Abstract

Unfortunately, an abrupt corona-virus disease (COVID-19) outbreak brought a drastic change in human lives. Almost every sector of human-beings and their related activities are severely infected and affected by this COVID-19 pandemic. As days are passing, the impact of the COVID-19 epidemic is going to be more severe. The fundamental needs for personal protective equipment (PPEs) are rising drastically all over the world. In India, many non-pharmaceutical companies or organizations such as automobile companies are engaged in producing the PPEs at a very marginal rate. Thus this paper proposes a modeling and optimization framework for sustainable production and waste management (SPWM) decision-making model for COVID-19 medical equipment under uncertainty. To quantify the uncertainties among parameter values, we have taken advantage of the intuitionistic fuzzy set theory. A robust ranking function is presented to obtain a crisp version of it. Furthermore, a novel interactive intuitionistic fuzzy programming approach is developed to solve the proposed SPWM model. An ample opportunity to generate the desired solution sets are also depicted. The performance analysis based on multiple criteria such as savings from baseline, co-efficient of variations, and desirability degrees is also introduced. Practical managerial implications are also discussed based on the significant findings after applying to the real case study data-set. Finally, conclusive remarks and the future research direction are also addressed on behalf of the current contributing study.

Keywords: Intuitionistic fuzzy parameters, Modified S-curve membership functions, Interactive intuitionistic fuzzy method, Sustainable production and waste management problem

1. Introduction

The whole world is currently in the trap of the “global war against the corona-virus disease (COVID-19) pandemic.” It comes from a family of vital viruses. Starting from China as an epicenter, it has widely been spread all over the world expediently. In China, the first case was detected in Wuhan, and after that, the chain of transmission began to date. Fighting against COVID-19, many precautionary and preventive measures have been initiated since the starting of October 2019. The ruling government of all the country have strictly imposed the complete Lockdown for the protection and welfare of peoples and citizens. The anticipated demand for medical equipment has been immensely raised due to low production and consumption in the regular days. Thus need for the Personal Protective Equipment (PPE) is among one the most demanded and consumed medical equipment. According to the World Health Organization (WHO), the PPE comprises garments used by healthcare workers or any other person from getting infected. It generally consists of standard precautions such as gloves, masks, and medicated gowns. It includes face protection, goggles, face shield, gloves, shoe cover, head cover, rubber boots in blood, or high airborne infections. PPEs kits are used by medical personnel working in isolation areas and intensive care units to protect them from acquiring infections. With the prospect of a massive requirement of PPEs arising shortly, many countries made proactive efforts to promote its manufacturing in its own country.

To meet the expected demand for highly demanded medical equipment, we have developed a multiobjective mixed-integer linear programming problem as a sustainable production and waste management (SPWM) model for COVID-19 medical equipment under uncertainty. The presented modeling approach comprises multiple objectives such as total cost, revenue, and total delivery time, exclusively related to medical equipment. The proposed SPWM model also reflects the very critical aspects of real-life such as budget allocation, safety measures, environmental protection, and various restrictions over production processes simultaneously. Most of the practical situations are consist of unavoidable uncertainty in the modeling processes of the proposed SPWM model. Due to the complexity of real-life problems, the decision-makers or managers most often face risks in determining parameter values. For instance, production processes vary with the availability of raw materials, human resources, working efficiency of machines, transportation of newly launched products for the first time from sources to consumer points may yield in an uncertain cost and time. Additionally, abrupt changes in environmental conditions, natural calamities, different modes of transportation, variations in the load capacity of various conveyances, unexpected changes in the price of fuel, total expected demand for new products, safety measures of the items due to road conditions are some influential factors for the existence of uncertainties among the parameters.

Impreciseness and vagueness among the input data are inevitable, and hence the data are not precise always and simultaneously are treated with the estimated values. Uncertainty among input data may take different forms, such as fuzzy, stochastic, and other uncertain types. The existence of uncertainty due to vagueness or ambiguity is dealt with fuzzy techniques, whereas uncertainty arises due to randomness treated with stochastic approaches. Both kinds of uncertainties have their limitations. For instance, if the decision-maker intends to quantify the value of different medical equipment requirements with some estimated value, such as each hospital requires approximately 14,000 items/day. The most likely estimated interval would be 12,000–16,000 items/day, along with some hesitation degree that may be given as 10,000–18,000 items/day, which ensures less violation of risks with acceptance and non-acceptance. Thus, this kind of quantification of parameters’ values reflects the more realistic approach to estimate the uncertain parameter compared to fuzzy and stochastic parameters.

Therefore, a well-organized multidimensional inter-connected setup for sustainable production and waste management model for COVID-19 medical equipment is much needed in the current scenario. An optimal production policy for newly manufactured medical equipment and adequate waste management strategies of the used medical equipment creates an eco-friendly production waste management planning network and contributes to the development of social prosperity and environmental protections.

1.1. Shortcomings of some solution methods and research gaps

Literature reveals several studies have taken the uncertain parameters, either fuzzy numbers or random variables followed by some distribution function. The fuzzy data only deals with the acceptance degree into the feasible solution set and does not consider the element’s rejection degree into the same feasible solution set. The random parameters need historical data for estimation purposes. It may not always be possible to have factual information for which the estimated values of parameters are suggested with the help of a suitable probability distribution function. In both cases (fuzzy and stochastic), the representation of parameters is not worth the effectiveness of yield incomparable outcomes and lacks the critical aspects of uncertainties. To overcome these issues, we have presented the intuitionistic fuzzy parameters, consisting of the element’s acceptance and rejection degrees, into the same feasible solution set. There is no scope for the historical data for the representation of intuitionistic fuzzy parameters.

The solution method proposed by Lai and Hwang, 1993, Lai and Hwang, 1994 discuss the overall achievement function by considering only the membership functions of each objective and do not consider the non-membership function simultaneously. Likewise, Li et al., 2006, Selim and Ozkarahan, 2008, Werners, 1988 suggested the overall satisfaction level using the membership function with their respective weight parameters and do not consider the non-membership functions at a time. Furthermore, Torabi and Hassini (2008) presented the overall achievement level by depicting the convex combination of the lower bound for satisfaction degree of each objective and the weighted sum of these achievement degrees and do not consider the non-membership function and upper bound of the dis-satisfaction degrees. Thus, the proposed IIFPA is exempted from the various shortcomings, drawbacks, and research gaps of the existing methods such as Lai and Hwang, 1993, Lai and Hwang, 1994, Li et al., 2006, Selim and Ozkarahan, 2008, Werners, 1988, Zimmermann, 1978, Torabi and Hassini, 2008. The detailed explanations are provided in Section 4.2. Therefore, the proposed IIFPA considers two aspects of the decision-making scenario by simultaneously dealing with membership and non-membership functions. This study fills the research gap by incorporating the intuitionistic fuzzy set theory in the parameters and solution techniques.

1.2. Motivation and research contributions

-

•

The proposed sustainable production policies and waste management strategies for COVID-19 medical equipment through a robust SPWM modeling framework need the present time. During the COVID-19 pandemic, the demand for personal protective equipment (PPEs) is very high, and the current production rate is unable to meet them efficiently. PPEs comprise medicated gown, N-95 masks, face shield, hand gloves, shoe-cover, sanitizers. In India, most of the PPEs were imported from outside of European countries. Nevertheless, the uncontrollable demand and an essential or indispensable requirement for PPEs worldwide made it crucial to export the PPEs to every leading exporting country. As a result, many automobiles and small-scale companies have taken initiatives to produce this medical equipment to meet the domestic demand. Thus, it is a very tough challenge before these companies to manufacture or produce PPEs due to the incomplete, inconsistent, inappropriate, and irrational knowledge and experiences to deal with this medical equipment explicitly starting from the acquirement of raw-materials, initiating the production and transportation processes and finally, the disposal operations to them. Preliminary safety measures and precautionary protection factors must be undertaken while handling this medical equipment starting from its production to its end-of-life phases. Thus an innovative, robust, and most prominent modeling approach for sustainable production and waste management policies for this COVID-19 medical equipment under a high level of uncertainty among different parameters is the essence of current time in decision-making scenarios.

