Abstract

Pilling is a common surface defect in fleece fabrics made of chief value cotton (CVC) and polyester cotton (PC). The term “Chief Value Cotton” refers to fabrics produced by mixing cotton and synthetic fiber such as polyester where cotton typically makes up more than half of the overall combination of polyester. Customers nowadays want polyester cotton blended fleece fabric with excellent pilling resistance, but it is difficult to improve pilling properties in polyester cotton blended fleece fabric. A variety of studies have been conducted to improve the pilling properties of single jersey CVC knit fabric. The primary goal of this study is to eliminate pilling in fleece fabrics made of three-thread polyester cotton blends. In this analysis, singeing with a heat setting was used to increase pilling resistance. According to this experimental study, the pilling resistance properties improve from grade 1 to grade 4, which is extraordinary. This method can be used to successfully solve the pilling problem in three thread polyester cotton blended fleece fabrics in the textile knitting industry.

Keywords: Fleece fabric, Pilling, Singeing, Heat setting, Polyester cotton blend

Fleece fabric; Pilling; Singeing; Heat setting; Polyester cotton blend

1. Introduction

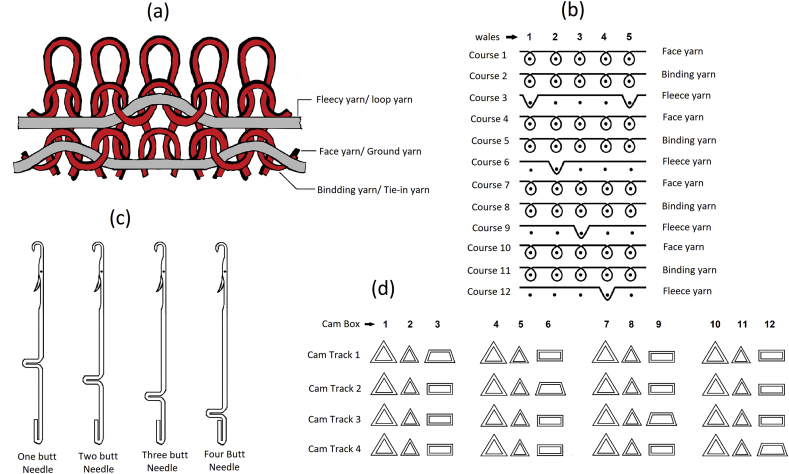

Because of its high GSM and nappy loop on the inner surface, three thread fleece fabric is becoming increasingly popular on the market [1]. Fleece is a heavy, bulky knitted fabric distinguished by its thick, soft nap and deep pile, and garments such as sweaters and jackets are commonly worn for outdoor activities, especially during the winter season [2]. The three layers of a three-thread fleece fabric are upper layer, middle layer and bottom layer. This top layer is made up of a separate yarn that is knitted in with the original jersey. The extra yarn creates larger loops that protrude from the fabric's surface. During the napping process, as the fabric is passed over spinning cylindrical brushes, the loops are split into a fuzzy sheet. Finally, spiraling blades are used to shear the fleece surface to achieve a uniform fabric thickness and avoid pilling. The extra fuzzy layer is what gives fleece fabrics their characteristic soft and warm properties [3]. While fleece fabric is in high demand, consumers are increasingly looking for suppliers who can provide higher-quality fleece fabric [4]. Cotton fiber is soft, easily deformable, and has a higher propensity to shrink than synthetic fiber. Cotton fleece, for example, is made entirely of cotton and is very cool to the touch. But, after many uses and washes, the shirts become easily deformed and are more susceptible to shrinking [5]. By mixing polyester with cotton fabric, garments become more durable, with less deformation and shrinkage, and provide better warmth than cotton. Various compositions are used to produce polyester cotton blended fleece fabric. The most common compositions are 60 percent cotton 40 percent polyester, 65 percent cotton and 35 percent polyester, 70 percent cotton and 30 percent polyester, 80 percent cotton and 20 percent polyester etc. The garments made from the polyester cotton blended fabric are more durable with less chance of deforming and shrinkage [6]. However, the introduction of polyester fiber into fabric construction has resulted in an increase in pilling [7]. Their electrostatic properties can function as a nucleus for pill formation [8]. Mechanical abrasion is essential in pill forming because it causes fuzz to form. Due to mechanical abrasion, fibers emerge from the inside of a fabric, aiding in the creation of fuzz. The fuzz fibers swell up and become smoother when they come into contact with water after the fabric has been washed. The swollen fuzz fibers are easily fibrillated by mechanical abrasion during the drying and washing process. The fibrillated fibers become intertwined with one another, forming pills. The pilling effect is most often seen on the fabric's face side. Some special properties of fiber, yarn, and fabric properties, such as percent elongation, tensile strength of fiber, yarn spinning methods, flex abrasion, bending rigidity, fiber titer, and the form of the fiber cross-section, as well as friction, influence pilling attitude [9]. The pilling rate of single Lacoste fabric is higher than that of double Lacoste single jersey fabric [10]. The singeing process has been found in the literature to minimize the pilling effect of single jersey polyester cotton blended knit fabric [11]. It is also difficult to increase the pilling resistance of three thread polyester cotton blended fleece fabric. The effect of heat setting combined with singeing on the pilling propensity of three thread fleece fabric is investigated in this report. The primary goal of this research is to enhance the pilling grade of polyester cotton blended fleece fabric while maintaining the other mechanical properties within the standard value range. As a result, the fabric's pilling grade, as well as its elastic recovery, shrinkage, spirality, and color fastness properties, were investigated after the singeing and heat setting operation. Figure 1: Represents the knitted structure, notation diagram, needle arrangement and cam arrangement of three-thread fleece fabric.

