Abstract

Background

The storability and eventual quality of flour is influenced by the optimality of the storage conditions. The present study assessed the effect of storage temperature on extruded composite flour packed in different packages.

Methods

Oats, soybean, linseed and premix (sugar, salt, Moringa & fenugreek) were blended and extruded. The extruded flour was packed in paper, polyethene and woven polypropylene bags and stored at -18, 25, 35, 45 °C. Moisture content, fat content, water activity, bulk density, aroma, color and microbial load were measured fortnightly for three months.

Results

The physico-chemical and sensory properties of the flour samples were significantly (p < 0.05) affected by the storage temperature and packaging material along the storage period. The highest moisture content (4.02 g/100g) was recorded on the 90th day of storage for flour stored in polypropylene bag at -18 °C. The highest water activity (0.68) was recorded from flour packed in woven polypropylene bags stored at 25 °C for 45 days and flour packed in paper bags at days 15 and 45 at 35 °C, whereas the lowest aw (0.18) was recorded for samples stored for 90 days at 45 °C packed in polypropylene bags. Flour samples packed in polyethene bags retained their moisture content. The highest bulk density (0.61 g/ml) was recorded on day 0 and it decreased gradually where the lowest value (0.51 g/ml) was recorded for flour samples packed in polypropylene for 90 days at -18 °C. The highest fat content (9.4g/100g) was recorded at day 0 and it decreased slowly during the storage period where the lowest value (8.2g/100g) was measured from flour samples packed in polypropylene for 90 days at 45 °C. None of the treatments had a microbial load exceeding the standards which could be attributed to extrusion of the food samples. The highest aroma and color liking scores were recorded on the 90th day of storage for woven polypropylene packed flour at 25 °C and for polyethylene packed flour at -18 °C, respectively. The predicted shelf life was 17 months for samples packed in polyethene and kept at 25 °C and 6.2 months for samples packed in polypropylene and held at 45 °C.

Conclusions

Woven polypropylene flour bags could be laminated or have a polyethylene liner, so that the flour does not absorb moisture. Shelf stability of the flour can help its successful marketing and distribution.

Keywords: Storage stability, Packaging, Extruded composite flour, Q10

Storage stability; packaging; extruded composite flour, Q10

1. Introduction

Fortification of cereal flours with nutrient-rich ingredients to improve nutritional, functional and sensory attributes has been well documented. Incorporation of protein-rich ingredients like legume flour improves not only protein quality but also sensory characteristics in the final product (Sharma et al., 2013). Similarly, incorporation of functional ingredients like oilseed flours into cereal-based products provide an appreciable amount of bioactive compounds such as dietary fibre and linolenic acid (Moraes et al., 2010). Blending of cereals and pulses for making food products is widely practiced in some countries as a strategy of cereal import reduction (Omeire et al., 2014). Generally, products with improved nutrient content and acceptable sensory attributes can be produced from cereal-pulse-oilseed composite flour.

Extrusion of composite flour to produce different high-value products is also reported. Extrusion involves a high temperature short time process for making food products, usually from cereals (Pérez-Navarrete et al., 2006). Other ingredients such as pulses and oilseeds are also commonly used. The characteristics of the food product is significantly affected by the type and proportion of ingredients used (Wani et al., 2015). Extruded composite flour can be potentially used for making snacks, noodles, infant foods etc (Mouquet et al., 2003; Omeire et al., 2014; Wani et al., 2015).

Flour's storability and shelf life depend on several factors. Intrinsic factors like water content and composition, and extrinsic factors such as temperature, package, gases or vapours affect physical, chemical, and biochemical changes in stored flour (Li et al., 2017). For composite extruded products, proportion of the ingredients and moisture and oxygen migration through the package affect the quality characteristics during storage (Shaviklo et al., 2015). Generally, the stability of a food product is a function of the processing techniques and storage conditions (Li et al., 2017).

Temperature and type of packaging materials are important factors in controlling flour deterioration. The shelf-life of fresh flour can be extended by regulating such parameters (Li et al., 2017). To realise the flour's full potential in food processing, either alone or together with other ingredients, understanding of the effects of storage temperature and packaging materials on physico-chemical, microbial and sensory properties of the stored flour is essential. Iqbal and Fitzpatrick (2006) stated that exposing of flours to some temperature and relative humidity has can lead to caking of the flour. The use of improper packaging materials is serious postharvest challenge, which affects the quality and shelf life of flour. Flour can readily take up and retain moisture during transportation and storage. Packaging materials differ in thier permeability to oxygen and moisture and choice of appropriate packaging material is vital.

In our previous work (Forsido et al., 2019), extruded composite flour with optimal nutrient content and a baby food acceptable sensory properties was developed based on a mixture of 55.0 g/100g oats (popular carbohydrate-rich ingredient for making complementary food), 21.0 g/100g soybean (a protein-rich ingredient) and 9.0 g/100g linseed (a fat-rich ingredient) and 15 g/100g premixes (for micronutrient supplementation and to enhance sensory attributes) of fenugreek, moringa, sugar and salt. The objective of this study is to investigate the physical, chemical, microbial and sensory changes of this extruded composite baby food flour that occur during storage under varying temperature and packaging conditions.

2. Materials and methods

2.1. Experimental materials and sample preparation

Oats (Sinana One), Soybean (Clark 63K), Linseed (Kulumsa One) and a premix of fenugreek (Chala), Moringa stenopetala, iodised salt and sugar were used in this study. The plant materials were collected from different agricultural research centers in Ethiopia and salt and sugar were bought from a supermarket. The preparation of the composite extruded complementary food flour is discussed in our previous paper (Forsido et al., 2019). Three packaging materials namely paper, polyethene (PE) and woven polypropylene (PP) bags (Figure 1) were purchased from a supermarket. These packaging materials are commonly used in the supply chain of flours in Ethiopia. Main characteristics of evaluated packages are presented in Table 1.

Figure 1.

Packaging materials used in this experiment namely paper, polyethene and woven polypropylene bags.

Table 1.

Main characteristics of evaluated packages (Wang et al., 2018).

| Package Material | Thickness (μm) | WVP# | OP |

|---|---|---|---|

| Paper¥ | 63 | 319 | 345,043- |

| Polyethylene$ | 30 | 86 | 50,000–200,000 |

| Polypropylene | 35 | 7–20 | 50,000–100,000 |

#WVP: moisture permeability in g·μm/m2·day·kPa; OP: oxygen permeability in cm3·μm/m2·day·atm.

¥Substrate: paper, 60 g/m2,63 μm; Coating: 10.93 μm Shellac topcoat +3.33 μm Cellulose microfibril basecoat

$Woven polypropylene is categorized as open (not hermetic) container (Williams et al., 2017) and the moisture and oxygen permeability are expected to be much higher than mentioned here.

