Abstract

In recent decades, the ever-growing demands for clean water in households and industries have urged researchers to take every possible step to deal with the global water crisis. Seawater desalination has turned out to be the most promising and efficient way to provide clean water. Owing to the advancement of synthetic chemistries and technologies, great success has been achieved in the desalination and utilization of seawater worldwide. China, with the world’s largest population, has pushed the development of desalination and multipurpose utilization of seawater further in respect of materials, technologies and services, etc. This review reports recent progress of desalination technologies accomplished in China, from the viewpoints of facilities and equipment, collaborations, technologies, applications, research abilities, services, and standard systems. Inspired by the Fourteenth Five-year Plan, it also proposes future perspectives of desalination in China.

Keywords: seawater desalination, project scale, application scenarios, standard systems, technical services

1. Introduction

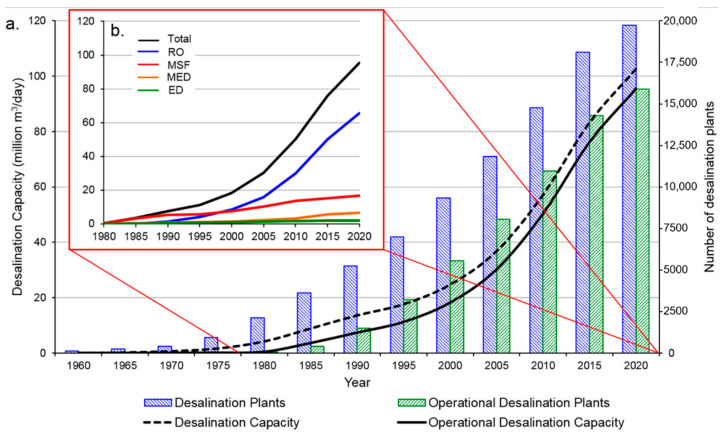

Reliable and stable freshwater supply is a prerequisite for the sustainable development of human society. However, the fast-growing world’s population and development of industrialization have made it difficult to acquire sufficient potable water. It has become an international task to deal with the water crisis. Freshwater has been considered as a strategic resource among the limited accessible resources [1]. Since seawater constitutes more than 97% of the total water resources, desalination offers an effective way to provide water supply via the extraction of freshwater from the sea [2]. Over the past decades, seawater desalination has evolved as the main freshwater source in many countries and areas, especially in the drought regions of the Middle East. As shown in Figure 1a, the desalination capacity has exceeded 100 million m3/d worldwide as the total plants number approaching 20,000 in 2020 [3].

Figure 1.

(a) Evolution of desalination capacity and the number of plants across the world over the past 60 years. Inset: (b) comparison of the desalination capacity evolution for four main desalination technologies since 1980 [3].

The well-developed desalination technologies mainly include membrane-based processes (e.g., forward osmosis (FO), reverse osmosis (RO), electrodialysis (ED) and nanofiltration (NF)) and thermal-based processes (e.g., multistage flash distillation (MSF), multi-effect distillation (MED) and thermal vapour compression). Thermal processes, however, are considered to be highly energy-intensive technologies due to their reliance on thermal energy for heating the saline feed and for driving the pumps [4]. In contrast, RO has become the most commonly used technology due to its simplicity and relatively low energy cost. Since 2000, the global desalination capacity has been dominated by RO based desalination plants (Figure 1b) [3]. Till now, about 80% of the total desalination is derived from RO technology around the world [5]. It could be attributed to the advancement in novel RO membrane materials as well as the reduction in energy consumption and pure water production cost [2,6]. The energy consumption of large-scale RO and MED projects in China was estimated about 4 and 1.5 kWh/m3, respectively. Depending on the salinity of the feed water, RO processes can be classified into SWRO and BWRO for seawater (SW) desalination and brackish water (BW) desalination, respectively. Generally, BWRO is less energy-consuming and more efficient than SWRO because of the low feed salinity [7].

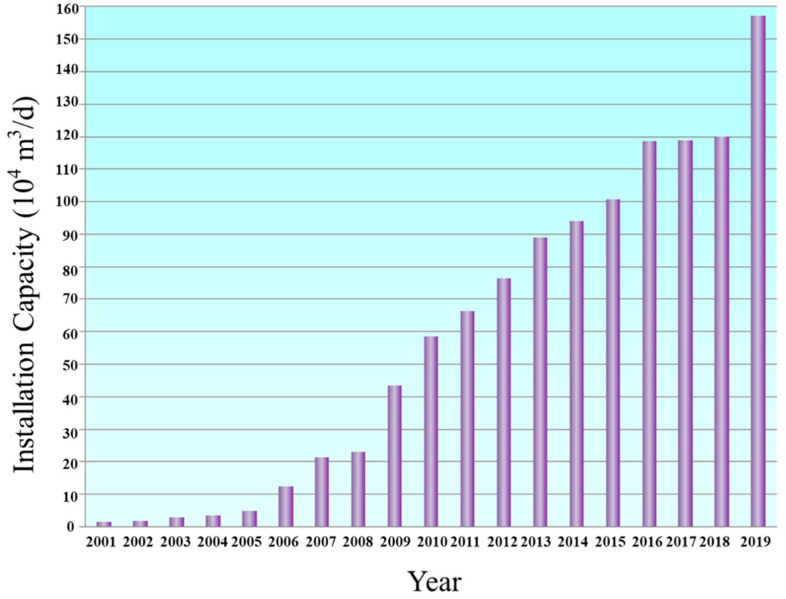

As of the end of 2019, there were 115 seawater desalination plants all together in China, with a total capacity up to 1,573,760 m3/d of potable water (Figure 2) [8]. Particularly, in 2019, China set up 17 desalination plants in Liaoning, Hebei, Shandong, Jiangsu, and Zhejiang, respectively, enabling a desalination capacity of about 399,055 m3/d. These plants were mainly built to supply the coastal industries, including petrochemical industries, steel industries, fossil plants and nuclear plants, etc. The detailed number and capacity range for local seawater desalination projects in China is depicted in Figure 3.

Figure 2.

Diagram for the evolution of national seawater desalination capacity over the past two decades in China [8].

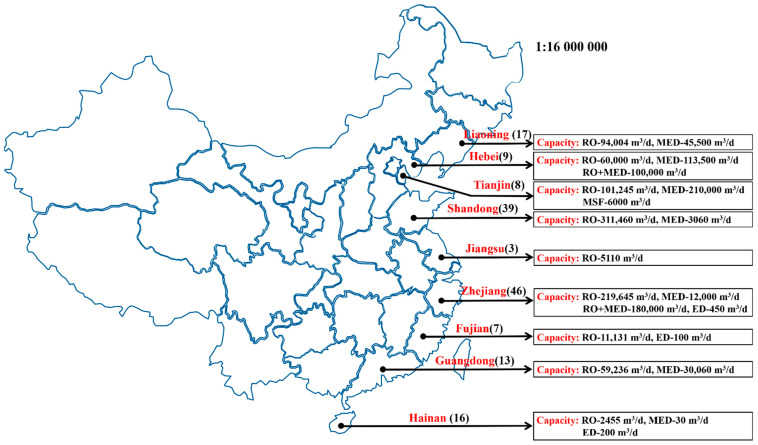

Figure 3.

The detailed number and capacity range for local seawater desalination projects in China.

Of all the seawater desalination plants in China, a majority of 97 plants are operated based on RO, possessing a capacity of 1,000,930 m3/d, which accounts for 63.6% of the total capacity. The second most popular type is MED plants, the number of which adds up to 15, generating 565,530 m3/d water desalination capacity, about 35.9% of the total capacity. There is only one plant that applies the MSF technique, with the capacity of 6000 m3/d, in the proportion of 0.38% of the total capacity. Three other plants rely on electrodialysis technique, exhibiting a capacity of 800 m3/d, less than 0.05% of the total capacity. Another one is based on FO technique, providing a desalination capacity of 500 m3/d, about 0.03% of the total capacity. Over several decades’ evolution, China has gained great progress in desalination industries in terms of products and engineering procurement construction (EPC) companies (Table 1).

Table 1.

