Abstract

A gas sensing method based on quartz-enhanced photothermal spectroscopy (QEPTS) demodulated by quartz tuning fork (QTF) sensing acoustic wave is reported for the first time. Different from traditional QEPTS, the method proposed in this paper utilizes the second QTF to sense acoustic wave produced by the first QTF owing to the vibration resulted from photo-thermo-elastic effect. This indirect demodulation by acoustic wave sensing can avoid QTF being irradiated by laser beam and therefore get less noise and realize better detection sensitivity. Four different sensing configurations are designed and verified. Acetylene (C2H2) with a volume concentration of 1.95 % is selected as the target gas. A model of sound field produced by the first QTF vibrating is established by finite element method to explain the variation trend of signal and noise in the second QTF. The measured results indicate that this technique had an enhanced signal-to-noise ratio (SNR) of 1.36 times when compared to the traditional QEPTS. Further improvement methods for such technique is proposed.

Keywords: Quartz tuning fork, Photothermal spectroscopy, Indirect demodulation, Acoustic wave sensing

1. Introduction

Gas sensors can effectively detect inflammable, explosive and toxic gases [[1], [2], [3], [4]]. Electrochemical and semiconductor sensors use changes in chemical processes and electrical properties to detect gases. They have the advantages of low cost, tiny volume and maturity [5]. Compared with these two types of sensors, optical gas sensors have a different principle of light absorption. Therefore, optical sensors have multiple advantages over electrochemical and semiconductor gas sensors, such as the feature of fast response, selective, sensitive and non-destructive sensing, high resistivity to electromagnetic noise, and intrinsically safe detection [[6], [7], [8], [9], [10], [11], [12], [13]]. They are widely used in numerous fields of combustion diagnostics, atmospheric monitoring and life sciences [[14], [15], [16], [17], [18]].

Quartz-enhanced photothermal spectroscopy (QEPTS), one of the sensitive optical trace gas sensing techniques, was invented in 2018 by Ma et al. [19], which is also called light-induced thermoelastic spectroscopy (LITES) [20]. When the modulated laser passes through a gas cell and irradiates to the surface of a quartz tuning fork (QTF) detector, QTF will partly absorb laser energy and translate it into thermal energy. The thermoelastic expansion converts the thermal energy to mechanical motion, which is enhanced by the resonant property of QTF. Owing to the piezoelectric effect of QTF, the mechanical motion produces an electric signal and finally the concentration of gas can be retrieved [21]. QTF has the merits of low cost (<$1), tiny volume (a few cubic millimeter), high dynamic range and no wavelength dependence [[22], [23], [24]]. Therefore, QEPTS has advantages of low budget, compact size and wide range of application. Furthermore, a QTF can be placed far from the target gas in QEPTS, so it is a non-contact measurement method, which is advantageous for the detecting of acidic and corrosive gases, such as HCl and H2S [18,25]. QEPTS has been widely studied since its invention. In 2019, a high Q-factor QTF and a multipass cell were adopted to improve the performance of QEPTS. A minimum detection limit (MDL) of 17 ppb was obtained for carbon monoxide (CO) detection [20]. In 2020, a multi-quartz-enhanced photothermal spectroscopy (M-QEPTS) was reported. In this M-QEPTS, two QTFs were used as the photothermal detectors, and a 1.51 times signal amplitude enhancement was achieved when compared to the traditional single QTF sensing [26]. A long-path QEPTS gas sensor using a Q-switched fiber laser was proposed by Zhang et al. in 2020. A MDL of 6.1 ppb at a 48 s integration time was obtained for acetylene (C2H2) detection [27].

The signal level of QEPTS sensor will be improved when the laser power increases. However, considering that the noise mainly comes from the thermal noise of QTF caused by laser absorption, when the laser power goes high, the noise amplitude will increase rapidly, and finally leads to the decrease of signal-to-noise ratio (SNR) and limits the detection performance [28]. As a consequence, how to reduce the thermal noise of QTF in QEPTS is critical.

In this paper, a novel demodulation method for QEPTS sensor is reported for the first time. In this technique, two QTFs were acted as a photothermal receiver and an acoustic wave detector, respectively. The first QTF was adopted to receive the laser energy as it usually used in QEPTS. The second QTF was used to detect the acoustic wave induced by photo-thermo-elastic energy conversion in the first QTF. Different from the traditional demodulation method of QEPTS, indirect demodulation by acoustic wave sensing can avoid QTF being irradiated by laser beam. Therefore, the sensing system can get less noise and realize better detection sensitivity. Due to applications in the detection of fault gases in transformers and polyethylene production [29,30], C2H2 was selected as the target gas to test and validate the reported technique in four different configurations. A model of sound field produced by the first QTF vibrating was established by finite element method to explain the variation trend of signal and noise in the second QTF.