-

•

In India, many companies from non-pharmaceuticals sectors are coming forward to contribute the society and humanity at this crucial time to build a one-nation spirit. As the managers or decision-makers are entering first time to manufacture and produce this medical equipment at high-level, it is obvious the lack or absence of historical data related to raw materials and this medical equipment such as purchasing, production, processing, transportation, service operating, inventory costs, quantity, time, budgets, safety factors. Thus to identify, assess, and quantify these data profitably and scientifically, the proposed SPWM model inevitably considered it an uncertain parameter. For example, in India, the expected demand for N-95 masks is around 31.6 million per day, while the COVID-19 cases are increasing rapidly day by day. In this situation, the uncertainty quantification based on the intuitionistic fuzzy concept would be more reliable and provide better estimates to those N-95 masks. Using fuzzy set theory, the most optimistic, the most likely, and the most pessimistic estimate maybe 25.2, 31.6, and 38.6 million per day, which violates the degree of hesitation regarding the rejection of these estimates. While using the intuitionistic fuzzy set theory, the projected estimation of these N-95 would be 27.2 to 35.6 million per day, along with the hesitation degrees of 22.5 to 42.67 million per day, which ensures less violation of shortages-risks with degrees of acceptance and rejection.

-

•

Of particular interest, the most crucial contribution is a novel Interactive Intuitionistic Fuzzy Programming Approach (IIFPA) to solve the crisp SPWM model under uncertainty.

-

•

The exclusive rationality and robustness of intuitionistic fuzzy parameters and the proposed IIFPA are also presented by proofing various theorems while solving the crisp SPWM model.

-

•

A marginal evaluation of each objective function means that degree of satisfaction level while obtaining the compromise solution by considering the multiple commensurable and conflicting objectives at a time. The marginal evaluations can be elicited by various sorts of membership functions such as linear, exponential, hyperbolic, modified S-curve that exist in the literature. A wide choice for selecting the desired form of marginal evaluations are suggested to the decision-makers or managers by incorporating the discussed membership and non-membership functions under the intuitionistic fuzzy environment. The robustness, rationality, and distinguishability of these marginal evaluations are reflected by proofing the appropriate theorems.

-

•

Performance analysis of the proposed SPWM model under different membership functions is measured based on multiple criteria. For this purpose, savings compared to baseline solution, co-efficient of variations and degrees of desirability (discussed in Section 4.3) are considered multiple criteria and used to examine the performances of applied solution approaches.

-

•

The whole solution schemes comprise various pre-determined parameters such as and (these parameters are defined at their usual place in Section 4) which are solely assigned by the decision-makers or practitioners. Thus there is an ample opportunity to generate as many solution sets as decision-makers or managers want and select the most desired ones.

-

•

A real case-study description is implemented and modeled as a crisp SPWM model under intuitionistic fuzzy environment. The proposed IIFPA with different membership functions approaches are applied, and outcomes are analyzed with the significant findings efficiently. The performance analysis is also depicted based on the obtained solution results. Managerial implication is also highlighted, which is worth the essential backbone of the current study. At last, conclusions and future research are also suggested.

The rest part of the manuscript is presented as follows: In Section 2, the related literature review is discussed while Section 3 represents the descriptions of proposed SPWM model. The solution methodology and proposed interactive intuitionistic fuzzy programming approach is investigated in Section 4, whereas Section 5 reveals a case study description to show the applicability and validity of the proposed modeling and solution approach. Finally, conclusions and future research scope are discussed in Section 6.

2. Literature review

Available literature work reveals a tremendous amount of research work that has been carried out in the production and waste management of healthcare products. Here, we present a few relevant research work on this current study. The production planning problem is one of the most suitable and well-known applications of multiobjective linear programming problems (MOLPPs). Different objectives such as minimization of production cost and time, maximization of total profit, quality of the products, and workers’ satisfaction are the most commonly occurring objectives under a set of resources, budget, machines capacity, etc. restrictions in production planning problems. Pandian, Nagarajan, and Yaacob (2003) suggested a decision-making approach using modified S-curve membership function and applied to production planning problems. Bhattacharya and Vasant (2007) also discussed soft-sensing satisfaction level for product mix-problem and solved using robust heuristic fuzzy programming approach. Wang and Lee (2015) proposed an algorithm for location-allocation problem with risky demand in supply chaiin planning network. Zabihzadeh and Rezaeian (2016) presented two meta-heurstic algorithm for flexible flow shop scheduling and transportation problem under release time. Chien, Dou, and Fu (2018) have also developed a smart production planning under uncertain demand ratios. Darvishi, Yaghin, and Sadeghi (2020) have also integrated the fabric procurement and production planning problem and solved using a hybrid fuzzy-robust stochastic programmig approach. Sooncharoen, Pongcharoen, and Hicks (2020) discussed the Grey wolf method for production scheduling problem for the capital goods industry. Zhou and Liao (2020) have developed a multiobjective hybridized particle swarm optimization approach for solving a job shop green sceduling with production and crane transportation problems. Ahmad, Adhami, and Smarandache (2020) also discussed closed-loop supply chain plannig problem under uncertainty and solved using modified neutrosophic optimization technique.

Furthermore, Wang, Deschamps, and Dupas (2016) presented production-transportation problem via co-operative game theoretic approaches. Postan and Filina-Dawidowicz (2016) discussed a dynamic optimization model for supply, production and trnsportation of the perishable products. Ekşioğlu, Karimi, and Ekşioğlu (2016) developed an effective integrated production-transportation optimization model and algorithm for coal-fire power plants. Maity, Roy, and Verdegay (2019) discussed the time-variant interval-valued transportation problem in the sustainable environment. Das and Roy (2019) pointed out the effect of variable carbon emission in a multi-objective transportation-p-facility location problem under neutrosophic environment. Roy and Midya (2019) attempted to solve the multiobjective fixed-charge solid transportation problem with product blending under an intuitionistic fuzzy environment. Roy and Midya, 2019, Roy et al., 2018, Midya and Roy, 2020 also solved multiobjective multi-item fixed-charge solid transportation problem under twofold uncertainty, rough random variables, and using rough programming. Midya and Roy, 2017, Roy and Midya, 2019 presented an analytical study on interval programming in different environments and its application to the fixed-charge transportation problem. Ahmad, Ahmad, and Sharaf (2021) solved the supplier selection problem using a neutrosophic algorithm under Type-2 fuzzy parameters. Ahmad, Ahmad, Zaindin, and Adhami (2021) discussed the energy-food-water security nexus management using neutrosophic optimization approach. Adhami and Ahmad (2020) also proposed the interactive Pythagorean-hesitant fuzzy method to solve the transportation problem. Ahmad and Adhami, 2019a, Ahmad and Adhami, 2019b solved the multiobjective transportation problem under neutrosophic environment. Ahmad, Adhami, and Smarandache (2018) proposed a novel computational algorithm to solve the multiobjective nonlinear programming problem.

Díaz-Madroñero, Mula, and Peidro (2017) have also investigated a mathematical model for an integrated production and procurement transportation problems. Li, Su, and Ma (2017) have also addressed the production outsourcing decisions in supply chain network under single and multiple carbon policies. Fakhrzad, Talebzadeh, and Goodarzian (2018) have studied a green closd-loop suply chain planning problem by considering the production, transportation and distribution under uncertain supply and demand. Fathollahi-Fard, Hajiaghaei-Keshteli, and Mirjalili (2018) have presented a multiobjective supply chain problem by considering social aspects. Feng, Liu, Wu, and Chu (2018) also addressed two heuristic approaches for integrated production-transportation problem under uncertainty. Gharaei and Jolai (2018) proposed a multiagent approach for integrated production scheduling and distribution problem in multi-factory supply chain network. Jia, Zhuo, Leung, and Li (2019) also discussed production for parallel batch machine and minimize the total weighted delivery time. He and Li (2019) also addressed two-echelon multi-trip vehicle routing problem for crop harvesting and transportation planning problems. Chen (2020) suggested an production multi-dimensional manufacturing system analysis. Kilic and Yalcin (2020) discussed two phase fuzzy goal programming method for integrated green supplier selection problem in supply chain network. Liu, Li, Li, and Zou (2020) also investigated co-ordinated production-transportation sceduling problems with minimum sum of total delivery time. Díaz-Madroñero, Peidro, and Vasant (2010) studied a vendor selection using modified S-curve membership function and used Torabi and Hassini (2008) method to solve it. Zheng, Yi, Wang, and Liao (2017) presented an efficient solution concept under multiobjective programming problems and applied it to different real-life applications.