Main products and EPC companies in China.

| Classification | Product Brands/Company Names | Location |

|---|---|---|

| Membranes | OriginWater | Beijing |

| Vontron | Guiyang | |

| Toray Bluestar | Beijing | |

| Koch | Beijing | |

| Zhaojin Motian | Yantai | |

| Motech | Tianjin | |

| Scinor | Beijing | |

| Equipment | Shandong Shuanglun | Weihai |

| Nanfang Pump Industry | Hangzhou | |

| Voitu | Shanghai | |

| Kaiquan | Shanghai | |

| Sulzer (Dalian) | Dalian | |

| KSB(Shanghai) | Shanghai | |

| EPC company | Beijing OriginWater Technology Co., Ltd. | Beijing |

| Qingdao Water Group Co., Ltd. | Qingdao | |

| Shanghai Electric Group Co., Ltd. | Shanghai | |

| ISDMU | Tianjin | |

| Hangzhou Water Treatment Technology Development Center Co., Ltd. | Hangzhou | |

| POWCHINA | Beijing |

So far, there have been many interesting review papers on the seawater desalination technology and engineering in China, ranging from the desalination industries, techniques, projects, and energy consumption to economic impact, etc. [9,10,11,12,13,14]. A comprehensive review covering the recent project scales, application scenarios, equipment series, standard systems and technical services undergoing in China, especially those initiated by the leading desalination organization of the Institute of Seawater Desalination and Multipurpose Utilization (ISDMU) is still missing. Therefore, in this review, the recent progress on desalination projects and techniques achieved by China are surveyed. Emphasis is put on the project scale, application scenarios, equipment, techniques, materials and services, especially achieved by ISDMU. In the end, it comes up with some perspectives in the future development of desalination in China.

2. The Main Technical Progress

2.1. The Expanded Project Scale and Single Plant Scale

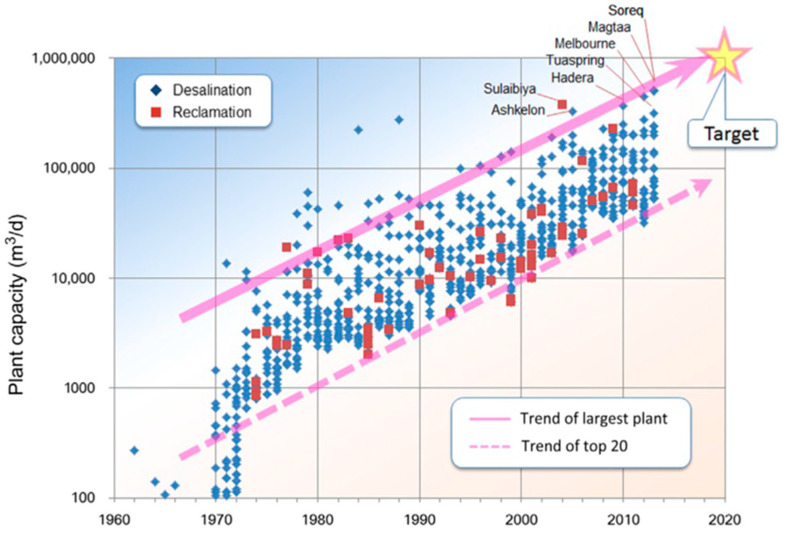

Plant capacity is one of the key indicators of the development degree of the desalination industry. To scale up the plant facility and capacity is highly desirable as larger plants offer the distinct advantages of energy-effectiveness, operational stability, and small footprint. The last 60 years have witnessed the evolution of the seawater desalination capacities of the top 20 plants worldwide, as shown in Figure 4 [15]. All of the plants had undergone steady increases in the plant capacities, especially the largest one in Sorek in Israel, the capacity of which increased by almost 1000-fold over 60 years (achieved 624,000 m3/day) [16]. It is predicted that the capacity of a single SWRO plant could exceed 1,000,000 m3/d in the future.

Figure 4.

The evolution of plant capacity worldwide over the past 60 years. The solid line shows the trend of the capacity of the largest plant and the dashed line showing that of the top 20 plants [15].

In recent years, China has been devoted to expanding the scale of plants as well. So far, the ≥10,000 m3/d desalination plants have added up to 37, with a total capacity of 1,403,848 m3/d. The number of plants with the capacity in therange of 1000–10,000 m3/d has reached 42, exhibiting a capacity of 162,522 m3/d. There are 36 plants under 1000 m3/d, with the total capacity of 7390 m3/d. In 2019, the capacity of largest newly built desalination plant is 180,000 m3/d.

The representative seawater desalination projects with the capacity of >100,000 m3/d are shown in Figure 5. In China, the largest seawater desalination plant of the Beijiang Power Plant MED project owns a capacity of about 2,000,000 m3/d (Figure 5a), whilst the largest SWRO plants in five corresponding projects have the capacity of 100,000 m3/d each (Figure 5b–f). Notably, Befesa SWRO project is attempting to expand its capacity to 200,000 m3/d in the expectation of becoming the largest SWRO plant in China soon. Moreover, it has become more and more popular to apply the integrated membrane/distillation systems in large plants. For example, in Zhejiang petroleum project, it makes good use of SWRO (75,000 m3/d) and MED (105,000 m3/d) in the integrated system.

Figure 5.

Seawater desalination projects with the capacity of >50,000 m3/d in China. (a) Beijiang Power Plant MED project, Tianjin (200,000 m3/d). (b) Dagang New Spring SWRO project, Tianjin (100,000 m3/d). (c) Caofeidian SWRO project, Tangshan (50,000 m3/d). (d) Befesa SWRO project, Qingdao (100,000 m3/d). (e) Dongjiakou SWRO project, Qingdao (100,000 m3/d). (f) Zhejiang Petroleum SWRO/MED project, Zhoushan (180,000 m3/d).

2.2. The Broadening Application Scenarios and Technical Integration

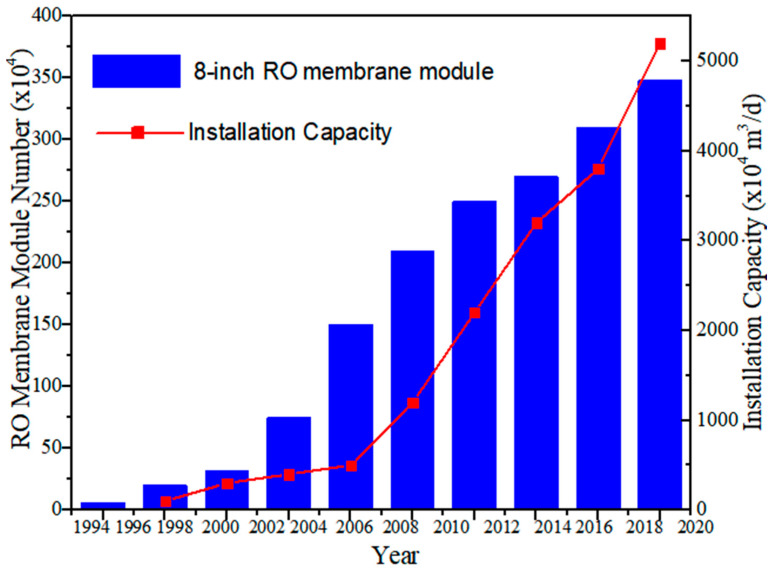

Apart from seawater desalination, desalination technologies have been widely used in other areas, such as water treatment for municipal and industrial usages. According to the statistic released by The Membrane Industry of Association of China (MIAC), the holding number of RO membrane modules has exceeded 3,500,000 and the installation capacity outnumbered 50,000,000 m3/d (Figure 6) [17]. Among them, only about 3% of the capacity was provided to seawater desalination projects (1573,760 m3/d), indicating that RO membranes have been extensively used in many other water treatment projects. Moreover, combination of different desalination technologies has become a new trend for various water treatment scenarios [18,19,20]. For instance, in the project of coal chemical industrial wastewater treatment, RO was coupled with membrane bioreactor (MBR) and MED processes as an integrated system, providing a capacity of 20,000 m3/d.

Figure 6.

The holding number of RO membrane modules and the installation capacity in China.

