Abstract

This research aimed to identify the differences in brewer's spent grains, which were collected from eight breweries for their physicochemical properties. The spent grains were dried until they reached stable weights, grounded to pass through a 385-μm sieve, vacuum-packed in nontransparent packaging, and kept in room temperature conditions for further analysis. The physicochemical properties, including proximate, color, water activity, water-holding capacity, oil-holding capacity, and density were evaluated. The results showed some differences in all measured quality parameters between all eight different spent barley grain samples. A similar pattern was noted in some properties studied. Hence, mathematical modeling of these studied properties should be undertaken with further qualities, such as fiber composition, mechanical properties, and thermal stability.

Keywords: Brewery spent grain, Waste characterisation, Valorization, Agricultural byproducts

brewery spent grain; waste characterisation; valorization; agricultural byproducts.

1. Introduction

Brewery spent grain (BSG), a byproduct of the brewery industry, is generated from 41% beer waste production and 31% malt materials (Garcia-Garcia et al., 2019; Nigam, 2017). Twenty kilograms of BSG is obtained from every 100 L of beer load. Indeed, in 2018, there were 1.94 billion hectolitres of beer produced worldwide (Conway, 2019). Agroindustrial byproducts are renewable resources because they are nonhazardous waste. Valorization of biowaste is profitable for environmental, economic, and human health reasons (Ravindran et al., 2018).

An excellent review (Nigam, 2017) mentioned that BSG has considerable potential to be used for several purposes, such as animal feed, food ingredients, polymer production, microbial products, and nutritional application. The versatility of BSG is supported by their fiber compounds. Fiber is a good source for nutraceuticals and nutrition, biopolymers, and bioactive compounds such as phenolic compounds and substrates for microflora, as well as a supply for biochemical and biofuel production (Amorim et al., 2019; Barbosa-Pereira et al., 2014; Berthet et al., 2015; Lorente et al., 2019; Reis et al., 2015).

Many researchers studied the possibilities of enhancing BSG quality materials for food, nutraceuticals, and biopolymers. Some popular methods include fiber modification, fermentation (Chu et al., 2019), physical treatment (Li et al., 2019), chemical treatment (Ravindran et al., 2018), and a combination of techniques (Espino et al., 2014; Gil-López et al., 2019). However, the expected results depend on the basic properties and quality of the BSG itself.

The factors which affect the characteristics of BSG include genetic variation in the crops used, specificity of brewery production, treatment, and pretreatment after beer production (Santos et al., 2003). Pretreatment strategies, including both chemical and physical techniques, of BSG were studied specifically for their impact on protein quality (Qin et al., 2018). The brewing process affects the amount of hydroxycinnamic acid (McCarthy et al., 2013), with drying methods (Santos et al., 2003) and types of malts (Moreira et al., 2013) previously compared; their impacts on phenolic and antioxidant activity were discovered as a result. Furthermore, different types of solvent used for phenolic extraction from BSG compound bioactivity (Socaci et al., 2018).

These differences depict that any treatments or methods directly impact the BSG properties, leading to differences in the effects of products. The main reason to use different sources of BSG regards the expression of different properties. There is a lack of reliable scientific reports regarding comparison of the quality of BSG from various sources. This study aimed to identify the differences in BSG from eight different brewery industries for their physicochemical properties, with the results used as basic information in order to establish the possibility of BSG for further valorization.

2. Material and methods

2.1. Materials

BSG were obtained from 8 different brewery industries in Poland, Germany, and Estonia (I-VIII: Foundation II German Pale Ale, Bojanowo, WB, Onnevalemi Komonendid, Drunken soiler india pale ale, Sto Mostow, Fest, and Elveliksiirid, respectively), and directly dried using convective drying at 70 °C maximum temperature. The samples were ground using a grinding mill laboratory scale to reach a maximum particle size of about 385 μm. The samples were kept in aluminium bags at room temperature for further analysis. All chemicals for fat and protein analysis were analytical grades obtained from Sigma Ltd.

2.2. Proximate analysis

Proximate analysis was conducted by the methods described by Ktenioudaki et al. (2013b) with 3 replications for moisture content, protein (N), extracted fat, and ash content. Carbohydrates were calculated by the difference (100 – moisture content – protein – fat – ash). Moisture content (MC) was measured using the oven method. Samples weighing 5 g were dried in the oven at 115 °C for 12 h until stable weights were reached. The crude protein (N) was measured according to the Kjeldahl method with a conversion factor of 6.25, while extracted fat was analyzed using the Soxhlet extraction method, as determined by weight difference before and after extraction. Ash content was determined gravimetrically in a muffle furnace by heating at 550 °C for 12 h, allowing complete decomposition of organic matter.

2.3. Water activity measurement

Water activity (Aw) measurement was done in triplicate using the water activity meter AquaLab Dew Point 4TE (Decagon Devices Inc., United States) at 24 °C (Park et al., 2015).

2.4. Color measurement

The color values, L∗, a∗, and b∗, of the BSG samples were evaluated using a Chroma meter (Park et al., 2015), where L∗ is lightness, a∗ is the degree of redness or greenness, and b∗ is yellowness or blueness. Samples were placed on a transparent glass plate along with the Chroma meter and measured in triplicate. The Chroma meter, Minolta Chroma Meter CR-400 (Minolta Co., Ltd., Osaka, Japan), was calibrated with a whiteboard supplied by the manufacturer.

2.5. Water- and oil-holding capacity

Water-holding capacity (WHC) and oil-holding capacity (OHC) were carried out in triplicate following the methods by Ktenioudaki et al. (2013b). Samples of BSG weighing 5 g were mixed with 50 mL of distilled water and left for 12 h to hydrate. The excess water was removed and the retained water per gram sample was determined as the water-holding capacity. Oil-holding capacity was determined by mixing 2.5 g of BSG with 6 mL of vegetable oil in a glass rod and leaving at room temperature for 30 min, then centrifuging the samples at 3000 rpm for 15 min. The oil retained was measured after removing the supernatant.

2.6. True density

True density measurement was done in duplicate using a density analyzer. Samples totalling 2 g were weighed into a sample cell for the system to perform the measurement. True density was calculated as a ratio of sample weight and true volume (Ho et al., 2019). True volume is the volume of the sample including closed pores but excluding open pores, which was obtained by comparing the air pressure on a sample cell with and without the sample.

2.7. Bulk density

Bulk density was carried out using three different particle sizes of sample, i.e., before grinding, after grinding with a particle size >385 μm, and particle size <385 μm. All analyses was performed in triplicate. The BSG samples were poured into 1 L graduated plastic cylinders and the samples were weighed. Bulk density was determined as the weight of the sample per unit volume of the sample (Bashir et al., 2017).

2.8. Data analysis

The analysis was carried out by analysis of variance (ANOVA) in Statistica software. Significance differences (p < 0.05; Tukey HSD post-hoc test) were evaluated using one-way ANOVA, except bulk density, which was analyzed using two-way ANOVA.

