Abstract

The macromolecule oligo(poly(ethylene glycol) fumarate) (OPF) exhibits promising attributes for creating suitable three-dimensional hydrogel environments to study cell behavior, deliver therapeutics, and serve as a degradable, nonfouling material. However, traditional synthesis techniques are time consuming, contain salt contaminants, and generate significant waste. These issues have been overcome with an alternative, one-pot approach that utilizes inert gas sparging. Departing from previous synthetic schemes that require acid scavengers, inert gas sparging removes byproducts in situ, eliminating significant filtration and postprocessing steps, while allowing a more uniform product. Characterized by nuclear magnetic resonance, gel permeation chromatography, and differential scanning calorimetry, nitrogen sparge synthesis yields an OPF product with greater polymer length than traditional acid scavenger synthesis methods. Furthermore, nitrogen-sparged OPF readily crosslinks using either ultraviolet or thermal initiator methods with or without the addition of short-chain diacrylate units, allowing for greater tunability in hydrogel properties with little to no cytotoxicity. Overall, inert gas sparging provides a longer chain and cleaner polymer product for hydrogel material studies while maintaining degradable characteristics.

Impact statement

Using nitrogen sparging, we have demonstrated that oligo(poly(ethylene glycol) fumarate) (OPF) can be produced with decreased postprocessing, increased product purity, greater oligomerization, and cell viability. These properties lead to greater tunability in mechanical properties and a more versatile hydrogel for biomedical applications. The simplification of synthesis and elimination of impurities will expand the utility of OPF as a degradable hydrogel for cell culture, tissue engineering, regenerative medicine, and therapeutic delivery, among other applications.

Keywords: oligo(poly(ethylene glycol) fumarate), OPF, polyethylene glycol, polymers, hydrogel

Introduction

Oligo(poly(ethylene glycol) fumarate) (OPF) has been extensively investigated as a biodegradable hydrogel for use in tissue-engineered scaffolds and drug delivery.1–13 The step-growth polymerization of polyethylene glycol (PEG) and fumaryl chloride (FuCl) produces a linear polyester with hydrochloric acid (HCl) byproducts. The resulting oligomer consists of a repeating scheme of PEG and fumarate, which can be chemically crosslinked into a nonfouling hydrogel (Fig. 1). The ability of OPF to undergo hydrolytic degradation through ester hydrolysis gives OPF greater utility over previous polyethylene glycol diacrylate (PEGDA) hydrogels.14–17 In addition, the physical properties of OPF can be easily tailored by changing the PEG length.1,18 Due to the presence of unsaturated double bonds, functionalization of the oligomer backbone can be achieved before or during crosslinking with the incorporation of short-chain molecules.4,10 Overall, these factors make OPF a desirable synthetic polymer for multiple applications.

FIG. 1.

Glassware set-up for the one-pot polycondensation of FuCl with PEG in DCM using (A) the acid scavenger TEA or (B) nitrogen sparging to remove HCl byproducts. (C) OPF reaction schemes for TEA-OPF and (D) (N2-OPF). (E) Crosslinking structure of OPF oligomers through consumption of unsaturated double bonds. DCM, dichloromethane; FuCl, fumaryl chloride; HCl, hydrochloric acid; N2-OPF, nitrogen-sparged OPF; OPF, oligo(poly(ethylene glycol) fumarate); PEG, polyethylene glycol; TEA, triethylamine.

Developed by Jo et al., OPF synthesis has not been significantly modified since its inception.1,2,19 However, several groups have reported issues with removal of HCl byproducts affecting crosslinking efficiency and cell viability.20–22 To trap HCl, groups have used acid scavengers such as triethylamine (TEA), potassium carbonate, and sodium hydroxide.16,23–28 However, batch-to-batch inconsistencies in polymer product are common due to inefficient removal of insoluble HCl-acid scavenger salts.22

Common in waste treatment and manufacturing procedures, sparging is a fast and efficient method easily introduced into the processing environment.29–33 By bubbling a chemically inert gas such as nitrogen through a liquid, sparging removes low boiling-point solutes in real-time.32,33 Furthermore, the introduction of compressed gas into the system serves as a heat sync through adiabatic expansion, maintaining the low temperatures required for efficient step-growth polycondensation.34 Through the introduction of gas sparging, we have developed a one-pot, straight-forward, and improved method for the production of OPF while simultaneously eliminating the complications of acid removal, filtration, and postprocessing.

Materials and Methods

Reagents and chemicals

PEG (Mn 4600), FuCl, ascorbic acid (AA), Irgacure 2959, trimethylamine, PEGDA (Mn 575), deuterated chloroform, and tetrahydrofuran were purchased from Sigma-Aldrich. Ammonium persulfate (APS; ACS grade) and ethanol along with cell culture reagents, Dulbecco's minimum essential growth medium (DMEM), fetal bovine serum (FBS), phosphate-buffered saline (PBS), penicillin–streptomycin, fungizone, trypsin-ethylenediaminetetraacetic acid (EDTA), and live/dead cell viability kit were purchased from ThermoFisher Scientific. Dichloromethane (DCM), ethyl ether, ethyl acetate, anhydrous toluene (99.8%), and sodium hydroxide were purchased from EMD Millipore.

OPF synthesis

PEG drying

PEG was dried by azeotropic distillation before use as previously described.2 In brief, 100 g of PEG was added to 200 mL of toluene. At least 150 mL of toluene and residual water were distilled off at 200°C. Toluene was removed on a rotary evaporator followed by drying in vaccuo overnight. Dried PEG was stored in a desiccator until used.

