Abstract

This opinion assesses the risk posed by different matrices to introduce African swine fever virus (ASFV) to non‐affected regions of the EU. Matrices assessed are feed materials, enrichment/bedding materials and empty live pigs transport vehicles returning from affected areas. Although the risk from feed is considered to be lower than several other pathways (e.g. contact with infected live animals and swill feeding), it cannot be ruled out that matrices assessed in this opinion pose a risk. Evidence on survival of ASFV in different matrices from literature and a public consultation was used in an Expert Knowledge Elicitation (EKE) on the possible contamination of products and traded or imported product volumes used on pig farms. The EKE results were used in a model that provided a risk‐rank for each product's contamination likelihood (‘q’), its trade or import volume from affected EU or Eurasian areas (N) and the modelled number of potentially infected pig farms (N × q). The products ranking higher regardless of origin or destination were mash and pelleted compound feed, feed additives and cereals. Bedding/enrichment materials, hydrolysed proteins and blood products ranked lowest regardless of origin or destination. Empty vehicles ranked lower than compound feed but higher than non‐compound feed or bedding/enrichment material. It is very likely (95–99% certainty) that compound feed and cereals rank higher than feed materials, which rank higher than bedding/enrichment material and forage. As this is an assessment based on several parameters including the contamination and delivery to a pig farm, all of which have the same impact on the final ranking, risk managers should consider how the relative rank of each product may change with an effective storage period or a virus inactivation step.

Keywords: African swine fever, virus survival, virus transmission, feed, vehicles

Short abstract

This publication is linked to the following EFSA Supporting Publications articles: http://www.efsa.europa.eu/en/supporting/pub/9993e and http://www.efsa.europa.eu/en/supporting/pub/9994e

Summary

This opinion is part of a series of reports addressing the risk of African swine fever virus (ASFV) to non‐affected regions of the EU. Specifically, it seeks to answer questions on the risk of ASF virus transmission posed by different feed, enrichment/bedding materials or empty vehicles introducing ASFV to a non‐affected region. Four steps were used: a systematic literature review of the capability of ASFV to survive in a matrix; a public consultation to identify any evidence missed in the literature review; an Expert Knowledge Elicitation (EKE) on the possible contamination of products and their traded/imported volumes used on pig farms; and a model to determine the likelihood of each product to introduce ASFV based on relative risk‐ranking.

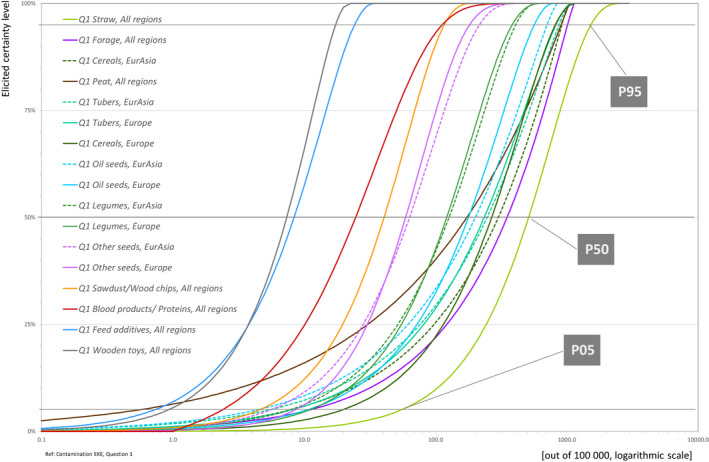

The outcome of the public consultation has been published as a technical report in the EFSA Journal (EFSA, 2021a). From the systematic literature review, recently published data were available for viral persistence on cereals, oil seeds, legumes, compound feed and feed additives. No data were available for contamination of tubers, forage and roughage, tote bags, vehicles or bedding and enrichment material. Data on the survival of virus in faeces, urine and slurry have been collated from literature and were provided to the experts for the EKE.

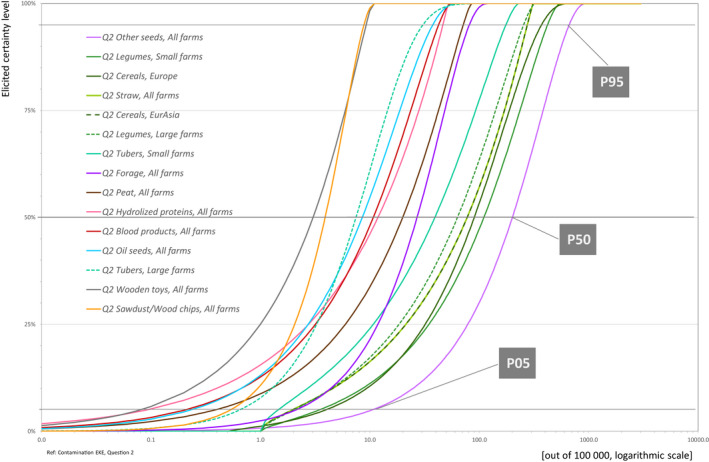

The EKE was carried out by three independent groups of six to eight experts each. It was carried out in three steps: assessing the likelihood of contamination of a product; assessing the likelihood of the contaminated product having enough viable virus to infect a pig (the infectious dose); and assessing the volume of trade or imports of each product from an affected area in either the EU or Eurasia1 which would be delivered to either a small‐scale or large‐scale pig farm.

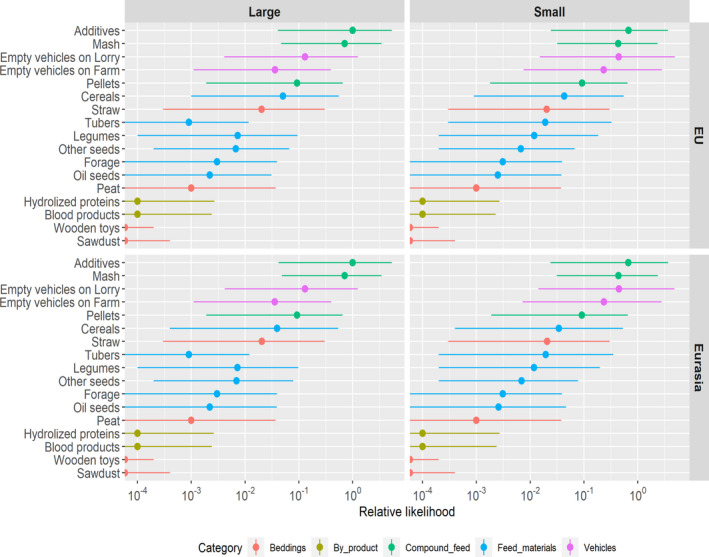

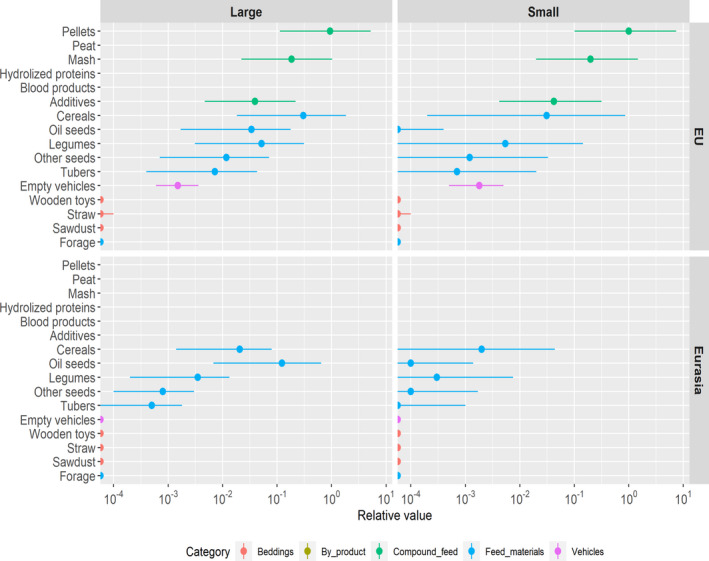

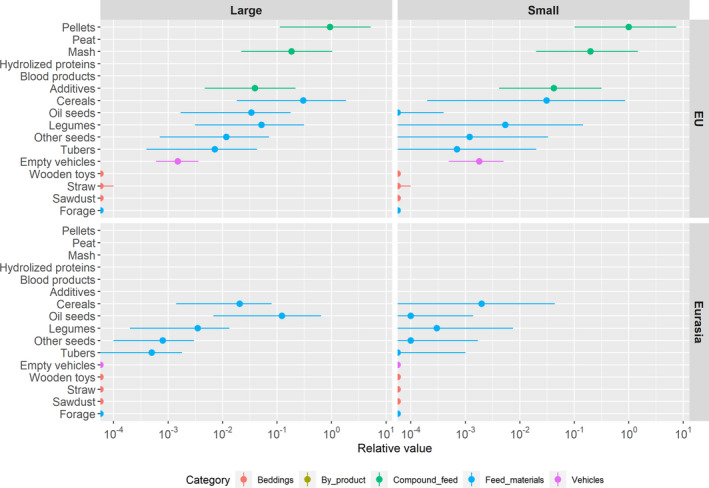

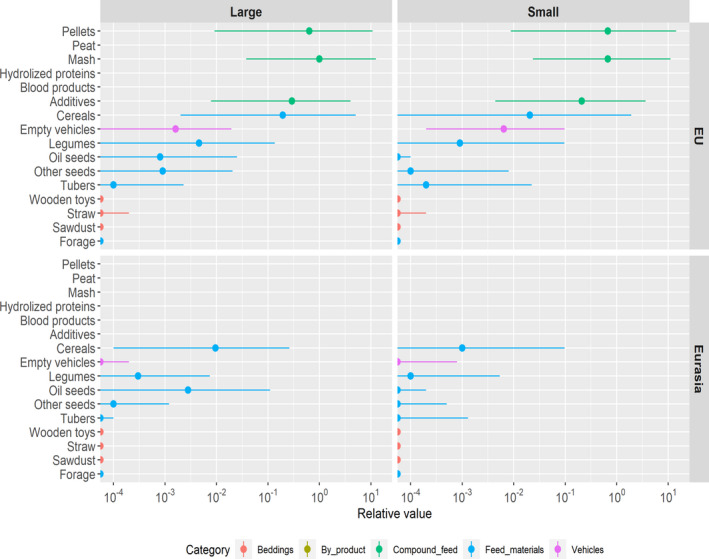

The outcome of the modelling provided a rank of the risk of each product by the likelihood of contamination (‘q’), by the volume of trade (from affected areas in Europe) or import (from affected areas in Eurasia) (N) and by the modelled number of potentially infected pig farms (N × q).

While the opinion identifies some types of feed, which may present a risk for transferring ASF to a farm, particularly in regions where wild boar contamination is present, other risk pathways are more likely to require risk management, such as moving live domestic pigs, swill feeding with products of porcine origin or allowing contact between wild boar and domestic pigs. Still, the EFSA scientific report (EFSA, 2021c) also concludes that use of locally produced hay, straw or grain, harvested from an area where ASF is present in the wild boar population, use of farm equipment from a similar area, or providing fresh forage to pigs have been identified as potential sources of ASF for domestic pigs, notably in backyard farms.