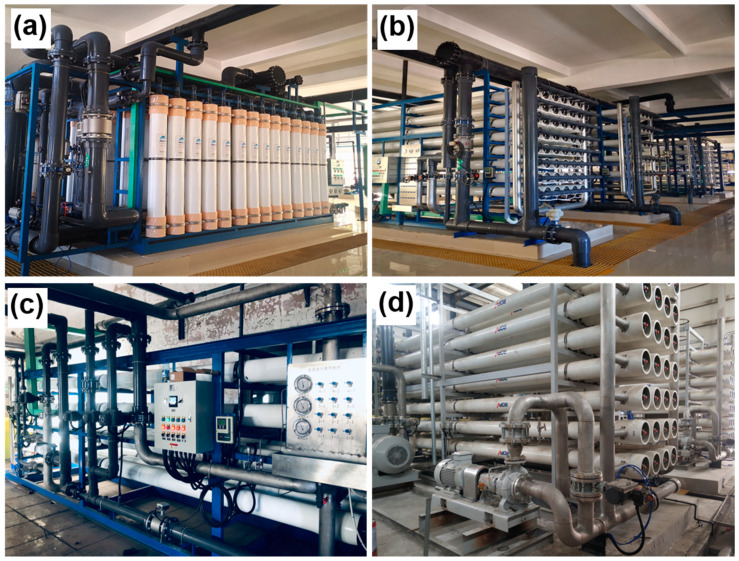

The ISDMU of the Chinese Ministry of Natural Resources, has taken over several industrial wastewater treatment projects in recent years (Figure 7). Despite the application in seawater desalination, desalination technologies have been applied in a wide range of water treatment applications.

Figure 7.

Desalination technologies used in industrial wastewater treatment projects from ISDMU. The ultrafiltration (a) and RO (b) systems for Lianyuan power plant project, Neimeng. (c) Temier power plant project, Neimeng. (d) Tianyu coal chemical industry project, Xinjiang.

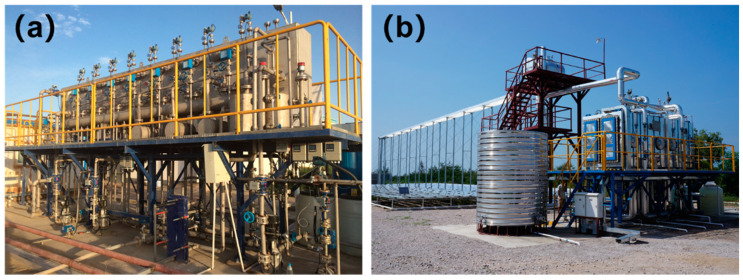

On another hand, efforts have been made in the combination of desalination with other energy technologies, such as nuclear power. Seawater desalination is an energy-intensive and/or thermal-intensive process, while nuclear power plants generally rely on excessive consumption of water for cooling and other operations [21]. The integration of seawater desalination and nuclear power plants could be beneficial for each other. Hongyanhe nuclear power plant SWRO project (10,000 m3/d) is the first to demonstrate the practical application of nuclear power and desalination integrated system. After that, SWRO desalination projects have been utilized in other nuclear power plants, such as Ningde, Sanmen, and Haiyang. Recently, researchers from Shandong have proposed an innovative integration idea, named “Co-transport of water and heat”. In their proposal, the product water from the nuclear desalination undergoes certain post-treatment processes first, following heating by the extra heat from the nuclear power plant. Then the heated desalination water was transported to the users, providing heat and clean water simultaneously. Using this proposal, the traditional three pipe systems could be replaced by one single pipe, thereby reducing the operation cost remarkably. The pilot project for water and heat simultaneous transmission has been put into operation, providing water and heat supply for nearly 2000 people at the same time. It provides technical support and demonstration for long-distance heat and water transmission. Additionally, other renewable energy sources such as solar, wind, and geothermal energy have also been considered as an alternative energy supply or desalination [22]. Particularly, solar energy has been widely applied as a heat source or power source for thermal and/or membrane desalination. In China, several solar-driven desalination projects have been implemented. For example, ISDMU has constructed a solar-driven eight-effect plate distillation in Xinjiang (Figure 8a) and solar-driven MED in Hainan (Figure 8b).

Figure 8.

Solar energy driven desalination projects in China. (a) Solar-driven eight-effect plate distillation in Luntai, Xinjiang (MEP, 24 m3/d). (b) Solar-driven low temperature MED in Ledong, Hainan (30 m3/d).

2.3. Further Improved Equipment Series and Strengthened Supporting Capability

Recent decades have seen great progress and advances in the evolution of seawater desalination facilities and capabilities for marine use. Particularly, ISDMU has developed the abilities in equipment series (Table 2) supply based on different utility sites and energy sources, which are classified as ship-based equipment, island-based equipment and all-in-one integrated equipment.

Table 2.

Specifications of equipment models from ISDMU.

| Model | Water Production Capacity (m3/d) |

Salt Rejection (%) |

Recovery Ratio (%) |

Operational Pressure (MPa) |

Equipment Size L × W × H/cm |

|---|---|---|---|---|---|

| CH-001 a | 1 | 99.2 | 12 | 5.5 | 100 × 60 × 150 |

| CH-005 | 5 | 99.2 | 24 | 5.5 | 100 × 60 × 150 |

| CH-010 | 10 | 99.5 | 30 | 5.5 | 100 × 60 × 160 |

| CH-020 | 20 | 99.5 | 30 | 5.5 | 150 × 75 × 180 |

| CH-050 | 50 | 99.5 | 40 | 5.5 | 190 × 110 × 180 |

| CH-100 | 100 | 99.5 | 40 | 5.5 | 220 × 130 × 180 |

| CH-200 | 200 | 99.5 | 40 | 5.5 | 400 × 150 × 180 |

| DH-005 b | 5 | 99.5 | 24 | 5.5 | 100 × 60 × 150 |

| DH-010 | 10 | 99.5 | 30 | 5.5 | 100 × 60 × 160 |

| DH-020 | 20 | 99.5 | 30 | 5.5 | 100 × 60 × 160 |

| DH-050 | 50 | 99.5 | 40 | 5.5 | 120 × 60 × 170 |

| DH-100 | 100 | 99.5 | 40 | 5.5 | 120 × 60 × 170 |

| DH-200 | 200 | 99.5 | 40 | 5.5 | 150 × 60 × 180 |

| DH-500 | 500 | 99.5 | 40 | 5.5 | 200 × 60 × 180 |

| DHP-005 c | 5 | 99.5 | 30 | 5.5 | 600 × 280 |

| DHP-010 | 10 | 99.5 | 30 | 5.5 | 1000 × 300 |

| DHP-020 | 20 | 99.5 | 30 | 5.5 | 1300 × 300 |

| DHP-050 | 50 | 99.5 | 40 | 5.5 | 2000 × 400 |

| DHP-100 | 100 | 99.5 | 40 | 5.5 | 2500 × 500 |

Note: a CH model series refers to desalination plant for marine use. b DH model series refers to desalination plant for island use. c DHP series refers to wind/light/oil-storage-integrated desalination plant.

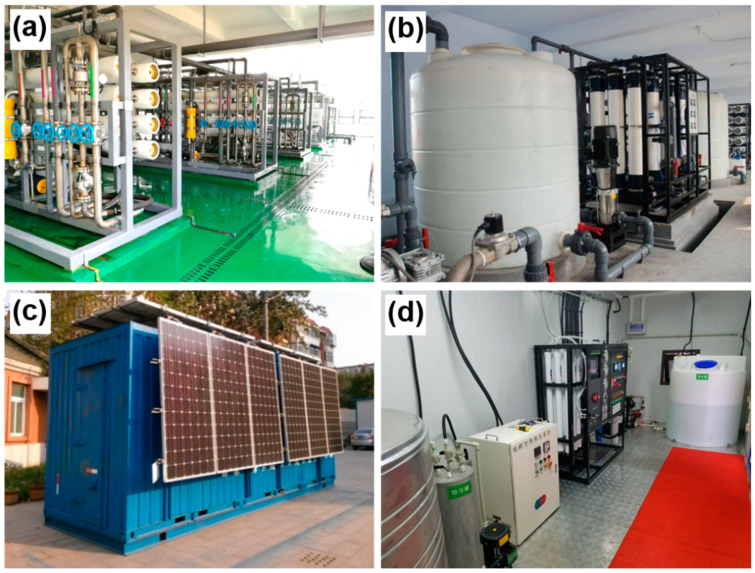

Generally, island-based seawater desalination units are located at remote islands and marine monitoring stations. These instruments should have the advantages of compact structures, less area occupation, easy to install, high automation, easy to operate and maintain. Examples include equipment series in Yongxing island (Figure 9a, with a capacity of 1000 and 100 m3/d, respectively), Chenhang island, Lingyang island, Dongmaozhou island, Xiaoqin island and Zhongjian island (with a capacity of 100 m3/d), Lingshan island in Qingdao (Figure 9b, with a capacity of 300 m3/d), and Daguan island in Qingdao (with a capacity of 5 m3/d using renewable energy). Alternatively, an all-in-one integrated system has been designed and developed to supply fresh water for remote places with no power or network coverages. With the combination of wind, solar, oil, desalination, and intelligent control systems, such a highly integrated plant has its energy supply systems without the need of additional power resources, thereby showing the advantageous features of energy-effective and highly automated operation (Figure 9c). Moreover, a low-temperature tolerable RO equipment realized by integration with thermal devices for extreme conditions, like in the South Pole (Figure 9d), was developed.

Figure 9.

Photographs of some different desalination devices from ISDMU. (a) Yongxing (capacity, 1000 m3/d). (b) Lingshan (capacity, 300 m3/d). (c) The all-in-one system (wind, solar, oil, desalination, and intelligent control integrated into one system). (d) The South Pole (the capacity of 5 m3/d).

Besides, seawater desalination has been extensively employed to generate freshwater to meet the regular need onboard ships (Figure 10) [23]. Such devices are designed specifically for ship users, offering the advantages of small size, lightweight, simple installation, and wide adaptability. Plus, the maintenance of these instruments is convenient and time-saving without frequent washing, as the instruments use one-key start/stop allowing the installation/maintenance to be carried out in narrow spaces, such as the cabins, decks, and corridors [23].

Figure 10.

Seawater desalination devices for ship use [23].

ISDMU has also developed chemical reagents for seawater desalination including scale inhibitors, defoaming agents, fungicides, and cleaning agents [24]. Scale inhibitors showed excellent performance, with the antiscale rate at about 95% [24]. The defoaming agents composed of polyether (SD501) and silicone (SD502), exhibited a defoaming rate of >90% at 70 °C without interfering with the scale inhibitors [24]. The developed DM fungicides have the advantages of broad-spectrum and fast sterilization, easy degradation and residual-free. Meanwhile, the cleaning agents are safe, environmentally friendly, as well as compatible with scale inhibitors and fungicide used. These new reagents have been applied in many desalination projects such as Baifa, Yongxing island, Cape Verde, and Djibouti seawater desalination plant.

In the typical SWRO system, pretreatment processes are utilized to ensure all the particulates are removed before the stream reaching the membranes without the incorporation of any strainers [5,25,26]. However, such pretreatment process is sensitive to the changes of source water characteristics, which would lead to a large consumption of processing chemicals, high operational costs and deterioration of environment [27,28]. Thus, it is desired to come up with new processes that allow minimum consumption of chemicals in different application scenarios.

2.4. Improved Research and Development Ability and Technical Level

2.4.1. Core Components and Equipment

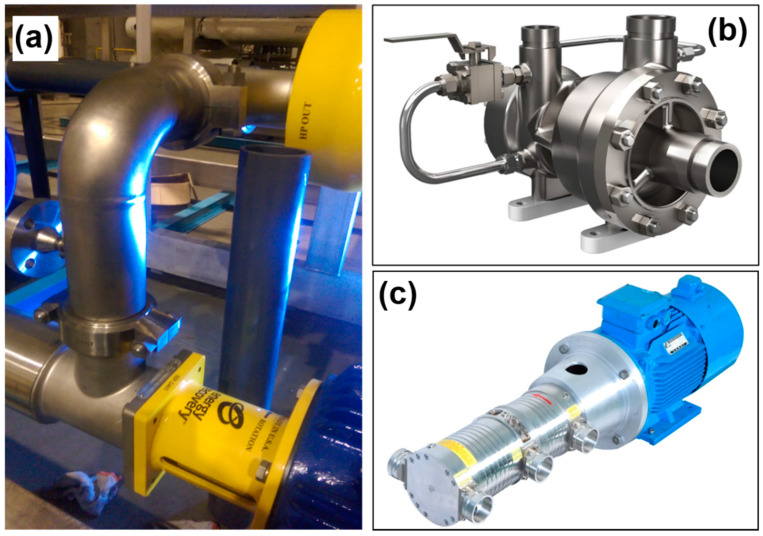

Despite the rapid development of seawater desalination technologies in China, the core materials, components, and equipment (e.g., RO membranes, energy recovery devices, and high-pressure pumps) are still cost sensitive on the importation. In recent years, ISDMU has been devoted to the research and development of key devices of desalination based on theoretic improvement, self-developed simulation and domestic materials. For instance, ISDMU developed a series of titanium-based pipelines and its fittings (Figure 11a), which showed excellent performances in several tropical island seawater desalination projects, especially the anticorrosive activity [29]. Energy recovery devices and high-pressure pumps were developed with higher efficiency and recovery tolerance (Figure 11b,c) [30,31]. The experiences of high-pressure components and the data accumulation of its site applications and cost evaluation will set up new frontier for SWRO material selection.

Figure 11.

Photographs of (a) titanium-based pipelines and (b,c) high-pressure pumps.

2.4.2. Membrane Materials and Technologies

During a desalination process, the membrane is one of the key elements determining the desalination performance. Generally, there are two main types of desalination membranes, namely ultrafiltration (UF) and RO membranes. However, membrane fouling (e.g., organic fouling, scaling/inorganic fouling, and biofouling) is a major concern in membrane-based applications [32]. For example, scaling could induce extra energy and operational cost in the RO process as a result from the contamination in feed water [33]. Membrane surface modification has been developed to improve the membrane antifouling properties, by physical or chemical methods like nanomaterial penetration, mixing, coating, grafting, self-assembly, chemical coupling, physical adsorption, and irradiation, etc. [32,34,35,36,37].

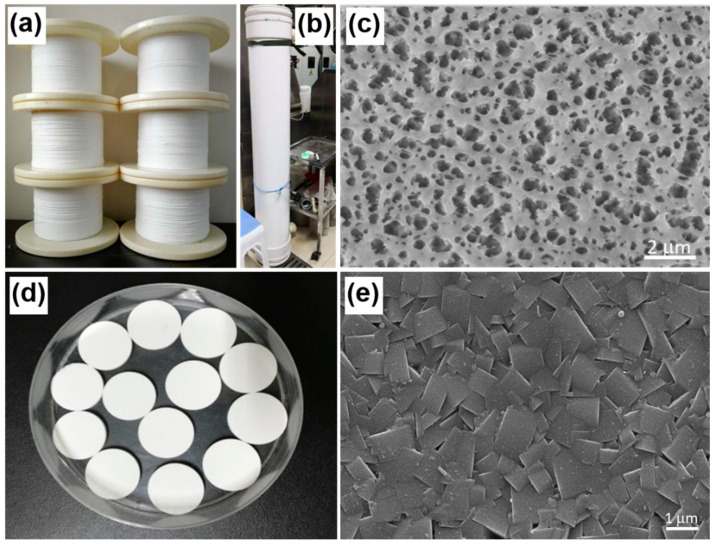

On another hand, novel membrane material synthesis, module design and processing approaches have been broadly explored, rendering the membranes chlorine-resistant, antifouling, stable, and highly efficient in terms of desalination and separation performance. Interested readers are referred to the excellent research and review articles [38,39,40,41,42,43,44,45,46]. In a recent work by ISDMU and Shandong University of Science and Technology, aminophenyl-modified mesoporous silica NPs were used to fabricate RO membranes, enabling enhanced water flux by 21% while maintaining high NaCl rejection of 98.97%, only slightly decreased by 0.29% compared with that of the pristine membrane [47]. Polytetrafluoroethylene (PTFE) hollow-fiber has emerged as a promising candidate for highly efficient water treatment applications due to its acid-resistant, alkali-resistant and antioxidant properties. Recently, ISDMU has developed a pilot line for PTFE hollow-fiber membranes (HFMs), producing versatile PTFE HFMs with tunable diameters of 0.8–1.5 mm and average pore size 0.28–2.17 µm (Figure 12a,c). The self-developed 10-inch module (Figure 12b) based on the produced PTFE HFMs yields the capacity of portable water of 140 L/h with a salt rejection of 99.9% in MD desalination. Apart from MD, PTFE HFMs are also widely used for UF desalination. Alternatively, ceramic membranes have been developed with outstanding features of tunable microstructures, excellent chemical and thermal properties, long lifetime, and little environmental impact [48]. Ceramic membranes are mostly used in UF, whilst in some cases, are used in NF and RO desalination applications. Some new types of ceramic membranes made of low-cost geomaterials from nature (i.e., clay, apatite, zeolite, and sand) have become a focus of research interests [49,50,51,52]. For instance, ISDMU has invented novel MFI-type zeolite membranes, for RO desalination applications (Figure 12d,e, unpublished work), exhibiting high salt rejection with diminished absorption for hydrated metal ions in saline water.

