Abstract

Studies accentuating nanomaterials suspensions and flow traits in the view of their applications are the focus of the present study. Especially, the usage of such materials in biomedical rheological models has achieved great importance. The nanofluids’ role is essential in the cooling of small electronic gizmos like microchips and akin devices. Having such exciting and practical applications of nanofluids our goal is to scrutinize the Maxwell MHD nanofluid flow over an extended cylinder with nonlinear thermal radiation amalgamated with chemical reaction in a Darcy–Forchheimer spongy media. The presence of gyrotactic microorganisms is engaged to stabilize the nanoparticles in the fluid. The partial slip condition is considered at the boundary of the stretching cylinder. The Buongiorno nanofluid model is betrothed with impacts of the Brownian motion and thermophoresis. The analysis of entropy generation is also added to the problem. The highly nonlinear system is tackled numerically is addressed by the bvp4c built-in function of the MATLAB procedure. The outcomes of the prominent parameters versus embroiled profiles are portrayed and conversed deeming their physical significance. It is perceived that fluid temperature is augmented for large estimates of the radiation and Darcy parameters. Moreover, it is noticed that the magnetic and wall roughness parameters lower the fluid velocity. To corroborate the presented results, a comparison of the current study with a previously published paper is also executed. An outstanding correlation in this regard is attained.

Subject terms: Software, Mechanical engineering

Introduction

Nanofluid, an arising field of engineering, has caught the eye of numerous researchers who were observing the ways to improve the efficiency of cooling measures in industries. Nanofluids are used to improve rates of heat transfer in an assortment of applications including nuclear reactors, transportation industry, mechanical cooling applications, heat exchangers, micro-electromechanical systems, fiber, and granular insulation, chemical catalytic reactors, packed blood flow in the cardiovascular system engaging the Navier–Stokes equation. Advanced thermal features of the nanofluid are imperative in many fields like pharmaceutical, air-conditioning, micromanufacturing, microelectronics, power generation, thermal therapy for cancer surgery, transportation, chemical, and metallurgical engineering fields, etc. Due to the significant advancement in aerodynamics automotive, there is great importance in breaking down systems by direct heat dissipation. Many investigators have recently added some work to promote solar cells with high digestion of solar radiation. As Choi and Eastman1 found that the incorporation of nanoparticles to the base liquids significantly enhances their thermal efficiency. The rising demand for highly efficient cooling devices encourages Koo and Kleinstreuer2 to study the steady laminar nanofluid flow in micro heat sinks. It is noticed that very low nanoparticle concentration in nanofluids results in a higher thermal conductivity that exhibits a remarkable state of nanofluids3,4. Bilal et. al5 scrutinized the numerical study of unsteady Maxwell flow of nanofluid influenced by the magnetic field, melting heat, and the Fourier and Fick laws. This investigation reveals that the liquid temperature is dropped for versus melting heat and unsteadiness parameters. The flow of 3D non-radiative Maxwell nanofluid with thermal and solutal stratification with chemical reaction is analytically studied by Tlili et. al6. Here, the noticeable outcome of the model is that the fluid concentration and temperature are declined for solutal and thermal stratifications respectively. Farooq et al.7 analytically conversed the Maxwell nanofluid flow over an exponentially extended surface. Various researchers revealed the numerous aspects of the Williamson nano liquid7–22.

The term Darcy–Forchheimer comes from the law of Darcy which interprets the liquid flow along a spongy channel. This law was originated and dependent upon the consequences of analysis on the water flow across the beds of sand. Movements in the spongy medium in which inertial effects are prominent come with the variations of Reynolds numbers. Therefore, this introductory term is adding up to the Darcy equation and is referred to as the Darcy–Forchheimer term. This term represents the non-linear behavior of the flow data versus pressure difference. With wide utilization of grain stockpiling, petroleum technology, frameworks of groundwater and oil assets, this Darcy law is of immense importance in the field of Fluid Mechanics. In places where the porous medium has larger flow rates due to non-uniformity, such as near the wall, Darcy's law is not applicable. The substance with stomata is named as a permeable medium. It includes an application of large numbers such that oil manufacturing, liquid flow in catalytic vessels, and reservoirs, etc. The suggestion of the fluid flow passes a porous surface was first given by Darcy23 in 1856. However, this idea couldn't be so famous inferable from its restrictions of lower porosity and smaller speed. Afterward, Forchheimer24 amended the equation of momentum by adding the square velocity condition into the Darcian velocity to convey the undeniable lack. Muskat25 later call it the "Forchheimer term" which is true of the high Reynolds number. Pal and Mondal26 addressed the Darcy–Forchheimer model over permeable media past the linearly expanded region and assume that concentration distribution is diminishing function of the electric field parameter. The movement of the hydromagnetic nano liquid past the Darcy–Forchheimer media forum effect on the boundary condition of second order is mathematically evaluated by Ganesh et al.27. Alshomrani et al.28 explained the 3D Darcy–Forchheimer law with carbon nanotubes and homogeneous heterogeneous reactions. The viscous nanofluid with Darcy–Forchheimer effect over a curved area is analyzed by Saif et al.29. Seth et al.30 examined mathematically the movement of carbon nanotubes over a porous Darcy–Forchheimer media in a rotating frame and many therein31–41.

In numerous processes including dispersion of nutrients in nerves, condensation in mixtures, and thermal insulation, mass transfer plays a vital role. One live example of transfer of mass may be seen in the living matter processes like respiration and sweating. A good number of studies may be quoted where chemical reactions play a vital role in mass transfer procedures.

Recently, Mahmood42 explored the nanofluid flow with an amalgamation of the CNT’s of both types and the engine oil over a stretched surface with the impact of the activation energy merged with the chemical reaction. The problem is solved numerically and with a surface response statistical technique. It is inferred from this model that the surface drag coefficient is negatively sensitive concerning the magnetic parameter. The numerical solution of the nanofluid flow involving the CNT’s and water over an extended/contracting sheet with quartic autocatalysis chemical reaction and Thompson and Troian slip boundary conditions is discussed by Ramzan et al.43. The results exposed that the fluid concentration is enhanced for quartic autocatalysis chemical reaction. Khan et al.44 numerically tackled the Carreau nanofluid flow over an extended surface in a Homann stagnation region with chemical reaction and modified Fourier law using shooting scheme. The study divulges that the fluid velocity hinders owing to the Hartmann number and the porosity parameter. In the perspective of its clarity, the remarkable work of current researchers, see few studies45–56.

In thermodynamics, entropy is an essential concept. One of the most powerful methods for investigating the efficiency of thermal systems is entropy generation analysis. The idea of irreversibility is inextricably related to the concept of entropy. All have an instinctive understanding of irreversibility. For example, by playing a video game in both forward and reverse, we can merely explain the irreversibility phenomenon by using backward order. There are numerous forward procedures of daily life that cannot be undone, such as pouring water into a bottle, egg unscrambling, unconstrained expansion of fluids, plastic deformation, gas uprising from the chimney, etc. In this perspective, Yusuf et al.57 explored the entropy generation in a Maxwell fluid flow over an inclined extended surface in a non-Darcian spongy media with thermal radiation. An analytical solution of the erected mathematical model is attained. The major result of the presented model is that the rate of the entropy generation is boosted for the local inertial coefficient parameter. In a recent study, Adesanya et al.58 performed the entropy generation appraisal for a couple stress fluid film flow on an inclined heated surface with viscous dissipation impacts. In this analysis, it is comprehended that the fluid temperature and velocity show opposing tendency versus the couple stress parameter. Furthermore, many investigators have worked on entropy generation analysis on a wide number of geometries that may found in58–65.

The studies deliberated above reveal that abundant literature discussing the nanofluid flow of an extended cylinder is available under the influence of varied impacts. Nevertheless, comparatively less literature can be witnessed that discusses the flow of Maxwell nanofluid over an extended cylinder. But so far one has discussed the Maxwell nanofluid flow past an extended cylinder with thermal radiation, chemical reaction, and gyrotactic microorganisms with partial slip in a Darcy–Forchheimer spongy medium. The problem is solved numerically, and pertinent graphs are plotted versus the involved profiles with logical descriptions. Table 1 illustrates the originality/uniqueness of the stated fluid mathematical model by assessing it with the available researches.

Table 1.

A literature analysis for the individuality of the stated model.

| Authors | Buongiorno model | Maxwell nanofluid flow over a cylinder | Darcy–Forchheimer impact | Nonlinear thermal radiation | Bioconve-ction | Chemical reaction |

|---|---|---|---|---|---|---|

| Islam et al.15 | √ | √ | × | × | × | × |

| Ahmed et al.16 | √ | √ | × | √ | × | × |

| Hayat et al.66 | √ | √ | × | × | × | √ |

| Raju et al.67 | √ | √ | × | × | × | × |

| Present | √ | √ | √ | √ | √ | √ |

(√) means said effect present, and ( ×) signifies the impact is absent.