Regarding the healthcare waste management, many researchers have presented emperical, theoritical and modeling studies under different scenarios. Recently, Accenture (2020) provided an empirical study on the consumption of healthcare products during the COVID-19 outbreak. Aung, Luan, and Xu (2019) performed analytical multi-criteria decision-making study for the healthcare waste management system in Mayanmar. Azzurra, Massimiliano, and Angela (2019) presented the sustainable food consumption policies and examined on a case study. Bradley, Parry, and O’Regan (2020) addressed a functional and sustainable business model for production and consumption purposes. Fernando and Wah (2017) also discussed the impact of eco-innovation drivers on the environment and performed an empirical study on the Malaysian context. Joshi and Rahman (2017) investigated a study reflecting the consumers’ sustainable buying behavior. Joshi and Bhargava (2019) integrated the waste management quality with Green Quality Function Deployment strategies for healthcare wastes. Lüdeke-Freund, Carroux, Joyce, Massa, and Breuer (2018) performed a study on sustainable business model pattern taxonomy to support the business models. Chien et al. (2018) also carried out a study for the strategic smart production planning and presented a model under the demand uncertainty. de Sousa Jabbour et al. (2020) performed a theoretical study on the sustainable supply chain in the wake of the COVID-19 outbreak. Deress, Jemal, Girma, and Adane (2019) presented a green practice for dental healthcare wastes. Moreover, Dewi, Sukendi, Ikhwan, and Nazrianti (2019) highlighted the essential and factors associated with dental healthcare wastes thorough an empirical study. Eren and Tuzkaya (2019) discussed health and safety-oriented waste management policies and implemented them in a case study in Istanbul. Khan, Cheng, Khan, and Ahmed (2019) also presented a mini-review for healthcare waste management strategies in Asian developing countries. Khobragade (2019) addressed healthcare waste management by avoiding hazards due to living and non-living environment. Kleber and Cohen (2020) performed a study for waste reduction and increased the sustainability of healthcare wastes management. Padmanabhan and Barik (2019) also efficiently studied hazard waste disposal management. Rehman and Yu (2020) discussed the assessment procedure of eco-environmental performances. Ahmad, Adhami, and Smarandache (2019) also presented an overall water management system during shale gas extraction processes in intuitionistic fuzzy environment. Tabrizi, Saadati, Heydari, Rezapour, and Zamanpour (2019) also suggested practice to improve healthcare waste management and applied on a case study in Iran. World Health Organization (2020) discussed the management of water, sanitation, and healthcare wastes amid COVID-19 pandemic situations. The interested reader may find the relevant information describing the effective waste management policies in the articles Win et al., 2019, Zamparas et al., 2019. Thus production and waste management planning are integral components of the industrial supply chain network.

All the above mentioned studies have their own importance depending upon criteria and domain of research. This current study solely highlights the modeling and formulation of the proposed SPWM model which deals with production and waste management of medical equipment in the time of financial and social crisis.

3. Problem description and modeling under uncertainty

A systematic production configuration and waste management strategies for the flow of newly manufactured medical equipment and generated wastes after its use are the most significant constituent of the proposed sustainable production and waste management model. The highly consumed medical equipment durnig COVID-19 outbreak is shown in Fig. 1 . The optimal production, consumption, and waste management plan of action signify the smooth running of the companies’ production processes. Thus a wholesome and robust optimization model may formulate the operating services under the different echelons and produce effective production, consumption, and waste management policies. Therefore the proposed SPWM model exhibits similar characteristics features, which is much required to such a non-pharmaceuticals company that indulges in producing the medical equipment at the time of need. It consists of various raw material supplier points, advanced manufacturing, plants, demand markets or consumption points, collection centers, distribution centers, and finally, various disposal facilities. The suppliers are responsible for the procurement of raw materials such as cotton, plastics, foam, silks, etc. to the advanced manufacturing plants. At the advanced manufacturing units, the medical equipment is produced under the optimum utilization of various resources such as the ratio of raw materials, available machine hour, budget availability, safety measures while handling (see, Baidya et al., 2013, Baidya et al., 2014), production capacity, mode of conveyance, different echelons’ capacities and warehouse storage space for the newly manufactured medical equipment to meet the anticipated demand. These medical equipment are transported from advanced manufacturing plants to expected demand markets such as hospitals and COVID-19 treatment facility centers. After their end-of-life phase, the accumulation or collection is done by collection centers. The used medical equipment is sent to the distribution center for disassembling and distribution purposes to other functional facility units. After inspecting the recoverable or recyclable medical equipment, they are directly sent back to the advanced manufacturing plants for further processing. The rest of the used medical equipment is shipped to the disposal facility center either for under-ground disposal or incineration purposes. The cycle of manufacturing is continuous to meet them on time expected demand. The Central Government of India highly recommends the production of medicated gown, N-95 masks, face shield, hand-gloves, sanitizers, and shoe-cover at massive scale due to their shortages and ever unmet demand.

Fig. 1.

Highly consumed COVID-19 medical equipments.

It is quite apparent to face the uncertainty factor in the relevant parameters’ values. The existence of uncertainty is a more realistic phenomenon in this real-world. Hence the proposed SPWM model also enviably exhibits the uncertainty among different parameters’ values or input data-set. It is incorporating the logic behind uncertainty quantification scientifically based on the intuitionistic fuzzy theory. Unlike fuzzy and random parameters, uncertain parameters are depicted as triangular intuitionistic fuzzy numbers. A fuzzy parameter only deals with the degree of belongingness (acceptance) of the element into a feasible solution set. It does not consider the degree of non-belongingness (rejections) of the component into the same feasible solution set, an integrated part of the decision-making processes. Furthermore, uncertainty due to randomness is indicated with random parameters. Sometimes, it may not be possible to have historical data for which the random parameters are estimated. According to some specified probability distribution function, the forecasting pattern and parameters estimation of random variables is much dependent on the behavior and nature of the historical data. An intuitionistic fuzzy parameter deals with the degree of belongingness (acceptance) and degree of non-belongingness (rejections) of the element into the same feasible solution set, simultaneously. Alsw, there is no scope for the historical data while dealing with intuitionistic fuzzy parameters. Thus, the main aim and motive behind the selection of intuitionistic fuzzy parameters are to avoid the above shortcomings of fuzzy and random parameters. By keeping these issues in mind, the SPWM model is developed under the intuitionistic fuzzy uncertainty. The useful notions and descriptions are summarized in Table 1, Table 2 . The diagrammatic representation of the proposed SPWM model is depicted in Fig. 2 .

Table 1.

Notions and descriptions.

| Indices | Descriptions |

|---|---|

| i | Denotes the number of raw material suppliers |

| j | Denotes the number of advanced manufacturing plants |

| k | Denotes the number of demand markets/consumption points |

| l | Denotes the number of collection centers |

| n | Denotes the types of conveyance (mode of transportatation) |

| w | Denotes the number of distribution centers |

| p | Denotes the number of disposal facility |

| q | Denotes the types of medical equipment |

| Decision variable | |

| Units of raw material for medical equipment q shipped from supplier i to manufacturing plants j using conveyance n | |

| Units of medical equipment type q transported from manufacturing plants j to demand markets/consumption points k using conveyance n | |

| Units of used medical equipment q collected from consumption points k to collection centers k using conveyance n | |

| Units of medical equipment q transported from collection centers k to distribution centers w using conveyance n | |

| Units of recoverable medical equipment q shipped from distribution centers w to manufacturing plants j using conveyance n | |

| Units of scrap medical equipment q shipped from distribution centers w to disposal facility p using conveyance n | |

| Represents the binary variable such that | |

| Tells us whether the route using conveyance n is active or not i.e., | |

| Parameters | |

| Rejection rates of medical equipment q at manufacturing plants j (unit) | |

| Total delivery time required to ship medical equipment q from manufacturing plants j to demand markets/consumption points k using conveyance n (hr) | |

| Total revenue generated by treating of unit medical equipment q ($/unit) | |

| Unit raw material cost required to produce medical equipment q at supplier i ($/unit) | |

| Unit production cost of medical equipment q at manufacturing plants j ($/unit) | |

| Time for machine usage to manufacture unit medical equipment q at manufacturing plants j (hr/unit) | |

| Maximum capacity allowed for medical equipment q by using conveyance n | |

| Total available budget for production and transportation purpose ($) | |

| Desired safety value | |

| Protection factor related to medical equipment q during handeling | |

| Maximum available machine capacity at manufacturing plants j (hr/unit) | |

| Warehouse space per unit delivered at manufacturing plants j (ft2/unit) | |

| Maximum available warehouse space for demand markets/consumption points k (ft2) | |

Table 2.

