Significance

Inorganic semiconductor based micro-LEDs have recently attracted tremendous interests of both industrial developers and academic researchers for the realization of next-generation displays. The reduction of LED sizes causes performance degradation and increased fabrication challenges. In this paper, we introduce a tandem device scheme based on stacked red, green, and blue (RGB) micro-LEDs for the realization of full-color lighting and displays. Thin-film micro-LEDs (size ∼100 μm, thickness ∼5 μm) based on III–V compound semiconductors are vertically assembled via epitaxial liftoff and transfer printing. A thin-film dielectric-based optical filter serves as a wavelength selective interface for performance enhancement. Furthermore, we prototype arrays of tandem RGB micro-LEDs and demonstrate display capabilities across the entire visible wavelength range.

Keywords: light-emitting diodes, micro-LEDs, transfer printing, displays, optical filters

Abstract

Inorganic semiconductor-based microscale light-emitting diodes (micro-LEDs) have been widely considered the key solution to next-generation, ubiquitous lighting and display systems, with their efficiency, brightness, contrast, stability, and dynamic response superior to liquid crystal or organic-based counterparts. However, the reduction of micro-LED sizes leads to the deteriorated device performance and increased difficulties in manufacturing. Here, we report a tandem device scheme based on stacked red, green, and blue (RGB) micro-LEDs, for the realization of full-color lighting and displays. Thin-film micro-LEDs (size ∼100 μm, thickness ∼5 μm) based on III–V compound semiconductors are vertically assembled via epitaxial liftoff and transfer printing. A thin-film dielectric-based optical filter serves as a wavelength-selective interface for performance enhancement. Furthermore, we prototype arrays of tandem RGB micro-LEDs and demonstrate display capabilities. These materials and device strategies provide a viable path to advanced lighting and display systems.

Microscale light-emitting diodes (micro-LEDs) based on inorganic semiconductors have been widely regarded as one of the most promising solutions to the next generation of emissive display technologies for versatile applications, from televisions, smartphones and wearable watches, to advanced virtual, augmented, and mixed realities (1–4). Constructed from single-crystalline–compound semiconductors like gallium arsenide (GaAs), gallium phosphide (GaP), and gallium nitride (GaN), these micro-LEDs present significant benefits over conventional liquid crystal displays (LCDs) (5), organic LEDs (OLEDs) (6–9), and more recent quantum dot (10, 11) and perovskite-based LEDs (12), in terms of their efficiencies, brightness, contrast, dynamic response, and long-time stability. High-resolution displays rely on arrays of polychromatic (red, green, and blue [RGB]) emissive elements with dimensions of less than 100 μm or even 10 μm, which are massively and heterogeneously assembled onto silicon, glass, or plastic substrates (13–17). This scaling down of device sizes enhances the display resolution and reduces the raw material cost; however, it is also accompanied by significant challenges. First, reducing LED size causes dramatic efficiency decreases for all types of LEDs (18–21), particularly GaAs- or GaP-based red LEDs that are more susceptible to sidewall defects (SI Appendix, Fig. S1). Second, device shrinkage also results in deteriorated uniformity, which influences the reliability and performance of display systems. Third, fabricating and transferring smaller devices demand higher accuracies for alignment and positioning (22), imposing greatly increased manufacturing expenses (SI Appendix, Fig. S2).

Alternatively, device arrays with a single-pixel, spectrally tunable LED (23) or vertically stacked tandem LEDs (24) relieve the above constraints associated with conventional laterally arranged RGB micro-LEDs. However, color-tunable LEDs based on voltage-dependent spectral change can neither achieve full-range tunability nor obtain independent color/intensity controllability (25, 26). On the other hand, the current state-of-the-art wafer-bonding–based assembly methods only realize double-layer stacking with the capability of dual-color tuning (green/blue or red/blue) (22, 27, 28). Although there are some reports on full-color stacked inorganic and organic RGB LEDs (24, 29–31), these demonstrations are only limited to a few of chip-scale, large or thick LEDs for lighting purposes.

In this paper, we report a tandem thin-film RGB micro-LED architecture with full-range color tunability to overcome the limitations of previously explored technologies. Based on the epitaxial liftoff and transfer printing method, arrays of thin-film, high-performance, inorganic RGB micro-LEDs made of different III–V compounds are assembled in a vertical stack. Embedded into the stacked structure, a thin-film dielectric filter serves as a wavelength selective interlayer to improve the LED light output. Independently addressable active arrays show full-color electroluminescent patterns, demonstrating the display capability of the tandem micro-LEDs.

