Abstract

The bacterial cell wall, composed of peptidoglycan (PG), provides structural integrity for the cell and is responsible for cell shape in most bacteria. Here we present tools to study the cell wall using a clickable PG-specific sugar, MurNAc-alk, as a metabolic probe. Here we present a new reaction pathway for generating MurNAc-alk. We also include protocols for labeling PG synthesis in Helicobacter pylori, determining the identity of the labeled muropeptides using LC-MS/MS, sample preparation of cells labeled for a short fraction of the doubling time, and visualization using 3D structured illumination microscopy.

Keywords: N-acetylmuramic acid, Helicobacter pylori, cell wall, microscopy, metabolic labeling, LC-MS/MS identification

INTRODUCTION:

Cell shape was one of the first noted properties of bacteria, but how bacteria maintain their diverse shapes was a largely impenetrable question until recently. For most bacteria, the bag-shaped peptidoglycan (PG) sacculus (commonly referred to as the cell wall), a single mesh-like molecule surrounding the cytoplasmic membrane, maintains cell shape (Höltje, 1998). PG subunits, muropeptides, are composed of N-acetylglucosamine (GlcNAc) linked to N-acetylmuramic acid (MurNAc) with an attached short peptide stem on the lactyl moiety, and are released from the PG sacculus by a muramidase such as lysozyme (Vollmer, Blanot, & de Pedro, 2008). The PG precursor is synthesized stepwise in the cytoplasm before being flipped across the cytoplasmic membrane to the periplasmic side and incorporated into the sacculus (Barreteau et al., 2008). Strands of PG are generated by glycosyltransferases, which catalyze the formation of β 1-4 linkages between disaccharides. These strands are interlinked to form a meshwork by the action of transpeptidases, which crosslink stem peptide of nearby PG strands (Sauvage, Kerff, Terrak, Ayala, & Charlier, 2008).

Helicobacter pylori is a helical Gram-negative bacterium with minimal genetic redundancy that is a useful model system to study bacterial cell shape (Tomb et al., 1997). In the PG of H. pylori and many other Gram-negative bacteria, the short peptide stem is comprised of L-alanine, D-glutamic acid, meso-diaminopimelic acid, D-alanine, and D-alanine, from position 1 through 5 respectively (Vollmer et al., 2008). In H. pylori, the only detectable crosslinks are between position 3 on one stem and position 4 on another, though other bacteria can also generate crosslinks between position 3 and 3 (Costa et al., 1999; Sycuro et al., 2010).

Bacteria must faithfully maintain the characteristic shape of their cell wall, which is a dynamic structure. For bacteria to grow, PG crosslinks must be broken to make space for the insertion of new PG strands (Singh, SaiSree, Amrutha, & Reddy, 2012). One mechanism for preserving cell shape is regulating where PG precursors are incorporated in the sacculus (Caccamo & Brun, 2018; Shi, Bratton, Gitai, & Huang, 2018; Taylor, Sichel, & Salama, 2019). Partnered with advances in microscopy, the development of probes to metabolically label the cell wall has facilitated an increased understanding of and interest in bacterial cell shape maintenance.

Within the past decade, a handful of probes that allow metabolic fluorescent labeling of PG have revolutionized the field. The available probes for labeling PG are incorporated through different steps of PG metabolism, which impacts interpretation of these labels. The first of these probes developed were D-Ala functionalized with either a fluorescent or clickable moiety (Kuru et al., 2012; Siegrist et al., 2013). These probes can be incorporated by the action of transpeptidases (Kuru et al., 2019). Shortly thereafter, clickable D-Ala-D-Ala dipeptide probes that can be incorporated into PG were developed. These are likely incorporated through the cytoplasmic steps of PG precursor synthesis (Kuru et al., 2019; Liechti et al., 2014). While D-amino acid probes are very useful for studying PG metabolism in a wide range of bacteria, there are some key limitations to this class of probe. Since D-amino acid probes label the peptide stem of muropeptides, they can be removed as the PG is modified after synthesis even if the rest of the muropeptide remains. Also, the D-Ala probes that are incorporated at sites of crosslinking activity label both sites of new PG synthesis as well as sites of modification of established PG via crosslinking.

Recently, a MurNAc probe modified with a clickable handle was developed (Liang et al., 2017). Because this probe is incorporated through the cytoplasmic steps of muropeptide synthesis, it reports only on sites of new PG synthesis. Furthermore, since the label is on the sugar backbone of the PG, the label is only removed with removal of the whole muropeptide, making this a much more straightforward reporter of PG synthesis. Using this probe requires the presence of PG recycling enzymes that can add UDP to MurNAc, which is the substrate used for muropeptide biogenesis. The recycling enzymes AmgK and MurU from Pseudomonas putida can be expressed in the organism to be labeled if this recycling activity is not natively present.

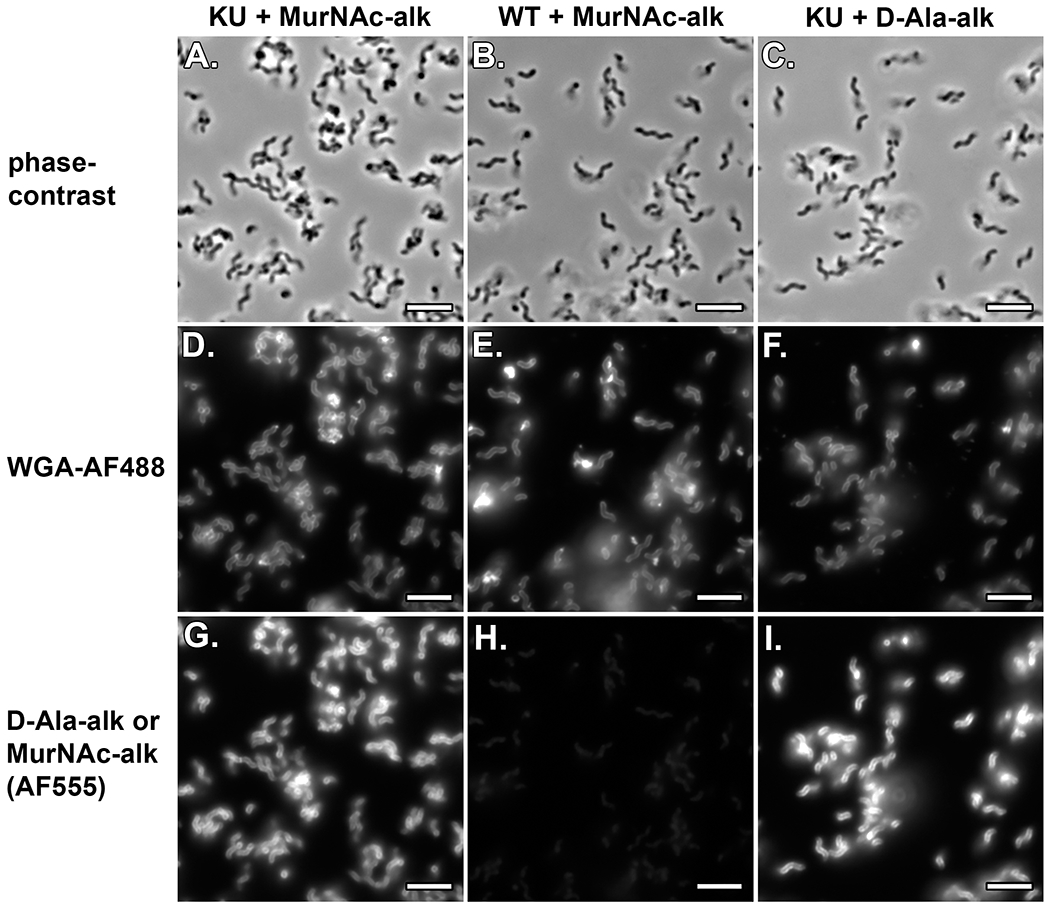

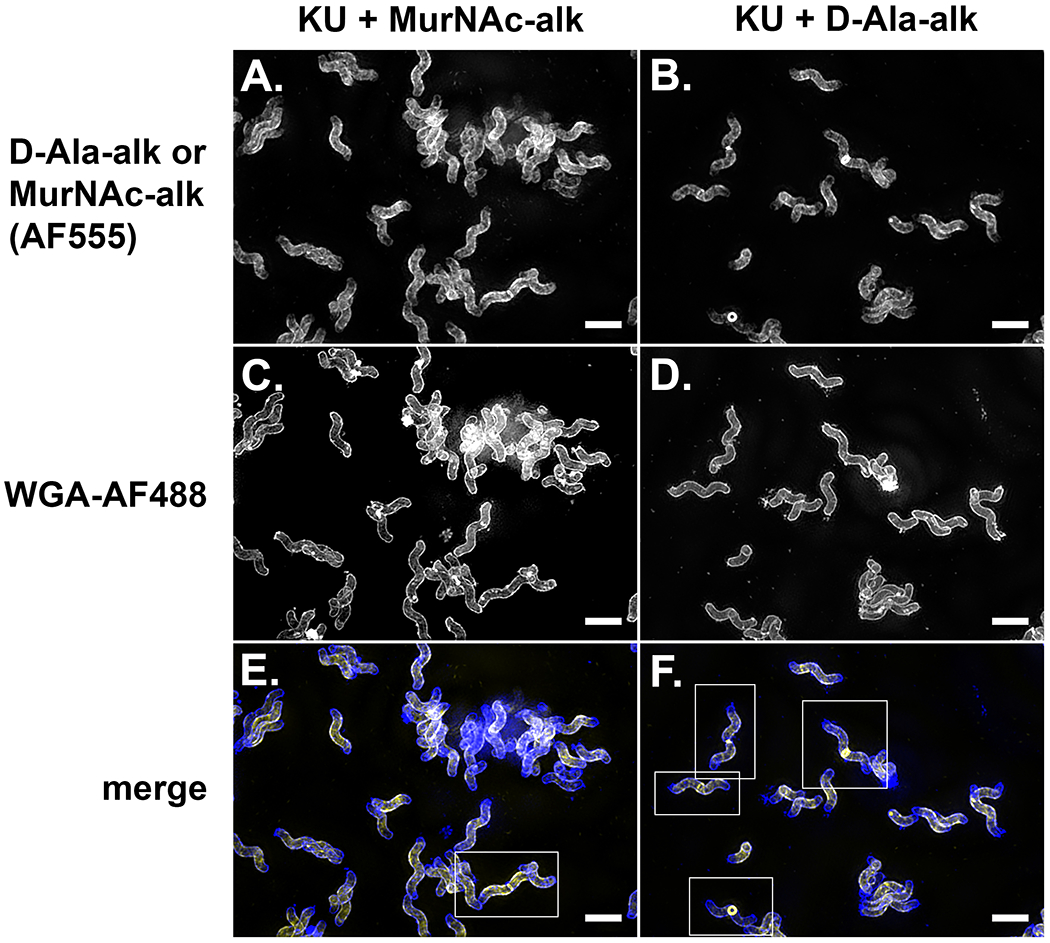

This manuscript will focus primarily on MurNAc-alk, with some included comparison to D-Ala-alk. Prior to our work (Taylor et al., 2020), MurNAc-alk had been primarily used for sparse labeling of the whole cell wall to verify incorporation of the probe into PG and to serve as a method for generating labeled PG for downstream experiments (DeMeester et al., 2018; DeMeester et al., 2019; Liang et al., 2017).

Our interest has been in characterizing the pattern of new PG incorporation as H. pylori grows and to determine if H. pylori uses spatial regulation of growth to help maintain helical shape. Accomplishing this goal required appreciable modifications to previous MurNAc-alk labeling and synthesis protocols. Since PG is modified as it matures, we needed to label incorporation for only a small fraction of the doubling time.

We had to take both our experimental goals and H. pylori physiology into consideration when deciding how to best image labeled cells. Our question of where PG synthesis occurs in H. pylori is inherently a three-dimensional question, considering the helical shape of the organism. We needed to collect images of cells that were of sufficient quality to allow us to computationally identify geographic landmarks on the cell and to determine how the amount of PG incorporation relates to these landmarks. H. pylori cells are on average approximately 0.45 μm in diameter and 2.5 μm in length, with a helical diameter of 0.3 μm (Taylor et al., 2020). Given these dimensions and the resolution limits of light microscopy, we relied on super-resolution microscopy, specifically 3D structured illumination microscopy (SIM) to elucidate subcellular details of PG incorporation. SIM is amenable to the use of a wide variety of fluorescent dyes but works best when labeling is bright and photostable. Furthermore, because SIM imaging requires acquisition of multiple images per z-slice and because samples can drift slightly, it is prudent to aim for as bright a signal as possible to reduce imaging time and ensure optimal image quality. To achieve an acceptable signal to noise ratio with a short labeling pulse, we labeled cells with a much higher concentration of MurNAc-alk than had been used previously for whole-cell labeling.

There were several requirements for sample preparation that necessitated creation of a tool for carefully affixing fixed cells to clean glass coverslips. We needed to preserve 3D geometry for subcellular analysis, so it was essential to prevent cells from drying out at any step during sample preparation. Because SIM works best for imaging close to the coverslip and because we needed to image and analyze hundreds of individual, well-separated cells per slide, we also needed to reproducibly obtain an optimal density of cells on the coverslip. Drawing inspiration from cytocentrifuges, we used readily-accessible materials to generate a sealed chamber above the coverslip that could be centrifuged in a swinging-bucket tabletop centrifuge that can accommodate 96-well plates. Depositing fixed cells on the coverslip also allows us to minimize the starting culture volume and thus amount of probe required. Thus, we can achieve an acceptable density of cells on the coverslip from a dilute suspension of cells. Additionally, the number of centrifugations required can be reduced because labeling steps following fixation and permeabilization can be performed on the coverslip rather than in suspension.

These protocols can be used as a starting point for short-pulse labeling of PG in other organisms to image new PG synthesis. Basic Protocol 1 outlines the synthesis of highly-purified MurNAc-alk. Basic Protocol 2 demonstrates a procedure for the detection of muropeptides using LC-MS/MS and how this can be used to prove incorporation of MurNAc-alk into the PG. Support Protocol 1 is used to grow H. pylori cells in liquid culture. Support Protocol 2 is used to determine if a strain can use exogenous MurNAc. Support Protocol 3 is used to determine if SDS has been completely removed from the PG preparation before moving on to the next step of Basic Protocol 2. Support Protocol 4 describes how to create cytocentrifuge units for high-quality slide preparation where fixed cells need to be reliably affixed to a coverslip for imaging. Basic Protocol 3 is used to perform a short pulse labeling of cell wall synthesis using MurNAc-alk or D-Ala-alk and to make high-quality slides of these cells. Basic Protocol 4 instructs the user how to perform structured illumination microscopy on the DeltaVision OMX microscope using the slides from Basic Protocol 3.

BASIC PROTOCOL 1

BASIC PROTOCOL TITLE

Alternative Synthesis of MurNAc-alk (direct coupling)

Introductory paragraph:

2-Alkyne Muramic acid (MurNAc-alk hereafter, Figure 1C.) is one of the most convenient and relevant compounds used for in bacterial peptidoglycan (PG) labeling techniques (DeMeester et al., 2019; Zhang, Wang, Yang, & Hang, 2020).

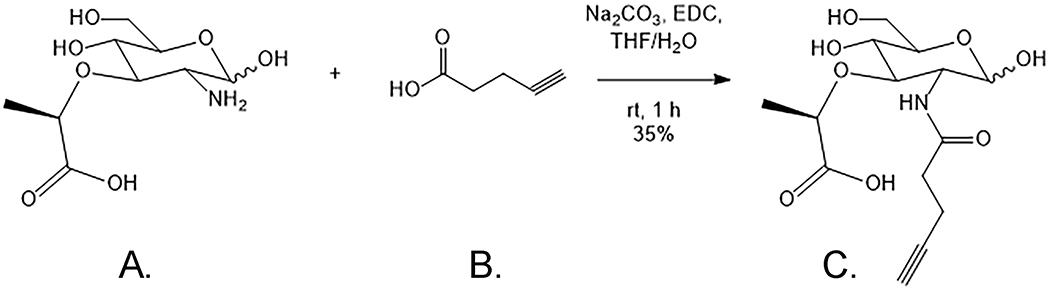

Figure 1.