OPF oligomer synthesis—TEA-OPF

TEA-OPF was prepared according to previously described methods.1,2 In brief, dried PEG (100 g) was dissolved in 700 mL of DCM in a 1 L three-neck round bottom flask set in an ice bath (Fig. 1A). Air was removed and replaced with a nitrogen environment. Using molar ratios of 1:0.9 PEG to FuCl and 1:2 FuCl to TEA, FuCl and TEA were dissolved in 60 mL DCM in separate addition funnels and simultaneously added dropwise to PEG solution over 4 h. The reaction was stirred vigorously. Upon complete addition of FuCl and TEA, the reaction mixture was continued over an ice bath overnight, followed by solvent removal in vacuo. The product was subsequently dissolved in warm ethyl acetate, chilled (−2°C) to recrystallize OPF and filtered to remove TEA-HCl salts (3 × ). After the final collection, the OPF was washed with ethyl ether and fully dried under reduced pressure overnight.

OPF oligomer synthesis—nitrogen sparging

Dried PEG (100 g) was dissolved in 700 mL DCM in a three-neck round bottom flask with a stir bar and nitrogen environment. Sparging with nitrogen was introduced through central arm with a 24/40 adaptor fitted with a fine-fritted gas dispersion tip and forced out through 90° flow control adapter into a secondary vessel containing 10 wt% sodium hydroxide in ethanol (Fig. 1B). FuCl was dissolved in 60 mL DCM at a molar ratio of 1:0.9 PEG to FuCl and added dropwise to the PEG solution over 4 h with vigorous stirring. Upon complete addition of FuCl to PEG solution, DCM was added to the reaction mixture to bring the volume back up to 700 mL. The reaction was allowed to progress overnight with sparging followed by solvent removal in vacuo.

OPF characterization

OPF structure

OPF products were characterized by hydrogen nuclear magnetic resonance (1H NMR) 300M Hz (Bruker Avance III 300; TopSpin V3.5) in deuterated chloroform. Peaks were assigned to confirm the hydrogen binding environment. The degree of polymerization was assessed through peak integration comparing olefin (6.87 ppm) and PEG (3.38–3.85 ppm) functional groups.

Molecular weight and oligomerization

Molecular weight of OPF was determined through gel permeation chromatography (GPC). Styragel HR 4 + 4E, 7.8 × 300 mm (WAT044225 and WAT044240) columns were used to elute the samples at a 1 mL/min flow rate on an Agilent 1100 Series high-performance liquid chromatography system (Hewlett Packard, RID G1362A; Chemstation B.04.01). Four to five samples of 3 mg were run in 1 mL of tetrahydrofuran. Sample weight-average (Mw) and number-average molecular weights (Mn) were calculated compared to PEG standards (PL2070-194, 440, 600, 1080, 1470, 4100, 7100, 12,600, 23,600; Polymer Laboratories/Agilent Technologies). The degree of oligomerization (Xn) was determined using Equation (1):

| (1) |

here, Mn, OPF and Mn, PEG represent the number-average molecular weight (Mn) of OPF, and monomeric PEG as determined by GPC.

Changes in molecular weight over time were measured by removing a small volume (1 mL) of OPF product from both TEA-OPF and nitrogen-sparged OPF (N2-OPF) synthesis reaction vessels over the initial 14 h of synthesis in parallel reactions. Solvent was removed in vacuo and 3 mg of product were suspended in 1 mL tetrahydrofuran. Refractive index intensity was normalized to the highest peak of the eluted product.

Fluorescent byproduct

Fluorescence of the polymer product was detected during GPC through the use of a fluorescence detector (Hewlett Packard, FLD G1321A, Ex 250 nm, Em 410 nm) upstream of the refractive index detector; retention time difference ∼1 min.

Melting temperature and crystallinity

Differential scanning calorimetry (DSC; TA instruments model 2920, Netzsch Proteus) was carried out to determine the crystallinity and melting properties of OPF. Samples were analyzed at a heating rate of 10°C/min from 0°C to 70°C. Melting temperature and the heat of fusion, ΔHm (cal/g), were obtained from the thermograms. The percent crystallinity (X) of OPF was determined from the following equation:

| (2) |

here, H*m, is the theoretical heat of fusion of 100% crystalline PEG (49 cal/g).35

Percent yield

Percent yield was calculated by weighing the product recovered from the reaction and dividing it by the weight of reagents originally added.

| (3) |

Characterization of crosslinked OPF hydrogels

Crosslinking of OPF

OPF hydrogel products were crosslinked with and without PEGDA (Sigma Aldrich). The ultraviolet (UV) crosslinked formulations were as follows: 25% (wt%) OPF, 0.5% Irgacure 2959 initiator, 74.5% deionized water or 16.5% OPF, 8.5% PEGDA, 0.5% Irgacure 2959 initiator, and 74.5% deionized water. UV formulations were exposed to 365 nm UV light in a CL-1000 lightbox (UltraViolet Products, UVP) for 15 min. The thermally crosslinked hydrogels had the same formulations stated above, except that 17.6 × 10−6 wt% (0.1 mM) AA with 22.8 × 10−6 wt% (0.1 mM) APS was added in place of Irgacure 2959. Polymer solutions (1 mL) were transferred to syringe molds before crosslinking.21 Thermally initiated formulations were placed in the incubator (37°C) for 15 min to form hydrogels. Final products were dried overnight at room temperature before being placed in the vacuum oven for 24 h.

