Abstract

With the ever-increasing development in science and technology, as well as social awareness, more requirements are imposed on the production and property of all materials, especially polymeric foams. In particular, rubber foams, compared to thermoplastic foams in general, have higher flexibility, resistance to abrasion, energy absorption capabilities, strength-to-weight ratio and tensile strength leading to their widespread use in several applications such as thermal insulation, energy absorption, pressure sensors, absorbents, etc. To control the rubber foams microstructure leading to excellent physical and mechanical properties, two types of parameters play important roles. The first category is related to formulation including the rubber (type and grade), as well as the type and content of accelerators, fillers, and foaming agents. The second category is associated to processing parameters such as the processing method (injection, extrusion, compression, etc.), as well as different conditions related to foaming (temperature, pressure and number of stage) and curing (temperature, time and precuring time). This review presents the different parameters involved and discusses their effect on the morphological, physical, and mechanical properties of rubber foams. Although several studies have been published on rubber foams, very few papers reviewed the subject and compared the results available. In this review, the most recent works on rubber foams have been collected to provide a general overview on different types of rubber foams from their preparation to their final application. Detailed information on formulation, curing and foaming chemistry, production methods, morphology, properties, and applications is presented and discussed.

Keywords: rubber, foam, morphology, curing, characterization, applications

1. Introduction

Cellular materials, commonly known as foams, both are widely used by man and appear in nature to reduce the weight of materials while increasing their strength [1]. Typical examples taken from nature are wood, cork, plant stalk, cancellous bone, sponge, coral, etc. [2], so the production of synthetic cellular materials was devoted to mimic nature leading to the development of one of the most important and widely used man-made class of materials with a wide range of applications in automobiles, aeronautics, packaging, medicine, construction, etc. [3,4,5,6,7,8,9].

Foams or sponges are generally defined as composite materials made from gaseous voids (dispersed phase) surrounded by a denser matrix (continuous phase) which is usually a liquid or a solid [10,11]. Depending on the matrix type, these foams can be classified into metal, concrete, biobased, polymeric, etc. [12,13,14,15,16,17]. Recently, polymeric foams have drawn a great deal of interest because of their good strength, high surface area, low weight and excellent energy damping properties performance, as well as good electrical, thermal and acoustic insulation combined with impact mitigation and cost reduction compared to other conventional foams [18,19]. In addition, it is easier to control their structure and properties [20].

The first cellular polymer reaching commercial markets was a rubber sponge developed as early as 1914 [21]. It was made by the addition of gas generating chemicals, like sodium and ammonium carbonate or sodium polysulfide, to natural rubber (NR) latex. However, the synthesis of thermoplastic foams started with polystyrene (PS) in 1931 [21]. Besides PS, other important thermoplastic foams, like polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), are used for different applications depending on their properties [22,23,24,25]. The development of polymeric foams is still ongoing, but some characteristics of rubber foams are making them preferable. For example, rubber foams have higher flexibility, resistance to abrasion and deformability (especially at low temperature) making them key materials in our everyday life. As technological development is made, their uses will continue to increase to a wider range of conditions such as high/low temperatures and pressures, vibration frequency, radiation or chemical environments [26,27,28]. In other words, their great elasticity, strength-to-weight ratio, impact and energy absorbing capabilities have secured their widespread use in several applications based on their chemical, mechanical, physical and thermal properties [29,30].

Based on the large body of literature now available on rubber foams, the main objective of this review is to provide a general overview on the relation between rubber formulation and foaming conditions. In particular, the curing kinetics, foaming chemistry and processing conditions are related to the final foam’s morphology, while their general properties and applications are discussed to get a state of the current knowledge and openings for future development.

2. Structural Features

2.1. Open and Closed Cell Structures

Rubber foaming relies on the expansion of a gaseous phase dispersed throughout the rubber melt. In porous materials, the pores are usually divided into two types: open cells which are interconnected throughout the material and also connected to the ambient environment, and closed cells where the gas is dispersed as separate/individual bubbles throughout the matrix and are isolated from the outside [31]. According to the reported qualitative findings, open cell foams are predominant from low-viscosity materials, while a closed cell structure is mostly seen for highly viscous conditions [32]. According to their structural differences, their properties as well as their applications are varied. Open cell foams usually have higher porosity, lower weight and cost which are used as supports, fuel tank inserts and loudspeakers. Due to these interconnections between the cells, they have the ability to allow fluids pass through their structure, which is useful for membranes or filters in separation processes [33]. On the other hand, closed cell foams, which are denser and more expensive, show higher mechanical strength and lower moisture absorption which can be used as thermal or electrical insulators. Closed or open cell structures can be prepared using a chemical (CFA) and/or physical (PFA) foaming agent.

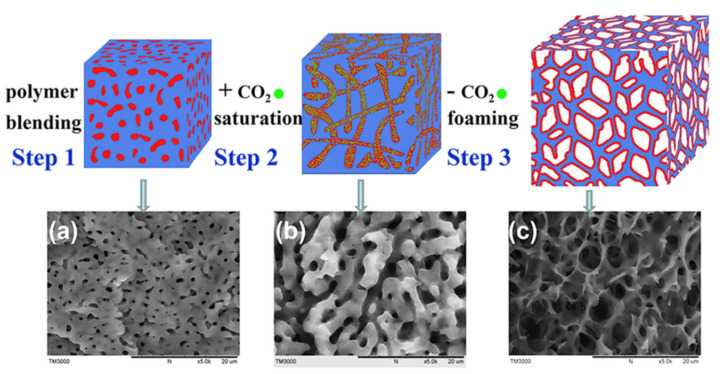

Kong et al. prepared an open cell PP/EPDM foam using carbon dioxide (CO2) as a physical foaming agent [34]. They found that using a polymer blend with a co-continuous morphology, for which one phase is CO2-philic and has a low glass transitions temperature or melting point, can lead to the production of an open cell structure using CO2 (Figure 1). In another work using CO2 as a PBA, the formation of a closed-cell structure was possible using a poly(ethylene-co-octene) rubber as the matrix [35]. Ethylene vinyl acetate (EVA) foams based on supercritical carbon dioxide (scCO2) using various sorption temperatures showed that the rapid expansion of EVA below and above its melting point led to open cell and collapsed closed cell morphologies, respectively [36]. Inorganic CFA, like ammonium carbonate and sodium bicarbonate, mainly release CO2 [37]. Their endothermic decomposition produces a slow gas generation producing an open cell structure. On the contrary, organic CFA, which are mostly exothermic, mainly produce closed cell morphologies [35,38].

Figure 1.

Schematic representation and SEM images of the steps leading to an open cell PP/EPDM foam [34].

Another important additive in rubber foams is incorporation of nanofillers which can act as nucleating agents to control the foam porosity [39]. Shojaei et al. prepared ethylene propylene diene monomer (EPDM) foams with 4,4′-oxybis(benzene sulfonyl hydrazide) (OBSH) and observed that nanoparticles addition can lead to different close/open cell ratio depending on their geometry [40]. For instance, carbon nanotubes (CNT), with their tubular structure, produced closed cells at low content, but higher open cell content was observed with increasing concentration. Conversely, organo-modified nanoclay (NC), having a plate-like shape, hindered the formation of open cells and their number decreased with increasing NC content. Finally, the spherical shape of nanosilica did not have a significant effect on open/closed cell structure of the foams.

2.2. Cell Size, Cell Density and Cell Wall Thickness

Controlling the cell size, density and uniformity of rubber foams is a challenging issue because the structure has a direct effect on the properties of rubber foams. Progress in the field of foam processing technology led to the fabrication of foams with different cell sizes including macrocellular foams (cell size > 100 µm), microcellular foams (cell size ≤ 100 µm and cell density > 109 cells/cm3) and nanocellular foams (cell size < 1 µm and cell density >1015 cells/cm3). It has been shown that foams with smaller and more uniform cell size offered improved properties, especially mechanical ones [41]. For a quantitative analysis of the foam morphology, several parameters like Dn, Dw, PDI and ρcell can be used as [42]:

| (1) |

| (2) |

| (3) |

| (4) |

where ni is the number of cells with a diameter Di, ρcell is the cell density (number of cell per unit volume), A is the surface of the foam, ρbulk is the density of the unfoamed matrix and ρfoam is the foam density. These data are usually obtained from the cell structure using 2D scanning electron microscopy (SEM) images.

In order to control the foams’ cell size and cell density, nanoparticles can be added as nucleation agents [43]. In general, nanoparticles addition results in lower cell size and cell wall thickness with higher cell density [44,45]. In this case, the nanoparticles affect both the nucleation and growth steps. On the one hand, nanoparticles act as nucleation agents and facilitate the formation of gas cells via heterogeneous nucleation. On the other hand, the addition of nanoparticles increases the viscosity limiting bubble growth due to higher matrix viscosity. During the foaming process, the pressure from the released gas (foaming agent) is the driving force for cell growth [46,47]. This is combined with lower average cell size and cell wall thickness with narrower cell size distribution while the number of cells per unit volume increase. The amount and distribution of the nano-reinforcements are also important factors to determine the foam quality. The influence of nanoparticle content is explained in detail in Section 3.4, but a nonuniform distribution of nanoparticles leads to a nonuniform cell size distribution. Another factor controlling the cell structure is the content of chemical and physical foaming agent [48,49]. As the concentration of foaming agent increases, the cells become smaller, finer, and more uniform. This is especially the case for CFA since their decomposition generates more gas and nucleation points [50]. Consequently, the cell density increases resulting in a smaller average cell size since the total amount of gas is constant. On the other hand, the cell size and cell density are mainly determined by the diffusivity and solubility of PFA. Yan and coworkers reported that when the saturation pressure increases (fixed temperature), the cell size decreases resulting in narrower cell size distributions [51]. Hence, increasing the CO2 saturation pressure in their case led to more molecules being absorbed by the silicone rubber matrix leading to a more important homogeneous nucleation effect producing a higher number of larger cells.

3. Rubber Foaming Formulation

Several parameters must be controlled to produce a foams with a specific morphology and properties [52]. These parameters are divided in two categories. The first category includes parameters related to formulation (type and content) including the rubbers, accelerators, fillers, and foaming agents. The second category is associated to processing conditions (batch or continuous) like temperature, pressure, time, number of steps and their sequence [53,54,55]. All these parameters can control the foam microstructure leading to different physical and mechanical properties of the final product. It is very important to choose an optimum formulation-processing combination to achieve suitable foams properties. The formulation parameters are presented next.

3.1. Type and Amount of Foaming Agents

Commercial and industrial applications require rubber foams with appropriate physical and mechanical properties, as well as uniform cell structures. An accurate control of the foam structure directly depends on the proper selection of foaming and curing agents to achieve a balance between gas production and degree of curing [56]. Two types of foaming agents (physical and chemical) can be used for rubber foam production, each having pros and cons. In general, physical foaming agents (PFA) are inexpensive and do not leave any solid residues which might affect the color or properties of the polymer. On the other hand, some have safety issues (explosion and flammability) and environmental issues (ozone depletion potential, greenhouse emission), as well as working with gases requires specific additional equipment (high pressure pump and flow meter) and thus more complex processes are required. It is also more complex to separate the foaming and crosslinking steps make it more difficult to control the foaming [57]. These conditions increase the interest of using chemical foaming agents (CFA) which are mainly powders. Despite their wide use, easier handling, and manufacturing (dosing), several CFA pose health hazards. In addition, unwanted byproducts and high cost have restricted their use. However, despite all these problems, CFA are more commonly used in the rubber foam industry.

3.1.1. Physical Foaming Agent (PFA)

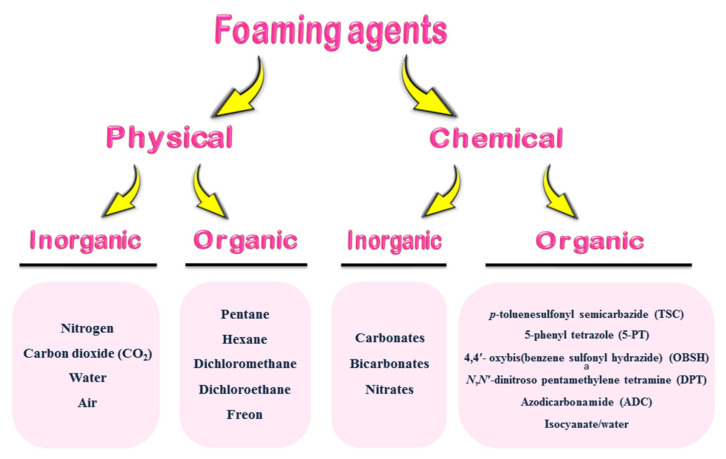

Some volatile liquids are able to generate gases by altering their physical state (liquid to gas) to produce a foam [58]. On the other hand, some compressed gas can be injected in the matrix under high pressure [59]. A good physical foaming agent should be nontoxic, nonflammable, odorless and noncorrosive with high vapor pressure and solubility. They must also be thermally stable and chemically inert and must not affect the physical or chemical properties of the rubber matrix. PFA are classified into inorganic and organic molecules (Scheme 1). The most important inorganic PFA are nitrogen (N2), CO2, water and air [60,61,62,63,64,65], while organic PFA are based on pentane, hexane, dichloromethane, dichloroethane, freon and similar structures [66,67].