Figure 12.

Photographs of (a) PTFE hollow-fiber membrane and (b) the membrane module. (c) Scanning electron microscopy (SEM) surface image of the PTFE hollow-fiber membrane. (d) Photograph and (e) SEM surface image of the MFI-type zeolite membrane (unpublished work).

Researchers from the Nanjing University of Technology have promoted the advancement of ceramic membranes and cut the price of imported ceramic membranes in Chinese markets [17]. It is mainly realized by shifting the research focus from process engineering to nanostructured membrane design, the fabrication technology from experience-driven to quantification control. Up to now, the domestic enterprise values of the ceramic membrane industries have risen from the initial million to 100-million scale. Large scale production lines for ceramic membranes have enabled their applications in traditional Chinese medicine clarification, biological fermentation broth purification, petro-chemical as well as environmental protection fields [17]. The ceramic membranes developed in China exhibited better separation and operational stability, more than 1000 application cases, and exported to 55 countries. Some typical ceramic membrane projects have been listed in Table 3. In supplement for ultra-large companies, listed companies, large private enterprises, as well as research institutions, the ceramic membrane markets have brought about more than one-billion-yuan direct profits and 10-billion-yuan indirect profits [17]. The development of ceramic membranes in Chinese industries is considered to be continuously accelerating in the future.

Table 3.

Summary of some typical ceramic membrane projects in China.

| Company | Project Name | Area | Feed Solution | Capacity |

|---|---|---|---|---|

| Jiangsu Jindong Salt Refining Co., Ltd. | Salt refining project | Process dissociation | Saline water | 800 m3/h |

| Wudi Xinyue Chemical Co., Ltd. | Ionic membrane caustic soda one pass salt refining project | Process dissociation | Saline water | 360 m3/h |

| Shandong Haobang Chemical Co., Ltd. | Ionic membrane caustic soda one pass salt refining project | Process dissociation | Saline water | 360 m3/h |

| Hulun Buir Northeast Bufeng Biotechnology Co., Ltd. | Continuous separation of fermented broth | Process dissociation | Fermented broth | 1200 m3/d |

| Xinjiang Bufeng Biotechnology Co., Ltd. | Continuous separation of fermented broth | Process dissociation | Fermented broth | Valine, 900 m3/d Isoleucine, 800 m3/d |

| Yili Chuanning Biotechnology Co., Ltd. | Continuous separation of fermented broth | Process dissociation | Fermented broth | 400 m3/d |

| North China Pharmaceutical Hebei Huamin Company, Ltd. | The continuous filtration system of fermented broth |

Process dissociation | Fermented broth | 300 m3/d |

2.4.3. Chemical Resources Recovery

Seawater contains a large number of chemicals which could potentially be extracted to add to the chemical resources on the land. It has drawn the world’s attention to recover and reuse these chemical resources for the sake of sustainable development of natural resources. In conventional desalination process, especially SWRO, rejected brine containing the majority of chemicals was supposed to discharge into the ground or sea. Thus, it is essential to improve the recovery of chemical resources from the brine to alleviate the discharge environmental compact. Various strategies have been proposed, including solar ponds, membrane distillation/crystallization, electrodialysis and reverse electrodialysis, chemical precipitation, adsorption/desorption, eutectic freezing and crystallization, pressure infiltration and microbial desalination ponds [53]. Apart from salt, the main chemical resources produced from brine include bromine, potassium chloride, magnesium chloride, magnesium sulfate, and potassium sulfate, etc. In China, most of such enterprises are located in Tianjin, Hebei, Shandong, Fujian, and Hainan. The Chinese government offers great financial supports for research programs on chemical resource recovery from brine, promoting advances in unique chemical extraction technologies, high efficiency equipment and industrial-level energy-saving demonstration. ISDMU has achieved progress in the research of continuous hydrothermal preparation of high purity magnesium hydroxide as well as in the construction of a pilot line for the macro process. Still, there are some challenges in these areas such as high costs, large energy consumption, relatively deficient equipment, and low efficiency. In 2019, Tianjin Changlu Hangu Saltern Co., Ltd. (Tianjin, China) successfully implemented the equipment remodeling for bromine recovery from highly concentrated seawater, enabling the construction of thousand-ton demonstration installation. As a result, the energy consumption was reduced by nearly 10% and the recovery rate increased by 8%, providing excellent demonstration for further applications of this technology in Shandong and other places (unpublished work). The extraction of strategic chemical elements such as lithium and uranium through inorganic ion adsorption method is still in the experimental stage.

2.4.4. Boron Removal

Seawater contains varied content of boron in different geographical locations. Typical, the boron content is in the range of 4–6 mg/L in most seawater resources whilst about 4.6 mg/L in standard seawater [54]. The existence of residual borides from desalination has become a major concern among people, as minute boron would be detrimental to human health and plant growth. The limit level of boron content in drinking water was established in different countries to guarantee safe drinking, for example, the World Health Organization (WHO, 2.4 mg/L, 2011), Japan (1.0 mg/L, 2015), European Commission (1.0 mg/L, 1998), and China (0.5 mg/L, 2006) [55]. As the majority of the boron compounds in seawater is in the form of small molecules of H3BO3 and the remaining being H2BO3-, it is difficult to get rid of boron residues to meet such criterion via traditional desalination [55]. In fact, the removal of boron can be sensitive to the temperature, salinity and pH of the feed water in the thermal desalination processes [56]. Whilst, in SWRO, the boron removal level is closely related to the pH value, which affects the dissociation of boric acid and surface charge negativity of the RO membrane [57]. Moreover, two-pass system or integrated technologies have been adopted in SWRO to realize the higher boron removal in desalination [58].

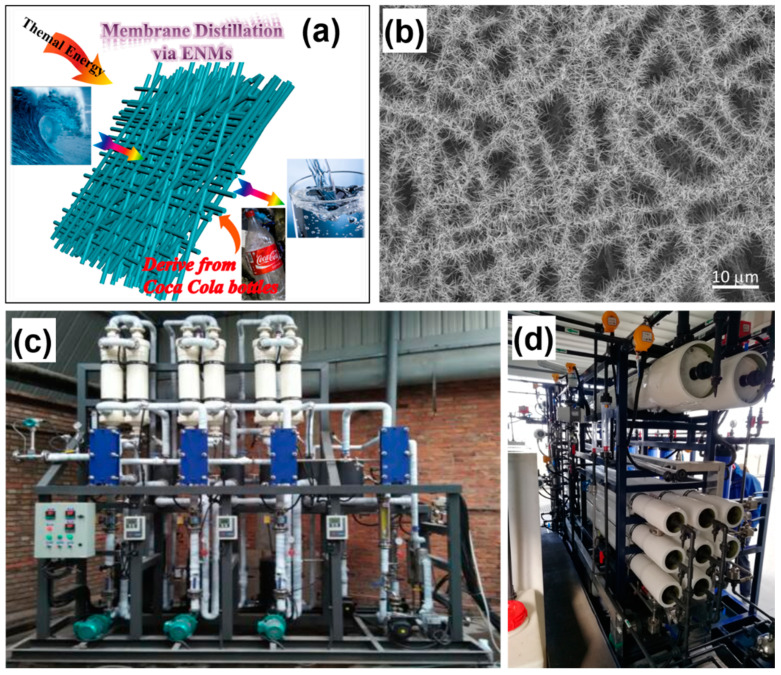

2.4.5. Novel Technologies

ISDMU has undertaken a lot of research based on desalination technologies beyond traditional SWRO process, including but not limited to MD, FO and CDI [59,60,61]. For example, Xu et al. reported a novel electrospun nanofibril membrane derived from Coca Cola bottles (Figure 13a), which was successfully used in the MD process [59]. In another ongoing work, the performance of the membrane was improved by enhancing the hydrophobicity of the membrane surface through hierarchical inorganic nanostructure design (Figure 13b). Figure 13c displays the pilot equipment based on a novel three-effect MD process, the capacity of which turned out to be 2 m3/d. This configuration was designed to promote thermal energy efficiency by reusing latent evaporation heat. It should be noted that FO, MD, or CDI is not standalone and always combined with other technologies (i.e., hybrid configuration) when being used in desalination [62]. For example, FO-NF, FO-RO, and FO-MD hybrid systems were designed for wastewater reuse [63,64,65]. A FO-RO hybrid system was used to improve the antifouling and antiscaling properties of desalination [66]. A RO-MD-PRO hybrid system was used to increase the energy efficiency of desalination [67]. In China, FO and MD have been applied in high-concentration water treatment whilst CDI is only for lab-scale study. As depicted in Figure 13d, an FO-MD hybrid system was designed exhibiting a capacity of 12.5 m3/d. FO, as a spontaneous osmotic-driven process, was coupled with MD to recover water from draw solutions while the MD process was used to concentrate the draw solution from FO to obtain the maximum energy utilization. Furthermore, as an emerging novel desalination technology, FO has undergone significant development during the past decades, due to its high energy efficiency and favorable separation performances [68]. Interested readers are referred to the excellent review literature on FO [69,70,71].