Results

Fig. 1A schematically illustrates and compares laterally arranged RGB micro-LED arrays and vertically stacked, tandem arrays. To realize the same resolution (or pixels per inch, PPI) for display purposes, the minimum required LED size in the tandem design can be three times larger than that in the lateral arrangement structure. As described in aforementioned discussions and SI Appendix, Figs. S1 and S2, the use of larger LEDs holds the advantages of enhanced device performance and reduced nonuniformity as well as higher tolerance to alignment errors during microfabrication and device placement. The exploded cartoon image of our tandem micro-LED array and pixel design is depicted in Fig. 1B. Details of fabrication are described in the SI Appendix, Figs. S3–S9 and Tables S1–S4. From top to bottom, a single pixel comprises an indium gallium nitride (InGaN) blue LED, an InGaN green LED, a longpass band selective filter, and an indium gallium phosphide (InGaP) red LED. The designed epitaxial structures of these blue, green, and red LEDs are adopted from the standard multiple quantum wells incorporating emissive layers made of In0.15Ga0.85N, In0.3Ga0.7N, and In0.5Ga0.5P, respectively, as well as cladding layers (32). In particular, a distributed Bragg reflector is designed within the red LED for improved light extraction (35). These thin-film–based, microscale devices are epitaxially grown and lithographically fabricated on rigid, single-crystalline wafers (sapphire for InGaN blue and green LEDs and GaAs for InGaP red LEDs and filters) and subsequently separated from original substrates by laser liftoff (for sapphire) (33, 34) or selective etching (for GaAs) (13, 35–37). Optical images and electroluminescence (EL) spectra of individual RGB micro-LEDs are provided in SI Appendix, Fig. S6, showing EL emission peaks at 628 nm, 530 nm, and 475 nm for RGB LEDs, respectively. Released, freestanding thin-film devices are transfer printed onto foreign rigid (e.g., glass) or flexible (e.g., polyimide) substrates (38, 39), forming a vertically assembled stack. In such a tandem structure, RGB micro-LEDs share the same geometries and are accurately overlaid. In addition, the designed optical filter layer between the red and green LEDs offers not only high transmission for red light but also a near-unity reflectivity at shorter wavelengths (<600 nm), increasing the light extraction for blue and green LEDs. Most active layers (GaN, ITO, etc.) in the blue and green LEDs are inherently transparent in the visible range, further minimizing the optical losses for red light emitted from the bottom InGaP LED. The active InGaN emitter (thickness ∼20 nm in the quantum wells) in the green LED only slightly absorbs blue light (with an optical loss around 10% at 475 nm) (40). Besides, the large spectral overlap of the blue and green LEDs makes the design of a filter layer for optimized reflection (for blue) and transmission (for green and red) difficult and unnecessary. Irradiations from the RGB micro-LEDs in a tandem stack with a thin-film filter are schematically illustrated in SI Appendix, Fig. S10. Different device layers are separated by SU-8 epoxy–based thin films, which serve as electrically insulating, optically transparent, and mechanically adhesive bonding interfaces. During the transfer process, these heterogeneously integrated micro-LEDs can be further metalized to form electrically-driven emissive arrays for display applications (schematically illustrated in Fig. 1B). Fig. 1C illustrates a representative array (more than 6 × 8 pixels) of tandem RGB micro-LEDs printed onto a polyimide substrate without metal lines. Fluorescence images captured at various spectral ranges clearly reveal photoluminescent emission from the RGB LEDs, indicating that these micro-LEDs are well positioned with minimal misalignments. Although each micro-LED has a lateral dimension around 125 μm × 180 μm, the presented tandem array holds a resolution that is identical to a conventional lateral RGB array with LED sizes three times smaller (around 125 μm × 60 μm). Display systems based on arrays of such a tandem RGB pixel can reach a PPI of 200 to 400, which is higher than state-of-the-art high-definition televisions and on a par with those in smartphones. The scanning electron microscope (SEM) image in Fig. 1D presents the cross-sectional structure of a tandem RGB micro-LED. Thin-film RGB LEDs and the filter have thicknesses around 5 to 7 μm, with 2 to 5 μm thick SU-8 epoxy interlayers between each device, resulting in a total thickness of around 45 μm. Shown in the SEM image, the tilted device layers are mainly attributed to the nonuniformity of the organic adhesive (SU-8 epoxy), which can be addressed by reducing the adhesive thickness and optimizing the baking and transfer processes.

Fig. 1.

Schematic illustrations and images of tandem RGB thin-film micro-LEDs and device arrays, assembled by the transfer printing method. (A) Comparison of a conventional parallel RGB micro-LED array (Left) and our proposed tandem RGB micro-LED array (Right), with the same display resolution. (B) Exploded schematic of tandem RGB micro-LED arrays, with the inset showing a single pixel, comprising an InGaP red LED, a multilayer SiO2/TiO2 filter, an InGaN green LED, and an InGaN blue LED (from bottom to top). The stacked devices can be assembled on various substrates. (C) Fluorescent microscopic images for an array of tandem RGB micro-LEDs. From top to bottom: bright field view, RGB emissions under green/blue/ultraviolet (UV) illuminations, respectively. (D) Cross-sectional scanning electron microscope (SEM) image of tandem RGB micro-LEDs with colorized regions showing thin films of RGB micro-LEDs as well as the filter interlayer. Different device layers are separated by layers of SU-8 epoxy.

