Abstract

Nanomaterials like silver, iron, ceramic, graphene carbon nanotubes, etc. These are used to develop and create multifunctional materials to fight the corona virus. This work focuses on analyzing and discussing the developments of Nano-materials and their effectiveness in fighting and preventing the spread of the corona virus. The paper also analyses the use of Nano-materials in the development of vaccines and anti-viral drugs. However, the use of carbon-based materials like carbon dots and other forms of carbon has not only helped in increasing the protection levels in human life but also provided greater security and freedom for people to carry out day-to-day activities without any fear of being infected by the virus. The application of graphene-based materials for making unique face masks and germ trap technologies is presented. Nano-compounds blended with hand sanitizers have played an active role in the control of coronavirus along with soap-based liquids that are used for handwashing. Some of the Nano-materials like gold nanoparticles are extensively used in the making of detection devices like RT-PCR, etc. The use of Nano-polymer coatings has created a safe environment for users by preventing the spread of coronavirus through surfaces. Different coating methods used for the application of nanomaterials are explained with suitable technical interpretations The anti-viral efficiency of different coatings is also discussed through surfaces. Nano-materials and contributions from the synthetic biology area have helped to develop vaccines and anti-viral drugs which are presently used to cure and prevent the spread of coronavirus infected patients. The method followed in analyzing the Nano-materials and their applications mainly focused on tracing the development and applications of Nano-materials. This analysis proves and shows that Nano-materials are playing a vital role in fighting the corona virus.

Keywords: Snoods, Photoactive compounds, Anti-viral coatings, Carbon-dots, Graphene, Silver Nano-particles

1. Introduction

The coronavirus has affected the entire world and altered the behavior patterns of human beings and their day-to-day life. The present coronavirus is easily transmitted by air and surface contaminations and can impact the entire respiratory system of the human body and, finally, leading to death. The present situation at the community level has warranted people to stay at home and prevent the chances of them being infected with the coronavirus. The fight at the community level against the corona virus is not possible without the use of proper personal protective equipment and nanomaterials. So far, human society has been successful in utilizing Nano-materials and chemical compounds to fight the spread of coronavirus. The use of nanomaterials has lowered the transmission levels and controlled infection levels of coronavirus at public places. Nano-material-based anti-viral coatings are also used in snoods and face masks to prevent and kill the virus. The use of these anti-viral coatings has also resulted in the transmission chain being used very effectively. They are also used in Personal Protective Equipment (PPE) due to their anti-viral properties. Many high-end Nano-materials like carbon dots, photoactive compounds, and semiconductor materials are used in tandem to prevent the spread of the virus. Carbon-based Nano-materials are effectively used in air and water filtration and safeguard the living environment so that the safety levels against the attack of the coronavirus are improved. Nano-compounds are also used in making hand sanitizers, diagnostic and prevention kits, and in making vaccines and anti-viral drugs. Table 1 summarizes the application of some of the Nano-materials and their functional use.

Table 1.

Summary of Nano-Material Applications.

| SL No | Nano-Material | Application |

|---|---|---|

| 1 | Silver Nano-particles | Anti-bacterial finishing |

| 2 | Fe (Iron) Nano-particles | Conductive magnetic properties, remote heating |

| 3 | Zinc Oxide (ZnO) and Titanium di-oxide (Tio2) | UV protection, fire protection, Oxidative catalysis |

| 4 | Titanium di-oxide (Tio2) and Magnesium oxide (Mgo) | Chemical and biological protective performance, provide self-sterilizing function |

| 5 | Silicon di-oxide (Sio2) and Aluminum oxide (Al2O3) Nano particles with Polypropylene (PP) or Polyethylene (PE) coating | Super water repellent finishing |

| 6 | Indium-tin oxide Nano-particles | Electromagnetic/Infra-red protective clothing |

| 7 | Ceramic Nano-particles | Increasing resistance to abrasion |

| 8 | Carbon black Nano-particles | Increasing resistance to abrasion, chemical resistance and impart electrical conductivity, coloration of some textiles |

| 9 | Clay Nano-particles | High electrical, Heat and chemical resistance |

| 10 | Cellulose Nano-whiskers | Wrinkle resistance and water repellency |

The analysis and review of the developments of Nano-materials, coating methods, the anti-viral activity of different coatings have proven the importance and highlighted the contribution of Nano- materials like Graphene, Carbon Nano-materials, etc. in fighting the corona virus.

2. Methodology

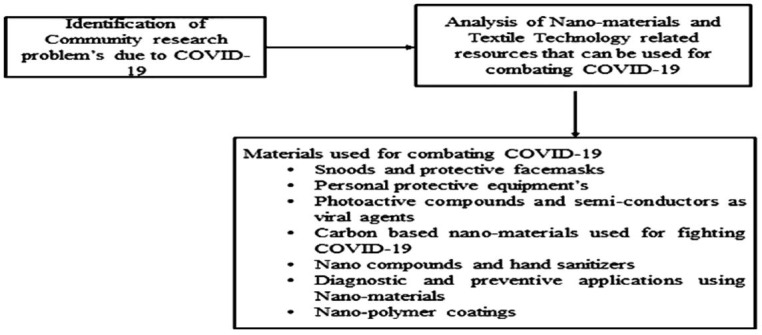

This research primarily focuses on the identification of community research problems due to COVID-19. This research objective is to analyze the nanomaterials and textile technology concepts that would help to combat COVID-19. Many high-end materials like snoods, face masks, personal protective equipment, Graphene face masks, carbon nanomaterials, and other Nano compounds are discussed. The application of Nano-materials as a coating technology is also emphasized with reference to its technicality in this research work. The research methodology followed in this work is shown in Fig. 1 .