Figure 13.

(a) A brief illustration of MD membranes based on the electrospun nanofibrous membranes derived from Coca Cola bottles [59]. (b) SEM image of the hierarchical nanostructures on nanofibrous membranes (unpublished work). (c) Three-effect MD pilot equipment with a capacity of 2 m3/d. (d) A hybrid FO-MD system.

2.5. Enriched Standard Systems and Technical Services

As of the end of 2019, China had established 166 standards on seawater utilization, including 43 national standards, 116 industrial standards, and 7 local standards. ISDMU is conducting the first ISO standard on the product water of seawater desalination and it is speculated to be released in 2021.

ISDMU is planning to build the seawater desalination innovation base, combining the functions of scientific research, detection and evaluation, product development, reconnaissance design, communication and training, and information integration. In November of 2016, the construction of pilot laboratory started, with the investment of about CNY 0.46 billion for infrastructure and about CNY 0.5 billion for instruments and equipment. This pilot laboratory would provide platforms for seawater resources innovative utilization, including seawater desalination innovative service, island and vessel use small-medium desalination manufacturing, preparation and evaluation of chemical agents, and desalination device monitoring/evaluating platforms. The second phase project would mainly involve the construction of research buildings, testing centers, information centers as well as reconnaissance and design institute, etc.

This project would bring about a series of benefits for the desalination market and industry which entail (1) providing high-end research facilities for breaking the bottleneck technical problems for self-developed products; (2) enabling the third-party evaluation of related products from home and abroad and promoting their market application; (3) offering industry–academia–research innovative centers and attracting excellent research teams from both home and abroad for collaborations; (4) enabling the pilot experiments of the laboratory outcome to facilitate the maturation of the technology; (5) attracting the joining of innovative technologies and personnel to become the center of innovation and one of the world’s competitive desalination industrial communities

3. Summary and Perspectives

In the long term, it is of significant importance to develop desalination technologies to face the challenges of global water crisis. Desalination technologies in China are vital both in the field of freshwater extraction from the sea and the improvement of water environment and ecology. Specifically, emphasis should be put on the following aspects.

-

(1)

Technology innovation

Further improve the performance of large-scale SWRO plants. Efforts include the enlargement of single unit capacity, decrease of energy consumption, improvement of system integration, operational stability and reliability, and desalination cost. Further endeavors should be made towards pretreatment and system instrumentation, high-performance RO membranes and elements, high-pressure pumps and energy recovery devices, etc.

-

(2)

Utilization of chemical resources from seawater

The extraction and reuse of chemical resources from seawater desalination is an attractive topic from a scientific point of view. Better technologies need to be explored to recover chemicals and reduce possible cost. Moreover, the extraction of strategic elements such as lithium and uranium is more challenging and needs better technologies.

-

(3)

Green pretreatment methods

Attention should be paid to the development of green pretreatments involving green antiscaling agents and agent-free biological methods. It is advisable to investigate electrocoagulation and dissolved air flotation techniques.

-

(4)

Emerging desalination technologies

Apart from the traditional SWRO desalination technologies, emerging technologies including MD, CDI, and ED desalination processes require more research efforts, from the exploitation of novel membrane materials to the fabrication of core components and equipment. In addition, hybrid systems coupling the traditional technologies and the emerging technologies should be further promoted to make the most of the less-popular technologies.

Overall, with the ongoing research and development of desalination, China is believed to play a more and more important role in the international desalination market with remarkable openness and inclusiveness, providing state-of-the-art desalination technologies, facilities and services, benefitting the water-stressed countries and regions in the world.

Author Contributions

G.R. conceptualized the idea of this review and guided the preparation of the manuscript. M.W., Z.A., G.X. and Y.G. reviewed the literature and prepared the original draft. M.W. and G.X. edited the manuscript and arranged the graphs. H.Z. supervised the project and guided the preparation of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

The research work was funded by National Key Research and Development Plan (No. 2018YFE0196000), Tianjin Technical Cooperation R&D and Industrialization Projects for the Belt and Road Initiative (Grant Number: 18YDYGHZ00100) and Central-Level Research Institutes Fundamental Research Team Project (K-JBYWF-2019-CR02).

Conflicts of Interest

The authors declare no conflict of interest.

Footnotes

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Elimelech M., Phillip W.A. The future of seawater desalination: Energy, technology, and the environment. Science. 2011;333:712. doi: 10.1126/science.1200488. [DOI] [PubMed] [Google Scholar]

- 2.Shannon M.A., Bohn P.W., Elimelech M., Georgiadis J.G., Mariñas B.J., Mayes A.M. Science and technology for water purification in the coming decades. Nature. 2008;452:301–310. doi: 10.1038/nature06599. [DOI] [PubMed] [Google Scholar]

- 3.Jones E., Qadir M., van Vliet M.T.H., Smakhtin V., Kang S.-m. The state of desalination and brine production: A global outlook. Sci. Total Environ. 2019;657:1343–1356. doi: 10.1016/j.scitotenv.2018.12.076. [DOI] [PubMed] [Google Scholar]

- 4.Nassrullah H., Anis S.F., Hashaikeh R., Hilal N. Energy for desalination: A state-of-the-art review. Desalination. 2020;491:114569. doi: 10.1016/j.desal.2020.114569. [DOI] [Google Scholar]

- 5.Valavala R., Sohn J., Han J., Her N., Yoon Y. Pretreatment in reverse osmosis seawater desalination: A short review. Environ. Eng. Res. 2011;16:205–212. doi: 10.4491/eer.2011.16.4.205. [DOI] [Google Scholar]

- 6.Qasim M., Badrelzaman M., Darwish N.N., Darwish N.A., Hilal N. Reverse osmosis desalination: A state-of-the-art review. Desalination. 2019;459:59–104. doi: 10.1016/j.desal.2019.02.008. [DOI] [Google Scholar]

- 7.Ruiz-García A., Nuez I., Carrascosa-Chisvert M.D., Santana J.J. Simulations of BWRO systems under different feedwater characteristics. Analysis of operation windows and optimal operating points. Desalination. 2020;491:114582. doi: 10.1016/j.desal.2020.114582. [DOI] [Google Scholar]

- 8.2019 National Bulletin of Seawater Use. [(accessed on 18 October 2020)]; Available online: http://www.gov.cn/xinwen/2020-10/18/content_5552185.htm.

- 9.Lin S., Zhao H., Zhu L., He T., Chen S., Gao C., Zhang L. Seawater desalination technology and engineering in China: A review. Desalination. 2021;498:114728. doi: 10.1016/j.desal.2020.114728. [DOI] [Google Scholar]

- 10.Liu S.Y., Wang Z.Y., Han M.Y., Wang G.D., Hayat T., Chen G.Q. Energy-water nexus in seawater desalination project: A typical water production system in China. J. Clean. Prod. 2021;279:123412. doi: 10.1016/j.jclepro.2020.123412. [DOI] [Google Scholar]

- 11.Wang H., Jiang X. Legal measures to reduce marine environmental risks of seawater desalination in China. Nat. Resour. Forum. 2020;44:129–143. doi: 10.1111/1477-8947.12188. [DOI] [Google Scholar]

- 12.Zheng X., Chen D., Wang Q., Zhang Z. Seawater desalination in China: Retrospect and prospect. Chem. Eng. J. 2014;242:404–413. doi: 10.1016/j.cej.2013.12.104. [DOI] [Google Scholar]

- 13.Zhang L., Xie L., Chen H.-L., Gao C.-J. Progress and prospects of seawater desalination in China. Desalination. 2005;182:13–18. doi: 10.1016/j.desal.2005.03.005. [DOI] [Google Scholar]