The types of feed, which consistently were ranked higher, were the feed additives, mash compound feed and pelleted compound feed and cereals. However, the detail highlights that certain feeds is more likely to be contaminated (high rank in q), but as trade/import volumes direct to farm rather than to feed producers were low (low N), these products ranked low in the modelled number of potentially infected pig farms (N × q). And conversely, some feeds may be assessed as very low risk of contamination (q), but due to the high volumes of trade/imports direct to farm (N), the ranking in the modelled number of potentially infected pig farms (N × q) was higher. For example, high volumes of pelleted compound feed and cereals are traded/imported direct to farm so even though the likelihood of contamination for an individual consignment is very low, the overall rank is higher than for those feeds, which are not used as frequently or which are moved to a compound feed producer prior to the farm even if they have the same likelihood of contamination.

Certain products, such as blood products (spray‐dried blood plasma) and hydrolysed proteins, are not produced from pigs from affected areas. This information, combined with the short time window in which animals can be infected without showing clinical signs and the production of these products, results in a low rank in terms of the likelihood that infectious ASFV is present at the time of usage. The risk may increase in recently affected areas (prior to detection of outbreaks), where infected animals in the early stages of infection and without clinical signs might go undetected at ante‐ and post‐mortem inspection in slaughterhouses. Once detected, affected areas would fall under protection/surveillance zones or infected zones, where general prohibition to move pigs apply and additionally, back tracing of prior movements takes place. Furthermore, the protein content of the products might protect the virus from the short‐term high‐temperature treatment expected to inactivate the virus (EFSA, 2021b).

Tubers are frequently fed to pigs, but while commercial farms mainly use dehydrated tubers, experts considered that small‐scale farms using fresh tubers may not be able to avoid contamination even if these are boiled on farm before being fed. Similarly, for feed additives, if a vegetable carrier material such as corn cob and rice hulls is used in their manufacturing, and there is no storage period or virus reduction step, the risk‐rank of contamination (‘q’) is higher.

For bedding material, such as straw, and forage, such as grasses and legumes, no data were available for the survival of ASFV. Therefore, faecal and urinal contamination data were used as a proxy for ASFV survival. The time of year and proximity of a non‐affected area to an affected area of origin are important considerations, as contamination decreases with increased travel or storage time and temperature. If stored or transported for considerable periods, any ASFV present will have a lower risk of survival in such products.

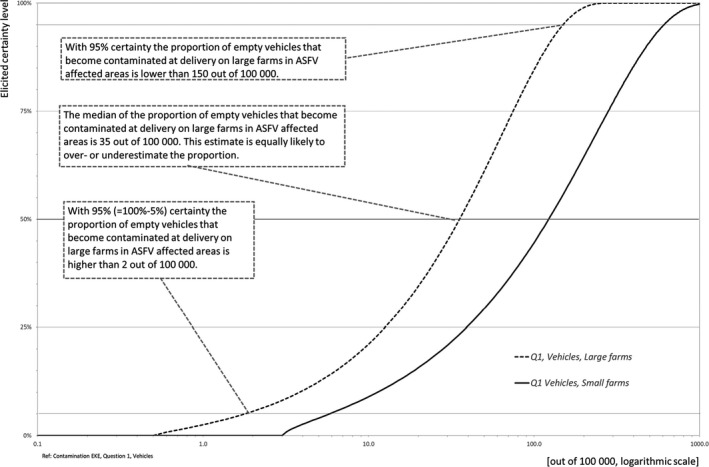

Transport vehicles were calculated to have a relatively lower risk‐rank than compound feed and consistently higher than non‐compound feed or bedding/enrichment materials; however, this depended on the origin as vehicles were considered unlikely to arrive to unaffected areas from Eurasia (low value of N). Furthermore, the rank was higher for small‐scale farms than large‐scale farms, when the origin was affected areas of the EU, because of the perceived lack of cleaning and disinfection standards on such small‐scale farms.

This assessment has been undertaken for all unaffected areas of the EU. The hierarchy of the ranking is unlikely to change for ‘q’, while it could change for ‘N’, as in general there was little difference in rank whether a product was produced in an affected area of the EU or in Eurasia. The results suggest that some products have a higher rank when the final destination is a small‐scale rather than a large‐scale farm, such as tubers and empty transport vehicles, because of the perception of lower levels of biosecurity on smaller non‐commercial farms. Certain feed or bedding materials are not traded over long distance or between affected and non‐affected areas. For such products, the likelihood of leading to an adverse outcome is reduced for the non‐affected area, but cannot be ruled out for establishments, which are in close proximity to affected areas.

For vehicles returning from other countries, the risk can be reduced by controlling whether the vehicle has transported pigs to or within affected areas, and through controls of cleaning and disinfection of trucks (certificates and visual inspection). For trucks driving back and forth between affected and non‐affected areas, reduction of the risk for the farm, at which the animals are loaded onto the truck, can be achieved by loading pigs from assembly centres or transportable loading docks at some distance from the farm.

In general, strict adherence to relevant decontamination and storage processes (storage time, treatment temperature) leading to a reduction of a potential virus contamination is recommended.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor2

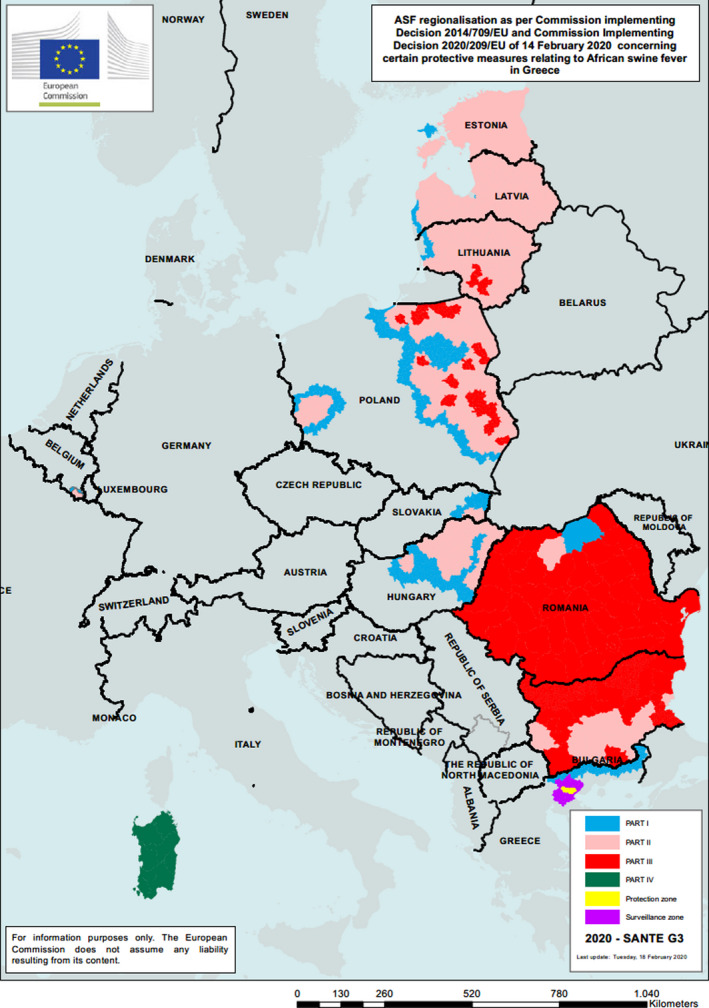

African Swine Fever (ASF) Genotype II is now present in nine EU Member States: Belgium, Bulgaria, Czech Republic, Estonia, Hungary, Latvia, Lithuania, Poland and Romania. As in 2014, the disease is mainly limited geographically to the Eastern part of the EU, with the disease being maintained in the wild boar population along the EU Eastern borders, followed by occasional spill over in domestic pig holdings.

The recent developments in Romania during the summer of 2018 have highlighted a new pattern mainly focused on domestic pig holdings of any size, with few occurrences reported in wild boar. It is likely that this latter situation heavily relies on the spread through the human factor.

For the near future, the two main risks for the EU are represented by (i) the specific situation in Romania, and (ii) a more generalised risk of witnessing the so‐called “jumps” of the disease, due to the long distance spread by human factor. Additionally, many Member States are also concerned on the role of different matrices in the transmission of the diseases.

Member States and the Commission are continuously updating the EU strategic approach to ASF and the related legislation. There is knowledge, legislation, scientific, technical and financial tools in the EU to properly face ASF.

The current situation in EU calls for the development of an EU strategy for the South Eastern Part of Europe based on scientific recommendations by EFSA. This strategy should be built and evolved on the base of new science available and on new experiences gained.

It is therefore necessary to better determine the extent of the problem in order to better target preventive and control measures in the light of the current evolution of the ASF epidemic updating and completing previous EFSA scientific opinions.

Terms of Reference (TOR).

In accordance with Article 29 of Regulation (EC) No 178/2002, EFSA is requested to provide a Scientific Opinion on the:

-

1

Estimation of the risk of spread of ASF in the South Eastern Countries of Europe; identification and description of the main risk factors.

-

2

Review the evaluation of the ability of matrices,3 including vegetables, crops, hay and straw as well as sawdust, wood chips and similar materials likely to present a risk to transmit ASF. This review should take into account a retrospective analysis of ASF spread mechanisms. The different matrices should be ranked on the basis of their level of risk with a view to enhance preparedness and prevention. Propose and assess a strategy to manage the risks posed by different matrices.

In accordance with Article 31 of Regulation (EC) No 178/2002, EFSA is requested to provide a Scientific Report on the:

-

3

Review the epidemiological data and available information on the development of ASF in Romania and include an analysis of the temporal and spatial patterns of ASF in domestic pigs. Analyse the risk factors involved in the occurrence, spread and persistence of the ASF virus in the domestic population.

1.2. Interpretation of the Terms of Reference

ToR 1 and ToR 3 have been addressed in separate scientific assessments (EFSA AHAW Panel, 2019; EFSA, 2020).

This scientific opinion addresses ToR 2 of the mandate. EFSA is asked to assess the ability of products or materials (matrices) to present a risk of transmitting ASF, and to rank them. The full pathway from the origin in an affected area to the contact with pigs within the non‐affected area should be considered in the evaluation.

To address this mandate, several assessments steps have been carried out:

Systematic literature review (SLR) on any kind of matrix that could pose a risk for transmission of ASF virus (ASFV), focussing in particular on the survival time of ASFV in the matrices.

Public consultation on the data collected through step 1 to identify any additional scientific findings not captured by the SLR.

Expert knowledge elicitation (EKE) focussing on the potential transmission of ASFV from matrices that are either feed (feed materials, compound feed, feed additives), bedding and enrichment materials used in pig farms in non‐affected areas, which have their origin, partly or entirely, in ASF‐affected areas and which are legally traded/moved, or empty livestock transport vehicles returning from ASF‐affected areas to non‐affected areas.

The likelihood of ASF transmission from affected areas in the EU and Eurasia to non‐affected area of the EU, within the next 12 months via the defined products and materials, was estimated using a pathway model incorporating the estimates obtained from the EKE.

The overall aim of the risk assessment was to rank these matrices (feed, bedding or enrichment materials and empty livestock transport vehicles) according to the likelihood that they would cause an infection of a pig herd in a non‐infected area.