3. Results and discussion

3.1. Proximate analysis and water activity

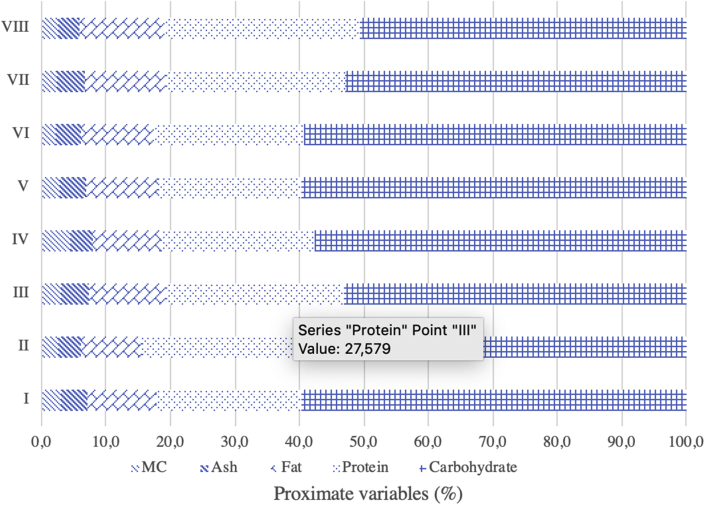

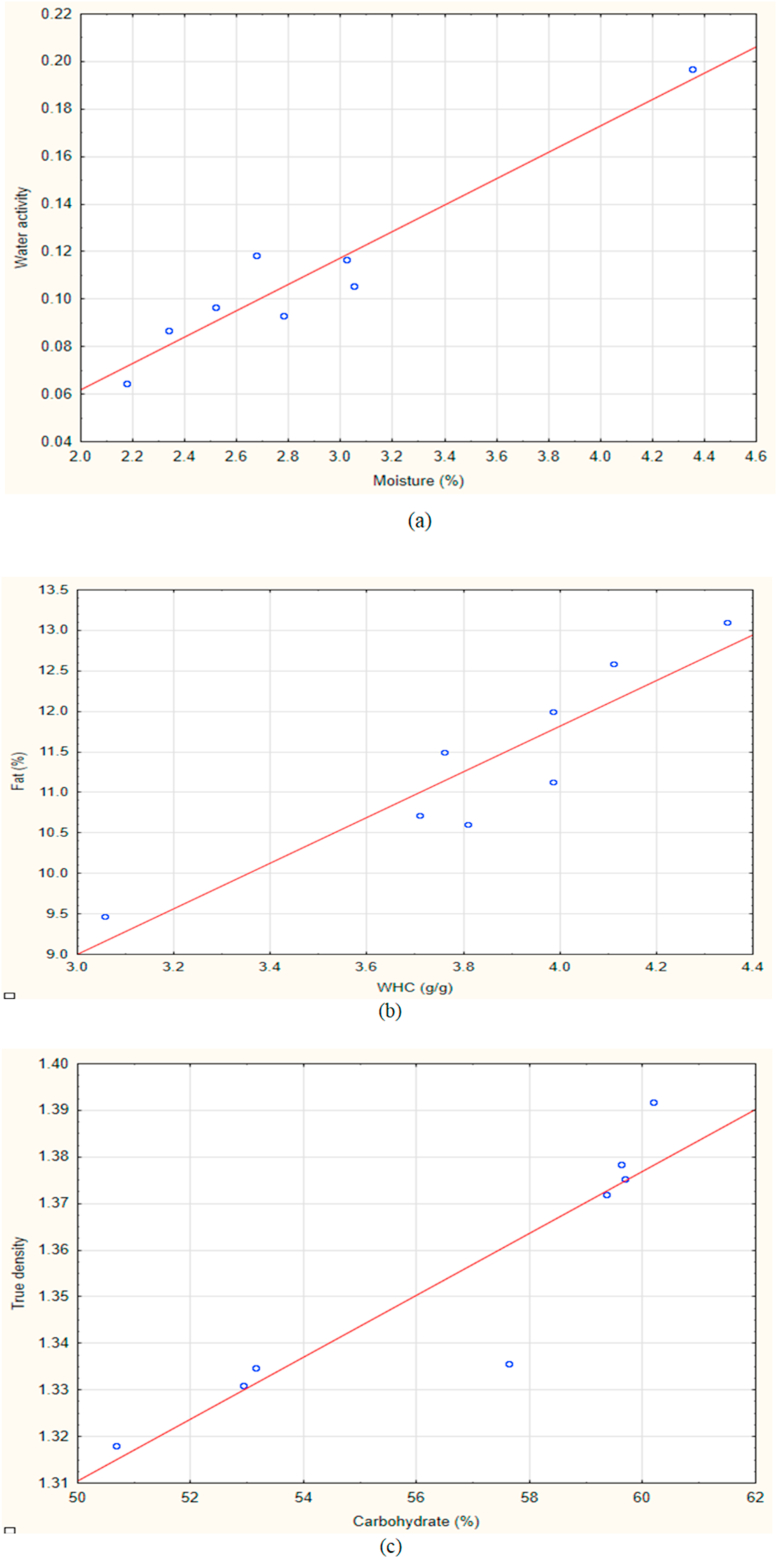

The results of the proximate as dry matter and water activity measurements are shown in Table 1. In general, statistical analysis showed significant differences (p < 0.05) for the eight different spent grains in all proximate parameters, including moisture, ash, fat, protein, and carbohydrate contents. There were some factors which affected the characteristics of the BSG, including genetic variation in the crops used, specificity of the brewery production, treatment, and pretreatment after beer production (Santos et al., 2003). As depicted in Figure 1, the following ranges were observed: moisture content, 2.178–4.353%; ash content, 3.303–4.290%; extracted fat, 9.47–13.11%; crude protein, 22.22–30.24%; and carbohydrate, 50.68–60.19%. Water activity of the spent grains ranged from 0.087 to 0.197. The highest moisture content was observed in BSG IV, the highest ash content in BSG VII, the highest fat and protein contents in BSG VIII, and the highest carbohydrate content in BSG II, while the highest water activity was in BSG IV. In addition, the results depicted the relationship between moisture content and water activity (Table 1). As depicted in Figure 4a, the higher the moisture content, the higher the level of water activity.

Table 1.

Proximate and water activity measurements or brewery spent grain (mean ± standard deviation value).

| Brewery spent grain | Moisture (%) | Ash (%) | Fat (%) | Protein (N %) | Carbohydrate∗ (%) | Aw |

|---|---|---|---|---|---|---|

| I | 3.052 ± 0.032b | 4.067 ± 0.008c | 10.715 ± 0.349d | 22.543 ± 0.236d | 59.623 ± 0.551ab | 0.106 ± 0.004c |

| II | 2.518 ± 0.056de | 3.552 ± 0.056e | 9.470 ± 0.534e | 24.270 ± 1.510c | 60.190 ± 1.692a | 0.097 ± 0.002d |

| III | 3.024 ± 0.081b | 4.245 ± 0.012ab | 11.996 ± 0.441bc | 27.579 ± 0.073b | 53.156 ± 0.415c | 0.117 ± 0.002b |

| IV | 4.353 ± 0.109a | 3.591 ± 0.032e | 10.600 ± 0.447d | 23.817 ± 0.005cd | 57.639 ± 0.567b | 0.197 ± 0.004a |

| V | 2.782 ± 0.034c | 4.195 ± 0.030b | 11.125 ± 0.097cd | 22.217 ± 0.050d | 59.681 ± 0.037ab | 0.093 ± 0.002de |

| VI | 2.178 ± 0.030f | 3.828 ± 0.028d | 11.490 ± 0.122cd | 23.159 ± 0.131cd | 59.346 ± 0.190ab | 0.064 ± 0.004f |

| VII | 2.336 ± 0.073ef | 4.290 ± 0.018a | 12.583 ± 0.215ab | 27.855 ± 0.648b | 52.935 ± 0.715c | 0.087 ± 0.003e |

| VIII | 2.673 ± 0.073cd | 3.303 ± 0.048f | 13.105 ± 0.314a | 30.236 ± 0.133a | 50.683 ± 0.442d | 0.118 ± 0.003b |

Note: ∗: carbohydrate value was calculated by difference; letters show the significant differences from other group in the same column (p < 0.05). (I: Foundation II German Pale Ale; II: Bojanowo; III: WB; IV: Onnevalemi Komonendid; V: Drunken soiler india pale ale, VI: Sto Mostow; VII: Fest; VIII: Elveliksiirid).