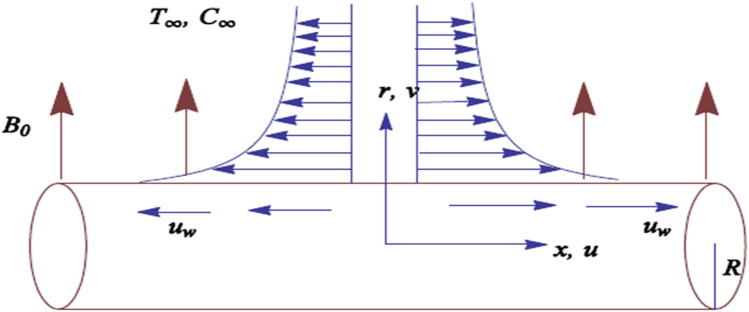

Mathematical modeling

We examine an incompressible flow outside a cylinder having radius R and the constant temperature . As the axial direction of a cylinder along the x-axis while radial direction along r-axis. A stretching surface of the cylinder has velocity , where is the characteristic length and shows the reference velocity. The flow situation induced by a magnetic field of intensity is displayed in Fig. 1.

Figure 1.

The geometry of the flow.

The resulting boundary layer equations defining the depicted scenario are given as66:

| 1 |

| 2 |

| 3 |

| 4 |

| 5 |

With boundary conditions66:

| 6 |

The radiative heat flux is given by:

| 7 |

The following transformation is used to obtain the non-dimensional structure of the above-mentioned flow model66:

| 8 |

Equation (1) trivially fulfilled and Eqs. (2–6) are as follows:

| 9 |

| 10 |

| 11 |

| 12 |

| 13 |

Particular dimensionless parameters emerging in the above equations are portrayed as:

| 14 |

The dimensional form of drag force coefficients, rate of mass transfer, rate of heat transfer, and Motile microorganisms are appended as below:

| 15 |

With

| 16 |

The Drag force coefficient, mass transfer rate, Motile microorganism, and rate of heat in the dimensionless form are supplemented below:

| 17 |

Rate of entropy generation (EG)

The volumetric equation is represented as:

| 18 |

The characteristics EG is framed as:

| 19 |

The entropy generation is given as the quotient of the and , i.e.,

| 20 |

In dimensionless form:

| 21 |

The parameters used in Eq. (22) are defined as:

| 22 |

Numerical procedure

For the nonlinear arrangement of equations and boundary conditions (9)–(13) the finite difference MATLAB bvp4c procedure is applied which is solid at 4th order and the grid size of 0.01 is viewed as acknowledged 10–6. The numerical plan requires the change of higher-order differential equations into one-order differential equations.