Figure 1.

(a) knitted structure, (b) notation diagram, (c) needle arrangement and (d) cam arrangement of three-thread fleece fabric.

2. Experimental

2.1. Sample preparation

Three types of fleece fabric samples were developed in this experiment to improve the pilling properties of fleece Table 1. Fabric characteristics may be affected by the structure and composition of the base or face, binder, and fleecy yarn. The difference was made in the base yarn, which was made up of 80/20 CVC, 60/40 CVC, and 65/35 PC yarn, 100 percent polyester filament as the binder, and 100 percent cotton yarn as the fleecy yarn. Face yarn, binding yarn, and fleecy yarn had yarn counts of 30 Ne, 100 Denier, and 10 Ne, respectively. Twist multiplier (TM), Twist per inch (TPI) and Imperfection index (IPI) of the base and fleecy yarn were held within a defined range to get the more reliable results. The fleece samples were created on a special form of circular fleece knitting machine from Gong Lih. (model: GLF/3.2–3T, origin: Taiwan), with a diameter of 34 inches and a gauge of 20 needles per inch. Face yarn, binding yarn, and fleecy yarn stitch lengths were set at 4.6mm, 3.1mm, and 1.8mm, respectively. In this experiment, three different types of fleece fabrics were developed and finished (Table 1). However, in the finishing segment, each sample was divided into four sections, each of which was subjected to a different type of finishing. Before the pilling test, the first part of each sample S01 (a), S02 (a), and S03(a) were left untreated, which implies they were not subjected to any kind of finishing phase such as singeing or heat environment. The heat setting process was applied to the second part of each sample S01 (b), S02 (b), and S03 (b). After that, the third part of each sample S01 (c), S02 (c), and S03 (c) went through only the singeing phase, with no heat setting. However, the fourth part of every sample S01 (d), S02 (d) and S03 (d) experienced both heat setting and singeing.

Table 1.

Mechanical finishing route of experimental fabric.

| Pilling Sample | Sample Condition | Finishing Route |

|---|---|---|

| S01(a) | Untreated sample | Which didn't get any singeing or any heat setting before pretreatment. |

| S02(a) | ||

| S03(a) | ||

| S01(b) | Only Heat setting | Only heat setting process is applied before pretreatment. |

| S02(b) | ||

| S03(b) | ||

| S01(c) | Only Singeing | Only singeing process is applied before pretreatment. |

| S02(c) | ||

| S03(c) | ||

| S01(d) | Both singeing and heat setting | Both singeing and heat setting parameter is applied before pretreatment. |

| S02(d) | ||

| S03(d) |

Heat setting was performed at 190 °C using an EhwhaGlotech stenter machine (model Platinum, origin South Korea). By keeping the fabric speed steady at 18 m per minute, the fabric samples went through 8 chambers in under a minute. The fabrics had a 20 percent fed at limit. Following the heat setting, the samples were singed to eliminate any floating or hairy fibers that were visible on the fabric surface. In the singeing process the protruding fibers are burned off from the face side of the fabric to create a clean surface which improves the overall quality of the fabric. For the singeing process of fleece fabrics, a Dornier (model CMB/2, origin Germany) gas singing machine was used. The fabrics were singed at a rate of 60–80 m per minute. The compacting process was then completed using a Lafer compacting machine (model: KSA500, origin: Italy). At a speed of 20 m per minute and a temperature of 120 degrees Celsius, the fabrics were subjected to 4% compaction and 35% overfeed.