Alternative synthesis of MurNAc-alk (C.) from Muramic acid (A.) and 4-pentynoic acid (B.).

As a muramic acid analog, this probe can be effectively (metabolically) incorporated into the bacterial cell wall of a wide variety of microorganisms. Moreover, its key alkyne moiety allows a sensitive fluorescent visualization of the labeled structures through a simple and accessible click reaction.

Therefore, in addition to the previously reported synthesis protocol (DeMeester et al., 2019), we developed a second reaction pathway in order to generate this essential probe. (Figure 1). This alternative method, that also uses muramic acid (Figure 1A.) as substrate, consists of a coupling reaction with the free acid, 4-pentynoic acid (Figure 1B.), catalyzed by EDC (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride). Basic conditions and a polar binary solvent system are also necessary. At the end of this protocol, the user will have generated purified MurNAc-alk that can be used to label PG in H. pylori and other bacteria.

Materials:

Muramic acid (Figure 1A.) (Prepared as in DeMeester et al. 2019, Liang et al. 2017 or as in Brown et al. 2021, or purchased from Sigma-Aldrich, #M2503)

4-pentynoic acid (Figure 1B., Sigma-Aldrich, #232211)

1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC, Chem-Impex International, Inc. #00050)

Sodium carbonate (Na2CO3) (Fisher Scientific #S263-500)

Tetrahydrofuran (THF) (Sigma, #186562)

Deionized H2O (dH2O)

Dichloromethane (DCM) (Fisher Scientific, #D37-20)Ethyl acetate (EtOAc) (Fisher Scientific, #124-20)

Methanol (MeOH) (Fisher Scientific, #A412-20)

p-anisaldehyde stain (see Reagents and Solutions)

Celite (Fisher Chemical, #C212-500)

Silica Gel, Standard Grade, 60 Å, 40-63 μm (Sorbtech, #30930M)

10-mL round bottom flasks

Stir bars

Stir plate

Pasteur pipettes

Rotary evaporator

Lyophilizer

5 mL collection tubes

Glass chromatographic column (or pipette with a cotton)

Tube rack

TLC plates

TLC Spotting Capillary Tubes

TLC Chamber

Tweezers

Hot plate

Additional reagents and equipment for LC/MS

Protocol steps — Step annotations:

Prepare Mixture A

Add 4-pentynoic acid (Figure 1B., 43.2 mg, 0.4404 mmol, 1.1 eq) to a 10-mL round-bottom flask.

Add EDC (92.8 mg, 0.4841 mmol, 1.2 eq).

Finally add 2 mL of THF to both solids.

-

Stir the reaction at room temperature for 0.5 h.

The appearance of This mixture will appear as either a cloudy solution or an off-white suspension

Prepare Mixture B

5. Add Muramic acid (Figure 1A., 100 mg, 0.3981 mmol) to a 10-mL round-bottom flask.

6. Add Na2CO3 (127.2 mg, 1.201 mmol, 3 eq).

7. Dissolve these solids in 2 mL of dH2O

-

8. Stir the reaction at room temperature for 0.5 h.

Due to the high solubility of these compounds in water, mixture B is always a yellowish solution

Perform the coupling reaction

9. Add Mixture B (Muramic acid aqueous basic solution) to Mixture A (activated 4-pentynoic acid). Stir for approximately 1h at room temperature.

10. Monitor reaction by LC/MS ESI pos [M+23]+ = 354 and by TLC (MeOH/EtOAc 4:5, Spot with Rf = 0.39, detection by p-anisaldehyde stain). Typically, after 1-2 h, the reaction is isolated to avoid probable product degradation. Once complete, evaporate the THF under reduced pressure without heat using a rotary evaporator.

-

11. Wash the resulting aqueous phase with DCM three times (3 x 1 ml).

This step is intended to extract the remaining 4-pentynoic acid and EDC from the reaction crude

12. Lyophilize the crude to obtain an off-white solid.

- 13. Purify the crude utilizing a silica gel chromatographic column, considering the following features.

- Use a dry load technique. Dissolve the crude in MeOH and use four times the weight of celite comparing to weight of the crude (x4 celite).

- Use an amount of silica gel at least 30 times the weight of crude material. In terms of volume, this ratio will be ml of silica = mass of crude x 60 ml.

- Apply a slow gradient of MeOH/EtOAc 2:8 through 4:5.

-

Collect the product based on TLC control (Spot with Rf = 0.39, detected by p-anisaldehyde stain).The excess 4-pentynoic acid elutes first (Rf = 0.8) and then the product (Rf = 0.39)

-

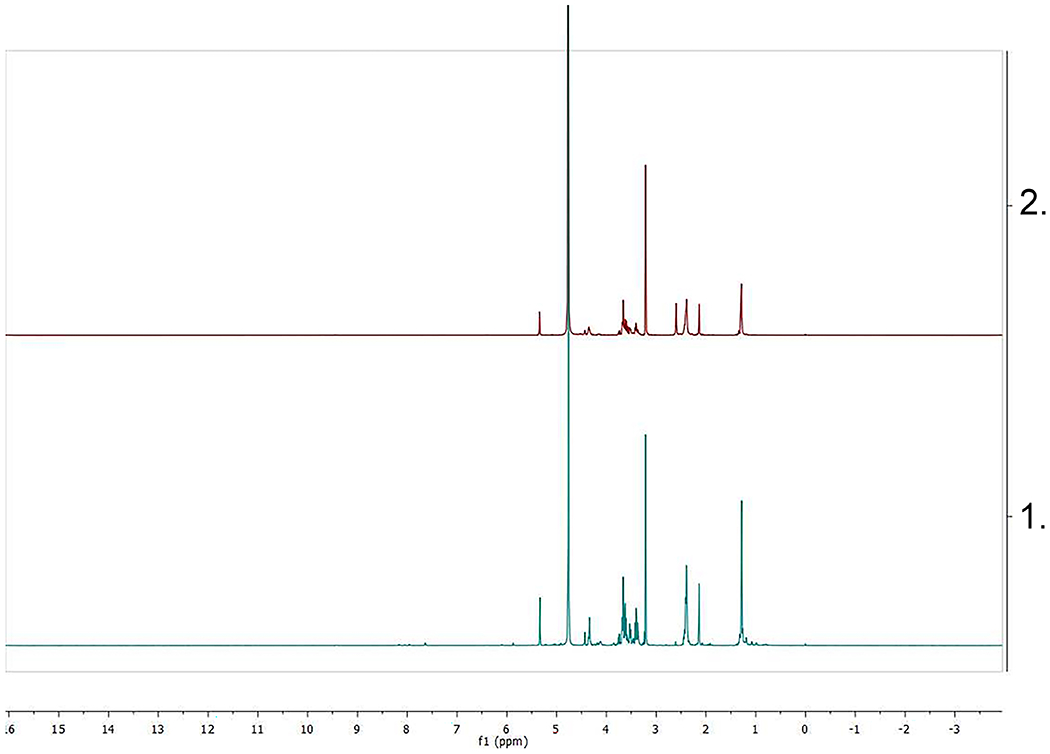

14. Lyophilize the collected fractions to obtain a white solid (46.3 mg, Yield = 35%, see NMR spectra on Figure 2).

We note that yields can be significantly improved by using larger amounts of starting material. Using 0.5 g of muramic acid, the yield reaches 40% +/- 5%. Since approximately 30% of the initial amount of muramic acid can be recovered for use in a second reaction, the overall yield will be even higher.

Figure 2.

Spectral analysis of MurNAc-alk (Figure 1C.). A. (top): 1H NMR (600 MHz, Methanol-d4) δ 5.34 (d, J = 3.0 Hz, H1α), 4.45 (d, J=7.81 Hz, H1β), 4.36–4.32 (m, CH propionic), 3.76–3.74 (dd, J=2.44 Hz, H6a), 3.69–3.57 (m, H6b, H4, H3), 3.53–3.51 (dd, H2), 3.42–3.36 (m, H5), 2.42–2.38 (m, methylene adjacent to amide and methylene adjacent to alkyne), 2.15–2.13 (m, CH alkyne), 1.30–1.26 (bd, CH3 propionic acid). Ratio α/β=3. B. (bottom): 13C NMR (151 MHz, MeOD) δ 173.08 (carbonyl), 97.09 (C1β), 90.38 (C1α), 82.35 (C quaternary α), 82.19 (C quaternary β), 77.54 (CH propionic), 77.02 (C3), 72.12 (C4), 71.25 (C5), 68.78 (CH alkyne β), 68.69 (CH alkyne α), 61.07 (C6), 56.59 (C2β), 54.53 (C2α), 34.74 (CH2 adjacent to amide), 18.71 (CH3 propionic acid β), 18.62 (CH3 propionic acid α), 14.18 (CH2 adjacent to alkyne α), 14.11 (CH2 adjacent to alkyne β). Note: The upper green lines in A. are called integral lines and measure the area below the curve of the 1H NMR signal which is proportional to the number of protons that originate the signal (the larger the signal, the more protons).

Sample Data

SUPPORT PROTOCOL 1

SUPPORT PROTOCOL TITLE

Growing Helicobacter pylori in liquid culture

Introductory paragraph:

This protocol instructs the user how to reliably grow a robust culture of H. pylori starting from a frozen stock. The included calculations are helpful for planning experiments, as the user can inoculate cells to be ready at a desired time the following day. The user will likely need to go through several iterations to determine the precise doubling time of the strain grown under these conditions.

Materials:

Helicobacter pylori −80°C freezer stock (strain G27, or alternatively J99, ATCC® 700824™)

Horse blood plates (See Reagents and Solutions)

BB10 (See Reagents and Solutions)

Sterile wooden sticks

Inoculating loops

50 ml baffled culture flasks with lids

Trigas incubator with a shaker (Sanyo O2/CO2 incubator; 10% O2, 10% CO2, Nitrogen to balance)

spectrophotometer

cuvettes

Protocol steps—Step annotations:

Remove a small amount of the H. pylori freezer stock using a sterile wooden stick. Inoculate a horse blood agar plate from the freezer stock. Once the liquid has soaked into the plate, invert the plate and place it in a Trigas incubator set at 10% CO2, 10% O2, 37°C for 24-72 hours until growth occurs. If you are not ready to begin a liquid culture for labeling, passage the culture on horse blood plates daily.

To start a liquid culture of H. pylori, in the morning the day before using cells, pick a small patch of low-density culture growth from the horse blood plate and use it to inoculate 10 ml of BB10 in a small baffled culture flask. Grow the culture in the trigas incubator shaking at 150-200 RPM.

In the evening the day before using cells, pipette 1 ml of BB10 into one cuvette and 1 ml of the liquid culture into another. Blank the spectrophotometer using the cuvette of BB10 and then read the optical density at 600 nm (OD600) of the liquid culture. (Note if OD600 > 1.5, dilute the sample 1:10 and reread to ensure you are within the linear range of the spectrophotometer.)

-

Calculate the inoculum in μl:

(1000*V*ODlabel)/(ODinoculant*2T/DT)

where

V = overnight culture volume (10 ml)

ODlabel = target OD600/ml of labeling culture (0.4 OD600/ml)

ODinoculant = measured OD600/ml of liquid culture for inoculating (target 0.1-1.0)

T = number of hours desired between inoculating culture and having culture ready for labeling (target 12-18)

DT = doubling time in hours (approximately 2.1 for LSH100 under these conditions; your strain and growth conditions will likely vary)

Inoculate 10 ml BB10 in a small baffled culture flask with the volume of inoculant culture calculated in Step 4. Grow the flask overnight in the Trigas incubator shaking at 150-200 RPM.

Sample Data

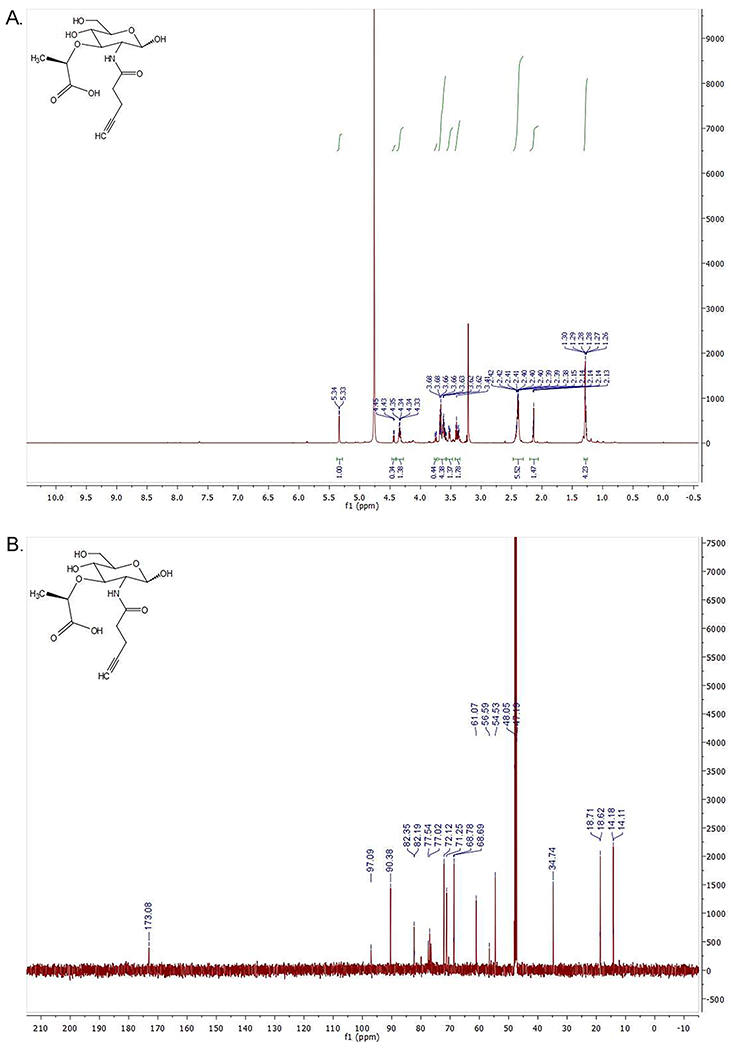

After successfully following this protocol, the user should have a culture of exclusively rod-shaped (mostly helical rods, though there is cell-to-cell variability in morphological parameters) H. pylori cells without any coccoid cells (see Figure 3). Some swimming cells should be observed when looking at fresh cells in suspension using phase contrast microscopy (at least 400x magnification). There should be no contaminating organisms present. The culture should reach the target density at approximately the calculated time. Large deviations indicate a problem with the culture or growth conditions and the problem(s) should be diagnosed.

Figure 3:

Image of a wet mount of a mid-log phase H. pylori culture using a 60x objective. Scale bar = 5 μm.

SUPPORT PROTOCOL 2

Fosfomycin rescue assay

Introductory paragraph:

This protocol is used to verify that a strain of interest is capable of using exogenously provided MurNAc. In this protocol, the user will be growing H. pylori in liquid culture under several different conditions to determine if adding MurNAc to cells treated with fosfomycin will help rescue growth. Serial dilutions of each culture will be plated to determine cell viability after 12 hours. Partial growth rescue indicates that the strain should be appropriate for labeling with MurNAc-alk (detailed in Basic Protocol 3).

