Abstract

Due to their outstanding and versatile properties, polybenzoxazines have quickly occupied a great niche of applications. Developing the ability to polymerize benzoxazine resin at lower temperatures than the current capability is essential in taking advantage of these exceptional properties and remains to be most challenging subject in the field. The current review is classified into several parts to achieve this goal. In this review, fundamentals on the synthesis and evolution of structure, which led to classification of PBz in different generations, are discussed. Classifications of PBzs are defined depending on building block as well as how structure is evolved and property obtained. Progress on the utility of biobased feedstocks from various bio-/waste-mass is also discussed and compared, wherever possible. The second part of review discusses the probable polymerization mechanism proposed for the ring-opening reactions. This is complementary to the third section, where the effect of catalysts/initiators has on triggering polymerization at low temperature is discussed extensively. The role of additional functionalities in influencing the temperature of polymerization is also discussed. There has been a shift in paradigm beyond the lowering of ring-opening polymerization (ROP) temperature and other areas of interest, such as adaptation of molecular functionality with simultaneous improvement of properties.

Keywords: benzoxazine, polybenzoxazine, low-temperature polymerization

1. Introduction

Benzoxazine (Bz) monomer is typically synthesized via Mannich-like condensation of a phenolic and a primary amine derivative in the presence of formalin or paraformaldehyde to form 1,3-benzoxazines (e.g., 3,4-dihydro-3-methyl-2H-1,3-benzoxazine). Bz contains a heterocyclic six-membered ring in an irregular chair conformation with oxygen and nitrogen atoms at the 1- and 3- positions, respectively. The monomer undergoes cationic ring-opening polymerization (ROP) to form polybenzoxazines (PBzs). Holly and Cope [1] first reported the synthesis of benzoxazine monomers, which was extended by Burke et al. [2,3] followed by Schreiber [4,5] and Higginbottom [6] to PBz resins. Ning and Ishida [7] reported the properties of PBzs in 1994. This led to an emergence of the PBz era. This class of polymers is an attractive alternative to many traditional thermosets, such as epoxies, phenol-formaldehyde, bismaleimides, cyanate ester resins, and even polyimides due to its excellent properties, rich design flexibility at the molecular level and competitive cost.

Since the discovery of PBzs, a large number of structural modifications have been considered to advance their applications. Due to their very complex structure and IUPAC names, the benzoxazine community has come up with an abbreviated monomer nomenclature where phenolic source is abbreviated in upper case character(s) and amine is abbreviated with lower case character(s); these two abbreviated names are connected by a hyphen. The corresponding polymer is abbreviated as poly(abbreviated name of monomer), and the same will be followed in this review article [8].

Depending on the molecular structure and functionality present in the monomer, they can be conveniently categorized into four generations. First generation benzoxazine includes monomers containing only benzoxazine functionality with rather benign substituents.

Second generation monomers possess additional functionalities, which undergoes either self-polymerization or crosslinking, or aid ROP reaction. In this category, benzoxazines can undergo other polymerization mechanisms in addition to the basic oxazine ring-opening reaction. Third generation benzoxazines include structures where oxazine groups are present in the main-chain of polymer, in the side-chain and as terminal groups to be classified as the main-chain, side-chain, and telechelic benzoxazines, respectively. These polymeric precursors have higher molecular weight than the traditional monomeric-type benzoxazines. Due to their oligomeric and polymeric architectures, they exhibit thermoplastic polymer-like properties prior to the crosslinking reactions. Preparation of self-supporting film thus becomes possible using this class of oligomeric precursors. Fourth generation benzoxazines possess smart architectures which include functionalities that affect formation of more stable in situ structures; these impart a set of unbelievable extraordinary properties to PBz frameworks, extending their scope to unconventional applications, which are limited otherwise by ordinary benzoxazine architecture.

In general, PBzs emerged as a promising class of thermoset polymers exhibiting versatility in a wide range of applications including adhesives [9,10,11,12,13,14], flame resistant polymers [15,16,17,18], cathodic material in batteries [19,20,21,22,23,24], coatings [14,25,26,27,28], materials for aerospace applications [29], carbon dioxide adsorbent [30,31,32,33,34], detection of metal ions [35,36,37,38], 3D printing [39] and electronics [40,41]. Besides effective compatibilization with many polymers, they also offer notable properties such as good mechanical strength [42,43,44,45,46,47,48], high thermal stability [49,50,51,52,53,54,55,56,57], flame retardance [58,59,60], good chemical and water resistance [61,62,63], near-zero shrinkage during polymerization [42,64,65], low dielectric properties [66,67,68,69] and lower surface free energy than PTFE being fluorine free structures [70,71,72,73].

To mitigate environmental issues, designing and structural changes of monomers that allow degradation of thermoplastics is gaining importance. Likewise, thermosets polymers based on bio-origin feedstocks and incorporation of labile linkages are being considered by the research community to allow reprocessability, recycling, and to tackle degradation. Recyclable and reprocessable PBz based on dynamic sulfide linkages [74] and labile Si–O–Ph bonds [75] are reported. A reprocessable polybenzoxazine thermoset is also achieved using nature inspired catechol-Fe3+ coordination chemistry [76].

The purpose of this review is not to introduce benzoxazines using natural renewable resources or development of flame-retardant polymers without using toxic additives. These are the reasons for polybenzoxazines to be attractive class of polymers for the green and sustainable technologies and are well recognized [77,78]. However, in order for the benzoxazine resins to be effectively and widely used to make them green, sustainable technologies, there are a few areas that need to overcome. One of such obstacles is to polymerize benzoxazine resins at low temperatures. Upon successful understanding of the effective approaches, it becomes possible to potentially green and sustainable materials to be actually useful materials.

2. Classification of Benzoxazine Monomers

2.1. First Generation Benzoxazines

2.1.1. General Benzoxazine Synthesis and Structure

Amongst other generations, they are the simplest structures and are formed by either one-step via the Mannich-like condensation or multi-step synthesis of an o-phenolaldehyde compound with any primary amine in solvent or solventless conditions [79]. The substituents present in the final benzoxazine monomers are rather inert groups, and thus, the polymerization mechanisms are the simplest among all the generations. A typical synthetic scheme for Bz monomer is shown in Figure 1.

Figure 1.

Synthesis of Bz monomers (a) one-step synthesis of representative benzoxazine monomer using phenol (PH), aniline (a) and formaldehyde, (b) asymmetric benzoxazine [80] and (c) multi-step synthetic approach [81].

It must be noted that not all phenolic-OH groups may condense with amine and formaldehyde to form oxazine ring. Interestingly, a dimeric phenol with an amine bridge led to the formation of an asymmetric mono-oxazine inevitably instead of expected bisbenzoxazine as in Figure 1b. This unusual and inequivalence of phenolic-OH reactivity is due to the existence of a strong intramolecular H-bonding (bond length ~0.18 nm) of one phenolic-OH with the >N- group, hampering its accessibility for ring-closure reaction [80].

Aside from highly reduced reactivity by intra-molecular hydrogen bond formation, lack of free o-position of phenolic structure can also prevent oxazine ring formation. Phenolic compounds, such as pyrogallol, 3-methoxycatechol, novolac, lignin, and tannin that contain some phenolic groups with no open o-position will remain as such rather than being involved in formation of oxazine. Such uncondensed OH groups will act as ring-opening initiators and/or catalysts and are known to shorten shelf life unless they are inactivated via intramolecular hydrogen bonding interactions or modified to chemical latent structures. In certain monomers, when some components interfere with the traditional mode, a three-step synthesis is found to be convenient in place of a one-step Mannich condensation reaction as shown in Figure 1c [81].

In general, the oxazine functionality number can be varied depending upon the nature of the starting materials and reaction conditions. The representative structures of mono- and bis-oxazine monomers based on phenols and amines in this first generation are shown in Figure 2.

Figure 2.

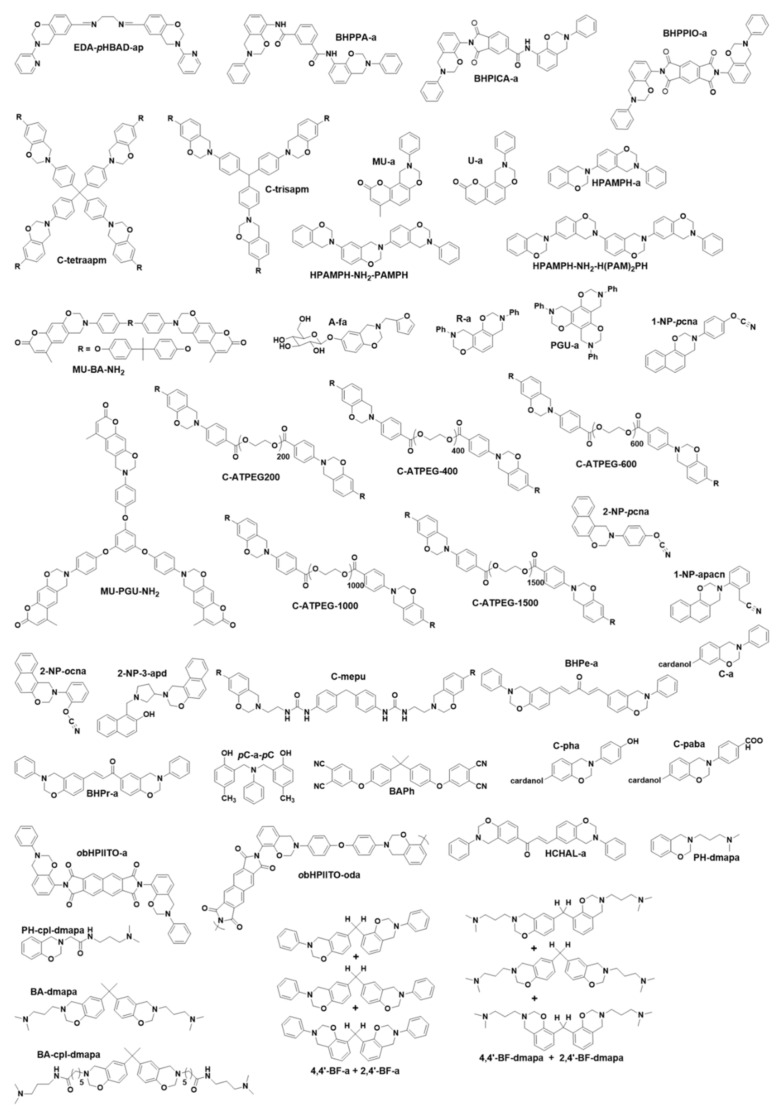

To reduce the carbon foot print, exploration of non-petrochemical feedstocks that are obtained naturally or in bio-wastes is actively sought both as solvent or solvent-free reactions [84]. These include cardanol (C) [85,86,87,88,89,90]; guaiacol (G) [89,91,92]; eugenol [93,94]; isoeugenol [95]; vanillin (V) [96,97,98]; umbelliferone (U) [99]; catechol [100]; cinnamic, ferulic, coumaric [101,102] and phloretic acid [101,103,104]; magnolol [105]; resveratrol [106]; humic acid (coal origin) [107]; daidzein [108]; naringenin [109]; arbutin-linked phenol [110]; levulinic acid based diphenolic acid [111,112]; sesamol [113]; apigenin [84] and amines such as stearylamine [93], dopamine [114], furfuryl amine (fa) [95,115], aminolysed poly(ethylene terephthalate) [116] and isomannide diamine (ima) [89], as shown in Figure 3.

