Abstract

Considering the significance of the gut microbiota on human health, there has been ever-growing research and commercial interest in various aspects of probiotic functional foods and drugs. A probiotic food requires cautious consideration in terms of strain selection, appropriate process and storage conditions, cell viability and functionality, and effective delivery at the targeted site. To address these challenges, several technologies have been explored and some of them have been adopted for industrial applicability. Encapsulation of probiotics has been recognized as an effective way to stabilize them in their dried form. By conferring a physical barrier to protect them from adverse conditions, the encapsulation approach renders direct benefits on stability, delivery, and functionality. Various techniques have been explored to encapsulate probiotics, but it is noteworthy that the encapsulation method itself influences surface morphology, viability, and survivability of probiotics. This review focuses on the need to encapsulate probiotics, trends in various encapsulation techniques, current research and challenges in targeted delivery, the market status of encapsulated probiotics, and future directions. Specific focus has been given on various in vitro methods that have been explored to better understand their delivery and performance.

Keywords: Probiotics, Targeted delivery, Encapsulation, Stability, Probiotic foods

Introduction

In the early twentieth century, Elie Metchnikoff discovered the beneficial gut microbe which normalizes gut health and prolongs life, later it was termed as “probiotic” [1]. Probiotics refer to “live organisms which when administered in adequate amounts confer a health benefit to the host” [2]. Probiotics are health-promoting microorganisms and are also considered next-generation bio-therapeutics in the field of gut microbiomics [3]. Several bacterial species of Lactobacillus, Lactococcus, Bacillus, Streptococcus, Bifidobacterium, Pediococcus, and Propionibacterium are well-known probiotics [4]. Yeasts such as Saccharomyces cerevisiae, S. carisbergensis, and S. boulardii and fungi such as Aspergillus niger and A. oryzae are also considered as probiotics. However, the most common probiotic bacterial genera are Lactobacillus and Bifidobacterium [5]. Until March 2020, the Lactobacillus genus contained 261 genetically diverse species. Recently, it was reclassified into 25 genera by a group of scientists based on whole-genome sequencing [6]. The update of this current taxonomic classification may help in understanding the mechanisms of probiotics for health benefits.

Apart from modulating the gut functionality, probiotics have also been associated with various other health benefits such as brain functioning, boosting immunity, reducing cholesterol, and promoting metabolic homeostasis through their biological mechanisms in the body. Probiotics can produce short-chain fatty acids, vitamins, enzymes, organic acids, and antimicrobial peptides [7]. These compounds are involved in the physiological functions of the body. “Probiotic Supplements Market—Global Outlook and Forecast 2020–2025” reported that the growth in immune health concerns among people leads to an elevation in the market growth of the probiotic supplements during the COVID-19 pandemic [8]. The recent report on “Probiotics Market—Growth, Trends, and Forecast” forecasted the global probiotics market to reach USD 76.85 billion by 2024, registering a CAGR of 8.15% during the forecast period between 2020 and 2025 [9]. The report also indicated that the bacteria market would grow at the fastest CAGR, owing to the growing demands for prominent applications in fortifying foods with probiotics.

The science of probiotics covers aspects from the field of microbiology to food processing and has found applications in various fields such as nutraceuticals and functional foods, therapeutics in dental care, skincare, oncology, gastroenterology, immunology, and psychoneuroendocrinology [10]. In general, probiotics are orally administered and are commercially available in the forms of functional foods, dietary supplements, and drugs (medicinal probiotics). Usually, people prefer food over supplements/medicinal drugs considering the hedonistic aspects of food ingestion [11]. FAO/WHO 2002 reported that the viability of probiotics in food products must be in adequate amounts to confer a health benefit. Also, it has been reported that probiotic foods should have at least 106 CFU/g viability of live microorganisms [12–14]. However, the stability of probiotics is the most desirable concern for targeted colon delivery when ingested orally. It is necessary to maintain its viability during gastrointestinal (GI) transit to promote its efficacy. Probiotics require protection against various stress factors during processing, storage, and digestion. Different strains of probiotics show variations in their abilities such as functional properties, stability, and efficacy. The stability of probiotics can be improved by various strategies such as stress adaptations through pre-treatment, mutagenesis, selective pressure treatment, and genetic modifications through omics technologies [15]. However, some of these processes may alter the potential of probiotics, and also genetically modified strains are not well accepted for food applications [16, 17]. Encapsulation is proved to be the best way for the protection of probiotics to ensure their stability without any change in native strain properties.

“Food Encapsulation: Global Market Analysis, Trends, and Forecasts” report has highlighted the encapsulation market outlook (2019–2024) on microencapsulation of probiotics to drive the growth of this sector [18]. The recent report on “Food encapsulation market by shell material, technology, application, method, core phase, and the region” forecasted the food encapsulation market to reach USD 14.1 billion by 2025, registering a CAGR of 7.5% during the forecast period between 2020 and 2025. The functional food segment accounted for the largest market share in 2020, also the probiotics market is projected to record the highest CAGR during the forecast period [19].

Encapsulation of probiotics provides the protection made up of encapsulating materials that stabilize the probiotics during processing, storage, and at the site of action by enhancing stress resistance [20]. Thereby, the encapsulation process also imparts targeted delivery. The formulation is one of the critical considerations for a targeted delivery system and can be developed by proper designing of the process. Many approaches are available for the delivery of probiotics to the lower intestinal tract toward the colon. Lee et al. [21] reviewed various formulation approaches for colon targeted delivery such as polymeric/lipid-coated, pH-controlled, magnetic/enzyme-triggered, and ligand-receptor-based delivery systems. Milk, yogurt, cheese, ice cream, honey, chocolate, and fermented foods (rice/fruit/vegetables) are natural delivery systems of probiotics. Besides, prebiotics are nondigestible food ingredients that support the delivery of probiotics to the colon (as encapsulation agents) and in all cases, nourish probiotic microbes [22, 23]. Natural prebiotics includes raw banana, onion, garlic, sugarcane, artichokes, and the roots of chicory and yacon [24, 25], and are commercially available as resistant starch, inulin, lactulose, lactitol, lactosucrose, fructooligosaccharide (FOS), xylooligosaccharides, and galactooligosaccharides [26, 27]. Probiotics along with prebiotics are termed “synbiotics” that improve the survivability of probiotics, whilst stimulating the growth of specific native strains present in the GI tract through a synergistic approach [28, 29]. Synbiotics in which prebiotics are considered as a substrate is selectively utilized by the co-administered probiotics (synergistic synbiotic) or by the endogenous micro-organisms (complementary synbiotic) [30]. Generally, the viability of the microbes highly depends on various factors such as matrix, storage temperature, moisture, pH, and oxygen level [28, 31, 32]. The encapsulation matrix improves the stress tolerance of probiotics [33]. Thus, the synergistic synbiotic approach ensures the stability of the co-administered probiotics when both are combined in a matrix form. Also, this helps to maintain the potential of probiotics throughout the shelf-life.

Some of the recent reviews have explained the selection of probiotics, factors affecting the viability of probiotics, different encapsulation methods, encapsulating materials, and targeted delivery systems [28, 34–36]. There exists a gap particularly in terms of critical issues with non-encapsulated probiotics, the efficacy of encapsulated probiotics, in vitro and in vivo methods to confirm the targeted delivery of probiotics, market status, and feasibility of encapsulated probiotics at the industrial level for commercialization. Thus, the focus of this review is too ambitious to aim for a complete understanding of the need for encapsulating the probiotics, the prominence of the encapsulation process, their impacts on targeted delivery, in vitro and in vivo methods to confirm the targeted action, market status of encapsulated probiotics and economic feasibility for commercialization.

Biological Mechanisms and the Role of Probiotics in Human Health

Probiotics provide various health benefits through their biological mechanisms in the body. The “human microbiome project” has reported that the number of other bacterial cells in the human body is about 10 times the number of human cells [37]. These bacteria include beneficial microbes as well that play a vital role in the sustenance of human health. The exact mechanism of action is not fully known, but probiotic bacteria produce postbiotics such as short-chain fatty acids, enzymes, lactic acid, and also secrete antimicrobial peptides that kill pathogenic bacterial strains [7]. These bacteriocins are considered to be “natural preservatives” [38]. Probiotics have also been associated with nutrients to compete with pathogens, thereby inhibit/block pathogenic bacterial adhesion in the colonic lumen, and thereby improve mucus production, which in turn enhances the intestinal epithelial barrier for stimulation of the immune system [39, 40].

Probiotics reduce toxins through bile salt hydrolase [41] and increase the bioavailability of nutrients in the body through other enzymatic activities [42, 43]. Some probiotics even have the potential to secrete specific anticarcinogenic and antioxidant metabolites that help in disease treatment [44]. Endogenous supplementation of probiotics can help in the replenishment of the gut microbiome after antibiotic treatment. Consumption of probiotics along with antibiotics or after antibiotic treatment can prevent antibiotics-associated diarrhea [45]. Researchers have also found that specific mechanisms involved in probiotics-linked signaling of nerve functions in the central nervous system can promote potential therapeutic actions on neuropsychiatric disorders and stress-related diseases [46, 47].