Materials:

Liquid culture of wild-type Helicobacter pylori (from Support Protocol 1)

Liquid culture of Helicobacter pylori expressing AmgK and MurU (from Support Protocol 1)

BB10 (See Reagents and Solutions)

MurNAc (Sigma-Aldrich, #A3007), 200 mg/ml in ddH2O

Fosfomycin (Sigma-Aldrich, # 34089), 7.5 mg/ml in ddH2O

70% ethanol

50 ml baffled culture flasks

Trigas incubator [Sanyo O2/CO2 incubator; 10% O2, 10% CO2, Nitrogen to balance]

Spectrophotometer

Cuvettes

Sterile, flat-bottomed, untreated 96-well plates

5 ml polystyrene round-bottom tubes

Trigas incubator with shaker

Dan Kar Corp 48 Prong Frogger (ThermoFisher Scientific, #NC9843368)

Sterile reagent reservoir

Multichannel pipettes

Protocol steps—Step annotations:

As detailed in Support Protocol 1, prepare a liquid culture of H. pylori to reach 0.35-0.50 OD600/ml in the morning.

Check the culture density with the spectrophotometer. If the culture is between 0.35-0.5 OD600/ml, proceed with labeling. If OD600 > 0.5, dilute the culture and grow for at least 1 doubling to ensure the cells are in early/mid log phase.

Put the frogger tip side-down in a small open container of 70% ethanol.

Make 1 ml of each culture diluted to 0.002 OD600/ml in BB10.

-

Label eight 5 ml polystyrene round-bottom tubes 1-8. Add 200 μl of the diluted wild-type culture to tubes 1-4. Add 200 μl of the diluted AmgK MurU culture to tubes 5-8.

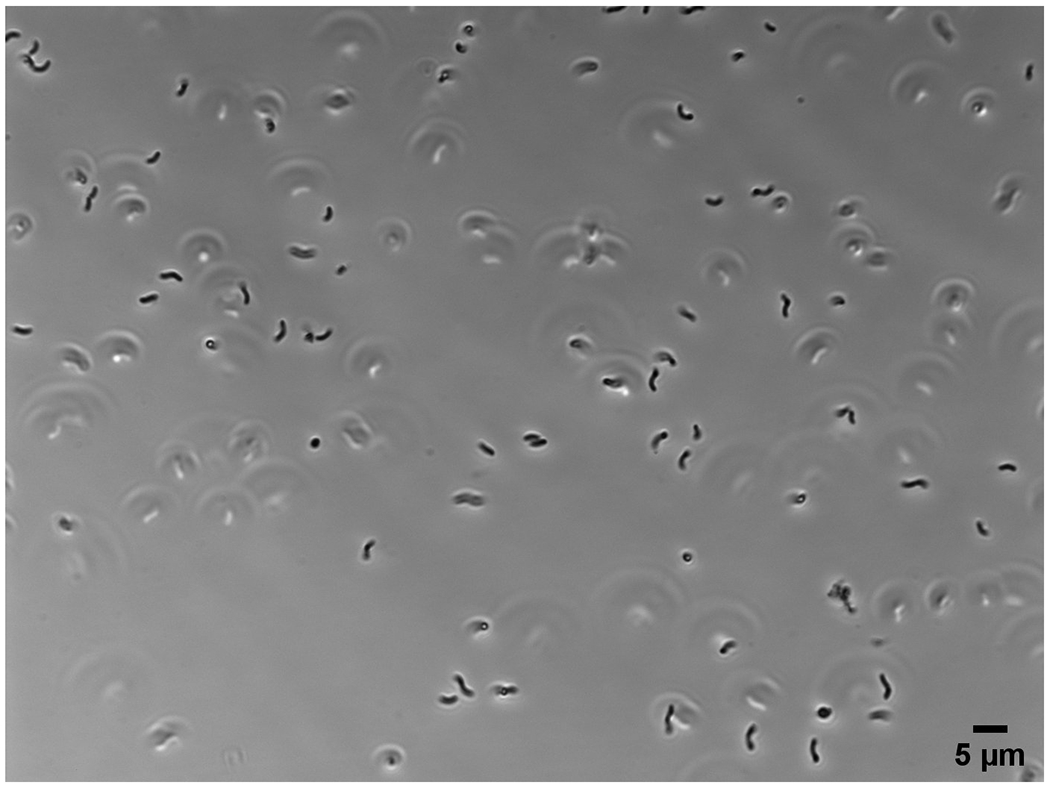

See Figure 4 for a schematic guide to the experimental setup in this protocol.

Add 1.33 μl of 7.5 mg/ml fosfomycin (final concentration = 50 μg/ml) to tubes 2, 4, 6, and 8.

Add 4 μl of 200 mg/ml MurNAc (final concentration = 4 mg/ml) to tubes 3, 4, 7, and 8.

Gently flick each tube 10 times to mix.

-

Take the frogger out of the ethanol, gently shake off the excess ethanol, and pass the frogger through a Bunsen burner flame to ignite any remaining ethanol. After the flames are extinguished, gently set the frogger on top of an open blood plate to mark faint indentations in a grid on the plate. No additional pressure beyond the weight of the frogger is required.

It is extremely important to make sure that no burning ethanol drips from the frogger and to ensure that the open container of ethanol is kept far from the flames. Make sure no loose papers or other flammable materials are above, below, or near the flame. The flame on the frogger may extend several inches vertically. Wait an extra 5 seconds after you think all the ethanol has burnt off to ensure the burn is indeed complete. Before igniting the ethanol, make sure you have a plan ready in case the ethanol vessel is accidentally set on fire.

First make a two-fold dilution in row A, columns 1-8 in a 96-well plate. To do this, pipette 20 μl of BB10 into columns 1-8 of row A. Then pipette 20 μl of each culture to the correspondingly numbered well in row A and pipette up and down 10 times to mix.

-

To make a series of 10-fold dilutions in the 96-well plate, use a multichannel pipette to add 180 μl of BB10 to row B-F, columns 1-8. Using a multichannel pipette, pipette up and down 10 times in column A to mix, then transfer 20 μl of each two-fold dilution in row A to the correspondingly numbered column in row B. Using a multichannel pipette set to 20 μl, pipette up and down 10 times in row B to mix, then transfer 20 μl from row B to row C. Pipette up and down 10 times to mix, then eject the tips. Using fresh tips, mix row C an additional 10 times, then transfer 20 μl from row C to row D. Repeat for each row, ending by adding 20 μl to row F and mixing.

It is crucial to change pipette tips between rows in the 10-fold dilution series. H. pylori sticks readily to pipette tips, so using the same tips for multiple dilution steps will not result in 10-fold dilutions.

Using the indentations on the blood plate made by the frogger as a guide, spot 2 μl of each dilution onto the plate, such that the dilutions from culture 1 are in the top row, with the most concentrated dilution on the left and down to the greatest dilution on the right. Repeat in rows 2-8 for cultures 2-8.

Allow all the spots to completely dry and then place the plate inverted in the Trigas incubator to grow for 3-5 days until distinct colonies are visible at the lower dilutions.

Incubate the tubes shaking in the Trigas incubator for 12 hours.

Repeat steps #9-13.

Once distinct colonies are clearly visible, photograph the plate to record the results.

Figure 4:

Schematic of the experimental setup for Support Protocol 2.

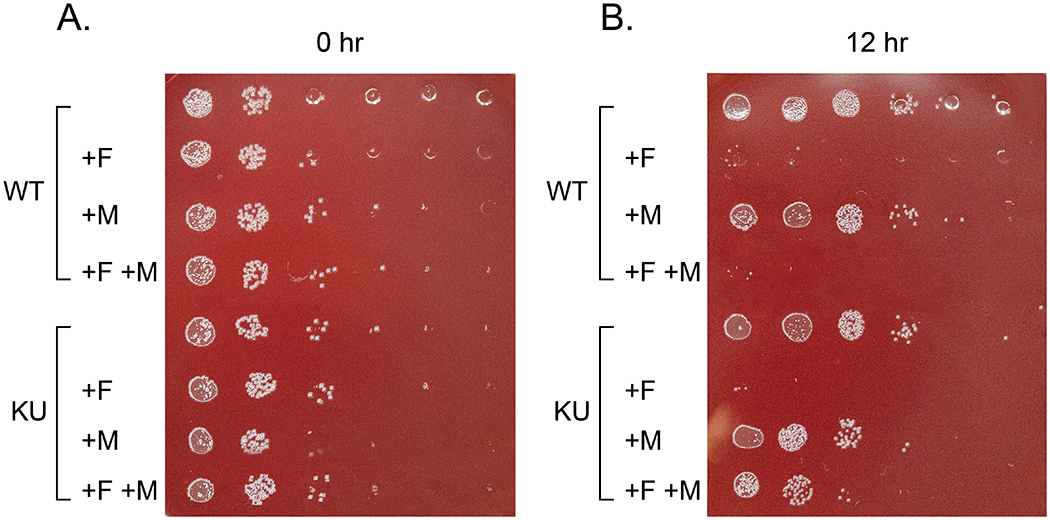

Sample Data

Figure 5:

An example of how plates should look if your H. pylori strain can successfully use exogenous MurNAc. All conditions should grow well on the plate from the 0 hour timepoint (A.). For a strain similar to LSH100 (WT), there should be robust growth for all conditions on the two most concentrated spots, and a few colonies at higher dilutions. On the 12 hour timepoint plate (B.), there should be robust growth for untreated cultures on the three most concentrated spots and scattered colonies at higher dilutions. Cultures with just MurNAc added may have a small reduction in growth. If AmgK and MurU (KU) are successfully expressed, there should be more growth in row 8 (AmgK MurU strain + fosfomycin, + MurNAc) than in row 4 (wild-type strain + fosfomycin, + MurNAc). (Note the top row indentations appear as shiny circles, but the colonies are much smaller dots.)

BASIC PROTOCOL 2

BASIC PROTOCOL TITLE

Mass Spectrometry (MS) analysis to determine incorporation of MurNAc-alk within the peptidoglycan of H. pylori

Introductory paragraph:

This protocol instructs the user how to determine the PG subunits (muropeptides) that are labeled by MurNAc-alk. As MurNAc-alk is incorporated into PG precursors in the cytoplasm, the initial labeled muropeptide in the PG is the pentapeptide, but other labeled species can be generated by modification and/or crosslinking of these initial labeled pentapeptides. H. pylori cell walls labeled with MurNAc-alk are purified, digested, and analyzed using LC-MS/MS. This protocol provides both a means for determining which muropeptides are labeled within the cell over a given labeling period and unambiguous validation that MurNAc-alk successfully labels the PG.

Materials:

Starting liquid H. pylori culture of a known density (generated using Steps 1-3 of Support Protocol 1)

BB10 (see recipe in the Reagents and Solutions section)

MurNAc-alk (from Basic Protocol 1), 200 mg/ml stock in ddH2O or D-Ala-alk (ThermoFisher Scientific, #AC441221000), 100 mM stock in ddH2O

8% solution of HPLC electrophoresis-grade SDS (FisherScientific #BP166-500) in ddH2O

0.5% (w/v) methylene blue (Millipore Sigma # M9140)

0.2% sodium azide (w/v) (Millipore Sigma, #71289)

0.7 M sodium phosphate buffer pH 7.2 (see recipe in the Reagents and Solutions section)

10 mM Tris-HCl, 10 mM NaCl pH 7.0 (see recipe in the Reagents and Solutions section)

3.2 M Imidazole (see recipe in the Reagents and Solutions section)

10 mg/ml α-amylase in 10 mM Tris-HCl, 10 mM NaCl pH 7.0 (see recipe in the Reagents and Solutions section)

10 mg/ml Pronase E (Fisher Scientific, #50-146-956) in 10 mM Tris-HCl, 10 mM NaCl pH 7.0 (see recipe in the Reagents and Solutions section)

10% Formic acid (v/v) LC-MS grade (Millipore Sigma, #5.33002)

Water with 0.1% (v/v) Formic acid (VWR, #85960.320)

Acetonitrile with 0.1% (v/v) Formic acid (VWR, #84866.320)

50 mM Ammonium Formate Buffer pH 4.8 (see recipe in the Reagents and Solutions section)

0.5 mg/ml cellosyl (kind gift from Hoechst, Frankfurt am Main, Germany) in 10 mM Ammonium Formate Buffer pH 4.8 (see recipe in the Reagents and Solutions section)

50 ml baffled culture flasks with lids

Trigas incubator with a shaker [Sanyo O2/CO2 incubator; 10% O2, 10% CO2, Nitrogen to balance]

Spectrophotometer

Tabletop centrifuge

Two crystallizing dishes (FisherScientific #50-121-5014)

Two magnetic stirring hotplates

Small stir bars

50 ml flasks

Aluminum foil

Two round covered lead flask ring

50 ml conical tubes

Glass rods

Vortex mixer

Two P1000 pipettors

Glass Pasteur pipettes and bulb

15 ml conical vials

Ultracentrifuge

Ultracentrifuge tubes

2 ml microcentrifuge tubes

Speedvac vacuum concentrator (Thermo Scientific)

HPLC system (NanoACQUITY UPLC, Waters).

HPLC sample loop, 2 μL (Waters, # 430001264).

ACE Ultracore 2.5 super C18, 0.5 X 150 mm microbore column (VWR, #CORE-25A-15005).

Impact II QTOF LC-MS/MS system (Bruker).

Dry heat block (Dri-Block, Techne, Cole-Parmer).

Compass DataAnalysis™ software (Bruker).

ChemDraw™ software package (Perkin Elmer).

Protocol steps—Step annotations:

Digestion Protocol

-

Calculate the inoculum of the liquid H. pylori culture in ml using the following equation:

(V*ODlabel)/(ODinoculant*26)

where

V = overnight culture volume (330 ml)

ODlabel = target OD600/ml of labeling culture (1.0 OD600/ml)

ODinoculant = measured OD600/ml of liquid culture for inoculating (target 0.1-1.0)

Or more simply,

(5.16)/(ODinoculant)

-

Add 330 ml of BB10 to a sterile 500 ml bottle. Add in the calculated volume of liquid culture H. pylori calculated (in ml) above. Add 20.625 mg MurNAc-alk (103.1 μl of the 200 mg/ml stock; 62.5 μg/ml final concentration) or 33 mg D-Ala-alk (2.92 ml of the 100 mM stock; 100 μg/ml final concentration). Mix and aliquot into three 500-ml baffled culture flasks.

Note that in earlier cell shape publications, H. pylori cells for PG preps were harvested from agar plates rather than from liquid culture. One consequence of analyzing PG from cells grown on plates is that there is a greater distribution of growth phases represented in the population, including a notable proportion of cells near/at stationary phase. Older cultures of H. pylori will have a higher dipeptide composition (Costa et al., 1999), so PG composition results obtained from liquid cultures are best compared to more recent publications that also used liquid H. pylori cultures.

To make the negative control culture, add 330 ml of BB10 and the calculated volume of liquid culture H. pylori calculated (in ml) above to a second sterile 500 ml bottle. Mix and aliquot into three 500-ml baffled culture flasks.

-

Check the culture OD. Once the cultures reach 1 OD600/ml, put the flasks on ice.

A higher culture density is used here than in Basic Protocol 3 to strike a compromise between growth phase and amount of cells harvested per ml of culture, and thus amount of MurNAc-alk needed.

-

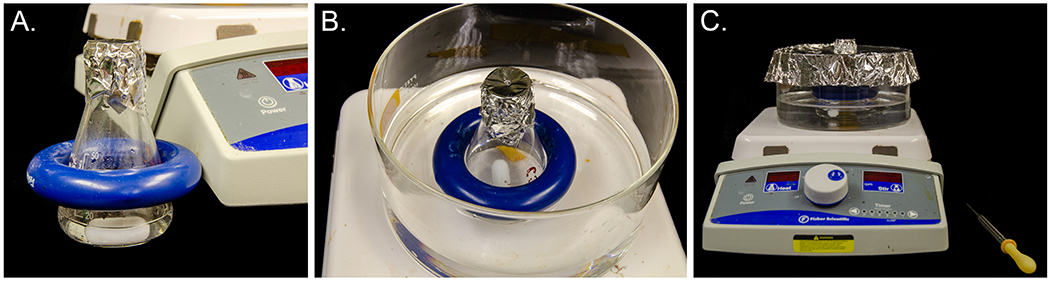

Add 6 ml of an 8% SDS solution to a 50 ml flask, add a small stir bar, and cover the top of the flask with aluminum foil. Poke a small hole in the top of the foil (Figure 6A.). Place a crystallizing dish on the hotplate, place the flask in the crystallizing dish, and weigh down the flask with a covered lead flask ring. Add water to the crystallizing dish to about midway up the culture flask (Figure 6B.). Add aluminum foil with a hole in the center over the top of the crystallizing dish to minimize steam escaping. The top of the flask should stick out above the aluminum foil (Figure 6C.). Turn on the hotplate and stirrer and to begin heating the water to boiling. Repeat to make a second setup for lysing the second set of cells.