Fig. 1.

Methodology.

3. Developments and analyzing the functionality of nano-materials used in fighting COVID-19

3.1. Nano-materials applications in snoods and protective facemasks

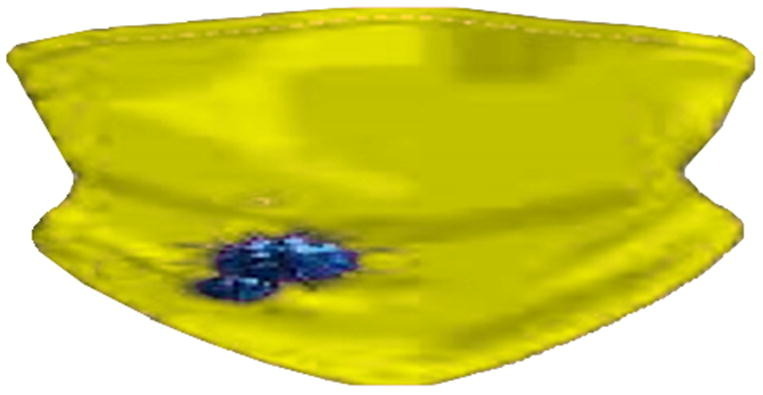

Carrington textiles, a UK (United Kingdom) based company has succeeded in making a snood that can prevent the spread of airborne viruses like MERS (Middle East respiratory syndrome), SARS (Severe Acute respiratory syndrome), and influenza. Due to 10 years of extensive research work by their scientists and the involvement of the Manchester Institute of Biotechnology, Carrington textiles is able to make such innovative products that combat COVID-19 disease. Their research focused on developing anti-viral protective coating material (Fig. 2 ) which traps the airborne viral droplets and kills them before entering into the human respiratory system. Their innovative coating has ensured 360 protection and 96% efficiency in controlling the spread of the virus. The coating is also characterized by having the capacity to screen the airborne viral droplets having sizes 15 times smaller than the dimensions of human hair. The handle properties of the snood are also excellent and have better reuse ability levels and a soft feel to the wearer, which is quite different as compared to face masks that are being sold on the market so far. This technology added in the snood is popularly called germ trap technology. The coating technology is made from anti-viral Nano-compounds which become active when they come in contact with the viral droplets. Due to the airborne spread of the coronavirus, the use of face masks in public places in many countries is made mandatory now a days, as per the guidelines laid out by the USFDA (United states food and drug administration) and WHO (world health organization). The USFDA and WHO have given guidelines for making face masks to manufactures. The face masks should have the capacity to filter and should be made as per the guidelines laid out by the National Institute for Occupational Safety and Health. The code used to represent the standard face mask is N95, where the letter ‘N’ stands for ‘Non-oil” underlining the ban of the use of oil-based particles in the face mask, and 95 stands for the efficiency of filtration that the mask can do when it comes in contact with the airborne viral droplets. Higher numbers like 99.97 and 100 indicate the high-efficiency ones (HEPA). Most of the masks available today are able to screen the viral particles of size 0.3 µm. Polypropylene fibers which are highly hydrophobic are the preferred material used for making face masks. Many face masks are designed in such a way that they provide exhaust values in order to enable comfortable breathing by the wearer. Surgical masks made using cloth layers are also found to be very efficient in such circumstances. Due to the shortage of N95 masks, many have started making face masks using textile coated fabrics to prevent the transmission of viral droplets [1], [6].

Fig. 2.

Germ Trap Technology in Snood.

3.1.1. Graphene face masks

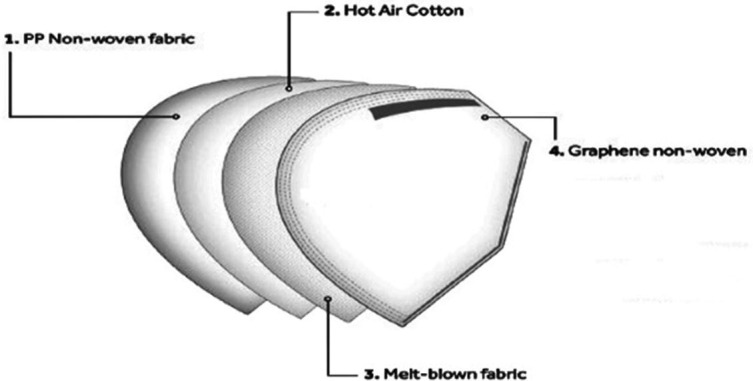

Graphene-enhanced face masks offer useful anti-bacterial and anti-viral properties. These masks protect the wearer from airborne bacterial and viral particles. These masks are usually made using 4 layers of fabric as shown in the Fig. 3 . The usage of 4 layers of fabric enables the mask to attain a filtration efficiency of 95%. There is no loss in the fabric property, and the mask is reported to be a reusable one. Polygreen and Nanene are examples of graphene-based face masks. These masks are been verified and certified by the graphene council. The graphene outer protective layer forms 28.6%, Polypropylene non-woven fabric makes 14.2% and the melt-blown fabric is 28.6%. The other components are the cotton filtering layer in the outer shell.