Swell ratio and sol fraction

Hydrogels were weighed after drying in a vacuum oven to measure the initial mass of polymer (Wi). Hydrogels were then soaked in 5 mL of deionized water and allowed to swell. After 4 days, the maximum swollen weight (Ws) was recorded. Swollen gels were then removed from water and redried in the vacuum oven for 48 h before being weighed to measure the final dry weight (Wd). The swelling ratio was calculated by subtracting the dry weight (Wd) from the wet weight (Ws), then dividing by the final dry weight (Wd) [Eq. (4)]. Sol fraction was calculated taking the initial dry weight (Wi) minus the final dry weight (Wd) divided by the initial dry weight (Wi) [Eq. (5)]. Sample size of six hydrogels was tested for swelling ratio and sol fraction.

| (4) |

| (5) |

Hydrogel elasticity

Hydrogel samples of height to width of 2:1 (diameter = 5 mm) were fabricated for compression testing on an mechanical testing system (MTS) (Chatillon TCD 200; Wagner Instruments, Greenwich, CT, USA). Before testing, hydrogels were swollen in deionized (DI) water for 12 h in ambient conditions. Compression testing was run on an unclosed platform using flat platen with a crosshead speed of 5 mm/min. Load and displacement was recorded until failure, in which the Young's modulus was determined by calculating the stress versus strain curves and determining the slope of the elastic region.

Cytotoxicity analysis

NIH/3T3 cells were purchased from ATCC (CRL-1658) and cultured in DMEM medium supplemented with 10% FBS and 1% penicillin–streptomycin and fungizone and maintained at 37°C with 5% carbon dioxide. Culture medium was changed every 2 days.

In vitro cytotoxicity was investigated using live/dead viability cytotoxicity kit. Cells were enzymatically removed (0.25% trypsin-EDTA), seeded in 24-well plates at 40,000 cells/cm2. Following 24-h attachment and incubation, the cells were treated by adding 500 μL of 25% (wt%) hydrogel solutions dissolved in growth media with and without thermal crosslinking initiators (0.1 mM AA/APS) and copolymer PEGDA (16.5% OPF and 8.5% PEGDA). After a 15 min incubation, 1 mL of additional media was added to each well. After an additional 24 h, cells were washed 3 × with PBS and stained with dye solutions according to manufacturer's instructions. In brief, 4 μM ethidium homodimer-1 and 2 μm calcein AM were reconstituted in growth media. Five hundred microliters of dye solution was added to each sample followed by a 45 min incubation. Cells were imaged using confocal microscopy (Olympus IX81; live: ex 488 nm/em BA505–525 nm, dead: ex 543 nm/em 560–660 nm) at a 40 × magnification. Control samples consisted of living cells, with media changes during solution exchange procedures, and dead controls incubated with 70% ethanol for 30 min before assay.

Statistics

All groups were compared in GraphPad Prism 6 starting with a one-way analysis of variance with 95% confidence interval. If significance was found, then a two-way t-test was used to determine statistical differences between treatments. Sample sizes equaled three unless otherwise noted.

Experiment

Physical characterization

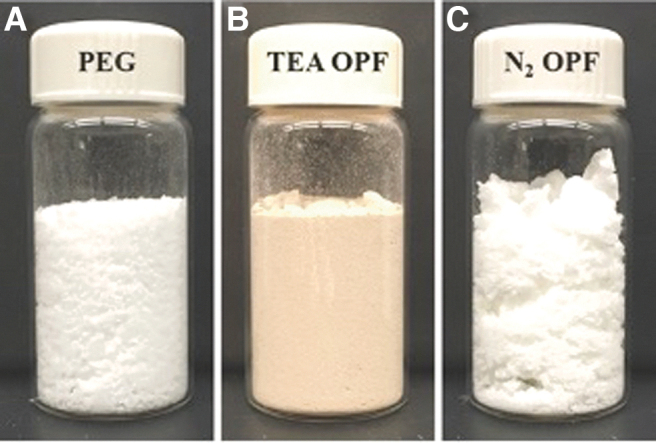

Nitrogen sparging technique exhibits visual and physical differences when compared to the TEA acid scavenger method. N2-OPF appeared to be whiter than TEA-OPF, comparable to the PEG (Mw 4600) precursor (Fig. 2). TEA-OPF had a light brown coloration to it even after postprocessing washes and precipitations, indicative of trace amount of HCl salts within the polymer.1 After N2-OPF went through the final drying stage, it appeared to be clumped due to intermolecular forces, while TEA-OPF had a fine grain consistency because of salt contamination. Furthermore, it was observed that TEA-OPF dissolved into aqueous solutions easier than the N2-OPF.

FIG. 2.

Samples of (A) precursor PEG (Mw 4600) material and OPF product using (B) TEA-OPF synthesis and (C) N2-OPF synthesis. Color images are available online.

Increased oligomerization of OPF utilizing nitrogen sparging methods

Proton NMR of TEA-OPF and N2-OPF schemes both show the formation of an ester bond at 4.33 ppm corresponding to the formation of PEG/fumarate oligomers. A shift in fumarate olefin signal from 7.87 ppm to 6.87 ppm also denotes attachment of FuCl to PEG (Fig. 3).36 DSC revealed no significant difference between the Tm and crystallinity of N2-OPF (60.7 ± 0.4°C and 64.1% ± 2.1%) and TEA-OPF (60.3 ± 1.3°C and 58.3% ± 3.4%; Table 1). However, the ratio of PEG hydroxyl end groups (3.01 ppm) to monomer units was lower in N2-OPF compared to TEA-OPF indicating increased oligomerization.

FIG. 3.

1H NMR spectra of 4.6 K OPF from (A) nitrogen sparging or (B) TEA scavenging methods. The presence of ester groups (b, 4.33 ppm) and olefin groups (c, 6.87 ppm) indicate bond formation and oligomerization of OPF. NMR (300 MHz) measurements were carried out in CDCl3 (7.24 ppm). Some residual DCM can be observed at 5.26 ppm with TEA contaminates at 1.43 ppm. CDCl3, deuterated chloroform; 1H NMR, hydrogen nuclear magnetic resonance.