Make sure to seal the top of the flask very tightly with the aluminum foil to minimize evaporation.

Begin harvesting the cells by filling a two 50-ml conical tubes per sample (4 in total) and centrifuging in a tabletop centrifuge at 2400 x g at 4°C for 10 min. Pour off the supernatant and repeat centrifugations until all of the culture volume for the labeled culture and experimental control have been processed.

-

Set aside one glass rod for the labeled cells and one glass rod for the negative control. Using the appropriate rod, resuspend each pellet in the residual media. To resuspend, hold the end of the rod gently between 2-3 fingers of one hand and hold the 50 ml conical on a running vortex mixer with the other hand. Move the rod up and down in the base of the tube and adjust the speed of the vortex mixer until the rod swirls readily about the sides of the tube. With the glass rod swirling, move the rod up and down the tube to distribute the pellet so that no discrete chunks of cells remain.

This may take some practice to get a feel for how best to hold the rod. This method will also be used to resuspend sacculi pellets following ultracentrifugation in later steps. For E. coli cells, harvested cell pellets can easily be resuspended by pipetting up and down. However, H. pylori cells tend to both clump to each other and to stick to pipette tips. Therefore, the glass rod resuspension method is much easier.

Begin consolidating the labeled cell pellets into one tube and the negative control cell pellets into one tube. Use two P1000 pipettors, one for pipetting PBS and one for transferring cell slurries. Transfer the cell suspension from one conical to the other. Then pipette 1 ml PBS into the emptied vial using the PBS pipette and wash the walls of the vial using the cell slurry pipette. Repeat until the volume of the collected cell suspension reaches 6 ml.

-

Keep the cell suspension on ice. Using a Pasteur pipette, slowly add the cell suspension to the boiling SDS. Once all of the cell culture has been pipetted into the flask with SDS, let the cells sit in the boiling SDS stirring for 30 minutes.

Take up only 1 ml of suspension at a time so the rest of the culture stays cold. Stick the end of the Pasteur pipette into the small hole in the foil on the top of the SDS flask. Add the suspension in tiny vigorous squirts (several squirts per ml) such that the cell suspension is rapidly dispersed into the SDS solution (each squirt dispersed within a few seconds). Wait until the previous addition is fully dispersed before adding more cells. At the end of this process, the liquid should be a golden color. Note the coloration varies based on the species of bacteria harvested but the final suspension should be clear regardless of color. If the SDS solution begins to bubble up, add a few drops of cold ddH2O, decrease the heat, and/or speed of the stir bar.

Repeat step 9 for the second set of cells with the second flask of SDS.

-

After each flask is finished boiling, remove the flask and cool at RT. Transfer each to a 15 ml conical vial and store at 4°C.

These samples can be stored for months at 4°C if necessary without degradation of the sample. The sacculi will eventually settle out and may be visible as a very faint clear pellet.

Repeat for the second set of cells with the second flask of SDS.

Place a bottle of ddH2O in a 60°C water bath.

Place the conical vials in an 80°C water bath for 30 minutes to redissolve SDS. Then cool to room temperature.

-

Pipette to mix each cell suspension then transfer each to an open-top ultracentrifuge tube. Balance the two tubes to within 0.01g of one another and fill tubes enough to prevent collapse (within 2-3 mm of top).

Nearly all if not all of the cell suspension should fit in the ultracentrifuge tube. If there is some left over, it can be discarded. Tubes can be topped off with ddH2O if more volume is necessary. Note that we use a larger ultracentrifuge (tube volume of approximately 12 ml) for the first set of washes and a smaller ultracentrifuge (tube volume of approximately 3 ml) for washes after digestion with α-amylase and Pronase E since pellets shrink notably after that step. It is acceptable to perform all washes in the smaller tubes, but this will increase the number of washes that need to be performed.

-

Ultracentrifuge for 60 minutes at 28°C at 133 907 RCF.

We use a Beckman-Coulter Optima L-90K ultracentrifuge with a SW41 rotor. Centrifugation steps should be performed warm to ensure that SDS does not precipitate. The size and appearance of the pellet will vary based on SDS concentration. The high concentration of SDS generally results in a much smaller pellet that will be larger after the following wash. Do not be alarmed. Also, prior to using an ultracentrifuge for the first time, seek out training to ensure you use this equipment properly.

-

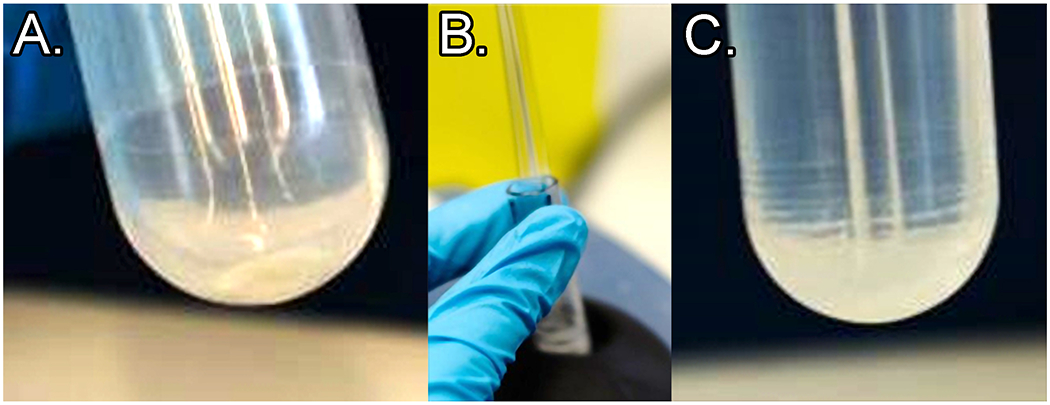

After the first ultracentrifugation, pipette out the supernatant, leaving a small amount above the pellet.

PG pellets of H. pylori are very loose with 4% SDS, but will be much more robust in all subsequent wash steps in this protocol. E. coli pellets are robust even at 4% SDS. Supernatant should be pipetted, or in later steps decanted, into a small beaker to allow recovery in case the pellet is disrupted or lost during removal of the supernatant. If this occurs, ultracentrifuge the supernatant again. See Figure 7 for images of how the pellets should appear (A.) after removal of the supernatant, (B.) during resuspension with the glass rod, and (C.) After initial disruption of the pellet.

-

Resuspend the pellet using a clean glass rod. First vortex with the rod only (moving rod up and down while vortexing as in Step 7), then slowly add a drop or two of ddH2O (60°C) and vortex with rod as before. Continue adding and vortexing until a few ml have been added and no more water can be safely added without risk of losing some sample. Rinse the glass rod with water into the ultracentrifuge tube to avoid sample loss and return it to a labeled 15ml conical vial. Fill the rest of the centrifuge tube with water (to within 2-3 mm of the top) and balance to within 0.01g. Return the ddH2O to 60°C.

Note to pause for the day, add sodium azide (0.02% final concentration) and store at 4°C. Seal open-top ultracentrifuge tubes with parafilm. The next day, replace the parafilm with aluminum foil and reheat any samples still containing SDS in 80°C water bath for 30 minutes to redissolve SDS.

-

Repeat ultracentrifugation and wash steps approximately 3-4 times to completely remove SDS.

You can check for complete removal of SDS earlier; the number of wash steps required depends on wash volume (determined by ultracentrifuge and corresponding tube). After the first wash is complete, the supernatant can be decanted from rather than pipetted out of the tube in all following wash steps.

Use Support Protocol 3 (Hayashi Test) to check if all the SDS has been removed from the sample. Proceed to step 21 once the SDS has been removed from each sample.If one sample is SDS free before the second, use water in a blank tube to balance the remaining sample. Minimizing the number of wash steps for each sample minimizes the amount of PG loss.

-

Resuspend sacculi in 900 μl of 10 mM Tris HCl with 10 mM NaCl, pH 7.0.

To achieve quantitative transfer, resuspend the pellet by first vortexing the pellet alone (with a glass rod), then adding one to two drops of solution from a pipette tip containing 900 μL of solution and vortexing again with the glass rod. Carefully set the pipette with solution aside. Transfer the PG material to a 2 ml microcentrifuge tube using a different 1 ml pipette tip. Do not eject the tip. Carefully set this other pipette with tip aside. Using half of the remainder of the solution in the pipette tip, rinse the glass rod into the ultracentrifuge tube and again set the rest of the solution in the pipette aside. Place the glass rod back in its container. Using the pipette tip used to transfer the sacculi, pipette the solution down the sides of the ultracentrifuge tube to rinse them. Then pipette all this liquid into the 2 ml microcentrifuge tube. Still keep the pipette tip. Pipette the remainder of the solution into the ultracentrifuge tube. Then using the tip used for transfer, again rinse the walls of the ultracentrifuge tube and transfer this liquid to the microcentrifuge tube.

-

Add 100 μl of 3.2M imidazole, pH 7.0 and 15 μl α-amylase (10 mg/ml), vortex briefly, and incubate for 2 hours at 37°C.

This degrades the high molecular-weight glycogen that is trapped inside the sacculi.

-

Add 20 μl Pronase E (10 mg/ml) and incubate for 1 hour at 60°C.

This releases the covalently bound lipoproteins, which should not be present in H. pylori, but this step is necessary for other bacteria and is thus included for uniformity. Note that Pronase E needs to be pre-incubated for two hours at 60°C to degrade a contaminating enzyme that comes with it. You can pre-incubate aliquots and then store them at −20°C.

-

Add 500 μL 8% SDS and boil for 15 minutes on heating block.

Alternatively, samples can be incubated at 80°C for 30 minutes. Beware the caps popping off. At this stage, the PG prep can be stored over the night or weekend at 4°C without the addition of sodium azide.

-

Quantitatively transfer the material to ultracentrifuge tubes and remove SDS again by ultracentrifugation followed by washes with 60°C water as described above.

Using a tabletop ultracentrifuge, tube balancing can be performed by eyeballing equal volumes. We used a TLA 100.3 fixed angle rotor. Take care not to fill the tubes too full to ensure sample is not lost in the fixed angle rotor, but do include enough volume to support the tubes during ultracentrifugation (fill such that when angled, the side of the liquid closest to the tube rim is 3-4 mm below the rim).

Suspend isolated PG saccculi in 100 μl of 20 mM ammonium formate pH 4.8, add 10 μg of 0.5 mg/ml cellosyl, and incubate overnight at 37⁰C on a Thermomixer (Eppendorf) at 900 rpm.

Figure 6:

(A.) 50 ml flask with 6ml 8% SDS and a small stir bar. The top is tightly covered with aluminum foil with a small hole poked in the center and a lead weight is placed around the flask. (B.) The flask is placed in a crystallizing dish with water. (C.) The top of the crystallizing dish is covered with aluminum foil with a hole in the center to accommodate the top of the flask.

Figure 7:

(A.) PG pellet at the tube bottom (material should be almost clear; sometimes a small amount of opaque material is present at the very bottom of the pellet – this is acceptable). (B.) Example of desired rod motion during proper vortexing. (C.) PG pellet after vortexing with glass rod: note rings of sacculus material up the side of the tube.

Sample Preparation for LC-MS

-

27. Following digestion, place samples in a dry heat block at 100⁰C for 10 min and then centrifuge at room temperature for 15 min at 15,000×g. Retrieve the supernatant and place in a clean tube.

Note: In conventional muropeptide preparation methods the released muropeptides are finally treated with a reducing agent (sodium borohydride/Tetramethyl ammonium borohydride) to remove anomerization by reducing the aldehyde group of the muramic acid (at sugar carbon position 1). Reduction is used in order to prevent the formation of anomer-related chromatographic artefacts such as peak splitting (see Figure 10D). Unfortunately, the reduction step (in our hands) seems to degrade or modify the MurNAc-alk label, and so this step is omitted from our protocol.

28. Dry supernatant samples using a vacuum concentrator.

-

29. Resuspend MurNAc-alk labeled digests in 1% formic acid (20 – 50 μL of distilled water plus 1/10th volume of 10% formic acid) with vortexing for 5 minutes.

Sometimes it is difficult to completely resuspend all of the muropeptide pellet. Samples may be cleared by centrifugation (next step).

30. Centrifuge at 15 000xg for 3 minutes. Carefully remove the supernatant to a clean microcentrifuge tube.

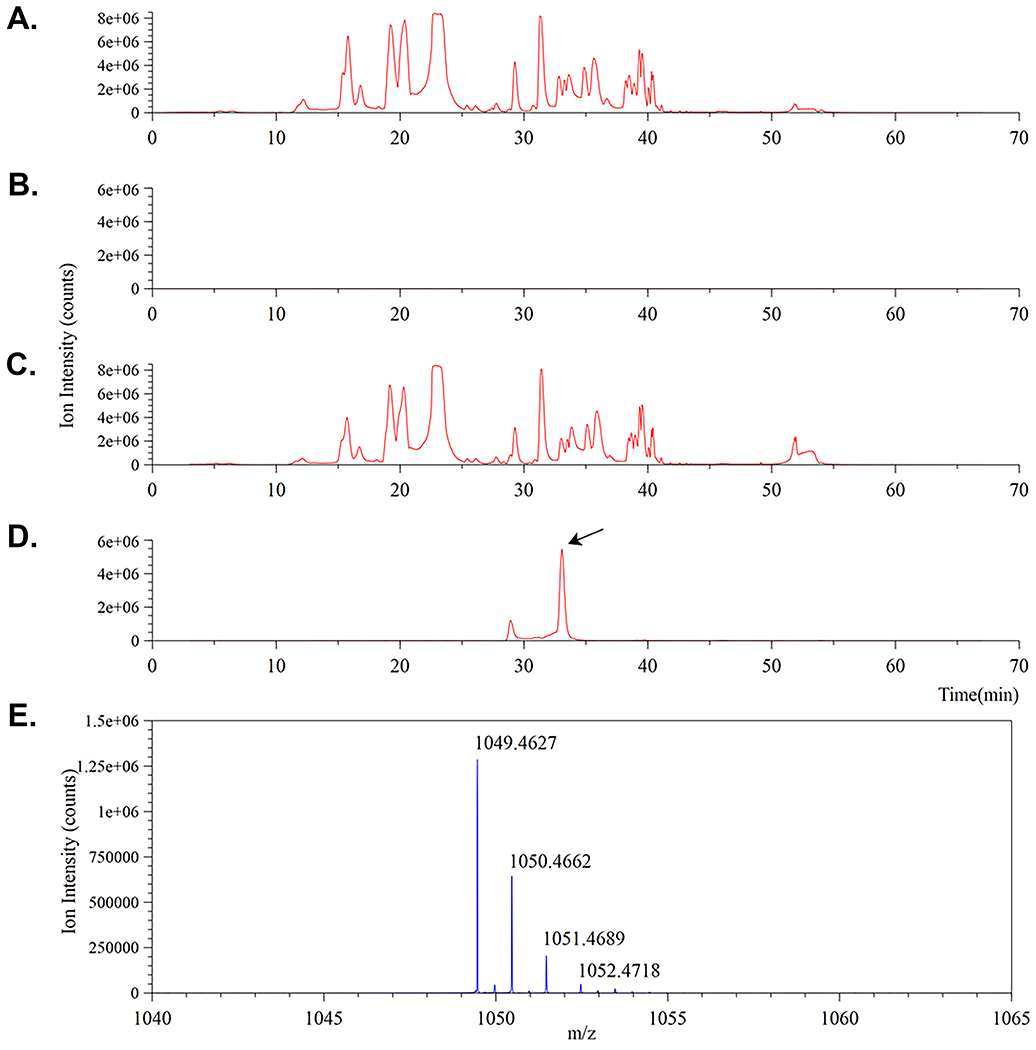

Figure 10.