Apart from enhancing digestive health, probiotics also relate to brain functioning [48–50], help to treat irritable bowel syndrome [51], and reduce the level of low-density lipoprotein in the blood [52, 53], prevent vaginal and urinary tract infections (yeast/ bacterial) in women [54–56], prevent pancreatitis and improve pancreatic health [57], contribute to respiratory tract health [58–60], inhibit tumorigenesis [61], regulate immune responses [7, 62], and contribute to metabolic homeostasis [63, 64]. Moreover, probiotics aid in the treatment of metabolic disorders such as diabetes, non-alcoholic fatty liver disease and cardiovascular diseases [65–68], cancer [52, 69–71], oral Candida infections, and periodontitis [72, 73]. As different strains provide specific health effects, the selection of appropriate strains and genus of probiotics is a key for distinct applications and it must be done carefully [74, 75].

The biological effects of probiotics can be explained based on their metabolic processes, describing the significance of probiotics in the human body, i.e., the physiologic effects of probiotics. Such effects are categorized below:

Modulation

Probiotics involve metabolic modulations through direct or indirect influences on the signaling pathways that either suppress or activate the regulation of pathways [50, 76]. The ability of probiotics to adhere to the intestinal mucosa for colonization and their interaction with innate immune responses can modulate the barrier functions of intestinal epithelial cells, thereby conferring health benefits to the host [77, 78]. These modulatory mechanisms assist in antagonism against pathogens, thereby improving immunity (immunomodulation), increase the anti-oxidant potential, improve intestinal transit, enhance nervous reflexes (neuromodulation), regulate vascular endothelial function and blood pressure, reduce cholesterol level, and maintain the dynamic balance of healthy and damaged cells [79–85].

Synthesis

Synthesis of bioactive metabolites through their mechanism of action is a key aspect of probiotics. For instance, synthesis of short-chain fatty acids (acetic, butyric, and propionic acids) through non-specific mechanism [86], vitamins by species-specific mechanism (Vit-B2 and Vit-K2 by B. subtilis, and Vit-B12 by B. megaterium) [87], signaling molecules (strain-dependent release of cytokines by LDR0723, BNL1059, RGS1746, and CRL1528 strains of L. salivarius) by strain-specific mechanism [62].

Absorption

Probiotics can enhance the bioavailability of micronutrients and their metabolism [88]. Iron absorption in Fe2+ form is significant; however, in the intestinal mucosa, iron binds with apoferritin which converts Fe2+ to Fe3+ (ferritin) [89]. Probiotics present in the gut microbiome can help in the reduction of Fe3+ to Fe2+, facilitating an increased duodenal absorption of iron [42]. Hoppe et al. [90] reported that the intake of lactic acid bacteria increases iron absorption rates and the relative iron bioavailability through extracellular enzymes. Similarly, Dubey and Patel [43] found that probiotics play a significant role in the enhancement of calcium uptake, and the improvement of its absorption through colonic fermentation. In another study, Costanzo et al. [91] revealed that probiotics are involved in vitamin D synthesis and absorption. These examples explain the role of probiotics in improving the bioavailability of vitamins and minerals in the human body.

Prophylaxis

The prophylaxis mechanism of probiotics helps to prevent diseases and to reduce the risk of infections, type 1 allergies, viral infections, and cancers [92–94]. Monteagudo-Mera et al. [39] have explained the role of probiotic prophylaxis in the treatment of bacterial vaginosis. Importantly, several interventional clinical trials are being conducted to understand the effectiveness of probiotic prophylaxis. Panigrahi et al. [95] conducted the randomized clinical trials registered under NIH clinicaltrials.gov (NCT01214473 and NCT00518596) to study the efficacy of synbiotic supplement (L. plantarum with FOS) against neonatal sepsis and reported significant reductions in both culture-positive and culture-negative sepsis. Some other ongoing clinical trials are probiotic prophylaxis on microbiome modulation and prevention of severe infections like pneumonia in multi-trauma patients (NCT03074552) and the effect of probiotic oral mixture Labinic® on preventing sepsis infection by the colonization of extended-spectrum beta-lactamase (ESBL) caused by Enterobacteriaceae (NCT04172012).

Encapsulation of Probiotics: Need and Critical Considerations

Probiotics ingested through the oral route encounter several stress environments in the alimentary pathway. For instance, the human digestive system has variable pH levels. Approximately, the mouth has a pH of 6–7, the stomach has a lower pH of 1–3, and the pH ranges from 6 to 7 in the small and large intestines [96]. Owing to the low pH conditions in the stomach and the high bile salt content in the small intestine, maintaining the viability of probiotic microorganisms that reach the large intestine (colon-target site of action) is a challenge.

Accordingly, appropriate protection of probiotics is vital during the development of any functional probiotic food product. Apart from the conditions of the human body, other factors such as processing temperature, pH of encapsulating/matrix material, the oxygen level in the product, presence of other competing bacteria, and toxicity of metabolites have implications on probiotic viability [28]. In this context, during storage, the temperature and the moisture content of the products are major factors to be considered. Moreover, the rehydration and solubility behavior of dried probiotics are related to their survival and revival [97].

Various technologies have been developed to improve the external stress tolerance by probiotics, thereby enhancing colonization of gut microbiota through food matrix modifications and by engaging process engineering approaches. In this regard, food matrix selection and formulation are critical considerations in terms of technological performance and probiotic stability [98–100].

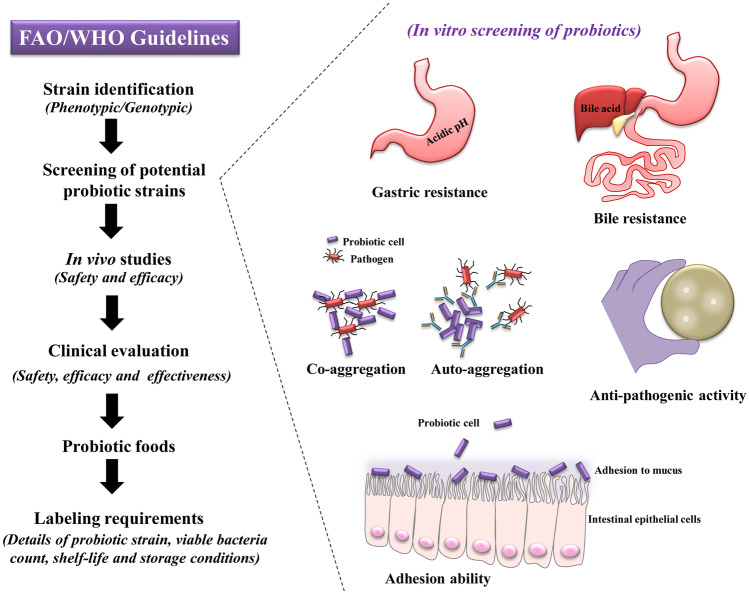

The encapsulation of probiotics as powder formulations can protect these live microorganisms and improve their stability and offer benefits in terms of targeted delivery [20]. Importantly, in the process of optimizing an encapsulation methodology for probiotics, microbial stability, functionality, safety, efficacy, and targeting ability must be established before and after the encapsulation process [28]. Figure 1 explains various screening sections involved in the evaluation of probiotics for food use as per FAO/WHO guidelines. To maintain the characteristic features of probiotics, an encapsulation approach should consider the following aspects.

-

i)

Stability of probiotics: assurance for improved retention of the viability of encapsulated probiotic bacteria

-

ii)

The functionality of probiotics: functional aspects such as resistance to gastric acids, bile salts and digestive enzymes, antimicrobial activity against potential pathogens, adhesion to mucus, aggregation, and other potential characteristics should be retained after encapsulation

-

iii)

Safety and efficacy: the probiotic strain should be safe, free from contamination, non-toxicogenic, retention of therapeutic efficiency after encapsulation

-

iv)

Targeting ability: improved tolerance towards environmental stress and the ability to target the colon for the enhancement of gut microbiota and beneficial health effects

Fig. 1.