The parameters needed to assess this likelihood were retrieved from scientific literature, survey data, or similar data sets such as trade records. The weighing of the retrieved evidence and the quantification of remaining uncertainties due to evidence gaps, low data quality, or necessary extrapolations were addressed by the EKE.

For this assessment, the matrices were clustered into five groups (Table 1).

Table 1.

Groups of matrices included in the assessment that could potentially be contaminated with infectious ASFV and lead to further transmission

| Group | Products | Key example(s) |

|---|---|---|

| 1. Animal by‐products for use in feed | 1a. Hydrolysed proteins | |

| 1b. Pig blood products, spray dried porcine plasma | ||

| 2. Feed materials (contaminated, not pig derived) | 2a. Cereal grains, their products and by‐products | Wheat, maize, barley |

| 2b. Oil seeds, oil fruits, their products and by‐products | Soybeans, rapeseeds (canola) | |

| 2c. Other seeds, fruits and their by‐products | Acorns, chestnuts, apples | |

| 2d. Forages and roughage | Hay | |

| 2e. Tubers, roots, their products and by‐products | Potatoes, beetroot | |

| 2f. Legume seeds, their products and by‐products | Peas | |

| 3. Compound feed (includes products of categories 1 and 2) | 3a. Mash (complete feeding‐stuff) | Organic or inorganic substances in mixtures, whether or not containing additives, intended for feeding to pigs in the form of complete feeding‐stuffs or complementary feeding‐stuffs |

| 3b. Pellets (complete feeding‐stuff) | ||

| 3c. Minerals, Feed additives (complementary feeding‐stuff) | ||

| 4. Bedding | 4a. Straw | |

| 4b. Sawdust/woodchips | ||

| 4c. Peat/Turf | ||

| 5. Vehicles | 5. Empty vehicles for live pig transport, returning from affected areas (including equipment, like boards and gates) |

The possible spread of ASFV through empty vehicles transporting feed and bedding materials or packaging material was considered during the assessment of feed and bedding materials.

Other pathways of ASFV spread, e.g. by the movement of different types of contaminated products, fomites or vehicles and infected pigs or wild boar, by pig‐derived meat or meat products that are illegally entering the food chain, or infected animals which were slaughtered and not notified or not recognised to be infected, meat or meat products which are illegally moved into non‐affected areas and/or illegally swill‐fed to pigs, were not part of this assessment, because regulations concerning the regionalisation, restrictions of movements of pigs, wild boar, pig meat and meat products from affected areas already exist to cover these.

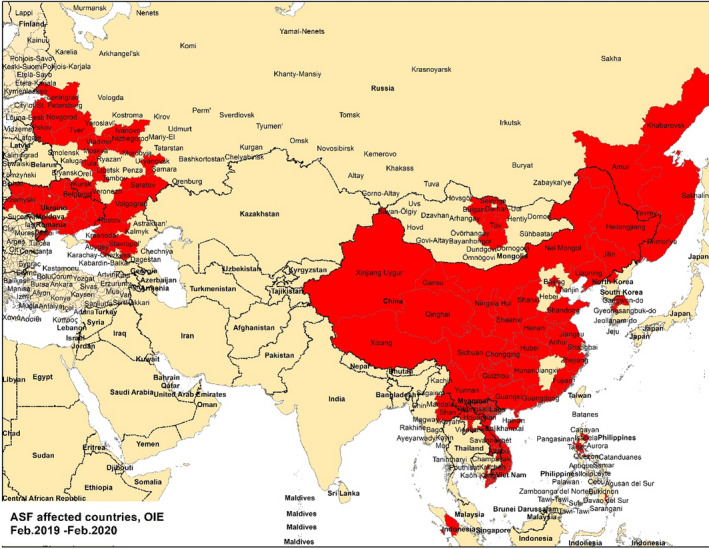

The ASF‐affected areas were grouped into two strata, the area within EU27 that is affected by ASFV genotype II (EU‐stratum) and the area within Eurasia that is affected by ASFV genotype II (EURASIA‐stratum). The latter area comprises areas in Europe, which are not EU Member States, and areas in Asia affected by ASFV genotype II.

The reasons for stratifying the affected area from which potentially contaminated matrices can originate into affected areas in the EU and in Eurasia are the different trade regulations and control measures and the different sources of trade data and outbreak data available in the EU compared to the other affected areas.

Additionally, as the mandate only required the assessment of the likelihood of transmission of ASFV genotype II, which has spread since the introduction in 2007 into Europe and Asia, the origin of potentially contaminated matrices concentrated on these two continents, and not on endemic areas in Africa.

2. Data and methodologies

2.1. Literature review

Peer‐reviewed literature was systematically searched for experimental infection or virus survival studies that examined the ability of ASFV to survive and remain viable in different matrices, as evidenced by virus isolation or in vivo studies. Studies demonstrating only the presence of ASFV‐DNA through PCR and not using virus isolation were excluded from the review, as PCR‐positive samples do not necessarily contain infectious virus. The review included studies on any of the different ASFV strains, as to date there is no scientific evidence that suggests that certain strains would survive better than others would. For details of the search carried out, see the protocol in Annex 1.

Where available, information on the matrix's storage conditions, its humidity, the duration of the experiment, the maximum number of days the matrix was found ASFV‐positive, the first day of negative results as well as ASFV half‐life were extracted from the papers identified by the search.

For categories of matrices that the Animal Health and Welfare (AHAW) panel considered to have the potential to become contaminated with ASFV, but for which no data were identified in the literature, information on the matrix production or processing parameters was collated from legal documents and peer‐reviewed literature, to understand if the production process or the processing of the matrices would allow the virus to remain viable, should the matrices have been contaminated with ASFV before their production and/or processing.

2.2. Public Consultation

A public consultation on the draft data section on the ability of ASFV to survive and remain viable in different matrices was carried out from 3 to 28 February 2020. Its objectives were: i) to check the completeness of the data on ASFV survival in different categories of matrices identified in the literature review and ii) to identify other studies on the survival of ASFV in these matrix categories that had not been captured. Further, the AHAW Panel wanted iii) to gather knowledge about the production/processing parameters that might affect ASFV survival, such as temperature‐time curves, pH, etc., of those matrix categories for which ASFV survival has not been studied. Finally, stakeholders were invited iv) to suggest additional categories of matrices that should be considered by the AHAW Panel regarding the likelihood of transmitting ASFV to domestic pigs. The draft data section was accessible through the EU‐Survey tool and participants were able to provide comments and upload documents. The outcome of the public consultation has been published as a technical report in the EFSA Journal (EFSA, 2021a).

