Abstract

The objective of the study was to screen amongst various gluten free flours to prepare Indian unleavened flatbread using principal component analysis (PCA) and hierarchical cluster analysis (HCA) as a mathematical tool. Gluten free flours studied in this work were, rice, sorghum, moong, amaranth, sama, ragi, water chestnut, buckwheat, soy, tamatind kernel, chickpea, black gram and unripe banana flour. The characteristics of sorghum: rice flatbread was analyzed such as dough making ability, subjective rollability, puffing and acceptability with respect to wheat. Interrelationship between the parameters analyzed and the different gluten free flours were investigated by using PCA and HCA. PCA revealed that the first two components represented 92.56% of the total variability in flatbread making characteristics. HCA classified samples into 6 clusters on the basis of measured flatbread making characteristics. From the results, moong, water chestnut and unripe banana flour in addition to mixture sorghum: rice (30:70) flour were chosen as ingredients for the preparation of Indian unleavened flatbread.

Keywords: Chemometrics, PCA, HCA, Gluten free, Flatbread

Introduction

Celiac disease is a prolonged intestinal syndrome which is characterized by an inadequate immune response caused by gluten consumed from wheat, rye, barley and in some cases oats. This disease has spread everywhere in the world including Asia population. According to a recent study, the prevalence of this disease is around 1.6% in Asia (Singh et al. 2016). This intolerance results in damage to the small intestinal mucosa, hence malabsorption of nutrients (Chirdo et al. 2002). Till date, only accepted treatment involves complete adherence to gluten free diet. More and more consumers today prefer for foods that are gluten free, that aren’t genetically modified, and that are healthy and organic doesn’t matter whether the person consuming it is a celiac or not.

Flatbreads (chapattis) have good shelf life and strong consumer preference. These are the staple bakery products in India consumed in day to day life. Traditionally, flatbreads are made from whole wheat flour dough by adding required amount of water into whole wheat flour. Gluten is the main structure forming agent in flatbread which is responsible for its characteristic texture and spoon ability (Patil and Arya 2016). The spoon ability is the ability of the chapatti to get formed into a shape while concerning with carried preparation.

Gallagher et al. (2004) have stated about the structure-forming ability of gluten that influences the rheological properties of dough and affects overall appearance of flatbread. The absence of gluten in dough production often results in inferior qualities of dough, the production process and final gluten free flatbread (GFFB). The gluten-free doughs are much less cohesive and elastic than wheat dough. They are highly smooth, sticky, less elastic and difficult to handle. Indeed, these gluten-free doughs are often called batters instead of dough. The absence of gluten often results in flatbread with an undesirable texture, color and other quality defects.

Various flours and starches from different sources have been utilized for gluten free formulations (Gallagher et al. 2004). However, it was observed that no single flour can mimic the wheat flour properties (Hadnađev et al. 2011). Probably, the most commonly used gluten free flour in industry as well as for research purposes is rice flour (Oryza sativa) (Rai and Agrawal 2008). Rice flour is a cheap and easily available source. It consists of about 80% starch and its proteins are not considered celiac toxic. Various other sources are available those used for the production of gluten-free products.

The huge amount of raw materials and their combinations that can be used for the elaboration of gluten-free products makes it impossible to generalize about their behavior in a gluten-free dough. Moreover, the availability in the market of flours obtained from sources different from wheat is non-continuous and hence increases the cost of the raw material. According to survey conducted by Bagolin do Nascimento et al. (2014), amount and variety of gluten-free food products are limited in stores; in addition, their prices are high. This situation may have a negative impact over diet adherence and stimulate the intake of conventional products, with harmful consequences to the quality of life and health of the coeliac patient population. Also, amongst the diverse resources available selection of few becomes difficult. Hence, efforts were made in the present investigation on selection of better suitable raw materials for development of GFFB depending on their properties with the help of chemometric tools. Chemometric tools analyze the data which provided by studying the numerous variables from number of samples.

The application of chemometric tools for research area has recently become a very active. These chemometric tools are employed by many authors to understand the classification and comparison between various gluten free flours (Alonso-Salces et al. 2007). Chemometric tools have been applied for the purpose of classifying the food products based on their properties (Alonso-Salces et al. 2007). Hrušková et al. (2013) studied Chemometrics (PCA and hierarchical clustering) of wheat Composites with Hemp, Teff, and Chia Flour in comparison of rheological features. Bagolin do Nascimento et al. (2014) also used hierarchical cluster analysis (HCA) to understand similarities in the nutritional content of gluten-free and conventional food products. However, no data is available on the application of chemometrics for selection of raw materials to be used in the preparation of GFFB taking into consideration its dough and flatbread making characteristics and sensory overall acceptability. Hence, the objectives of the present investigation were to explore the possibilities of making flatbreads from gluten free flours and to use chemometric tools to gain insights into variations in different gluten free flours profiles based on their flatbread making characteristics.

Materials and methods

Materials

Whole wheat (Triticum aestivum) flour (Aashirvaad, ITC™) and gluten free flours like rice (Oryza sativa) flour (Bhagirathi™), sorghum (Sorghum bicolor) flour (Bhagirathi™), moong (Vigna radiate) flour (Swad™), amaranth (Amaranthus caudatus) flour (Bhagirathi™), sama (Echinochloa colona) flour (Bhagirathi™), ragi (Eleusine coracana) flour (Bhagirathi™), water chestnut (Trapa natans) flour (Swad™), buckwheat (Fagopyrum tataricum) flour, soy (Glycine max) flour (Bhagirathi™), chickpea (Cicer arietinum) flour (Bhagirathi™), blackgram (Vigna mungo) flour (Bhagirathi™) were purchased from local market of Mumbai, Maharashtra. Unripe banana (Musa paradisiaca) flour (Mahila Gruh Udyog™, Jalgaon, Maharashtra, India)) was purchased from Jalgaon banana market. The manufacturers (ITC, Swad, Bhagirathi products) were situated in Mumbai, Maharashtra, India. Tamarind kernel powder was prepared in the laboratory. To prepare tamarind (Tamarindus indica) kernel powder, tamarind kernels were roasted for 190º C, peeled manually, and ground in pulverizer (Natraj Pulvrizer, India) to obtained fine flour. All the flours under study were passed through 60 mesh to obtain uniform particle size flour and were used in further studies.

Methods

Base flours such as sorghum and rice were initially chosen. The eleven combinations/mixture were made (shown in Table 2). The mixture of these two flours was optimized on the basis of the subjective evaluation of their dough and flatbread making characteristics and sensory overall acceptability. To this optimized combination, other gluten free flours were added in the concentration varying from 5 to 30% and evaluated subjectively for the same parameters. Observations were subjected to chemometric analysis to understand the variation between these flours and select proper raw material.

Table 2.

Effect of sorghum and rice flour combinations on dough making and flat bread making characteristics of gluten free flours on 9-point hedonic rating scale

| Sorghum: rice | Dough making ability | Subjective Rollability | Puffing | Sensory overall acceptability | Comments |

|---|---|---|---|---|---|

| Wheat | 8.83 ± 0.40 g | 8.83 ± 0.40i | 8.83 ± 0.40f | 8.83 ± 0.40e | Excellent |

| 100–0 | 1.83 ± 0.25b | 1.66 ± 0.51a | 1.08 ± 0.20a | 1.83 ± 0.25a | No binding properties |

| 90–10 | 2 ± 0.31b | 2.33 ± 0.25b | 1.41 ± 0.20a | 2.00 ± 0.31a | Difficult dough making and bhakari taste |

| 80–20 | 2.91 ± 0.20c | 2.83 ± 0.40c | 1.91 ± 0.20b | 2.91 ± 0.20a | Sorghum taste |

| 70–30 | 3.91 ± 0.20d | 4.41 ± 0.20d | 5.83 ± 0.40c | 5.00 ± 0.31bc | Improved dough stickiness and rollability |

| 60–40 | 4.83 ± 0.40e | 4.91 ± 0.20e | 5.83 ± 0.40c | 5.41 ± 0.49bcd | Good rollability and puffing |

| 50–50 | 5.58 ± 0.37f | 5.83 ± 0.25 fg | 6.33 ± 0.25d | 5.91 ± 0.20 cd | Good rollability and puffing |

| 40–60 | 5.83 ± 0.25f | 5.83 ± 0.25 g | 6.33 ± 0.25de | 5.91 ± 0.20 cd | Good dough |

| 30–70 | 6.08 ± 0.49f | 6.91 ± 0.20 g | 6.83 ± 0.40e | 6.66 ± 0.26 cd | Good dough with good rollability |

| 20–80 | 4.16 ± 0.98d | 6.83 ± 0.40h | 6.83 ± 0.40e | 6.25 ± 0.61d | Sticky dough with good rollability |

| 10–90 | 1.83 ± 0.40b | 6.25 ± 0.61h | 6.83 ± 0.40e | 5.08 ± 0.20bc | Sticky dough good puffing |

| 0–100 | 1.16 ± 0.40a | 5.66 ± 0.51f | 6.83 ± 0.50f | 4.08 ± 0.80ab | Very Sticky dough |

Values are represented as mean ± SD of ten determinations

Means with same subset are not significantly different from each other (p ≤ 0.05)

Dough preparation

In the present study, flatbread dough samples were prepared using 100 g of flour and an appropriate amount of water to get the desired dough consistency to be used in making flat bread. It was then kneaded for 2 min (by hand). The dough was rested at 30 ± 2 °C for 30 min covering the dough with wet muslin cloth and then used for flatbread preparation.

Preparation of flatbread

The GFFB was made according to the method of Shaikh et al. (2008). Briefly the dough was divided into 30 g portions and rolled to circular shape to a diameter of 15 cm and thickness of approximately 2 mm (by hand). It was then baked on a preheated griddle (240 °C) under controlled flame exposing one side for 15 s followed by the other side for 10 s. The flatbread was puffed directly on maximum flame for 10 s on both sides. Flatbreads were cooled to room temperature and stored in self-sealable low-density polyethylene plastic pouches. These flatbreads were subjected for evaluation on the basis of subjective parameters.

Subjective evaluation of gluten free flours for dough making, dough handling and flatbread characteristics

Subjective evaluation methods were designed and developed by Bhattacharya et al. (2006). Further modifications were made according to GFFB as tabulated in Table 1.

Table 1.

Methods of evaluation of subjective attributes (dough making ability, rollability, puffing, and overall acceptability) with respect to 9-point hedonic sensory scale

| Attribute | Desirable criteria | Scale used | Method of determination |

|---|---|---|---|

| Dough making ability | Easy dough formation with moderate stickiness | 9-point |

It was rated depending on the ease of dough formation where, 1: difficult to form and very sticky 9: easy to form and desired stickiness |

| Rollability | Least sticky but soft enough to flatten/roll easily | 9-point |

Rollability was scored on the basis of ease to flatten by employing a rolling pin on flat plate where, 1: unfit for rolling 9: No signs of cracking (best) and easily rollable |

| Puffing | Quick and highly elevated puff | 9-point |

Puffing was scored depending on height and speed of puffing where, 1: low height of puff and maximum time required to puff 9: high and quick puffing |

| Overall acceptability | Pleasant appearance and mastication | 9-point |

It was graded on the basis of sensory perception of the final product where, 1: Dislike extremely 9: Like extremely |

Table 1 elaborates on the subjective evaluations of various attributes. Dough making ability of the flours and flour mixtures were assessed according to the kneading required, stickiness and dough handling properties. 100 g of flour was provided to each panelist and asked to prepare the dough. The evaluation was done on a 9-point scale. The scale ranged amid 1 (difficult to form and very sticky) and 9 (easy to form and desired stickiness). Average of ten scores were reported as kneading score.

The dough samples, about 30 g, were assessed for non-oral sensory attributes. The definitions of rollability were followed as suggested by Kälviäinen et al. (2000). The procedures for sensory analysis were indicated by Bhattacharya et al. (2006) as shown in Table 1. Rollability was rated taking into consideration elasticity, breaking and cracking observed during the rolling. These sensory parameters were scored based on a 9-point scale. The scales were between 1 (unfit for rolling) and 9 (No signs of cracking and easily rollable) for rollability. The desirable criteria for the dough was least sticky but soft enough to flatten/roll easily. Results were expressed as mean of ten scores.

The sheeted flatbreads were baked and evaluated for their puffing characteristics by the panelists. Puffing was scored depending on height and speed of puffing. Here also 9-point scale was used for assessment defining 1 to be low height of puff and maximum time required to puff whereas 9 stands for high and quick puffing. Average of ten scores was reported as puffing score of the GFFB.

Sensory (oral) analysis of the flatbreads was evaluated for overall acceptability depending on tearing strength, chewiness, color, aroma and taste using the 9-point scale (9, like extremely; 1, dislike extremely) with 5 as the limit of acceptance with the help of the same sensory panel members. The whole process of sensory assessment was replicated twice.

Ten semi trained panelists were asked to rate the samples for subjective analyses. All the panelists including male and female were healthy individuals between the age group of 20–40. These panelists were the staff and students of Department of Food Engineering and Technology, Institute of Chemical Technology, Mumbai. The panelists were trained for quality attributes before sensory trials. The products labelled with a random alphabet and provided with written instructions to evaluate samples.

Chemometric analyses

All determinations were obtained from ten measurements and results were expressed as mean ± standard deviation. The Statistical Package for Social Sciences (SPSS) for Windows version (16.0) was used to analyze the data (SPSS Inc., Chicago, IL, USA). Statistical significance was declared at p < 0.05 for analysis of variance (ANOVA) to find if there were significant differences among the treatments. Post-hoc Duncan test was done to determine where the differences occurred. Pearson’s correlation coefficients (r) were also computed to understand the relationships between different variables.

Data were analyzed using principal component analysis (PCA) to explore the underlying relationships between and among different parameters including subjective data using the software Statistica (v 7, Stat Soft, Tulsa, USA). PCA results were presented as loading and score plots.

Hierarchical cluster analysis (HCA) was performed using SPSS 16.0. The method used was Ward’s method. The distances between samples were calculated using square Euclidean distances. This method uses an analysis of variance approach to evaluate the distances between clusters. In general, this method is very efficient. Cluster membership was assessed by calculating the total sum of squared deviations from the mean of a cluster. The dendrogram similarity scales were generated by the SPSS program ranged from zero (greater similarity) to 25 (lower similarity). The similarities between the analyzed samples are represented in the form of dendrograms for variation in the concentration of each ingredient (da Silva Torres et al. 2006).

Results and discussion

Optimization of base flour

Table 2 shows the effect of sorghum and rice flour combinations on gluten free dough and flatbread making characteristics of gluten free flours as compared to that of whole wheat flour. It can be observed that flat bread made from wheat received higher sensory scores for both dough as well as flat bread such as subjective rollability, puffing and overall acceptability of 8.83 each. Also, the comments received were excellent quality for all the flat bread samples made from whole wheat flour. This could be due to the fact that it is made from whole wheat flour containing minimum 6% gluten content. It has been reported that whole wheat flour 9.5–10.5% protein is suitable for the preparation of chapatti (Austin 1971). When the flat bread was prepared from 100% sorghum in the absence of rice (sorghum: rice—100:0), the dough making and subjective rollability scores received were 1.83 and 1.66 respectively. This could be due to the absence of gluten in sorghum. Sensory scores were drastically low as 1.83. As the rice content increased by partially replacing sorghum, the score for dough making ability went on increasing up to 6.08 when the ratio was 30:70 and further decreased to 1.16 when the ratio was 0:100 (sorghum to rice). Subjective rollability also followed the similar trend of increasing the score up to 6.91 at 30:70 ratio and further decrease up to 5.66 at the ratio of 0:100. Scores for puffing were 1.08 at 100:0 ratio and found to be highest at ratio of 30:70 (6.83) but showed a little variation further. This ratio affected sensory acceptability in the similar trend. Increase in sorghum: rice ratio led to an increase in score upto 6.66 at the ratio of 30:70 followed by further decrease in score up to 4.08 when the ratio was 0:100.

It was observed that initially at low levels of rice (higher levels of sorghum) the flour was lacking binding properties and the flatbread resembled like Bhakri (A traditional flatbread of rural India made from sorghum flour) (Badgujar et al. 2017). Vidya et al. (2013) have specified the easy flattening of sorghum dough as in case of bhakri. Regarding dough making ability, increase in rice percentage positively influenced the scores but at higher levels dough started becoming very sticky. Hence, difficulty in dough development was experienced. As the percentage of rice flour went on increasing certain binding required for the dough were perceived to minimize cracking during rolling. But at higher levels dough became very sticky that was difficult to handle due to high percentage of starches and low content of protein (Schober et al. 2003). Vidya et al. (2013) have reported the higher stickiness in rice flour doughs due to the presence of high levels of amylopectin. Amylopectin is a highly branched molecule of starch that is responsible for making rice glutinous and sticky. Optimum levels of sorghum and rice were found to be 30 and 70% respectively which gave dough optimum stickiness and rollability and the final product thus developed was having good overall acceptance. A range of gluten free flours were added to this mixture and evaluated further.

Principal component analysis

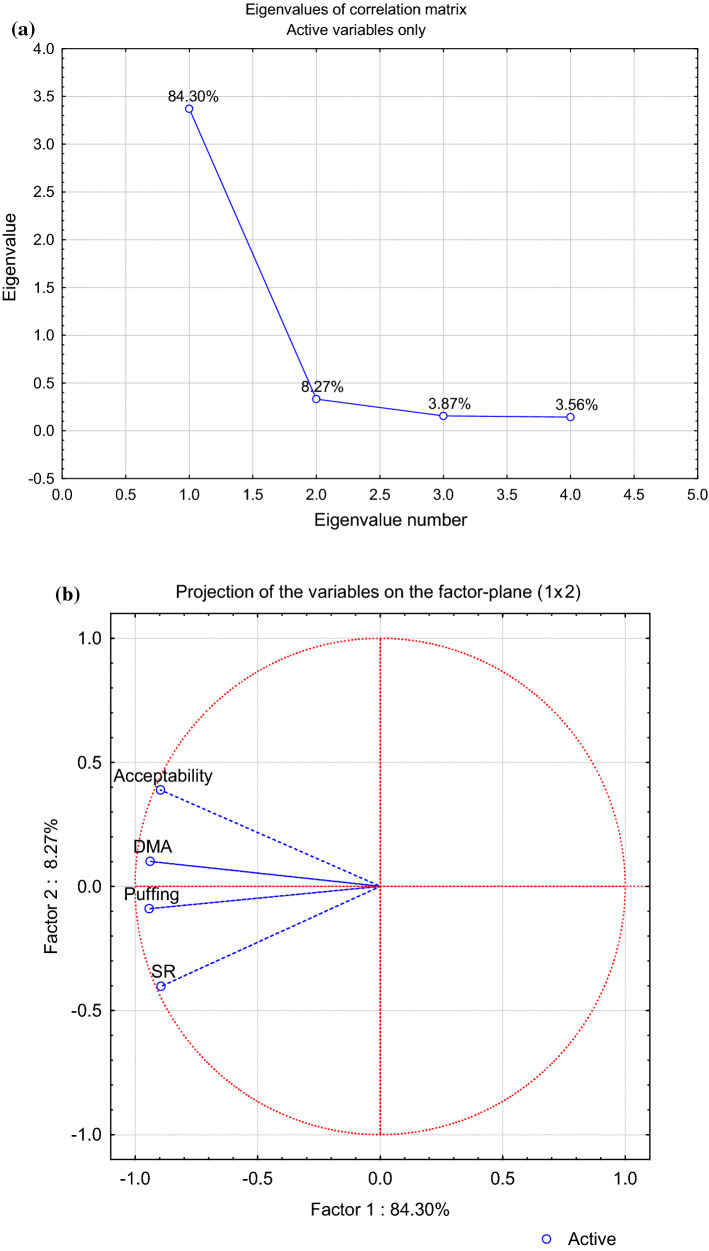

The PCA is a helpful tool for understanding the structure in the relationship between measured parameters that give complimentary information for the analysis. The eigenvalues for successive factors are displayed on a so-called “screeplot”, Fig. 1a. The number of factors retained in the model for proper classification of experimental data, in original matrix into loading (gluten free flours) and score matrices (dough making ability, subjective rollability, puffing, sensory acceptance) for glute free flat breads prepared with added gluten free flours to the sorghum: rice mixture were determined by application of Kaiser and Rice’s rule (Otto 1999). This criterion retains only principal components with eigenvalues > 1.

Fig. 1.

a Scree plot of the subjective analyses of Eigen values for gluten free flours mixed to Sorghum: rice. b Principal component analysis: score plot of PC1 and PC2 describing the variation among the rheological properties of flours (DMA: Dough making ability, SR: Subjective rollability)

PCA gave an insight of the studied characteristic which provide a perceptual map of the GFFB. The data were standardized and submitted to the correlation matrix. The first two dimensions accounted for 92.96% of the total variance, 84.76% of which were explained by the first dimension. F2, F3 and F4 components carried out 8.27, 3.87 and 3.50% of the total information given by the subjective evaluation of gluten-free flatbread. The factor loadings (correlation coefficients between variables and F-factors) are listed in Table 3.

Table 3.

Principal component analysis: Factor-variable correlations (factor loadings) of subjective analyses based on correlations of the factors for gluten free flours mixed to sorghum rice

| Variables | F1 | F2 | F3 | F4 |

|---|---|---|---|---|

| Rollability | − 0.89 | − 0.40 | − 0.02 | 0.20 |

| Puffing | − 0.94 | − 0.09 | − 0.17 | − 0.27 |

| Acceptability | − 0.90 | 0.39 | − 0.14 | 0.16 |

| DMA | − 0.94 | 0.10 | 0.32 | − 0.07 |

DMA Dough making ability

All the parameters are found to be highly influenced by factor 1. The squared cosine values for dough making ability, rollability, puffing and sensory overall acceptability were − 0.94, − 0.89, − 0.94 and − 0.90 respectively for factor 1. This helps to conclude that variables are well linked with an axis based on the squared cosine values (factor loadings). The higher the value of the factor loadings (≥ 0.5), the more important that variable is to the corresponding axis. Therefore, the properties with high positive or negative loadings summarized the meaning of the first two components.

Figure 1b shows score plot of first principal component (PC 1) and second principal component (PC 2) describing the overall variation amongst the dough and flatbread making characteristics and sensory overall acceptability of the gluten free flours. It can be seen from Fig. 1b that all the subjectively evaluated characteristics (Dough making ability, subjective rollability, puffing and sensory acceptance) contributed mostly to the first principal component (PC 1) due to their high squared cosine values. Also, being placed in the same side quadrants, all the characteristics are positively correlated with each other. Second principal component (PC 2) is contributed mostly by subjective rollability and sensory overall acceptability as shown in Fig. 1b.

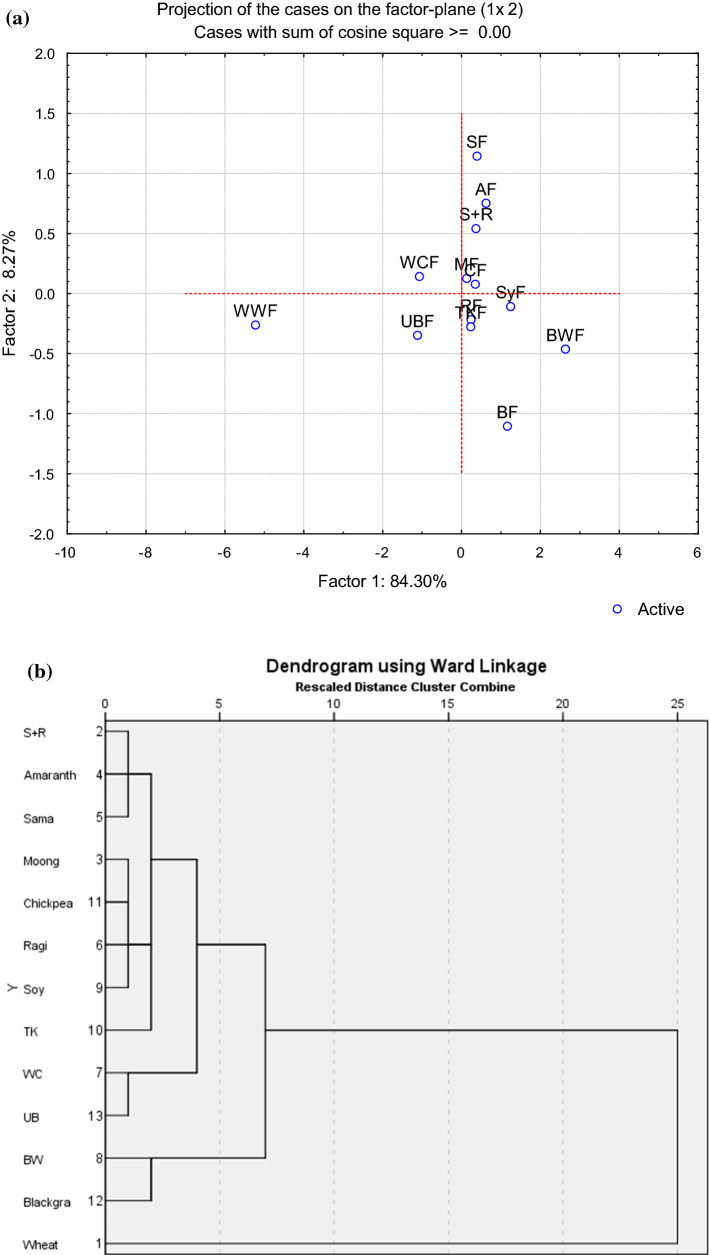

As depicted by Fig. 2a, (score plot of PC1 and PC2 describing the variation among the flours) whole wheat, water chestnut and unripe banana flour are separated from rest of the flours significantly by PC 1. While PC 2 separates sorghum and amaranth flour substantially from buckwheat and black gram flour. As can be seen, there is a neat separation of the observed samples, according to the evaluation used. Whole wheat flour being much distant apart from gluten free flours is characterized by higher scores in subjective evaluation for dough making ability, subjective rollability, puffing and sensory acceptability. This is because of the poor quality of doughs and flatbreads prepared from gluten free flours due to the lack of the gluten network (Gallagher et al. 2004). While wheat produced dough and flatbread with superior quality. In wheat the gliadins (prolamins) are responsible for dough’s cohesiveness, while the glutenins (glutelins) are apparently responsible for the dough’s resistance to extension (Hoseney 1986). The combination of these two proteins, which results in the gluten complex, confers the dough unique viscoelastic properties and the ability to retain gasses, resulting in good quality breads. Such properties are not found in proteins from gluten-free flours.

Fig. 2.

a Principal component analysis: loading plot of PC1 and PC2 describing the variation among the gluten free of flours. (WWF: Whole wheat flour, WCF: Water chestnut flour, UBF: Unripe banana flour, AF: Amaranth flour, MF: Moong flour, CF: Chickpea flour, RF: Ragi flour, TKP: Tamarind kernel powder, SyF: Soy flour, BF: Blackgram flour, BWF: Buckwheat flour). b Hierarchical cluster analysis: Dendrogram showing clusters of gluten free flours based on their subjective analyses scores ((TKP: Tamarind kernel powder, WCF: Water chestnut flour, UBF: Unripe banana flour, BW: Buckwheat flour)

Sama and amaranth flour when added to the sorghum and rice mixture have lower values for dough making ability while somewhat higher in subjective rollability and puffing. Buckwheat being placed in the same quadrant possess lower scores for puffing. Figure 2a enlightens a cluster of chickpea, ragi, soy, moong and tamarind flour near the axes. These flours are characterized by similar values for these parameters. Flours have better values for dough making ability and rollability but overall acceptability scores are comparatively low. Higher rollability values in case of tamarind kernel powder may be associated with the presence of polysaccharides in kernel with high viscosity (Mirhosseini and Amid 2012). Rosales-Juárez et al. (2008) have reported improvement in bread quality when soy flour was added but have stated the typical beany flavor to be responsible for the lower acceptance of the product. Also, it can be seen that sama and blackgram flours being in opposite quadrant and much distant apart, have much difference in evaluated parameters. Sama is characterized by higher scores for acceptability whereas black gram is characterized by higher scores for rollability. Moderate dough strength of black gram flour may be responsible for higher rollability scores. Despite of higher scores for puffing and rollability, black gram has lower score for acceptability due to its beany taste imparted to flatbread.

Pearson’s correlation

Table 4 shows the pearson’s correlation coefficients amongst the flatbread making characteristics viz; dough making ability, rollability, puffing and overall acceptability of gluten free flatbreads prepared with added gluten free flatbreads to sorghum: rice mixture.

Table 4.

Principal component analysis: Correlation matrix of the subjective analyses of gluten free flours mixed to sorghum rice

| Rollability | Puffing | Acceptability | DMA | |

|---|---|---|---|---|

| Rollability | 1.00 | 0.87 | 0.68 | 0.78 |

| Puffing | 1.00 | 0.79 | 0.84 | |

| Acceptability | 1.00 | 0.82 | ||

| DMA | 1.00 | |||

**Correlation is significant at the 0.01 level (2-tailed). DMA Dough making ability

In general, correlation coefficient (r) has values that range from − 1 ≤ r ≤ + 1. The r value of − 1 describes a perfect negative correlation, i.e. all the experimental points lie on a straight line with a negative slope. Similarly, the r value of + 1 describes a perfect positive correlation, all the points lying exactly on a straight line with a positive slope (Miller and Miller 1993). All the relationships observed were significant at 0.01 level. It showed strong positive linear relationships, which implies that the subjectively evaluated flatbread making characteristics in this investigation are directly related with each other. The strongest correlation (r = 0.87) was observed between rollability and puffing followed by dough making ability and puffing (r = 0.84), dough making ability and sensory overall acceptability (r = 0.82) and others. All the characteristics were found to be positively correlated with each other.

Hierarchical cluster analysis

In hierarchical cluster analysis, samples are grouped on the basis of similarities, without taking into account the information about the class membership. The results obtained following HCA are shown as a dendrogram (Fig. 2b) in which six well-defined clusters are visible.

Cluster A comprises wheat flour alone. Cluster B includes buckwheat and blackgram flour. Cluster C is composed from underutilized gluten free flours viz; unripe banana and water chestnut flour, which as of now lead application as fasting ingredients. Tamarind kernel flour alone has turned into cluster D. Cluster E has involved a high number of gluten free flours viz; soy, ragi flour, chickpea and moong flour. Base flour (sorghum and rice) along with amaranth and same flour have assembled together in cluster F.

Dendrograms are the graphs obtained from HCA; explains distance between more than two clusters. More the distance between two groups; more is difference between sensory score (da Silva Torres et al. 2006).

Group A of is placed at the highest rescaled distance on the histogram stating its highest level of dissimilarity from others in the subjective evaluation done so far. Wheat flour has found to have highest scores for all the four parameters tested. The separation of wheat flour from gluten free flours has also been supported by PCA as shown in Fig. 2a.

