Abstract

Total Worker Health™ (TWH) interventions for improved employee safety, health and wellbeing depend on integrated approaches that involve changes to the workplace or work organisation as well as behavioural or lifestyle changes made by workers. Intervention Design and Analysis Scorecard (IDEAS) Tool to engage front-line employees in planning TWH interventions and obtaining needed management support. The IDEAS Tool consists of seven planning steps in a scorecard approach that helps front-line employees systematically examine root causes of health/safety problems/issues and develop intervention alternatives. A comprehensive business case is then developed for each proposed intervention through analysis of costs/benefits, resources and barriers, and scope of impact. A case study is presented in which maintenance technicians at a property management firm used the IDEAS Tool to plan and successfully implement multiple interventions to reduce work overload. A participatory systems taxonomy is used to help explain why such a structured approach to intervention planning is needed to create a sustainable program for the continuous improvement of employee safety, health and wellbeing for TWH.

Keywords: participatory ergonomics, workplace safety and health, workplace health promotion, prevention and sustainability, business case, Total Worker Health, TWH

1. Introduction

The most disabling workplace injuries and illnesses in 2008 amounted to more than $53.4 billion in direct US workers compensation costs, averaging more than a billion dollars per week (2010 Workplace Safety Index). These costs highlight the need for sustainable and effective programs to protect and promote worker safety, health and wellbeing. Conventional workplace safety and health programs with a top-down management approach are limited in their effectiveness, appear to be short lived, and are not well integrated into organisational cultures (e.g., Punnett et al., 2009; NIOSH, 2015; Marcus et al., 1998).

Therefore, a primary research-to-practice focus by researchers in the Center for the Promotion of Health in the New England Workplace (CPH-NEW) has been to develop a way to fully engage front-line employees and managerial/supervisory personnel in the collaborative, iterative design of workplace interventions. Our novel approach expands the participatory ergonomics (PE) process to encompass integrated safety and health promotion (HP) interventions consistent with the principles of Total Worker Health™ (TWH) (NIOSH TWH, 2015) in order to improve employees’ safety, health and wellbeing.

This paper describes the development of the Intervention Design and Analysis Scorecard (IDEAS), a Tool that is specifically designed to support collaborative, participatory planning efforts for TWH interventions, along with findings from a case study where the IDEAS Tool was used. Also described are a set of start-up tools for establishing a Healthy and Safe Workplace Participatory Program (HWPP, http://www.uml.edu/cphnewtoolkit) that supports regular use of the IDEAS process for continuous improvement. Further, we introduce a participatory taxonomy based on findings from this case study, the literature, and our other field studies showing why the progressive implementation of participatory ergonomics elements in a more structured manner is needed to create a fully sustainable program for the continuous improvement of employee safety, health and wellbeing. The role of a multilevel steering committee in a HWPP is also described.

2. Development of a PExHP approach

We refer to the ‘bottom-up’ approach that actively engages employees in using participatory ergonomics to design workplace interventions to address safety, health and wellbeing as PExHP (Henning and Reeves, 2013; Henning et al., 2009; Kuorinka, 1997). Engaging front-line employees in this central role of designing interventions can benefit intervention effectiveness because it fully utilises the expertise and understanding front-line workers have of their own work processes. A bottom-up approach also increases front-line employees’ sense of ownership over any resulting intervention, which can greatly contribute to intervention implementation and sustainability. True participatory approaches also invite management and supervisory personnel into an ongoing – and somewhat unconventional – process of collaborative intervention design with front-line employees. Teams of employees, supported by a multilevel steering committee, are involved in the decision-making, problem-solving actions, and even the evaluation of these interventions; all of which appear to be necessary for the success and sustainability of a functioning program (Henning and Reeves, 2013; Henning et al., 2009; Fielding, 1984; Brown, 2002).

We had originally developed and field-tested an approach to intervention planning that was modelled after best practices in participatory ergonomics programs (Haims and Carayon, 1998; Haines et al., 2002; Henning and Reeves, 2013; Henning et al., 2009). In conventional participatory ergonomics programs small ‘design teams’ of front-line employees plan and design ergonomic interventions, usually with the help of an ergonomics professional or trained facilitator. Throughout the design process, a steering committee of management and supervisory personnel acts as a sounding board and provides company-level knowledge to help select the best interventions developed through the participatory design process. Our novel approach at that time was to develop a program structure that would support continuous engagement of front-line employees in participatory ergonomics design efforts that are focused exclusively on designing interventions to promote employee safety, health and wellbeing.

Instances of front-line employees taking a lead role in proposing workplace interventions, as opposed to only being brought in to provide secondary support or serve in a consulting role commonly found in management-led safety and health initiatives, is already common practice in the total quality management programs upon which many organisations have grown to depend. A key element of these total quality management programs is the ‘quality circle’, consisting of a small team of front-line employees who regularly engage in planning system interventions to improve process or product quality. Similarly, a key element in a HWPP is that front-line employees regularly engage in the PExHP planning process facilitated by a health and safety professional, with the overall goal being the continuous improvement of employee safety, health and wellbeing.

Early attempts to use the PExHP approach for planning interventions revealed the need to bring much more structure to the planning process (Henning and Reeves, 2013). Design teams tended to rush through the seven conventional intervention planning steps, resulting in intervention proposals that were not fully developed nor carefully thought through in terms of root causes of the problem at hand, the resource costs of the proposed intervention, nor its scope of impact. In addition, in the event that the program steering committee rejected a design team’s intervention proposal, design team members perceived the rejection as a sign that the program was no longer supported by upper management, and/or that management did not consider the health/safety problem/concern being addressed sufficiently important. In general, any time the steering committee rejected a proposal it was demoralising to design team members, and this made it much harder for the program facilitator to engage the design team members in further intervention planning efforts to address either the same or a new safety/health problem/concern.

3. Development of the IDEAS Tool

As a way to increase the quality of intervention proposals developed by a design team, as well as the likelihood that a steering committee would support these proposals, CPH-NEW developed a more structured approach to intervention planning, the IDEAS.

The IDEAS Tool supports a process of modelling alternative solutions, an approach that was originally developed for use by system analysts and public policy decision makers (Thompson, 1980; Warfield, 1971, 1977). The IDEAS Tool is closely framed after an intervention planning process developed for use by professional macroergonomists, as described in a case study by Robertson and Courtney (2004), and is built on the previous work of Robertson and Rahimi (1990). The IDEAS Tool is designed to be facilitated by a trained facilitator without a background in either ergonomics or health promotion. Use of the IDEAS Tool fulfils four key scientific and programmatic needs:

to address the multiple contributing and root causes of health/safety problems/issues

to provide interventions that balance changes to work organisation and the workplace with employee behavioural and lifestyle improvements and adjustments

to propose more than one intervention option for the steering committee to consider for any specific health/safety problem/concern that has been identified

to develop intervention proposals based in business decision making practices that consider return-on-investment metrics (Robertson, 2005; Robertson et al., 2002) in addition to other metrics deemed important by the organisation.