- 14.Zhou Y., Tol R.S.J. Implications of desalination for water resources in China—An economic perspective. Desalination. 2004;164:225–240. doi: 10.1016/S0011-9164(04)00191-2. [DOI] [Google Scholar]

- 15.Kurihara M., Takeuchi H. Current Trends and Future Developments on (Bio-) Membranes. Elsevier; Amsterdam, The Netherlands: 2019. The next generation energy efficient membrane desalination system with advanced key technologies; pp. 387–406. [DOI] [Google Scholar]

- 16.World’s Largest SWRO desalination Plant Operational. [(accessed on 21 October 2013)]; Available online: Https://www.desalination.biz/news/0/Worlds-largest-SWRO-desalination-plant-operational/7292/

- 17.The Membrane Industry of Association of China . 2019–2020 National Bulletin of Membrane Industry Development. The Membrane Industry of Association of China; Beijing, China: 2020. [Google Scholar]

- 18.Yao S., Ji M. A small RO and MCDI coupled seawater desalination plant and its performance simulation analysis and optimization. Processes. 2020;8:944. doi: 10.3390/pr8080944. [DOI] [Google Scholar]

- 19.Khoshgoftar Manesh M.H., Ghalami H., Amidpour M., Hamedi M.H. Optimal coupling of site utility steam network with MED-RO desalination through total site analysis and exergoeconomic optimization. Desalination. 2013;316:42–52. doi: 10.1016/j.desal.2013.01.022. [DOI] [Google Scholar]

- 20.Tourab E., Blanco-Marigorta A.M., Elharidi A.M., Suárez-López M.J. A novel humidification technique used in water desalination systems based on the humidification-dehumidification process: Experimentally and theoretically. Water. 2020;12:2264. doi: 10.3390/w12082264. [DOI] [Google Scholar]

- 21.Kavvadias K.C., Khamis I. Sensitivity analysis and probabilistic assessment of seawater desalination costs fueled by nuclear and fossil fuel. Energy Policy. 2014;74:S24–S30. doi: 10.1016/j.enpol.2014.01.033. [DOI] [Google Scholar]

- 22.Alkaisi A., Mossad R., Sharifian-Barforoush A. A review of the water desalination systems integrated with renewable energy. Energy Procedia. 2017;110:268–274. doi: 10.1016/j.egypro.2017.03.138. [DOI] [Google Scholar]

- 23.Seawater Desalination Equipment Series for Ship Use. [(accessed on 20 April 2020)]; Available online: http://www.tjlanshizi.cn/chanpinyufuwu/haishuidanhuazhuangzhi/20200420/7.html.

- 24.Products: Chemical Reagents for Seawater Desalination. [(accessed on 9 October 2018)]; Available online: http://www.zhonghaiscl.com/index.php?m=content&c=index&a=lists&catid=21.

- 25.Abushaban A.M.J., Mangal M.N., Salinas-Rodriguez S.G., Nnebuo C., Mondal S., Goueli S.A., Schippers J.C., Kennedy M.D. Direct measurement of ATP in seawater and application of ATP to monitor bacterial growth potential in SWRO pre-treatment systems. Desalination Water Treat. Sci. Eng. 2017;99:91–101. doi: 10.5004/dwt.2017.21783. [DOI] [Google Scholar]

- 26.Alshahri A.H., Dehwah A.H.A., Leiknes T., Missimer T.M. Organic carbon movement through two SWRO facilities from source water to pretreatment to product with relevance to membrane biofouling. Desalination. 2017;407:52–60. doi: 10.1016/j.desal.2016.12.015. [DOI] [Google Scholar]

- 27.Kim J., Park K., Hong S. Application of two-stage reverse osmosis system for desalination of high-salinity and high-temperature seawater with improved stability and performance. Desalination. 2020;492:114645. doi: 10.1016/j.desal.2020.114645. [DOI] [Google Scholar]

- 28.Bick A., Oron G. Post-treatment design of seawater reverse osmosis plants: Boron removal technology selection for potable water production and environmental control. Desalination. 2005;178:233–246. doi: 10.1016/j.desal.2005.01.001. [DOI] [Google Scholar]

- 29.Zhao F., Wang C., Zhou C., Liu S., Qiu G. The Utility Model Relates to an Angle Fine-Tuning Device for Seawater Desalination High Pressure Bending Pipe and Its Working Method. CN111496033A. Patent China. 2021 Feb 2;

- 30.Song D., Liu S., Wang S., Chu X., Huang Y., Jiang Z. High Pressure Pump Energy Recovery Machine with Adjustable Flow. CN107829896A. Patent China. 2018 Mar 23;

- 31.Liu S., Wang S., Wang C., Song D., Wang H., Huang Y., Qiu G. The Invention Relates to a Rotating Guide Vane Module Regulated under Hydraulic Working Conditions and an Assembly Method Thereof in a Turbine Pump. CN110410361A. Patent China. 2019 Nov 5;

- 32.Goh P.S., Zulhairun A.K., Ismail A.F., Hilal N. Contemporary antibiofouling modifications of reverse osmosis desalination membrane: A review. Desalination. 2019;468:114072. doi: 10.1016/j.desal.2019.114072. [DOI] [Google Scholar]

- 33.Ruiz-García A., Feo-García J. Estimation of maximum water recovery in RO desalination for different feedwater inorganic compositions. Desalination Water Treat. 2017;70:34–35. doi: 10.5004/dwt.2017.20476. [DOI] [Google Scholar]

- 34.Ruiz-García A., Melián-Martel N., Mena V. Fouling characterization of RO membranes after 11years of operation in a brackish water desalination plant. Desalination. 2018;430:180–185. doi: 10.1016/j.desal.2017.12.046. [DOI] [Google Scholar]

- 35.Ahmed F.E., Hashaikeh R., Hilal N. Fouling control in reverse osmosis membranes through modification with conductive carbon nanostructures. Desalination. 2019;470:114118. doi: 10.1016/j.desal.2019.114118. [DOI] [Google Scholar]

- 36.Melián-Martel N., Sadhwani Alonso J.J., Ruiz-García A. Combined silica and sodium alginate fouling of spiral-wound reverse osmosis membranes for seawater desalination. Desalination. 2018;439:25–30. doi: 10.1016/j.desal.2018.03.032. [DOI] [Google Scholar]

- 37.Karabelas A.J., Mitrouli S.T., Kostoglou M. Scaling in reverse osmosis desalination plants: A perspective focusing on development of comprehensive simulation tools. Desalination. 2020;474:114193. doi: 10.1016/j.desal.2019.114193. [DOI] [Google Scholar]

- 38.Johnson D.J., Hilal N. Can graphene and graphene oxide materials revolutionise desalination processes? Desalination. 2021;500:114852. doi: 10.1016/j.desal.2020.114852. [DOI] [Google Scholar]

- 39.Alihemati Z., Hashemifard S.A., Matsuura T., Ismail A.F., Hilal N. Current status and challenges of fabricating thin film composite forward osmosis membrane: A comprehensive roadmap. Desalination. 2020;491:114557. doi: 10.1016/j.desal.2020.114557. [DOI] [Google Scholar]

- 40.Alnoor O., Laoui T., Ibrahim A., Kafiah F., Nadhreen G., Akhtar S., Khan Z. Graphene oxide-based membranes for water purification applications: Effect of plasma treatment on the adhesion and stability of the synthesized membranes. Membranes. 2020;10:292. doi: 10.3390/membranes10100292. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Anis S.F., Hashaikeh R., Hilal N. Functional materials in desalination: A review. Desalination. 2019;468:114077. doi: 10.1016/j.desal.2019.114077. [DOI] [Google Scholar]

- 42.Yao Y., Zhang P., Jiang C., DuChanois R.M., Zhang X., Elimelech M. High performance polyester reverse osmosis desalination membrane with chlorine resistance. Nat. Sustain. 2021;4:138–146. doi: 10.1038/s41893-020-00619-w. [DOI] [Google Scholar]

- 43.Han H., Dai R., Wang Z. Fabrication of high-performance thin-film composite nanofiltration membrane by dynamic calcium-carboxyl intra-bridging during post-treatment. Membranes. 2020;10:137. doi: 10.3390/membranes10070137. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Anis S.F., Hashaikeh R., Hilal N. Reverse osmosis pretreatment technologies and future trends: A comprehensive review. Desalination. 2019;452:159–195. doi: 10.1016/j.desal.2018.11.006. [DOI] [Google Scholar]