2.2. Experimental procedure of measuring pilling properties of fleece fabric

After that, all of the samples were subjected to pilling using an ICI pilling box according to the ISO 12945-1:2000 test process, which involved exposing all of the samples to 14,400 revolutions in the ICI pilling box. The pilling test samples were then compared to the pilling gray scale. There are five grades on the gray scale that show the condition of the fabric after the pilling test. The worst pilling grade is grade number-1. It means that the sample fabric has undergone significant changes and thick pilling has developed on the fabric's surface. Pilling grade 2 means that the fabric appearance has changed significantly after the pilling test, and a distinct pill has developed on the fabric's surface. In pilling grade 3, moderate fuzzing or isolated fully formed pilling can be seen on the fabric's surface. Pilling grade-4 is much stronger than the previous grades, with just a small difference in the fabric's surface and minor pilling forming. However, piling grade-5 indicates the best result among all the grades where no change is observed and no pilling informed on the surface of the fabric.

2.3. Measurement of elastic recovery, shrinkage, spirality and color fastness properties of three thread fleece fabric

The three thread polyester cotton blended fleece fabric samples were subjected to a variety of tests in order to determine their different physical and mechanical properties. The samples were tested using the BS EN 14704-1:2005 system with a 15 N load in a GT-C13B CRE (constant rate of elongation) elastic recovery testing machine (Gester, China). Since all of the samples were knitted in the weft direction, both extensibility and recovery percentages were calculated in that direction. The elastic recovery test was used to assess the stretch properties of knitted fabric when stress and extension were applied to it. Fabric elastic recovery was calculated on the percentage of the fabric extension recovered with respect to the fabric extension determined after a specific tension (15 N) was applied at various intervals. Shrinkage test was also done to sample fabrics to determine the shrinkage of the fabrics occurred because of laundry process. Due to the high tension during fabric manufacturing the yarns were stretched, so when the fabric went through the washing the shrinkage occurred to the fabrics and lengthwise shrinkage & widthwise shrinkage was determined. The shrinkage percentage of the samples was tested using ISO 6330:2012 standard method. Spirality occurs in knitted fabrics as a result of the washing process, so the spirality test was performed on the samples to search for dimensional distortion. The ISO 6330:2012 test method was used to determine the spirality of the fabric samples. After that, samples were obtained to test the fabrics' color fastness. Color fastness refers to a color's resistance to things like cleaning, rubbing, sweat, perspiration, and light. Different methods for determining the fabric's color fastness have been developed. Wash fastness refers to a color's resistance to fading or bleeding when washed. The fabric's wash fastness was tested using the ISO 105-C06:2010 method. The ability of a color to withstand rubbing on a fabric is referred to as rubbing fastness. The rubbing fastness of the fabrics was determined using the ISO 105-X12:2001 test process. The water fastness test was introduced to determine a dyed fabric's resistance to water. The water fastness of the colors in the fabrics was determined using the EN ISO 105-E01 process. A color fastness to perspiration test was performed to assess the fabrics' color tolerance to all types of perspiration. The EN ISO 105-E04 method was used to assess color fastness to perspiration. The aim of a color fastness to light test was to see how much color faded from fabrics when exposed to light. In order to assess the color fastness to light the ISO 05B02 2014 testing method was used. The pH value of fabric samples was tested as they went through heat setting and singeing to see if the value of pH was within the normal range. The pH level of the finished fabric was measured using a standard method (ISO 3071:2005).