Scheme 1.

Classification of foaming agents.

According to the literature, several substances, such as compressed inert gases and supercritical fluids, in particular supercritical carbon dioxide (scCO2), have been proposed as inorganic PFA [68]. Compressed gases are incorporated into the matrix by using special extruders and screws for gas injection [69]. The foaming process can be decomposed into four steps: gas dissolution, bubble nucleation, bubble growth and structure stabilization. The latter in rubber foams can be achieved by vulcanization (curing). Although CO2 and N2 are mainly used, scCO2 has several advantages including a tunable solvent strength, high diffusion rates and good solubility due to its low critical temperature (Tc = 304.15 K) and pressure (Pc = 7.38 MPa) [70,71,72]. N2 is also commercially highly used because of its inertness and high availability with low cost.

Jacobs et al. produced EVA foams with scCO2 and found that increasing the sorption pressure led to denser foams with smaller cell sizes after rapid expansion [36]. Tessanan and coworkers used scCO2 to prepare natural rubber (NR) foams [73]. They reported that increasing the scCO2 saturation time and pressure resulted in lower average cell size and volume expansion ratio, leading to significantly smaller cell size and narrower distribution.

Until some years ago, chlorofluorocarbon (CFC) and hydrochlorofluorocarbon (HCFC) were the main organic PFA for the foam industry, but the main concern about them was the presence of chlorine in their structure, which was known to attack the ozone layer. Furthermore, they have very high global warming potential (GWP). Therefore, they were phased out and the industries turned to hydrofluorocarbon (HFC). However, HFC are strong greenhouse gases and will no longer be used as replacements. Hydrofluoroolefin (HFO) were recently proposed since they do not have ozone depletion potential, but need more time before any conclusion about their long-term environmental effects is understood [74].

3.1.2. Chemical Foaming Agent (CFA)

CFA are widely used to produce elastomer foams. They are also classified as inorganic and organic types (Scheme 1) [38]. Inorganic CFA, mostly leading to the formation of open cells, are based on ammonium, sodium and potassium carbonates, bicarbonates and nitrates [75,76,77,78,79]. They usually release CO2 and water under the action of heat (thermal decomposition) and acids (accelerators). Most of the aforementioned inorganic CFA decompose endothermically; i.e., they absorb energy to react. These reactions are usually slow leading to the formation of open cell foam with a coarse cell structure [80]. To produce a finer cell structure, bicarbonates are combined with an acid activator like hydrogen phosphates, tartaric acid or citric acid [81]. A typical dosing is 5 to 10 phr (parts per hundred rubber).

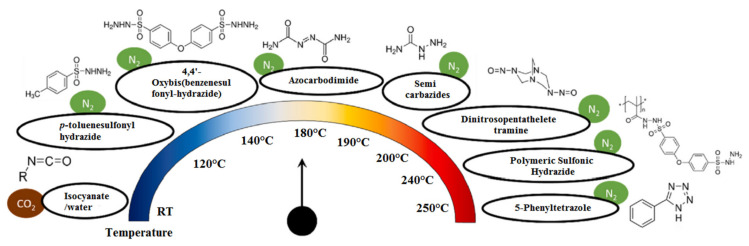

On the other hand, organic CFA mainly react exothermically, i.e., they release energy while decomposing. The main organic CFA are p-toluenesulfonyl semicarbazide (TSSC), 5-phenyl tetrazole (5-PT), OBSH, N,N′-dinitroso pentamethylene tetramine (DPT), azodicarbonamide (ADC) and isocyanate/water which release a gas mixture of N2, CO2, carbon monoxide (CO), ammonia and water. However, the main CFA is ADC and the predominant gas released is N2 [82,83,84]. Figure 2 presents a list of typical organic CFA and their gas produced depending on the temperature. The information is mainly based on the work of Coste and coworkers [85].

Figure 2.

Typical organic CFA and their gas produced depending on the temperature [85].

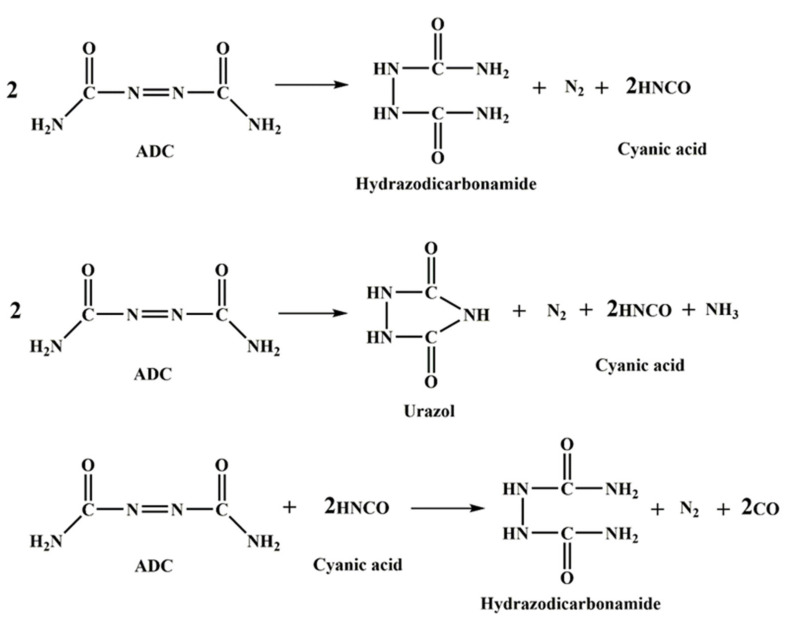

For CFA, the molecules breakdown via a series of reactions after reaching the decomposing temperature and the heat released can activate adjacent particles. This cascade-like process (autocatalytic reaction) leads to a fast foaming process mainly resulting in closed cell foams with uniform cell structures [86]. ADC is a versatile and well-known organic CFA because of the ability to tailor its decomposition temperature (pure ADC’s decomposition temperature is around 210 °C) and high gas yield efficiency (231 cm3 of gas generated per each gram of ADC) [87,88]. Although time and temperature have a direct effect on the thermal decomposition behavior, particle size, kind and amount of activator, and the quality of distribution of the activator and CFA also affect the decomposition temperature [89]. By reaching its decomposition temperature, ADC starts to generate gas molecules to expand the rubber matrix [90].

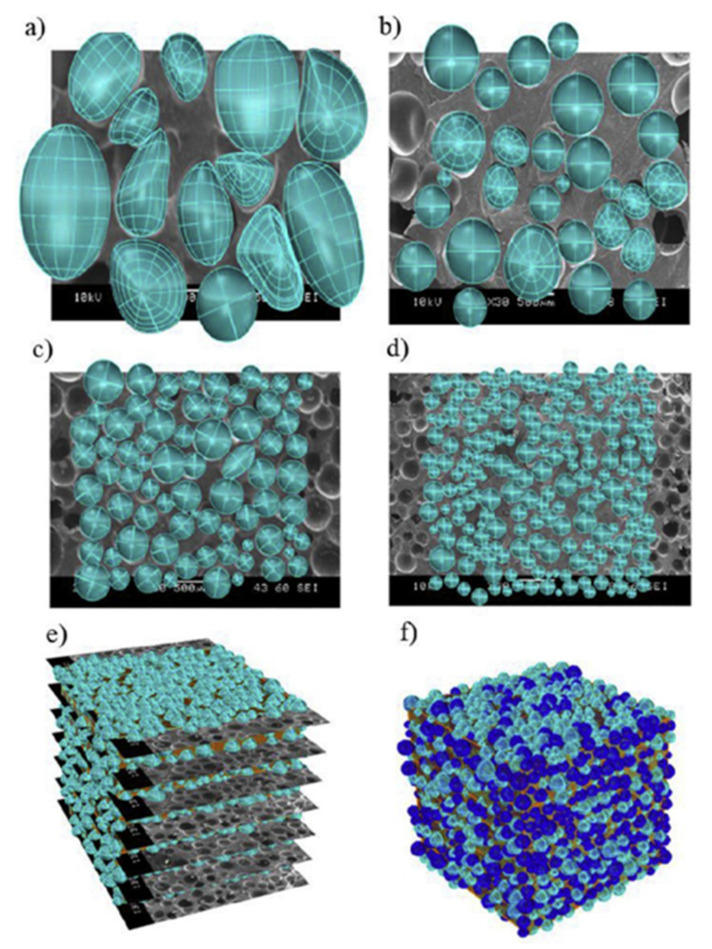

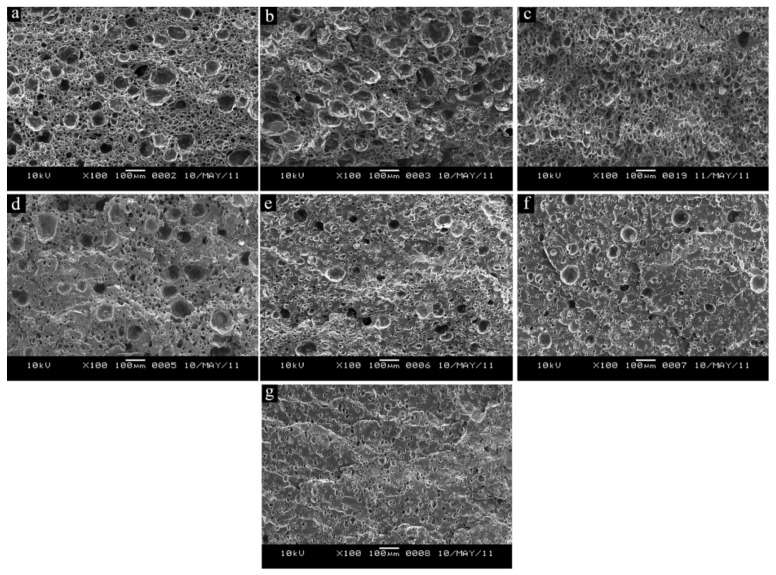

All the foaming agents can be used alone or together. For example, Hongling and coworkers found that using a mixture of ADC/OBSH was more effective than ADC alone because chloroprene rubber (CR) foams with higher porosity, larger cell size and more uniform cell distribution were produced [90]. Moreover, the foams prepared with ADC/OBSH had better tensile strength and tear strength than neat ADC, as well as higher hardness. Charoeythornkhajhornchai et al. reported that increasing ADC content from 3 to 4 phr in NR foams led to smaller cell size because of faster vulcanization rate (less time for cell growth) owing to the presence of amine species (curing accelerators) as ADC decomposition by-products [91]. However, further ADC increase (5 and 6 phr) produced cell coalescence because of a high gas content and internal cell pressure. They also stated that 4 phr ADC produced the lowest thermal expansion coefficient due to better cell uniformity and smaller cell size (low coalescence). Heydari et al. generated closed cell NR foams by ADC and use their data to validate various numerical models [92]. They achieved relative foam densities between 0.3 and 0.5 by enhancing the mold filling ratio (compound weight inside a fixed mold volume). Their SEM analysis (Figure 3) revealed that increasing the filling ratio resulted in lower average cell sizes (from 530 to 234 μm), narrower cell size distributions (from 225–800 to 50–400 μm), and higher cell densities (from 29 to 294 cell/mm3). In particular, they simulated their 3D foam structures using real 2D SEM images to predict the mechanical behavior of NR foams via finite element methods (FEM). Their FEM outcomes at the macroscopic level were in good agreement with mechanical test results for the range of conditions tested.

Figure 3.

Real 2D geometry models from SEM images for NR foams with different foam relative density of: (a) 0.3, (b) 0.4, (c) 0.45, (d) 0.5, as well as (e) the real 3D geometry obtained from 2D data for a sample with a relative density of 0.5 and (f) the final 3D structure for a foam with a relative density of 0.5 [92].