Figure 3.

Representative bio- and petro-sourced phenolic and amine resources utilized to form Bz monomers.

They exhibit the potential to compete with the existing petro-based high performance thermosets [117]. Lignin is a vast source of renewable phenols and used to produce biobased polymers. In general, besides as source for feedstocks replacement, greenness of the overall process should also be a criterion to judge the sustainability when compared with fossil-derived materials [118].

As proposed by Burke and Ishida [2,119], formation of benzoxazine monomer (PH-a) in acidic conditions preferentially proceeds via iminium ion intermediate instead of the sequential reaction of aniline and resultant intermediate with formaldehyde molecules, as supported by ionization mass spectrometry (ESI-MS) with infrared multiple photon dissociation (IRMPD) spectroscopy [120]. Small ring strain in oxazine ring due to the presence of two heteroatoms, N and O, demands a modestly high temperature ~140–240 °C to mediate ROP under catalyst-free conditions [121]. Besides thermal polymerization, monomers are also susceptible to electrochemical polymerization in acetonitrile/alkali aqueous media [122,123,124]. Experimentally, it was observed that the PBzs properties, especially thermal degradation characteristics, are improved by the incorporation of amines with the tendency to extend physical and chemical crosslinked networks [50,51,53,125,126,127,128,129]. Replacement of aniline with furfurylamine (fa) [130] and tritylaniline [131] showed predominance of amine-based polymer linkages.

2.1.2. Mono-Oxazine Functional Monomers

The PBzs based on mono-oxazine monomers are mainly linear and may be lightly branched with the exception of PH-a, which is lightly crosslinked, whereas higher functionality monomers improve the crosslink density and, thereby, affect other properties of the polymer. The functionality of either phenol or primary amine is altered to increase the oxazine functionality in the monomer. The higher functionality ensures an infinite network growth, which is beneficial for thermosets. The intra-molecular hydrogen bond formation, propagation [80,132] and thermal dissociation of the mono-oxazine monomer compete with chain propagation reaction preventing growth of high-molecular weight linear structures. Another potential problem is the relatively easy evaporation of small, monofunctional monomer during polymerization process. Very recently, this termination of the chain propagation was attributed to the cyclic oligomer formation [133].

2.1.3. Multi-Oxazine Functional Monomers

Problems associated with mono-oxazine functional monomers can be overcome by adopting multi-oxazine functional monomers. Ning and Ishida [134] synthesized first bis-benzoxazine using bisphenol-A (BA) with methylamine (ma) and aniline (a). Differential scanning calorimetry (DSC) kinetic studies revealed that polymerization proceeds via an autocatalytic mechanism [135]. The temperature and activation energy (Ea) of polymerization of Bz monomers was found to increase under high pressure differential scanning calorimetry (HP DSC), and the resultant polymer showed a decrease in both Tg and thermal stability than the polymers polymerized at normal pressure [136].

Besides BA, other bisphenols with various units between two phenyl groups and their bridging group are used to affect the PBz structure and tailor their properties. Simultaneously, similar variations are explored in the amine component, too. Representative bis-phenols and bis-amines reported in Bz chemistry are shown in Figure 3.

A predominance of BA based benzoxazine monomers with a monofunctional amine is widely reported in literature. The bifunctionality in benzoxazine can also be affected in reverse fashion, by condensation of bis-amine with mono-phenol. Besides formation of new structures, such variation at molecular level imparts additional benefits of low viscosity during both synthesis and processing [137]. Regioselectivity, which is controlled by the position of the electron-donating and electron-withdrawing groups on the benzene ring, influences ROP temperature, Tp [138]. If an electron-withdrawing group is located p- to the phenolic-OH, this leads to a lower Tp due to resonance stabilization of the ring-opened structure; however, if located p- to the amine group, this has an opposite effect as illustrated in Figure 4a. PBzs based on o/m/p-cresol vs. phenol revealed methyl substitution at the o-position increases Tp, suggesting a decrease in the reactivity of the monomer as shown in the structures of the monomers provided in Figure 4b and DSC traces in Figure 4c. The rate of polymerization is highest when R = H i.e., unsubstituted > p-(methyl) > o-(methyl) [137].

Figure 4.

DSC thermograms of the (a) unsubstituted, para-, ortho- and meta-substituted mono-oxazine by varying substituents in phenol and aniline ring [138]. Copyright 2008. Reproduced with permission from Wiley Periodicals, Inc. (b) Bisbenzoxazine based on diaminohexane by varying methyl substituent in phenol ring (o-, m- and p-cresol) and (c) non-isothermal DSC thermograms of the PH-hda, pC-hda, oC-hda and mC-hda monomers based on diaminohexane (hda) [137]. Copyright 2009. Reproduced with permission from Elsevier Ltd., Amsterdam, The Netherlands.

Of particular interest is the replacement of methyl to methoxy group at the meta-position with respect to the phenolic-OH led to a substantial reduction in Tp [139].

A structurally induced effect is studied in the benzoxazine monomers based on BA and 4,4’-methylenediphenol (BF) with aniline (a) and cyclohexylamine (cha) [140]. The BA based monomers produce a higher concentration of oligomers than those based on BF. This suggests that the nature of bridge between phenyl group affects the basicity of oxygen and nitrogen atom of the oxazine ring, which influences oxazine ring-opening and thus the subsequent formation of oligomers.

The nature of substituents, primarily electronic and steric effects, not only affects the temperature required for ROP but also governs the nature of linkages (mainly, N,O-acetal and/or Mannich structure) formed in the resultant polybenzoxazine network. For instance, Ishida et al. [141] reported the existence of non-Mannich type linkages, arylamine- and methylene-type, in addition to the traditional Mannich-bridges. Tritylaniline-based mono-oxazine sourced PBz framework revealed various such type of bonding as shown in Figure 5 [131]. ROP with methyl-substituted anilines revealed methyl substituents at the o-position of the arylamine ring sterically hinder the polymerization process. While the m-position facilitates polymerization at lower temperatures to generate bisphenolic methylene linkages, on the other hand, arylamine Mannich bridges that have reacted to the p-positions on arylamine ring appeared to be less thermally stable and may cleave during polymerization to yield methylene linkages [142]. The activation of the p-position on arylamine ring increases the extent of ring-opening during polymerization whereas the rings of the non-activated materials are much less likely to fragment and release the free amine.

Figure 5.

Polybenzoxazine framework with variable linkages in poly(C-ta) [131]. Copyright 2016. Reproduced with permission from Elsevier Ltd.

A systematic enhancement of the number of oxazine functionality in symmetric fashion in the monomer from 1 to 4 (Figure 6a) led to a decrease in Tp from 265 to 190 °C as a result of close proximity of benzoxazine units [87]. The values of Tg (58–109 °C), thermal stability (T5% 355–391 °C), char yield (13–37%), limiting oxygen index (LOI) (23–31) and storage modulus (3.6–66.5 MPa) improved significantly due to the growth of polymer network from one- to four-directions.

Figure 6.

Higher functionality benzoxazine monomers [87,143,144,145,146,147].

In a similar analogy, the existence of mono-, bis- and tris-oxazine functionality on the same benzene core revealed lowering in Tp with increase in functionality due to its specific condensed structure and the electronic effects of the aryl ethers at 1,3- and 1,3,5-positions as shown in Figure 6b [143]. On the contrary, an extreme lowering in thermal stability is observed at highest functionality which is due to the inability for PBz network growth as a result of non-availability of free ortho-position [144]. Interestingly, tris-oxazine with 1,3,5-triphenyl benzene (TPHB) core based Bz monomer (TPHB-a) showed a much higher Tp of 238 °C than phloroglucinol (PGU) based monomer PGU-a, suggesting close spatial proximity of oxazine rings is essential to lowering the ROP temperature [145]. Similar to the aforementioned example of an electron-donating methoxy group para- to the amine group, the reactivity of the resorcinol-based benzoxazine is highly elevated [146].

Sini and Endo [147] synthesized a series of di-, tri- and tetra- functional Bz monomers in ladder form via a multi-step synthetic procedure (Figure 6c) and found a reduction in Tp from 264 °C (mono) to 237 °C (tetra) and a simultaneous increase in char yield from 44% to 62% with an increase in the number of oxazine rings.