3. Result and discussion

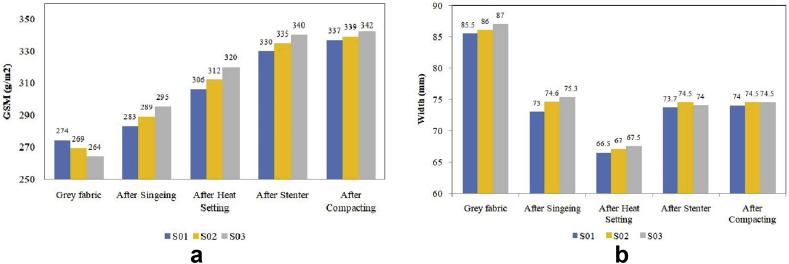

3.1. Change of fabric GSM and width

Target GSM and width were determined as 300 g/m2and 74 inch after the finishing process. Change of GSM and width for all the three samples (S01, S02& S03) at different stages of fabric processing are represented in Figure 2(a) and (b) respectively. Standard deviation for GSM and width were less than or equal 7.21 and 0.30, respectively for all the listed data. In Figure 2(a) it is seen that the GSM of all the fabric samples gradually increased in each finishing process. The gray fabric GSM was 264–274 which was seen to slightly increase after the singeing process and continued increasing at each finishing process with reaching the GSM value 337–342 after the compacting process. On the other side, fabric width decreased after the singeing and heat setting process followed by a gradual increase after the stenter and compacting process. The gray fabric width was 85.5–87 inch which was gradually increased during the singeing and heat setting process and reaching a value of 66.5–67.5 inch. However, an opposite trend was seen after the stenter and compacting process. Fabric width increased to 73.7–74.5 inch after the stenter and remained almost stable after the compacting process.

Figure 2.

(a) Graphical representation of fabric GSM value (b) Graphical representation of fabric width.

From the Figure 2(a) and (b) it can be seen that after the singeing process, the GSM of the fabric increased while the width of the fabric decreased from the gray state. In singeing process the fabric moves towards the lengthwise direction with the help of rollers that imparts a tangential force along the fabric length. This tangential force caused length wise elongation and width wise contraction. Due to the contraction of the fabric width, courses of the knitted structure come closer than before which allows more courses in a unit area eventually increased the fabric GSM. Due to the similar reason the fabric width further decreased and the GSM increased after the heat setting process. However, the fabric GSM increased after the stenter and compacting process due to over feed of the material (40% overfeed in stenter and 35% overfeed in compacting).

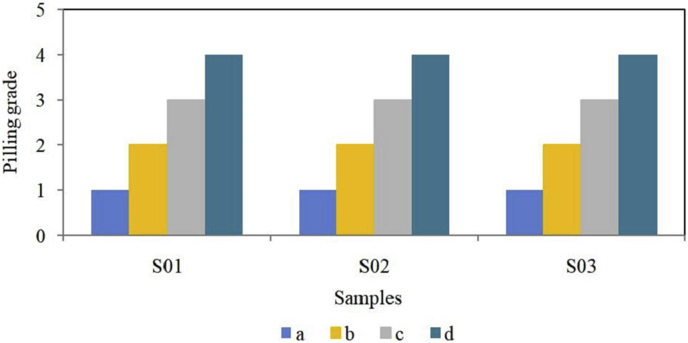

3.2. Analysis of pilling properties of three thread fleece fabric by singeing and heat setting

All the 12 samples faced the pilling testing process where ICI pilling tester (ISO 12945-1:2000 test method) was used in order to check their pilling grades. In the pilling test result it can be observed that the samples S01(d) S02 (d) and S03 (d) showed the best pilling result where the result was grade-4 according to the pilling gray scale. S01 (d), S02 (d) and S03 (d) samples went through both heat setting and singing finishing process and these processes ameliorated the pilling resistance of the fabrics. Though the S01, S02 and S03 have different face yarn composition but the finishing processes increased the pilling resistance quality for all the samples. On the other hand samples S01 (a), S02 (a) and S03 (a) showed the worst piling grade as they did not obtain any kind of finishing treatment. The pilling grade for S01 (a), S02 (a) and S03 (a) samples was grade-1 according to the pilling gray scale. It is clearly understood that without any finishing process the pilling resistance of the fabric samples are really poor. To increase the pilling resistance quality of the samples only heat setting was done to S01 (b), S02 (b) and S03 (b) samples. Heat setting improved the pilling grade of the samples which can be seen from the pilling test result as their pilling grade was grade-2 which is better than grade-1. Significant improvement was observed due to the heat setting process. The heat setting is a thermal process which helps the thermo plastic fibers to develop more dimensional stability during the washing and drying by applying excessive heat. Most probably due to the heat temperature set the fiber within the fabric surface and improves proportional pilling resistance. However, singeing process was done to the S01 (c), S02 (c) and S03 (c) samples which also helped the fabrics to increase their pilling grade even more. The pilling grade of the S01 (c), S02 (c) and S03 (c) sample was grade-3. Singeing process helps to remove the neps in the yarn which ultimately decrease the chance of pilling formation. The short and loosen fibers can easily get entangled with each other and create pills. Therefore it is important to remove those fibers to make the clean and smooth surface of the fabric, which is done in the singeing process. As the amount of the short fibers were burnt off after the singeing process, so the chances of entanglement of short fiber is decreased which eventually results in less pill formation. Heat setting and singeing process was done to the S01 (d), S02 (d) and S03 (d) sample. So the positive effect of both heat setting and singeing was present in those samples. That is why the S01 (d), S02 (d) and S03 (d) sample showed the best pilling grade which is acceptable according to the buyer's requirements. Figure 3 shows the pilling grades of the samples.