3.2. Type of Rubbers

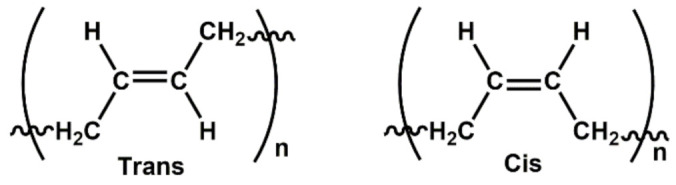

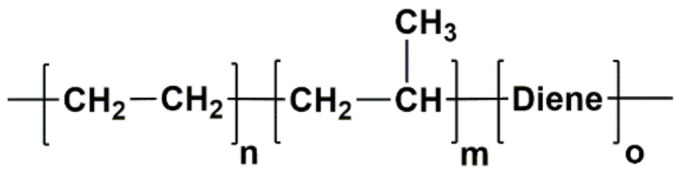

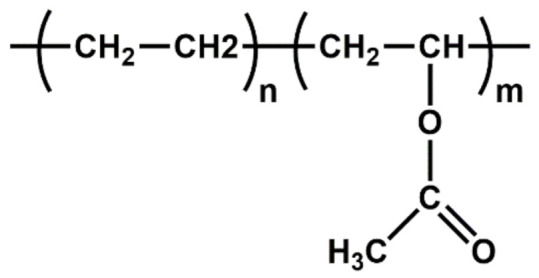

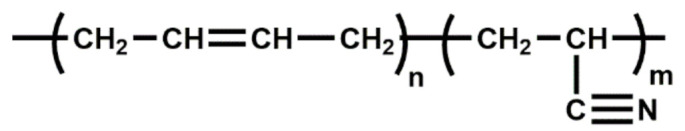

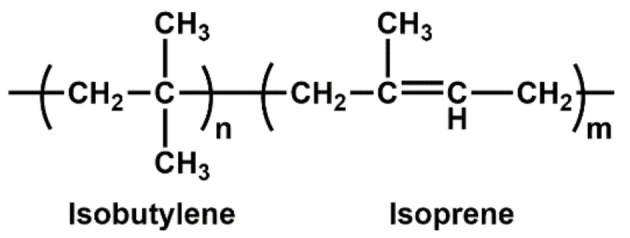

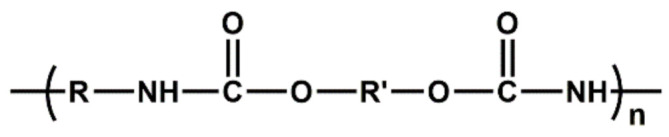

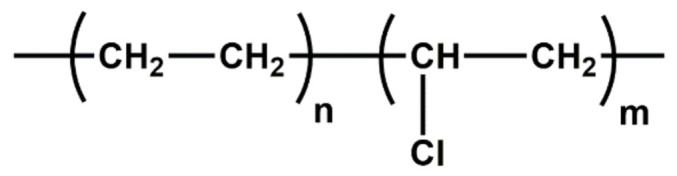

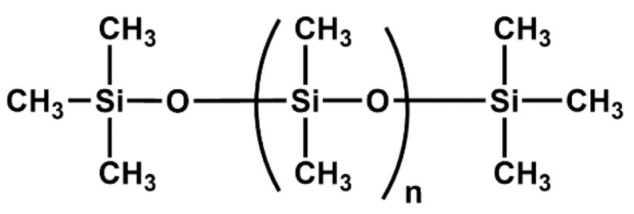

The curing characteristics and cellular structure, as well as the mechanical and physical properties of the foams, can be controlled by a careful selection of the rubber type. So far, various rubber foams were reported based on NR, EPDM, polyisoprene rubber (IR), CR, styrene butadiene rubber (SBR), EVA, isobutylene rubber (IIR), acrylonitrile butadiene rubber (NBR), polyurethane (PU), chlorinated polyethylene rubber (CPE), silicone rubber (SR), etc. [93,94,95,96,97,98]. A summary of the main rubber types with their properties and molecular structure is presented in Table 1.

Table 1.

| Rubber | Properties | Molecular Structure |

|---|---|---|

| NR | Biocompatibility; high elasticity, tear and abrasion resistance; high resilience, damping behavior and tensile strength; good oxidation resistance; low compression set; low ozone resistance; poor chemical resistance and processing ability |

|

| EPDM | High chemical stability; high tear, impact and abrasion resistance; high heat-aging (100 °C), weather, ozone and oxidation resistance; high resistance to break down |

|

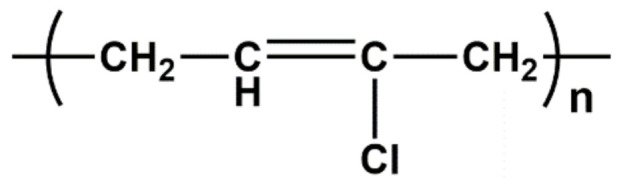

| CR | Self-extinguishing behavior; good chemical stability; maintains flexibility over a wide temperature range |

|

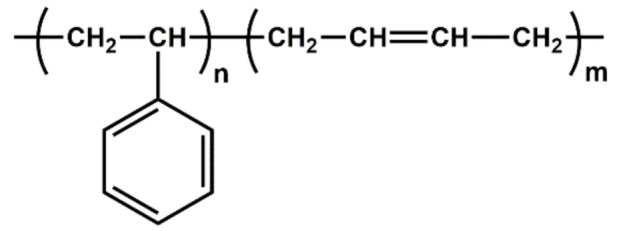

| SBR | Good heat aging (100 °C); high elongation; good resistance to diluted and concentrated alkalis, alcohols and solvents |

|

| EVA | Low-temperature toughness; stress-crack resistance; hot-melt adhesive; waterproof properties; resistance to UV radiation |

|

| NBR | Resistance to nonpolar oils, silicon oils, fuels and ordinary diluted acids and alkalis; good oxidation resistance; good heat aging (100 °C); high thermal stability |

|

| IIR | High resistance to heat, oxygen and ozone; low gas and moisture permeability; poor resilience |

|

| PU | Good abrasion resistance, tensile strength, tear strength, hardness, compression strength, impact resistance and elongation; high moisture sensitivity |

|

| CPE | High resistance to ozone, hydrocarbon oil, heat and weathering; good blending ability with both polar and nonpolar materials |

|

| SR | Biocompatibility; high thermal and UV radiation stability; high elongation, elasticity and tensile modulus; good heat aging (100 °C) and compression set rating; adhesion to metals; good ozone, oxidation and weathering resistance; low resistance to alkaline solvents; good dielectric properties |

|

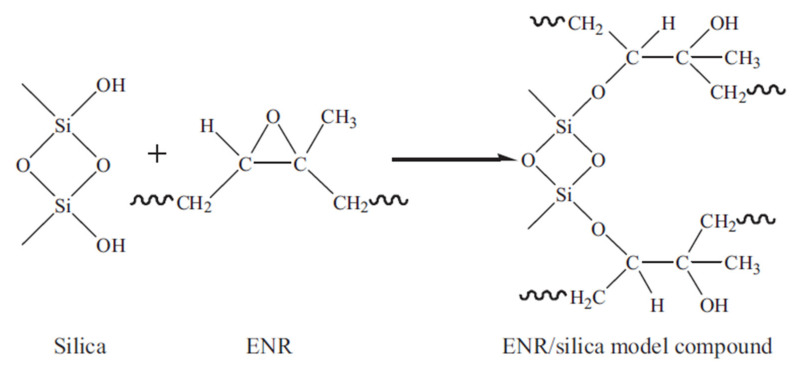

Among the rubbers, NR is the main matrix for foam production due to its natural origin (biosourced), availability, renewability and appropriate mechanical and electrical properties [99]. Good mechanical properties include high elastic properties, high resilience and damping behavior, high tensile strength, low compression set, resistance to tear and abrasion, but poor chemical resistance and processing ability [50,100]. NR has four possible microstructures in its molecular chains: cis-1,4-, trans-1,4-, 1,2- and 3,4-polyisoprene [101], but the main component is cis-1,4-polyisoprene. NR is obtained in a latex from trees like Hevea brasiliensis (Para rubber trees) and banyan fig trees (Ficus bengalensis) or various plants like guayule shrub (Parthenium argentatum Gray) and the Russian dandelion (Taraxacum koksaghyz), but contains various impurities (mainly proteins, amino acids, phospholipids and gel components) [102]. The standard Malaysian rubber (SMR) categorized NR latex into various grades according to the amount of main impurities (dirt, ash, nitrogen, volatile matter). Nitrogenous materials in the rubber are related to proteins, as determined through its nitrogen content, can provide an estimation of the protein content in the rubber [103]. SMR-L, SMR-5, SMR-10 and SMR-20 are the main NR grades and the main impurities are listed in Table 2. Another important grade is epoxidized natural rubber (ENR) which is a chemically-modified grade of NR obtained via epoxidation [104]. The presence of epoxy groups on the backbone increases the NR polarity leading to faster curing rate and better final properties of the foams. Ariff et al. investigated the effect of various NR grades on the morphological, mechanical and physical properties of NR foams [105]. They used three different NR grades (SMR-L, SMR-10 and ENR-25: ENR with 25 mole% epoxide). Their results showed that both unmodified grades (SMRL and SMR-10) did not exhibit significant difference in cell size, crosslink density (CLD), rate of expansion, rate of curing and mechanical properties because of their similar chemical structure [106]. On the other hand, ENR-25 foams had smaller cell size, higher cell wall thickness, higher density, and better mechanical properties. This behavior was attributed the epoxide groups on the ENR backbone reacting with the carbon double bond sites and increasing the CLD. Xu et al. found that the mechanical properties of NR/silica were improved after ENR addition [107]. This improvement was attributed to the ring-opening reaction between the epoxy groups of ENR and the Si-OH groups on the silica surface which improved the dispersion of silica in the rubber matrix and enhanced the interfacial interactions between rubber and silica (Figure 4). Salmazo et al. produced SMR-L and ENR-25 foams separately in the presence of ADC and cured with different electron beam irradiation doses (50, 100 and 150 kGy) [108]. Their results revealed that ENR foams had higher cell nucleation rates and less cell degradation than those produced from SMR-L alone. This was attributed to the presence of epoxide groups in the cured ENR foam promoting a higher degree of curing. Consequently, the ENR foams had more uniform porous structures and smaller cell sizes.

Table 2.

Natural rubber grades with their impurities content [109].

| Impurities | SMR-L | SMR-5 | SMR-10 | SMR-20 |

|---|---|---|---|---|

| Dirt (max) wt.% | 0.02 | 0.05–0.08 | 0.08 | 0.16 |

| Ash (max) wt.% | 0.50 | 0.60–0.75 | 0.75 | 1.00 |

| Nitrogen (max) wt.% | 0.60 | 0.60 | 0.60 | 0.60 |

| Volatile matter (max) wt.% | 0.50 | 0.80 | 0.80 | 0.80 |

Figure 4.

The ring-opening reaction between an epoxy group of ENR and Si-OH on the surface of silica [107].

SBR is a synthetic rubber derived from petroleum. It was initially developed as an alternative for NR. SBR is fabricated by the copolymerization of ~75% butadiene (CH2=CH-CH=CH2) and 25% styrene (CH2=CHC6H5) [110]. Some SBR properties, like excellent compression set, enhanced crack resistance, abrasion-resistance, wear resistance and cost reduction, enable its industrial use due to improved aging properties and thermal insulation [111]. However, SBR foams have rarely been reported because of their very high viscosity and shrinkage [112]. The effect of CFA type (OBSH and ADC) and content (0, 2, 4, 6, 8 and 10 phr) on the curing characteristics, mechanical and morphological properties of cellular NR/SBR was studied by Wimolmala et al. [113]. They reported that 4 phr was the optimum concentration of foaming agent (for both OBSH and ADC), but OBSH led to higher curing rate (lower curing time) compared to ADC. Furthermore, increasing the foaming agent content led to lower elastic recovery and higher resilience of NR/SBR foams. Shao et al. were able to decrease the shrinkage of SBR foams to 2.25% by using sulfur and dicumyl peroxide (DCP) producing a double crosslinking system [96]. Their study reported that shrinkage mainly depended on a synergy effect between both cross-linkers. SBR/RR (recycled rubber) foams with different ratios (100:0, 80:20 and 60:40) were prepared with sodium bicarbonate by Algaily and coworkers [114].

Increasing the RR concentration resulted in better mechanical properties (higher elongation at break and tensile strength), higher curing characteristics (maximum/minimum torque and crosslink density), and higher foam density. Changing the RR:SBR ratio resulted in a shift of the resonant frequency from 500 Hz (100:0) to a higher frequency of 800 Hz (80:20 and 60:40). Bahadar et al. prepared a single wall carbon nanotube (SWCNT)-reinforced EPDM/SBR blend for shock absorbing applications [115]. The introduction of SWCNT in an EPDM/SBR matrix led to a substantial improvement of the storage modulus (80%), but a 27% decrease in the loss modulus for the highest SWCNT content tested (0.6 mass%). Rheological studies showed that adding SWCNT into a rubber blend increased the loss factor (tan δ = E′/E″) but decreased the mixing torque. Degradation with increasing filler/matrix ratio was observed in compressive strength and energy absorption efficiency. All these effects were related to the superior mechanical strength, more uniform dispersion, and long-lasting bonding between the matrix and SWCNT.