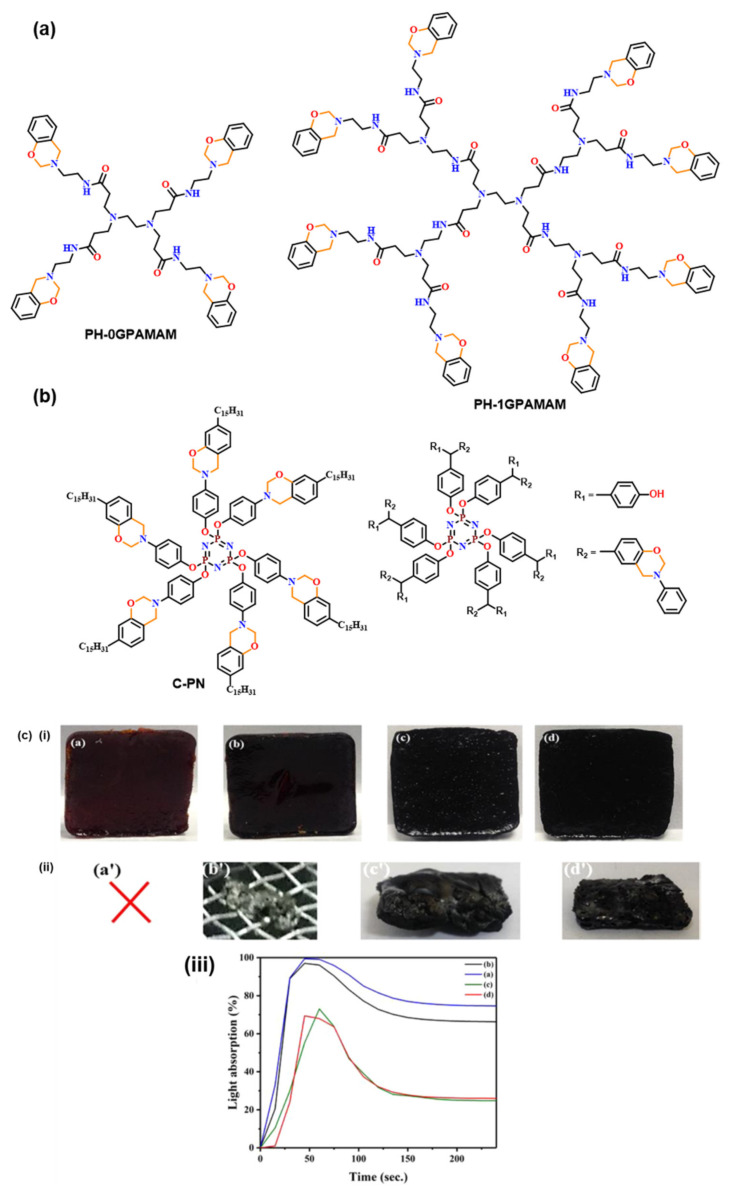

Interestingly, the dendrimers synthesized by Lu et al. [143], as shown in Figure 7a,b, exhibited a modest effect of increased number of dendritic arms on Tp; however, the dendrimers in general showed lower Tp’s than ordinary benzoxazines. A 4- and 8-functionality of benzoxazine monomers is obtained using different generation poly(amido amine) (PAMAM) dendritic amines. The 0th generation dendrimer with 4 oxazine ring showed Tp of 224 °C, whereas for the 1st generation dendrimer with 8 oxazine ring in the molecule, Tp = 220 °C. The spherical molecular architecture allowed a lowering of monomer viscosities. In general, the low viscosity of Bz monomer is advantageous as it allows solventless synthesis of other rigid monomers, which otherwise demands solvents for the synthesis [86]. Dendritic organic–inorganic hybrid cyclotriphosphazene (PN) based benzoxazine also revealed halogen-free flame resistivity as shown in Figure 7b,c [18,148].

Figure 7.

Higher order benzoxazine monomers with (a) 0th and 1st generation PAMAM dendritic [143], (b) phosphazene core [18,148] and (c) flame resistive analysis: digital images of cured samples [l × w × h: (25.0 ± 0.1) × (25.5 ± 0.1) × 3.0 mm] of poly (C-trisapm) and poly (C-PN) blends in different ratio (a) 100:0, (b) 90:10, (c) 20:80 and (d) 0:100 (i) before and (ii) after smoke density test; (iii) plot of light absorption by sensor with time during burning of the sample [18]. Copyright 2017. Reproduced with permission from American Chemical Society, Washington, DC, USA.

Another example of dendrimer that has been reported by Lin et al. [149] showed little effect to the number of oxazine groups per molecule on the Tp at higher generations despite showing generally lower Tp than mono- or bis-oxazine benzoxazines. A facile one-pot Mannich condensation divergent approach was adopted with triphenylamine (tpa) as the core and phenol (tpa–2NH2–OH, as the AB2 branching group) to synthesize dendrimers with both bridged and surface oxazine surface groups. The 1st generation dendrimer with 9 oxazine rings per molecule showed the Tp of 231 °C, and the 2nd generation with 21 oxazine groups in the molecule, Tp = 235 °C, and the 3rd generation dendrimer with 45 oxazine groups per molecule, Tp = 235 °C.

Besides dendritic, hyperbranched benzoxazine monomers based on trifunctional amine such as triphenyl amine (tpa) [150] and Jeffamine T-403 [151] with phenol and bisphenol A are also reported.

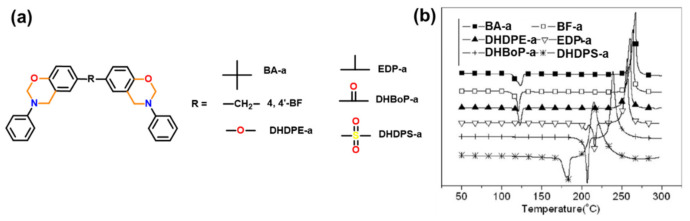

Aside from increasing the number of oxazine functionalities in the monomer, the isomeric effect of oxazine ring position also shows a profound effect on polymerization characteristics. The Tp decreased in the order of 4,4′-, 2,4′-, and 2,2′-isomers albeit showing only less than 10 °C difference between 4,4′- and 2,2′-isomers. A 2,2′-isomer of bisphenol F based polymer exhibited a much higher thermal stability and Tg than the 2,4′- and 4,4′- isomer as shown in Figure 8, which is attributed to better packing and high crosslink density for the 2,2′-based PBz framework. The superiority of the 2,2′-isomer over the 4,4′-isomer is highly unexpected, since all other PBz polymer literature studying the effect of isomerism reports otherwise [152].

Figure 8.

(a) Structures of isomeric BF-a monomers [152]. (b) Variation in tan δ of polybenzoxazines [152]. Copyright 2014. Reproduced with permission from American Chemical Society.

Incorporation of a rigid aromatic structure in the PBz backbone such as fluorenyl and naphthol resulted in an improvement in properties, especially thermal stability, high char yield, LOI, and flame-retardance [153,154,155,156,157]. Incorporation of fluorene moiety in the Bz monomer imparted photoluminescence and UV stabilization characteristics to the PBz [158].

Similarly to thermoplastics, properties of PBz framework are also affected by the chirality of the monomer [89,159]. The S-configuration origin PBz (S-tbtmpPH-pea) showed a slightly higher Tg (31 °C) than the racemic (rac-tbtmpPH-pea) (19 °C) due to stereoregular arrangement of units in the polymer backbone [160]. However, these values are much lower than the reported values for mono-oxazine based resins, due to blocked o- and p- positions with bulky t-butyl groups (Figure 9a). Recently Nagarjuna et al. [89] reported utility of chiral biobased isomannide sourced diamine (ima) to induce chirality in bis-oxazine monomers. This resulted in an unusual multiplet oxazine 1H NMR signals as compared to singlet signal, which are typically observed in traditional Bz monomers. The incorporation of rigid isomannide core resulted in fully biobased chiral PBz as illustrated in Figure 9b, a comparable Tg to their petro-based aromatic diamine counterparts and a 2-fold higher adhesive strength than poly(BA-a) (Figure 9c).

Figure 9.

Synthesis and ROP of chiral Bz monomers (a) S- tbtmpPH-pea and rac-tbtmpPH-pea mono-oxazine [160], (b) G-ima and C-ima bis-oxazine [89] and (c) lap shear strength (LSS) values of C-ima, G-ima and BA-a benzoxazine based thermosets at room temperature [89]. Copyright 2019. Reproduced with permission from American Chemical Society.

2.2. Second Generation Benzoxazines

2.2.1. Multiple Polymerization Mechanisms

In second-generation monomers, besides oxazine functionality, the monomer also contains additional reactive functionalities. Either these groups undergo polymerization by itself, or they assist polymerization of oxazine ring. The former category includes acetylene, allyl, epoxy, glycidyl, maleimide, methacrylate, nitrile, norbornene, oxazoline, phthalonitrile, propargyl, vinyl ester, cyanate ester, etc. The latter involves phenol, carboxyl, primary amine, methylol, ethylol, hydroxyl ethylether, etc.

The position, nature, and number of oxazine rings affect the polymerization behavior and lead to various types of linkages in the resultant network. Figure 10 clearly shows a broad DSC exotherm in 3,5-xylidine (35x) based monomer, BA-35x, as compared to aniline based BA-a. This infers the existence of two polymerization reactions in BA-35x; the lower temperature exotherm is accounted for the ROP reaction, while the higher temperature shoulder corresponds to the side reactions such as formation of bisphenolic methylene linkages, arylamine Mannich bridge and methylene linked structures. Ishida and Sanders [142,161] supported existence of these linkages in BA-35x by FTIR spectroscopy. The structural variation of the polymer network is highly dependent on the nature of constituent phenol and amine and the additional functionalities present therein. BA-m and BA-a showed a significant effect on degree of polymerization and the crosslink density as investigated by 13C solid-state NMR [162]. A substantial influence on the degradation behavior of resultant polybenzoxazines is observed. Secondary amines are detected at temperatures <400 °C while phenols are detected at temperatures >400 °C in aliphatic amine based polybenzoxazines. In the case of poly(BA-a) and poly(22PP-a) below 600 °C, the degradation behavior of Mannich base cleavage under an oxidative environment is influenced significantly by the nature of constituent phenols below 600 °C [163].

Figure 10.