The separated metallization for RGB micro-LEDs in the tandem structure allows independent electrical control of individual devices. Fig. 2 A–C plot micrographs and measured EL spectra for RGB micro-LEDs in the tandem structure. The emission spectra are identical to those for micro-LEDs on original substrates (SI Appendix, Fig. S6), showing that these micro-LEDs in the tandem design can work independently with negligible electrical or optical crosstalk. Continuously adjustable currents can be injected into two or three micro-LEDs in the stack, and the combined spectra realize emissions of different colors like white, cyan, yellow, and purple (Fig. 2 D–G). Dynamic color change is also captured and shown in Movie S1. The color space achieved by our tandem micro-LED emitter is provided in Fig. 2H, which has a 93% overlap with the Adobe RGB color gamut within the CIE 1931 chromaticity diagram by the International Commission for Illumination (Commission International de L’Eclairage, CIE) (32). Coordinates for various EL spectra presented in Fig. 2 D–G are also indicated in Fig. 2H, which are (0.68, 0.30), (0.24, 0.72), (0.12, 0.14), (0.33, 0.33), (0.16, 0.36), (0.49, 0.48), (0.39, 0.23) for red, green, blue, white, cyan, yellow, and purple emissions, respectively. These results clearly demonstrate the capability of full-color coverage within the visible range for display applications.

Fig. 2.

Optical micrographs and EL performance of tandem RGB micro-LEDs. (A–G) EL spectra of a tandem device when currents are injected into different LEDs. Insets show optical images displaying different colors: (A) red, (B) green, (C) blue, (D) white, (E) cyan, (F) yellow, and (G) purple. (H) Chromaticity of tandem RGB micro-LEDs (solid line) in the CIE1931 color space, comparing with the Adobe RGB (dashed line). The stars represent the coordinates for spectra measured in A–G.

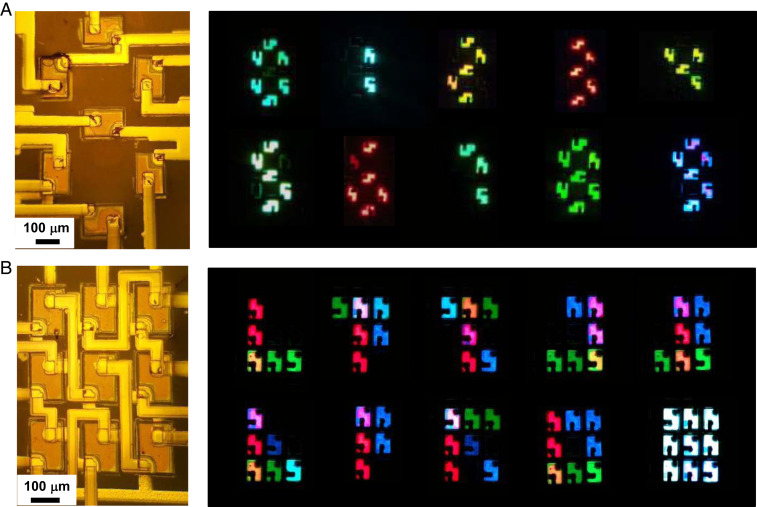

To offer a proof of concept, we prepare arrays of tandem RGB micro-LEDs metalized with independent electrical contact pads for active display demonstrations in Fig. 3. Fig. 3A presents a pixel array to realize a simple seven-segment display, which is able to dynamically output decimal digits from 0 to 9 with various colors (SI Appendix, Fig. S11 and Movie S2). Additionally, Fig. 3B shows a device array with 3 × 3 pixels displaying different colored patterns (SI Appendix, Fig. S12 and Movie S3). The overall yield for micro-LED fabrication, transfer, stacking, and interconnection can reach nearly 100% for these small-scale arrays. The tandem design has the potential to be expanded for large-scale emissive arrays, leveraged by automated, massive transfer technique (41) and advanced driver circuits with matrix-addressable functions (2, 42).

Fig. 3.

Arrays of tandem RGB micro-LEDs interconnected for display demonstration. (A) Micrograph for an array forming seven-segment display (Left), showing decimal numerals 0 through 9 with various colors (Right). (B) Micrograph for a 3 × 3 array (Left), showing different color patterns.

