Abstract

The Coronavirus pandemic affected activities worldwide, among which the supply chain (SC) disruptions is significant. The impact is expected to affect businesses indefinitely; thus, the SC is unlikely to resume its pre‐COVID‐19 status. This study examines the impact of the COVID‐19 pandemic on SCs regarding its disruptions, associated challenges, and trend. It conducts an analysis of SCs stages, phases, and manifestations regarding the consequences, opportunities, and developments induced by the pandemic. A framework for the SC with COVID‐19 is presented towards a future global value chain and continuous improvements. It explores and connects the relevant elements to address the relations of SC‐COVID19 (SCC19). This study is novel as it identifies, categorises, and frames the essential factors and their interrelationships in a comprehensive framework. The SCC19 framework can be of value for decision‐makers and researchers, and can be generalised to other industries. Furthermore, study limitations and future research directions are discussed.

Keywords: supply chain, COVID‐19 pandemic, SCC19 framework, supply chain disruptions, SC‐COVID‐19 manifestations, supply chain improvements

Introduction

Global supply chain (GSC) disruptions started after the World Health Oganization (WHO) declared the coronavirus disease outbreak to be global health emergency at the end of January 2020. During the first half of 2020, the virus spread to almost all the countries in partial or total lockdown (McKenzie, 2020). Such a crisis affects the supply network at the source and destination, has extreme effects on GSC, and interrupts production process (Choudhury, 2020). According to Institute of Supply Management (ISM), about 75% of the companies reported supply chain (SC) disruptions, 80% expected some kind of disruptions in the near future, 62% reported delays in receiving goods, and 53% of firms reported difficulties in getting information from China (McCrea, 2020a, 2020b). More than five million companies with Tier 2 supplies were impacted by the pandemic (Dun and Bradstreet, 2020). It is estimated that among the 450 million persons working in GSCs, many have faced reduced income or even job loss due to COVID‐19 (Kippenberg, 2020). Globally, organisations have been shutting down shops, deleting orders, and suspending production. Some sectors like garment, mining, jewelry, and automobiles have been suffering as the employees in these sectors are among the most vulnerable and being affected by the pandemic (Kippenberg, 2020).

Traditionally, research has focused on resource allocation and distribution during the pandemic using different approaches such as optimisation (Queiroz et al., 2020). Ivanov and Dolgui (2020b) examined the available literature to conceptualise the ripple effect of the pandemic, focusing on SCs structural dynamics, and derived the managerial implications. Some researchers study and proposed reconfigurable SC by comprehensively merging components taken from resilient, digital, lean, agile, and sustainable SC to adjust to sudden changes (Battaïa et al., 2020; Dolgui et al., 2020). A viable supply chain that balances sustainability, agility and resilience can support the organisation on recovery decisions and rebuild their SC after long standing crises like COVID‐19 pandemic (Ivanov, 2020b). Some studies have introduced models to solve specific problems with specific applications (Mehrotra et al., 2020). Researchers in the field of operations and management can also contribute to critical economic activities (Gao and Su, 2017). Choi (2020) introduced an analytical model to discover whether technology based logistics management can support the continuity of businesses, while (Gao and Su, 2017) proposed a hybrid forecasting technique dependent on nearest supplier and clusters to estimate COVID‐19 growth to help decision‐makers and SC executives to make decisions during the current crisis and future pandemics. Modelling, technology, and organisation raises questions and provides opportunities as the impact of the COVID‐19 pandemic on SCs continues to be increasingly destructive (Queiroz et al., 2020).

Previous research largely analysed the impact of COVID‐19 on SC performance (Ivanov, 2020a), focusing on solutions (Rowan and Laffey, 2020; Staal, 2020) to enhance the decision‐making process and viability (Ivanov and Dolgui, 2020c), and utilising different tools, like simulation and ISN viability, to resist the pandemic and reach future resilience (Cheng and Lu, ; Golan et al., 2020; Kahiluoto et al., 2020; Ivanov, 2020a; Ivanov and Dolgui, 2020c). Studies have also investigated challenges (BESSON, 2020), explored SC disruptions (Cheema‐Fox et al., 2020; Craighead et al., 2020; Hobbs, 2020), examined SC security and safety issues (Liu et al., 2020), estimated SC losses (Guan et al., 2020), studied SC sustainability (Mari et al., 2014; Hakovirta and Denuwara, 2020), evaluated localisation of the supply (de Sousa Jabbour et al., 2020; McCrea, 2020b), measured for critical goods (Lopes de Sousa Jabbour et al., 2020), and investigated unusual SC events associated with COVID‐19 (Anner, 2020; Ivanov, 2020a).

The future directions for research involve focusing and deepening investigation on SC and the innovation and development accompanying it. Studies should engage with sustainable supply and economic aspects to explore the impact of and to deal with COVID‐19 (Hensel et al., 2020). They can also uncover several future SC trends (Liu et al., 2020), explore the opportunities arising from the pandemic (Staal, 2020), focus on the complicated solutions for the shortage of critical products (Rowan and Laffey, 2020), and conduct an evaluation of economic effects, the delivery and supply system, as well as the monitoring and improvement policy to combat the possible threats (Gray, 2020) and sustain SC with the rapid propagation of the virus and the economic shock (Cheema‐Fox et al., 2020), and understand the SC phenomenon to make the system more prepared for the future crises and risks (Craighead et al., 2020).

The motivation of this study came from the instability and rapid changes in the business environment caused by the disruptions of global businesses and trades, which have been greatly affecting SCs. Such a pandemic requires making rapid decisions in a complex and challenging environment, considering many factors like SC responsiveness, costs and quality. This necessitates companies to set up tools to estimate, assess, respond to, and measure the effect of the pandemic on demand, supply, and, thus, SC. These tools should consider the critical element and different factors related to the SC‐COVID‐19 (SC and COVID‐19 pandemic) relationship to assess and respond to crises and consider solutions that guarantee the continuation of supply and delivery. The proposed framework introduces these components and their interrelationships to help organisations in building their tools and to support their decision‐making process.

This study investigates 75 articles dealing with the impact of the pandemic, its manifestation, and factors related to SC‐COVID‐19 and seek to contribute to SC recovery. It streamlines the literature and explores several new tensions and novel interconnections among various SC‐COVID‐19 factors. Therefore, this study seeks to address key research questions, namely: What are the factors that affect the performance of the supply chain, cause supply disruption, interrupt SC flows, and impact strategies to build end‐to‐end SC capability? What are the recurring, infrequent, and unique phenomena accompanying the COVID‐19 pandemic? How can decision‐makers employ the main interconnected SC‐COVID‐19 factors to overcome this ordeal and face similar crises in the future?

The literature review allows recognising combinations of factors related to SC‐COVID‐19 and could help decision‐makers enable recovery from the ongoing and future similar crises. For the purpose of this study, nine factors and relevant 58 elements are considered in structuring the comprehensive framework. Although many of these elements have evolved from growing topics in the literature as main factors in SC management and operations, the focus has been on their individual contributions to organisational performance and efficiency. This study differs from its predecessors as it tries to arrange, map out, and combine these factors in a comprehensive framework that can be used by researchers in future developments and provides a chance for decision‐makers to contemporise their SCs. This study, thus, pursues the following contributions:

It seeks to extend the investigation of the pandemic's impact on end‐to‐end GSC, considering the main causes of the disruption, the challenges associated with the pandemic, and the trend of the crises. Moreover, it examines the main interconnected factors leading to the disruption of SC operations: change in supply, fluctuation in demand, and the reaction of governments and countries to confront the pandemic.

It explores the main SC stages, phases, and manifestations of the crises against its consequences, opportunities, and developments to clarify their interrelationships based on cumulative experience, new businesses, and the economic environment.

It extends the analysis to comprehend the COVID‐19 consequences, measures, and solutions related to existing SCs. It describes the capability building method and crisis aspects, areas of developments and the principal steps relating to the future global value chain (GVC) and links the cost and continuous enhancements to resist the effect of COVID‐19 and possible future crises.

Additional contributions comprise the continuous developments methodology to allow SC managers and executives to express requirements, decision‐making process and inputs. The study introduces the triangular pedestal loop of continuous improvements: solutions, decision requirements, and evaluation tool.

The main structure of the framework interlinks these factors to assure analysis, improvements, and responsiveness to help decision‐makers endorse SCs future flexibility and competition. Other contributions involve an identification of several open research questions to be explored in the future.