2. Experimental setup

The experimental setup of QEPTS sensor demodulated indirectly by acoustic wave detection using a QTF is shown in Fig. 1. When the first QTF receives modulated light in a normal QEPTS sensor, the prongs of this QTF will vibrate due to the photo-thermo-elastic conversion [19,31]. The vibrated QTF acts as an acoustic source and the generated acoustic wave from this first QTF can be detected by the second QTF, which is used as an acoustic wave transducer. Two commercially available QTFs (QTF1 and QTF2) with resonance frequency f0 of 32.768 kHz (in vacuum) were employed in the experiments. C2H2 with concentration of 1.95 % was adopted. According to HITRAN 2016 database, an intense absorption line with a line-strength of 1.2 × 10−20 cm-1/(mol cm-2) located at 6534.37 cm-1 (1530.37 nm) was selected. The laser excitation source was a continuous wave, distributed feedback (CW-DFB) fiber-coupled diode laser with a wavelength of 1.53 μm and output power of 10.3 mW. An integrated laser controller was used to display and alter the temperature and injection current of the diode laser. The laser power was amplified by an erbium doped fiber amplifier (EDFA). Wavelength modulation spectroscopy and second harmonic (2f) detection were utilized to detect the electrical signals. As wavelength modulated signal, a sawtooth ramp of 10 mHz engendered by a signal generator and a high frequency sinusoidal wave of f0/2 produced by a lock-in amplifier were added and sent to the laser controller. The modulated laser beam emitted from the fiber was collimated by a fiber collimator (FC) and then sent into a C2H2 absorption cell with 20 cm length. Both ends of the cell was equipped with wedged CaF2 window to avoid optical interference. After passing through the gas cell, the laser beam was focused by a lens with 40 mm focal length and converged to the base of the QTF1 prongs, where the maximum thermal stress field was located [20]. Due to the photo-thermo-elastic energy conversion, the prongs of QTF1 vibrated at resonant frequency f0 and acted as an acoustic source and transmitted acoustic wave in all directions. QTF2 was employed as an acoustic wave detector, whose prongs vibrated under the influence of generated acoustic wave from QTF1. An electrical signal was produced from QTF2 due to the piezoelectric effect [32,33], and finally the signal was sent to a lock-in amplifier. The integration time of the used lock-in amplifier was 200 ms.

Fig. 1.

Schematic diagram of the experimental setup.

In order to investigate how the relative position between QTF1 and QTF2 influences the acoustic wave detection, four different configurations are here reported and discussed. As shown in Fig. 2, the stereogram and corresponding top viewport of lateral parallel configuration (--), lateral vertical configuration (-|), rear parallel configuration (=), rear vertical configuration (丄) and the size of QTF were depicted separately. In order to express the relative position between QTF1 and QTF2, rectangular coordinate systems were established to describe the displacement of QTF2. A red dot marked in QTF2 is used to present QTF2 in the rectangular coordinate system and therefore to indicate the displacement.

Fig. 2.

Four configurations of QTF1 and QTF2.

3. Experimental results and discussions

The measurements were carried out at atmospheric pressure and room temperature. Firstly, the diode laser was used without EDFA. In this sensing system, two QTFs of QTF1 and QTF2 played the roles of acoustic source and acoustic wave detector, respectively. Ensuring that the acoustic wave generated by QTF1 makes the prongs of QTF2 swing violently to get a strong 2f signal, the resonance frequency difference between QTF1 and QTF2 should be as little as possible. In the ideal condition, the frequencies of the two QTFs are same and the strongest response could be obtained. In the acquirement of resonance frequency, the method of light excitation was applied. The laser irradiated on the base of QTFs’ prongs and the sinusoidal wave frequency of the excitation was scanned. The variation curve and Lorentz fitting of the normalized squared voltage amplitude of QTFs along with the frequency of sinusoidal wave are shown in Fig. 3. It can be directly acquired that resonance frequency f1 = 32759.33 Hz, f2 = 32759.34 Hz and bandwidth Δf1 = 2.38 Hz, Δf2 = 2.59 Hz by the Lorentz fitting for QTF1 and QTF2, respectively. The difference of resonance frequency between the two QTFs was 0.01 Hz, indicating a good matching between QTF1 and QTF2. According to the definition of Q=f/Δf, Q1 = 13733.55 and Q2 = 12619.11 were calculated for QTF1 and QTF2, respectively. Since the function of QTF1 was to vibrate and produce acoustic wave, the modulation frequency of sinusoidal wave was set at the half of resonance frequency of QTF1 (f1/2 = 16379.67 Hz) to generate a strong acoustic wave in the following experiments.

Fig. 3.

Frequency response curve of QTF1 and QTF2.