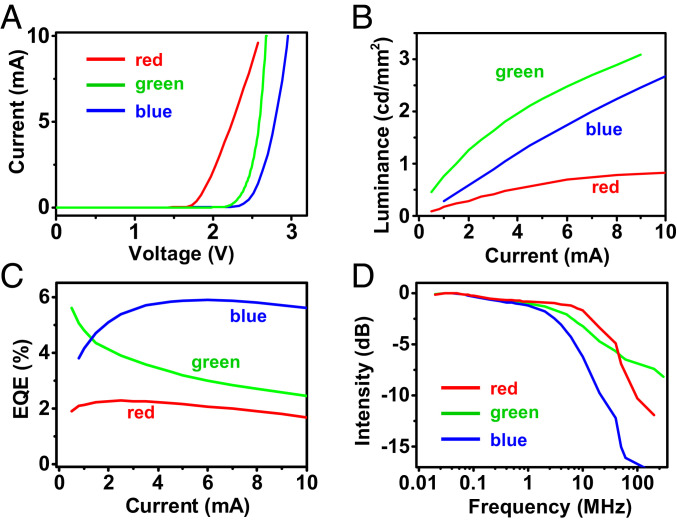

Fig. 4 and Table 1 summarize the measured optoelectronic performance for RGB micro-LEDs in a representative, complete tandem stack. Current and voltage characteristics in Fig. 4A show threshold voltages of about 1.6 V, 2.2 V, and 2.4 V, and currents reaching 10 mA at 2.5 V, 2.6 V, and 2.9 V for red, green and blue micro-LEDs, respectively. Compared to unreleased micro-LEDs on original growth substrates, performances for these devices in the tandem structure do not experience degradations after wafer separation and transfer printing. Furthermore, the results verify that the tandem device configuration do not induce unwanted interferences among the individual micro-LEDs. For all the micro-LEDs, measured luminance levels are in the range of 1 to 10 cd/mm2 at injected currents of 1 to 10 mA (Fig. 4B). The performances are similar to those for previously reported inorganic micro-LEDs (in the order of 106 to 107 cd/m2) (3, 15, 43) and much higher than those reported OLEDs (103 to 104 cd/m2) (8) and conventional LCDs (102 to 103 cd/m2) (5). Fig. 4C plots measured external quantum efficiency (EQE) spectra for different micro-LEDs. At currents of 1 to 10 mA, EQEs for micro-LEDs in the tandem structure are in the range of 2% to 6%, mostly limited by the inefficient light extraction at the high-index semiconductor and air interfaces. Since the current state-of-the-art EQEs are around 20% to 50% for LEDs in the lighting field, there is still room for improvement in the future research, for example, by introducing photonic structures for better light extraction (44, 45), reducing nonradiative recombination by sidewall passivation (46), facilitating the thermal dissipation with a heat sink (33), etc. Fig. 4D shows measured electrical-to-optical frequency responses for these devices, at a current of 3 mA. The 3 dB modulation bandwidths are around 17 MHz, 9 MHz, and 4 MHz for red, green and blue micro-LEDs, respectively. The results indicate that these micro-LEDs present a fast response time (less than 1 μs) superior to LCDs and OLEDs (typically in the order of 1 to 100 kHz).

Fig. 4.

Optoelectronic properties of the RGB micro-LEDs in a tandem structure. (A) Current–voltage curves. (B) Brightness versus current. (C) EQEs as a function of current. (D) Emissive power versus modulation frequency.

Table 1.

Performance of individual red, green, and blue micro-LEDs in a tandem RGB LED structure

| LED color | Red | Green | Blue |

| λpeak (nm) | 628 | 530 | 475 |

| Full width at half maxima (FWHM) (nm) | 14 | 32 | 23 |

| EQEmax (%) | 2.6 | 5.8 | 6.0 |

| ηmax (cd/A) | 4.6 | 20.6 | 6.8 |

| V @ ηmax (V) | 1.8 | 2.3 | 2.6 |

| V @ 1 cd/mm2 | 2.1 | 2.3 | 2.6 |

| CIE coordinates (x, y) | (0.68, 0.30) | (0.24, 0.72) | (0.12, 0.14) |

| 3 dB frequency (MHz) | 17 | 9 | 4 |

As previously described, an optical design for wavelength selective transmission/reflection at the interface between the green and the red micro-LEDs is crucial for optimizing the performance of the tandem RGB devices. High-performance optical filters are normally made of multilayer dielectric structures that are deposited on glass (47). Here, we show that thin-film microscale filters can be heterogeneously integrated into the tandem micro-LED structure, with a similar printing-based approach (Fig. 5). The designed filter structure is made of multilayered titanium dioxide (TiO2) and silicon dioxide (SiO2) stacks that are deposited on GaAs by sputtering (Fig. 5A and SI Appendix, Table S4). Freestanding, thin-film filters with geometries similar to RGB micro-LEDs can be formed by eliminating the GaAs substrate and laser milling (Fig. 5 B and C), with fabrication details provided in SI Appendix, Fig. S5. Angular-dependent transmittance spectra for a filter membrane printed on glass are measured in Fig. 5 D and E. Experimental results are in good agreement with optical simulations provided in Fig. 5 F and G. At normal incidence, the designed longpass filter exhibit a cutoff wavelength at around 590 nm, achieving >95% transmission at longer wavelengths (red and near infrared) and nearly zero transmission (in other words, ∼100% reflection) at shorter wavelengths (green and blue). In the tandem micro-LED structure, the filter layer reflects emissions from the green and the blue micro-LEDs back to the air and permits the transmission of red light. Therefore, the filter design is able to improve the light extraction from the green and the blue micro-LEDs, while maintaining the descent performance for the red micro-LED. Moreover, the filter layer helps minimize the photon coupling among the micro-LEDs. The cutoff wavelength for the filter exhibits a blue shift at oblique angles, which could slightly diminish the efficiencies of the green micro-LED at emissive angles larger than 40 degrees to normal.