Figure 3.

Graphical representation of pilling grade of experimental samples.

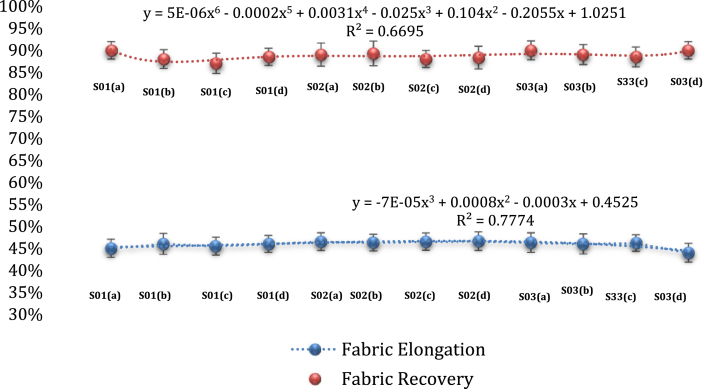

3.3. Fabric elastic property after heat set and singeing

In this experiment, a total of 12 samples were made, each with three different face yarn constructions. It means that each of the four samples has the same face yarn construction, but the key difference between them is the finishing process they underwent. Each of the four samples was subjected to four separate finishing procedures. There was no substantial difference in the results when the elastic recoveries of certain sample fabrics were calculated using the BS EN 14704-1:2005 test process. Figure 4 depicts the elastic recovery values. The maximum value of standard deviation were measured 0.36 for the elongation % at 15N force and the total length after 15N force whereas this value was measured 0.10 for the fabric recovery % after 30 min.

Figure 4.

Graphical representation of Fabric Elongation and Fabric Recovery.

The Figure 4 represents the fabric elongation and recovery percentage for all the fabric samples. The fabric elongation percentage for all of the samples was found to be around 45 percent, and the fabric recovery percentage was found to be around 87 percent, as shown in Figure 4. The fabric elongation and fabric recovery percentage were not affected by the different fabric processing method used in this experiment, as seen in this graph. The untreated gray fabrics are S01(a), S02(a), and S03(a). S01(b), S02(b), and S03(b) were the only ones who went through the heat setting process. The fabric had already been subjected to longitudinal force during the heat setting process. As a result, the fabric cannot be further elongated because the elongation process occurred during the heat setting process. As a result, the fabric elongation percentage remained nearly identical to that of the gray fabric. The fabric recovery percentage for the S01(b), S02(b) and S03(b) samples remained identical to the gray fabric because the fabric elongation percentage did not alter much. Only the singeing method was used on S01(c), S02(c), and S03(c). Fabric sample was also subjected to longitudinal force during the singeing process. As a result, the fabric elongation and recovery percentages were almost identical to those of the gray fabric samples. Heat setting and singeing were performed on S01(d), S02(d), and S03(d). As a result, they also generated similar results. Finally, it can be concluded that none of these processes had a significant impact on the sample fabrics' fabric elongation and recovery percentage.

