Abstract

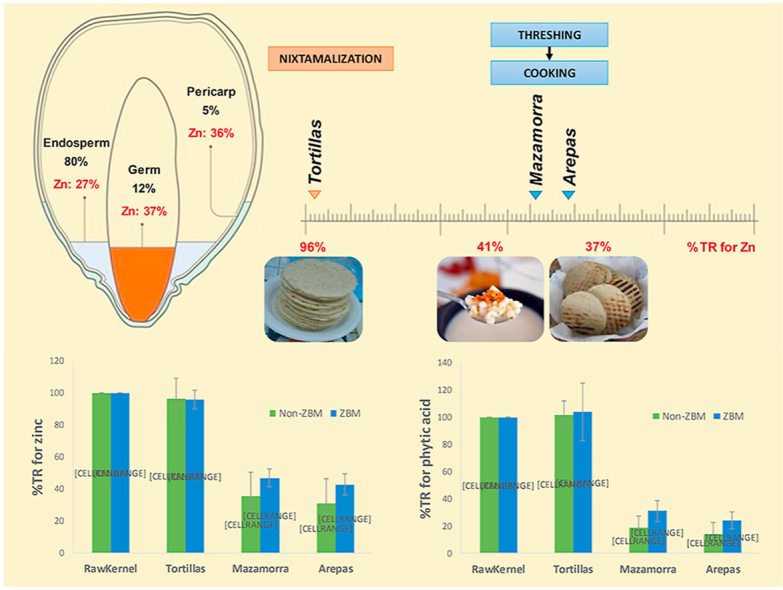

High kernel-zinc maize varieties are available to consumers in several countries in Latin America to contribute to increase the zinc intake of their populations. Minerals, phytic acid and amino acids retention were measured after processing six maize varieties including three high kernel-zinc, one quality protein maize and two conventional maize. Grain for each variety was processed into tortillas, arepas and mazamorra, common maize dishes in the region. To evaluate the effect of processing kernel-zinc maize varieties on zinc retention, varieties were grouped in zinc biofortified maize (ZBM) and non-ZBM. Iron, zinc, phytic acid, tryptophan and lysine concentrations in non-processed maize were 17.1–19.1 μg/g DW, 23.9–33.0 μg/g DW, 9.9–10.0 mg/g DW, 0.06–0.08% and 0.27–0.37%, respectively. In tortillas, the iron, zinc, phytic acid and lysine content did not change (p < 0.05) compared to raw grain, while tryptophan decreased by 32%. True retention of iron in arepas and mazamorra was 43.9 and 60.0%, for zinc 36.8 and 41.3%, and for phytic acid 19.3 and 25.1%. Tortillas had higher zinc retention than arepas and mazamorra due to use of whole grain in the nixtamalization process. Therefore, to contribute to higher zinc intake, nixtamalized tortilla prepared with biofortified zinc maize is recommended. Additionally, promotion of whole grain flour to prepare arepas should be explored to enhance the intake of minerals that are usually confined to aleurone layers and germ.

Keywords: Biofortification, Zinc, Lysine, Tryptophan, Maize dishes, Nixtamalization

Graphical abstract

Highlights

-

•

High kernel-zinc maize varieties are available to consumers in several Latin American countries.

-

•

In nixtamalized tortillas, the iron, zinc, phytic acid and lysine content did not chage compared to raw grain.

-

•

Nixtamalized tortillas prepared with biofortified zinc maize is recommended.

1. Introduction

Maize is the most consumed cereal in Mexico and several countries in Central and South America. It is also a staple crop in Sub-Saharan Africa. In Mexico and Guatemala, the daily per capita consumption of maize is 290 g, while in Venezuela and Colombia is approximate 100 g (Ranum et al., 2014; Govaerts et al., 2019; Ekpa et al., 2019).

In Latin America, maize dishes include beverages, snacks, and flatbreads. In Mexico and Central America, more than 600 food products and dishes are derived from maize and about 300 of them use the ancient alkaline cooking process called nixtamalization, which consists of boiling and steeping whole maize grains in an alkaline solution. Tortillas are the most consumed product prepared from nixtamalized dough and today tortillas are found worldwide (Ekpa et al., 2018; Escalante-Aburto et al., 2020). The most common maize product in Venezuela, Colombia and Panama is a flatbread called arepa, a thick round dough generally prepared with pre-cooked decorticated and degermed maize kernels although in some regions of Colombia is made of whole grain previously treated with ash or lime (Ranum et al., 2014; Espinoza et al., 2018; Guzzon et al., 2021). Another popular form of maize consumption in Colombia, Argentina and Peru is mazamorra. In Colombia, it is boiled decorticated and degermed maize normally served semi-liquid in combination with milk (Nuss and Tanumihardjo, 2010; Guzzon et al., 2021).

Biofortification, a breeding strategy to develop staple crops with higher micronutrient content while ensuring good agronomical performance it has been led for the last 20 years by Harvest Plus working with several stakeholders (Bouis and Saltzman, 2017). The first considered biofortified maize, however, was developed in 1970’s, Quality Protein Maize (QPM), maize with higher content of lysine and tryptophan, two essential amino acids (Atlin et al., 2011). Most recently, high kernel-zinc maize was developed and made available to farmers in Colombia, Guatemala, Honduras and Nicaragua (Listman et al., 2019). Zinc (Zn) is an essential micronutrient which deficiency results in a compromised immune system. In order to consider a maize variety high in zinc, HarvestPlus recommended a target increase in the kernel of more than 12 μg/g (total Zn concentration >30 μg/g) compared to non-biofortified maize (Listman et al., 2019). Bauman (1975) and Chakraborti et al. (2011) reported a significant positive correlation between QPM and Zn content in maize kernels. Currently, most of the commercialized high Zn maize varieties and hybrids are both high Zn and QPM.

The Zn content in maize kernels varies due to the genetic background and the environmental conditions where the crop is grown (Hindu et al., 2018). Post-harvest management and cooking processes can affect the vitamin, mineral and amino acid composition in the final product as compared to raw kernels (Taleon et al., 2017). Since the majority of zinc is located in the maize embryo and pericarp (Cheah et al., 2020) processes that remove large quantities of these two grain structures could reduce the zinc content in the final food product, even below to 10 ppm (Bevis and Hestrin, 2020). Processes where not much embryo or pericarp is removed yields high zinc retention (Bressani et al., 2004). Zinc bioavailability is affected by phytic acid which binds zinc to produce zinc-phytate (Miller et al., 2007). Phytate is also located largely in the embryo and pericarp (Raboy et al., 2000). High zinc maize could improve zinc deficiency in populations only if the zinc is retained in similar or higher quantities compared to conventional maize. Up to date no information is available on the zinc and phytic acid retention in biofortified maize.

In this work, we used high kernel-zinc maize varieties to elucidate the effect of processing and cooking methods (nixtamalized tortillas, arepas and mazamorra) on Zn retention and to assess the implications for Zn bioavailability.

2. Materials and methods

2.1. Maize germplasm

Five white maize breeding experimental varieties (hybrids) were used: three high kernel-zinc biofortified varieties (ZBM) and two non-biofortified varieties (non-ZBM). The non-ZBM varieties were: one QPM variety and one conventional maize variety. One commercial non-ZBM hybrid was used as a control (Table 1).

Table 1.