Confirmation of MurNAc-alk incorporation into H. pylori PG. A.-D. comprises four ion traces. A. and C. correspond to total ion chromatograms for the control and labeled muropeptide digests respectively. B. and D. correspond to mass extracted ion chromatograms for the same control and labeled muropeptide digests set to monitor for the predicted 1+ monomer ion mass (m/z = 1049.45) eluting around 33 min and shown in E. The presence of the MurNAc-alk pentapeptide muropeptide monomer (D.) is indicated by an arrow.

The samples are now ready for electrospray mass spectrometry analysis as described below

LC-MS Setup

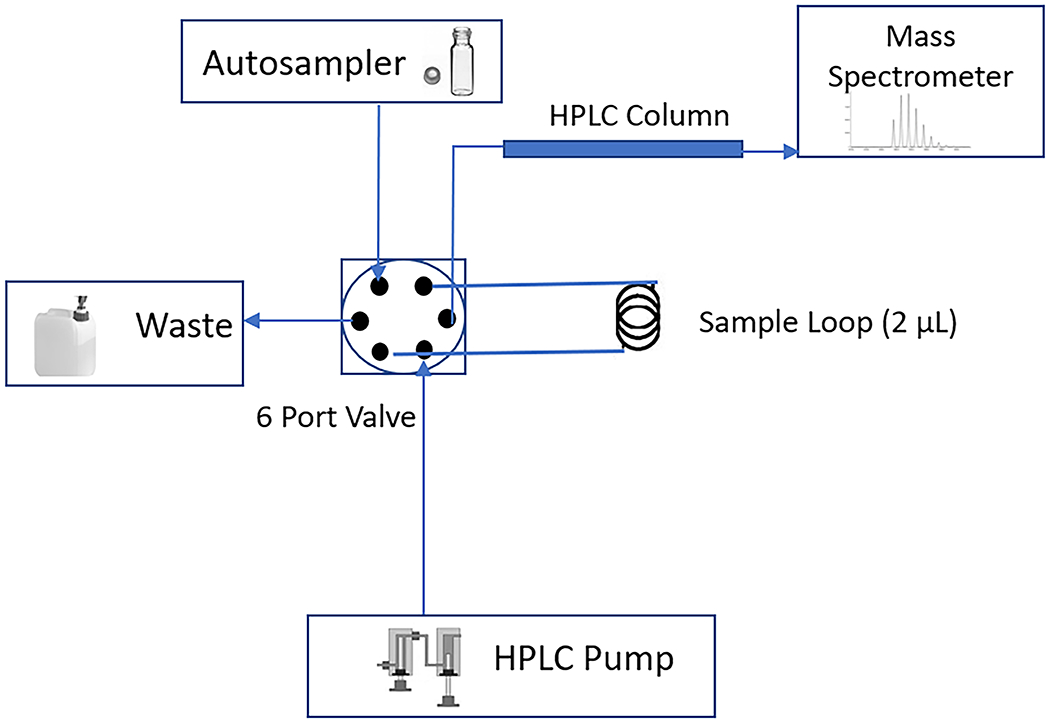

For sensitive LC-MS/MS analysis, prepare a microbore HPLC resolving column arrangement based around a 6-port selection valve and a 2 μl injection loop. Any modern HPLC system equipped with such a switching valve may be configured in the arrangement shown in the schematic in Figure 8 (below). HPLC requires configuration of a 6-port valve for low/sub-microliter volume injections. To maintain the separation efficiency of the microbore column, target injection volumes of 0.1-0.2 μl are required. A HPLC system equipped with a 2 μl (or lower) injection loop is suitable. If such a setup is not available, adaption of the HPLC gradient and flow rate (below) to suit a larger diameter column and injection volume should be possible.

Figure 8:

Schematic representation of the microbore column LC-MS/MS arrangement for muropeptide analysis.

HPLC Conditions

For buffer A, use 0.1% formic acid in water (VWR). For buffer B, use 0.1% formic acid in acetonitrile (VWR).

31. Use the following microbore RP-HPLC conditions: 0% buffer B for 3 min, rising to 1.5% B at 20 min, then on to 3.0% B at 35 min, ramp the gradient to 15% B at 45 min, then on to 50% B at 50 min, followed by 2 min at 85% B, and finally 15 min re-equilibration at 0% B.

32. Set the HPLC flow rate to 20 μl/min and the microbore column temperature to 35°C.

-

33. Dilute sample 1:5 (v/v) with buffer A and then place 10 μl in an autosampler vial. Inject directly (typically 0.2 μl) onto the microbore HPLC column configured as shown in Figure 8.

Muropeptides have quite hydrophilic properties. In the presence of a low percentage of organic solvent, they will elute in order of increasing hydrophobicity and size.

MS conditions

Mass spectrometers can be rather complicated instruments to program for LC-MS/MS analysis.For novice users we highly recommend that you consult an experienced operator or service provider. The instrument settings below should provide enough detail for data acquisition.

34. Direct the microbore column eluate to the mass spectrometer via an Apollo electrospray ion source (Bruker, Billerica, MA). Typical settings for the ion source are capillary voltage and temperature settings of 3200 V and 150oC respectively, together with a drying gas flow of 5 L/min and nebulizer pressure of 0.6 Bar.

35. Collect the MS data in positive ion mode over the range of 50 – 2000 m/z at a spectral rate of 2 Hz.

36. Perform MS/MS acquisition on the top 5 intense precursors in each scan (exclude these ions after two MS/MS events). The preferred charge states are set at +1 to +4 (undetermined charge states are excluded) and the sampling rate is varied from 0.5 Hz at low ion counts (10,000) to 5.0 Hz for intense ion counts (500,000).

37. The resulting MS spectral data can be opened for analysis using Compass DataAnalysis™ software (Bruker).

Data Analysis – Example data

This section presents an overview of how MS data files are manipulated to extract ion chromatogram traces and to interpret MS/MS data to confirm muropeptide structures. This is best explained with a few worked examples (below).

-

38. For the purpose of this protocol, we shall illustrate how to link accurate mass and fragmentation patterns to structure models in order to confirm identity for an exemplar monomer and dimer muropeptide.

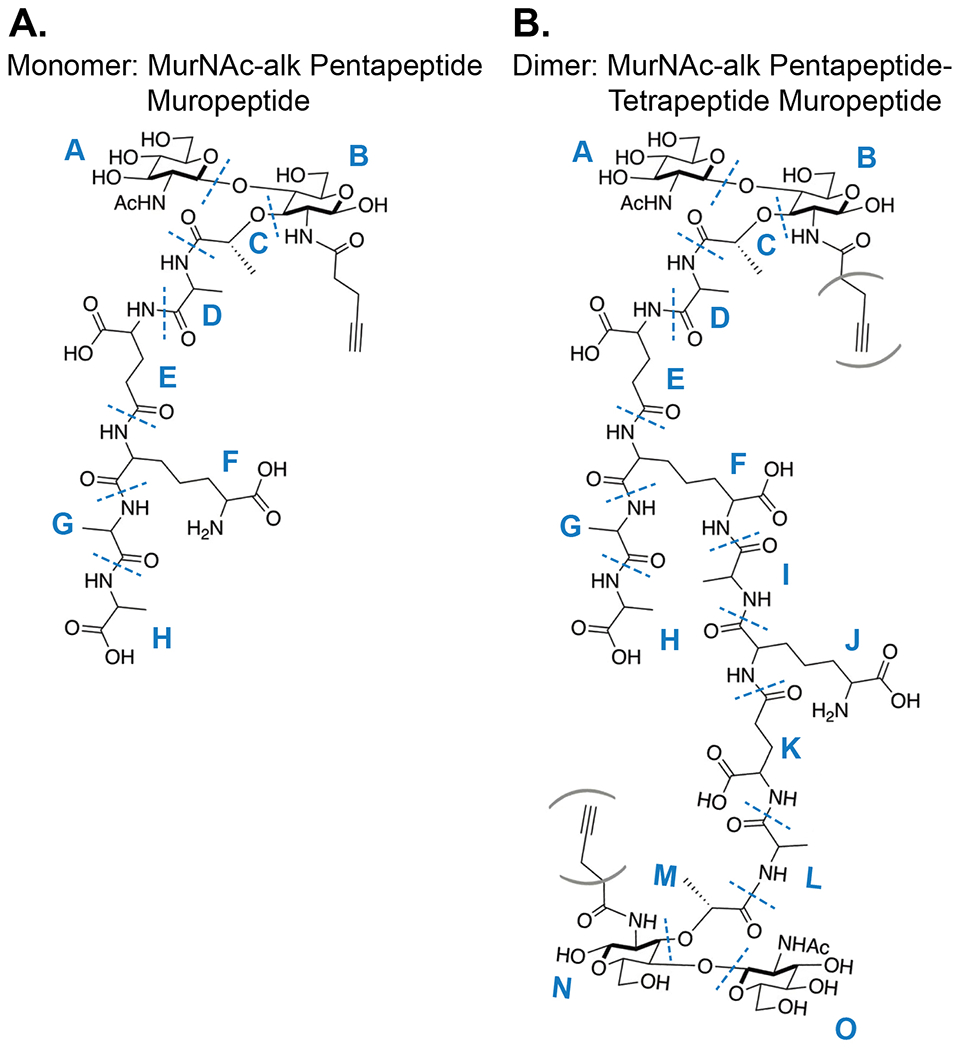

Use the ChemDraw™ software package (Perkin Elmer) to model the structures of predicted MurNAc-alkyne labeled muropeptides as shown below in Figure 9. Then confirm structure models using MS data manipulation with the Compass DataAnalysis™ software (Bruker) as illustrated.

This example shows confirmation of the presence and identity of two suspected MurNAc-alkyne labelled muropeptides in cellosyl digest profiles of the H. pylori KU strain (rdxA::amgKmurU) cell wall grown in the presence of fosfomycin and supplemented with MurNAc-alkyne. The control digestion is grown without addition of MurNAc-alkyne.

39. Figure 9 illustrates the complete structures and MS/MS fragmentation points for the predicted modified MurNAc-alk pentapeptide (monomer) and MurNAc-alk pentapeptide-tetrapeptide (dimer) muropeptides. The calculated theoretical masses are 1048.44 and 1969.83 Da respectively, with expected singly [M+H]+ (monomer) and doubly [M+2H]2+ (dimer) charged ions to be observed at m/z = 1049.45 (1+) and 985.92 (2+) respectively (ChemDraw™).

-

40. The first exemplar mass spectral data is for the MurNAc-alk pentapeptide monomer whose structure is illustrated in Figure 9A. Load the labeled and non-labeled (control) MS data files into Compass DataAnalysis. Initial MS ion traces for the unlabeled cell wall digest and MurNAc-alk labelled cell wall digest are shown below in Figure 10A. and C., respectively.

Notice how the traces appear to be essentially identical. This is because the alkyne label is only incorporated as a small percentage of the total MurNAc during cell wall synthesis. Therefore, superficially all traces will look alike, hence the reason why we must ‘search’ for predicted modified muropeptide masses as determined in ChemDraw™.

41. Figure 10 (A.–D.) illustrates four ion chromatograms representing muropeptide LC-MS analysis performed following the digest and LC-MS conditions outlined in the previous sections. As stated, traces A. and C. represent total ion chromatogram traces (TICs) for the H. pylori KU strain PG digests that were grown in the absence (A.) and presence (C.) of MurNAc-alkyne.

-

42. Traces B. and D. represent ‘extracted’ ion chromatograms (XICs) taken from A. and C. respectively. set the DataAnalysis™ software to monitor for the expected 1+ ion of the MurNAc-alkyne pentapeptide at m/z = 1049.45 ± 0.1 (Figure 9A.).

Notice the absence of the expected ion signal in trace B. and the presence of a major ion peak around 33 min in D. (black arrow).

-

43. Figure 10E. shows the mass spectrum of the peak at approximately 33 min in D. confirming the presence of an ion at m/z = 1049.46 as expected.

Note: The presence of a second, lower intensity peak (here ~29 min) is something we commonly observe with non-reduced muropeptides. We suspect it to be a feature of the anomeric carbon because muropeptide reduction resolves such chromatograms to just a single peak.