DSC thermograms of BA-a and (◦) BA-35x (▫) [165]. Copyright 2006. Reproduced with permission from Elsevier Ltd.

Table 1 clearly shows that both introduction and position of methyl substituent on arylamine influences growth and degradation behaviors of PBz bis-benzoxazines prepared with various amines [164], possess the processing window as BA-35x < BA-mt < BA-a. The Tg were found to be consistent with the Tp of the polymerization exotherms, suggesting a significant variation in structure dependent reactivity to form crosslinking networks. The Tg of PBz based dimethyl substituted aniline (35x) is much higher at 243 °C than unsubstituted aniline of 168 °C [161,164]. Additionally, poly(BA-mt) and poly(BA-35x) display a delayed onset of thermal degradation (T5%) until around 350 °C, as compared to poly(BA-a). A regioselective control was found to improve the mechanical and thermal properties due to the occurrence of secondary crosslinking mechanism, leading to a predominance of thermally stable arylamine bridges [83,162,163].

Table 1.

Thermal characterization of substituted polybenzoxazines [161].

| Tga (°C) | Tp (°C) | H (J/g) |

T5% (°C) |

Y c | |

|---|---|---|---|---|---|

| BA-a | 168 | 251 | 340 | 315 | 30 |

| BA-ot | 114 | 247 | 289 | 228 | 32 |

| BA-mt | 209 | 231 | 325 | 350 | 31 |

| BA-pt | 158 | 259 | 310 | 305 | 32 |

| BA-35x | 243 | 217 | 298 | 350 | 28 |

a: Tg values are reported from DSC data.

Likewise in BA-35x, a very broad DSC polymerization exotherm comprised of several overlapped peaks was also observed in case of ethylenediamine (eda) based bis-benzoxazine monomers [137]. The two overlapped exotherm peaks of PH-eda are centered at temperatures that are atypically low for benzoxazines. This is attributed to the short ethylene linkage between the oxazine rings leading to steric hindrance or other structural interactions destabilizing the oxazine rings to affect polymerization at low temperatures [166]. A simultaneous occurrence of both polymerization and degradation is also reported in these structures. The highest temperature peak in these exotherms is ascribed to the degradation mechanism.

A significant influence of methyl-substituent in Bz polymerization is also reported. In case of BA-a, oMBA-a and oMBA-35x, the polymer network growth proceeded by only one dominant auto-catalytic process with the existence of either phenol Mannich or arylamine Mannich bridge structure. On the other hand, BA-35x shows simultaneous occurrence of both crosslinking reactions. The nature and presence of methyl substituent in Bz monomer profoundly controls the type of linkages in polymer structure, as illustrated in Figure 11 [83,165].

Figure 11.

Possible polymerization routes for bisphenol-arylamine-based benzoxazines [83]. Copyright 2018. Reproduced with permission from Elsevier B. V.

However, exhibiting multiple polymerization exotherms is not a common phenomenon in multi-functional benzoxazine monomers. Rather, multifunctional benzoxazines with possible multiple polymerization mechanisms often display a single exothermic peak. This seemingly a contradictory phenomenon was reported by Zhang et al. [167] and recently by Lyu et al. [139] Regio-isomers 5,5′-, 5,7′-, and 7,7′- based on 3-alkoxyphenol (methoxy, butoxy) and ddm, shown in Figure 12a, were purified to form single crystals to study the effect of benzoxazines with different reactivity within the same molecule. The DSC thermograms of individual isomers are shown in Figure 12b. Despite having 5- and 7-methoxy isomers in the same molecule, 5,7′-MOPH-ddm shows a symmetric and rather sharp exothermic peak at 226 °C, and this phenomenon is explained using the rate of reaction theory.

Figure 12.

(a) Synthesis of 3-methoxyphenol and ddm based benzoxazine isomers and (b) DSC thermograms of MOPH-ddm isomers showing only well-defined single exotherm for each isomer [139]. Copyright 2020. Reproduced with permission from Royal Society of Chemistry, London, UK.

Besides classical linkages formed by oxazine ROP, formation of other types of crosslinks such as ester linkages due to copolymerization, [168] triazine ester/isocyanurate [169] are also reported. Introduction of such additional linkages in PBz is advantageous and found to increase Tg of PBz. For instance, copolymerization of BA-a with 3,3′,4,4′-benzophenonetetracarboxylic dianhydride (BTDA) enhanced Tg to 263 °C. Nitrile based Bz monomers are prone to undergo phenolic group-mediated nucleophile triggering, which may form various nitrile-nitrile addition structures. These structures affect the crosslink density of the polymer network [170,171]. Figure 13a shows the synthesis of BA and 4-(3-aminophenoxy)phthalonitrile (appn) based phthalonitrile benzoxazine monomer. The nitrile groups form triazine and phthalocyanine structures, Figure 13b, in addition to oxazine ring-polymerization, thereby imparting a very high thermal stability (>400 °C) to poly(BA-appn). A simultaneous occurrence of oxazine ring-opening and triazine/phthalonitrile ring-forming reaction led to an improved mechanical performance, which is attributed to synergistic interactions between the polymer framework [172]. Curing kinetics of bisphthalonitrile Bz monomer was found to involve a free radical mechanism, where methine and methylene promote cyclization reactions of the cyano group [173].

Figure 13.

(a) Synthesis of phthalonitrile containing benzoxazine monomer [171] and (b) proposed nitrile groups based cyclic structures formed during polymerization [171].

Like nitrile, cyanate ester functionality also affects polymerization of benzoxazine functionality [174,175,176,177,178]. It was proposed that the phenolic hydroxyl group generated by benzoxazine ring-opening reaction reacts with the cyanate ester group to form iminocarbonate intermediate, which triggers cyclotrimerization of cyanate groups [174,175,179,180]. Further, it was proposed that the ring-opened oxazine rings insert into the triazine rings to form cyanurates and isocyanurates, which then probably further react with oxazine rings to form other structures [176]. Wang et al. [178] proposed the benzoxazine ring itself catalyzes both trimerization of cyanate ester and isomerization (cyanurate to isocyanurate) reactions upon heating. They showed the possibility of ROP for benzoxazine at 30 °C as evident from Figure 14i. This supported that the benzoxazine ring only induces the catalytic effect in trimerization of cyanate linkage as proposed in Figure 14ii. Ohashi et al. [181] proposed that the existence of cyanate ester functionality in the benzoxazine monomer affects its polymerization at a lower temperature than the benzoxazine/cyanate ester blends. Figure 14iii clearly supports the existence of multiple exotherms due to two different types of crosslinking processes in the DSC trace. They proposed the cyanate ester reaction promotes benzoxazine cationic ring-opening polymerization more efficiently when it is present in the benzoxazine structure itself. TGA thermogram, Figure 14iv, shows the improved thermal stability of PBz containing cyanate ester group. Besides cyanate ester crosslinking reactions, the high thermal stability is also attributed to the co-reaction of the resultant amine moiety to form additional crosslinks and thereby may prevent decomposition or evaporation of aniline component from PBz during heating.

Figure 14.

(i) Digital images of a 50 wt% methyl ethyl ketone solution of PH-oda/BADCY (Bisphenol A dicyanate ester) (1/1, mol/mol): (a) freshly prepared solution, and the thermally treated solution at (b) 30 °C for 24 h, (c) 50 °C for 4 h and (d) 100 °C for 2 h [178]. (ii) Proposed catalytic mechanism of benzoxazine to the trimerization of cyanate ester solutions [178]. Copyright 2015. Reproduced with permissions from American Chemical Society. (iii) DSC thermograms of monomers [181]. Copyright 2015. Reproduced with permissions from American Chemical Society. (iv) TGA thermogram of poly(PH-a) and poly(PH-pcna) polymerized at 220 °C/2 h [181]. Copyright 2015. Reproduced with permissions from American Chemical Society. (v) Cyanate ester functionalized benzoxazine (cna) [182].

Despite expected higher thermal properties of PBzs based on naphthol, use of non-functional naphthoxazines is somewhat limited due to evaporation of the naphthoxazine units prior to polymerization [183,184]. Naphthoxazines functionalized with cyanate ester, Figure 14v, revealed minimization of such mass losses as indicated by multiple exotherm maxima, to support cyanate ester trimerization along with ROP of Bz ring. Additionally, incorporation of cyanate ester functionality not only lowered the polymerization temperature but also led to a relatively higher stability than their aniline counterparts as shown in Table 2 [182].

Table 2.

Thermal characterization of naphthoxazine and general benzoxazine [182].

A simultaneous trimerization and oxazine ROP is observed only in cases of 1NP-pcna and 2NP-pcna while o-substituted cyanate esters, 1NP-ocna and 2NP-ocna, showed multiple exothermic peaks with a lower exothermic temperature than p-substituted cyanate ester functional naphthoxazines.

Other reactive functionalities, such as propargyl [185,186,187], epoxide [188,189], oxyalcohol [190] and amino [191] groups, are also incorporated in benzoxazine structures to impart additional crosslinks or other related benefits due to ease of structural control at the molecular level. Interestingly, aldehyde-containing benzoxazine, upon modification to a Schiff base, enables its applicability to sequester metals ions [192].

2.2.2. Smart Benzoxazine Monomers

In addition to obvious reactivities of the additional substituent other than an oxazine ring as discussed in the previous section, there are certain structures or groups, which themselves do not possess ability to polymerize and yet can influence the rate or mechanism of oxazine polymerization. Such smart molecules can be quite useful as demonstrated in the following sections.

A unique class of o-amide functional Bzs was found to polymerize at much lower temperature than traditional Bz, without any help of initiator or catalyst. The presence of intramolecular H-bonding between an amide group and the adjacent oxazine ring acts as an internal trigger to stimulate ROP of oxazine ring at low temperature to form PBz with o-amide phenol functionalities. The Tp of Bz with o-amide found to be lower than p-amide isomer by 47 °C supporting the catalyzing effect induced by neighboring amide functionality via a 5-membered intramolecular H-bonding interaction. With further treatment at higher temperature (>ROP temperature) during post-curing or any event of catching fire, intramolecular cyclization between the neighboring hydroxyl and amide groups occurs to form oxazole rings with the elimination of water. Such interconversion of PBzs to polybenzoxazole imparts a better set of thermal properties due to formation of a more stable polymeric network as shown in Figure 15.