Biofortified and control varieties used. Group non-ZBM: non-biofortified maize varieties (A-B-C), and group ZBM: high kernel-zinc biofortified maize varieties (D-E-F).

| Group | Code | Variety | Type of maize | |

|---|---|---|---|---|

| Non-ZBM | A | S06TLWQHGAB02-B | No zinc | QPM |

| B | S11TLWNHGAB06-B | No zinc | No QPM | |

| C | Commercial check | No zinc | No QPM | |

| ZBM | D | S13LTWQHZNHGAB01 | Zinc | QPM |

| E | S13LTWQHZNHGAB02 | Zinc | QPM | |

| F | S13LTWQHZNHGAB03-B | Zinc | QPM | |

2.2. Grain physical traits

Subsamples (100 g) were used for physical characterization, including kernel size (length, width and thickness), thousand kernel weight (TKW), percentage of vitreous (VE) and floury endosperm (FE), and kernel hardness (flotation index and hectoliter weight), according to methodologies described by Palacios-Rojas (2018).

2.3. Food products preparation processes

All food products were prepared in duplicate and sampled at every different stage in the processes.

2.3.1. Arepa and mazamorra preparation

Whole maize (10 kg) was threshed during 5 min (5 hp engine at 500 rpm) in a dry-degermination machine, used for pilot laboratory studies, to mechanically remove the pericarp, tip cap and most of the germ (maize bran). Maize bran was estimated based on a preliminary test and according to maize weight after degermination and visual verification (16.0–20.5% of the kernel weight).

For arepas, 200 g of threshed maize was washed and mixed with 2500 mL of ultrapure water (18.0 MΩ) (MilliQ® Merck-Millipore, Germany) and 2 g of sodium bicarbonate (baking soda). Maize was cooked in a pressure cooker for 90 min, cooled down without the cooking water, and then ground using a disk mill (Corona grain mill grinder, Landers & Co, Colombia). Butter (25 g) and salt (2.5 g) were added to the dough. Cakes weighing 50 g (1 cm thick) were formed by hand and cooked in a Teflon-coated pan, preheated at 150 °C, for 8 min per side (two times). For mazamorra, the same quantities of threshed maize, ultrapure water and baking soda were used, but the grain was cooked in a pressure cooker for 120 min. The cooked maize was cooled down in the same water where it was cooked.

2.3.2. Nixtamalization and tortilla preparation

Whole maize kernels (250 g) were cooked at 85 °C with 750 mL of ultrapure water and 2.5 g of calcium hydroxide (Ca(OH)2, 1% w/w) for 50 min. The nixtamalized grain (nixtamal) was soaked at room temperature for 16 h. The cooking liquid (nejayote) was drained and the nixtamalized samples were washed with ultrapure water twice to remove excess of Ca(OH)2 and the released pericarp of the nixtamal. The washed nixtamal was weighed and then ground using a disk mill (Corona grain mill grinder, Landers & Co, Colombia). Ultrapure water was added to make the dough smooth and malleable. Balls (25 g) were formed, pressed flat in a tortilla press, and cooked on a Teflon-coated pan preheated at 270 °C for 45 s per side (three times).

2.4. Chemical analysis

Samples of raw kernels, threshed grains, nixtamalized grain and dough, cooked grain and dough, tortillas, arepas and mazamorra were lyophilized and ground using a Retsch Mixer Mill MM 400 fitted with zirconium grinding jars and balls (Retsch GmbH & Co KG, Germany). Samples were stored at 4 °C until further analysis.

2.4.1. Determination of minerals and phytic acid (PA)

Iron (Fe), Zn and Ca concentrations were determined in duplicate using inductively-coupled plasma-optical emission spectroscopy (ICP-OES) (7500cx; Agilent Technologies, USA) after a closed-tube nitric acid/hydrogen peroxide digestion method (Wheal et al., 2011). Aluminum was analyzed as an indicator of potential sample contamination (Palacios-Rojas, 2018). PA content was determined following extraction in 1.25% H2SO4 and subsequent analysis by Dionex liquid chromatography using 200 mM NaOH and deionized water as the eluents (Dipti et al., 2017).

2.4.2. Determination of molar ratio of PA:minerals

Molar ratios between PA and Fe and Zn in food were calculated to estimate the bioavailability of Fe and Zn contained in the final food products (Norhaizan & Nor Faizadatul Ain, 2009). The molar ratios were obtained after dividing the mole of PA by the mole of minerals, which were calculated by dividing their weight by atomic weight. As described by Gibson et al. (2010), values of PA:Fe > 1 and PA:Zn > 15 were used as indicators of the low bioavailability (<15% absorption) of such minerals.

2.4.3. Determination of lysine, tryptophan and protein content

Protein and lysine were measured as described elsewhere (Palacios-Rojas, 2018). For tryptophan determination the colorimetric method described by Nurit et al. (2009) was used.

2.5. Nutrients true retention calculation

True retention measures the proportion of a nutrient remaining in processed food compared to the amount of that nutrient originally present in a given weight of the food before processing (Taleon et al., 2017).

Percentage of true retention (%TR) of Fe, Zn and PA was calculated using the equation %TR = (Nutrient content/g of processed food ∗ g of food after processing/Nutrient content/g of raw food ∗ g of food before processing) ∗ 100.

2.6. Contribution to the daily intake of Zn

The potential contribution of foods made from high kernel-zinc maize to the daily intake of Zn and Estimated Average Requirement (EAR) was calculated based on the average amount of maize product consumed (100 g for children aged 4–6 years and 250 g for women), and the typical processing methods used in Latin American countries with high maize consumption (Ranum et al., 2014). An EAR for Zn of 1390 μg/day for children aged 4–6 years and 2969 μg/day for women of childbearing age were used as a reference, and a 30% bioavailability was considered to calculate the total absorbed zinc, following the recommendations of the European Food Safety Authority (EFSA, 2014).

2.7. Statistical analysis

To evaluate the effect of processing kernel-zinc maize varieties on zinc retention, varieties were grouped as ZBM and non-ZBM. Fe, Zn, Ca and PA content, %TR was expressed as mean ± standard deviation of 3 varieties (repetitions). The effect of processing type and maize type was evaluated using a two-way analysis of variance model. Analysis of variance was done using the mixed procedure in SAS 9.4 (SAS Institute, Cary, NC). Means separation for processing type was calculated using Tukey’s method. Differences between means were considered significant at p < 0.05.

3. Results and discussion

3.1. Physical and chemical characterization of maize kernels

Physical properties of the maize kernels were analyzed (Table 2). Although significant differences are observed for most of the physical parameters measured, in general, all evaluated varieties are classified within similar types of kernels, very hard ones with low percentage flotation index (0–12%) and low percentage of floury endosperm. The commercial check had similar hardness but with higher ratio of vitreous/floury endosperm (VE/FE) compared to the other varieties analyzed (Table 2). The higher the VE/FE ratio, the higher the flour extraction rate expected during degerming/threshing, and therefore this type of maize is commonly used in processing of arepas (Ranum et al., 2014; Gwirtz and Garcia-Casal, 2014). The variety B as well as the commercial check had the lower percentages of germ (10.4% and 9.1%, respectively) and the higher kernel weight (31.5% and 31.8%, respectively) compared to the ZBM group and the QPM maize genotype. The differences in grain hardness, kernel size, weight and percentage of germ caused final threshed products with different percentages of bran removal (16.1–20.4%). Cheah, Kopittke, Scheckel, Noerpel, and Bell (2020), showed that large amount of Zn accumulated in the germ compared to other areas of the kernels; thus, differences in the percentages of germ could also explain the differences in Zn content. Average Fe content in non-ZBM and ZBM grain (whole kernel) was 19.07 μg/g (ranged 16.61–23.02 μg/g) and 17.10 μg/g (ranged 16.18–17.80 μg/g), respectively; while, Zn content in the non-ZBM group was 23.91 μg/g (19.71–26.07 μg/g) and that of the ZBM group was 33.02 μg/g (32.55–33.67 μg/g) (Table 3 and Suppl. Table 2). The average Zn increment in the ZBM compared to the non-ZBM group was +9.1 μg/g. Fe and Zn levels were within values reported for maize (8.19–25.65 μg/g for Fe and 17.11–43.69 μg/g for Zn) from a diverse panel of 923 inbred lines (Hindu et al., 2018; Ortiz-Monasterio et al., 2007).