| 23 |

| 24 |

| 25 |

| 26 |

| 27 |

| 28 |

Results with discussion

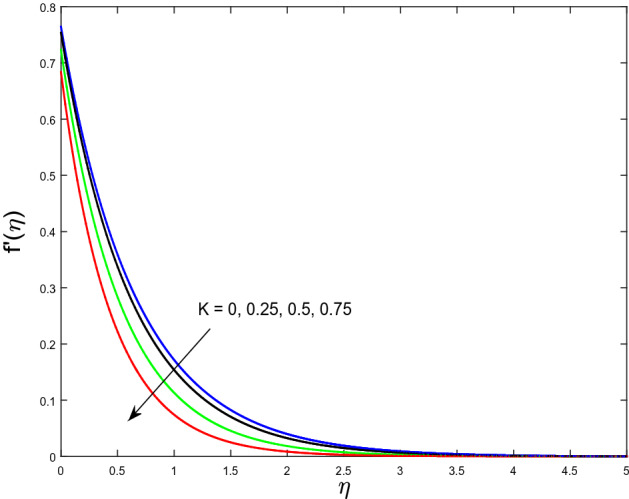

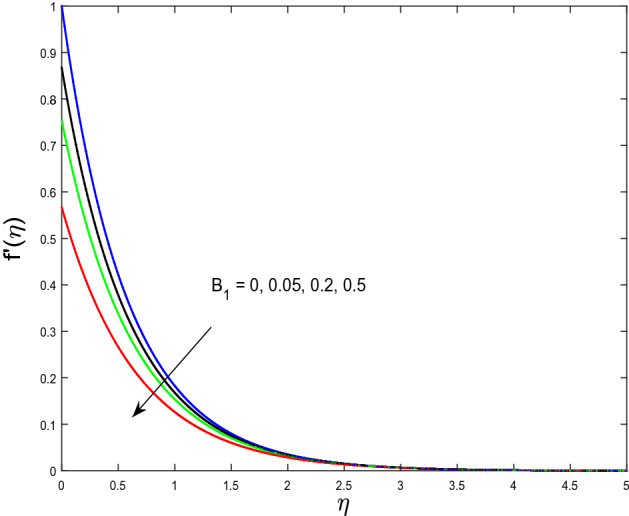

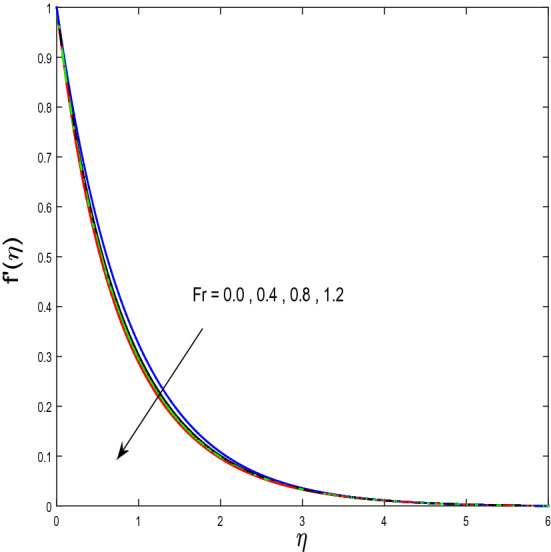

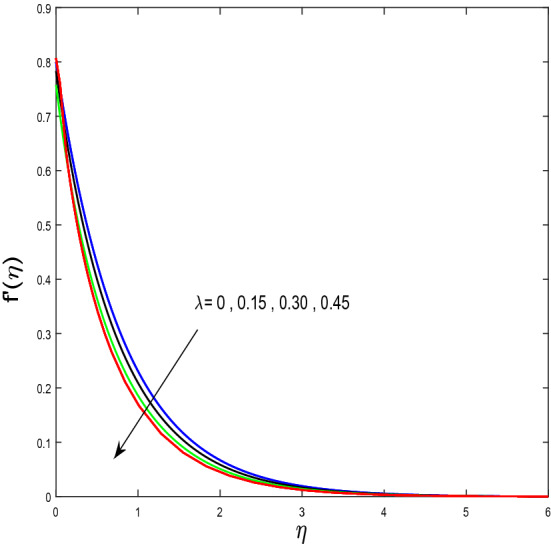

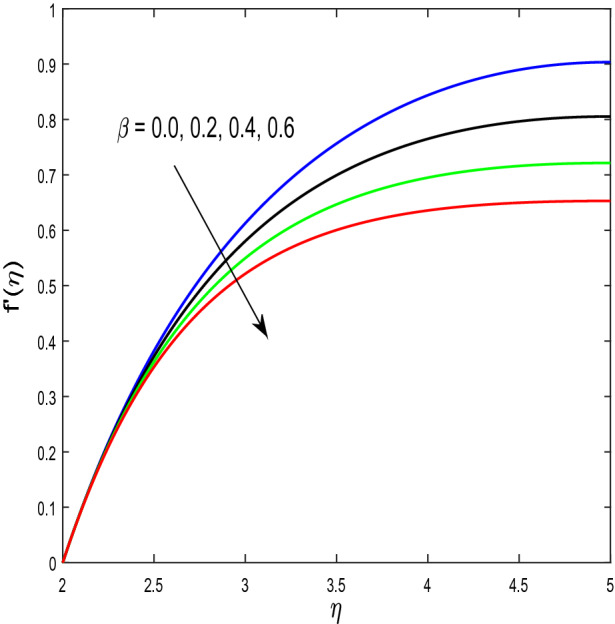

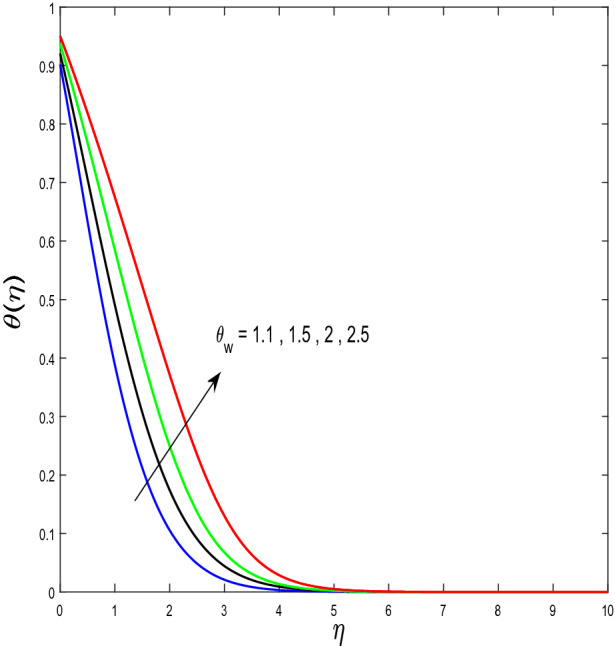

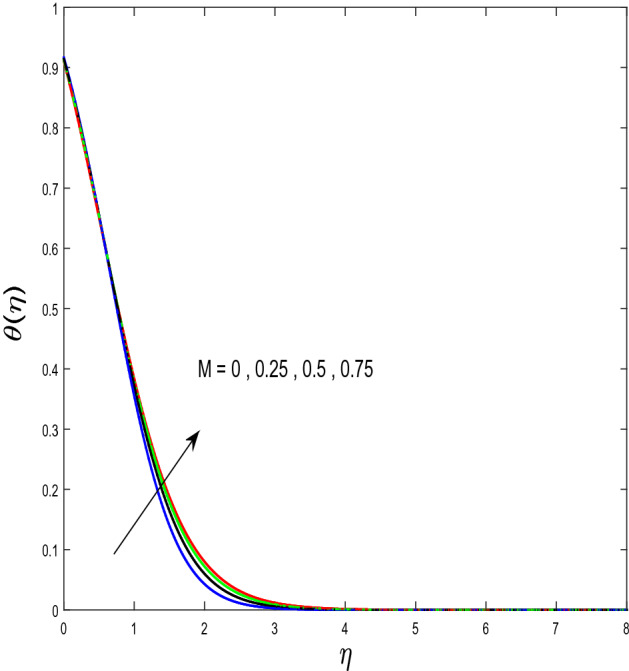

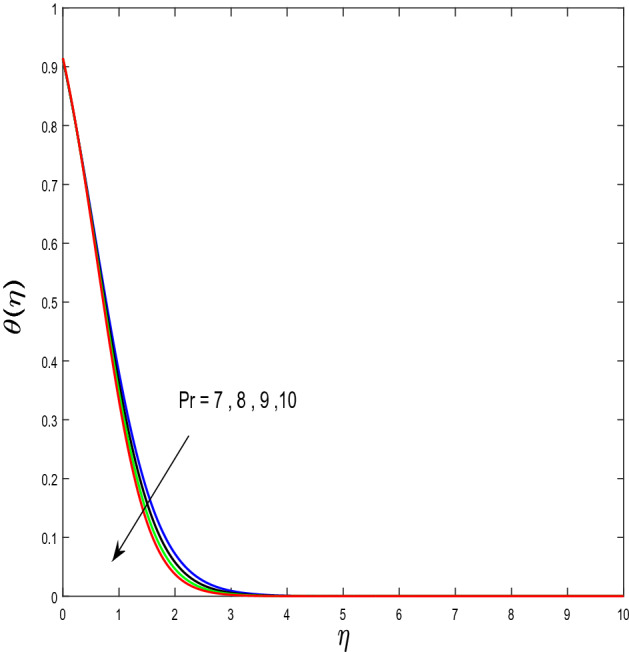

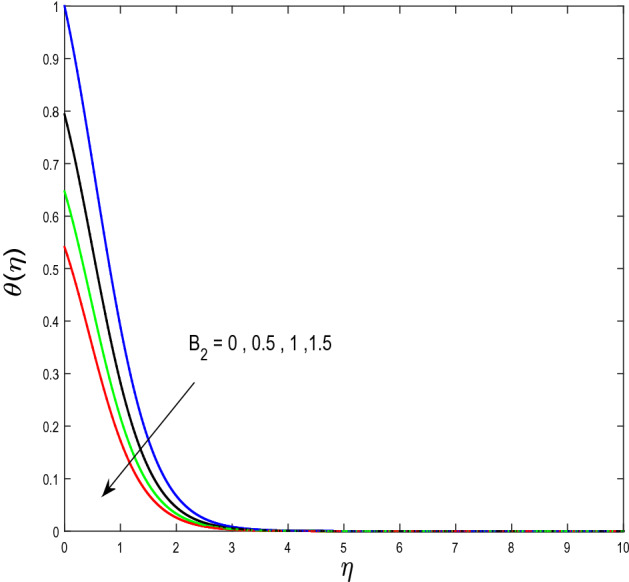

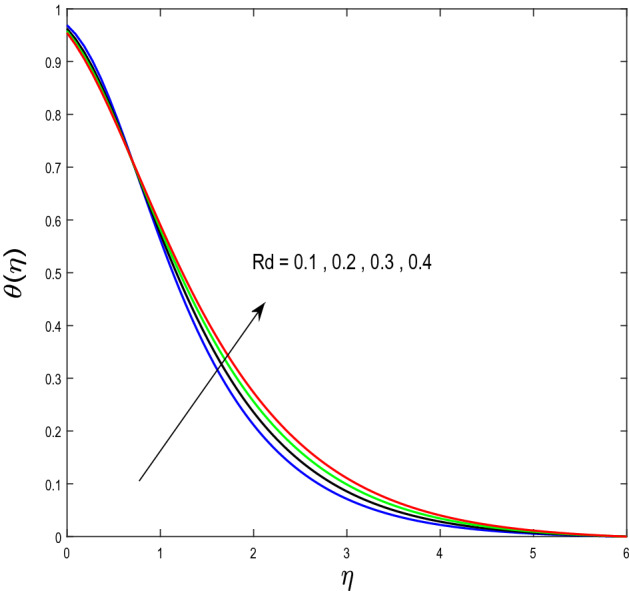

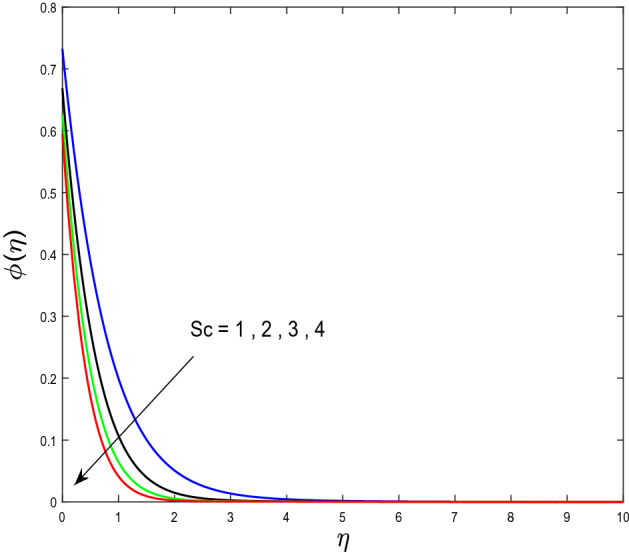

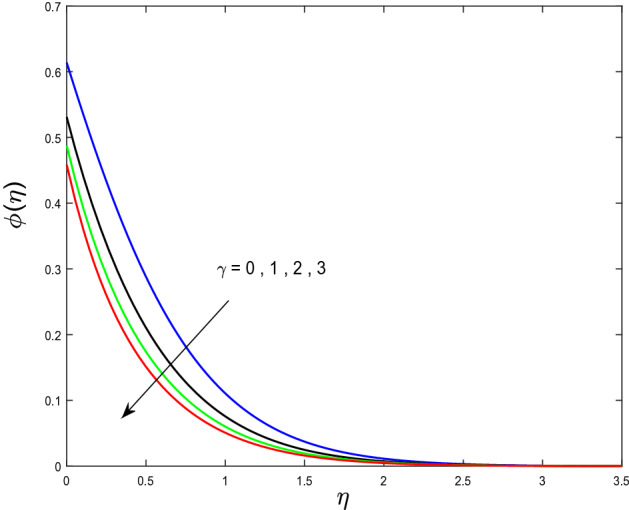

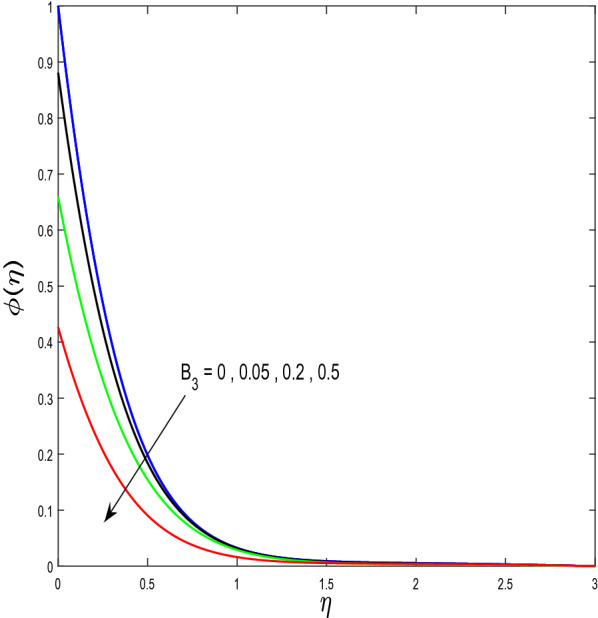

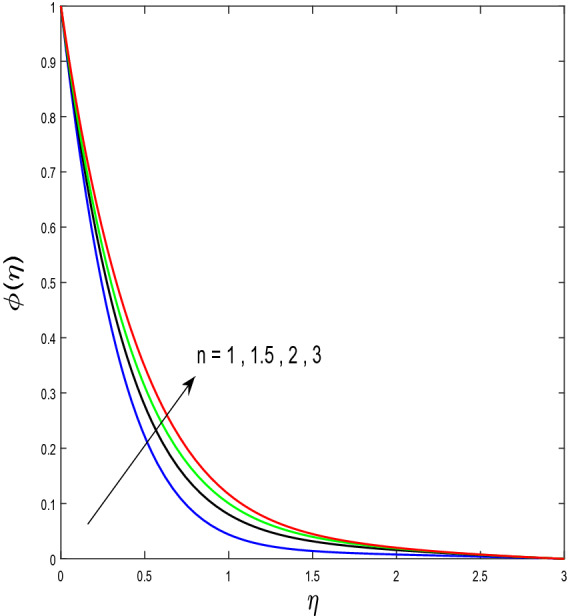

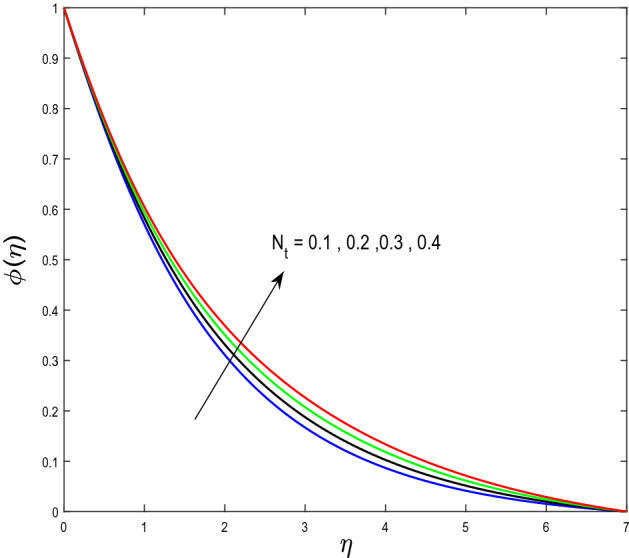

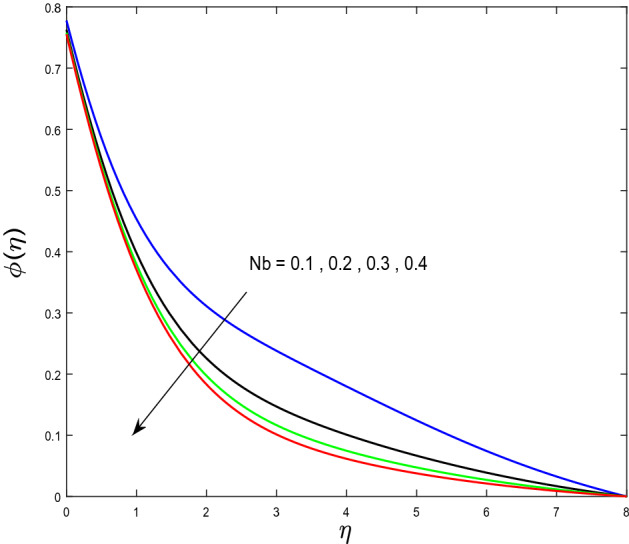

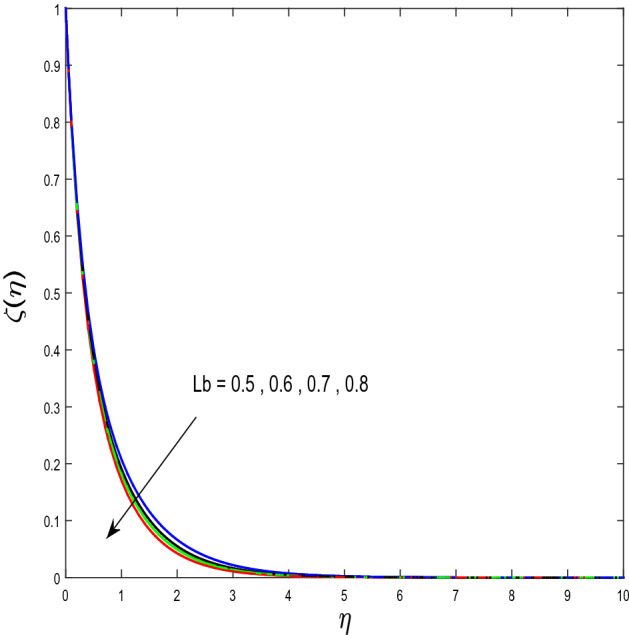

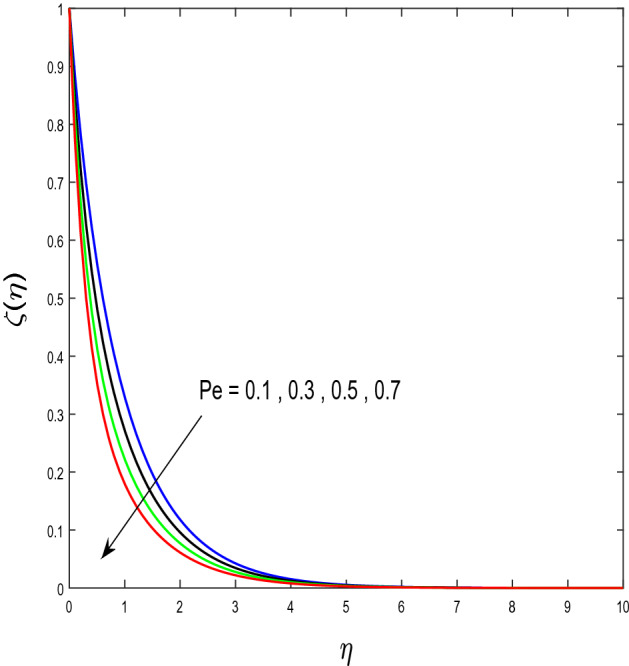

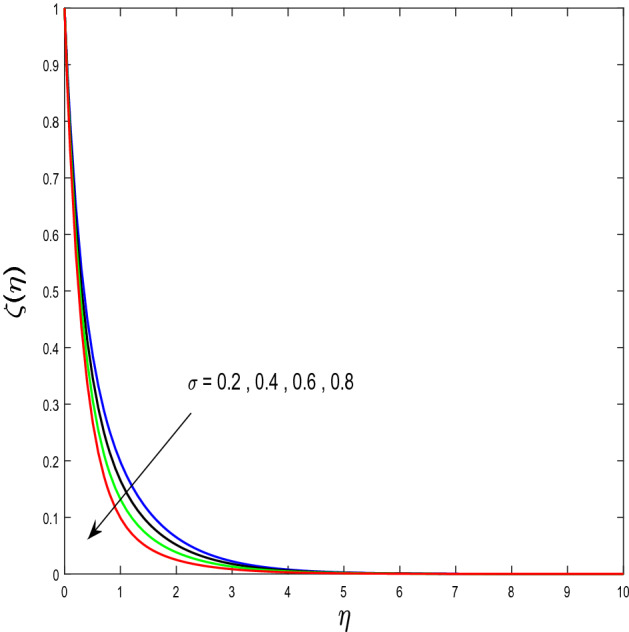

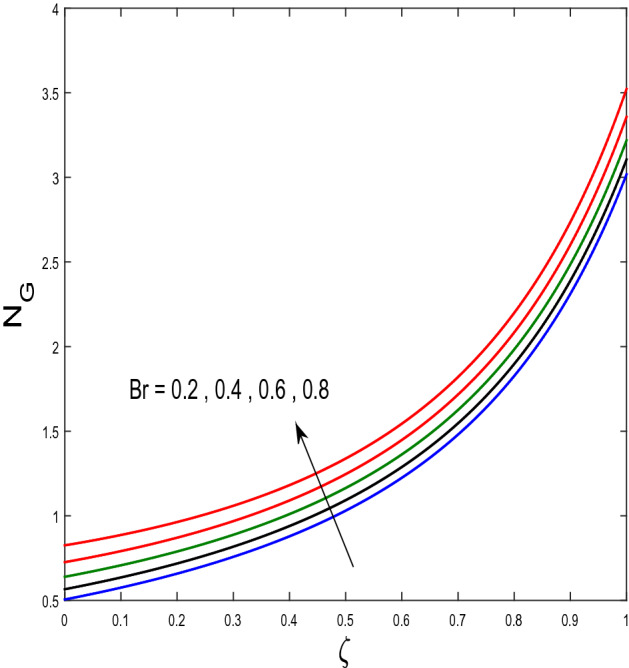

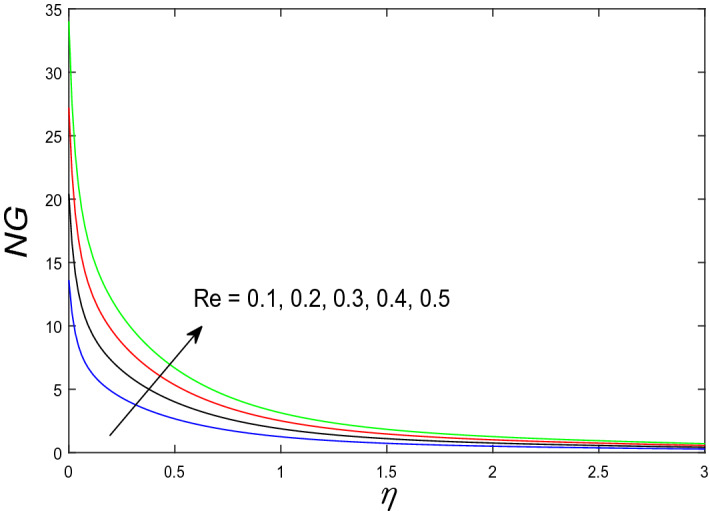

In this segment, we will examine the effect of distinct parameters on velocity, concentration, temperature, and gyrotactic microorganism fields. The numerous parameters like the magnetic interaction parameter Darcy parameter radiation parameter Schmidt number temperature ratio parameter porosity parameter Deborah number thermophoresis parameter curvature parameter bioconvection Lewis number Prandtl number Brownian motion parameter wall roughness parameter chemical reaction parameter concentration slip parameter thermal slip parameter Peclet number Bioconvection parameter and reaction order are discussed on temperature, velocity and nanoparticles concentration, and gyrotactic microorganism fields. Figure 2 demonstrated the behavior of on the . The strength of the Lorentz force is measured by The increase in enhances the Lorentz force strength and due to the rise in the velocity in axial direction decreases. As a result, the gradient of velocity at the surface is decreased. The wall effect on the velocity profile is described in Fig. 3. The slip decreases the speed close to the disk and this condition enhances by increasing in . Practically, the stretched impact of a cylinder is moderately shifted to the liquid layers which result in a decrease in . The influence of on the velocity field is investigated in Fig. 4. It is examined that by escalating the variations of , the decreasing trend of the velocity field is seen. This is because the higher values of produce resistance in a liquid flow and hence velocity decreases. Figure 5 demonstrated the effect of the on the velocity distribution of . The liquid's velocity diminishes on greater estimations of the . Actually, the movement of the liquid is stalled because of the presence of permeable media, and this results in the falloff of the liquid velocity. The effect of on the velocity field is investigated in Fig. 6. It is examined that by escalating the variations of , the diminishing behavior of the velocity field is seen. The impact of the upon is explained by Fig. 7. A significant increase in is observed. Enhancing signifies the temperature of the wall that causes thicker penetration depth for temperature profile. Likewise, the thermal diffusivity lies in the boundary layer with the relating exchange of heat. The thermal boundary layer corresponds to be larger nearby the region where the hotness is larger while it is lower a long way from cylinder because here temperature is low when compared to others. Subsequently, an intonation point emerges on the region when greater is considered. The temperature field for numerous is shown in Fig. 8. A generous upgrade in the temperature of the liquid is seen when the radius of the cylinder is reduced. The effect of on the thermal profile is described in Fig. 9. It is observed that the existence of melting phenomenon of the liquid temperature increases with rising variations of . Therefore, we can judge that greater variation of enhances the temperature field. Figure 10 defines that the large estimation of the descends the dimensionless liquid's temperature. From the figure, it is noticed that the thermal boundary layer becomes thicker on enhancing the values of the curvature parameter. Figure 11 is outlined to show the plots of for numerous terms of when other variables are fixed. It can be judged that growing values of increase the temperature and its parallel thickness of layer become thicker. Figure 12 elucidates that an increment in decays the nanoparticle concentration distribution . There is an opposite relationship between the and the Brownian diffusion coefficient. Greater the values of Schmidt number lower will be the Brownian diffusion coefficient, which tends to decrease the . Figure 13 portrays the concentration field for different estimations of . Large variations of the tend to smaller the nanoparticle concentration field. The descending behavior of a concentration profile on a is drawn in Fig. 14. Figure 15 demonstrated that for greater values of reaction order the concentration profile becomes higher. Figure 16 depicts the influence of on . Both the concentration and thermal layer thickness are increased by accumulating the variations of the . Greater estimations of the give rise to thermophoresis force which increases the movement of nanoparticles from cold to hot surfaces and also increases in the thermal layer thickness. The descending