Buckwheat and blackgram flour as depicted in cluster B have similar scores for dough making ability, puffing and overall acceptability but a little higher rescaled distance if cluster combine is observed due to differences in subjective rollability of the two. Figure 2a also substantiates the separation of the two. Higher distance for black gram flour is due to the good cohesive properties which makes the flour suitable for getting rolled but lower scores of acceptability tend to arise due to the typical beany flavor of the flatbread thus developed which is not acceptable. McWatters (1990) has discussed about the typical beany flavor of legume flours that leads to decrease in consumer acceptance.

Again, cluster C is consisted of two flours as obtained in the subjective evaluation; water chestnut and unripe banana flour. Both of them have got analogous score for dough making ability, rollability and puffing. Even effective scores are observed for their overall acceptability. These two have acquired the highest scores in the subjective evaluation followed by wheat and hence are most likely to be a proven gluten free flour to substitute wheat in the manufacture of flatbread. Walde and Misra (2016) noticed decrease in dough extensibility with increase in water chestnut flour concentration which is negatively correlated to dough strength. This might be responsible for higher scores for dough making ability and rollability of these flours.

As Fig. 2a demonstrates, tamarind kernel flour unaccompanied displays cluster D influenced by high scores of subjective rollability and puffing compared to others. Even dough making ability was found to be effectual with the same due to the presence of tamarind seed polysaccharide which is obtained from the seed kernel of Tamarindus indica. It possesses properties like high viscosity, broad pH tolerance, noncarcinogenicity, mucoadhesive nature, and biocompatibility. It is used as stabilizer, suspending agent, thickener, gelling agent, and binder in food and pharmaceutical industries (Sano et al. 1996).

The largest group of the dendrogram, E is comprised of legumes (moong, chickpea, soy) and pseudocereal (ragi). These are characterized by similar scores for dough making ability, rollability and puffing but have lower scores for sensory acceptability except for moong. Typical beany flavor may be responsible for lower scores of sensory acceptability in case of chickpea and soy. Moong has higher scores of sensory acceptability (7.08). Similar point has been reviewed by McWatters (1990) saying about the typical beany flavor of legume flours that leads to decrease in consumer acceptance.

As depicted in the Fig. 2a, base flour combination (sorghum and rice), amaranth and sama flours constitute group F according to their scores for the subjective analyses. Table reveals their lower scores for dough making ability due to absence of binding ability of the flours. These flours have average scores in the other subjective analyses. Figure 2a has also placed these flours in a single quadrant neighboring each other. Vidya et al. (2013) have specified the easy flattening of sorghum dough as in case of bhakri. All added gluten free flours to sorghum: rice mixture are having similar properties.

Conclusion

Optimum proportion of sorghum and rice to be used as a base composition for development of GFFB was found to be 30% and 70% respectively with good dough making ability, rollability, puffing and sensory overall acceptability. Addition of gluten free flours in the rage of 5–30% to the sorghum and rice mixture (30:70) which affect dough and flatbread making characteristics as well as sensory overall acceptability of the GFFB. Moong flour, water chestnut flour and unripe banana flour improved the properties of the final GFFB in terms of the studied characteristics. Considerable variations were observed between wheat and gluten free flours in terms of dough making ability, rollability, puffing and sensory overall acceptability analyzed subjectively. Chemometric techniques enabled visualization of the subjective score’s dataset and underlying relationships responsible for clustering observed. It was observed that all the subjectively evaluated characteristics contributed mostly to the first principal component. First two components explained 92.96% of the total variance. Loading plot shows resemblance of mixture of gluten free flours to the wheat flour. Pearson’s correlation showed the positive correlation between dough and flatbread making characteristics as well as sensory overall acceptability. HCA helped in clustering of flours according to their similarities and differences. Mixture of flours were found to possess higher levels of similarities with wheat flour thus proves their use to substitute wheat in the development of flatbread. Information from this study will be useful for coeliac sufferers and processing industries.

Acknowledgement

Author are thankful to UGC for providing funding’s

Compliance with ethical standards

Conflict of interest

All authors in the manuscript do not have any conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Alonso-Salces RM, Herrero C, Barranco A, López-Márquez DM, Berrueta LA, Gallo B, Vicente F. Polyphenolic compositions of Basque natural ciders: a chemometric study. Food Chem. 2007;97(3):438–446. doi: 10.1016/j.foodchem.2005.05.022. [DOI] [Google Scholar]

- Austin A. Studies on chapati making quality of wheat. indian council of agricultural research. New Delhi Technical Bulletin. 1971;31:96–101. [Google Scholar]

- Badgujar J, Gaikwad S, Sonawane SK, Arya SS. Low glycaemic index bhakri: Indian sorghum unleavened flat bread. Food Measure. 2017;11(2):768–775. doi: 10.1007/s11694-016-9447-4. [DOI] [Google Scholar]

- Bagolin do Nascimento A, Medeiros Rataichesck Fiates G, dos Anjos A, Teixeira E. Availability, cost and nutritional composition of gluten-free products. British Food J. 2014;116(12):1842–1852. doi: 10.1108/BFJ-05-2013-0131. [DOI] [Google Scholar]

- Bhattacharya S, Narasimha HV, Bhattacharya S. Rheology of corn dough with gum arabic: Stress relaxation and two-cycle compression testing and their relationship with sensory attributes. J Food Eng. 2006;74(1):89–95. doi: 10.1016/j.jfoodeng.2005.02.006. [DOI] [Google Scholar]