Fig. 3.

Grapheme based face masks for better filtration efficiency.

3.2. Nano-materials applications in personal protective equipment’s

The novel coronavirus is present usually in the environment as aerosols. The viral droplets have the capacity to transmit and circulate up to a distance of 2 m. The regular use of face masks and other personal protective equipment in public places has brought down the number of infected people in many countries. Many of the personal protective equipment used in hospitals and workplaces are mostly made from textile fabrics. Natural eco-friendly and skin-friendly textile fibers like cotton, silk, polyester in different structural configurations are used for making this personal protective equipment. Most of the cellulose materials are used after coating with Nano-compounds like silver Nano-particles (AGNPs) in order to achieve the anti-viral and anti-bacterial functionality into the product. Graphene is also being used as a coating material to enhance its mechanical properties and anti-microbial activity. Graphene is mainly used for coating woven and non-woven PPEs due to its lightweight, fire-resistant, UV resistance, and conductive properties. These properties are very helpful in making a PPE material to fight against the corona virus[2], [3].

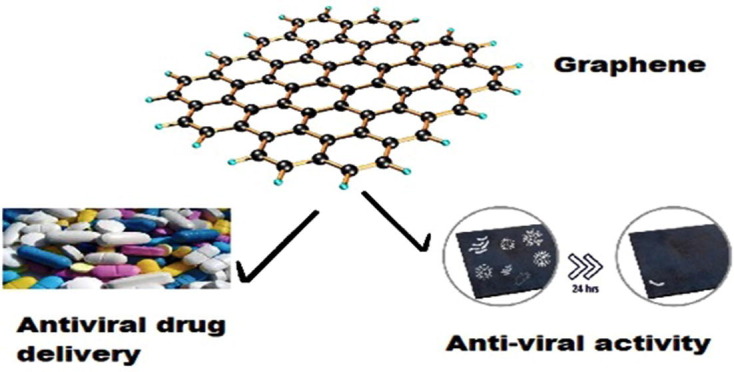

In the ventilation system, graphene has helped to increase the effectiveness of controlling the spread of the virus (Fig. 4 ). At public places like commercial buildings, homes, cars, aircraft cabins, etc., the carbon granulated powder coupled with graphene helps to filter out the viral particles whose sizes are above 50–130 nm. The use of activated carbon with fibers as a protective coating for air filters has ensured the biocidal activity of the viral particles. A few of the nanoparticles like silver nanoparticles (AGNP) and copper oxide (Cuo) have proven to control the transmission of this virus. In addition to the biocidal activity of nanoparticles, they also increase the filtration efficiency and provide round-the-clock protection against viral attacks. Metal Nano-particles like Ag, ZnO, Zn, Cu, and Cuo is frequently used in ventilation systems now-a-days.

Fig. 4.

Applciations of Graphene in reduction of corona virus through anti-viral acitivty.

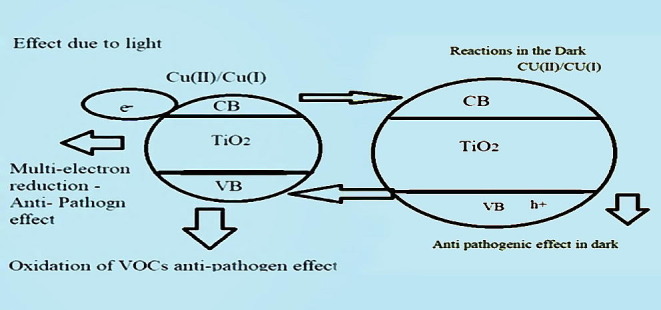

3.3. Photoactive compounds and semi-conductors as viral agents

Nano-particles having semiconducting properties and photosensitizing (PS) properties are recently being used to kill the virus. These photoactive compounds and semiconducting particles have the potential to kill the virus and act as virucidal due to the production of such chemical radicals which are generated when the nano-material compound is exposed to light. Generally, this process is referred to as photodynamic inhibition (PDI). The interaction of the photosensitive nanoparticle in the presence of light kills the protein component, ruptures the cell membrane, and damages the RNA/DNA component of the virus, thus ensuring the virucidal activity of the photosensitizing compound is executed at the right place. In many instances, multiple combinations of nano-particle functions have been investigated for their virucidal activity. For example, when methylene blue (MB) a photosensitive material is used along with organic-coloured dyes coupled with gold, titanium dioxide, silica particles, it is found to be very effective in sanitizing the indoor premises along with lighting devices. This nano-particle helps in killing the bacteria, virus, fungi, and other germs that may be accumulated on the surface of the premises. Fig. 5 presents the action of a semiconductor doped material for killing the micro-organisms in premises where the indoor lighting device is installed. CB is the conduction band level; Inter-facial charge transfer is indicated by (ICFT) and Volatile organic compound is indicated by VOC [16].