behavior in concentration distribution against is shown in Fig. 17. An enhancement in increases the Brownian motion due to which there is an escalation in the movement of nanoparticles and hence boundary layer thickness reduces. Figure 18 plotted to draw the curves of for different terms of while other variables are fixed. It is observed that depicts the decreasing behavior for large values of . Figure 19 shows the behavior of on gyrotactic microorganisms’ profile . Here, is an increasing function of that effects to a decrease the diffusivity of microorganisms. Figure 20 indicates the variations in gyrotactic microorganism profile for distinct estimations of the. Large variations of decrease the gyrotactic microorganism field. Figure 21 is drawn to illustrates the impact of the Brinkman numbers on the Entropy generation number. It is found that Entropy escalates for the Brinkman number. In Fig. 22, with rising estimations of , an increase is seen in the entropy generation number. A higher causes more aggravation in the field and expand fluid friction and heat transfer, which eventually increases the rate of entropy in the boundary layer region.

Figure 2.

Plot of for .

Figure 3.

Plot of for .

Figure 4.

Plot of for .

Figure 5.

Plot of for .

Figure 6.

Plot of for .

Figure 7.

Plot of for .

Figure 8.

Plot of for .

Figure 9.

Plot of for .

Figure 10.

Plot of for .

Figure 11.

Plot of for .

Figure 12.

Plot of for .

Figure 13.

Plot of for .

Figure 14.

Behaviour of for .

Figure 15.

Plot of for .

Figure 16.

Plot of for .

Figure 17.

Plot of for .

Figure 18.

Plot of for .

Figure 19.

Plot of for .

Figure 20.

Plot of for .

Figure 21.

Plot of for .

Figure 22.

Plot of for .

Table 2 is generated to substantiate the outlined results in this study by comparing it with Khan and Mustafa68 and Tamoor et al.56 in limiting case. A good agreement between the two outcomes is seen. Besides, Tables 3, 4, 5 express the numerical variations of the local Sherwood number , local Nusselt number and density amount of motile microorganism for distinct estimations of , , , , , , , , , , , , and . It is witnessed in Table 3 here that the heat flux rate is escalated for the growing estimates of , but the opposite trend is perceived for the estimations of , , In Table 4, it is witnessed that the mass flux rate is declined for the values of the , and , however, it is enhanced for the increasing estimates of the and The behavior of the varied parameters versus the density amount of motile microorganism is portrayed in Table 5. It is renowned that density amount of motile microorganism is improved for the estimations of , , , , and .