During the development of the IDEAS Tool, the HWPP facilitator in the present case study reviewed the associated group processes and objectives for each of the seven planning steps with CPH-NEW researchers as they prepared for design team meetings. The facilitator also reported back during bi-weekly project meetings what had occurred during these meetings, including the successes and challenges of each step in the intervention design process. The facilitator also suggested ways to improve clarity and effectiveness of the seven-step planning tool, leading to its further refinement. Through these iterative design efforts, a step-by-step guide was created for each IDEAS planning step for use by a program facilitator, and also worksheets to record and track the decisions and choices made in each planning step. Information captured on these worksheets can be used when explaining the basis of a proposed intervention to the steering committee.

When the IDEAS Tool is used to guide the design team in developing an internal business case for each proposed intervention idea, this is consistent with the best practices organisations use to consider any new initiative (Robertson et al., 2013; Henning et al., 2009). The business case, as it is used here, is not limited to estimating the return-on-investment in purely financial terms (Robertson and Rahimi, 1990). Rather, the IDEAS Tool is used to provide guidance to the design team on how to develop an internal business case that will eventually be reviewed by the management-led steering committee. In the process of building this internal business case, employees are asked to consider worksite-specific key performance indicators (KPIs) of each of their intervention IDEAS, such as the number and types of employees who are likely to benefit from this intervention (scope), as well as any potential obstacles/barriers to implementing this intervention, including personnel time or material costs. The IDEAS Tool not only facilitates development of a business case for each intervention idea, it also supports making systematic comparisons of competing intervention IDEAS through use of a scorecard (Robertson et al., 2013; Henning et al., 2009). Once a design team has successfully completed at least one complete intervention planning cycle, it has acquired skills that will support collaboration on interventions that are initiated by themselves or by the steering committee. Thus, a well-implemented HWPP can involve all levels of employees in the participatory design of workplace interventions for TWH.

Supporting a design team’s efforts in developing business cases for interventions one workplace intervention at a time offers a number of strategic benefits to an organisation (Henning et al., 2013). The IDEAS Tool allows an integrated health promotion and protection program to be established without requiring a large up-front commitment of resources to a limited set of top-down initiatives that may or may not be effective. The context-specific approach to intervention planning also does not risk attempts to duplicate interventions that were successful in other organisational contexts but which may not be successful in the present organisational context. This grass roots approach to intervention design takes into account known differences in employee demographics, physical infrastructure, workplace culture, leadership style, regional norms, and so forth that may impact intervention effectiveness. Components of interventions that are successful elsewhere can still be adopted but only after these are determined within the IDEAS Tool planning process to be a good fit for the organisation. For leaders of organisations as well as safety and health professionals who must decide how best to invest organisational resources, employing a grass-roots approach can provide several distinct advantages over more conventional top-down approaches. These include:

A structured design process that allows front-line employees to assume a lead role in identifying and prioritising important health and safety problems/issues. In this way, front-line employees become enthusiastic partners in collaborative planning efforts with management.

Employees are usually the most knowledgeable about the complex interactions between physical design factors in their workplace and how their work is organised (Smith, 2001, 2002). This job expertise is critically important at the very earliest stages of intervention planning when the root causes of a health or safety problem/concern are being considered, and when solution activities for these problems or issues are being explored. Employees are also able to factor lifestyle and other behavioural influences into solution activities that go beyond the immediate workplace, in keeping with TWH principles.

Front-line employees are often able to identify potential unanticipated consequences of an intervention idea, allowing rejection of IDEAS that have a high probability of failure (Van Eerd et al., 2010).

A collaborative and iterative intervention design and refinement process results in more solid ‘buy-in’ from all parties – a necessary prerequisite for a sustainable health and safety improvement program (Haims and Carayon, 1998). In general, the substantive involvement of employees in the earliest stages of intervention planning can be considered the key to developing interventions that are well received (Van Eerd et al., 2010). Employees who become actively involved at the very beginning of intervention planning tend to develop a sense of ownership of these same interventions, a hallmark of participatory initiatives (Haims and Carayon, 1998). Furthermore, employees become committed to making these interventions successful, and this ‘buy-in’ translates into help with evaluation and any needed iterative design changes or modifications (Haines et al., 2002). In parallel, program steering committee involvement in the later stages of this participatory process also serves to build management commitment and engagement (Henning et al., 2009).

4. Field test of the IDEAS: IDEAS Tool

The IDEAS Tool was tested at a property management and realty company which had agreed to implement a HWPP. This family owned company employed 60 full-time maintenance and landscape workers (mean age = 41 yrs). A trained health professional and member of the research team served as the program facilitator for intervention planning, outlining program communication announcements involving senior management, and facilitating collaboration between the design team and steering committee.

CPH-NEW offers a Toolkit to assist with start-up and day-to-day operations of a HWPP which consists of a condensed suite of organisational assessment instruments and program implementation protocols and tools including an All-Employee Health and Work Environment Survey and a set of companion step-by-step guides to assist the program facilitator when establishing a steering committee and a design team, and when using the IDEAS Tool. Start-up organisational assessment instruments are used to accomplish multiple goals:

to identify salient health/safety problems/issues as a starting point for issue prioritisation

to target initial training of the design team on ergonomic, safety and health promotion principles in order to better prepare them for initial intervention planning and design efforts

to measure aspects of organisational readiness for participatory planning and design

to establish baseline measures used to track the safety and health impact of the program.

These organisational assessment instruments are designed for ease of use and have high construct and surface validity, and produce a record of choices and decisions made at each step that is easy to interpret by members of the host organisation (please see http://www.uml.edu/cphnewtoolkit for program start-up tools, the IDEAS Tool and associated worksheets and accompanying Quick Reference Guides).

The key feature of the IDEAS Tool is the use of a scorecard approach to develop, evaluate and refine intervention IDEAS. This is accomplished through practical choices made early in the intervention planning process when a wide range of intervention alternatives are first being considered. Importantly, this structured process brings to the design team’s attention a given intervention’s costs, barriers, resources, benefits and scope of impact, making it possible to develop a comprehensive internal business case for each intervention proposal. Making these internal and context-specific business cases results in intervention proposals that the program steering committee and upper management are much more likely to support.

