Abstract

Phenolics are ubiquitous in nature and have gained immense research attention because of their unique physiochemical properties and widespread industrial use. In recent decades, their accessibility, versatile reactivity, and relative biocompatibility have catalysed research in phenolic-enabled nanotechnology (PEN) particularly for biomedical applications which have been a major benefactor of this emergence, as largely demonstrated by polydopamine and polyphenols. Therefore, it is imperative to overveiw the fundamental mechanisms and synthetic strategies of PEN for state-of-the-art biomedical applications and provide a timely and comprehensive summary. In this review, we will focus on the principles and strategies involved in PEN and summarize the use of the PEN synthetic toolkit for particle engineering and the bottom-up synthesis of nanohybrid materials. Specifically, we will discuss the attractive forces between phenolics and complementary structural motifs in confined particle systems to synthesize high-quality products with controllable size, shape, composition, as well as surface chemistry and function. Additionally, phenolic’s numerous applications in biosensing, bioimaging, and disease treatment will be highlighted. This review aims to provide guidelines for new scientists in the field and serve as an up-to-date compilation of what has been achieved in this area, while offering expert perspectives on PEN’s use in translational research.

1. Introduction

Phenolic compounds are a large family of naturally occurring molecules present in a wide range of organisms. From fungi to bacterium and from plants to animals, these ubiquitous compounds have gained immense research attention because of their unique physiochemical properties.1-3 Phenolics have many uses—one of the earliest examples being leather manufacturing.4 In the late twentieth century, Waite and Tanzer piqued the interest of chemical researchers by discovering the presence of phenolic-containing proteins (i.e., mussel adhesive protein, MAP) in the adhesive pads of marine mussels.5 Subsequent discoveries made by several groups over a period of many years have gradually revealed details of the adhesive mechanism of mussels,6-11 inspiring biomimetic systems such as synthetic polymers and peptides that carry catechols.12 In 2007, Messersmith and co-workers were similarly successful in mimicking the adhesive properties of mussels by using the mussel-inspired simple molecule, dopamine, which can undergo oxidation in a basic environment and self-polymerize into polydopamine (PDA).13 Of particular importance is the universal processing method that can be used to emulate the underwater adhesive properties of mussels on virtually any natural substrate.14 These two discoveries lead to the development of synthetic polymers containing phenolic (e.g., catechols) and amine (e.g., PDA) groups and have now been extensively explored for material-independent surface engineering applications.15 In 2013, Caruso and co-workers reported a simple and rapid conformal coating method for various films and particles using assembly via coordination between tannic acid (TA), a natural polyphenol, and Fe3+.16 This stimulated interest in phenolic-based coatings by using natural polyphenols and metal ions. These seminal examples show the robustness of both covalent and non-covalent chemistries of phenolic compounds and demonstrate their great potential for engineering materials with targeted applications.

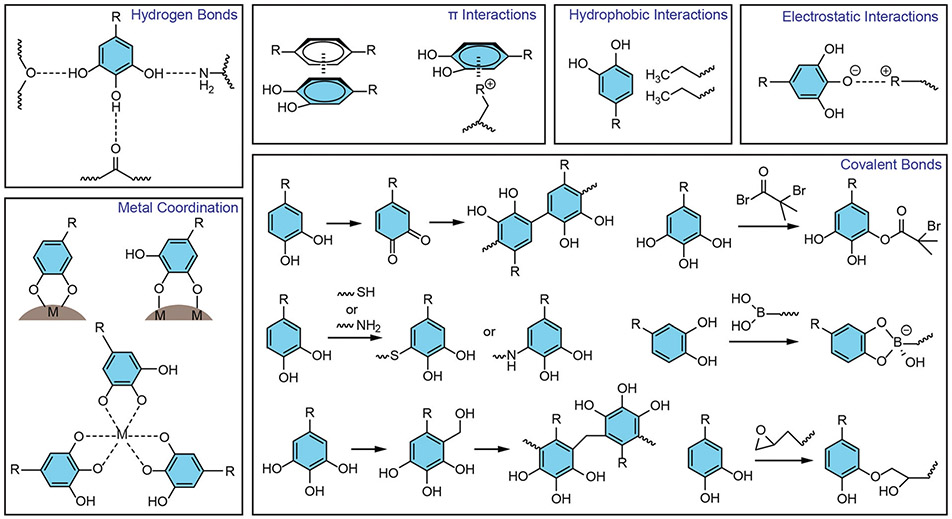

The ever-increasing attention of phenolic compounds in materials engineering is mainly due to their unique structural and chemical features.17 In particular, the presence of versatile phenolic moieties (e.g., catechol and gallol groups) in the structures can form diverse non-covalent and covalent interactions with various materials including inorganic materials (e.g., metal ion, metal, metal oxide, semiconductor, carbon, silica), organic materials (e.g., small molecule, synthetic polymers), and even bioactive biomacromolecules and living microorganisms. In such scenarios, phenolic compounds exert multiple physicochemical interactions with one or two being dominant (e.g., metal coordination, hydrogen bonds, hydrophobic interactions, π interactions, covalent bonds, and electrostatic interactions) with the complementary building blocks (Fig. 1).18 Moreover, adding phenolics can potentially endow the hybrid materials with a variety of excellent phenolic-based properties including adhesiveness, antioxidation, antibacterial properties, etc., which in turn make the products multifunctional towards diverse applications.

Fig. 1.

Phenolic-mediated interactions with different materials in PENs.

Over the past decades, we have witnessed rapid advances in exploiting nanotechnology in biomedical applications including biosensing, imaging, drug delivery, and many other disease theranostic modalities.19,20 The accessibility, versatile reactivity, and relative biocompatibility of phenolics have catalysed the broad research in nanotechnology. As an emerging field, phenolic-enabled nanotechnology (PEN) provides simple yet versatile approaches for assembling nanostructures with unique properties and high flexibility in biomedical applications. Consequently, a number of engineered nanostructures have been developed with controllable size, shape, composition, surface chemistry, as well as degradability and function underscoring the immense potential of PEN for nanomedicine.

Efforts to create various phenolic-based materials have been accompanied by reviews of the latest progress but most of the literature emphasizes either PDA- or polyphenol-based materials for applications in surface coatings and hydrogels, respectively.21,22 PDA-based platforms have been reviewed recently with a focus on surface modification for nanomedicine.23 An even more recently published review covers plant polyphenols where the six different fundamental interactions between polyphenols and other materials are discussed but the strategies for making these nanostructures were not discussed.18 Biomedical applications that utilize PEN have been a major benefactor of this emergence, yet a timely and comprehensive review is lacking. Based on the increasing interest in phenolic-based materials, a comprehensive review summarizing the fundamental mechanisms and synthetic strategies of PEN for state-of-the-art biomedical applications is in demand. Therefore, it is critical to consolidate this information into a single piece of literature to provide a complete picture of phenolic-based materials. This review aims to provide guidelines for new scientists in the field while offering expert perspectives on PEN’s use in translational research.

In light of the exceptional advantages of PEN for synthesizing functional materials for biomedical applications—as well as the extensive interest and the high level of activity of this area—we will overview the development of phenolic-based nanosystems and reveal how PEN can be utilized for biomedical applications, not only for surface modification but also for delicate material design (Fig. 2). Specifically, the physicochemical interactions of phenolics with organic, inorganic, and biogenic substrates in confined nanosystems will be discussed from the molecular to nano scale to paint a comprehensive picture. Three main strategies for particle engineering are highlighted with relevant fundamental mechanisms and representative nanostructures. Their potential in biomedicine will be discussed starting from their bio-nano interactions, pharmacokinetics, and toxicology profiles before moving onto their specific applications in biosensing, bioimaging, and disease treatment. This review will be of great value to those working in phenolic-based materials, supramolecular chemistry, bio-inspired self-assembly, functional nanohybrid synthesis, and especially for those in biomedicine and translational medicine. We hope that this review will not only become a resource for what has been achieved in this field but also provide a go-to reference that facilitates the rational design of nanosystems with customized properties.

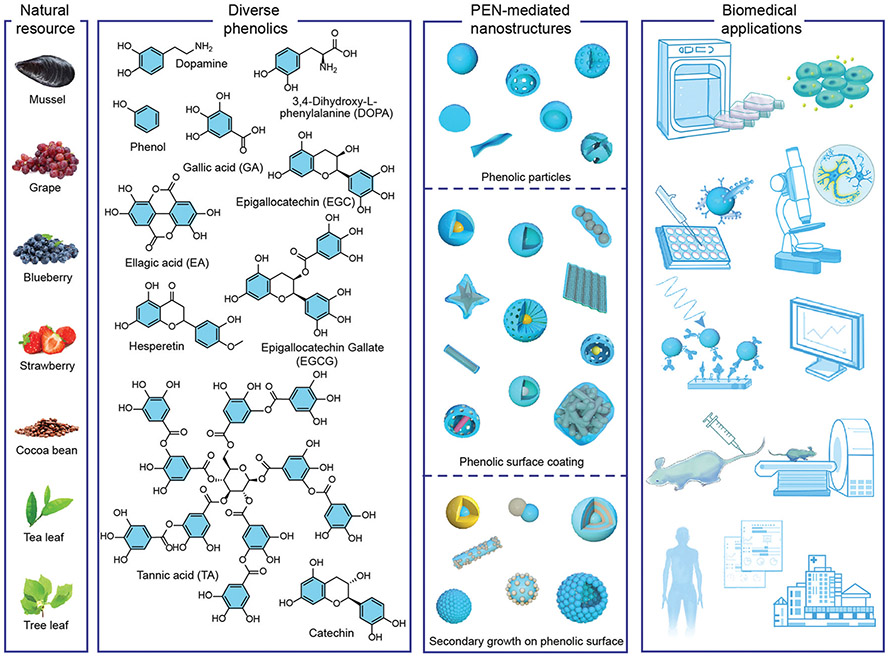

Fig. 2.

The development of PEN for biomedical applications. From left to right: Representative natural resource of phenolics, chemical structure of representative phenolic molecules, schematic illustration of some typical PEN-mediated particles, and the potential applications in biomedical field, including study of bio–nano interactions, biosensing, imaging and disease treatment, from single molecular and cellular level to animal and clinical trials.

2. The physicochemical interaction of phenolics from molecular level in PEN

The physicochemical interactions of phenolics with other chemical building blocks play a mediating role in the design of nanostructures. Inorganic, organic, and biological substances have all been reported to interact with phenolics, and it is important to point out the fundamental interactions prior to the discussion of the use of PEN for engineering diverse nanostructures. Due to the versatile physical properties of phenolics, their presence in one nanosystem may have multiple roles. To better understand this complexity, the next section discusses the interactions between phenolics and other types of materials by considering each discrete component. We hope that this will clarify the interactions between phenolics and other materials and will enable the reader to design functional materials more intelligently using PEN.

2.1. Inorganic materials with phenolics

Inorganic nanoparticles exhibit novel electronic and optical properties at the nanometer length scales due to quantum effects.24,25 Therefore, using PEN to create functional phenolic–inorganic hybrid nanoparticles with physicochemical properties arising from both the inorganic and phenolic components is attractive in biomedical applications.

