Abstract

Since Vedic times, traditional Indian cultured butter or makkhan has been one of the most demanding and extensively used food items in the village households of Indian subcontinent. Its processing and overall quality suffers due to the use of conventional practices, which has probably discouraged the production of product in organized sectors. No scientific intervention has taken place to improve the product quality and process since the inception of makkhan making. As an initiative towards the improvement, the present study is focused to prepare a detail scientific background on chemistry, quality attributes, utilization, preparation methods, and storage of product for identifying challenges and scopes of overall improvement in production status. To validate the opportunities identified for the improvements in production various approaches especially mechanized approaches are suggested in this review.

Keywords: Makkhan, Fermented milk, Churning, Flavour, Conjugated linoleic acid, Improvement approaches

Introduction

Makkhan is a traditional cultured fat rich milk product of Indian subcontinent (India and Pakistan). It is quite similar to butter (i.e. western style butter) according to composition, appearance and method of production. Since Vedic times (3000 to 2000 BC), it has been extensively produced by village households of the subcontinent for use in daily diets and religious practices (Aneja et al. 2002). There are recorded evidences that, Lord Krishna, the popular character of the Hindu epic Mahabharata, was very much fond of makkhan during his childhood days (Deosarkar et al. 2016). Now in India, millions of village households, one out of every two households in rural areas, are engaged in milk production. Around 52% of this production is sold to different enterprises for commercial uses and remaining 48% is retained at home to consume as such (DAHD 2020) or to use in production of products like dahi (traditional Indian fermented milk), lassi (traditional Indian buttermilk of thick consistency), chhach (traditional Indian buttermilk of thin consistency), makkhan, ghee etc. for daily use. It is reported that, the estimated market of ghee, makkhan and malai (clotted cream layer formed after boiling of milk) together was around 210 billion US dollar in the year 2002–03 (Dairy India 2007). The current makkhan production occupies a very important share, because major proportion of ghee preparation in the villages of Indian subcontinent still follows the conventional practices of dahi-makkhan route (Ahmad and Saleem 2018).

At the rural household level, whole milk or cream which is processed or unprocessed is first converted into dahi and then it is churned into makkhan at ambient condition (De 1991). Due to the variations in the methods of preparations there is wide variation in overall quality of product. It is quite similar to ‘whipped cream cheese’ in terms of flavour and appearance (Aneja et al. 2002). An average composition of makkhan has been proposed by scientists after an extensive survey as 18–20% moisture, 78.5–81.3% fat, 0.7–1.5% non-fatty solids and not more than 0.2% lactic acid (Rangappa and Achaya 1973). According to FSSAI (2017) makkhan should contain not less than 76.0% of milk fat by weight.

Makkhan is widely known for its distinct flavour and attributes such as mouthfeel and texture. The flavour of makkhan is contributed from dahi, which is prepared after lactic fermentation of whole milk. During direct consumption with different daily used foods it adds value to foods and culinary dishes. When makkhan is used in ghee production it contributes a distinct and pleasant aromatic flavour to ghee also (Aneja et al. 2002). The process of churning at ambient temperature contributes makkhan with a greater proportion of high melting fraction (HMF) of milk fat (Aneja et al. 2002). HMFs like strearins are also believed to enrich flavour and texture of fat rich products (Deffense 1993). As the HMFs of milk fat are stable at higher temperature and stable against microbial growth due to low water activity, those can be applied in the chocolate and confectionery products to improve overall properties of those products (Shukla et al. 1994).

According to Charak Samhita fresh makkhan has several health benefits for human body. It helps in treating malabsorption syndrome, piles, facial paralysis, indigestion, cardiac problems, and anorexia (Easy Ayurveda 2019). It contains fat soluble vitamins, small amount of essential fatty acids and conjugated linoleic acid (CLA) (Aneja et al. 2002). Milk fat is the most important natural source available for fulfilling dietary requirement of CLA (Luo et al. 2017). Chin et al. (1992) reported that, cow milk contains an average of 5.5 mg CLA/g of fat. He has also mentioned that, the CLA content of different milk products varies in the range of 2.9–7.1 mg CLA/g of fat. The old traditional methods of makkhan preparation from dahi convert small amount of fatty acids i.e. linoleic acids, linolenic acid, ricinoleic acid and their methyl esters present in milk to CLA because of fermentation of milk by lactic cultures (Aneja and Murthi 1990; Aneja et al. 2002). Large number of published information is available on CLA and its efficacy over the cancer prevention activities and anticarcinogenic attributes (Aneja et al. 2002).

Although, makkhan is consumed in everyday diets by a large population, there is limited scientific information available about the product and its manufacturing. This in turn has affected improvements in product quality and further large-scale production. The published literature indicates that there are huge opportunities for the improvement of the product matrix characteristics, flavour profile, and manufacturing processes of makkhan. Therefore, the present initiative is taken to prepare a detail scientific background on product chemistry, quality attributes, utilization, preparation methods, storage and handling of product from the relevant latest published information available on milk fat, other fat rich dairy products of similar category (such as butter, ghee, traditional fat rich dairy products and cultured fat rich products of different countries) and products similar to the intermediary product used in makkhan production i.e. dahi. The information on product and its detail scientific background have been used to identify the challenges and future scopes for improvements in the production. For every scope of improvements in the production various approaches, especially mechanized approaches are suggested here from the latest published information available.

Conventional household practices for preparation of makkhan

There are two major conventional practices followed for preparation of makkhan as discussed below-

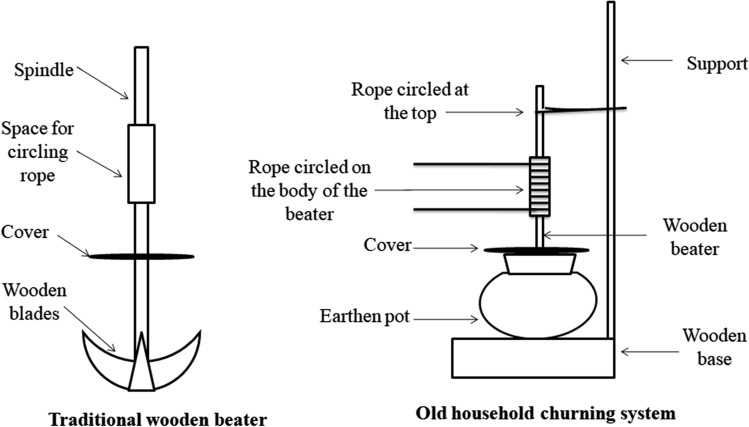

Old household practice This method was mainly followed by the early inhabitants and still prevailing in some parts of the subcontinent. In this, dahi prepared from unprocessed whole milk (i.e. buffalo milk or cow milk or mixture of cow, buffalo, sheep and goat milk) is used frequently for makkhan making. Mixing of unprocessed milk with boiled milk is also found. Sometime malai is collected for several days and used for makkhan preparation (Aneja et al. 2002). Usually, milk or cream is inoculated at room temperature either by self-souring or addition of dahi from previous runs. Sometimes, the dahi is held up to 48 h after souring and collection is done for 8–12 days to make a sizable volume before churning (De 1991; Sserunjogi et al. 1998). In the early hours of any morning the dahi is churned in earthen pot with a wooden beater by moving it in alternate direction with help of a special arrangement made by circling a thick rope on the body of the beater (Aneja et al. 2002) as shown in Fig. 1. In the process of churning, cold or warm water is added to maintain the temperature of churn depending on the seasonal variation and the extent of water addition varies widely. Fat particles float over the surface of churned milk and collected in small lump form. In this method, about 14 kg of mixed milk (cow and buffalo milk) is required to produce 1 kg of makkhan and only 75–78% of fat can be recovered in makkhan and rest goes to chhach or lassi (Rangappa and Achaya 1973).

