Abstract

Purpose

to review advances and clinical performance of polyethylene in total joint arthroplasty, summing up historical problems and focusing on the latest innovations.

Methods

search for medical grade Ultra-High-Molecular-Weight-Polyethylene (UHMWPE); Data Sources: PubMed, Scopus, Cochrane Library.

Results

the increasing number of joint arthroplasties and high-activity patients led to progressive developments of bearing surfaces to improve performance and durability. Different strategies such as crosslinking UHMWPE (HXLPE) and the addition of vitamin-E (HXLPE) have been tested to improve wear and oxidation resistance.

Conclusion

Recent innovations about UHMWPE showed improvements either for hip and knee, with the potential of long-term survivorship.

Keywords: Polyethylene, UHMWPE, Crosslinking, Vitamin E, Wear, Mechanical properties, Hip, Knee, Arthroplasty

1. Introduction

Since its introduction in 1962, ultra-high molecular weight polyethylene (UHMWPE) remains the most commonly used bearing material in joint arthroplasties, due to its high mechanical properties and wear resistance.1 The longevity of the implants is closely related to the wear of the polyethylene component which leads to debris and subsequently aseptic loosening, with the need for revision.2 In recent decades, the increasing number of joint arthroplasties and high demand in young and active patients has led to a progressive development of bearing materials to improve performance and durability.

Historical issues associated with UHMWPE were a) particulate wear and the consequent osteolysis related to the wear debris of the material, especially in total hip replacement prostheses; b) delamination wear due to oxidation, related to the sterilization method using high-energy irradiation and followed by storage and packaging in the presence of air (oxygen). These concerns have been addressed during the last two decades and no longer represent clinical problems. In 1998, highly cross-linked and thermally treated polyethylene (HXLPE), which has exhibited high wear resistance,2 was introduced in clinical procedures. Then, in the last decade, alpha-tocopherol, the synthetic analogue of vitamin E, a biological antioxidant, has been added to HXLPE to prevent oxidative degradation to decrease the incidence of delamination wear.3

The aim of this review is to provide the orthopaedic surgeon with an overview of the mechanical properties and clinical performance of polyethylene in total joint arthroplasty, summarizing historical problems and focusing on the latest innovations.

2. Biochemical and mechanical characteristics of polyethylene, evolution over time

UHMWPE is a specific type of polyethylene (PE): a linear, semi crystalline homopolymer with high molecular mass. Orthopaedic medical grade UHMWPE typically has a molecular weight between 3.5 and 6 million g/mole and a degree of crystallinity ranging around 50–55%. The American Society for Testing and Materials (ASTM) defines UHMWPE as having a molecular weight greater than 3.1 million a.m.u. (atomic mass units). Instead, the international Standards Organization (ISO 11542) (ISO, 2001) specifies that UHMWPE has a molecular weight of at least 1 million g/mol.4 UHMWPE is composed of two phases: 1) an ordered crystalline lamellae phase in which the chains organize in a crystalline orthorhombic lattice and 2) amorphous phase, in which the macromolecules form entangled, random coils and/or act as tie molecules that exit a crystalline lamella and then re-enter another crystalline lamella or the same one. Unlike high density polyethylene, UHMWPE has a significant interphase, or a third phase in between the crystalline and amorphous phases, which is a partially ordered intercalated phase wherein the macromolecules form loose and tight chain folds and where the tie molecules enter or exit the lamella. Summarizing, the crystalline phase provides modulus or stiffness to the material while the amorphous, rubber-like phase provides ductility, and consequently, toughness.5 The first use of UHMWPE in the clinical setting was in the sixties, while between 1970 and 1990, three new materials (polyacetal homopolymer produced by polymerization of formaldehyde, polyethylene-based carbon-fiber reinforced Poly Two and polyethylene-based high-pressure crystallized Hylamer) were introduced but their use was discontinued due to unacceptably high wear rates It was later discovered that osteolysis was an inflammatory process induced by exposure to wear particles of UHMWPE, in part due to the oxidation process, more evident when using gamma sterilization in air. This led to the introduction of gamma irradiation in an inert environment, ethylene oxide and gas plasma.5 High wear rates in conventional UHMWPE that have been sterilized with gamma radiation in air, decreased with the use of inert environment, ethylene oxide and gas plasma sterilization. Nevertheless, it was well known in chemistry that the cross-linking process, also induced by irradiation, had the potential to increase the wear resistance, therefore in the late nineties cross-linked – UHMWPEs were proposed for joint arthroplasties (Fig. 1).

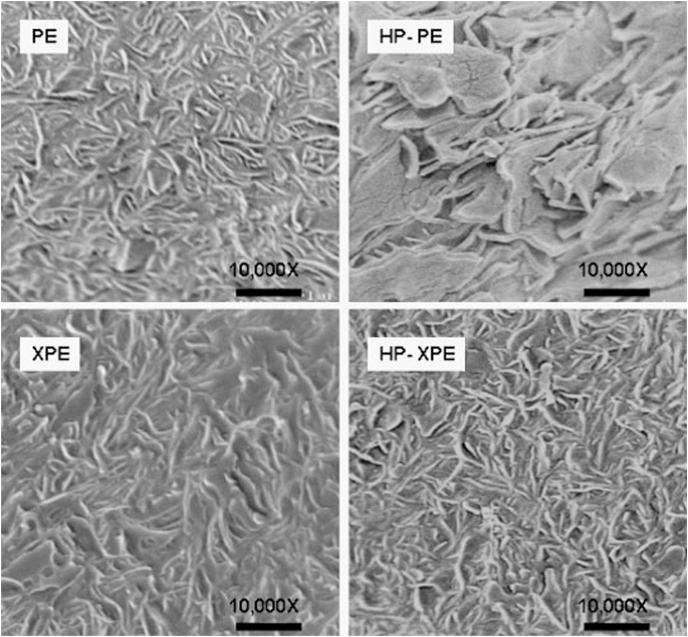

Fig. 1.

Low voltage scanning electron microscopy LVSEM (JEOL 6320FV low-voltage microscope operating at 1 kV) images of permanganic acid etched freeze fracture surfaces coated with a gold–palladium layer (10 nm thickness) of four polyethylenes obtained with different pressure and thermal treatments. The following polyethyelenes were studied: (1) untreated control (PE) (2) high-pressure crystallized, uncrosslinked polyethylene (HP-PE), (3) 50 kGy gamma radiation crosslinked polyethylene (XPE), and (4) high-pressure crystallized, 50 kGy gamma radiation crosslinked polyethylene (HP-XPE).36

3. Historical problems of oxidative degradation related to sterilization and packaging

Sterilization. From the early 1960s to the late 1990s, polyethylene implants, before their clinical application, were mostly sterilized by 25–40 kGy of gamma radiation in air. In the following years, several studies had shown that this procedure modifies the chemical, physical, mechanical and tribological properties of the polyethylene. Gamma radiation is capable of breaking the C–C bonds of the PE chain and creates free radicals and cross-linking. In an inert environment, the main effect of this treatment is the formation of cross-linking. However, irradiation in air leads to the cleavage of C–C bonds and to the creation of free radicals and oxidation products, which can further increase the C–C scissions, through a complex chemical mechanism, ultimately leading to a deleterious change in the mechanical properties of PE. After gamma irradiation in air, the free radicals generated can self-support the C–C scission leading to a further increase in the crystallinity with a reduction in the molecular mass.5 Macroscopically, oxidative degradation creates a “crown effect” or white band on PE implants; this is an area with a large reduction in the molecular mass and therefore with lower mechanical properties that can lead to delamination and fracture of the implants2,5 (Fig. 2). To overcome the oxidative degradation induced by sterilization in the last decade, manufacturers began to perform this process in a low-oxygen environment to reduce the free radicals generated, such as under vacuum or with inert gases, like argon or nitrogen, which allows a significant reduction in the oxidation.7,8 The most commons sterilization methods not involving gamma radiation includes ethylene oxide (EO) or gas plasma (GP) (Fig. 3 and Fig. 4). Nevertheless, it has been demonstrated oxidation can also occur under these conditions, albeit to a much lower extent than in air sterilization.5,6