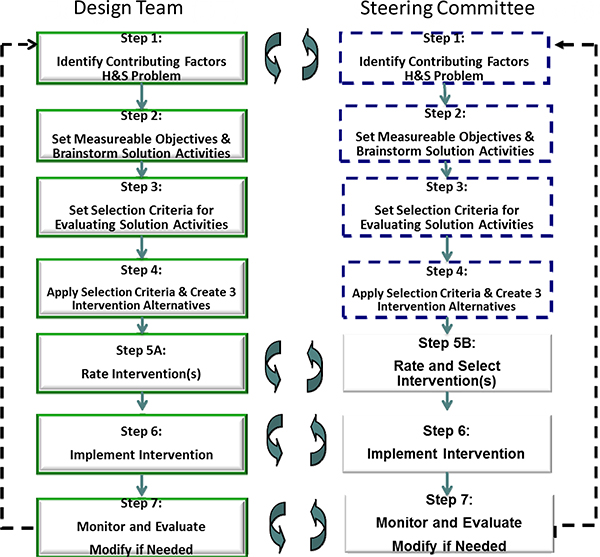

Illustrated in Figure 1 are the seven steps of the IDEAS Tool planning process as well as indicators for where in the process collaboration normally occurs between the design team and steering committee. The solid-lined boxes show Steps 1–4 in which the design team independently identifies a health and safety problem/concern and then initiates and completes the intervention planning process. Steps 5B–7 show the main steering committee activities where sets of intervention proposals are received from the design team, and decisions are made whether to reject or approve proposals. The roles of the steering committee are to provide the design team with constructive feedback about the proposals, and to provide any needed resources for both implementing and evaluating interventions, sometimes enlisting the assistance of the design team in these activities. Each of the IDEAS Tool planning steps are described below along with intermediate process outcomes from the case study.

Figure 1.

Flow chart depicting the IDEAS planning process and where collaboration normally occurs between the employee design team and program steering committee

Establishing a HWPP at the property management company first involved forming employee design teams with a representative group of seven maintenance technicians and landscapers who could meet on a regular basis. A steering committee was formed consisting of four members representing the Departments of Human Resources, Maintenance, and Property Management. As part of their orientation and training provided by the program facilitator, empirical and qualitative data about health and safety problems or issues at their workplace, gathered during the program start-up process, were shared with the design and steering committee team members.

At the first design team meeting, the members prioritised these identified health and safety problems or issues in order to focus their initial intervention design efforts. After a health and safety issue or concern was selected as the primary focus, the facilitator guided the employee design team through an intervention planning process that began with identifying root causes of the issue or concern, and ended with a prepared set of intervention proposals that were submitted to a program steering committee. The program steering committee ultimately decided which interventions to support, which to revise in collaboration with the employee design team, and which to outright reject.

Step 1

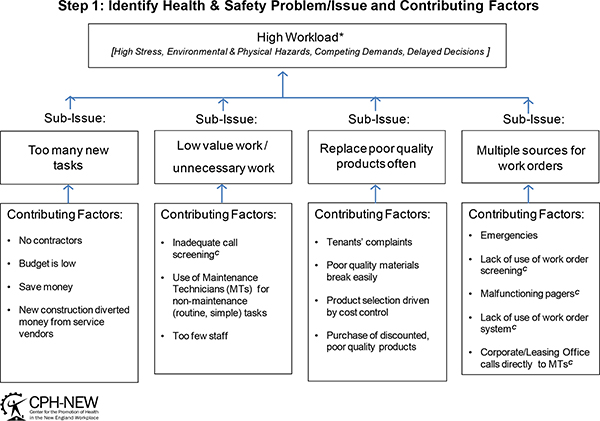

Once the design team selected a health and safety problem/concern to focus on the facilitator engaged the design team in a systems analysis process to breakdown the problem/concern into sub-issues. Next, the design team worked to identify the multiple factors that contribute to each sub-issue. The worksheet in Figure 2 shows the results of the design team’s effort in determining how the contributing factors (bottom boxes on figure), led to the sub-issues and then ultimately to the identified major problem/concern. This hierarchical ‘problem factor tree’ (Figure 2) is organised to depict the flow of the contributing factors and sub-issues to the major problem as indicated by the directional arrows. Completing Step 1 required an iterative process where the design team met several times to continually refine what the multiple sub-issues were until the design team was satisfied with having identified all potential contributing factors. Figure 2 shows the efforts of the design team as they identified five problems/issues, ranked them, and then selected the problem/concern of ‘high workload’ to address.

Figure 2.

This worksheet shows the wide range of contributing factors the design team identified as contributing to high workload

Notes: *Health and safety emergent themes from the focus groups/interviews/work environment survey. High workload issue was rated as the top priority concern to address by the Design Team. ‘C’ indicates communication-related issue–members of the design team identified many of the contributing factors as communication related.

Step 2

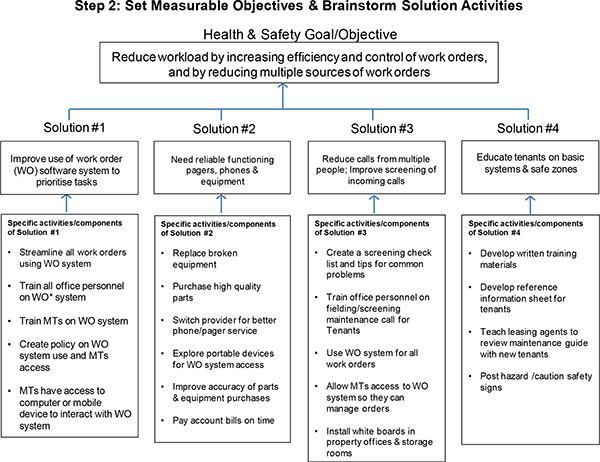

The facilitator then worked with the design team to develop an objectives/activities tree (with measurable objectives and supporting activities) that addressed the problem/issue and sub-issues identified in Step 1. The worksheet in Figure 3 illustrates the results of the design team effort in creating a tree where each column of activities would lead to the accomplishment of one of the sub-objectives, which in combination would ultimately accomplish the major objective and goal of the proposed intervention. The facilitator guided the design team in a brainstorming effort to generate as many activities as possible until it is agreed that most of the important contributing factors identified in Step 1 had been addressed. In creating these activities, a balanced mix of both ergonomic, safety and health promotion themes and activities are represented. By doing so, health and safety is supported at the organisational, job, and personal/behavioural levels which are designed to complement one another to help maximise the impact and sustainability of the interventions, consistent with TWH principles.

Figure 3.

Objectives/activities tree depicting measurable objectives and associated set of solution activities: to reduce workload by increasing efficiency and control of work orders and by reducing multiple sources of work orders

Note: *Work order (WO) software system is used for scheduling/assigning work tasks.

Step 3

Design team members created a mutually agreed upon set of KPIs to be considered as the criteria to evaluate any of the interventions that would address the problem/issues and sub-issues identified in Step 1, Figure 2. These KPIs were later used to evaluate each set of intervention activities in Step 4. KPIs were generated in four categories:

scope of project

short-term/long-term benefits/effectiveness

obstacles/barriers

resources/costs.

These criteria allowed the design team to consider important trade-offs among the various set of activities being considered for an intervention alternative. The resulting KPIs the design team created for evaluating each of the intervention alternatives are displayed in Table 1.

Table 1.