Table 2.

Physical grain characteristics of six non-ZBM and ZBM varieties.

| Code | Variety | 100-Kernel Weight (g) | Flotation Index (%) | Pedicel (%) | Pericarp (%) | Germ (%) | Floury Endosperm (%) | Vitreous Endosperm (%) | VE/FE Ratioa |

|---|---|---|---|---|---|---|---|---|---|

| A | S06TLWQHGAB02-B | 29.57 ± 0.97 ab | 11.0 ± 2.8a | 4.8 ± 1.0a | 5.0 ± 0.1 ab | 12.2 ± 0.1a | 18.5 ± 2.5a | 59.6 ± 1.3d | 3.3 ± 0.5d |

| B | S11TLWNHGAB06-B | 31.46 ± 0.44a | 3.5 ± 0.7b | 4.2 ± 0.2a | 5.5 ± 0.5a | 10.4 ± 0.8a | 9.5 ± 2.0c | 70.4 ± 3.4 ab | 7.7 ± 2.0abc |

| C | Commercial check | 31.76 ± 0.79a | 4.0 ± 0.0 ab | 4.1 ± 0.1a | 4.1 ± 0.2c | 9.1 ± 0.6b | 6.5 ± 1.0c | 76.2 ± 1.3a | 11.9 ± 2.0a |

| D | S13LTWQHZNHGAB01 | 25.33 ± 0.19c | 5.0 ± 2.8 ab | 5.2 ± 1.0a | 4.6 ± 0.1abc | 12.7 ± 0.1a | 8.7 ± 0.2c | 68.8 ± 1.0bc | 7.9 ± 0.1abc |

| E | S13LTWQHZNHGAB02 | 26.49 ± 0.30c | 1.0 ± 0.0b | 4.0 ± 0.1a | 4.5 ± 0.2bc | 12.4 ± 0.1a | 9.6 ± 0.1bc | 69.5 ± 0.3b | 7.2 ± 0.1bcd |

| F | S13LTWQHZNHGAB03-B | 27.87 ± 0.23bc | 5.5 ± 2.1 ab | 5.3 ± 0.7a | 4.7 ± 0.2abc | 12.6 ± 1.1a | 14.6 ± 0.6 ab | 62.8 ± 1.2cd | 4.3 ± 0.3cd |

Differences between means were considered significant at p < 0.05.

Ratio of vitreous to floury endosperm.

Table 3.

Mineral and phytic acid (PA) content of two groups of maize (non-ZBM and ZBM) and molar ratio of PA:minerals in raw kernels and processed products.

| Group/Varieties | Product | Fe (μg/g DW) | Zn (μg/g DW) | Ca (μg/g DW) | PA (mg/g DW) | Ratio PA:Fe | Ratio PA:Zn |

|---|---|---|---|---|---|---|---|

| Non-ZBM (A + B + C) | Raw kernel | 19.07 ± 3.59a-c | 23.91 ± 3.81b | 59.60 ± 28.44b | 10.04 ± 1.04b | 46.05 ± 10.36a | 42.10 ± 4.33a |

| Tortillas | 22.25 ± 4.96a | 25.72 ± 4.31b | 1560 ± 384a | 11.48 ± 1.14a | 44.98 ± 8.22a | 44.84 ± 5.44a | |

| Arepas | 13.38 ± 5.42de | 10.98 ± 6.00e | 86.09 ± 9.32b | 2.12 ± 1.21d | 12.77 ± 3.92d | 18.91 ± 1.94cd | |

| Mazamorra | 9.82 ± 4.54e | 13.63 ± 7.47de | 43.18 ± 13.81b | 3.03 ± 1.68d | 24.57 ± 6.73bc | 21.95 ± 2.47c | |

| ZBM (D + E + F) | Raw kernel | 17.10 ± 0.95b-d | 33.02 ± 1.39a | 56.61 ± 5.40b | 9.92 ± 1.55b | 49.01 ± 6.59a | 29.77 ± 4.55b |

| Tortillas | 20.99 ± 1.99 ab | 34.82 ± 0.85a | 1445 ± 239a | 11.10 ± 0.51 ab | 45.08 ± 4.75a | 31.58 ± 1.40b | |

| Arepas | 15.20 ± 3.06cd | 18.56 ± 2.72cd | 88.85 ± 9.09b | 3.06 ± 0.57d | 17.72 ± 4.94cd | 16.85 ± 4.76d | |

| Mazamorra | 12.94 ± 1.58de | 22.68 ± 2.86bc | 41.66 ± 4.94b | 4.43 ± 0.78c | 28.99 ± 4.02b | 19.30 ± 1.92cd |

Data are means ± SD of duplicated analyses. Different letters indicate a statistically significant difference (p < 0.05) between products.

Calcium content of whole kernel ranged 32.60 and 91.79 mg/g and PA content was 8.61–11.36 mg/g, similar to values reported for maize grain (Bressani et al., 2004). There was no significant difference between the non-ZBM and the ZBM groups for either of these two compounds (Table 3). All samples had similar protein content (8.6–9.7%). Maize is normally considered QPM when more than 0.07% of tryptophan and 0.35% of lysine is present in the whole kernel (Nurit et al., 2009). Grain from samples A, D, E and F had the expected high content of tryptophan (0.065–0.081%) and lysine (0.33–0.38%), while samples B and C had 0.053–0.056% and 0.27% of tryptophan and lysine, respectively (Table 4).

Table 4.

Protein, lysine and tryptophan content of two groups of maize (non-QPM and QPM maize) and true retention (%TR) after processing as tortillas, arepas and mazamorra.

| Group/Varieties | Final product | Protein (%) | Tryptophan (%) | Lysine (%) | Protein (%TR) | Tryptophan (%TR) | Lysine (%TR) |

|---|---|---|---|---|---|---|---|

| Non-QPM (B + C) | Raw kernel | 9.57 ± 0.25b | 0.055 ± 0.002b | 0.269 ± 0.006c | 100.00 ± 0.00a | 100.00 ± 0.00a | 100.00 ± 0.00a |

| Tortillas | 11.06 ± 0.38a | 0.038 ± 0.006c | 0.306 ± 0.019b | 104.18 ± 6.06a | 62.27 ± 10.38b | 102.65 ± 4.05a | |

| Arepas | 10.62 ± 0.22a | 0.013 ± 0.002e | 0.159 ± 0.028e | 77.89 ± 4.49b | 16.67 ± 3.80c | 41.66 ± 7.82b | |

| Mazamorra | 8.34 ± 0.56d | 0.012 ± 0.003e | 0.164 ± 0.033e | 62.90 ± 7.09c | 15.91 ± 2.33c | 43.18 ± 1.42b | |

| QPM (A + D + E + F) | Raw kernel | 9.09 ± 0.56bc | 0.076 ± 0.009a | 0.367 ± 0.024a | 100.00 ± 0.00a | 100.00 ± 0.00a | 100.00 ± 0.00a |

| Tortillas | 10.50 ± 0.36a | 0.050 ± 0.005b | 0.383 ± 0.020a | 101.94 ± 6.75a | 66.29 ± 13.30b | 102.73 ± 14.68a | |

| Arepas | 8.58 ± 0.79cd | 0.021 ± 0.002d | 0.237 ± 0.014d | 69.18 ± 9.00c | 23.44 ± 4.27c | 52.63 ± 7.18b | |

| Mazamorra | 8.60 ± 0.60cd | 0.020 ± 0.003d | 0.241 ± 0.024d | 62.72 ± 6.96c | 19.69 ± 4.44c | 48.86 ± 10.96b |

Data are means ± SD of duplicated analyses. Different letters indicate a statistically significant difference (p < 0.05) between products.