The study outcomes and results can be used by logisticians, researchers, policymakers, and specialists in the field of supply chain to assist their organisations in decision support systems during the period of this pandemic and to ensure resistance to future crises. The framework can be extended to other industries and other related sectors.

In particular, this study finds that the outcomes are structured into nine factors: disruptions, cost control, capability building, aspects, facts, phenomena, areas of enhancement, steps towards SC stability, and continuous development. The rationality and practicality of the proposed model components was checked with a few SC and logistics specialists. The study can be used by both researchers and the industry to improve decision support systems and enable readjustment and restoration during the ongoing pandemic and future crises. Further future research directions are introduced and discussed as well.

The rest of the paper is organised as follows. The following section presents the SC and COVID‐19 related literature. The third section discusses the impact of the pandemic on the SCs. The fourth section analyses SC manifestations associated with the pandemic. The fifth section proposes a framework to understand SC systems with COVID‐19 and related solutions. The final section concludes and presents future research suggestions.

Literature review

The complex networks of recent SCs can be exposed to disruptions due to shutdowns, which can be directly or indirectly caused by risk factors from natural, social, political, and economic phenomena (Scheibe and Blackhurst, 2018). Pandemic outbreaks are special cases of SC risks with indefinite disruptions, propagation, and considerable uncertainty (Ivanov, 2020a). Such a crisis is not new, as SC vulnerabilities were exposed during the H1N1 and Ebola outbreaks in 2009 and 2014, respectively, thereby creating a critical demand for necessities. Thus, firms realised that they must quickly respond to current SC disruptions regarding what to produce, for whom, and how it should be produced (Armani et al., 2020).

Today, Chinese SCs are under significant pressure (Chatterjee, 2020). Given, the rising global concern for the shortage of critical products like personal protective equipment (PPE), SCs can help supply crucial health care items and help reduce infections. The health care SC is global and requires urgent actions to ensure support to the health care systems during times of crises (Mirchandani, 2020). Contingency plans for critical product shortage are, thus, vital (Rowan and Laffey, 2020).

The COVID‐19 pandemic has placed the spotlight on SCs and challenged more than 30 years of progress towards globalisation. Moreover, the pandemic coincided with the current trade wars between the USA and China, thus uncovering the instability of GSCs and trading systems. It highlights the need to build more resilient SC operations (Feinmann, 2020).

The COVID‐19 outbreak introduced an unprecedented and extraordinary situation for SC resilience (Ivanov and Dolgui, 2020c), during which SC survivability requires large scale resilience. SC network resilience and its ripple effect give scope for decision‐making. It grants access to short‐ and long‐term performance and behaviour of the network after the disruptions; supports design suitable for sourcing, production, and marketing in preparation for potential disruptions; and maintain competitive advantages in risky surroundings (Li and Zobel, 2020; Ivanov and Dolgui, 2020b).

Companies should consider the ripple effect when investigating their resilience practices. Resilience can mitigate disruptions when considering SC complexity (Birkie and Trucco, 2020). SC resilience depends on the capability of rearranging resources to control disruptions (de Sá et al., 2019). Collaborative activities, such as information sharing and communication, enhance SC resilience by improving visibility, quickness, and flexibility (Scholten and Schilder, 2015). External and internal SC network can improve SC resilience and customer‐related performance (Asamoah et al., 2020). Increasing redundancy associated with operational flexibility ultimately enhances network resilience; moreover, simulations offer a holistic methodology to evaluate SC resilience (Childerhouse et al., ).

As the pandemic is expected to progress indefinitely, much will be learned about how SCs respond to the crisis, modify strategies to improve resilience, and maintain customer trust (Hobbs, 2020). SC monitoring, proactive development strategies, assessment of economic impacts and delivery systems are necessary to address potential SC threats (Gray, 2020). Well known and emerging theories can reduce challenges and provide potential solutions. These theories help scholars study the pandemic, its impact on SC, and support decision‐makers to formulate responses (Craighead et al., 2020).

Instability and rapid changes in the business environment require strategic alliances and inter‐organisational collaboration (Cravens et al., 1996). Multi sourcing, quality, and flexibility can help achieve efficient coordination throughout the network and lead to different levels of collaboration to improve SC integration and sustainability (Kumar et al., 2020; Vlachos and Dyra, 2020).

SC policymakers should respond to the spread of COVID‐19 while minimising its impact and maintaining the SCs (Guerin et al., 2020). Decision‐making can be based on available data, demand, and past decisions (Mehrotra et al., 2020). Applications of big data and analytics, machine learning, and digitisation can be applied to crises management activities and efforts (Cheema‐Fox et al., 2020). Lean management practices and sustainability innovations enable SMEs to improve sustainability performance and economic efficiency (Dey et al., 2020). Given that the digital transformation is rapidly and significantly changing business processes (He et al., 2020), digital SC networks must be aligned with business strategies to enable businesses to adjust and recover from future SC disruptions.

Impact of COVID‐19 pandemic on SCs

The COVID‐19 pandemic has significantly impacted end‐to‐end GSC activities, especially medical and food supplies. Thus, the integrity and stability of the value chain (VC) have been compromised. The global media has covered other angles from threats to accusations and even intercepting shipments, where countries scrutinise anything that enters respective territories, given its right to protect people and avoid catastrophe by all means. Such events have profoundly impacted GSCs.

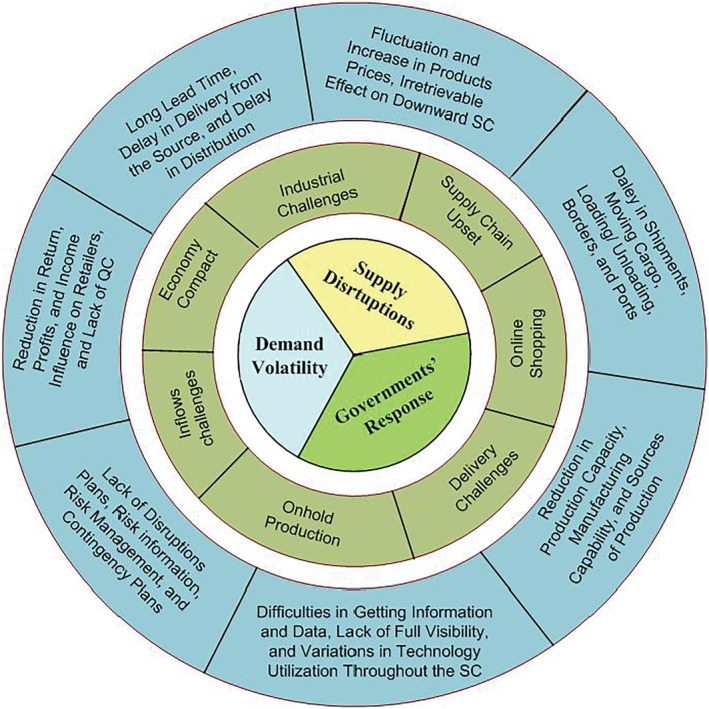

Figure 1 illustrates the impact of the pandemic on SCs. The study considers three main aspects: the main causes of the disruptions, the challenges associated with the pandemic, and the trend of the crises. Three main interrelated factors led to the disruption of the SC operations: change in supply, fluctuation in demand, and the reaction of governments and countries to confront the pandemic.

Figure 1.

Impact of the COVID‐19 pandemic on SCs

The pandemic affected SC activities, operations, processes, and management due to supply disruptions, demand volatility, and government actions to combat the crisis. Factory closures, border restrictions, travel bans, ports closures, and suspended transportations interrupted the entire supply network, thus leading to shortages. GSCs connected to China, USA, and Europe were greatly affected and induced spikes in many products in response to panic buying, which, in turn, led to price fluctuations, as supplies become limited. High demand and order congestions from the delays resulted in demand vulnerability and shocks, which impacted both offline and online purchases. Furthermore, complex challenges in addressing the massive demand while maintaining quality and continuity persisted. Many countries acted proactively to protect its people and imposed strict restrictions on movements via lockdowns, social distancing, and quarantining measures in the early parts of this year. The tension and panic from such decisions affected SC operations and performance. Government measures led to the decline in production and considerable contractions in international trade flows.