Fig. 5.

Mechanism of Photoactive compounds.

3.4. Carbon based nano-materials used for fighting COVID-19

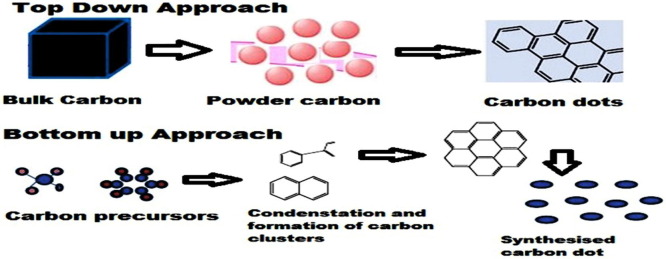

Nano-particles made from carbon are also found act as virucidals when used in cleaning air, surfaces and fluids like water in and around the living premises. The surface charges that are generated by the carbon nano-particles help in arresting the viral activity by neutralizing the electric charge of the virus, hence ensuring protection against such transmission of the virus. Carbon nano-particles in its different forms like the carbon dots is used to enhance the virucidal activity of the compound. The addition of metal nano-particles with carbon nano-particles also help in inactivation of the viral particles. Some of the functionalized nano-particles used in such a process are like the carboxylic acid, hydroxyls and lactone functional group derivatives ones (Fig. 6 ). Carbon dots, Carbon Nano-tubes, Nano-diamonds and Single walled carbon Nano tubes are proven to possess virucidal properties. The presence of Nano pores in activated carbon nanomaterials has shown to be an excellent feature that increases the hydrophobic activity on the coated surface and enhancing the ability of the Nano-material to trap and kill the viral particles. These special features of activated carbon Nano-materials find application in adsorption-based filtration process, water purification and in air filtration equipment’s that help to prevent virus transmission at any given premises. Some of the Nano-materials like carbon dots are reported to destroy the DNA/RNA components of the virus.

Fig. 6.

Synthesis of Carbon nano materials – Carbon dots.

3.4.1. Application of carbon nano-tubes

Carbon nanotubes are found to have good anti-viral activity properties. They can be both virustatic and virucidal in nature. The carbon dots, fullerene, carbon nanotubes, and graphene oxide are found to possess good anti-viral properties. The carbon nanotubes and fullerene have a very high binding affinity towards the protein component of the coronavirus. This binding property may be utilized to make it functional to kill the coronavirus. Carbon nanotubes coupled with metal complex compounds would result in an anti-viral compound that can potentially deactivate the RNA virus-like the coronavirus. Recent researches on these aspects have shown that carbon dots and graphene oxide can have good anti-viral activity. They inhibit viral replication by stimulating interferon-stimulated genes. Fig. 6 shows the synthesis of carbon dots by top-down and bottom-up approaches. Arunkmar et.al (2018) have reported in their research a method of synthesizing multiwall carbon nanotubes using a spark plasma sintering technique. They were able to obtain a nanocomposite of higher fracture toughness and enhanced wear resistance. In another study, they found the blending of Nano-crystalline silicon carbide with carbon nanotube by ball milling processes and fabricated using spark plasma sintering technique resulted in higher fracture toughness of the composite substance. They have also synthesized multiwall carbon nanotubes using acetylene (C2H2) gas and Fe/MgO as a catalyst [21], [22], [23].