3.2. Fe, Zn, Ca and PA content in arepas and mazamorra

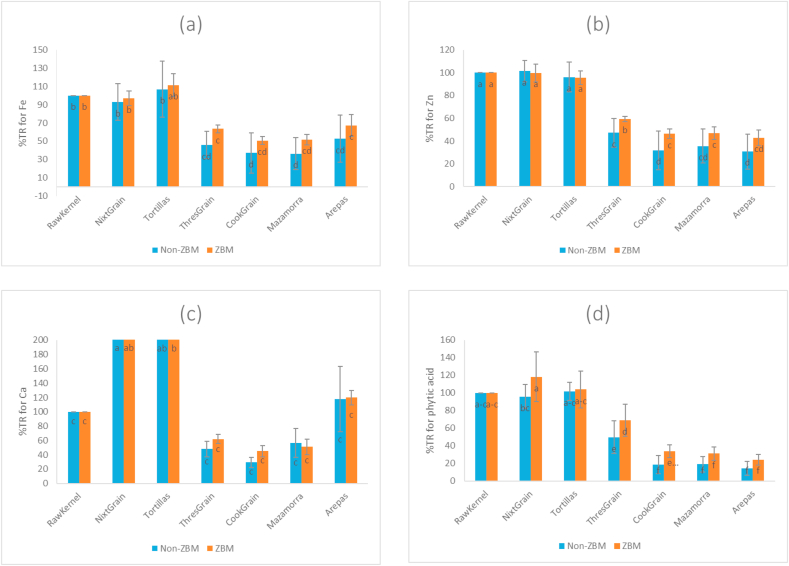

Fe and Zn content in the threshed maize from the non-ZBM group was 10.29 μg/g (8.10–12.77 μg/g) and 14.24 μg/g (7.77–18.40 μg/g), respectively, whereas for the ZBM group it was 13.19 μg/g (12.97–13.55 μg/g) and 23.88 μg/g (23.27–24.29 μg/g), respectively (Suppl. Table 1). Individual data on the mineral content of each maize variety after threshing is shown in the Suppl. Table 2. After degermination, Fe TR was 45.8% and Zn TR was 47.2% for the non-ZBM group, whereas in ZBM varieties it was 63.4% and 59.4%, respectively. Significant decreases in TR found in the cooking of threshed maize kernels compared to raw whole kernels, corresponding to 37.1% TR for Fe and 31.9% TR for Zn for the non-ZBM group, and 50.6% TR for Fe and 46.4% TR for Zn for the ZBM group (Fig. 1 a-b).

Fig. 1.

True retention of iron (a), zinc (b), calcium (c) and phytic acid (d) in raw kernels, intermediate and final products elaborated with two groups of maize (non-ZBM and ZBM). Note y-scale is cut in Figure 2c to better show details of each product.

Fe and Zn content in arepas from the non-ZBM group was 13.39 μg/g (ranged 7.21–16.87 μg/g) and 10.98 μg/g (3.66–15.31 μg/g), respectively, whereas for the ZBM group it was 15.20 μg/g (11.53–17.21 μg/g) and 18.56 μg/g (16.64–21.96 μg/g), respectively (Table 3). Fe TR was 52.7% and Zn TR was 30.9% for the non-ZBM group, whereas in ZBM varieties it was 67.3% and 42.8%, respectively (Fig. 1 a-b). On the other hand, Fe and Zn content in mazamorra was 9.82 μg/g (4.19–13.97 μg/g) and 13.63 μg/g (4.09–19.43 μg/g) for non-ZBM varieties and 12.94 μg/g (11.93–14.78 μg/g) and 22.68 μg/g (20.27–25.83 μg/g) for the ZBM group, respectively (Table 3); the non-ZBM group had 36.3% TR for Fe and 35.7% TR for Zn, while the ZBM group had 51.6% TR for Fe and 46.9% TR for Zn, which was not significantly different from arepas (Fig. 1 a-b). Traditionally, arepas and mazamorra are generally made by dehulling and degerming whole kernels using a mechanical thresher. In such processes, the separation of maize constituents (bran, germen and some endosperm) varies, but could range from 25 to 30% depending on the grain morphology, type of thresher used and consumer preferences, affecting the vitamin and mineral content of the finished product (Cheah et al., 2020; Bressani et al., 2002). Threshing is done to ensure sufficient shelf life of the product by excluding rancidity development factors (fatty acids) which can cause off-odor or off-taste and poor industrial performance. Since threshing efficiency depends on grain characteristics, it is important to ensure that the grain used has adequate physicochemical characteristics to prevent excessive dry matter losses during threshing and consequently higher micronutrient losses.

The calcium content in arepas and mazamorra produced from non-ZBM varieties was 86.09 μg/g (77.09–91.06 μg/g) and 43.18 μg/g (29.14–53.28 μg/g), respectively; whereas that of ZBM varieties, Ca content was 88.85 μg/g (81.57–99.97 μg/g) in arepas and 41.66 μg/g (36.89–45.43 μg/g) in mazamorra, which was not significantly different from raw threshed grain of non-ZBM and ZBM varieties (Table 3). Calcium content did not change, as previously reported by Bressani et al.(2004), when cooking whole maize kernels in water. Noteworthy, the TR was higher than 100% due to the use of butter in the arepas making process, (Fig. 1 c).

PA is a powerful chelator of divalent cations such as Ca2+, Fe2+ and Zn2+, limiting their bioavailability due to the formation of insoluble complexes. However, PA is also important antioxidant with potential to reduce lipid peroxidation (Vashishth et al., 2017). PA content of the threshed maize was 2.90 and 9.24 mg/g, whereas that of cooked threshed grain was 0.88–5.19 mg/g. PA content of the threshed and cooked grain of non-ZBM varieties (2.90–8.81 mg/g and 0.88–4.29 mg/g, respectively) was significantly different from that of the ZBM varieties (6.52–9.24 mg/g and 4.67–5.25 mg/g) (Suppl. Table 1). The losses of PA in arepas and mazamorra were large due to the removal of most of the germ and pericarp which contain a large amount of it (Cheah et al., 2020). PA content in arepas made from non-ZBM group did not show significant differences compared to the ones made with ZBM, ranging from 0.67 to 3.59 mg/g. Similarly, no difference in PA content was found between mazamorra, made with non-ZBM maize and ZBM (0.89–4.93 mg/g) (Table 3).