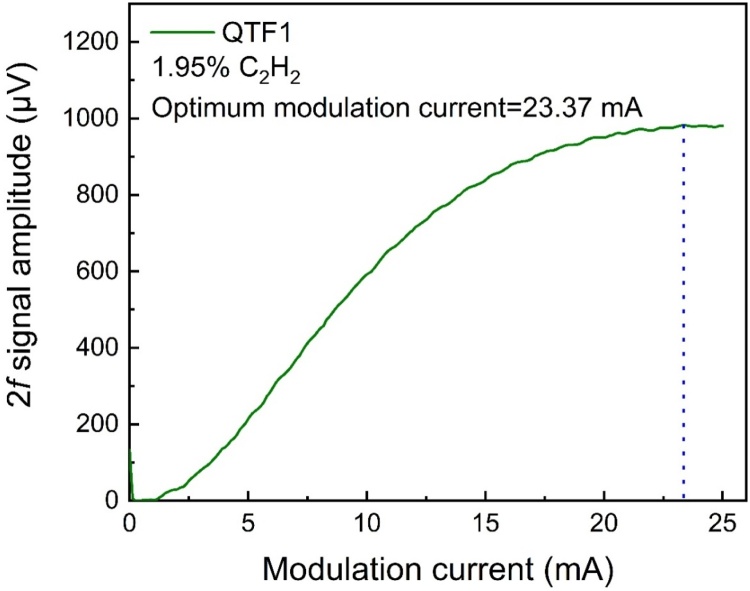

The amplitude of the second harmonic 2f in wavelength modulation spectroscopy has a great relationship with the laser wavelength modulation current/depth. The line broadening changes with different pressures, which brings different optimum wavelength modulation depth. Therefore, it is necessary to optimize the modulation current of diode laser for achieving the strongest sensor response. The dependence of 2f signal amplitude with laser wavelength modulation current is shown in Fig. 4 when the photothermal signal from QTF1 was measured. As it can be seen from this figure, 2f signal amplitude at first increased rapidly, and subsequently tended to be flat with increasing of modulation current. The maximum value reached when the modulation current was 23.37 mA. Therefore, this value was found to be optimum and chosen in the following measurements.

Fig. 4.

2f signal amplitude of QTF1 versus modulation current.

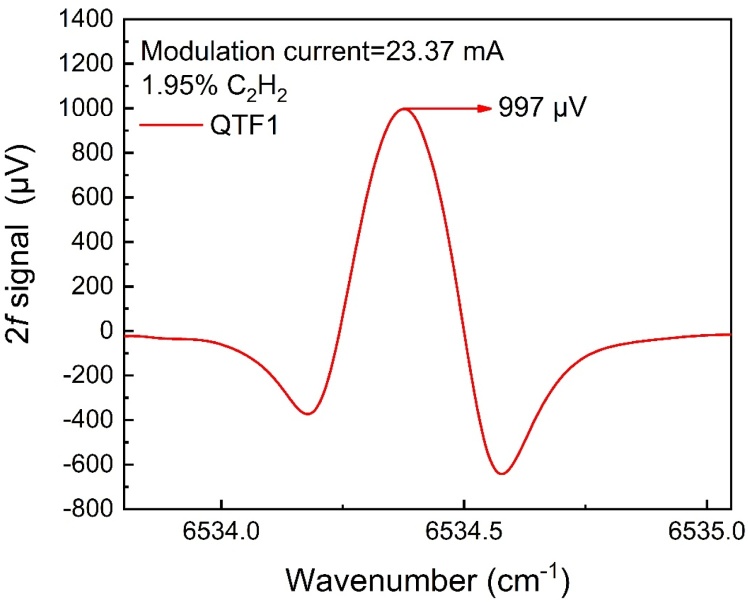

The traditional QEPTS sensor performance was investigated firstly in order to make a comparison with this new method. A 2f signal waveform was measured and shown in Fig. 5. The maximum signal amplitude was 997 μV. Filled the gas chamber with pure nitrogen (N2), while other conditions were unchanged, the noise was determined by calculating the standard deviation of the obtained data. The measured noise value was 1.46 μV, and the calculated SNR of QTF1 for traditional QEPTS was 683.

Fig. 5.

2f signal of QTF1.