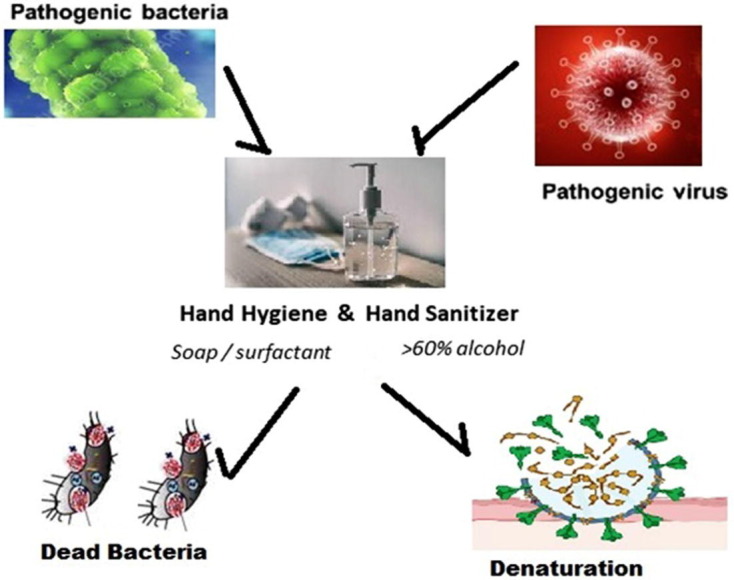

3.5. Nano compounds and hand sanitizers

Hand sanitizers today are one of the methods which are used along with soap hand washing to kill the virus and prevent the transmission from touching infected surfaces (Fig. 7 ). The synthesis of hand sanitizers using natural plant extracts that have medicinal value is found to be very effective. Some of the plant extract and sources of energy that are used for making hand sanitizers are garlic, turmeric, spinach, camphor, etc. They are blended with other ethanolic substances and combined with Isopropyl alcohol of 70% strength to make an effective hand sanitizer. Sometimes even glycerine is also used for making the sanitizer smooth and having a gel appearance. The hand sanitizer to be effective should have an overall alcohol strength greater than 62%. Non-alcohol-based sanitizers can also be manufactured using anti-microbial agents and soap solutions. In this case, the metal oxide nano-compounds which have anti-microbial activity are used. Examples of such metal oxide nano-compounds include Neosporin, muprocin, and tetracycline blended with soap solution to impart antiviral activity into the non-alcohol-based sanitizer. Chitosan can also be used as a bio-based antimicrobial agent due to its natural bio-degradable property and non-toxic effects. Even though alcohol-based hand sanitizers are effective in eliminating the virus, their regular use on the hands has side effects resulting in skin irritation and damage caused to the oily layer of the skin. Therefore, the use of non-alcohol-based hand sanitizers along with natural anti-bacterial agents in soap solution should be encouraged. Recent research has shown that nearly 50% of the coronavirus transmission can be prevented if the public and community at large follow the handwashing practice using hand sanitizers regularly. The compliance percentage may be enhanced by providing cost-effective and skin-friendly hand sanitizers with nanoparticles dissolved in soap solution to ensure excellent virucidal activity of the hand sanitizer [7], [8], [9], [10], [11], [12].

Fig. 7.

Mechanism of Hand Sanitizers.

3.6. Diagnostic and preventive applications using nano-materials

Nano-materials are also being used in testing devices used for detecting coronavirus. These devices are supported by digital technologies and integrated virus testing labs so that the analysis is accurate and fast. The nanomaterials are also used in making Nanomedicines, Nano biosensors, and effective Nano drugs that are used to detect and prevent the spread of coronavirus. Many of the Nano-compounds are also used in making medicines and vaccines that are used for treating and preventing corona disease. The novel coronavirus is basically made up of ribonucleic acid that is encapsulated in a shell composed of protein layers like nucleocapsid protein, envelop protein, and glycoprotein. UV exposure and chemical treatments with alcohols, surfactants, and acids destroy the nucleocapsid protein. The outer layer of spike protein is destroyed easily by Nano-particles which are used in the form of coatings or protective layers or incorporated in the Nano-drugs and vaccines to kill the virus and destroy its RNA strands [5].

Covid-19 detection involves the use of identification techniques like genome sequencing and identification procedures coupled with electron image analysis and computed tomography. These procedures are lengthy procedures and would take about 24–48 h of testing and analysis. Recently with the application of Nano-technology, many high-end diagnostic tools have been developed by researchers like the Reverse Transcription Polymerase Chain Reaction (RT-PCR) based on corona virus detecting set-up contacting different tools and software which can detect and analyse the genome sequence using the blood, stool, serum and nasal swab drawn from the patients. The Nano-technology based detection devices work on the operating principle of Nano-biosensors and Nano-materials properties that are designed to track the changes in RNA of the patient. The Rapid diagnostic tests (RDT) use nano-technology to detect and report the results within the time span of 30 min. RDT devices use the antibody detection methods that are present in the blood or by analysing and measuring the response of antigen. However, the accuracy of these RDT devices is limited due to the range of application and, moreover, its sensitivity levels ranging from 30 to 80 % [19], [20].

The more accurate device used in the detection of the covid-19 virus as of today is the RT-PCR corona detection device. These devices use the patient’s RNA condition as a target to confirm whether the patient is infected with COVID-19 or not. The diagnostic kits are incorporated with gold nano-particles and iron oxide to analyse the presence of coronavirus. Immunoglobulin M and G antibodies of an infected individual are identified by the test kits. These devices work on the principle of Plasmon resonance property when applied to the surface of the samples. Some of the device’s work using the thermal plasmonic effect for the identification of RNA and DNA. MIT (Massachusetts Institute of Technology (MIT)) has developed diagnostic devices using gold Nano-particles. Their research involves the use of heat produced due to surface plasmonic and thermoplasmonic properties of gold nano-particles. This approach has proven to be more accurate and can easily differentiate between sequences of RNA which have similar virus sequences.

Some of the rapid detection devices were also developed using magnetic nanoparticles. Iron oxide is one of the prominent nano-particles that has been used to develop rapid testing kits to identify coronavirus. The working principle of these magnetic nanoparticles is to bind with the DNA and RNA of the virus when a magnetic field is generated around the infested sample. The device transmits a signal after magnetic nanoparticles bind to RNA and hence make faster and effective results available to the users. Recent researches also report on the use of graphene-based nanomaterials and bio-sensors which also bind to the coronavirus and help in identifying electrical signals from the samples and in the detection of the virus within a minute [15], [17], [18].