2.1.1. Metal ions.

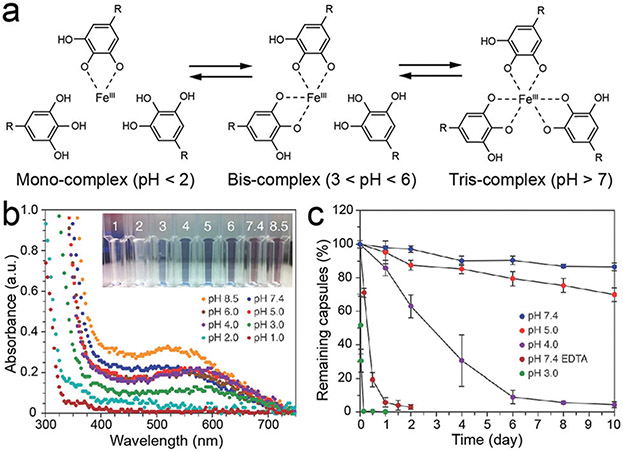

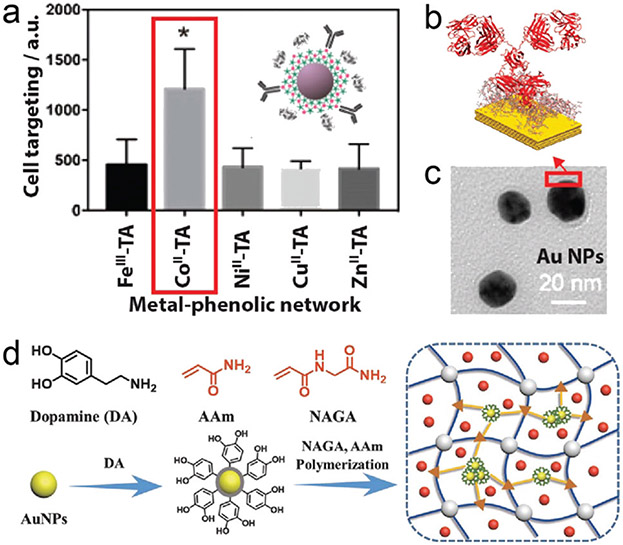

The coordination between phenolics and metal ions is one of the most well-studied topics. It is well-known that catechol or gallol groups can coordinate to various metal ions such as Fe3+, Zn2+, Cu2+, Al3+, and Zr4+ forming a class of metal-organic materials: metal–phenolic networks (MPNs) (Fig. 3).16 MPNs are a rapid, robust, and universal method for coating various substrates by using the coordination of polyphenols and metal ions.26,27 Since the chelation between the catechol and/or gallol groups of polyphenol and metal ions is pH-dependent, MPN materials have interesting assembly–disassembly properties. When the catechol and gallol groups are protonated at low pH, the MPNs disassemble due to the breakdown of coordination bonds.28 The tuneable disassembly profiles in acidic environments using different or mixed metal ions allowed for customizable degradation kinetics and permeability.

Fig. 3.

(a) pH-Dependent transition of dominant TA–Fe coordination interaction. (b) UV absorption spectra and photo of spherical TA–Fe capsule dispersions at different pH. (c) Stability profiles of capsules at different pH. Reproduced with permission. Copyright 2013, American Association for the Advancement of Science.

Metal ions not only contribute to the final function of hybrid MPNs but also modulate the assembly of phenolic compounds thermodynamically.29 For example, the polymerization of dopamine and the deposition rate of PDA was greatly accelerated using CuSO4/H2O2 as a trigger.30 The Cu2+ and H2O2 produce reactive oxygen species (ROS) in an alkaline medium that aids in the polymerization of dopamine. Substitution of Fe3+ with Fe2+, as formulated in the iron gall ink, can produce a thickness-controllable (i.e., from 120 nm to 2.5 μm) MPN film at the interface without the assistance of stabilizers. The steady O2 oxidation of Fe2+ to Fe3+ in a Fe2+–TA complex generates Fe3+–TA species in situ leading to the formation of micrometer-thick Fe3+–TA films that are transferable and self-healable.31

2.1.2. Metal and metal oxides.

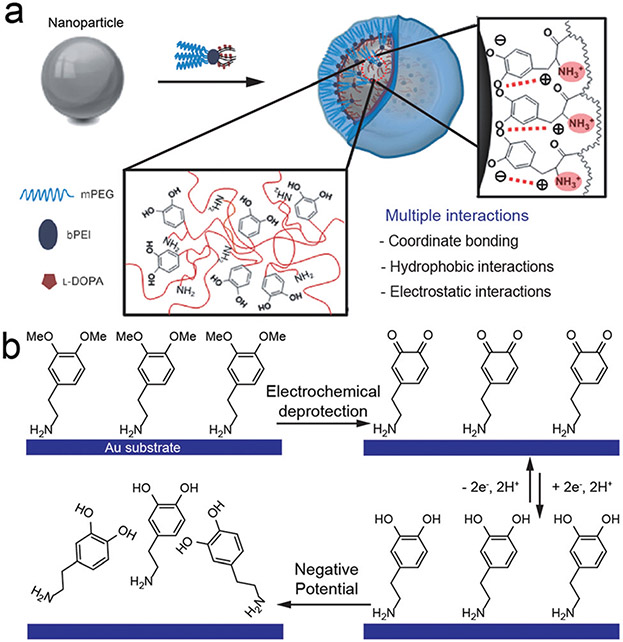

The coordination chemistry of phenolics has also been used for coating and stabilizing metal and metal oxide nanoparticles.32 A representative example is the use of dopamine derivative ligands for iron oxide nanoparticles: a spectroscopic study showed that the bidentate catechol can convert the under-coordinated Fe on the surface to oxygen-coordinated Fe with an octahedral geometry resulting in tight binding of dopamine to iron oxide.33 Hyeon and co-workers developed a multivalent ligand that contains a MAP-mimicking poly(l-3,4-dihydroxyphenylalanine) (polyDOPA) domain with catechol and primary amine groups.34 This ligand can stabilize various nanoparticles (e.g., Fe3O4, MnO, and Au) through a combinational binding effect including directional interactions arising from catechol and amine groups, micelle formation, and electrostatic interactions between positively charged ligands and negatively charged nanoparticle surfaces (Fig. 4a). Similarly, multivalent peptide dendrons containing a surface-binding catechol domain exhibit binding affinity for a wide range of metal oxides (hydroxyapatite, TiO2, ZrO2, CeO2, Fe3O4).35

Fig. 4.

(a) Schematic illustration of the synthesis of water-dispersible nanoparticles using a ligand with multiple interactions. Reproduced with permission. Copyright 2011, Wiley-VCH. (b) Construction and release process of dopamine self-assembled monolayers on the Au surface under electrochemical modulation. Reproduced with permission. Copyright 2019, American Chemical Society.

Aside from the native functional groups, other moieties on phenolic compounds can offer chelation properties. The amino group in dopamine is one such group and can interact with Au. To better understand the binding mechanism, Jiang and co-workers protected the two hydroxyl groups on dopamine with methyl groups leaving the amino groups free to bind to Au substrates (Fig. 4b). They further confirmed and investigated the binding using X-ray photoelectric spectroscopy.36

Phenolic compounds usually exhibit a typical redox behaviour due to the presence of alcohol groups. While the electrochemical oxidation is affected by the chemical substituents on the aromatic rings (e.g., amine, sugar, etc.), environmental pH is a key factor because it directly determines phenolics’ antioxidant capacity, radical scavenging activity, and oxidative product formation. Differential pulse voltammograms showed that phenol oxidation to a phenoxy radical on the first scan is pH-dependent corresponding to an irreversible electron-proton exchange.37 On the second scan, the oxidation peaks of the adsorbed phenol oxidation products, i.e., ortho-quinone (catechol) and para-quinone (hydroquinone), also showed a reversible two-electron and two-proton transfer. As is typical for the electrochemical oxidation of organic species, a higher pH triggers easier electron loss. Furthermore, as a general rule, para-benzenediol and ortho-benzenediol (+0.15 V and 0.20 V vs. Ag/AgCl at pH 7) oxidize at a lower potential than meta-benzenediol and mono-phenols (> 0.70 V, vs. normal hydrogen electrode (NHE)) at neutral pH.

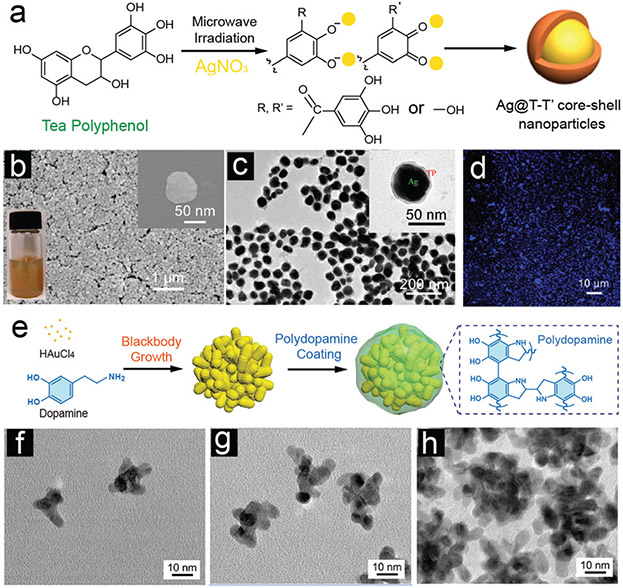

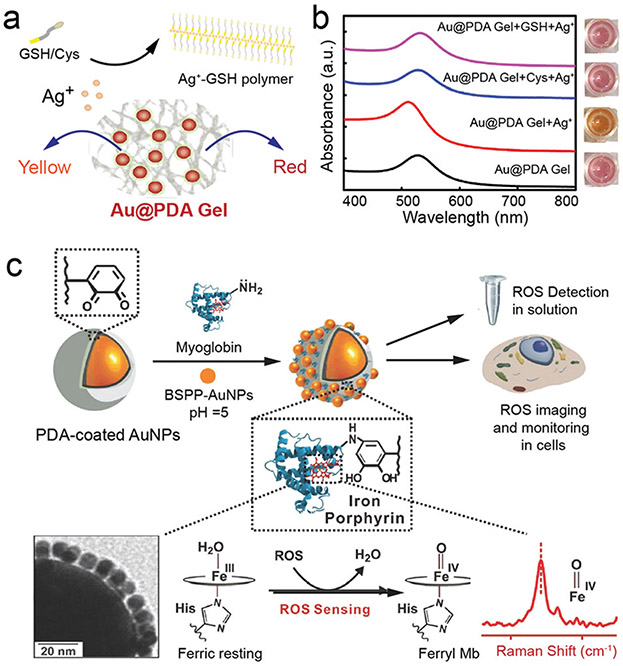

Therefore, phenolic compounds have been directly used to reduce noble metal ions such as Ag+, Au3+, Pt4+, etc., which represents a “green” method to synthesize nanoparticles. For example, dopamine has been used as a reductant for synthesizing Au nanoparticles from Au3+ by taking advantage of the two-electron oxidation of dopamine.38 Moreover, diverse plant polyphenols such as TA and epigallocatechin gallate (EGCG) have been used to synthesize noble metal nanoparticles.39

With this reductive property in mind, phenolic groups were also conjugated to polymers to create multivalent polymers that act as strong reductants. For example, Duan and co-workers developed a block copolymer where the hydrophilic block of 4-vinylphenol (VPh) and di(ethylene glycol)methyl ether methacrylate (EGM) copolymer (PVPhEGM) contains a number of pendant phenolic group.40 Au nanoparticles were produced upon addition of KAuCl4 into the solution of PVPhEGM emphasizing its strong reducing activity. Micelles made from this polymer enabled Au precursor reduction on the micelle surface producing a complete nanoshell. In addition to the formation of monodisperse metallic nanoparticles in solution, the phenolic-containing peptide coating can efficiently reduce Ag+ into a seamless Ag layer and form a remarkable seamless metallic coating on the surface.41