The main challenges associated with the COVID‐19 pandemic include industrial, economic, inflow, on‐hold production, delivery, online shopping, and SC upsets. Components needed to assemble final products are procured from (and assembled in) several locations. They are then re‐exported, transferred, or shipped to specified locations worldwide. Thus, disruption in the SC complicates the process. Supply and demand disruptions, along with governments' responses, contribute to external and internal economic risks in the short‐ and long‐term. Given such disruptions, against the backdrop of government protection measures, several manufacturing plants and factories suspended production. Delivery and distribution faced several challenges, including direct distribution difficulties, increased online orders, re‐staffing of distribution centres (DCs) and warehouses (WHs), and changes in the allocation of inventory across the network and distribution channels to increase responsiveness. Thus, the pandemic proved to be an opportunity for online stores and businesses. Moreover, online shopping increased, especially for food and grocery products. The pandemic changed customer trends, as many of them relied on online shopping and reduced their visits to the retailer centres. Furthermore, there were freight prices spikes, a low travel interest, and increases (decreases) in demand for key products (luxury products), as well as cancelled and extra orders. Thus, organisations are pressured to lay off workers and halt productions.

Most of the world companies are affected by the pandemic; they also report disruptions in their SCs. The main trends of this effect include the following. (1) Prices fluctuate, as the extraordinary increase in prices during the pandemic negatively affect the relationship between suppliers, retailers, and customers. (2) There is a long lead time due to delays in receiving items from the source and delays in distribution. (3) There are delays in shipments, moving cargo, loading, shipping, and unloading, as well as extra delays at the borders and ports. (4) Return, profits, and income reduce, thus hurting retailers' abilities regarding their quality control. (5) Production capacity and manufacturing capability decrease and affects the sources of production. (6) Lack of disruptions plans associated with small inventory levels, single supplier, or minor diversification underestimate the possibility of severe disruptions; the focus on short‐term and costs minimisations lead to a lack of risk information and contingency plan. (7) Moreover, there are difficulties in getting information and data from partners, lack of end‐to‐end visibility, lack of integrations and coordination, and variations in technology utilisation throughout the SC.

In general, global trade and business experience abnormal interruptions, which affect the demand and supply end of the SC. Thus, organisations face significant challenges in maintaining a continuous flow of goods and services.

SCs manifestations

It is too early to evaluate and quantify the total effect of COVID‐19 on the SC disruptions. However, the primary decline in production, business, and trade in China and other industrial nations will strongly impact many countries down the SC as most countries restrict the movement of supplies to combat the spread of the virus.

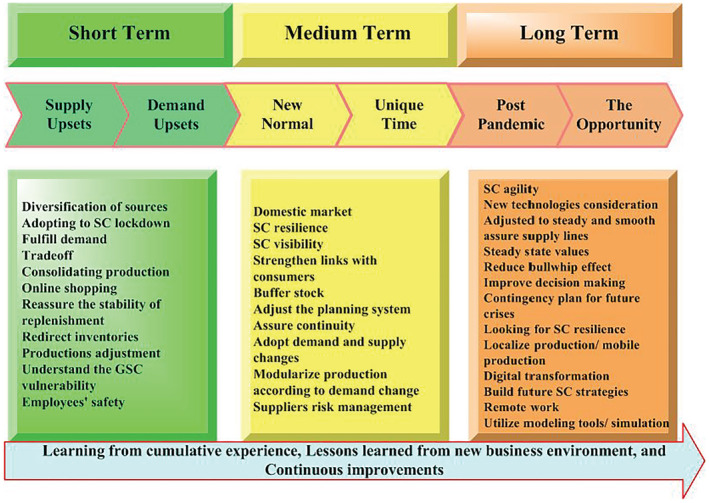

Figure 2 shows three main stages that characterised the SC: short‐, medium‐, and long‐term shocks and developments. The SCs will go through six phases: supply upset, demand upset, new ordinary, unique time, post‐pandemic, and the opportunity. COVID‐19 manifestations on SCs are briefly discussed, based on their connection with each stage, to clarify the interrelationships. The arrow at the bottom indicates the development of the SC, based on continuous improvements taken from the cumulative experience, new business, and the economic environment.

Figure 2.

SCs stages, phases, and manifestations, given COVID‐19

The main SC stages, as shown in Figure 2, explores the periods of GSC related to COVID‐19 pandemic. All stages are interconnected. Each stage, however, has its own characteristics. SC decision‐makers and managers must consider the disruptions, consequences, and solutions of each stage carefully.

Short‐term stage

Short‐term disruptions lead to a considerable readjustment from the usual supply sources, like China, and result in long‐term benefits to the local industry and domestic sources. The two phases of this stage are supply and demand upsets. Since the availability of raw materials, components, finished products, and items used in the factories were interrupted, organisations strived to fulfil demand requirement at the minimum level or partially. The demand shock began when people started to engage in panic‐driven hoarding of goods. Given the empty warehouses, DCs, retailers, and supply lines, rerouting and redirecting inventories and available products to newly identified priorities and bypassing supply decision systems was a challenge. Human resources are the most crucial components; nonetheless, many factory and service employees were infected. Hence, measures are required to improve continuity, cut costs, produce cash, develop agile SCs, and guarantee the safety of the employees.

Medium‐term stage

The prevalent opinion indicates that recovery from the pandemic and its consequences is here to stay. The phases associated with this stage are new normal and unique time. In this stage, it is necessary to build new supply continuity beyond COVID‐19. When the demands reach a new steady‐state value, there should be production adjustments to reflect the real new demand (whether an increase or decrease), along with the supply lines adaptations. Inventory bounce should be treated carefully to avoid the bullwhip effect. As the length and magnitude of the pandemic remain unclear, the consequences will persist, even after the outbreak is contained. For some companies, the impact will stay longer and worsen without stable GSCs, as well as vulnerable sources. Thus, SCs must review their strategies since the pandemic has introduced unique moments to SC managers, decision‐makers, planners, and regulators to reconsider the global SC model, new supply needs, and dependencies. Moreover, they can realise and develop SCs for the domestic market, SC resilience, and SC visibility. Furthermore, they can strengthen consumer relationships, buffer stock, adjust the planning system, assure continuity, adopt demand and supply changes, modularise production according to demand change, and develop risk management plans.

Long‐term stage

If the crises persist, further SC interruptions on delivery and distribution delays are expected. The phases of this stage represent the post‐pandemic and the opportunity. In the post‐pandemic phase, the crises will speed up the digital transformation of SCs and businesses to address inherent weaknesses and vulnerability. Technology will be the main player in building future SC strategies. Moreover, several methods explored can help businesses generate resilience SCs post‐COVID‐19. The opportunity from the pandemic stems from key technologies that support businesses in making them efficient and capable of handling risks after surviving the crises. Employing digital technologies help build resilient GSCs. Moreover, digital technology, visibility, integration, and collaboration with other partners are crucial to survive a future crisis. Industrial establishments that can modularise production according to demand change could be the norm in the future in supporting the SC network in communications and agility. Moving to the cloud may be necessary to ensure business continuity. Safety is one of the main factors as companies need to consider risk management in any future strategy and planning. Remote working post‐COVID‐19 must be carefully considered, as it will change tradition work processes and operating principals.

SC and COVID‐19 (SCC19) framework

It is clear that the SC‐COVID‐19 perspectives will dominate the researchers in the industry throughout the pandemic effect and recovery era (Ivanov and Dolgui, 2020b). There are many studies in the literature considering the different risks, impact, and solutions of the pandemic. Moreover, they investigate different tools and techniques like modelling, optimisation, and simulation. The COVID‐19 pandemic resulted in a unique environment of disruption, implications, and risks on SCs, and thus the SC‐COVID‐19 components are affected at different levels and times. With the pandemic's impact, it is difficult to apply the majority of common SC techniques such as risk mitigation, transportation, inventory, and smooth flow of material, money, and information. So, there is a necessity of framing the main component of SC‐COVID‐19 factors and elements with their interconnections to help decision‐makers combat the ongoing and future crises.

The selected literature of the latest contributions is used to explore and connect the relevant elements to address the SC‐COVID‐19 relationship. The studies relevant to SC with COVID‐19 are reviewed towards future resilience and continuous improvements. This selection was complemented with a search in common available database including journal articles, periodicals, publications of international organisations like the WHO and World Bank, and experts' reports. To ensure representativeness of studies, the following rules are used: SC and COVID‐19 is used as the basic search protocol and subsequently, one of the nine factors (disruptions, facts, phenomena, capability building, crisis aspects, steps towards resilience and new normal, areas of improvements, continuous developments, and costs) is added every time there is new search; for example: (SC, COVID‐19, and disruptions), (SC, COVID‐19, cost). The keywords are selected based on an analysis of relevant literature on SC‐COVID‐19.

After narrowing the search and filtering the articles according to the scope of the study, a list of 75 articles related to SC‐COVID‐19 are selected to be used in the study. In each reviewed paper, three factors were selected from the nine that were considered. These factors are arranged in descending order according to the extent of focus on them in the research paper being reviewed.