Table 1.

Material Properties of Triethylamine-Oligo(Poly(ethylene glycol) Fumarate) and Nitrogen-Sparged Oligo(Poly(ethylene glycol) Fumarate)

| Synthesis method | Percentage of yield | Tm (°C) | Percentage of crystallinity (X) | Mn (g/mol) | Mw (g/mol) | PDI | Xn |

|---|---|---|---|---|---|---|---|

| TEA-OPF | 86.8 ± 9.2 | 60.7 ± 0.4 | 64.1 ± 2.1 | 7779 ± 847 | 10,891 ± 1368 | 1.4 ± 0.04 | 1.8 ± 0.2 |

| N2-OPF | 95.1 ± 3.0 | 60.3 ± 1.3 | 58.3 ± 3.4 | 13,097 ± 3494 | 17,271 ± 3632* | 1.3 ± 0.06* | 3.93 ± 0.8* |

All OPF synthesized with 4.6 K PEG.

Mn, number average molecular weight; Mw, weight average molecular weight; N2-OPF, nitrogen-sparged OPF; OPF, oligo(poly(ethylene glycol) fumarate); PDI, polydispersity index; PEG, polyethylene glycol; TEA, triethylamine; Xn, degree of polymerization.

p < 0.05, n = 3–4.

Utilizing size exclusion chromatography to determine N2-OPF molecular weight (Mw = 17,271 ± 3632) and degree of polymerization (Xn = 3.9 ± 0.8) confirmed significant increases in OPF oligomerization over TEA-OPF (Mw = 10,891 ± 1368, Xn = 1.8 ± 0.2; Table 1 and Figs. 4A and 5A, B). Furthermore, N2-OPF had a significantly lower polydispersity index 1.3 ± 0.06 compared to TEA-OPF 1.4 ± 0.04, indicating a more homogeneous product (Table 1 and Fig. 4A). OPF product removed during both reactions shows the difference in rate of oligomerization during TEA-OPF and N2-OPF processing (Fig. 5). However, fluorescent analysis of eluted TEA-OPF revealed a fluorescent molecule associated with the elution of TEA-OPF oligomers that is absent from N2-OPF (Fig. 4B).

FIG. 4.

(A) Representative elution profiles of OPF polymer products and pure 4.6 K PEG as determined by GPC. Decreased retention time indicates higher molecular weight N2-OPF oligomers. (B) Fluorescence profiles of OPF products and 4.6 K PEG were collected in series with GPC. A large fluorescence peak was detected only in TEA-OPF indicating unremoved TEA-HCl, Ex 250 nm/Em 410 nm. GPC, gel permeation chromatography.

FIG. 5.

During synthesis, small samples of (A) N2-OPF and (B) TEA-OPF product were removed periodically over 14 h and analyzed by GPC. Each labeled peak (i–iv) corresponds to an increasing oligomer length. TEA method limits molecular weight after addition of fumarate to reaction vessel (4 h). Color images are available online.

Characteristics of crosslinked hydrogels

Using the thermal initiator AA/APS, N2-OPF crosslinked by itself and had a significantly higher swell ratio than all other groups (Fig. 6). However, when crosslinked in the presence of PEGDA, there was no difference in water uptake between TEA-OPF and N2-OPF hydrogels. Using UV initiation, N2-OPF with PEGDA had a significantly lower sol fraction than UV-initiated N2-OPF without PEGDA but no comparison could be made with TEA-OPF as it would not crosslink using the UV initiator even with the addition of PEGDA (Fig. 6). Furthermore, TEA-OPF by itself did not crosslink with either UV or thermal crosslinking methods, while N2-OPF crosslinked under all conditions (Fig. 6).

FIG. 6.

Swelling ratio of crosslinked OPF hydrogels using (A) thermal and (C) UV initiator methods. Sol Fraction of crosslinked OPF hydrogels using (B) thermal and (D) UV initiator methods. Swelling of N2-OPF without PEGDA was significantly greater than all other gels, †p < 0.05, n = 6. UV-initiated N2-OPF with PEGDA had significantly lower sol fraction than N2-OPF without PEGDA, ††p < 0.05, n = 6. Δ indicates that gels did not crosslink sufficiently to be characterized. PEGDA, polyethylene glycol diacrylate; UV, ultraviolet.

Compressive modulus of the OPF varied in range from 7.32 ± 1.39 to 189.23 ± 56.04 KPa, depending on the synthesis and crosslinking method, as well as presence of PEGDA linker (Mn 575; Fig. 7). TEA-OPF only crosslinked with the addition of PEGDA linkers and thermal crosslinking initiators. Following crosslinking, TEA-OPF's modulus was 20.67 ± 1.77 kPa while the N2-OPF hydrogels was 82.59 ± 10.62 KPa, roughly a three-fold increase in compressive modulus. The presence of PEGDA also has the same trend of increasing stiffness. Photoinitiated and thermal initiated crosslinking methods with PEGDA caused photoinitiated hydrogels to have a higher modulus (189.23 ± 56.04 KPa) than thermally initiated hydrogels (82.59 ± 10.62 KPa). Statistics indicated that all OPF hydrogel moduli were significantly different (p < 0.05).

FIG. 7.

Compression strength of OPF hydrogels with and without PEGDA linkers, and UV or thermally crosslinked. N2-OPF hydrogels crosslinked with both UV and thermal initiators, with and without PEGDA linkers. TEA-OPF only crosslinked with thermal initiation with PEGDA linkers. All hydrogel types had significantly different moduli, †p < 0.05, n = 8. N2-OPF with PEGDA hydrogels had a significantly stronger modulus, ††p < 0.05, n = 8.