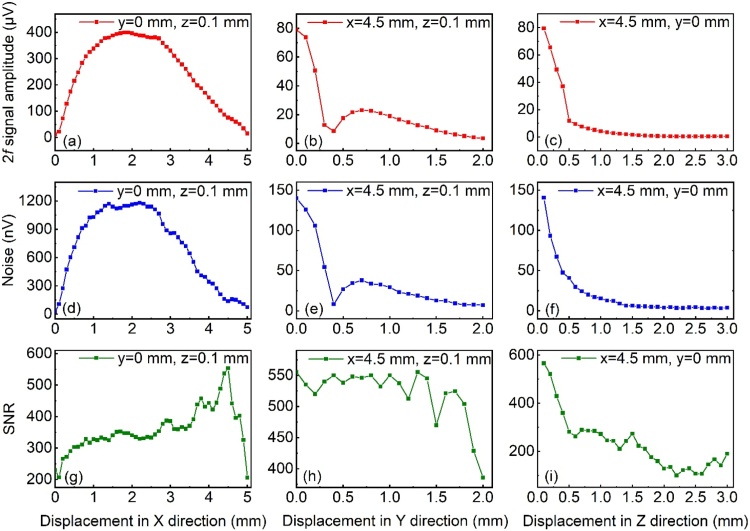

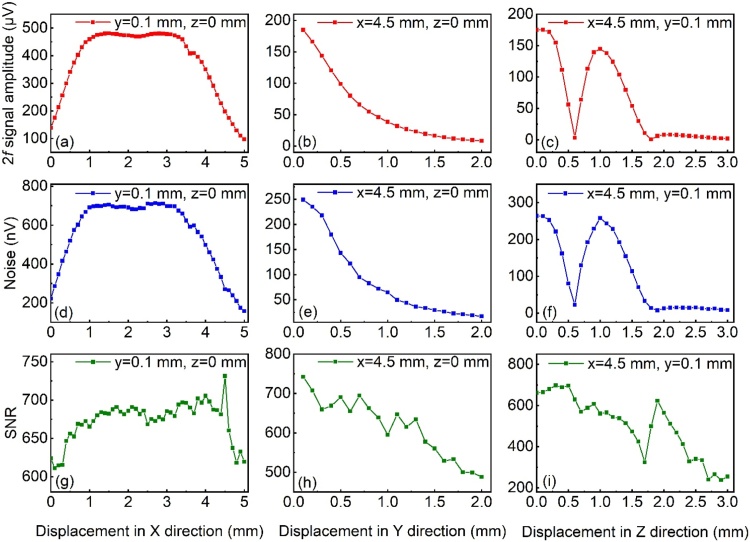

The position between QTF1 and QTF2 will affect the performance of QTF2 sensing acoustic wave generated from QTF1. Therefore, four configurations for these two QTFs were proposed as shown in Fig. 2. A rectangular coordinate system and a red dot marked in QTF2 were used to describe the motion of QTF2. In each configuration, the relationship among 2f signal amplitude, noise, SNR and x, y, z (displacement in X, Y, Z directions) for QTF2 were investigated. In order to avoid contact with QTF1, the initial position of the red dot in QTF2 were set as x = 0 mm, y = 0 mm and z = 0.1 mm for the lateral parallel configuration (--) and lateral vertical configuration (-|). In the rear parallel configuration (=) and rear vertical configuration (丄), the initial position of the red dot in QTF2 were set as x = 0 mm, y = 0.1 mm and z = 0 mm. The displacement in X, Y, Z directions were optimized respectively. The measured results are shown in Figs. 6,8,9, and 10. In these four figures, the columns from the first to the third are the displacement in X, Y, Z directions, respectively. The first, second and third rows are 2f signal amplitude, noise and SNR, respectively. The 2f signal amplitude and noise were measured when the gas cell filled with 1.95 % C2H2 and pure N2, respectively. The SNR was calculated based on the 2f signal amplitude and noise at the same location.

Fig. 6.

2f signal amplitude, noise and SNR versus displacement in X, Y and Z directions for QTF2 in the lateral parallel configuration (--).

The variation of 2f signal amplitude, noise and SNR with displacement in the lateral parallel configuration (--) are shown in Fig. 6. In the X direction, displayed in Fig. 6(a), the 2f signal amplitude firstly increased with displacement and subsequently remained unchanged. And it decreased finally. This phenomenon can be explained as follow. With the increasing of displacement in X direction, the distance between acoustic source (QTF1) and acoustic wave detector (QTF2) was reduced and a strong acoustic wave acted on the prongs of QTF2, which brought an increased 2f signal amplitude. When the displacement x continuously increased, the equivalent action point of acoustic wave gradually approached to the base of prongs of QTF2. Due to the structural characteristics of QTF, the torque of the prongs of QTF2 reduced in this condition, which resulted in a decreased 2f signal amplitude [34]. As a trade-off between the increased and decreased situations of signal response, the 2f signal amplitude remained unchanged in a certain x range. The variation trend of noise with displacement was as same as that of signal because even if there was no C2H2 in the gas cell, the modulated laser still pushed QTF1 to vibrate and produce acoustic wave due to the effect of light-induced thermoelastic energy conversion. This status occurred no matter QTF2 in any directions and configurations. The SNR, shown in Fig. 6(g), was calculated based on 2f signal amplitude and noise. It increased as the displacement increases until x = 4.5 mm. Therefore, the optimal position in X direction was identified as x = 4.5 mm, and the following optimization of Y direction was carried out at this condition. In Y direction, with increasing of the displacement, the signal (Fig. 6(b)) and noise (Fig. 6(e)) firstly decreased sharply, and then increased and finally decreased again. To explain this phenomenon, the sound field produced by QTF vibrating at fundamental frequency was calculated by finite element method with COMSOL Multiphysics software. Physical for pressure acoustics and solid mechanics were built. A sphere with a radius of 20 mm was set as air domain and its physic was pressure acoustics. The boundary of the sphere was a perfectly matched layer (PML) used to indicate the boundary conditions of infinite air domain. The physic of QTF was solid mechanics. The surface of QTF was set as sound hard boundary. When the two prongs of QTF1 vibrated, the created two sound fields coupled together. The distribution of sound pressure level (SPL) in the cross-section of QTF1 is shown in Fig. 7(a). Different colors indicated different SPL, shown in the color bar. Along Y direction, taking a section line at x = 4.5 mm and z = 0.1 mm in the coupled sound pressure field, the variation of SPL with y is shown in Fig. 7(b). As it can be seen from this figure, the simulated result is consistent with the experiment in Y direction. Fig. 6(h) showed the variation of SNR with displacement of y. The maximum SNR was obtained at y = 0 mm. The optimization of displacement in Z direction was conducted when x and y were fixed to the optimized value of 4.5 mm and 0 mm, respectively. Due to the attenuation of acoustic wave with distance, 2f signal amplitude and noise level decreased obviously with the displacement of z. SNR in Z direction reached the maximum at z = 0.1 mm. According to the criterion of maximum SNR, the optimal location for QTF2 was achieved when x = 4.5 mm, y = 0 mm and z = 0.1 mm in the lateral parallel configuration (--), and SNR was 553 in this condition.