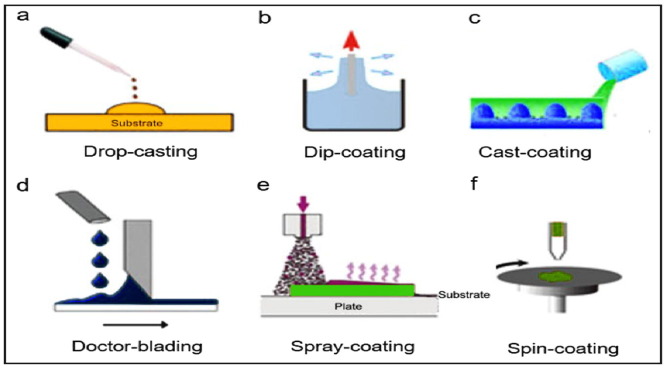

3.7. Nano-polymer coatings

Textile substrates are coated with PEI (N, N-dodecyl methyl-polyethyleneimine) which can kill the bacteria and viruses by killing the virus after attacking the cell membranes of the virus (Fig. 8 ). The deactivation process of the viral protein and the lipid membrane rupture is brought about by the poly-cationic chains that are present in the polymer coating substance. Depending on the nature of the functional and reactive group that is present in the polymer, these polymer coatings are classified into different groups. Some of the most commonly used surface coatings materials include functional Nano-materials, metal oxides, and antiviral polymers. Many medical instruments, personal protective equipment, cleaning devices, and others are usually coated with anti-viral polymer coatings. By modifying the surface of the substrate, these antiviral polymer coatings are deposited to ensure efficiency in anti-viral activity [4], [13]. Nano metal oxides like Ag, Au, Cu, etc. are frequently used in textile substrate coating to render anti-viral functionality to the material. Some of the medical-surgical materials are also being coated with chlorhexidine along with lubricants so as to make it anti-infective. Nonoxynol-9 (N-9) and povidone-iodine (PVP-I) are also used as an agent to prevent the attack of pathogens (Fig. 8). Anti-viral agents like quaternary ammonium groups and polymers with hydrophilic properties having hydrocarbon chains are also used as anti-viral agents. Hydrophobic materials and coating surfaces which aid excellent water repellent features are normally preferred for anti-viral coating. The utilization of the super-hydrophobicity concept works well when designing a non-polymer coating with anti-viral features [14].

Fig. 8.

Application of anti-viral polymer coating a) Drop casting b) Dip-coating c) Cast coating d) Doctor blading e) spray coating f) Spin-coating.

3.7.1. Coating process used for developing nano-materials

The coating process is one of the common methods used for the application of nanomaterials on textile and other substrates. Drop casting is one of the coating processes where a solid film is developed by depositing coating solution on the substrate's flat surface. Mostly an evaporating solvent is used in this process along with the coating solution (Fig. 8 a). In the case of dip coating, a coating solution is developed with all the additives and the substrate is dipped and withdrawn. This method results in the formation of a wet-liquid film on the substrate surface. This method is low-cost and reliable (Fig. 8 b). A reliable one (Fig. 8 b). In the case of cast coating (Fig. 8 C), a casting set is developed using a suitable polymer. A poly tetra fluro ethylene (PTFE) dispersion on metal or polymeric carrier is poured to the cast and this is dried and sintered to obtain the cast coated substrate. Doctor Blading is a similar method of coating the substrate to what is followed in screen printing. This method is used to develop thin films on a fabric substrate. Graphene inks on fabrics can be coated using this method. The coating solution and solvent are mixed with binders and other auxiliaries to obtain a uniform coat on the substrate with better adhesion properties (Fig. 8 de). In spray coating, spray guns with different nozzle dimensions are used for the development of thin films on the substrate. The thermal spraying technique is one of the popular spraying methods used for aluminum metals being coated with nano compounds (Fig. 8 e). Spin coating is used for the preparation of uniform thin films of manometer thickness, they form a very thin coating on the flat substrate. The coating solution is deposited on the surface of the substrate with high-velocity spin. Arun Kumar et al. (2020) have worked on the surface coating techniques of poly urea coating using the spray coating method. They report an increased performance of the coated material with reference to original corrosion values (10%). They have used spray process parameters in their study and optimized the process using the taguchi method [24], [25].

3.7.2. Adhesion properties of nano-materials

Adhesion property is important for analyzing the coated substrate behavior to frictional and other wear factors. Arunkumar et al. (2020) in their work studied the adhesive power of polyurea coated substrates using a spray coating method. They conclude that the spray coating method improves the adhesion strength of the substrate. Adhesion properties of Nano-materials depend on the surface morphology of the substrate and the coating material used. The adhesive ability of the nano-materials can be improved using epoxy-based adhesives and acrylic polymer binders. In the case of silver nano-particle coating by the Pad-Dry-Cure process, the adhesive property of AGNPs can be improved by adding acrylic polymer binder to the coating solution.