Notions and descriptions.

| Parameters | Descriptions |

|---|---|

| Unit transportation cost of raw materials for medical equipment q from supplier i to manufacturing plants j by conveyance n ($/unit) | |

| Unit transportation cost of medical equipment q from manufacturing plants j to demand/consumption points k by conveyance n ($/unit) | |

| Unit transportation cost of medical equipment q from demand/consumption points k to collection center l by conveyance n ($/unit) | |

| Unit transportation cost of medical equipment q from collection center l to distribution center w by conveyance n ($/unit) | |

| Unit transportation cost of medical equipment q from distribution center w to manufacturing plants j by conveyance n ($/unit) | |

| Unit transportation cost of medical equipment q from distribution center w to disposal facilities p by conveyance n ($/unit) | |

| Unit inspection and accumulation cost for used medical equipment q at collection center l ($/unit) | |

| Unit distribution cost of used medical equipment q at distribution center w ($/unit) | |

| Unit disassembly and recovery cost of recoverable medical equipment q at manufacturing plants j ($/unit) | |

| Unit disposing cost of scrap medical equipment q at disposal facility p ($/unit) | |

| Unit inventory holding cost of medical equipment q at distribution center w ($/unit) | |

| Total inventory holding capacity of scrap medical equipment q at distribution center w ($/unit) | |

| Maximum supply capacity of raw material for medical equipment q at supplier i | |

| Total availability of medical equipment q at manufacturing plants j | |

| Total expected demand of medical equipment q at demand/consumption point k | |

| Maximum capacity of accumulation for used medical equipment q at collection center l | |

| Maximum capacity for disposing purpose of medical equipment q at disposal facilities p |

Fig. 2.

Diagrammatic representation of proposed SPWM model.

3.1. Objective functions

Objective 1: Minimization of total economic cost

The total economic cost involved in the proposed SPWM model has a significant impact while extracting the overall profits for the organizations or firms. It consists of purchasing, production, transportation, and service operating costs associated with different service providing sectors to COVID-19 medical equipment. Thus the first objective function is linear and represented by (1) encompasses minimization of the total economic cost. The different prices associated with COVID-19 medical equipment are as follows: cost of purchasing raw material and transportation cost from supplier point to advanced manufacturing/ plant, production cost and transportation cost from advanced manufacturing plant to demand market, collection cost and transportation cost from demand market to collection center, distribution and inventory holding costs at the distribution center, transportation cost from collection center to the distribution center, disassembly, manufacturing, and transportation cost from distribution center to manufacturing plant, and disposal and transportation cost from distribution center to disposal facility by using various modes of transportation (conveyances).

| (1) |

Objective 2: Maximization of total revenue gained

Sustainable or green practices for the management of generated waste are quite indispensable for both economic and environmental points of view. The end-of-life phase of COVID-19 medical equipment has a severe impact on the ecosystem, as most raw materials are plastics and foams. After their useful life, there is an option before the managers or decision-makers re-manufacture into some other trivial products. Therefore the collected COVID-19 medical equipment wastes are distributed from distribution centers to either advanced manufacturing plants or directly disposal facilities for land-fills and incineration purposes. Thus the second objective function represented by (2) ensures the maximization of the total revenue gained on the unit recoverable or re-manufactured product transported from distribution centers to advanced manufacturing plants.

| (2) |

Objective 3: Minimization of total delivery time

In the current COVID-19 situations, on-time deliveries of sufficient medical equipment are of prime concern for the firms or companies. Instant delivery policy enhances the company’s market values and goodwill, which is an utmost competitive advantage. Hence, the third objective function depicted by (3) assures the significant reduction in total delivery time for medical equipment transported from advanced manufacturing plant to demand market or consumption points.

| (3) |

3.2. Constraints

The entire modeling configuration of the proposed SPWM model exhibits the integration of well-known planning and strategic policies such as purchasing, production, transportation, collection, distribution, storage, supply, demand, safety, disposal, and budgets, respectively. Thus, restrictions imposed over different parameters inevitably signify the more effective and realistic modeling framework.

Production and consumption constraints:

In COVID-19 crucial situations, availability and acquirement of raw materials are not easily possible for every production company at a commercial level. In India, some NGOs and non-profit organizations are also producing this medical equipment for distribution among medical personnel and hospitals. Thus suppliers have a limited amount of raw materials for commercial purposes. Hence the constraint (4) ensures the unit of raw materials supplied to advanced manufacturing plants must be less than or equals to its maximum capacities at different supplier points. The total machine capacity to produce each of these medical equipment at advanced manufacturing plants must be less than and equals to its respective maximum positions in the production processes. Thus, the constraint (5) ensures the total machine capacity available at each advanced manufacturing plant to produce the optimal number of this medical equipment. Alsw, this medical equipment’s total quantity must be less than and equal to the respective supply capacity at each advanced manufacturing plant and represented by constraint (6). The storage capacity due to space limitations is also an important issue associated with this medical equipment. To ensure the maximum warehouse space utilization at each demand market or consumption points, the constraint (7) is incorporated. Most importantly, this medical equipment requirement is essential for medical personnel or practitioners to treat COVID-19 infected patients. Thus constraint (8) ensures the maximum shipment of this medical equipment must be higher than or equals to the total expected demand that is to be met at different consumption zones or hospitals.

| (4) |

| (5) |

| (6) |

| (7) |

| (8) |

Budget availability constraint:

The total availability of budget for the purchasing, production, and transportation purpose of this medical equipment must be in the prescribed limit. To ensure the budget restrictions, constraint (9) is constrained in the proposed SPWM model.

| (9) |

Safety factor constraint:

Moreover, the most important characteristic feature of the proposed SPWM model is to enhance the safety factors associated with this medical equipment while handling it at different points as the contamination and transfusion rates of COVID-19 is very high and drastically communicable. The safety factors are measured using the concept of Baidya et al., 2013, Baidya et al., 2014. To achieve the desired safety protection related to each of this medical equipment, the constraint (10) is depicted.

| (10) |

Transportation capacity constraint:

Related to the transportation problem, the usage of appropriate conveyance is somehow economic in some places. The maximum quantity of this medical equipment from various sources to different destination points must be less than or equals to its respective maximum conveyance capacities. Thus constraint (11) ensures the restrictions over conveyances capacity.

| (11) |

Capacity constraints:

After a one-time-use of this medical equipment, the end-of-life phase initiates, and they are treated as generated wastes. The proper management of this used medical equipment needs careful precaution while handling them. The various collection, distribution, and disposal facilities are build-up for the treatment of these wastes efficiently. There is a maximum capacity associated with each of these facilities centers for the allocation of quantity or units of these wastes to different facilities. Thus the maximum units of these waste medical equipment that are shipped from consumption points to a collection center, from collection center to distribution center and from distribution center to disposal facilities must be less than or equals to their respective maximum allowed capacities and represented in constraints (12), (13), (14), respectively. The constraint (15) ensures the flow of medical equipment associated with different sources to various destinations in the proposed SPWM model. Constraint (16) tells us whether the given route are active or not. The non-negativity restriction (17) is also presented.

| (12) |

| (13) |

| (14) |

| (15) |

| (16) |

| (17) |

Thus the formulation of intuitionistic fuzzy sustainable production and waste management model (IFSPWM) (18) can be summarized as follows:

| (18) |

where represents the triangular intuitionistic fuzzy parameters involved in the objective functions and constraints, respectively.

3.3. Treating intuitionistic fuzzy parameters

For treating intuitionistic fuzzy parameters, we have discussed some basic concepts related to intuitionistic fuzzy set (IFS).

Definition 1 Atanassov (1986) Intuitionistic Fuzzy Set —

Assume that there be a univeral set X. Then, an intuitionistic fuzzy set in X is difined by the ordered triplets as follows:

where denotes the membership function and denotes the non-membership function of the element into the set , respectively, with the conditions . The value of , is called the degree of uncertainty of the element to the IFS . If , an IFS becomes fuzzy set and takes the form .

Definition 2 Ahmad et al. (2019) Intuitionistic fuzzy number —

An intuitionistic fuzzy set is said to be an intuitionistic fuzzy number if and only iff

- 1.

There exist a real number for which and .

- 2.

The membership function of is fuzzy convex and non-membership function of is fuzzy concave.

- 3.

Alsw, is upper semi-continuous and is lower semi-continuous.

- 4.

The support of is given by .

Definition 3 Ahmad et al. (2019) Triangular intuitionistic fuzzy number —

A triangular intuitionistic fuzzy number (TrIFN) is represented by where such that ; and its membership function and non-membership function is of the form

Definition 4 Ahmad et al. (2019) —

Consider that a TrIFN is given by where such that . Then the parametric form of are and . Further, and are the parametric form of TrIFN corresponding to membership and non-membership functions such that and respectively. A TrIFN is said to be positive TrIFN if and hence are all positive numbers.

Some important properties of TrIFN are as follows:

Property 1

Assume thatandare two TrIFNs. Then addition ofandis again a TrIFN.

Property 2

Consider thatbe a TrIFN and. Then scaler multiplication ofis again a TrIFN.

Property 3

The two TrIFNsandare said to be equal iff.