Fig. 5.

Structures, images, and optical performance of the thin-film wavelength selective filter. (A) Cross-sectional SEM image showing the multilayered SiO2/TiO2 stacks. (B) Photograph of a released thin-film filter on a flexible polydimethylsiloxane sheet. (C) Microscopic image of a filter (size: 150 μm × 230 μm) patterned by laser milling. (D–G) Measured and simulated transmission spectra and contour plots at varied incident angles for a filter transferred on glass.

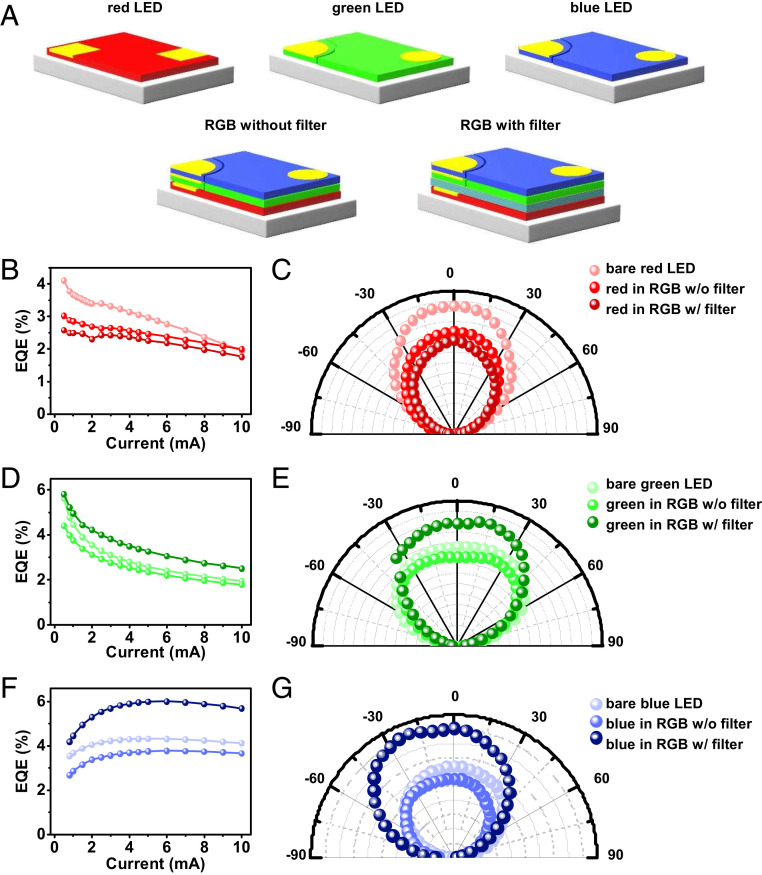

Fig. 6 compares the performance for RGB micro-LEDs in different configurations. Fig. 6A schematically summarizes different device layouts, including RGB micro-LEDs separately printed on polyimide, as well as RGB tandem stacks with and without the filter interlayer. All the micro-LEDs share the same geometries. Fig. 6 B–G plot measured EQEs versus currents as well as far-field angular emission profiles for these micro-LEDs in various structures. For red micro-LEDs, the stacked filter, green, and blue micro-LEDs on top slightly decreases their EQEs (Fig. 6 B and C), because of the intrinsic absorptions in the stacked devices on top, as well as the shadowing effects due to the device misalignment. For both green and blue micro-LEDs, the use of the selective filter clearly enhances the emission intensities and device efficiencies (Fig. 6 D–G). These micro-LEDs in a tandem structure without filter exhibit lower EQEs than those bare ones due to the strong absorption of the red micro-LED in the bottom. By contrast, the introduction of the filter increases the device efficiencies by more than 50%. All of the micro-LEDs present a near Lambertian radiation pattern, indicating a large viewing angle for desirable display applications.

Fig. 6.

Schematic illustrations of micro-LEDs on original substrates and those in tandem structures and comparisons of their optical performance. (A) Schematic illustrations of individual RGB micro-LEDs (Top), and tandem RGB devices with and without the filter interlayer (Bottom). (B–G) Measured EQEs versus current (B, D, and F) and angular emission profiles. (C, E, and G) for bare micro-LEDs and devices in tandem RGB structures. (B and C) red LEDs; (D and E) green LEDs; and (F and G) blue LEDs.