A detailed article‐by‐article analysis is shown in Table 1, which shows the major outcomes of the main factors related to SC‐COVID‐19 insights. Table 1 summarises the author(s), title, journal, and the factors of focus. The study focuses on the major insights relevant to supply chains in the context of COVID‐19. The insights are generalised from every single article and classified into nine factors.

TABLE 1.

Studies related to the proposed SCC19 framework factors

| Author (Year of publication) | Title | Journal/periodic | Factors of focus | |

|---|---|---|---|---|

| 1 | (Armani et al., 2020) | Low‐tech solutions for the COVID‐19 supply chain crisis | Nature Reviews Materials | Continuous developments, Phenomena, Areas of enhancements |

| 2 | (Choi, 2020) | Innovative “Bring‐Service‐Near‐Your‐Home” operations under Corona‐Virus (COVID‐19/SARS‐CoV‐2) outbreak: Can logistics become the Messiah? | Transportation Research Part E: Logistics and Transportation Review | Areas of enhancements, Facts, continuous developments |

| 3 | (Ivanov, 2020a) | Predicting the impacts of epidemic outbreaks on global supply chains: A simulation‐based analysis on the coronavirus outbreak (COVID‐19/SARS‐CoV‐2) case | Transportation Research Part E: Logistics and Transportation Review | Disruptions, Facts, Phenomena |

| 4 | (Ivanov, 2020b) | Viable supply chain model: integrating agility, resilience and sustainability perspectives—lessons from and thinking beyond the COVID‐19 pandemic | Annals of Operations Research | Areas of enhancements, Steps, Aspects |

| 5 | (Ivanov and Dolgui, 2020a) | A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. | Production Planning and Control | Areas of enhancements, Disruptions, Continuous developments |

| 6 | (Ivanov and Dolgui, 2020b) | OR‐methods for coping with the ripple effect in supply chains during COVID‐19 pandemic: Managerial insights and research implications |

International Journal of Production Economics |

Areas of enhancements, Continuous developments, Capability building |

| 7 | (Kahiluoto et al., 2020) | Supplying resilience through assessing diversity of responses to disruption | International Journal of Operations and Production Management | Areas of enhancements, Capability building, Disruptions |

| 8 | (Sharma et al., 2020) | Covid‐19's impact on supply chain decisions: Strategic insights from NASDAQ 100 firms using Twitter data | Journal of Business Research | Steps, Areas of enhancements, Continuous developments |

| 9 | (Shokrani et al., 2020) | Exploration of alternative supply chains and distributed manufacturing in response to COVID‐19; a case study of medical face shields | Materials and Design | Capability building, Aspects, Facts |

| 10 | (Queiroz et al., 2020) | Impacts of epidemic outbreaks on supply chains: mapping a research agenda amid the COVID‐19 pandemic through a structured literature review | Annals of Operations Research | Disruptions, Facts, Steps |

| 11 | (Ratnasingam et al., 2020) | How are Small and Medium Enterprises in Malaysia's Early Evidences from a Survey and Recommendations | BioResources | Disruptions, Costs, Facts |

| 12 | (Remko, 2020) | Research opportunities for a more resilient post‐COVID‐19 supply chain – closing the gap between research findings and industry practice | International Journal of Operations and Production Management | Disruptions, Capability building, Steps |

| 13 | (Rowan and Laffey, 2020) | Challenges and solutions for addressing critical shortage of supply chain for personal and protective equipment (PPE) arising from Coronavirus disease (COVID19) pandemic – Case study from the Republic of Ireland | Science of the Total Environment | Continuous developments, Disruptions, Areas of enhancements |

| 14 | (Batistič and van der Laken, 2019) | History, Evolution and Future of Big Data and Analytics: A Bibliometric Analysis of Its Relationship to Performance in Organizations | British Journal of Management | Continuous developments, Steps, Areas of enhancements |

| 15 | (Battaïa et al., 2020) | Sustainable and Energy Efficient Reconfigurable Manufacturing Systems | In Reconfigurable Manufacturing Systems: From Design to Implementation. Springer | Steps, facts, capability building |

| 16 | (Cheema‐Fox et al., 2020) | Corporate Resilience and Response During COVID‐19 | SSRN Electronic Journal | Steps, phenomena, facts |

| 17 | (Cheng and Lu, ) | Enhancing effects of supply chain resilience: insights from trajectory and resource‐based perspectives | Supply Chain Management | Steps, Areas of enhancements, phenomena |

| 18 | (Cox and Koepsell, 2020) | 3D‐Printing to Address COVID‐19 Testing Supply Shortages | Laboratory Medicine | Areas of enhancements, facts, continuous developments |

| 19 | (Craighead et al., 2020) | Pandemics and Supply Chain Management Research: Toward a Theoretical Toolbox | Decision Sciences | Disruptions, Phenomena, steps |

| 20 | (Asamoah et al., 2020) | Social network relationship, supply chain resilience and customer‐oriented performance of small and medium enterprises in a developing economy | Benchmarking: An International Journal | Steps, Disruptions, Phenomena |

| 21 | (Birkie and Trucco, 2020) | Do not expect others do what you should! Supply chain complexity and mitigation of the ripple effect of disruptions | International Journal of Logistics Management | Steps, Disruptions, Continuous developments |

| 22 | (Dun and Bradstreet, 2020) | Business Impact of the Coronavirus. | Dun & Bradstreet Team | Capability building, Costs, continuous developments |

| 23 | (Gao and Su, 2017) | Online and offline information for omnichannel retailing | Manufacturing and Service Operations Management | Areas of enhancements, Continuous developments, facts |

| 24 | (Goel et al., 2020) | Supply Chain Reliability and International Economic Growth: Impacts of Disruptions like COVID‐19 | SSRN | Disruptions, Phenomena, capability building |

| 25 | (Golan et al., 2020) | Trends and applications of resilience analytics in supply chain modeling: systematic literature review in the context of the COVID‐19 pandemic | Environment Systems and Decisions | Steps, Aspects, capability building |

| 26 | (Gray, 2020) | Agriculture, transportation, and the COVID‐19 crisis | Canadian Journal of Agricultural Economics | Disruptions, Continuous developments, facts |

| 27 | (Guan et al., 2020) | Global supply‐chain effects of COVID‐19 control measures | Nature Human Behaviour | Disruptions, Steps, continuous developments |

| 28 | (Haghani et al., 2020) | The scientific literature on Coronaviruses, COVID‐19 and its associated safety‐related research dimensions: A scientometric analysis and scoping review | Safety Science | Disruptions, Capability building, Aspects |

| 29 | (Hakovirta and Denuwara, 2020) | How COVID‐19 redefines the concept of sustainability | Sustainability (Switzerland) | Capability building, Phenomena, continuous developments |

| 30 | (Hensel et al., 2020) | Challenges at the Time of COVID‐19: Opportunities and Innovations in Antivirals from Nature | Planta Medica | Disruptions, Facts, phenomena |

| 31 | (Hobbs, 2020) | Food supply chains during the COVID‐19 pandemic | Canadian Journal of Agricultural Economics | Steps, Disruptions, Areas of enhancements |

| 32 | (Hsiao et al., 2020) | Can 3D printing of oral drugs help fight the current COVID‐19 pandemic (and similar crisis in the future)? Expert Opinion on Drug Delivery | Expert Opinion on Drug Delivery | Areas of enhancements, Continuous developments, Aspects |

| 33 | (Inoue and Todo, 2020) | The Propagation of the Economic Impact through Supply Chains: The Case of a Mega‐City Lockdown against the Spread of COVID‐19 | SSRN Electronic Journal | Disruptions, Facts, phenomena |

| 34 | (Akhtar et al., 2019) | Big Data‐Savvy Teams' Skills, Big Data‐Driven Actions and Business Performance | British Journal of Management | Areas of enhancements, Continuous developments, frame |

| 35 | (Knut et al., 2020) | Supply‐chain recovery in coronavirus times‐‐plan for now and the future | McKinsey & Company Insigths | Steps, Capability building, Aspects |

| 36 | (Liu et al., 2020) | The challenges and opportunities of a global health crisis: the management and business implications of COVID‐19 from an Asian perspective | Asian Business and Management | Steps, Disruptions, Areas of enhancements |

| 37 | (de Sousa Jabbour et al., 2020) | Sustainability of supply chains in the wake of the coronavirus (COVID‐19/SARS‐CoV‐2) pandemic: lessons and trends | Modern Supply Chain Research and Applications | Capability building, Aspects, Continuous developments |