Definition 5 Ahmad et al. (2019) Expected interval and expected value of TrIFNs —

The concept of expected interval and expected value was defined by Heilpern (1992). Thus, we re-defined it for TrIFNs. Suppose that be a TrIFN and and depict the expected intervals for membership and non-membership functions respectively. Thus, these can be defined as follows:

Moreover, consider that and represent the expected values corresponding to membership and non-membership functions respectively. These can be depicted as follows:

(19)

(20) The expected value EV of a TrIFN is given as follows:

Definition 6 Accuracy function —

The expected value for TrIFN with the help of Eqs. (19), (20) and for can be represented as follows:

Thus is also known as accuracy function of .

Theorem 1

Suppose thatbe a TrIFN. Then for any; the expected valuefor all.

Proof

Let us consider that be a TrIFN. Then, based on the nature of k, three different cases will arise:

Case I: when , there is nothing to prove.

Case II: when , then we have by using Property 2. Now taking expected value of , we get

Case III: when , then we have by using Property 2. Now taking expected value of , we get

In each case, we have proven that . □

Theorem 2

Suppose thatandbe two TrIFNs. Then the accuracy functionis a linear function i.e.,for all.

Proof

Please visit Singh and Yadav (2018). □

Theorem 3

Suppose thatbe a TrIFN. If, then, which is ranking of triangular fuzzy number based on expected values.

Proof

Please visit Singh and Yadav (2018). □

Theorem 4

The expected value, where.

Proof

Please visit Singh and Yadav (2018). □

With the aid of accuracy function , the IFSPWM model (18) can be transformed into the crisp SPWM model (21) and can be stated as follows:

| (21) |

Of particular interest, we have proven the existence of an efficient solution of the IFSPWM model (18) and the convexity property of the crisp SPWM model (21) in the Theorem 5, Theorem 6, respectively. Hence the obtained crisp SPWM model (21) can be solved using the proposed interactive intuitionistic fuzzy programming approach (see Section 4.2) to get the optimal global solutions.

Definition 7

Assume that X be the set of feasible solution for the crisp SPWM model (21). Then a point is said to be an efficient or Pareto optimal solution of the crisp SPWM model (21) if and only iff there does not exist any such that, and for all at least one . Here, m is the number of objective function present in the proposed sustainable production and waste management model.

Definition 8

A point is said to be weak Pareto optimal solution for the crisp SPWM model (21) if and only iff there does not exist any such that, .

Theorem 5

An efficient solution of the crisp SPWM model(21)is also an efficient solution for the IFSPWM model(18).

Proof

The proof is similar to Singh and Yadav (2018). □

Definition 9

Let and be comonotonic functions, then for any intuitionistic fuzzy parameter , we have

For the sake of simplicity, let us consider an auxiliary model (22) which is an equivalent to the crisp SPWM model (21) and can be given as follows:

(22) where in auxiliary model (22) represents the expected values (accuracy function) of the intuitionistic fuzzy parameters.

In the Theorem 5, we have already proven the expected value EV efficient solution for the IFSPWM model (18). This concept is obtained by presenting the crisp SPWM model (21) in which the objective functions are the expected value of the intuitionistic fuzzy uncertain objectives of the IFSPWM model (18). Intuitionally, if the intuitionistic fuzzy uncertain vectors in the auxiliary model (22) are degenerated into intutionistic fuzzy parameters, then the following convexity Theorem 6 of the auxiliary model (22) can be proved.

Theorem 6

Suppose that the functionis differentiable and a convex vector function with respect to X and. Thus, for any given, ifandare comonotonic on intuitionistic fuzzy parameters, then the auxiliary model(22)is a convex programming problem.

Proof

Since, the feasible solution set X is a convex set, intuitionally, it is sufficient to obtain that the auxiliary model (22) is a convex vector function.

Note that the is a convex vector function on X for any given , the inequality

holds for any and , i.e.;

holds for each .

By using the assumed condition that and are comonotonic on , it follows from Definition 9 that

which implies that

The above inequality shows that is a convex vector function. Hence the auxiliary model (22) is a convex programming problem. Consequently, the crisp SPWM model (21) is also a convex programming problem. Thus Theorem 6 is proved. □

The convexity property (Theorem 6) of the crisp SPWM model (21) typically ensures or strongly guarantees the existence of convex decision set under which the optimal solution exists. Moreover, it also supports the robust modeling approach of the crisp SPWM model (21) which also validate the scope for obtaining the optimal solution sets under intuitionistic fuzzy uncertainty.

4. Solution methodology

Most often, real-life problems exhibits optimization of more than one objectives at a time. The most promising solution set that satisfies each objectives efficiently is termed as the best compormise solution. In the past few decades, it is observed that the situation may arise where the degree of hesitation may exists in real life decision-making problems. Since fuzzy set (FS) deals with the membership function (degree of belongingness) only, it is not capable to capture the hesitation degrees simultaneously. Therefore, the further generalization of FS is presented by introducing a new member into the feasible decision set. First, Atanassov (1986) investigated intuitionistic fuzzy set which comprise membership (degree of belongingness) and non-membership (degree of non-belongingness) functions of the element into feasible solution set. The IFS is based on more intuition as compared to FS and generalizes the decision-making processes more conveniently. Based on IFS, Angelov (1997) developed the intuitionistic fuzzy optimization techniques for the multiobjective programming problem under intuitionistic fuzzy uncertainty. Recent literature on IFS reveals that many researchers have shown the research interest in the intuitionistic fuzzy domain and would be a prominent emerging research area in future. The current study is also taken advantage of the versatile and effective texture of a intuitionistic fuzzy decision set to develop the proposed interactive intuitionistic fuzzy programming approach. The proposed IIFPA quantify the marginal evaluation of each objective function by depicting membership and non-membership functions, respectively. In the proposed IIFPA, an achievement function is represented by the convex combination of the overall satisfactory degrees and weighted intuitionistic score functions of multiple objective programming problem under a set of well-defined constraints. Moreover the proposed IIFPA is elaborately discussed in Section 4.2. Thus the intuitionistic fuzzy optimization techniques for multiobjective programming problem has a significant role in the implementation and execution of the hesitation degrees in decision-making processes.

To construct the membership and non-membership functions for each objectives of the crisp SPWM model (21), the minimum and maximum values of each objective functions can be calculated and are represented by and as follows:

| (23) |

Now, we will proceed towards the characterization of marginal evaluations (membership functions) for each objectives under intuitionistic fuzzy uncertainty. For this purpose, we present different kinds of membership functions along with their robustness properties in decision-making scenario.

4.1. Characterization of various membership functions

In MOLPP, the marginal evaluation of each objective function is depicted by its respective membership and non-membership functions under intuitionistic fuzzy uncertainty. Most commonly, the marginal evaluations are evaluated by using linear type membership function to obtain the individual satisfactory degree. However, it may be possible to represent the achievement level of each objectives with the aid of nonlinear membership and non-membership functions. The flexible behavior of non-linear membership and non-membership functions are also well enough to quantify the marginal evaluations of each objectives and, consequently determine the satisfaction degrees more efficiently. It also depends on some additional parameters’ value that are assigned by the decision-makers only. By tuning the additional parameters such as shape, scale, measures of vaguness, etc., the decision-maker(s) are well enough capable to execute his/her(their) strategy effectively. There are different types of membership functions that exist in the literature such as linear, exponential, hyperbolic, modified S-curve etc. Therefore, to deal with the crisp SPWM model (21) under intuitionistic fuzzy uncertainty, one can apply linear, exponential, hyperbolic or modified S-curve membership functions depending upon the choice of decision-makers. Thus the linear, exponential, hyperbolic or modified S-curve membership functions are constructed under intuitionistic fuzzy environment. Each of them are defined as the acceptance (degree of belongingness) and rejection (degree of non-belongingness) degrees of each objective functions which seems to be more realistic in nature.