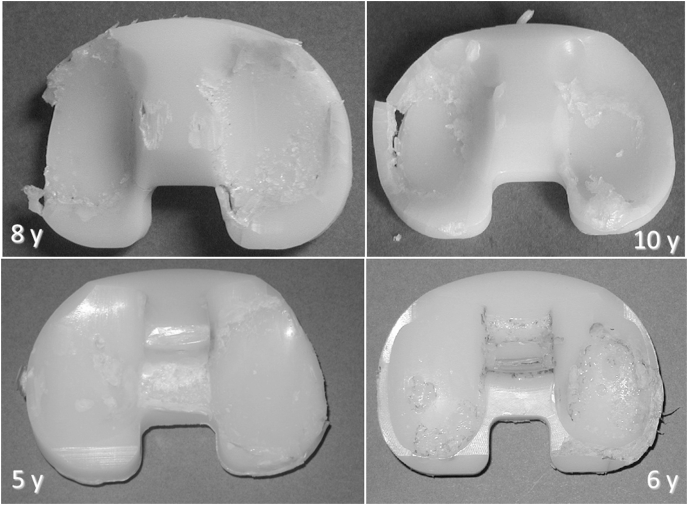

Fig. 2.

Pictures of retrieved tibial plateau, after revision for aseptic loosening. The figure reports the year of service in vivo for each implant. Macroscopic damages, as delamination, fractures, pitting and signs of oxidative degradation are visible on the implants. All implants were gamma sterilized.

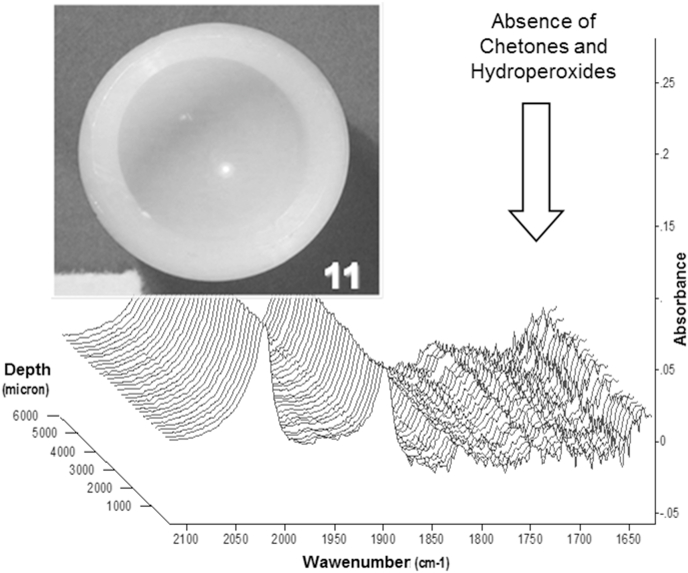

Fig. 3.

Oxidation levels within the UHMWPE components characterized using FTIR microspectroscopy (MicroFTIR) (AutoImage FTIR Microscope System, Perkin–Elmer). Spectra were run in transmission mode, with a 4 cm1 resolution and 16 scans per spectrum. In preparation for FTIR analysis, the UHMWPE components were sectioned using a microtome into 180-m-thick specimens. FTIR microscopy spectra of EtO sterilized acetabular liner after 11 years in vivo service and removed for aseptic loosening, shows the presence of esters and acids at a minimum oxidation level (0.02 A) and after NO treatment, any nitrate absorption at 1650–1620 cm–1 is visible (means no oxidation) (Fig. 3).

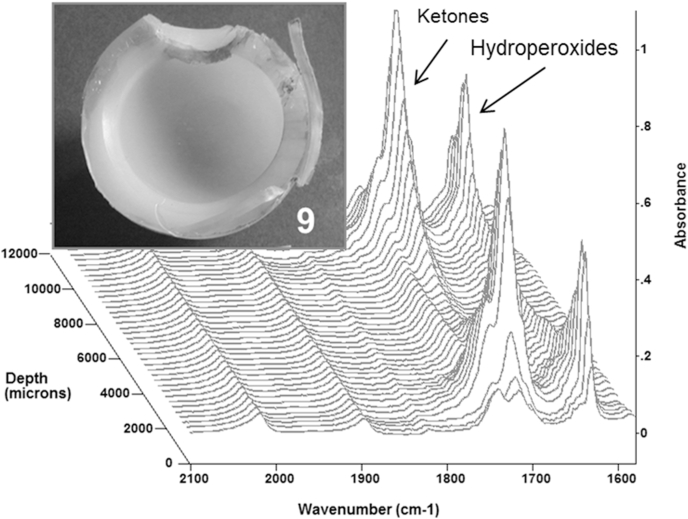

Fig. 4.

Oxidation levels within the UHMWPE components characterized using FTIR microspectroscopy (MicroFTIR) (AutoImage FTIR Microscope System, Perkin–Elmer). Spectra were run in transmission mode, with a 4 cm1 resolution and 16 scans per spectrum. In preparation for FTIR analysis, the UHMWPE components were sectioned using a microtome into 180-m-thick specimens. FTIR microscopy spectra of gamma-sterilized acetabular liner after 9 years in vivo service and removed for aseptic loosening shows two absorptions at 1740 (0.03 A) and at 1717 cm–1 (0.04 A) due to ester and ketone groups; after NO treatment, a secondary nitrate absorption appears at 1633 cm–1, which increases inside the sample up to 0.13 A (means oxidation).

Packaging and Storage. Another “historical” problem was post irradiation ageing related to the packaging and storage of PE implants. From sterilization to their clinical use, the implants can often be stored for several months; during this period, the oxidative process started during the sterilization can continue, altering the properties of PE.9 For this reason, the choice of a packaging impermeable to gases is crucial to mitigate the oxidation process. There are three categories of packaging: 1) Gas permeable packaging: allows the diffusion of all the gases including oxygen; 2) Polymer barrier packaging: a multi-layer plastic bag that reduces but does not eliminate the oxygen permeability; 3) Aluminium gas barrier packaging: it is impermeable to oxygen and all gases therefore only the oxygen dissolved in the PE implant before the irradiation process is still present in the implant.

4. The role of cross-linking in polyethylene: HXLPE

First generation HXLPE was commercially released between 1998 and 1999, to reduce wear debris and subsequent osteolysis generated by the inflammatory response to wear particles (Fig. 5). Curiously, the first cross-linked polyethylene insert applied in TKA was not intentionally cross-linked: Wang et al. observed that PE insert treated with gamma sterilization had lower wear debris.10 It occurred when the ultra-high molecular weight polyethylene (UHMWPE) was exposed to a high-dose of radiation; this procedure led to a decrease in the molecular weight between cross-links and therefore to an improvement of wear resistance demonstrated in vitro and in vivo.11

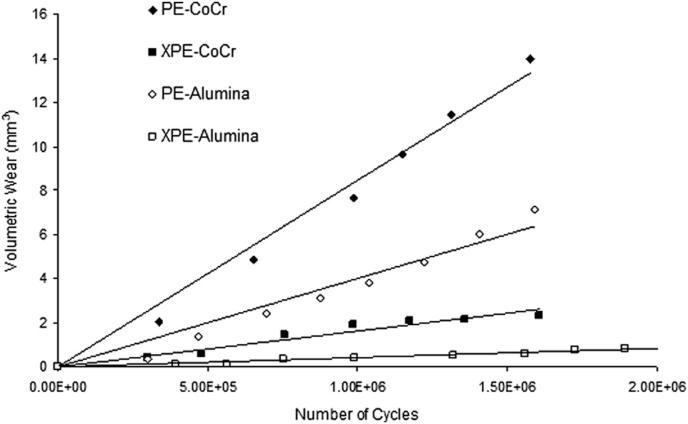

Fig. 5.