Screening sections involved in each stage for the functional and safety aspects of probiotics (FAO/WHO guidelines)

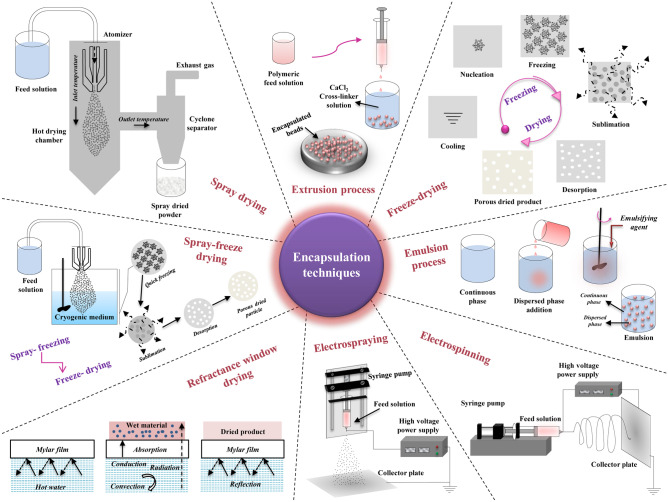

Various techniques have been explored for the encapsulation of probiotics (Fig. 2). Though the focus of all such methods is to protect probiotic viability/stability, the concept of each technique is unique and has direct implications on the product quality. Processing conditions are considered as the major factors that are responsible for the retention of quality and viability of encapsulated probiotics. Further, different wall materials have been explored as protecting/coating agents for the encapsulation of probiotics. They are sourced from dietary fibers, polysaccharides, proteins, and synthetic polymers. Typically, the selection depends on their functionality, film-forming ability, stability, solubility, digestibility, and releasing properties. To attain the desired properties, a combination of wall materials or the addition of emulsifier/ filling agents can also be employed. However, most established encapsulation approaches for probiotics have considered only the survivability of probiotics, and not the functionality or characteristics of probiotics. During encapsulation/drying of probiotics, the surface properties of the cell and their functionality can be impacted. This can have effects on probiotic characteristics such as aggregation (autoaggregation and co-aggregation) property, intestinal mucus adhesion ability, antagonistic activity, and bile salt hydrolase activity. Hence, future research needs to explore the functional characteristics of encapsulated probiotics in addition to the survivability of encapsulated probiotics, providing a better focus on the health benefits of probiotics.

Fig. 2.

Techniques for the encapsulation of probiotics

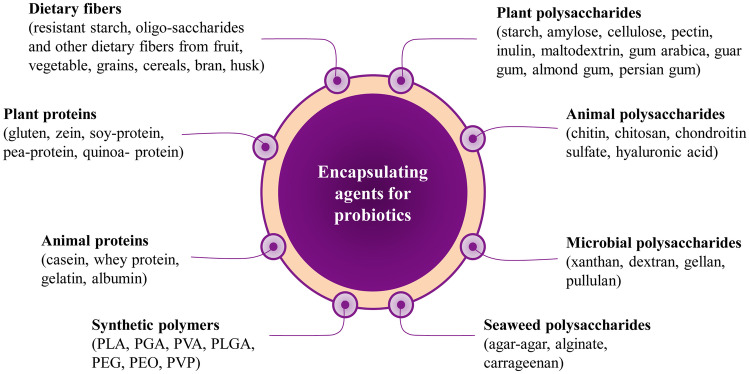

Critical Issues with Non-encapsulated Probiotics

Non-encapsulated probiotics (free cells) lose their viability at high temperatures, high operational pressures, shear stresses, and under low gastric pH, which in turn results in the depletion of probiotic cell count and performance [28, 101, 102]. The encapsulation process can protect probiotics by entrapping them in a protective wall material/matrix [28, 103–105]. Prebiotic materials such as FOS, inulin, and filler materials such as maltodextrin (MD), whey protein (WP), whey protein isolate (WPI), whey protein concentrate (WPC), alginate, gelatin, etc. have been reportedly used to encapsulate probiotics and have shown a significant role in improving the stability of probiotics in different external environments [106–109]. Different wall materials reportedly used for encapsulating probiotics have been detailed in Fig. 3.

Fig. 3.

Various encapsulating agents for probiotics

Several studies have confirmed that the encapsulated form of probiotics performs better than their non-encapsulated counterparts. As an example of the former, Rajam et al. [110] reported that the synergistic effect of DWPI (denatured whey protein isolate) and sodium alginate could provide better protection during high-temperature spray drying. Praepanitchai et al. [101] have encapsulated probiotics (L. plantarum) in hydrogel beads made up of alginate-soy protein isolate and studied the survivability of probiotics at different pH and temperature in pasteurized mango juice. Encapsulated probiotics showed enhanced survival during the thermal processing of mango juice. The viability of encapsulated probiotics was retained; whereas, non-encapsulated free cells lost their viability within 3 h when exposed to strong acidic conditions (pH 2). In another study, it was observed that non-encapsulated L. acidophilus showed a drastic loss in its viability in harsh environmental conditions such as high thermal pasteurization and acidic gastric conditions, whereas encapsulated probiotics in hydrogel beads made up of WPI and alginate showed reverse trends [111].

During transit through adverse and fluctuating conditions of the GI, encapsulation can provide significant protection to probiotics. For example, Del Piano et al. [112] observed intestinal colonization of microencapsulated probiotics and compared it with non-encapsulated probiotics. They explained that microencapsulated probiotic bacterial species showed improved gastric and bile tolerance owing to the protective coating, apart from enhanced probiotic activity. Interestingly, five-fold higher efficiency in colonization effect was observed as compared with non-encapsulated probiotics. It was reported that layer-by-layer encapsulation of probiotics with alginate and chitosan can improve the stability of probiotics and enhance their mucoadhesive properties [113].

Encapsulation contributes significantly to the storage stability and post-storage performance of probiotics. Prasanna and Charalampopoulos [114] conducted a study on the encapsulation of B. animalis subsp. lactis BB-12 using alginate–goats’ milk–inulin as the matrix. A significant loss in viability of non-encapsulated probiotics (reduction in 3.67 log10 CFU/g) compared to encapsulated probiotics was reported during the storage period. In another study, polysaccharides (sodium alginate and carrageenan) were used as encapsulating material for L. acidophilus and the encapsulated probiotics were incorporated into ice cream. Storage studies were conducted at −20 °C for 120 days. Results revealed that free cells showed 3 to 4 log reductions, while only 1 and 1.5 log reduction was observed in the sodium alginate and carrageenan encapsulated probiotics, respectively [115]. Hossain et al. [102] studied the survival of encapsulated and non-encapsulated antibiotics-resistant lactic acid bacteria in orange juice. They reported a significant reduction in viability of non-encapsulated probiotics at both 37 °C and 4 °C temperatures as compared with encapsulated probiotics; by the fifth week, almost no viable cells remained in the non-encapsulated form. Moreover, it is established that the post-acidification process is slower in encapsulated probiotics than in non-encapsulated probiotics [116].

A study on the effect of co-administration of antibiotics along with encapsulated probiotics (antibiotic-susceptible probiotics) revealed the improved therapeutic efficacy of encapsulated probiotics against antibiotic-resistant pathogens [117]. Further, antibiotic treatments can kill beneficial bacteria apart from the targeted pathogens; hence, to nourish the gut microbiome, probiotic supplementation is necessary. Encapsulated probiotics have a protective shell made up of alginate or another suitable biocompatible material that protects against antibiotics. Oral delivery of probiotics requires such coatings. Qi et al. [118] studied the microencapsulation of S. boulardii and E. faecium in microbeads using sodium alginate through the emulsion and internal gelation techniques. Survival of bacteria was studied under high temperatures, extreme humidity, gastric, and intestinal conditions. Encapsulated probiotics have better survival rates as compared to their non-encapsulated forms. In another study, Cao et al. [119] reported that the biocompatible lipid coating provides bio-interfacial supramolecular self-assembly of gut microbes for enhanced oral delivery and treatment .

Techniques Used for Encapsulation of Probiotics

Different methods of encapsulation have been explored by the researchers and the industry for encapsulation of different ingredients of interest. As well-established merit, encapsulated probiotics can offer better scope for targeted delivery. This section explains the concept of each technique as well as recent applications in the context of encapsulation efficiency, viability, and stability of probiotics. Table 1 represents the summary of different encapsulation techniques.

Table 1.