Table 2.

Table 3.

Computations of for various variations of , , , when = 7 and = = 0.5.

| 0.5 | 0.2 | 1.5 | 0.7654 | |

| 1 | 0.6803 | |||

| 1.5 | 0.5851 | |||

| 2 | 0.5003 | |||

| 0.5 | 0.7745 | |||

| 0.7 | 0.7801 | |||

| 1 | 0.7883 | |||

| 2 | 1.1440 | |||

| 2.5 | 1.4871 | |||

| 3 | 1.7770 | |||

| 0.1 | 1.3736 | |||

| 0.3 | 2.2339 | |||

| 0.5 | 3.3713 |

Table 4.

Computations of for numerous variations of ,, and when = 7, = 0.5 and = = = 0.5.

| 0.2 | 5 | 1 | 1 | 1.15817 |

| 0.5 | 1.17480 | |||

| 0.7 | 1.18683 | |||

| 1 | 1.20568 | |||

| 2 | 0.97565 | |||

| 3 | 1.05478 | |||

| 7 | 1.22726 | |||

| 2 | 1.27036 | |||

| 3 | 1.34142 | |||

| 4 | 1.39264 | |||

| 2 | 0.99641 | |||

| 3 | 0.92496 | |||

| 5 | 0.87854 |

Table 5.

Computations of for various variations of , , , and .

| 0.3 | 1.5 | 0.2 | 0.3 | 0.2 | 0.935596 |

| 0.6 | 1.059580 | ||||

| 0.9 | 1.193600 | ||||

| 1.0 | 0.915801 | ||||

| 1.5 | 0.935596 | ||||

| 2.0 | 0.940771 | ||||

| 0.2 | 0.935596 | ||||

| 0.4 | 1.012580 | ||||

| 0.6 | 1.089560 | ||||

| 0.4 | 1.065290 | ||||

| 0.5 | 1.189010 | ||||

| 0.6 | 1.307130 | ||||

| 0.3 | 0.963155 | ||||

| 0.6 | 1.038210 | ||||

| 0.9 | 1.103780 |

Concluding remarks

In the current investigation, we have discussed nonlinear radiative MHD Williamson nano liquid flow via a stretched cylinder in a Darcy–Forchheimer porous media. The flow is assisted by the impacts of the chemical reaction, and gyrotactic microorganisms with partial slip condition at the boundary. The solution to the problem is addressed by the MATLAB scheme of the bvp4c built-in function. The main results of the present investigation are appended below:

and show the opposing nature against the concentration field.

The velocity distribution is lowered for large variations of , and

decreases the gyrotactic microorganism profile.

An increment in , and leads to a lowering concentration profile.

Enhanced variations of and display the decreasing behavior on the temperature profile.

Large values of , and causes an increment in temperature distribution.

Gyrotactic microorganism profile reduces for greater variations of and .

Entropy intensifies for ; however, an opposite tendency is observed for .

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University, Abha 61413, Saudi Arabia for funding this work through research groups program under Grant number RGP-1-96-42.

List of symbols

Magnetic field intensity

Wall roughness parameter

Wall thermal parameter

Concentration slip parameter

Motile slip parameter

Brinkman number

Thermophoretic diffusion coefficient ()

Capacity

Drag force coefficients

Permeability of porous medium

Wall’s concentration

Brownian diffusion coefficient ()

Ambient liquid concentration

Liquid concentration ()

Heat Specific capacity ()

Diffusivity of the microorganism ()

Peclet numbers

Non-uniform inertial coefficient

Forchheimer number

Motile slip coefficient

Characteristic length

Mass flux ()

Bioconvection Lewis number

Magnetic interaction parameter

Thermal slip coefficient

Mean absorption coefficient

Surface motile microorganisms ()

Brownian motion parameters

Reference velocity ()

Reaction order

Thermal conductivity

Velocity slip coefficient

Rate of Entropy generation

Concentration slip coefficient

Local Nusselt number

Curvature parameter

Wall heats ()

Thermophoresis parameter

Prandtl number

Radiation heat flux ()

Density number of motile microorganisms

Radial coordinate

Radiation parameter

Wall’s temperature ()

Electrical conductivity

Velocity component along -direction ()

Schmidt number

Diffusion parameter

Ambient fluid temperature ()

Stefan–Boltzmann constant

Constant all-out cell swimming speed ()

Entropy generation

Bioconvection parameter

Temperature difference

Local Sherwood number

Velocity component along -direction ()

Axial coordinate

Stretching velocity ()

Greek symbols

Thermal diffusivity ()

Temperature difference parameter

Concentration difference parameter

Motile difference parameter

Deborah number in terms of velocity time

Chemical reaction parameter

Porosity parameter

Reaction rate

Relaxation time

Kinematic viscosity ()

Density ()

Absolute viscosity ()

Similarity variable

Stream function ()

Temperature ratio parameter

The quotient of the effective heat capacity of the nano-particle material and of the fluid

Subscripts

Condition at the infinity

Condition at the wall

Author contributions

M.R. did conceptualization, M.U.K. worked on methodology, C.L. did validation and formal analysis, Y.M.C. wrote the original draft, S.K., and C.L. worked on software. Y.M.C. arranged the funds, M.Y.M and R.C. helped in the revised draft and partial funding arrangements.

Funding

The research was supported by the National Natural Science Foundation of China (Grant Nos. 11971142, 11871202, 61673169, 11701176, 11626101, 11601485).

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Choi, S. U. S., & Eastman, J. A. Enhancing thermal conductivity of fluids with nanoparticles. (IMECE). 66, 99–105 (1995).

- 2.Koo J, Kleinstreuer C. Laminar nanofluid flow in microheat-sinks. Int. J. Heat Mass Transf. 2005;48(13):2652–2661. doi: 10.1016/j.ijheatmasstransfer.2005.01.029. [DOI] [Google Scholar]

- 3.Eastman JA, Choi SUS, Li S, Yu W, Thompson LJ. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl. Phys. Lett. 2001;78(6):718–720. doi: 10.1063/1.1341218. [DOI] [Google Scholar]

- 4.Choi SUS, Zhang ZG, Yu W, Lockwood FE, Grulke EA. Anomalous thermal conductivity enhancement in nanotube suspensions. Appl. Phys. Lett. 2001;79(14):2252–2254. doi: 10.1063/1.1408272. [DOI] [Google Scholar]

- 5.Bilal M, Mazhar SZ, Ramzan M, Mehmood Y. Time-dependent hydromagnetic stagnation point flow of a Maxwell nanofluid with melting heat effect and amended Fourier and Fick's laws. Heat Trans. 2021 doi: 10.1002/htj.22081. [DOI] [Google Scholar]

- 6.Tlili I, Naseer S, Ramzan M, Kadry S, Nam Y. Effects of chemical species and nonlinear thermal radiation with 3D Maxwell nanofluid flow with double stratification—an analytical solution. Entropy. 2020;22(4):453. doi: 10.3390/e22040453. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Sheikholeslami, M., Arabkoohsar, A., & Jafaryar, M. (2020). Impact of a helical-twisting device on the thermal--hydraulic performance of a nanofluid flow through a tube. J. Therm. Anal. Calorim. 139(5), 3317–3329 (2020).

- 8.Farooq U, Lu D, Munir S, Ramzan M, Suleman M, Hussain S. MHD flow of Maxwell fluid with nanomaterials due to an exponentially stretching surface. Sci. Rep. 2019;9(1):1–11. doi: 10.1038/s41598-019-43549-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Ramesh GK, Shehzad SA, Rauf A, Chamkha AJ. Heat transport analysis of aluminum alloy and magnetite graphene oxide through permeable cylinder with heat source/sink. Phys. Scr. 2020;95(9):095203. doi: 10.1088/1402-4896/aba5af. [DOI] [Google Scholar]

- 10.Reza-E-Rabbi S, Ahmmed SF, Arifuzzaman SM, Sarkar T, Khan MS. Computational modelling of multiphase fluid flow behaviour over a stretching sheet in the presence of nanoparticles. Int. J. Eng. Sci. Technol. 2020;23(3):605–617. [Google Scholar]

- 11.Abbasi A, Mabood F, Farooq W, Hussain Z. Non-orthogonal stagnation point flow of Maxwell nano-material over a stretching cylinder. Int. Comm. Heat Mass. Tran. 2021;120:105043. doi: 10.1016/j.icheatmasstransfer.2020.105043. [DOI] [Google Scholar]