-

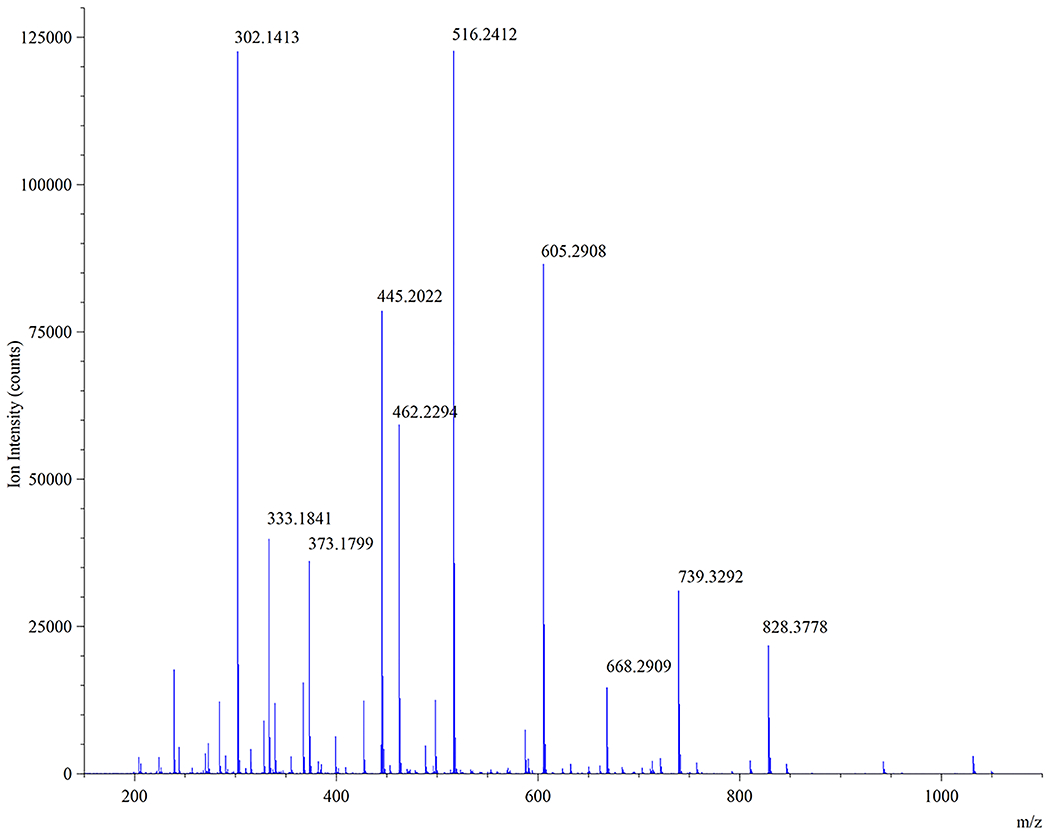

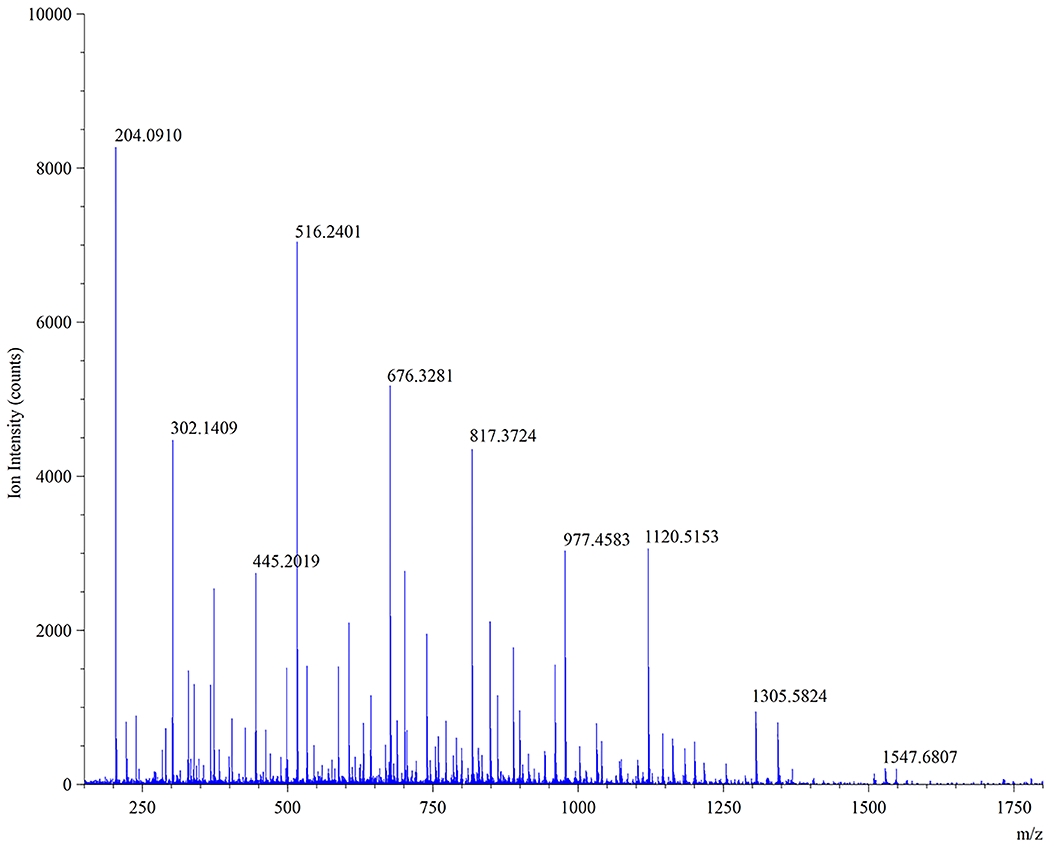

44. In order to confirm that the ion at m/z = 1049.46 is indeed the expected MurNAc-alk pentapeptide muropeptide, refer to the MS/MS fragmentation spectrum for this ion. Figure 11 shows the MS/MS spectrum obtained from fragmentation of the parent ion at m/z = 1049.46 that eluted at around 33 min. We list abundant fragment ions (m/z labeled) that contributed to the positive identification of the MurNAc-alkyne pentapeptide in Table 1.

Fragment ion structures can be modeled and verified using the ChemDraw™ software package (Perkin Elmer).

-

45. Table 1 illustrates assignment of the top 10 ion peaks in Figure 11 (descending intensity) confirming the modified MurNAc-alk pentapeptide (monomer) structure as predicted in Figure 9A.

Notice how all the ion fragmentations have taken place across the peptide and glycosidic bonds that link the subunits. Loss of water (δ = 18) is not uncommon with peptidoglycan during MS/MS fragmentation.

-

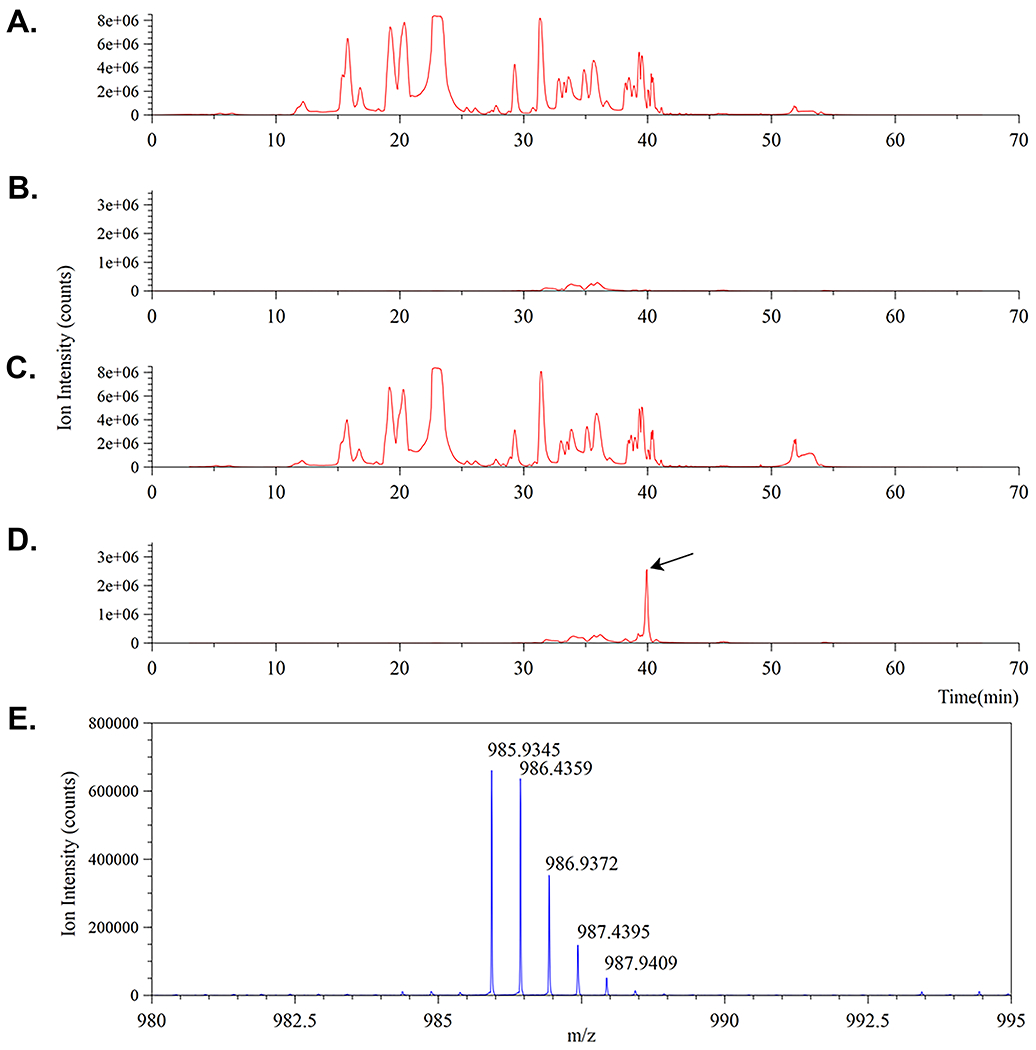

46. The second exemplar mass spectral data is for the MurNAc-alk pentapeptide-tetrapeptide dimer muropeptide structure illustrated in Figure 9B. Again, load the two MS data files. The initial TIC ion traces for the unlabeled cell wall digest and MurNAc-alk labelled cell wall digest are shown below in Figure 12A. and C., respectively.

Notice once again how these TIC traces appear to be essentially identical for the same reason of low percentage incorporation of tag discussed previously.

47. Once more, Figure 12A.–D. shows four ion chromatograms representing DataAnalysis™ software analysis of muropeptide LC-MS data acquired following cell wall digest and muropeptide LC-MS separation. Traces A. and C. represent total ion chromatograms for the H. pylori KU strain PG digests that were grown in the absence (A.) and presence (C.) of MurNAc-alkyne.

-

48. Traces B. and D. are extracted ion chromatograms taken from A. and C. respectively, with the DataAnalysis™ software set to monitor for the expected 2+ ion of the MurNAc-alkyne pentapeptide-tetrapeptide at m/z = 985.92 ± 0.1 (Figure 9B.).

Again, note the absence of the expected ion signal in trace B. and the presence of a major ion peak around 40 min in D. (black arrow).

49. Figure 12E. shows the mass spectrum of the peak eluting around 40 min in D. confirming the presence of an ion at m/z = 985.93 as expected.

50. Once more use the MS/MS spectrum obtained from fragmentation of the parent ion at m/z = 985.93 (eluting around 40 min) to confirm identity, as shown in Figure 13. Abundant fragment ions (m/z labeled) that contributed to the positive identification of the MurNAc-alkyne pentapeptide-tetrapeptide are listed in Table 2 below.

-

51. Table 2 shows assignment of the top 10 ion peaks in Figure 13 (descending intensity) confirming the modified MurNAc-alk pentapeptide-tetrapeptide (dimer) structure as predicted in Figure 9B.

Again, note how the intense ions are comprised from fragmentations that have taken place across the peptide and glycosidic bonds that link the subunits, thereby confirming the structure as predicted in Figure 9B.

52. Lastly, repeat the above process of modelling predicted structures in ChemDraw™, using the calculated ion masses to search raw data files (labelled versus unlabeled control) with DataAnalysis™, and finally confirming all predicted ion identities via inspection of the MS/MS fragmentation spectrum of each and applying the rules for expected ion fragmentation across peptide and glycosidic bonds, until you have sufficient conclusive evidence to prove tag labelling.

Figure 9.

Target structures to test for incorporation of MurNAc-alk into H. pylori cell wall peptidoglycan. Bonds predisposed to MS/MS fragmentation are indicated with blue dotted lines. Subunit structures are labelled (A.) A – H (monomer) and (B.) A – O (dimer) respectively. Parentheses indicate that the Alk motif could be present at either position.

Figure 11.

MS/MS spectrum of suspected MurNAc-alk pentapeptide muropeptide ion (m/z = 1049.46) eluting around 33 min in Fig. 9A.

Table 1.

Top 10 abundant ion fragment peaks in Figure 11 (MS/MS spectrum of the m/z = 1049.46 ion) confirming the MurNAc-alk pentapeptide muropeptide structure as depicted in Figure 9A.

| Ion Peak | Observed m/z | Ion Fragment Containing |

|---|---|---|

| 1 | 516.24 | [A to C]+ |

| 2 | 302.14 | [E to F]+ |

| 3 | 605.29 | [C to H]+ |

| 4 | 445.20 | [A + B]+ |

| 5 | 462.23 | [E to H]+ |

| 6 | 333.18 | [F to H]+ |

| 7 | 373.18 | [E to G]+ |

| 8 | 739.33 | [B to G – H2O]+ |

| 9 | 828.38 | [B to H – H2O]+ |

| 10 | 668.29 | [B to F – H2O]+ |

Figure 12.

Confirmation of MurNAc-alk incorporation into H. pylori PG. A.-D. are four ion traces. A. and C. correspond to total ion chromatograms for the control and labeled muropeptide digests respectively. B. and D. correspond to mass extracted ion chromatograms for the same control and labeled muropeptide digests set to monitor for the predicted 2+ dimer ion mass (m/z = 985.92) eluting around 40 min and shown in E. The presence of the MurNAc-alk pentapeptide-tetrapeptide muropeptide dimer (D.) is indicated (black arrow).

Figure 13.

MS/MS spectrum of MurNAc-alk pentapeptide-tetrapeptide muropeptide ion (m/z = 985.93) eluting around 40 min in Fig. 12D.

Table 2.

Top 10 abundant ion fragment peaks in Figure 13 (MS/MS spectrum of the m/z = 985.93 ion) confirming the MurNAc-alk pentapeptide-tetrapeptide muropeptide structure as depicted in Figure 9B.

| Ion Peak | Observed m/z | Ion Fragment Containing |

|---|---|---|

| 1 | 204.09 | [A & O]+ |

| 2 | 516.24 | [C to F + I – H2O]+ |

| 3 | 676.33 | [C to I – H2O]+ |

| 4 | 302.14 | [E to F – H2O]+ |

| 5 | 817.37 | [C to F + I to K – H2O]+ |

| 6 | 977.46 | [C to K – H2O]+ |

| 7 | 1120.51 | [C to M – H2O]+ |

| 8 | 445.20 | [C to F – H2O]+ |

| 9 | 1305.58 | [C to N – H2O]+ |

| 10 | 1547.68 | [B to N – H2O]+ |

SUPPORT PROTOCOL 3

SUPPORT PROTOCOL TITLE

Hayashi test to determine if SDS is present in the supernatant of peptidoglycan preparations.

Introductory paragraph:

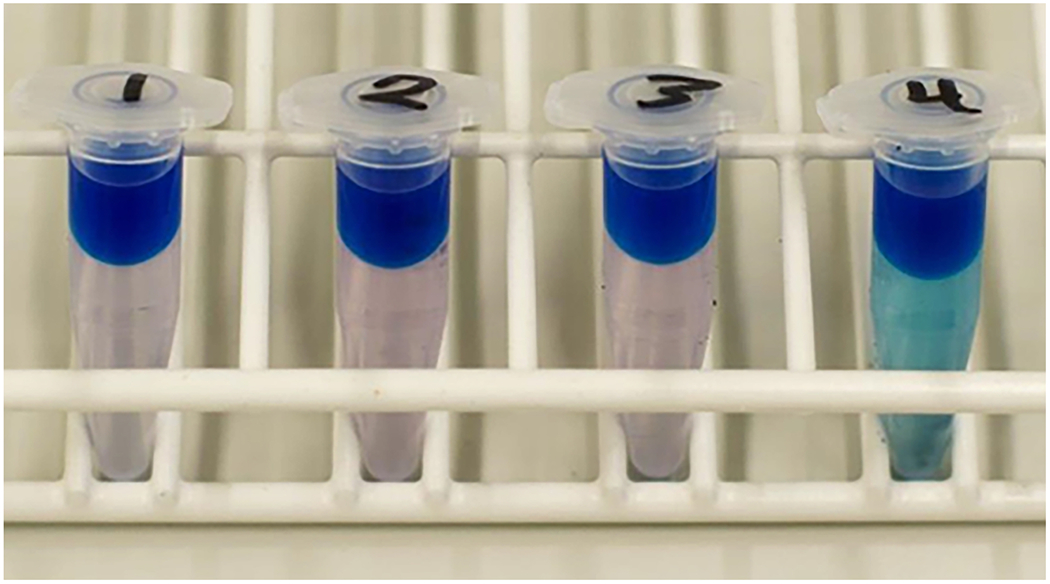

Here, the user performs a colorimetric assay on the supernatant of each peptidoglycan prep after washing to determine if all the SDS has been removed from the sample (Hayashi, 1975). The sample is SDS-free when the blue color is only present in the upper layer and the lower (chloroform) layer is clear or tinted slightly pink.

Materials:

335 μl sample of the supernatant after centrifugation

7 μl 0.5% methylene blue

170 μl 0.7 M sodium phosphate buffer pH 7.2

1 ml chloroform

2 ml microcentrifuge tube

vortexer

Protocol steps—Step annotations:

Pipette a 335 μl sample of supernatant after centrifugation, 7 μl 0.5% methylene blue, and 170 μl 0.7 M sodium phosphate buffer pH 7.2 into a 2 ml microcentrifuge tube and mix.

Add 1 ml chloroform, cap, and mix using a vortex mixer for 30 sec.Chloroform that has been stored in the dark must be used, otherwise the test may indicate that SDS is still present when it has already been successfully removed. You may need to invert/shake the tube by hand prior to vortexing to get layers to mix properly.

Let the tubes sit for 30 sec or centrifuge briefly to separate the phases.

-

Immediately look for coloration in the chloroform (lower) layer. Appearance of blue color in the chloroform layer indicates the presence of SDS. If the chloroform layer is clear or tinted pink, SDS has been successfully removed.

Eventually the lower phase will turn blue even if all the SDS has been removed from the sample. Reading the test too late may incorrectly indicate that SDS is still present.

Sample Data

At the end of this protocol, users will have determined whether SDS has been completely removed from their peptidoglycan prep. If so (Figure 14, Samples 1-3), the user may proceed to the next step of Basic Protocol 1. If not (Figure 14, Sample 4), repeat the wash step and subsequent Hayashi test until all of the SDS has been removed.

Figure 14:

Samples 1–3 are SDS-free, while sample 4 still contains SDS; sample 4 must be washed again and re-tested.