2.3. Expert Knowledge Elicitation

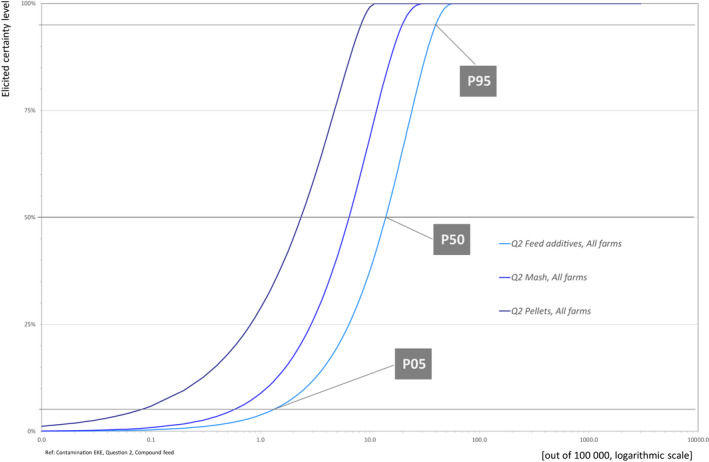

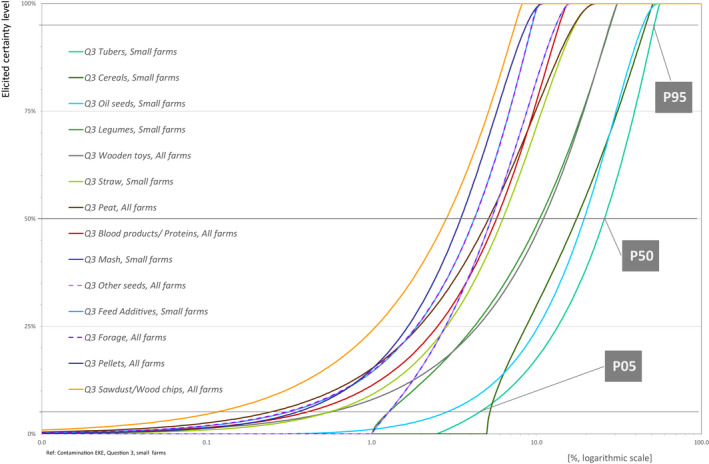

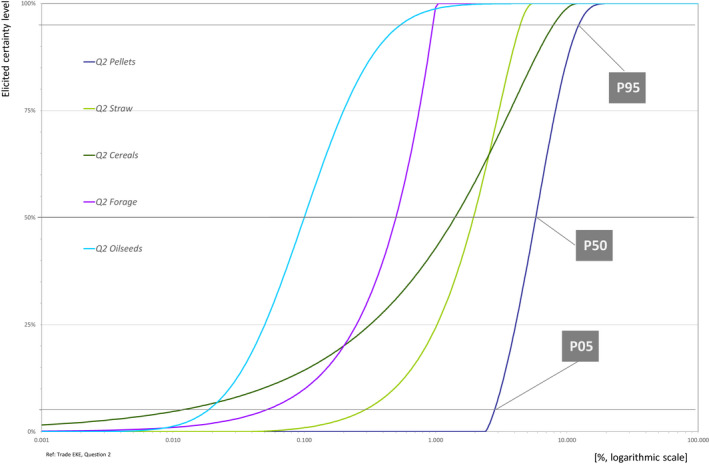

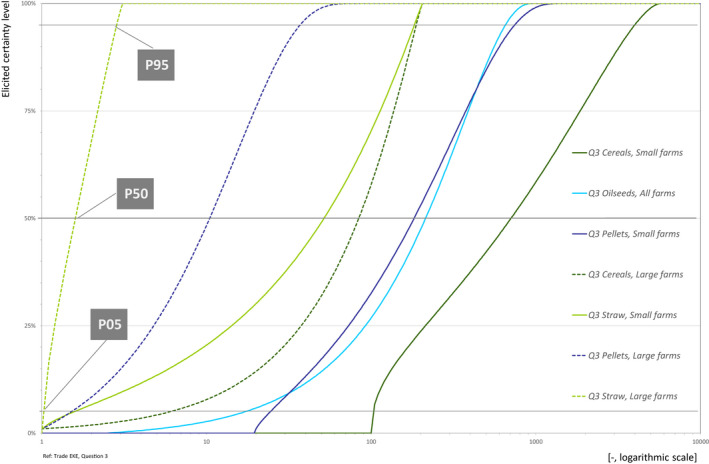

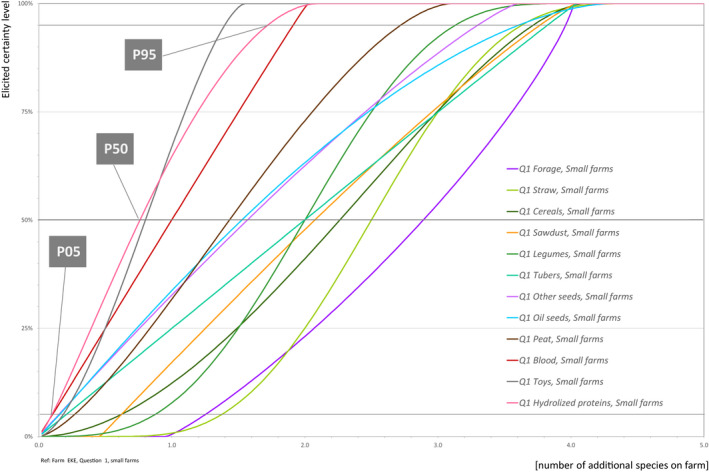

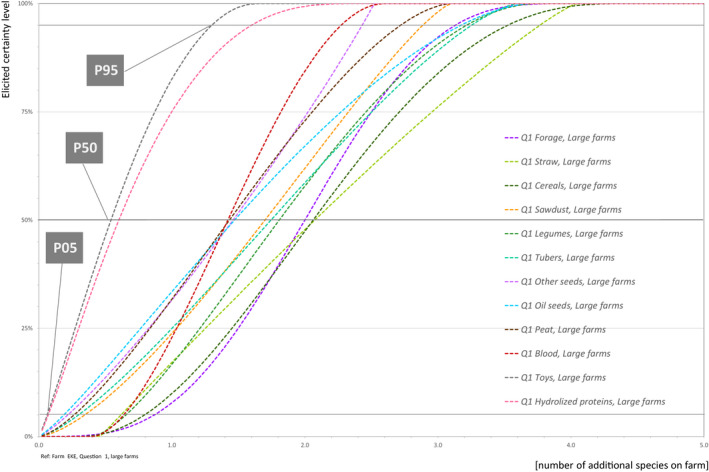

Three expert knowledge elicitations (EKEs) were carried out to elicit estimates of the likelihood that the different matrices contain infectious ASFV (‘Contamination EKE’), their trade flow/movement from affected areas in the EU and Eurasia to non‐affected areas in the EU (‘Trade EKE’) and their distribution to pig farms and their likelihood to be in contact with pigs (‘Farm exposure EKE’).

For each EKE, a group of six to eight experts with the relevant expertise was established. One expert supported both the Trade and the Contamination EKE, and another expert supported both the Trade and the Farm Exposure EKE. The results of each EKE were only shared after the completion of the EKE with those experts participating in it. The EKEs consisted of a series of preparatory meetings, individual elicitations and a final group discussion following the Sheffield method4 (EFSA, 2014). The elicitation meetings were facilitated by EFSA staff. Details on the EKEs can be found in Annex 2.

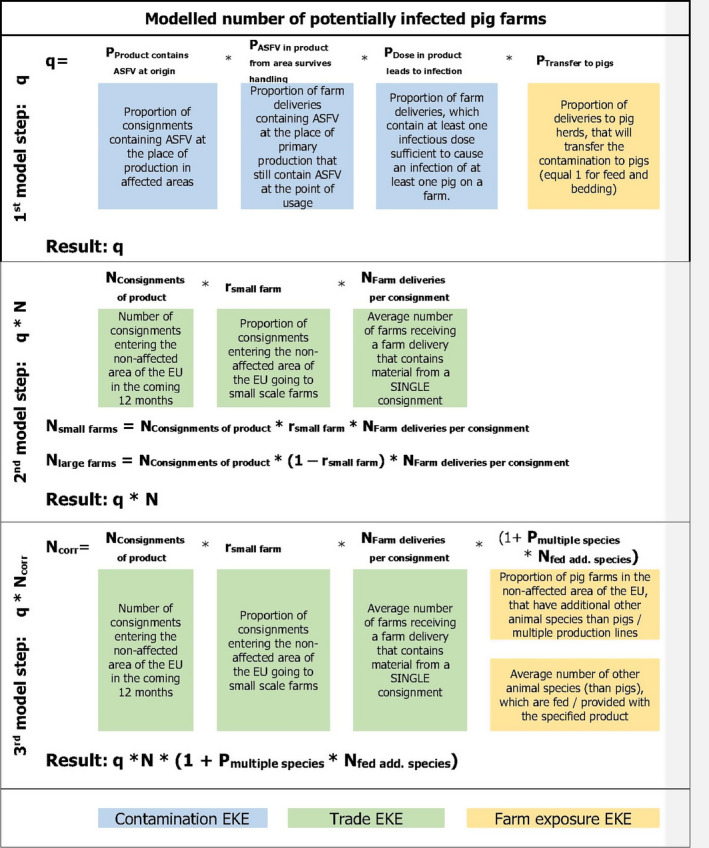

The questions on which expert knowledge was elicited and how they relate to the different elements of the pathway model (see Section 2.4) are shown in Figure 1.

Figure 1.

Mapping of estimations done in the EKEs to the three model steps (blue = estimations done in the Contamination EKE, green = estimations done in the Trade EKE, yellow = estimations done in the Farm Exposure EKE)

The Contamination EKE experts were provided with data on wild boar (density data mapped to crop production areas, habitat suitability information), data on ASF prevalence in wild boar, information on ASFV survival in different matrices, feed crops harvesting techniques, processing parameters for feed/animal by‐products potentially affecting ASFV survival, cleaning and disinfection of live pig transport vehicles and on the infectious ASFV dose.

For the Trade EKE, EKE experts received data on crop production and trade/movements, information on the most common transport means, consignment sizes and duration, the distribution of the crops in the non‐affected area of the EU, including delivery and storage on farm as well as the use of the final product on farm. In addition, experts were referred to data on pig farm size and pig diet composition.

For the Farm exposure EKE, EKE experts were provided with information on size and livestock composition of farms in the EU, on the use of feed on farms, pig diet composition and the use of feed and bedding material by other livestock species than pigs.

Further details can be found in the EKE report (EFSA, 2021b).

2.4. Modelling

In order to rank the different products and materials based on their likelihood to transmit ASFV to pigs in non‐affected areas of the EU, a simple, three‐step pathway model from primary production to farm was applied, using the estimates made by the EKE experts in the three EKEs (Figure 1). In the first step, the likelihood that a single farm delivery of a given product contains a dose of infectious ASFV sufficient to infect at least one pig on the farm was calculated. In a second step, the volumes of each product reaching different farm types (small/large) in non‐affected areas of the EU were calculated. The modelled number of potentially infected pig farms is the product of the likelihood that a single farm delivery of a product will contain a dose of ASFV that is large enough to cause an infection in at least one pig on the farm (first step) and the number of deliveries. Finally, in the third step, the number of farm deliveries was corrected to account for the possibility that additional deliveries of feed or bedding or enrichment material intended for other animal species than pigs are provided to pigs (see Section 2.4.3). Where no relevant differences of the products’ estimates existed for the regions of origin (EU/Eurasia) of the products or the place of use (small‐ or large‐scale farms), or where the uncertainty of the estimate of one stratum was considered to cover also the other stratum, the estimations were not stratified by these. An overview of the stratifications done for the different questions is provided in Table 3.

Table 3.

Strata assessed as being different within each combination of model parameters and products

| Parameter definition | Products | Vehicles | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stratification: None, Regions (Reg: EU/Eurasia), Farms (Farm: small‐/large‐scale farms) [na=not used in the model/const = constant value/Extra = extrapolated from the reference] | Animal by‐products | Non‐pig derived feed materials | Compound feed | Bedding | |||||||||||||||

| Hydrolysed proteins | Blood products, spray dried plasma1 | Cereal grains, their products and by‐products1 | Legume seeds, their products and by‐products | Tubers, roots, their products and by‐products | Other seeds, fruits and their by‐products | Oil seeds, oil fruits, their products and by‐products | Forages and roughage | Feed additives, premix | Mash | Pellets1 | Straw1 | Sawdust/woodchips | Peat/Turf | Enrichment/wooden toys | EMPTY vehicles2 | ||||

| Products | Vehicles | ||||||||||||||||||

| Single feeding products/bedding material | Compound feed | ||||||||||||||||||

| Step 1: Likelihood of an outbreak caused by one farm delivery | P Product contains ASFV at origin : Proportion of consignments containing ASFV at the place of production in affected areas | P Product contains ASFV at usage: Proportion of farm deliveries containing any material from affected areas that contain ASFV at the point of usage | P Vehicle contains ASFV at unloading : Proportion of empty vehicles used for transport of pigs returning from affected areas to non‐affected areas of the EU that will become contaminated with ASFV at place of unloading in the affected areas. | None | Reg | Reg | Reg | Reg | Reg | None | None | None | None | None | None | None | None | Farm | |

| P ASFV in product from area survives handling : Proportion of farm deliveries containing ASFV at the place of primary production that still contain ASFV at the point of usage | P ASFV in vehicle survives handling : Proportion of empty vehicles containing ASFV after unloading that still contain ASFV at the point of loading (usage) after cleaning, travel etc. | None | None | Reg | Farm | Farm | None | None | None | None | None | None | None | None | |||||

| P Dose in product leads to infection : Proportion of farm deliveries, which contain at least one infectious dose sufficient to cause an infection of at least one pig on a farm. | P Dose in empty vehicles leads to infection : Proportion of empty vehicles, which contain at least one infectious dose sufficient to cause an infection of at least one pig during a following pig transport | None | Farm | Farm | Farm | None | Farm | None | Farm | Farm | None | Farm | None | None | None | None | |||

| P Transfer to pigs = 1 (na) | P Empty vehicles come into contact with pigs : Proportion of empty vehicles, that will transfer an existing contamination with ASF to at least one pig on the farm | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Const = 1 | Farm | ||

| Step 2: Estimated number of ASF outbreaks | N Consignments of product : Number of consignments entering the non‐affected area of the EU in the coming 12 months | N Empty vehicles : Number of empty vehicles entering the non‐affected area of the EU in the coming 12 months | Extra | Reg | Reg | Extra | Extra | Extra | Reg | Reg | Extra | Extra | EU/EA = 0 | Reg | Extra | Extra | Extra | Reg | |

| r small farms: Proportion of consignments entering the non‐affected area of the EU going to small scale farms | r small farms (vehicles): Proportion of empty vehicles returning to the non‐affected area of the EU going to small scale farms | Const = 0 | Const = 0 | None1 | None | None | None1 | None1 | None | ||||||||||

| N Farm deliveries per consignment : Average number of farms receiving a farm delivery that contains material from a SINGLE consignment | N Farms per return : Average number of farms reached with a single vehicle for loading | Const = 0 | Const = 0 | Farm1 | None | Const = 1 | Farm1 | Farm1 | Farm | ||||||||||

| Step 3: Additional scenarios | P multiple species : Proportion of pig farms in the non‐affected area of the EU, that have additional other animal species than pigs/multiple production lines. | na | General parameter (all feed products): Farm | na | |||||||||||||||

| N fed add. species : Average number of animal species (other than pigs), which are fed/provided with the specified product. | na | Farm | Farm | Farm | Farm | Farm | Farm | Farm | Farm | const = 0 | const = 0 | const = 0 | Farm | Farm | Farm | Farm | na | ||

EU: European Union; EA: Eurasia.