Various techniques used to encapsulate probiotics

| Encapsulation techniques | Encapsulate structure(s) | Typical size range | Critical parameters | Merits | Demerits | References |

|---|---|---|---|---|---|---|

| Conventional approaches | ||||||

| Spray drying |

|

The diameter of particles about 5–20 µm (varies with the size of the nozzle) |

Temperature -optimization of temperature is required to maintain the viability of probiotics as well as product with less residual moisture content. Approximately inlet temperature ranges between 110–160 °C and outlet temperature ranges between 55–85 °C. The concentration of wall material—normally in the range of 15–50% (w/v). Low concentration (less viscous) is preferable to avoid clogging and for easy atomization. The feed flow rate in a range of 2–12 ml/min (vary based on chamber capacity, nozzle size, atomization air flow rate, and aspirator rate) |

Rapid process, continuously operatable single process unit for particle formation, high reproducibility, low operational/production cost, easily scalable without major modifications, and adaptability to most common industrial equipment; The liquid feed system can operate at relatively low pressure; Powders obtained by spray drying have better flow properties; Suitable for the production of monodisperse powders with particle size in the micrometer scale; Particle size can be optimized by changing nozzle size, design, and operation parameters; The smooth skin-forming ability of the spray-dried particles offer a protective environment to the entrapped probiotic cells |

High capital cost, expensive maintenance, low yield due to the loss of product in the walls of the drying chamber; The feed solution has to be pumpable for the atomization process (low viscous solution/ slurry/ suspension). Hence, spray drying is not suitable for highly viscous feed material; Thermal inactivation of probiotics due to high inlet temperature and evaporation rates causes cellular damage to probiotic cells; High temperature does not have a direct impact on the viability of probiotics; rather, it depends on the time–temperature combination that decides the extent of microbial inactivation during spray drying. Short-time exposure might avoid thermal inactivation; Shear force/ stress acting on the core and air occlusion in the atomized droplet during atomization have a direct impact on the viability of probiotics; The loss of viability also depends on the type of carrier/wall material used |

[106–108, 121, 126, 128, 129, 241, 242] |

| Freeze-drying |

|

Irregular in shape, particle size > 1 mm, polydisperse (broad particle size distribution) |

Condenser temperature should be less than the product temperature during the sublimation process of freeze-drying Vacuum pressure: 0.1- 0.5 Torr. Lower pressure is preferred for the sublimation process |

Highly porous structure, better rehydration, and solubility; Sublimation of moisture under vacuum avoids water phase transition and oxidation |

Longer drying time, high energy consumption, and high operational/ production costs limit their commercial-scale application; More expensive (30–50 times higher than the spray drying process); Amorphous and hygroscopic irregular porous structure leads to stability loss of the product (core instability due to large air–solid interface); Probiotic cells are entrapped close to the surface of freeze-dried powders, which affects the stability of probiotics during transit through the acidic conditions of the upper GI tract |

[121, 134, 242, 243] |

| Extrusion technique |

|

Microbeads around 0.5- 3 mm diameter (varies with needle gauge size) | Concentration of gelling agent (0.5–2.5% w/v), solution pH and viscosity, ionic strength and concentration of cross-linker solution (concentration 2–5% w/w), and reaction time |

Simple and inexpensive method; Gentle operation—provides better probiotic viability and protects the cells from damage; It does not involve deleterious solvents and can be done under both aerobic and anaerobic conditions |

Difficult to scale-up at the industry level due to slow process and very low production capacity; Particles with larger size distribution (polydispersity); Limited choice of wall material |

[151, 241, 244] |

| Emulsion technique |

|

Emulsion size about 25 µm – 2 mm | Speed of agitation, phase-volume ratio, emulsifier type, solution pH, and viscosity |

Probiotics entrapment in the oil phase of protein-stabilized emulsions protected the cells when exposed to GI tract enzymes/ acids; High survival rate of encapsulated probiotics; The emulsion methods produce capsules sized from a few micrometers to 1 mm |

Particles with extremely large size distribution (polydispersity) and low yield; Controlled stirring and homogenization are required to achieve a narrow particle size distribution; High-shear process—prolonged shear forces may cause damage to cells which affects the viability of probiotics during processing |

[118, 158, 243] |

| Emerging approaches | ||||||

| Spray-freeze-drying |

|

The diameter of particles is about 20–80 µm (varies with the size of the nozzle) |

Concentration of feed solution, viscosity, feed flow rate, nozzle size, atomization air flow rate, aspirator rate, and type of cryogenic medium. Also during freeze-drying, the conditions such as shelf temperature, vacuum pressure, and drying time |

Spray-freeze-dried particles exhibits controlled size and large specific surface area than spray-dried particles; Excellent reconstitution capacity; Improved yield as compared to the spray drying process; Low-density particles with porous nature; Spray-freeze-dried probiotic microcapsules showed high cell viability and stability |

High energy consumption, more expensive and requires additional coating/ capsule for protection against adverse environmental conditions; It requires cryogenic medium (liquid nitrogen/ liquid hydrogen/ liquid argon); Dual stress (thermal and osmotic stress) to the probiotic cells; To prevent viability loss during quick freezing, stabilizing additives are required |

[121, 138, 167, 241, 245] |

| Refractance window drying |

|

Flaky structure with a preferred thickness, after blending the particle size > 1 mm, polydisperse (broad particle size distribution) | The temperature of hot water (for probiotics preferably 40–60 °C), concentration/ total soluble solids of the feed solution, feed layer thickness, and drying time |

Dried products are of high quality due to the self-limiting dehydration method; Suitable for heat-sensitive materials; A simple and inexpensive method with less energy consumption; Rapid drying at atmospheric pressure; A suitable method for drying low viscous liquids, high viscous slurries, purees, pastes, wet solids/ slices of fruits and vegetables |

Inconvenient in handling powder with high sugar content; exhibits high stickiness due to their hygroscopic nature and high ˚brix | [171, 246, 247] |

| Electrohydrodynamic processes |

|

The average diameter of electrospun probiotic fibers is around 100–150 nm with a probiotic bead size of 300–800 nm; The diameter of electrosprayed particles around 200–800 nm |

Solution parameters such as molecular weight of polymer, concentration, viscosity, conductivity, and surface tension. Process parameters are applied voltage, flow rate, and tip-target distance |

Encapsulation without application of heat with relatively high encapsulation efficiency; Monodisperse electrosprayed particles with a high surface area; Electrospun fibers with high reproducibility and yield |

Low throughput technology—difficult to scale-up; Challenge of mass production—low yield (typically in the range of milligrams/hour); High voltage electrohydrodynamic processes can be injurious to cells and can affect probiotics cell viability |

[147, 248, 249] |

Conventional Approaches

Spray Drying

The spray drying technique helps in producing probiotic powders with desired powder properties such as bulk density, flowability, uniform spherical shape, and size distribution [120]. In the spray drying process, probiotics along with the encapsulating wall material (liquid feed) are atomized into the hot gas drying chamber, the wet droplets transit through high temperature. In a short span, crust formation occurs, leading to the formation of dried solid particles. The encapsulated powder can be separated from the drying air using a cyclone separator. This technique is known for its merits in terms of the flexibility to have high production volumes, high reproducibility, low production cost, and the convenience to scale-up [121–123]. The major drawback of this technique is the use of high temperatures as it can severely affect encapsulation efficiency [124].

The selection of wall material is a key aspect in the science of encapsulation as it directly links to encapsulation efficiency, stability, and release. Rajam and Anandharamakrishnan [106] studied the encapsulation of L. plantarum (MTCC 5422) using FOS along with WPI and DWPI as wall materials at a constant air inlet temperature of 110 ± 2 °C and outlet temperature of 55 ± 3 °C. These researchers reported encapsulation efficiency ranging between 70.77 and 72.82% in formulations with FOS. Higher values were noted when FOS was used with WPI or DWPI as they provide combined protection to the cell wall and in the prevention of cellular destruction, thereby contributing to the retention of cell viability. During storage at 4 °C for 60 days, loss of cell viability was found to be higher in FOS formulations. These values were reduced in formulations with WPI owing to the high moisture retaining capacity of FOS. FOS with DWPI can be an effective wall material for the encapsulation of probiotics as it has proven benefits during the spray drying process, storage, and digestion.

Inlet air temperature and concentration of the wall material also influence the encapsulation efficiency. Nunes et al. [108] explained the effect of an inlet air temperature of 130 °C and outlet temperature of 76 ± 5 °C on L. acidophilus La-5 with inulin, Hi-maize, and trehalose as thermal protectants. They reported encapsulation efficiencies of 93.12%, 94.26%, and 90.34%, respectively. Under GI conditions, better survivability was found in Hi-maize encapsulated probiotics. Behboudi-Jobbehdar et al. [125] also reported that an increase in inlet temperature from 120 to 160 °C could reduce the total viable count of L. acidophilus from 9.02 to 7.20 log10 CFU/g when MD, WPC, and D-glucose (60:20:20 w/w) were used as wall materials. However, using feed flow rates from 6 to 7.5 mL/min would decrease viability loss caused by the effects of temperature.

Burns et al. [126] evaluated the impact of the spray drying process on the stability and immunomodulation capacities of breast milk-derived B. lactis INL1 and compared it with commercial strain B. lactis BB12. The bacterial cells were re-suspended in 20% (w/v) skim milk and then spray-dried at an inlet temperature of 137.5 ± 3.5 °C, and outlet temperature of 82.5 ± 7.8 °C. The study resulted in the retention of viability and functionality of spray-dried probiotics.

In another study, Agudelo et al. [107] studied the encapsulation efficiency of L. rhamnosus with WPI and MD as encapsulating materials using an inlet temperature of 160 °C and outlet temperature of 62–65 °C. They reported that there was no significant loss in cell viability in the process. Avila-Reyes et al. [127] reported the effect of different inlet temperatures (135, 145, and 155 °C) on L. rhamnosus using native rice starch and inulin as wall materials. Probiotic viabilities of around 74% and 54% were observed with rice starch and inulin, respectively, at 145 °C.