Figure 15.

Smart features for easy synthesis of benzoxazole resin via o−amide functional benzoxazine monomer [193]. Copyright 2012. Reproduced with permission from American Chemical Society.

Regiochemistry of o- and p-amide substituents in Bz monomer containing pyridine ring affects the strength of intramolecular H-bonding interactions with the O in oxazine ring and N-H⋯N interaction with pyridine ring affecting polymerization characteristics and its conversion to PBO [194].

Similarly, o-imide functional Bz monomers are synthesized using the simplistic approach shown in Figure 16a via condensation reaction of 2-(2-hydroxyphenyl)isoindoline-1,3-dione (2,2-HPIO) with aniline (a) [195]. Benzoxazine resins with o-imide functionality revealed advantageous properties as compared with p-imide functional isomers. The crosslinked polybenzoxazine based on o-imide unit undergoes decarboxylation at high temperature to form a more thermally stable crosslinked polybenzoxazole (with T5% = 505, Yc = 73%). This method allows elimination of the traditionally used expensive raw materials and harmful solvents for polybenzoxazole synthesis.

Figure 16.

Synthesis of (a) o-imide [195], (b) o-norbornene functional imide Bz monomer [196] and (c) dynamic mechanical spectra of poly(oHPNI-ddm), upon further thermal treatment (280 °C, 1 h) [196]. (d) TGA of poly(oHPNI-ddm). At 280 °C, isothermal heating was applied for 1 h [196]. Copyright 2015. Reproduced with permission from Elsevier Ltd. (e) Synthesis of amide-co-imide functional benzoxazine monomer [197].

Utilization of an o-norbornene functionalized, phenol sourced, oHPNI Bz monomer as illustrated in Figure 16b [196] led to minimization in degradation from the usual reverse Diels–Alder reaction. A very high Tg (365 °C) and high thermal stability (T5% = 463 °C, Yc = 61%) are reported, Figure 16c,d suggesting synergism provided by the co-existence of alkene and benzoxazine origin networks in the resultant polymer.

The polybenzoxazole thermosets based on the ortho-(amide-co-imide) functional benzoxazine monomers (BHPICA-a and BHPICA-ddm) are synthesized as shown in Figure 16e. As illustrated in Table 3, the attainment of very high Tg and thermal stability of these polymers upon heating at high temperature (400 °C) is supported by the formation of thermally stable linkages. This strategy demonstrates an easier and promising synthetic route of such polymers which can be used for high performance demanding applications [198].

Table 3.

Thermal characterization of o-(amide-co-imide) functional polybenzoxazines [198].

|

Tgc (°C) |

T5% (°C) |

T10% (°C) |

Yc (%) |

|

|---|---|---|---|---|

| poly(BHPICA-a) a | 332 | 406 | 476 | 63 |

| poly(BHPICA-ddm) a | >400 | 410 | 473 | 52 |

| poly(BHPICA-a)-400 b | - | 536 | 589 | 71 |

| poly(BHPICA-ddm)-400 b | - | 503 | 555 | 60 |

Obtained after heating at 300 °C a and 400 °C b for 1 h to assist cyclodehydration reaction; c Tg values are reported from dynamic mechanical analysis.

The presence of ortho-nitrile group functionality in ortho-phthalimide-functionalized benzoxazine monomer revealed exceptionally high thermal stability (T5% = 550 °C) and high char yield value (70%). This is accounted to by the formation of highly crosslinked network, stemming from the occurrence of multiple polymerization reactions, namely, oxazine ROP, cyano cyclotrimerization and benzoxazole ring formation [199]. Benzoxazine monomers with atropisomerism [200,201,202,203] account for a more interesting set of properties than traditional benzoxazine structures. The formation of highly cross-linked networks through multiple polymerization behaviors in single-component resins is advantageous in terms of ease of processability and high performance properties of ortho-maleimide functional benzoxazines with additional crosslinking such as cyano or acetylene functionalities [203].

A wide family of allyl functionalized benzoxazine monomers is shown in Figure 17a. Variation in position, number and hybrid structure of benzoxazine monomer is reported in the literature. Allyl groups were found to influence the polymerization behavior of Bz monomer [53,94,95,204,205,206]. The higher rate of polymerization of N-allyl substituted benzoxazine (PH-ala) as compared to N-(n-propyl) benzoxazine is attributed to the neighboring group participation of allyl group to assist oxazine ring-opening reaction [53]. PH-ala showed two exotherms with Tp at 207 and 260 °C that are associated with the thermal polymerization of the allyl group (attached to N) and formation of PBz, respectively. With an allyl group at the o-position, for o-allylphenol aniline (oALPH-a) monomer, a single exotherm Tp at 263 °C is observed. Steric hindrance to polymerization is inferred from the observed low value of Tg and poor thermal stability of poly(oALPH-a) [205]. Among difunctional allyl benzoxazines (oALPH-hda and oALPH-dds), sulfone bridged PBz showed relatively high thermal stability which is due to the significant difference in polarity of aliphatic and sulfoxide linkages [206]. The presence of inherent allyl groups in naturally occurring phenol, eugenol (E), was also explored for PBz. However, due to blocked o- and p-positions, it revealed limited polymerizability. This can be overcome by synthesizing hybrid bis-Bz monomer using phenol and eugenol. It was found that a variation in phenol to eugenol ratio in polymer allowed tunability in Tg (Figure 17b) along with the renewable content [94]. Isoeugenol (IE) is a naturally occurring structural isomer to eugenol, which has a propenyl instead of allyl group at the p-position. This variation in the position of double bond in phenol made a lower Tp value of IE-fa in comparison to E-fa. This suggested a prior involvement of double bonds to mediate ROP reaction of Bz monomer as the ring-opened phenolate ion is in conjugation with the alkenyl π bonds in IE-fa. A copolymerization of double bonds with oxazine is proposed as shown in Figure 17c [95]. Similarly, involvement of propenyl group in the crosslinking reactions was also noticed by Sha et al. [207].

Figure 17.

(a) Structures of allyl-functional benzoxazines [53,95,204,205,206]. (b) Strategy to affect Tg using hybrid bio-based monomer [94]. Copyright 2015. Reproduced with permission from Royal Society of Chemistry. (c) Probable mechanism of ring-opening polymerization in IE-fa Bz monomer [95].

Introduction of photoreactive functionalities, coumarin [208,209,210,211], chalcone [212], and bis-benzylidene as another smart feature in Bz monomer is reported. This created their capability for photodimerization [213,214] and exploration for self-healing applications. Kiskan and Yagci [209] utilized photoreactive coumarin functionality containing phenol, methyl substituted umbelliferone (MU), and p-toluidine (pt) based benzoxazine monomer, which upon irradiation at 300 nm underwent photodimerization via [2π + 2π] cycloaddition with alkenyl bonds as shown in Figure 18a. Like coumarin based Bz monomer, photosensitive bis-benzylidene linked Bz, BHPe-a (structure is shown in Figure 18b [213]) also undergoes [2π + 2π] cycloaddition to form cyclobutane ring-linked dimer. This allowed an increase in oxazine functionality and an extended monomer capability to undergo crosslinking reactions at the oxazine ring and double bonds. Figure 18c shows monitoring of dimerization reaction of monomer by UV–VIS. studies. A decrease in intensity at 365 nm due to π−π* absorption of a double bond of bis-benzylidene acetone, and increase in intensity at 280 nm due to δ−δ* absorption of newly formed cyclobutane ring with the irradiation time was observed.

Figure 18.

Synthesis of photoreactive unit: (a) coumarin [208] and (b) bis-benzylidene containing benzoxazine monomers and their light mediated dimerization [213]. (c) UV absorption spectra of BHPe-a in DMAc at a concentration of 0.8 mg/40 mL after irradiation at 365 nm for various periods of time [213]. Copyright 2017. Reproduced with permission from American Chemical Society.

Besides the capability for photo-induced dimerization, the coumarin as compared with non-coumarin containing monomers (Figure 19a) showed a low Tp for ROP reaction [210]. High stability of the ring opened phenoxide ion via extended resonance occurs in both U-a and MU-a. This resulted in a reduction in Tp of PH-a from 261 °C to 220 °C (U-a) and 232 °C (MU-a) as illustrated in Figure 19b,c [210]. The methyl group in coumarin in MU-a indirectly affects the reactivity of oxazine by being less electrophilic, i.e., less electron-withdrawing in nature, and thus, it has lower stability and hence accounts for observed higher ROP temperature than U-a. Alagar et al. [214] extended copolymerization of chalcone benzoxazine with bismaleimides to improve thermal stability of polymers.

Figure 19.

(a) Coumarin based monomers, (b) schematic depiction showing the resonance of a compound and the electronic implications, evidencing the origin of the activated electrophilic olefins, also referred to as Michael acceptors, and (c) DSC thermograms of the benzoxazine monomers [210]. Copyright 2015. Reproduced with permission from 2015 Wiley Periodicals, Inc.

As discussed previously, mono-oxazine functional monomers suffer from a few problems. They tend to evaporate significantly prior to polymerization and, upon polymerization, form small oligomers with molecular weight of several hundred to few thousands, despite their processing advantage of very low viscosity and ease of purification upon synthesis. Zhang et al. [215] reported the first example of AB-type benzoxazine monomer having maleimide and furan as the terminal functionalities of the monomer. They proposed that the Diels–Alder reaction takes place between the maleimide and furan below the polymerization temperature of oxazine to form small oligomers of several repeat units during melt processing. This approach maintains the advantage of very low viscosity mono-benzoxazine yet prevents evaporation of the monomer, as the increased molecular weight of the oligomer means it will not evaporate at the processing temperature as compared in Figure 20 for mono-oxazine benzoxazine monomers with and without Diels–Alder reacting pair. This further leads to a crosslinked polymer chain structure that exhibits good mechanical and thermal properties by reducing the number of dangling chain ends, a usual issue in mono-benzoxazine polymers. The main-chain type oligomers with several repeat units have been reported to offer good trade-off between processability and high thermal properties as discussed in Section 2.2. They exhibit high char yield, resulting in one of the smallest heat release capacities (HRC), 33.4 J/g.K, of all polymers. Certain monomers possess self-catalyzed cationic ring-opening polymerization for example, deoxybenzoin-based benzoxazine monomer [216]. Lowering the polymerization temperature reduces the chance of monomers to evaporate.