- Chirdo FG, Ben R, Saldungaray I, Villalobos R. Evaluation of coeliac disease serological markers in Down syndrome patients. Dig Liver Dis. 2002;34(2):116–121. doi: 10.1016/S1590-8658(02)80240-7. [DOI] [PubMed] [Google Scholar]

- da Silva Torres EA, Garbelotti ML, Neto JM. The application of hierarchical clusters analysis to the study of the composition of foods. Food Chem. 2006;99(3):622–629. doi: 10.1016/j.foodchem.2005.08.032. [DOI] [Google Scholar]

- Gallagher E, Gormley TR, Arendt EK. Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci Technol. 2004;15(3–4):143–152. doi: 10.1016/j.tifs.2003.09.012. [DOI] [Google Scholar]

- Hadnađev TD, Torbica A, Hadnađev M. Rheological properties of wheat flour substitutes/alternative crops assessed by Mixolab. Procedia Food Sci. 2011;1:328–334. doi: 10.1016/j.profoo.2011.09.051. [DOI] [Google Scholar]

- Hoseney RC (1986) Principles of cereal science and technology. A general reference on cereal foods. American association of cereal chemists, Inc.

- Hrušková M, Švec I, Jurinová I. Chemometrics of wheat composites with hemp, teff, and chia flour: comparison of rheological features. Int J Food Sci. 2013 doi: 10.1155/2013/968020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kälviäinen N, Roininen K, Tuorila H. Sensory characterization of texture and flavor of high viscosity gels made with different thickeners. J Texture Stud. 2000;31(4):407–420. doi: 10.1111/j.1745-4603.2000.tb00299.x. [DOI] [Google Scholar]

- McWatters KH. Functional characteristics of cowpea flours in foods. J Am Oil Chem Soc. 1990;67(5):272–275. doi: 10.1007/BF02539675. [DOI] [Google Scholar]

- Miller JC, Miller JN (1993) Statistics for analytical chemistry. Ellis Horwood PTR Prentice Hall, New York. https://trove.nla.gov.au/version/45464904

- Mirhosseini H, Amid BT. A review study on chemical composition and molecular structure of newly plant gum exudates and seed gums. Food Res Int. 2012;46(1):387–398. doi: 10.1016/j.foodres.2011.11.017. [DOI] [Google Scholar]

- Otto M (1999) Statistics and computer application in analytical chemistry; chemometrics. ISBN: 978–3–527–34097–2

- Patil SP, Arya SS. Influence of additives on dough rheology and quality of Thepla: an Indian unleavened flatbread. Food Measure. 2016;10(2):327–335. doi: 10.1007/s11694-016-9310-7. [DOI] [Google Scholar]

- Rai R, Agrawal M. Evaluation of physiological and biochemical responses of two rice (Oryza sativa L.) cultivars to ambient air pollution using open top chambers at a rural site in India. Sci Total Environ. 2008;407(1):679–691. doi: 10.1016/j.scitotenv.2008.09.010. [DOI] [PubMed] [Google Scholar]

- Rosales-Juárez M, González-Mendoza B, López-Guel EC, Lozano-Bautista F, Chanona-Pérez J, Gutiérrez-López G, Farrera-Rebollo R, Calderón-Domínguez G. Changes on dough rheological characteristics and bread quality as a result of the addition of germinated and non-germinated soybean flour. Food Bioprocess Tech. 2008;1(2):152–160. doi: 10.1007/s11947-007-0004-3. [DOI] [Google Scholar]

- Sano M, Miyata E, Tamano S, Hagiwara A, Ito A, Shirai T. Lack of carcinogenicity of tamarind seed polysaccharide in B6C3F 1 mice. Food Chem Toxicol. 1996;34(5):463–467. doi: 10.1016/0278-6915(96)87356-X. [DOI] [PubMed] [Google Scholar]

- Schober TJ, Obrien CM, McCarthy D, Darnedde A, Arendt EK. Influence of gluten-free flour mixes and fat powders on the quality of gluten-free biscuits. Eur Food Res Technol. 2003;216(5):369–376. doi: 10.1007/s00217-003-0694-3. [DOI] [Google Scholar]

- Shaikh IM, Ghodke SK, Ananthanarayan L. Inhibition of staling in chapati (Indian unleavened flat bread) J Food Process Preserv. 2008;32(3):378–403. doi: 10.1111/j.1745-4549.2008.00185.x. [DOI] [Google Scholar]

- Singh P, Arora S, Singh A, Strand TA, Makharia GK. Prevalence of celiac disease in Asia: a systematic review and meta-analysis. J Gastroenterol Hepatol. 2016;31(6):1095–1101. doi: 10.1111/jgh.13270. [DOI] [PubMed] [Google Scholar]

- Vidya S, Ravi R, Bhattacharya S. Effect of thermal treatment on selected cereals and millets flour doughs and their baking quality. Food Bioprocess Tech. 2013;6(5):1218–1227. doi: 10.1007/s11947-012-0888-4. [DOI] [Google Scholar]

- Walde SG, Misra AK. Studies on physicochemical properties and effect of pretreatment on drying characteristics of water chestnut. Int Food Res J. 2016;23(1):102–108. [Google Scholar]