Fig. 7.

Simulated results using finite element method based on COMSOL software; (a) Distribution of coupled sound pressure field in the cross-section of QTF1; (b) Variation of sound pressure with displacement in the Y direction.

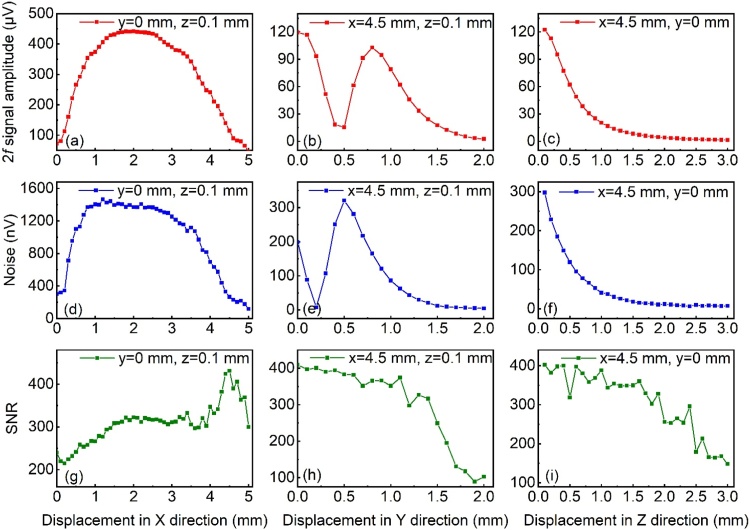

In the lateral vertical configuration (-|), as shown in Fig. 8, the variation trend of 2f signal amplitude, noise and SNR with displacement was consistent with that in the lateral parallel configuration (--). The maximum SNR of 471 for QTF2 was obtained when x = 4.5 mm, y = 0 mm and z = 0.1 mm.

Fig. 8.

2f signal amplitude, noise and SNR versus displacement in X, Y and Z directions for QTF2 in the lateral vertical configuration (-|).

As shown in Fig. 9, in the rear parallel configuration (=), the variation of 2f signal amplitude and noise with displacement x was same as that in the lateral parallel configuration (--) and lateral vertical configuration (-|), but different with displacement in Y and Z directions. Because of the attenuation of acoustic wave with distance the 2f signal amplitude and noise decayed significantly with displacement y. In Z direction, the signal and noise firstly decreased sharply, and then increased and finally decreased again, which is attributed to the intensity distribution of sound field, as explained in Fig. 7. The maximum SNR of 737 for QTF2 was obtained when x = 4.5 mm, y = 0.1 mm and z = 0 mm.

Fig. 9.

2f signal amplitude, noise and SNR versus displacement in X, Y and Z directions for QTF2 in the rear parallel configuration (=).

As shown in Fig. 10, in the rear vertical configuration (丄), the variation trend of 2f signal amplitude, noise and SNR with displacement was similar to that in the rear parallel configuration (=). In Z direction, the range was set from -3 mm to 3 mm to investigate the symmetry. The results are shown in Fig. 10(c), (f) and (i). It can be seen that the behavior with respect to Z direction was symmetrical. It can be predicted that the symmetry in Z direction should appear in the similar configurations such as rear parallel (=). The maximum SNR of 564 for QTF2 was obtained when x = 4.5 mm, y = 0.1 mm and z = 0 mm in the rear vertical configuration (丄).

Fig. 10.

2f signal amplitude, noise and SNR versus displacement in X, Y and Z directions for QTF2 in the rear vertical configuration (丄).

In the above four configurations of lateral parallel (--), lateral vertical (-|), rear parallel (=) and rear vertical (丄), the 2f signal, noise and SNR as a function of displacement in three directions of X, Y and Z were investigated. Based on the criterion of maximum SNR, the optimum location was found to be x = 4.5 mm, y = 0 mm and z = 0.1 mm for the lateral parallel configuration (--) and lateral vertical configuration (-|). For the rear parallel configuration (=) and rear vertical configuration (丄), the optimum location was found to be x = 4.5 mm, y = 0.1 mm and z = 0 mm. In order to compare the performance of each configuration and traditional QEPTS, Table 1 was presented to illustrate the SNRs for QTF1 and QTF2. The rear parallel configuration (=) was recognized as the optimum structure because it achieved the maximum SNR of 737, which is better than the SNR of 683 of QTF1 for traditional QEPTS sensor shown in Fig. 5.

Table 1.