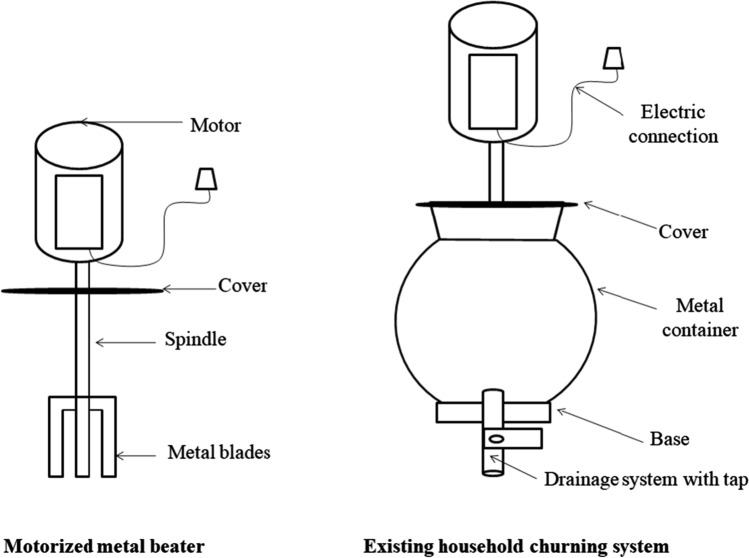

Existing household practice Now, most of the village households throughout India use fresh whole milk (preferably buffalo milk) having higher fat content and good proportion of large size fat globules, and this is said to improve the yield and quality of makkhan (Aneja et al. 2002). Appropriate thermal processing, mainly boiling of raw milk to remove all undesirable microorganisms and followed by immediate cooling to room temperature prior to inoculation are found as most commonly followed thermal processing in practice (Joshi 2014; Ahmad and Saleem 2018). Good and fresh starter cultures (free from any defects) in the form of dahi or chhach or lassi, collected from previous runs, but not more than 24 h old are used in appropriate proportions depending on seasonal variations and time allowed for incubation (De 1991). While adopting this method, the inoculated milk is held at room temperature for 10–16 h (Ganguli and Jain 1973) or 8–10 h (Joshi 2014) or 8–12 h (Ahmad and Saleem 2018) or overnight (Aneja et al. 2002) for setting of dahi. Churning of dahi is carried out in a specifically designed metal container having proper drainage facilities preferably at morning time using a wooden beater or a motor driven beater (De 1991) as shown in Fig. 2. Dahi is diluted with water at different stages of churning (Ahmad and Saleem 2018) and approximately, the total volume of water used in dilution is kept equal to that of dahi to obtain maximum yield of makkhan (Rangappa and Achaya 1973; De 1991).

Fig. 1.

Schematic diagram of equipments used in old household practice

Fig. 2.

Schematic diagram of equipments used in existing household practice

Comparison of butter with makkhan

Makkhan is a fat rich dairy product with similar fat content and unit operations followed for preparation as that of butter. However, there are some distinct differences in the method of preparation and quality attributes of makkhan and butter. At the inception of butter making use of milk was in regular practice; now-a-days, it is derived mostly from fresh or sour cream (Deosarkar et al. 2016). No culture is added for the preparation of most commonly used butter, but in case of cultured butter production, lactic starters are used to produce diacetyl from citrate (Frede and Buchheim 1994). In case of makkhan preparation, use of unprocessed or semi-processed or boiled whole milk is fermented using a lactic starter culture (Joshi 2014; Ahmad and Saleem 2018). Although fat content in butter and makkhan is approximately same, the amount of moisture, curd (coagulated protein particles) and lactic acid is observed higher in makkhan as compare to butter. Therefore, storage quality of butter is better than makkhan. Makkhan contains good amount of diacetyl flavour contributed from milk fermentation by lactic cultures. Because of lactic fermentation, makkhan contains more amount of conjugated linoleonic acid (CLA), which attributes several benefits to human body as compared to butter. Texture, mouthfeel and flavour contributed by fat in makkhan is more, because of higher amount of high melting fraction of fat as compared to butter. Normally, addition of colour and salt is observed during butter making, which is not carried out in makkhan preparation (Aneja et al. 2002). Butter is mainly used for preparation of different products such as bakery, confectionery, ice-cream making, butter oil, sauces and ghee, while makkhan is used in regular diets of a large number of Indian population and major proportion of ghee production (De 1991).

Factors influencing quality attributes of makkhan

Raw milk composition

Traditionally, cow, buffalo or mixed milk is used for the preparation of makkhan. In some places, small amount of sheep or goat milk is also mixed. Quality of makkhan is strongly influenced by the amount of fat and fat globule size present in milk used for its preparation (De 1991; Aneja et al. 2002). Quantity of fat in the bovine milk varies from 3 to 5% (Singh 2006). While, buffalo milk contains an average of 8.3% fat and may reach up to 15% under favourable conditions. It is preferred for production of fat rich dairy products such as butter, cheese etc. (Varrichio et al. 2007). Milk fat is one of the most complex forms of lipids with unique composition and present in the form of spherical globules of different sizes. Size of naturally occurring fat globules varies from 0.2 to 15 µm in diameter with an average of 4 µm (Walstra 1969; Mulder and Walstra 1974; Michalski et al. 2004). It is explained from different studies that, milk contains three separate size fractions of MFGs (Martini et al. 2016). Fat globules with diameter more than 8 µm are larger globules, less than 1 µm are smaller globules and globules sizes in between these two sizes (1–8 µm) are medium. In a specific quantity of raw whole milk large diameter globules occupies only 1–2% of fat volume, 94% volume of fat belongs to medium size globules and remaining 4–5% consists of small diameter globules whose number fraction is around 80% of total (Walstra 1969). The fact behind the excretion of MFGs of different diameters is not very clearly explained anywhere (Walstra and Mulder 1974; Martini et al. 2016). However, in some studies it is reported that, intracellular fat droplets may be the source of small size globules and large globules may be generated from cytoplasmic droplets. Cytoplasmic droplets are formed as a result of fusion among many intracellular droplets and may grow in size further by fusion of globules after secretion (Luo et al. 2017). Later on, several other studies on size based separation of MFGs suggested that fat globules having diameter of less than 3 µm are “small” and bigger than 5 µm are larger (Briard et al. 2003; Michalski et al. 2004; Fauquant et al. 2005). Milk containing good proportion of large size native fat globules can yield more amount of products, reduce fat loss in chhach or lassi and increase firmness and mouthfeel of makkhan (Mulder and Walstra 1974; De 1991). Some studies reported that the large size fat globules contain more amounts of saturated fatty acids (Mesilati-Stahy et al. 2011; Martini et al. 2016) and melting temperatures of fatty acids decrease with decrease in degree of saturation or increase in number of double bonds (Creamer and MacGibbon 1996). But, LMFs are more acceptable by health conscious people (Khan et al. 2019), because those contain more medium chain and unsaturated fatty acids such as palmitoleic acid and linoleic acid (Michalski et al. 2005; Mesilati-Stahy et al. 2011; Lopez et al. 2011), more CLA (Fauquant et al. 2005; Lopez et al. 2011), and higher amount of phosphatidylserine, phosphatidylinositol, phosphatidylethanolamine (Lopez et al. 2011). In bovine milk fat containing native small size fat globules has positive correlation between degree of unsaturation and melting fraction of fat (Rønholt et al. 2013), but those may not be much beneficial in makkhan preparation because of negative influence in churning (Martini et al. 2016). Amount of citrate present in milk has strong influence on aroma production in makkhan, as citrate is used as substrate by lactic acid bacteria for producing such type of flavour (Hugenholtz 1993). Due to compositional differences in cow and buffalo milk especially carotene content, makkhan prepared from buffalo milk posses light greenish-white colour, while that from cow milk has yellow colour (De 1991; Aneja et al. 2002).

Processing Conditions

The major processing conditions involved in makkhan making are processing of raw milk, fermentation and crystallization as discussed below-

Processing of raw milk Processing of milk includes filtration, heating and cooling prior to inoculation. Filtration is necessary to eliminate visible dirt and it is normally carried out using clean cloth at cottage level. The heat treatment of milk before fermentation is required to destroy undesirable bacteria, enzymes, eliminate growth inhibitors and thus creates a favourable environment for the growth of desirable starter organisms, and improves the physical properties of products (Sarkar 2008). De (1991) reported that boiling of milk followed by immediate cooling to room temperature is the most efficient form of processing of milk before inoculation for makkhan preparation. Most of the existing household methods use boiled milk (boiled for at least 10 min), which is reported to have pleasant aroma, firm body and good storage quality of 2–3 weeks under refrigerated condition, whereas, the products prepared in old household methods from unprocessed milk have undesirable flavour, poor storage quality and weak body (De 1991). The extent of heat treatment of milk used for makkhan preparation may also influence the metabolic activities of different starter cultures during fermentation process. Various temperature–time combinations (82.2 °C for 16–20 s, 85 °C for 15 min, 85 °C for 30 min, 85 ± 1 °C for 10 min, 90 °C for 10 min, 95 °C for 30 min, boiling/pasteurization, 121 °C for 15 min) for the heat-treatments of milk before fermentation were suggested by different studies as reported by Sarkar (2008).