Yoha et al. [128] studied the effects of encapsulation methods on the stability of probiotics and reported the encapsulation efficiency of 89.21% using FOS:WP:MD (2:0.5:0.5) as prebiotic encapsulating material in the spray drying process; and also highlighted 0.95-fold increased viability retention achieved by spray drying as compared with spray-freeze-drying during storage. Ma et al. [129] reported that an increase in feed flow rate (550 mL/h, 650 mL/h, and 750 mL/h) can increase the viability (83.57%, 82.24%, and 84.73%) of Bacillus subtilis (B99-2); however, these changes were not very significant.

Freeze-drying

Freeze-drying is a very effective and widely used method for the encapsulation of probiotics [130]. Freeze-drying occurs in three steps: freezing, primary drying, and secondary drying. Probiotics along with the encapsulating material (liquid feed) first undergo freezing in which the water is converted into ice at sub-zero temperatures. The process is dependent on several aspects such as the initial amount of solute present in the feed solution, freezing temperature, and freezing rate. During the freezing stage, the product temperature is decreased, resulting in the formation of ice through effects associated with nucleation and latent heat of crystallization. In the primary drying step, frozen water is removed by sublimation under vacuum, and in the secondary drying step, unfrozen water is removed by the desorption process, resulting in the dried end-product. To protect live organisms from adverse stress conditions, cryoprotectants (like sugars) are used as they can, in turn, alter the state of the material and contribute to retention of cell viability [131–133]. Nevertheless, longer drying time and higher power consumption are the major drawbacks associated with the freeze-drying process [134].

Rajam et al. [110] studied the effect of encapsulation of L. plantarum (MTCC 5422) with FOS and WP using freeze-drying and its subsequent addition to noodles [135]. The encapsulation efficiency was reported above 98%, attributed to the usage of low temperatures (−40 to 30 °C). Survivability was also high when stored for 60 days, 9% cell viability loss was observed when only FOS was used as wall material. However, when FOS was combined with WPI or DWPI only 2% loss occurred and this was attributed to the fact that WP contributes to low oxygen and water vapor permeability, thereby restricting the movement of substances across the wall, in turn improving storability [136]. Another comparative study conducted by Barbosa et al. [137] also reported that a higher number of viable cells can be obtained using freeze-drying, based on studies conducted on L. plantarum (299v) and P. acidilactici (HA-6111–2). The addition of cryoprotectants could increase the viability of cells during the freeze-drying process.

The freeze-drying process gives a more porous structure to encapsulated probiotics, resulting in poor barrier effects [138]. With a large air–solid interface area, the faster death rate of probiotics has been reported during storage [139]. However, the addition of nanoparticles during the freeze-drying process is known to increase the viability of encapsulated probiotics. Yao et al. [140] reported enhancement in the encapsulation efficiency of Pediococcus pentosaceus (Li05) when incorporated with magnesium oxide (MgO) nanoparticles. Encapsulated probiotics showed a lower reduction in viable cells (2 log10 CFU/g) unlike the free cells (5 log10 CFU/g) under gastric conditions. Increased encapsulation efficiency was observed in all conditions (long-term storage in an aerobic environment, heat treatment, and GI transit) when doped with nanoparticles owing to the infilling of pores in the microgel matrix, in turn protecting the cells during various stress conditions.

Sakai et al. [141] evaluated the survivability of encapsulated freeze-dried probiotics on the International Space Station for a storage period of one month under the temperature range 20–24.5 °C and reported that the genetic and functional characteristics of freeze-dried probiotics were well-retained during storage. Thomas et al. [142] explained a layer-by-layer coating approach for freeze-drying in which S. boulardii was encapsulated using layers of chitosan and dextran sulfate. The coated cells were subsequently frozen in liquid nitrogen before freeze-drying. Enhanced viability was observed in encapsulated S. boulardii and the permeability of the encapsulated cells was studied using confocal imaging. Permeation of dyes confirmed the presence of pores on the surface of encapsulated cells. Moreover, it was observed that the low molecular weight fluorescence dye (DAPI (4′,6-diamidino-2-phenylindole)) showed blue fluorescence inside the cells unlike the high molecular weight fluorescence dye (dextran-FITC (fluorescein isothiocyanate)/dextran-TRITC (tetramethylrhodamine isothiocyanate)) which showed green/red fluorescence in the encapsulated wall, indicating selective permeability of pores in the surface of the encapsulated cells.

The study by Bora et al. [143] reported an encapsulation efficiency of 98% in studies conducted on the microencapsulation of L. acidophilus and L. casei using freeze-drying with a combination of WPI and FOS as wall materials. WPI and FOS used as the sole wall materials provided 86% and 90% encapsulation efficiency, respectively. A high number of viable cells were attributed to the use of low temperatures. After incorporation of these probiotics with WPI + FOS into banana powder, a higher survival rate was observed in samples stored at 4 °C, as compared with those at 25 °C, since lower temperatures can significantly contribute to the survivability of bacteria [144]. Higher viability can also be linked to the use of WPI that is known to give improved protection in buffered pH [145], apart from the role of FOS in providing ATP during the glycolysis process [146].

Moayyedi et al. [147] reported higher cell viability in the freeze-dried L. rhamnosus (ATCC 7469) encapsulated with WPI, inulin, and Persian gum, in comparison with spray drying and electrospraying methods. Viability during a storage time of 24 weeks at 25 °C was reported as 10.44–10.78 log10 CFU/g of freeze-dried samples, indicating higher values compared to the other two techniques. Similarly, higher survivability was observed under digestive conditions. Halim et al. [148] reported that encapsulation of P. acidilactici (ATCC 8042) with calcium alginate and incorporation of cryoprotectant (10% w/w skim milk) can increase cell viability as skim milk provides sufficient barrier to the cell walls, thus protecting harsh conditions, apart from behaving as a buffer in the system [149].

Extrusion Technique

The extrusion process is easy to perform, cost-effective, and provides good cell viability. In the extrusion process, the feed solution is dripped or sprayed through a nozzle at high pressure, to form encapsulated gel beads. This process is accompanied by vibration or pulsation technology it is explained as a prilling or vibrational jet that can provide standardized production of capsules without affecting the viability of the microflora [150]. When the probiotic solution is passed through the nozzle at a defined flow rate, the laminar jet breaks up at different positions due to applied stress and surface tension which results in the formation of spherical droplets or capsules as it free-falls into the hardening agent. Morphology of the droplets plays a crucial role as it impacts the stability and viability of the microflora being encapsulated. However, the process is slow, offering very low production capacities, limiting its usage at the industry-scale [151].

The study reported by Poletto et al. [152] used prebiotic dietary fibers and observed encapsulation efficiencies of 96.75%, 94.87%, 94.10%, and 76.17% for the extrusion-encapsulation of L. acidophilus with inulin, rice bran, alginate, and Hi-maize treatment, respectively. Storage studies conducted over 120 days at three different temperatures (25 °C, −18 °C, and 7 °C) concluded that alginate, rice bran, and Hi-maize encapsulated L. acidophilus maintained the viability at 25 °C. In the case of inulin encapsulates, storage at −18 °C could only retain viability; other storage conditions resulted in a significant loss in cell viability, even below 6 log10 CFU/g. Such variations explicit the influence of storage conditions on the viability of probiotics. Jantarathin et al. [153] also used the extrusion approach for encapsulation of L. acidophilus TISTR 133 using artichoke and inulin (separately) in sodium alginate (gelling agent). Following this, chitosan coating was performed and results indicated 88.19 to 90.40% encapsulation efficiencies. Eckert et al. [150] observed minimal losses (~ 0.07 to 0.74 log10 CFU/mL) in encapsulates obtained through vibrational extrusion technique in studies on encapsulation of probiotics (Lactiplantibacillus plantarum ATCC8014, Lacticaseibacillus paracasei ML33, and Lactiplantibacillus pentosus ML82) using whey-alginate-pectin (WAP) and whey permeate-alginate-pectin (WPAP) wall materials. During the storage period of three months (at 4 °C), cell viability was found to be higher than 6 log10 CFU/mL. Among the different species, L. plantarum ATCC8014 and L. pentosus ML82 showed the highest encapsulation efficiencies during storage.

In another study, Silva et al. [154] performed extrusion and co-extrusion for the encapsulation of L. acidophilus LA3 with alginate and a mixture of alginate shellac as wall materials. They reported viability ranges of probiotics co-extrusion-encapsulated with alginate or alginate-shellac of 6.2 and 7.2 log10 CFU/g, respectively. During the storage period (60 days at 25 °C), these values were found to be around 5.3 and 6.2 log10 CFU/g in encapsulates prepared using the extrusion technique. It is well-explained that the wall material has significant implications on the survival of microorganisms. A different study involving the use of alginate, Gul and Dervisoglu [155] reported wall material concentration-dependent encapsulation efficiencies ranging from 95.92–99.75% for L. casei Shirota.