EPDM is an unsaturated polyolefin rubber obtained by the copolymerization of ethylene, propylene and a nonconjugated diene (ethylidene norbornene, dicyclopentadiene or 1,4 hexadiene) which provides crosslinking sites for vulcanization [116]. The presence of propylene in the EPDM backbone prevents the formation of crystallinity to keep a higher amorphous content. The lack of unsaturated double bond in the main-chain of EPDM provides great heat aging resistance, chemical stability, ozone, UV and oxidation resistance, as well as high load capacity and high resistance to break down during [116,117]. EPDM has attracted high attention for outdoor applications such as automotive sealing systems, wire materials, building profiles, white sidewalls of tires, electric-electronic components, roofing sheets and sporting goods. The selection of an appropriate vulcanization systems in combination with a suitable foaming agent has always been a challenge for EPDM foams because of its slow vulcanization rate [118]. By blending EPDM with NR, Lewis and coworkers found that the structure, properties and cure characteristics of EPDM/NR foams are affected by the amount of NR in the blend [119]. The scorch time and cure time decreased with increasing NR content due to the high reactivity of the double bonds and methyl group enhancing the activity of the double bond in NR [120]. EPDM/halloysite nanotube (HNT) nanocomposite foams were produced using a batch process in an autoclave with scCO2 as PFA by Lee and coworkers [121]. They achieved microcellular foams with an average cell size of 7.8 µm and a cell density of 1.5 × 1010 cell/cm3, revealing that HNT acted as an effective nucleating agent for the foaming process. This microcellular elastomeric nanocomposite foam could potentially be used in a variety of industrial applications involving gaskets and seals for automotive and electrical enclosures. Suntako investigated the effect of synthesized ZnO nanoparticles by a precipitation method as sulfur vulcanization activator compared with conventional ZnO on the curing characteristics and morphology of EPDM foams [122]. It was shown that EPDM foams based on synthesized ZnO nanoparticles exhibited higher ultimate torque, compressive load and hardness with increasing nanoparticles content, while the optimum cure time and scorch time decreased. The cell structure of the EPDM foams was more spherical, and the cell size decreased with increasing synthesized ZnO nanoparticles. It was also possible to decrease the amount of synthesized ZnO from 5 to 3 phr (40%) because the ZnO nanoparticles have much higher specific surface areas. Ma et al. developed EPDM composite foams with various SR ratios to determine its effect on the wear resistance, structure, curing, rheological and mechanical properties of the blends [27]. The torque values and curing level were both increased with SR concentration. The mechanical properties of the composite foams were all improved with SR addition, except for the elongation at break. More importantly, the wear resistance and compression set were substantially enhanced with increasing SR content. Bio-EPDM foams with various ratio of tungsten bronze nanorod (TBNR) were fabricated to improve the thermal insulation properties for application in highly functional eco-friendly diving wetsuits [123]. The crosslinking delay and stabilization of the foaming speed upon TBNR addition controlled the bubble growth and induced the formation of smaller cells with a more uniform size distribution. The processing stability of the foam was also improved leading to an elastomer foam with excellent thermal insulation, flexibility, elastic properties, and foam stability without significant changes in mechanical properties. Moreover, an excellent photothermal stability after light irradiation indicated that the material developed was suitable for thermo-functional wetsuits in water sports and activities.

EVA foams have been industrially applied in a broad range of products like shoe soles and midsoles, sports equipment, insulation materials and drug delivery systems because they are highly durable, very comfortable and soft [36]. However, some disadvantages, such as high density and low physical properties, restricted further applications [28]. To overcome these disadvantages, Park et al. blended EVA with ethylene-1-butene copolymer (EtBC) to improve the physical properties of EVA foams including tensile strength, rebound resilience and compression set [124]. Kim et al. achieved low density, high rebound resilience and tear strength of EVA foams (at optimal crosslinking temperature) through blending with NR [125].

The random substitution of chlorine atoms on the PE backbone results in its transformation from a thermoplastic material to a rubber material (CPE) by suppressing crystallization. CPE has high resistance to hydrocarbon oil, heat and weathering from the addition of chlorine atoms on the PE backbone [126]. Moreover, the presence of both nonpolar groups (unmodified methylene units) and polar groups (chlorinated methylene co-units) in the CPE’s backbone increase its compatibility to blend with either polar or nonpolar polymers for a specific sets of properties and cost advantages purposes [127]. Zhang and coworkers prepared a series of foams to investigate the effect of CPE/EVA ratio on the curing, foaming and mechanical properties [128]. They found that increasing the EVA content had a negligible effect on the scorch and curing time, but higher hardness with lower rebound resilience and shrinkage ratio were obtained. The expansion ratio and void fraction increased with increasing EVA content, while the cell density decreased from 100:0 to 50:50 of CPE:EVA, and then considerably increased from 70:30 to 90:10.

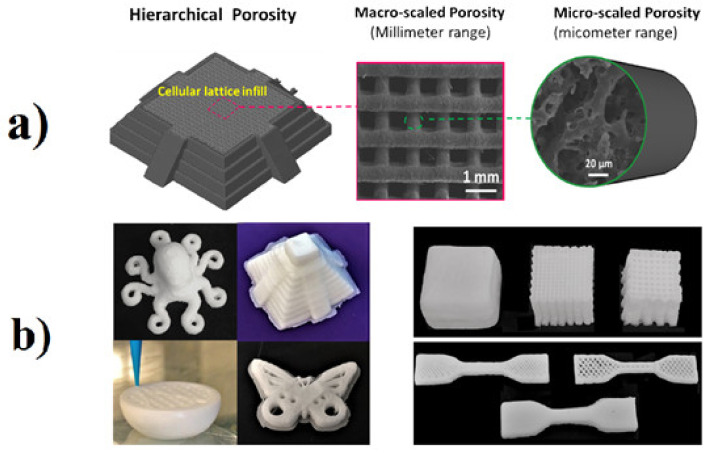

Silicone (polyorganosiloxane) consists of alternating silicon and oxygen atoms (siloxane units) with hydrocarbon side radicals combined directly with silicon [129,130,131]. The characteristics of the Si-O-Si bond, large bond length (0.163 nm), bond angle (130°) and bond energy (445 kJ/mol) provide SR with superior performance properties including excellent chemical resistance, good electrical insulation capacity, high elasticity, excellent thermal, ultraviolet and ozone stability, high weathering resistance and very low glass transition temperature (Tg ≈ −120 °C), as well as biocompatibility [132,133,134,135]. SR foams combine the characteristics of silicone rubber and foam materials such as good resilience, high thermal stability, shape conformity, low density and light weight [136]. Silicone rubber foams exhibit enhanced temperature stability (–60 °C to 250 °C for long-term performance and up to 400 °C for short-term application), offering a wider range of operating temperature compared with any other organic rubber foams [137]. Luo et al. fabricated methyl vinyl silicone rubber foams with different spherical cell sizes via physical foaming (using spherical urea with different sizes as cell-forming agent) to study the relationship between the cell size and the mechanical properties [138]. They showed that silicone rubber foams with spherical cell diameter between 300 and 450 µm exhibited very good compression strength and compression stress-relaxation property. Liao et al. evaluated the effect of silica content, temperature and pressure on the viscoelastic properties of silicone rubber compounds prepared with scCO2 [139]. According to their results, the concentration of silica had an effect on both cell nucleation and cell growth because it acted as a heterogeneous nucleation agent and also increased the viscosity of the SR compounds. In addition, by reducing the saturation temperature (Ts = 40 °C), cell nucleation was prominent owing to the generation of a large volume of CO2 molecules. On the contrary, increasing Ts (60 °C and 80 °C) led to cell coalescence associated to rapid cell growth (controlling step). Altogether, they obtained SR foams with lower cell densities and larger cell sizes at high temperatures. Finally, high saturation pressure resulted in higher scCO2 plasticization effect and lower viscosity of the SR matrix leading to improved cell growth rates. Chen and coworkers developed 3D printed SR foams with trimodal porosity leading to outstanding properties, multifunctionality and multidimensional tunability (Figure 5) [140]. Printable viscoelastic inks were prepared by simply mixing sodium chloride (NaCl) with a polydimethylsiloxane (PDMS) precursor gel. The hierarchical porosity, produced by salt leaching and solvent removal, produced PDMS foams with unprecedented hyper-elasticity, extreme compressibility, cyclic endurance (near-zero irreversible shape deformation under extreme compression of 90% strain and 1000 cycles of large compression) and excellent stretching ability (maximum strain of 210%). The porous structure also worked as surface roughness to offer super-hydrophobicity. The modulus, elasticity, stretching ability and oil absorbance capacity were all tunable through ink formulation or computer aided drawing. Silicone rubber (VMQ) foams combined with chemically reduced graphene oxide (rGO) and 3-aminopropyltriethoxysilane functionalized graphene (FG) were prepared by Shi et al. to evaluate their rheological behavior, cell structure and mechanical properties [141]. The presence of rGO improved the strength of the matrix by two times, while FG increased it by six times. The main reason was the stronger interaction and excellent compatibility of FG with VMQ. The increased matrix strength also limited the shrinkage of the cell walls leading to VMQ/FG foams having larger cell size compared to VMQ/rGO foams. The mechanical results showed that FG can improve the tensile strength (130%) and elongation at break (140%) compared to VMQ/rGO foams. The lightweight and flexible SR/Ag plated hollow glass microspheres (HGM) were used for electromagnetic interference (EMI) shielding in composite foams with a gradient structure prepared by the combination of density induction and scCO2 foaming [142]. The composite foams have a conductivity of up to 279.3 S/m with only 0.51 vol.% Ag and a corresponding EMI shielding effectiveness (SE) reaching 30 dB when the thickness was only 0.7 mm. The multilayer structure design of the composite foam not only increased the EMI SE, but also did not increase the reflection. The three-layer composite foam presented an average EMI SE of 59 dB and a reflection power coefficient (R value) of 0.60 at a thickness of 2 mm. An excellent EMI SE stability of the composite foam was obtained due to the good flexibility of the SR matrix.

Figure 5.

(a) Illustration of hierarchical porosity in 3D printed objects. Left: schematic drawing. Middle: macro-pores under SEM. Right: micro-pores under SEM. (b) Optical images of 3D printed PDMS sponge structures [140].

3.3. Type and Amount of Accelerators

In order to get useful properties, elastomers must be vulcanized. Despite the presence of various crosslinking process and systems, the rubber industries generally use sulfur or peroxide vulcanization systems for rubber curing [143,144,145,146]. Rubber vulcanization by sulfur may take several hours without any accelerator, but in their presence the reactions are completed in a few minutes. Furthermore, adding accelerators decreases the amount of sulfur needed leading to improved oxidation resistance [147,148]. For good control of the cellular structure and final properties, selection of a suitable accelerator type and content is crucial. In other words, during the curing process, the scorch time (the time required, at a fixed temperature, for the onset of crosslink formation) should be long enough to prevent complete rubber vulcanization before filling the mold cavity, but it should be short enough to increase the production rates [149,150]. That is why the vulcanization rate plays an important role because it affects both the cellular structure and crosslink density of the final foams.

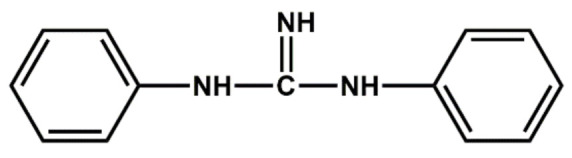

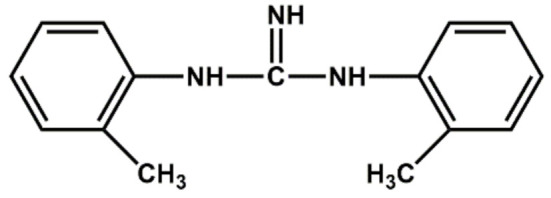

The curing reaction of elastomeric foams based on sulfur and accelerators is very complex due to a large number of simultaneous reactions. So far, several accelerator systems have been used, but the most important can be divided into four groups based on their curing reaction scheme and chemical structure [151]. Firstly, aniline and thiocarbanilide (amine derivatives) were developed but these are not used anymore because of their toxicity. Secondly, dithiocarbamates and xanthates have high crosslinking rates, but almost no scorch time. Then, benzothiazoles and sulphenamides are the most extensively used today because of their excellent scorch properties. Finally, thiurams can be used as both ultra-accelerators and vulcanizing agents.

In general, the accelerator reacts with sulfur to produce monomeric polysulfides which are interacting with the rubber molecules to form polymeric polysulfides, as well as to reduce the time required for vulcanization [152]. The structure, properties and name of the most important accelerators are listed in Table 3.