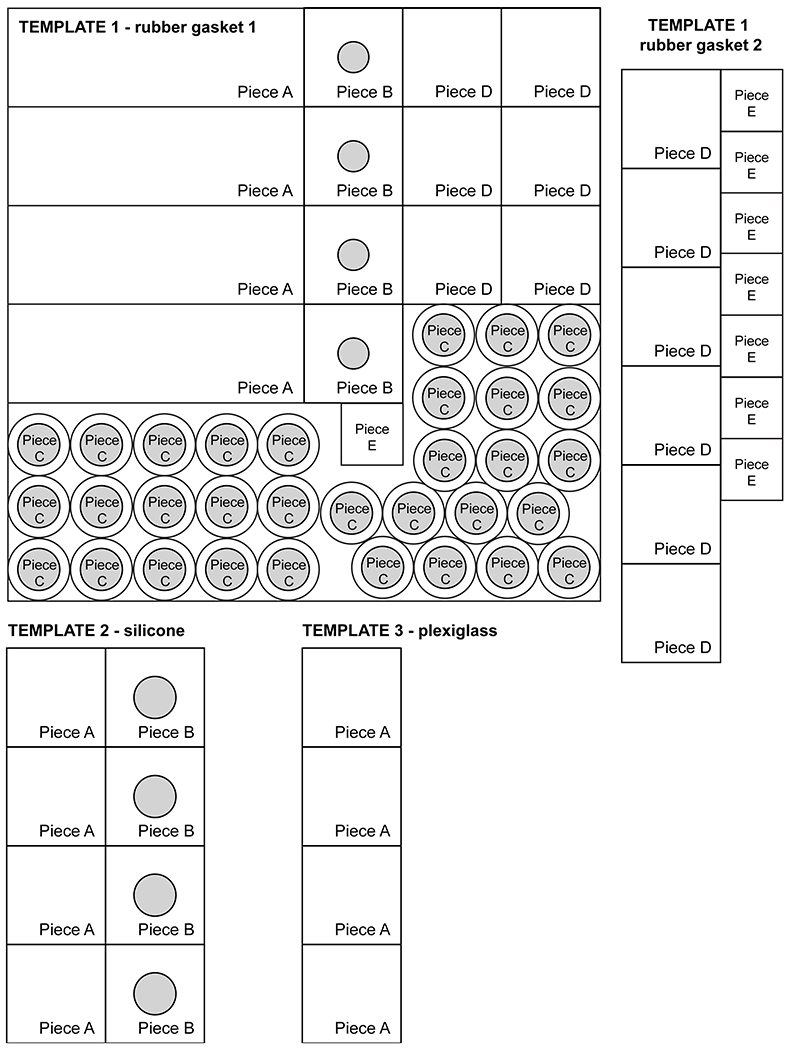

SUPPORT PROTOCOL 4

SUPPORT PROTOCOL TITLE

Creating custom cytocentrifuge units for use in a swinging bucket tabletop centrifuge

Introductory paragraph:

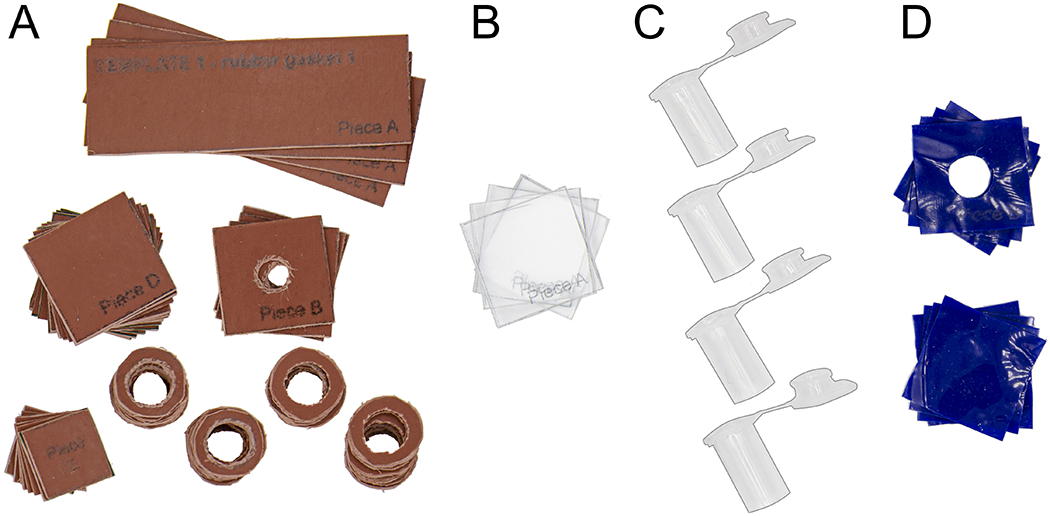

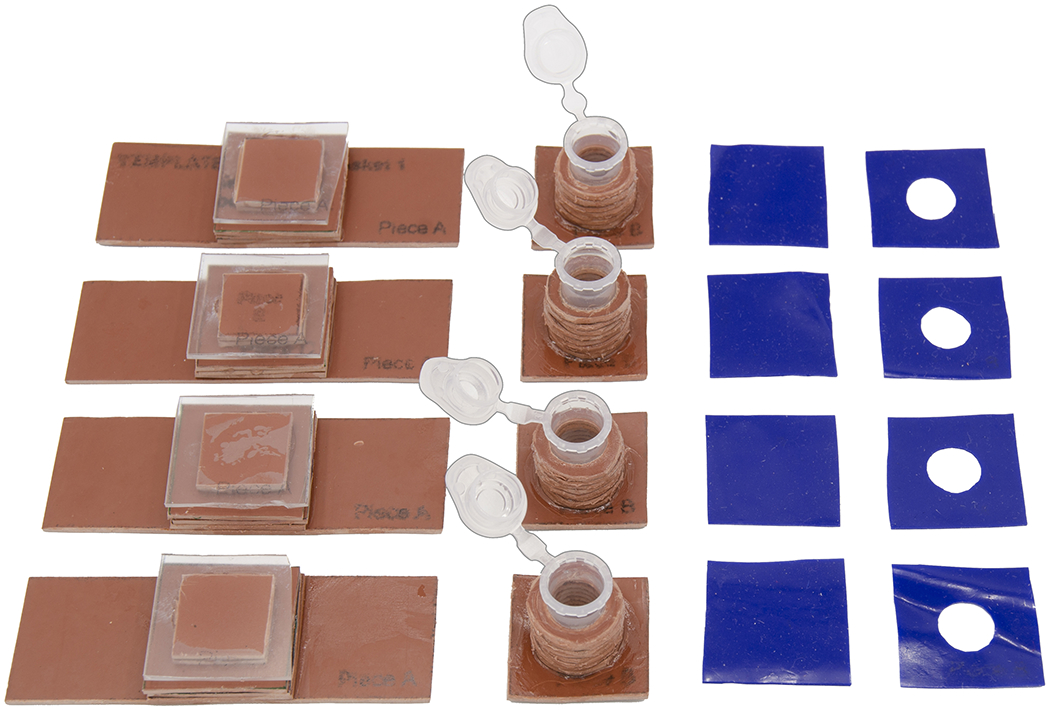

Here, the user creates cytocentrifuge units that can be used in a standard tabletop swinging-bucket centrifuge that can accommodate 96-well plates. The user will cut out the necessary pieces using a provided template and will assemble four top and four bottom units using superglue. Wear gloves and take care not to glue skin. Use superglue in a well-ventilated area.

Materials:

Materials list to make four cytocentrifuge units:

two sheets of gasket rubber: 6” x 6” x 1/16”

Tenura anti-slip silicone roll

four 1.5 ml microcentrifuge tube

one sheet of 1.3 mm thick plexiglass

scissors

dissecting scissors

razor blade or exacto knife

safety glasses

straight edge for a cutting guide

disposable gloves

superglue

Templates 1 and 2 (included with this manuscript), printed at 100% size

Protocol steps—Step annotations:

Cut out the pieces from the rubber gasket (Figure 15A.). Using a razor blade, exacto knife, or scissors, cut four 1” x 3” rubber gasket base pieces (Template 1, Piece A).

Using a razor blade, exacto knife, or scissors, cut four 1” x 1” rubber gasket pieces. Using the dissecting scissors, cut one hole 5/16” in diameter in the center of each piece (Template 1, Piece B).

Using the dissecting scissors, cut 32 rubber gasket circles with a diameter of 5/8”. Then cut one hole 10.8 mm in diameter (or the outer diameter of the flat side of your 1.5 ml microcentrifuge tube) in the center of each of these pieces (Template 1, Piece C).

Using a razor blade, exacto knife, or scissors, cut 12 1” x 1” and eight 5/8” x 5/8” rubber gasket pieces (Template 1, Piece D and E, respectively).

-

Using a razor blade or exacto knife and a straight edge as a guide, cut four 1” x 1” squares out of the 1.3 mm-thick plexiglass (Template 2, Piece A) and remove protective coating, if present (Figure 15B.).

To cut the plexiglass, deeply score the plexiglass with the blade. This will take multiple passes of the blade. Score the outer edges of the rectangle of squares first. Once these edges are scored to a depth of at least half the thickness of the plexiglass, carefully bend the plexiglass at the score lines until it snaps. Wear safety glasses and gloves while snapping the plexiglass. If the plexiglass snaps at the wrong location, repeat the process and score more deeply. After snapping the rectangle from the sheet of plexiglass, repeat the scoring and snapping process for each of the squares within the rectangle. Be cautious both when scoring and snapping the plexiglass to prevent lacerations.

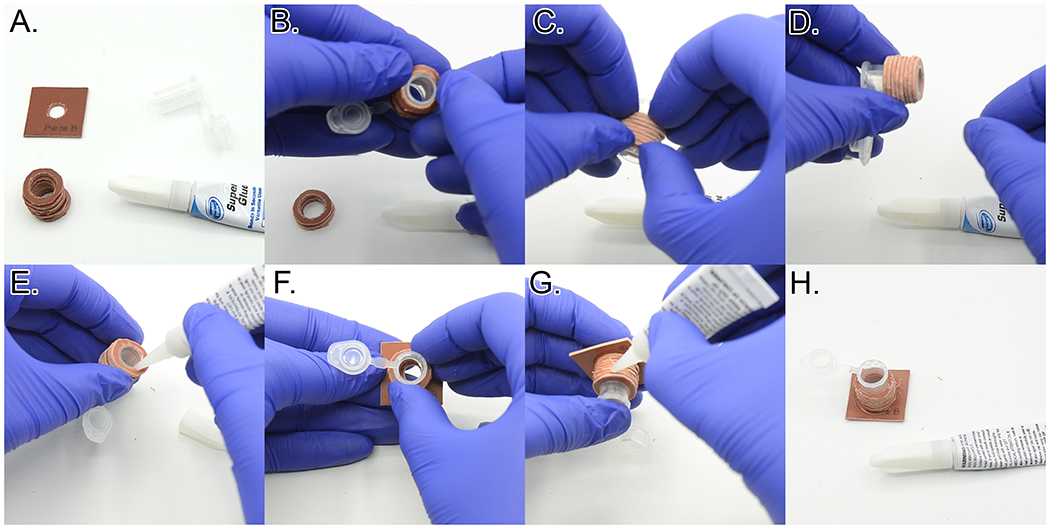

To make the tops (Video 1), use a razor blade to carefully cut four 1.5ml centrifuge tubes at the point where the walls begin to taper in to form the point at the bottom of the tube such that the straight-walled cylindrical part of the tube and the cap apparatus remain (Figure 15C.).

Thread eight rubber gasket rings (Template 1, Piece C) onto the base of each cut centrifuge tube. Squeeze the stack of rings together and the push the stack of rings to the base of the tube (Figure 16A.–D. and Video 1).

Wearing gloves, apply a small amount of superglue around the lowest ring (Template 1, Piece C) on the cytocentrifuge tube (Figure 16E.). Place the cut centrifuge tube cut-side down on top of the superglue, centered on the hole (Figure 16F.). If necessary, add a little more superglue around the outer base of the tube.

Before the superglue dries, carefully push the rings (Template 1, Piece C) around the centrifuge tube down to contact the rubber gasket base (Template 1, Piece B), such that the rings are tightly stacked. Add superglue to the exposed ring faces (sides and top) and let thoroughly dry (Figure 16G.–H.).

To make the bottoms (Video 2), wearing gloves, superglue one Template 1 Piece D to the center of each Template 1, Piece A. Superglue two additional Template 1, Piece D on to the first Piece D and then two Template 1, Piece E to create a stack.

Superglue one Template 2, Piece A to the top of each Template 1, Piece D stack and let dry.

Using scissors, cut four 1” x 1” silicone squares (Template 3, Piece A). Cut an additional four 1” x 1” silicone squares, and using dissecting scissors, cut out one 5/16” diameter hole in the center of each (Template 3, Piece B) (Figure 15D.).

Figure 15:

Rubber gasket pieces (A.), plexiglass pieces (B.), and cut microcentrifuge tops (C.) for assembling cytocentrifuge tops and bottoms. (D.) Silicone pieces for creating a liquid-tight seal in assembled cytocentrifuge units.

Figure 16:

Assembling the cytospin tops. A. Components needed to make one cytospin top. B. Adding a stack of rubber gasket rings to the cut microcentrifuge tube. C. Squeezing the rubber rings together to remove spaces between the rings. D. Final position of the stack of rubber rings. E. Applying superglue to the bottom of the ring stack. F. Gluing the cut microcentrifuge tube and ring stack to the bottom rubber gasket piece, centering the hole. G. Applying superglue to the side of the ring stack. H. Completed cytocentrifuge top. See Video 1.

Sample Data

At the end of this protocol, users should have successfully created four cytocentrifuge units, as pictured in Figure 17. Each unit consists of a base and a top. The base serves as a pedestal to support the coverslip during centrifugation. The top serves as a container for the cell suspension during centrifugation. The tops and bottoms should be interchangeable and should seal securely when assembled with the silicone pieces and the micro binder clips.

Figure 17:

Completed cytocentrifuge unit components

BASIC PROTOCOL 3

BASIC PROTOCOL TITLE

Labeling H. pylori with MurNAc-alk or D-Ala-alk

Introductory paragraph:

This protocol instructs the user how to create high-quality slides of H. pylori cells labeled for a short pulse with MurNAc-alk or D-Ala-alk. Cells are grown in liquid culture with the metabolic probe, fixed, and permeabilized. Cells are then spun onto coverslips using the cytospin units from Support Protocol 4. Click labeling and whole cell wall staining are performed on cells on the coverslips, and coverslips are mounted on slides and cured before imaging.

Materials:

Liquid Helicobacter pylori culture (from Support Protocol 1)

BB10 (see recipe in the Reagents and Solutions section)

D-Ala-alk (ThermoFisher Scientific, #AC441221000), 100 mM stock in ddH2O

MurNAc-alk (from Basic Protocol 1), 200 mg/ml stock in ddH2O

10% sodium azide stock in ddH2O

Brucella broth (see recipe in the Reagents and Solutions section)

20% paraformaldehyde (PFA) aqueous solution (Fisher Scientific, #50-980-492)

70% ethanol, aqueous solution

Alconox® detergent (Sigma-Aldrich, #Z273228-1PAK)

0.05% Tween-20 in Dulbecco’s Phosphate Buffered Saline (PBST) (PBS from ThermoFisher Scientific #14190144)

Click-iT Cell Reaction Buffer Kit (ThermoFisher Scientific #C10269)

Dimethyl sulfoxide >99.9% , Alfa Aesar (Fisher, #AA22914K2)

Alexa Fluor 555 Azide, Triethylammonium Salt (Thermofisher Scientific, #A20012)

Dulbecco’s Phosphate Buffered Saline (PBS)

Wheat Germ Agglutinin Alexa Fluor 488 Conjugate (ThermoFisher Scientific, #W11261)

ProLong™ Diamond Antifade Mountant (ThermoFisher Scientific, #P36961)

Trigas incubator with shaker [Sanyo O2/CO2 incubator; 10% O2, 10% CO2, Nitrogen to balance]

Water bath, set to 55°C

spectrophotometer

cuvettes

5 ml polystyrene round-bottom tubes

timer

ice and ice bucket

1.5 ml microcentrifuge tubes

circular sticker labels

fine-tipped permanent marker

microcentrifuge

Glass screw-cap test tube for storing excess PFA at −20°C

Rotisserie shaker

hemocytometer with cover glass

phase contrast microscope

Corning™ Square cover classes, No. 1.5 (Fisher Scientific, #12-553-453)

cytocentrifuge units (from Support Protocol 4)

micro binder clips

two 96-well plate lids

laboratory tape

swinging bucket centrifuge that can accommodate 96-well plates

high precision tweezers (Electron Microscopy Sciences, #78752-08)

parafilm

paper towels

opaque box lid

Plain glass slides (FisherScientific, #12-549-3)

microfiber towel

Protocol steps—Step annotations:

As detailed in Support Protocol 1, prepare a liquid culture of H. pylori to reach 0.35-0.50 OD600/ml in the morning.