- 12.Li F, Sheikholeslami M, Dara RN, Jafaryar M, Shafee A, Nguyen-Thoi T, Li Z. Numerical study for nanofluid behavior inside a storage finned enclosure involving melting process. J. Mol. Liq. 2020;297:111939. doi: 10.1016/j.molliq.2019.111939. [DOI] [Google Scholar]

- 13.Komeilibirjandi A, Raffiee AH, Maleki A, Nazari MA, Shadloo MS. Thermal conductivity prediction of nanofluids containing CuO nanoparticles by using correlation and artificial neural network. J. Therm. Anal. Calorim. 2020;139(4):2679–2689. doi: 10.1007/s10973-019-08838-w. [DOI] [Google Scholar]

- 14.Waqas H, Imran M, Bhatti MM. Influence of bioconvection on Maxwell nanofluid flow with the swimming of motile microorganisms over a vertical rotating cylinder. Chin. J. Phys. 2020;68:558–577. doi: 10.1016/j.cjph.2020.10.014. [DOI] [Google Scholar]

- 15.Islam, S., Khan, A., Kumam, P., Alrabaiah, H., Shah, Z., Khan, W., & Jawad, M. Radiative mixed convection flow of Maxwell nanofluid over a stretching cylinder with Joule heating and heat source/sink effects. Sci. Rep. 10(1), 1–18 (2020). [DOI] [PMC free article] [PubMed]

- 16.Ahmed A, Khan M, Ahmed J. Thermal analysis in swirl motion of Maxwell nanofluid over a rotating circular cylinder. Appl. Math. Mech. 2020;41(9):1417–1430. doi: 10.1007/s10483-020-2643-7. [DOI] [Google Scholar]

- 17.Kumar RV, Gowda RP, Kumar RN, Radhika M, Prasannakumara BC. Two-phase flow of dusty fluid with suspended hybrid nanoparticles over a stretching cylinder with modified Fourier heat flux. Appl. Sci. 2021;3(3):1–9. [Google Scholar]

- 18.Kumar, R. N., Gowda, R. P., Abusorrah, A. M., Mahrous, Y. M., Abu-Hamdeh, N. H., Issakhov, A., & Prasannakumara, B. C. Impact of magnetic dipole on ferromagnetic hybrid nanofluid flow over a stretching cylinder. Phys. Scr. 96(4), 045215 (2021).

- 19.Jayadevamurthy, P. G. R., Rangaswamy, N. K., Prasannakumara, B. C., & Nisar, K. S. Emphasis on unsteady dynamics of bioconvective hybrid nanofluid flow over an upward–downward moving rotating disk. Num. Methods Part. Diff. Equ. (2020).

- 20.Khan, S. U., Shehzad, S. A., & Ali, N. Bioconvection flow of magnetized Williamson nanoliquid with motile organisms and variable thermal conductivity. Appl. Nanosci. 1–12 (2020).

- 21.Ramesh GK, Gireesha BJ, Gorla RSR. Study on Sakiadis and Blasius flows of Williamson fluid with convective boundary condition. Nonlinear Eng. 2015;4(4):215–221. doi: 10.1515/nleng-2015-0020. [DOI] [Google Scholar]

- 22.Anwar, M. I., Rafique, K., Misiran, M., Shehzad, S. A., & Ramesh, G. K. Keller-box analysis of inclination flow of magnetized Williamson nanofluid. Appl. Sci. 2(3), 1–9 (2020).

- 23.Darcy, H. Les fontaines publiques de la ville de Dijon: exposition et application...Victor Dalmont (1856).

- 24.Forchheimer, P. Wasserbewegung durch boden. Z. Ver. Deutsch, Ing., 45, 1782–1788 (1901).

- 25.Muskat, M. The flow of homogeneous fluids through porous media (No. 532.5 M88) (1946).

- 26.Pal D, Mondal H. Hydromagnetic convective diffusion of species in Darcy–Forchheimer porous medium with non-uniform heat source/sink and variable viscosity. Int. Commun. Heat Mass Transf. 2012;39(7):913–917. doi: 10.1016/j.icheatmasstransfer.2012.05.012. [DOI] [Google Scholar]

- 27.Ganesh NV, Hakeem AA, Ganga B. Darcy–Forchheimer flow of hydromagneticnanofluid over a stretching/shrinking sheet in a thermally stratified porous medium with second order slip, viscous and Ohmic dissipations effects. Ain Shams Eng. J. 2016;9(4):939–951. doi: 10.1016/j.asej.2016.04.019. [DOI] [Google Scholar]

- 28.Alshomrani AS, Ullah MZ. Effects of homogeneous-heterogeneous reactions and convective condition in Darcy–Forchheimer flow of carbon nanotubes. J. Heat Transfer. 2019;141(1):012405. doi: 10.1115/1.4041553. [DOI] [Google Scholar]

- 29.Saif, R. S., Hayat, T., Ellahi, R., Muhammad, T., & Alsaedi, A. Darcy–Forchheimerflow of nanofluid due to a curved stretching surface. Int. J.Num. Method H. 29, (2018).

- 30.Seth GS, Kumar R, Bhattacharyya A. Entropy generation of dissipative flow of carbon nanotubes in rotating frame with Darcy–Forchheimer porous medium: A numerical study. J. Mol. Liq. 2018;268:637–646. doi: 10.1016/j.molliq.2018.07.071. [DOI] [Google Scholar]

- 31.Hayat, T., Ra…que, K., Muhammad, T., Alsaedi, A., & Ayub, M. Carbon nanotubessignificance in Darcy–Forchheimer flow. Res. Phys. 8, 26–33 (2018).

- 32.Ramesh GK, Kumar KG, Gireesha BJ, Shehzad SA, Abbasi FM. Magnetohydrodynamic nanoliquid due to unsteady contracting cylinder with uniform heat generation/absorption and convective condition. Alex. Eng. J. 2018;57(4):3333–3340. doi: 10.1016/j.aej.2017.12.009. [DOI] [Google Scholar]

- 33.Arifuzzaman SM, Khan MS, Al-Mamun A, Reza-E-Rabbi S, Biswas P, Karim I. Hydrodynamic stability and heat and mass transfer flow analysis of MHD radiative fourth-grade fluid through porous plate with chemical reaction. King Saud Univ. Sci. 2019;31(4):1388–1398. doi: 10.1016/j.jksus.2018.12.009. [DOI] [Google Scholar]

- 34.Reza-E-Rabbi S, Arifuzzaman SM, Sarkar T, Khan MS, Ahmmed SF. Explicit finite difference analysis of an unsteady MHD flow of a chemically reacting Casson fluid past a stretching sheet with Brownian motion and thermophoresis effects. J. King Saud Univ. Sci. 2020;32(1):690–701. doi: 10.1016/j.jksus.2018.10.017. [DOI] [Google Scholar]

- 35.Arifuzzaman SM, Khan MS, Mehedi MFU, Rana BMJ, Ahmmed SF. Chemically reactive and naturally convective high speed MHD fluid flow through an oscillatory vertical porous plate with heat and radiation absorption effect. Eng. Sci. Technol. 2018;21(2):215–228. [Google Scholar]

- 36.Shankaralingappa, B. M., Gireesha, B. J., Prasannakumara, B. C., & Nagaraja, B. Darcy–Forchheimer flow of dusty tangent hyperbolic fluid over a stretching sheet with Cattaneo-Christov heat flux. Waves Rand. Comp. Media. 1–20 (2021).

- 37.Ramzan M, Abid N, Lu D, Tlili I. Impact of melting heat transfer in the time-dependent squeezing nanofluid flow containing carbon nanotubes in a Darcy–Forchheimer porous media with Cattaneo-Christov heat flux. Comm. Theo. Phy. 2020;72(8):085801. doi: 10.1088/1572-9494/ab8a2c. [DOI] [Google Scholar]

- 38.Jawad M, Saeed A, Kumam P, Shah Z, Khan A. Analysis of boundary layer MHD Darcy–Forchheimer radiative nanofluid flow with Soret and Dufour effects by means of marangoni convection. Case Stud. 2021;23:100792. [Google Scholar]

- 39.Khan MI. Transportation of hybrid nanoparticles in forced convective Darcy–Forchheimer flow by a rotating disk. Int Com. Heat Mass Tran. 2021;122:105177. doi: 10.1016/j.icheatmasstransfer.2021.105177. [DOI] [Google Scholar]

- 40.Muhammad T, Lu DC, Mahanthesh B, Eid MR, Ramzan M, Dar A. Significance of Darcy–Forchheimer porous medium in nanofluid through carbon nanotubes. Comm. Theo. Phys. 2018;70(3):361. doi: 10.1088/0253-6102/70/3/361. [DOI] [Google Scholar]

- 41.Ramzan, M., Gul, H., & Zahri, M. Darcy–Forchheimer 3D Williamson nanofluid flow with generalized Fourier and Fick’s laws in a stratified medium. Bull. Polish Acad. Sci. Tech. Sci. 68(2) (2020).