SNRs for QTF1 and QTF2 with different configurations.

| Configuration | SNR |

|---|---|

| QTF1 | 683 |

| QTF2 with lateral parallel configuration | 553 |

| QTF2 with lateral vertical configuration | 471 |

| QTF2 with rear parallel configuration | 737 |

| QTF2 with rear vertical configuration | 564 |

The optimization of laser power was carried out in the rear parallel configuration (=) at the optimum location of x = 4.5 mm, y = 0.1 mm and z = 0 mm for QTF2. The laser power was amplified by an EDFA. The relationship between SNR and laser power for QTF1 and QTF2 is shown in Fig. 11. The SNR measured for QTF1 refers to the piezo current directly measured from QTF1 as effect of the photo-thermo-elastic energy conversion, while the SNR measured for QTF2 is obtained from the acoustic wave demodulation. Initially, the SNR increased with laser power, but when the power further increased, the thermal noise and acoustic noise imposed on QTF1 and QTF2 became obvious, which resulted in a decrease of SNR. When the laser power was 15 mW, both SNRs for QTF1 and QTF2 reached maximum and the SNR of QTF2 was 1.36 times larger than that of QTF1, which means that compared with the traditional QEPTS technique (QTF1), the proposed method of indirect demodulation by acoustic wave sensing (QTF2) can realize better detection performance.

Fig. 11.

SNR of QTFs versus laser power.

4. Conclusion

A gas sensing method based on QEPTS demodulated by a QTF sensing acoustic wave was demonstrated in this paper for the first time. Different from traditional QTPTS, the proposed method was utilizing the second QTF to sense acoustic wave produced by the first QTF owing to the vibration resulted from photo-thermo-elastic energy conversion in QEPTS. This indirect demodulation by acoustic wave sensing can avoid QTF being irradiated by laser beam and therefore reduce noise level. Two QTFs of QTF1 and QTF2 with resonance frequency difference of 0.01 Hz were used to serve as an acoustic source and an acoustic wave detector, respectively. C2H2 with a volume concentration of 1.95 % was used to verify this sensor performance. Four configurations for different structures of QTF1 and QTF2, including lateral parallel configuration (--), lateral vertical configuration (-|), rear parallel configuration (=) and rear vertical configuration (丄) were proposed. In each configuration the 2f signal amplitudes, noises and SNRs versus the displacements in X, Y and Z directions were investigated. The maximum SNR for QTF2 was achieved when the rear parallel configuration (=) was selected and the location of QTF2 was set as x = 4.5 mm, y = 0.1 mm and z = 0 mm. A model of sound field produced by QTF1 vibrating was established by finite element method with COMSOL software to explain the variation trend of signal and noise in QTF2. The dependence of SNR with optical exciting power was performed after a EDFA was added in the sensor system to amplify the diode laser power. When the laser power was 15 mW, the SNR of QTF2 was 1.36 times larger than that of QTF1. Compared with the traditional QEPTS, the proposed technique of indirect demodulation by acoustic wave sensing provided a feasible method for signal demodulation in QEPTS and realized a better detection performance. This method can be further improved when multiple QTFs are used for acoustic wave sensing and micro-resonators are employed to amplify the generated acoustic wave. It is also worth to investigate the sensor performance at lower pressure to increase the quality factor of QTF.

Declaration of Competing Interest

The authors declare that there are no conflicts of interest.

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant No. 62022032, 61875047 and 61505041), Natural Science Foundation of Heilongjiang Province of China (Grant No. YQ2019F006), Fundamental Research Funds for the Central Universities, Financial Grant from the Heilongjiang Province Postdoctoral Foundation (Grant No. LBH-Q18052).

Biographies

Ziting Lang received her B.S. degree in optoelectronic information science and engineering from Yanshan university, China, in 2020. She is now pursuing a PhD degree of physical electronics from Harbin Institute of Technology. Her research interest is photoacoustic spectroscopy based gas sensing.

Shunda Qiao received his B.S. degree in electronic science and technology from Yanshan university, China, in 2018. In 2020, he received his M.S. degree and began to pursue a PhD degree of physical electronics from Harbin institute of technology. His research interests include photoacoustic spectroscopy and its applications.

Ying He received his B.S. degree in optoelectronic material and device from Harbin Engineering University, China, in 2015, and received his M.S. degree in physical electronics from Harbin Institute of Technology China, in 2017. He is now pursuing a PhD degree of physical electronics from Harbin Institute of Technology. His research interests include photoacoustic spectroscopy and photothermal spectroscopy.

Yufei Ma received his PhD degree in physical electronics from Harbin Institute of Technology, China, in 2013. From September 2010 to September 2011, he spent as a visiting scholar at Rice University, USA. Currently, he is a professor at Harbin Institute of Technology, China. His research interests include optical sensors, trace gas detection, laser spectroscopy, solid-state laser and optoelectronics. He has published more than 100 publications, including four invited review papers, and given more than 10 invited presentations at international conferences. He serves as associate editors for Optics Express, Optical Engineering, Microwave and Optical Technology Letters, Sensors, and Applied Sciences.