Figure 1.

The variability of proximate value between 8 different spent grains (I: Foundation II German Pale Ale, II: Bojamowo, III: WB, IV: Onnevalemi Komonendid, V: Drunken soiler india pale ale, VI: Sto Mostow, VII: Fest, VIII: Elveliksiirid).

Figure 4.

Relation between several quality parameters on BSG: moisture content and water activity (a), water holding capacity and extracted fat content (b), true density and carbohydrate amount (c).

The dried BSG composition varied quite widely, containing approximately 5–8% moisture content, 2.7–5% ash, 14.5–30% protein nitrogen, and 8–34.82% extracted fat (Balogun et al., 2017; Čater et al., 2015; Coelho et al., 2014; Niemi et al., 2013; Nocente et al., 2019; Stojceska and Ainsworth, 2008). All proximate variables were comparable with previously published data, except moisture content, which was discovered to be lower, possibly because of the differences in the drying techniques used. Drying techniques, which were reported in previous studies, included oven drying at 100 °C for 18 h (Balogun et al., 2017), oven drying at 60 °C for 73 h (Nocente et al., 2019), and hot air (Niemi et al., 2013). However, convective drying with a maximum temperature of 70 °C was used in this research until the sample reached a stable weight. Convective drying using hot air as a drying agent was noted for its simplicity, low cost, and easiness to operate (Calín-Sánchez et al., 2020). The differences in temperature and time consequently generated different levels of moisture contents in the BSG.

The variability of the results between all spent grain samples may have led to variation in the other properties. The wide variety of ash content among the eight different spent grains generated variety in mineral contents. As Table 1 shows, most of the samples were significantly different (p < 0.05) from each other in ash content, except BSG VII and III. The main minerals in BSG include phosphorus, calcium, sulfur, magnesium, and potassium (Meneses et al., 2013). Protein content was discovered to be significantly different (P < 0.05) between several samples. Protein isolates from BSG showed 34 peptides with high ACE inhibitory activity (Connolly et al., 2015a; Lee and Hur, 2017); the protein content of BSG was also positively related to the amount of β-glucan (Zielke et al., 2017). In other words, if the crude protein was significantly different between the spent grains, differences could be observed in the peptide compounds and their bioactivity levels. However, protein quality is also influenced by several factors, including pretreatment strategies, chemical treatment, and physical treatment such as hydrothermal treatment (Qin et al., 2018). The bioactivity of BSG protein was explored regarding the functionality of isolate protein and bioactive peptides, and reported for its activity levels, such as peroxidase (Kurnik et al., 2018), immunomodulatory (Cian et al., 2018), antioxidant (Vieira et al., 2016), anti-inflammatory (McCarthy et al., 2013), antithrombotic (Cian et al., 2018), and angiotensin-converting enzyme activity (Connolly et al., 2015b).

Besides protein content, significant differences (p < 0.05) were also shown in fat and carbohydrate contents. BSG fat content from BSG was noted for its potential as a source of antioxidants, fatty acids, and volatile tocotrienol compounds (Bohnsack et al., 2011; del Río et al., 2013; Fărcaş et al., 2015; Parekh et al., 2017; Patel et al., 2018; Patrignani and González-Forte, 2020; Ribau Teixeira et al., 2020). The carbohydrate content roughly describes the fiber amount. BSG fiber contains cellulose, hemicellulose, and lignin (Amorim et al., 2019; Balogun et al., 2017; Čater et al., 2015; Fu et al., 2011; Meneses et al., 2013; Nigam, 2017; Ravindran et al., 2018). The differences in carbohydrate content show differences in the amount of cellulose and hemicellulose contained in spent grain and their impact on the approach product. Brewery spent grain was studied for its ability to be a material for biopolymer packaging (Berthet et al., 2015), biofuel production (Lorente et al., 2019), and food production (Nascimento et al., 2017).

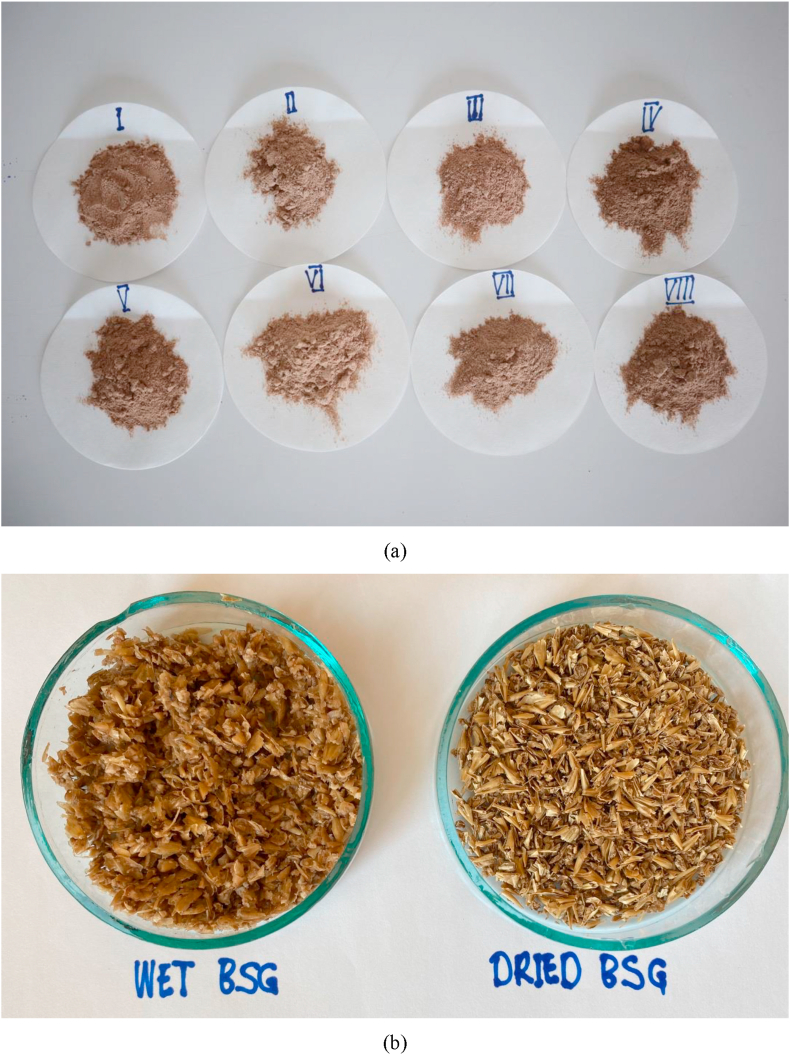

3.2. Color analysis

Color parameter values of the eight samples of spent grain are shown in Table 2. All color variables studied (L∗, a∗, and b∗) showed significant differences (p < 0.05) in most of the analyzed spent grain samples. L∗ describes the lightness from 0–100, a∗ describes redness (+) to greenness (-), and b∗ describes yellowness (+) to blueness (-). All the spent grain samples showed L∗ values varing from 58.436% to 63.732%, the a∗ value varied between 3.732 and 5.574, and the b∗ value ranged between 14.610 and 17.116. The physical appearances of the eight BSG samples are shown in Figure 2a in addition to the wet and dried BSG (Figure 2b).

