Highlights

A new heteronuclear bi-atom electrocatalyst has been proposed by Ma and his co-workers.

The FeV@C2N bi-atom electrocatalyst achieved excellent electrochemical NRR performance.

The FeV@C2N bi-atom electrocatalyst could effectively suppress the side and competing HER reaction, and thus possess better electrochemical NRR selectivity.

Keywords: Electrochemical nitrogen reduction reaction, Bi-atom catalysts, Excellent activity, High selectivity

Abstract

The electrochemical nitrogen reduction reaction (NRR) to directly produce NH3 from N2 and H2O under ambient conditions has attracted significant attention due to its ecofriendliness. Nevertheless, the electrochemical NRR presents several practical challenges, including sluggish reaction and low selectivity. Here, bi-atom catalysts have been proposed to achieve excellent activity and high selectivity toward the electrochemical NRR by Ma and his co-workers. It could accelerate the kinetics of N2-to-NH3 electrochemical conversion and possess better electrochemical NRR selectivity. This work sheds light on the introduction of bi-atom catalysts to enhance the performance of the electrochemical NRR.

The electrochemical nitrogen reduction reaction (NRR) to directly produce NH3 from N2 and H2O under ambient conditions has attracted significant attention due to its ecofriendliness compared with the traditional Haber–Bosch process [1, 2]. Nevertheless, the electrochemical NRR presents several practical challenges, including sluggish reaction and low selectivity [3, 4]. The slow kinetics is caused by the extremely strong N≡N triple bond (941 kJ mol−1) and the great energy gap between highest occupied molecular orbital (HOMO) and the lowest unoccupied molecular orbital (LUMO) of the N2 molecule [5]. The hydrogen evolution reaction (HER) is the main side reaction responsible for the low selectivity, which shares a very close potential window with the NRR in both alkaline and acidic electrolytes [6, 7]. Fortunately, the electrochemical NRR depends heavily on its electrocatalysts [8–10]. Therefore, advanced rational design of the electrochemical NRR electrocatalysts to achieve outstanding performance and high selectivity is urgently required [11–13]. Various NRR electrocatalysts, including metal-free catalysts, single-atom catalysts, metal nanomaterials, nitrides/oxides/sulfides/carbides, etc., have been reported with the aim of high NH3 yield since 2016 [14]. Nevertheless, a promising candidate, a heteronuclear bi-atom electrocatalyst, has been little studied for the electrochemical NRR.

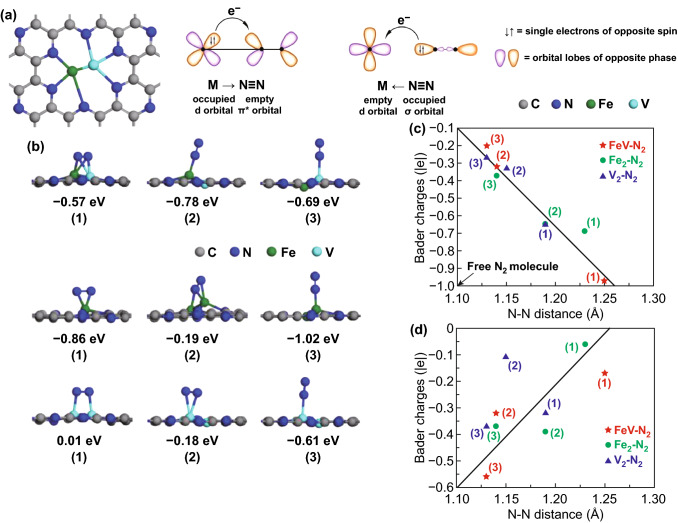

Recently, Ma and co-workers [15] designed a new heteronuclear bi-atom electrocatalyst, Fe, V co-doped C2N (FeV@C2N), to accelerate the kinetics of the NRR and suppress the hydrogen evolution reaction (HER), which occurs as a side reaction. This FeV@C2N electrocatalyst achieved excellent electrochemical NRR performance. The nitrogenated holey structures in C2N could anchor these Fe and V atoms; additionally, the unoccupied/occupied d orbitals of Fe and V atoms may accept/donate electrons from/to N2 (Fig. 1a). Therefore, Fe and V atoms could be stable on the C2N matrix and serve as active sites to electrocatalytically transform N2 into NH3. The FeV@C2N could weaken the N≡N triple bond and increase the Bader charge difference of two chemisorbed N atoms, as shown in Fig. 1b−d. More importantly, the FeV@C2N possesses the greatest ability to activate N2 compared to Fe2@C2N and V2@C2N.