Emulsion Technique

Emulsification is a chemical process that involves the interaction between a continuous phase and a discontinuous phase with the addition of an emulsifier. In this technique, microcapsules are formed after the formation of a water-in-oil emulsion, usually stabilized by surfactants like Tween 80/Span 20/glycerol, and gelled by external gelation by the addition of calcium chloride solution. Small capsules (size ≤ 100 μm) are produced using this technique and the size of beads/ capsules can be controlled by varying the process parameters [156, 157]. However, variable distribution of particle size and low yields obtained against the amount of material used in this process are key limitations of the technique [118]. Further, the viability of probiotics also gets affected when during the intermediate high-shear processes [158].

The double emulsion process of L. plantarum was studied by de Almeida Paula et al. [109] and reported an encapsulation efficiency of 97.78% with gelatin and gum arabic following a coacervation process. During coacervation, one phase becomes slightly richer in the solvent and the other in both polymers [159]. High viability of cells can be obtained because of the dual protection offered by the water–oil interface and the wall material; these act as a barrier for the probiotics and do not allow cells to move out easily. In another study conducted by Eratte et al. [160], encapsulation efficiency of 84.95% was observed by microencapsulating probiotic (L. casei 431) and omega-3, followed by a coacervation process with WPI and gum arabic. Gul and Dervisoglu [155] studied the encapsulation of L. casei Shirota with different sodium alginate concentrations (0.5–3%) using the emulsion method. They reported an increase in encapsulation efficiency from 86.71 to 95.25% with an increase in alginate concentration. With the increment in the alginate concentration, the viscosity of the solution also increases and results in the formation of a protective layer over the cells/beads, in turn improving cell viability [161]. Qi et al. [118] varied conditions of the emulsion process by modifying temperature and humidity values for the encapsulation of S. boulardii and Enterococcus faecium, and reported encapsulation efficiencies of 25% and 40%, respectively.

Multi-layer encapsulation studied by Zhang et al. [162] reported the encapsulation efficiencies ranging from 77 to 90% for spray-dried L. salivarius (NRRL B-30514) when encapsulated in primary (milk fat/WPI/sodium caseinate) and secondary (milk fat/WPI/sodium caseinate/pectin) emulsions. The highest encapsulation efficiency of 90% was observed in the secondary emulsion because of the thicker interface it provides, in turn improving the stability and viability of probiotics [163]. Holkem et al. [164] conducted a study using Bifidobacterium (BB-12) by emulsification using sodium alginate as wall material and reported encapsulation efficiency of ~ 89.71%. A similar study was reported by Martín et al. [165] using the same wall material, with an encapsulation efficiency of 80–98%, indicating that emulsion-encapsulation is an effective approach for encapsulation of probiotics.

Emerging Approaches

Spray-freeze-drying

Spray-freeze-drying possesses advantages of the spray drying as well as those of freeze-drying. Spray-freeze-drying is carried out in three stages, namely atomization, freezing, and freeze-drying. In this process, probiotics along with the encapsulating wall material (liquid feed) are atomized, forming fine droplets with a high interfacial area. This is then allowed to get in contact with a cryogenic medium such as liquid nitrogen at very low temperatures. This freezes the probiotic cell in the wall matrix with the formation of frozen droplets. These frozen droplets are further subjected to drying in a freeze dryer. Particle size can be easily controlled in the spray-freeze-drying process and these particles have a larger specific area than spray-dried particles [165, 166]. The spray-freeze-drying method produces highly porous particles with excellent reconstitution capacity. However, the method is time-consuming, and handling cryogens remains a major concern, particularly to convert the technology to industry-scale. Further, energy consumption is higher, and overall process cost is reportedly 30–50 times higher than the spray-drying process [138].

The effect of different wall materials on the encapsulation of L. plantarum (MTCC 5422) using spray-freeze-drying was studied by Rajam and Anandharamakrishnan [166] and reported the encapsulation efficiencies of around 87.92–94.86% with different combinations of wall material including WPI + sodium alginate (SA), WPI + FOS, DWPI + SA, and DWPI + FOS. Among that, DWPI + FOS gave maximum viability and stability during the storage period. However, encapsulation efficiency was around 3.16–6.73% lesser as compared with those obtained through freeze-drying. This reduction is because of the effect of atomization pressure and freezing conditions on cell viability. Semyonov et al. [167] studied spray-freeze-drying of L. paracasei (LMG P-21380) with MD and trehalose as encapsulating materials and obtained encapsulation efficiency of ~ 60%. During the spraying stage, cell viability was not affected; however, the osmotic pressure created by the solute concentration is known to affect cell viability during the freezing stage [168].

An increase in the concentration of the solute can result in the improvement of probiotic viability owing to the formation of a glassy-state that would act as a protectant [28, 169]. A variant, the vacuum spray-freeze-drying method is known to have reduced effects of oxidation and lesser drying temperature, both of which are key essentials to prevent loss of probiotic cell viability. Cao et al. [170] reported encapsulation efficiencies of 56.58–74.79% for S. cerevisiae in different skimmed milk powder concentrations (wall materials) produced through vacuum spray-freeze-drying. In a recent study, Yoha et al. [128] reported the encapsulation efficiency of 96.16% using spray-freeze-drying when encapsulating with the prebiotic FOS:WP:MD (2:0.5:0.5) and observed 1.3-fold increased cell viability in spray-freeze-dried synbiotics as compared with spray-dried synbiotics.

Refractance Window Drying

Refractance window (RW) drying and its variant, conductive hydro drying are emerging drying techniques for the encapsulation of probiotics. A typical RW dryer consists of a hot water reservoir above which a food-grade infrared transparent polyester film is placed. The homogenized mixture of probiotics and encapsulating material is spread over the film and is allowed to dry. All three modes of heat transfer occur, resulting in enhanced drying rates and reduced drying times. Raghavi et al. [171] have clearly explained the mechanism of the drying approach. Once the product gets dried, with a mismatch in the refractive index between dried product and hot water, the “window” is said to get closed at a Mylar film and deflecting the incident radiation back into the hot water [172]. The product temperature is much lower than the temperature of the hot water, and the effects of over-drying can be eliminated. The approach has been successfully used for the drying of several products such as slurries, purees [173], slices of fruits and vegetables [174], and meat powders [175]. The high-quality flakes or films can be effectively obtained using this low-cost (operational) technique [172]. Importantly, the drying method is considered to be a nonthermal drying approach [176] and works very well for heat-sensitive food and bioactive ingredients.

Not many studies report the use of RW drying for the production of probiotic powders. In recent work, Yoha et al. [177] reported the encapsulation of L. plantarum (NCIM 2083) with different combinations of prebiotics such as FOS, WP, and MD using RW drying technique. Better viability of probiotics was achieved at 40 °C using the RW drying and encapsulation using FOS:WP:MD (2:0.5:0.5) exhibited higher viability. Drying temperature and wall material composition affect the encapsulation efficiency. For example, it was observed that the FOS:WP:MD combination showed higher viability than the other two wall material combinations. The encapsulation technique had a significant impact on the surface morphology of the synbiotic flakes. RW dried synbiotic flakes had porous structures owing to rapid surface drying before the expansion of a thin layer surface that results in crust formation on the top layer, which in turn restricts capillary forces that are responsible for the collapse. Moisture content was found to be lesser in RW dried samples (5.25–6.51%) as compared with freeze-dried samples (5.84–6.75%), contributing to extended shelf-life. The encapsulation efficiency of RW dried synbiotic flakes was lesser (88.05–93.29%) than that of freeze-dried (89.62–95.74%) counterparts. However, being a very cost-effective and rapid method, RW drying was explained to be an alternative to freeze-drying for the commercial production of probiotic powders.

Electrohydrodynamic Processes

Electrohydrodynamic processes such as electrospinning and electrospraying involve the use of electrostatic force to produce polymeric materials in the form of fibers (electrospinning) or powders (electrospraying). A typical electrohydrodynamic system consists of a spinneret needle, syringe pump, and collector, connected to a high voltage power supply. Feed solution in the spinneret needle is induced by electrostatic forces (repulsion and Coulombic) to form a Taylor cone jet during the spinning/spraying process. This electrostatic force is created by the applied high electric field at a particular critical voltage that overcomes the surface tension of the feed solution, with ejection from the tip of the Taylor cone. Increasing the voltage and decreasing the polymer concentration leads to electrospraying. In this encapsulation approach, the encapsulation efficiency of probiotics can be enhanced by optimizing the operating parameters and the consistency of the feed solution.