Wear of polyethylene (PE) and crosslinked polyethylene (XPE) respectively on ceramic (Al2O3) and metal (CoCr) surfaces. A 5 × 5 mm square articulation pattern was performed into a multidirectional wear tester OrthoPOD™ (Advanced Mechanical Technology Inc.). The wear tests revealed a linear increase in wear with number of cycles for all four groups; nevertheless, the wear factor of PE–CoCr was the highest and was twice as high as that of PE–Al2O3, while the wear factor of XPE–CoCr was 2.8 times higher than that of XPE–Al2O3.11

The first HXLPE generation was produced with the idea of exploiting the cross-linking process and, simultaneously, reducing the oxidative process induced by the free radicals generated during the PE irradiation. Several studies12,13 show that the cross-linking of HXLPE increased linearly up to radiation doses of 100 KGy, above which a plateau is reached. With higher doses of radiation, the cross-link density did not further increase substantially, instead the tensile and fracture toughness was unacceptably low. For this reason, all first generation HXLPE were irradiated with a dose between 50 KGy and 100 KGy.12

To preserve the mechanical properties, it is essential to remove the free radicals trapped in the crystalline phase, which can promote premature oxidative ageing. Two different thermal treatments were used to remove free radicals: remelting or annealing.13 In the first one, the temperature was increased to a temperature (150 °C) above the melting point (138–141 °C), therefore this procedure could remove all the free radicals trapped in the crystalline phase but, on the other hand, the overall crystallinity decreased, leading to a lower fatigue resistance. In the annealing thermal treatment, the temperature was increased to an elevated value (approximately 120 °C) that was however below the melting temperature. In this procedure there was no substantial change in crystallinity and fatigue resistance but a measurable amount of free radicals remained in HXLPE which made it possible for oxidative process to continue to progress. In summary, remelting can remove all free radicals but decreases the mechanical properties, while annealing does not alter the mechanical properties significantly but cannot remove all free radicals. Therefore, in the latter case, the oxidative process continues during storage and in vivo after the implantation.

Muratoglu et al.14 in their in-vitro study, demonstrated that remelted PE, after accelerating ageing, remained unaffected by oxidation without significant changes in the wear rate, while annealed PE had obvious signs of oxidation. However, both remelted and annealed HXLPE exhibited superior wear resistance compared to UHMWPE in vitro tests.

In general, conventional UHMWPE exhibits good oxidation and fatigue resistance but has low wear resistance. Remelted HXLPE (9 MRad) has good oxidation and wear resistance but has poor fatigue properties. Annealed HXLPE (9 MRad) shows good wear and fatigue resistance but has poor oxidation resistance. Moderately cross-linked and remelted UHMWPE (5–7.5 MRad) exhibits good oxidation resistance, but moderate wear and fatigue resistance.15 The remelting treatment reduces crystallinity, with a reduction in resistance to fracture toughness and fatigue crack propagation. Conversely, the annealing process preserves crystallinity while preserving mechanical properties,16 but at the expenses of the oxidation and wear resistance.

In 2005, second-generation HXLPE liners that were sequentially irradiated and annealed demonstrated improved resistance to oxidation, mechanical properties and equivalent wear rates compared to the first-generation annealed HXLPE. This second generation of HXLPE was developed with the idea of maintaining the same wear resistance as the first generation HXLPE but also of overcoming the low oxidation resistance highlighted in the latter. Sequential annealing thermal treatments showed that they preserve the microstructure and did not affect the mechanical properties substantially, which remained similar to UHMWPE. Unfortunately, the presence of free radicals continued to favour the oxidation process during storage and after implantation. Dumbleton et al.17 assumed that it was possible to create an HXLPE through a sequential irradiation/annealing process. Using a low dose of radiation (30 KGy) the mobility of the chain at the annealing temperature would be higher, therefore the treatment should be more efficient in the removal of free radicals. By repeating the same process three times, PE insert received a cumulative radiation dose of about 90 KGy. Several studies17,18 reported similar mechanical properties and fatigue resistance to UHMWPE. Unfortunately, again, the annealing process leaves a low but measurable level of free radicals that can lead to oxidation.

Commercial release of a second generation HXLPE stabilized with vitamin E began in 2007–2008. Two methods are currently used to incorporate vitamin E: doping19 or blending.3 Both revealed excellent oxidative resistance. It is essential to achieve a balance of oxidation, wear resistance and mechanical properties.6

5. Effectiveness of vitamin E and other new antioxidants on the polyethylene

A synthetic form of vitamin E (VE), a biological antioxidant, has been added to HXLPE in order to prevent the oxidative process induced by free radicals, so that it becomes unnecessary to conduct any post-irradiation thermal treatment, which could modify the mechanical properties of HXLPE.3 VE could be added to HXLPE using two different procedures: before cross-linking (Blended vitamin E) or after this process (Doped vitamin E). In the first case it is easier to add appropriate controlled amount of uniformly dispersed VE to the polyethylene but it can interfere with the cross-linking process, while in the second case the amount of VE is spatially non-uniform and requires a thermal treatment to make the distribution of VE uniform at all subsurface depths.20 The general idea was to incorporate vitamin E into polyethylene to scavenge the free radicals remaining from the cross-linking process so that the reduction in mechanical properties caused by the thermal treatment could be prevented. Thus, the incorporation of vitamin E into polyethylene provides oxidative protection, prevents reduction of mechanical properties, preserves low wear rates and reduces the inflammatory response to its wear particles.21

Vitamin E-blending UHMWPE is accomplished by mixing vitamin E with resin powder before the irradiation and cross-linking process. Vitamin E can react with or even bind to free radicals during cross-linking. This leads to a reduction in the cross-link formation and thus to an increase in wear rates, if compared to the wear rate of HXLPE without vitamin E. A 0.3 wt% is generally the maximum amount of vitamin E blended into UHMWPE. In the second process, UHMWPE is first irradiated and subsequently doped with vitamin E. Vitamin E is hydrophobic and it diffuses into the cross-linked UHMWPE. The maximum concentration of vitamin E is about 0.7 wt% due to the saturation limit of the cross-linked polyethylene, as shown by studies on vitamin E doped UHMWPE.19,22

The oxidation index (normalized concentration of oxidized bonds in the material) is used as a measure of the oxidation level in UHMWPE. Vitamin E-blended and vitamin E-doped UHMWPE reported lower oxidation indexes after accelerated ageing, compared to conventional UHMWPE without stabilizer. When vitamin E-blended UHMWPE was compared to HXLPE that had been stabilized by remelting, the former showed lower oxidation indexes after accelerated ageing.23 The incorporation of vitamin E appears to have a more important role in determining protection against oxidative embrittlement than remelting. Furthermore, vitamin E-blended and Vitamin E-doped UHMWPE reveal a lower decrease in mechanical strength compared to HXLPE that had been stabilized by remelting. This can be explained by the fact that cross-linking reduces the fatigue strength and remelting further reduces it.19

Different secretions of inflammatory mediators, such as cytokines, could be affected by vitamin E. There are only a few in vitro and in vivo studies and vitamin E-blended wear particles are more complex to analyse. Bacterial strains showed reduced adherence to vitamin E–incorporated UHMWPE; however, the clinical relevance of this finding is doubtful. In particular, it is unclear whether there is an effect of vitamin E incorporation on the immune system response.24, 25, 26 This is important for total joint replacement because, besides wear and material degradation, the main cause of early revision is infection whereas the primary cause of late revision is aseptic loosening,27 (Fig. 6 and Fig. 7).