Cell viability in the presence of polymer products

The influence of OPF oligomer products on cell growth and viability was examined by 24 h incubation of NIH/3T3 cells with different OPF hydrogel solutions. The cytotoxicity of all thermal initiator containing solutions was significant and resulted in low viability in culture. With the addition of PEGDA, little increase in viability was observed. Furthermore, PEGDA alone was shown to be acutely toxic to cells (Fig. 8). To assess the cytotoxicity of individual OPF products, solutions containing 25 wt% N2- and TEA-OPF in complete growth media were exposed to cells for 24 h. As a result of residual TEA-HCl salts, cells exposed to TEA-OPF alone were nonviable after 24 h, while cells exposed to N2-OPF were over 90% viable in culture (Fig. 8).

FIG. 8.

Cell viability and cytotoxicity staining of NIH/3T3 (A) living controls compared to cell exposed to (B) N2-OPF, (C) PEGDA, and (D) TEA-OPF solutions. TEA-OPF as well as the required secondary crosslinker PEGDA shows acute toxicity, while N2-OPF shows no toxicity over live cell controls. Images are colocalized (green = live, red = dead, Scale 50 μm). Color images are available online.

Discussion

The reaction of PEG and FuCl form linear polyester dimers, trimers, and eventually oligomers in a step-growth process. The primary limitation of this reaction is the production of HCl byproducts which must be isolated to prevent secondary reactions. Previously, removal of HCl was accomplished by acid scavengers such as TEA, potassium carbonate, or sodium hydroxide.16,23–28 In the current work, OPF synthesis using TEA was compared to an OPF synthesis using nitrogen sparging. The use of sparging for the in situ removal of HCl eliminates the need for an acid scavenger, thereby avoiding the production of difficult to remove TEA salts.

For both reaction methods, formation of PEG/fumarate oligomers was confirmed by 1H NMR. With greater olefin (6.87 ppm) to PEG (3.38–3.85 ppm) ratio and a reduction in signal from PEG hydroxyl end-groups (3.01 ppm), N2-OPF resulted in a greater degree of oligomerization and larger molecular weight than TEA-OPF synthesis methods.1 Size exclusion chromatography confirms a significant increase in N2-OPF molecular weight and a more uniform product over TEA-OPF (Table 1 and Figs. 4A and 5A, B).

In side-by-side comparison of TEA-OPF and N2-OPF reactions, temporal analysis of the product demonstrates a limited maximum achievable molecular weight using TEA-OPF methods. After 4 h, the maximum molecular weight was obtained by TEA-OPF with no additional oligomerization at subsequent time points. In contrast, the oligomerization of the N2-OPF method continues through 12 h (Fig. 5). In step-growth processes, the final conversion, and hence the average molecular weight, is affected by the concentration of condensation byproducts.37 In situ removal of acid byproducts during nitrogen sparging eliminates TEA salt formation allowing for the synthesis of a higher molecular weight OPF (Fig. 5A).1,22

In contrast to the nitrogen sparge method, TEA-OPF synthesis requires the additional steps of filtration, recrystallization, and solvent washing to remove acidic byproducts.1,2 The incomplete removal of TEA salts during filtration, recrystallization, and solvent washing is apparent in 1H NMR (1.4 ppm). The TEA-OPF also retains a brown coloration even after repeated filtrations steps. Alternatively, the pure N2-OPF appears white immediately after synthesis and does not require additional purification steps. Fluorescent analysis of eluted product through GPC reveals the presence of a fluorescent molecule within TEA-OPF that is absent in N2-OPF (Fig. 4B). The fluorescent signal corresponds with the elution time of TEA-OPF oligomers, indicating that the TEA salts are complexed to the OPF backbone. Cai and Wang have previously reported the formation of cell-cytotoxic TEA complexes during polymerization of FuCl, in the presence of TEA, that cannot be completely removed during purification.22 This behavior is confirmed in the cytotoxicity analysis of OPF products.

To examine the crosslinking capabilities of N2-OPF and TEA-OPF, two different commonly used free-radical initiator systems were applied; AA/APS, a thermally activated initiator, and Irgacure 2959, a UV activated initiator.1,2,20,21,38 In addition, hydrogels were fabricated with and without PEGDA, a copolymer commonly used in the crosslinking of PEG-based hydrogels due to the presence of highly reactive acrylic end groups. The use of PEGDA allows for more efficient network formation of resulting hydrogels.39,40

Hydrogels were successfully crosslinked with AA/APS and PEGDA for both TEA-OPF and N2-OPF. However, UV-initiated TEA-OPF/PEGDA and TEA-OPF hydrogels did not crosslink adequately to maintain their three-dimensional structure when placed in water, and subsequently fell apart. In comparison, N2-OPF readily crosslinked using both initiator systems with and without PEGDA, highlighting the versatility of N2-OPF product (Figs. 6 and 7). The inefficient removal of TEA salts in the TEA-OPF synthesis method is likely a significant factor in the crosslinking behavior of TEA-OPF. The presence of TEA salts limits UV intensity and penetration into the gels. Also, the TEA salts may directly interfere with free-radical propagation and crosslinking reaction. To overcome the limitations of TEA-OPF, previous groups have increased reaction time to an hour to fully crosslink TEA-OPF.1,18,21 As OPF is commonly used as a biomaterial for cell encapsulation, minimizing UV exposure time reduces cellular cytotoxicity.20,21 Crosslinking of hydrogels was therefore limited to a 15 min exposure period, a time which has been shown to optimally balance the crosslinking reaction with cell viability.21