Electrohydrodynamic methods of probiotic encapsulation with different biopolymers and prebiotic materials are considered a promising method to protect microbial cells under various stress conditions. Coghetto et al. [35] have electrosprayed L. plantarum using sodium alginate and pectin as encapsulating materials. Storage studies of electrosprayed probiotics showed retention in cell viability of 9 log10 CFU mL−1 over 21 days under refrigeration. Librán et al. [178] developed a new encapsulation method (electrospray coating atomization) for the encapsulation of probiotics using WP-MD-polyvinylpyrrolidone. Storage studies on encapsulated probiotics were performed at different conditions and significant differences were observed under stress conditions. In short, the results explained that the electrospray coating improved the survivability of probiotics. Feng et al. [179] reported the synbiotic effect of probiotics and prebiotics in their study on L. plantarum by electrospinning it with polyvinyl alcohol and FOS. Results confirmed that the addition of FOS enhanced cell viability and the thermal stability of probiotics.

Some studies have also reported that high voltage electrospraying can be injurious to cells and can affect cell viability. Moayyedi et al. [147] have comparatively studied electrospraying, freeze-drying, and spray-drying. Their results indicate that electrosprayed probiotics were perfectly spherical compared to the other methods. However, in terms of viability, electrosprayed probiotics showed a higher loss in viability due to cell damage. Whereas, Gomez-Mascaraque et al. [180] reported that there was no significant loss in viability during electrospraying and also explained that electrospraying of L. plantarum could offer enhanced protection to cells in gastric conditions as well as during storage under high humid conditions. Škrlec et al. [181] produced L. plantarum loaded polyethylene oxide (PEO) fibers and reported that the concentration of probiotic cells and lyoprotectants have a significant impact on cell viability. Also, they studied the release kinetics of probiotic-PEO fibers and concluded that almost all cells get released in 30 min, indicative of its potential for local administration.

Coaxial electrospraying of probiotics was conducted by Gómez-Mascaraque et al. [182] using gelatin-WP wall material. Increased loss in viability was reported and was explained to have occurred because of the acidic gelatin solution and the effect of acetic acid (low pH) on a drastic reduction of cell viability during storage. In a different approach, Zaeim et al. [183] performed double-layer co-encapsulation of probiotics along with inulin (prebiotic) using electrospraying. They reported better encapsulation yield and GI survival rates of 5.9 log10 CFU/g and 7.2 log10 CFU/g for L. plantarum and B. lactis, respectively. Amna et al. [184] encapsulated L. gasseri in polymeric nanofibers using electrospinning and concluded that there was no significant reduction in cell viability. However, loss in cell viability was reported during the storage period. López-Rubio et al. [185] encapsulated Bifidobacterium strains using electrospinning with WPC and pullulan. These researchers reported retention in the viability of probiotic fibers even at high humidity conditions. Liu et al. [186] fabricated L. rhamnosus GG loaded polysaccharide fibrous mats using pectin and pullulan. The fibrous mat was then post-processed with calcium chloride for improving its structural integrity through cross-linking. Around 90% of cell viability was achieved concluding that the exposure to calcium chloride had an insignificant impact on the viability of probiotics (reduction in cell viability from 7.4 log10 CFU/g to 7.18 log10 CFU/g). Lancuški et al. [187] developed probiotic fibers by coaxial electrospinning. L. paracasei was electrospun with starch-formate/glycerol and storage viability was monitored over 21 days.

In an interesting study, Akbar et al. [188] explained the synergistic effect of probiotics in encapsulating fibers. B. animalis subsp. Lactis Bb12 and a combination of three probiotics (Streptococcus thermophilus (TH-4®), L. paracasei 431®, and Bb-12) were encapsulated with polyvinyl alcohol by electrospinning. High encapsulation efficiency (90.09%) was obtained in the synergistic probiotic fibers than B. animalis subsp. LactisBb12 fiber (84.07%).

Other Emerging Techniques

3D Printing

3D printing is an emerging technology and has promising applications for the food industry [189]. Apart from unmatched customization in terms of shape and designs of the product, 3D food printing can also facilitate customization and nutrient levels, providing new insights for personalized nutrition. Different researchers have studied the printability of different nutrient-rich food ingredients [190]. Recent reports also explain the scope of printing high-fiber foods [191], focusing on developing a novel range of healthy food products using 3D food printing. Different nutraceuticals and functional food ingredients can also be added to the printing material supply. For example, Liu et al. [192] reported the printability of probiotics incorporated in mashed potatoes and observed the influence of variables such as nozzle diameter and printing temperature on the viability of probiotic cells. Also, Zhang et al. [193] 3D printed food structures incorporated with probiotics and reported cell viability of > 106 CFU/g even after the baking process. Food 3D printing can also be integrated with encapsulation and electrohydrodynamic processes to load the printed constructs with probiotics. Importantly, apart from understanding printability, it is important to understand the effect of post-printing conditions on the stability and viability of probiotic cells. Recently, Yoha et al. [271] studied the combined effect of encapsulation and 3D printing process on the viability of probiotics and reported that the printing process has no adverse effect on the viability of probiotic cells. They concluded that the spray-freeze dried encapsulation approach followed by the freeze drying post-processing method has the highest cell viability of 8.18±0.16 log10 CFU/g. Further, they observed better survival rates of 6.43±0.17 log10 CFU/ml and 7.98±0.48 log10 CFU/g under static in vitro digestion conditions and during 35 days of storage, respectively.

Microfluidics

Recently, microfluidic approaches have been used for the cultivation of individual bacteria inside microfluidic droplets that are double-layered emulsions. The microfluidic double water-in-oil-in-water emulsion (MDE) is considered a “deep functional profiling” technique, with the advantages of providing a single-cell functional characterization of microbes [194]. Chen et al. [195] used droplet-based microfluidics for lactic acid bacterial strain improvement, performing cell encapsulation through a droplet generator (T-junction on a chip). The applied cell concentration in the disperse phase and its distribution patterns can influence droplet formation. Accordingly, cell density determines the ratio of cells in a droplet (single-cell/multi-cell). This high-throughput droplet technology can provide monodisperse and highly stable microbeads. In another study, the combined effect of microfluidics and molecular techniques have been reported for developing the “MicDrop” platform for isolation of individual gut bacteria, explaining the suitability of this approach for personalized microbiota-directed therapies in the future [196].

Methods to Confirm the Targeted Delivery and Viability of Encapsulated Probiotics

Encapsulation of probiotics can protect cell viability until it reaches the colon, allowing improved effectiveness of probiotic functions after reaching the distal part of the intestine (lower GI tract). Confirmation of the delivery of probiotics can be done initially by in vitro studies using simulated static in vitro digestion or dynamic in vitro digestion system (simulator). These can provide a proof-of-concept for targeted delivery. Further, in vivo studies on the delivery of probiotics are needed to have a realistic view of the delivery and the need for extended research on health effects, efficacy, and safety.

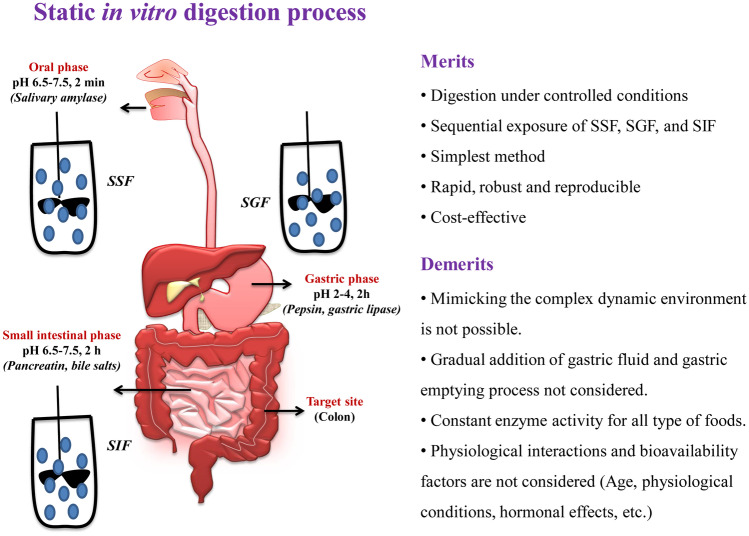

Static In vitro Digestion Studies

In vitro digestion studies can be performed using simulated digestion fluids such as simulated salivary fluid (SSF), simulated gastric fluid (SGF), and simulated intestinal fluid (SIF) under controlled temperature, pH, and continuous shaking conditions; nevertheless, these sparingly mimic the digestion process (Fig. 4).

Fig. 4.