| 38 | (Mari et al., 2014) | Sustainable and resilient supply chain network design under disruption risks | Sustainability (Switzerland) | Steps, Capability building, Continuous developments |

| 39 | (Mehrotra et al., 2020) | A model of supply‐chain decisions for resource sharing with an application to ventilator allocation to combat COVID‐19 | Naval Research Logistics | Capability building, Aspects, Facts |

| 40 | (Dey et al., 2020) | The Impact of Lean Management Practices and Sustainably‐Oriented Innovation on Sustainability Performance of Small and Medium‐Sized Enterprises: Empirical Evidence from the UK | British Journal of Management | Areas of enhancements, Facts, steps |

| 41 | (Dolgui et al., 2020) | Reconfigurable supply chain: the X‐network | International Journal of Production Research | Steps, Areas of enhancements, continuous developments |

| 42 | (He et al., 2020) | Strategic Alliance Research in the Era of Digital Transformation: Perspectives on Future Research | British Journal of Management | Areas of enhancements, Phenomena, Aspects |

| 43 | (Mikalef et al., 2020) | Big Data Analytics Capabilities and Innovation: The Mediating Role of Dynamic Capabilities and Moderating Effect of the Environment | British Journal of Management | Areas of enhancements, Steps, Continuous developments |

| 44 | (Mirchandani, 2020) | Health Care Supply Chains: COVID‐19 Challenges and Pressing Actions | Annals of Internal Medicine | Disruptions, Areas of enhancements, Phenomena |

| 45 | (Nikolopoulos et al., 2020) | Forecasting and planning during a pandemic: COVID‐19 growth rates, supply chain disruptions, and governmental decisions | European Journal of Operational Research | Capability building, Aspects, Disruptions |

| 46 | (OECD, 2020) | Food Supply Chains and COVID‐19: Impacts and Policy Lessons. Comparing Crises: Great Lockdown versus Great Recession | OECD | Disruptions, Facts, Phenomena |

| 47 | (Seifert, 2020) | How supply chains are adapting to the COVID‐19 lockdowns | IMD research and knowledge | Disruptions, Steps, Fact |

| 48 | (Staal, 2020) | IMPACT OF COVID‐19 ON PROCUREMENT & SUPPLY CHAINS ‐ a way forward for New Zealand? | Auckland University of Technology/Research Proposal | Disruptions, Facts, Phenomena |

| 49 | (McKenzie, 2020) | Beyond COVID‐19: Supply Chain Resilience Holds Key to Recovery Fecha | Oxford economics | Continuous developments, Areas of enhancements, Steps |

| 50 | (McCrea, 2020a) | Measuring COVID‐19’s Impact on the World's Supply Chains | SourceToday | Areas of enhancements, Steps, Continuous developments |

| 51 | (McCrea, 2020b) | Reshoring and Onshoring Trend Update | SourceToday | Aspects, Disruptions, Facts, |

| 52 | (Kappenberg, 2020) | COVID‐19 Puts Millions of Global Supply Chain Workers at Risk | Human Rights Watch | Disruptions, Areas of enhancements, Phenomena |

| 53 | (Besson, 2020) | COVID‐19 (coronavirus): Panic buying and its impact on global health supply chains | Worldbank blog | Disruptions, Facts, Phenomena |

| 54 | (Chatterjee, 2020) | Indian pharma threatened by COVID‐19 shutdowns in China | The Lancet | Disruptions, Facts, Phenomena |

| 55 | (Guan et al., 2020) | Global economic footprint of the COVID‐19 pandemic | Research square preprint/CC by 4.0 | Costs, Phenomena, capability building |

| 56 | (Balleer et al., 2020) | Demand or supply? Price adjustment during the Covid‐19 pandemic | IZA – Institute of Labor Economics | Costs, Disruptions, facts |

| 57 | (World Bank, 2020) | Transforming Philippine Agriculture: During COVID‐19 and Beyond | World Bank: OKR | Disruptions, Costs, Phenomena |

| 58 | (Boissay and Rungcharoenkitkul, 2020) | Macroeconomic effects of Covid‐19: an early review (No. 7) | Bank for International Settlements: BIS Bulletins | Costs, Facts, phenomena |

| 59 | FAO (2020) | Agri‐food markets and trade policy in the time of COVID‐19 | FAO | Disruptions, Aspects, Costs |

| 60 | (World‐Health‐Organization, 2020) | COVID‐19 Supply Chain System: Requesting and Receiving Supplies | WHO | Disruptions, Facts, Aspects |

| 61 | (Guerin et al., 2020) | The consequence of COVID‐19 on the global supply of medical products: Why Indian generics matter for the world? | F1000Research | Disruptions, Aspects, Costs |

| 62 | (Childerhouse et al., ) | Network resilience modelling: A New Zealand forestry supply chain case | International Journal of Logistics Management | Steps, Disruptions, Facts |

| 63 | (Cravens et al., 1996) | New organizational forms for competing in highly dynamic environments: The network paradigm | British Journal of Management | Capability building, Aspects, Areas of enhancements |

| 64 | (Feinmann, 2020) | PPE: What now for the global supply chain? | BMJ | Disruptions, Facts, Phenomena |

| 65 | (Kumar et al., 2020) | Learning orientation and innovation performance: the mediating role of operations strategy and supply chain integration | Supply Chain Management | Costs, Capability building, Aspects |

| 66 | (Li and Zobel, 2020) | Exploring supply chain network resilience in the presence of the ripple effect | International Journal of Production Economics | Steps, Phenomena, Aspects |

| 67 | (de Sá et al., 2019) | Supply chain resilience: the whole is not the sum of the parts | International Journal of Operations & Production Management | Capability building, Steps, Disruptions |

| 68 | Scheibe and Blackhurst (2018) | Supply chain disruption propagation: A systemic risk and normal accident theory perspective | International Journal of Production Research | Disruptions, Aspects, Phenomena |

| 69 | (Scholten and Schilder, 2015) | The role of collaboration in supply chain resilience | Supply Chain Management | Capability building, Aspects, Areas of enhancements |

| 70 | (Vlachos and Dyra, 2020) | Theorizing coordination, collaboration and integration in multi‐sourcing triads (B3B triads) | Supply Chain Management | Capability building, Aspects, Areas of enhancements |

| 71 | (Ivanov and Dolgui, 2020c) | Viability of intertwined supply networks: extending the supply chain resilience angles towards survivability. A position paper motivated by COVID‐19 outbreak | International Journal of Production Research | Areas of enhancements, Aspects, capability building |

| 72 | (Ivanov et al., 2020) | Researchers' perspectives on Industry 4.0: multi‐disciplinary analysis and opportunities for operations management | International Journal of Production Research | Areas of enhancements, Capability building, continuous developments |

| 73 | (Iyengar et al., 2020) | Challenges and solutions in meeting up the urgent requirement of ventilators for COVID‐19 patients | Diabetes and Metabolic Syndrome: Clinical Research and Reviews | Continuous developments, Facts, Disruptions |

| 74 | (Free and Hecimovic, 2021) | Global supply chains after COVID‐19: the end of the road for neoliberal globalisation?. | Accounting, Auditing & Accountability Journal | Costs, Steps, continuous developments |

| 75 | (Gölgeci et al., 2020) | The rising tensions between efficiency and resilience in global value chains in the post‐COVID‐19 world | Transnational Corporations Journal | Costs, Steps, Capability building |

As summarised in Table 2, the analysis revealed several components that have been effectively applied to SC elements related to the main factors. It was found that each of the nine factors is aligned with several elements. The total number of elements consider in the study is 58, as shown in Table 2. Such an organisation seemed the most reasonable and convenient manner for constituting the SCC19 framework and conducting further analysis. The SCC19 framework links the components that are composed of the factors and their relevant elements.

TABLE 2.