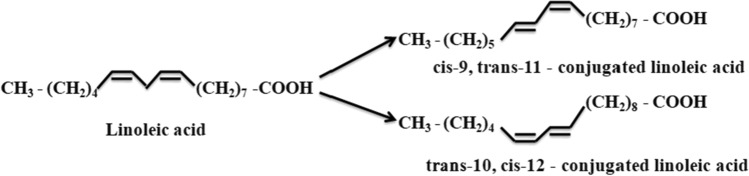

Fermentation Since milk fermentation is an important intermediate step in the preparation of makkhan, appropriate starter addition and proper condition for incubation (temperature and time combination) are very significant. However, because of variation in mode of production and handling practices the microbial population and quality of makkhan becomes unpredictable (De 1991). Makkhan is usually expected to contain similar kind of microflora those present in dahi. Rangappa and Achaya (1973) reported that lactobacilli are the major bacteria present in dahi, followed by streptococci, coliforms and aerobic spore-formers; however, yeasts and moulds are also found. The pleasant aroma in makkhan is mainly contributed from fermentation of milk by lactic acid bacteria (Aneja et al. 2002). The major contributor in creating this aroma is diacetyl flavour which is a final product obtained from citrate metabolism by lactic acid bacteria such as Lactococcus lactis subsp. lactis biovar. diacetylactis and leuconostocs, especially the strains of Leuconostoc mesenteroides subsp. cremoris as reported from different studies by Gokce et al. (2014). In this process of metabolism first citrate is hydrolysed in presence of citrate lyase to produce pyruvate alongwith other products. This pyruvate is converted into α-acetolactate, which is not stable. Because of that, at low pH after non-enzymatic decarboxylation it may be converted to acetoin or, after oxidation may be converted to diacetyl (Walstra et al. 2006; Gokce et al. 2014). Fermented dairy products prepared using lactic acid bacteria may contain diacetyl and acetoin both in different concentrations. Sarkar (2008) reported that, combined diacetyl and acetoin content of dahi generally varies in the range of 76–165 ppm. The recommended temperature–time combinations obtained from different studies for incubation in dahi manufacturing are 37 °C for 16–17 h, 30 ± 2 °C for 16 h, 30 °C for 16 h or 30 °C for 18 h, and selection of time for incubation at a particular temperature may vary with desired flavour content in fermented milk as reported by Sarkar (2008). Apart from the above, the fermentation of milk by lactic acid bacteria may produce CLA by isomerisation and structural changes of mainly linoleic acid. According to the configuration of linoleic acid, it is a long chain (having eighteen carbons) fatty acid with double bonds in cis configuration at positions 9 and 12. After isomerisation at position 10 and 11 two isomers (cis-9, trans-11 and trans-10, cis-12) of CLA are formed (Pandit et al. 2012) as shown in Fig. 3. The cis-9, trans-11 isomer occupies major share and it varies in the range of 80–95% of total CLA in any product (Chin et al. 1992).

Fig. 3.

Flow diagram for conversion of linoleic acid to two different isomers of CLA (Bernas and Murzin 2005)

Crystallization Crystallization of milk fat is very important phenomena for the structural development of makkhan. In crystallization, milk fat changes from liquid to solid state through processes such as nucleation, crystal growth and crystal rearrangement (Sato et al. 1989; Fox and McSweeney 2006). Nucleation is the first step of crystallization process. Temperature is the major determinant of the condition (i.e. ‘supersaturation’) which is required for nucleation. When milk fat is cooled below its melting point, the fat molecules start to aggregate into tiny clusters. These clusters are not stable until a critical size is reached. The stable cluster is called nucleus. The stability of the critical radius of any nucleus depends on temperature (Fox and McSweeney 2006). There are three types of nucleation such as primary homogeneous, primary heterogeneous and secondary nucleation generally observed in different fat systems. Among those, secondary nucleation is very common in milk fat system (Walstra 1998). After nucleation crystals grow in size and that process is known as ‘crystal growth’. Major driving force for these is degree of supersaturation and molecular diffusion of materials to solid surfaces (Mulder and Walstra 1974; Fox and McSweeney 2006). The process of milk fat crystallization have been elucidated in different studies and the major factors which influence this complex phenomena are reported as composition of milk fat, parameters involved in thermal and mechanical treatment on milk (Herrera et al. 1999; Vanhoutte et al. 2002; Wiking et al. 2009; Fredrick et al. 2011; Budlo et al. 2013; Rønholt et al. 2013). The above factors are discussed below in detail.