Schematic diagram of static in vitro digestion conditions

The efficiency of dual-process microencapsulation of L. plantarum on the survival of probiotics under simulated GI conditions was evaluated by de Almeida Paula et al. [109] who reported that the cell viability was observed to be higher (80.4%) in microencapsulated L. plantarum as compared with free cells (25%). The survival of encapsulated L. plantarum (MTCC 5422) was evaluated by Rajam et al. [110] under SGF and SIF conditions, separately. In both fluids, denatured whey protein isolate (DWPI) encapsulated cells showed better stability than whey protein isolate (WPI). Also, it was reported that the synergistic effect of DWPI and sodium alginate wall matrix could deliver probiotics with high cell survival rates. In another study, FOS was used along with WPI and DWPI for the encapsulation of L. plantarum (MTCC 5422), resulting in more viable cells under simulated gastric conditions [106]. This is because of the barrier properties offered by whey protein (WP), which slow-down the diffusion of the gastric medium into the cells, thereby retaining viable cell counts.

Afzaal et al. [115] developed the encapsulated probiotic beads using an encapsulator. They have explored the effect of encapsulating materials (sodium alginate and carrageenan) on the stability of probiotics (L. acidophilus) under simulated GI conditions and observed that non-encapsulated probiotics had 7 log reductions as compared with 3 log reductions in the cell viability of the encapsulated form. In a different study with L. acidophilus and L. casei, the microencapsulated probiotics were incorporated into freeze-dried banana powder and its survivability under simulated GI conditions (for 90 min) was found to be 7.05 ± 0.1 log10CFU/g and 5.48 ± 0.1 log10 CFU/g for L. acidophilus and L. casei, respectively. Whereas, the unencapsulated probiotics loss their viability even under SGF conditions was found to be 4.69 log10 CFU/g and 5.64 log10 CFU/g for L. acidophilus and L. casei, respectively [143]. In another report, Eckert et al. [150] concluded that encapsulation with whey-alginate-pectin (WAP) was more effective than whey permeate-alginate-pectin (WPAP) based on observations made on the stability of probiotics under GI conditions. They have studied the simulated gastric digestion under three different pH (2, 2.5, and 3) of SGF and reported that the unencapsulated cells were not survived at pH of 2 and the encapsulated cells showed 3 log reductions still maintained the viability 6 log10 CFU/ml. Further, it showed 3 and 2 log reductions from initial cell count at pH of 2.5 and 3, respectively, under simulated gastric conditions. Also, they have studied the simulated intestinal digestion under two different conditions (with and without bile salts) and reported that there is no significant difference in survival rate between unencapsulated and encapsulated cells under SIF without bile salts. Whereas, significant log reductions (4 log reductions) were reported under SIF with bile salts at a concentration of 0.5% (w/v). Silva et al. [154] reported that alginate-shellac encapsulating material provided better survival of L. acidophilus LA3 in simulated GI fluids because of the resinous nature of shellac. Similarly, Poletto et al. [152] have studied the influence of different prebiotic materials (inulin, rice bran, alginate, and Hi-maize) on the survival of encapsulated L. acidophilus and reported that all these prebiotic materials provided improved protection and enhanced stability of probiotics under simulated GI conditions.

The efficiency of solid/oil/water emulsions prepared with sugar beet pectin as a delivery system for spray-dried L. salivarius (NRRL B-30514) was evaluated and observed the increase in cell viability in simulated GI conditions when the secondary emulsion was cross-linked with calcium [197]. Recently, Yoha et al. [128] studied the effect of encapsulation methods (spray drying and spray-freeze drying) on the survivability of L. plantarum NCIM 2083 under simulated oral-GI conditions. They concluded that free cells lose their viability, whereas encapsulated probiotics are retained. In another study, Yoha et al. [177] evaluated the stability of RW dried and freeze-dried synbiotics under oral-GI conditions. Their results indicated that RW dried synbiotics showed similar efficiency in cell survivability with freeze-dried synbiotics.

Dynamic In vitro Digestion Studies

Static models can only represent the biochemical processes in the GI tract, but fail to provide the dynamic environment such as constant physical forces (axial and shear) on the stomach, gastric emptying, synchronized contractions of involuntary muscles for the intestinal peristaltic movement, feedback mechanisms, and the effects of meal and resident microflora. To address these challenges dynamic in vitro digestion models have been developed.

Mainville’s Model (IViDiS)

A dynamic model of the human upper GI tract mimics the events of the upper GI tract transit. This model consists of the stomach (gastric) and duodenum reactors which can be used for validation of the survival of probiotic bacteria isolated from humans, animals, and fermented dairy products. This model considering the pH variations in the presence of meal in the stomach and bile salt in the small intestine. Especially, it demonstrates the impact of the meal as well as encapsulation matrix on the viability of probiotics [198].

Reid et al. [199] evaluated the stability of extrusion-based encapsulated probiotics using this model. In this study, L. rhamnosus was entrapped with Ca2+ induced WPI gels and subjected to freeze-drying. The viability of micro-entrapped cells was measured and compared with the viability results of free cells freeze-dried in a milk-based cryo-protective solution and free cells freeze-dried in a pre-denatured WPI solution. Viability was measured by the plate count method after 30, 60, and 90 min from the gastric and the duodenum reactors. They have reported that there was no significant difference in viability among the samples between 60 and 90 min in the gastric reactor. At the end of 90 min under GI conditions in the stomach-gastric reactor, free cells significantly lose their viability (~ 4 log reductions), whereas micro-entrapped cells maintain their viability even after 90 min. The study concluded that the Ca2+ induced WPI gelation could protect the cells in the upper GI tract and deliver towards the colon. Following this study, Tompkins et al. [200] studied the impact of meals on a probiotic during transit through the same model. They observed that the milk with 1% milk fat and oatmeal-milk gruel showed better survival of probiotics than apple juice or spring water and concluded that the protein content of the meal was probably not very important for the survival of the bacteria, unlike the fat content. Further, the study highlighted that non-enteric coated probiotics should be taken with or just before a meal containing some fats. More recently, Aragón-Rojas et al. [201] investigated the effect of the carrier material (culture medium and culture medium with 0.6:0.4 ratio of maltodextrin (MD):sweet whey), drying technology (spray-drying and freeze-drying), and dissolution media (water and milk) on the viability of L. fermentum K73 during simulated GI transit in this model. They observed that the viability of probiotics was not dependent on the drying technology used and the culture medium as a carrier material provided the highest viability with water or milk (both dissolution media) than the culture medium with MD and sweet whey. Further, cell survival was found to increase when digested with milk as the medium. Though this model is more realistic for the validation of probiotics viability, it is not suitable to evaluate the functional properties such as mucus adhesion, aggregation effect, and the impact of resident microflora in the gut [198].

SHIME®

The Simulated Human Intestinal Microbial Ecosystem (SHIME®) is a computer-controlled simulated human GI model. This model consists of five reactors that simulate from the stomach to the descending colon of the large intestine. The stomach reactor mimics the acidic environment with pepsin digestion, the small intestine reactor provides the bile conditions for digestive processes and the three reactors of the large intestine mimic the differential regions (ascending, transverse, and descending) of the colon which helps to study the microbial processes. Urbanska et al. [202] evaluated the targeted delivery of alginate-chitosan microencapsulated L. acidophilus using SHIME® and observed that the cell viability was retained at about 8.37 log10 CFU/mL and 7.96 log10 CFU/mL after the exposure of gastric (2 h) and intestinal (6 h) conditions, respectively. Thereby, they confirmed the successful delivery of probiotics at the target site. Pham and Mohajeri [203] highlighted the applications of the SHIME® model for the screening of probiotics and prebiotics. Later, Patrignani et al. [204] studied the potential of L. crispatus BC4 along with squacquerone cheese for the prevention of gynecological infections in women. They have evaluated GI stability using SHIME® model and the presence of L. crispatus BC4 was verified using genomic DNA extraction followed by sequencing of the 16S rRNA region. The study confirmed that the viability of probiotic strain was more significantly affected by the low pH of the stomach, whereas the strain was observed to be resistant toward bile salts and pancreatic juices.

SIMGI®

SIMulator of the Gastro-Intestinal tract (SIMGI®) is a multi-compartmental GI model designed to simulate the digestion process in the stomach, small intestine, and large intestine (with ascending, transverse, and descending colon compartments). Yao et al. [205] highlighted that the SIMGI® system could handle the proliferation of colonic microbiota. Gil-Sánchez et al. [206] studied the impact of L. plantarum CLC17 supplementation in polyphenol metabolism. They used the SIMGI® model for simulated GI digestion and the microbiota composition was quantified by qPCR (quantitative polymerase chain reaction) and 16S rRNA gene sequence analyses. The results inferred that the strain could be successfully delivered in compartments of the colon region. Cueva et al. [207] studied the impact of silver nanoparticles on human gut microbiota using the SIMGI® model and reported that nanoparticles do not affect the metabolic activity of human intestinal microbiota.

ARCOL

The Artificial Colon (ARCOL) is a mono-compartmental model that simulates the colon (large intestine) digestion. It can be employed with any other dynamic upper GI system. The composition of intestinal microbiota and its activity can be studied using the ARCOL model. Moreover, the dialysis fibers present in this model mimics the passive absorption of microbial metabolites [208].

The TIM