2.1.3. Semiconductor materials and upconversion materials.

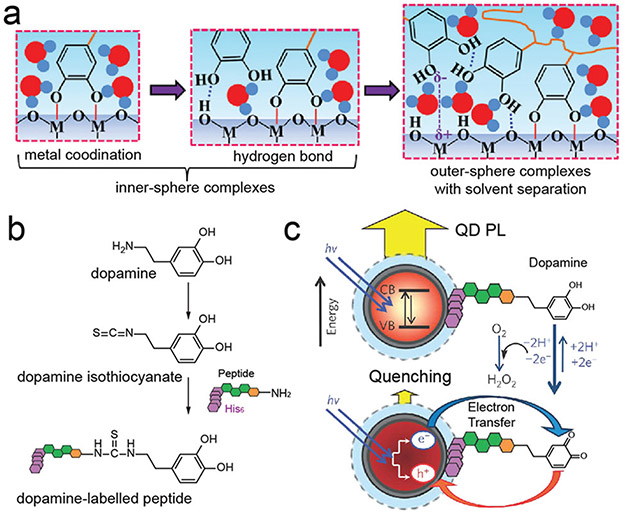

In addition to coordination, hydrogen bonding is also present in the interactions with semiconductor and upconversion materials. Waite and co-workers investigated the interactions of catechol-containing peptides on TiO2 (anatase).42 The results revealed that bidentate coordinative bonds on TiO2 were formed at the initial stage of absorption. Hydrogen bonding later became dominant; long-range electrostatic and van der Waals interactions would emerge later (Fig. 5a). Hydrophobic interactions between the aromatic structures in phenolic and semiconductor materials are also notable. For instance, several polyphenols have been used to exfoliate various transition metal dichalcogenide (TMDs) into monolayer nanosheets via ultrasonication. The hydrophobic aromatic structures in polyphenols can interact with the TMD monolayer via hydrophobic interactions while the hydrophilic hydroxyl of polyphenols can improve the colloidal stability of exfoliated nanosheets.43 In the example of PDA-mediated MoSe2 nanosheets, the interactions involved not only hydrophobic interactions but also electrostatic interactions between the negatively charged phenolic group and the positively charged MoSe2.44

Fig. 5.

(a) Proposed adsorption mechanism of catechol groups on metal oxide (e.g., TiO2) surface. Reproduced with permission. Copyright 2016, Wiley-VCH. (b) Synthesis of a dopamine–peptide via amine-reactive isothiocyanate. The His6 sequence in dopamine–peptide can self-assemble onto DHLA–PEG QDs. (c) Proposed energy-transfer mechanism between dopamine–peptide and QD. (b and c) Reproduced with permission. Copyright 2010, Nature Publishing Group.

The surface effects on catechol–semiconductor (SiC, GaN, InN, CdS, CdSe) interfaces have been simulated and investigated.45 One interesting result is that catechol is located in the proximity of two Cd surface cations while the produced Cd–O coupling is weak as suggested by the absence of the surface dimer relaxation and the lower adsorption energy. Moreover, catechol maintains its original geometry without protonating or rotating the lateral hydroxyl groups.

In one example, ZnS was modified with catechol-functionalized polyethylene glycol (PEG) via a bidentate and/or a bridging bidentate interaction.46 The directly chelated catechol-containing molecules efficiently quenched the fluorescence of the nanoparticles due to their fast and reversible oxidation processes. Specifically, it was hypothesized that when an electron of quantum dot (QD) is excited to the conduction band, an electron from the catechol ligand can immediately refill the valence band hole to quench the fluorescence. Moreover, linear assembly of QDs can be obtained via catechol-conjugated hyaluronic acid (HA) as a soft template by taking advantage of the affinity between catechol and QDs.47

Besides direct conjugation with semiconductor materials, it is also notable that the redox-active phenolic moiety can conjugate with QD via other groups (e.g., Histag) to modulate the photophysics of the complex (Fig. 5b and c).48 For example, the oxidation of dopamine to quinone by O2 readily occurs at basic pH, and this quinone can act as an electron acceptor to quench the photoluminescence of QD in a pH-dependent manner due to electron transfer. In another work, two typical phenol derivatives with electron-donating (i.e., 4-methoxy) and electron-withdrawing (i.e., 4-nitro) moieties were investigated to reveal the charge transfer dynamics of QD-phenolic molecules.49 The results showed that both 4-nitrophenol (4NP) and 4-methoxyphenol (4MP) can quench the photoluminescence of CdSe QD; cyclic voltametric analysis suggested that the excited CdSe transferred electrons to 4NP and holes to 4MP.

Similarly, phenolic shells on the surface of sodium citrate-capped upconversion nanoparticles (UCNPs) can also serve as efficient quenchers for the upconversion fluorescence. Of particular interest, the fluorescence of the UCNP can be retained after phenolic coating by using a water-in-oil microemulsion method where hydrophobic oleic-acid-capped UCNPs (NaGdF4: Yb,Er@NaGdF4) were directly coated with PDA.50,51 Moreover, the upconversion fluorescence intensity of UCNP@PDA–PEG is similar to that of UCNP@SiO2. This is likely due to the presence of oleic acids which serve as an insulator to reduce the electron transfer between the PDA and UCNP. It is notable that the PDA shell can also significantly inhibit the leaking of Gd3+ from UCNP over time.

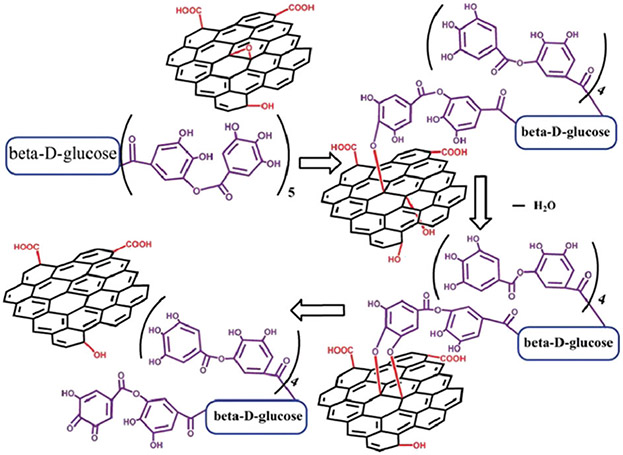

2.1.4. Carbon materials.

Polyphenols can also conjugate to various carbon materials such as graphene oxide, carbon nanotubes (CNTs), and carbon QDs.52,53 For example, reduced graphene oxide (rGO) with good colloidal stability was prepared via an environmentally-friendly method where TA serves as the reductant for graphene oxide (GO) as well as a stabilizing ligand for rGO.54 Compared with traditional chemical reducing agents such as hydrazine or dimethylhydrazine, polyphenols are safe and economical. The reduction of GO was proposed to involve two steps: first, the phenolic hydroxyl groups of TA attacks the epoxy group on graphene oxide simultaneously generating a new hydroxyl nearby; second, this new hydroxyl is attacked by another phenolic hydroxyl of TA. The resulting intermediate undergoes an elimination reaction resulting in a conjugate bond at the original epoxy site while the gallol groups convert into diquinone (Fig. 6). The successful reduction of graphene oxide was proved by XPS in which the sp2 fraction of rGO was as high as 71%—close to the reduction by hydrazine and thermal annealing at 1000 °C (80%). Due to the π–π stacking with TA, the rGO sheet had a thickness of ~1.5 nm compared to pristine GO (1.1 nm). The electrostatic repulsion and sterics of TA facilitated the good dispersion of rGO in diverse solvents such as ethanol, dimethylformamide, and dimethylsulfoxide, which allowed for the preparation of high-performance polymer composites by direct blending.55

Fig. 6.

Proposed mechanism of reduction of GO by TA. Reproduced with permission. Copyright 2011, Royal Society of Chemistry.

To understand how TA can stabilize CNTs, Xing and co-workers proposed a two-step adsorption model to explain their interaction.56 First, the aromatic rings of TA molecules interact with the surface carbon rings of CNTs through π–π interactions to form a monolayer of TA molecules; the TA monolayer then further interacts with the dissolved TA by hydrogen bonding and other polar interactions. The adsorbed TA increases the steric repulsion between individual CNTs to produce relatively monodisperse CNT and stabilize them. Furthermore, the authors showed that the adsorption of phenolic compounds on CNTs increased when aromatic rings with a higher number of hydroxyl substituents were emploited.57 This suggests that electron-donating substituents on phenolics can facilitate the π–π electron donor–acceptor interaction. In another study, Wang and co-workers investigated the absorption mechanism of three aromatic compounds (i.e., salicylic acid, phthalic acid, and catechol) by using CNT and activated carbon.58 Their results indicated that hydrophobic interactions, π–π interactions, electrostatic interactions, and hydrogen bonding collectively contribute to the interaction between carbon materials; the magnitude of each type of interaction varies with the specific chemical structure of different aromatic compounds. In addition, activated carbon exhibited higher adsorption capacities compared to MWCNTs suggesting a pore-filling effect.

2.1.5. Silica materials.

Simulation results show that the underwater adhesion mechanism of catechol molecules on hydrophilic silica is hydrogen bonding. Catechol can displace the pre-adsorbed water molecules on silica to bond directly on the surface silanol.59 The calculated binding energy is 23 kcal mol−1, and the bond can be destroyed by a force of 0.5 nN. Encouraged by this, phenolic compounds have been used to modify silica nanoparticles, mesoporous silica nanoparticles (MSN), etc.60-62

However, recent studies with dopamine indicate that the interaction is less favourable due to the surface charge repulsion between silica and dopamine molecules.63 To address this challenge, amino groups modified with silica particles by a co-condensation approach were used to improve the deposition of phenolics (e.g., dopamine) through Schiff base formation and/or Michael type addition.64

In addition to post-synthesis methods to modify silica materials, phenolic compounds can also interact with silica precursors to fabricate hybrid silica materials.65,66 To understand the roles of polyphenol in the synthesis of silica nanoparticles, gallic acid, ethyl gallate, eudesmic acid, quercetin, and TA were used to investigate the effect of chemical structure on their templating ability.67 The results revealed the mechanism of TA-templated MSN where the silica precursors can attach to the irregular TA supramolecular framework via hydrogen bonding, which subsequently acts as the skeleton for porous silica. If dopamine was used instead of TA, PDA would be introduced into the silica framework. This result suggests the important role of amines in PDA towards stable hybridization in the particles.68

2.1.6. Other materials.

Due to the multifaceted physicochemical properties of the phenolic group, phenolic compounds have been used to design inorganic hybrids with components of different material species although some of the mechanistic details are lacking. For example, Liu and co-workers investigated the formation of CaCO3–PDA hybrid nanoparticles and found that the coordination between Ca2+ and PDA could facilitate their biomineralization.69 Similarly, PDA coatings have been also applied on other carbonates such as Gd2(CO3)3 nanoparticles.70

Phenolic compounds also interact with nanoclays. As discussed in the previous section, the chemisorption of phenolics to metal oxide surfaces was the monodentate and/or bidentate bond while that of catechol to silica was hydrogen bonding (typically regarded as a weaker bond). Considering these properties, Takahara and co-workers demonstrated that the dopamine derivative can also be firmly linked to alumina on the innermost surface of a halloysite tube instead of to the silica on the outermost surface of halloysite.71 This selective modification by immobilization of phenolic groups via robust coordination bonds could lead to more opportunities for anisotropic surface engineering. In another example, Lu and co-workers found that the catechol moieties can chelate with ions such as Mg and Si and therefore facilitate the conjugation of dopamine molecules to the nanoclay surface. Furthermore, the amino groups of dopamine can provide additional electrostatic interactions in the clay nanosheets similar to the role of common intercalation reagents (e.g., quaternary ammonium halides).72

Two-dimensional (2D) MXene materials, such as transition metal carbides, nitrides, and carbonitrides, have demonstrated immense potentials such as photothermal properties. However, MXene-based materials often suffer from mechanical fragility and vulnerability to oxidation. To remedy this, PDA has been used to improve interflake interactions and ordering in MXene-assembled films. The XPS data confirmed that the catechol groups have strong affinities to the multivalent metal ions via coordination bonding especially a catechol–titanium oxide complex. In addition, the primary and secondary amine peaks in the PDA-treated MXene films have obvious binding energy downshifts by 0.4–0.6 eV versus pure PDA possibly due to the formation of hydrogen bonding with −O and −F terminates of MXene.73 The facile PEN-mediated Mxene has been widely investigated to address its intrinsic limitation and improve its potentials for a variety of applications.74

Phenolics can also be used to modify black phosphorous.75 The amine group of dopamine can interact with the negatively charged BP.76 Moreover, redox-active PDA was reported to not only isolate the interior BP nanosheets from oxygen and water to improve its stability but also to enhance its photothermal performance.77

Of course, it is impossible to highlight all of the emerging materials that have been integrated with phenolic compounds much less offer a comprehensive discussion of the interactions between the phenolics and diverse materials. For example, phenolic compounds have been also used to design hybrid cobalt phosphides nanoparticle,78 FeC,79 and so on. But we hope what the summary here will inspire readers to not only design diverse functional hybrid nanoparticles but also look into the detailed formation mechanisms to underpin the future development of PEN.

