Intraoral optical scanners (IOS) eliminate the necessity for traditional impressions by enabling the acquisition of digital impressions. Recent studies have demonstrated that high trueness and precision can be attained by digital impressions.1,2 Until recently, the only output generated by IOS for digital impressions was the STL (Standard Tessellation Language) file format.2 Now, some IOS provide alternative file formats such as OBJ (OBJect) and PLY (PoLYgon). OBJ and PLY file formats enable a more accurate model than the traditional STL file format. These newer formats encode 3-D (3-Dimensional) models via tessellation with polygonal facets, and additionally capture information about color and surface texture, allowing for extremely accurate, multicolor 3-D printing.

Smile design can be performed digitally and allows a patient to have heightened awareness of the anticipated treatment outcomes, prior to initiation of a treatment plan.3,4 Some digital smile design software programs are time-consuming and difficult to incorporate into a clinical workflow. However, the software program (Zbrush, Pixologic, Los Angeles, CA, USA) used in this report is one of the most advanced digital sculpting and painting programs, providing an intuitive workflow.4 This software allows several actions (i.e., pushing, pulling) by using millions of polygons simultaneously, and it is traditionally used by professional artists and computer graphics designers in the film and videogame industries.

This clinical report describes a comprehensive technique using an intraoral optical scanner, advanced 3-D digital sculpting software program, and a 3-D printer to rehabilitate an unpleasant smile.

The chief complaint of our 55-year-old patient was “I don't like my front teeth” and she requested a more esthetic smile. After various treatment options were discussed with the patient, she elected to proceed with the fabrication of porcelain veneers on the ten maxillary teeth.

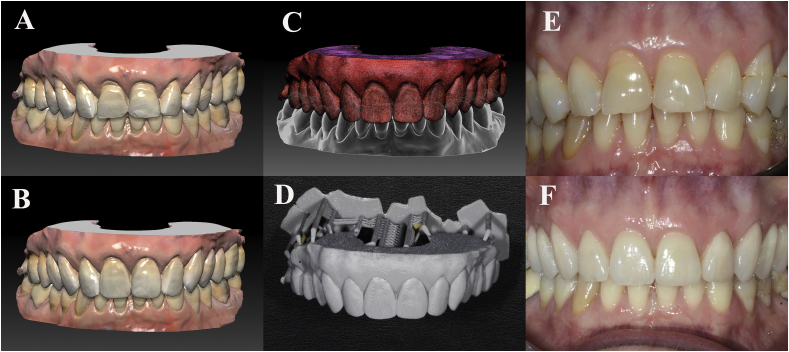

Our digital workflow began with extraoral digital photographs (frontal facial view with full lip retraction, exaggerated smile, and teeth in maximum intercuspal position). An intraoral optical scanner (Medit i500, Medit Corp., Seoul, South Korea) was utilized to acquire the digital impressions of both arches (Fig. 1A). Then the extraoral digital photographs and digital impressions, in OBJ file format, were superimposed with the 3-dimensional sculpting software program, and the designs of the proposed restorations were completed (Fig. 1B).

Figure 1.

Digital scan of the teeth before (A), and after the digital design of proposed restorations (B). Digital file of both arches before 3-D printing (C). The maxillary resin cast with new smile design was fabricated with a 3-D printer (D). Intra-oral views of the patient before (E) and after (F) the treatment.

Mandibular and maxillary resin cast with the new smile design were fabricated using a 3-D printer (Sprintray Pro 3D Printer, Sprintray, Los Angeles, CA, USA) (Fig. 1C and D). A silicone matrix was created from an impression of the maxillary resin cast, and the temporary crowns were fabricated (Luxatemp, DMG America, Ridgefield Park, NJ, USA). The temporary crowns were inserted intraorally, and esthetics, phonetics, and occlusion were confirmed.

Tooth preparations were completed by using temporary crowns as a guide. After gingival retraction was performed, the final impression was made using vinyl polysiloxane impression material (Aquasil, Dentsply, York, PA, USA) and the definitive cast was poured. The veneer restorations were fabricated in lithium disilicate glass-ceramic in the laboratory (IPS e.max CAD, Ivoclar Vivadent, Amherst, NY, USA). Each tooth surface and veneer was prepared (i.e., etching, bonding) according to the manufacturer's instructions, and then all veneers were permanently cemented (Variolink Esthetic, Ivoclar Vivadent, Amherst, NY, USA) (Fig. 1E and F). An occlusal guard for the patient was manufactured from the 3-D digital scan. The patient did not have any problems during the one year follow-up. The outcomes of this report indicate that the advanced treatment modality presented here may be a viable option to predictably restore unpleasant smiles.

Declaration of Competing Interest

The authors have no conflicts of interest relevant to this article.

References

- 1.Ahlholm P., Sipila K., Vallittu P., Jakonen M., Kotiranta U. Digital versus conventional impressions in fixed prosthodontics: a review. J Prosthodont. 2018;27:35–41. doi: 10.1111/jopr.12527. [DOI] [PubMed] [Google Scholar]

- 2.Nagy Z., Simon B., Mennito A., Evans Z., Renne W., Vag J. Comparing the trueness of seven intraoral scanners and a physical impression on dentate human maxilla by a novel method. BMC Oral Health. 2020;20:97. doi: 10.1186/s12903-020-01090-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Stanley M., Paz A.G., Miguel I., Coachman C. Fully digital workflow, integrating dental scan, smile design and CAD-CAM: case report. BMC Oral Health. 2018;18:134. doi: 10.1186/s12903-018-0597-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Unkovskiy A., Spintzyk S., Brom J., Huettig F., Keutel C. Direct 3D printing of silicone facial prostheses: a preliminary experience in digital workflow. J Prosthet Dent. 2018;120:303–308. doi: 10.1016/j.prosdent.2017.11.007. [DOI] [PubMed] [Google Scholar]