Fully crosslinked OPF hydrogels exhibited swelling characteristics dependent on the synthesis method and the use of the crosslinking molecule. Using AA/APS and PEGDA as the crosslinker, there was no difference in swelling between TEA-OPF and N2-OPF hydrogels. While TEA-OPF did not crosslink using the UV initiator, the choice of initiator did not influence the swelling of the N2-OPF/PEGDA hydrogels. Furthermore, N2-OPF was able to form hydrogels without the addition PEGDA, but resulted in a hydrogel with less crosslinking density and greater water uptake capability (Fig. 6A).17,41

All formulations were fabricated into gels of a 2:1 height to diameter ratio (diameter = 5 mm). As seen with the swell ratio study, the only TEA-OPF formulation that maintained its integrity was the TEA-OPF with PEGDA and the thermal initiator, so it was the only TEA-OPF formulation studied. When compared to thermally crosslinked TEA-OPF with PEGDA, N2-OPF was found to be four times stronger than the TEA-OPF hydrogels (Fig. 7). This is due to the lack of crosslinking efficiency of the TEA-OPF, in part, to the reduced quantity of fumaryl groups in each TEA-OPF molecule. In addition, the presence of HCl salts in the TEA-OPF could be hindering the crosslinking efficiency, which explains the reduced amount of crosslinking, thus leading to a weaker modulus when compared to thermally crosslinked N2-OPF with PEGDA.

The presence of PEGDA, a known linker for creating uniform polymer networks, increased the moduli of both thermal and photoinitiated N2-OPF hydrogels.42,43 As such, PEGDA allows for tunable compressive moduli ranging from 7 to 190 kPa. Interestingly, when N2-OPF was crosslinked with PEGDA the modulus of UV crosslinking was increased over thermal crosslinking methods. However, in the absence of PEGDA thermal initiation method exhibited increased the modulus over UV methods. It is believed that the UV crosslinking is more efficient at radicalizing the acrylates in PEGDA, resulting in a higher density of crosslinkable bonds, thus a stiffer material.42–44 The sol fraction of the N2-OPF with PEGDA supports that more of the hydrogel solutions has been crosslinked (Fig. 6).44

Since N2-OPF is the only product that can be crosslinked with and without PEGDA and utilize both light and heat activated free-radical initiators, N2-OPF can be fabricated into hydrogels with a wider range of mechanical properties, increasing its utility beyond that of TEA-OPF.45

The importance of producing a polymer, which can be crosslinked without the addition of PEGDA, becomes even more apparent when cell cytotoxicity is analyzed. With the addition of PEGDA, significant cytotoxicity of NIH/3T3 cells was observed (Fig. 8). Similar behavior has been observed in low molecular weight PEG methyl ether acrylate (Mn ∼ 480) solutions, caused by a decline in the antioxidant levels of glutathione and increased intracellular reactive oxygen cytotoxicity.46 Furthermore, the exposure of cells to uncrosslinked N2-OPF showed little cytotoxicity, while TEA-OPF solutions showed significant cell death due to the persistence of cytotoxic HCl salts.22

Conclusion

Through nitrogen sparging, we have shown that OPF can be produced with decreased postprocessing, increased product purity, greater oligomerization, and cell viability. These properties lead to greater tunability in mechanical properties and a more versatile hydrogel for biomedical applications. Instead of using TEA, an acid scavenger, in situ nitrogen gas sparging eliminates the need for postprocessing washes using ethyl acetate and ethyl ether, which have proven to be inefficient while also being acutely toxic and potentially explosive through peroxide formation. With greater oligomerization, N2-OPF has more unsaturated double bonds per molecule that can be used for crosslinking and addition of covalently bound side chains. This straightforward method of fabrication allows for facile production that eliminates postprocessing. The simplification of synthesis and elimination of impurities will expand the utility of N2-OPF as a degradable hydrogel for cell culture, tissue engineering, regenerative medicine, and therapeutic delivery, among other applications.

Acknowledgments

The authors thank Dr. Shawn Dirk and Dr. Chester Simoko for their assistance with OPF synthesis and hydrogel characterization, respectively.

Authors' Contributions

M.N.R. wrote and edited the article. K.E.C., C.T.D., D.S., Q.M.H., K.N.C., and E.L.H-D. reviewed the article and provided feedback. All authors agreed on the final version of the article.

Disclosure Statement

No competing financial interests exist.

Funding Information

This work was supported by awards from the American Heart Association (10BGIA4570031), the National Science Foundation (CBET 1351947), NSF IGERT (0504276), NSF LS-AMP (HER1026412 [BDVIII]), NIH IMSD (5R25-GM060201), and NIH PREP (R25-GM075149). This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy (DOE), Office of Science by Los Alamos National Laboratory (Contract DE-AC52–06NA25396), and Sandia National Laboratories (Contract DE-AC04-94AL85000).

References

- 1. Jo, S., Shin, H., Shung, A.K., Fisher, J.P., and Mikos, A.G.. Synthesis and characterization of oligo(poly(ethylene glycol) fumarate) macromer. Macromolecules 34, 2839, 2001 [Google Scholar]

- 2. Kinard, L.A., Kasper, F.K., and Mikos, A.G.. Synthesis of oligo(poly(ethylene glycol) fumarate). Nat Protoc 7, 1219, 2012 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3. Ewald, T.J., Walker, J.A., Lewallen, E.A., et al. Safety of intra-articular implantation of oligo poly(ethylene glycol) fumarate scaffolds into the rabbit knee. Tissue Eng Part C Methods 22, 991, 2016 [DOI] [PubMed] [Google Scholar]