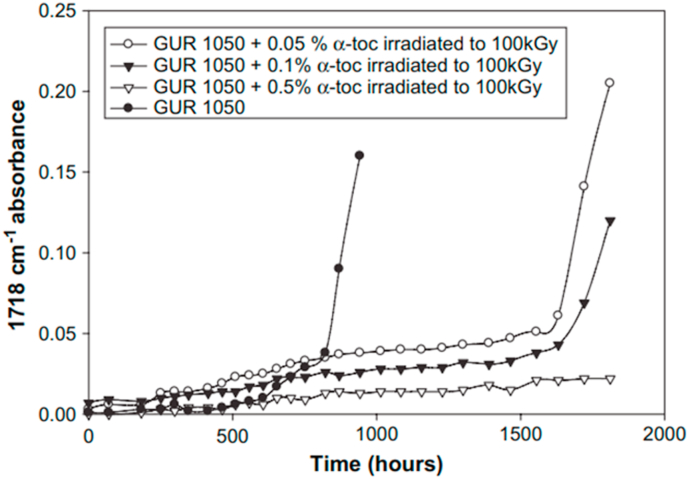

Fig. 6.

Oxidation (Ketone formation) profiles as a function of time at 90 C for the specimens irradiated to ta 100 kGy radiation dose and doped with different doses of Vitamin E and for an additive-free, not-irradiated UHMWPE for control. The sample with the highest tocopherol concentration (0.5%) did not show oxidation, on the contrary the control material showed high oxidation, while a stabilizing effect can be observed in all the tocopherol-containing samples proportionally to the initial tocopherol percentage.7

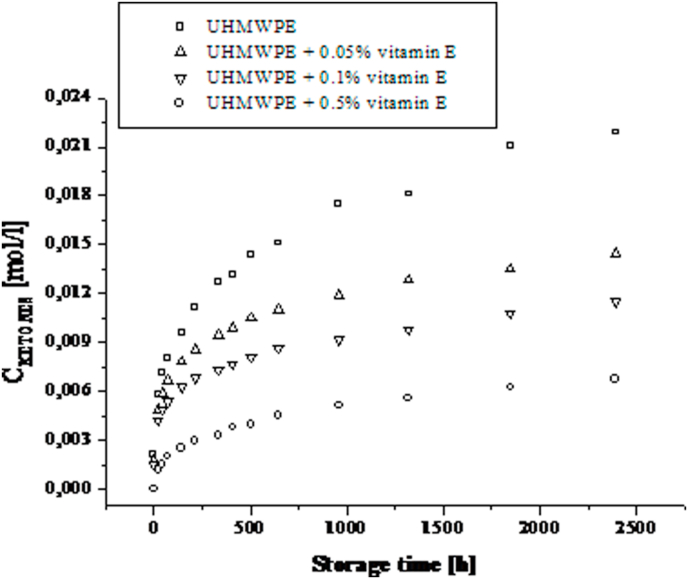

Fig. 7.

Oxidation (Hydroperoxides) as a function of the amount of Vitamin E and of the time of stocking at environmental temperature in irradiated UHMWPE at 60 kGy in air. The samples with the hicghest initial concentration of Vitamin E showd the lower formation of Hydroperoxides as index of oxidation. An increased formation of Hydroperoxides can be observed in the others tocopherol-containing samples inversely proportional to the initial tocopherol percentage, with the highest values for the material without Vitamin E.5,9

6. Wear and debris today

The term “osteolysis” refers specifically to a pathological process, in which a complex inflammatory response results from recruitment and activation of osteoclasts in the presence of wear particles. It has been established that an increase in wear rates is associated with a higher incidence of osteolysis. Decreased incidence of osteolysis has been observed with reduced wear rates with the use of HXLPE. HXLPE liners have lower wear rates than conventional UHMWPE. These data have been confirmed by several studies.28,29 The same benefits were observed in revision rates, with a reduced cumulative revision rate with HXLPE compared to conventional UHMWPE.30 Second-generation HXLPE liners have low wear rates like first generation HXLPE liners, but their long-term survival remains to be seen.21,31

Although in smaller quantity and of smaller size, HXLPE can also generate sub-micron wear particles, which produces an inflammatory response and may result in osteolysis. Issues about HXLPE had been raised because of the size of the debris: since the smaller wear particles that shed from HXLPE could be more biologically active and could result in a higher incidence of osteolysis than wear particles generated by conventional UHMWPE. It has been hypothesized that the wear particles produced by HXLPE have a different role in biological reactions than those generated by UHMWPE.32 Greater numbers and more elongated particles lead to a stronger inflammatory response. The particles produced by HXLPE debris are smaller and can be more reactive than those generated by conventional PE. The size of the debris plays a key role because particles smaller than 0.05 μm do not activate the inflammatory response whereas particles larger than 10 μm cannot be phagocytosed. The real biological implication of these smaller PE particles is not so clear because opposite results are found in literature.32,33 A study reported a similar number of wear particles in joint fluid aspirated in vivo after 1 year following TKA with both HXLPE and conventional UHMWPE.34 Despite these reports, a significant reduction in the incidence of osteolysis has been reported in several papers with an important reduction in wear rates with the use of HXLPE.28,35,36 Clinical studies of total hip and knee arthroplasties with vitamin E–incorporated HXLPE have reported wear rates similar to HXLPE without vitamin E. The former may have the beneficial effect of reduced inflammatory response to its wear particles.31 For instance, Bladen et al. found that vitamin E-containing particles secreted much lower levels of osteolytic mediators than particles of virgin UHMWPE at comparable volumes.37 Vitamin E–incorporated HXLPE offers even better protection against oxidative embrittlement than remelting.3,23 Therefore, since today we are expecting a long survival from the implants, there is a reason to aim to reduce any potential source of wear related osteolysis (Fig. 8).

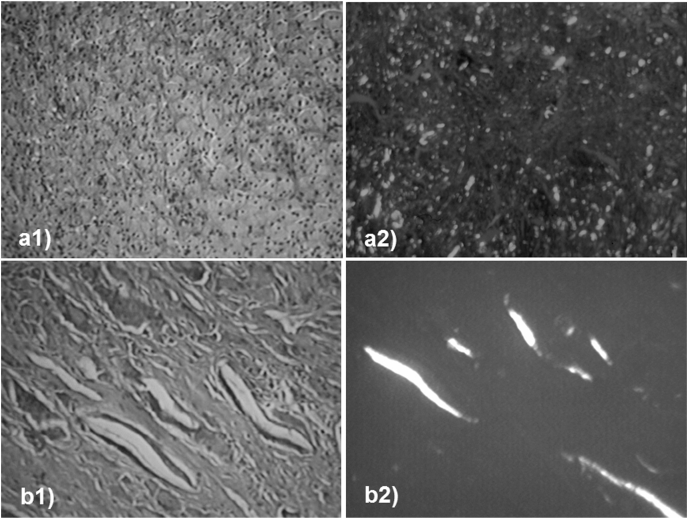

Fig. 8.

Histological analysis of peri-prosthetich membranes after aseptic loosened total hip arthroplasties, with respectively Ethylene Oxide (EtO) sterilized acetabular liner (a1 and a2) and gamma-sterilized acetabular liner (b1 and b2). Tissues are prepared with Hematoxylin and eosin stain, optical microscope, magnification (figure a1 and b1). Figures a2 and b2 have an optical filter to increase the fluency of the polyethylene debris. This Figure shows how the debris from EtO sterilized implants are smaller compared to those from gamma-sterilized implants and the consequent less aggressive inflammatory reaction.

7. Clinical data

In the last decades, different types of polyethylene (UHMWPE, HXLPE, vitamin E− HXLPE), with bearing surfaces (i.e., metal and ceramic) have been tested to improve wear resistance in joint arthroplasties.38 Several in vivo clinical studies have demonstrated better survival outcomes for HXLPE in THA than for conventional UHMWPE.39 The biomechanical properties of the knee are different from the hip, so the clinical successes of HXLPE achieved in THA could not be directly replicated in TKA. This can be explained by the fact that in TKA polyethylene insert is subjected to a greater contact stress. The rolling, sliding and rotational movement mechanism in the knee carries a greater risk of delamination and fatigue fracture increased by ageing and oxidation of PE compared to the lower contact stress acting in the more congruent “ball and socket” hip joint,40 while the wear patter remains different (Fig. 9).

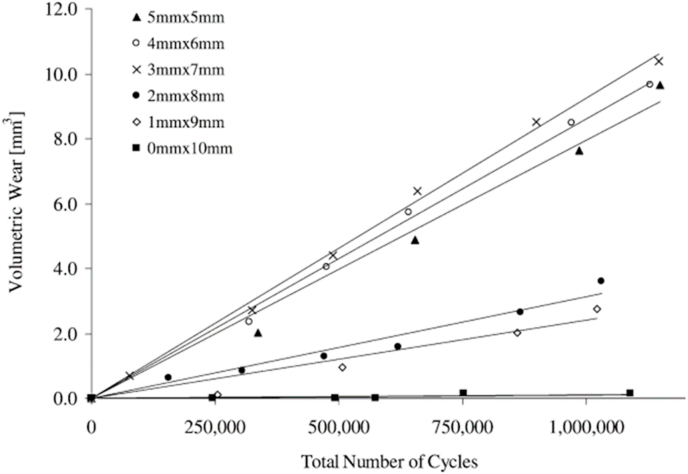

Fig. 9.

Volumetric wear rate for HUMWPE (Ultra High Molecular Weight Polyethylene) according to five different rectangular motion path patterns and linear tracking. The wear tests showed that the motion path pattern had a significant impact upon the wear rate: the volumetric wear rate was found to decrease significantly from the more square motion path (5 mm × 5 mm) to the more elongated path. Since the first is more likely hip situation, while the second would better reproduces a knee-like motion, this finding has a number of clinically relevant implications [36, Turell et al. Quantification of the effect of cross-path motion on the wear. Wear 2003; 255 (7–12):1034-1039.

Currier et al. in their studies reported that unexpected oxidation in vivo was observed in some retrieved remelted HXLPE Tibial Inserts. No free radicals were present during implantation and the polyethylene was expected to be stable to oxidation.41,42 It is supposed that there are two causes that might explain the onset of this unexpected phenomenon. The first one is the cyclic load to which the components are exposed in vivo that might have generated free radicals, triggering mechano-oxidation. The second one is related to lipids absorbed in vivo by the synovial fluid. Yet, this was never the primary cause of failure, therefore it would seem to have a lower clinical relevance than oxidation that occurs when using gamma sterilization in air.43

7.1. THA: HXLPE and vitamin-E HXLPE vs UHMWPE

Kuzyk et al. in their meta-analysis analysed 12 randomized controlled trials at an average follow up of 5.1 years finding statistical significance differences in volumetric, linear wear rate and incidence of osteolysis between HXLPE and UHMWPE with better result in the former.30 Bragdon et al. at a 7–10 years follow up demonstrated no incidence of periprosthetic osteolysis around the acetabular or femoral components of THA. Recently, Moon at al. Conducted a retrospective cohort study (15 years follow-up) in which they confirmed lower wear rate in both linear and volumetric wear and osteolysis in the HXLPE group compared to UHMWPE.44 Van Erp et al. in their RCT with a 2-years follow up demonstrated a lower linear femoral head penetration and better clinical results in the vitamin E-blended HXLPE acetabular cup compared to UHMWPE acetabular cup, confirming the better performance of the former.45 Regarding the use of vitamin E to reduce the oxidative degradation of HXLPE a recent meta-analysis of Wyatt et al. which included 5 studies with a short-term follow-up, showed that vitamin E-HXLPE had reduced femoral head penetration compared to HXLPE. Although these results can be promising, there were no statistically significant differences in terms of revision rate. Long-term follow-up and further RCT studies, regarding THA, would be needed to better understand the role of vitamin E in reducing the amount of revision rate on HXLPE.46

7.2. TKA: HXLPE and vitamin-E HXLPE vs UHMWPE

The use of HXLPE in TKA remains controversial. Several retrieval studies over the past 15 years have reported the same results in terms of wear debris for CPE and HXLPE.47,48 There were probably no differences in these studies because early revision was not related to debris and aseptic loosening. Yu et al. included six studies (3 RCT and 3 CT) in their meta-analysis and compared CPE and HXLPE over a 2–6 years follow-up period. Outcomes analysed included total number of operations, re-operations for prosthesis loosening, osteolysis and mechanical failures. All patients were assessed with total knee score and functional scores after surgery. There were no statistical significance differences between all the measured variables.49 Meneghini et al. and Wilhelm et al. in their clinical studies confirmed that there were no differences between HXLPE and CPE.50,51 Longer term follow-up studies are needed to evaluate the superiority of HXLPE over CPE in TKA. There are only a few studies that analysed the in vivo use of vitamin-E HXLPE in TKA. Takemura et al. in their study enrolled 175 patients (200 knees) that underwent TKA using the same total knee prostheses. One hundred knees had a vitamin E-infused HXLPE insert and the other 100 knees had a conventional polyethylene insert. Clinical (KSS and ROM) and radiological (incidence of a radiolucent line) results were comparable between the two groups at two years after TKA.52 Flament et al. enrolled 148 patients (163 knees) with 3.2 years follow-up (range 6 weeks–6.4 years) in their study. The purpose was to analyse the early result of TKA with vitamin-E HXLPE. Three revisions were performed for infection, two for arthrofibrosis and two for late instability. Good clinical results and no aseptic loosening were recorded.53 Currier et al. analysed polyethylene tibial insert treated with antioxidant. The antioxidants used appeared to be effective in reducing oxidation in the 0–3 years follow-up of the study. The authors assumed that antioxidants could prevent oxidation-mediated fatigue due to the absence of subsurface peak oxidation.54

In summary, short-term clinical studies (maximum of 5-year follow-up) on THA (total hip arthroplasty) and TKA (total knee arthroplasty) with vitamin E–incorporated HXLPE reported clinical results and wear rates similar to HXLPE without vitamin E. Long-term clinical studies for vitamin E–incorporated UHMWPE are not available yet, and studies will require many patients to follow for several decades.21,51

8. Discussion

UHMWPE has a long and glorious history in orthopaedics because it is a tough and wear resistant polymer. Nevertheless, catastrophic failures occurred in the past, and we know now that they were due to the fractures/delamination from oxidation and to particulate wear and the consequent osteolysis. Today the severe problem of oxidation has been dramatically reduced by replacing the radiation sterilization in air by gas sterilization methods or radiation sterilization in low oxygen environments, while the wear has been controlled by cross-linking.

A general consideration regarding the use of UHMWPE in total joint replacement is that there are differences between articulation in the hip and knee, where squared or quasi-elliptical movement are more like the hip gait, while rectangular or linear motion are more like knee gait, with the consequence that the particulate wear rates are higher in THR than TKR motion. Another consideration is that cross-linking reduces the mechanical properties. The main factors for total knee arthroplasty applications that must be considered are: Wear Resistance (abrasive wear in TKA), Oxidation Resistance (delamination wear in TKA) and Mechanical Properties (fracture, catastrophic failure). Consequently, shortcomings of current polyethylenes still exist, regarding application in TKRs. The first concerns are regarding particulate wear in UHMWPE under conditions of abrasive wear, where the roughness of the metallic component affects wear rate in the knee more than in hip. For instance, the presence of cement fragments can influence the rate of abrasive wear. Another issue is regarding particulate wear: the particles produced by HXLPE debris are smaller than wear particles of conventional UHMWPE and could be more biologically active.

Other concerns are the decrease in mechanical properties in HXLPE which can cause fractures and ruptures, in addition to the extensive delamination wear observed clinically and in the laboratory in oxidized UHMWPE. Even if these are not generally observed in unoxidized UHMWPE and XPE cross-linked UHMWPE needs thermal treatments or stabilizers to avoid oxidation (from remelting to antioxidants). In fact, another concern is regarding oxidation: unexpected phenomenon of oxidation in vivo was observed in some retrieved remelted HXLPE Tibial Inserts. No free radicals were present during implantation and therefore the materials were expected to be stable to oxidation. This phenomenon can be attributed to the cyclic load to which the components are exposed in vivo that might have generated free radicals, triggering mechanic-oxidation. Another source of in vivo oxidation is by the diffusion of lipids, absorbed in vivo from the synovial fluid. Luckily, until now, these have been no reported failures associated with these phenomena, and they have shown no clinical relevance to date, especially when compared to gamma sterilized oxidation. Finally, concerns remain whether HXLPE is adequate for TKA in the long-term, since all clinical results are at midterm. These studies have not demonstrated a significant difference between HXLPE and conventional PE. There have been no complications, but also no significant advantages, related to the use of XLPE tibial liners and also no differences in risk of revision during the short-term to mid-term in vivo life.

Therefore, the question remains: do we need to improve the performance of UHMWPE for arthroplasty and specially for TKA applications? If we consider that we expect longer survivorships of TKA and THA, that we have younger and active patients and that we have high-performance implant designs and tibial liners, the answer is obviously in the affirmative.

9. Further strategies to improve the performance of UHMWPE in TKA application

Several strategies have been proposed or hypothesized as solutions to improve the polyethylene:

-

1)

To improve the performance of antioxidants, whose objective is to prevent oxidation and to avoid thermal treatment and consequent loss of mechanical properties: in this case the dose can be optimized or new antioxidants can be used.

-

2)

The second strategy can be referred to as morphology tuning: an appropriate combination of cross-linking/crystallization degree by altering the thermal history, high-temperature melting (HTM) and high-pressure crystallization (HPC), to balance wear resistance and mechanical properties appropriate to the application and the specific part of the tibial liner.

-

3)

Alternative methods of cross-linking have been proposed, like the use of peroxides. The use of chemical cross-linking as an alternative to radiation would avoid the radiation cross-linking step and offer higher versatility. For example, the choice of the appropriate peroxide/concentration/incorporation method would provide better spatial control of cross-linking.

-

4)

Drug-eluting polyethylenes: another promising and interesting application is the use of the polymer for the delivery of anaesthetic, antibacterial drugs, antibiotics.

-

5)

Last, but not least, alternative bearings are developing: PEEK on Polyethylene. PEEK is a polyether ether ketone and is a high performance thermoplastic polymer. It is considered an advanced biomaterial used in medical implants due to its high strength and robustness. Bearing surface could be a polymer-on-polymer and not metal-on-polymer. Other advantages are that it offers optimal bone growth, is radiolucent, technically feasible to process into 3D-printed parts and can be used with high-resolution magnetic resonance imaging.

10. Conclusions

Currently, polyethylene (PE) inserts can be a choice in THA but are mandatory in TKA, therefore there is a reason to develop and research for more and more performant materials. HXLPE is considered the most appropriate solution in hip arthroplasty. Whereas the degree of crosslinking remains a subject of debate in knee joint arthroplasty, where the mechanical stresses are different from hip. The addition of anti-oxidants (vitamin E) is useful to reduce oxidation, to maintain the mechanical properties and therefore for a long lasting materials; vitamin E doped PE is a relatively new material, but no adverse events have been reported. In summary, the most recent materials showed reduced wear, no catastrophic fractures and acceptable mechanical properties, either for hip and knee, with the potential of long-term survivorship.

Declaration of competing interest

All authors have nothing to disclose.

Footnotes

The study was performed in accordance with the ethical standards and data are available upon request. The work has not been published before in any language, is not being considered for publication elsewhere, and has been read and approved by all authors. Each author contributed significantly to one or more aspects of the study. No benefits in any form have been received or will be received from a commercial party related directly or indirectly to the subject of this article.

Contributor Information

Alessandro Bistolfi, Email: abistolfi@cittadellasalute.to.it, a.bistolfi@libero.it.

Fortunato Giustra, Email: fortunato.giustra@gmail.com.

Francesco Bosco, Email: francescobosco@icloud.com.

Luigi Sabatini, Email: luigisabatini.ort@gmail.com.

Alessandro Aprato, Email: ale_aprato@hotmail.com.

Pierangiola Bracco, Email: pierangiola.bracco@unito.it.

Anuj Bellare, Email: anuj@apiboston.com.

References

- 1.Evans J.T., Evans J.P., Walker R.W., Blom A.W., Whitehouse M.R., Sayers A. How long does a hip replacement last? A systematic review and meta-analysis of case series and national registry reports with more than 15 years of follow-up. Lancet. 2019;393(10172):647–654. doi: 10.1016/S0140-6736(18)31665-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Kurtz S.M., Ong K.L., Lau E. International survey of primary and revision total knee replacement. Int Orthop. 2011;35(12):1783–1789. doi: 10.1007/s00264-011-1235-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Oral E., Greenbaum E.S., Malhi A.S., Harris W.H., Muratoglu O.K. Characterization of irradiated blends of alpha-tocopherol and UHMWPE. Biomaterials. 2005;26(33):6657–6663. doi: 10.1016/j.biomaterials.2005.04.026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Sobieraj M.C., Rimnac C.M. Ultra high molecular weight polyethylene: mechanics, morphology, and clinical behavior. J Mech Behav Biomed Mater. 2009;2(5):433–443. doi: 10.1016/j.jmbbm.2008.12.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Bracco P., Bellare A., Bistolfi A., Affatato S. Ultra-high molecular weight polyethylene: influence of the chemical, physical and mechanical properties on the wear behavior. A Rev Mater (Basel) 2017;10(7):791. doi: 10.3390/ma10070791. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Singh G., Klassen R., Howard J., Naudie D., Teeter M., Lanting B. Manufacturing, oxidation, mechanical properties and clinical performance of highly cross-linked polyethylene in total hip arthroplasty. Hip Int. 2018;28(6):573–583. doi: 10.1177/1120700018780677. [DOI] [PubMed] [Google Scholar]

- 7.Bracco P., Brach del Prever E.M., Cannas M., Luda M.P., Costa L. Oxidation behaviour in prosthetic UHMWPE components sterilised with high energy radiation in a low-oxygen environment. Polym Degrad Stabil. 2006;91(9):2030–2038. [Google Scholar]

- 8.Brach del Prever E.M., Bistolfi A., Costa L. The biological reaction to polyethylene wear debris can be related with oxidation of the UHMWPE cups. Chir Organi Mov. 2003;88(3):291–303. [PubMed] [Google Scholar]