Components used in the SCC19 framework

| Factor | Number of studies | Elements |

|---|---|---|

| SC interruptions/disruptions | 37 | Trade barriers, delivery challenges, suspended operations, social distances, border restrictions, productions constraints, flows problems, supply and constraints, inventory constraints, storage constraints, |

| SC‐COVID19 facts | 26 | SC will adopt, the necessity of restructuring the SC, the need for alterative SC‐suppliers, trends to reliance on local and regional sources, the necessity to joint working |

| SC‐COVID19 associated phenomena | 23 | Panic buying, Supply disruptions, Localization trends, Raw material limitations, Transportation problem, and political, Social, and health problems associated with the pandemic. Increase fraudsters and proliferation activities, Deficient and falsified products, Varying on the impact based on country income, and Government panic to secure national supply |

| SC Capability building | 24 | Planning, integration, optimization, digital collaboration, rapid insights, quality test, empowered SC team, correct ERP system, network agility, and reliable supply |

| Pandemic Aspects | 21 | Impact, readiness, response, and recovery |

| Cost control | 11 | Cost–benefit analysis, Prices control, Costs reductions, Cash flow, Economical evaluation |

| Steps toward future | 30 | Start‐up solutions, short‐ and medium‐term measures, transforming and recovery, SC resilience, reshaping and risk management, future global value chain |

| Areas of enhancement | 29 | Visibility, technology, blockchain, automation, digitization |

| Continuous development | 25 | Solutions, decision requirements, evaluation tools |

These components are confined by the scope of the framework at the strategic and process levels, which bound the structure required to connect the impact and manifestation associated with SC‐COVID‐19, SC pillars, costs issues, and actions and solutions suggested to determine the areas of improvements and come up with steps towards continuous improvements. However, the model does not elaborate on details regarding other elements like flows, inventory, ordering, and collaboration process as they are accommodated at the operational level. The model comprises the major components required to support decision‐making processes and help researchers implement further analysis.

SC disruptions and recommendations for the future are mentioned in the highest number of publications, followed by the areas of enhancements, SC‐COVID‐19 facts, and SC capability building. Meanwhile, cost control got the lowest number. Based on the reviewed papers, the number of citations per factor is shown in Table 2. Such an arrangement seemed reasonable and convenient for developing further classifications of the main SC‐COVID‐19 outcomes, and deriving better conclusions and future research guidelines.

SC and pandemic analysis is a huge area and is expected to increase over time. It is clear that there is an urgent need to determine the main factors related to SC‐COVID‐19, their interconnections, and how to utilise the outcomes from different studies to help SC managers evaluate their situation, make their decision, survive the current disruptions, recover and build new normal, and resist future crises. The analysis of SC‐COVID‐19 in the context of the connection among different factors and elements represents a novel study array. Based on the above analysis and findings, the SCC19 framework is structured.

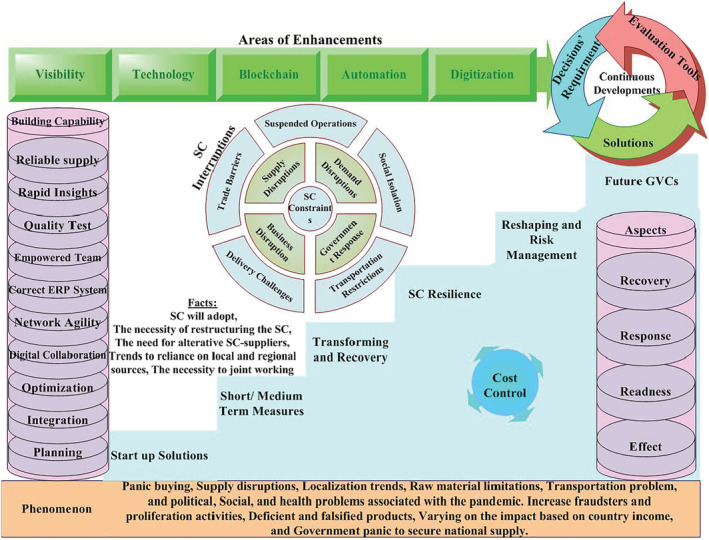

Figure 3 presents the framework to understand the COVID‐19 effect, measures, and solutions related to existing SCs. Initially, SC curators must understand the phenomena that accompanied the spread of the virus. They should then study and realise the interruptions that negatively affected the performance of the existing SC, whether they are constraints, disruptions, and challenges. Thus, to build any short‐, medium‐, or long‐term solutions, including the necessary immediate solutions, it is essential to realise the necessary pillars to support the areas of development, future GVC, and continuous improvement. The first pillar represents capacity‐building to mitigate any future threat to the SC. The second pillar represents the crises aspects for readiness, response, and recovery of the VC, followed by an adequate appreciation of the SC in the pandemic period. These facts should be considered in any developments of plans, procedures, and policies. The next segment represents development areas, which include five main areas necessary to support continuous improvement and ensure continuity, responsiveness, and future SC competition. Furthermore, the necessary steps to ensure the performance and effectiveness of the SC include several steps towards the future SC development. This improvement is a guarantee for resilience towards unknown challenges that often disrupt the SC in crisis situations like COVID‐19. The continuous improvements approach enables SC managers and executives to define requirements, decision‐making and inputs, as well as finds appropriate solutions, associated evaluations, and measurement processes while ensuring that these procedures continue to be revised in the future. The following sectors constitute the main structures of the framework in analysing, improving, and ensuring SC future resilience and competition.

Phenomena

Panic buying, supply disruptions, localisation trends, raw material limitations, and transportation problems, as well as political, social, and health problems associated with the COVID‐19 are the main SC phenomena from the impact of the pandemic. Moreover, the phenomena are accompanied by delivery delays, unpredicted practices, stockpiling, hoarding goods to sell later with inflated prices, reduction in quality assurance of products, reduction in data access, banning exports, and panic‐induced buying. The panic buying phenomenon made the international headlines as it provided the opportunities for fraudsters to fill out the gaps.

SC interruptions

Every SC has its own constraints, such as productions, flows, locations, inventory, and storage constraints. In addition to the normal SC constraints, planning, decision‐making, capability, visibility, quality constraints, capacity, legal, regulation, institutions, sustainability, talent, liquidity, and responsiveness limits the ability of delivery. SC disruptions from government measures and actions significantly impact the global SC chains as they abandon exports, imports, travelling, transportations, and social isolations, in addition to many other restricted actions. SC challenges, such as trade barriers, delivery challenges, suspended operations, social distances, and border restrictions impact SC continuous improvement, strategies, and competitiveness if appropriate measures are not considered promptly with the right tools. Other parts of the segments in Figure 3 help prevent SC interruptions from affecting the SC in the short‐, medium‐, and long‐term regarding the development of future VCs.

Figure 3.

SCC19 Framework

SC pillars

The first pillar represents the strategies for building SC capability, which is the main supporter of any SC process, operations, and activities during crises. The second pillar represents crisis aspects, which supports the future reliance of SC and prevent disruptions from aborting SC operations and continuity.

Ten success strategies help build SC capability to maintain SC operations, given the COVID‐19 pandemic. These strategies include planning, integration, optimisation, digital collaboration, rapid insights, quality test, empowered SC team, correct ERP system, network agility, and reliable supply. Companies should ensure a reliable and predictable supply and attain the greatest value from suppliers. Diversification of supply base and sourcing strategies must focus on returning to full production beyond the outbreak. Building for rapid generation of insights allows SCs to respond to changes and shocks. Resilience in SC operations is a key factor for the success of many strategies. It empowers SC teams and involves all staff in the supply chain management. Decentralised teams can respond quickly to insights and generate recovery capabilities to disruptions. A correct ERP system is a necessary component with many industrial systems to eliminate the use of manual systems. Moreover, if the organisation already has an ERP system, they should use an advanced system to increase the production with efficiency improvements. An adaptive, flexible, and agile SC network with quick planning and integrated implementation should be formed. Dynamic planning capability may ensure agility for SC changes and enable continuous, dynamic SC modifications and adjustments to respond to the changes quickly and efficiently. Digital collaboration increases with information sharing enhanced by cloud technology, collaborative base, and suitable tools. Optimisation of product designs and management for supply, production, and sustainability will speed up the advancement of innovations. Innovation is crucial for competition and can be reflected in the design of the product regarding price, time, and location. Embedded sustainability into SC operations is a crucial success factor. SCs should be aligned with business objectives by integrating trades and operations with business planning. In any strategy, resources planning is the key to improving SC success. Failing to plan resources requirements lead to delays in deliverables and delivery, reduction in quality, overtime, and a reduction in consumers' satisfaction.

The crisis is discussed here from four aspects, including impact, readiness, response, and recovery. Operations were affected by different levels like volume decline, transit delay, inadequate capacity, delivery delay, late payments, cancelled credit lines, inconsistent demand quantity, and increased costs. Moreover, there was a delay in communication with sources and shippers.