- 4. Hakim, J.S., Rad, M.E., Grahn, P.J., et al. Positively charged oligo poly(ethylene glycol) fumarate scaffold implantation results in a permissive lesion environment after spinal cord injury in rat. Tissue Eng Part A 21, 2099, 2015 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5. Lam, J., Lu, S., Kasper, F.K., and Mikos, A.G.. Strategies for controlled delivery of biologics for cartilage repair. Adv Drug Deliv Rev 84, 123, 2015 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6. Guo, X., Park, H., Young, S., et al. Repair of osteochondral defects with biodegradable hydrogel composites encapsulating marrow mesenchymal stem cells in a rabbit model. Acta Biomater 6, 39, 2010 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7. Kim, K., Lam, J., Lu, S., et al. Osteochondral tissue regeneration using a bilayered composite hydrogel with modulating dual growth factor release kinetics in a rabbit model. J Control Release 168, 166, 2013 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8. Park, H., Temenoff, J.S., Tabata, Y., Caplan, A.I., and Mikos, A.G.. Injectable biodegradable hydrogel composites for rabbit marrow mesenchymal stem cell and growth factor delivery for cartilage tissue engineering. Biomaterials 28, 3217, 2007 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9. Park, H., Temenoff, J.S., Holland, T.A., Tabata, Y., and Mikos, A.G.. Delivery of TGF-beta 1 and chondrocytes via injectable, biodegradable hydrogels for cartilage tissue engineering applications. Biomaterials 26, 7095, 2005 [DOI] [PubMed] [Google Scholar]

- 10. Jo, S., Shin, H., and Mikos, A.G.. Modification of oligo(poly(ethylene glycol) fumarate) macromer with a GRGD peptide for the preparation of functionalized polymer networks. Biomacromolecules 2, 255, 2001 [DOI] [PubMed] [Google Scholar]

- 11. Park, H., Guo, X., Temenoff, J.S., et al. Effect of swelling ratio of injectable hydrogel composites on chondrogenic differentiation of encapsulated rabbit marrow mesenchymal stem cells in vitro. Biomacromolecules 10, 541, 2009 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12. Kasper, F.K., Seidlits, S.K., Tang, A., et al. In vitro release of plasmid DNA from oligo(poly(ethylene glycol) fumarate) hydrogels. J Control Release 104, 521, 2005 [DOI] [PubMed] [Google Scholar]

- 13. Holland, T.A., Tabata, Y., and Mikos, A.G.. In vitro release of transforming growth factor-beta 1 from gelatin microparticles encapsulated in biodegradable, injectable oligo(poly(ethylene glycol) fumarate) hydrogels. J Control Release 91, 299, 2003 [DOI] [PubMed] [Google Scholar]

- 14. Scott, R.A., and Peppas, N.A.. Compositional effects on network structure of highly cross-linked copolymers of PEG-containing multiacrylates with acrylic acid. Macromolecules 32, 6139, 1999 [Google Scholar]

- 15. Scott, R.A., and Peppas, N.A.. Kinetics of copolymerization of PEG-containing multiacrylates with acrylic acid. Macromolecules 32, 6149, 1999 [Google Scholar]

- 16. Lu, S., and Anseth, K.S.. Release behavior of high molecular weight solutes from poly(ethylene glycol)-based degradable networks. Macromolecules 33, 2509, 2000 [Google Scholar]

- 17. Keys, K.B., Andreopoulos, F.M., and Peppas, N.A.. Poly(ethylene glycol) star polymer hydrogels. Macromolecules 31, 8149, 1998 [Google Scholar]

- 18. Temenoff, J.S., Athanasiou, K.A., LeBaron, R.G., and Mikos, A.G.. Effect of poly(ethylene glycol) molecular weight on tensile and swelling properties of oligo(poly(ethylene glycol) fumarate) hydrogels for cartilage tissue engineering. J Biomed Mater Res 59, 429, 2002 [DOI] [PubMed] [Google Scholar]

- 19. Jo, S., and Mikos, A.G.. Biocompatible Macromers [US Patent]. University Rice William Marsh 2000, US6884778B2 [Google Scholar]

- 20. Shin, H., Temenoff, J.S., and Mikos, A.G.. In vitro cytotoxicity of unsaturated oligo poly(ethylene glycol) fumarate macromers and their cross-linked hydrogels. Biomacromolecules 4, 552, 2003 [DOI] [PubMed] [Google Scholar]

- 21. Temenoff, J.S., Shin, H., Conway, D.E., Engel, P.S., and Mikos, A.G.. In vitro cytotoxicity of redox radical initiators for cross-linking of oligo(poly(ethylene glycol) fumarate) macromers. Biomacromolecules 4, 1605, 2003 [DOI] [PubMed] [Google Scholar]

- 22. Cai, L., and Wang, S.F.. Elucidating colorization in the functionalization of hydroxyl-containing polymers using unsaturated anhydrides/acyl chlorides in the presence of triethylamine. Biomacromolecules 11, 304, 2010 [DOI] [PubMed] [Google Scholar]

- 23. Peter, S.J., Suggs, L.J., Yaszemski, M.J., Engel, P.S., and Mikos, A.G.. Synthesis of poly(propylene fumarate) by scylation of propylene glycol in the presence of a proton scavenger. J Biomater Sci Polym Ed 10, 363, 1999 [DOI] [PubMed] [Google Scholar]

- 24. Suggs, L.J., Payne, R.G., Yaszemski, M.J., Alemany, L.B., and Mikos, A.G.. Synthesis and characterization of a block copolymer consisting of poly(propylene fumarate) and poly(ethylene glycol). Macromolecules 30, 4318, 1997 [Google Scholar]

- 25. Hedberg, E.L., Tang, A., Crowther, R.S., Carney, D.H., and Mikos, A.G.. Controlled release of an osteogenic peptide from injectable biodegradable polymeric composites. J Control Release 84, 137, 2002 [DOI] [PubMed] [Google Scholar]