References

- 1.Sedghi S.M., Mortazavi Y., Khodadadi A. Low temperature CO and CH4 dual selective gas sensor using SnO2 quantum dots prepared by sonochemical method. Sens. Actuators B. 2010;145(1):7–12. [Google Scholar]

- 2.Yuasa M., Masaki T., Kida T., Shimanoe K., Yamazoe N. Nano-sized PdO loaded SnO2 nanoparticles by reverse micelle method for highly sensitive CO gas sensor. Sens. Actuators B. 2009;136(1):99–104. [Google Scholar]

- 3.Jiménez I., Arbiol J., Dezanneau G., Cornet A., Morante J.R. Crystalline structure, defects and gas sensor response to NO2 and H2S of tungsten trioxide nanopowders. Sens. Actuators B. 2003;93(1–3):475–485. [Google Scholar]

- 4.Li Y., Wang R.Z., Tittel F.K., Ma Y.F. Sensitive methane detection based on quartz-enhanced photoacoustic spectroscopy with a high-power diode laser and wavelet filtering. Opt. Laser. Eng. 2020;132 [Google Scholar]

- 5.Nam H.J., Sasaki T., Koshizaki N. Optical CO gas sensor using a cobalt oxide thin film prepared by pulsed laser deposition under various argon pressures. J. Phys. Chem. B. 2006;110(46):23081. doi: 10.1021/jp063484f. [DOI] [PubMed] [Google Scholar]

- 6.Yin X.K., Wu H.P., Dong L., Li B., Ma W.G., Zhang L., Yin W.B., Xiao L.T., Jia S.T., Tittel F.K. Ppb-level SO2 photoacoustic sensors with a suppressed absorption-desorption effect by using a 7.41 μm external-cavity quantum cascade laser. ACS Sens. 2020;5:549–556. doi: 10.1021/acssensors.9b02448. [DOI] [PubMed] [Google Scholar]

- 7.Yoshino T., Tanaka H., Tai H. Fiber-optic evanescent-wave methane-gas sensor using optical absorption for the 3.392-μm line of a He–Ne laser. Chin. Opt. Lett. 1987;12(6):437–439. doi: 10.1364/ol.12.000437. [DOI] [PubMed] [Google Scholar]

- 8.Patimisco P., Sampaolo A., Zheng H., Dong L., Tittel F.K., Spagnolo V. Quartz–enhanced photoacoustic spectrophones exploiting custom tuning forks: a review. Adv. Phys.-X. 2017;2:169–187. [Google Scholar]

- 9.Ma Y.F., Lewicki R., Razeghi M., Tittel F.K. QEPAS based ppb-level detection of CO and N2O using a high power CW DFB-QCL. Opt. Express. 2013;21(1):1008–1019. doi: 10.1364/OE.21.001008. [DOI] [PubMed] [Google Scholar]

- 10.Ma Y., Tong Y., He Y., Jin X., Tittel F.K. Compact and sensitive mid-infrared all-fiber quartz-enhanced photoacoustic spectroscopy sensor for carbon monoxide detection. Opt. Express. 2019;27(6):9302–9312. doi: 10.1364/OE.27.009302. [DOI] [PubMed] [Google Scholar]

- 11.Patimisco P., Sampaolo A., Dong L., Tittel F.K., Spagnolo V. Recent advances in quartz enhanced photoacoustic sensing. Appl. Phys. Rev. 2018;5(1) [Google Scholar]

- 12.Waclawek J.P., Moser H., Lendl B. Compact quantum cascade laser based quartz-enhanced photoacoustic spectroscopy sensor system for detection of carbon disulfide. Opt. Express. 2016;24:6559–6571. doi: 10.1364/OE.24.006559. [DOI] [PubMed] [Google Scholar]

- 13.Zhang B., Chen K., Chen Y., Yang B., Guo M., Deng H., Ma F., Zhu F., Gong Z., Peng W., Yu Q. High-sensitivity photoacoustic gas detector by employing multi-pass cell and fiber-optic microphone. Opt. Express. 2020;28(5):6618–6630. doi: 10.1364/OE.382310. [DOI] [PubMed] [Google Scholar]

- 14.Shi C., Wang D., Wang Z., Ma L., Wang Q., Xu K., Chen S., Ren W. A mid-infrared fiber-coupled QEPAS nitric oxide sensor for real-time engine exhaust monitoring. IEEE Sens. J. 2017;17(22):7418–7424. [Google Scholar]

- 15.Ma Y.F., Qiao S.D., Patimisco P., Sampaolo A., Wang Y., Tittel F.K., Spagnolo V. In plane quartz-enhanced photoacoustic spectroscopy. Appl. Phys. Lett. 2020;116 [Google Scholar]

- 16.Qiao S.D., Ma Y.F., Patimisco P., Sampaolo A., He Y., Lang Z.T., Tittel F.K., Spagnolo V. Multi-pass quartz-enhanced photoacoustic spectroscopy based trace gas sensing. Opt. Lett. 2021;46:977–980. doi: 10.1364/OL.418520. [DOI] [PubMed] [Google Scholar]

- 17.Zheng H.D., Liu Y.H., Lin H.Y., Liu B., Gu X.H., Li D.Q., Huang B.C., Wu Y.C., Dong L.P., Zhu W.G., Tang J.Y., Guan H.Y., Lu H.H., Zhong Y.C., Fang J.B., Luo Y.H., Zhang J., Yu J.H., Chen Z., Tittel F.K. Quartz-enhanced photoacoustic spectroscopy employing pilot line manufactured custom tuning forks. Photoacoustics. 2020;17 doi: 10.1016/j.pacs.2019.100158. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Wu H.P., Sampaolo A., Dong L., Patimisco P., Liu X.L., Zheng H.D., Yin X.K., Ma W.G., Zhang L., Yin W.B., Spagnolo V., Jia S.T., Tittel F.K. Quartz enhanced photoacoustic H2S gas sensor based on a fiber-amplifier source and a custom tuning fork with large prong spacing. Appl. Phys. Lett. 2015;107 [Google Scholar]