Set selection criteria for evaluating solution activities and interventions

| Scope/impact | Benefts/effectiveness | Resources/costs | Obstacles/barriers |

|---|---|---|---|

| (Who will benefit from the intervention) Office personnel Maintenance office Tenants All maintenance technicians (MTs) |

Increased job satisfaction/morale – long term Increased maintenance quality and resident satisfaction – short term Increase in teamwork and collaboration – short term Increased productivity – short term Decreased stress and frustration – long term Improved communication – short term |

Materials, equipment, service fees, etc. Consultant/trainers Translation fees Production downtime to implement solutions |

Time for training Time for other office and corporate involvement Resistance to change– personnel and tenants Getting approval from property and corporate managers Fears about tenants’ reactions |

Step 4

The design team used the KPIs developed in Step 3 to review and compare the intervention activities under consideration. The goal of this step is to combine the most viable activities into at a minimum of three intervention alternatives for further development and eventual presentation to the program steering committee. A critical outcome of this process is to create multiple intervention alternatives that can be presented to the steering committee to increase the likelihood that at least one of the intervention alternatives will be supported. For example, the set of alternatives may have different costs associated with them and also differ in terms of short-term and long-term health and safety benefits. Having at least three to four viable intervention alternatives also allows the steering committee the flexibility of considering a new subset of activities that the design team had not considered, and increases the likelihood that an intervention in some form will be supported. Table 2 shows the four viable intervention alternatives the design team created, each with a potential to reduce workload by increasing efficiency and control of work orders, or by reducing multiple sources of work orders.

Table 2.

KPIs were applied as selection criteria to solution activities, resulting is the creation of four intervention alternatives

| Solution activities | Scope/impact | Benefits/outcomes | Resources | Obstacles |

|---|---|---|---|---|

| Improve the use of WO system to prioritise tasks | Streamline work orders to avoid confusion, stress, duplication. Create checklist for office to screen calls. |

Increase in efficiency, organisation, satisfaction, time-response, communication, proactive behaviour, reliability. Less unnecessary work and lost time; better prepared when arrive to fix problem; less frustration, less stress caused by time management. Better communication; resolve resident issues more quickly. |

Set up workstations for maintenance workers; time needed to train maintenance and office personnel on WO system; use of guidelines; inform tenants of call procedures; train office personnel. Train office personnel on how to field it maintenance calls from tenants. Design team – time to create guidelines and screening checklist; train office personnel. Office personnel – time to assist tenants; more effort to screen calls completely |

Resistance to change Time for other offices and corporate involvement Getting approval form property and corporate manager Time for training |

| Need reliable functioning pagers, phones and equipment | Help order supplies for storage room; help locate MT by order on a daily basis | Better communication; organised way to order supplies; improve work flow; make completion of orders more expedient. Office staff know where you are you are. | Funds needed to purchase boards; multiple boards per site Time: very little – coordinate purchasing (supervisor orders it); installation (MT can do it) installation (MT can do it) |

Resistance to change Time for other offices and corporate involvement |

| Reduce calls from multiple people and improve screening of incoming calls | Improve communication. | Save money on contract; improved signal strength; less dropped/missed calls; less frustration; faster service provided; better response from maintenance for residents. | Lunds and staff time – new plans, phones and accessories. May be low priority for decision- makers; needs VP/mgt. review and approval. | Getting approval from property and corporate manager |

| Educate tenants on basic systems and safe zones | Instruct residents on what/how to do in light of a problem; indicate what’s (not) emergency. Increase level of communication with tenants. |

Maintenance – reduce time spent on simple tasks so more time to work on complex orders; more organised; less stress; faster problem-solution for tenants. Less stress for maintenance and office–can work safely and uninterrupted. Avoided injuries for tenants. |

Time for Design Team and office staff to write instructions; time and effort to train leasing agents on common problems to discuss with tenants; print and distribute material; money for translation. Safety and property committee effort to discuss and approve; money to buy signs; time to put up signs. |

Time for training Pears about tenants’ reactions Resistance to change – personnel Resistance to change – tenants |

Step 5A

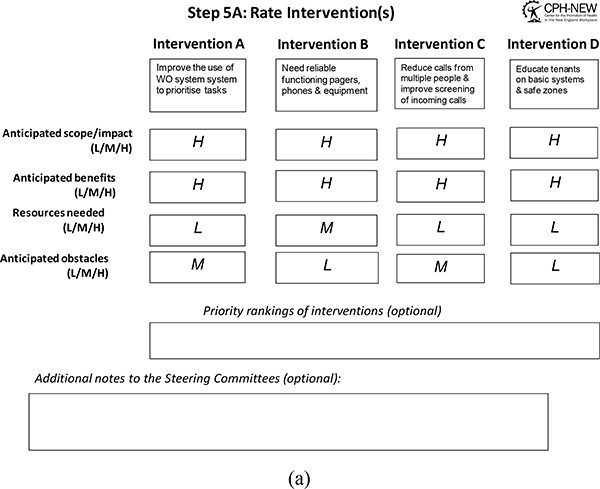

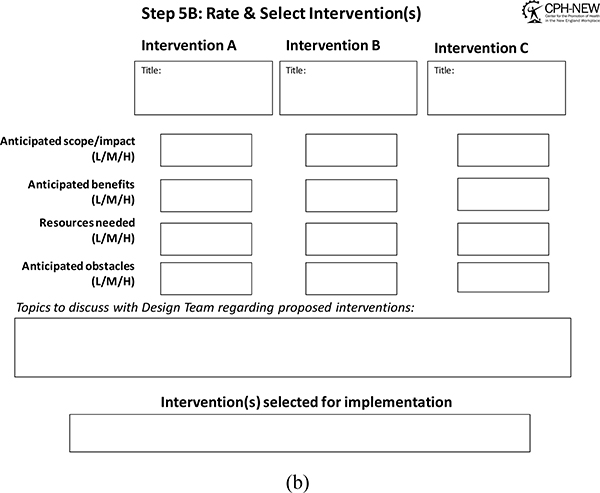

The design team then rated the set of proposed intervention alternatives designed to benefit employee health and safety on a scorecard. The worksheet listed each of the intervention alternatives created, and the design team rated each of them according to the KPIs identified in Step 3. As presented in Figure 4(a), the four intervention alternatives (A–D) were rated using either ‘low, moderate, or high’ to designate the extent that the KPIs would be met.

Figure 4.

(a) Scorecard for design team to rate intervention(s) and to support steering committee review of a set of four intervention alternatives (A–D) (b) Scorecard for steering committee to rate a set of intervention alternatives and select intervention(s)

Step 5B

The steering committee reviewed the intervention alternatives proposed by the design team, and later held an additional three-hour meeting to discuss the proposals in depth. The steering committee provided helpful feedback, and began the process of determining how to implement selected interventions. Further, the steering committee created a new intervention from others (A and D), and proceeded to plan financial support of this intervention. Several months later, as the design and steering committee continued to meet, they targeted the other two proposed interventions for implementation as well, and collaborated on a fourth intervention to address the physical hazard of overheating due to poor uniform design. For illustrative purpose, Figure 4(b) shows how this worksheet and the information captured in this scorecard can provide the basis for an organised presentation of the entire planning process and the many trade-off choices that are made over the course of the planning effort.

Step 6

After the combined intervention was selected by the steering committee, a schedule of activities for successful implementation of the intervention was developed. With the guidance of the facilitator, the steering committee can use this IDEAS Tool checklist to consider KPIs identified from Step 3 for generating a list of key considerations prior to developing an implementation schedule. However, this organisation used its own internal planning and scheduling tool to complete this step.