2.2. Storage stability tests

The flour samples (250 g) were packed in paper, polyethene and polypropylene bags of 20 cm by 25.5 cm. The samples were incubated at four different temperatures: -18 °C (deep freezer, not frost free model, Ugur, UCF 600 S), 25±3 °C (room), 35 °C (growth cabinet, RGX 250), and 45 °C (incubator, MJX 150 B) for three months. The mean relative humidity in the deep freezer, room, growth cabinet and incubator were 50 ± 0.5, 39 ± 1, 28.9 ± 0.5 and 15.5 ± 0.5%, respectively. Samples were removed at fifteen-day intervals and analysed for change in quality. The different rates of deterioration occurring in the sealed samples at different temperatures were used in calculating the shelf life of the flour samples (Labuza, 1979). As we used several fat-rich ingredients (linseed and soybean), we chose crude fat content to be used as the index for deterioration and shelf life estimation. The Arrhenius plots (log k vs 1/T) were used to obtain the activation energies, Ea, from which the temperature quotient (Q10) was calculated and shelf life at lower temperatures was predicted using Q10 values (Plahar et al., 2003).

2.3. Experimental design and treatments

An experiment having three factors was laid out in a completely randomised design (CRD) and replicated three times. The three factors used in this experiment were storage temperature, packaging materials and storage time. Three levels for packaging materials (paper bag, polyethene bag and woven polypropylene), four levels of storage temperature (-18, 25, 35 and 45 °C) and seven levels of time (0, 15, 30, 45, 60, 75 and 90 days) were combined in a factorial arrangement. Even if it is important to control relative humidity as it could play an important role in moisture migration and chemical reactions as consequence, due to limitation in facility we tried to offset this by using different packaging materials with different water vapour transmission rate.

2.4. Measurements

The flour samples were evaluated for water activity, bulk density, moisture content (MC) and fat content. Data were collected every two weeks for all samples. Water activity (aw) was measured by half-filling the sample cups of water activity meter (LabMaster, CSC Scientific Company, Inc) with 5g flour. The prepared sample was placed in the sample drawer and the sample cup was sealed with the chamber. The aw of powder was determined at 21 °C during about 5 min (Rhim and Hong, 2011). Bulk density, on the other hand, was determined by adding fifty grams of flour into a graduated cylinder (100 ml) and tapping to a constant volume. Bulk density (g/cm3) is defined as the weight of a unit volume of flour (Okaka and Potter, 1979).

The moisture content and crude fat content (dry matter basis) of the flour samples were determined following the Association of Official Analytical Chemists (AOAC) method 925.10 and method 920.39, respectively (AOAC International, 2005).

Total aerobic microbes were counted for extruded composite baby food flour using the pour plate method. Appropriate dilutions of the samples were plated onto sterile Plate Count Agar (PCA) plates, and 36 h of incubation at 30 °C (Swanson et al., 1992). Total coliforms were counted by surface plating on the standard medium violet red bile agar and 24–48 h of incubation at 35 °C (Hitchins et al., 1992). For thermophilic bacteria, appropriate dilutions were surface –plated on MRS agar (de Man-Rogosa-Sharpe) (Merck) containing 0.02% sodium azide followed by 48 h of incubation at 42 °C (Sengun et al., 2009). For yeast and molds enumeration, 1 ml of appropriate dilution was placed into acidified (10% tartaric acid) potato dextrose agar (PDA) plates followed by 72 h incubation at 25 °C was added to the PDA so that bacterial growth is inhibited (Mislivec et al., 1992). Plates containing 10–150 colony forming units per gram (CFU/g) were counted (Benson, 1990).

2.5. Sensory evaluation

Twenty five untrained mothers who had children age of 6–24 months and were selected to do the sensory analysis for each time point from a record controlled by the RELOAD project at Jimma University. The inclusion criteria were no impairment to vision, smell, or taste and willingness to participate in the test. The study was approved by the Ethical Review Board of Jimma University (R/GS/160/2006) and is in accordance with the Declaration of Helsinki. Informed consent was obtained from each participant.

Twelve flour samples were presented to participants in off-white, noise-controlled sensory analysis booth. The flour samples were put on a white, 10-cm diameter circular plate labelled with three random digits. Latin square design was used to randomize the serving order across consumers. Consumers rated the color liking, and aroma liking. Liking were evaluated using a five point hedonic scale rated from 1 = dislike extremely to 5 = like extremely (Muhimbula et al., 2011). This procedure was repeated every fifteen days starting with beginning (or Day 0) until the end of the storage (day 90).

2.6. Statistical analysis

Analysis of variance was used to determine the effects of storage temperature (numeric), packaging materials (categoric) and storage time (numeric) on aw, bulk density, moisture content, fat content, color liking, aroma liking, and microbial load of extruded composite flour at the 5% level of significance. All analyses, except for microbial and sensory analysis, were repeated three times (n = 3) per replication. Model assumptions were validated (Montgomery, 2013). Data were analysed using Minitab Statistical Software, Version 16.0 for windows.

3. Results and discussion

ANOVA result showed that moisture content and aw of the flour was significantly influenced by the interaction between storage temperature, packaging material and storage duration. Only aw was affected considerably by the interaction of packaging material and storage temperature. On the contrary, all response variables were significantly influenced by the interaction of storage temperature and duration. Moisture content, aw and fat content of the stored flour samples were also significantly affected by the interaction effect of packaging material and storage time. The main effects of all factors did significantly affect all measured responses of the stored samples (Table 2).

Table 2.

ANOVA p-values for main and interaction effects of storage temperature (A), packaging material (B) and storage duration (C) on chemical, physical and sensory properties of extruded composite flour.

| Term | Moisture (g/100g) | aw | Fat (g/100g) | BD (g/ml) | Aroma Liking | Color Liking |

|---|---|---|---|---|---|---|

| A | 0.000∗ | 0.000∗ | 0.000∗ | 0.000∗ | 0.000∗ | 0.000∗ |

| B | 0.000∗ | 0.000∗ | 0.000∗ | 0.000∗ | 0.276 ns | 0.076 ns |

| C | 0.000∗ | 0.000∗ | 0.000∗ | 0.000∗ | 0.000∗ | 0.000∗ |

| A∗B | 0.296ns | 0.000∗ | 0.197 ns | 0.503ns | 0.002∗ | 0.742 ns |

| A∗C | 0.003∗ | 0.000∗ | 0.000∗ | 0.000∗ | 0.000∗ | 0.000∗ |

| B∗C | 0.000∗ | 0.000∗ | 0.000∗ | 0.037∗ | 0.924 ns | 0.252 ns |

| A∗B∗C | 0.009∗ | 0.000∗ | 0.912 ns | 0.625 ns | 0.957 ns | 0.972 ns |

| Predicted R-Sq | 0.9667 | 0.9633 | 0.9899 | 0.9304 | 0.7557 | 0.7735 |

| Adjusted R-Sq | 0.9502 | 0.945 | 0.9877 | 0.896 | 0.6350 | 0.6616 |

Significant difference was considered at p ≤ 0.05.