The large losses of PA in non-ZBM threshed maize and cooked grain represented TR of 49.9% and 18.7% respectively, whereas for ZBM intermediate products it was 69.0% and 33.6%, respectively. No significant differences in TR of PA between the non-ZBM and ZBM groups in arepas (14.5% and 24.1%, respectively) and mazamorra (19.1% and 31.2%, respectively) was found (Fig. 1 d). PA retention was significantly correlated to the retention of Zn (R2 = 0.84) and Fe (R2 = 0.60). Fractionation steps have shown to decrease not only chelating compounds such as PA and fiber, but also minerals including Fe and Zn. This is because both, chelating agents and minerals, are mainly in the germ and aleurone layer (Greffeuille et al., 2011; Cheah et al., 2020; Gannon and Tanumihardjo, 2014). For threshed maize intermediate and final products, large losses of PA and to a lesser extent Fe and Zn were observed due to the physical losses of germ and pericarp.

3.3. Fe, Zn, Ca and PA content in lime-cooked tortillas

Iron content did not change during nixtamalization for ZBM and non-ZBM varieties. Fe content in the nixtamal was 17.84 μg/g (16.80–18.89 μg/g) for the non-ZBM group and 16.98 μg/g (15.91–18.42 μg/g) for the ZBM group, whereas in tortillas it was 19.88–24.92 μg/g for the non-ZBM group and 22.25 μg/g (20.06–21.85 μg/g) for the ZBM group (Suppl. Table 1). Likewise, zinc content did not change when maize was nixtamalized. The Zn content in nixtamal of non-ZBM varieties was 25.22 μg/g (19.44–28.25 μg/g), while in tortillas it was 25.72 μg/g (20.39–29.09 μg/g); for the ZBM group, Zn content was 33.67 μg/g (33.11–34.79 μg/g) in nixtamal and 34.82 μg/g (34.66–35.05 μg/g) in tortillas (Suppl. Table 1). There was no significant difference in %TR between the ZBM and non-ZBM groups for Fe as well as Zn (Fig. 1 a-b). %TR for Fe and Zn in nixtamal in the non-ZBM was 92.9% and 101.4%, whereas for the ZBM it was 96.9% and 99.7%, respectively. %TR for Fe and Zn in tortillas of non-ZBM was 106.9% and 96.1%, whereas for the ZBM it was 111.4% and 95.6%, respectively (Fig. 1 a-b). In general, for the evaluated ZBM and non-ZBM groups, Fe and Zn were highly retained during the nixtamalization process, and more than 90% of their content was found in the tortillas (Escalante-Aburto et al., 2020). The high retention of these minerals could be due to the low dry matter loss in tortillas, since most of the zinc is located in the endosperm and germ, and only part of the pericarp was removed during the nixtamalization process. It is well documented that mineral retention when preparing tortillas varies according to the type and concentration of Ca (OH)2 used, the cooking time and the steeping time (Bressani et al., 2004; Bressani et al., 2002; Mariscal et al., 2015). No significant losses of Zn or Fe were observed in tortillas, most likely because during nixtamalization, only the outermost pericarp layer was removed, which is mostly composed of polysaccharides/hemicelluloses, whereas the aleurone and germ were not removed. Although intrinsic minerals can be reduced during processing, iron contamination of maize products has been found during postharvest treatments, such as harvesting, milling, cooking, under uncontrolled conditions (Greffeuille et al., 2011). Thus, the mineral content in tortillas could also come from the stone grinder. Similarly, no differences were observed in %TR of minerals in QPM vs non-QPM varieties. This is in agreement with previous results reported by Serna-Saldivar et al. (1991), who compared QPM and normal endosperm maize processed into nixtamalized tortillas. For these set of samples, the proportion of variability in %TR due to genotype was similar to the proportion due to processing, suggesting that processing is as important as the type of grain when it comes to Zn retention in the final product and therefore the Zn intake of consumers.

Ca content in nixtamal ranged from 1215 to 2350 μg/g which represented an increase of 16–72 times the original content. Ca content in nixtamal and tortillas for the non-ZBM group was 1750 μg/g (1435–2350 μg/g) and 1560 μg/g (1325–2015 μg/g), respectively, whereas the Ca content for the ZBM group was 1560 μg/g (1215–1895 μg/g) in nixtamal and 1445 μg/g (1305–1690 μg/g) in tortillas (Suppl. Table 1), which indicates an expected and well documented significant increase in Ca due to the process of cooking and steeping raw whole grain with Ca(OH)2. (Escalante-Aburto et al., 2020). In fact, nixtamalization has been recognized as a way to increase the Ca supply to consumers, even when PA content is elevated (>1500 mg/180 g of tortilla). Rosado, Diaz, Rosas, Griffit, and Garcia (2005) found that the percentage of Ca absorption was high in a group of Mexican women who consumed nixtamalized tortillas. Ca uptake by the kernels during nixtamalization has found to be dependent on Ca concentration, steeping time, changes in the pericarp and the diffusive mechanisms. Additionally, differences in Ca uptake by dent or flint kernels, have been reported. Tortillas prepared with soft kernels cooked at higher temperatures and longer steeping times will retain more Ca (Bressani et al., 2004; Bressani et al., 2002; Mariscal et al., 2015; Samil and Sait, 2016). The six varieties used in this study showed the same trend in Ca retention in the tortilla (Fig. 1 c) and as reported previously, slightly more Ca was observed in the nixtamal compared to the tortillas (Escalante-Aburto et al., 2020).

PA content of the nixtamal for non-ZBM (8.93–10.94 mg/g) was not significantly different than for ZBM varieties (10.07–13.14 mg/g). PA content of tortillas for non-ZBM (10.29–12.67 mg/g) were similar than ZBM varieties (10.70–11.45 mg/g) (Suppl. Table 1). %TR of PA in nixtamal and tortilla for non-ZBM group was 95.9% and 101.9%, respectively. For ZBM varieties, %TR of PA in nixtamal and tortilla was 118.3% and 103.9%, respectively (Fig. 1 d). Since the dry matter losses were low and most of the germ remained in the dough, the PA content was as expected (Greffeuille et al., 2011). Between 0 and 35% PA reductions have also been reported; however, in this study, losses of PA in tortillas were not found. Such differences in PA loss are dependent on the maize genotype and PA levels in the raw kernels, percentage of Ca(OH)2, cooking and steeping time, as well as the intensity at which the nixtamal is washed, prior to milling (Bressani et al., 2004; Bressani et al., 2002). Research on the effect of nixtamalization on PA content is not extensive, but previous studies have shown a decrease in PA of 0.25–35% (Gomez-Aldapa, Martínez-Rustos, Figueroa-Cárdenas, Orodrica-Falomir and González-Hernández, 1996; Urizar and Bressani, 1997). Bressani, Turcios, Colmenares de Ruiz, and Palacios de Palomo (2004) showed higher PA loss when using 1% lime and 75 min of cooking. A reduction of about 18% in PA content in whole grain and germ was reported but losses were higher in the endosperm (46%). Greffeuille et al. (2011), reported PA losses of up to 14% in the first steps of ogi preparation, which are like the nixtamalization steps, but without using an alkaline solution. In the present study, nixtamalization was done using 1% of Ca (OH)2, 50 min of cooking and a relatively long steeping time (16 h); however, no significant losses of PA were observed, presumably due to the relatively hard kernels, which limited the effect of lime during cooking and steeping.

