Abstract

Passive explosion suppression remains an indispensable auxiliary method for gas explosion suppression due to its low cost. To explore a new type of explosion passive suppression technology, three rectangular cavities with different width–diameter ratios were designed and laid in a large-scale methane/air explosion experiment system, and its explosion suppression performance was evaluated by measuring the changes in the explosion flame and shock wave before and after passing through the cavity. The results show that the suppression effect of the cavity is affected by its width. The larger the width–diameter ratio, the faster the attenuation of the flame and shock wave. The cavity-combined aluminum hydroxide powder effectively improves the suppression effect. When the filling amount of the powder is 140 g, the flame is quenched. However, there is an optimal powder filling degree for the suppression of the shock wave in the limited space of the cavity. In the test range, the maximum decay rate of the overpressure and impulse are 49.4 and 39.4%, respectively. This study can provide theoretical guidelines for the suppression of gas explosion.

1. Introduction

Energy is the foundation of economic development and social progress.1 With the consumption of crude oil fuel and the enhancement of the awareness of reducing fuel pollution to the environment, people begin to pay more attention to the characteristics of alternative fuels.2,3 Methane, as the main component of natural gas, is considered to be one of the best fuels.4 Any work which results in an improvement in the safety and efficiency of exploitation of the methane plays an enormous economic and social role. However, methane is one of the most harmful greenhouse gases.5 If it is directly discharged into the atmosphere without treatment or recycling, it can survive for 9–15 years (average perturbation life 12.4), and the greenhouse effect will be about 21 times that of CO2. Based on artificial neural networks and selected statistical methods, Tutak and Brodny6 developed a method to predict methane emissions and determine trends in terms of the amount of methane that may enter the natural environment in the coming years and the amount that can be used as a result of the methane drainage process. Reasonable development and utilization of gas can avoid ecological pollution and resource waste effectively. However, due to its flammable and explosive properties, methane also poses a significant threat to the safety of mining processes.7 Methane/air explosion accidents often occur in the process of underground mining excavation and pipeline transportation, which cause damage of shock waves and high-temperature burning to the surrounding long-narrow confined spaces. Moreover, it will certainly result in property losses and even casualties, seriously restricting the safety of industrial production. Therefore, it is of great practical significance to study how to suppress gas explosion and minimize the hazards of explosion to ensure the safe production of coal mines and promote the safe utilization of clean energy.

The explosion of flammable gas in pipes and the explosion of coal mine gas are two main forms of explosion disasters in the field of industrial production.8,9 At present, the prevention and control of explosion accidents usually adopt measures such as explosion suppression and explosion venting. Among them, explosion suppression is one of the most effective measures to reduce and control explosion hazards,10−12 and it has been widely used in industrial explosion prevention practice. The effective gas explosion suppressants currently known include inert gas,13,14 water mist,15,16 chemical dry powder,17 rock dust,18 porous material,19,20 and aerosol.21 Moreover, a large number of studies show that the type, particle size, spray mode, and mass concentration of the explosion suppression medium can affect the suppression effect to a certain extent.18,22−24 In order to further enhance the explosion suppression effect of the medium, Pei et al.25 studied the synergistic inhibition effect of CO2 and ultrafine water mist on methane explosion. The experimental results showed that the inhibiting effect on flame propagation speed and overpressure of the combined use was greater than that of either individual suppressant, and Wang et al.26 also pointed out that the gas–solid two-phase synergistic suppression of gas explosion is better than a single explosion suppression method. In terms of explosion suppression devices, AL-Zuraiji et al.27 evaluated the effectiveness of an inline flame arrester for the mitigation of methane explosions in a large-scale detonation tube and verified that the flame propagation speed and explosion pressure wave velocity of the 9.5% methane–air mixture can be reduced by 40 and 44%, respectively. Jiang et al.28 designed an explosion suppression structure of the vacuum chamber attached to the side of a straight pipe, which used its pressure difference to suck the ignited gas and unignited gas into the chamber, so as to reduce the harm of flame and overpressure caused by the explosion. Moreover, it was pointed out that the explosion suppression effect of the vacuum chamber was affected by the diaphragm thickness and vacuum degree.29,30