Reference product within the product group.

empty vehicles used for pig transport returning from affected areas.

2.4.1. Likelihood that a single farm delivery of a product will contain a dose, which is large enough to cause an infection in at least one pig on the farm (Step 1)

2.4.1.1. Feed products and bedding or enrichment material

In the first step, we calculated the likelihood that a single farm delivery of a product under consideration will contain a dose large enough to cause an infection in at least one pig on the farm.

First the proportion of consignments within the next 12 months, which could become contaminated with infectious ASFV at the place of primary production was calculated: P Product contains ASFV at origin . This calculation considered the primary production in affected‐areas of the EU and Eurasia (e.g. statistics on area and yield of primary production), the habitat suitability to wild boars (e.g. statistics on predicted prevalence) and the prevalence of ASF in the wild boar and domestic pig population (e.g. statistics on positive wild boars/domestic pigs).

The inactivation of ASFV taking place between the primary production and the final use of the product on the pig farm was taken into account, considering the duration and conditions of storage and transport between primary production and point of use, the different processing steps, the level of decontamination they achieve, characteristics of the existing quality control and possibilities for cross‐contamination. This resulted in a single parameter, the proportion of farm deliveries containing infectious ASFV at the place of primary production that still contain infectious ASFV at the point of usage: P ASFV in product survives handling .

For compound feed products, which consist of several ingredients, such as feed additives, minerals and complete compound feed in the form of mash or pellets, the probability of the final product containing infectious ASFV (after transport and processing of the ingredients of the compound product) was calculated, resulting in the proportion of farm deliveries containing any material from affected areas that could contain infectious ASFV at the point of usage: P Product contains infectious ASFV at usage .

Finally, the probability that the farm deliveries contaminated with infectious ASFV contain at least one infectious dose sufficient to cause an infection of at least one pig on a farm was calculated. Information on the kind of contamination at origin, the homogenisation, dilution and inactivation of virus was used, as well as the frequency and mode of feeding to pigs. This resulted in the proportion of deliveries, which contain at least one infectious dose sufficient to cause an infection of at least one pig on a farm: P Dose in product leads to infection .

For all feed stuff it was assumed that the material is given in its entirety to pigs and not used for other livestock species. The last model parameter (P Transfer to pigs) has been set to 1 for feed and bedding/enrichment materials, as these products have per definition direct contact to pigs. The step was concluded by the multiplication of the factors as follows:

Single feeding products and bedding material: q = PProduct contains ASFV at origin × PASFV in product survives handling × PDose in product leads to infection × PTransfer to pigs

Compound feed: q = PProduct contains ASFV at usage × PDose in product leads to infection × PTransfer to pigs (PTransfer to pigs = 1)

The product ‘q’ is the estimate of the likelihood that a single farm delivery of the product under consideration will contain a dose of ASFV that is large enough to cause an infection in at least one pig on the farm.

2.4.1.2. Empty vehicles for pig transport returning from affected areas to the non‐affected area of the EU

A similar approach is taken for empty vehicles returning after unloading in affected areas of the EU and Eurasia. The three parameters have the following adapted definitions:

P Vehicle contaminated with infectious ASFV at unloading : Proportion of empty vehicles returning from affected areas to non‐affected areas of the EU that will have become contaminated with infectious ASFV at the place of unloading in the affected area.

P ASFV in vehicle survives handling : Proportion of empty vehicles that will have become contaminated with infectious ASFV at the place of unloading in the affected area and that still contain infectious ASFV at the point of loading (usage) after cleaning and disinfection, travel etc.

P Dose in empty vehicles leads to infection : Proportion of empty vehicles, which contain at least one infectious dose of ASFV sufficient to cause an infection of at least one pig during the next pig transport.

Further, an additional parameter was introduced to account for the transfer of the infectious dose from the empty lorry to the pigs on the farm, considering biosecurity procedures on the farm, pig behaviour during loading and transmission via staff and equipment on the lorry or farm. The parameter: P Empty vehicles come into contact with pigs describes the proportion of empty vehicles that will transfer an existing contamination with infectious ASFV on the lorry to at least one pig on the farm.

Therefore, two results describe the likelihood that a single empty vehicle for pig transport will contain an amount of infectious ASFV that is sufficient to cause an infection in at least one pig on the lorry (infection on lorry) or on the farm (infection on farm):

Empty vehicles (infections on lorry): q = PVehicle contaminated with infectious ASFV at unloading × PASFV in vehicle survives handling × PDose in empty vehicle leads to infection

Empty vehicles (infections on farm): q = PVehicle contains infectious ASFV at unloading × PASFV in vehicle survives handling × PEmpty vehicles come into contact with pigs × PDose in empty vehicles leads to infection

.

2.4.2. Modelled number of potentially infected pig farms in non‐affected areas of the EU (Step 2)

In the second step, the modelled number of potentially infected pig farms in the non‐affected area of the EU was calculated. This included the calculation of the number of farm deliveries of the product to farms in the non‐affected area with material originating in the affected areas of the EU or Eurasia.

The annual number of consignments going from the affected areas of the EU and Eurasia to the non‐affected area of the EU was calculated: N Consignments of product . For this calculation, the annual import and intracommunity trade volume of the product under consideration (based on EUROSTAT statistics), typical sizes of trade consignments by different means of transportations (e.g. lorry, coastal ship, container, etc.) and the proportion which is used as pig feed were considered. The calculation was done for the two areas of origin, the EU and Eurasia; and for six reference products of the different feed categories: blood products (animal by‐products), cereal grains (non‐pig‐derived feed materials), oil seeds, forage, pellets (complete compound feed) and straw (bedding material).

For compound feed, it was assumed that its place of production is close to the place of usage in the EU and that only the ingredients are imported from Eurasia or traded from EU MS. Instead of using trade consignments, production lots, which are used in the non‐affected areas of the EU, were counted. The place of production was counted as the EU (including affected and non‐affected areas).

The import and intracommunity trade of the other products within the feed categories was extrapolated using the average need of these products for pig feeding/bedding in the non‐affected areas of the EU:

NConsignments of product = Extrapolation factor × NConsignments of reference product.

The extrapolation factors are listed with the reasoning provided in Table 2.

Table 2.

Calculation of extrapolation factors from different patterns of product use

| Farm type | Small farms | Large farms | Weighted average | Extrapolation factor | |||||

|---|---|---|---|---|---|---|---|---|---|

| Pig type | Breeding sows | Piglets | Fatteners | Breeding sows | Piglets | Fatteners | |||

| Unit | |||||||||

| Weighing | |||||||||

| Total number of pigs in non‐affected areasof EU1 | [–] | 623,850 | 2,032,970 | 4,186,230 | 11,108,970 | 38,786,620 | 76,754,920 | 133,493,560 | |

| Feed per pig and day2 | [kg/day] | 3.65 | 0.55 | 2.20 | 3.65 | 0.55 | 2.20 | ||

| Total feed per day | [kg/day] | 2,277,053 | 1,118,134 | 9,209,706 | 40,547,741 | 21,332,641 | 168,860,824 | 243,346,098 | |

| Animal by‐products for use in feed | |||||||||

| Blood2 | [% diet] | 0.50 | 3.00 | 1.00 | 0.25 | 2.75 | 0.50 | 0.69 | 1 |

| Hydrolysed proteins2 | [% diet] | 0.25 | 1.00 | 0.00 | 1.00 | 2.25 | 0.00 | 0.37 | 0.541 |

| Non‐pig derived feed materials | |||||||||

| Cereals2 | [% diet] | 65.00 | 62.50 | 67.50 | 67.50 | 62.50 | 70.00 | 68.75 | 1 |

| Legumes2 | [% diet] | 12.50 | 12.50 | 14.50 | 13.00 | 13.75 | 11.00 | 11.73 | 0.171 |

| Oil seeds (2, not extrapolated) | [% diet] | 8.50 | 8.50 | 7.00 | 8.50 | 10.25 | 9.00 | 8.94 | 0.130 |

| Tubers2 | [% diet] | 2.50 | 3.50 | 2.50 | 3.00 | 3.25 | 1.00 | 1.61 | 0.023 |

| Other seeds2 | [% diet] | 2.50 | 4.50 | 2.50 | 2.50 | 2.25 | 2.75 | 2.66 | 0.039 |

| Forage (2, not extrapolated) | [% diet] | 4.00 | 0.25 | 2.00 | 4.00 | 0.25 | 1.50 | 1.84 | 0.027 |

| Weighing | |||||||||

| Total number of pigs in non‐affected areas of EU 1 | [–] | 623,850 | 2,032,970 | 4,186,230 | 11,108,970 | 38,786,620 | 76,754,920 | 133,493,560 | |

| Bedding per pig and year | |||||||||

| Straw2 | kg/year | 165.0 | 5.0 | 65.0 | 210.0 | 35.0 | 97.5 | 86.6 | 1 |

| Sawdust2 | kg/year | 165.0 | 36.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.3 | 0.015 |

| Peat2 | kg/year | No correction factor was used for peat | |||||||

| Toys2 | kg/year | 0.0 | 0.0 | 0.5 | 0.0 | 0.0 | 0.5 | 0.3 | 0.004 |

| Weighing | |||||||||

| Number of pig holdings in non‐affected areas 3 | [–] | 255,370 | 173,920 | 574,850 | 80,120 | 58,250 | 95,810 | 1,238,320 | |

| Compound feed | |||||||||

| Pellets2 | [%farms] | 82.5 | 82.5 | 84.0 | 67.0 | 72.5 | 61.5 | 80.1 | 1 |

| Additives2 | [%farms] | 0.5 | 0.5 | 0.1 | 20.0 | 9.0 | 18.5 | 3.4 | 0.042 |

| Mash2 | [%farms] | 15.5 | 8.5 | 17.5 | 13.8 | 18.0 | 19.5 | 15.8 | 0.197 |

Rows in blue: reference products/rows in grey: products were directly assessed.

Ref.: Livestock of pigs in small‐ and large‐scale farms, organic farming for different pig types in the year 2013 (EUROSTAT: ef_lspigaa).

Ref.: Midpoint of ranges elicited from trade experts (EFSA, 2021b).

Ref.: Pig holdings in small‐ and large‐scale farms for different pig types in the year 2013 (EUROSTAT: ef_lspigaa).

The incoming consignments were divided into the part going to small‐scale5 farms and the remaining part going to large‐scale farms. The proportion of consignments entering the non‐affected area of the EU going to small‐scale farms was calculated, considering the farm structures and sizes, and average use in the non‐affected areas of the EU (r small farms) (proportion going to large‐scale farms: (1– rsmall farms)). The calculations were done for the reference products and transferred to all products within the same feed category. Because the handling of animal by‐products is allowed only in registered feed mills, we assumed that these products do not reach pig farms directly.