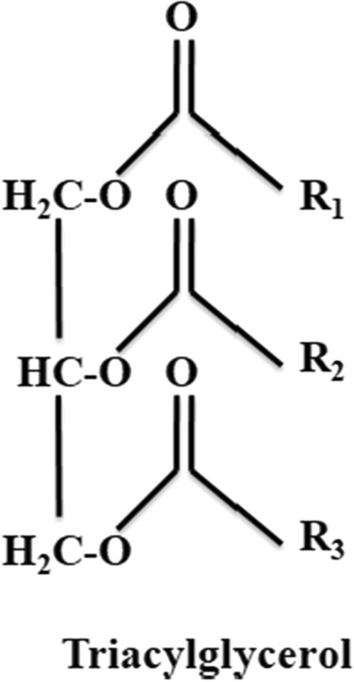

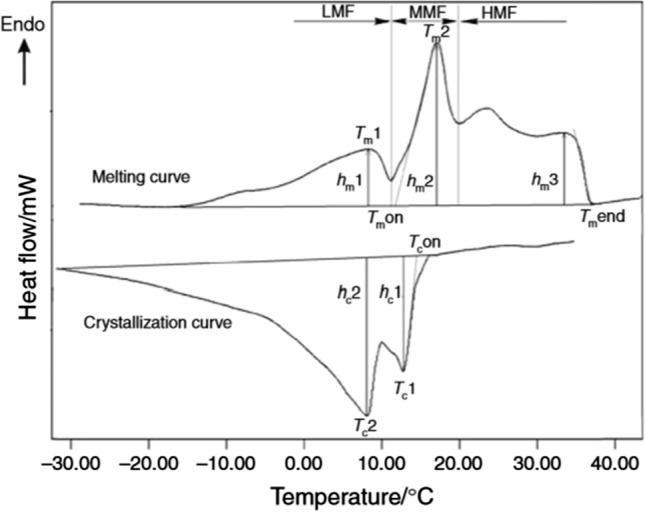

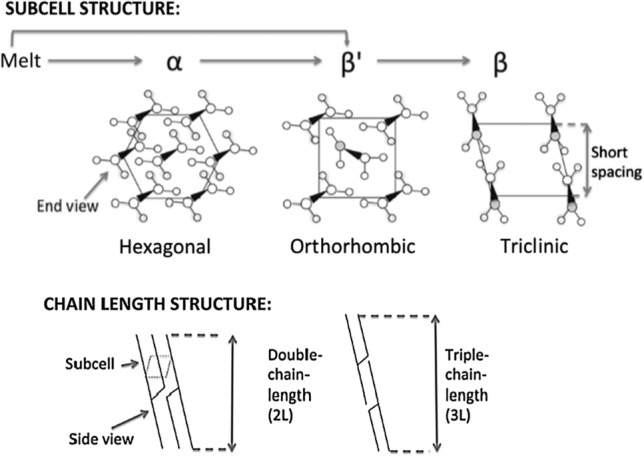

Composition of milk fat has strong influence over crystallization of milk fat. Triglycerides are major components (98% of total fat) present inside of milk fat globules (MFG) alongwith an adsorbed layer of material outside the fat globules known as milk fat globule membrane (MFGM) which contains complex lipids like phospholipids and proteins (Keenan and Dylewski 1995). Presence of TAGs significantly affects the properties of milk fat, especially melting characteristics. TAGs are complex mixture, and the complexity arises due to esterification of a large number of fatty acids (400 fatty acids) at different positions of TAG molecules (Fox and McSweeney 2006; Truong et al. 2016). The configuration of a general triacylglycerol molecule has been shown in Fig. 4. In each triacylglycerol three fatty acids are attached to a glycerol backbone. The chain length and number of double bonds are also different in each fatty acid. However, only 14 fatty acids (C4–C18, saturated and unsaturated both) have been identified as major for their proportionate share (more than 1%) in total fatty acids present in milk fat (Creamer and MacGibbon 1996). Typical fatty acid composition and melting temperatures of major fatty acids present in bovine milk has been shown in Table 1. According to variation in melting temperature of different fatty acids, milk fats are categorized into low melting, middle-melting and high-melting fractions. Low melting fraction (LMF) melts below 10 °C, middle melting fraction (MMF) and high melting fraction (HMF) melt from 10 to 19 °C and above 19 °C, respectively (Deffense 1993; Rønholt et al. 2014b). The crystallization and melting profile of milk fat obtained from differential scanning calorimetric method at a scanning rate of 5 °C/min has been shown in Fig. 5. The ‘supersaturation’ condition required for nucleation is only possible when milk fat is cooled below its melting point (Fox and McSweeney 2006). Variation in melting characteristics in fatty acids results into variation in meting characteristics of respective TAGs. The complex melting behaviour of different TAGs and inter-solubility of one TAG with other TAGs make the crystallization process very complex (Truong et al. 2016). However, this complex phenomenon generates several polycrystals (1–3 μm) and those aggregate to form network of fat crystals (20–100 μm) (Acevedo and Marangoni 2010). The fat crystal network of any fat rich dairy product dominated with many small fat crystals is said to be harder than the product containing few large crystals (Wiking et al. 2009). Upon crystallization fat present in any fat rich dairy product is converted into solid state and at that condition individual TAG molecule of milk fat can exist in two major structural arrangements or polymorphs, i.e. arrangement in longitudinal and lateral dimension, depending on previous thermal history. The polymorphs are characterized by set of d-spacings. The arrangement in longitudinal dimension is known as long spacing (38–72 Ǻ). Those are denoted as 2L (double chain length), 3L (triple chain length), 4L (quartet chain length) etc. The arrangement of TAGs in lateral dimensions is known as the short spacing (3–6 Ǻ). The arrangement of these types are denoted as- α, β′, and β polymorphs having hexagonal (4.15 Ǻ), orthorhombic and perpendicular (4.1–4.2 Ǻ), and triclinic parallel chain packing (4.6 Ǻ), respectively. Among these α is least stable or having lowest melting point and can easily convert to β′ or β polymorphs depending upon thermal conditions. On the other side, β polymorphs are most stable and linked with high melting point (Truong et al. 2016). The subcell structures and chain length structures of TAGs have been shown in Fig. 6. According to Rønholt et al. (2013) polymorphism is correlated with rheological and textural properties of fat rich dairy products. Now, it can be interpreted that the proportion of β′ or β polymorphs may be more in makkhan as it contains good proportion of high melting fraction of fat, which are stable at room temperature and the texture of product is firmer as compared to western butter. The polymorphism and structural characteristics are yet to be explained scientifically.

Fig. 4.

Structure of a typical triacylglycerol

Table 1.

Composition and melting temperature of 14 major fatty acids present in bovine milk fat

| Fatty acid | Common name | Typical proportional concentration (m/m, %)a | Melting Temperature (°C) |

|---|---|---|---|

| C4:0 | Butyric | 3.9 | − 7.9b |

| C6:0 | Caproic | 2.5 | − 4c |

| C8:0 | Caprylic | 1.5 | 15.4d |

| C10:0 | Capric | 3.2 | 30.80d |

| C12:0 | Lauric | 3.6 | 43.29d |

| C14:0 | Myristic | 11.1 | 53.47d |

| C15:0 | Pentadecanoic | 1.2 | 52.15d |

| C16:0 | Palmitic | 27.9 | 62.20d |

| C16:1 | Palmitoleic | 1.5 | 1.22–32.22d |

| C18:0 | Stearic | 12.2 | 69.29d |

| C18:1 | Oleic | 21.1 | 12.82–52.38d |

| C18:2 | Linoleic | 1.4 | − 7.15d |

| C18:3 | Linolenic | 1.0 | − 11.48d |

| C18:2 (main CLA) | Conjugated linoleic acid | 1.1 | 20–54d |

| Minor acids | 4.8 | – |

Fig. 5.

A typical crystallization and melting profile of milk fat. HMF, High Melting Fraction; MMF, Medium Melting Fraction; LMF, Low Melting Fraction; Tcon, Tc1, Tc2, crystallization temperatures; hc1, hc2, peak heights for crystallization; Tmon, Tm1, Tm2, Tmend, melting temperatures; hm1, hm2, hm3, peak heights for melting; (Tomaszewska-Gras 2013)

Fig. 6.

The subcell structures and chain length structures of TAGs obtained from milk fat crystallization (Rønholt et al. 2013)

Thermal treatments like cooling and ageing have significant role in crystallization of milk fat. Studies conducted on the effect of cooling rate in butter making revealed that, it influences the crystallization of milk fat and microstructure of product. In case of rapid cooling (10 °C/min) a large number of small crystal are formed and amount of solid fat increases. Therefore, the product becomes firmer. In contrast, slow cooling (0.1 °C/min) produces few large crystals with more amount of liquid fat in it, less contact points between crystals gives a product with softer consistency (Wiking et al. 2009; Rønholt et al. 2014a). Cooling rate significantly influence churning time. It is reported that larger crystal formed due to slow cooling facilitates more in rupture of fat globules as compared to fast cooling. Hence, time taken for churning will be less in slow cooling (Rønholt et al. 2014a). In case of makkhan preparation milk is heated to boiling temperature and then allowed to cool slowly to room temperature by natural air cooling before fermentation. Therefore, there is a chance of partial coalescence of HMF fractions of TAGs within fat globules and formation of large crystals of irregular shape from HMF upon churning as LMF remains in liquid phase at ambient condition. Product becomes richer with HMF fractions and time taken for churning is less. There is no clarity about ageing step during makkhan preparation. In case of makkhan preparation, prior to churning, milk is held for overnight or to maximum period up to 48 h at room temperature for fermentation. Traditionally, the dahi is collected everyday in a particular container for few days to make a sizable quantity before churning. This allows ageing of dahi and subsequently affects the quality of resulting makkhan. The container used in storing of makkhan is held at ambient condition which fluctuates throughout the holding period and that fluctuation may change the consistency of butter because of change in polymorphic structures and rheology. As this process occurs in uncontrolled manner the changes are totally unpredictable. However, changes in polymorphic structures during storage at any constant temperature and at fluctuating temperatures have been discussed later.

Mechanical treatment or churning is an important step in milk fat crystallization. During ripening, milk fat is partially crystallized within the globules and further aggregation of crystallized globules occurs if shear is induced into the system. In churning process, fat globule membranes are ruptured and liquid fat leaks out to create a semisolid connection between globules. As churning proceeds aggregation increases and destabilization of emulsion occurs when average size of aggregates reaches a critical value of approximately 52 µm. Then grainy structures start to form and those aggregate to lead partial phase inversion, and water phase starts separating out (Budlo et al. 2013). Simultaneous crystallization milk fat and aggregation of fat crystals during churning are mainly influenced by the factors as listed below-

Fat content in milk and fat globule size The fat content and size of native fat globule have influence on churning time, yield, crystallization and texture of fat rich dairy products (Truong et al. 2016). Higher amount of fat increases agglomeration of fat globules at low shear rate and reduces churning time (Mulder and Walstra 1974; Funahashi and Horiuchi 2008). Churning of cream containing high fat at a given high shear rate increases number of small butter grains and water holding capacity between grains (Funahashi and Horiuchi 2008). Therefore, fat content of raw materials used in makkhan making has strong influence in the texture and microstructure of product. When any dairy product is prepared from a raw material containing native MFGs of different diameters, then the sizes of fat globules will have impact over the process and the product. According to Michalski et al. (2004) large size globules (greater than 5 μm) being less stable as compared to smaller globules (smaller than 3 μm), those easily form butter grains upon churning with minimum mechanical influence. Additionally, large globules contain protruding fat crystals, which increases chances of partial coalescence also (Truong et al. 2016).Whereas, on the other side because of greater stability of smaller globules (Truong et al. 2016), those are lost in butter milk. Michalski et al. (2004) has shown impact of different native fat globule size fractions i.e. large (5–7 μm) and small (1–3 μm) fractions, separated using microfiltration on crystallization. It is reported that, time taken for crystallization was longer in case of smaller MFG (D4,3-0.93 μm) compared to large MFG (D4,3-7.15 μm). Depending upon different size fractions the changes in structural characteristics inside the native MFG occur during crystallization. More 2L structures were formed in large size fractions. 2L structures are mostly related with saturated fat present in TAG. It means large fat globules contain more amount of saturated fat. However, short chain saturated fatty acids mainly forms 3L structure because of their location at R3 position of TAG. However, the differences were negligible when previous thermal histories and associated cooling rate were omitted (Michalski et al. 2004; Truong et al. 2016). It is also reported that, crystallization temperature decreases with size of native MFG and the reason behind that is explained by the increment in the ratio of number of fat globules to impurities, which is used as ‘seeding’ material for crystallization of individual fat globules (Truong et al. 2016). Regarding morphology of crystals, observation under polarised light microscopy revealed the existence of fat crystals of different morphology in size differentiated native MFGs and rate of cooling has greater influence over this (Truong et al. 2016). Presence of different crystals has impact on rheology and mouthfeel of fat rich dairy products (Rønholt et al. 2013). Without knowing the above scientific facts, simply by experience whole milk (especially buffalo milk) containing more large size fraction of fat globules is preferably used for makkhan making to improve yield and texture of product. Use of buffalo milk is said to reduce churning time also (De 1991).