3.4. True retention of protein, lysine and tryptophan in final products

The protein content in tortillas, arepas and mazamorra in non-QPM varieties was 11.1%, 10.5–10.8% and 7.9–8.8%, corresponding to TR of 104.2%, 77.9% and 62.9%, respectively. Protein content in the same foods made from the QPM group was 10.0–10.8%, 8.0–9.8% and 8.0–9.3%, corresponding to TR of 101.9%, 69.2% and 62.7% for tortillas, arepas and mazamorra, respectively (Table 4). Tryptophan content in tortillas ranged between 0.033–0.042% and 0.045–0.053% when using non-QPM and QPM grains, respectively, while in arepas and mazamorra it was 0.011–0.015% in non-QPM and 0.017–0.023% in QPM. Lysine content in tortillas was 0.29–0.32%, while in arepas and mazamorra, it was 0.14–0.18% for both when using non-QPM varieties; in the QPM group, lysine content was 0.37–0.41% for tortillas, 0.22–0.25% for arepas and 0.21–0.27% for mazamorra. %TR for tryptophan and lysine among processed products was not significantly different between non-QPM and QPM groups (Table 4). These results agree with previous reports where in average more than 90% and 80% TR has been found for lysine and tryptophan, respectively, in nixtamalized tortillas (Gomez-Aldapa, Martínez-Rustos, Figueroa-Cárdenas, Orodrica-Falomir and González-Hernández, 1996; Vasquez-Carrillo et al., 2014; Bressani et al., 1990).

3.5. Mineral bioavailability in final products

In whole grain the PA:Fe molar ratio was 46.1 (33.6–56.0) for the non-ZBM group and 49.0 (45.1–55.5) for ZBM, without significant differences between groups. The PA:Zn ratio in non-ZBM (38.4–46.1) was significantly higher than for ZBM (26.0–34.6) (Table 3). For non-ZBM tortillas, PA:Fe and PA:Zn molar ratios were 45.0 (41.4–48.9) and 44.8 (41.0–50.4), whereas for ZBM tortillas, the molar ratio were 45.1 (43.1–48.5) and 31.6 (30.5–32.7), respectively. In general, molar ratios in tortillas were similar to the ratios found in raw maize grain probably because no major Fe, Zn and PA losses were found after processing maize into tortillas (Table 3). The PA:Fe molar ratio for arepas produced with non-ZBM and ZBM was 12.8 (8.9–14.9) and 17.7 (12.6–22.7), respectively, whereas the PA:Zn molar ratio was 18.9 (17.5–21.2) and 16.9 (11.2–21.3), respectively. The PA:Fe molar ratio for mazamorra produced with non-ZBM and ZBM was 24.6 (17.8–32.4) and 29.0 (25.9–32.8), respectively, while the PA:Zn molar ratio was 22.0 (19.7–24.7) and 19.3 (18.1–20.9), respectively. Ratios were not different between non-ZBM and ZBM (Table 3). Theoretical estimations of Zn bioavailability based on PA:Zn molar ratios (EFSA, 2014) suggest that their absorption might be 25–45% with lower absorption at high PA:Zn ratios. Hambidge et al. (2017) reported Zn absorption of 22–34% when using maize as the main component of a diet with relatively high PA, and 22–40% when using maize in a diet with lower PA. High Ca levels could exacerbate the bounding of Zn to PA during processing and make Zn less available. Additionally, large amounts of Ca in nixtamalized products may reduce Fe bioavailability (Bressani et al., 2004), and therefore the bioavailability of Zn and Fe in products made with nixtamalized maize could be low (Gibson et al., 2010; Suri and Tanumihardjo, 2016). However, for Mexican and several Central American populations, the high intake of Ca through nixtamalized products is recognized and well documented (Rosado et al., 2005). Although PA content in mazamorra and arepas was lower than in tortillas, PA:Zn and PA:Fe ratios were also higher than 15, suggesting low mineral bioavailability. Furthermore, the lower PA:Zn ratio found in tortillas made with ZBM could result in better Zn absorption compared to tortillas made with non-ZBM. In vitro studies with caco-2 cells or absorption studies will be helpful to further validate these results.

3.6. Impact of high kernel-zinc maize on Zn intake

The contribution of ZBM to Zn EAR would be up to 76% for children aged 4–6 years and 89% for women of child-bearing age when consumed as minimally processed products such as tortilla and if ZBM is the only type of maize consumed (Table 5). The contribution to daily Zn intake could be lower and directly related to the proportion of ZBM consumed relative to the total amount of maize consumed. Furthermore, the contribution of ZBM would be only 34–44% if consumed as arepa or mazamorra because the process removes the germ and pericarp of the grain, that contain most of the Zn (Table 5). However, the Zn bioavailability in processed arepas and mazamorra could be higher compared to tortillas due to the lower PA concentration in threshed grain used to make these products. Besides, although the most common type of arepa is prepared with decorticated kernels, recent healthier trends may create a consumer demand for whole grain products over highly processed ones (Willet et al., 2019; Palacios-Rojas et al., 2020). In summary, the potential contribution of zinc to the EAR for children 4–6 years old and women of child-bearing age was between 18 and 29% higher in all products made with ZBM than non-ZBM (Table 5).

Table 5.

Contribution of maize to zinc EAR% for children 4–6 years old and women of childbearing age.

| Population | Process | Maize type | Zn in maize (μg/g) | Zn process retention (%) | Zn in processed maize (μg/g) | Zn daily intake (mg)a | Zn absorbed (μg)b | Contribution to EAR (%)c |

|---|---|---|---|---|---|---|---|---|

| Children | Not processed | ZBM | 37 | 100 | 37.0 | 3.70 | 925 | 80 |

| non-ZBM | 25 | 100 | 25.0 | 2.50 | 625 | 54 | ||

| Tortillas (limited bran removal) | ZBM | 37 | 96 | 35.4 | 3.54 | 884 | 76 | |

| non-ZBM | 25 | 96 | 24.0 | 2.40 | 601 | 52 | ||

| Mazamorra (extensive bran removal) | ZBM | 37 | 47 | 17.3 | 1.73 | 434 | 37 | |

| non-ZBM | 25 | 36 | 8.9 | 0.89 | 223 | 19 | ||

| Arepas (extensive bran removal) | ZBM | 37 | 43 | 15.8 | 1.58 | 396 | 34 | |

| non-ZBM | 25 | 31 | 7.7 | 0.77 | 193 | 17 | ||

| Women | Not processed | ZBM | 37 | 100 | 37.0 | 9.25 | 2313 | 93 |

| non-ZBM | 25 | 100 | 25.0 | 6.25 | 1563 | 63 | ||

| Tortillas (limited bran removal) | ZBM | 37 | 96 | 35.4 | 8.84 | 2211 | 89 | |

| non-ZBM | 25 | 96 | 24.0 | 6.01 | 1502 | 61 | ||

| Mazamorra (extensive bran removal) | ZBM | 37 | 47 | 17.3 | 4.34 | 1084 | 44 | |

| non-ZBM | 25 | 36 | 8.9 | 2.23 | 557 | 23 | ||

| Arepas (extensive bran removal) | ZBM | 37 | 43 | 15.8 | 3.96 | 990 | 40 | |

| non-ZBM | 25 | 31 | 7.7 | 1.93 | 482 | 19 |

Maize intake = 100 g for children 4–6 years and 250 g for women.

Bioavailability = 30% (EFSA, 2014).

Physiological daily average requirement for zinc = 1390 μg for children 4–6 years and 2969 μg for women of childbearing age (EFSA, 2014).