-

•

Linear membership and non-membership functions

In general, the most extensive and widely used membership function is linear one due to its simple structure and easier implications. The linear membership function contemplates over constant marginal rate of satisfaction or dissatisfaction degrees towards an objective. The graphical depiction of linear membership and non-membership functions is done in Fig. 3 . Thus the linear membership and non-membership functions under intuitionistic fuzzy uncertainty can be furnished as follows:

In the above case, for all m objective function. If for any membership , then the value of these membership will be equal to 1. -

•

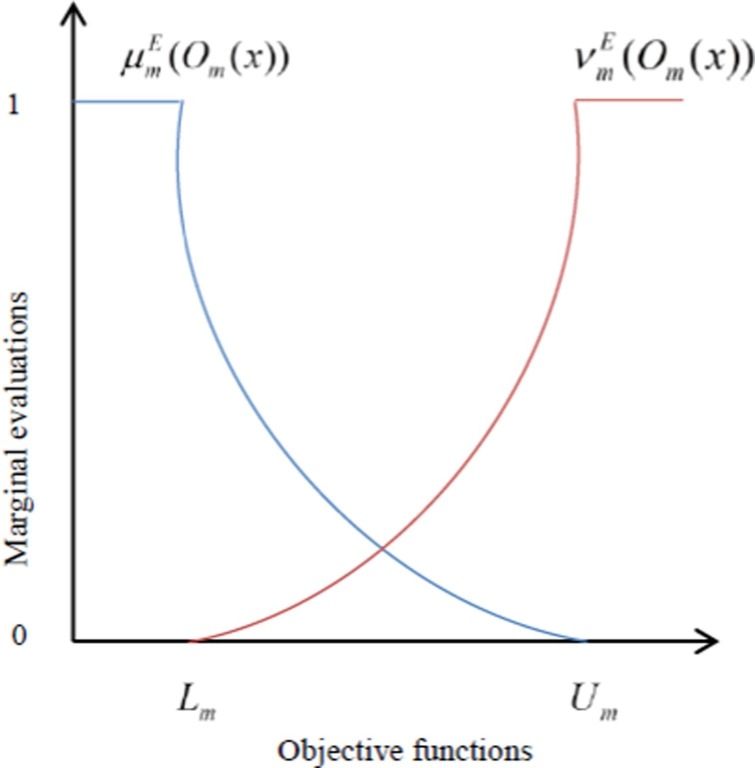

Exponential membership and non-membership functions

An exponential membership reflects the situation when decision-maker is worse off with respect to an objective and choose for a higher marginal rate of satisfaction. Thus by prefering an exponential membership function, the decision-maker can also able to reduce duality gaps by selecting appropriate shape parameters involved in the development of membership function. The pictorial depiction of exponential membership and non-membership functions is presented Fig. 4 . The exponential membership and non-membership functions under intuitionistic fuzzy uncertainty can be stated as follows:

where are the measures of vagueness degree (shape parameter) and assigned by the decision-makers. -

•

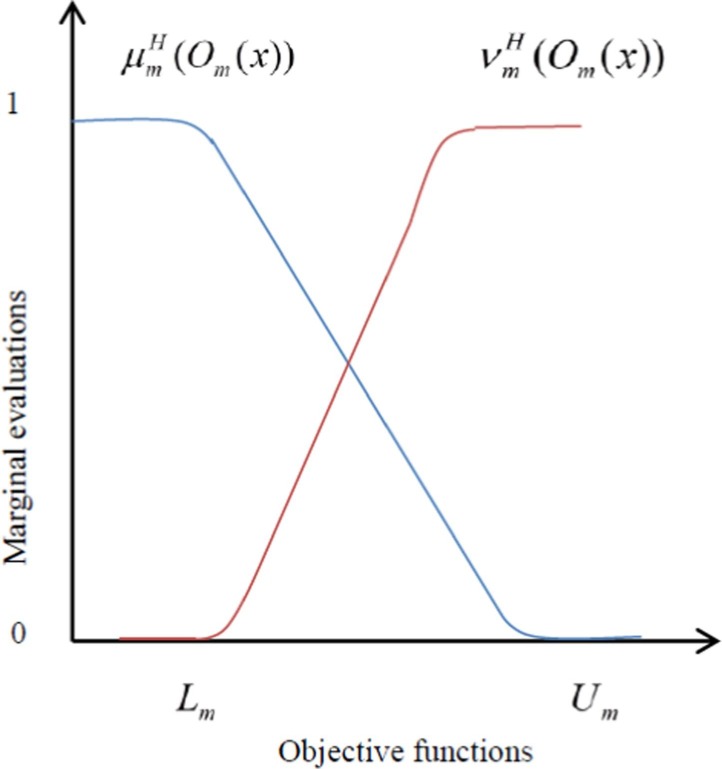

Hyperbolic membership and non-membership functions

A hyperbolic membership function shows the flexible characteristic behavior with respect to objective function. It is convex over a part of the objective function values and is concave over the remaining part. When the decision maker is worse off with respect to a goal, the decision-maker tends to have a higher marginal rate of satisfaction with respect to that goal. A convex shape part of the membership function captures that behavior. On the other hand, when decision-maker is better off with respect to a goal, the decision maker tends to have a smaller marginal rate of satisfaction. Such behavior is modeled using the concave portion of the membership functions. The graphical representation of hyperbolic membership and non-membership functions is shown in Fig. 5 . Hence the hyperbolic membership and non-membership functions under intuitionistic fuzzy uncertainty can be depicted as follows:

where . -

•

Modified S-curve membership and non-membership functions

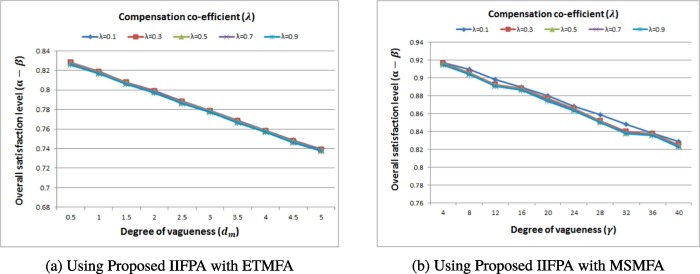

A special case of logistic function at different values of parameters are known as modified S-curve membership function. The structure of modified S-curve membership function allows the decision-maker to incorporatte the degree of vaguness hesitations under intuitionistic fuzzy uncertainty. Unlike other linear and nonlinear membership functions, the modified S-curve membership function is more flexible and much dependent on the various parameters involved for marginal evaluations of each objective functions. The diffrent parameters such as and are responsible for the abrupt change or fluctuation in the shape of modified S-curve membership function and assist in the quantification of acceptance and rejection degrees of each objectives efficiently. The parameter depicts degree of vagueness, meaning the larger value of signify the higher degree of vagueness. Therefore the greater concern to fuzziness or ambigousness can be measured at whereas implies crisp. It is quite indespensable that the value of should be determined by experts based on the heuristical and experimental studies. The values of and are to be determined. An analytical study performed by Peidro and Vasant (2011) calculated these values as and respectively. The continuous flexible nature of modified S-curve membership function provides an opportunity to the decision-maker(s) to execute the desired strategies at different parameters’ values. The graphical representation of modified S-curve membership and non-membership functions is depicted in Fig. 6 . Thus the modified S-curve membership and non-membership functions under intuitionistic fuzzy uncertainty can be furnished as follows:

where is the measure of fuzziness degree.

Fig. 3.

Linear membership and non-membership functions.

Fig. 4.

Exponential membership and non-membership functions.

Fig. 5.

Hyperbolic membership and non-membership functions.

Fig. 6.

Modified S-curve membership and non-membership functions.

4.2. Proposed interactive intuitionistic fuzzy programming approach

The concept of fuzzy decision (FD), fuzzy goal (FG) and fuzzy constraints (FC) was first discussed by Bellman and Zadeh (1970) and extensively used in many real life decision-making problems under fuzziness. Therefore, fuzzy decision set can be defined as follows:

Consequently, intuitionistic fuzzy decision set , with the set of intuitionistic fuzzy objectives and constraints, can be defined as follows:

where

where and are the membership and non-membership functions of intuitionistic fuzzy decision set respectively.

By utilizing the concept of Bellman and Zadeh (1970), our intention is to maximize the minimum of membership (degree of belongingness) and minimize the maximum of non-membership (degree of non-belongingness) functions at a time. Therefore an acheivement function can be defined as the differences of satisfaction and dissatisfaction degrees to reach the optimal solution of each objectives under intuitionistic fuzzy uncertainty. Thus the mathematical expression for achievement function is defined as follows (24):

| (24) |

where the superscript in the membership and non-membership functions represent the different types of membership functions such as linear , exponential , hyperbolic and modified S-curve respectively.