The effectiveness and reliability of the explosion suppression technology depend not only on the physical and chemical properties of the explosion suppression medium and the spatial geometric parameters of the explosion suppression device but also on the triggering method of the explosion suppression system. According to different triggering modes of explosion suppression devices, explosion suppression technology can be divided into active explosion suppression and passive explosion suppression. The effect of active explosion suppression is better, but the production and maintenance costs are high.31 Once the active measures fail, the passive prevention and control measures are particularly important. However, the traditional passive explosion suppression devices, such as watershed and rock dust shed, have poor explosion suppression effects,32 so it is necessary to explore a new type of gas explosion suppression device. Based on this, the authors designed a kind of rectangular cavity connected in the straight pipe, hoping that the structure can attenuate the explosion intensity to a certain extent. The aim of this research was to verify the explosion suppression performance of the cavity and to explore the influence of the cavity width on the explosion suppression effect. In addition, on the basis of the explosion suppression by the device of the cavity, the authors envisaged combining the material wave elimination mechanism (i.e., by filling the cavity with explosion suppression powder) to further improve the explosion suppression performance of the passive explosion suppression device. If the scheme is feasible, a cavity with hanging explosion suppression dry powder shed can be set in the gas extraction roadway and transportation pipeline every certain distance, so as to reduce the scope and intensity of the gas explosion as much as possible. Some of the features of the paper prove that it is original and innovative. First, the rectangular cavity used in this paper is self-designed, and it is also the first proposal to lay it in a straight pipeline for the suppression of gas explosion. Therefore, the explosion suppression performance of this structure is explored for the first time. Second, to our knowledge, the current research on explosion suppression tests is more unilaterally focusing on explosion suppression devices or explosion suppression materials, and there are few studies combining the two to explore the effects of explosion suppression. In this paper, both wave elimination by the device (the cavity) and explosion suppression by the powder material (aluminum hydroxide) are integrated to explore their effects on explosion suppression performance. Third, gas explosions have been usually conducted in laboratory chambers of different sizes. The mostly used chambers include 20 L explosion chambers and 1 m3 explosion chambers. In this paper, in order to better simulate the actual gas explosion environment, the authors used a self-built large-scale circular tube gas explosion experiment system with a length of 36 m and a pipe diameter of 200 mm.

In order to verify the explosion suppression effect of the rectangular cavity, the experiments were carried out by installing a single rectangular cavity with different widths in the self-built gas explosion test system. Based on the theoretical analysis, the relationship between the width of the cavity and the evolution law of gas explosion characteristic parameters was explored. In addition, in order to try to further improve the effect of explosion suppression, the experiment was carried out in combination with the wave elimination method of the material by filling aluminum hydroxide powder in the cavity, and the explosion suppression mechanism of the cavity-combined suppressant was expounded by means of thermal analysis of powder materials. The results of the study have a positive effect on exploring new technologies for the prevention and control of methane/air explosions.

2. Experimental Setup and Methods

2.1. Experimental Apparatus

The experiment was carried out using a large-scale round pipe gas explosion system with a length of 36 m, which consists of the explosion test pipe network, gas distribution, ignition, explosion suppression device, and data acquisition, as shown in Figure 1. The explosion test pipe network system is made of steel round pipes with a diameter of 200 mm and a thickness of 10 mm, which are resistant to explosion impact. The flanges, rubber gaskets, and asbestos gaskets are used to connect and seal round pipes to ensure air tightness between pipes. The gas distribution system consists of the air compressor, vacuum pump, high-pressure methane, digital vacuum pressure gauge, and circulation pump. The ignition system is composed of the fuse, electrode, wire, and power supply. The electrode is placed on the flange at the beginning of the pipe network system, and an ignition energy of 10 J is selected as the starting energy for the experiments.33 The explosion suppression device is a self-designed rectangular cavity, and its physical picture is shown in Figure 2. The dimensions of the cavity (length × width × height) mentioned in the experiments include 500 mm × 300 mm × 200 mm, 500 mm × 500 mm × 200 mm, and 500 mm × 800 mm × 200 mm. The data acquisition system consists of pressure sensors, flame sensors, transmitter, data collector, and working machine. Among them, the pressure sensor is the CYG1401 pressure sensor with a range of 0–1 Mpa and an accuracy class of 0.5% full scale. The flame sensor adopts the CKG100 flame sensor, which records the flame signal and flame arrival time. The flame signal refers to the electrical signal converted from a flame optical signal. The initial rising moment of the flame signal is close to the initial moment of the flame front in the preheating zone, so it can be selected as the flame arrival time.10 The data collector uses the 16-channel TST5206 high-speed data with the highest sampling rate of 20MSPS and accuracy level of 0.1% full scale. The photograph of the experiment system is shown in Figure 3, and the positions of the pressure and flame sensor measuring points are shown in Table 1.

Figure 1.

Schematic diagram of the gas explosion experiment system.

Figure 2.

Rectangular cavity.

Figure 3.

Photograph of the experimental system.