In the morning, before beginning labeling, put ice in a bucket and place the 70% EtOH on ice to cool. If you are using a previously-used aliquot of PFA stored in a screw-top glass test tube at −20°C, place the test tube in a 55°C water bath to warm. Place a tube of ProLong Diamond Antifade Mountant cap-down in a tube rack to thaw.

Check the culture density with the spectrophotometer. If the culture is between 0.35-0.5 OD600/ml, proceed with labeling. If OD600 > 0.5, dilute the culture and grow for at least 1 doubling to ensure the cells are in early/mid log phase.

Label two round-bottomed 5 ml polystyrene tubes, one for the culture to be labeled and one for the unlabeled control.

Pipette 400 μl culture into each polystyrene tube and place the tube in the incubator for 15 minutes, shaking at an angle.

While the cultures are warming in the incubator, thaw the MurNAc-alk or D-Ala-alk stock.

After 15 minutes, add 8 μl of the 200 mg/ml MurNAc-alk stock or 4 μl of the 100 mM D-Ala-alk stock to the culture and put the culture back into the Trigas incubator, shaking at an angle for 18 minutes.

After 18 minutes, take the tubes out of the incubator, add 4 μl 10% sodium azide to suspend growth, swirl to mix, and place on ice for 5 minutes.

While the cells sit on ice, label one 1.5 microcentrifuge tube per sample using a circular sticker label.

Transfer each culture from the 5 ml round bottom polystyrene tube to a 1.5 ml microcentrifuge tube.

-

Centrifuge cultures for 5 minutes at 5000 rpm [2300 RCF].

Helical H. pylori cells tend to clump tightly, so gentle spins are important.

Resuspend each pellet in 1 ml Brucella Broth (without FBS). Add 250 μl 20% PFA (final concentration = 4% PFA) to each sample and invert to mix. Rotate at room temperature 45 minutes to fix cells. Store any unused 20% PFA in a screw cap glass test tube at −20°C.

Centrifuge cells for 5 minutes at 5000 rpm [2300 RCF] and remove supernatant.

Resuspend pellets in 1 ml ice cold 70% ethanol. Place tubes on ice for 30 minutes.

During this step, get the Click-iT® reaction buffer additive out of the freezer and place on the benchtop to thaw.

Centrifuge cells for 5 minutes at 2000 rpm [400 RCF] and remove supernatant.

-

Thoroughly and quickly resuspend pelleted cells in 200 μl PBS.

Note that cells will likely be pelleted up the side of the tube where the pellet formed, so make sure to pipette PBS over this surface multiple times to resuspend these cells.

Let the cell suspensions sit 10 minutes at room temperature.

-

Place the cover glass on top of the hemocytometer. Pipette 10 μl of one sample into the top wedge and 10 μl of the second sample into the bottom wedge. Observe the density of the cell suspension at 400x magnification with phase contrast. Within the smallest squares, the optimal density is approximately three cells per square per focal plane (Video 3).

Because of the small size of the cells and the extremely narrow depth of field, not all of the cells within the liquid volume above the square will be visible at any given focal point. Adjust the focus up and down between the cover glass and the hemocytometer to get a proper estimate of cell density.

If necessary, dilute the cell suspensions with PBS to achieve the appropriate cell density as visualized on the hemocytometer.

-

Clean two No. 1.5 glass coverslips by placing a small amount of Alconox™ detergent powder into one gloved hand. Add a few drops of distilled H2O to the powder and mix. Get a small amount of the detergent mix on the thumb and forefinger. Rub the coverslip thoroughly between these fingers and then rinse completely with distilled H2O, ensuring no detergent remains. Blot dry on paper towels.

Coverslips can be cleaned in advance. Keep clean coverslips in a Petri dish on top of a small piece of Kimwipe.

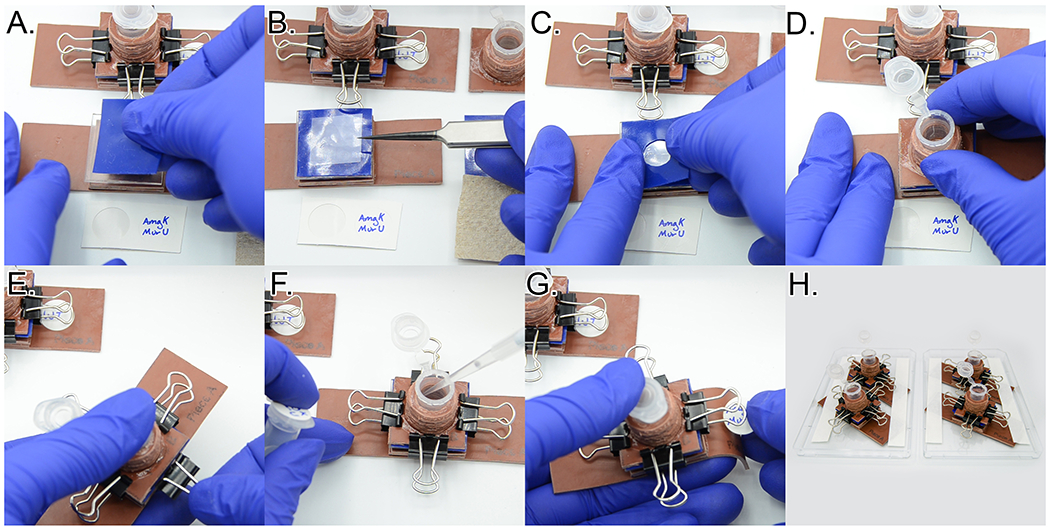

Assemble cytocentrifuge units by placing the base on the benchtop, then place one 1”x1” silicone square (Template 3, Piece A) on top of the center pedestal. While wearing gloves to prevent oil transfer from your fingers, carefully place one clean No. 1.5 coverslip on top of the silicone square. It is best to handle the coverslip by just touching the edges. Then place one 1”x1” silicone square with a hole in the center (Template 3, Piece B) on top of the coverslip. Next place the cytocentrifuge unit top on top of the stack. Holding the entire stack together between thumb and forefinger of your non-dominant hand, use your dominant hand to clip all four sides of the apparatus together using micro binder clips. See Figure 18A.–E. and Video 4 for a detailed assembly diagram.

Pipette 200 μl of the normalized density suspension into the modified 1.5 ml microcentrifuge tube and close the lid. Using a circular label sticker, label the base of the cytocentrifuge apparatus. Tape the base of each cytocentrifuge unit onto the inside surface of a 96-well plate. See Figure 18F.–H. for a detailed assembly diagram.

Place each 96-well plate cytocentrifuge apparatus into a tabletop swinging bucket centrifuge and spin at 500 rpm [59 RCF] for 5 minutes.

-

Remove from the centrifuge. Open the lid of each cytocentrifuge apparatus and pipette in 200 μl of PBST. Wait five minutes to disassemble.

This step helps allay issues with hydrophobicity of the coverslip and helps ensure cells remain hydrated throughout the whole protocol.

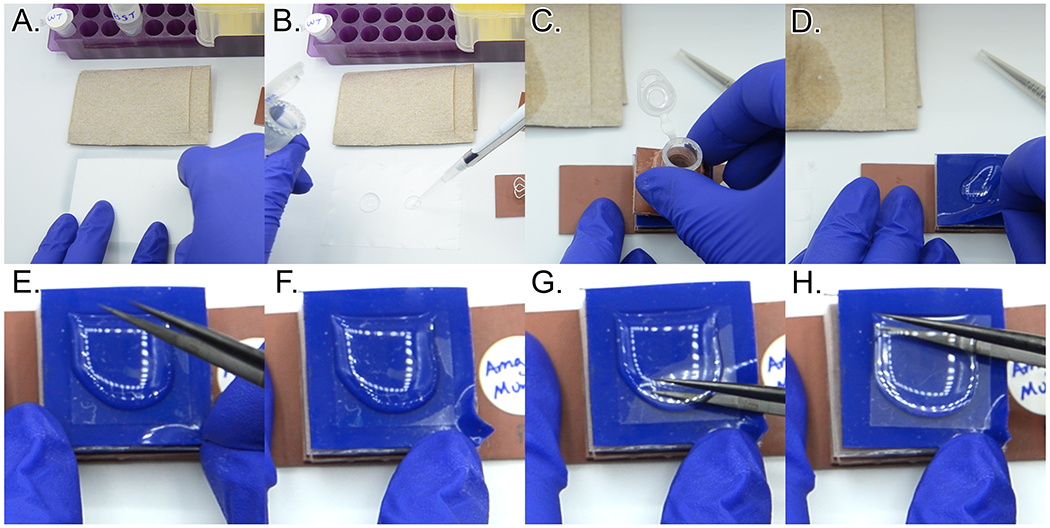

In the meantime, cut a strip of parafilm 0.25 m in length. Remove the paper backing. Lay the parafilm flat on the benchtop and tack it to the surface along the edges using your fingernail. Use a permanent marker to label columns on the parafilm for labeling. Pipette 200 μl PBST on top of the parafilm, one for each coverslip (Figure 19A.–B. and Video 5).

-

Carefully disassemble the cytocentrifuge units (Figure 19C.–H. and Video 5). Set the cytocentrifuge unit on top of a paper towel. Unclip all four micro binder clips. Peel off the top of the cytocentrifuge unit, and if necessary, the 1”x1” piece of blue silicone with a hole in the center (Template 3, Piece B). Make sure some liquid remains on the top surface of the coverslip. Exercising extreme care to avoid breaking the coverslip, pull a corner of the 1”x1” silicone square (Template 3, Piece A) parallel to the plane of the coverslip to help release the coverslip. While holding the corner of the silicone, gently slide one pincer of the tweezers between the coverslip and the silicone square and move pincer as necessary to release the seal between the coverslip and silicone. Pick the coverslip up using the tweezers (Figure 19C.–H.).

This step is the most likely time to accidentally break a coverslip. It may take some practice to reliably be successful with releasing the coverslip. If you do break a coverslip into two pieces, you can carefully carry both pieces through the labeling and mounting steps.

With the coverslip gripped securely in the tweezers, rotate the coverslip 90° and carefully wick the liquid off on a paper towel. Quickly place the coverslip cell side-down on the corresponding droplet of PBST on the parafilm. Repeat for any remaining coverslips.

Once all of the coverslips are cell side-down on PBST, make a Click-it reaction master mix: 396 μl ddH2O, 44 μl 10x buffer, 10 μl CuSO4, 50 μl reaction additive, and 4 μl AF555 azide (1 mg/ml).

-

Pipette 50 μl of the Click-it reaction master mix to the next position on the parafilm. Pick up each coverslip securely with the tweezers, rotate the coverslip 90°, wick it on paper towels, and quickly place it cell side-down on the drop of Click-it reaction master mix. Cover with a box lid to block light exposure and wait 30 minutes.

All wicking steps will be done with the coverslip approximately perpendicular to the paper towel and coverslips will always be placed onto liquid drops cell side-down. In all following steps, coverslips will be handled exclusively with tweezers and coverslips will be protected from light. After a drop has been used, you can aspirate or wipe it away.

Pipette two 200 μl drops of PBST per coverslip onto the parafilm. After 30 minutes of Click-it labeling, pick up each coverslip, wick it, and quickly place it cell side-down on the corresponding PBST drop. Once all coverslips are on PBST, you may pick up and place the coverslip back on the droplet to mix the solution to promote optimal washing.

Let the coverslip sit on the PBST droplet for 10 minutes, then wick and transfer it to the next PBST drop and let sit another 10 minutes.

While the coverslips are in the second wash step, make a master mix of fluorescent Wheat Germ Agglutinin (1.5 μl of a 1 mg/ml solution per 50 μl PBS). Pipette 50 μl of the WGA solution per coverslip onto the parafilm. Once the second wash is finished, wick and transfer each coverslip onto the corresponding WGA drop. Let coverslips label for 30 minutes.

Pipette 4 x 200 μl drops of PBST per coverslip onto parafilm. When the WGA labeling has been completed, wick each coverslip and place it cell side-down on the corresponding PBST drop. Proceed with four washes as described above in Steps 31-32.

While washing the coverslips, spray slides with 70% ethanol and rub dry with the microfiber towel to clean them. Label slides.

-

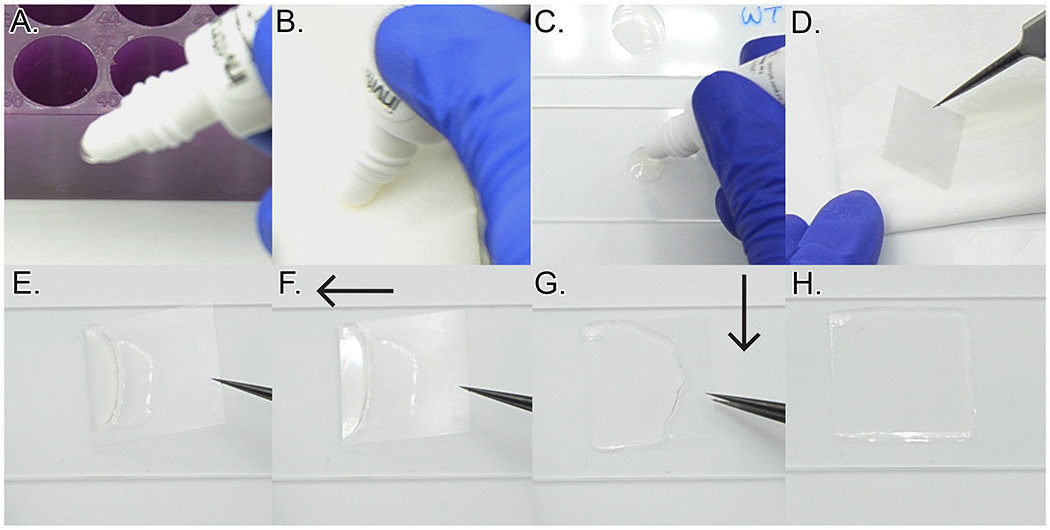

Once the final wash is finished, carefully add one drop of ProLong Diamond anti-fade mountant to the top, center of each slide. Ensure that there are no bubbles in the drop of mountant. If there are bubbles, fold a kimwipe several times and use the resulting corner to pop or move bubbles away from the drop. Pick up each coverslip, wick well on a paper towel, and mount on the slide (Figure 20 and Video 6).

To minimize the risk of generating bubbles under the coverslip, at a 60°angle from the coverslip, contact the coverslip bottom edge with the drop of mountant. Then, keeping the edge of the coverslip near the slide, move the coverslip edge along the long axis of the slide away from the drop of mountant to spread out the drop some. Then, slowly and gently decrease the angle of the coverslip until the coverslip is parallel to the slide.

-

Place the slides on a level surface under an opaque box lid to cure for one week.

Slides can be imaged immediately with great care after tacking the corners with VALP for screening purposes if necessary. It is preferable to wait 24 hours to screen slides; VALP is not necessary after the slide mountant has been able to cure for 24 hours.

Evaluate the quality of the slide using a basic widefield fluorescence microscope.

Figure 18: