suitable sealing material, it must be taken into account whether the seal is only to protect against leaks or to work well with the moving surface and ensure the highest possible tightness in dynamic conditions [5].

As far as the shape of the seal is concerned, a lot depends on the operating conditions of the sealing elements. Seals operating under static conditions most often occur in round cross-section varieties (so-called O-rings). This is because a complex sealing profile is not required here [1]. Seals of this type may also act as pressure rings.

In [54], three types of piston sealing systems used were analyzed. These are:

- combined sealing system consisting of:

- flexible sealing element;

- two rings to prevent squeezing of the seals;

- two piston guide rings.

- seal with a Glyd ring consisting of:

- Glyd ring, pre-compressed by the O-ring;

- backup ring to protect against contact between metal and metal.

- U-profile sealing for double-acting actuators consisting of:

- U-profile seals;

- backup ring to protect against contact between metal and metal.

In the same work, a system of three seals was proposed for the piston rod:

wiper ring;

a standard U-profile piston rod seal;

guide ring.

Materials used in power hydraulics are required to be insensitive to greases or oils and have good resistance to abrasion, wear, and high pressure. At the same time, a small coefficient of surface friction of such elements is important [10].

Among the materials used for sealing systems, most come from the polymer category. These are different types of rubber. The simplest polymer division divides these materials into [76,103]:

-

(a)

thermoplastics (thermoplastic polymers)—under the influence of higher temperature they become plastic and after cooling down they harden again;

-

(b)

duroplastics (thermo-set or chemo-set polymers)—after being exposed to temperature or chemical substance, they become hard, their formation is irreversible;

-

(c)

elastomers—they deform to a large extent under low stress, it is possible to return to their original shape.

One of the most commonly used sealing materials is PTFE (polytetrafluoroethylene) [5,10,11,32,50,51,54,104] or PTFE with added bronze [13,51,54,104]. PTFE with other materials, e.g., carbon, is also mentioned in [104]. The PTFE has high chemical resistance and a very favourable friction coefficient, which translates into minimizing the risk resulting from the stick-slip phenomenon [11].

In [54], pure PTFE was used for piston guide rings, while PTFE with bronze was used for backup rings for pistons and guide ring for the piston rod. In [104], the results showed that pure PTFE, bronze-filled PTFE, and carbon-filled PTFE allow for lower breakaway friction. In [32], the application of PTFE to piston rod guides was described.

In [51], the effect of the operation of seals of different profiles made of PTFE with bronze and PU (PUR, polyurethane) for high operating speeds, such as those found in mining, was examined. The results showed that the seal’s suitability for given operating conditions depends on the seal profile.

The regular PU mentioned in [51] is also a frequently used material for sealing systems [7,8,11,48,52,54,57,105]. It can also be found in thermoplastic version of TPU [9,10,13,50] or as HPU (resistant to hydrolysis) [13].

In [51], PU is used for sealing elements U of the piston as well as for scrapers and main sealing elements in the piston rod sealing system. In [55,105], PU was used for sealing the piston rod.

Another material used for seals is NBR (nitrile butadiene rubber) [9,10,11,54,58,59] and HNBR (hydrogenated nitrile butadiene rubber) [10].

In [54], NBR is used for the main piston sealing element and Glyd sealing of the piston. The papers [58,59] describe the testing of O-rings made of this material. In [9], NBR was described for use on the piston rod wipers.

In [10,13], the application of FPM/FKM for sealing elements of hydraulic cylinders was described. FKM and FPM are the other names for the same material (fluorocarbon rubber). It is resistant to weather conditions and high temperature. It is also characterized by high chemical resistance.

For rings protecting against extrusion of seals in sealing systems of the piston rod, PE (polyethylene) is used [54]. It is a relatively cheap polymer that can be used even at low temperatures.

Other plastic materials used for seals in power hydraulics are: POM [13,73,74], MVQ, EPDM and PE-UHMW [13].

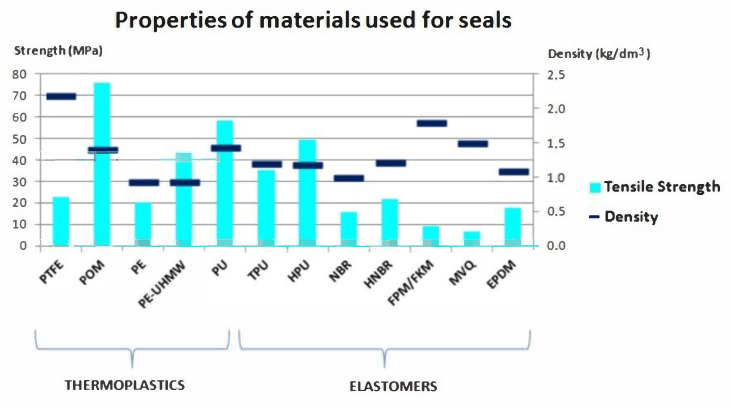

Table 9 and Figure 10 show the basic properties of the polymers discussed.

Table 9.

Basic properties of the materials used for sealing purposes.

| Material | Density (kg/dm3) | Minimum Tensile Strength (MPa) | Minimum Service Temperature (°C) | Maximum Service Temperature (°C) | Description |

|---|---|---|---|---|---|

| THERMOPLASTICS | |||||

| PTFE | 2.2 | 17–28 | −200 | 250 | polytetrafluoroethylene |

| POM | 1.41 | 67–85 | −50 | 90 | polyoxymethylene |

| PE * | 0.91–0.94/ 0.95–0.98 |

7–17/ 20–37 |

−50/−50 | 75/80 | polyethylene |

| PE-UHMW | 0.94 | 38.6–48.3 | −150 | 90 | polyethylene (ultra high molecular weight) |

| ELASTOMERS | |||||

| PU | 1.45 | 20.7–96.0 | −60 | 90 | polyurethane |

| TPU | 1.2 | 30–40 | −40 | 80 | thermoplastic polyurethane |

| HPU | 1.19 | 49.2 | −30 | 110 | hydrolysis resistant polyurethane |

| NBR | 1.0 | 6.89–24.1 | −30 | 120 | nitrile butadiene rubber |

| HNBR | 1.23 | 21.7 | −30 | 150 | hydrogenated nitrile butadiene rubber |

| FPM/FKM | 1.8 | 9 | −35 | 220 | fluorocarbon rubber |

| MVQ | 1.5 | 6.4 | −60 | 200 | methylvinyl silicone rubber |

| EPDM | 1.1 | 17.4 | −45 | 125 | ethylene-propylene-diene monomer |

* Depending on the structure, a distinction is made between low-density PE (first value) and high-density PE (second value).

Figure 10.

Chart of properties of the materials used for the seals.

5. Conclusions

The article presents a literature review which allowed systematizing the currently available knowledge on materials and methods of surface modifications used in power hydraulics. The issue is quite important, as currently the industry is strongly interested in new materials and technologies for the production of hydraulic system components.

When choosing the appropriate material or surface modification, it is necessary to take into account the working conditions of the component. Hydraulic actuator elements often operate under high loads and are exposed to an aggressive environment. This must be noted as early as at the design stage, because possible failures endangering human health and life and can cause adverse environmental or economic effects.

Currently, there is a significant increase in the use of light alloys or composites in the production of power hydraulics components. This is due to the increasing climate requirements, but also to the greater awareness of manufacturers about environmental protection. The use of modern materials often increases the efficiency of the system and extends the durability of components occurring in it.

Surface parameters of hydraulic actuator parts can be improved in various ways. The area of materials testing and surface modification is almost unlimited, so it is important to look for more environmentally friendly solutions to reduce costs and increase productivity.

Acknowledgments

The first author would like to acknowledge the financial support from the project co-financed by the European Union under the European Social Fund as a part of the Operational Program: Knowledge, Education, Development, project No. POWR.03.02.00-0-I042/16-00.

Author Contributions

Conceptualization, J.S. and A.K.; methodology, J.S. and A.K.; software, J.S.; validation, J.S., A.K. and Ł.S.; formal analysis, Ł.S and A.K.; investigation, J.S., A.K. and Ł.S.; resources, J.S.; data curation, J.S.; writing—original draft preparation, J.S.; writing—review and editing, J.S., A.K. and Ł.S.; visualization, J.S., A.K. and Ł.S.; supervision, A.K.; project administration, J.S. and Ł.S.; funding acquisition, J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

Footnotes

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Bohman E. Understanding Buckling Strength of Hydraulic Cylinders. The Hydraulics & Pneumatics Article 2017. [(accessed on 8 January 2021)]; Available online: http://www.hydraulicspneumatics.com/technologies/cylinders-actuators/article/21887243/understanding-buckling-strength-of-hydraulic-cylinders.

- 2.Nicoletto G., Marin T. Failure of a heavy-duty hydraulic cylinder and its fatigue re-design. Eng. Fail. Anal. 2011;18:1030–1036. doi: 10.1016/j.engfailanal.2010.12.019. [DOI] [Google Scholar]

- 3.Uzny S., Kutrowski Ł. Strength analysis of a telescopic hydraulic cylinder elastically mounted on both ends. J. Appl. Math. Comput. Mech. 2019;18:89–96. doi: 10.17512/jamcm.2019.1.08. [DOI] [Google Scholar]

- 4.Osiecki A. Hydrostatyczny Napęd Maszyn. 1st ed. Wydawnictwa Naukowo-Techniczne; Warsaw, Poland: 1998. pp. 199–216. [Google Scholar]

- 5.Bauer W. Hydropneumatic Suspension Systems. 1st ed. Springer-Verlag Berlin Heidelberg; Berlin, Germany: 2011. pp. 95–140. [DOI] [Google Scholar]

- 6.Luo P., Hu J., Tan S. Design and Realization of Hydraulic Cylinder. Reg. Water Conserv. 2018;1:27–34. [Google Scholar]

- 7.Huang Y., Salant R.F. Numerical analysis of a hydraulic rod seal: Flooded vs. starved conditions. Tribol. Int. 2015;92:577–584. doi: 10.1016/j.triboint.2015.07.037. [DOI] [Google Scholar]

- 8.Sealing system for piston rods. Seal. Technol. 1995;18:4. doi: 10.1016/1350-4789(95)90099-3. [DOI] [Google Scholar]

- 9.Peppiatt N., Seals H. The influence of the rod wiper on the leakage from a hydraulic cylinder gland. Seal. Technol. 2003;12:5–8. doi: 10.1016/S1350-4789(03)00014-X. [DOI] [Google Scholar]

- 10.McBride T. Seals for Hydraulic Cylinders. The Hydraulics & Pneumatics Article 2019. [(accessed on 8 January 2021)]; Available online: https://www.hydraulicspneumatics.com/technologies/seals/article/21118898/seals-for-hydraulic-cylinders.

- 11.Barth S. Sealing the Deal in Hydraulic Cylinders. P.I. Process Instrumentation Article 2018. [(accessed on 8 January 2021)]; Available online: https://www.piprocessinstrumentation.com/bearings-seals/article/15564050/sealing-the-deal-in-hydraulic-cylinders.

- 12.Uzny S., Kutrowski Ł. Obciążalność rozsuniętego teleskopowego siłownika hydraulicznego przy uwzględnieniu wyboczenia oraz wytężenia materiału. Modelowanie Inżynierskie. 2018;37:125–131. [Google Scholar]

- 13.Kowalski K., Złoto T. Exploitation and Repair of Hydraulic Cylinders Used in Mobile Machinery. Teka Comm. Mot. Energetics Agric. 2014;14:53–58. [Google Scholar]

- 14.Chalamoński M. Równomierność ruchu tłoka siłownika hydraulicznego. Diagnostyka. 2004;30:97–100. [Google Scholar]

- 15.Skowrońska J., Zaczyński J., Kosucki A., Stawiński Ł. Modern Materials and Surface Modification Methods Used in the Manufacture of Hydraulic Actuators. In: Stryczek J., Warzyńska U., editors. Advances in Hydraulic and Pneumatic Drives and Control 2020. Spinger; Cham, Switzerland: 2021. pp. 427–439. [DOI] [Google Scholar]

- 16.Ashby M.F. Materials Selection in Mechanical Design. 4th ed. Butterworth-Heinemann; Oxford, UK: 2011. pp. 15–27. [DOI] [Google Scholar]

- 17.Kijewska A., Bluszcz A. Analiza poziomów śladu węglowego dla świata i krajów UE. Syst. Wspomagania W Inżynierii Prod. 2017;6:169–177. [Google Scholar]

- 18.Harvey F. New Technology Could Slash Carbon Emissions from Aluminium Production. The Guardian Article 2018. [(accessed on 8 January 2021)]; Available online: http://www.theguardian.com/environment/2018/may/10/new-technology-slash-aluminium-production-carbon-emissions.

- 19.Solazzi L. Stress variability in multilayer composite hydraulic cylinder. Compos. Struct. 2021;259:113249. doi: 10.1016/j.compstruct.2020.113249. [DOI] [Google Scholar]

- 20.Solazzi L. Design and experimental tests on hydraulic actuator made of composite material. Compos. Struct. 2020;232:111544. doi: 10.1016/j.compstruct.2019.111544. [DOI] [Google Scholar]

- 21.Solazzi L., Buffoli A. Telescopic Hydraulic Cylinder Made of Composite Material. Appl. Compos. Mater. 2019;26:1189–1206. doi: 10.1007/s10443-019-09772-8. [DOI] [Google Scholar]

- 22.Formicola R., Solazzi L., Buffoli A. The Multi-Parametric Weight Optimization of a Hydraulic Actuator. Actuators. 2020;9:60. doi: 10.3390/act9030060. [DOI] [Google Scholar]

- 23.Madej M., Ozimina D., Pająk M. Właściwości powłok węglowych uzyskiwanych w procesach fizycznego osadzania z fazy gazowej. Mechanik. 2015;88:151–156. doi: 10.17814/mechanik.2015.4.190. [DOI] [Google Scholar]

- 24.Wang H., Ma G., Xu B., Yong Q., He P. Design and application of friction pair surface modification coating for remanufacturing. Friction. 2017;5:351–360. doi: 10.1007/s40544-017-0185-3. [DOI] [Google Scholar]

- 25.Tonelli L., Martini C., Ceschini L. Improvement of wear resistance of components for hydraulic actuators: Dry sliding tests for coating selection and bench tests for final assessment. Tribol. Int. 2017;115:154–164. doi: 10.1016/j.triboint.2017.05.021. [DOI] [Google Scholar]

- 26.Jakubczak H., Rojek J. Zmęczeniowe pękanie siłowników hydraulicznych. Diagnostyka. 2005;36:61–66. [Google Scholar]

- 27.Bednarek T., Sosnowski W. Practical fatigue analysis of hydraulic cylinders—Part II, damage mechanics approach. Int. J. Fatigue. 2010;32:1591–1599. doi: 10.1016/j.ijfatigue.2010.02.013. [DOI] [Google Scholar]

- 28.Menchen P. Analiza nierównomierności ruchu tłoka siłownika hydraulicznego. Diagnostyka. 2005;33:277–280. [Google Scholar]

- 29.Tomczyk J., Kosucki A. Hydrostatic drive of the ferry approach bank. Transp. Probl. 2007;2:15–25. [Google Scholar]

- 30.Sochacki W., Bold M. Damped Vibrations of Hydraulic Cylinder with a Spring-damper System in Supports. Procedia Eng. 2017;177:41–48. doi: 10.1016/j.proeng.2017.02.180. [DOI] [Google Scholar]

- 31.Zh Aizhambaeva S., Maximova A.V. Development of control system of coating of rod hydraulic cylinders. IOP Conf. Ser. Mater. Sci. Eng. 2018;289:012020. doi: 10.1088/1757-899X/289/1/012020. [DOI] [Google Scholar]

- 32.Stryczek S. Napęd Hydrostatyczy. 4th ed. Volume 1. Wydawnictwa Naukowo-Techniczne; Warsaw, Poland: 2013. pp. 260–281. [Google Scholar]

- 33.Danzer E. Guidelines to Avoid Those Hydraulic-Cylinder Headaches. The Hydraulics & Pneumatics Article 2018. [(accessed on 8 January 2021)]; Available online: https://www.hydraulicspneumatics.com/technologies/cylinders-actuators/article/21887578/guidelines-to-avoid-those-hydrauliccylinder-headaches.

- 34.Denisov L.V., Boitsov A.G., Siluyanova M.V. Surface Hardening in Hydraulic Cylinders for Airplane Engines. Russ. Eng. Res. 2018;38:1080–1083. doi: 10.3103/S1068798X18120237. [DOI] [Google Scholar]

- 35.Marczewska I., Bednarek T., Marczewski A., Sosnowski W., Jakubczak H., Rojek J. Practical fatigue analysis of hydraulic cylinders and some design recommendations. Int. J. Fatigue. 2006;28:1739–1751. doi: 10.1016/j.ijfatigue.2006.01.003. [DOI] [Google Scholar]

- 36.Holyakevych A., Orlov L., Pokhmurs’ka H. Restoration of the rods of hydraulic cylinders of mining equipment (in Ukrainian) In: Andreykiv O., Hrytsai I., Kindratsky B., Kuzio I., Kushnir R., Pavlishche V., Palash V., Panasyuk V., Pokhmursky V., Stotsko Z., et al., editors. Abstract of the 11th International Symposium of Ukrainian Mechanical Engineers in Lviv. Kinpatri LTD; Lviv, Ukraine: 2013. p. 185. [Google Scholar]

- 37.Tian J., Wang W., Yan W., Jiang Z., Shan Y., Yang K. Cracking due to Cu and Ni segregation in a 17-4 PH stainless steel piston rod. Eng. Fail. Anal. 2016;65:57–64. doi: 10.1016/j.engfailanal.2016.03.011. [DOI] [Google Scholar]

- 38.Israelson P. Better Steels Make Better Cylinders. The Hydraulics & Pneumatics Article 2016. [(accessed on 8 January 2021)]; Available online: https://www.hydraulicspneumatics.com/technologies/cylinders-actuators/article/21885260/better-steels-make-better-cylinders.

- 39.Moreira D.C., Furtado H.C., Buarque J.S., Cardoso B.R., Merlin B., Moreira D.D.C. Failure analysis of AISI 410 stainless-steel piston rod in spillway floodgate. Eng. Fail. Anal. 2019;97:506–517. doi: 10.1016/j.engfailanal.2019.01.035. [DOI] [Google Scholar]

- 40.Rütti T.F., Wentzel E.J. Investigation of failed actuator piston rods. In: Jones D.R.H., editor. Failure Analysis Case Studies II. Pergamon; Oxford, UK: 2001. pp. 139–146. [DOI] [Google Scholar]

- 41.Tian J., Wang W., Yan W., Jiang Z., Shan Y., Yang K. Microstructure characteristics of segregation zone in 17-4PH stainless steel piston rod. J. Iron Steel Res. Int. 2017;24:718–723. doi: 10.1016/S1006-706X(17)30108-5. [DOI] [Google Scholar]

- 42.Tavares S.M.O., Viriato N., Vaz M., de Castro P.M.S.T. Failure analysis of the rod of a hydraulic cylinder. Procedia Struct. Integr. 2016;1:173–180. doi: 10.1016/j.prostr.2016.02.024. [DOI] [Google Scholar]

- 43.Knez M., Glodež S., Kramberger J. Fatigue assessment of piston rod threaded end. Eng. Fail. Anal. 2009;16:1977–1982. doi: 10.1016/j.engfailanal.2008.10.003. [DOI] [Google Scholar]

- 44.Nefed’ev S.P., Dema R.R., Kharchenko M.V., Pelymskaya I.S., Romanenko D.N., Zhuravlev G.M. Experience in Restoring Hydraulic Cylinder Rods by Plasma Powder Surfacing. Chem. Pet. Eng. 2017;52:785–789. doi: 10.1007/s10556-017-0271-4. [DOI] [Google Scholar]

- 45.Boye T., Adeyemi O., Emagbetere E. Design and Finite Element Analysis of Double—Acting, Double—Ends Hydraulic Cylinder for Industrial Automation Application. Am. J. Eng. Res. 2017;6:131–138. [Google Scholar]

- 46.Tao C., Xi N., Yan H., Zhang Y. Fatigue failure of hold-down bolts for a hyraulic cylinder gland. Eng. Fail. Anal. 1998;5:241–246. doi: 10.1016/S1350-6307(97)00035-6. [DOI] [Google Scholar]

- 47.Deaconescu T., Daconescu A. The Annals of University ‘Dunărea De Jos’ of Galaţi, Fascicle VIII: Tribology. University ‘Dunărea De Jos’ of Galaţi; Galati, Romania: 2002. An analysis of the sealing element—Hydraulic cylinder tribosystem; pp. 108–111. [Google Scholar]

- 48.Bae J., Chung K.H. Accelerated wear testing of polyurethane hydraulic seal. Polym. Test. 2017;63:110–117. doi: 10.1016/j.polymertesting.2017.08.014. [DOI] [Google Scholar]

- 49.Tomasiak E. Napędy i Sterowania Hydrauliczne i Pneumatyczne. 1st ed. Wydawnictwo Politechniki Śląskiej; Gliwice, Poland: 2001. pp. 55–76. [Google Scholar]

- 50.Papatheodorou T., Hannifin P. Influence of hard chrome plated rod surface treatments on sealing behavior of hydraulic rod seals. Seal. Technol. 2005;4:5–10. doi: 10.1016/S1350-4789(05)00600-8. [DOI] [Google Scholar]

- 51.Heipl O., Murrenhoff H. Friction of hydraulic rod seals at high velocities. Tribol. Int. 2015;85:66–73. doi: 10.1016/j.triboint.2015.01.002. [DOI] [Google Scholar]

- 52.Peng C., Ouyang X., Guo S., Zhou Q., Yang H. Numerical analysis of the traction effect on reciprocating seals in the hydraulic actuator. Tribol. Int. 2020;143:105966. doi: 10.1016/j.triboint.2019.105966. [DOI] [Google Scholar]

- 53.Thatte A., Salant R. Transient EHL analysis of an elastomeric hydraulic seal. Tribol. Int. 2009;42:1424–1432. doi: 10.1016/j.triboint.2009.05.026. [DOI] [Google Scholar]

- 54.Pan Q., Zeng Y., Yi-bo L., Jiang X., Huang M. Experimental investigation of friction behaviors for double-acting hydraulic actuators with different reciprocating seals. Tribol. Int. 2021;153:106506. doi: 10.1016/j.triboint.2020.106506. [DOI] [Google Scholar]

- 55.Zhao X., He X., Wang L., Chen P. Research on pressure compensation and friction characteristics of piston rod seals with different degrees of wear. Tribol. Int. 2020;142:105999. doi: 10.1016/j.triboint.2019.105999. [DOI] [Google Scholar]

- 56.Tran X.B., Hafizah N., Yanada H. Modeling of dynamic friction behaviors of hydraulic cylinders. Mechatronics. 2012;22:65–75. doi: 10.1016/j.mechatronics.2011.11.009. [DOI] [Google Scholar]

- 57.Kanters A.F.C., Visscher M. Lubrication of reciprocating seals: Experiments on the influence of surface roughness on friction and leakage. Tribol. Ser. 1989;14:69–77. doi: 10.1016/S0167-8922(08)70182-2. [DOI] [Google Scholar]

- 58.Wang B., Meng X., Peng X., Chen Y. Experimental investigations on the effect of rod surface roughness on lubrication characteristics of a hydraulic O-ring seal. Tribol. Int. 2021;156:106791. doi: 10.1016/j.triboint.2020.106791. [DOI] [Google Scholar]

- 59.Scaraggi M., Angerhausen J., Dorogin L., Murrenhoff H., Persson B. Influence of anisotropic surface roughness on lubricated rubber friction with application to hydraulic seals. Wear. 2018;410–411:43–62. doi: 10.1016/j.wear.2018.02.023. [DOI] [Google Scholar]

- 60.Muraki M., Kinbara E., Konishi T. A laboratory simulation for stick-slip phenomena on the hydraulic cylinder of a construction machine. Tribol. Int. 2003;36:739–744. doi: 10.1016/S0301-679X(03)00054-9. [DOI] [Google Scholar]

- 61.Rana A.S., Sayles R.S. An experimental study on the friction behaviour of aircraft hydraulic actuator elastomeric reciprocating seal. Tribol. Interface Eng. Ser. 2005;48:507–515. doi: 10.1016/S0167-8922(05)80052-5. [DOI] [Google Scholar]

- 62.Dašić P., Manđuka A., Pantić R. Annals of the Oradea University—Fascicle of Management and Technological Engineering VII (XVII) Editura Universităţii din Oradea; Oradea, Romania: 2008. Research of optimal parameters of machining big hydraulic cylinders from the aspect of quality; pp. 1563–1571. [Google Scholar]

- 63.Solazzi L. Feasibility study of hydraulic cylinder subject to high pressure made of aluminum alloy and composite material. Compos. Struct. 2019;209:739–746. doi: 10.1016/j.compstruct.2018.11.021. [DOI] [Google Scholar]

- 64.Przybylski W. Zastosowanie obróbki nagniataniem w technologii siłowników hydraulicznych. Postępy Nauk. I Tech. 2011;6:196–201. [Google Scholar]

- 65.Balavignesh V.N., Balasubramaniam B., Kotkunde N. Numerical investigations of fracture parameters for a cracked hydraulic cylinder barrel and its redesign. Mater. Today Proc. Part A. 2017;4:927–936. doi: 10.1016/j.matpr.2017.01.104. [DOI] [Google Scholar]

- 66.Otsima M. Material Selection Process for Hydraulic Cylinder. [(accessed on 13 March 2021)];2015 Eat309 Mechanical Design. Part 5, Materials Review and Selection. Available online: https://www.researchgate.net/publication/272506787_Material_Selection_Process_for_Hydraulic_Cylinder.

- 67.Pawłowski W., Kępczak N. Teoretyczne badania właściwości dynamicznych łóż obrabiarki wykonanych z żeliwa i hybrydowego połączenia żeliwa z odlewem mineralnym. Mechanik. 2015;8:199–203. doi: 10.17814/mechanik.2015.8-9.370. [DOI] [Google Scholar]