Conclusion

In this work, we report materials and device assembly strategies to create vertically stacked, tandem inorganic RGB thin-film micro-LEDs and arrays for full-color display demonstrations. The tandem device architecture can mitigate the effects of performance degradation along with the LED size reduction, as well as the stringent quality requirements for fabrication and transfer. Although the micro-LEDs’ performances are not optimized and can be further enhanced by using advanced electronic and photonic designs, the inorganic RGB micro-LEDs presented here have already shown full-color coverage, high brightness, and fast response superior to LCDs and OLEDs. The demonstrations here are performed using device with a size of around 125 μm × 180 μm, but these concepts and approaches can be adapted for the assembly of micro-LEDs with sizes of tens of micrometers and even several micrometers. Unequivocally, challenges remain for manufacturing practice, in terms of massive device transfer to realize large-scale arrays (for example, millions of pixels) with a nearly 100% yield. In addition, the design combining the micro-LED arrays and active driving circuits should be taken into account (42, 48). Compared with conventional lateral RGB configuration, the tandem device design would increase the fabrication complexity and create difficulties for connecting LEDs at different layers with driving circuits. Such challenges can be mitigated by employing planarization and interconnection methods used for standard silicon-based chip fabrication, as well as reducing the LED thicknesses down to the submicrometer scale, which would become necessary for making micro-LEDs smaller than 10 μm for virtual and augmented reality applications. Fast responses of these inorganic micro-LEDs also create possibilities for the integration of telecommunication with lighting and display systems (49). Other potential research directions include employing these tandem micro-LEDs onto flexible, stretchable, and biocompatible substrates for wearable and implantable systems in biomedical areas (50, 51). In summary, these schemes and results establish promising routes to next-generation micro-LED–based lighting and display systems.

Materials and Methods

Device Fabrication.

Details about device structures and fabrication process are provided in SI Appendix, Figs. S3–S9 and Tables S1–S4. The InGaP-based red LED structure is grown on a GaAs substrate, and the InGaN-based green and blue LED structures are grown on sapphire, both by metal-organic chemical vapor deposition (MOCVD). The micro-LEDs are fabricated with a standard photolithographic process, and freestanding, thin-film micro-LEDs are formed by selectively etching the Al0.95Ga0.05As sacrificial layer (for red LEDs) (34) or ultaviolet laser liftoff (for green and blue LEDs) (33). The multilayered TiO2/SiO2 wavelength selective filter is deposited on GaAs by ion beam–assisted sputtering, with freestanding, thin-film filters formed by wet etching the GaAs and laser milling (35). Tandem device structures comprising RGB micro-LEDs and filters are fabricated by transfer printing with poly(dimethylsiloxane) stamps using a customized setup based on a mask aligner (with a lateral alignment accuracy of less than 5 μm) (32, 39). Spin-coated, thin-film SU-8 epoxy layers serve as bonding interfaces. Sputtered Cr/Au/Cu/Au (10/20/500/60 nm) layers serve as interconnect contacts for different micro-LEDs.

Device Characterization.

Current–voltage curves are measured with a Keithley 2400 source meter. LED electroluminescence is measured with a spectrometer (HR2000+, Ocean Optics). EQE is measured using a spectroradiometer system with integrating sphere (LabSphere). SEM images are captured by with an electron microscope (ZEISS Auriga SEM/FIB Crossbeam System, Germany). The optical microscopy images are taken by an optical microscope MC-D800U(C). The transmittance spectra of the optical filters are measured using an ultraviolet-vis-infrared spectrophotometer (Cary 5000, Varian). For angular dependent emissive profiles, devices are mounted onto a goniometer scanning from −90° to +90° at a step of 5° at an injection current of 3 mA. The emission intensity is captured by a standard Si photodetector (DET36A, Thorlabs). Fluorescence images of the stacked RGB micro-LED array are captured by an Olympus IX53 microscope.

Supplementary Material

Acknowledgments

The research is supported by the National Natural Science Foundation of China (NSFC) (61874064, X.S.), the Beijing Innovation Center for Future Chips, Tsinghua University, and the Beijing National Research Center for Information Science and Technology (BNR2019ZS01005). X.S., M.F., and Q.S. are also grateful for the financial support from the CAS Interdisciplinary Innovation Team. We thank Profs. L. Liu and G. Zou (Tsinghua University) for the laser milling, and D. Zheng and Prof. H. Zhang (Tsinghua University) for LED response time measurements.

Footnotes

The authors declare no competing interest.

This article is a PNAS Direct Submission.

This article contains supporting information online at https://www.pnas.org/lookup/suppl/doi:10.1073/pnas.2023436118/-/DCSupplemental.

Data and Materials Availability

All data needed to evaluate the conclusions in the paper are present in the paper and/or the SI Appendix, Supplementary Materials.

References

- 1.Lee H. E., et al., Micro light-emitting diodes for display and flexible biomedical applications. Adv. Funct. Mater. 29, 1808075 (2019). [Google Scholar]

- 2.Huang Y., Hsiang E.-L., Deng M.-Y., Wu S.-T., Mini-LED, micro-LED and OLED displays: Present status and future perspectives. Light Sci. Appl. 9, 105 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Jiang H. X., Lin J. Y., Nitride micro-LEDs and beyond—a decade progress review. Opt. Express 21, A475–A484 (2013). [DOI] [PubMed] [Google Scholar]

- 4.Wu T., et al., Mini-LED and micro-LED: Promising candidates for the next generation display technology. Appl. Sci. (Basel) 8, 1557 (2018). [Google Scholar]