Method of churning The churning methods have strong impact over the crystallization of milk fat and physical quality of products. All traditional churning processes yield low shear to rupture fat globules, does not effectively aggregate and separate crystallized fats as compared to continuous churning methods. The traditional churning process cannot rupture all the fat globules which are completely destroyed in continuous churning (Fox and McSweeney 2006). The intensities of shear have greater influence in partial coalescence and fat crystallization during churning. It influences the movement of fat globules, coalition among them and their interaction. The amount of shear has an important role in breaking MFGM and flow of liquid fat from the globules to make bonds among the globules by partial coalescence (Budlo et al. 2013). Rate of primary nucleation is accelerated by shear, which supplies energy to overcome the hurdles created by activation energy. Amount of shear generated during different churning methods influences secondary nucleation by creating and distributing new surfaces as seeding material throughout the agitated volume (Buyukbese et al. 2017), which has greater impact over the texture of resulting butter (Kawanari et al. 1981).

Churning temperature Temperature has influence on the degree of fat coalescence and churning time (Mulder and Walstra 1974). Degree of fat coalescence and churning time affects the crystallized fat grain size. At Low churning temperature (5 °C) greater proportion of the fat exist in solid state inside the globule and it becomes difficult to squeeze out, and after a longer churning period small size fat crystals form. On the other side, at high churning temperature (above 13 °C) time taken for churning is less as relatively higher proportion of fat exists in liquid state (Nielsen 1971). However, the influence of churning temperature on crystallization is always anticipated by previous thermal history i.e. cooling rate (Rønholt et al. 2014b). The churning temperature is typically in the range of 11–19 °C for traditional rotary churning process, 8–12 °C for Fritz process and 7–13 °C for Cherry-Burrell process (Mulder and Walstra 1974). In case of makkhan production, ambient temperature at morning time is mostly preferred for churning due to cold environment. Although, the temperature varies depending on season and region, but still it is relatively higher temperature than that employed for butter. Frequently warm or cold water is added during churning to control crystallization process. Because of this high churning temperature used for makkhan making, it contains more amount of HMF and a good proportion of fat being liquid, gets dissolved and lost in chhach or lassi (Aneja et al. 2002).These facts are in line with the report presented by Rønholt et al. (2013). In that it is stated that at high churning temperature more fat loss occurs in butter milk as a significant proportion of fat is liquid at that temperature. Rønholt et al. (2014b) later on focused experiments on churning of cream at two different temperatures (10 °C and 22 °C) and it is reported that churning at 22 °C decreased churning time, required less amount of shear and more fat loss in butter milk as compared to 10 °C. Due to long churning time more stable crystal polymorphs were formed at 10 °C.

Acidity of dahi Fermentation increases acidity or reduces pH of milk. As pH decreases the film surrounding the fat globules becomes weaker and churning becomes easier (Fox and McSweeney 2006). Acidity of fermented milk or cream during churning determines the yield, quality and storage property of product also (Rangappa and Achaya (1973). The effect of pH of milk or cream on churning is not clearly understood. However, according to Mulder and Walstra (1974) pH has influence over churning time and efficiency of traditional churning in terms of percentage of fat in butter milk. It has been shown that, the effect of pH strongly depends on temperature. Rangappa and Achaya (1973) reported that, the optimum level of acidity of dahi for producing good quality makkhan and maximum yield should lie between 0.9 and 1.1%. Acidity above the upper limit reduces churning time without affecting yield, but makkhan cannot retain texture and its keeping quality reduces significantly. Acidity of dahi below the lower limit improves the keeping quality, but it has severe negative influence on yield and typical flavour of makkhan. In old conventional practices of makkhan making, fermentation is totally uncontrolled and sometimes acidity reaches to 2%. This happens because of the addition of indifferent quality starter and use of longer ripening time which is 20–24 h in summer, and 2–3 days in winter (De 1991). For ripened cream butter or soured cream butter it is reported that, if specific lactic acid bacteria (i.e. L. lactis subsp. lactis, L. lactis subsp. cremoris or a citrate positive strain L. lactis) is added, the pH of cream reduced to 4.5–5 (Fox and McSweeney 2006).

Dilution of dahi During churning dahi is diluted with warm or cold water depending on weather condition. Probably, water addition helps in removal of acids, microorganisms, coagulated casein particles and improves storage qualities. It may also be helpful in maintaining crystallization temperature during churning. Facts behind the water dilution are not properly explored yet. The extent of dilution depends on type of traditional butter milk is to be produced. But, on the other hand low melting fraction of fat and small crystallized fat grains are lost in water used in dilution (Rangappa and Achaya 1973). Rangappa and Achaya (1973) also noted that about 80% of acids of dahi and nearly all microflora were washed out into chhach or lassi while churning dahi with an equal volume of water. It contributed towards the highest yield of makkhan with good storage properties.

Post-process handling and storage conditions

After churning the aggregated fat is placed in water for washing of residual butter milk and thereafter, patted into a compact mass (Aneja et al. 2002). Except these no treatment or unit operation is followed before storage of makkhan. Surplus amount of makkhan after daily consumption is stored in existing rural condition for few days before conversion to ghee. Now-a-day refrigerated storage is also found in some places where electricity is available and it is said to improve its keeping quality up to 3–5 days. Rønholt et al. (2014a) reported that, the cream used for butter preparation initially contains α and traces of β′ crystal polymorphs, but when cream is cooled to 5 °C, converted into butter and stored at 5 °C for 4 weeks, those contain β′ and β-crystal polymorphs only. Storage of products at isothermal condition (5 °C) for longer time increases solid fat content (SFC) because of postcrystallization of milk fat and hardness of product increases due to the increase in crystal–crystal linkages (Rønholt et al. 2014a). Increasing the storage temperature does not induce difference in polymorphism as a predominance of β′-crystals is still present. If storage temperature increases the hardness of product decreases because of increase in liquid fat content. Fluctuating storage temperature did not show any difference in polymorphic structures when compared with storage at isothermal condition (5 °C), but amount of SFC was more. In that case elastic modulus (G’) of product decreases because of dominance of large crystals and reduction in crystal–crystal interaction (Rønholt et al. 2013). Different milk fat-based products coalesce in different manner during storage at low temperature due to the variation in microstructure and chemical composition. Because of this phenomenon a wide variation in the rheological behaviour of butter during storage is observed. Brittleness of butter increases due to the increased rate of moisture evaporation and coalescence of the water droplets. Brittleness of product increases internal cracks which result into larger standard deviation for G’ (Rønholt et al. 2014a).

Challenges of makkhan production methods

The major challenge in makkhan production is that, yield of product is less as compared to the input of raw material, which is impacting the commercial viability of production. It has been estimated that up to 27% of the milk fat is lost when makkhan is made by old conventional method. Existing household method gives little better result but still loss of fat and quantity of chhach or lassi create problems. Churning temperature used in makkhan preparation increases HMF fat, but more beneficial LMF is lost in chhach or lassi. Because of the use of simple and low cost set up for churning, the control over the process parameters are not possible during churning in traditional churn. Addition of water used in dilution of dahi during churning increases the quantity of chhach or lassi. About 15–20 kg of chhach or lassi is generated for every kg of ghee prepared from makkhan using conventional practices (Aneja et al. 2002). Huge fat loss along with chhach or lassi and disposal of large quantity of chhach or lassi are also the challenges for the production of makkhan in large quantity.