2.2. Organic materials with phenolics

The interaction of organic materials with phenolics involve both supramolecular chemistry and covalent bonds. The intermolecular forces in phenolic compounds include hydrogen bonding, π–π interactions, hydrophobic effects, coordination and electrostatic attractions, and common covalent bonds formed by oxidative coupling or base-catalysed reactions. Synthetic details have been discussed in several reviews elsewhere.21,80 Here, we focus on the types of materials used to design functional hybrids. The interaction between organic materials and phenolics usually involves multiple attractive forces, and thus it is worthwhile to highlight these key interactions to simplify these complex processes.

2.2.1. Small molecules.

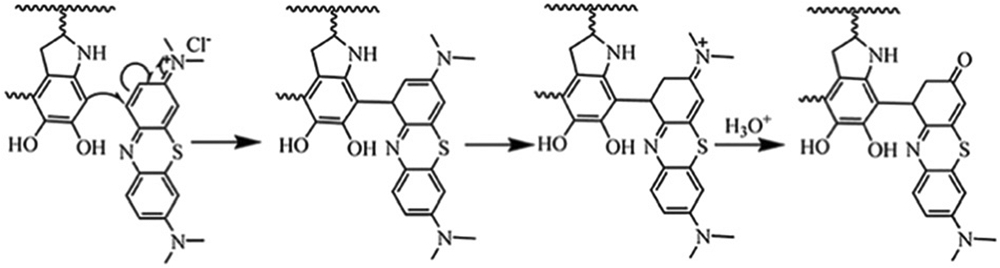

Phenolics are typical aromatic compounds with hydroxyl moieties, which indicates a suitable electron-rich π system for aromatic π–π stacking.81 One typical example is the interaction of phenols with organic dyes. Methylene blue was used as a model to investigate the adsorption processes of organic dyes by PDA. The results showed that the adsorption was dependent on several interactions such as π–π stacking and electrostatics.82 In addition, the catechol groups can react with many organic compounds (e.g., amine and thiol groups) via Michael addition or Schiff-base formation.80 Based on the versatile properties of phenolics, a series of organic dyes were used to study the absorbance mechanism on PDA. The results indicate that the PDA-based hydrogel could selectively adsorb the dyes with an Eschenmoser structure (i.e., dimethyl(methylidene)ammonium salts) because the ortho position of catechol group can undergo a Michael addition with Eschenmoser groups in the dyes (Fig. 7).83

Fig. 7.

The proposed adsorption mechanism between PDA and MB. Reproduced with permission. Copyright 2014, Royal Society of Chemistry.

In addition to decontamination of dye pollutants from wastewater, functional dyes such as indocyanine green (ICG), can also complex with PDA as imaging probes. At a pH of 2–3, negatively charged ICG was absorbed on the surface of PDA nanoparticles (isoelectric point ~4.6) by electrostatic and hydrophobic interactions.84 The anti-cancer drug doxorubicin (DOX) can also strongly interact with PDA via π–π stacking and hydrophobic interactions due to its aromatic structure. For example, a high loading efficiency (99%) was achieved with a weight ratio of PDA to DOX of 2.85 Therapeutic chlorin e6 (Ce6) was also conjugated to the amino groups of PDA through a conventional carbodiimide reaction.86

Another commonly used phenolic chemistry is the facile conjugation with small molecules containing amine or thiol moieties. One representative example is the use of 3-aminopropyltriethoxysilane (APTES) and TA to fabricate a hierarchical layer-nanosphere structure on diverse substrate. Here, the TA has two key roles: it is an adhesive layer on the surface of substrates, and it subsequently conjugates with APTES to form a rough layer.87 Dopamine also contains amines in its structure. Lee and co-workers demonstrated that cation–π interactions are the primary intermolecular interactions during the formation of PDA coating rather than the hydrogen bonding and π–π interactions that are conventionally considered to be responsible for supramolecular assembly of PDA. Moreover, the quaternary ammonium ion has the strongest cation–π interactions with the aromatic rings among different cations including Li+, Na+, K+, R–NH3+, and NR4+.88

Phenolic compounds can serve as surfactants and interaction with oil-in-water emulsion to prepare capsules. For example, the ultrasonication of oleic acid mixtures in water generated nanoemulsions of 100–250 nm in diameter, and amphiphilic phenolic compounds self-assembled at the oil/water interface. A phenolic capsule will be produced after crosslinking the phenolic coating.89

2.2.2. Synthetic polymers.

Phenolic compounds can also form multidentate interactions with synthetic polymers such as PEG, poly(allylamine) (PAH), and poly(vinyl alcohol) (PVA) through multiple hydrogen bonding sites to produce hydrogels used for adhesive purpose.90 Lee and co-workers reported a class of medical adhesives that were obtained via the intermolecular hydrogen bonding between TA and PEG. The TAPE system had an adhesion strength 2.5 times higher than that of fibrin glue, and the good adhesion was retained in aqueous environments.91 The strong hydrogen bonding formed between PVA and TA can also give the PVA–TA hydrogels excellent mechanical properties as confirmed by the high tensile strengths (up to 2.88 MPa) and high elongations (up to 1100%).92 More recently, a similar attempt was tried by mixing PVA and TA to produce a reusable underwater adhesive. In contrast to previously reported PVA–TA systems, increasing the amount of TA (10–50 folds) and molecular weight of PVA led to a sticky sol-state glue with the unique underwater adhesive features of TA due to the formation of hydrogen bonding networks.93

Phenolic compounds have shown strong affinities with amine-containing polymers via abundant hydrogen bonding and electrostatic interactions. A range of neutral polymers including poly(N-vinylpyrrolidone) (PVPON), poly(N-vinylcaprolactam) (PVCL), poly(N-isopropylacrylamide) (PNIPAM), or poly(N-vinylamide) and TA have been assembled to make multi-layer coatings by layer-by-layer (LbL) technique.94,95 For example, Caruso and co-workers exploited the ability of TA to serve as an efficient hydrogen bond donor to design multicomponent LbL capsules with PVPON at physiological pH.96

Another issue that should be considered is hydrolysis of tannin molecules that may occur under basic conditions (e.g., the pKa of phenolic groups in TA is 8.5) and at elevated temperatures. The deprotonation states make them negatively charged and can interact with positively charged polymers.97,98 For example, the alternated deposition of PAH and TA can produce multi-layered films (PAH–TA) via electrostatic interactions.99 The deprotonation of TA can also be exploited to form electrostatic interaction with zwitterionic polymers such as poly(sulfobetaine methacrylate) (PSBMA).100 More specifically, electrostatic interactions between the deprotonated phenolic groups of TA and the quaternary ammoniums of PSBMA comprised the driving force for the TA/PSBMA LbL films. Moreover, the (TA/PSBMA) multilayer film had an improved stability compared to (PAA/PSBMA)—the authors attribute this to the high pKa of phenolic groups and the dendritic structure of TA, which is in contrast to carboxyl moieties and the linear structure of PAA.

In addition to non-covalent interactions, the amino groups in polymers also formed covalent interactions with the oxidized catechol of TA.101,102 Inspired by insect cuticle sclerotization, Lee and co-workers demonstrated a biocompatible and waterborne adhesive.103 The results showed the mixture of phenol (i.e., PG), polyamine (i.e., polyethylenimine, PEI), and silica agglomerates in aqueous environment produced strong adhesion strength (>6 MPa). A two-step reaction was proposed: the oxidation of phenol into phenolquinone by air and the subsequent cross-linking between phenolquinone and PEI. Despite the simple synthesis and strong adhesion, the adhesive had no volatile organic compounds and good biocompatibility suggesting potential as a medical adhesive.

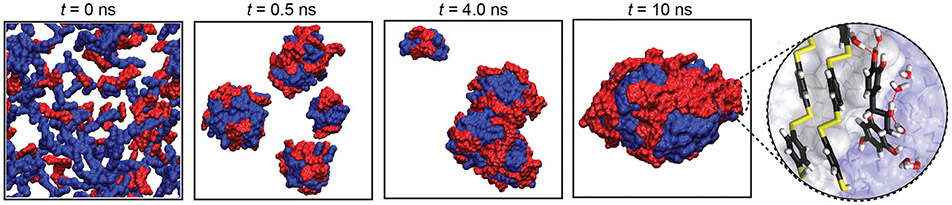

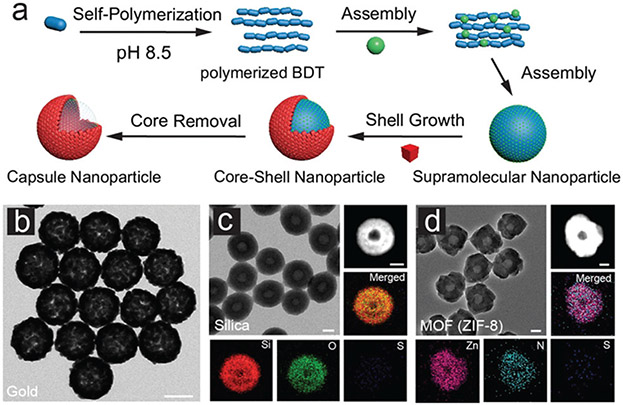

The presence of aromatic group in phenolic compounds further allows the interaction with hydrophobic polymers containing aromatic moieties. For example, PDA and TA have been widely used to surface modify PS nanoparticles for diverse biomedical applications.104 Recently, Caruso and co-workers used phenolic compounds to mediate the assembly of benzene-1,4-dithiol (BDT) into monodisperse supramolecular nanoparticles via π–π interaction, revealing the general formation mechanism for such systems.105 Co-precipitation is the main driving force for this assembly. The molecular dynamics (MD) simulations also highlighted that the phenolic molecules can interact with BDT through π–π stacking without compromising their ability to form hydrogen bonds (Fig. 8). This further explains the excellent colloidal stability of the nanoparticles in aqueous environment where the phenolics can provide bridging interactions between pBDT and water. Additionally, the π–π interactions in the nanoparticles can be easily destroyed in organic solvents (e.g., dimethylformamide, DMF) triggering the disassembly of the supramolecular nanoparticles.

Fig. 8.