Table 2.

Colour measurements of brewery spent grain and water (WHC) and oil (OHC) holding capacity of brewery spent grain (mean ± standard deviation value).

| Brewery spent grain | Color Value |

WHC (g/g) | OHC (g/g) | ||

|---|---|---|---|---|---|

| L∗ | a∗ | b∗ | |||

| I | 60.036 ± 0.021bc | 5.254 ± 0.006b | 16.984 ± 0.026a | 3.710 ± 0.164b | 1.916 ± 0.021d |

| II | 59.214 ± 0.082d | 3.732 ± 0.015f | 14.610 ± 0.053f | 3.055 ± 0.383c | 2.085 ± 0,023b |

| III | 60.390 ± 0.262b | 5.574 ± 0.060a | 16.974 ± 0.085ab | 3.986 ± 0.080ab | 2.127 ± 0.028b |

| IV | 58.436 ± 0.104f | 4.946 ± 0.035c | 15.908 ± 0.006c | 3.810 ± 0.306ab | 2.212 ± 0.006a |

| V | 60.110 ± 0.250b | 5.326 ± 0.029b | 17.116 ± 0.075a | 3.985 ± 0.062ab | 2.095 ± 0.023b |

| VI | 63.732 ± 0.040a | 4.566 ± 0.006d | 16.676 ± 0.098b | 3.761 ± 0.043b | 1.999 ± 0.043c |

| VII | 60.068 ± 0.130bc | 4.550 ± 0.006d | 15.404 ± 0.0150d | 4.111 ± 0.084ab | 2.219 ± 0.014a |

| VIII | 59.908 ± 0.129c | 4.420 ± 0.051e | 15.452 ± 0.066e | 4.346 ± 0.052a | 2.200 ± 0.018a |

Note: letters show the significant differences from other group in the same column (p < 0.05); (I: Foundation II German Pale Ale; II: Bojanowo; III: WB; IV: Onnevalemi Komonendid; V: Drunken soiler india pale ale, VI: Sto Mostow; VII: Fest; VIII: Elveliksiirid).

Figure 2.

Visual appearance of: a) eight different BSG (I: Foundation II German Pale Ale, II: Bojamowo, III: WB, IV: Onnevalemi Komonendid, V: Drunken soiler india pale ale, VI: Sto Mostow, VII: Fest, VIII: Elveliksiirid); b) representative of wet and dried BSG.

The color value of the byproducts is an important parameter for the evaluation of their ability to be utilized in specific products. Application of spent grain in food products and biopolymer generates a darker color. The level of impact on food products color can be explained by the color analysis L∗, a∗, and b∗ values. According to L∗ value from Table 2, BSG VI had the highest impact on the darker color and BSG IV had the highest impact on lightness color. Moreover, BSG III had the highest impact on redness while BSG II affected the level of green. The highest level of yellowness was produced by BSG V and the highest level of blueness was demonstrated by BSG II.

The valorization of spent grain in baked food products (Liu et al., 2011; Waters et al., 2012), such as cookies (Ajanaku et al., 2011; Heredia-Sandoval et al., 2020; Petrovic et al., 2017), in an excessive amount decreased the color acceptability. These data were important in order to characterize the level of addition of spent grain as a food ingredient. In the utilization of BSG as a food ingredient for pasta production, it was reported that pasta with b∗ values (yellowness) below 19 were considered to be low quality, with higher than 26 considered as a good color value (Nocente et al., 2019). The yellowness of the spent grain was very low for pasta production, but rose when applied as a food ingredient. However, in biopolymer composites, chemical methods could be applied in order to reduce the adverse effects of the color (López Durán et al., 2018).

3.3. Water-holding capacity (WHC) and oil-holding capacity (OHC)

WHC is the ability of the sample to bind the maximum amount of water after exposure, while OHC is the maximum capacity of the sample to trap the oil. The ability to bind water and oil is important when it comes to food applications, because they are related to mechanical and mouthfeel properties. Table 2 shows that there were some groups of spent grain which were not significantly different (p < 0.05) in terms of WHC as well OHC properties. The WHC level varied from 3.055 to 4.346 g/g, while the OHC ranged from 1.916 to 2.219 g/g. Compared to other reports, the WHC in this research was lower while the OHC was higher. It is reported WHC and OHC values of 5.07 g/g and 1.21 g/g, respectively were observed (Ktenioudaki et al., 2013b). These differences in WHC and OHC level impact the properties in food processing. Wheat byproducts have a WHC of 7.7 g/g and an OHC of 7.8 g/g (Sarfaraz et al., 2017), while pear byproducts have a WHC and an OHC 3.44 g/g and 1.82 g/g, respectively (Yan et al., 2019). However, the WHC and OHC of fiber can be modified by several treatments depending on the purposes. High-pressure treatment can increase the levels of WHC and OHC, while reducing particle size to superfine grinding can reduce WHC and OHC (Yan et al., 2019). The change in WHC might be due to the loosening of the dietary fiber structure, consequently exposing hydrophilic groups (Yan et al., 2019).

Interestingly, WHC (Table 2) was shown to be related to carbohydrate amount (Table 1). BSG VIII showed the highest WHC level and the lowest carbohydrate amount, while BSG II showed the lowest WHC value and the highest carbohydrate level. However, this pattern did not exist for all spent grains. This phenomenon supported the idea that the different sources of spent grain influence their properties. WHC represents the hydration properties of DF, which increases when added to food processing techniques (Benitez et al., 2019). Chemical treatment of DF enhances the water-holding capacity (López Durán et al., 2018). Hydration properties play an important role in reducing calories and modifying the viscosity and texture of formulated foods (Benitez et al., 2019). The increase in the water-holding capacity is beneficial for inhibiting syneresis and modifying viscosity and texture (Kieserling et al., 2019). WHC contributes to textural (hardness) properties of the utilization of byproducts as food ingredients (Park et al., 2015). It was observed that WHC was related to the impact of DF in changing food structure and their interactions in food matrices (Muneer et al., 2018).

The levels of WHC are connected to fat content, as depicted in Figure 4b. WHC is responsible for thickness and viscosity, while OHC is responsible for food stabilization, acting as a flavouring retainer and increasing mouthfeel (Benitez et al., 2019). Furthermore, the OHC of DF was observed to predict the ability to reduce loss during food processing, and it was noted that the amount of soluble dietary fiber played an important role in the amount of OHC (Yan et al., 2019). The ability of the spent grain to absorb water was contradictory to the free water contained, because it reduced the availability of the hydrophilic functional groups (Yan et al., 2019). BSG is a highly crosslinked material, thus impacting the release of polysaccharide components and, consequently, its physical properties (Robertson et al., 2010). Therefore, WHC and OHC are affected by the functional polysaccharide group, amino acids, and the fat content. This is probably related to the solubility of the protein. The ability of the spent grain to absorb oil was shown to be related to lipophilic compounds, such as fat, as well as amino acid contents, which bind to BSG fiber.