Organisations require the development of readiness capability while decreasing the decision uncertainty during response and recovery. Companies may build readiness through three main phases: development, assessment, and finalising. Response plans should determine actions to minimise and shorten the length of the disruption and its effect on SC. The consideration of available resources (human, financial, and assets) is required to accomplish the plans. Further, recovery comprises the prevention strategies and policies, control measurements, treatment programs, manpower management, and disruption elimination.

Facts

SCs will adapt, and businesses and the economy usually find a way to survive adverse situations. Thus, the SC must be restructured for alterative SC suppliers to initiate more redundant SCs. Current trends indicate that firms are working towards reliance on local and regional sources and have become more responsive to disruptions. The COVID‐19 pandemic is different from any other black swan event and affects both demand and supply, simultaneously. The crisis gives scope for exploring the necessity of joint working. Many countries and organisations are convinced that stabilising their SCs require nearby local or regional sources. Joint working by sharing information and understanding suppliers in the SC promotes good preparations for future crisis.

Areas of enhancement

Organisations should first focus on short‐term solutions and management to recover and enable the continuity of flows. They may hold operation and activities for a while, such as money transfer, resources exchange, cooperative applications, and systems developments and technology deployment until they recover and resume work. The long‐term plan should focus on solutions and strategies to mitigate matching future events. The fields of improvements include visibility and monitoring, adoption of emerging technology, blockchain technology, automation, and digitisation and transparency.

The visibility of the inventory in the entire SC allows organisations to integrate their efforts, database, and decision process for the necessary flexibility and agility to react to rapid changes, speed up processes, and reduces costs. Several technologies rapidly change the SC process, such as 3DP, IoT, predictive technology, cloud computing, big data and analytics, and autonomous systems. Industry 4.0 technologies, SC 4.0, and augmented reality can expedite SC digital transforming. Blockchain technology encourages suppliers to share data and ensure data confidentiality. Moreover, it should quickly be implemented since disruptions may happen anytime. Automation systems in the workflow, process, and operations increase the agility of replenishment. Automation greatly impacts the SCs and continues to reshape the costs of sourcing, especially in production lines that are suited to automation like electronics. SC digitisation should be integrated as part of its design. Digitisation enables risk management and business continuity as part of the entire business strategy.

Forward steps towards SC stability

There are six main forward steps towards SC stability. They include start‐up solutions to guarantee the recovery from the first shock, short‐ and medium‐term measures to assure the continuity of flows, and the recovery from the pandemic disruptions, as well as transforming the SC to face challenges. Moreover, the key steps for more SC resilience include reshaping the SC based on the technologies, lessons learned, best practices, and building the future SC model to combat current and future crises.

Any start‐up solution should consider the economic effect and direct impact on sources and supplies, escalations in prices, and the employees' safety and income. Start‐up solutions may include an electronic platform to connect with entities that can transport cargo across the country. An immediate business model should be built to make SCs more effective, transparent, increase logistics capacity, and reduces the travel time as much as possible. Organisations should make sure of correct procedures for a strong protection system for workers in line with international standard and social security.

Measures to respond to short‐medium change and protect SC operations include the following. Train employees about COVID‐19 symptoms, precaution, prevention, and protection. Concentrate on human resources planning and strategies with work flexibility to allow for remote work. Organisations should efficiently make sure of the IT system infrastructure, networks, and its suitability for a seamless flow of operations. Supply networks should focus on direct suppliers, reduce extended supply networks, and supply from closer sources. Organisations should employ digital methods to build supplier networks and visibility for critical SC activities.

Flexibility is necessary to prepare for smooth factory closure. Moreover, production rescheduling and agility must be emphasised to prepare for global scenario planning, and a rebound as production is moved to another location within the SC network. Experts can introduce innovative and agile solutions like mobile production entity. It is important to update the plans frequently, including supply, demand, impacted markets, and the virus controlled or spread locations.

Many organisations and businesses have been forced to transform their SC model to a flexible and responsive one. New technologies and digital SC could assist organisations to oversee their entire supply network from routing, rerouting, destination change, and bypass process to guarantee the continuations of flows.

Organisation recovery varies based on SC risk management, disruptions mitigation plans, business strategies, geographical area (close suppliers, factories, and industry in the region), reliance on multi suppliers and sources, and stock size to buffer against SC instability.

The new normal is necessary to guarantee refreshments, prevent productions and industry shutdown, and generate the ability to face shocks to be more reliable, secure, and responsive after the experience.

Three key factors make SCs more resilience: SC visibility, digitisation, and data confidentiality for suppliers. During crises, visibility via SC is vital to understand the impact on the rest of the SC network so that other partners can plan and take actions like evolving routes to other sources. Digitising SC will create more resilience to future disruptions. Organisations should initiate a digital transformation to make the process more efficient and secure. Blockchains could be the solution to satisfy confidentiality and encourages suppliers to share information, contribute to SC, and increase visibility, thus leading to a resilient SC.

Beyond COVID‐19, SC resilience is the key to recover from the global crises. It is reshaping SCs and sectoral activities via recovery lessons to long‐term resilience. GSCs will require restructuring to ensure business goals and objectives are met. GSCs must avoid prolonged economic suffering and distress. Moreover, coordination policies could be a promising path to recovery from the crisis.

Risk elements are interconnected with geopolitical, social, and regulatory uncertainties, especially with the global economy. Organisations should study the potential risks in other countries and regions to specify the actions and plans that will appropriately protect against these risks. Organisational recovery will vary based on their SC risk management. Understanding risk divers, priorities, and solutions is the best way to plan for a future risk management system. Organisations must quickly arrange for inventory and cash flow during SC crisis to mitigate the risks of SC critical disruptions.

Crucial elements for future SCs include intelligent procurements, SC control tower, SC data management with intelligent automation and analytics, supplier risk management, and SC simulation. Intelligent procurements help companies know where and when to supply based on previous procurements, commodity pricing, industrial trends, and machine learning systems. SC control tower allows for the visibility of the external SC environment, the entire SC, trading partners. SC data management with intelligent automation and analytics based on accurate real‐time data about SC transactions without redundancy is one of the keys for the future GVC. Further, SC simulation could model and optimise new strategies changes.

Cost control

Given the pandemic, SC cost control and management is vital to support business objectives amid the increases and change in demand and financial volatilities. SC costs impact most of SC decisions and business. Decision‐makers try to manage margins and improve liquidity during the crisis. Thus, it is crucial to reshape SC costs in an innovative way to confront future growth and organisational agility. All businesses and SCs are worried about sudden changes in their tariffs, currency changes, currency depreciation, taxes, drops in revenues, operations and capital strategies, and conducting trade‐offs of cost reduction in various areas of SC. Such concerns are important for SC managers, executives, and decision‐makers for the future. Organisations that invest in high flexible SCs and resilience to reduce the product development cycle can adjust faster to market changes. Moreover, their revenue will increase.

Continuous developments

SCs have no choice but to evolve, and organisations require additional innovation to prepare for the future. Continuous development is a vital way to prepare for future crisis. It requires decision inputs, solutions, and evaluation tools.

Decision‐making requires the reconsideration of the GSC strategy, the demand impact specific to businesses, and the utilisation of SC experts. Given COVID‐19, additional decision‐making requirements include open‐source COVID‐19 data, real‐time SC data, and demand change per region or country, considering the opportunities and drawbacks of each decision. Thus, developing and enhancing SC excellence requires decision‐making skills, analytics capabilities, understanding costs and constraints, and business capability to support SC continuity to become a right business partner in the SC.

Solutions amid the pandemic include sourcing diversity, online delivery, contracts revision, sustainability, government support, and continuous development. Solutions can be implemented in steps as follows. Develop contingency plans with scenarios for different demand surroundings and changes. Reduce supply shock by working closely with the current suppliers and diversifying the sources. Arrange for demand volatility by mitigating panic buying, supporting retailers, promoting a safe work environment, protecting SC employees via investments, making PPEs available, and looking ahead to facilitate the resumption of business. Solutions require communication to manage time, availability, and safety.

Organisations require the establishment of a tool to evaluate, assess, and measure the effect of COVID‐19 on demand, supply, and, thus, the SC. The challenging times call for the latest analytics solutions. Many companies use software to analyse situations during crises and make decisions. Organisations’ evaluation tools may include software, analytics programs, group meeting, expert interviews and opinions, prioritising products, and best scenarios. Furthermore, validation of the decision‐making and solutions can employ benchmarking.