- 19.Ma Y.F., He Y., Tong Y., Yu X., Tittel F.K. Quartz-tuning-fork enhanced photothermal spectroscopy for ultra-high sensitive trace gas detection. Opt. Express. 2018;26(24):32103–32110. doi: 10.1364/OE.26.032103. [DOI] [PubMed] [Google Scholar]

- 20.He Y., Ma Y.F., Tong Y., Yu X., Tittel F.K. Ultra-high sensitive light-induced thermoelastic spectroscopy sensor with a high Q-factor quartz tuning fork and a multipass cell. Opt. Lett. 2019;44(8):1904–1907. doi: 10.1364/OL.44.001904. [DOI] [PubMed] [Google Scholar]

- 21.Ma Y.F. Recent advances in QEPAS and QEPTS based trace gas sensing: a review. Front. Phys. 2020;8:268. [Google Scholar]

- 22.Russo S.D., Zifarelli A., Patimisco P., Sampaolo A., Wei T.T., Wu H.P., Dong L., Spagnolo V. Light-induced thermo-elastic effect in quartz tuning forks exploited as a photodetector in gas absorption spectroscopy. Opt. Express. 2020;28:19074–19084. doi: 10.1364/OE.393292. [DOI] [PubMed] [Google Scholar]

- 23.Ma Y.F., He Y., Zhang L.G., Yu X., Zhang J.B., Sun R., Tittel F.K. Ultra-high sensitive acetylene detection using quartz-enhanced photoacoustic spectroscopy with a fiber amplified diode laser and a 30.72 kHz quartz tuning fork. Appl. Phys. Lett. 2017;110 [Google Scholar]

- 24.Wu H., Dong L., Yin X., Sampaolo A., Patimiscoc P., Ma W., Zhang L., Yin W., Xiao L., Spagnolo V., Jia S. Atmospheric CH4 measurement near a landfill using an ICL-based QEPAS sensor with V-T relaxation self-calibration. Sens. Actuators B. 2019;297 [Google Scholar]

- 25.Ma Y.F., He Y., Yu X., Chen C., Sun R., Tittel F.K. HCl ppb-level detection based on QEPAS sensor using a low resonance frequency quartz tuning fork. Sens. Actuators B. 2016;233:388–393. [Google Scholar]

- 26.Ma Y.F., Hu Y.Q., Qiao S.D., He Y., Tittel F.K. Trace gas sensing based on multi-quartz-enhanced photothermal spectroscopy. Photoacoustics. 2020;20 doi: 10.1016/j.pacs.2020.100206. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Zhang Q.D., Chang J., Cong Z.H., Wang Z.L. Long-path quartz tuning fork enhanced photothermal spectroscopy gas sensor using a high power Q-switched fiber laser. Measurement. 2020;156 [Google Scholar]

- 28.Ma Y.F., He Y., Patimisco P., Sampaolo A., Qiao S.D., Yu X., Tittel F.K., Spagnolo V. Ultra-high sensitive trace gas detection based on light-induced thermoelastic spectroscopy and a custom quartz tuning fork. Appl. Phys. Lett. 2020;116(1) [Google Scholar]

- 29.Lu J., Zhang X.X., Wu X.Q., Dai Z.Q., Zhang J.B. A Ni-doped carbon nanotube sensor for detecting oil-dissolved gases in transformers. Sensors. 2015;15(6):13522–13532. doi: 10.3390/s150613522. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Vogler D.E., Sigrist M.W. Near-infrared laser based cavity ringdown spectroscopy for applications in petrochemical industry. Appl. Phys. B. 2006;85:349–354. [Google Scholar]

- 31.Hu Y.Q., Qiao S.D., He Y., Lang Z.T., Ma Y.F. Quartz-enhanced photoacoustic-photothermal spectroscopy for trace gas sensing. Opt. Express. 2021;29(4):5121–5127. doi: 10.1364/OE.418256. [DOI] [PubMed] [Google Scholar]

- 32.Wu H., Dong L., Zheng H., Yu Y., Ma W., Zhang L., Yin W., Xiao L., Jia S., Tittel F.K. Beat frequency quartz-enhanced photoacoustic spectroscopy for fast and calibration-free continuous trace-gas monitoring. Nat. Commun. 2017;8:15331. doi: 10.1038/ncomms15331. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Dong L., Kosterev R.A., Thomazy R., Tittel F.K. QEPAS spectrophones: design, optimization, and performance. Appl. Phys. B. 2010;100(3):627–635. [Google Scholar]

- 34.Patimisco P., Scamarcio G., Tittel F.K., Spagnolo V. Quartz-enhanced photoacoustic spectroscopy: a review. Sensors. 2014;14(4):6165–6206. doi: 10.3390/s140406165. [DOI] [PMC free article] [PubMed] [Google Scholar]