- 9.Costa L., Bracco P. UHMWPE Biomaterials Handbook. third ed. Elsevier Inc.; Amsterdam, The Netherlands: 2016. Mechanisms of cross-linking, oxidative degradation, and stabilization of UHMWPE; pp. 467–487. [Google Scholar]

- 10.Wang A., Essner A., Polineni V., Stark C., Dumbleton J. Lubrication and wear of ultra-high molecular weight polyethylene in total joint replacements. Tribol Int. 1998;31:17–33. [Google Scholar]

- 11.Bistolfi A., Bellare A. The relative effects of radiation crosslinking and type of counterface on the wear resistance of ultrahigh-molecular-weight polyethylene. Acta Biomater. 2011;7(9):3398–3403. doi: 10.1016/j.actbio.2011.05.018. [DOI] [PubMed] [Google Scholar]

- 12.Akagi M., Asano T., Clarke I.C. Wear and toughness of crosslinked polyethylene for total knee replacements: a study using a simulator and small-punch testing. J Orthop Res. 2006;24(10):2021–2027. doi: 10.1002/jor.20223. [DOI] [PubMed] [Google Scholar]

- 13.Muratoglu O., Bragdon C.R. UHMWPE Biomaterials Handbook. third ed. Elsevier Inc.; Amsterdam, The Netherlands: 2016. Highly cross-linked and melted UHMWPE; pp. 264–273. [Google Scholar]

- 14.Muratoglu O.K., Merrill E.W., Bragdon C.R. Effect of radiation, heat, and aging on in vitro wear resistance of polyethylene. Clin Orthop Relat Res. 2003;417:253–262. doi: 10.1097/01.blo.0000093004.90435.d1. [DOI] [PubMed] [Google Scholar]

- 15.Endo M., Tipper J.L., Barton D.C., Stone M.H., Ingham E., Fisher J. Comparison of wear, wear debris and functional biological activity of moderately crosslinked and non-crosslinked polyethylenes in hip prostheses. Proc Inst Mech Eng H. 2002;216(2):111–122. doi: 10.1243/0954411021536333. [DOI] [PubMed] [Google Scholar]

- 16.Pruitt L.A., Ansari F., Kury M. Clinical trade‐offs in cross‐linked ultrahigh‐molecular‐weight polyethylene used in total joint arthroplasty. J Biomed Mater Res B Appl Biomater. 2013;101B:476–484. doi: 10.1002/jbm.b.32887. [DOI] [PubMed] [Google Scholar]

- 17.Dumbleton J.H., D'Antonio J.A., Manley M.T., Capello W.N., Wang A. The basis for a second-generation highly cross-linked UHMWPE. Clin Orthop Relat Res. 2006;453:265–271. doi: 10.1097/01.blo.0000238856.61862.7d. [DOI] [PubMed] [Google Scholar]

- 18.Wang A., Zeng H., Yau S.-S., Essner A., Manely M., Dumbleton J. Wear, oxidation and mechanical properties of a sequentially irradiated and annealed UHMWPE in total joint replacement. J Phys D. 2006;39:3213–3219. [Google Scholar]

- 19.Oral E., Wannomae K.K., Rowell S.L., Muratoglu O.K. Diffusion of vitamin E in ultra-high molecular weight polyethylene. Biomaterials. 2007;28(35):5225–5237. doi: 10.1016/j.biomaterials.2007.08.025. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Tanino H., Sato T., Nishida Y., Mitsuake R., Ito H. Vitamin E blended highly cross-linked polyethylene liner compared to standard liners in total hip arthroplasty. J Orthop Res. 2017;35(S1) [Google Scholar]

- 21.Lambert B., Neut D., van der Veen H.C., Bulstra S.K. Effects of vitamin E incorporation in polyethylene on oxidative degradation, wear rates, immune response, and infections in total joint arthroplasty: a review of the current literature. Int Orthop. 2019;43(7):1549–1557. doi: 10.1007/s00264-018-4237-8. [DOI] [PubMed] [Google Scholar]

- 22.Oral E., Godleski Beckos C., Malhi A.S., Muratoglu O.K. The effects of high dose irradiation on the cross-linking of vitamin E-blended ultrahigh molecular weight polyethylene. Biomaterials. 2008;29(26):3557–3560. doi: 10.1016/j.biomaterials.2008.05.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Gigante A., Bottegoni C., Ragone V., Banci L. Effectiveness of vitamin-E-doped polyethylene in joint replacement: a literature review. J Funct Biomater. 2015;6(3):889–900. doi: 10.3390/jfb6030889. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Banche G., Bracco P., Allizond V. Do crosslinking and vitamin E stabilization influence microbial adhesions on UHMWPE-based biomaterials? Clin Orthop Relat Res. 2015;473(3):974–986. doi: 10.1007/s11999-014-4024-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Banche G., Bracco P., Bistolfi A. Vitamin E blended UHMWPE may have the potential to reduce bacterial adhesive ability. J Orthop Res. 2011;29(11):1662–1667. doi: 10.1002/jor.21432. [DOI] [PubMed] [Google Scholar]

- 26.Banche G., Allizond V., Bracco P. Interplay between surface properties of standard, vitamin E blended and oxidised ultra high molecular weight polyethylene used in total joint replacement and adhesion of Staphylococcus aureus and Escherichia coli. Bone Joint J. 2014;96-B(4):497–501. doi: 10.1302/0301-620X.96B4.32895. [DOI] [PubMed] [Google Scholar]

- 27.Rohde H., Frankenberger S., Zähringer U., Mack D. Structure, function and contribution of polysaccharide intercellular adhesin (PIA) to Staphylococcus epidermidis biofilm formation and pathogenesis of biomaterial-associated infections. Eur J Cell Biol. 2010;89(1):103–111. doi: 10.1016/j.ejcb.2009.10.005. [DOI] [PubMed] [Google Scholar]

- 28.Garvin K.L., White T.C., Dusad A., Hartman C.W., Martell J. Low wear rates seen in THAs with highly crosslinked polyethylene at 9 to 14 years in patients younger than age 50 years. Clin Orthop Relat Res. 2015;473(12):3829–3835. doi: 10.1007/s11999-015-4422-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Pang H.N., Naudie D.D., McCalden R.W., MacDonald S.J., Teeter M.G. Highly crosslinked polyethylene improves wear but not surface damage in retrieved acetabular liners. Clin Orthop Relat Res. 2015;473(2):463–468. doi: 10.1007/s11999-014-3858-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Kuzyk P.R., Saccone M., Sprague S., Simunovic N., Bhandari M., Schemitsch E.H. Cross-linked versus conventional polyethylene for total hip replacement: a meta-analysis of randomised controlled trials. J Bone Joint Surg Br. 2011;93(5):593–600. doi: 10.1302/0301-620X.93B5.25908. [DOI] [PubMed] [Google Scholar]

- 31.Bichara D.A., Malchau E., Sillesen N.H., Cakmak S., Nielsen G.P., Muratoglu O.K. Vitamin E-diffused highly cross-linked UHMWPE particles induce less osteolysis compared to highly cross-linked virgin UHMWPE particles in vivo. J Arthroplasty. 2014;29(9 Suppl):232–237. doi: 10.1016/j.arth.2014.03.044. [DOI] [PubMed] [Google Scholar]

- 32.Iwakiri K., Minoda Y., Kobayashi A. In vivo comparison of wear particles between highly crosslinked polyethylene and conventional polyethylene in the same design of total knee arthroplasties. J Biomed Mater Res B Appl Biomater. 2009;91(2):799–804. doi: 10.1002/jbm.b.31458. [DOI] [PubMed] [Google Scholar]