- 26. Hedberg, E.L., Kroese-Deutman, H.C., Shih, C.K., et al. Effect of varied release kinetics of the osteogenic thrombin peptide TP508 from biodegradable, polymeric scaffolds on bone formation in vivo. J Biomed Mater Res Part A 72, 343, 2005 [DOI] [PubMed] [Google Scholar]

- 27. Hedberg, E.L., Shih, C.K., Lemoine, J.J., et al. In vitro degradation of porous poly(propylene fumarate)/poly(DL-lactic-co-glycolic acid) composite scaffolds. Biomaterials 26, 3215, 2005 [DOI] [PubMed] [Google Scholar]

- 28. Hedberg, E.L., Kroese-Deutman, H.C., Shih, C.K., et al. In vivo degradation of porous poly(propylene fumarate)/poly(DL-lactic-co-glycolic acid) composite scaffolds. Biomaterials 26, 4616, 2005 [DOI] [PubMed] [Google Scholar]

- 29. Bredwell, M.D., and Worden, R.M.. Mass-transfer properties of microbubbles. 1. Experimental studies. Biotechnol Prog 14, 31, 1998 [DOI] [PubMed] [Google Scholar]

- 30. Nosse, B., Schall, A., Jeong, W.B., and Reiser, O.. Optimization of ring-closing metathesis: inert gas sparging and microwave irradiation. Adv Synth Catal 347, 1869, 2005 [Google Scholar]

- 31. Miller, W.D., Fray, A.H., Quatroche, J.T., and Sturgill, C.D.. Suppression of a palladium-mediated homocoupling in a Suzuki cross-coupling reaction. Org Process Res Dev 11, 359, 2007 [Google Scholar]

- 32. Tufvesson, P., Bach, C., and Woodley, J.M.. A Model to assess the feasibility of shifting reaction equilibrium by acetone removal in the transamination of ketones using 2-propylamine. Biotechnol Bioeng 111, 309, 2014 [DOI] [PubMed] [Google Scholar]

- 33. Pedersen, S.L., and Jensen, K.J.. Instruments for automated peptide synthesis. In: Jensen, K.J., Shelton, P.T., and Pedersen, S.L., eds. Peptide Synthesis and Applications, 2nd ed., Chapter 15. Totowa: Humana Press Inc., 2013, pp. 215–224 [DOI] [PubMed] [Google Scholar]

- 34. Knight, R.D. Work, heat, and the first law of thermodynamics. In: Physics for Scientists and Engineers a Strategic Approach, 3rd ed., Chapter 17. Glenview, IL: Pearson Education Inc., 2013, pp. 488–490 [Google Scholar]

- 35. Chaikof, E.L., and Merrill, E.W.. Bulk properties of poly(ethylene oxide)/polysiloxane networks. New Polym Mat 2, 124, 1990 [Google Scholar]

- 36. Gordon, A.J., and Ford, R.A.. The Chemist's Companion: A Handbook of Practical Data, Techniques, and References. New York, NY: John Wiley & Sons, 1972 [Google Scholar]

- 37. Choi, K.Y., and McAuley, K.B.. Step-growth polymerization. In: Asua, J.M., ed. Polymer Reaction Engineering, Oxford: Wiley-Blackwell Publishing Ltd, 2007, pp. 273–314 [Google Scholar]

- 38. Dadsetan, M., Szatkowski, J.P., Yaszemski, M.J., and Lu, L.C.. Characterization of photo-cross-linked oligo poly(ethylene glycol) fumarate hydrogels for cartilage tissue engineering. Biomacromolecules 8, 1702, 2007 [DOI] [PubMed] [Google Scholar]

- 39. Sawhney, A.S., Pathak, C.P., and Hubbell, J.A.. Bioerodible hydrogels based on photopolymerized poly(ethylene glycol)-co-poly(hydroxy acid) diacrylaye macromers. Macromolecules 26, 581, 1992 [Google Scholar]

- 40. Timmer, M.D., Jo, S.B., Wang, C.Y., Ambrose, C.G., and Mikos, A.G.. Characterization of the cross-linked structure of fumarate-based degradable polymer networks. Macromolecules 35, 4373, 2002 [Google Scholar]

- 41. Valdesaguilera, O., Pathak, C.P., Shi, J., Watson, D., and Neckers, D.C.. Photopolymerization studies using visible-light photoinitiators. Macromolecules 25, 541, 1992 [Google Scholar]

- 42. Mironi-Harpaz, I., Wang, D.Y., Venkatraman, S., and Seliktar, D.. Photopolymerization of cell-encapsulation hydrogels: crosslinking efficiency versus cytotoxicity. Acta Biomater 8, 1838, 2012 [DOI] [PubMed] [Google Scholar]

- 43. Timmer, M.D., Ambros, C.G., and Mikos, A.G.. Evaluation of thermal- and photo-crosslinked biodegradable poly(propylene fumarate)-based networks. J Biomed Mater Res Part A 66, 811, 2003 [DOI] [PubMed] [Google Scholar]

- 44. Fisher, J.P., Dean, D., and Mikos, A.G.. Photocrosslinking characteristics and mechanical properties of diethyl fumarate/poly(propylene fumarate) biomaterials. Biomaterials 23, 4333, 2002 [DOI] [PubMed] [Google Scholar]

- 45. Lam, J., Kim, K., Lu, S., et al. A factorial analysis of the combined effects of hydrogel fabrication parameters on the in vitro swelling and degradation of oligo(poly(ethylene glycol) fumarate) hydrogels. J Biomed Mater Res Part A 102, 3477, 2014 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46. Liu, G.Q., Li, Y.S., Yang, L., et al. Cytotoxicity study of poly(ethylene glycol) derivatives. RSC Adv 7, 18252, 2017 [Google Scholar]