- 5.Yang D.-K., Wu S.-T., Fundamentals of Liquid Crystal Devices (John Wiley & Sons, ed. 2, 2015). [Google Scholar]

- 6.Chen H.-W., Lee J.-H., Lin B.-Y., Chen S., Wu S.-T., Liquid crystal display and organic light-emitting diode display: Present status and future perspectives. Light Sci. Appl. 7, 17168 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Lee J.-H., et al., Blue organic light-emitting diodes: Current status, challenges, and future outlook. J. Mater. Chem. C 7, 5874–5888 (2019). [Google Scholar]

- 8.Tsujimura T., OLED Display Fundamentals and Applications (John Wiley & Sons, 2017). [Google Scholar]

- 9.Zheng H., et al., All-solution processed polymer light-emitting diode displays. Nat. Commun. 4, 1971 (2013). [DOI] [PubMed] [Google Scholar]

- 10.Han H. V., et al., Resonant-enhanced full-color emission of quantum-dot-based micro LED display technology. Opt. Express 23, 32504–32515 (2015). [DOI] [PubMed] [Google Scholar]

- 11.Jiang Y., Cho S.-Y., Shim M., Light-emitting diodes of colloidal quantum dots and nanorod heterostructures for future emissive displays. J. Mater. Chem. C 6, 2618–2634 (2018). [Google Scholar]

- 12.Van Le Q., Jang H. W., Kim S. Y., Recent advances toward high-efficiency halide perovskite light-emitting diodes: Review and perspective. Small Methods 2, 1700419 (2018). [Google Scholar]

- 13.Park S. I., et al., Printed assemblies of inorganic light-emitting diodes for deformable and semitransparent displays. Science 325, 977–981 (2009). [DOI] [PubMed] [Google Scholar]

- 14.Kim H. S., et al., Unusual strategies for using indium gallium nitride grown on silicon (111) for solid-state lighting. Proc. Natl. Acad. Sci. U.S.A. 108, 10072–10077 (2011). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Day J., et al., III-Nitride full-scale high-resolution microdisplays. Appl. Phys. Lett. 99, 031116 (2011). [Google Scholar]

- 16.Bower C. A., et al., Emissive displays with transfer-printed assemblies of 8 μm × 15 μm inorganic light-emitting diodes. Photon. Res. 5, A23–A29 (2017). [Google Scholar]

- 17.Guo W., Meng H., Chen Y., Sun T., Li Y., Wafer-level monolithic integration of vertical micro-LEDs on glass. IEEE Photonics Technol. Lett. 32, 673–676 (2020). [Google Scholar]

- 18.Seong D.-H. K. T.-Y., Influence of size reduction and current density on the optoelectrical properties of green III-nitride micro-LEDs. ECS Trans. 85, 13–18 (2018). [Google Scholar]

- 19.Olivier F., et al., Influence of size-reduction on the performances of GaN-based micro-LEDs for display application. J. Lumin. 191, 112–116 (2017). [Google Scholar]

- 20.Oh J. T., et al., Light output performance of red AlGaInP-based light emitting diodes with different chip geometries and structures. Opt. Express 26, 11194–11200 (2018). [DOI] [PubMed] [Google Scholar]

- 21.Jin S. X., Shakya J., Lin J. Y., Jiang H. X., Size dependence of III-nitride microdisk light-emitting diode characteristics. Appl. Phys. Lett. 78, 3532–3534 (2001). [Google Scholar]

- 22.Geum D.-M., et al., Strategy toward the fabrication of ultrahigh-resolution micro-LED displays by bonding-interface-engineered vertical stacking and surface passivation. Nanoscale 11, 23139–23148 (2019). [DOI] [PubMed] [Google Scholar]

- 23.Tchoe Y., et al., Variable-color light-emitting diodes using GaN microdonut arrays. Adv. Mater. 26, 3019–3023 (2014). [DOI] [PubMed] [Google Scholar]

- 24.Cheung Y. F., Choi H. W., Color-tunable and phosphor-free white-light multilayered light-emitting diodes. IEEE Trans. Electron Dev. 60, 333–338 (2013). [Google Scholar]

- 25.Wang R., et al., Color-tunable, phosphor-free InGaN nanowire light-emitting diode arrays monolithically integrated on silicon. Opt. Express 22, A1768–A1775 (2014). [DOI] [PubMed] [Google Scholar]

- 26.El-Ghoroury H. S., Yeh M., Chen J. C., Li X., Chuang C.-L., Growth of monolithic full-color GaN-based LED with intermediate carrier blocking layers. AIP Adv. 6, 075316 (2016). [Google Scholar]

- 27.Chun J., et al., Vertically stacked color tunable light-emitting diodes fabricated using wafer bonding and transfer printing. ACS Appl. Mater. Interfaces 6, 19482–19487 (2014). [DOI] [PubMed] [Google Scholar]

- 28.Kang C. M., et al., Fabrication of a vertically-stacked passive-matrix micro-LED array structure for a dual color display. Opt. Express 25, 2489–2495 (2017). [DOI] [PubMed] [Google Scholar]