Scopes for improvement in makkhan preparation practices

The makkhan production technique and the overall developments since its inception are evolved through experience without any scientific approach. The characteristics of product, method of production and its commercial importance indicate huge scope of development in processing of raw material, starter inoculation and techniques of churning.

Processing of raw material Selection of raw material (whole cow or buffalo milk) is very important factor to improve the present status of makkhan making. It directly affects the processing parameters and quality of makkhan. Production of makkhan from milk containing higher fat content and good proportion of larger fat globules (bigger than 5 µm) is always preferred as it yields more amount of makkhan with greater firmness (De 1991). However, production of makkhan from milk cannot solve the problems of fat loss in chhach or lassi and quantity of chhach or lassi. The reason behind this is milk contains small amount of fat and a wide range of different size fat globules in different proportions. Due to fermentation fat globules get trapped in the coagulated protein network and it is very difficult to release fat from small globules. For releasing fat greater amount of water dilution is done. So, fat loss in chhach or lassi and quantity of chhach or lassi cannot be controlled. Therefore, without selecting raw material (whole milk), it would be better option to prepare raw material which is suitable for makkhan production. Raw material can be cream or high fat milk (fat percentage more than normal range) containing higher fat content and good proportion of large size fat globules. At rural household level production, high fat milk or cream prepared by gravity separation may be used. However, preparation of that kind of raw material will not very economical by manual or batch methods, as those processes are not effective in specific fractionation, time consuming, due to manual method and long holding period food safety may be an issue (Dhungana et al. 2017). Therefore, mechanized approaches may be suitable. Preparation of cream containing size based fractioned native fat globules using mechanized approaches such as centrifugal separation, microfiltration etc. have already been attempted for different purposes as listed in Table 2. For heat treatment, the raw material can follow the standard protocol of cream pasteurization at 95 °C without holding and cooled to appropriate temperature using continuous systems. Continuous systems consist of a heat exchanger having heating and cooling facilities with control systems. According to the report of Sarkar (2008) a processing condition of 90 °C for 10 min is reported to be suitable for enhancing acid and diacetyl flavour content in buffalo milk dahi due to reduction in dissolved oxygen content from 5.5 to 2.9 ppm.

Table 2.

Mechanized approaches for production of raw materials (mainly cream) containing size based fractioned native fat globules

| Mechanized approach | Process of separation | Average size (diameter) of native MFG | Advantages | Disadvantages | References |

|---|---|---|---|---|---|

| Centrifugal separation | 1. Two-stage centrifugal separation process was conducted at different temperature (7, 15, 25, and 35 °C), feed flow rate (600, 1200, and 1800 mL/min). First stage it separates whole milk (4% fat) into two fractions and separator did not contain any separating disc (i.e., a modified centrifugal cream separator). Second stage two fractions generated from first stage were concentrated using normal separator | Volume mean particle size at D[4,3] for the cream obtained from one fraction was in the range of 1.35 to 3.28 µm and cream obtained from another fraction was in the range of 4.20–26.70 µm | Operate well at 35 °C without coalescence of fat. Separation efficiency is good | Does not operate well at low temperatures such as below 35 °C | Dhungana et al. (2017) |

| 2. Two-stage centrifugal separation process was conducted at 55 °C. In first stage milk (standardized to 4% fat) was separated in a modified separator (i.e., separator contained four separating cones and was able to operate at 1200 X g or 4800 rpm) into two fractions. Second stage two fractions generated from first stage were diluted and again concentrated to 36% (w/w) fat using normal separator at 5300 X g. In second stage standardized milk containing 4% (w/w) fat was also concentrated to 36% (w/w) fat using normal separator at 5300 X g | From the experiments three fractions were obtained. A. Centrifuged large MFG with mean size of 4.9 ± 0.1 µm, B. Centrifuged small MFG with mean size of 4.1 ± 0.1 µm, and C. Centrifuged medium size MFG with mean size of 4.4 ± 0.0 µm | By combining a lower number of discs with lower rpm fractionation was possible | Only decrease in rotation speed or decreasing number of discs cannot do fractionation | Edén et al. (2016) | |

| Ultrasonic assisted creaming | Multistage ultrasonic fractionation technique was employed at different frequencies (1 and 2 MHz) | At the last stage of the process dual 1 and 2 MHz was able to produce smallest size fraction (i.e. D [4,3] 3.38 ± 0.03 µm) and at that condition size of largest globule was D [4,3] 4.15 ± 0.05 µm, whereas average fat globule size was 4.28 ± 0.01 µm | Successful to enhance cream separation | Not suitable for specific size based fractionation | Leong et al. (2016) |

| Membrane microfiltration | A cross flow microfiltration process was applied several times to separate milk to obtain different size fat globules based on membrane pore size | Able to fractionate whole milk into two fractions such as smaller fat globules fraction (i.e. 0.9–3.3 µm) larger fat globules fraction (i.e., 5–7.5 µm) | Is able to separate milk into any fraction | Not commercially viable to obtain milk stream with D [4,3] less than 3.26 µm and fouling is a serious problem | Goudédranche et al. (2000), Briard et al. (2003), Michalski et al. (2004), (2006) |

Inoculation of starter The preparation and addition of starter cultures after its judicious selection are very important unit operations in the production of fermented dairy products based on the requirement of desired physico-chemical properties (acidity, flavour content, CLA content, rheology, melting characteristics and microstructure) in makkhan. Use of pure starter culture such as L. lactis subsp. cremoris (NCDC-86) and L. lactis subsp. lactis biovar. diacetylactis (NCDC-60) (Kaushal and Kansal 2011), which are capable of producing higher diacetyl content within a minimum incubation period of 5 h or 6–12 h are encouraged. Use of an incubation temperature of 22 °C, which is reported to produce higher diacetyl content as compared to 30 °C (Rangappa and Achaya 1973). Faulty starter preparation has also strong detrimental influence on appearance, texture and flavour of the end product (Ignatova et al. 2009). For small scale production addition of good starter cultures (free from any defects and contaminations) procured from market and their proper mixing in recommended proportion is suggested (De 1991) using batch methods. In large scale production to avoid loss of bulk product caused from any process failure in-line addition and mixing of starter following mechanized approaches have been attempted (Prevost and Divies 1987; Sodini et al. 1997; Macedo et al. 1999; Funahashi and Nakamura 2007). Pre-fermentation and acidification were studied by inoculating with immobilized bacterial cells (Prevost and Divies 1987; Sodini et al. 1997; Macedo et al. 1999; Doleyres et al. 2004). The continuous inoculation and pre-fermentation of milk for yoghurt production by immobilized bacterial cells of L. lactis, L. lactis subsp. diacetylactis and L. cremoris in Ca-alginate gel beads was studied by Prevost and Divies (1987). Continuous pre-fermentation of yoghurt starter culture is well established and efficient, method of pre-fermentation. In this milk is inoculated with active yogurt bacteria with high-bacterial concentrations. This ensures the effective growth and acidification (Ignatova et al. 2009). Likely, continuous as well as batch inoculation by immobilized bacterial cells could be recommended for makkhan production. Continuous addition of starter may eliminate problem of localized acidification, if there is any mistake in process then it can be immediately stopped for rectification.

Churning operation Latest development in makkhan preparation indicates that the dahi is churned in a specifically designed container having suitable a drain trap preferably at morning time using a wooden beater or a gear driven beater (Ganguli and Jain 1973; De 1991; Joshi 2014). This system has no proper temperature control during ageing, cooling, and churning. Sun et al. (2007) and Sun et al. (2013) investigated an alternative method of churning during butter making by utilizing Stirling cooler. This was a batch type mechanized system having temperature control system and churning speed control mechanism. Kalla et al. (2016) also attempted studies on churning operation to optimize churning parameters such as churning temperature and churning speed using a batch type mechanized Frustum Cone Shaped Butter Churn (FCSBC). However, batch type mechanized systems having certain controls for cooling and ageing, speed of churning, temperature, suitable drainage facilities for butter milk and suitable facilities for hygienic drawing of product for cream churning can be used for batch production. If cream is used for makkhan preparation then continuous butter making machines based on ‘Fritz process’ (Funahashi and Horiuchi 2008; Mulder and Walstra 1974), ‘Alfa-Laval process’ or ‘Cherry Burrell process’ (Mulder and Walstra 1974; De 1991) may be useful for large scale production.