The framework was discussed with several experts in logistics and supply chain systems (two procurement specialists, two academicians, and three managers from companies specialising in global trade in Jordan). Trade companies are import and export firms that usually deal with bids to supply the local market with imported products. The nine factors that were adopted in the framework were reviewed, along with their interactions, by the experts. They emphasised the framework's applicability, the importance and effectiveness of the framework in reducing the impact of the pandemic on the performance of the supply chain in the short and long run. They also emphasised the effectiveness of the continuous development steps outlined in the framework. They focused on the importance of the framework in assisting managers in making decisions and planning for the supply chain in light of the pandemic and the post‐pandemic status, until it reaches the new normal. They also stressed the need to keep pace with these changes by utilising emerging technologies that help to overcome future crises, such as 3D printers and smart systems, and to increase reliance on local and nearby sources within the global supply chains. Their comments on areas of improvement ranged from adding new areas to rearranging them according to their priority. They added that an implementation of the framework must be accompanied by supportive government measures and the cooperation of the private sector, to facilitate and support the provisioning measures. They also stressed the need to identify the main SC‐COVID‐19 solutions and arrange them according to the priority of implementation and their importance in overcoming the crisis. They mentioned that these measures could lead to the stability of the supply chain and the aforementioned factors should be taken into consideration by decision‐makers at all levels.

COVID‐19 underlined the necessity to transform traditional SC models. During a ‘black swan’ event like COVID‐19, a strong understanding of the factors that could help organisations to initiate the correct plan to face the unexpected. New forms of tools can play a critical role in assisting SC managers view the potential SC‐COVID‐19 risks and use the framework to take corrective actions to ensure better SC flows. The multi‐factor framework enables enhanced characterisation of the complexity of SC‐COVID‐19, and therefore it offers support for more cognisant professional decision‐making regarding investing in improving SC stability. The observed results could help decision‐makers and managers make better decisions regarding the current and future crises.

Conclusion

The COVID‐19 pandemic disrupted global business and trades, thus severely affecting SCs. The shutdown of factories and disrupted the VCs left many businesses struggling to source materials and fulfil demand. Most organisations reported SC disruptions in their capacity because of the pandemic. It is challenging for a planner to prepare for crises, such as the COVID‐19 pandemic. Such crises require rapid decisions in a complicated and challenging environment, given SC costs and quality.

The effects are unlikely to stop soon. It will reasonably continue to affect businesses and trade policies for a long time. SCs will not be the same post‐COVID‐19. The shocks of the panic and the resulting economic impact led to a disruption in most of the GSCs. Generally, the pandemic impacted SCs and their management in several critical capacities. Many companies are continually analysing and tracking new trends in the SC and procurement process. Organisations that take steps to mitigate risks are better prepared to face future challenges. Companies that diversified their suppliers are poised to overcome the impact of the pandemic on SCs.

The COVID‐19 outbreak disrupted many businesses and related SC operations. Motivated by the findings of the literature analysis, the study examines the contribution by answering fundamental questions including: the factors impacting the performance, interrupting flows, and building SC end‐to‐end capability; the recurring and unique phenomena associated with COVID‐19 and their short‐medium‐long term consequences, opportunities, and developments; and how SC managers and decision‐makers can utilise the SC‐COVID‐19 framework components to face such crises, existing and future.

This study examined 75 articles on coping with the impact, manifestation, and factors connected to SC‐COVID‐19 and those that might contribute to SC recovery. Streamlining the literature uncovered several new prospects and novel interconnections among several SC‐COVID‐19 factors. The initial outcomes revealed that each factor or element was discussed thoroughly, but there is no congregation of these factors in a single study or framework.

This study differs from its predecessors as it tries to integrate different elements and factors together in a comprehensive framework. For this purpose, we first analysed the impact of COVID‐19 on SC operations and performance in terms of its disruptions, associated challenges, and new trends, and subsequently investigated SC manifestations arranged in three phases: short, medium, and long term. Finally, we build the framework based on the nine factors to explore the elements that could help decision‐makers withstand and recover from the ongoing as well as similar crises in the future. In addition, the framework introduced the triangular pedestal of continuous improvements: solutions, decision requirements, and evaluation tool. To the best of our knowledge, this research is the first to combine and emphasise the impact, phenomena, and propose a multi‐factor multi‐step framework for SC‐COVID‐19. It also contributes to the literature by defining the components of SCC19: disruptions, facts, phenomena, capability building, crisis aspects, costs control, areas of improvements, steps, and continuous developments towards SC resilience and the new normal. It provides a road map (enhancement areas and steps) to resist the ongoing and future crisis.

SCC19 frames the essential elements, understands their structure, sequences, and captures their relations. SCC19 can assist decision‐makers to build SCs that can respond adaptively and help organisations to guide their decisions on surviving, recovering, improving, and rebuilding their SCs beyond global long‐term crises like the COVID‐19 pandemic. The initial rationality and applicability of the model was checked with several experts in the field of logistics and SC systems.

Though it is early to evaluate and measure the entire effect of COVID‐19 on SCs, the study provides several implications to help SC managers better understand the interrelation between these factors and pandemic and boost the decision‐making process. Firms' practitioners can estimate the enhancement areas and steps towards resilience based on the environment and phenomena associated with the pandemic. This allows the evaluation of the post‐pandemic behaviour to help them reassert new normal and ensure continuous improvements against a risky environment. Our results evidently identify the main factors and elements related to SC‐COVID‐19 and propose the interrelationships between the components constituting the framework to support policymakers making proactive decisions.

In conclusion, the study explores the impact of the COVID‐19 pandemic on SCs be discussing the causes of disruptions, related challenges, and the trend of the pandemic. SC stages, phases, and manifestations of COVID‐19 were analysed. Moreover, the consequences, opportunities, and developments to explore the interconnections between different elements depend on aggregate experience, benchmarking, and a new business environment. A comprehensive SCC19 framework explores the interrelationships between the three factors of SC interruptions and the resulting facts and phenomenon from the crisis. Descriptions of the capability building process and crisis aspects are presented regarding SC resilience. Areas of improvements and the main steps concerning the future GVC were presented and linked to the cost control and continuous improvements to survive the impact of COVID‐19 and potential future crises.

The continuous developments methodology allows SC managers and executives to express requirements, decision‐making process and inputs, in addition to finding the appropriate solutions, related evaluations, and measurement practices while make sure of the continuous revisions in the future. The main structures of the framework interlinked these factors to assure the analysis, improvements, and responsiveness to help decision‐makers endorse SCs future flexibility and competition.

Perhaps, COVID‐19 will lead a new era and revolution in the SCs, and the time is ripe to review the performance and evaluation of the GSCs. Among the most important results of this crisis is the increased focus on the local and regional SCs. Investment in local SCs has several benefits but no company that can operate alone. Thus, GCSs remain necessary.

Given the COVID‐19 pandemic, organisations must encourage more information sharing, communications, and visibility regarding SCs. Technologies and enabling plans and procedures will help rebuild the SC system and improve its resilience in the future. Technology, digital SC, and visibility through the VC and blockchain supply should be a priority for future SCs.

Nevertheless, there are several limitations which include narrowing the literature review and limiting the factors to those extracted from the reviewed articles. Consequently, the analysis may miss some key components influencing the SC‐COVID‐19 relationship. This research is limited by the scarcity of the number of studies related to a comprehensive analysis of SC‐COVID‐19. There are studies that may not have been published and, thus, are still outside the review. The framework may benefit from empirical studies and application of the study in real SCs as well. In general, development of logistics systems is challenging and requires a long time due to the complexity involved.

It is expected that the novel identification and categorisation of factors and elements proposed in the framework with their connections and relations will be of value for practitioners, managers, and researchers in directing SCs during and after the pandemic. The framework is constructed with a generalised view to be utilised by other industries and professionals to survive the current pandemic and to resist and recover from future crises. The framework application can be extended to other industries and related sectors.

Utilising the analysis of the SCC19 framework and literature review findings and outcomes, there are several opportunities for future research directions as follows:

Extend the literature review to include new factors and elements to support the framework comprehensiveness. Future studies may focus on developing and testing new models, frameworks, and components related to SC‐COVID‐19 to build a tool to improve DSS. Further, they may extend the knowledge of how SCC19 influences the DSS and performance of organisations.

The proposed framework can be extended by incorporating more complexity and more components; empirically testing the framework with quantitative data to validate and generalise the findings, and checking the impact on different business performance; developing SC‐pandemic plans to enhance coping strategies and achieve organisational goals; or considering the interrelationship between the framework components in the geographical context.

Investigate the emerging technologies that can lead to continuous development and help SC recovery and withstand future pandemics. Moreover, they may explore changes brought about by digital transformation and other emerging technologies like AI, 3D printers, and machine learning.