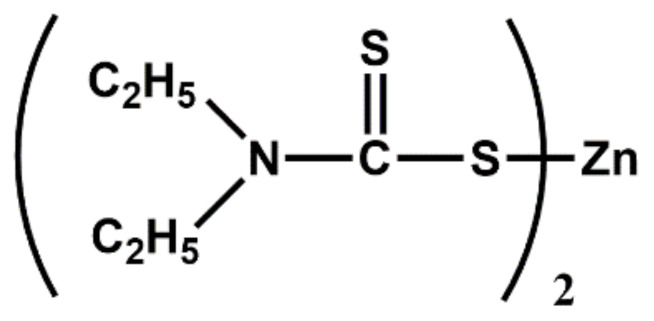

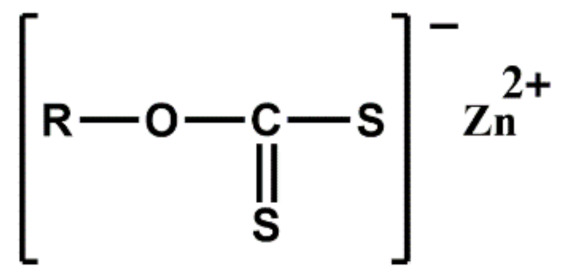

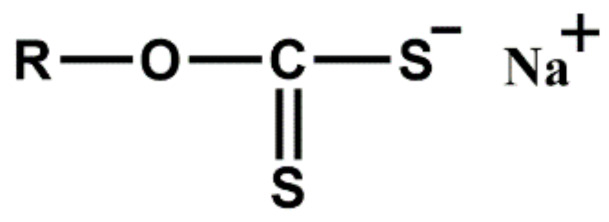

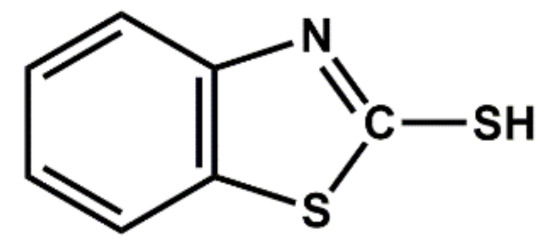

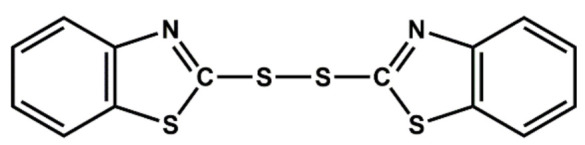

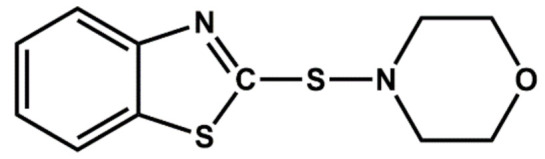

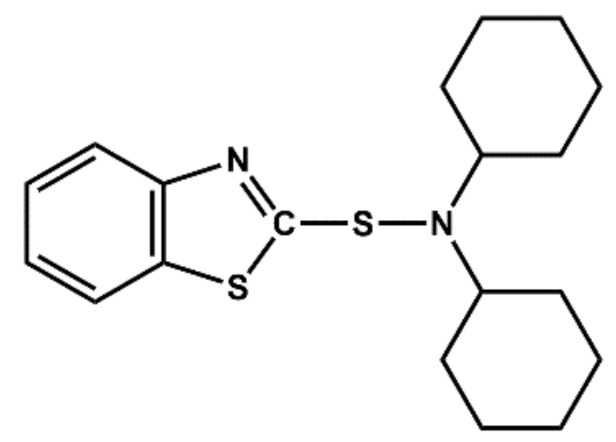

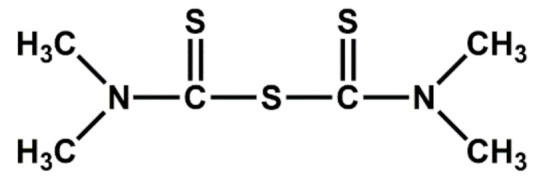

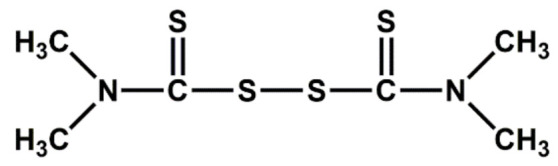

Table 3.

| Group | Name | Properties | Structure |

|---|---|---|---|

| Amines | Diphenyl guanidine | Medium accelerator used along with other accelerators |

|

| Di-orthotolyl guanidine | Medium accelerator |

|

|

| Dithiocarbamates | ZDEC | Ultra-accelerator |

|

| Xanthates | ZIX | Ultra-accelerator, low temperature curing |

|

| SIX | Water soluble ultra-accelerator for latex work |

|

|

| Benzothiazoles | MBT | Semi-ultra-accelerator, scorchy |

|

| MBTS | Delayed action, semi-ultra-accelerator |

|

|

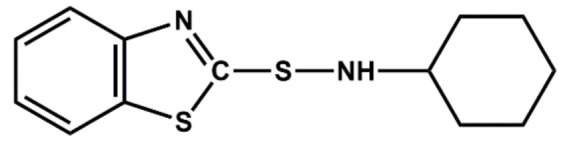

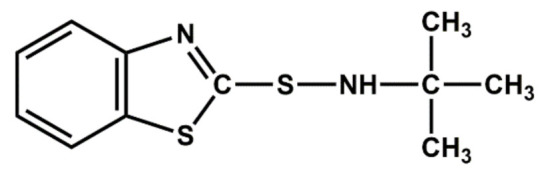

| Sulphenamides | CBS | Delayed action, semi-ultra-accelerator |

|

| TBBS | Delayed action |

|

|

| MBS | Delayed action |

|

|

| DCBS | Delayed action, accelerator |

|

|

| Thiurams | TMTM | Ultra-accelerator |

|

| TMTD | Ultra-accelerator, vulcanizing agent |

|

The effect of sulphenamide accelerator (MBS, TBBS and CBS) on the curing kinetics and properties of natural rubber foams was investigated by Charoeythornkhajhornchai et al. [154]. The main information is listed in Table 4. Foams based on CBS show the fastest vulcanization rate with the lowest activation energy because CBS produces higher level of basicity of the amine species than any other accelerator, forming a complex structure with zinc ions as ligands in sulfur vulcanization. In addition, the fast curing rate of CBS leads to the formation of foams with the smallest bubble size, narrowest bubble size distribution and lowest cell density resulting in the lowest thermal conductivity and thermal expansion coefficient than other foams.

Table 4.

Typical composition of rubber foam compounds [154].

| Accelerators | NR (g) | ZnO (phr) | Steric Acid (phr) | Sulfur (phr) | ADC (phr) | Accelerators | |

|---|---|---|---|---|---|---|---|

| Content (phr) | (Acc:S) 1 (mol) | ||||||

| MBS | 40 | 5 | 2 | 0.5 | 4 | 2.5 | 5.08 |

| TBBS | 40 | 5 | 2 | 0.5 | 4 | 2.5 | 5.38 |

| CBS | 40 | 5 | 2 | 0.5 | 4 | 2.5 | 4.85 |

| CBS | 40 | 5 | 2 | 0.5 | 4 | 2.775 | 5.38 |

1 Ratio of accelerators to sulfur.

Despite the presence of an accelerator, zinc oxide and a fatty (stearic) acid are also added to activate the vulcanization reaction. Zinc oxide in combination with an acid forms a salt increasing the accelerator efficiency [155]. Ariff and coworkers examined the effect of different ratio of accelerator between TMTD and CBS on the properties of SMR-L/ENR-25 foams [156]. The results indicated that the induction time was increased with increasing CBS ratio because CBS is not an effective sulfur donor compared to TMTD. Higher CBS ratio also led to larger average cell size, thicker cell wall, lower expansion ratio (higher relative density) and higher compression set. The stress under compression increased with increasing CBS ratio since the resulting foams were highly affected by the matrix properties and higher relative density, i.e., a higher amount of stronger material in the cell walls.

3.4. Type and Amount of Fillers

Because neat elastomers have low strength and modulus, rubber foams can be reinforced by filler addition to significantly improve their stiffness and strength for practical use [157]. In fact, filler addition affects not only the mechanical properties, but also on the curing characteristics of the foams including the curing time, scorch time and aging properties. Different types of fillers have been used to reinforce rubber foams, but the most important ones are carbon black (CB), fibers, clay and silicates [40,158,159]. As expected, the level of property improvement depends on various parameters including particle size and geometry, degree of dispersion, aspect ratio and orientation in the rubber matrix, as well as the level of bonding (chemical, mechanical and physical interactions) with the rubber chains [160].

Vahidifar and coworkers reported that increasing the CB content (0–20 phr) in NR foams increased the cell density, compression modulus and hardness, but decreased the cell size [46]. Moreover, the sound absorption of NR foams was improved with higher CB content due to a stiffening effect of the matrix (cell walls). In another work, Vahidifar et al. used a hybrid reinforcing system containing organo-modified nanoclay (NC) and nanocarbon black (NCB) to determine the effect of NC content (0–10 phr) on the curing behavior, morphological and mechanical properties of NR foams including 10 phr of NCB [161]. The rheological results showed that increasing the NC content (0 to 10 phr) gradually changed the curing parameters such as 50% shorter scorch and curing time, higher curing rate, as well as higher initial and final torque. Furthermore, increasing the NC content resulted in higher tensile modulus and hardness, but decreased the foam resilience and elongation at break. Increasing the NC content from 0 to 5 phr led to the formation of foams with more uniform and smaller cells, while 7 phr NC produced a foam structure having two areas composed of different cell sizes (bimodal distribution). Nayak et al. found that increasing the CB content in ethylene-octene copolymer (EOC) foams resulted in lower curing time and foam expansion ratio [162]. On the other hand, their results showed that CB addition increased the cell density and decreased the average cell size. Higher number of cells was associated to a heterogeneous nucleation effect created by the CB surfaces, while smaller cell size was related to higher processing viscosity and faster curing rate inhibiting cell growth. Furthermore, Dalen et al. reported that kaolin addition (2–8%) can better improve the curing rate than calcium carbonate for polyurethane (PU) foams, but an excess of kaolin reduced the curing rate leading to processability problems [163]. Bashir and coworkers observed that the thermal stability of EPDM foams was improved with increasing CB content [164]. The viscoelastic and foaming behavior were decreased, while the curing and mechanical strength of the EPDM foams were improved. Phumnok et al. investigated the effect of filler types (CB, calcium carbonate and china clay) and their content (0 to 50 phr) on the physical properties of NR foams [159]. The results showed that for specific filler concentration, CB produced the highest tensile modulus and strength, as well as the highest torque difference and hardness, while china clay led to the highest elongation at break.

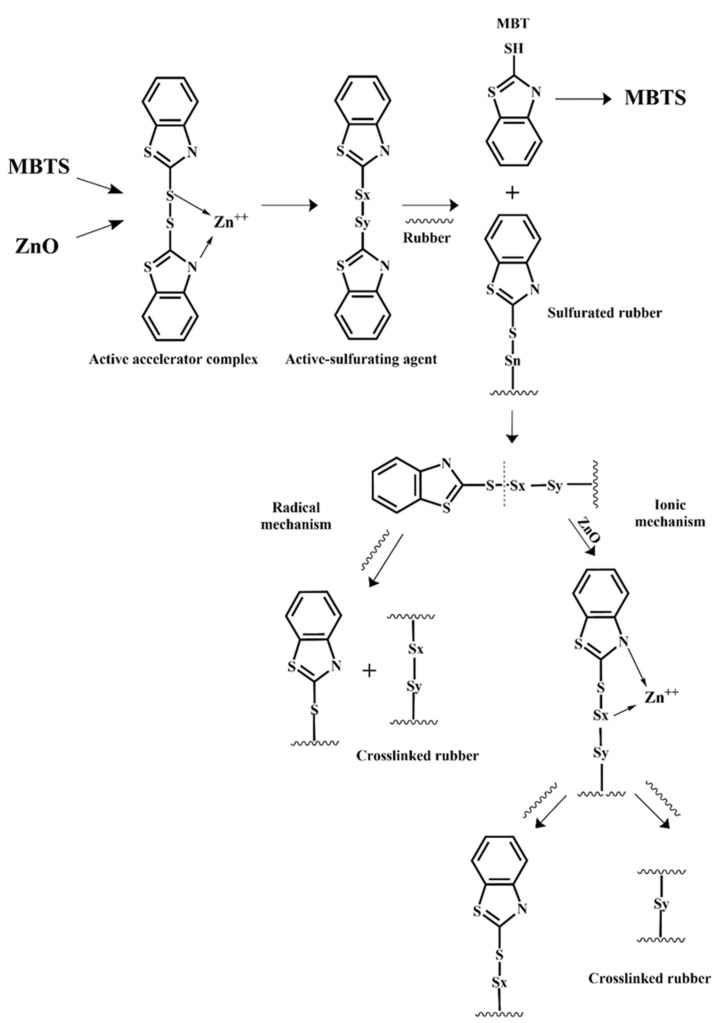

4. Chemistry of Foams

In the production of rubber foams, two counteracting mechanisms are playing an important role to control the final foam properties by affecting the cell morphology: the foaming and crosslinking reaction. In fact, the curing reaction among the rubber molecules is necessary to stabilize the morphology and increase the viscosity of the foaming medium, but the effective amount of gas produced through the CFA thermal decomposition is the foaming driving force [165]. In general, curing reactions based on sulfur are performed in three steps [150]. The first step is the production of an active-sulfurating agent. In this step, the accelerator and the activator form the active accelerator complex. This complex reacts with the available sulfur and generates an active-sulfurating agent. In the second step, the active-sulfurating agent attacks the double bond of the weak allyl carbon inside the rubber chain forming the sulfurated rubber. Then, the sulfurated rubber attacks another double bond and the curing process continues. The third step is the postcuring step. The crosslink bonds produced in the previous step are mostly polysulfide (two to eight sulfur atoms in the crosslink bonds). Sulfur curing is also classified according to another method. In this classification, the chains can be cured with two ionic mechanisms and a radical mechanism. Studies have shown that in the presence of an accelerator, ZnO activator and stearic acid, both ionic and radical mechanisms occur. The mechanism of sulfur curing in the presence of MBTS and ZnO activators is shown in Scheme 2. On the other hand, the decomposition mechanism of ADC, as the most used CFA, is presented in Scheme 3 [166]. It can be seen that ADC decomposition is an auto-catalytic reaction [167]. Therefore, increasing the foaming agent content leads to faster gas generation rates.