- 33.Hinarejos P., Piñol I., Torres A., Prats E., Gil-Gómez G., Puig-Verdie L. Highly crosslinked polyethylene does not reduce the wear in total knee arthroplasty: in vivo study of particles in synovial fluid. J Arthroplasty. 2013;28:1333–1337. doi: 10.1016/j.arth.2013.01.026. [DOI] [PubMed] [Google Scholar]

- 34.Hinarejos P., Torres A., Pinol I., Valverde D., Prats E., Puig L.I. Polyethylene particles in synovial fluid after knee arthroplasty with a conventional or highly cross-linked polyethylene. Preliminary study. Rev Esp Cir Ortop Traumatol. 2012;56:210–215. doi: 10.1016/j.recot.2011.12.001. [DOI] [PubMed] [Google Scholar]

- 35.Lee J.H., Lee B.W., Lee B.J., Kim S.Y. Midterm results of primary total hip arthroplasty using highly cross-linked polyethylene: minimum 7-year follow-up study. J Arthroplasty. 2011;26(7):1014–1019. doi: 10.1016/j.arth.2011.03.015. [DOI] [PubMed] [Google Scholar]

- 36.Bistolfi A., Turell M.B., Lee Y.L., Bellare A. Tensile and tribological properties of high-crystallinity radiation crosslinked UHMWPE. J Biomed Mater Res B Appl Biomater. 2009;90(1):137–144. doi: 10.1002/jbm.b.31265. [DOI] [PubMed] [Google Scholar]

- 37.Bladen C.L., Teramura S., Russell S.L. Analysis of wear, wear particles, and reduced inflammatory potential of vitamin E ultrahigh-molecular-weight polyethylene for use in total joint replacement. J Biomed Mater Res B Appl Biomater. 2013;101(3):458–466. doi: 10.1002/jbm.b.32904. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Brach Del Prever E.M., Bistolfi A., Bracco P., Costa L. UHMWPE for arthroplasty: past or future? J Orthop Traumatol. 2009;10(1):1–8. doi: 10.1007/s10195-008-0038-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Partridge T.C.J., Baker P.N., Jameson S.S., Mason J., Reed M.R., Deehan D.J. Conventional versus highly cross-linked polyethylene in primary total knee replacement: a comparison of revision rates using data from the national joint registry for England, wales, and northern Ireland. J Bone Joint Surg Am. 2020;102(2):119–127. doi: 10.2106/JBJS.19.00031. [DOI] [PubMed] [Google Scholar]

- 40.Brown T.S., Van Citters D.W., Berry D.J., Abdel M.P. The use of highly crosslinked polyethylene in total knee arthroplasty. Bone Joint J. 2017;99-B(8):996–1002. doi: 10.1302/0301-620X.99B8.BJJ-2017-0028.R1. [DOI] [PubMed] [Google Scholar]

- 41.Currier B.H., Currier J.H., Franklin K.J., Mayor M.B., Reinitz S.D., Van Citters D.W. Comparison of wear and oxidation in retrieved conventional and highly cross-linked UHMWPE tibial inserts. J Arthroplasty. 2015;30(12):2349–2353. doi: 10.1016/j.arth.2015.06.014. [DOI] [PubMed] [Google Scholar]

- 42.Currier B.H., Van Citters D.W., Currier J.H., Carlson E.M., Tibbo M.E., Collier J.P. In vivo oxidation in retrieved highly crosslinked Tibial inserts. J Biomed Mater Res B Appl Biomater. 2013;101B:441–448. doi: 10.1002/jbm.b.32805. [DOI] [PubMed] [Google Scholar]

- 43.Medel F., Kurtz S., MacDonald D., Pascual F.J., Puértolas J.A. Does cyclic stress play a role in highly crosslinked polyethylene oxidation? Clin Orthop Relat Res. 2015;473(3):1022–1029. doi: 10.1007/s11999-015-4153-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Moon N.H., Shin W.C., Do M.U., Kang S.W., Lee S.M., Suh K.T. Wear and osteolysis outcomes for highly cross-linked polyethylene in primary total hip arthroplasty compared with conventional polyethylene: a 15- to 18-year single-centre follow-up study [published online ahead of print, 2020 Jan 8] Hip Int. 2020 doi: 10.1177/1120700019896970. 1120700019896970. [DOI] [PubMed] [Google Scholar]

- 45.Van Erp J.H.J., Massier J.R.A., Halma J.J., Snijders T.E., de Gast A. 2-year results of an RCT of 2 uncemented isoelastic monoblock acetabular components: lower wear rate with vitamin E blended highly cross-linked polyethylene compared to ultra-high molecular weight polyethylene. Acta Orthop. 2020;91(3):254–259. doi: 10.1080/17453674.2020.1730073. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Wyatt M.C., Roberton A., Foxall-Smi M., Beswick A.D., Kunutsor S.K., Whitehouse M.R. Does vitamin E highly-crosslinked polyethylene convey an advantage in primary total hip replacement? A systematic review and meta-analysis. Hip Int. 2020;30(5):598–608. doi: 10.1177/1120700019858335. [DOI] [PubMed] [Google Scholar]

- 47.Liu T., Esposito C., Elpers M., Wright T. Surface damage is not reduced with highly crosslinked polyethylene tibial inserts at short-term. Clin Orthop Relat Res. 2016;474(1):107–116. doi: 10.1007/s11999-015-4344-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Lachiewicz P.F., O'Dell J.A. Prospective randomized trial of standard versus highly crosslinked tibial polyethylene in primary posterior-stabilized total knee arthroplasty: clinical and radiological follow-up at 2 to 11 years. Bone Joint J. 2019;101-B(7_Supple_C):33–39. doi: 10.1302/0301-620X.101B7.BJJ-2018-1126.R2. [DOI] [PubMed] [Google Scholar]

- 49.Yu B.F., Yang G.J., Wang W.L., Zhang L., Lin X.P. Cross-linked versus conventional polyethylene for total knee arthroplasty: a meta-analysis. J Orthop Surg Res. 2016;11:39. doi: 10.1186/s13018-016-0374-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Meneghini R.M., Ireland P.H., Bhowmik-Stoker M. Multicenter study of highly cross-linked versus conventional polyethylene in total knee arthroplasty. J Arthroplasty. 2015;10(4):34–1016. doi: 10.1016/j.arth.2015.10.034. [DOI] [PubMed] [Google Scholar]

- 51.Wilhelm S.K., Henrichsen J.L., Siljander M., Moore D., Karadsheh M. Polyethylene in total knee arthroplasty: where are we now? J Orthop Surg. 2018;26(3) doi: 10.1177/2309499018808356. 2309499018808356. [DOI] [PubMed] [Google Scholar]

- 52.Takemura S., Minoda Y., Sugama R. Comparison of a vitamin E-infused highly crosslinked polyethylene insert and a conventional polyethylene insert for primary total knee arthroplasty at two years postoperatively. Bone Joint J. 2019;101-B(5):559–564. doi: 10.1302/0301-620X.101B5.BJJ-2018-1355.R1. [DOI] [PubMed] [Google Scholar]

- 53.Flament E.M., Berend K.R., Hurst J.M., Morris M.J., Adams J.B., Lombardi A.V., Jr. Early experience with vitamin E antioxidant-infused highly cross-linked polyethylene inserts in primary total knee arthroplasty. Surg Technol Int. 2016;29:334–340. [PubMed] [Google Scholar]

- 54.Currier B.H., Currier J.H., Holdcroft L.A., Van Citters D.W. Effectiveness of anti-oxidant polyethylene: what early retrievals can tell us. J Biomed Mater Res B Appl Biomater. 2018;106(1):353–359. doi: 10.1002/jbm.b.33840. [DOI] [PubMed] [Google Scholar]