- 29.Hui K. N., Wang X. H., Li Z. L., Lai P. T., Choi H. W., Design of vertically-stacked polychromatic light-emitting diodes. Opt. Express 17, 9873–9878 (2009). [DOI] [PubMed] [Google Scholar]

- 30.Fröbel M., et al., Three-terminal RGB full-color OLED pixels for ultrahigh density displays. Sci. Rep. 8, 9684 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Shen Z., Burrows P. E., Bulović V., Forrest S. R., Thompson M. E., Three-color, tunable, organic light-emitting devices. Science 276, 2009–2011 (1997). [Google Scholar]

- 32.Schubert E. F., Light-Emitting Diodes (Cambridge University Press, Cambridge, ed. 2, 2006). [Google Scholar]

- 33.Li L., et al., Heterogeneous integration of microscale GaN light-emitting diodes and their electrical, optical, and thermal characteristics on flexible substrates. Adv. Mater. Technol. 3, 1700239 (2018). [Google Scholar]

- 34.Kim T. I., et al., High-efficiency, microscale GaN light-emitting diodes and their thermal properties on unusual substrates. Small 8, 1643–1649 (2012). [DOI] [PubMed] [Google Scholar]

- 35.Ding H., et al., Microscale optoelectronic infrared-to-visible upconversion devices and their use as injectable light sources. Proc. Natl. Acad. Sci. U.S.A. 115, 6632–6637 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Liu C., et al., High performance, biocompatible dielectric thin-film optical filters integrated with flexible substrates and microscale optoelectronic devices. Adv. Opt. Mater. 6, 1870061 (2018). [Google Scholar]

- 37.Lee H. E., et al., Trichogenic photostimulation using monolithic flexible vertical AlGaInP light-emitting diodes. ACS Nano 12, 9587–9595 (2018). [DOI] [PubMed] [Google Scholar]

- 38.Meitl M. A., et al., Transfer printing by kinetic control of adhesion to an elastomeric stamp. Nat. Mater. 5, 33–38 (2005). [Google Scholar]

- 39.Carlson A., Bowen A. M., Huang Y., Nuzzo R. G., Rogers J. A., Transfer printing techniques for materials assembly and micro/nanodevice fabrication. Adv. Mater. 24, 5284–5318 (2012). [DOI] [PubMed] [Google Scholar]

- 40.Kazazis S. A., Papadomanolaki E., Iliopoulos EJIJoP. Polarization-engineered InGaN/GaN solar cells: Realistic expectations for single heterojunctions. IEEE J. Photovoltaics 8, 118–124 (2017). [Google Scholar]

- 41.Sheng X., et al., Printing-based assembly of quadruple-junction four-terminal microscale solar cells and their use in high-efficiency modules. Nat. Mater. 13, 593–598 (2014). [DOI] [PubMed] [Google Scholar]

- 42.Jain N., et al., More than microLEDs: Mass transfer of pixel engines for emissive displays. SID Symposium Digest of Technical Papers 51, 642–645 (2020). [Google Scholar]

- 43.Templier F., GaN-based emissive microdisplays: A very promising technology for compact, ultra-high brightness display systems. J. Soc. Inf. Disp. 24, 669–675 (2016). [Google Scholar]

- 44.Wierer J. J., David A., Megens M. M., III-nitride photonic-crystal light-emitting diodes with high extraction efficiency. Nat. Photonics 3, 163–169 (2009). [Google Scholar]

- 45.Sheng X., et al., Design and fabrication of high-index-contrast self-assembled texture for light extraction enhancement in LEDs. Opt. Express 19, A701–A709 (2011). [DOI] [PubMed] [Google Scholar]

- 46.Wong M. S., et al., High efficiency of III-nitride micro-light-emitting diodes by sidewall passivation using atomic layer deposition. Opt. Express 26, 21324–21331 (2018). [DOI] [PubMed] [Google Scholar]

- 47.Macleod H. A., Thin-Film Optical Filters (CRC Press, 2017). [Google Scholar]

- 48.McKendry J. J. D., et al., Visible-light communications using a CMOS-controlled micro-light-emitting-diode array. J. Lightwave Technol. 30, 61–67 (2011). [Google Scholar]

- 49.Rajbhandari S., et al., A review of gallium nitride LEDs for multi-gigabit-per-second visible light data communications. Semicond. Sci. Technol. 32, 023001 (2017). [Google Scholar]

- 50.Xu H., Yin L., Liu C., Sheng X., Zhao N., Recent advances in biointegrated optoelectronic devices. Adv. Mater. 30, e1800156 (2018). [DOI] [PubMed] [Google Scholar]

- 51.Zhao Y., et al., Wirelessly operated, implantable optoelectronic probes for optogenetics in freely moving animals. IEEE Trans. Electron Dev. 66, 785–792 (2018). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All data needed to evaluate the conclusions in the paper are present in the paper and/or the SI Appendix, Supplementary Materials.