All-atom MD simulation of the assembly of pBDT (blue) and catechin (red) at 0, 0.5, 4.0, and 10 ns in water. Magnified interface section illustrating the aromatic stacking of BDT and CAT and hydrogen bonding between CAT and water (red lines); carbon, oxygen, hydrogen, and sulphur are coloured black, red, white, and yellow, respectively. Reproduced with permission. Copyright 2020, Nature Publishing Group.

2.3. Biomacromolecules with phenolics

Phenolic compounds also interact with virtually all biomacromolecules including proteins, polysaccharides, DNA, RNA, etc. People have long consumed phenolics as a food and medicine. One notable example is the astringent sensations of wine due to their interactions with salivary proteins in mouth.106 Tannins have been used in leather-making because phenolics bind to animal skin collagen via hydrogen bonding and hydrophobic interactions to give leather improved thermal and enzymatic stability. TA also exhibits strong antioxidant and α-amylase inhibitory activity, which is useful for obese people and type II diabetes patients.107

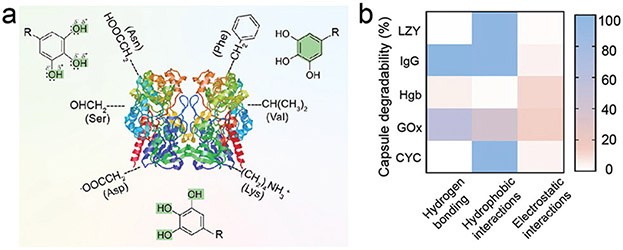

Although the combination of polyphenol and proteins has been explored for a wide range of functional materials, the underlying interaction between phenolics and proteins are unclear.108,109 Phenolics have shown strong yet reversible interactions with various proteins especially for proline-rich and histidine-rich proteins such as gelatin,109 thrombin,110 and elastin.111 Recently, supramolecular interactions (i.e., hydrogen bonding, hydrophobic interactions, and ionic interactions) between TA and a number of proteins with different pi, molecular weight, and aliphatic index were investigated to reveal the roles of proteins on the properties of the protein–polyphenol assemblies (Fig. 9).112 The three key findings are summarized as follows. (1) The contribution of hydrogen bonding in the assembly mainly relies on the molecular weight of the proteins because the peptide backbone and most of the exposed protein surface is hydrophilic (i.e., polar amino acids). (2) Proteins with high aliphatic indexes (i.e., those containing hydrophobic side chains such as alanine, valine, and isoleucine) often form more hydrophobic interactions with the aromatic groups of phenolics compared to proteins with low aliphatic indexes. (3) The strength of ionic interactions between proteins and phenolics largely relies on the charge of the protein. This work offers a streamlined way to evaluate the stabilizing force in the assembly of polyphenols and diverse proteins; it can serve as a guideline for future systemic investigations of the complex nature of molecular interactions between polyphenols and proteins.

Fig. 9.

(a) Schematic illustration of the proposed interactions between the functional moieties of phenolics and different amino acid of proteins. Asn = asparagine, Val = valine, Asp = aspartic acid. (b) Stability of protein–polyphenol capsules (LYZ, IgG, Hgb, GOx, and CYC) after 1 h of incubation with 100 mM of urea, Tween 20, or NaCl, corresponding to the dominant interactions between the different proteins and TA. Reproduced with permission. Copyright 2020, Wiley-VCH.

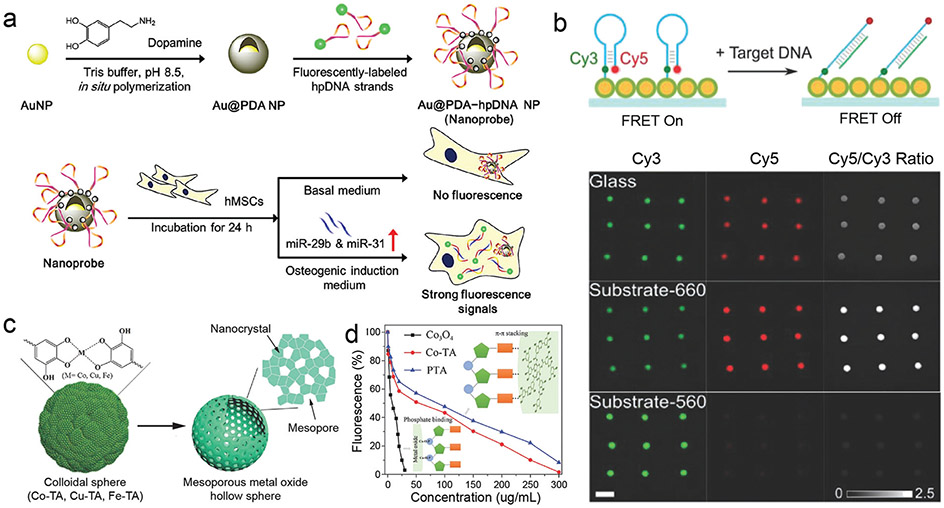

Messersmith and co-workers reported the use of random copolymers containing catechol and amine groups to immobilize DNA and then used this platform for DNA microarrays.113 They proposed that the DNA probes interact with the polymer in both covalent and noncovalent ways. Specifically, catechols in the polymers that were not bound to the substrate may be oxidized into quinones and react with the amines and thiols of the captured DNA sequence;114,115 Supramolecular interactions, such as hydrogen bonding, π–electron interactions, and electrostatic interactions between the amines of the copolymer and the DNA phosphate backbone were also likely to play an important role in DNA binding.116,117

The temperature-dependent rheological change of a TA–DNA gel suggested that the key driving force for the TA–DNA gels is the formation of reversible hydrogen bonds.118 Upon mixing with TA, the wavenumber corresponding to antisymmetric vibration of phosphate groups in DNA was significantly shifted from 1238.22 cm−1 to 1199.64 cm−1. Meanwhile, the ribose vibrational mode (C–C sugar) was shifted from 1095.49 cm−1 to 1085.85 cm−1. Moreover, there is an overall shift in the peaks to lower wavenumbers indicating increased TA-DNA interactions. Therefore, the stabilizing interaction between TA and DNA was proposed to the hydrogen bonding between the gallol group of TA and DNA phosphate backbone. The complexed DNA was released from the assembly due to the degradation of TA through cleavable ester bonds.

More recently, Weil and co-workers used PDA as “supramolecular glue” for modulating DNA origami conformations. Specifically, PDA nanostructures have been fabricated based on the DNA origami templates in acidic medium, where a G-quadruplex (G4)/hemin-based DNAzyme can accelerate the oxidation of dopamine into PDA. The negatively charged DNA domains with multiple DNAzyme molecules can accumulate positively charged dopaminochrome/dopamine in a high local concentration thus leading to their preferential polymerization at the DNAzyme domain.119

Phenolic compounds can also interact with polysaccharides. TA was used as cross-linkers to improve the hydrogel strength of carboxymethyl chitosan (CMC) as proven by rheological measurements.120 Under mild conditions, many intermolecular hydrogen bonds formed physical cross-linking on the surface of the microemulsion droplets for rapid hemostasis. In another work, catechol-carrying hyaluronic acid prepared by carbodiimide chemistry can form multilayer films with chitosan via electrostatic interactions to produce a bioadhesive film.121 Phenolic groups can also conjugate to cellulose nanofibers (CNF) via covalent bonds. For example, a N-(3-(dimethylamino)-propyl)-N′-ethylcarbodiimide (EDC)/N-hydroxysuccinimide (NHS) catalysed amidation reaction can proceed via the amine group of dopamine.122 The free catechol group can be therefore used for a secondary reaction such as chelation.

The various chemical groups in biomacromolecules offer tremendous opportunities to convert the existing groups into phenolic groups. Lignin can exhibit some tannin-like properties. However, such tannin-like properties of lignin are typically poor due to the limited free phenolic groups in lignin versus tannin. Lignin has many phenolic oxygens, and most of them are in the form of aromatic methoxy groups and inter-monomeric ether linkages. Therefore, using chemical or biochemical methods to increase the number of free phenolic groups in lignin can definitely give it a tannin-like functionality. To this end, lignin was functionalized with chemical demethylation to obtain demethylated guaiacyl-type synthetic lignins with tannin-like properties.123 Meanwhile, tyrosinase led to a biofriendly enzyme-mediated process that can convert the monophenols into catechols in situ. This can create catechol groups in a target of interest (e.g., peptides and proteins) that has native monophenol moieties while preserving its inherent function. The modified proteins can thus be used for surface coating while offering additional benefits such as biomineralization and metal ion chelation.124

2.4. Other biomaterials with phenolics

Cell engineering is an important topic for the biomedical applications, but it often involves complicated methods such as the introduction of non-biogenic functional groups by metabolic or genetic engineering. Recently, adsorption of bioactive macromolecules onto cell surfaces or their intracellular delivery into the cytosol has been attempted to manipulate chemical and biological functionalities into living cells. The biogenic nature of phenolics thus provides opportunities to interact with biological substances for functional biomaterials.

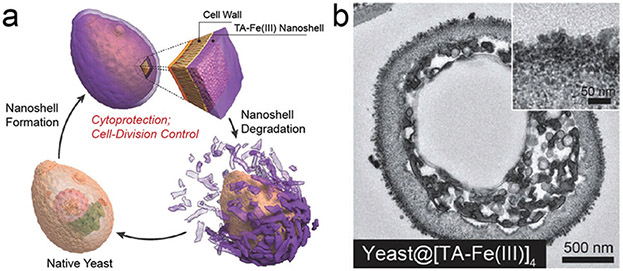

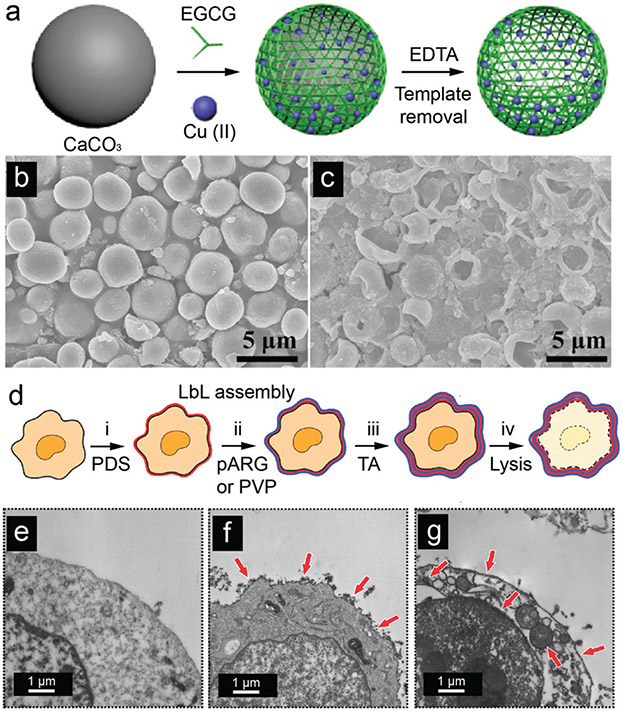

Choi and co-workers reported the use of covalently cross-linked dopamine to coat the surface of Saccharomyces cerevisiae (i.e., yeast).125 The PDA encapsulation on yeast cells can control cell division, which is an essential characteristic for artificial spore structures. However, the robust PDA shell was a physical barrier to the biological activity of the encapsulated cells especially if the shell did not disassemble in response to external environmental stimuli. To this end, a cytoprotective shell that can be degraded on-demand was developed via MPN (Fig. 10).126 The TA–Fe(III) shell (~40 nm) was clearly observed on the yeast@MPN biohybrid and suppressed cell division in plate cultures. interestingly, the growth of yeast dramatically increased after the MPN shell disassembled under mild conditions; the reproduction of coated yeast was similar to native yeast. Besides the cyto-compatible degradability of the MPN shell, the shell can also act as a protective layer against multiple stressors such as UV radiation and silver (Ag) nanoparticles.