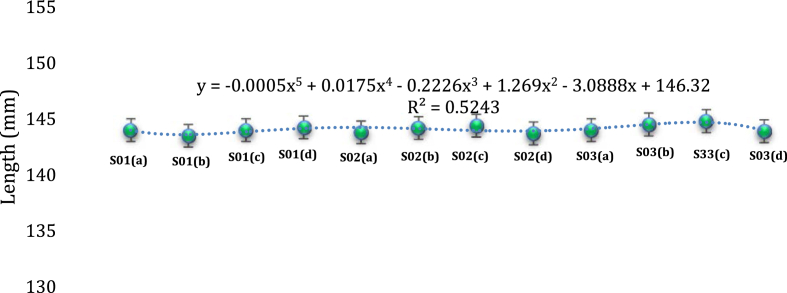

The fabric length after applying 15N force for all of the sample fabrics is shown in Figure 5. After applying 15N force, the fabric lengths of the sample fabrics were almost identical (around 145 inch). As, S01 (a), S02 (a) and S03 (a) are the untreated gray fabric they did not went through any kind of finishing process. S01 (b), S02 (b), and S03 (b) on the other hand, just went through a heat setting phase and obtained longitudinal stability. As a result, their length did not change significantly after applying 15N force. S01(c), S02(c), and S03(c) underwent only the singeing process and achieved longitudinal stability. As a result their length after applying 15N force did not change much. Heat setting and singeing were applied to S01 (d), S02 (d), and S03 (d), resulting in a more stable condition. After applying 15N force, the length of the samples S01 (d), S02 (d), and S03 (d) were almost identical to the gray fabric samples.

Figure 5.

Graphical representation of Fabric Length after applying 15N force.

The fabric recovery percentage after a certain amount of time for all the samples was almost the same value, according to the results of the elastic recovery test using 15N force. Since the knitting parameters for all of the sample fabrics were kept stable, there was no impact of the finishing phase on the elastic recovery percentage of the fabrics. The stitch lengths of the base, binder, and fleecy yarn were 4.60 mm, 3.10 mm, and 1.80 mm for all of the samples, respectively. All 12 samples had yarn counts of 30 Ne, 100 Denier, and 10 Ne for the base, binder, and fleecy yarns, respectively. When producing all of the samples, machine diameter was 34 inches and a gauge of 20. The elastic recovery percentage of the sample fabrics was also kept the same since the knitting parameters of the sample fabrics were kept the same. However, it was critical to examine the elastic recovery values of the samples to see whether there was any unintended adjustment in the fabric elastic recovery percentage as a result of the various finishing processes. Despite going through the heat setting and singeing processes, there was no noticeable difference in the elastic recovery percentage of the sample fabrics.

3.4. Analysis of shrinkage and spirality of three thread fleece fabric

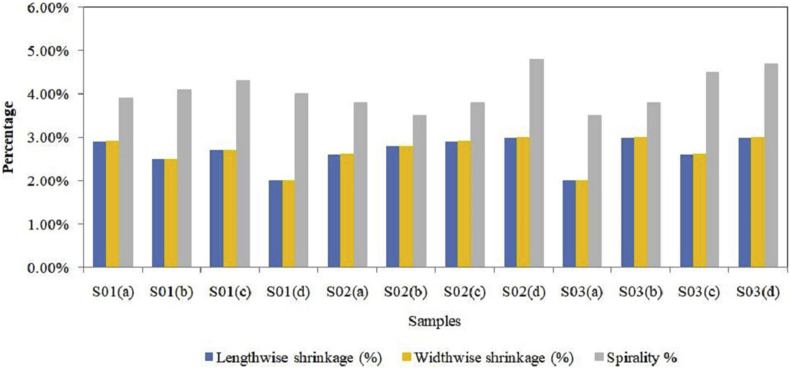

Fabric shrinkage and spirality were measured according to ISO 6330:2012 test Method to determine whether there was any change due to heat setting and singeing process. The test result of fabric shrinkage and spirality are shown in the Figure 6. The maximum value of standard deviation were measured 0.26, 0.78 and 0.36 for the length wise shrinkage, width wise shrinkage and spirality.

Figure 6.