Finally, to adjust for the distribution of large trade consignments to smaller farm deliveries, the average number of farms receiving a farm delivery that contains material from a single consignment was calculated, considering the typical sizes of trade consignments, farm deliveries, the average number of pigs on small‐ and large‐scale farms and the demand of the pigs during a typical storage time for the different products: N Farm deliveries per consignment. For forage, it was assumed that the processing takes place on the farm of its final use; therefore, this factor was set to one farm per consignment. For all other reference products, the estimates were calculated separately for small‐ and large‐scale farms, and these reference estimates were used for the other products within the same feed category.

Wooden toys were handled under the category of bedding material and therefore extrapolated from the calculations for straw, despite wooden toys having a different trade pattern (e.g. being traded more globally).

The product of all factors is the number of farm deliveries of the product under consideration to farms in the non‐affected area of the EU containing material from the affected areas of the EU or Eurasia:

Feed deliveries to small‐scale farms: N = NConsignments of product × rsmall farms × NFarm deliveries per consignment

Feed deliveries to large‐scale farms: N = NConsignments of product × (1– rsmall farms) × NFarm deliveries per consignment

A similar approach was taken for empty vehicles returning after unloading in affected areas of the EU and Eurasia. The three parameters have the following adapted definitions:

N Empty vehicles : Number of empty vehicles returning from affected areas in the EU or Eurasia to the non‐affected area of the EU in the coming 12 months.

r small farms : Proportion of empty vehicles entering the non‐affected area of the EU going to small‐scale farms.

N Farms per return : Average number of farms reached with a single vehicle for loading.

This results in the following numbers of farm contacts by empty vehicles for loading in the non‐affected areas of the EU:

Empty vehicles loading on small‐scale farms: N = NEmpty vehicles × rsmall farms × NFarms per return

Empty vehicles loading on large‐scale farms: N = NEmpty vehicles × (1−rsmall farms) × NFarms per return

Finally, the modelled number of potentially infected pig farms in the non‐affected areas of the EU was calculated as the product of the likelihood for an infection after one delivery ‘q’ and the number of deliveries ‘N’:

Modelled number of potentially infected pig farms: N × q

.

2.4.3. Effect of multiple species on farms on the expected number of outbreaks (Step 3)

In the third step, the effect of multiple species on farms on the expected number of outbreaks was calculated. On farms with multiple animal species and/or multiple production lines, farm deliveries intended for animal species other than pigs being used for feeding of pig cannot be excluded. As the proportion of small farms with multiple species is high, some farm deliveries that are diverted to feed pigs might be missed in the assessment. To account for this possibility, two more parameters were calculated.

For small‐ and large‐scale farms, the proportion of pig farms in the non‐affected area of the EU that have additional animal species other than pigs/multiple production lines was calculated, considering the farm structure (e.g. data from EUROSTAT) in non‐affected areas of the EU: P multiple species . This proportion (stratified by farm type) was used in the calculation for all products, as they are product independent.

Finally, the main animal production lines that use similar feed as pig production lines were computed. The average number of animal species (other than pigs), which are fed/provided with the product under consideration, was calculated per product and farm type: N fed add. species . This led to a corrected number of farm deliveries that can infect pigs on the farm:

Corrected number of farm deliveries: Ncorr = N × (1 + Pmultiple species × Nfed add. species)

and a corrected expected modelled number of potentially infected pig farms in the non‐affected area of the EU:

Corrected modelled number of potentially infected pig farms considering multiple species on farm: Ncorr × q.

The third step was not performed for empty vehicles, as it was assumed that lorries for pig transport are specialised for transporting pigs.

2.4.4. Final calculation leading to the ranking of the different products

The three‐step pathway model was developed to compare the risk of transmission of ASFV through different products for feed and bedding material: the model parameters were estimated by three separate groups of experts and no calibration step by adjusting to the current number of newly infected farms in the non‐affected areas of the EU was performed after the calculation of the modelled number of potentially infected pig farms. Therefore, the model results rate the ability of different matrices to present a risk of transmitting ASF, and consequently, the final comparison between matrices was performed in a relative manner.

The ratios between the risk of different products are described for the likelihood of products containing enough ASFV to infect a pig (q), for the number of farm deliveries of products (N) and finally for the modelled number of potentially infected pig farms (N × q). The results of each model step were standardised to the maximum of 1. The reported risks in the final comparisons are expressed as relative values compared to the maximum risk of all products and strata (EU/Eurasia, small‐/large‐scale farms).

3. Assessment

3.1. Results of the Literature Review and Public Consultation

The literature search identified 21 peer‐reviewed publications that fulfilled the eligibility criteria. During the public consultation, two additional papers that fulfilled the eligibility criteria were identified and included in the data extraction. In addition, information on processing parameters provided by the European Feed Manufacturers Federation (FEFAC) and the Gelatine Manufacturers of Europe were included in the data section.

The data section has been structured into two parts: the first (Section 3.1.1) is related to survival of ASFV in products derived from ASFV‐infected domestic pigs, focussing on animal by‐products for use in feed; the second (Section 3.1.2) summarises data regarding ASFV‐survival in other matrices that may become contaminated with ASFV through direct contact with ASFV‐infected animals and/or through indirect contact (e.g. excretions) with ASFV infected animals. Information on survival of ASFV in unprocessed meat and processed meat products derived from ASFV‐infected domestic pigs identified in the literature review and the public consultation is available in Annex 3 (Section 1).

The literature review includes only experimental infection or virus survival studies that examined the ability of ASFV to survive and remain viable in different matrices, as evidenced by virus isolation. Studies demonstrating only the presence of ASFV DNA through PCR and not using virus isolation were excluded from the review, as PCR‐positive samples do not necessarily contain infectious virus. However, products found negative by virus isolation may still contain a small amount of infectious virus, and so relying only on studies using virus isolation as a detection method could therefore underestimate the survival time of ASFV. In most of the identified studies, except one (Petrini et al., 2019), which carried out challenge studies on virus isolation negative samples, inoculation of pigs with these samples did not result in infection.

3.1.1. ASFV survival in products derived from infected pigs

3.1.1.1. Animal by‐products for use in feed

Category 3 animal by‐products (ABP) destined for use in feed must have undergone one of the processes listed in Chapter III of Annex IV of Regulation 142/2011. These include methods 1–5 and 7 as listed in Table 4. For method 7, no standard conditions are prescribed, however, the method should be authorised by the competent authority in the MS.

Table 4.

Standard processing methods for Category 3 animal by‐products, Chapter III of Annex IV of Regulation 142/2011

| Method | Maximum particle size of raw material to be treated | Core temperature achieved | Minimum time at core temperature | Special details |

|---|---|---|---|---|

| Method 1 (pressure sterilisation at 3 bars) | 50 mm | > 133°C | 20 min without interruption | The pressure (3 bars) must be produced by the evacuation of all air in the sterilisation chamber and the replacement of the air by steam (‘saturated steam’); the heat treatment may be applied as the sole process or as a pre‐ or post‐process sterilisation phase; the processing may be carried out in batch or continuous systems |

| Method 2 | 150 mm | > 120°C | 50 min | Processing must be carried out in batches |

| Method 2 | 150mm | > 110°C | 120 min | Processing must be carried out in batches |

| Method 2 | 150 mm | > 100°C | 125 min | Processing must be carried out in batches |

| Method 3 | 30 mm | > 120°C | 13 min | Processing may be carried out in batch or continuous systems |

| Method 3 | 30 mm | > 110°C | 55 min | Processing may be carried out in batch or continuous systems |

| Method 3 | 30 mm | > 100°C | 95 min | Processing may be carried out in batch or continuous systems |

| Method 4 | 30 mm | > 130°C | 3 min | After reduction the animal by‐products must be placed in a vessel with added fat Processing may be carried out in batch or continuous systems |

| Method 4 | 30 mm | > 120°C | 8 min | After reduction the animal by‐products must be placed in a vessel with added fat Processing may be carried out in batch or continuous systems |

| Method 4 | 30 mm | > 110°C | 13 min | After reduction the animal by‐products must be placed in a vessel with added fat Processing may be carried out in batch or continuous systems |

| Method 4 | 30 mm | > 100°C | 16 min | After reduction the animal by‐products must be placed in a vessel with added fat Processing may be carried out in batch or continuous systems |

| Method 5 | 20 mm | > 100°C | 60 min | After reduction and before application of the heat treatment, the animal by‐products must be heated until they coagulate and then pressed so that fat and water are removed from the proteinaceous material Processing may be carried out in batch or continuous systems |

| Method 6 | 20 mm | > 80°C | 120 min | After reduction and before application of the heat treatment, the animal by‐products must be heated until they coagulate and then pressed so that fat and water are removed from the proteinaceous material Processing may be carried out in batch or continuous systems |

| Method 7 * (alternative methods) | Not defined | Not defined | Not defined | Any processing method that has been authorised by the competent authority and has been demonstrated to reduce relevant hazards in the starting material to a level which does not pose any significant risks to public and animal health with the final product complying with specific microbiological standards |

A list of approved methods in 2018 is available at https://efsa.onlinelibrary.wiley.com/cms/attachment/3483307c-9a2f-436f-8715-082174dd3dfe/efs25314-fig-0003-m.jpg.

3.1.1.1.1. Hydrolysed proteins for use in feed

No data on ASFV survival in hydrolysed proteins were identified in the literature review. Hydrolysed proteins must be produced by a process, which involves appropriate measures to minimise contamination (Regulation 142/2011, Annex X, chapter II, section 5). According to Hou et al. (2017), the general procedures for the production of hydrolysed proteins from animal products (including by‐products) through chemical, enzymatic, or microbial hydrolysis include a heat treatment (pasteurisation) (Table 5). These general procedures may be modified for peptide production, depending on protein sources and product specifications.

Table 5.

Production process of hydrolysed proteins (Hou et al., 2017)

| Hydrolysis | Separation | Decontamination | Further processing |

|---|---|---|---|

| Hydrolysis of proteins by cell‐free proteases, microorganisms, acids, or bases | Centrifugation, filtration, microfiltration | Heat‐treatment (pasteurisation) | Drying |

3.1.1.1.2. Rendered fats for use in feed

No data on ASFV survival in rendered fats were identified in the literature review. According to Commission Regulation (EU) No 142/2011, Annex IV Chapter III, rendered fats must be produced using any of the processing methods 1–5 or processing method 7 (Table 8).

Table 8.

Production process of dicalcium phosphate and tricalcium phosphate (Commission Regulation (EU) No 142/2011)

| Product | Pre‐treatment | Treatment 1 | Treatment 2 | Drying |

|---|---|---|---|---|

| Dicalcium phosphate | Crushing degreasing with hot water | Treatment with dilute hydrochloric acid (minimum concentration 4%, pH < 1,5) for at least 2 days | Treatment with lime, resulting in a precipitate of dicalcium phosphate at pH 4–7 | Air‐drying (inlet temperature 65–325°C, end temperature 30–65°C |

| Tricalcium phosphate | Crushing (bone chips must be < 14 mm) degreasing in counterflow with hot water | Continuous cooking with steam at 145°C during 30 min at 4 bars | Separation of protein broth from hydroxyapatite (tricalcium phosphate) by centrifugation | Granulation after drying in a fluidised bed with air at 200°C |

3.1.1.1.3. Gelatine for use in feed

No data on ASFV survival in gelatine for use in feed were identified in the literature review. The following raw material from pigs can be used for the production of gelatine intended for human consumption: bones and pig skins (Regulation (EC) No 853/2004, Section XIV of Annex III), and category 3 material can be used to produce gelatine suitable for animal consumption (Commission Regulation (EU) No 142/2011) (Table 6). In both cases, the process includes treatment with acid or alkali and extraction of gelatine by heating one or several times in succession (for gelatine from species other than bovines no specific temperatures are prescribed in the Regulation).