Scheme 2.

Sulfur curing process of NR in the presence of MBTS and ZnO as activator.

Scheme 3.

Decomposition mechanism of ADC [166].

These reactions can be controlled by appropriate selection of the processing conditions, such as temperature, formulation (concentrations) and components (molecules), involved in the foaming and curing systems [168]. As mentioned above, a balance between the kinetics of these two reactions is crucial to control the final foam morphology in terms of cell size and cell density. For example, if the rubber has slow curing rate and has not been given sufficient precure at the time of pressure release or once the foaming agent starts to decompose and releases the gas, the gas would either escape from the mass (low efficiency) or the generated cells will collapse due to a lack of material strength (cell wall rupture). On the other hand, if the curing is too far before the gases are released, these molecules will not be able to expand the “stiff” rubber (high viscosity and elasticity) resulting in a hard and high density foam containing a very low number of small cells [169].

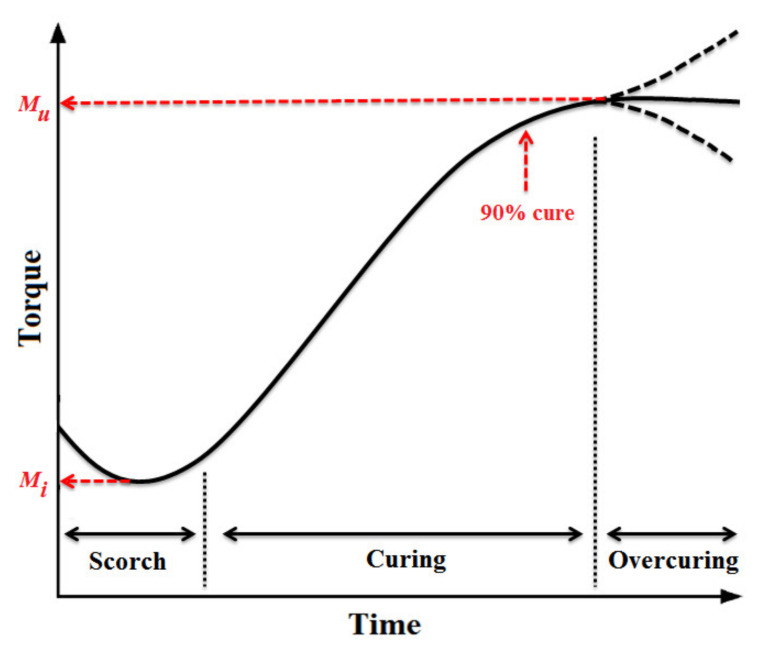

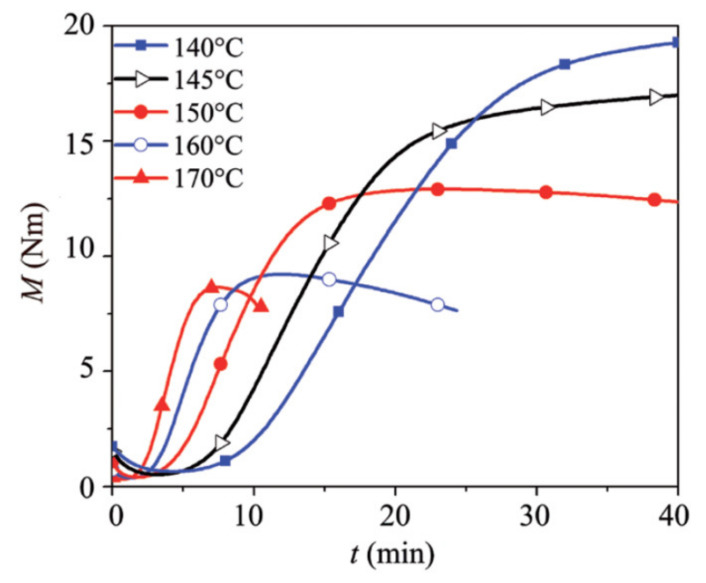

In general, these two chemical reactions occur simultaneously making the system very complex [170]. For a better understanding of the chemical reactions between all the components, the degree of reaction can be indirectly measured. For example, measuring the rubber stiffness via a torque rheometer can be related to the crosslinking density inside rubber compounds. In addition, the pressure–time curve can be another way to get an accurate understanding of the CFA decomposition kinetics. The degree of cure (vulcanization) (αv) and the level of CFA decomposition (αD) can be calculated as [165]:

| (5) |

| (6) |

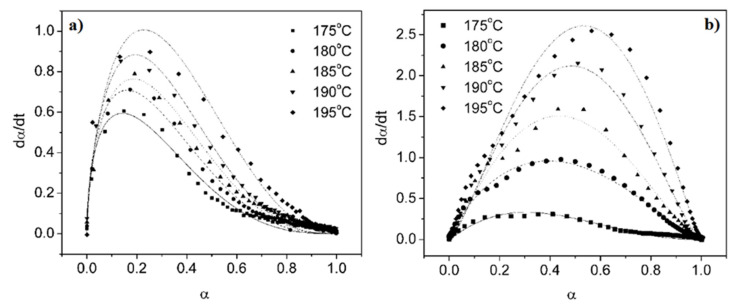

where Mt, Mi and Mu are the torque at a given time t, initial torque (t = 0) and ultimate torque (equilibrium value) respectively, while Pt, Pi and Pu are the pressure at a given time t, initially and equilibrium, respectively. By plotting the reaction rates (dα/dt) as a function of conversion (αv and αD) for various temperatures, Wang and coworkers proposed a mathematical model to relate the time and temperature for EPDM as (Figure 6) [165]:

| (7) |

where K(T) is a function of temperature and f(α) is a function associated with a phenomenological kinetic model and may have different forms based on the reaction mechanisms [171].

Figure 6.

Reaction rate (dα/dt) as a function of conversion (α) for different temperatures: (a) vulcanization and (b) CFA decomposition [165].

According to Figure 6, the shape of the reaction curves is temperature dependent as increasing the temperature results in higher reaction rates. Since the reaction rates are faster at higher temperature, the maximum conversion (α) for both rubber vulcanization and foaming agent decomposition are about 0.24 and 0.50 before the reaction rates decreased. The peak height for foaming agent decomposition was achieved at higher conversion than that of vulcanization for the same temperature. In a similar work, Vahidifar et al. found that the rate of conversion (dα/dt) for ADC decomposition is higher than that for IR vulcanization [93]. The rate of conversion was close to zero at both the beginning and the end of the conversions, while the maximum rate of conversion was larger than zero. These results are characteristics of auto-catalytic reactions and can be approximated by the Šesták-Berggren model as [172,173]:

| (8) |

Combining Equations (7) and (8) gives:

| (9) |

Moreover, the K(T) function depends on the activation energy (Ea) which can be written in the form of an Arrhenius equation as:

| (10) |

Linearization of the Arrhenius equation yields:

| (11) |

where A is the Arrhenius constant, R is the universal gas constant and T is the absolute temperature. According to Equation (11), Ea and A can be calculated from the slope and intercept of the linear form of the Arrhenius plot: ln K(T) vs. 1/T. The results show that Ea for ADC decomposition (Ea = 182 kJ/mol) is higher than that of rubber curing (Ea = 79 kJ/mol), which confirmed that by increasing the temperature of foaming agent decomposition accelerates more than the rubber vulcanizing reaction [93,165].

5. Foaming Technology

There are three main techniques for rubber foam processing: batch foaming, extrusion and injection molding [16,174,175]. Batch foaming is mostly used for bulk products, fundamental studies, laboratory investigations and small production runs, while the other methods are often used for large-scale production at an industrial scale.

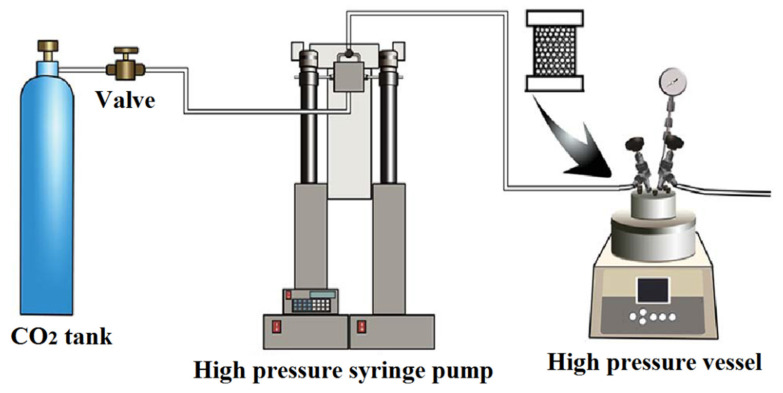

5.1. Batch Foaming

Batch foaming, also known as “solid state foaming”, as the name implies is a batch-wise process in a closed system. Firstly, the neat rubber has to be masticated to decrease the molecular weight and viscosity allowing a simple and homogeneous mixing of additives. Then, all the ingredients, except for the curing agent, are added and mixing is continued for several minutes. Finally, the curing agent is fed and mixed. The prepared compound is stored overnight at room temperature to release residual stress of the rubber molecules during mixing. Then, the compound is placed in a mold and hot pressed at a defined pressure, temperature and time depending on the curing and foaming kinetics as described above. Figure 7 presents a schematic representation of the batch foaming process using a physical foaming agent [176]. The polymer pellets are placed in a stainless-steel mold with micro-nozzles. Then, the mold is put inside a high-pressure vessel (autoclave). After being saturated (specific conditions), the foamed parts are obtained by a rapid depressurization (thermodynamic instability due to the creation of a supersaturated state leading to cell nucleation). The samples produced are usually in the form of circular discs or rectangular/square plates. The sample thickness is usually between 5 mm and 50 mm which is a very important dimensional factor related to gas diffusivity.

Figure 7.

Schematic illustration of the batch foaming process using CO2 as a PFA [176].

5.2. Foam Extrusion

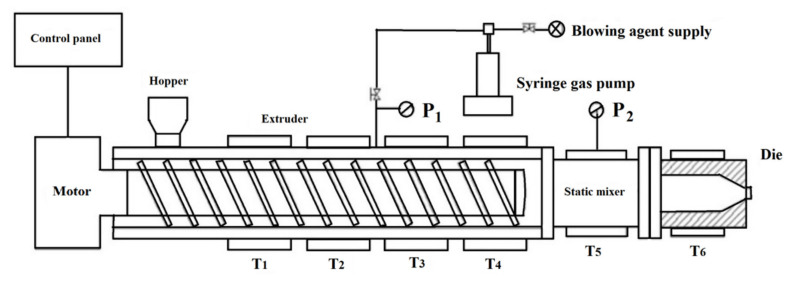

The term extrusion is derived from Greek meaning to ‘‘push out” [177]. Extrusion is a continuous process composed of an extruding unit and a die-shaping unit (Figure 8) [178]. The rubber compounds in strip or pellet forms are fed into the extruder through the feed hopper and drawn into the rotating screw. The screw speed and the barrel temperature profile are controlling the flow rate and temperature [179]. As mentioned before, the crosslinking and foaming reactions are strongly dependent on temperature. Hence, the barrel temperature and the screw speed are two important parameters also affecting the material self-heating via viscous dissipation [180]. On the other hand, the surface quality is an important feature of rubber foam profiles. During extrusion, the high shear stresses in the extrusion die can exceed the tear strength of the rubber compound, resulting in surface defects (cracks) of the extrudate. In addition, the foaming reaction during vulcanization can produce small bubbles on the surface layer resulting in undesired roughness. Thus, the temperature profile and screw speed control the vulcanization and extrusion process, especially for extrusion foaming [181]. In most cases, the final part of this process is calibration and cutting of the extruded profiles. The products of extrusion foaming include insulation foam boards, pipes and other products which can be made by profile extrusion [182,183]. Hopmann and coworkers used extrusion to produce EPDM and NBR foams using water as a physical foaming agent [179]. They found that due to dissipative heating and heat conduction from the extruder into the rubber, the tendency to generate surface defects (cracks and bubbles) increased. Park et al. stated that the cell density of foams produced via extrusion depends on the of rate pressure drop [184,185]. When the pressure drop occurs, the gas molecules in solution either lead to the growth of pre-formed cells or generate new nuclei to lower the system’s free energy. However, increasing the pressure drop leads to the nucleation process being favoredinstead of existing cell growth. Therefore, higher cell density and lower cell size is obtained [186]. The effect of pressure and shear stress on cell nucleation in foam extrusion was studied by Lee, who found that shear rate has a direct effect on cell nucleation [187]. Chen and coworkers stated that the relation between pressure drop rate and shear stress is very critical when the saturation pressure is low [188]. This is due to the lack of sufficient driving force for cell nucleation. In general, shear stresses have a higher effect on cell nucleation compared to the pressure drop rate. The main reason is that the volume of gas molecules needed for cell nucleation decreases by imposing shear stresses.