- 45.Ahmed F.E., Hashaikeh R., Hilal N. Hybrid technologies: The future of energy efficient desalination—A review. Desalination. 2020;495:114659. doi: 10.1016/j.desal.2020.114659. [DOI] [Google Scholar]

- 46.Kim N., Lee J., Kim S., Hong S.P., Lee C., Yoon J., Kim C. Short review of multichannel membrane capacitive deionization: Principle, current status, and future prospect. Appl. Sci. 2020;10:683. doi: 10.3390/app10020683. [DOI] [Google Scholar]

- 47.Wang J., Wang Q., Gao X., Tian X., Wei Y., Cao Z., Guo C., Zhang H., Ma Z., Zhang Y. Surface modification of mesoporous silica nanoparticle with 4-triethoxysilylaniline to enhance seawater desalination properties of thin-film nanocomposite reverse osmosis membranes. Front. Environ. Sci. Eng. 2019;14:6. doi: 10.1007/s11783-019-1185-5. [DOI] [Google Scholar]

- 48.Elomari H., Achiou B., Ouammou M., Albizane A., Bennazha J., Alami Younssi S., Elamrani I. Elaboration and characterization of flat membrane supports from Moroccan clays. Application for the treatment of wastewater. Desalination Water Treat. 2016;57:20298–20306. doi: 10.1080/19443994.2015.1110722. [DOI] [Google Scholar]

- 49.Das R., Sondhi K., Majumdar S., Sarkar S. Development of hydrophobic clay–alumina based capillary membrane for desalination of brine by membrane distillation. J. Asian Ceram. Soc. 2016;4:243–251. doi: 10.1016/j.jascer.2016.04.004. [DOI] [Google Scholar]

- 50.Abo-Almaged H.H., Gaber A.A. Synthesis and characterization of nano-hydroxyapatite membranes for water desalination. Mater. Today Commun. 2017;13:186–191. doi: 10.1016/j.mtcomm.2017.10.002. [DOI] [Google Scholar]

- 51.Zhu B., Hong Z., Milne N., Doherty C.M., Zou L., Lin Y.S., Hill A.J., Gu X., Duke M. Desalination of seawater ion complexes by MFI-type zeolite membranes: Temperature and long term stability. J. Membr. Sci. 2014;453:126–135. doi: 10.1016/j.memsci.2013.10.071. [DOI] [Google Scholar]

- 52.Alftessi S.A., Othman M.H.D., Adam M.R., Farag T.M., Ismail A.F., Rahman M.A., Jaafar J., Habib M.A., Raji Y.O., Hubadillah S.K. Novel silica sand hollow fibre ceramic membrane for oily wastewater treatment. J. Environ. Chem. Eng. 2021;9:104975. doi: 10.1016/j.jece.2020.104975. [DOI] [Google Scholar]

- 53.Mohammad A.F., El-Naas M.H., Al-Marzouqi A.H., Suleiman M.I., Al Musharfy M. Optimization of magnesium recovery from reject brine for reuse in desalination post-treatment. J. Water Process. Eng. 2019;31:100810. doi: 10.1016/j.jwpe.2019.100810. [DOI] [Google Scholar]

- 54.Boubakri A., Bouguecha S.A.-T., Dhaouadi I., Hafiane A. Effect of operating parameters on boron removal from seawater using membrane distillation process. Desalination. 2015;373:86–93. doi: 10.1016/j.desal.2015.06.025. [DOI] [Google Scholar]

- 55.Güler E., Kaya C., Kabay N., Arda M. Boron removal from seawater: State-of-the-art review. Desalination. 2015;356:85–93. doi: 10.1016/j.desal.2014.10.009. [DOI] [Google Scholar]

- 56.Alpatova A., Alsaadi A., Ghaffour N. Boron evaporation in thermally-driven seawater desalination: Effect of temperature and operating conditions. J. Hazard. Mater. 2018;351:224–231. doi: 10.1016/j.jhazmat.2018.02.056. [DOI] [PubMed] [Google Scholar]

- 57.Rahmawati K., Ghaffour N., Aubry C., Amy G.L. Boron removal efficiency from Red Sea water using different SWRO/BWRO membranes. J. Membr. Sci. 2012;423–424:522–529. doi: 10.1016/j.memsci.2012.09.004. [DOI] [Google Scholar]

- 58.Ban S.-H., Im S.-J., Cho J., Jang A. Comparative performance of FO-RO hybrid and two-pass SWRO desalination processes: Boron removal. Desalination. 2019;471:114114. doi: 10.1016/j.desal.2019.114114. [DOI] [Google Scholar]

- 59.Xu G.-R., An X.-C., Das R., Xu K., Xing Y.-L., Hu Y.-X. Application of electrospun nanofibrous amphiphobic membrane using low-cost poly (ethylene terephthalate) for robust membrane distillation. J. Water Process Eng. 2020;36:101351. doi: 10.1016/j.jwpe.2020.101351. [DOI] [Google Scholar]

- 60.Xing Y.-L., Qi C.-H., Feng H.-J., Lv Q.-C., Xu G.-R., Lv H.-Q., Wang X. Performance study of a pilot-scale multi-effect vacuum membrane distillation desalination plant. Desalination. 2017;403:199–207. doi: 10.1016/j.desal.2016.07.008. [DOI] [Google Scholar]

- 61.Xu K., Liu Y., An Z., Xu G., Gadgil A.J., Ruan G. The polymeric conformational effect on capacitive deionization performance of graphene oxide/polypyrrole composite electrode. Desalination. 2020;486:114407. doi: 10.1016/j.desal.2020.114407. [DOI] [Google Scholar]

- 62.Ghaffour N., Soukane S., Lee J.G., Kim Y., Alpatova A. Membrane distillation hybrids for water production and energy efficiency enhancement: A critical review. Appl. Energy. 2019;254:113698. doi: 10.1016/j.apenergy.2019.113698. [DOI] [Google Scholar]

- 63.Giagnorio M., Ricceri F., Tagliabue M., Zaninetta L., Tiraferri A. Hybrid forward osmosis-nanofiltration for wastewater reuse: System design. Membranes. 2019;9:61. doi: 10.3390/membranes9050061. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 64.Choi B.G., Kim D.I., Hong S. Fouling evaluation and mechanisms in a FO-RO hybrid process for direct potable reuse. J. Membr. Sci. 2016;520:89–98. doi: 10.1016/j.memsci.2016.07.035. [DOI] [Google Scholar]

- 65.Xie M., Nghiem L.D., Price W.E., Elimelech M. A forward osmosis-membrane distillation hybrid process for direct sewer mining: System performance and limitations. Environ. Sci. Technol. 2013;47:13486–13493. doi: 10.1021/es404056e. [DOI] [PubMed] [Google Scholar]

- 66.Zaviska F., Chun Y., Heran M., Zou L. Using FO as pre-treatment of RO for high scaling potential brackish water: Energy and performance optimisation. J. Membr. Sci. 2015;492:430–438. doi: 10.1016/j.memsci.2015.06.004. [DOI] [Google Scholar]

- 67.Kim J., Park M., Shon H.K., Kim J.H. Performance analysis of reverse osmosis, membrane distillation, and pressure-retarded osmosis hybrid processes. Desalination. 2016;380:85–92. doi: 10.1016/j.desal.2015.11.019. [DOI] [Google Scholar]

- 68.Kim C., Lee C., Kim S.W., Kim C.S., Kim I.S. Performance evaluation and fouling propensity of forward osmosis (FO) membrane for reuse of spent dialysate. Membranes. 2020;10:438. doi: 10.3390/membranes10120438. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 69.Suwaileh W., Pathak N., Shon H., Hilal N. Forward osmosis membranes and processes: A comprehensive review of research trends and future outlook. Desalination. 2020;485:114455. doi: 10.1016/j.desal.2020.114455. [DOI] [Google Scholar]

- 70.Ibrar I., Naji O., Sharif A., Malekizadeh A., Alhawari A., Alanezi A.A., Altaee A. A review of fouling mechanisms, control strategies and real-time fouling monitoring techniques in forward osmosis. Water. 2019;11:695. doi: 10.3390/w11040695. [DOI] [Google Scholar]

- 71.Suzaimi N.D., Goh P.S., Ismail A.F., Mamah S.C., Malek N.A., Lim J.W., Wong K.C., Hilal N. Strategies in forward osmosis membrane substrate fabrication and modification: A review. Membranes. 2020;10:332. doi: 10.3390/membranes10110332. [DOI] [PMC free article] [PubMed] [Google Scholar]