Graphical representation of Fabric Shrinkage and Spirality

The lengthwise shrinkage percentage, widthwise shrinkage percentage, and spirality of the sample fabrics are shown in Figure 6. The lengthwise shrinkage percentage and the widthwise shrinkage percentage for each individual sample fabric were almost identical, as shown in the graph. The spirality percentage for the sample fabrics, on the other hand, was much higher than the lengthwise and widthwise shrinkage percentages. There was no discernible pattern in this graph. The primary purpose of this graph was to see how the heat setting and singeing processes affected the sample fabrics. The desire value for shrinkage percentage for a higher quality fabric is less than 5%, and the desire value for spirality percentage is less than 7%. The mean value of lengthwise shrinkage percentage and widthwise shrinkage percentage was 3 percent, and the minimum value was 2 percent, as seen in the graph. Each sample has a lengthwise shrinkage percentage of less than 5% and a widthwise shrinkage percentage of less than 5%. The highest value of sprirality was 4.80 percent, while the minimum value was 3.50 percent. As a result, all of the samples have a spirality of less than 7%, which is the optimal amount. In conclusion, both samples have excellent dimensional stability, as their shrinkage percentage was less than 5% and their sprilality was less than 7%, indicating that the samples are suitable for use. Both lengthwise and widthwise shrinkage percentages were found within a 5-percentage-point range. With or without heat setting and singeing, the sample fabrics showed excellent shrinkage both lengthwise and widthwise, according to the test results. Because of the high GSM of the fleece fabrics, it is obvious that the heat setting and singeing processes had little effect on the shrinkage percentage of the polyester cotton blended fleece fabrics, and the shrinkage percentage values were within the appropriate range. In terms of spirality percentage, a range of 7% is appropriate. Since the spirality percentage test outcome was within the appropriate range, the heat setting or singeing process had no effect on the spirality percentage. The spirality of the heavy GSM three thread fleece fabrics was excellent and was unaffected by the finishing process.

4. Conclusion

To meet consumer demand in the global knit industry, circular weft knitted polyester cotton blended fabric must boost physical properties (pilling resistance, perspiration and rubbing) as well as some mechanical properties (elastic recovery, shrinkage, spirality). The main goal of this research is to improve the pilling behavior of three-thread polyester cotton fleece fabric. All of the study's objectives were met, and it can be concluded that singeing and heat setting are the most effective methods for reducing pilling in polyester cotton blended three thread fleece cloth. Excellent pilling resistance grade (4) is achieved after applying both singeing and heat setting. Without singeing and heat setting, the pilling grade is found to be very low. In the knitting industry, this method may be used to reduce the pilling tendency of CVC knit fabric.

Declarations

Author contribution statement

Md. Shakhawat Hossain: Conceived and designed the experiments; Performed the experiments.

Md. Momtaz Islam: Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Sumon Chandra Dey, Naimul Hasan: Contributed reagents, materials, analysis tools or data.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

The authors would like to express appreciation to Iris fabrics limited for their technical support in knitting, dyeing and finishing those experimental fabrics.

References

- 1.Spencer J.D. third ed. Woodhead Publishing Limited; Cambridge, Englind: 2001. Knitting Technology; p. 42. Chapter 5. [Google Scholar]

- 2.Ozcan G., Candan C. Properties of three-thread fleece fabrics. Textil. Res. J. 2005;75(2):129–133. [Google Scholar]

- 3.Anbumani N. first ed. New age International (P) Ltd; New Delhi, India: 2007. Knitting Fundamentals, Machines,Structures and Developments; pp. 48–49. Chapter 6. [Google Scholar]

- 4.Smriti S.A., Islam M.A. An exploration on pilling attitudes of cotton polyester blended single Jersey knit fabric after mechanical singeing. Sci. Innovat. 2015;3(1):18–21. [Google Scholar]

- 5.Yesmin S., Hasan M., Miah M.S., Momotaz F., Idris M.A., Hasan M.R. Effect of stitch length and fabric constructions on dimensional and mechanical properties of knitted fabrics. World Appl. Sci. J. 2014;32(9):1991–1995. [Google Scholar]

- 6.Saville B.P. 1 st Edition. 2000. Physical Testing of Textiles. Serviceability, U.K; pp. 186–195. Chapter 7. [Google Scholar]

- 7.Li L., Zhu M., Wei X. 2014. Pilling Performance of Cashmere Knitted Fabric of Woollen Ring Yarn and Mule Yarn. Fibres& Textiles in Eastern Europe. [Google Scholar]

- 8.Sivakumar R., Pillay K.P.R. 1981. Study of Pilling in Polyester/cotton Blended Fabrics. [Google Scholar]

- 9.Abd El-Hady R.A.M., Abd El-Baky R.A.A. The influence of pile weft knitted structures on the functional properties of winter outerwear fabrics. J. Am. Sci. 2015;11(9) [Google Scholar]

- 10.Fouda A.E. Effect of backed yarn characteristics on two-thread fleece knitted fabric properties. Indian J. Fiber Textil Res. 2018;43(2):247–251. [Google Scholar]

- 11.Shakhawat H. Effect of singeing and heat setting on pilling properties of CVC single Jersey knit fabric. Int. J. Cur. Eng. Technol. 2017;1 [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.