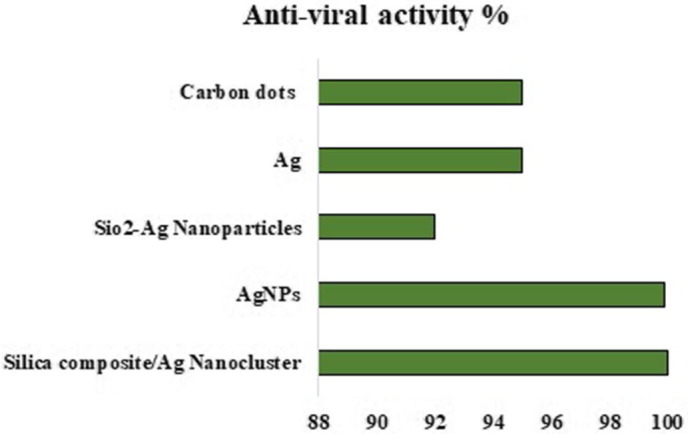

3.7.3. Anti-viral activity of some nan-materials

The anti-viral activity of some of the nano-materials for textile usage is shown in Table 2 and Fig. 9 . The application methods are also shown in the method with its anti-viral activity % value. Co-sputtering methods give 100% anti-viral activity when used for silica composite/AG nanocluster. Carbon dots and silver nanoparticle coating using spray coating, screen printing, and dip coating give an anti-viral activity of 95%.

Table 2.

Effect of Nano-materials on corona virus.

| Nano-material | Usage | Application method | Anti-viral activity % |

|---|---|---|---|

| Silica composite/Ag Nanocluster | Face masks and PPE | Co-sputtering/Radio frequency | 100 |

| AgNPs | Poly/cotton fabrics | Pad-Dry-Cure | 99.90 |

| Sio2-Ag Nanoparticles | Air filter | Aerosolized Coating | 92 |

| Ag Nanoparticles | Cotton and blends | Spray coating after processing fabric surface | 95 |

| Carbon dots | Cotton and blends | Screen printing, dip coating | 95 |

Fig. 9.

Anti-viral activity of some Nano-materials.

3.8. Nano-materials applications in synthetic biology

The branch of biology that involves the synthesis and extraction of bio-Nano materials and compounds from nature, utilizing bio-engineering concepts to create Nano-products and drugs to combat coronavirus, and using the molecular and genetic designs obtained from high-end research equipment and tools is commonly referred to as synthetic biology. In the research on synthetic biology, much computer-assisted software and design tools are employed to build and simulate the biochemical synthesis process of the virus. The study on the biological behavior of these viruses has helped to develop vaccines and drugs that are today used to combat and prevent the spread of the COVID-19 virus at the community level. Synthetic biology has also helped to bring out the genetic sequence of the virus and has helped to develop vaccines and drugs based on mRNA and other biological systems carriers to combat coronavirus spread and infection. The overall contribution of synthetic biology ranges from making vaccines, tracing the genomic sequence, and developing anti-viral drugs that can be used to treat and prevent the spread of coronavirus at the community level. Certain antigen-carrying Nano-particles are used to trigger the immune system in human beings. Many lipid nano-particle-based vaccines are also being made by drug manufacturing companies like Moderna, Pfizer, Novovax, etc. [15]

3.9. Action of nitric oxide and other nasal spray sanitizers

Nitric oxide (NO) is also a good anti-viral agent due to its specific attack on pathogens, bacteria and viruses. Due to its excellent anti-viral property, much research and medicines are being developed to treat severely infected corona patients. The use of nitric oxide is also beneficial in corona patients due to its secondary advantages. Many nano-materials may also be coupled with nitric oxide to deliver effective drugs for the treatment of corona patients.

4. Conclusion

Nano-materials are effectively used today to develop drugs and vaccines in order to combat the spread and prevent infection of coronavirus at the community level. Nano-materials are also used to coat the fabrics used for making hoods and masks. Spray coating and screen-printing methods are effective coating methods used for the application of textile nano-materials. The coating of anti-viral nano-materials like graphene on face masks, silver nano-particles on fabric, and PPEs have proven to be very effective in controlling the spread of the virus. Nano-materials also find application in a coating on fabrics intended for making personal protective equipment. Pho-active compounds and semi-conductor substances are also found to be very effective in preventing the spread of the virus inside homes and other open spaces. Air filtration and water filtration equipment use nano-materials like carbon nanotubes and carbon dots, which help to increase the protection in living rooms and enclosed spaces. Anti-viral polymer coatings work well in preventing the surfaces of medical and household equipment from being contaminated with viruses. Nano bio-sensors and Nano-particles also help to develop fast detection and analysis devices like RT-PCR which is widely used for detecting the presence of coronavirus in prospective infected patients. Nano-particles and compounds are also being used in synthetic biology to develop vaccines and antiviral drugs thus ensuring the community is benefitted from the development and research that is presently being carried out at Nano-materials. Nitric oxide as an anti-viral sanitizer spray is also proven to be very effective in killing the coronavirus.

5. Scope for further studies

The present analysis is carried out keeping all the theoretical aspects in view. The discussion and understanding can be used for practically conducting trials to establish a functional relationship and make comments on the specific effects of Nano-materials in fighting COVID-19.