Using the auxiliary variables and , the problem (24) can be transformed into the following problem (25):

| (25) |

To solve a MOLPPs, Torabi and Hassini (2008) presented a single-phase solution method and named as TH-method by overcoming the drawbacks of existing approaches suggested by Lai and Hwang, 1993, Lai and Hwang, 1994, Li et al., 2006, Selim and Ozkarahan, 2008, Werners, 1988, Zimmermann, 1978, Ahmadini and Ahmad, in press. In Torabi and Hassini (2008) approach, the achievement function is defined as a convex combination of the lower bound for satisfaction degree of objectives , and the weighted sum of these achievement degrees to confirm the yielding an adjustably balanced compromise solution. The shortcomings of existing methods Lai and Hwang, 1993, Lai and Hwang, 1994, Li et al., 2006, Selim and Ozkarahan, 2008, Werners, 1988 is pointed out by Torabi and Hassini (2008) and presented TH method (Torabi & Hassini, 2008) to overcome these issues. Of particular interest, the TH method (Torabi & Hassini, 2008) deals only the satisfaction degree of each objective function and do not considers the dissatisfaction degree which is also an important integrated part of the decision-making processes. All the above discussed methods Lai and Hwang, 1993, Lai and Hwang, 1994, Li et al., 2006, Selim and Ozkarahan, 2008, Werners, 1988, Zimmermann, 1978, Torabi and Hassini, 2008 do not takes into consideration the degree of dissatisfation (rejection) that exists in real-life decision-making scenarios. To integrate the dissatisfaction degree in TH method (Torabi & Hassini, 2008), we have re-defined a new achievement function and consequently proposed a novel interactive intuitionistic fuzzy programming approach (hereafter the FA method) to obtain the optimal compromise solution. More specifically, the proposed IIFPA can be considered as the extended version of TH method (Torabi & Hassini, 2008). Therefore proposed IIFPA (26) can be an equivalent modeling and optimizing approach for solving the crisp SPWM model (21). Thus the problem (25) can be transformed into an equivalent proposed IIFPA (26) and can be summarized as follows:

| (26) |

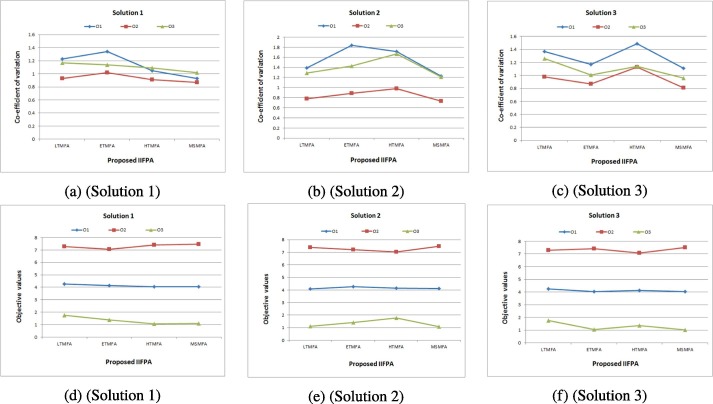

where and represent the satisfaction and dissatisfaction degrees of m-th objective function under intuitionistic fuzzy environment. Also and denote the minimum satisfaction and maximum dissatisfaction degrees of each objectives, respectively. Thus the formulation of proposed IIFPA (26) has a new achievement function which is elicited as a convex combination of the difference between lower and upper bounds for satisfaction and dissatisfaction degrees of objectives , and the weighted sum of the difference between these achievement degrees to make sure generating an established balanced compromise solution. Furthermore, and depict the relative preference of the m-th objective function and the co-efficient of compensation, respectively. The parameters are identified by the decision-maker based on her/his importances such that . Further, monitors the overall satisfaction level of objectives as well as the compromise achievement degrees among the objective functions implicitly. It means that the proposed IIFPA (26) is most promising and reliable of generating both unbalanced and balanced compromised solutions for a given MOLPPs situation based on the decision maker’s importances through tuning the value of parameter .

Remark 1

In current context, a greater value for means more concern is offered to determine a higher overall bounds for satisfaction and dissatisfaction degrees of objectives and consequently more balanced compromise solutions.On the other hand, the smaller value for means more concern is shown to get a solution with high satisfaction and low dissatisfaction degrees for some objectives with higher relative preference without any attention paid to the overall satisfaction degree of other objective functions. It should be worth important to note that there exists a correlation between and the range of values (i.e. ) so that there will be specific pre-determined interval of in which it could be chosen for a given vector. Furthermore, Singh and Goh (2019) also investigated that Torabi and Hassini (2008) method outperform with respect to their proposed algorithm. For instance, for the probably high values of this range, consequent should be chosen as a small value (e.g. less than 0.2) because of explicit importance of the decision-maker for obtaining an unbalanced compromise solution in this case.

Definition 10

A vector is said to be an optimal solution to proposed IIFPA (26) or an efficient solution to the crisp SPWM model (21) if and only iff there does not exist any such that, and . Alsw, and for at least one .

Theorem 7: A unique optimal solution of proposed IIFPA (26) is also an efficient solution to the crisp SPWM model (21).

Proof

Consider that be a unique optimal solution of proposed IIFPA (26) which is not an efficient solution to crisp SPWM model (21). It means that there must be an efficient solution, say , for the crisp SPWM model (21) so that we can have: and . Alsw, there exists and for at least one t. Thus for the minimum satisfaction and maximum dissatisfaction levels of each objective functions in and solutions, we would have , and concerning the related objective values we would have the following inequalities:

Hence, we have arrived at a contradiction that is not a unique optimal solution of proposed IIFPA (26). This completes the proof of Theorem 7. □

4.2.1. Linear-type membership functions approach (LTMFA)

Assuming that and , for all m. Using the linear-type membership and non-membership functions, the proposed IIFPA (26) can be transformed into problem (27):

| (27) |

Remark 2

The ultimate aim of problem (27) (LTMFA) manifests the maximization of minimum possibility level (degree of belongingness) to accept the best possible solution and minimization of maximum possibility level (degree of non-belongingness) to reject the worst possible solution by considering all the objective functions at a time. It means that we try to determine a solution in such a way that it maximizes the minimum membership (acceptance) and minimizes the maximum non-membership (rejection) degrees by taking all objectives simultaneously, to attain the optimal compromise solution.

Theorem 7

A unique optimal solution of problem(27)(LTMFA) is also an efficient solution for the crisp SPWM model(21).

Proof

The proof is similar to Singh and Yadav (2018). □

4.2.2. Exponential-type membership functions approach (LTMFA)

We assume that and , for all m. With the help of exponential-type membership and non-membership functions, the proposed IIFPA (26) can be transformed into problem (28):

| (28) |

Remark 3

If , then the exponential-type membership functions will be reduced into linear-type membership functions.

Theorem 8

A unique optimal solution of problem(28)(ETMFA) is also an efficient solution for the crisp SPWM model(21).

Proof

The proof is similar to Singh and Yadav (2018). □

4.2.3. Hyperbolic-type membership functions approach (HTMFA)

Consider that and , for all m. With the aid of hyperbolic-type membership and non-membership functions, the proposed IIFPA (26) can be converted into problem (29):

| (29) |

Equivalently, we have problem (30) as follows:

| (30) |

Theorem 9

A unique optimal solution of problem(30)(HTMFA) is also an efficient solution for the crisp SPWM model(21).

Proof

The proof is similar to Singh and Yadav (2018). □

4.2.4. Modified S-curve membership functions approach (MSMFA)

Alsw, assume that and , for all m. Using the modified S-curve membership and non-membership functions, the proposed IIFPA (26) can be converted into problem (31):

| (31) |

Consequently, we have problem (32) as follows:

| (32) |

Theorem 10

A unique optimal solution of problem(32)(MSMFA) is also an efficient solution for the crisp SPWM model(21).

Proof

Suppose that be a unique optimal solution of problem (32) (MSMFA). Then, for any feasible to the problem (32) (MSMFA). On the contrary, assume that is not an efficient solution of the crisp SPWM model (21). For that, there exists feasible to the crisp SPWM model (21), such that for all and for at least one m.

Hence, we have

for all and

for all for at least one m.

Thus, .

If , then .

Similarly, we have for all and for at least one m.

Consequently, it gives

for all and

for at least one m.

Hence, .

Assuming , we have .

This gives . Thus, we have arrived at a contradiction with the fact that is the unique optimal solution of (MSMFA). Therefore, it is also an efficient solution of the crisp SPWM model (21). This completes the proof of Theorem 11. □

4.3. Performance analysis based on multiple criteria

-

•

Savings compared to baseline solution: The most reasonable compromise solution is assumed to be a baseline solution for each objective function. The comparison is made with a different optimal solution which is then selected in terms of more savings.

-

•

Co-efficient of variation (CV): It is a relative measure and most suitable method to compare two series. The size of the measure of dispersion also depends on the size of the measurement. Thus, it is an appropriate measure of dispersion to compare two series which differs largely in respect of their means. Moreover, a series or a set of values having a lesser co-efficient of variation as compared to others is more consistent. It also indicates how much fluctuation is happening in the existing mean response. The lower value of co-efficient of variation indicates the more homogeneous and robustness of the data.

-

•

Degrees of desirability: The concept of degrees of desirability has been first proposed by Baril et al., 2007, Baril et al., 2011, Baril et al., 2013. Linear physical programming Abdel Haleem (1991) is a method that is used to depict the degrees of desirability (priority) for each objective function of MOLPP. The degree of desirability is a beneficial and handy tool for assigning the target values () for the objective function and for categorizing the solutions. By obtaining the individual best and worst solution of each objective function, the upper and lower bound for target values () can be determined directly. By using the pay-off matrix (individual best and worst solutions of each objective function), bound () and () can be obtained. These bounds provide the reduction in solvability set which can be denoted as and mathematically it can be shown expressed as where is a set of parameter values for which the problem is solvable. Thus, the reduced solvability set can be used for defining the degree of desirability in the form of linguistic preferences. For more information and a stepwise procedure, one can visit the research paper by Baril et al. (2011). The details can be found in Baril et al., 2007, Baril et al., 2011, Baril et al., 2013.