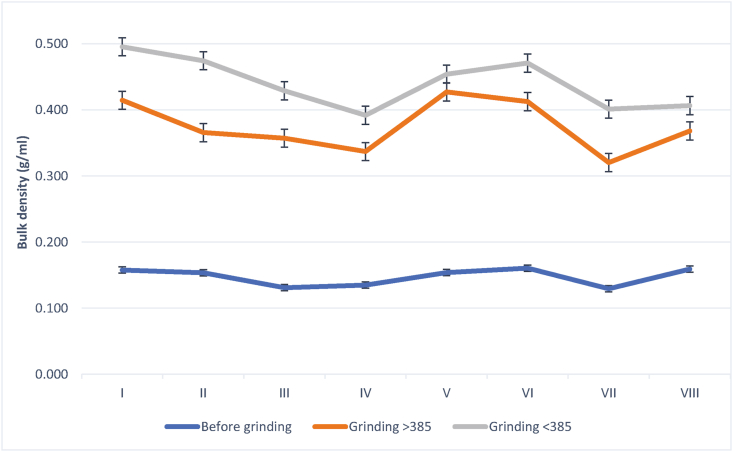

3.4. True density and bulk density

Statistical analysis on true density (Table 3) shows that only two out of the eight samples were significantly different (p < 0.05), with BSG II showing the highest (1.392 g/mL) and BSG III the lowest true density (1.318 g/mL). However, statistical analysis on bulk density (Table 3) showed significant difference (p < 0.05) between most of the spent grain samples. Furthermore, there was a significant difference (p < 0.05) between before grinding and after grinding (>385 μm and <385 μm). Interestingly, the true density of all the spent grain samples was discovered to be attributed to their carbohydrate levels (Figure 4c). The difference in true density and bulk density between the spent grain samples might show a significant difference in their mechanical properties, texture impact, and thermal stability, particularly because there is a correlation with the fiber composition.

Table 3.

Bulk density and true density of brewery spent grains (mean ± standard deviation value).

| Brewery spent grain | Bulk density (g/ml) |

True density (g/ml) | ||

|---|---|---|---|---|

| Before grinding | Grinding >385 | Grinding <385 | ||

| I | 0.158 ± 0.005i | 0.415 ± 0.007cd | 0.495 ± 0.012a | 1.378 ± 0.003ab |

| II | 0.154 ± 0.002ijk | 0.366 ± 0.003f | 0.474 ± 0.014ab | 1.392 ± 0.033a |

| III | 0.131 ± 0.007kl | 0.357 ± 0.004fg | 0.429 ± 0.008c | 1.335 ± 0.011ab |

| IV | 0.135 ± 0.001jkl | 0.337 ± 0.003gh | 0.392 ± 0.008e | 1.336 ± 0.003ab |

| V | 0.154 ± 0.008ij | 0.427 ± 0.010c | 0.454 ± 0.004b | 1.375 ± 0.005ab |

| VI | 0.161 ± 0.003i | 0.413 ± 0.005cde | 0.471 ± 0.012b | 1.372 ± 0.025ab |

| VII | 0.129 ± 0.004l | 0.320 ± 0.007h | 0.401 ± 0.010de | 1.331 ± 0.004ab |

| VIII | 0.159 ± 0.006i | 0.368 ± 0.009f | 0.406 ± 0.002cde | 1.318 ± 0.003b |

Note: letters show the significant differences from other group in the same column (p < 0.05); (I: Foundation II German Pale Ale; II: Bojanowo; III: WB; IV: Onnevalemi Komonendid; V: Drunken soiler india pale ale, VI: Sto Mostow; VII: Fest; VIII: Elveliksiirid).

The differences in bulk density regarding specific particle size are depicted in Figure 3. In general, the smaller particle size obtained the highest bulk density. Spent grains before grinding showed the lowest bulk density, ranging from 0.129 to 0.161 g/mL, followed by the spent grains after grinding >385 μm and <385 μm, ranging from 0.320 to 0.427 g/mL and 0.392–0.495 g/mL, respectively. The bulk density of BSG was lower compared to flaxseed and wheat flour, which were 0.58 and 0.63 g/mL, respectively (Kaur et al., 2017). Apparently, the spent grains in the same particle size demonstrated a significant difference (p < 0.05) in bulk density. Particle size variability of the spent grains might contribute to the amount of fiber composition (Angioloni and Collar, 2011). Furthermore, particle reduction increased the brightness of pulse flours (Zucco et al., 2011). Image analysis showed an intact appearance at a higher particle size, while cell disruption was observed at a lower particle size (Reis et al., 2015). In food products, it was observed that particle size impacted the volume expansion and texture of bread (Martínez et al., 2014). A lower particle size improved the specific volume, while a higher particle size decreased the specific volume and hardened the bread (Martínez et al., 2014).

Figure 3.

Bulk density in a different particle size of brewery spent grains (I: Foundation II German Pale Ale, II: Bojamowo, III: WB, IV: Onnevalemi Komonendid, V: Drunken soiler india pale ale, VI: Sto Mostow, VII: Fest, VIII: Elveliksiirid).

Bulk density could show the effects on quality during storage because of the amount of air between the spent grain particles, potentially leading to differences in water absorption and consequently affecting the spent grain quality during storage or transportation systems. Furthermore, the bulk density showed the voluminous level of the spent grain. The higher the bulk density, the smaller space needed to store the spent grain. The density profile is related to the ability to act as a bulking agent or filler in food matrices, as well as a sucrose replacer in order to maintain thinning behaviour (Bonarius et al., 2014).

As mentioned previously, several studies were related to each other in terms of trend linearity, as shown in Figure 4, such as water activity and moisture content (a), fat content and WHC (b), and carbohydrate amount with true density (c). BSG is mainly dominated by dietary fiber, including soluble and insoluble dietary fiber. Lower moisture content describes the availability of free water contained in BSG. BSG contains a high hydroxyl group, therefore, a lower MC increases the ability of BSG to bind to water (Aprodu et al., 2017; Magabane, 2017), consequently impacting the WHC. It was reported that the addition of BSG in breadmaking diminishes water availability and therefore intensifies solidity and reduces the tendency to flow (Ktenioudaki et al., 2013b).

The amount of carbohydrate positively related to the level of true density (Figure 4c). The study of BSG addition in food processing identified the increase in bulk density in extrusion processes (Sobukola et al., 2013) and cookie production (Okpala and Ofoedu, 2018). Since BSG carbohydrates are mainly composed of dietary fiber, this phenomenon might be influenced by dietary properties and its importance relative to the true density of BSG. Furthermore, closed and compact structure formation was investigated in food processing regarding the substitution of BSG (Ktenioudaki et al., 2013a), which is closely related to the density profile.

If the spent grain is applied as a food ingredient, protein, fat, and carbohydrate play important roles since they impact the composition as well as taste, flavour, texture, and mechanical properties (Ktenioudaki et al., 2013b; Nascimento et al., 2017; Żelaziński et al., 2018). Interactions between fat, protein, and carbohydrate during food processing can enhance volatile and nonvolatile compounds (Nigam, 2017). Therefore, when it comes to food application, adjustment of the spent grain is needed in order to produce the same quality. The circulated relation between those properties of BSG shows that the valorization of BSG can be proposed depending on the application. However, the utilisation of spent grain from different sources may need further study regarding their applications.