4. Conclusions

In the present study, tortillas had a higher Fe, Zn and PA retention than arepas and mazamorra. QPM products had higher lysine and tryptophan content compared to products prepared with non-QPM. In countries where arepas and mazamorra are consumed, the promotion of whole grain flour should be explored to enhance the intake of minerals that are usually confined to aleurone layers and germ. Zn biofortified maize could contribute to increase the Zn intake of populations where maize is an essential part of the diet.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was financially supported by the HarvestPlus program and the CGIAR research program (CRP) on Maize Agri-food Systems for financial support. The CGIAR Research Program MAIZE receives W1 and W2 support from the governments of Australia, Belgium, Canada, China, France, India, Japan, Korea, Mexico, Netherlands, New Zealand, Norway, Sweden, Switzerland, U. K., and U. S., as well as the World Bank. The authors kindly thank Drs. Felix San Vicente and Luis Narro, maize breeders at CIMMYT, and their teams for facilitating the varieties used in the study. They also thank the Maize Quality Laboratory “Evangelina Villegas” at CIMMYT, the laboratory of School of Biological Sciences of Flinders University, and the HarvestPlus Nutrition Quality Laboratory at Alliance of Bioversity International and CIAT, for analyzing the samples.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.crfs.2021.03.007.Multim

Appendix A. Supplementary data

The following is/are the supplementary data to this article:

References

- Atlin G.N., Palacios-Rojas N., Babu R., Das B., Twumasi-Afriyie S., Friesen D., De Groote H., Vivek B.S., Pixley K.V. Quality protein maize: progress and prospects. Janick J., editor. Plant Breed. Rev. 2011;34:83–129. [Google Scholar]

- Bauman L.F. High Quality Protein Maize. Dowden, Hutchinson & Ross Inc; Stroudsburg, PA: 1975. Germ and endosperm variability, mineral elements, oil content, and modifier genes in opaque-2 maize; pp. 217–227. [Google Scholar]

- Bevis L.E.M., Hestrin R. Variation in crop zinc concentration influences estimates of dietary Zn inadequacy. PloS One. 2020;15(7) doi: 10.1371/journal.pone.0234770. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bouis H.E., Saltzman A. Improving nutrition through biofortification: a review of evidence from HarvestPlus, 2003 through 2016. Global Food Security. 2017;12:49–58. doi: 10.1016/j.gfs.2017.01.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bressani R., Benavides V., Acevedo E., Ortiz M.A. Changes in selected nutrient contents and in protein quality of common and quality protein maize during rural tortilla preparation. Cereal Chem. 1990;67(6):515–518. [Google Scholar]

- Bressani R., Turcios J.C., De Ruiz A.S. Nixtamalization effects on the contents of phytic acid, calcium, iron and zinc in the whole grain, endosperm and germ of maize. Food Sci. Technol. Int. 2002;8:81–86. [Google Scholar]

- Bressani R., Turcios J.C., Colmenares de Ruiz A.S., Palacios de Palomo P. Effect of processing conditions on phytic acid, calcium, iron and zinc contents in lime-cooked maize. J. Agric. Food Chem. 2004;52:1157–1162. doi: 10.1021/jf030636k. [DOI] [PubMed] [Google Scholar]

- Chakraborti M., Prasanna B.M., Hossain F., Singh A.M. Evaluation of single cross quality protein maize (QPM) hybrids for kernel iron and zinc concentrations. Indian J. Genet. Plant Breed. 2011;71:312–319. [Google Scholar]

- Cheah Z.X., Kopittke P.M., Scheckel K.G., Noerpel M.R., Bell M.J. Comparison of Zn accumulation and speciation in kernels of sweetcorn and maize differing in maturity. Ann. Bot. 2020;125:185–193. doi: 10.1093/aob/mcz179. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dipti S.S., Hotz C., Kabir K.A., Bipul M. Changes in the zinc content of selected Bangladeshi rice varieties through modified parboiling and milling methods. SAARC Journal of Agriculture. 2017;15(2):31–43. [Google Scholar]

- Ekpa O., Palacios-Rojas N., Kruseman G., Fogliano V., Linnemann A.R. Sub-Saharan African maize-based foods: technological perspectives to increase the food and nutrition security impacts of maize breeding programmes. Global Food Security. 2018;17:48–56. [Google Scholar]

- Ekpa O., Palacios-Rojas N., Kruseman G., Fogliano V., Linnemann A.R. Sub-Saharan African maize-based foods: processing practices, challenges and opportunities. Food Rev. Int. 2019;35(7):609–6039. [Google Scholar]

- Escalante-Aburto A., Mariscal-Moreno R., Santiago-Ramos D., Ponce-Garcia N. An update of different nixtamalization technologies, and its effects on chemical composition and nutritional value of corn tortillas. Food Rev. Int. 2020;36(5):456–498. [Google Scholar]

- Espinoza H.R., Isaza J.H., Restrepo K.B. 2018. Innovación en la industria de la arepa de maíz en Colombia. Fondo Editorial Biogénesis; pp. 113–130. [Google Scholar]

- European Food Safety Authority NDA Panel Scientific opinion on dietary reference values for Zn. EFSA Journal. 2014;12(10):3844. https://efsa.onlinelibrary.wiley.com/doi/pdf/10.2903/j.efsa.2014.3844 [Google Scholar]

- Gannon B., Tanumihardjo S. Milling method affects zinc content of maize and health status of Mongolian gerbils. FASEB (Fed. Am. Soc. Exp. Biol.) J. 2014;28:646. 5. [Google Scholar]

- Gibson R.S., Bailey K.B., Gibbs M., Ferguson E.L. A review of phytate, iron, zinc, and calcium concentrations in plant-based complementary foods used in low-income countries and implications for bioavailability. Food Nutr. Bull. 2010;31(2):134–146. doi: 10.1177/15648265100312S206. [DOI] [PubMed] [Google Scholar]

- Gómez-Aldapa C.A., Martínez-Rustos F., Figueroa-Cárdenas J.D., Orodrica-Falomir C.A., González-Hernández J. Cambios en algunos componentes químicos y nutricionales durante la preparación de tortillas de maíz elaboradas con harinas instantáneas obtenidas por extrusión continua. Arch. Latinoam. Nutr. 1996;46:315–319. [PubMed] [Google Scholar]

- Govaerts B., Chávez X., Fernández A., Vega D., Vázquez O., Pérez M., Carvajal A., Ortega P., López P., Rodríguez R., Kruseman G., Donnet L., Palacios-Rojas N., Verhulst N., Gardeazabal A., González G., Sánchez K.C., Rosado L.G. Maíz para México – plan Estratégico 2030. CIMMYT: México. 2019. https://repository.cimmyt.org/xmlui/bitstream/handle/10883/20219/60937.pdf Accessed.