3.1. Moisture content

Figure 2 shows that throughout the storage period, the flour contained more moisture at low temperature (-18 °C) than at high temperature (45 °C). The highest moisture content (4.02g/100g) was measured for flour stored in polypropylene bag at -18 °C on the 90th day of storage. The rise in MC in the flour was because of the water vapor permeability of the woven PP bags, higher relative humidity present in the deep freezer and hygroscopic nature of the flour. Even if our study provides evidence that statistically significant difference in moisture content exists, but it is too small to be meaningful in the real world. Flour samples packed in PE exhibited a constant MC. This finding is consistent with a record by Williams et al. (2017) who reported that sorghum seeds stored in hermetic bags exhibited little change in MC while woven bags facilitated moisture equilibration between the grains and ambient environment (Williams et al., 2014). Woven PP flour sacks could be laminated or have a polyethylene liner, so that the flour does not absorb moisture. Moisture content in food can have a significant impact on product's quality and shelf life (Li et al., 2017). Flour is a moisture-sensitive product and long-term storage using permeable packaging materials can lead to absorption of moisture by the flour (Sakač et al., 2016). On the other hand, increased moisture content in flour disfavours its shelf life stability (Eleazu et al., 2012). Increase in moisture content can enhance the activities of microorganisms which can lead to deterioration of flour.

Figure 2.

Moisture content changes of extruded composite baby food flour stored at different temperatures and packaging materials.

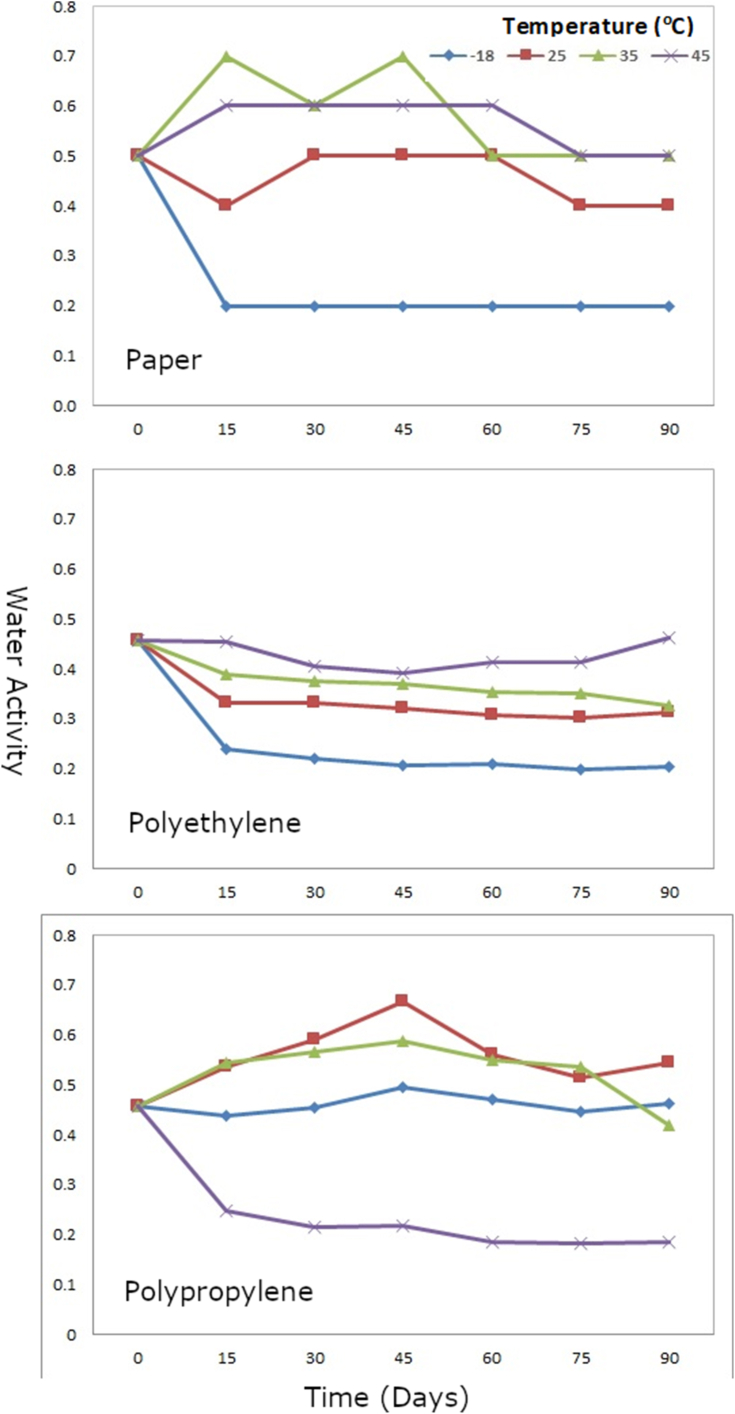

3.2. Water activity

Figure 3 presents the water activity values of the stored extruded composite flour samples. The highest aw (0.68) was recorded from flour packed in woven PP bags stored at 25 °C for 45 days and flour packed in paper bags at days 15 and 45 at 35 °C. The lowest aw (0.18) was recorded for samples stored for 90 days at 45 °C packed in woven PP bags. The possible explanation for the strange water activity readings recorded among flour samples packed in woven PP bags could be the fact that this packaging material is not hermetic, which means moisture and other gases can penetrate the package. A study by Williams et al. (2017) reported that large fluctuations in relative humidity of the storage environment did not lead to humidity changes inside hermetic bags. On the contrary, a close change in humidity was observed between inside of the woven bags and ambient environment. Water activity is defined as equilibrium relative humidity divided by 100. In very low aw (<0.2) the rate of deteriorative changes like lipid oxidation is higher (Rahman, 2010). Except for woven PP bags, flour samples stored at higher temperature had the highest aw. This is in agreement with the increase in aw with increase in temperature for foods (Labuza et al., 1985). The results of aw are consistent with that of MC. This similarity could be caused by the process of vapour transmission. Water vapour can transmit through a packaging material via two processes, namely diffusion and sorption-desorption (Venkataraman et al., 2014). Woven polypropylene is categorized as open (not hermetic) container (Williams et al., 2017) and pore size of fabrics is significantly correlated with air permeability (Epps and Leonas, 2000). Figure 3 indicates that the water activity values of flour samples stored in polyethylene were relatively constant, even at elevated temperature, as compared to paper and woven PP bags. Therefore, polyethylene is the best material for flour packaging based only on aw. Water activity is a more meaningful predictor of food quality and shelf life than moisture content (Li et al., 2017). Water activity is closely related to the physical, chemical and microbial properties of flour (Maltini et al., 2003). Textural changes in the stored products could partly attributed to the changes in aw during storage. Products which are characterised by lower aw values (aw < 0.6) are characterized by long shelf life (Sakač et al., 2016). Low aw is recommended for flour storage. Care should be taken not to store flour samples in conditions that increase aw for this could predispose flour to biochemical changes leading to irreversible organoleptic changes (Abdullah et al., 2000).