Figure 20.

Thermogravimetric analysis of HPMI-fa and PH-a, showing nearly complete prevention of the evaporation of the resin prior to polymerization [215]. Copyright 2019. Reproduced with permission from American Chemical Society.

2.3. Third Generation Benzoxazines

The third generation consists of reactive PBzs (with both thermoplastic/thermoset characteristics), namely, (i) main-chain type, where oxazine group is part of every chemical repeat unit of the oligomer chain; (ii) side-chain type based on thermoplastic backbone, where oxazine ring is part of the side chain of every chemical repeat unit; and (iii) telechelic, where oligomer of any polymer chain is terminated by reactive oxazine functionalities at each of the chain ends.

In general, mono-oxazine based PBzs containing several dangling-chain ends account for a lower thermal stability [131,217,218,219,220]. This concept of the chain end of PBz being the cause of the lowest degradation temperature of multiple degradation scheme was first presented by Chernykh et al. [221].

The incorporation of benzoxazine moieties as repeating units into polymer main chains reduces the number of chain ends in the crosslinked polymers, thus providing an enhanced thermal stability. Therefore, if the mono-amine used as the raw material contains an additional reactivity either by having reactive substituent or added reactivity of the phenyl ring by regioselectivity, the thermal stability of the polymer was found to improve substantially [141]. This main-chain type architecture provides benefits of both thermoplastic and thermoset polymers. Advantages include both solution and melt processability, tunability in Tg and production of self-supporting films, which further upon crosslinking improve thermal and mechanical strength [222,223,224]. The presence of additional functionalities other than oxazine is beneficial to modify properties, e.g., poly(benzoxazine-co-urea) [225], Figure 21a, showed attractive adhesion properties due to existence of polar linkages of both urea and ring-opened benzoxazine and ductile nature of the reactive polymeric chain precursor. The LSS value of poly(benzoxazine-co-urea) determined from plot Figure 21b was found to be 61 kg cm−2, which is lower than poly(C-ddm) [87] (79.0 kg cm−2). This could be attributed to a higher crosslinking density in the latter and existence of better adhesion properties of ring-opened oxazine structure vs urea linkages in the polymer framework. Cardanol based PBz resins revealed a great potential in many applications [117]. For instance, the adhesive strength of cardanol derived monomers was found to increase with the increase in number of benzoxazine rings in the monomer, as shown in Figure 21c [90]. This enhancement in LSS values is accounted to an interplay of the low viscosity of monomers and flexibility and crosslink density of the polymer.

Figure 21.

(a) Synthesis of main chain-type urea linked polybenzoxazine and (b) representative stress-strain curve for a stainless steel coupon held together with poly(benzoxazine-co-urea) as adhesive for LSS measurement [225]. Copyright 2017. Reproduced with permission from John Wiley & Sons, Inc. (c) Adhesive strength of polybenzoxazines based on cardanol [90]. Copyright 2018. Reproduced with permission from WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany.

Main-chain type polybenzoxazine with and without free o- and p-positions to the O of oxazine undergoes polymerization due to the free o-position to the N of oxazine are shown in Figure 22. The latter polymer, which is based on the crosslinking from o-position to the oxazine N, revealed a lower To and a wider width of the tan δ peak suggesting the ROP occurs through the o-position to the O of oxazine led to better thermal properties than that through the o-position to the N of oxazine [226].

Figure 22.

(a) Mode of polymerization of main chain type o- ad p-blocked benzoxazine polymer. (b) Proposed ROP Mechanism for PBz-2M [226]. (c) DMA thermograms of C-PBz-0M and C-PBz-2M [226]. Copyright 2015. Reproduced with permission from American Chemical Society.

In summary, main chain type subclass polybenzoxazines provides benefits of an easy synthesis and processability without compromising thermal stability and mechanical property between the polymers obtained from monomeric and high molecular weight oligomeric oxazine precursors. Furthermore, additional reactive functionality other than oxazine ring provides capability to optimize the benefits of both thermoplastic and thermoset polymers. For example, additional functionalities modify the properties of the polymer such as tunability in Tg, solubility in solvents, formation of self-supporting films and may provide opportunities to control over ductility and adhesive properties to name a few.

Selective introduction of benzoxazine moieties into polymer side chains and terminals [227], and the attachment of radically polymerizable groups such as methacryloyl group to Bz monomers [228,229], led to more variation in functional properties than those discussed above. Few representative structures are shown in Figure 23. Radically polymerizable functionalities in benzoxazine monomers were synthesized to incorporate the benzoxazine units within the side-chain of constituent repeat unit.

Figure 23.

(a) Representative photopolymerizable benzoxazine containing monomers [228,229] and (b) TGA curve of methacryloyl-benzoxazine monomer [228]. Copyright 2011. Reproduced with permission from American Chemical Society.

Radically polymerizable groups bearing benzoxazine monomers first photopolymerize and are then followed by a thermally activated ROP reaction. However, polymerization of oxazine ring is not realized due to the limit of thermoplastic polymer degradation at a much lower temperature of 200 °C, as can be seen from TGA trace in Figure 23b [228,229]. Copolymerization of poly(PH-pva) (va, vinylaniline) with methyl methacrylate (MMA), and n-butyl acrylate (BuA) followed by polymerization led to the formation of a tough and flexible film, respectively [230]. The molecular weight of both homopolymer i.e., poly(PH-pva) and poly(vPH-a) (vPH, vinylphenol) was found to be relatively low, which is attributed to the steric hindrance of benzoxazine groups and can be affected by copolymerization with N-phenylmaleimide [231]. The polymer, poly(PH-pva), showed a higher stability (>400 °C), supporting the concept that control at molecular level is the key to guide properties.

Instead of polymerizing monomers containing benzoxazine units, another facile approach involves tethering of pre-synthesized monomers to the polymer backbone directly via potential and affordable chemistries [232] such as click [185,233,234,235], esterification chemistry, and so on [229]. Representative examples are shown in Figure 24.

Figure 24.

Representative side-chain benzoxazine linked polymers [229,232,235].

Interestingly, in the aforementioned side-chain polymers, the benzoxazine units are grafted at a higher concentration. Sparse population of benzoxazine can also be possible by milder photochemical approaches. Temel et al. [236] synthesized a one-component type II photoinitiator based on the BOP-a benzoxazine monomer derived from benzophenone (BoP). This monomer revealed better light absorption characteristics than BoP alone. BoP-a initiated free radical photopolymerization of MMA to form BoP-a tethered PMMA, showing a higher Tg (135 °C) than neat PMMA (100–105 °C). Bai and Shi [237] reported a BoP based bisbenzoxazine photoinitiator revealed four times higher photopolymerization rate of acrylate monomers than BoP based system.

Telechelic structures are macromonomers containing non-reactive oligomeric chains in the structure with terminal oxazine groups. The low concentration of oxazine functionality allows for development of lightly crosslinked networks. However, they can be effective for copolymerization with other monomers and polymers. Several reactive thermoplastic telechelic architectures are reported with the variation in linking units from flexible to rigid linkages as shown in Figure 25, to tailor their properties [238]. Unfortunately, due to the dilution effect of the reactive oxazine rings, the Tp might increase as compared with ordinary monomeric counterparts.

Figure 25.

Representative structures of telechelic benzoxazines [46,238,239,240].

2.4. Fourth Generation

2.4.1. Smart Benzoxazines

Despite having outstanding performances, polybenzoxazoles (PBO), usage is still limited both by synthetic and fabrication challenges. Additionally, the stringent synthetic requirements, such as expensive and higher structural rigidity of raw materials as shown in Figure 26a, sensitive reaction conditions, and difficulty of completely eliminating the solvent used leads to aging of the properties. This demands exploration of alternative simpler and facile routes. Recently, a new class of benzoxazine monomers and main-chain type polymers that contain o-amide, o-imide, and o-amide-imide groups have been reported [56,195,198,241]. These benzoxazine resins undergo usual ROP to form crosslinked PBzs at temperatures lower than ordinary benzoxazine polymerization. Upon further heating the crosslinked polybenzoxazines, in situ structural transformation takes place that converts polybenzoxazine to PBO. Correlating this intermediate structure with the smart designing of the benzoxazine monomer, Agag et al. [193] first reported an easier synthetic route for PBO via polybenzoxazine through the process shown in Figure 26b. This synthetic aspect was further confirmed as only o-amide benzoxazine isomer account to PBO formation, but p-amide benzoxazine failed to undergo such intramolecular cyclization reaction, as illustrated in Figure 26c.

Figure 26.

(a). Two-step condensation synthesis of polybenzoxazole via intermediate poly(o-hydroxyamine); (b,c) probable synthetic route of polybenzoxazole from o-amide benzoxazine monomer, p-amide benzoxazine monomer disfavor cyclization reaction [193].

The work was further extended by Zhang et al. [241,242] where they reported formation of crosslinked PBO via poly(benzoxazine amic acid), poly(Bzaa), using o-benzoxazine chemistry as shown in Figure 27. Synthesis involved imidization to form crosslinked polyimide, (cPI) which upon further heating undergoes simultaneous decarboxylation and cyclization reaction to give crosslinked polybenzoxazole (cPBO).

Figure 27.

Preparation of cPBO via poly(Bzaa) from benzoxazine monomer [241].