Fig. 10.

(a) Schematic illustration of the controlled formation and degradation of the TA–Fe(iii) shell on individual S. cerevisiae. (b) TEM image of yeast@MPN. Reproduced with permission. Copyright 2014, Wiley-VCH.

PEN can also mediate the interaction of diverse materials and the microorganism. Guo and co-workers developed a bioinorganic hybrid system that consists of TA-modified indium phosphide nanoparticles and genetically engineered Saccharomyces cerevisiae.127 The polyphenol facilitated the immobilization of functional nanoparticles on the surface of yeast, where light-harvesting indium phosphide nanoparticles produces photogenerated electrons for cytosolic regeneration of redox cofactors. Similar biosynthesis-control strategies have been used for TA-capped Au nanoparticles for functionalizing microalgae.128

PEN-engineered biomaterials can also be developed from mammalian cells. For example, “cell-particle hybrids” consisting of pancreatic islets and PDA-coated FK506 (a potent calcineurin inhibitor)-loaded biodegradable microspheres (PD-FK506-MS) were fabricated to locally control the immune response at the transplantation site. The results demonstrated that the coating of FK506-MS with PDA allowed for the rapid assembly of stable islet-particle hybrids without significant changes in islet viability and functionality.129

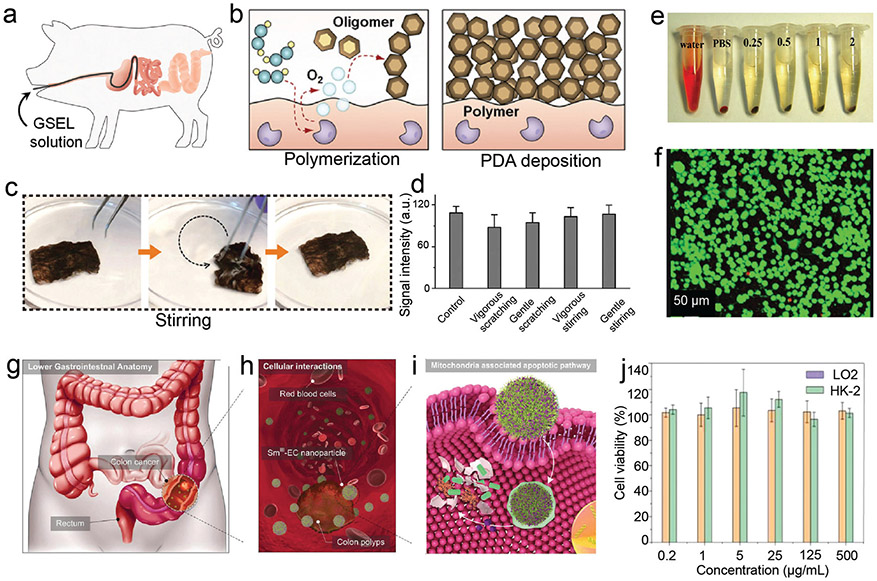

Some phenolic compounds have specific affinity to certain cell lines or tissue.130 The modification of protein and peptide therapeutics with TA can facilitate their adherence to extracellular matrices, elastins, and collagens, which improve heart tissue targeting.131 Specifically, TA-modified (TANNylated) proteins preferably penetrated the endothelium to bind to myocardium extracellular matrix rather than being captured on endothelial glycocalyx layers in blood vessels. In another example, polyphenols such as TA were found to be mucoadhesive molecules. Therefore, a nanoparticle system assembled from F-68, TA, and anti-inflammation corticosteroid dexamethasone (DEX) was designed for inflammatory bowel disease therapy.132 The inflamed colon epithelium is positively charged due to accumulation of positively charged proteins (e.g., transferrin) and bactericidal/permeability-increasing proteins. Therefore, negatively charged phenolic nanoparticles can preferentially adhere to the inflamed mucosa in mice with colitis providing both anti-inflammatory and colon-targeting ability.

3. PEN for functional particle systems

The versatile phenolic chemistry underpinning PEN allows for engineering particle systems with customized structures and properties. However, phenolics were not popular particle building blocks in the beginning, as most phenolic compounds were used in the leathering, wine and food industry.133 The investigation of PEN-based particles underwent a quick and large expansion after mussel-inspired materials were developed for surface coatings.13,134

For materials engineering, phenolics may play different roles either during the synthesis or in post-modification processes. By controlling the physicochemical interactions with stabilizing molecules, phenolics can self-assemble into particles in a confined space, form coating shells on the surface of preformed particles, or serve as templates for secondary growth of other functional materials. in addition to self-assembled particles, phenolics with specific monomers including metal ions, polymers, proteins, nucleic acids, and other functional molecules can co-assemble into particles.17 Depending on the molecular interactions between each building block, particles with multiple components can be obtained in a simple “one-pot” or “one-step” synthesis. This co-assembly strategy by PEN increases the synthetic library of multifunctional particle systems. Intensive efforts have been made to construct functional particle systems by PEN, and one of the key rules in PEN is that the attractive force between phenolics and complementary structural motifs be balanced with a repulsive force among confined hybrid particles. in this section, we will introduce PEN-derived particle systems with unique architectures, particle surface coatings using PEN, and engineered secondary nanostructures derived from phenolic-based templates.

3.1. Particle systems with engineered composition and structure

3.1.1. Particles.

Phenolic particle systems can be formed by a variety of building blocks through covalent and/or non-covalent interactions. The phenol groups of these building blocks such as catechol and gallol groups can be turned into quinones in oxidative conditions and lead to self-polymerization to form final particles.22,135 For instance, mussel-inspired dopamine is a famous phenolic compound for particle engineering. In weak alkaline solutions or when treated by oxidants, dopamine molecules easily undergo oxidative self-assembly into PDA.136 The colloidal PDA particles exhibited excellent physicochemical properties and great potential in biomedical applications.3 However, along with the investigation of fundamental chemistry of phenolics, a series of multi-component particulate structures have been synthesized by co-assembly of phenolic compounds and other functional motifs including metal ions, small molecule drugs, polymers, peptides, proteins, and nucleic acids. This synthetic strategy provides a new and facile route to integrate different modalities in a single particle system.

Phenolic groups show strong coordination toward metal ions, which enable co-assembly of each component, leading to the formation of metal-contained phenolic particles. For example, Gianneschi and co-workers prepared Fe3+-doped PDA nanoparticles through self-polymerization of dopamine monomers in the presence of Fe3+.137 This was achieved through the use of a pre-polymerization doping strategy, which employs tris-Fe3+–dopamine complexes and free dopamine as the precursors for the formation of Fe3+-doped PDA. The Fe3+ can be continuously incorporated into the particles allowing for tuneable doping levels. The chelating molar ratio of dopamine and Fe3+ varied in response to the pH change. Excessive addition of free dopamine could result in the formation of mono- or bis-Fe3+–dopamine precursors. Due to the strong chelating ability of the catechol groups, they further applied this method for the co-assembly of other transition metal ions including Mn3+, Ga3+, Co2+, Ni2+, Cu2+, and Zn2+.138 PDA nanoparticles of various sizes, shapes, and morphologies could be obtained in the presence of different metal ions. Though the precise mechanism for metal ion-polymerization still needs to be explored, the authors prepared specific metal ion-loaded PDA nanoparticles for on-demand applications such as magnetic resonance imaging.139 Dopamine can co-assemble into particles with metal ions. Other phenolic compounds including TA and EGCG can also chelate metal ions to fabricate hybrid phenolic particles. Metal–polyphenol coordination crystals were synthesized through oxidative self-polymerization of TA and metal salts under hydrothermal treatment.140 The coordination interactions between Co2+ and TA could be enhanced in alkaline conditions resulting in deprotonation of trihydroxyphenyl groups. Further, the radical generation and oxidative process for self-assembly were driven by dissolved oxygen. Metal/tannic particles (> 2 μm) are normally larger than the hybrid PDA particles (20–500 nm), which could be attributed to the different polymerization mechanisms of the two phenolics.

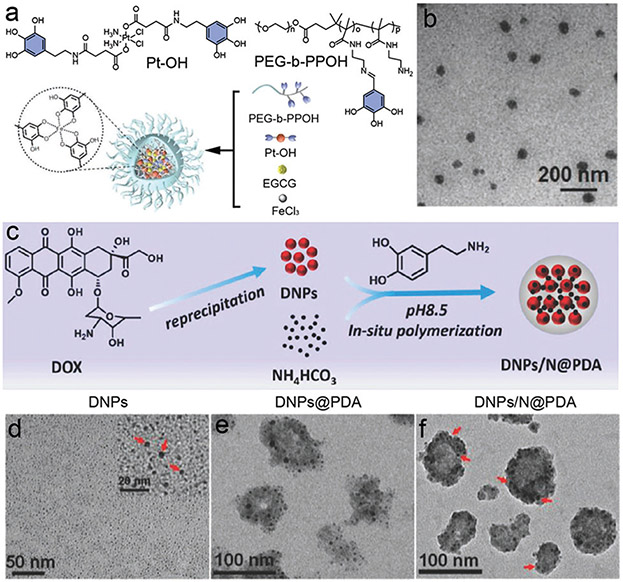

Moreover, the self-assembly of phenolic compounds could also incorporate small molecule drugs in the metal-doped particle system leading to a hybrid particle system for drug delivery. Cheng and co-workers conjugated Bortezomib, a protea-some inhibitor, with four kinds of polyphenols (catechin, EGCG, TA, procyanidin) via borate ester bounds.141 Fe3+ was used to form interchain Fe3+–catecholate coordination, and the hybrid conjugates could co-assemble into a highly stable supramolecule. The authors claimed that this strategy could reduce the adverse effects and retain the anticancer activity of the drugs. Similar strategies have also been utilized for hybrid phenolic particle synthesis via EGCG, platinum(iv) prodrug, Fe3+, and block copolymers as building blocks (Fig. 11a).142 The as-prepared particles exhibited a size distribution of 60 nm to 110 nm and showed high stability during in vivo circulation (Fig. 11b). In this case, EGCG was a natural nanoplatform consisting of different functional modalities including drug delivery and bioimaging by simple processes—this offers a new avenue for multifunctional nanomedicine. Other metal ions, such as molybdenum (Mo),143 gadolinium (Gd),144 and lanthanide (La)145 have also been successfully imparted into phenolic particles by co-assembly of metal ions and phenolic monomers suggesting the wide applicability of the strategy. The presence of metal ions did not disrupt the polymerization process, and they could even serve as oxidative agents further facilitating the self-assembly. Therefore, PEN offers a simple method for incorporation of functional metal ions within phenolic particulate substrates.

Fig. 11.

Co-assembled phenolic particles with metal ions and small molecule drugs. (a) The chemical structures of building blocks (Pt–OH, PEG-b-PPOH) and schematic illustration of a phenolic particle prepared by co-polymerization. (b) TEM image of the as-prepared phenolic particles. (a and b) Reproduced with permission. Copyright 2020, Wiley-VCH. (c) Schematic illustration of synthesis of PDA-coated and NIR-responsive carrier-free “nanobomb” (DNPs/N@PDA). (d) TEM images of the DOX nanoparticles (DNPs), PDA-coated DNPs (DNPs@PDA), and NH4HCO3-loaded DNPs@PDA (DNPs/N@PDA). (c–f) Reproduced with permission. Copyright 2018, Wiley-VCH.