Fig. 1.

a Optimized structures of FeV anchored on C2N substrate and simplified schematic diagram of the bonding between the transition metal and N2. b Optimized structures and corresponding adsorption energies of N2 adsorption on FeV@C2N, Fe2@C2N, and V2@C2N. c Relationship between Bader charges of adsorbed N2 and N–N bond lengths. d Relationship between Bader charge difference of two adsorbed N atoms and N–N bond lengths [15].

Copyright 2020 Elsevier

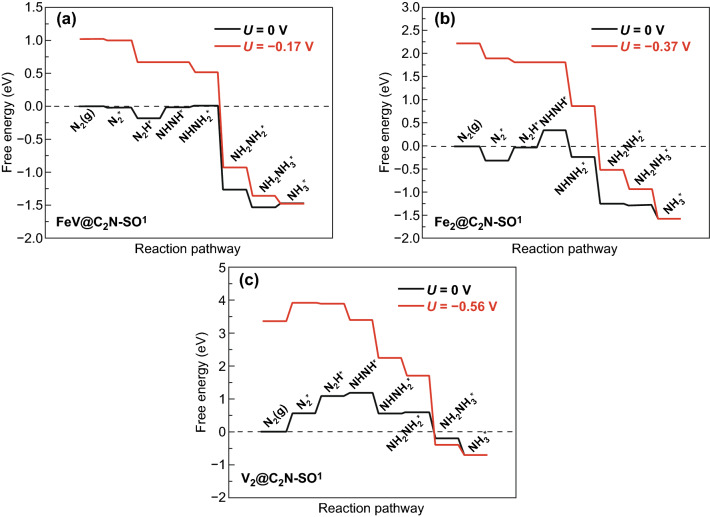

Furthermore, Ma and co-workers [15] proposed the mechanism of N2 reduction and free energy diagrams on side-on configurations of FeV@C2N, Fe2@C2N, and V2@C2N, and they believe that FeV@C2N is the most promising electrocatalyst for the NRR compared with the other two. There are only two reaction steps from N2H* to NHNH* and NHNH* to NHNH2*, which are endothermic for FeV@C2N; thus, these two steps are the potential-determining step (PDS) with free energy of 0.17 eV, as shown in Fig. 2a. The Fe2@C2N shares the same PDS but with a higher free energy of 0.37 eV (Fig. 2b). In V2@C2N, the PDS is the formation of N2*, with the greatest free energy of 0.56 eV (Fig. 2c). The HER, as a competing and side reaction, was also investigated for these three samples. The calculated results indicated that FeV@C2N and Fe2@C2N have better NRR selectivity. V2@C2N, because of the competing HER, is not a good candidate for the electrochemical NRR.

Fig. 2.

a–c Free energy diagrams of the three electrocatalysts [15].

Copyright 2020 Elsevier

In sum, Ma and co-workers proposed FeV@C2N as an outstanding heteronuclear bi-atom electrocatalyst for the electrochemical NRR, with high activity and better selectivity. It could enhance the kinetics of N2-to-NH3 electrochemical conversion with a low potential PDS of -0.17 V. Moreover, this FeV@C2N electrocatalyst could effectivity suppress the side and competing HER reaction, and thus possess better electrochemical NRR selectivity. This work sheds light on the introduction of heteronuclear bi-atom electrocatalysts to enhance the performance of the electrochemical NRR and opens a new way to understand the electrochemical NRR mechanism.

In the future, two possible prospects could be effective approaches to optimize the electrocatalysts with the aim of improved NRR activity and selectivity, and reveal the mechanisms of the electrochemical NRR as well. Firstly, theoretical calculations could be employed to predict potential NRR electrocatalysts and provide various types of optimization guidance to the experiments. For example, high-throughput computing can identify the poisoning and decomposition of electrocatalysts under electrochemical conditions, including the pH and the electrolyte effect, which can provide a deeper insight into the mechanism under real operation conditions. On the other hand, advanced characterization, including in-situ and operando atomic-resolution transmission electron microscopy and X-ray absorption spectroscopy, can be developed to identify the real active sites and composite evolution of the electrical double layer. With the significant efforts that have been made in the past few years, the electrochemical NRR appears promising to replace the traditional Haber–Bosch process to produce NH3. Nevertheless, a reproducible and excellent electrochemical NRR catalyst is still expected to be proposed as a standard electrocatalyst, due to the doubt that has arisen on the actual NRR performance. A benchmarking protocol to accurately quantify the electrochemical NRR activity and selectivity should be established. We believe that, with much effort, the fundamental issues and technological drawbacks will be addressed in the not-too-distant future, and the electrochemical NRR can play an important role in NH3 yield.

Contributor Information

Wenchao Zhang, Email: wz990@uowmail.edu.au.

Bin-Wei Zhang, Email: bz370@uowmail.edu.au.