Figure 8.

Schematic representation of an extrusion foaming system based on PFA [189].

5.3. Foam Injection Molding

Conventional injection molding (CIM) and foam injection molding (FIM) are methods used for unfoamed and foamed products, respectively. In general, injection molding is composed of two parts: injection unit and clamping unit [190,191]. After adding the rubber compounds into the screw in the shape of pellets through the hopper, the injection unit melts the rubber compounds and maintains the injection pressure during mold filling. The function of the clamping unit is for precise mold opening and closing with an appropriate clamping force, cooling, and sample demolding.

The reciprocating screw motion in the injection molding is the main difference with extrusion. In foam extrusion, the screw rotation continuously pushes the melt forward and out of the extruder through the die. However, in injection molding, the screw rotates and moves backwards due to the accumulation of a pool of gas-loaded melt at the tip of the screw. Thereafter, the gas-filled melt is injected through the nozzle (channel) into the mold cavity at high temperature and pressure. In order to compensate for shrinkage, a holding step is applied to further fill-in the mold after the melt injection process is completed. The mold is then opened, and a rapid pressure drop occurs (atmospheric pressure). Cell growth occurs after cell nucleation, followed by expansion and stabilization of the cellular foam with an unfoamed layer (skin) which is dependent on the degree of rapid cooling of the mold [192]. Altogether, this method decreases the cycle time and improves the quality of foaming as much lower pressure and clamping force is needed leading to lower production cost [41]. Injection molding is the most promising process because it can produce products of variable geometry and size ranging from microprocessor sockets to automobile door modules [183]. Moreover, foamed rubber molded parts are used in several applications due to their low material use, great dimensional stability, low back pressure, wide range of mechanical properties and high stiffness-to-weight ratio [56,74,193,194,195,196]. Today, the process is highly controlled and understood via several tools like numerical analysis and process parameter optimization [197]. Table 5 presents a comparison between batch foaming, extrusion foaming and injection molding foaming to manufacture rubber foams.

Table 5.

Comparison between the main rubber foaming methods: batch, extrusion and injection molding.

| Technique | Formation Method | Structure | Properties |

|---|---|---|---|

| Batch foaming | After masticating the neat rubber, all the ingredients, except for the curing agent, are added and mixing is performed for several minutes. Finally, the curing agent is added and mixed. The prepared compound is placed in a stainless-steel mold. Thereafter, the mold is put inside a high-pressure vessel (autoclave) at a defined pressure, temperature and time depending on the curing and foaming kinetics. After being saturated, the foamed parts are obtained by a rapid depressurization. |

|

|

| Foam extrusion | The prepared rubber compounds in strip or pellet forms are fed into the extruder through the feed hopper and drawn into the rotating screw. The screw rotation continuously pushes the melt forward and out of the extruder through the die. The final part of this process is calibration and cutting of the extruded profiles. |

|

|

| Foam injection molding | After adding the prepared rubber compounds into the screw in the shape of pellets through the hopper, the injection unit melts the rubber compounds and maintains the injection pressure during mold filling. Then, the gas-filled melt is injected through the nozzle into the mold at high temperature and pressure. Finally, the mold is opened, and a rapid pressure drop occurs leading to foaming. |

|

|

6. Foam Morphology

As mentioned before, two categories of parameters are affecting the physical and mechanical properties, as well as the microstructure of rubber foams. The foaming process consists of two fundamental steps: nucleation and growth. After decomposition of the chemical foaming agent or injection of a physical foaming agent, a new phase (bubble phase) is generated that is called the nucleation step. In the growth phase, the bubble nuclei grow into final bubbles or cells. Both steps are affected by several physical properties such as viscosity, solubility, diffusivity, surface tension and glass transition temperature. Since the foaming and curing processes are performed simultaneously, controlling the nucleation and growth steps is very complex. A proper selection of the formulation (foaming and curing systems) and processing parameters (pressure, temperature, time, etc.) is crucial to obtain a specific morphology and structure of rubber foams [198,199]. In the next section, the effect of these processing parameters (foaming and curing) is discussed in detail.

6.1. Thermodynamics of Nucleation

Foaming is an intricate process involving some thermodynamics phenomena, kinetics and transport phenomena [200]. The complete control of all the aspects related to cell morphology is a challenging issue in the rubber foam industry. Since cell nucleation and growth are the main steps governing the final foam structures and quality, a better understanding of the mechanisms involved in these processes is important for process optimization and to control the final foam structure.

During foaming with a chemical foaming agent, the decomposition of the solid CFA (powder) produces some residues remaining in the rubber matrix. This can be advantageous (heterogeneous nucleation effect) or not (contamination/properties loss). Since a small amount of gas molecules is used for the nucleation step, achieving a product with high cell density and uniform cell morphology is difficult. Therefore, the main part of gases produced is used for cell growth. On the other hand, the viscoelastic behavior of the matrix plays an important role in rubber foaming: low viscosity leads to cell collapse and cell coalescence, while high elasticity restricts the bubble nucleation and growth steps. Therefore, a balance must be achieved as a minimum level of pre-crosslinking is helpful to optimize the foaming behavior, but not too much to impede it [201].

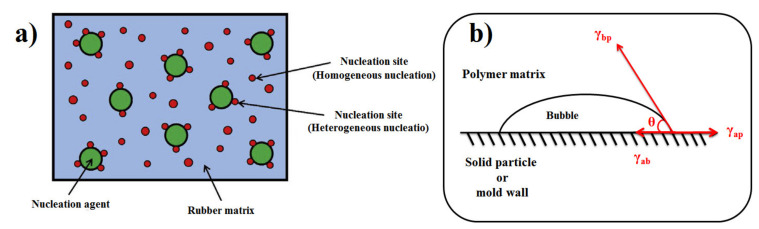

The classical nucleation theory is mostly used to model the bubble nucleation inside the rubber matrix [202,203]. This theory was originally developed for liquid droplet formation from a vapor, but it can also be applied to the inverse case of interest in polymer foaming applications. However, several approximations are needed for using this method. Firstly, only homogeneous nucleation takes place and the interfacial tension between the gas nuclei and the matrix is considered equal to the surface tension [204,205]. The CFA decomposition produces the gas nuclei inside the rubber matrix which can be attributed to both homogeneous and heterogeneous nucleation. The gathering of gas molecules inside the rubber matrix leads to homogeneous nucleation. On the contrary, heterogeneous nucleation occurs when the nuclei are formed on the boundaries between two phases like on the surface of solid particles (fillers or impurities), on preexisting gas cavities, or between areas of different density due to the dispersed crystallites or due to insufficient thermal processing during rubber molding. However, the activation energy of homogeneous nucleation is much higher than that of heterogeneous nucleation, so the latter is more favorable. Figure 9a presents a schematic diagram of the homogeneous and heterogeneous nucleation during foaming in the presence of nucleation agent. Although this theory has been able to describe the effect of pressure and temperature on nucleation (qualitative analysis), it has been shown to be inappropriate to describe with precision the bubble nucleation step inside polymer matrices [206]. The generation of bubbles via homogenous nucleation occurs randomly and spontaneously without any foreign bodies or additives (like for heterogeneous nucleating agents). In fact, a local fluctuation in temperature and/or pressure leads to homogenous nucleation. On the contrary, heterogeneous nucleation does not occur spontaneously. It is triggered by the presence of a second phase (additives) acting as nucleation points decreasing the nucleation energy and increasing the nucleation rate [207]. The presence of additives lowers the Gibb’s free energy, but this depends on the particle surface topography (shape factors).

Figure 9.

(a) Schematic diagram of homogeneous and heterogeneous nucleation during foaming in the presence of a nucleation agent [73] and (b) interfacial tensions of the optimum bubble shape for heterogeneous nucleation.

The homogeneous nucleation of gas nuclei inside a metastable polymer matrix with dissolved additives can be defined by the classical nucleation theory with modifications accounting for changes in free volume and interfacial energy [208]. The production of a gas bubble in a polymer through a reversible thermodynamic process has an excess energy associated to:

| (12) |

where Vb is the volume of the bubble nuclei, ΔP is the pressure difference between the inside and outside of the gas bubble, Abp is the surface area of the bubble and γbp is the interfacial tension associated to the matrix-bubble interface. This excess energy can be minimized by a suitable choice of the bubble shape. If γbp is isotropic, this shape will be spherical with a radius r and Equation (12) becomes [209,210]:

| (13) |

When ΔG is plotted against r, the curve shows a maximum at a critical radius rc given by:

| (14) |

The maximum value of ΔG for homogeneous nucleation is obtained by substituting Equation (14) into Equation (13) to give:

| (15) |

As mentioned before, heterogeneous nucleation occurs on the mold walls or/and by addition of an insoluble phase (solid particles) to the solution as illustrated in Figure 9b. The nucleus has the shape of a spherical cap to minimize the energy and the ‘wetting’ angle θ is given by a force balance at the interface. The relation for stress equilibrium is [211]:

| (16) |

where γap, γbp and γab are the interfacial tension between the solid particle-polymer matrix, bubble-polymer matrix and solid particle-bubble, respectively. The heterogeneous critical nucleation energy at equilibrium state is given by:

| (17) |

| (18) |

| (19) |

where Vb is the volume of the bubble, while Abp, Aab and Aap are the bubble-polymer matrix, solid particle-bubble and solid particle-polymer matrix interfaces, respectively. The differentiation of Equation (18) provides an expression for the critical nucleus radius r* as:

| (20) |

so,

| (21) |

| (22) |

Because S(θ) has a value always smaller than 1, the heterogeneous critical nucleation is smaller than for the homogenous one according to Equation (22) [207].

6.2. Foaming Process

The rubber foaming process can be decomposed into three steps: creating small discontinuities or cells in a fluid or polymer phase (nucleation), allowing these cells to grow to a desired volume (growth) and stabilizing this cellular structure by physical or chemical means (stabilization). Temperature, pressure, and number of expansion step (one-stage or two-stage) are important foam processing factors affecting these three steps controlling the microstructure, density, mechanical and physical properties of the final foams. The next section reports on the effect of these three factors.