Phenolic molecules can co-polymerize with peptides/proteins into bioavailable particles. Peptides/proteins are easily degraded over long rounds of blood circulation. They may fail to function in the absence of protective delivery. Therefore, co-assembly with phenolics into particles could be an ideal strategy for protective delivery of peptides/proteins due to the protection from biocompatible phenolics. Kurisawa and co-workers demonstrated that EGCG derivatives could complex with an anticancer protein (Herceptin) to form micellar nanoparticles.108 The micellar nanocomplex is obtained by complexation of oligomerized EGCG with Herceptin to form a core followed by complexation of PEG-EGCG to form the shell. The protein-contained particles with a monodispersed hydrodynamic size (ca. 90 nm) featured a longer blood half-life time in vivo than free proteins. Importantly, the particles displayed stabilized protein activity during complexation and dissociation, and this largely improved the therapeutic index. Cheng and co-workers developed a series of polyphenolic-based nano-carriers for cytosolic protein delivery.146 Four kinds of polyphenols (EGCG, catechin hydrate, procyanidin, ellagic acid) were used for direct co-assembly of protein-contained particles. The authors indicated that both hydrogen bonding and hydrophobic interactions directed the particle assembly. Isothermal titration calorimetry results indicated that the binding of EGCG with bovine serum albumin is an exothermic reaction and the hydrogen bonding dominates the phenol–protein formation. Zhang and co-workers introduced PDA in particle engineering for hemoglobin delivery, which also takes advantage of PEN for protein encapsulation. The abundant catechol groups in PDA permitted non-covalent bonding with hemoglobin forming protein-contained PDA particles.147

Phenolic compounds can also be used for high loading of small molecular drugs in self-assembled particles instead of traditional polymeric micelles with low drug loading capacity. The strong binding of phenolic compounds to small molecule drugs formed through hydrophobic interactions, hydrogen bonding, and π–π stacking contributes to the encapsulation of a wide range of drug molecules. Kurisawa and co-workers developed a highly stable and large drug loading micellar nanocomplex based on the self-assembly of DOX and PEG–EGCG.148 Favourable intermolecular interactions between the DOX and EGCG molecules improved the drug loading capability by 88%. This PEN-based strategy of particle engineering is particularly applicable to small molecule compounds with multiple-ringed structures with structural similarity to phenols. A PDA-coated carrier-free particle was developed for protective delivery of DOX and NH4HCO3 (Fig. 11c-f).149 The biocompatibility and hydrophilicity of PDA prolonged the blood circulation time and prevented the leakage of drug molecules. Meanwhile, NH4HCO3 here served as “remote bomb” to facilitate DOX release, which could be triggered by non-invasive NIR irradiation. By taking advantages of PEN for particle fabrication, multifunctional modalities including drug loading, prolonged blood circulation, photothermal conversion, and secondary modification of targeting/imaging were achieved by this “all-in-one” phenolic particle.

3.1.2. Porous particles.

Porous particles have been widely used in biomedicine due to their high loading capacity, large surface area, and structural advantages.150,151 PEN has been considered a powerful toolkit to develop porous particles for specific applications. The intrinsic chemistry of phenolics further endows porous particles with tuneable pore size and shape, potential for second modifications, and stable bonding sites for cargo loading. The combined physical and chemical features of porous phenolic materials enable their widespread use in biomedical applications including drug delivery, bio-catalysis, biosensing, and bioimaging.

Phenolic-based porous particles can be synthesized via self-assembly on “soft templates”. Direct coating of phenolic compounds on pre-formed porous particles is another choice for preparation of porous phenolic-based materials.152 This coating strategy for porous particle synthesis will be introduced in Section 3.2.1. “Soft templates” such as amphiphilic block copolymers interact with phenolics though hydrogen bonding, electrostatic interactions, and other non-covalent interactions. Yamauchi and co-workers prepared mesoporous PDA nanoparticles (particle size: ca. 200 nm; pore size: ca. 16 nm) through self-polymerization of dopamine and spontaneous co-assembly of diblock copolymers. The authors found that dopamine molecules could form stable composite micelles with high-molecular-weight block polymer (PS-b-PEO). The PS-b-PEO micelles herein acted as a sacrificial pore-forming agent that could be removed after particle synthesis. The results indicated that the particle size and pore size of PDA nanoparticles were largely dependent on the ratio of hydrophobic to hydrophilic chains in PS-b-PEO.153

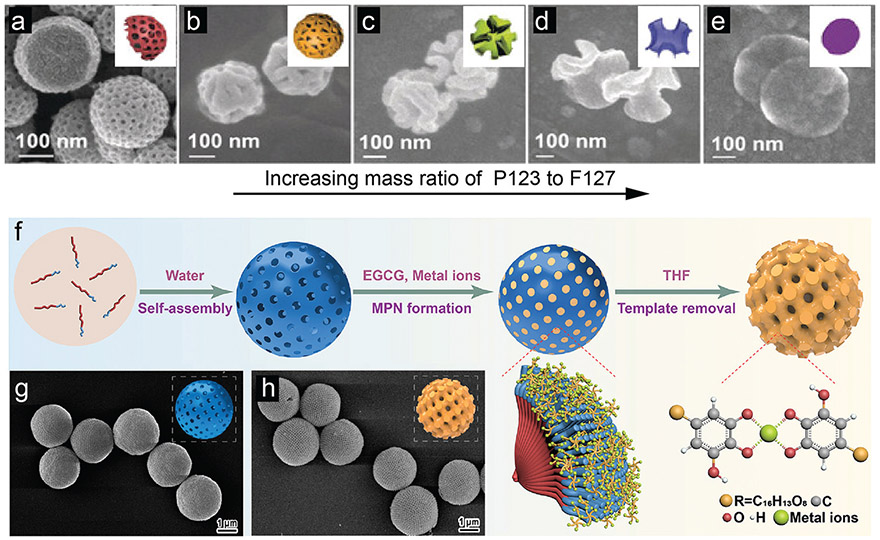

A similar strategy of copolymer templating was used to prepare bowl-like mesoporous PDA by Lou and co-workers.154 The dopamine molecules were first dissolved in a quaternary nanoemulsion system consisting of F127 block copolymer/1,3,5-trimethylbenzene/ethanol/water to form stable dopamine micelles. After the addition of an ammonia trigger, continuous cooperative assembly drove the oriented growth of PDA mesochannels. In this case, the F127 block copolymer served as sacrificial surfactant whereas 1,3,5-trimethylbenzene acted as pore swelling agent. By increasing 1,3,5-trimethylbenzene, the resulting product could be continuously tuned from symmetric nanoparticles to asymmetric bowl-like particles. Moreover, in order to increase the pore size, they introduced another block copolymer (P123) with shorter hydrophilic chains.155 After the same assembly process, walnut-shaped macro-/mesoporous PDA particles with wide pore size distributions from 20 nm to 95 nm could be fabricated (Fig. 12a-e).

Fig. 12.

“Soft template”-directed synthesis of mesoporous phenolic particles. (a–e) SEM images of PDA particles prepared with different mass ratios of P123 to F127: (b) 0 : 1; (c) 1 : 15; (d) 1 : 3; (e) 1 : 1; (f) 5 : 3. Insets: Schematic representation of mesophase transition of PDA particles at different P123/F127 mass ratio. (a–e) Reproduced with permission. Copyright 2018, Wiley-VCH. (f) Schematic illustration of synthesis of the mesoporous MPN particles using polymer cubosomes (PCs) as templates. SEM images of (g) PCs and (h) mesoporous MPN-coated PCs after template removal. (f–h) Reproduced with permission. Copyright 2020, American Chemical Society.

In porous particle engineering, the swelling agent is a crucial factor that determines the pore size and shape of particles. Zhao and co-workers provided a deep study of the micelle formation mechanism to give a clear description of mesoporous PDA self-assembly.156 The authors proposed that 1,3,5-trimethylbenzene can interact with the hydrophobic PPO segment of block polymers and dopamine molecules through van der Waals forces and π–π stacking. This interfacial mediation promotes the formation of a dopamine nanoemulsion with a size distribution from 8 nm to 52 nm, which in turn self-assembles into mesoporous PDA nanoparticles with pore sizes up to 37 nm. By increasing the amount of swelling agent, the nanoparticles varied from non-mesoporous particles to golf-ball-like nanospheres, multichambered mesoporous spheres, and dendritic-structured porous particles. In all, nanoemulsions are a facile route to prepare porous PDA particles. The results show that solvent, swelling agents, and surfactants are key factors for the fabrication of porous particles.

Unlike dopamine, natural polyphenols like TA, EGCG, and ellagic acid are usually used together with metal ions to prepare porous particles. Fechler and co-workers developed a facile and sustainable strategy to prepare hierarchically porous carbon particles.157 Polyphenols can chelate with metal ions through coordination interaction allowing the formation of metal–phenolic complexes. After complexing with Zn2+, ellagic acid monomers were directed into a well-organized framework, which assembled into mesocrystals. Finally, the high-temperature treatment enabled the thermal carbon conversion and removed the phenol–metal crystal, which transformed the as-prepared particles into a hierarchically porous carbon. The ellagic acid–Zn complex served as a carbon precursor and porogen in one unit—the so-called “salt-templating” strategy.

Recently, Caruso and co-workers reported a templating strategy using sacrificial polymer cubosomes (PS-b-PEO) to prepare ordered mesoporous metal–phenolic particles (Fig. 12f).158 The polymer cubosomes (PCs) has a bicontinuous triply periodic minimal surface structures leading to a water channel networks with a long-range cubic crystalline order. Importantly, this “soft template” was stable in aqueous solution and could be readily removed by tetrahydrofuran. Thus, the metal–phenolic complexes (i.e., EGCG and gallic acid; Fe3+, Cu2+ and Zr4+) fused with the PCs and subsequently assembled in situ. Finally, highly ordered mesoporous metal–phenolic particles with a large pore size of ca. 40 nm could be obtained (Fig. 12g and h). Relative to PDA of different porosities, fewer mesoporous polyphenol particles have been investigated. However, there are numerous studies focusing on polyphenol-based capsules with unique hollow structures that will be discussed in Section 3.2.2.

3.1.3. Anisotropic particles.

Colloidal anisotropic particles with controlled and tuneable internal architecture have gained great research attention due to their structure-dependent advantages in various applications including energy conversion and biomedicine. However, the accurate engineering of anisotropic particles at the nanoscale level remains challenging. PEN provides a relatively facile method for the fabrication of anisotropic nanoparticles. Driven by molecular interactions with either soft or hard template substrates, phenolic materials can be readily assembled for the manipulation of anisotropic nanoparticles with unique structures such as patchy surfaces.159

The precise control of intermolecular interactions makes anisotropic growth easier. PDA–Au Janus particles could be obtained by simply adding HAuCl4 to a PDA particle solution.160 Controlled electrostatic repulsion is key to formation of the Janus nanoparticles which could be only prepared in a narrow pH range of 2.5–3.0. The as-synthesized PDA–Au Janus particles could spontaneously self-assemble at oil/water interfaces as a result of the hydrophilic PDA and hydrophobic Au surface. In another study, various anisotropic PDA particles including nanobelts and nanofibers were prepared with the aid of folic acid.161 The authors hypothesized that folic acid may participate in the self-polymerization process of dopamine molecules. The π–π stacking interaction and hydrogen bonding between folic acid and proto-molecules of PDA may contribute to the formation of PDA nanobelts and nanofibers. Anisotropic nanoparticles with similar nanofibrous structures were obtained by co-assembly of dopamine and pyrrole.162,163 The oxidative co-polymerization of dopamine and pyrrole in alkaline solutions could produce hybrid nanostructures including nanospheres, nanofibers, nanorods, and nanoflakes by simply changing the molar ratio of two monomers.