Figure 3.

Water activity changes of extruded composite baby food flour stored at different temperatures and packaging materials.

3.3. Bulk density

As shown in Figure 4, the bulk density of the stored flour decreased significantly with storage time, and the decline was more prominent at -18 °C. On the other hand, flour samples stored at 45 °C showed consistently higher bulk density values throughout the storage period in all the three packaging materials. Flour samples packed in polypropylene bags and for a more extended period had the lowest bulk density values. Our results showed an inverse relationship between changes in bulk density and moisture content. The bulk density of soybean grains decreased with increasing moisture content (Tavakoli et al., 2009). The explanation given is the rise in mass because of water influx to the sample was less than associated expansion of the sample in all directions (Pradhan et al., 2008). Bulk density, which measures the density of a material, is a valuable physical property a large scale production of a material (Wani et al., 2015). The packaging requirement and material handling of flour are determined mainly by its bulk density (Adebowale et al., 2012). The tapped bulk density indicates more food samples are packed in the package, and can be considered less economical to the producer. Nutritionally, untapped (loose) bulk density promotes easy digestibility of food products, especially for kids with an immature digestive system (Ijarotim and Keshinro, 2012; Omeire et al., 2014).

Figure 4.

Bulk density changes of extruded composite baby food flour stored at different temperatures and packaging materials.

3.4. Crude fat content

A significant decrease in fat content was observed for samples stored for a longer duration (Figure 5). Fat content decreased by 0.8% between day 0 and day 90. Our finding is in line with a study which evaluated the fat contents in four varieties of almond during storage and reported that the fat contents significantly decreased upon storage, except for one variety (García-Pascual et al., 2003). Another study on storage stability of indigenous Fe fortified fruit bars which indicated that fat content followed a decreasing trend in 60 days, which decreased by 0.15–0.19% (Zahra et al., 2020). Lipid oxidation is the explanation for the decrease in fat content during prolonged storage. A study on meat tissue indicated that thiobarbituric acid reactive substances (TBARS), which is an indicator of lipid oxidation, was negatively correlated with fat content (Sasaki et al., 2001). Flour samples packed in woven PP bags exhibited the highest decline in fat content with storage duration. Lipid oxidation is higher at lower aw (<0.2) (Rahman, 2010), which is in line with our finding where higher fat loss was recorded for flour samples packed in woven PP at 45 °C whose aw was below 0.2. Flour samples stored at 45 °C also showed a similarly sharp drop in fat content with storage duration. The changes in the fat content of extruded composite flour samples stored at -18 °C and 25 °C followed a similar trend. Fat contents of the samples decreased progressively during storage the decline was more pronounced at higher temperature than ambient conditions. A measurement of the oxidation of linoleic acid in stored corn flour also showed that masas stored at higher temperatures (>55 °C) would show proof of rapid rancidity (lipid oxidation) than at lower temperature (López-Duarte and Vidal-Quintanar, 2009). The low-fat values were observed in the more extended stored flours relative to short stored powders. The primary explanation for reduction in fat content could be that fatty acids react with oxygen, resulting in oxidative deterioration of lipids. The production of reactive oxygen species, like the superoxide anion (O2-) and hydroxyl radical (OH−) is catalyzed by temperature. These reactive oxygen species increase the rate of lipid peroxidation by breaking down the preformed lipid peroxide to peroxyl or alkoxyl radicals (Lee and Hendricks, 1997; López-Duarte and Vidal-Quintanar, 2009).

Figure 5.

Fat content changes of extruded composite baby food flour stored at different temperatures and packaging materials.

3.5. Microbial analysis

At the beginning of storage the baby food flour had 103 thermophiles, 103 mesophiles/g with nil coliforms, yeasts, and molds. This result is consistent with (Rampersad et al., 2003) who reported that the high temperature range of 120–125 °C used for extrusion cooking was helpful in killing/reducing the number of microorganisms. After 90 days of storage, there was still generally low growth of microbes in the stored baby food flour samples (106 CFU/g total aerobic bacteria (mesophiles), 104 CFU/g thermophiles, 500 CFU/g yeast and mould count and coliforms absent in 1 g) and microbial growth was less in polyethylene and paper bags than in woven polypropylene bag. Woven polypropylene is categorized as open (not hermetic) container (Williams et al., 2017) and the moisture and oxygen permeability are expected to be much higher than mentioned in Table 1. Due to a higher moisture and O2 transmission (since it is not hermetic), the microbial contamination and its growth was promoted in the woven polypropylene bag. Extrusion of the food samples could contribute to the low microbial load. Thermal food processing techniques such as extrusion and roasting improve keeping qualities by reducing microbial load, and enzyme activity and destruction of insects. According to Fontana (2008), certain conditions like proper pH, water activity, right temperature and nutrients and time are needed for microbial proliferations in foods. Microbial growth can be prevented and shelf life of a food can be extended by controlling these conditions. Periodic verification of compliance with the requirements of food quality and safety management systems is recommended.