In general, all studied parameters were related to the fiber profiles of BSG because the fiber properties influenced the physical properties, chemical composition, and the expected products. It was observed that the impact of byproduct addition into food was mainly influenced by the fiber composition (Elleuch et al., 2011). Due to the fact that dietary fiber could be modified in order to achieve the desired quality for further utilization, it is suggested that fiber modification could be applied to BSG for valorization.

4. Conclusion

Brewery spent grain as a biowaste of beer production was studied for its selected properties. In this research, BSGs from different breweries were characterized by different properties profiles, such as proximate, water activity, hydration properties, and oil-holding capacity, as well as density profiles showing variability levels, as expected. These variabilities affected the valorization process as a food material or for biopolymer production. Noticeably, it was discovered that several properties of BSG demonstrated the same patterns. Mathematical modeling should be used to study the relationships between fiber composition, thermal stability, and mechanical properties in order to predict suitability of BSG with a valorization approach. In order to produce precise modeling, fiber modification treatment is proposed for combination. Pretreatment might be needed to generate different spent grains with similar properties.

Declarations

Author contribution statement

Joncer Naibaho: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Małgorzata Korzeniowska: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by UPWR 2.0, international and interdisciplinary programme of development of Wrocław University of Environmental and Life Sciences, co-financed by the European Social Fund under the Operational Programme Knowledge Education Development 2014–2020: Axis III Higher education for the economy and development; Action 3.5. Comprehensive programmes for schools of higher education (POWR.03.05.00–00-Z062/18). It was also supported by ERA-NET CO-FUND Horyzont 2020 - FACCE SURPLUS Sustainable and Resilient Agriculture for Food and Non-Food Systems. And PROWASTE Protein-fibre fibre biorefinery for scattered material streams (2019–2021).

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

Thank you to Professor Adam Figiel and team, Institute of Agriculture Engineering, WUELS for helping during the research.

References

- Ajanaku K.O., Dawodu F.A., Ajanaku C.O., Nwinyi O.C. Functional and nutritional properties of spent grain ENhanced cookies. Am. J. Food Technol. 2011;6(9):763–771. [Google Scholar]

- Amorim C., Silvério S.C., Rodrigues L.R. One-step process for producing prebiotic arabino-xylooligosaccharides from brewer’s spent grain employing Trichoderma species. Food Chem. 2019;270:86–94. doi: 10.1016/j.foodchem.2018.07.080. [DOI] [PubMed] [Google Scholar]

- Angioloni A., Collar C. Physicochemical and nutritional properties of reduced-caloric density high-fibre breads. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2011;44(3):747–758. [Google Scholar]

- Aprodu I., Simion A.B., Banu I. Valorisation of the brewers’ spent grain through sourdough bread making. Int. J. Food Eng. 2017;13(10) [Google Scholar]

- Balogun A.O., Sotoudehniakarani F., McDonald A.G. Thermo-kinetic, spectroscopic study of brewer’s spent grains and characterisation of their pyrolysis products. J. Anal. Appl. Pyrol. 2017;127:8–16. [Google Scholar]

- Barbosa-Pereira L., Bilbao A., Vilches P., Angulo I., LLuis J., Fité B., Paseiro-Losada P., Cruz J.M. Brewery waste as a potential source of phenolic compounds: optimisation of the extraction process and evaluation of antioxidant and antimicrobial activities. Food Chem. 2014;145:191–197. doi: 10.1016/j.foodchem.2013.08.033. [DOI] [PubMed] [Google Scholar]

- Bashir K., Swer T.L., Prakash K.S., Aggarwal M. Physico-chemical and functional properties of gamma irradiated whole wheat flour and starch. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2017;76:131–139. [Google Scholar]

- Benitez V., Rebollo-Hernanz M., Hernanz S., Chantres S., Aguilera Y., Martin-Cabrejas M.A. Coffee parchment as a new dietary fiber ingredient: functional and physiological characterization. Food Res. Int. 2019;122:105–113. doi: 10.1016/j.foodres.2019.04.002. 2. [DOI] [PubMed] [Google Scholar]

- Berthet M.-A., Angellier-Coussy H., Machado D., Hilliou L., Staebler A., Vicente A., Gontard N. Exploring the potentialities of using lignocellulosic fibres derived from three food by-products as constituents of biocomposites for food packaging. Ind. Crop. Prod. 2015;69:110–122. [Google Scholar]

- Bohnsack C., Ternes W., Büsing A., Drotleff A.M. Tocotrienol levels in sieving fraction extracts of brewer’s spent grain. Eur. Food Res. Technol. 2011;232(4):563–573. [Google Scholar]

- Bonarius G.A., Vieira J.B., van der Goot A.J., Bodnár I. Rheological behaviour of fibre-rich plant materials in fat-based food systems. Food Hydrocolloids. 2014;40:254–261. [Google Scholar]

- Calín-Sánchez Á., Lipan L., Cano-Lamadrid M., Kharaghani A., Masztalerz K., Carbonell-Barrachina Á.A., Figiel A. Comparison of traditional and novel drying techniques and its effect on quality of fruits, vegetables and aromatic herbs. Foods. 2020;9(9):1261. doi: 10.3390/foods9091261. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Čater M., Fanedl L., Malovrh Š., Marinšek Logar R. Biogas production from brewery spent grain enhanced by bioaugmentation with hydrolytic anaerobic bacteria. Bioresour. Technol. 2015;186:261–269. doi: 10.1016/j.biortech.2015.03.029. [DOI] [PubMed] [Google Scholar]

- Chu J., Zhao H., Lu Z., Lu F., Bie X., Zhang C. Improved physicochemical and functional properties of dietary fiber from millet bran fermented by Bacillus natto. Food Chem. 2019;294:79–86. doi: 10.1016/j.foodchem.2019.05.035. [DOI] [PubMed] [Google Scholar]

- Cian R.E., Garzón A.G., Martínez-Augustin O., Botto C.C., Drago S.R. Antithrombotic activity of brewers’ spent grain peptides and their effects on blood coagulation pathways. Plant Foods Hum. Nutr. 2018;73(3):241–246. doi: 10.1007/s11130-018-0682-1. [DOI] [PubMed] [Google Scholar]

- Coelho E., Rocha M.A.M., Saraiva J.A., Coimbra M.A. Microwave superheated water and dilute alkali extraction of brewers’ spent grain arabinoxylans and arabinoxylo-oligosaccharides. Carbohydr. Polym. 2014;99:415–422. doi: 10.1016/j.carbpol.2013.09.003. [DOI] [PubMed] [Google Scholar]

- Connolly A., O’Keeffe M.B., Piggott C.O., Nongonierma A.B., FitzGerald R.J. Generation and identification of angiotensin converting enzyme (ACE) inhibitory peptides from a brewers’ spent grain protein isolate. Food Chem. 2015;176:64–71. doi: 10.1016/j.foodchem.2014.12.027. [DOI] [PubMed] [Google Scholar]

- Connolly A., O’Keeffe M.B., Piggott C.O., Nongonierma A.B., FitzGerald R.J. Generation and identification of angiotensin converting enzyme (ACE) inhibitory peptides from a brewers’ spent grain protein isolate. Food Chem. 2015;176:64–71. doi: 10.1016/j.foodchem.2014.12.027. [DOI] [PubMed] [Google Scholar]

- Conway J. 2019 August 21. Global Beer Production 1998-2018. Alcohol Beverages.https://www.statista.com/statistics/270275/worldwide-beer-production/ [Google Scholar]

- del Río J.C., Prinsen P., Gutiérrez A. Chemical composition of lipids in brewer’s spent grain: a promising source of valuable phytochemicals. J. Cereal. Sci. 2013;58(2):248–254. [Google Scholar]

- Elleuch M., Bedigian D., Roiseux O., Besbes S., Blecker C., Attia H. Dietary fibre and fibre-rich by-products of food processing: characterisation, technological functionality and commercial applications: a review. Food Chem. 2011;124(2):411–421. [Google Scholar]

- Espino E., Cakir M., Domenek S., Román-Gutiérrez A.D., Belgacem N., Bras J. Isolation and characterization of cellulose nanocrystals from industrial by-products of Agave tequilana and barley. Ind. Crop. Prod. 2014;62:552–559. [Google Scholar]

- Fărcaş A.C., Socaci S.A., Dulf F.V., Tofană M., Mudura E., Diaconeasa Z. Volatile profile, fatty acids composition and total phenolics content of brewers’ spent grain by-product with potential use in the development of new functional foods. J. Cereal. Sci. 2015;64:34–42. [Google Scholar]

- Fu Q.Y., Yu X.C., Li L., Liu G.Q., Li B. Antioxidant activities of soluble dietary fiber extracted from brewers’ spent grain. Adv. Mater. Res. 2011;233–235:2824–2827. [Google Scholar]

- Garcia-Garcia G., Stone J., Rahimifard S. Opportunities for waste valorisation in the food industry e A case study with four UK food manufacturers. J. Clean. Prod. 2019;211:1339–1356. [Google Scholar]

- Gil-López D.I.L., Lois-Correa J.A., Sánchez-Pardo M.E., Domínguez-Crespo M.A., Torres-Huerta A.M., Rodríguez-Salazar A.E., Orta-Guzmán V.N. Production of dietary fibers from sugarcane bagasse and sugarcane tops using microwave-assisted alkaline treatments. Ind. Crop. Prod. 2019;135:159–169. doi: 10.1016/j.dib.2019.104026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Heredia-Sandoval N.G., Granados-Nevárez M. del C., Calderón de la Barca A.M., Vásquez-Lara F., Malunga L.N., Apea-Bah F.B., Beta T., Islas-Rubio A.R. Phenolic acids, antioxidant capacity, and estimated glycemic index of cookies added with brewer’s spent grain. Plant Foods Hum. Nutr. 2020;75(1):41–47. doi: 10.1007/s11130-019-00783-1. [DOI] [PubMed] [Google Scholar]

- Ho T.M., Chan S., Yago A.J.E., Shravya R., Bhandari B.R., Bansal N. Changes in physicochemical properties of spray-dried camel milk powder over accelerated storage. Food Chem. 2019;295:224–233. doi: 10.1016/j.foodchem.2019.05.122. [DOI] [PubMed] [Google Scholar]

- Kaur M., Singh V., Kaur R. Effect of partial replacement of wheat flour with varying levels of flaxseed flour on physicochemical, antioxidant and sensory characteristics of cookies. Bioact. Carbohydr. Diet. Fibre. 2017;9:14–20. [Google Scholar]

- Kieserling K., Vu T.M., Drusch S., Schalow S. Impact of pectin-rich orange fibre on gel characteristics and sensory properties in lactic acid fermented yoghurt. Food Hydrocolloids. 2019;94:152–163. [Google Scholar]

- Ktenioudaki A., Crofton E., Scannell A.G.M., Hannon J.A., Kilcawley K.N., Gallagher E. Sensory properties and aromatic composition of baked snacks containing brewer’s spent grain. J. Cereal. Sci. 2013;57(3):384–390. [Google Scholar]

- Ktenioudaki A., O’Shea N., Gallagher E. Rheological properties of wheat dough supplemented with functional by-products of food processing: brewer’s spent grain and apple pomace. J. Food Eng. 2013;116(2):362–368. [Google Scholar]

- Kurnik K., Krzyżyński M., Treder K., Tretyn A., Tyburski J. Study on utilizing solid food industry waste with brewers’ spent grain and potato pulp as possible peroxidase sources. J. Food Biochem. 2018;42(1) [Google Scholar]

- Lee S.Y., Hur S.J. Antihypertensive peptides from animal products, marine organisms, and plants. Food Chem. 2017;228:506–517. doi: 10.1016/j.foodchem.2017.02.039. [DOI] [PubMed] [Google Scholar]

- Li S., Chen G., Qiang S., Tang D., Chen Y., Zhang Z., Lei Z., Chen Y. Intensifying soluble dietary fiber production and properties of soybean curd residue via autoclaving treatment. Bioresou. Techn. Rep. 2019;7:100203. [Google Scholar]

- Liu S.X., Singh M., Inglett G. Effect of incorporation of distillers’ dried grain with solubles (DDGS) on quality of cornbread. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2011;44(3):713–718. [Google Scholar]

- López Durán V., Larsson P.A., Wågberg L. Chemical modification of cellulose-rich fibres to clarify the influence of the chemical structure on the physical and mechanical properties of cellulose fibres and thereof made sheets. Carbohydr. Polym. 2018;182:1–7. doi: 10.1016/j.carbpol.2017.11.006. [DOI] [PubMed] [Google Scholar]

- Lorente A., Remón J., Budarin V.L., Sánchez-Verdú P., Moreno A., Clark J.H. Analysis and optimisation of a novel “bio-brewery” approach: production of bio-fuels and bio-chemicals by microwave-assisted, hydrothermal liquefaction of brewers’ spent grains. Energy Convers. Manag. 2019;185:410–430. [Google Scholar]

- Magabane I.E. University of Pretoria; 2017. Technologies for Improving the Quality of Bread Doughs Made with Barley Spent Grain and Sorghum.https://repository.up.ac.za/handle/2263/65907 [Google Scholar]

- Martínez M.M., Díaz Á., Gómez M. Effect of different microstructural features of soluble and insoluble fibres on gluten-free dough rheology and bread-making. J. Food Eng. 2014;142:49–56. [Google Scholar]

- McCarthy A.L., O’Callaghan Y.C., Neugart S., Piggott C.O., Connolly A., Jansen M.A.K., Krumbein A., Schreiner M., FitzGerald R.J., O’Brien N.M. The hydroxycinnamic acid content of barley and brewers’ spent grain (BSG) and the potential to incorporate phenolic extracts of BSG as antioxidants into fruit beverages. Food Chem. 2013;141(3):2567–2574. doi: 10.1016/j.foodchem.2013.05.048. [DOI] [PubMed] [Google Scholar]

- Meneses N.G.T., Martins S., Teixeira J.A., Mussatto S.I. Influence of extraction solvents on the recovery of antioxidant phenolic compounds from brewer’s spent grains. Separ. Purif. Technol. 2013;108:152–158. [Google Scholar]

- Moreira M.M., Morais S., Carvalho D.O., Barros A.A., Delerue-Matos C., Guido Luís.F. Brewer’s spent grain from different types of malt: evaluation of the antioxidant activity and identification of the major phenolic compounds. Food Res. Int. 2013;54(1):382–388. [Google Scholar]

- Muneer F., Johansson E., Hedenqvist M.S., Plivelic T.S., Markedal K.E., Petersen I.L., Sørensen J.C., Kuktaite R. The impact of newly produced protein and dietary fiber rich fractions of yellow pea (Pisum sativum L.) on the structure and mechanical properties of pasta-like sheets. Food Res. Int. 2018;106:607–618. doi: 10.1016/j.foodres.2018.01.020. [DOI] [PubMed] [Google Scholar]

- Nascimento T.A., Calado V., Carvalho C.W.P. Effect of Brewer’s spent grain and temperature on physical properties of expanded extrudates from rice. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2017;79:145–151. [Google Scholar]

- Niemi P., Martins D., Buchert J., Faulds C.B. Pre-hydrolysis with carbohydrases facilitates the release of protein from brewer’s spent grain. Bioresour. Technol. 2013;136:529–534. doi: 10.1016/j.biortech.2013.03.076. [DOI] [PubMed] [Google Scholar]

- Nigam P.S. An overview: recycling of solid barley waste generated as a by-product in distillery and brewery. Waste Manag. 2017;62:255–261. doi: 10.1016/j.wasman.2017.02.018. [DOI] [PubMed] [Google Scholar]

- Nocente F., Taddei F., Galassi E., Gazza L. Upcycling of brewers’ spent grain by production of dry pasta with higher nutritional potential. Lebensm. Wiss. Technol. 2019;114:108421. [Google Scholar]

- Okpala L.C., Ofoedu P.I. Quality characteristics of cookies produced from sweet potato and wheat flour blend fortified with brewer’s spent grain flour. Curr. Res. Nutr. Food Sci. J. 2018;6(1):113–119. [Google Scholar]

- Parekh I., Khanvilkar A., Naik A. Barley-wheat brewers’ spent grain: a potential source of antioxidant rich lipids. J. Food Process. Preserv. 2017;41(6) [Google Scholar]

- Park J., Choi I., Kim Y. Cookies formulated from fresh okara using starch, soy flour and hydroxypropyl methylcellulose have high quality and nutritional value. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2015;63(1):660–666. [Google Scholar]

- Patel A., Mikes F., Bühler S., Matsakas L. Valorization of brewers’ spent grain for the production of lipids by oleaginous yeast. Molecules. 2018;23(12):3052. doi: 10.3390/molecules23123052. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Patrignani M., González-Forte L., del S. Characterisation of melanoidins derived from Brewers’ spent grain: new insights into their structure and antioxidant activity. Int. J. Food Sci. Technol. 2020:14653. ijfs. [Google Scholar]

- Petrovic J., Pajin B., Tanackov-Kocic S., Pejin J., Fistes A., Bojanic N., Loncarevic I. Quality properties of cookies supplemented with fresh brewer’s spent grain. Food Feed Res. 2017;44(1):57–63. [Google Scholar]

- Qin F., Johansen A.Z., Mussatto S.I. Evaluation of different pretreatment strategies for protein extraction from brewer’s spent grains. Ind. Crop. Prod. 2018;125:443–453. [Google Scholar]

- Ravindran R., Jaiswal S., Abu-Ghannam N., Jaiswal A.K. A comparative analysis of pretreatment strategies on the properties and hydrolysis of brewers’ spent grain. Bioresour. Technol. 2018;248:272–279. doi: 10.1016/j.biortech.2017.06.039. [DOI] [PubMed] [Google Scholar]

- Reis S.F., Coelho E., Coimbra M.A., Abu-Ghannam N. Improved efficiency of brewer’s spent grain arabinoxylans by ultrasound-assisted extraction. Ultrason. Sonochem. 2015;24:155–164. doi: 10.1016/j.ultsonch.2014.10.010. [DOI] [PubMed] [Google Scholar]

- Ribau Teixeira M., Guarda E.C., Freitas E.B., Galinha C.F., Duque A.F., Reis M.A.M. Valorization of raw brewers’ spent grain through the production of volatile fatty acids. N. Biotech. 2020;57:4–10. doi: 10.1016/j.nbt.2020.01.007. [DOI] [PubMed] [Google Scholar]

- Robertson J.A., I’Anson K.J.A., Treimo J., Faulds C.B., Brocklehurst T.F., Eijsink V.G.H., Waldron K.W. Profiling brewers’ spent grain for composition and microbial ecology at the site of production. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2010;43(6):890–896. [Google Scholar]

- Santos M., Jiménez J.J., Bartolomé B., Gómez-Cordovés C., del Nozal M.J. Variability of brewer’s spent grain within a brewery. Food Chem. 2003;80(1):17–21. [Google Scholar]

- Sarfaraz A., Azizi M.H., Ahmadi Gavlighi H., Barzegar M. Physicochemical and functional characterization of wheat milling co-products: fine grinding to achieve high fiber antioxidant-rich fractions. J. Cereal. Sci. 2017;77:228–234. [Google Scholar]

- Sobukola O.P., Babajide J.M., Ogunsade O. Effect of brewers spent grain addition and extrusion parameters on some properties of extruded yam starch-based pasta: effect of BSG on yam starch-based pasta. J. Food Process. Preserv. 2013;37(5):734–743. [Google Scholar]

- Socaci S.A., Fărcaş A.C., Diaconeasa Z.M., Vodnar D.C., Rusu B., Tofană M. Influence of the extraction solvent on phenolic content, antioxidant, antimicrobial and antimutagenic activities of brewers’ spent grain. J. Cereal. Sci. 2018;80:180–187. [Google Scholar]

- Stojceska V., Ainsworth P. The effect of different enzymes on the quality of high-fibre enriched brewer’s spent grain breads. Food Chem. 2008;110(4):865–872. doi: 10.1016/j.foodchem.2008.02.074. [DOI] [PubMed] [Google Scholar]

- Vieira E., Teixeira J., Ferreira I.M.P.L.V.O. Valorization of brewers’ spent grain and spent yeast through protein hydrolysates with antioxidant properties. Eur. Food Res. Technol. 2016;242(11):1975–1984. [Google Scholar]

- Waters D.M., Jacob F., Titze J., Arendt E.K., Zannini E. Fibre, protein and mineral fortification of wheat bread through milled and fermented brewer’s spent grain enrichment. Eur. Food Res. Technol. 2012;235(5):767–778. [Google Scholar]

- Yan L., Li T., Liu C., Zheng L. Effects of high hydrostatic pressure and superfine grinding treatment on physicochemical/functional properties of pear pomace and chemical composition of its soluble dietary fibre. Lebensm. Wiss. Technol. 2019;107:171–177. [Google Scholar]

- Żelaziński T., Ekielski A., Siwek A., Durczak K. Vol. 15. 2018. By-products from Brewery Industry as the Attractive Additives to the Extruded Cereals Food. [Google Scholar]

- Zielke C., Teixeira C., Ding H., Cui S., Nyman M., Nilsson L. Analysis of β-glucan molar mass from barley malt and brewer’s spent grain with asymmetric flow field-flow fractionation (AF4) and their association to proteins. Carbohydr. Polym. 2017;157:541–549. doi: 10.1016/j.carbpol.2016.10.045. [DOI] [PubMed] [Google Scholar]

- Zucco F., Borsuk Y., Arntfield S.D. Physical and nutritional evaluation of wheat cookies supplemented with pulse flours of different particle sizes. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2011;44(10):2070–2076. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.