Polymer–inorganic nanoparticles are a series of novel hybrid materials for multifunctional applications. Wang and co-workers utilized poly(acrylic acid) (PAA) particles as a structure-directed template for anisotropic growth of dopamine.164 Different from conventional examples where dopamine molecules could deposit on the surface to form a complete coating shell, the PDA coating on the PAA particles only occurred on one side of particles, as also confirmed by time-dependent electron microscopy observation. This is probably due to the island nucleation of PDA on PAA to reduce the number of interfaces, which is similar to the Volmer–Weber growth mode. Thus, after asymmetric PDA coating on PAA nanoparticles, the deposition of mesoporous calcium phosphate on the other side of the particles could be achieved by introducing CaCl2 leaving the PDA domain untouched. The resulting anisotropic particles could be further modified with PEG and ICG for cancer therapy.

Wang and co-workers developed hollow MOF-PDA Janus nanoparticles using a similar strategy, suggestive of its general applicability for diverse anisotropic particles of different compositions.165 Using the PAA-directed strategy for anisotropic particles synthesis, they further prepared a monstera flower-like Au nanorod (AuNR)/PDA bowl with spadix-bract nanostructure.166 The anisotropic structure is composed of AuNRs and bowl-like PDA shells, which allowed cargo loading of both hydrophobic and hydrophilic drugs. To the best of our knowledge, most phenolic-based anisotropic particles were derived from PDA; other phenolic-based materials are rarely reported. More effort should be paid to deciphering the underlying mechanisms so that different anisotropic PEN-particles can be used in the future.

3.2. Particle surface coating using phenolic-based materials

3.2.1. Surface coating on pre-formed particles.

Surface coating is a straightforward method to modify or functionalize pre-formed particles. It can alter their surface chemistry and allow for secondary functionalization. Inspired by nature, phenolic-based materials have been widely used for surface coating. Mussels adhere strongly to rocks, ships, and other seashells in wet conditions because they can secrete the adhesive Mytilus edulis foot protein that contains many catecholic amino acids.13 Therefore, phenolic compounds with a high content of catechols and pyrogallols could be a multifunctional coating on the substrate surface via strong interfacial bonding.80,167

Phenolics show a high affinity towards metallic substrates, leading to depositional coating in which the coordination bond is the main driving force. The surface coating of phenolic assembles could be applied in a variety of metal/metal oxide/metallic composite particles such as Au,168,169 Ag,170 magnetic nanoparticles (Fe3O4),171 manganese oxide (Mn3O4),172 molybdenum oxide (MoO3),173 aluminium oxide (Al2O3) particles,174,175 and MOF.176 The nature-inspired coating strategy significantly improves the stability, biocompatibility, and adhesion of the pre-formed particles. Duan and co-workers prepared PDA-coated magnetic nanochains by simply mixing Fe3O4 nanoparticles and dopamine molecules in alkaline buffer. Driven by a homogeneous magnetic field, the nanoparticles aligned in a row while the adhesive PDA concurrently formed a conformal coating on the nanochains. This surface coating not only acted as a scaffold to fix the chain structure but also allowed for further surface functionalization such as PEGylation.177

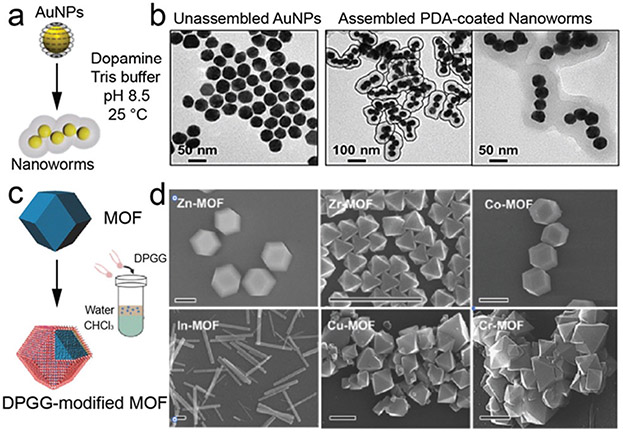

PDA-coated magnetic microswimmers were fabricated by dip-coating of magnetic nanoparticles on Spirulina and subsequent PDA coating on the outer shell surface.178 The latter coating enhanced the photoacoustic signal and photothermal effects of the microswimmer, which facilitated real-time tracking of photothermal therapy (PTT). The intrinsic quenching effect and the versatile surface reactivity of PDA also provided an off–on fluorescence diagnosis with sensitive probes. This could be a facile yet productive method to functionalize micro/nanorobots. Core–shell Au nanochains were prepared by dopamine mediation and subsequent self-polymerization.179 The resulting nanochain consisted of 4–5 Au cores and a PDA coating shell (Fig. 13a and b). The authors claimed that the interactions between the citrates on the Au surface and the protonated primary amines and catechols of PDA were key factors underlying assembly.

Fig. 13.

In situ deposition of adhesive phenolic coating on pre-formed nanomaterials. (a) Schematic illustration of dopamine-mediated assembly of Au nanoparticles (AuNPs) into PDA-coated nanoworms. (b) TEM images of unassembled AuNPs and assembled nanoworms. (a and b) Reproduced with permission. Copyright 2019, American Chemical Society. (c) Schematic illustration of the surface functionalization of MOF particles by a phase transfer reaction. (d) SEM images of the DPGG-modified MOF particles of different metal ions. Scale bar:1 μm. (c and d) Reproduced with permission. Copyright 2017, Wiley-VCH.

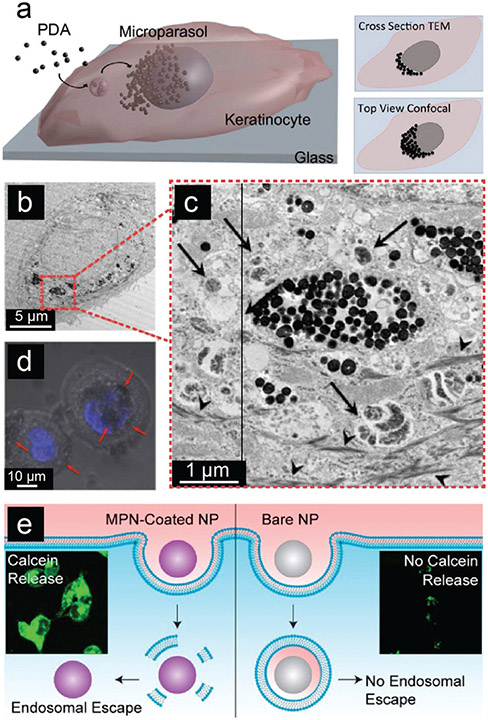

Hussain and co-workers functionalized AuNRs with TA for efficient endosomal uptake.180 The TA-coated nanorods showed strong affinity to serum proteins and formed a strong protein corona matrix that protected the particles. Retention of the nanorods was observed following endocytosis into keratinocyte cells, which may result from the tight association between TA and cellular membrane proteins. TA overcoats the whole nanorods with no direct interaction with the Au surface because the nanorods were coated with cetyltrimethyl ammonium bromide (CTAB) during the synthesis. Unlike thiols, the pyrogallol groups of TA are not sufficiently strong to remove CTAB from the surface—this is a key point in TA coating.

Polyphenol-coated titania particles have been developed by tannic adhering via metal–organic coordination.181 The slightly rough polyphenol surface showed additional reducing capacity enabling in situ deposition of Ag nanoparticles onto the shell surface. The pyrogallols could also react with thiol-terminated molecules for further modification.

Phenolic-based materials also showed conformational adhesion to other inorganic substrates such as silica particles,182 graphene QDs,183 carbon materials,184,185 and black phosphorus.76,186 MSNs have been used in a wide range of biomedical applications (e.g., drug delivery) due to their excellent chemical and mechanical stability, high pore volume, and surface area.187 Although MSNs are well-known for their high drug loading capacity, the unfunctionalized particles cannot release cargo in a controlled manner. Thus, the phenolic compounds deposited on MSN could act as a “gate keeper” blocking drug molecules inside MSN and releasing them under specific stimuli. In one example, Mei and co-workers modified DOX-loaded MSN with a mussel-inspired PDA coating and further attached d-α-tocopheryl polyethylene glycol 1000 succinate (TPGS) to the PDA surface through Michael addition.188 pH-Responsive drug release was observed; the resulting nanoparticles could release 38.9% and 47.7% of DOX molecules at pH = 6.5 and at pH = 5.0, respectively. Only moderate release (19.5%) was recorded when the nanoparticles were dispersed in neutral solutions over six days. The TPGS modification gave the nanoparticles the ability to overcome multidrug resistance. In this case, PDA exerts more than one functionality onto the pre-formed MSNs. Similarly, fluorescent nanodiamonds,189 graphene nanosheets,190 and carbon nanotubes185 were also incorporated into a PDA shell for surface coating of carbon particles showing enhanced physiochemical properties.

Black phosphorus is a novel two-dimensional material that has recently attracted great attention of researchers for its good compatibility, photothermal conversion, and drug loading. However, phosphorus is sensitive to oxygen and water, which hinders its potential in biomedicine. PDA coatings can protect interior black phosphorus from environmental damage largely improving its stability.77

The surface coating of phenolic materials has also been used to engineer MOFs. MOFs are of great interest in a number of host-guest interactions and applications. However, most MOFs (e.g. zeolitic imidazolate framework) possess vulnerable intermolecular interactions between metal ions and organic ligands, which are often unstable under acidic conditions. The surface coating is applied to improve the stability and biocompatibility of MOF particles. A biocompatible and biodegradable core–shell MOF nanoparticle for tumor photothermal-chemotherapy was developed by PDA coating on MOFs particles.191 The cytotoxicity and in vivo acute toxicity were evaluated and demonstrated that the biocompatibility of the MOF nanoparticles was greatly improved. Meanwhile, the degradation time was extended and regulated at a moderate rate. A novel strategy for the functionalization of MOFs was developed via a phenolic-inspired lipid molecule (1,2-dipalmitoyl-sn-glycero-3-gallol) as a coating shell. In particular, the intrinsic hydrophilicity of the MOF surface was altered to be hydrophobic and thus form various nanoarchitectures due to the amphiphilic particles (Fig. 13c).192 Density Functional Theory calculations showed that strong chelation of the metallic skeleton and trihydroxylphenol groups was the basis for the synthesis of amphiphilic MOFs. A variety of metal ion (Zn2+, Co2+, Zr4+, Fe3+, Cu2+, Cr3+, In3+, Al3+, and Eu3+)-based MOFs have been used to prove the generality of this coating strategy (Fig. 13d). Queen and co-workers revealed that the PDA coating strategy offered stability improvements for a diverse set of MOFs with varying metals, ligands, and topologies including ZIF-8, ZIF-8, UiO-66, Cu-TDPAT, Mg-MOF-74, MIL-100-Fe, and HKUST-1.193 However, phenolic compounds such as TA and gallic acid are weak organic acids that could release free protons and destroy MOFs. Much attention has been paid to the reaction conditions when preparing phenolic surface coatings on MOFs to avoid etching.80

Through covalent and non-covalent interactions, phenolic compounds can deposit on the polymeric particles and form a tight surface coating. For example, to facilitate the interactions with biological interfaces, polymeric nanoparticles usually need pre-functionalization, which is complicated and inefficient. Using phenolic-based materials as a surface coating is an easy and efficient method. Yeo and co-workers fabricated PDA-coated poly(lactic-co-glycolic acid) (PLGA) nanoparticles in a weak alkaline condition (pH = 8–8.5).194 The authors speculated that PDA deposits on the polymeric surface as a thin film rather than particulate aggregates. After the prime-coating, PLGA nanoparticles could be further conjugated with amine- or thiol-terminated functional ligands such as small molecules, peptides, and other polymer ligands.