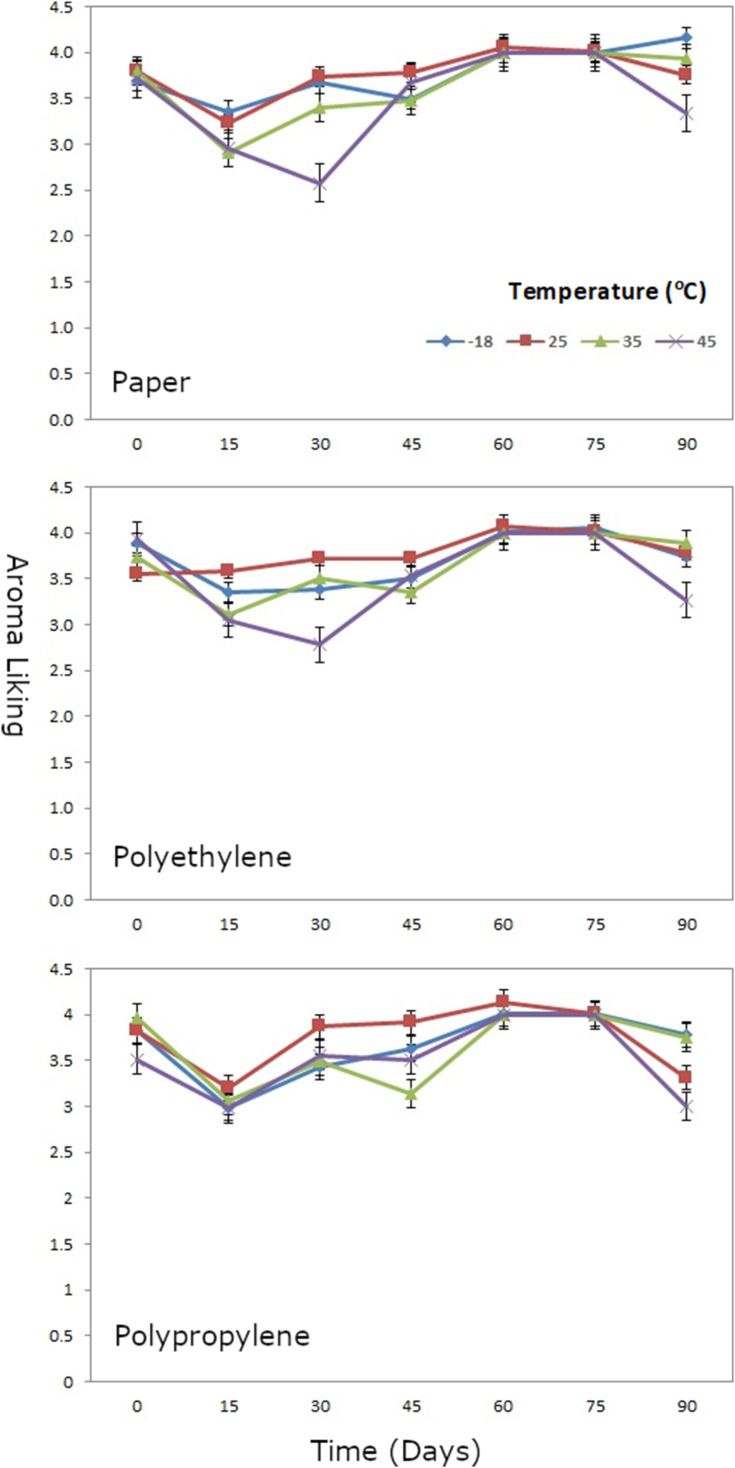

3.6. Sensory properties

3.6.1. Aroma

As shown in Figure 6, there was an increase in aroma liking with increasing storage time up to 75 days of storage regardless of packaging material. The aroma liking of flour stored in all packaging materials at 45 °C was slightly lower in all storage periods. Aroma of flour stored at 35 °C was better than others storage condition, but changes of flours aroma occurred in other storage conditions. The reason for lower liking of aroma of flour recorded at 45 °C at extended period of storage could be due to low temperature cooking which leads to changes in aroma.

Figure 6.

Aroma liking changes of extruded composite baby food flour stored at different temperatures and packaging materials.

The highest aroma liking (4.24) was recorded for extruded composite flour packed in woven polypropylene packed flour at 25 °C on 90 days of storage and the lowest aroma liking (2.75) was recorded for flour packed in woven polypropylene at stores at 45 °C on 75 days storage. The major causes of consumer rejection in packaged food include off-flavors, off-odors and loss of crispiness. These changes result from gain of oxygen and moisture through the package and reactions between packaging components with the food components (Han et al., 2018). Nantanga et al. (2008) reported that thermal processing can inhibit hydrolytic rancidity in pearl millet grain.