- Greffeuille V., Polycarpe-Kayode A.P., Icard-Verniere C., Gnimadi M., Rochetter I., Mouquet-Rivier C. Changes in iron, zinc and chelating agents during traditional African processing of maize: effect of iron contamination on bioaccesibility. Food Chem. 2011;126:1800–1807. doi: 10.1016/j.foodchem.2010.12.087. [DOI] [PubMed] [Google Scholar]

- Guzzon F., Arandia Rios L.W., Caviedes Cepeda G.M., Céspedes Polo M., Chavez Cabrera A., Muriel Figueroa J., Medina Hoyos A.E., Jara Calvo T.W., Molnar T., Narro Leon L.A., Narro Leon T.P., Mejía Kerguelen S.L., Ospina Rojas J.G., Vazquez G., Preciado Ortiz E.E., Zambrano J.L., Palacios Rojas N., Pixley K.V. Conservation and use of Latin America maize diversity: pillar of nutrition security and cultural heritage of humanity. Agronomy. 2021;11(1):172. [Google Scholar]

- Gwirtz J.A., Garcia-Casal M.N. Processing maize flour and corn meal food products. Ann. N. Y. Acad. Sci. 2014;1312:66–75. doi: 10.1111/nyas.12299. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hambidge K.M., Miller L.V., Mazariegos M., Westcott J., Solomons N.W., Raboy V., Kemp J.F., Das A., Goco N., Hartwell T., Wright L., Krebs N.F. Upregulation of zinc absorption matches increases in physiologic requirements for zinc in women consuming high or moderate phytate diets during late pregnancy and early lactation. J. Nutr. 2017;147:1079–1085. doi: 10.3945/jn.116.245902. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hindu V., Palacios-Rojas N., Babu R., Suwarno W.B., Rashid Z., Usha R., Saykhedkar G.R., Nair S.K. Identification and validation of genomic regions influencing kernel zinc and iron in maize. Theor. Appl. Genet. 2018;131:1443–1457. doi: 10.1007/s00122-018-3089-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Listman G.M., Guzman C., Palacios-Rojas N., Pfeiffer W., San Vicente F., Govidan V. Improving nutrition through biofortification: preharvest and postharvest technologies. CFW (Cereal Foods World) 2019;64(3) doi: 10.1094/CFW-64-3-0025. [DOI] [Google Scholar]

- Mariscal M.R.M., Figueroa J.D.C., Santiago R.D., Arambula V.G., Jimenez S.S., Rayas D.P., Veles M.J.J., Martinez F.H.E. The effect of different nixtamalization processes on some physicochemical properties, nutritional composition and glycemic index. J. Cereal. Sci. 2015;65:140–146. [Google Scholar]

- Miller L.V., Krebs N.F., Hambidge K.M. A mathematical model of zinc absorption in humans as a function of dietary zinc and phytate. J. Nutr. 2007;127(1):135–141. doi: 10.1093/jn/137.1.135. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Norhaizan M.E., Nor Faizadatul Ain A.W. Determination of phytate, iron, zinc, calcium contents and their molar ratios in commonly consumed raw and prepared food in Malaysia. Malaysian Journal of Nutrition. 2009;15:213–222. [PubMed] [Google Scholar]

- Nurit E., Tiessen A., Pixley K., Palacios-Rojas N. Reliable and inexpensive colorimetric method for determining protein-bound tryptophan in maize kernels. J. Agric. Food Chem. 2009;57:7233–7238. doi: 10.1021/jf901315x. [DOI] [PubMed] [Google Scholar]

- Nuss E.T., Tanumihardjo S.A. Maize: a paramount staple crop in the context of global nutrition. Compr. Rev. Food Sci. Food Saf. 2010;9:417–436. doi: 10.1111/j.1541-4337.2010.00117.x. [DOI] [PubMed] [Google Scholar]

- Ortiz-Monasterio J.I., Palacios-Rojas N., Meng E., Pixley K., Trethowan R., Peña R.J. Enhancing the mineral and vitamin content of wheat and maize through plant breeding. J. Cereal. Sci. 2007;46:293–397. [Google Scholar]

- Palacios-Rojas N. Calidad nutricional e industrial de Maíz: laboratorio de Calidad Nutricional de Maíz. CIMMYT: Mexico. 2018. https://repository.cimmyt.org/bitstream/handle/10883/19667/59829.pdf Accessed.

- Palacios-Rojas N., McCulley L., Kaeppler M.l., Titcomb T.J., Gunaratna N.S., Lopez-Ridaura S., Tanumihardjo S.A. Mining maize diversity and improving its nutritional aspects within agro-food systems. Compr. Rev. Food Sci. Food Saf. 2020;1–26 doi: 10.1111/1541-4337.12552. [DOI] [PubMed] [Google Scholar]

- Raboy V., Gerbasi P.F., Young K.A., Stoneberg S.D., Pickett S.G., Bauman A.T., Murthy P.N., Sheridan W.F., Ertl D.S. Origin and seed phenotype of maize low phytic acid 1-1 and low phytic acid 2-1. Plant Physiol. 2000;124:355–368. doi: 10.1104/pp.124.1.355. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ranum P., Peña-Rosas J.P., Garcia-Casal M.N. Global maize production, utilization, and consumption. Ann. N. Y. Acad. Sci. 2014;1312:105–112. doi: 10.1111/nyas.12396. [DOI] [PubMed] [Google Scholar]

- Rosado J., Diaz M., Rosas A., Griffit I., Garcia O.P. Calcium absorption from corn tortilla is relatively high as is dependent upon calcium content and liming in Mexican women. J. Nutr. 2005;135(11):2578–2581. doi: 10.1093/jn/135.11.2578. [DOI] [PubMed] [Google Scholar]

- Samil M.A., Sait I.D. Effects of varying nixtamalization conditions on the calcium absorption and pasting properties of dent and flint corn flours. J. Food Process. Eng. 2016;40 [Google Scholar]

- Serna-Saldivar S.O., Rooney L.W., Greene L.W. Effect of lime treatment on the availability of calcium in diets of tortillas and beans: rat growth and balance studies. Cereal Chem. 1991;68(6):565–570. [Google Scholar]

- Suri D.J., Tanumihardjo S.A. Effects of different processing methods on the micronutrient and phytochemical contents of maize: from A to Z. Compr. Rev. Food Sci. Food Saf. 2016;15:912–926. doi: 10.1111/1541-4337.12216. [DOI] [PubMed] [Google Scholar]

- Taleon V., Mugode L., Cabrera-Soto L., Palacios-Rojas N. Carotenoid retention in biofortified maize using different post-harvest storage and packaging methods. Food Chem. 2017;232:60–66. doi: 10.1016/j.foodchem.2017.03.158. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Urizar A.L., Bressani R. Efecto de la nixtamalización del maíz sobre el contenido de ácido fítico, calcio y hierro total y disponible. Arch. Latinoam. Nutr. 1997;47:217–223. [PubMed] [Google Scholar]

- Vashishth A., Ram S., Beniwal V. Cereal phytases and their importance in improvement of micronutrients bioavailability. 3 Biotech. 2017;7:42. doi: 10.1007/s13205-017-0698-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vazquez-Carrillo M.G., Santiago-Ramos D., Salinas-Moreno Y., López-Cruz J., Ybarra-Moncada M.C., Ortega-Corona A. Genotipos de maíz (Zea mays L.) con diferente contenido de aceite y su relación con la calidad y textura de la tortilla. Agrociencia. 2014;48:159–172. [Google Scholar]

- Wheal M.S., Fowles T.O., Palmer L.T. A cost-effective acid digestion method using closed polypropylene tubes for inductively coupled plasma optical emission spectrometry (ICP-OES) analysis of plant essential elements. Analytical Methods. 2011;3:2854–2863. [Google Scholar]

- Willett W., Rockström J., Loken B., Springmann M., Lang T., Vermeulen S., Garnett T., Tilman D., DeClerck F., Wood A., Jonell M., Clark M., Gordon L.J., Fanzo J., Hawkes C., Zurayk R., Rivera J.A., De Vries W., Sibanda L.M., Afshin A., Chaudhary A., Herrero M., Agustina R., Branca F., Lartey A., Fan S., Crona B., Fox E., Bignet V., Troell M., Lindahl T., Singh S., Cornell S.E., Reddy K.S., Narain S., Nishtar S., Murray C.J.L. Food in the Anthropocene: the EAT–Lancet Commission on healthy diets from sustainable food systems. Lancet. 2019;393:447–492. doi: 10.1016/S0140-6736(18)31788-4. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.