CRediT authorship contribution statement

Gurumurthy B. Ramaiah: Conceptualization, Methodology, Software, Data curation, Writing - original draft, Visualization, Investigation, Supervision, Validation, Writing - review & editing. Asmamaw Tegegne: . Bahiru Melese: .

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors wish to acknowledge Ethiopian Technical University (Federal TVET Institute), Addis Ababa, Ethiopia for permitting and providing an opportunity to undertake a community research work on assessment and analyzing the use of Nano-technology in fighting COVID-19.

References

- 1.M.H. Khan H. Yadav. Trans Indian Natl. Acad. Eng. 5. 2020. 617–627. doi.org/10.1007/s41403-020-00177-9.

- 2.Chen H., Shi L., Zhang Y. Global Health. 2021;17:22. doi: 10.1186/s12992-021-00672-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Abbasinia M., Karimie S., Haghighat M., Mohammadfam I. Safety. 2018;4(47):1–12. doi: 10.3390/safety4040047. [DOI] [Google Scholar]

- 4.Parve J., Kudryašova M., Shalima T., Villo L. ACS Sustainable Chem. Eng. 2021;9(4):1494–1499. doi: 10.1021/acssuschemeng.0c07918. [DOI] [Google Scholar]

- 5.Adhikari S., Adhikari U., Mishra A., Guragain B.S. Appl. Sci. & Techn. Annals. 2020;1(1):155–164. [Google Scholar]

- 6.Magni R., Espina B.H., Shah K. J Transl Med 13. 2015:346. doi: 10.1186/s12967-015-0701-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Pemmada R., Zhu X., Dash M., Zhou Y. Materials. 2020;13:4041. doi: 10.3390/ma13184041. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Y.A. Ali. Intenl. Res. Journal of Natu. And Appli. Scie. 2(2). 2015. 17-28.

- 9.Golin A.P., Choi D., Ghahary A. Ameri. J. of Inf. Cont. 2020;48:1062–1067. doi: 10.1016/j.ajic.2020.06.182. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.S.B. Acharya, S. Ghosh, G. Yadav, K. Sharma, S. Ghosh, S. Joshi. bioRxiv. 2018. 373928. doi=10.1101/373928

- 11.Rachel A., Leslie, Zhou S., Macinga D.R. Am. J. Infect. Control. 2021;49:401–402. doi: 10.1016/j.ajic.2020.08.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Mukherjee S., Vincent C.K., Jayasekera H.W., Yekhe A.S. Infect. Dis. Health. 2021;26:63–66. doi: 10.1016/j.idh.2020.09.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.C.V.M.D. Oliveira M.B. Juliana E. Jose S. Isabella F.L.M. Barboza et al. Front Nanotech. 2. 2020. 1–4. 10.3389/fnano.2020.588915.

- 14.J. Hodek V. Zajícova L. Slamborova I et al. BMC Microbiol. 16. 56. 2016. doi.org/10.1186/s12866-016-0675. [DOI] [PMC free article] [PubMed]

- 15.H. Alper, P. Cirino, E. Nevoigt, and G. Sriram. J. of Biomedi. And Biotech. 2010. Arti. ID 918391. 1-2, doi:10.1155/2010/918391. [DOI] [PMC free article] [PubMed]

- 16.Miyauchi M., Sunada K., Hashimot K. Catalysts. 2020;10:1093. doi: 10.3390/catal10091093. [DOI] [Google Scholar]

- 17.Basak S., Packirisamy G. Nano-Structures & Nano-Objects. 2020;24 doi: 10.1016/j.nanoso.2020.100620. [DOI] [Google Scholar]

- 18.Mallakpour S., Azadi E., Hussain C.M. Sci. Total Environ. 2021;776 doi: 10.1016/j.scitotenv.2021.145989. [DOI] [Google Scholar]

- 19.Shirvanimoghaddam K., Akbari M.K., Yadav R., Adil K., Tamimi A., Naebe M. APL Mater. 2021;9 doi: 10.1063/5.0043009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.A. Konda, A. Prakash, A. Moss, M. Schmoldt, G. D. Grant, S.Guha, ACS Nano,14, (2020), 6339−6347. dx.doi.org/10.1021/acsnano.0c03252. [DOI] [PubMed]

- 21.Arunkumar T., Anand G., Subbiah R. J. Materi. Eng. Perform. 2021 doi: 10.1007/s11665-021-05562-1. [DOI] [Google Scholar]

- 22.Arunkumar T., Karthikeyan R., Ram Subramani R. Curr. Anal. Chem. 2020 doi: 10.2174/1573411016666200102120121. [DOI] [Google Scholar]

- 23.Arunkumar T., Karthikeyan R., Subramani R., Viswanathan K., Anish M. Int. J. Ambient Energy. 2020;41(4):452–456. doi: 10.1080/01430750.2018.1472657. [DOI] [Google Scholar]

- 24.Arunkumar T., Anand G., Venkatachalam P., Anish M., Jayaprabakar J., Sajin J.B. J. Test. Eval. 2021 doi: 10.1520/JTE2020006. [DOI] [Google Scholar]

- 25.Arunkumar T., Ramachandran S. Int. J. Appl. Eng. Res. 2015;10(1):1143–1149. [Google Scholar]