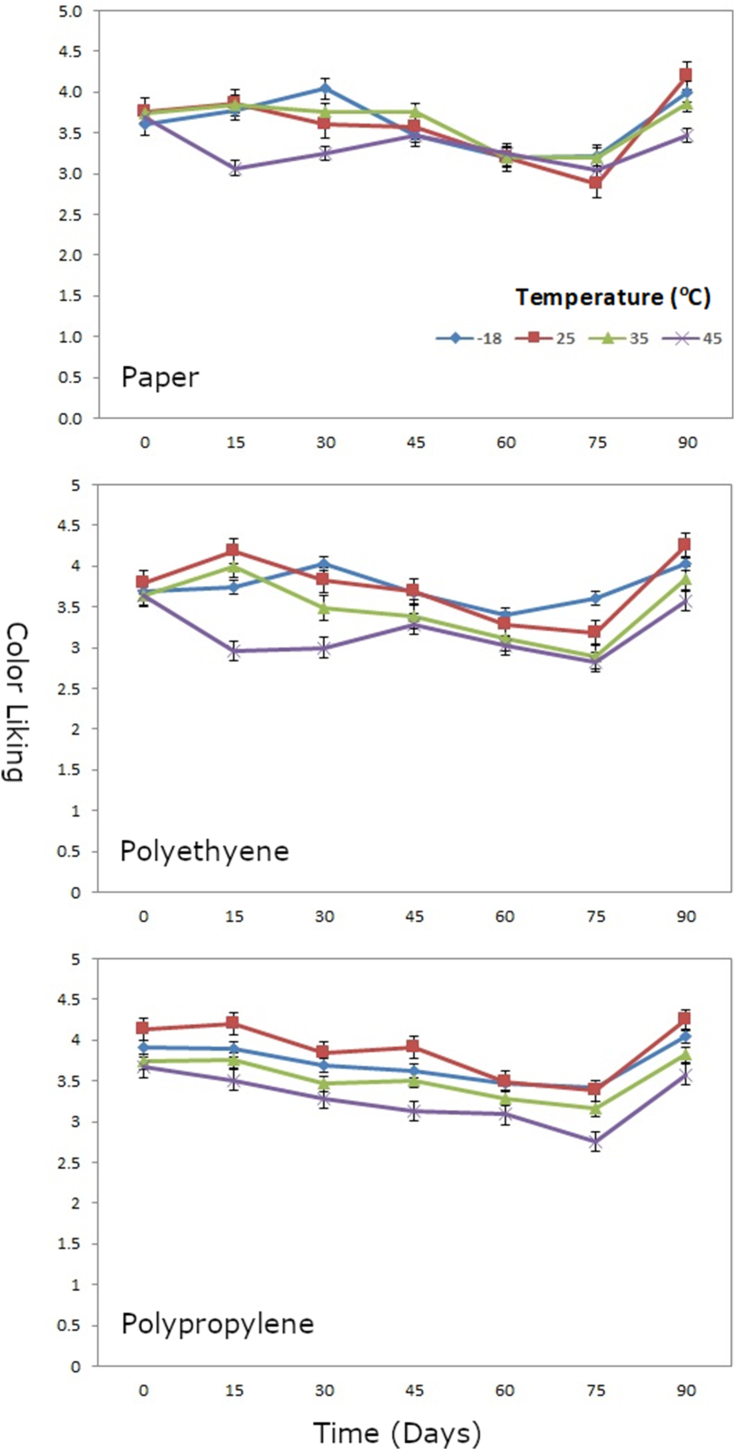

3.6.2. Color

Figure 7 shows that throughout the storage period, color liking has significantly decreased 0 up to 30 days and above 75 days of all storage temperature and packaging materials. Color liking of stored flour has increased from 30 up to 75 days in three packaging materials and storage temperature. The highest color liking (4.15) was obtained in polyethylene packed flour at -18 °C stored for 90 days and the least liking (2.57) was recorded in woven polypropylene bag at 45 °C stored for 30 days, respectively. Color is among the important factors affecting the consumer choice of stored food. Figure 7 shows that color liking did not vary much during storage, except during the final days. It has been reported that thermal treatment could reduce the activity of color changing enzymes like polyphenol oxidase (Yu et al., 2017). The change in color liking towards the end of the study period could be because of the enzymatic browning of polyphenols in the mixed flour (Hu et al., 2017).

Figure 7.

Color liking changes of extruded composite baby food flour stored at different temperatures and packaging materials.

3.7. Storage stability of extruded composite flour

In the current study, change in crude fat content was used as an index of storage stability of the extruded composite flour samples. The changes in fat content samples packed in different packaging materials during storage at different temperatures are shown in Table 3. The reduction rate of fat content was found to follow zero order kinetics at all temperatures used in the study. A faster rate of deterioration, regarding reduction in fat content, was observed in flour samples stored in polypropylene bags than in paper or polyethene bags.

Table 3.

Change in the fat content of extruded composite flour samples packed in paper, polyethene and polypropylene bags during accelerated storage tests at different temperatures.

| Storage period (Days) | Paper |

Polyethene |

Polypropylene |

||||||

|---|---|---|---|---|---|---|---|---|---|

| 25 °C | 35 °C | 45 °C | 25 °C | 35 °C | 45 °C | 25 °C | 35 °C | 45 °C | |

| 0 | 9.4 | 9.4 | 9.4 | 9.4 | 9.4 | 9.4 | 9.4 | 9.4 | 9.4 |

| 15 | 9.3 | 9.1 | 9.1 | 9.3 | 9.2 | 9.1 | 9.2 | 9.1 | 9.0 |

| 30 | 9.1 | 9.0 | 9.0 | 9.2 | 9.0 | 8.9 | 9.0 | 8.9 | 8.8 |

| 45 | 9.1 | 8.9 | 8.8 | 9.2 | 9.0 | 8.8 | 8.9 | 8.8 | 8.6 |

| 60 | 9.0 | 8.8 | 8.7 | 9.1 | 8.9 | 8.7 | 8.8 | 8.6 | 8.5 |

| 75 | 8.9 | 8.7 | 8.6 | 9.0 | 8.8 | 8.6 | 8.7 | 8.6 | 8.5 |

| 90 | 8.7 | 8.6 | 8.4 | 8.9 | 8.7 | 8.6 | 8.4 | 8.4 | 8.2 |

| Rate/day | 0.008 | 0.009 | 0.011 | 0.006 | 0.007 | 0.009 | 0.011 | 0.011 | 0.013 |

| End-point value | 6.9 | 6.9 | 6.9 | 6.9 | 6.9 | 6.9 | 6.9 | 6.9 | 6.9 |

| Shelf life (days) | 316.9 | 274.4 | 234.4 | 432.7 | 335.8 | 267.9 | 229.6 | 220.6 | 186 |

| Ea. (cals/mole) | 3152.5 | 4448.1 | 3317.6 | ||||||

| Q10 value | 1.25 | 1.38 | 1.27 | ||||||

The daily rate of fat loss for flour sample packed in paper bags was 0.0079% at 25 °C, 0.0091% at 35 °C, and 0.0107% at 45 °C. The polyethene packed flour had 0.0058, 0.0074, and 0.0093% daily rates of fat loss at 25, 35 and 45 °C, respectively. On the other hand, flour samples packed in polypropylene bags had 0.0109, 0.0113 and 0.0134% daily rate of fat loss at 25, 35 and 45 °C, respectively. In our earlier research (Forsido et al., 2019) we optimized the product so that the fat content is maximized so that the new product contains fat content as recommended by the Codex Alimentarius Commission (Codex Alimentarius Commission, 1991). The end-point values for the unacceptability of fat degradation were fixed at 6.9 g/100g, which is equal to the average fat content of oats (Souci et al., 2008). The end-point data were transformed into shelf life plots on a semi-log scale from which the shelf life of the extruded composite flour at different temperatures could be obtained. Based on the fat loss, the calculated Q10 values were 1.25, 1.38 and 1.27 for the paper, polyethene and polypropylene packed flour samples, respectively. The predicted shelf life of the products at the different temperatures based on the calculated Q10 values are given in Table 4. The extruded composite flour samples which were packed in polypropylene bags were found to have a significantly shorter shelf life than the samples packed in paper or polyethene bags at the average ambient temperature of about 25 °C in Ethiopia. The estimated shelf life of 12.2, 17.0 and 10.0 months is expected for the paper, polyethene and polypropylene packed flour samples, respectively.

Table 4.

The predicted shelf life of extruded composite flour samples at given temperatures based on the Q10.

| Temperature (◦C) | Predicted shelf life (months) |

||

|---|---|---|---|

| Paper |

Polyethene |

Polypropylene |

|

| (Q10 = 1.25) | (Q10 = 1.38) | (Q10 = 1.27) | |

| 45 | 7.81 | 8.93 | 6.20 |

| 35 | 9.77 | 12.32 | 7.87 |

| 25 | 12.21 | 17.00 | 10.00 |

| 15 | 15.26 | 23.46 | 12.70 |

| 5 | 19.07 | 32.38 | 16.12 |

The present study showed that packaging and storage temperature, as well as storage period, were an essential factor to be considered in establishing the shelf life stability of composite extruded flour. The more extended shelf life of the composite extruded flour at room temperature than in accelerated condition may be because of the relatively lower temperature and barrier properties of the packages. It was observed that the shelf life of samples packed in polyethene was more extended than that of paper and polypropylene which could be described in terms of the more elevated oxygen transmission rate of the woven polypropylene bags.