Step 7

The final step involved monitoring and evaluating the implemented intervention and making modifications as needed. A collection of process and outcome measures is necessary to provide an early indication as to the effectiveness of an intervention and measure the impact of the intervention. As indicated in Figure 1, it is likely that there will need to be some adaptation of the intervention when it is being implemented. An iterative cycle for refining interventions is considered essential to any continuous improvement process, and this was the case in our field testing. The steering committee worked with the proposed design team intervention alternatives and created a combined solution and set of activities to accomplish the proposed objective of decreasing workload. Furthermore, given this high level of engagement during this iterative design and implementation process, a continuous learning and sustainable process was evident by the fact that the design and steering committee continued to propose and implement other interventions, such as improving design of their work uniforms to reduce the physical health hazard of overheating.

5. Evaluation of the HWPP

Shown in Table 3 are the design team and steering committee member responses to open-ended questions asked by the facilitator four months following the implementation of selected interventions. Overall, members of both the design team and steering committee responded favourably regarding the usefulness and effectiveness of the IDEAS Tool and the HWPP. Both groups also stated that having an impartial outside facilitator was beneficial.

Table 3.

Qualitative assessments of the IDEAS process

| Responses | Design team focus group | Manager interviews |

|---|---|---|

| Benefits: usefulness and effectiveness | • Useful forum for venting issues • Tool for making workplace improvements • Empowerment: make change happen • Management more aware of employee issues • Improved worker/management communication • Design Team members engaged and invested in program • Felt proud, valued and respected • Learned new IDEAS and problem-solving skills • Improved awareness of health and safety |

• Good solutions to problems • Management more aware of employee issues • Improved worker/management communication • Personal development of Design Team members • Pride and feelings of accomplishment for Design Team • Improved problem-solving and communication skills for Design Team • Important feedback role for steering committee • Impartiality of the outside facilitator |

| Challenges | • Process takes too long • No direct communication between Design Team and Steering Committee • Other employees must take on additional work |

• Process takes too long • Planning tool not helpful to Steering Committee |

As noted in Table 3, design team members felt that the IDEAS process was a useful forum for venting issues, and that it provided them with an opportunity to suggest improvements to their workplace. Moreover, there was a high collective sense among design team members that workplace change did occur as a result of their efforts, and that it was solution driven. The interaction that occurred among and between the members of the design team and steering committee not only improved communication, it also increased management awareness of the maintenance technicians’ problems/issues, and ability to collaborate effectively on workplace change efforts. Personal development of the design team members was also noted. They appeared to become better problem solvers who were more effective at communicating, and showed a higher sense of pride and accomplishment. Thus, there were a number of indications that members of the design team were very engaged and invested in using the IDEAS Tool and being part of the HWPP.

Steering committee members indicated that the intervention planning process and tools were indeed effective approaches to problem solving. They had become invested in the process as well, as shown by how the steering committee created a new intervention alternative that was made up of a combination of the intervention alternatives originally proposed by the design team. This investment was further demonstrated by their assistance in planning and executing the interventions. Also, steering committee members noted that they had become more aware of employees’ workplace issues and felt that the communication with their employees had generally improved. They also recognised the importance of their role in the HWPP of providing realistic feedback to the design team regarding any proposed interventions. The steering committee expressed a desire to see the program continue as long as there were problems/issues for the design team to work on. These comments were further supported by subsequent organisational changes that occurred, including an increase in maintenance headcount at one location, changes in the work order process and policies, e-mail accounts that were established for all technicians, and funding was being requested for a new facilitator to continue the program after the field site testing was concluded.

Several challenges to the IDEAS planning process were noted by members of both the design team and steering committee. One was that some members of the design team had to take on additional work in order to be able to participate in the program. Another was that the planning process for an intervention was too time consuming. It can be noted that it is fairly common for organisations to resist committing employee work time for any new type of program, especially one in which workers function autonomously for part of the time. While the substantial and continuous benefits of these participatory design efforts outweigh the perceived negative drain on employee time, these benefits need to be openly demonstrated, with regular feedback to the senior decision makers to help justify this time investment, and also via general communications throughout the organisation.

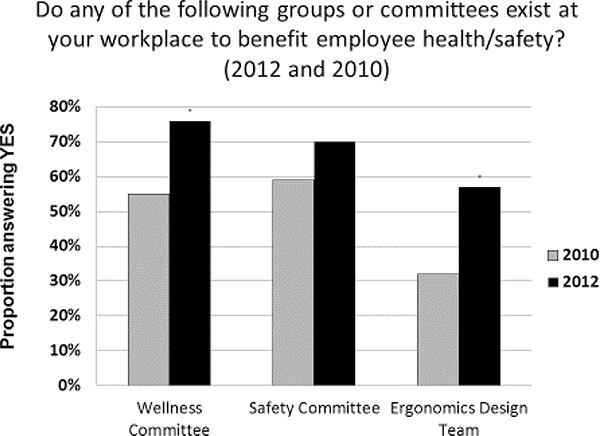

Illustrated in Figure 5 are responses from the field site workers regarding their awareness of existing safety and health initiatives in their organisation, sampled at two different periods, prior to (Time 1) and after (Time 2) establishing the HWPP. Significant changes occurred in their levels of awareness concerning the existence of the wellness committee and the (ergonomics) design team, suggesting that, overall, employees were becoming more aware of their company’s efforts to promote employee safety and health.

Figure 5.

Percentage of employees who were aware of worksite health and safety initiatives in 2010 and 2012 (after participatory ergonomics intervention)

Note: *p < .05

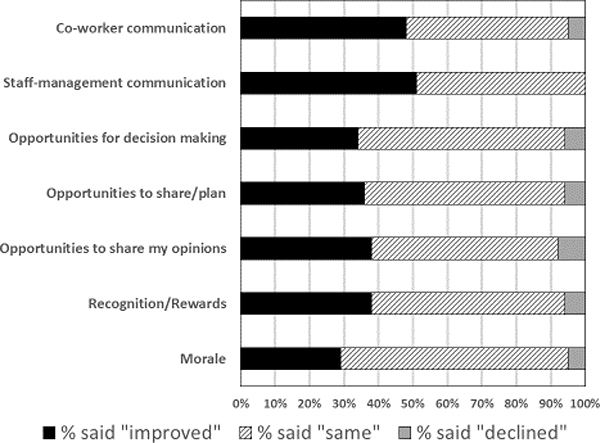

Employees at the participating worksite responded to seven questions about their perception of climate changes at their company after the implementation of the HHWP. Figure 6 shows the percentage of employee’s responses that noted whether their company’s climate had improved, stayed the same, or declined. Over 50% of the workers indicated that the communication between the staff and management had improved. Furthermore, over 35% responded that improvements in the number of opportunities to meet, plan, share their opinions, and to participate in the decision making process all had improved, suggesting the beneficial influence of a HWPP on employees perceived organisational climate.

Figure 6.

Percentage of employees who reported improvements, no change, or declines in company climate following the participatory ergonomics effort

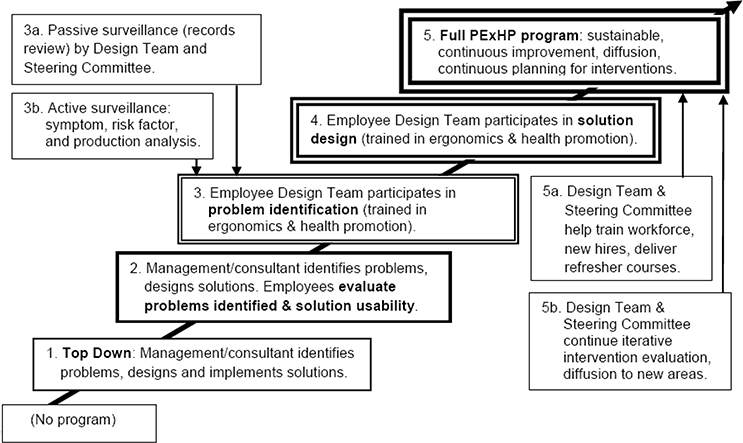

6. The IDEAS process within a hierarchical PExHP model

The structured participatory design process supported by the IDEAS Tool and the collaboration that develops between the design team and steering committee can be conceptualised within a taxonomy of participation in relation to the PExHP design process. A hierarchical taxonomy was created to show how successive program additions of employee participation would, when substituted for traditional top-down aspects of safety and health programs, contribute to a sustainable HWPP as advocated by CPH-NEW.

7. Potential uses for the IDEAS Tool

As noted above, the IDEAS Tool approach, which systematically integrates problem identification and solution development as an organised and balanced process for TWH, could be used to move a management-defined initiative through the very beginnings of a collaborative, participatory process, with attendant improvements in any resulting interventions.

Although not included in testing to date, active involvement of a design team in problem identification would naturally go beyond a qualitative assessment of health and safety problem areas. Design team members could be trained to analyse some administrative data collected by their organisation (frequencies of medical visits, OSHA first reports and recordables, etc.) – the passive surveillance of Box 3a. With appropriate training, members of a design team can help develop and administer surveys targeted to health and safety problem areas, and also carry out workstation evaluations – the active surveillance of Box 3b. To be acceptable, these surveillance activities would usually require active participation of the program steering committee. Incorporated into the IDEAS Tool, these activities would generate quantitative data to enhance problem identification and give weight to subsequent intervention proposals and the selection of the best intervention alternatives.

Figure 7.

Proposed hierarchical framework showing progressive implementation of PE elements to create a sustainable PExHP program

Note: Boxes with double outline depict elements currently tested with IDEAS Tool.

Source: Henning et al. (2009)

For an organisation to successfully advance to a higher level of participatory practice, training is a vital component of building competence and readiness at each level of this hierarchy. Boxes in the model in which we have field tested the IDEAS Tool (3 and 4) are shown with a double outline.

Box 1 Starting from the lower left (least participatory) region of the diagram in Figure 7, it is obvious that the top-down definition of problems and intervention activities, either by well-meaning management or expert consultants, is the antithesis of a true participatory program. This approach suffers from the list of problems noted earlier, resulting in interventions that, in most cases, function sub-optimally and may even have effects opposite in direction to those intended.

Box 2 While driven by top-down elements of problem identification and solution development, this box represents the opportunity for companies to first begin using a participatory design process. Employees are invited to give feedback on both the problems that management thinks are important and the solutions proposed by management. This is the secondary support role referred to above. Depending on the openness of management to rethinking both domains in light of employee suggestions, this process can ideally lead to management/employee agreement on what is wrong and how to fix it, or what needs attention and how to address it. Note that openness to this collaboration could easily move the program in the participatory direction, towards Boxes 3 and 4. Our testing did not use the IDEAS Tool in this situation, but its potential use at this level as a starting point is described below.

Box 3 At this increased level of participation, employees have primary responsibility for identifying and prioritising health problems in the workplace and clarifying their root causes. The Healthy and Safe Workplace Participatory Toolkit offers a number of tools to help identify and prioritise health/safety problems/issues, such as the All-Employee Survey. The IDEAS Tool, with its structured approach to seeking the root causes of a health/safety problem/concern once identified, has proved to be quite successful in helping employee design teams generate a succinct description of contributing factors and potential intervention points. While a program steering committee may be able to lend useful perspectives on problem definition and root causes analysis at this level, the full power of the collaborative, participatory process is usually seen in the design team working independently to combine problem identification with solution development efforts first, as represented in Box 4.

Box 4 In practice, once the employee design team is involved in problem identification (Box 3), the IDEAS Tool provides a mechanism for using this information to create sets of solution activities that become intervention alternatives. This is combined with the scorecard analysis of cost/benefit, range of effect, and promoters/barriers for each intervention alternative. The results are shared with the program steering committee, supporting further discussions and decisions on intervention selection by the steering committee. Collaboration between the design team and program steering committee is crucial at this stage. Again, the IDEAS Tool has been successfully tested in this function.

- Diffusion: One organisation had several satellite operations that were not fully involved in the PExHP program. The design team worked to afford more participation in intervention planning by employees in these operations.

- Sustainability: Efforts are underway to integrate participatory design activities within several existing groups within the organisation, including a safety committee and a conventional health promotion committee, which would embed PExHP initiatives in standing committees and initiatives already supported by the organisation.

- Upper management design: At another field site, Kaizen methods are being merged with IDEAS Tool activities to determine if this will promote more effective collaboration in organisations with a high degree of vertical differentiation in their organisational structure.

Many of the activities are dependent on other aspects of program development (delivering training to other employees and new hires, Box 5a). But the iterative processes of intervention evaluation and improvement as well as diffusion to new areas in the organisation (Box 5b) could all make use of the IDEAS Tool approach.

8. Discussion and conclusions

We proposed an integrated systems approach for engaging employees in a workplace safety and health protection and promotion program that expands the focus of PE programs to include iterative design of workplace interventions to address the full range of safety and health issues identified and prioritised by workers. A HWPP can complement other ongoing safety and health initiatives with the potential for synergistic beneficial effects on worker safety, health and wellbeing. The IDEAS Tool has proved effective in the two central boxes of the revised conceptual and hierarchical model. Employees were able to develop and gain management support for integrated interventions. We propose that use of the IDEAS planning process can be applied in both directions along the central axis, both downward (to transform top-down initiatives into collaborative activities) and upwards (in order to make the program more sustainable and diffusible).

The IDEAS Tool can be used effectively by front-line employees to plan integrated interventions in a program dedicated to continuous improvement of employee health protection/promotion, safety and TWH. The field test of the IDEAS Tool at the property management company led to several proposed interventions. A productive collaboration between the design team and steering committee emerged as discussions and feedback regarding adaptations to the proposed interventions occurred. Also, the steering committee was able to identify the additional costs of implementation-specific interventions that the design team had yet considered. Experience from the field test site indicated that results of this planning process provided a site-specific internal business case, which was well received from the steering committee, and this can be contrasted with a generic business case for successful interventions elsewhere that is often drawn from very different organisational contexts. These results provide evidence demonstrating that the use of the IDEAS Tool by an employee design team can generate integrated health and safety promotion/protection interventions that can be supported by management.

The participatory ergonomics, grass-roots intervention planning approach offered by the IDEAS Tool provides a number of strategic business benefits to companies. Applying the IDEAS Tool allows TWH to be fully realised within an integrated safety and health protection and health promotion program. Moreover, this process and resulting intervention solutions may occur without a large up-front commitment of resources. The IDEAS Tool incorporates organisational culture and practices, along with norms that are known to influence and affect intervention effectiveness. Additionally, the IDEAS Tool allows for adoption of other intervention models and approaches as the IDEAS process may benefit from incorporating evidence-based approaches from elsewhere, and adapting them so that they are consistent with the present organisational context and processes (e.g., Ipsen et al., 2015). Thus, evidence suggests that for programs that have proper training, resources, oversight, and tracking controls in place, organisational learning will occur (Haims and Carayon, 1998) to further support the safety and health protection and promotion activities, contributing to overall effectiveness and long-term sustainability of a HWPP for Total Worker Health™.

Supplementary Material

Acknowledgements and disclaimer

The Center for the Promotion of Health in the New England Workplace is supported by Grant No. 1 U19 OH008857 from the National Institute for Occupational Safety and Health. The contents of this book chapter are solely the responsibility of the authors, and do not necessarily represent the official views of NIOSH. We wish to acknowledge Diana Tubbs for technical editing.

Biographical notes:

Michelle M. Robertson is a Research Scientist in Human Factors/Ergonomics, Center of Behavioural Sciences, at the Liberty Mutual Research Institute for Safety. She is a board certified Professional Ergonomist and received her PhD in Instructional Technology, MS in Systems Management, from the University of Southern California and her BA in Human Factors from the University of California at Santa Barbara. She conducts applied field and laboratory research projects in human factors/ergonomics and management. She was on the faculty in human factors and management at the Institute of Safety and Systems Management, University of Southern California, for 12 years. She has published over 85 articles in human factors/ergonomics/safety and has presented her work nationally and internationally. She is a Fellow of the Human Factors & Ergonomics Society and the International Ergonomics Association. She was a co-Principal on the Healthy Worksite Participatory Program ToolKit project.

Robert A. Henning is an Associate Professor of Industrial/Organisational Psychology at the University of Connecticut. He received degrees from the University of Wisconsin-Madison in Psychology (BS), Biomedical Engineering (MS), and Industrial Engineering (PhD), and received post-doctoral training at the National Institute for Occupational Safety and Health (NIOSH). He is a board-certified Professional Ergonomist and an investigator in the Center for the Promotion of Health in the New England Workplace. He specialises in research on the social psychophysiology of teamwork and participatory ergonomics. He served as the President of Psychophysiology in Ergonomics (PIE), a technical group of the International Ergonomics Association, and helped found the Society for Occupational Health Psychology. He has co-directed a NIOSH-supported graduate training program in occupational health psychology since 2005. He was the Principal Investigator on the Healthy Worksite Participatory Program ToolKit project.

Nicholas Warren is an Associate Professor in the Division of Occupational and Environmental Medicine at UCHC, Ergonomics Coordinator for the Ergonomic Technology Center of Connecticut based in UCHC, founding faculty in the PhD program in Public Health (UCHC and Storrs), and collaborating faculty in the Occupational Health Psychology Program based in Storrs. He was a co-Principal on the Healthy Worksite Participatory Program ToolKit project.

Suzanne Nobrega is the Outreach Director at the Center for the Promotion of Health in the New England Workplace (CPH-NEW) at the University of Massachusetts Lowell. She oversees the Healthy and Safe@Work translational research project aimed at promoting dissemination and implementation of participatory, Total Worker Health programs in the workplace. As the Project Director, she coordinated development and testing of the CPH-NEW Healthy Worksite Participatory Program ToolKit. Other CPH-NEW work included the Stress@Workproject to train health professionals on job stress interventions for cardiovascular disease prevention. In prior years, she was the Program Manager, Trainer and Developer of community-based disease prevention programs. She ran an independent consulting business providing services in evaluation, curriculum development, and health communications writing services. She has completed graduate courses in work environment and healthy work organisation design, and received her Master’s in Nutritional Science from Cornell University.

Megan Dove-Steinkamp is a PhD student in Industrial-Organisational Psychology at the University of Connecticut. She is currently completing her dissertation research focused on resilience in the armed services.

Lize Tibiriçá is an internationally certified life coach who holds a BA in Psychology and a Masters in Occupational Safety and Ergonomics. Through coaching and training, she assists her clients in reaching their goals. Her passion for employees’ health and wellbeing has helped her develop a program that focuses on getting people to live their vision of a healthy lifestyle.

Andrea Bizarro is a doctoral student in industrial/organisational psychology at the University of Connecticut and is a NIOSH fellowship training grant in Occupational Health Psychology. She also does contract work for the Culture and Engagement team at PepsiCo. Her work and research focus on harnessing employee engagement as a critical resource for organisations looking to improve organisational performance through a focus on employee wellbeing. She is also interested in researching and developing work environments and work processes designed to support individual wellbeing as well as employee resilience to organisational stressors.

Contributor Information

Michelle M. Robertson, Center for Behavioral Sciences, Liberty Mutual Research Institute for Safety, 71 Frankland Road, Hopkinton, MA 01748, USA Center for the Promotion of Health in the New England Workplace (CPH-NEW), University of Connecticut, Storrs, CT, USA; University of Massachusetts Lowell, Lowell, MA, USA.

Robert A. Henning, Department of Psychological Sciences, University of Connecticut, 406 Babbidge Road, Unit 1020, Storrs, CT 06269-1020, USA Center for the Promotion of Health in the New England Workplace (CPH-NEW), University of Connecticut, Storrs, CT, USA; University of Massachusetts Lowell, Lowell, MA, USA.

Nicholas Warren, Center for Promotion of Health in the New England Workplace (CPH-NEW), University of Connecticut Health Center, 263 Farmington Avenue, Farmington, CT 06030-8077, USA; Center for the Promotion of Health in the New England Workplace (CPH-NEW), University of Connecticut, Storrs, CT, USA; University of Massachusetts Lowell, Lowell, MA, USA.

Suzanne Nobrega, Center for Promotion of Health in the New England Workplace (CPH-NEW), University of Massachusetts Lowell, One University Avenue, 200 Kitson Hall, Lowell, MA 01854, USA; Center for the Promotion of Health in the New England Workplace (CPH-NEW), University of Connecticut, Storrs, CT, USA; University of Massachusetts Lowell, Lowell, MA, USA.

Megan Dove-Steinkamp, Department of Psychological Sciences, University of Connecticut, 406 Babbidge Road, Unit 1020, Storrs, CT 06269-1020, USA; Center for the Promotion of Health in the New England Workplace (CPH-NEW), University of Connecticut, Storrs, CT, USA; University of Massachusetts Lowell, Lowell, MA, USA.