- 42.Mehmood T, Ramzan M, Howari F, Kadry S, Chu YM. Application of response surface methodology on the nanofluid flow over a rotating disk with autocatalytic chemical reaction and entropy generation optimization. Sci. Rep. 2021;11(1):1–18. doi: 10.1038/s41598-021-81755-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Ramzan M, Chung JD, Kadry S, Chu YM, Akhtar M. Nanofluid flow containing carbon nanotubes with quartic autocatalytic chemical reaction and Thompson and Troian slip at the boundary. Sci. Rep. 2020;10(1):1–13. doi: 10.1038/s41598-019-56847-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Khan M, Salahuddin T, Malik MY, Tanveer A, Hussain A, Alqahtani AS. 3-D axisymmetric Carreau nanofluid flow near the Homann stagnation region along with chemical reaction: Application Fourier’s and Fick’s laws. Math. Comp. Sim. 2020;170:221–235. doi: 10.1016/j.matcom.2019.10.019. [DOI] [Google Scholar]

- 45.Lu DC, Ramzan M, Bilal M, Chung JD, Farooq U. A numerical investigation of 3D MHD rotating flow with binary chemical reaction, activation energy and non-Fourier heat flux. Comm. Theo. Phys. 2019;70(1):089. doi: 10.1088/0253-6102/70/1/89. [DOI] [Google Scholar]

- 46.Khan M, Malik MY, Salahuddin T, Khan F. Generalized diffusion effects on Maxwell nanofluid stagnation point flow over a stretchable sheet with slip conditions and chemical reaction. J. Braz. Soc. Mech. Sci. Eng. 2019;41(3):1–9. [Google Scholar]

- 47.Ramzan M, Bilal M, Chung JD. Numerical simulation of magnetohydrodynamic radiative flow of Casson nanofluid with chemical reaction past a porous media. Theo. Nanosci. 2017;14(12):5788–5796. doi: 10.1166/jctn.2017.7013. [DOI] [Google Scholar]

- 48.Khan M, Shahid A, Malik MY, Salahuddin T. Chemical reaction for Carreau-Yasuda nanofluid flow past a nonlinear stretching sheet considering Joule heating. Res. Phys. 2018;8:1124–1130. [Google Scholar]

- 49.Khan M, Salahuddin T, Malik MY, Tanveer A, Hussain A, Alqahtani AS. 3-D axisymmetric Carreau nanofluid flow near the Homann stagnation region along with chemical reaction: application Fourier’s and Fick’s laws. Math. Compt. Simul. 2020;170:221–235. doi: 10.1016/j.matcom.2019.10.019. [DOI] [Google Scholar]

- 50.Rehman KU, Khan AA, Malik MY, Pradhan RK. Combined effects of Joule heating and chemical reaction on non-Newtonian fluid in double stratified medium: A numerical study. Res. Phys. 2017;7:3487–3496. [Google Scholar]

- 51.Ramzan M, Gul H, Chung JD. Double stratified radiative Jeffery magneto nanofluid flow along an inclined stretched cylinder with chemical reaction and slip condition. Eur. Phys. J. Plus. 2017;132(11):1–17. doi: 10.1140/epjp/i2017-11748-5. [DOI] [Google Scholar]

- 52.Lu D, Ramzan M, Ahmad S, Chung JD, Farooq U. Upshot of binary chemical reaction and activation energy on carbon nanotubes with Cattaneo-Christov heat flux and buoyancy effects. Phys. Fluids. 2017;29(12):123103. doi: 10.1063/1.5010171. [DOI] [Google Scholar]

- 53.Sohail M, Naz R, Abdelsalam SI. On the onset of entropy generation for a nanofluid with thermal radiation and gyrotactic microorganisms through 3D flows. Phys. Scr. 2020;95(4):045206. doi: 10.1088/1402-4896/ab3c3f. [DOI] [Google Scholar]

- 54.Khan MI, Qayyum S, Hayat T, Khan MI, Alsaedi A. Entropy optimization in flow of Williamson nanofluid in the presence of chemical reaction and Joule heating. Int. J. Heat Mass Transf. 2019;133:959–967. doi: 10.1016/j.ijheatmasstransfer.2018.12.168. [DOI] [Google Scholar]

- 55.Sarojamma G, Vijaya Lakshmi R, Satya Narayana PV, Animasaun IL. Exploration of the significance of autocatalytic chemical reaction and Cattaneo-Christov heat flux on the dynamics of a micropolar fluid. J. Appl. Comput. Mech. 2020;6(1):77–89. [Google Scholar]

- 56.Tamoor M, Waqas M, Khan MI, Alsaedi A, Hayat T. Magnetohydrodynamic flow of Casson fluid over a stretching cylinder. Res. Phys. 2017;7:498–502. [Google Scholar]

- 57.Yusuf TA, Gbadeyan JA. Entropy generation on Maxwell fluid flow past an inclined stretching plate with slip and convective surface conditon: Darcy–Forchheimer model. NHC. 2019;26:62–83. doi: 10.4028/www.scientific.net/NHC.26.62. [DOI] [Google Scholar]

- 58.Adesanya, S. O., Dairo, O. F., Yusuf, T. A., Onanaye, A. S., & Arekete, S. A. Thermodynamics analysis for a heated gravity-driven hydromagnetic couple stress film with viscous dissipation effects. Phys. A. 540, 123150 (2020).

- 59.Yusuf TA, Adesanya SO, Gbadeyan JA. Entropy generation in MHD Williamson nanofluid over a convectively heated stretching plate with chemical reaction. J. Heat Transfer. 2020;49(4):1982–1999. doi: 10.1002/htj.21703. [DOI] [Google Scholar]

- 60.Mabood, F., Yusuf, T. A., & Sarris, I. E. Entropy generation and irreversibility analysis on free convective unsteady MHD Casson fluid flow over a stretching sheet with Soret/Dufour in porous media. Int. J.11(6), (2020).

- 61.Mabood, F., Yusuf, T. A., & Khan, W. A. (2021). Cu–Al2 O3–H2O hybrid nanofluid flow with melting heat transfer, irreversibility analysis and nonlinear thermal radiation. J. Therm. Anal. Calorim. 143(2), 973–984 (2021).

- 62.Mabood, F., Yusuf, T. A., & Bognár, G. Features of entropy optimization on MHD couple stress nanofluid slip flow with melting heat transfer and nonlinear thermal radiation. Sci. Rep. 10(1), 1–13 (2020). [DOI] [PMC free article] [PubMed]

- 63.Mabood F, Yusuf TA, Rashad AM, Khan WA, Nabwey HA. Effects of combined heat and mass transfer on entropy generation due to MHD nanofluid flow over a rotating frame. CMC. 2021;66(1):575–587. [Google Scholar]

- 64.Yusuf TA, Mabood F, Khan WA, Gbadeyan JA. Irreversibility analysis of Cu-TiO2-H2O hybrid-nanofluid impinging on a 3-D stretching sheet in a porous medium with nonlinear radiation: Darcy–Forchhiemer’s model. Alex. Eng. J. 2020;59:5247–5261. doi: 10.1016/j.aej.2020.09.053. [DOI] [Google Scholar]

- 65.Almeida, F., Gireesha, B. J., Venkatesh, P., & Ramesh, G. K. Intrinsic irreversibility of Al2O3–H2O nanofluid Poiseuille flow with variable viscosity and convective cooling. Int. J. Numer. Method H. (2020).

- 66.Hayat T, Rashid M, Alsaedi A, Asghar S. Nonlinear convective flow of Maxwell nanofluid past a stretching cylinder with thermal radiation and chemical reaction. J. Braz. Soc. Mech. Sci. Eng. 2019;41(2):86. doi: 10.1007/s40430-019-1576-3. [DOI] [Google Scholar]

- 67.Raju CSK, Sanjeevi P, Raju MC, Ibrahim SM, Lorenzini G, Lorenzini E. The flow of magnetohydrodynamic Maxwell nanofluid over a cylinder with Cattaneo-Christov heat flux model. Cont. Mech. Thermodyn. 2017;29(6):1347–1363. doi: 10.1007/s00161-017-0580-z. [DOI] [Google Scholar]

- 68.Khan JA, Mustafa M. A numerical analysis for non-linear radiation in MHD flow around a cylindrical surface with chemically reactive species. Res. Phys. 2018;8:963–970. [Google Scholar]