4. Conclusions

Flour samples packed in woven PP bags equilibrated their moisture with the ambient environment over the storage period, which in turn lead to the change in physicochemical properties of the stored flour. In general, packing the flour samples in woven polypropylene bags, which is commonly used for commodity storage in developing countries, was found to deteriorate the chemical, physical, sensory and microbial characteristics of the extruded composite flour. Flour sacks could be laminated or have a polyethylene liner, so that the flour does not absorb moisture. Generally, the flour samples have excellent stability with predicted shelf life periods of up to 17 months when packed in polyethene bag stored at 25 °C. Storing the flour at higher temperatures 35 °C and 45 °C is not feasible because the shelf life is reduced by 1.38 times for every 10 °C increase in temperature. Even if storing the flour at low temperature prolongs the shelf life, it may not be practically and economically feasible to store the flour at refrigerated conditions. Shelf stability of the flour can help its successful marketing and distribution.

Declarations

Author contribution statement

Sirawdink Fikreyesus Forsido: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Eyuel Welelaw: Performed the experiments; Analyzed and interpreted the data.

Tefera Belachew, Oliver Hensel: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data.

Funding statement

This work was supported by The German Federal Ministry of Education and Research (031A247A).

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

The authors are grateful for Faculty of Chemical and Food Engineering, Bahir Dar Institute of Technology for allowing us to use the extruder.

References

- Abdullah N., Nawawi A., Othman I. Fungal spoilage of starch-based foods in relation to its water activity (aw) J. Stored Prod. Res. 2000;36(1):47–54. [Google Scholar]

- Adebowale A.A., Adegoke M.T., Sanni S.A., Adegunwa M.O., Fetuga G.O. Functional properties and biscuit making potentials of sorghum-wheat flour composite. Am. J. Food Technol. 2012;7(6):372–379. [Google Scholar]

- Aoac International . eighteenth ed. AOAC International; 2005. Official Methods of Analysis of AOAC International. [Google Scholar]

- Benson H.J. Wm, C. Brown Publishers; Dubuque: 1990. Microbiological applications. A laboratory manual in general microbiology. 459 p. [Google Scholar]

- Codex Alimentarius Commission . Joint FAO/WHO Food Standards Programme Codex Alimentarius Commission; Rome: 1991. Guidelines for formulated supplementary foods for older infants and young children. [Google Scholar]

- Eleazu C.O., Eleazu K.C., Awa E., Chukwuma S.C. Comparative study of the phytochemical composition of the leaves of five Nigerian medicinal plants. J. Biotechnol. Pharmaceut. Res. 2012;3(2):42–46. [Google Scholar]

- Epps H.H., Leonas K.K. Pore size and air permeability of four nonwoven fabrics. Int. Nonwovens J. 2000;2 1558925000OS – 900215. [Google Scholar]

- Fontana A.J. Inc; 2008. Water activity and pH measurement for Food Safety, Retail Food Systems Research Conference IFT Foodservice Division, Decagon Devices. [Google Scholar]

- Forsido S.F., Duguma H.T., Lema T.B., Sturm B., Hensel O. Nutritional and sensory quality of composite extruded complementary food. Food Sci. Nutr. 2019;7(2):882–889. doi: 10.1002/fsn3.940. [DOI] [PMC free article] [PubMed] [Google Scholar]

- García-Pascual P., Mateos M., Carbonell V., Salazar D.M. Influence of storage conditions on the quality of shelled and roasted almonds. Biosyst. Eng. 2003;84(2):201–209. [Google Scholar]

- Han J.-W., Ruiz-Garcia L., Qian J.-P., Yang X.-T. Food Packaging: A Comprehensive Review and Future Trends. Comprehen. Rev. Food Sci. Food Safe. 2018;17(4):860–877. doi: 10.1111/1541-4337.12343. [DOI] [PubMed] [Google Scholar]

- Hitchins A.D., Hartman P.A., Todd E.C.D. Coliforms—Escherichia coli and its toxins. In: Vanderzant C., Splittstoesser D.F., editors. Compendium of Methods for the Microbiological Examination of Foods. American Public Health Association; Washington, DC: 1992. pp. 325–369. [Google Scholar]

- Hu Y., Wei Z., Chen Y. Quality changes of fresh dumpling wrappers at room temperature. Acta Univ. Cibiniensis. Series E: Food Technol. 2017;21:63–72. [Google Scholar]

- Ijarotim O.S., Keshinro O.O. Formulation and nutritional quality of infant formula produced from germinated popcorn, Bambara groundnut and african locust bean flour. J. Microbiol. Biotechnol. Food Sci. 2012;1(6):1358–1388. [Google Scholar]

- Iqbal T., Fitzpatrick J.J. Effect of storage conditions on the wall friction characteristics of three food powders. J. Food Eng. 2006;72(3):273–280. [Google Scholar]

- Labuza T.P. A theoretical comparison OF losses IN foods under fluctuating temperature sequences. J. Food Sci. 1979;44(4):1162–1168. [Google Scholar]

- Labuza T.P., Kaanane A., Chen J.Y. Effect of temperature on the moisture sorption isotherms and water activity shift of two dehydrated foods. J. Food Sci. 1985;50(2):385–392. [Google Scholar]

- Lee B.J., Hendricks D.G. Metal-catalyzed oxidation of ascorbate, deoxyribose and linoleic acid as affected by phytic acid in a model system. J. Food Sci. 1997;62(5):935–984. [Google Scholar]

- Li M., Ma M., Zhu K.-X., Guo X.-N., Zhou H.-M. Critical conditions accelerating the deterioration of fresh noodles: a study on temperature, pH, water content, and water activity. J. Food Process. Preserv. 2017;41(4):e13173. [Google Scholar]

- López-Duarte A.L., Vidal-Quintanar R.L. Oxidation of linoleic acid as a marker for shelf life of corn flour. Food Chem. 2009;114(2):478–483. [Google Scholar]

- Maltini E., Torreggiani D., Venir E., Bertolo G. Water activity and the preservation of plant foods. Food Chem. 2003;82(1):79–86. [Google Scholar]

- Mislivec P.B., Beuchat L.R., Cousin M.A. Yeasts and molds. In: Vanderzant C., Splittstoesser D.F., editors. Compendium of Methods for the Microbiological Examination of Foods. American Public Health Association; Washington DC: 1992. pp. 239–249. [Google Scholar]