Lize Tibiriçá, Center for Promotion of Health in the New England Workplace (CPH-NEW), University of Massachusetts Lowell, One University Avenue, 200 Kitson Hall, Lowell, MA 01854, USA; Center for the Promotion of Health in the New England Workplace (CPH-NEW), University of Connecticut, Storrs, CT, USA; University of Massachusetts Lowell, Lowell, MA, USA.

Andrea Bizarro, Department of Psychological Sciences, University of Connecticut, 406 Babbidge Road, Unit 1020, Storrs, CT 06269-1020, USA; Center for the Promotion of Health in the New England Workplace (CPH-NEW), University of Connecticut, Storrs, CT, USA; University of Massachusetts Lowell, Lowell, MA, USA.

References

- Brown O Jr. (2002) ‘Macroergonomic methods: participation’, in Hendrick HW and Kleiner BM (Eds.): Macroergonomics: Theory, Methods, and Applications, pp.25–44, Lawrence Erlbaum Associates, Mahwah (NJ). [Google Scholar]

- Fielding JE (1984) ‘Health promotion and disease prevention at the worksite’, Ann. Rev. Public Health, Vol. 5, No. 1, pp.237–265. [DOI] [PubMed] [Google Scholar]

- Haims MC and Carayon P (1998) ‘Theory and practice for the implementation of ‘in-house’, continuous improvement participatory ergonomic programs’, Applied Ergonomics, Vol. 29, No. 6, pp.461–472. [DOI] [PubMed] [Google Scholar]

- Haines M, Wilson JR, Vink P and Koningsveld E (2002) ‘Validating a framework for participatory ergonomics (the PEF)’, Ergonomics, Vol. 45, No.4, pp.309–327. [DOI] [PubMed] [Google Scholar]

- Henning R, Robertson M and Punnett L (2013) ‘Making the business case for integrated worksite health promotion/protection interventions, one intervention at a time’, in Merchant JA, Hall JL and Howard J (2012) Total Worker Health™ Symposium: Safe, Healthy, Cost-Effective Solutions, Journal of Occupational and Environmental Medicine, American College of Occupational and Environmental Medicine, Vol. 55, Suppl. 12S, No. 12, pp.S1–S7. [Google Scholar]

- Henning RA and Reeves DW (2013) ‘An integrated health protection/promotion program supporting participatory ergonomics and salutogenic approaches in the design of workplace interventions’, in Bauer G and Jenny G (Eds.): Salutogenic Organizations and Change: The Concepts Behind Organizational Health Intervention Research, pp.307–325, Springer, The Netherlands. [Google Scholar]

- Henning RA, Warren ND, Robertson M, Faghri P, Cherniack M and CPH-NEW Research Team (2009) ‘Workplace health protection and promotion through participatory ergonomics: an integrated approach’, Public Health Reports, Vol. 124, Suppl. 1, pp.26–35. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ipsen C, Gish L and Poulsen S (2015) ‘Organizational-level interventions in small and medium-sized enterprises: enabling and inhibiting factors in the PoWRS program’, Safety Science, Vol. 71, pp.264–274. [Google Scholar]

- Kuorinka I (1997) ‘Tools and means of implementing participatory ergonomics’, International Journal of Industrial Ergonomics, Vol. 19, No. 4, pp.267–270. [Google Scholar]

- Marcus BH, Emmons KM, Simkin-Silverman LR, Linnan LA, Taylor ER, Bock BC et al. (1998) ‘Evaluation of motivationally tailored vs. standard self-help physical activity interventions at the workplace’, Am. J. Health Promot, Vol. 12, No. 4, pp.246–253. [DOI] [PubMed] [Google Scholar]

- NIOSH (2015) Total Worker Health™ Program [online] http://www.cdc.gov/niosh/twh/ (accessed 09/01/15).

- NIOSH TWH (2015) Center for the Promotion of Health in the New England Workplace [online] http://www.uml.edu/Research/centers/CPH-NEW/ (accessed 07/01/15).

- Punnett L, Cherniack M, Henning R, Morse T, Faghri P and CPH-NEW Research Team. (2009) ‘A conceptual framework for integrating workplace health promotion and occupational ergonomics programs’, Public Health Reports, Vol. 124, Suppl. 1, pp.16–25. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Robertson M, Henning R, Warren N, Nobrega S, Dove-Steinkamp M, Tibirica L and Bizarro A (2013) ‘The intervention design and analysis scorecard’, Journal of Occupational and Environmental Medicine, Vol. 55, No. 12, Suppl. 12S, pp.S86–S88. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Robertson MM (2005) ‘Systems analysis tool (SAT)’, in Stanton N, Hedge A, Brookhuis K, Salas E and Hendrick H (Eds.): Handbook of Human Factors and Ergonomics Methods, pp.88–1–88–7, CRC Press, Boca Raton (FL). [Google Scholar]

- Robertson MM and Courtney TK (2004) ‘A systems analysis approach to solving office work system health and performance problems’, Theoretical Issues in Ergonomics Science, Vol. 5, No. 3, pp.181–197. [Google Scholar]

- Robertson MM and Rahimi M (1990) ‘A systems analysis for implementing video display terminals’, IEEE Transactions on Engineering Management, Vol. 37, No. 1, pp.55–61. [Google Scholar]

- Robertson MM, Kleiner BM and O’Neill MJ (2002) ‘Macroergonomic methods: assessing work system processes’, in Hendrick HW and Kleiner BM (Eds.): Macroergonomics: Theory, Methods, and Applications, pp.67–96, Lawrence Erlbaum Associates, Mahwah (NJ). [Google Scholar]

- Smith EA (2001) ‘The role of tacit and explicit knowledge in the workplace’, Journal of Knowledge Management, Vol. 5, No. 4, pp.311–321. [Google Scholar]

- Smith TJ (2002) ‘Macroergonomic of hazard management’, in Hendrick HW and Kleiner BM (Eds.): Macroergonomics: Theory, Methods, and Applications, pp.199–221, Lawrence Erlbaum Associates, Mahwah (NJ). [Google Scholar]

- Thompson MS (1980) Benefit-Cost Analysis for Program Evaluation, pp.2–21, Sage Publications, London. [Google Scholar]

- Van Eerd D, Cole D, Irvin E, Mahood Q, Keown K, Theberge N, Village J, Vincent M St. and Cullen K (2010) ‘Process and implementation of participatory ergonomic interventions: a systematic review’, Ergonomics, Vol. 53, No. 10, pp.1153–1166. [DOI] [PubMed] [Google Scholar]

- Warfield JN (1971) ‘Toward interpretation of complex structural models’, IEEE Transactions of Systems and Man. Cybernetics, Vol. SMC-4, No. 5, pp.122–132. [Google Scholar]

- Warfield JN (1977) Societal Systems: Planning and Policy Complexity, pp.149–160, Wiley, New York. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.