The synthetic route was further simplified by the exclusion of amic acid intermediate via small molecule o-imide functional benzoxazines as a precursor for structural transformation to PBO. The polymer showed a very high thermal stability with T5% of 505 °C and an extremely high char yield of 73% [195]. Interestingly, o-amide functional benzoxazine monomers are found to undergo ROP at a much lower temperature than both the p-isomer and non-amide-based control monomer. The o-isomer revealed a lower polymerization temperature than the p-isomer due to the more stable intramolecular 5-membered ring hydrogen bonding interaction that accelerates the ring-opening process [243]. The above polymers revealed an extraordinary low heat release capacity (HRC) further making them strong contenders to replace poly(ether imide) and other high performance polymers.

In above-mentioned methodologies, the temperature required for conversion of o-amide benzoxazines and o-imide benzoxazines into benzoxazole structure was found to be high, ~300–400 °C, which led to difficulties during their fabrication. Zhang et al. overcame this difficulty by developing the endcapping trifluoro group. The incorporation of o-trifluoroacetamide in benzoxazine (oTFAPH-ddm) exhibits a low polymerization temperature compared to other reported o-amide benzoxazines due to higher acidity of amide hydrogen, Figure 28. Furthermore, a remarkably low temperature (260 °C) for interconversion to benzoxazole is observed. Additionally, existence of fluorine in PBO led to an attractive feature of low dielectric constant (2.42–2.19 within the frequency range of 1 Hz–1 MHz) in addition to high thermal stability and Tg of 354 °C.

Figure 28.

(a) DSC thermogram of oTFAPH-ddm and (b) five membered-ring hydrogen-bonding system at each side of the symmetric resin in chloroform. Copyright 2017. Reproduced with permission from American Chemical Society.

Mahdy and Kuo [244] reported a direct synthetic route for the preparation of o-imide containing benzoxazine monomer by condensation of anhydride (NTCDA) with o-amino phenol (o-APH) to produce o-imide phenol (NDoPH) which was then condensed with paraformaldehyde and aniline to form o-imide benzoxazine as shown in Figure 29. The monomer revealed miscibility with poly(4-vinylphenol) due to hydrogen bonding between C=O and OH groups. Upon polymerization of the monomer, the extensive H-bonding between polybenzoxazine led to an improvement in Tg, thermal stability, and char yields of the resultant polymer blends.

Figure 29.

Direct synthesis of o-imide benzoxazine monomer followed by polymerization [244].

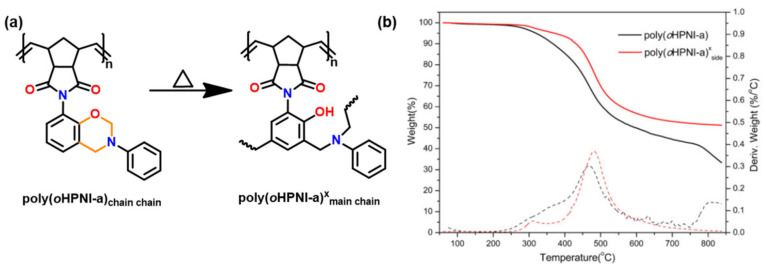

Zhang et al. [245] reported the synthesis of side chain containing an o-imide functionality to norbornene functional benzoxazine ring as shown in Figure 30. This allowed the monomer to undergo ring-opening metathesis polymerization (ROMP) to form a new polynorbornene functionalized benzoxazine. However, its interconversion to substituted PBO is not reported due to limitations of thermal stability of poly(oHPNI-a)xmain side as determined from the TGA curve in Figure 30b.

Figure 30.

(a) Syntheisis of ring-opened main chain polymer; (b) thermogravimetric analysis of poly(oHPNI-a) and poly(oHPNI-a)xmain chain [245]. Copyright 2019. Reproduced with permission from Sage publications.

2.4.2. Oxazine Ring Substituted Benzoxazine

Both the synthesis of 1,3-benzoxazine monomer and polymer and their properties are widely reported in literature. Supplementarily, substitution in oxazine ring at 2- and/or 4-position as shown in Figure 31 presents an attractive structural design, especially in polymer chemistry [246,247]. The nomenclature adopted in such structures is an extension to earlier proposition of benzoxazine structures. For abbreviation of the ring substituted benzoxazine, the following nomenclature is proposed: abbreviated benzoxazine monomer name-[position of substitution in oxazine ring] abbreviated phenyl/alkyl in lower case characters. Thus, for example, PH-a with phenyl ring substitution at 2-position is represented as PH-a-[2]ph.

Figure 31.

(a) Examples of oxazine ring substituted benzoxazine monomers; (b) proposed polymerization mechanism [247].

Ohashi et al. [247] first reported polymerization of phenyl substituted 1,3-benzoxazines. The substitution at 2-position is achieved via typical multi-step synthesis from salicylaldehyde involving condensation with benzaldehyde instead of formalin for ring closure reaction. The substitution in oxazine ring allowed a lower polymerization temperature than the general benzoxazines due to the resonance stabilization of iminium ion intermediate as shown in Figure 31b.

However, polymerization of oxazine ring-substituted monomers is currently limited due to evaporation of lower molecular weight N-benzylideneaniline molecule as a by-product accounting for a lower thermal stability of polymer. Alternatively, formation of ladder-type bisbenzoxazine PH-ppda-[2]ph lowered issues of volatilization, due to heavier and bulky nature of imine accounting for its entrapment in polymerization matrix and subsequent involvement in the polymerization reactions. Such losses can also be minimized to some extent by using catalyst mediated ROP at low temperature [248]. More recently, lack of the use of formaldehyde during the synthesis was emphasized as an environmentally friendly method by Travernier et al. [249].

2.4.3. Fused Ring Benzoxazines

Fused-ring benzoxazine structures contain a sandwiched oxazine ring between an aromatic ring and a cycloaliphatic ring 1-naphthol (1-NP) [250] or 2-naphthol (2-NP) [251,252]. This approach involves a two-step synthesis, firstly of cyclic imines and activated phenols reacted to form aminocycloalkylphenols by the Betti reaction [253]. Secondly, ring-closure reaction of amino derivative with formaldehyde as shown in Figure 32 is carried out [254]. The nomenclature follows numbering of the positions on the oxazine ring as in benzoxazine nomenclature. The aromatic portion contains numbers accompanied by the character “x” as abbreviation for the aromatic ring (b and n for benzene, and naphthalene, respectively) and finally the fused ring using alphabetic letters. For instance, 1-NP and formalin (f) based benzoxazine fused with 3,4-dihydro-2H-pyrrole (p) will be abbreviated as 1NP-p-f. Arza et al. [254] reported the polymerization of fused ring benzoxazine. These monomers show a much lower Tp as compared to the conventional mono-oxazine monomers. This is due to high basicity of tertiary amines and van der Waals’ strain in sandwiched oxazine ring geometry. Despite interesting structure, low temperature mass losses of polymers as shown in TGA trace Figure 32b demands exploration of alternative synthetic designs.

Figure 32.

(a) Synthesis of fused ring benzoxazine monomer and proposed polymerization, (b) TGA thermograms of (a) poly(1NP-p6-f), (b) poly(1NP-p-f) and (c) poly(1NP-dhiq-f). Inset shows the derivative of the weight loss of poly(1NP-p6-f) (green line), poly(1NP-p-f) (blue line) and poly(1NP-dhiq-f) (red line) as a function of the temperature [254]. Copyright 2017. Reproduced with permission from American Chemical Society.

3. Acceleration of the Rate of Polymerization via Intermolecular Interaction

Benzoxazine monomers tend to undergo thermally accelerated ring-opening polymerization in the temperature range 160–220 °C. This temperature range varies with the structure, number of oxazine rings, regio-position, and most importantly, purity of the monomer. In general, mono-oxazine benzoxazines have a Tp of ca. 250 °C. A low polymerization temperature is desired to improve processibility and compatibility with many other resins and substrates. Alternatively, physical blending of catalysts and initiators with the Bz monomer is one of the most efficient and economically viable approaches for the lowering of polymerization temperature [255,256,257,258,259].

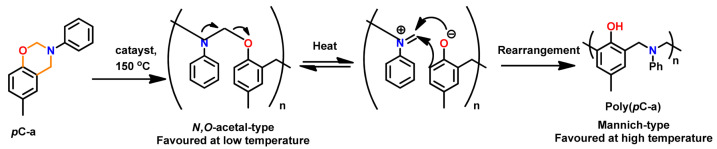

Burke and co-workers [2,260] first reported the ring-opening reaction of Bz, indicating that aminoalkylation preferred to occur at the free o-position rather than at the free p-position of the phenol in the reaction of 1,3-dihydrobenzoxazine with a phenol. Riess et al. [261] also observed preference of o-substitution during the investigation of the kinetics of mono-functional benzoxazines in the presence of catalytic amounts of 2,4-di-tert-butylphenol. McDonagh and Smith [262] suggested existence of ring-chain tautomerism in protonated benzoxazine. Dunkers and Ishida [256] proposed cationic ROP mechanism of Bz monomers. It occurs by protonation of the oxygen/nitrogen atom in oxazine ring in formation of an iminium ion intermediate. This then undergoes several electrophilic aromatic substitution reactions to form the PBz framework. A simplified structure of this phenolic polymer representation is shown in Figure 33. The oxazine ring in the monomer with free o-position undergoes a cleavage reaction at O-CH2-N bond to form a polymer with a Mannich base phenoxy-type polybenzoxazine structure [255]. This then rearranges to a thermally stable Mannich type phenolic polymer structure upon heating.

Figure 33.

Proposed polymerization mechanism to reflect the effect on structure linkages in PBz with variation in temperature and catalyst.

The Ishida group worked extensively in determining the thermally accelerated polymerization mechanism and supported ROP proceeds through cationic mechanisms [42,64,263,264,265,266,267]. The plausible mechanism is shown in Figure 33. More recently Liu et al. [268] provided an experimental evidence to support the intrinsic ROP without an added initiator using a high purity monomer, PH-a.