- Muhimbula H.S., Issa-Zacharia A., Kinabo J. Formulation and sensory evaluation of complementary foods from local, cheap and readily available cereals and legumes in Iringa, Tanzania. Afr. J. Food Sci. 2011;5(1):26–31. [Google Scholar]

- Montgomery D.C. 8th ed. Wiley; 2013. Design and Analysis of Experiments. [Google Scholar]

- Moraes É.A., Dantas M.I. de S., Morais D. de C., da Silva C.O., de Castro F.A.F., Martino H.S.D., Ribeiro S.M.R. Sensory evaluation and nutritional value of cakes prepared with whole flaxseed flour. Ciência Tecnol. Aliment. 2010;30(4):974–979. [Google Scholar]

- Mouquet C., Salvignol B., Van Hoan N., Monvois J., Trèche S. Ability of a “very low-cost extruder” to produce instant infant flours at a small scale in Vietnam. Food Chem. 2003;82(2):249–255. [Google Scholar]

- Nantanga K.K., Seetharaman K., de Kock H.L., Taylor J.R. Thermal treatments to partially pre-cook and improve the shelf-life of whole pearl millet flour. J. Sci. Food Agric. 2008;88(11):1892–1899. [Google Scholar]

- Okaka J.C., Potter N.N. PHYSICO-CHEMICAL and functional properties OF cowpea powders processed to reduce beany flavor. J. Food Sci. 1979;44(4):1235–1240. [Google Scholar]

- Omeire G.C., Umeji O.F., Obasi N.E. Acceptability of noodles produced from blends of wheat, acha and soybean composite flours. Niger. Food J. 2014;32(1):31–37. [Google Scholar]

- Pérez-Navarrete C., González R., Chel-Guerrero L., Betancur-Ancona D. Effect of extrusion on nutritional quality of maize and Lima bean flour blends. J. Sci. Food Agric. 2006;86(14):2477–2484. [Google Scholar]

- Plahar W.A., Okezie B.O., Annan N.T. Nutritional quality and storage stability of extruded weaning foods based on peanut, maize and soybean. Plant Foods Hum. Nutr. 2003;58(3):1–16. [Google Scholar]

- Pradhan R.C., Naik S.N., Bhatnagar N., Swain S.K. Moisture-dependent physical properties of Karanja (Pongamia pinnata) kernel. Ind. Crops Prod. 2008;28(2):155–161. [Google Scholar]

- Rampersad R., Badrie N., Comissiong E. Physico-chemical and Sensory characteristics of flavored snacks from extruded Cassava/Pigeonpea Flour. J. Food Sci. 2003;68(1):363–367. [Google Scholar]

- Rahman M.S. Food stability determination by macro–micro region concept in the state diagram and by defining a critical temperature. J. Food Eng. 2010;99(4):402–416. [Google Scholar]

- Rhim J.-W., Hong S.-I. Effect of water activity and temperature on the color change of red pepper (Capsicum annuum L.) powder. Food Sci. Biotechnol. 2011;20(1):215–222. [Google Scholar]

- Sakač M., Pestorić M., Mandić A., Mišan A., Nedeljković N., Jambrec D., Jovanov P., Lazić V., Pezo L., Sedej I. Shelf-life prediction of gluten-free rice-buckwheat cookies. J. Cereal. Sci. 2016;69:336–343. [Google Scholar]

- Sasaki K., Mitsumoto M., Kawabata K. Relationship between lipid peroxidation and fat content in Japanese Black beef Longissimus muscle during storage. Meat Sci. 2001;59(4):407–410. doi: 10.1016/s0309-1740(01)00093-6. [DOI] [PubMed] [Google Scholar]

- Sengun I.Y., Nielsen D.S., Karapinar M., Jakobsen M. Identification of lactic acid bacteria isolated from Tarhana, a traditional Turkish fermented food. Int. J. Food Microbiol. 2009;135(2):105–111. doi: 10.1016/j.ijfoodmicro.2009.07.033. [DOI] [PubMed] [Google Scholar]

- Sharma C., Punia D., Khetarpaul N. Sensory characteristics, proximate composition, dietary fibre content and storage stability of barley, wheat and chickpea composite flour biscuits. Br. Food J. 2013;115(6):876–883. [Google Scholar]

- Shaviklo A.R., Azaribeh M., Moradi Y., Zangeneh P. Formula optimization and storage stability of extruded puffed corn-shrimp snacks. LWT - Food Sci. Technol. 2015;63(1):307–314. [Google Scholar]

- Souci S.W., Fachmann W., Kraut H. seventh ed. MedPharm; 2008. Food Composition and Nutrition Tables. [Google Scholar]

- Swanson K.M.J., Busta F.F., Peterson E.H., Johnson M.G. Colony count methods. In: Vanderzant C., Splittstoesser D.F., editors. Compendium of Methods for the Microbiological Examination of Foods. American Public Health Association; Washington, DC: 1992. pp. 80–87. [Google Scholar]

- Tavakoli H., Rajabipour A., Mohtasebi S.S. Moisture-dependent some engineering properties of soybean grains. Agric. Eng. Int.: CIGR J. 2009 [Google Scholar]

- Venkataraman M., Mishra R., Militky J., Hes L. Aerogel based nanoporous fibrous materials for thermal insulation. Fibers Polym. 2014;15(7):1444–1449. [Google Scholar]

- Wang J., Gardner D.J., Stark N.M., Bousfield D.W., Tajvidi M., Cai Z. Moisture and oxygen barrier properties of cellulose nanomaterial-based films. ACS Sustain. Chem. Eng. 2018;6(1):49–70. [Google Scholar]

- Wani S., Solanke N., Kumar P. Extruded product based on oat and fenugreek and their storage stability. Curr. Nutr. Food Sci. 2015;11(1):78–84. [Google Scholar]

- Williams S.B., Baributsa D., Woloshuk C. Assessing Purdue Improved Crop Storage (PICS) bags to mitigate fungal growth and aflatoxin contamination. J. Stored Prod. Res. 2014;59:190–196. [Google Scholar]

- Williams S.B., Murdock L.L., Baributsa D. Sorghum seed storage in Purdue Improved Crop Storage (PICS) bags and improvised containers. J. Stored Prod. Res. 2017;72:138–142. [Google Scholar]

- Yu X., Chen J., Zhou Z. Effect of microwave treatment on color and quality of fresh wet flour. J. Henan Univ. Technol. 2017;38:35–41. [Google Scholar]

- Zahra S.M., Hussain S., Mahmood S., Kausar T., Mueen Ud Din G., Tufail T., Altaf N., Yousaf Quddoos M., Rafique A., Zia Shahid M. Shelf stable iron fortified fruit bar’s development, proximate estimation and organoleptic characterization. Int. J. Biosci. 2020;2020 [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.