Conclusion

As makkhan is closely attached with daily diet of one out of two village households and it is used as intermediate product for producing major proportion ghee in India, it has a great future ahead. Although it is similar to butter in terms chemistry and unit operation followed in processing, but its flavour and inherent beneficial components are quite different. It has tremendous market potential, because the production is still exclusively confined to rural households and organized sectors have not introduced it in market because of difficulties in production. Exclusive information is presented here in this review to address the issues scientifically and to explore various scopes for improvements. It is found that, there are numerous scopes to upgrade raw material containing appropriate fat content and size fractions of milk fat globules, use of appropriate heating or cooling and churning systems with all controls, and use of proper fermentation by selecting appropriate starter culture, favourable fermentation conditions and mechanized starter addition methods. Various scientific approaches to validate the explored opportunities have also been discussed to bring change in the production status. Up-gradation in processing methods will increase its acceptability both in organized sectors and unorganized sectors.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Acevedo N, Marangoni AG. Toward nanoscale engineering of triacylglycerol crystal networks. Cryst Growth Des. 2010;10:3334–3339. [Google Scholar]

- Ahmad N, Saleem M. Studying heating effects on desi ghee obtained from buffalo milk using fluorescence spectroscopy. PLoS ONE. 2018;13:e0197340. doi: 10.1371/journal.pone.0197340. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aneja RP, Murthi TN. Conjugated linoleic acid contents of Indian curds and ghee. Ind J Dairy Sci. 1990;43:231–238. [Google Scholar]

- Aneja RP, Mathur B, Chandan RC, Banerjee AK. Technology of Indian milk products. Delhi: A Dairy India Publication; 2002. [Google Scholar]

- Bernas A, Murzin DY. Linoleic acid isomerization on Ru/Al2O3 catalyst 1: conjugation and hydrogenation. Chem Eng J. 2005;115:13–22. [Google Scholar]

- Briard V, Leconte N, Michel F, Michalski M-C. The fatty acid composition of small and large naturally occuring milk fat globules. Eur J Lipid Sci Technol. 2003;105:677–682. [Google Scholar]

- Budlo P, Jacob JK, Wiking L. Crystallization mechanism in cream during ripening and initial butter churning. J Dairy Sci. 2013;96:6782–6791. doi: 10.3168/jds.2012-6066. [DOI] [PubMed] [Google Scholar]

- Buyukbese D, Rousseau D, Kaya A. Composition and shear crystallization of milkfat fractions extracted with supercritical carbon dioxide. Int J Food Prop. 2017;20:S3015–S3026. [Google Scholar]

- Chin SF, Liu W, Storkson JM, Ha YL, Pariza MW. Dietary sources of conjugated dienoic isomers of linoleic acid, a newly recognized class of anticarcinogens. J Food Compos Anal. 1992;5:185–197. [Google Scholar]

- Creamer LK, MacGibbon AKH. Some recent advances in the basic chemistry of milk proteins and lipids. Int Dairy J. 1996;6:539–568. [Google Scholar]

- DAHD (2020) Cattle and Dairy Development. http://www.dahd.nic.in/about-us/divisions/cattle-and-dairy-development. Accessed 1 Jan 2020

- Dairy India (2007) Sixth Edition. Dairy India Yearbook, New Delhi

- De S. Outlines of dairy technology. New Delhi: Oxford University Press; 1991. [Google Scholar]

- Deffense E. Milk fat fractionation today: a review. J Am Oil Chem Soc. 1993;70:1193–1201. [Google Scholar]

- Deosarkar SS, Khedkar CD, Kalyankar SD. Butter: manufacture. In: Caballero B, Finglas P, Toldrá F, editors. The encyclopedia of food and health. Oxford: Academic Press; 2016. pp. 529–534. [Google Scholar]

- Dhungana P, Truong T, Palmer M, Bansal N, Bhandari B, Hub ARCDI. Size-based fractionation of native milk fat globules by two-stage centrifugal separation. Innov Food Sci Emerg Technol. 2017;41:235–243. [Google Scholar]

- Doleyres Y, Fliss I, Lacroix C. Continuous production of mixed lactic starters containing probiotics using immobilized cell technology. Biotechnol Prog. 2004;20:145–150. doi: 10.1021/bp020096w. [DOI] [PubMed] [Google Scholar]

- Easy Ayurveda (2019) Classification of foods and drinks charaka samhita sutrasthana 27. https://easyayurveda.com/2014/08/08/classification-of-foods-and-drinks-charaka-sahmita-sutrasthana-27/. Accessed 25 Nov 2019

- Edén J, Dejmek P, Löfgren R, Paulsson M, Glantz M. Native milk fat globule size and its influence on whipping properties. Int Dairy J. 2016;61:176–181. [Google Scholar]

- Fauquant C, Briard V, Leconte N, Michalski M-C. Differently sized native milk fat globules separated by microfiltration: fatty acid composition of the milk fat globule membrane and triglyceride core. Eur J Lipid Sci Technol. 2005;107:80–86. [Google Scholar]

- Fox PF, McSweeney PLH (eds) (2006) Lipids. In: Advanced dairy chemistry, vol 2, 3rd edn. Kluwer Academic/Plenum Publisher, New York

- Frede E, Buchheim W. Buttermaking and the churning of blended fat emulsions. J Soc Dairy Technol. 1994;47:17–27. [Google Scholar]

- Fredrick E, van de Walle D, Walstra P, Zijtveld JH, van der Meeren P, Dewettinck K. Isothermal crystallization behavior of milk fat in bulk and emulsified state. Int Dairy J. 2011;21:685–695. [Google Scholar]

- FSSAI . The Food Safety & Standards Act 2006. New Delhi: Commercial Law Publishers (India) Pvt. Ltd; 2017. [Google Scholar]

- Funahashi H, Horiuchi J. Characteristics of the churning process in continuous butter manufacture and modelling using an artificial neural network. Int Dairy J. 2008;18:323–328. [Google Scholar]

- Funahashi H, Nakamura Y. Model of the continuous prefermentation process in cheese manufacture and stability analysis of steady state. J Food Process Eng. 2007;30:522–537. [Google Scholar]

- Ganguli NC, Jain MK. Ghee: its chemistry, processing and technology. J Dairy Sci. 1973;56:19–25. [Google Scholar]

- Gokce R, Akdogan A, Divriklib U, Elci L. Simultateneous determination of diacetyl and acetoin in traditional Turkish butter stored in sheep’s rumen (Karinyagi) Grasas Aceites. 2014;65:e010. [Google Scholar]

- Goudédranche H, Fauquant J, Maubois JL. Fractionation of globular milk fat by membrane microfiltration. Le Lait. 2000;80:93–98. [Google Scholar]

- Herrera ML, Gatti MD, Hartel RW. A kinetic analysis of crystallization of a milk fat model system. Food Res Int. 1999;32:289–298. [Google Scholar]

- Hugenholtz J. Citrate metabolism in lactic acid bacteria. FEMS Microbiol Rev. 1993;12:165–178. [Google Scholar]

- Ignatova M, Lyubenova V, Mihail A, Kostov G. pH control during continuous prefermentation of yoghurt starter culture by strains Streptococcus thermophilus 13A and Lactobacillus bulgaricus 2-11. C R de L’Acad Bulg des Sci. 2009;62:1587–1594. [Google Scholar]

- Joshi KS. Docosahexaenoic acid content is significantly higher in ghrita prepared by traditional Ayurvedic method. J Ayurveda Integr Med. 2014;5:85–88. doi: 10.4103/0975-9476.131730. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kalla AM, Sahu C, Agrawal AK, Bisen P, Chavhan BB, Sinha G. Development and performance evaluation of frustum cone shaped churn for small scale production of butter. J Food Sci Technol. 2016;53:2219–2226. doi: 10.1007/s13197-015-2110-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaushal D, Kansal VK. Probiotic Dahi containing Lactobacillus acidophilus and Bifidobacterium bifidum alleviates age-inflicted oxidative stress and improves expression of biomarkers of ageing in mice. Mol Biol Rep. 2011 doi: 10.1007/s11033-011-0920-1. [DOI] [PubMed] [Google Scholar]

- Kawanari M, Hamann DD, Swartzel KR, Hansen AP. Rheological and textural studies of butter. J Texture Stud. 1981;12:483–505. [Google Scholar]