6.2.1. Temperature

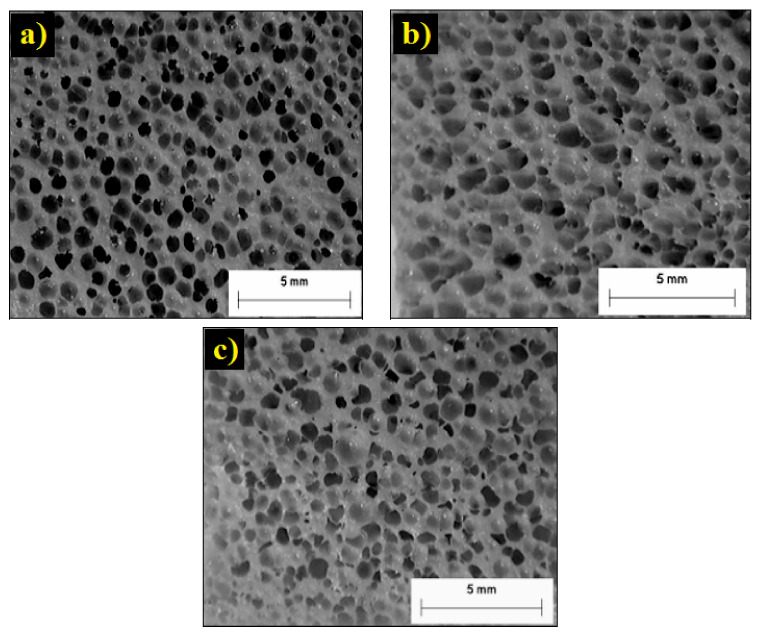

Temperature mainly controls the melt viscosity which has a direct effect on cell size and cell density (foam density) [212]. For a successful foaming process, the temperature must be low enough to increase the viscosity and have good nucleation, while cell expansion requires low viscosity (high temperature) for easier expansion, but not too much to prevent cell collapse/coalescence. Vahidifar et al. reported that the cell structure evolution is related to a competition between two phenomena. The first one is the volume and the rate of gas released from the foaming agent decomposition as a foaming driving force resulting in high cell nucleation and growth, while the second one is an increased resistance of the matrix (viscosity) due to the crosslinking reaction limiting further expansion leading to stabilization [169]. Hence, the optimum foaming temperature can be determined due to a competition between foaming and curing processes. Zakaria and coworkers investigated the effect of foaming temperature (140, 150 and 160 °C) on the cell morphology of EPDM foams [199]. They used sodium bicarbonate as CFA which has a decomposition temperature in the range of 120–200 °C. Increasing the foaming temperature resulted in foams with larger cells as indicated in Figure 10. The foam prepared at 140 °C had a more uniform cell structure with discrete cells compared to the cell morphology produced at 150 °C and 160 °C. In addition, the foam prepared at lower temperature had thicker cell walls than the foams made at high temperatures due to the smaller cell produced at lower temperature. However, the cell size at 160 °C is slightly smaller than at 150 °C. The reason is that at higher foaming temperature the crosslink rate is significantly increased preventing complete expansion. At higher foaming temperature, higher volume of gas is generated by the CFA promoting the cell expansion and subsequently the cells will come into contact and combine with each other to produce larger cells (coalescence). The physical and mechanical properties of NR foams were investigated as a function of the foaming temperature (145–155 °C) [213]. The density of the foamed NR decreased with increasing foaming temperature. The NR foamed at lower temperature (145 and 150 °C) had lower densities than those foamed at higher temperature (155 °C) because the cell density inside the rubber matrix increased with increasing temperature. They also found that the optimal temperature for vulcanization and foaming was 155 °C for these NR foams. The tensile strength was found to decrease with increasing temperature because of the lower density, indicating better foaming efficiency. Moreover, the tear strength and tensile modulus continuously decreased with increasing temperature.

Figure 10.

Morphology of EPDM foams produced under different temperatures: (a) 140 °C, (b) 150 °C and (c) 160 °C [199].

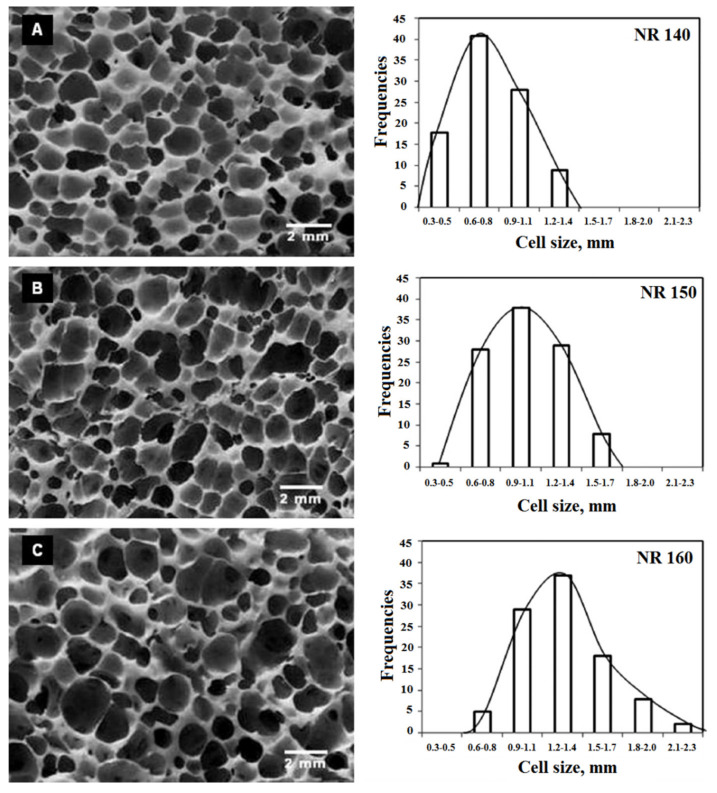

Najib and coworkers reported that a higher foaming temperature generates a higher gas pressure stretching more the cell walls [77]. This expansion of the cell walls led to a relatively larger cell structure resulting in lower foam density. Hence, the amount of solid phase is reduced (per unit volume), and less crosslinking occurs. Figure 11 shows the variation of the foam morphology and cell size distribution as a function of foaming temperature. Increasing the foaming temperature not only improved the cell size distribution, but also extended the cell size distribution range. NR foams produced at 140 °C had a more uniform cell size distribution compared to the foams manufactured at 150 °C and 160 °C.

Figure 11.

Morphology and cell size distribution of NR foamed under different temperature: (A) 140 °C, (B) 150 °C and (C) 160 °C [77].

6.2.2. Pressure

Another important factor affecting the morphology of rubber foams is the pressure used to form/mold a sample. The effect of foaming pressure on the morphology and mechanical properties of NR foam using DPT was studied by Kim and coworkers [214]. Increasing the foaming pressure resulted in higher foam density (lower expansion ratio) and lower foaming efficiency. The mechanical properties of NR foams, such as tear strength and hardness, gradually increased with increasing foaming pressure, while the elongation at break decreased.

Since the most widely used physical foaming agent is scCO2, as an environmentally friendly alternative, the saturation pressure is strongly affecting the cellular microstructure [146,215]. Tessanan and colleagues examined the effect of pressure (0, 8.5, 10.5 and 12.5 MPa) on the structure of NR foams using scCO2 [73]. Their results showed that the average cell size decreased (less than 10 µm) and the cell size distribution was relatively narrower by increasing the saturation pressure. The main reason is that the activation energy for nucleation is lower with increasing pressure (Equation (15)) and a higher amount of gas molecules (saturation/solubility) is available to generate the nuclei. This large amount of cell nuclei density simultaneously growing in a restricted volume leads to a higher number (cell density) of smaller cells (average diameter) and a more uniform cell structure (narrower distribution) [176]. In another work, a series of microcellular high temperature vulcanizates (HTV) silicone rubber foams were produced using CO2 [216]. It was shown that CO2 diffusivity in the HTV silicone rubber also increased with saturation pressure. Moreover, the cell diameter decreased, and the cell density increased with increasing saturation pressure because higher pressure led to more CO2 absorbed by the matrix (higher gas concentration). Therefore, this high CO2 concentration increased the nucleation ability leading to a cell diameter reduction, i.e., since the amount of gas is fixed, a higher number of smaller cells is produced.

6.2.3. Number of Stages

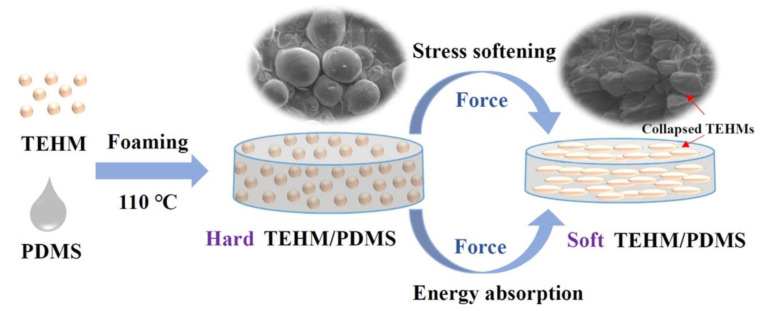

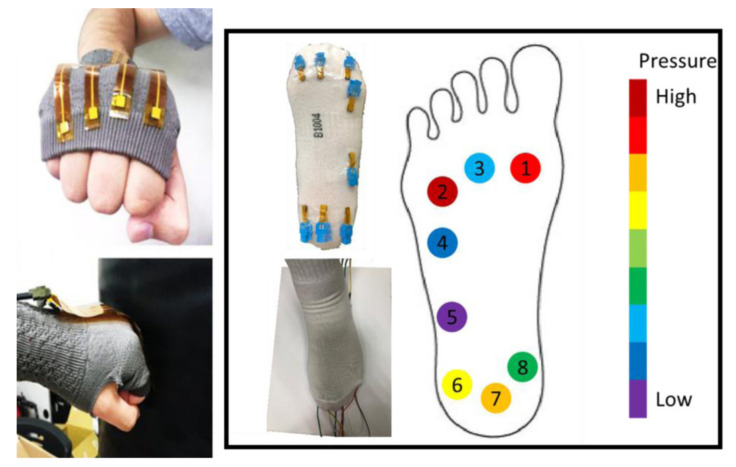

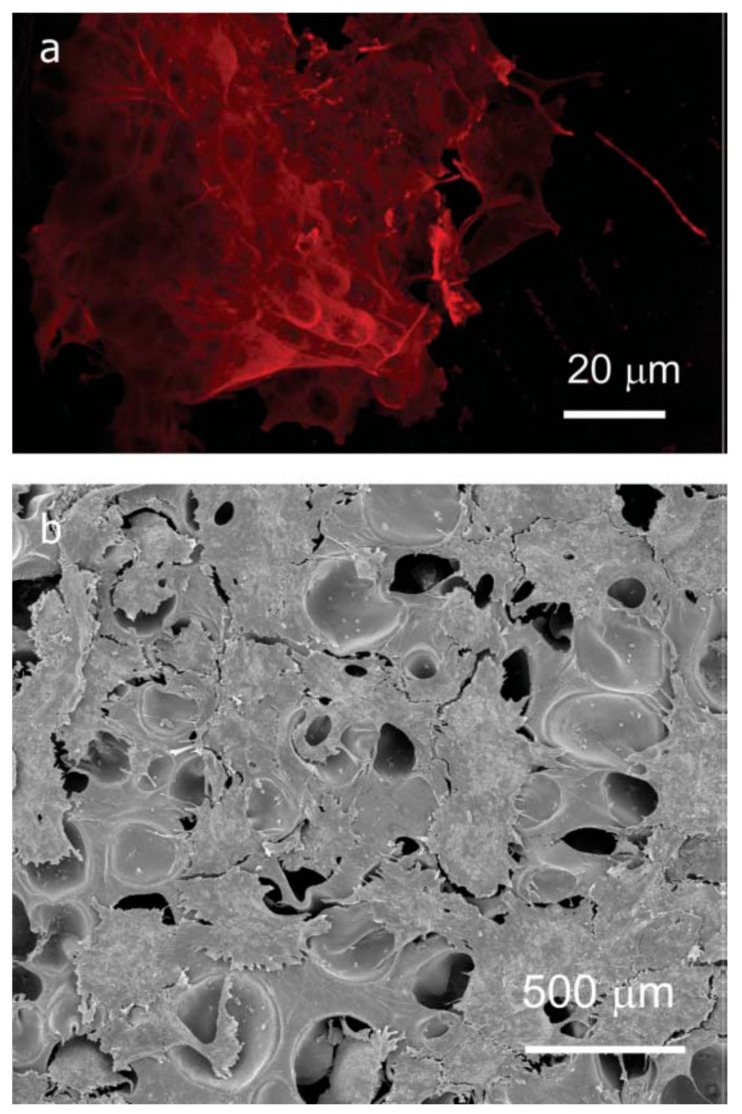

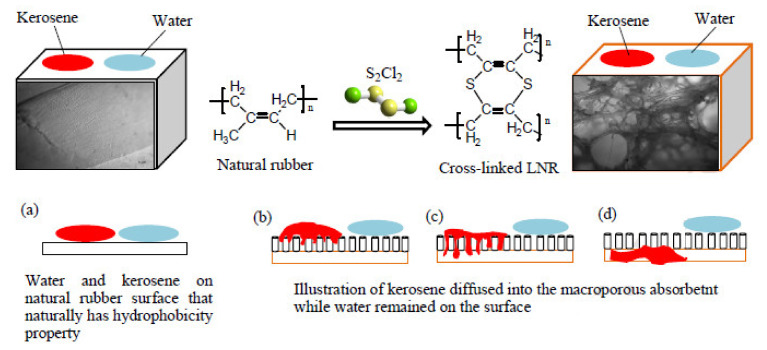

The expansion of rubber foams can be performed via a single stage or multiple (usually two) stages [217,218]. Basically, the first stage of a two-stage expansion is the same as for the single-stage process, but after pressure release (mold opening or outside an extrusion die), the expandable compound is immediately transferred to a circulating hot air oven at a higher temperature [83]. The one-stage process is known as a pressure-induced method, while the two-step process is usually referred to as a temperature-induced method [41].