The ring-opening polymerization is primarily guided by the strong Lewis basicity of both N and O atoms present in the oxazine ring. It was proposed that the acidic catalyst allows polymer network growth via cationic ring-opening reaction while basic catalyst proceeds by nucleophilic ring-opening reaction as illustrated in Figure 34 [268].

Figure 34.

Proposed mechanism of ring-opening reaction in presence of acid and basic catalysts [268].

Wang and Ishida first reported the formation of arylether structure instead of traditional phenolic structure as the repeat unit of polybenzoxazine chains when the monomer was polymerized at low temperatures using catalysts [255]. Sudo et al. [269] then reported that this N,O-acetal structure (unit A) formed during polymerization of p-substituted monomer at lower temperatures in the presence of a catalyst and can undergo structural transformation to thermally stable phenolic structures (unit B) upon heating above 150 °C. The existence of different types of linkages in polymer structure is guided by temperature, and their extent in polymer architecture is quantified by NMR spectroscopy as shown in Figure 35. Additionally, the main chain rearrangement was prominent in the polymerizations of N-aryl- over N-alkyl-1,3-benzoxazines, while the latter favors the formation of Mannich-type structure polymers.

Figure 35.

1H NMR spectra of the polymer obtained after heating for (a) 5 h at 150 °C in the presence of 1 mol% EMI, (b) 9 h at 150 °C in the presence of 1 mol% EMI, (c) 1 h at 200 °C and (d) the polymer obtained by the reaction of the polymer (c) and tert-butylisocyanate. [269]. Copyright 2008. Reproduced with permission from American Chemical Society.

An understanding of the polymerization mechanism provides a strategy to utilize or design structures of catalysts/initiators. Done effectively, this provides insight into methods for the acceleration of polymerization. Besides structure of monomers, polymerization behavior is a combination of effects which are primarily guided by the amount, acidity, basicity and structural compatibility of the initiator/catalysts. It must also be noted that purity of monomer is essential as the presence of unconsumed reactants and oligomers initiate polymerization reaction, thereby affecting the rate and temperature required for polymerization. The purity of a benzoxazine monomer has been documented to have a dramatic effect on melting and polymerization behavior [270].

3.1. Use of Cationic Initiators

3.1.1. Ordinary Acids

Acidic initiators are usually preferred due to ease of availability and variable acidity to mediate cationic ROP. Acids protonate either the oxygen or the nitrogen atom of oxazine ring and thereby facilitate intermediate iminium ion formation. The former is preferred as the resultant iminium ion intermediate is relatively more stable, as shown in Figure 36 [271]. Repetitive electrophilic reactions involving the generated intermediate and the O-attack, N-attack, and aryl-attack by the Bz monomer results in the growth of polymer, which may contain phenoxy and phenolic linkages. In structures where o-positions are blocked or sterically hindered, polymerization is expected to occur at an available p-position to the benzoxazine ring.

Figure 36.

ROP of Bz monomers initiated by proton catalyst [271].

Ishida et al. [266] reported the use of phenols with a free o-position (BA, poly(p-hydroxystyrene), 2,2’-dihydroxybenzophenone and 2,6-di-tert-butyl-p-cresol), with mild and strong organic and mineral acids (acetic, adipic, sebacic, benzoic, sulfuric, p-toluenesulfonic, phosphoric acids) as catalysts for the ROP of Bz monomer. Adipic acid (6 mol%) was found to be the most effective and showed a 17% decrease in the curing parameters. PBzs obtained using strong carboxylic acids were inferior to those formed with weak carboxylic acids. The pKa of the acid appeared to control the interconversion of the reactive intermediate, aminomethyl ester and the iminium ion affecting crosslinking reactions. Figure 37 shows a faster decrease in the normalized areas of the characteristic oxazine ring vibrations at 1050 and 813 cm−1 in presence of p-cresol (pKa = 10.2) than sebacic acid (pKa = 4.7, 5.4), supporting that the former mediates faster oxazine ring-opening reaction [256].

Figure 37.

(a) Conversion of benzoxazine monomer (pC−ma) with (a) 10 mol% pC and (b) 9 mol% sebacic acid at 160 °C [256]. Copyright 1999. Reproduced with permission from John Wiley & Sons, Inc.

The effect of phenol on the polymerization reaction and associated reaction pathways was explicitly understood using the reaction of 2,4-xylenol (2,4-XY) with 3-aryl substituted benzoxazine. The intermediate species formed were several inter- and intra- molecular rearranged products [272]. Bisphenol F acts as a better catalyst than BA which may be due to differential electron donating capability of methylene vs isopropylidene bridge in biphenols [273]. A very high loading (~40 wt%) of phenolic compound, cashew nut shell liquid (CNSL), in BA-a led to a decrease in both Tp and ΔH from 216 °C and 246 J g−1 to 197 °C and 194 J g−1 [274]. Furthermore, the polymerization reaction proceeds in an autocatalytic manner due to the formation of ring-opened phenolic structures [266], which itself promotes the initiation reaction and induces a catalytic effect. For instance, resorcinol-aniline (R-a) benzoxazine undergoes polymerization (Ti 146 °C, Tp 179 °C) at a much lower temperature as compared to PH-a [146]. This is accounted to the formation of two vs one phenolic -OH in ring-opened structure in R-a vs. PH-a.

The low percentage of phenols act as an initiator and affect both rate and the temperature required for ROP reaction. Hamerton et al. [275] reported that TDA (3,3-thiodipropionic acid, pKa = 4.11) is a superior initiator to 3,3-thiodiphenol due to its higher pKa value. TDA has a greater effect on the reduction of To with simultaneous increase in crosslink density as reflected from a high Tg value in the resultant polymer.

Natural renewable phenolic acids, cinnamic [102], ferulic [101], coumaric [101] and phloretic acids [104] besides their utility as a feedstock for the synthesis of benzoxazine monomer, were also used as catalyst to reduce the polymerization temperature of the polymerization reaction.

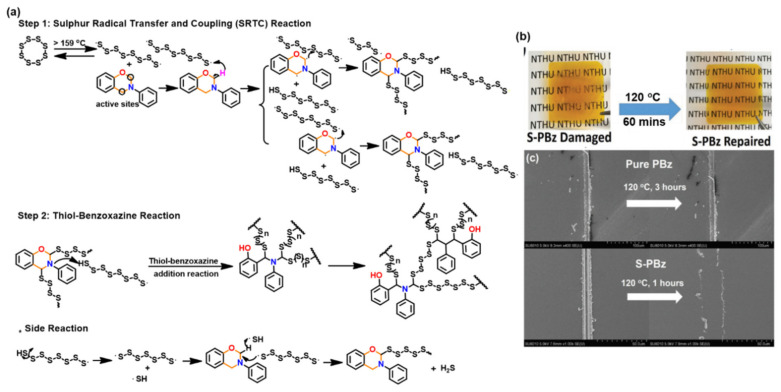

3.1.2. Thiols and Elemental Sulfur

Unlike phenols, thiophenols react with Bz monomers in a reversible manner at ambient temperature. Additionally, high miscibility, inexpensive cost, and stability towards moisture are encouraging towards their practical use. As compared to phenols, thiol compounds are more efficient at lower weight percent loading due to their active hydrogen donating ability. Gorodisher et al. [276] in 2011, reported addition reaction of thiols with Bz for adhesive application. They proposed a two-step Catalytic Opening of the Lateral Benzoxazine Rings by Thiols (COLBERT) mechanism as shown in Figure 38a. A first step involving protonation of the nitrogen atom of an oxazine ring by thiol was proposed. Subsequently, the thiolate ion attacks >CH2 group between heteroatoms to enable oxazine ring-opening reaction. The overall process is similar to acid catalyzed nucleophilic addition and simultaneous ring-opening reaction of benzoxazines. Due to reversibility of the reaction, only small amounts of thiols reduce the polymerization temperature as shown in DSC thermograms in Figure 38b, and due to a continuous regeneration of active species, thiol and iminium ion, which then mediate polymerization reaction.

Figure 38.

(a) Proposed COLBERT reaction mechanism and (b) DSC comparisons of aliphatic vs aromatic benzoxazine/thiol polymerization profiles [276]. Copyright 2011. Reproduced with permission from Elsevier B. V.

The protonation of the N or O atom of an oxazine ring by thiol is considered a rate-determining step as supported by catalytic, and inhibitory effect of acids, and bases on ROP of oxazine ring, respectively. It is observed that monomers sourced from aliphatic amines undergo a more rapid reaction with thiols than aromatic amines due to their more basic nature. The rate of reaction is strongly affected by the acidity of thiol and nature of solvent (protic vs aprotic). Kawaguchi et al. [277,278] investigated the reversible nature of polymerization-depolymerization reaction of pC-a with p-methoxythiophenol (pMOTPH) to form a ring-opened adduct as illustrated in Figure 39a. The yield of adduct is higher in polar solvents as compared to polar aprotic solvents, Figure 39b, which is due to stabilization of the polar zwitter ion/ammonium cation intermediate [277,279,280].

Figure 39.

(a) Reversible addition-dissociation reaction of pC−a with p-methoxythiophenol (MOTPH) at 0.1 M concentration of reagents. (b) Time-dependence yield of adduct [280]. Copyright 2014. Reproduced with permission from Wiley Periodicals, Inc.

Besides monomer, main-chain type PBz was polymerized at room temperature with various thiols, namely, thiophenol, 2-ethanethiol and 1-butanthiol in CH3OH/CHCl3 for 24 h. Successful incorporation of the thiol compounds to PBz was confirmed by spectral and molecular weight characterizations [279]. Urbaniak et al. [281] proposed that reversible ring-opening of 1,3-benzoxazine with thiols proceeds via an iminium ion intermediate rather than the cyclic six-membered transition state, as shown in Figure 40 [278]. p-Nitrothiophenol and thiophenol promotes a substantial increase in % conversion of monomer as can be seen from Figure 40b, which illustrates the strong influence of thiols with low pKa values. Their work emphasizes the relevance of the protonation step in the ring-opening reactions of benzoxazine with thiols in solvent/solvent-free conditions, allowing predominance of acidity over nucleophilicity [277,281].

Figure 40.