- Keenan TW, Dylewski DP. Intracellular origin of milk lipid globules and the nature and structure of the milk lipid globule membrane. In: Fox PF, editor. Advanced dairy chemistry: lipids. London: Chapman and Hall; 1995. pp. 89–130. [Google Scholar]

- Khan IT, Nadeem M, Imran M, Asif M, Khan MK, Din A, Ullah R. Triglyceride, fatty acid profile and antioxidant characteristics of low melting point fractions of Buffalo milk fat. Lipids Health Dis. 2019;18:59. doi: 10.1186/s12944-019-0995-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Knothe G, Dunn RO. A comprehensive evaluation of the melting points of fatty acids and esters determined by differential scanning calorimetry. J Am Oil Chem Soc. 2009;86:843–856. [Google Scholar]

- Leong T, Johansson L, Mawson R, McArthur SL, Manasseh R, Juliano P. Ultrasonically enhanced fractionation of milk fat in a litre-scale prototype vessel. Ultrason Sonochem. 2016;28:118–129. doi: 10.1016/j.ultsonch.2015.06.023. [DOI] [PubMed] [Google Scholar]

- Lopez C, Briard-Bion V, Ménard O, Beaucher E, Rousseau F, Fauquant J, Leconte N, Robert B. Fat globules selected from whole milk according to their size: different compositions and structure of the biomembrane, revealing sphingomyelin-rich domains. Food Chem. 2011;125:355–368. [Google Scholar]

- Luo J, Wang Y, Guo H, Ren F. Effects of size and stability of native fat globules on the formation of milk gel induced by Rennet. J Food Sci. 2017;82:670–678. doi: 10.1111/1750-3841.13649. [DOI] [PubMed] [Google Scholar]

- Macedo MG, Champagne CP, Vuillemard JC, Lacroix C. Establishment of bacteriophages in an immobilized cells system used for continuous inoculation of lactococci. Int Dairy J. 1999;9:437–445. [Google Scholar]

- Martini M, Salari F, Altomonte C. The macrostructure of milk lipids: the fat globules. Crit Rev Food Sci Nutr. 2016;57:1209–1221. doi: 10.1080/10408398.2012.758626. [DOI] [PubMed] [Google Scholar]

- Mesilati-Stahy R, Mida K, Argov-Argaman N. Size-dependent lipid content of bovine milk fat globule and membrane phospholipids. J Agric Food Chem. 2011;59:7427–7435. doi: 10.1021/jf201373j. [DOI] [PubMed] [Google Scholar]

- Michalski M-C, Ollivon M, Briard V, Leconte N, Lopez C. Native fat globules of different sizes selected from raw milk: thermal and structural behaviour. Chem Phys Lipids. 2004;132:247–261. doi: 10.1016/j.chemphyslip.2004.08.007. [DOI] [PubMed] [Google Scholar]

- Michalski M-C, Briard V, Juaneda P. CLA profile in native fat globules of different sizes selected from raw milk. Int Dairy J. 2005;15:1089–1094. [Google Scholar]

- Michalski M-C, Leconte N, Briard-Bion V, Fauquant J, Maubois J, Goudédranche H. Microfiltration of raw whole milk to select fractions with different fat globule size distributions: process optimization and analysis. J Dairy Sci. 2006;89:3778–3790. doi: 10.3168/jds.S0022-0302(06)72419-5. [DOI] [PubMed] [Google Scholar]

- Mulder H, Walstra P. The milk fat globule emulsion science as applied to milk products and comparable foods. The Netherlands: Centre for Agricultural Publishing and Documentation, Wageningen; 1974. [Google Scholar]

- Nielsen VH. Curing the texture defects in butter. Am Dairy Rev. 1971;33:28–29. [Google Scholar]

- Pandit A, Anand S, Kalscheur K, Hassan A. Production of conjugated linoleic acid by lactic acid bacteria in milk without any additional substrate. Int J Dairy Technol. 2012;65:603–608. [Google Scholar]

- Prevost H, Divies C. Fresh Fermented cheese production with continuous pre-fermented milk by mixed culture of mesophilic lactic streptococci entrapped in Ca-alginate. Biotechnol Lett. 1987;9:789–794. [Google Scholar]

- Rangappa KS, Achaya KT. Indian dairy products. Bombay: Asia Publishing House; 1973. [Google Scholar]

- Rønholt S, Mortensen K, Knudsen JC. The effective factors on the structure of butter and other milk fat-based products. Compr Rev Food Sci Food Saf. 2013;12:468–482. doi: 10.1111/1541-4337.12022. [DOI] [PubMed] [Google Scholar]

- Rønholt S, Kirkensgaard JJ, Mortensen K, Knudsen JC. Effect of cream cooling rate and water content on butter microstructure during four weeks of storage. Food Hydrocoll. 2014;34:169–176. [Google Scholar]

- Rønholt S, Madsen AS, Kirkensgaard JJ, Mortensen K, Knudsen JC. Effect of churning temperature on water content, rheology, microstructure and stability of butter during four weeks of storage. Food Struct. 2014;2:14–26. [Google Scholar]

- Sarkar S. Innovations in Indian fermented milk products-a review. Food Biotechnol. 2008;22:78–97. [Google Scholar]

- Sato K, Yoshimoto N, Arishima T. Crystallization phenomena in fats and lipids. J Dispers Sci Technol. 1989;10:363–392. [Google Scholar]

- Shukla A, Bhaskar AR, Rizvi SS, Mulvaney SJ. Physicochemical and rheological properties of butter made from supercritically fractionated milk fat. J Dairy Sci. 1994;77:45–54. [Google Scholar]

- Sigma-Aldrich (2020) Online product directory. https://www.sigmaaldrich.com/catalog/product/aldrich/153745?lang=en®ion=IN. Accessed 14 Mar 2020

- Singh H. The milk fat globule membrane—a biophysical system for food applications. Curr Opin Colloid Sci. 2006;11:154–163. [Google Scholar]

- Sodini I, Boquien CY, Corrieu G, Lacroix C. Use of an immobilized cell bioreactor for the continuous inoculation of milk in fresh cheese manufacturing. J Ind Microbiol Biotechnol. 1997;18:56–61. doi: 10.1038/sj.jim.2900362. [DOI] [PubMed] [Google Scholar]

- Sserunjogi ML, Abrahamsena RK, Narvhusa J. A review paper: current knowledge of ghee and related products. Int Dairy J. 1998;8:677–688. [Google Scholar]

- Sun JF, Kitamura Y, Satake T. Application of Stirling cooler to food processing: feasibility study on butter churning. J Food Eng. 2007;84:21–27. [Google Scholar]

- Sun JF, Congzhi Z, Jianlou M, Huiyong J, Zhixing S, Wang J. Tentative application of Stirling cooler technology in butter churning process. Eur Food Res Technol. 2013;237:223–228. [Google Scholar]

- Tomaszewska-Gras J. Melting and crystallization DSC profiles of milk fat depending on selected factors. J Therm Anal Calorim. 2013;113:199–208. [Google Scholar]

- Truong T, Palmer M, Bansal N, Bhandari B. Effect of milk fat globule size on the physical functionality of dairy products. New York: Springer; 2016. pp. 35–67. [Google Scholar]

- Vaclavik VA, Christian EW. Essentials of food science. 3. New York: Springer; 2008. [Google Scholar]

- Vanhoutte B, Dewettinck K, Foubert I, Vanlerberghe B, Huyghebaert A. The effect of phospholipids and water on the isothermal crytallization of milk fat. Eur J Lipid Sci Technol. 2002;104:490–495. [Google Scholar]

- Varrichio ML, Di Francia A, Masucci F, Romano R, Proto V. Fatty acid composition of Mediterranean buffalo milk fat. Ital J Anim Sci. 2007;6:509–511. [Google Scholar]

- Walstra P. Studies on milk fat dispersion. The globule size distribution of cow’s milk. Neth Milk Dairy J. 1969;28:3–9. [Google Scholar]

- Walstra P. Secondary nucleation in triglyceride crystallization. Progr Colloid Polym Sci. 1998;108:4–8. [Google Scholar]

- Walstra P, Wouters JT, Geurts TJ. Dairy Science and Technology. 2. Cambridge: CRC/Taylor & Francis; 2006. [Google Scholar]

- Wiking L, Graef VD, Rasmussen M, Dewettinck K. Relation between crystallization mechanism and microstructure of milk fat. Int Dairy J. 2009;19:424–430. [Google Scholar]