Table 6.

Production process of gelatine, (Regulation (EC) No 853/2004, Commission Regulation (EU) No 142/2011)

| Treatment of material | Extraction of gelatine | Purification | Further processing | Preservatives |

|---|---|---|---|---|

| Treatment with acid or alkali, followed by one or more rinses; adjustment of pH | Heating one or several times in succession | Filtration and sterilisation | Drying, pulverisation or lamination | Sulfur dioxide, hydrogen peroxide |

According to information provided to EFSA by the Gelatine Manufacturers of Europe, gelatine fit for human consumption, including all products derived from the production of gelatine fit for human consumption, and collagen fit for human consumption are obtained from raw materials pursuant to Regulation (EC) No 853/2004. This means that all the raw materials used for the manufacture of these products derive from animals which have been slaughtered in a slaughterhouse and whose carcasses have been found fit for human consumption following ante‐ and post‐mortem inspection. Technical gelatine needs to be produced in accordance with the ABP regulation and only category 3 material can be used. The gelatine manufacturing process follows the steps of bone pretreatment (degreasing of porcine bones and production of processed animal proteins and fat, followed by demineralisation of bones and production of Dicalcium Phosphate (DCP) (see also Section 3.1.1.1.6) and pretreatment of pigskins.

For the degreasing of porcine bones and production of processed animal proteins and fat, the soft tissue including fat on the untreated bones has to be removed. In the EU, bones are degreased with hot water at a temperature of minimum 70°C for at least 30 min. Other degreasing processes complying with Regulation EC 853/2004 Annex III Section XIV/XV may also be used. Bones are subsequently washed and dried. The turbulent action of the hot water and the sliding and rubbing of the crushed bone loosens the soft tissue from the bone. The contents of the degreasing vessel are separated into bones and liquids containing meat, fat and water. The suspended solids in the meat/fat/water liquid originated during the degreasing process are separated from the fat/water liquid and dried to processed animal proteins (first by‐product). The fat/water liquid is purified to result in water and bone fat, which is a second by‐product of the bone degreasing process. For the demineralisation of bones and production of DCP, the degreased bone chips are submitted to a demineralisation process where the inorganic component of the bones (mainly natural phosphates and calcium carbonate) are removed. The defatted bones are treated with dilute hydrochloric acid (pH 1–2) over a period of at least two days for bovine bones; shorter times are usually used for porcine bones. The phosphoric liquor obtained is treated with lime, resulting in a precipitate of dicalcium phosphate at pH 4–7. The precipitate of dicalcium phosphate is finally dried with hot air until DCP with a moisture content of 1–2% is obtained. Degreased and deionised bone chips, named ossein, are neutralised before extraction of the gelatine and further processing for the production of acid bone gelatine, or they are treated with lime (pH > 12) for at least 20 days before extraction and further processing for the production of limed bone gelatine.

During the pretreatment of pig skins, the pig skins are cut into pieces and acidified, to a pH of below 3, for at least 5 h. The treated pig skins, after neutralisation, are transferred to the extraction tanks.

After the pretreatment of the raw materials described above, the following common steps are applied for all types of gelatine. The gelatine is extracted from the porcine ossein or pig skins, with hot water at temperatures between 50 and 60°C and 100°C. This is followed by a filtration and deionisation of the extracted gelatine. During filtration and ion exchange the temperature of the solution is kept at minimum 55°C. After the ion exchangers the gelatine solution is concentrated by evaporation at a minimum temperature of 80°C. The concentrated gelatine solution is submitted to a UHT treatment. The greaves remaining in the extraction tanks after the gelatine extraction are further processed. They are separated into suspended solids and a fat/water liquid. The suspended solids are dried to processed animal proteins (gelatine process‐derived proteins, GPD). The fat/water liquid and the fat from the extraction are purified to porcine fat and water (Gelatine Manufacturers of Europe, 2020) (Table 7).

Table 7.

Temperatures and pH involved in the production of gelatine and collagen and their by‐products by raw material used (Gelatine Manufacturers of Europe, 2020)

| Product | Feed material catalogue | Raw material | T° | pH |

|---|---|---|---|---|

| Gelatine | 9.12.1 | Porcine Skins | UHT treatment Drying at 50–60°C | Below pH 3 |

| Gelatine | 9.12.1 | Porcine Bones | Degreasing (70–90°C). Heat treatment min. 138°C for min. 4 s | Below pH 2 and/or above pH 12.0 |

| Collagen | 9.10.1 | Porcine Skins | Below pH 3 | |

| Collagen | 9.10.1 | Porcine Bones | Degreasing (70–90°C) | Below pH 2 and/or above pH 12.0 |

| GPDP (gelatine process derived proteins) | 9.5.1 | Porcine Bones | Degreasing (70–90°C). Min. 30 min | na |

| GPDP (gelatine process derived proteins) | 9.5.1 | Porcine Skins | Extraction (at least 95°C). Min. 30 min | Preparation pH below 3 |

| Greaves | 9.13.1 | Porcine Skins | Extraction (at least 95°C) | Preparation pH below 3 |

| Animal fat | 9.2.1 | Porcine Bones | Degreasing (70–90°C) | na |

| Animal fat | 9.2.1 | Porcine Skins | Preparation pH below 3 | |

| Bone DCP | 11.3.1 | Porcine Bones | Degreasing (70–90°C) | Demineralisation of the defatted bones in HCl solution of pH below 2 |

DCP: Dicalcium Phosphate.

3.1.1.1.4. Collagen for use in feed

No data on ASFV survival in collagen for use in feed were identified in the literature review. Collagen for use in feed must be produced by a process ensuring that unprocessed Category 3 material is subjected to a treatment involving washing, pH adjustment using acid or alkali followed by one or more rinses, filtration and extrusion. After that treatment, collagen may undergo a drying process (Commission Regulation (EU) No 142/2011) (Table 7).

3.1.1.1.5. Blood products for use in feed

No data on ASFV survival in blood products for use in feed were identified in peer‐reviewed scientific literature. Blood products for use in feed must be submitted to any of the processing methods 1–5 or processing method 7 (Commission Regulation (EU) No 142/2011) (Table 4).

The plasma utilised for production of spray‐dried porcine plasma (SDPP) is collected at veterinary‐inspected abattoirs from animals designated fit for human consumption. Specifically, blood is collected into containers with anticoagulant and the erythrocytes are removed by centrifugation. The blood of 6,000–10,000 animals slaughtered on the same day is pooled. The plasma obtained is subsequently spray‐dried and used for the production of food, feed and for industrial applications. Commercial spray‐driers used for the industrial production of SDPP reach an outlet temperature of 80°C (Gerber et al., 2014). The main applications of spray‐dried porcine plasma (SDPP) in animal feed include its use to improve performance and gut health in young piglets where SDPP is used in milk replacers, creep feed and weaning diets as an alternative source of lactogenic immunoglobulins and other bioactive glycoproteins that are present in sow's milk, and as a gelling agent in wet pet food (Kalmar et al., 2018). In a study funded by the European Association of Blood Products Producers (EAPA), Blazquez et al. (2018) spray‐dried 0.5 kg samples of liquid concentrated porcine plasma (28% solid) inoculated with ASFV (strain BA‐71) (final TCID50 concentration of 105.77 per mL of liquid concentrated plasma) in a laboratory spray‐dried at an inlet temperature of 200°C and at 80°C outlet temperature. Virus titration results showed that the spray drying had inactivated 4.11 ± 0.20 log10 TCID50/mL of the inoculated ASFV.

3.1.1.1.6. Dicalcium phosphate and tricalcium phosphate of animal origin for use in feed

No data on ASFV survival in dicalcium phosphate or tricalcium phosphate for use in feed were identified in the literature review. According to Commission Regulation (EU) No 142/2011, dicalcium phosphate must be prepared from Category 3 material that has been finely crushed and degreased with hot water and treated with dilute hydrochloric acid (at a minimum concentration of 4% and a pH of less than 1.5) over a period of at least two days. The obtained phosphoric liquor must be treated with lime, resulting in a precipitate of dicalcium phosphate at pH 4–7, which has to be air‐dried with an inlet temperature of 65–325°C and an end temperature between 30°C and 65°C (Table 8). A detailed description of the demineralisation of bones and production of DCP has been provided by the Gelatine Manufacturers of Europe (2020) (see Section 3.1.1.1.3).

Tricalcium phosphate must be prepared from Category 3 material that has been finely crushed and degreased in counterflow with hot water (bone chips must be less than 14 mm in diameter). Subsequently, it has to be continuously cooked with steam at 145°C during 30 min at 4 bars. The protein broth must be separated from the hydroxyapatite (tricalcium phosphate) by centrifugation and the tricalcium phosphate has to be granulated after drying in a fluidised bed with air at 200°C (Table 8).

3.1.2. ASFV survival in contaminated material

ASFV‐infected domestic pigs and wild boar shed the virus through excreta, such as faeces, urine and oral fluid (with or without blood). These excreta can contaminate other materials. It has been shown that ASFV survives in chilled (4°C) and cooled (12°C) faeces for at least 5 days, but not 7 days (Davies et al., 2017). In faeces stored at room temperature (21°C), the virus was shown to survive for at least 3 days, but less than 5 days (Davies et al., 2017), while an earlier study (Montgomery, 1921) found viable virus in faeces stored at room temperature (21°C) after 11 days. Faeces stored at 37°C were ASFV‐negative 2 days after the start of the experiment (Davies et al., 2017). The ASFV has been shown to survive in chilled (4°C) and cooled urine (12°C) as well as urine stored at room temperature (21°C) for at least 5 days, but less than 7 days (Davies et al., 2017). In an earlier challenge study, Montgomery (1921) found viable virus in urine stored at room temperature (21°C) for less than 2 days. Urine stored at 37°C was ASFV‐negative 2 days after the start of the experiment (Davies et al., 2017). A study conducted on slurry showed that slurry heated to 53°C in a reactor for 5.2–7.4 min did not contain active ASFV after this treatment (Turner and Williams, 1999) (Table 9).

Table 9.