References

- 1.Fu Y, Richardson P, Li K, Yu H, Yu B, et al. Transition metal aluminum boride as a new candidate for ambient-condition electrochemical ammonia synthesis. Nano Micro Lett. 2020;12:65. doi: 10.1007/s40820-020-0400-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Tang JC, Qiao S-Z. How to explore ambient electrocatalytic nitrogen reduction reliably and insightfully. Chem. Soc. Rev. 2019;48:3166–3180. doi: 10.1039/C9CS00280D. [DOI] [PubMed] [Google Scholar]

- 3.Zhang B-W, Wang Y-X, Chou S-L, Liu H-K, Dou S-X. Fabrication of superior single-atom catalysts toward diverse electrochemical reactions. Small Methods. 2019;3:1800497. doi: 10.1002/smtd.201800497. [DOI] [Google Scholar]

- 4.J.G. Chen, R.M. Crooks, L.C. Seefeldt, K.L. Bren, R.M. Bullock et al. Beyond fossil fuel—driven nitrogen transformations. Science 360, 6611 (2018). 10.1126/science.aar6611 [DOI] [PMC free article] [PubMed]

- 5.Foster SL, Bakovic SIP, Duda RD, Maheshwari S, Milton RD, et al. Catalysts for nitrogen reduction to ammonia. Nat. Catal. 2018;1:490–500. doi: 10.1038/s41929-018-0092-7. [DOI] [Google Scholar]

- 6.Zhang B-W, Yang H-L, Wang Y-X, Dou S-X, Liu H-K. A comprehensive review on controlling surface composition of Pt-based bimetallic electrocatalysts. Adv. Energy Mater. 2018;8:1703597. doi: 10.1002/aenm.201703597. [DOI] [Google Scholar]

- 7.Zhang B-W, Sheng T, Wang Y-X, Qu X-M, Zhang J-M, et al. Platinum–cobalt bimetallic nanoparticles with Pt skin for electro-oxidation of ethanol. ACS Catal. 2017;7:892–895. doi: 10.1021/acscatal.6b03021. [DOI] [Google Scholar]

- 8.Zhang B-W, Ren L, Wang Y-X, Du Y, Jiang L, et al. New monatomic layer clusters for advanced catalysis materials. Sci. China Mater. 2019;62:149–153. doi: 10.1007/s40843-018-9317-7. [DOI] [Google Scholar]

- 9.Zhang B-W, Sheng T, Liu Y-D, Wang Y-X, Zhang L, et al. Atomic cobalt as an efficient electrocatalyst in sulfur cathodes for superior room-temperature sodium-sulfur batteries. Nat. Commun. 2018;9:4082. doi: 10.1038/s41467-018-06144-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Suryanto BHR, Du H-L, Wang D, Chen J, Simonov AN, et al. Challenges and prospects in the catalysis of electroreduction of nitrogen to ammonia. Nat. Catal. 2019;2:290–296. doi: 10.1038/s41929-019-0252-4. [DOI] [Google Scholar]

- 11.Zhang B-W, Sheng T, Wang Y-X, Chou S, Davey K, et al. Long-life room-temperature sodium–sulfur batteries by virtue of transition-metal-nanocluster–sulfur interactions. Angew. Chem. Int. Ed. 2019;131:1498–1502. doi: 10.1002/anie.201811080. [DOI] [PubMed] [Google Scholar]

- 12.Jia H-P, Quadrelli EA. Mechanistic aspects of dinitrogen cleavage and hydrogenation to produce ammonia in catalysis and organometallic chemistry: relevance of metal hydride bonds and dihydrogen. Chem. Soc. Rev. 2014;43:547–564. doi: 10.1039/C3CS60206K. [DOI] [PubMed] [Google Scholar]

- 13.Tang X, Wei Z, Liu Q, Ma J. Strain engineering the D-band center for Janus MoSSe edge: Nitrogen fixation. J. Energy Chem. 2019;33:155–159. doi: 10.1016/j.jechem.2018.09.008. [DOI] [Google Scholar]

- 14.Qing G, Ghazfar R, Jackowski ST, Habibzadeh F, Ashtiani MM, et al. Recent advances and challenges of electrocatalytic n2 reduction to ammonia. Chem. Rev. 2020;120:5437–5516. doi: 10.1021/acs.chemrev.9b00659. [DOI] [PubMed] [Google Scholar]

- 15.Wei Z, He J, Yang Y, Xia Z, Feng Y, et al. Fe, V-co-doped C2N for electrocatalytic N2-to-NH3 conversion. J. Energy Chem. 2021;53:303–308. doi: 10.1016/j.jechem.2020.04.014. [DOI] [Google Scholar]