4.4. Proposed solution algorithm

The step-wise procedures for modeling and optimization of integrated production-transportation planning problem is summarized as follows:

Step-1. Formulate the IFSPWM (18) under intuitionistic fuzzy uncertainty.

Step-2. Using accuracy function, obtain the crisp SPWM model (21).

Step-3. Solve each objective function individually and determine the upper and lower bounds using Eq. (23).

Step-4. With the help of and , define the membership and non-membership functions under intuitionistic fuzzy envirnment.

Step-5. Elicit the various types of marginal evaluations such as linear, exponential, hyperbolic or modified S-curve membership functions (see Section 4.1) according to decision-makers’ preferences.

Step-6. Follow up with proposed IIFPA (26), construct the various approaches with diffrent membership functions such as LTMFA (27) or ETMFA (28) or HTMFA (30) or MSMFA (32) under the well-defined constraints of the crisp SPWM model (21).

Step-7. Solve the obtained intuitionistic fuzzy programming model to determine the balanced optimal compromise solution using appropriate techniques or some optimizing software packages.

Step-8. To generate the desired number of solution sets, tune the compensation co-efficient parameter. Moreover, one can tune some additional parameters such as and to get the ample number of solution sets.

Step-9. Execute performance analyses by using different criteria such as savings compared to baseline solution, CV and degree of desirability (discussed in subSection 4.3) to analyze the better performance of different solution schemes and choose the desired balanced compromise solutions.

5. A case study

The central government has ramped up domestic manufacturing of personal protective and medical equipment, including ventilators, to meet the increasing demand, amid serious concerns over shortage of PPE for health workers. The prevention, containment, and management of COVID-19 in the country are monitored at the highest level governing body. Various actions have been initiated in collaboration with the States. Talking about the criterion used, besides the number of cases, ”density of population, testing ratio and the likelihood of an area posing a challenge have also been considered while classifying States into red and orange zones.” The biggest challenge is not whether a State is in the red or orange zone, but if the containment measures are being adequately followed to curb the spread of the COVID-19. Containment zones should be delineated duly, considering mapping cases and contacts, geographical dispersion of cases and contacts, areas with a well-demarcated perimeter, and enforceability. States and UTs are also advised that containment zones can be residential colony/mohallas/municipal wards or police station area/municipal zones/towns in urban areas as appropriate. In containment zones, stringent perimeter control, active search for cases through house-to-house surveillance by special teams formed for the purpose, testing all cases as per sampling guidelines, contact tracing, and clinical management of all confirmed cases need to be done. In buffer zones, extensive surveillance through monitoring of ILI/SARI cases in health facilities need to be expedited.

The Central Government of India has scaled up medical equipment production in response to the coronavirus disease (Covid-19) outbreak and ordered its preparedness to tackle the infectious disease. Some government institutes like Defense Research and Development Organization (DRDO), South India Textile Research Association (SITRA), and Ordnance Factory Board are the front runners in developing new technologies, materials, and testing facilities. DRDO has also developed new PU coated nylon/polyester for supply to domestic manufacturers. Arvind, The Trident Group, Welspun JCT Mills, and Shahi Exports are domestic companies involved in the production.

The strategy devised is to see an opportunity to create supply chains and manufacturing in India by helping existing producers expand and identify new manufacturers. To meet the requirement of PPEs, especially medicated gown, face masks, face shields, hand gloves, sanitizers, and shoe covers, factories producing essential items are working around the clock, and ordinance factories are trying to produce personal protection equipment for medical personnel. Thus in containment zones, a leading Indian based automobile company gear up its production towards the above furnished COVID-19 medical equipment for the first time. For the raw material acquirement, the company has an agreement with six raw materials suppliers in Chennai, Coimbatore, Bengaluru, Kochi, Delhi, and Patna, respectively. The automobile company has established twelve advanced manufacturing plants in a different part of the nation. The medical equipment is transported to highly demanded zones at thirty-two markets of Maharashtra, Delhi, Chandigarh, Punjab, Karnataka, and Chennai from these production units. The six medical equipment is identified as an essential requirement for health personnel and sanitation workers to fight with COVID-19 battle, namely; medicated gown, face masks, face shield, hand gloves, sanitizers, and shoe covers are successfully produced to meet the anticipated demand. The end-of-life phase is initiated after its use, where the well-functional collection centers are responsible for collecting used medical equipment for further processing. For this purpose, eight different collection centers are established near the medical equipment’s high demand zones. After accumulating used medical equipment, four distribution centers receive the generated wastes for assembling and recovery purposes by inspecting them one-by-one with proper safety measures. Those wastes that can be recovered are shipped to the advanced manufacturing plants for further processing. Finally, non-recoverable or end-of-use wastes are transported to six different disposal facilities such as under-ground dumping and incineration purpose to reduce the social and ecological impacts. Thus the SPWM model under intuitionistic fuzzy uncertainty is easily implemented on the presented case study data. To examine the applicability and validity of the proposed modeling and optimizing approach, the manager has will-fully provided the relevant data in uncertain form except for the maximum machine capacity, available warehouse space limitation, and maximum available warehouses space. All the relevant data-set are summarized in Table 3 . The managers intend to minimize the total economic costs and delivery time and maximize the revenue gained by enhancing it as an objective function under the well-defined constraints.

Table 3.

Triangular intuitionistic fuzzy parameters.

| Parameters | Highly consumed COVID-19 medical equipments |

|||||

|---|---|---|---|---|---|---|

| Medical gown | Face mask | Face shield | Hand gloves | Hand sanitizer | Shoe cover | |

| (30,32,34; 28,32,36) | (34,36,38; 32,36,40) | (38,40,42; 36,40,44) | (35,39,43; 33,39,45) | (38,40,42; 36,40,44) | (35,37,39; 34,37,40) | |

| (60,65,70; 55,65,75) | (66,69,72; 65,69,73) | (71,74,77; 70,74,78) | (25,27,29; 24,29,34) | (35,39,43; 33,39,45) | (50,53,56; 49,53,57) | |

| (30,32,34; 28,32,36) | (34,36,38; 32,36,40) | (38,40,42; 36,40,44) | (35,39,43; 33,39,45) | (38,40,42; 36,40,44) | (35,37,39; 34,37,40) | |

| (28,29,30; 27,29,31) | (35,37,39; 34,37,40) | (42,44,46; 40,44,48) | (33,36,39; 32,36,40) | (25,27,29; 24,27,30) | (45,48,51; 44,48,52) | |

| (30,32,34; 28,32,36) | (34,36,38; 32,36,40) | (38,40,42; 36,40,44) | (35,39,43; 33,39,45) | (38,40,42; 36,40,44) | (35,37,39; 34,37,40) | |

| (40,42,44; 38,42,46) | (45,48,51; 44,48,52) | (50,55,60; 45,55,65) | (60,65,70; 58,65,77) | (66,69,72; 65,69,73) | (25,27,29; 24,29,34) | |

| (44,48,52; 42,48,54) | (50,53,56; 49,53,57) | (55,59,63; 54,59,64) | (52,56,60; 50,56,62) | (60,63,66; 58,62,66) | (35,39,43; 33,39,45) | |

| (34,36,38; 32,36,40) | (66,69,72; 65,69,73) | (52,56,60; 50,56,62) | (60,63,66; 59,63,67) | (66,67,68; 65,67,69) | (50,53,56; 49,53,57) | |

| (52,56,60; 50,56,62) | (60,63,66; 59,63,67) | (66,69,72; 65,69,73) | (66,67,68; 65,67,69) | (50,53,56; 49,53,57) | (34,36,38; 32,36,40) | |

| (50,53,56; 49,53,57) | (34,36,38; 32,36,40) | (66,69,72; 65,69,73) | (52,56,60; 50,56,62) | (66,67,68; 65,67,69) | (60,63,66; 59,63,67) | |

| (34,36,38; 32,36,40) | (66,69,72; 65,69,73) | (66,67,68; 65,67,69) | (50,53,56; 49,53,57) | (66,69,72; 65,69,73) | (34,36,38; 32,36,40) | |

| (28,29,30; 27,29,31) | (35,37,39; 34,37,40) | (42,44,46; 40,44,48) | (50,53,56; 49,53,57) | (34,36,38; 32,36,40) | (66,69,72; 65,69,73) | |