Survival time of ASFV as shown by virus isolation in excreta from ASFV infected domestic pigs or wild boar as reported in literature

| Matrix | Temperature range (°C) | Humidity range (%) | Maximum number of days infectious virus was detected | First ASFV negative observation in days | Duration of the experiment in days | Half‐life in days | LCI 95%1 | UCI 95%2 | Comment | References |

|---|---|---|---|---|---|---|---|---|---|---|

| Faeces | Chilled (4°C) | nr | 5 | 7 | 98 | 0.65 | nr | nr | na | Davies et al. (2017) |

| Faeces | Cooled (12°C) | nr | 5 | 7 | 98 | 0.5 | nr | nr | na | Davies et al. (2017) |

| Faeces | Room temperature (21°C) | nr | 3 | 5 | 98 | 0.39 | nr | nr | na | Davies et al. (2017) |

| Faeces | Room temperature (21–23°C) | nr | 11 | nr | 23 | nr | nr | Challenge study, no virus isolation | Montgomery (1921) | |

| Faeces | Hot (37°C) | nr | 1 | 2 | 98 | 0.29 | nr | nr | na | Davies et al. (2017) |

| Urine | Chilled (4°C) | nr | 5 | 7 | 126 | 2.19 | nr | nr | na | Davies et al. (2017) |

| Urine | Cooled (12°C) | nr | 5 | 7 | 126 | 1.07 | nr | nr | na | Davies et al. (2017) |

| Urine | Room temperature (15–25°C) | nr | < 2 | na | 2 | nr | nr | nr | Challenge study, no virus isolation | Montgomery (1921) |

| Urine | Room temperature (21°C) | nr | 5 | 7 | 126 | 0.68 | nr | nr | na | Davies et al. (2017) |

| Urine | Hot (37°C) | nr | 1 | 2 | 126 | 0.41 | nr | nr | na | Davies et al. (2017) |

| Slurry | Heated (53°C) | nr | na | nr | Time in reactor 5.2–7.4 min | nr | nr | nr | Virus was inactivated below detectable levels after treatment in a reactor | Turner and Williams (1999) |

nr: not reported; na: not applicable.

LCI 95% Half‐life in days for the lower limit of the confidence interval.

UCI 95% Half‐life in days for the upper limit of the confidence interval.

3.1.2.1. Feed materials

Commission Regulation (EU) 2017/1017 provides a catalogue of feed materials. It also contains animal products. These must fulfil the requirements of the Regulation (EC) No 1069/2009 and Regulation (EU) No 142/2011 and may be subject to restrictions in use according to Regulation (EC) No 999/2001. This section lists only feed material that the AHAW Panel considers to be potentially contaminated with ASFV and that have not already been covered in previous sections. Where the literature review did not identify any studies that investigated the survival time of ASFV in feed material, parameters that could influence the potential survival of ASFV during the production and processing processes that were identified are listed in the sections below. The possibility of re‐contamination after these processes is beyond the scope of this section.

3.1.2.1.1. Cereal grains, their products and by‐products

Dried distillers’ grains with solubles1 that had been contaminated post‐processing with ASFV and stored for 30 days at varying temperatures (mean 15°C) were ASFV negative 30 days post contamination (Dee et al., 2018). Wheat, rye, barley, triticale and corn (humidity 11.5–14.2%) contaminated with ASFV‐positive blood (106 HAD50/mL) and subjected to 2 h of drying (incubation at room temperature) followed by incubation at temperatures between 40 and 75°C for 1 h were ASFV‐negative by HAT after drying and after any of the eight drying and heat treatments tested (Fischer et al., 2020) (Table 12).

Table 12.

Survival of ASFV as shown by virus isolation in feed matrices contaminated with infectious material originating from infected domestic pigs or wild boar as reported in literature

| Matrix category | Matrix | Temperature range (oC) | Humidity range (%) | Maximum number of days infectious virus was detected | First ASFV negative observation in days | Duration of the experiment in days | Half‐life in days | LCI 95%1 | UCI 95%2 | Comment | References |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cereal grains | Dried distillers’ grains with solubles | Room (15°C (mean)) | 75 (mean) | 0 | na | 30 | nr | nr | nr | na | Dee et al. (2018) |

| Cereal grains | Wheat | Room temperature for 2 h | 11.5–14.2% | < 1 | 1 | 1 | nr | nr | nr | na | Fischer et al. (2020) |

| Cereal grains | Barley | Room temperature for 2 h | 11.5–14.2% | < 1 | 1 | 1 | nr | nr | nr | na | Fischer et al. (2020) |

| Cereal grains | Rye | Room temperature for 2 h | 11.5–14.2% | < 1 | 1 | 1 | nr | nr | nr | na | Fischer et al. (2020) |

| Cereal grains | Triticale | Room temperature for 2 h | 11.5–14.2% | < 1 | 1 | 1 | nr | nr | nr | na | Fischer et al. (2020) |

| Cereal grains | Maize | Room temperature for 2 h | 11.5–14.2% | < 1 | 1 | 1 | nr | nr | nr | na | Fischer et al. (2020) |

| Oil seeds | Soy oil cake | Room (15°C (mean)) | 75 (mean) | 30 | na | 30 | 5.0 | nr | nr | na | Dee et al. (2018) |

| Oil seeds | Soy oil cake | Room (12.3°C (mean)) | 74.1 (mean) | 30 | na | 30 | 12.4 | 10.4 | 14.3 | na | Stoian et al. (2019) |

| Oil seeds | Soybean meal conventional | Room (15°C (mean)) | 75 (mean) | 30 | na | 30 | 4.6 | nr | nr | na | Dee et al. (2018) |

| Oil seeds | Soybean meal conventional | Room (12.3°C (mean)) | 74.1 (mean) | 30 | na | 30 | 9.6 | 8.7 | 10.4 | na | Stoian et al. (2019) |

| Oil seeds | Soybean meal organic | Room (15°C (mean)) | 75 (mean) | 30 | na | 30 | 4.7 | nr | nr | na | Dee et al. (2018) |

| Oil seeds | Soybean meal organic | Room (12.3°C (mean)) | 74.1 (mean) | 30 | na | 30 | 12.9 | 11.5 | 14.3 | na | Stoian et al. (2019) |

| Legume seeds | Peas | Room temperature for 2 h | 11.5–14.2% | negative | 1 | 1 | nr | nr | nr | na | Fischer et al. (2020) |

| Compound feed | Complete feed | Room (15°C (mean)) | 75 (mean) | 30 | na | 30 | 4.3 | nr | nr | na | Dee et al. (2018) |

| Compound feed | Complete feed | Room (12.3°C (mean)) | 74.1 (mean) | 30 | na | 30 | 14.2 | 12.4 | 15.9 | na | Stoian et al. (2019) |

| Compound feed | Feed | Frozen (–16 to –20°C) | nr | ≥ 60 | na | 60 | nr | nr | nr | na | Sindryakova et al. (2016) |

| Compound feed | Feed | Chilled (4–6°C) | nr | 30 | 40 | 60 | nr | nr | nr | na | Sindryakova et al. (2016) |

| Compound feed | Feed | Room (22–25°C) | nr | 1 | 5 | 60 | nr | nr | nr | na | Sindryakova et al. (2016) |

| Feed additives | Choline | Room (15°C (mean)) | 75 (mean) | 30 | na | 30 | 5.1 | nr | nr | na | Dee et al. (2018) |

| Feed additives | Choline | Room (12.3°C (mean)) | 74.1 (mean) | 30 | na | 30 | 11.9 | 10.9 | 12.9 | na | Stoian et al. (2019) |

| Feed additives | Lysine | Room (15°C (mean)) | 75 (mean) | 0 | na | 30 | na | nr | nr | na | Dee et al. (2018) |

| Feed additives | Vitamin D | Room (15°C (mean)) | 75 (mean) | 0 | na | 30 | na | nr | nr | na | Dee et al. (2018) |

nr: not reported; na: not applicable.

LCI 95% Half‐life in days for the lower limit of the confidence interval.

UCI 95% Half‐life in days for the upper limit of the confidence interval.

3.1.2.1.2. Oil seeds, oil fruits, their products and by‐products

Soy oil cake, conventional soybean meal and organic soybean meal that had been contaminated post‐processing with ASFV and stored for 30 days at varying temperatures (mean 12.3 or 15°C) were ASFV positive 30 days post contamination (Dee et al., 2018; Stoian et al., 2019) (Table 12). The process of soybean meal includes several process steps, in which the raw material is heated (toasting by using dry heat to reduce or remove naturally occurring antinutritive factors). When leaving the toasting unit, the residual temperature is 105°C with 16–20% residual moisture (Witte, 1995) (Table 10).

Table 10.

Soybean meal production for animal feed (Witte, 1995)

| Product | Oil extraction | Solvent removal | Cooking | Drying and cooling | Grinding and sizing |

|---|---|---|---|---|---|

| Soybean meal | Hexane‐wet flakes leave the extractor at 53°C | Desolventising of extracted soy flakes with steam of 71–80°C | Toasting of flakes (105°C at the exit, residual moisture 16–20%) | Drying (45–75°C at exit, residual 12% moisture) cooling to 32°C (or ambient temperature +6°C) | Size reduction by hammer or roller mills |

3.1.2.1.3. Legume seeds, their products and by‐products

Only one study on ASFV survival in legume seeds, their products and by‐products contaminated with ASFV or infectious material originating from infected domestic pigs or wild boar was identified in the literature review. Peas (humidity 11.5–14.2%) contaminated with ASFV‐positive blood (106 HAD50/mL) and subjected to 2 h of drying (incubation at room temperature) followed by incubation at temperatures between 40 and 75°C for 1 h were ASFV‐negative by HAT after drying and after any of the eight drying and heat treatments tested (Fischer et al., 2020) (Table 12).

3.1.2.1.4. Tubers, roots, their products and by‐products

No data on ASFV survival in tubers, roots, their products and by‐products contaminated with ASFV or infectious material originating from infected domestic pigs or wild boar were identified in the literature review.

3.1.2.1.5. Other seeds and fruits, their products and by‐products

No data on ASFV survival in other seeds and fruits, their products and by‐products contaminated with ASFV or infectious material originating from infected domestic pigs or wild boar were identified in the literature review.

3.1.2.1.6. Forages and roughage

No data on ASFV survival in forages and roughages contaminated with ASFV or infectious material originating from infected domestic pigs or wild boar were identified in the literature review. Meals produced from certain forages, such as lucerne, clover or grass, are dried and milled. Hay stored in uncovered bales of different diameters and different moisture contents were shown to reach maximum temperatures of 77.2°C (Coblentz and Hoffman, 2009), bales covered in tarpaulin reached temperatures of 40.7–44.9°C, depending on location of storage and tarpaulin colour (Guerrero et al., 2010). In silage, during natural fermentation, the pH gradually drops and temperatures between 20 and 30°C are reached. The exact temperature and final pH in the ensiled crop largely depend on the type and moisture of the forage being ensiled. Maize silage terminates at or below pH 4, legumes silage generally reaches a terminal pH of about 4.5 (Seglar, 2013) (Table 11).

Table 11.

Production parameters reported for hay and silage

| Matrix | Maximum temperature observed | Moisture concentrations (prestorage) | pH | Reference |

|---|---|---|---|---|

| Hay bales uncovered | 77.2°C | 9.3–46.6% | nr | Coblentz and Hoffman (2009) |

| Hay bales covered in tarpaulin | 40.7–44.9°C | nr | nr | Guerrero et al. (2010) |

| Silage | 20–30°C | nr | 4–4.5 | Seglar (2013) |

nr: not reported.

3.1.2.1.7. Other plants, their products and by‐products

This category contains cane molasses, cane vinasse, cane sugar and seaweed meal. No data on ASFV survival in these matrices contaminated with ASFV or infectious material originating from infected domestic pigs or wild boar were identified in the literature review.

3.1.2.2. Compound feed