Table 1. Positions of Pressure and Flame Measuring Points in the Pipe (m).

| no. of pressure sensors | M1 | M2 |

| distance from the ignition end | 13.25 | 14.35 |

| no. of flame sensors | N1 | N2 | N3 | N4 |

| distance from the ignition end | 13.20 | 13.30 | 14.30 | 14.40 |

2.2. Experimental Methods

The experiments were conducted under three conditions: (1) explosion in a straight pipe without a cavity attached, (2) a single cavity with different widths was attached at a distance of 13.5 m from the ignition end, and (3) the single cavity was filled with aluminum hydroxide powders of different qualities.

Test steps: (1) connecting the pipe network system according to the test plan, sealing the detonating tube with the polyethylene film with a thickness of 0.4 mm at the position of 11 m away from the ignition electrode, and using the air compressor to supply the air under positive pressure to check whether the sealing performance of each connection was intact; (2) using a vacuum pump to vacuum the pipes and adopting the Dalton partial pressure method to complete the configuration of explosive mixed gas; in this experiment, 11% gas concentration was chosen as the mixed concentration of each experiment, which had the greatest impact effect under the experimental conditions;34 (3) using a circulating pump to circulate the mixed gas of methane and air in the detonation tube for 10–20 min, so that methane and air could be mixed evenly in the pipes, and (4) after clearing the site and confirming the safety, the ignition system was used to initiate the explosion. The flame and pressure parameter evolution curves were obtained through the cooperation of flame sensors, pressure sensors, and data acquisition processor test software.

3. Results

Although the explosion accident has its own destructive effects, such as thermal radiation, debris effects, and toxic gases, the most dangerous and destructive effect is the explosion wave.30 The suppression effect of the cavity on the methane/air explosion was investigated by analyzing the four parameters (the maximum flame signal, flame propagation speed, overpressure peak, and impulse) in front of and behind the cavity. The decay rate of the abovementioned four physical parameters is defined as the ratio of the loss value of the physical quantity pass through the cavity to the initial value of the physical quantity in front of the cavity, which is expressed as a percentage. Three sets of gas explosion experiments were carried out for each cavity structure, and one typical set of experimental data was selected for result analysis.

3.1. Explosion Suppression by a Single Cavity with Different Widths

3.1.1. Analysis of Explosion Flame

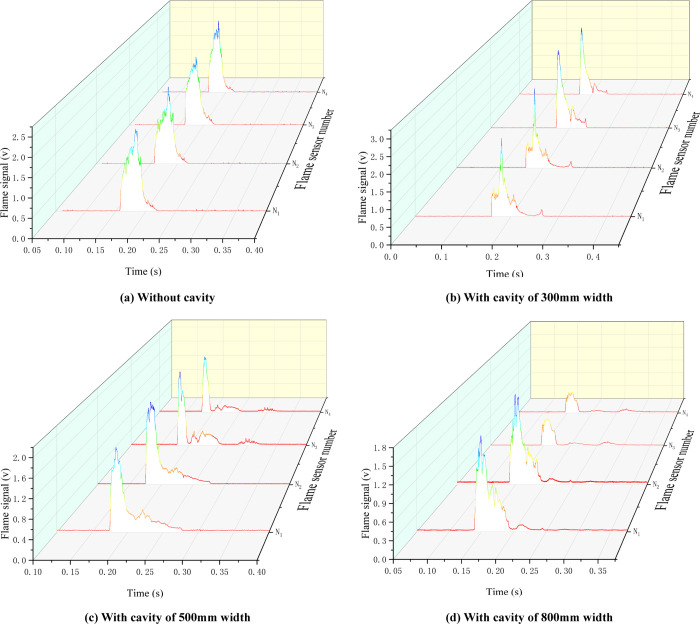

Figure 4 shows the signal intensity curves at each flame measuring point under the condition without a cavity and a cavity with different widths attached to the straight pipe. The maximum value of the flame signal at each measuring point is sorted out, as shown in Table 2. The maximum signal at each flame measuring point is represented by Fi (i is the number of the flame sensor). It can be seen that with the increase in cavity width, the maximum flame signal value at the measuring points (N3 and N4) behind the cavity decreases significantly compared with those at the measuring points (N1 and N2) before the cavity, that is, the intensity of the flame is obviously attenuated after it has propagated through the cavity. Moreover, the flame oscillation is more obvious after laying a cavity. This is due to the instability of flame propagation caused by diffusion, reflection, and superposition in the cavity when the flame passes through the cavity.35 When no cavity is attached, the maximum signal decay rate of flame is −5.8%. It shows that the intensity of explosion flame continues to increase when it passes through this part between the measuring points. When the cavity with a width of 300 mm is attached, the decay rate of the maximum signal is −9.7%. The maximum flame signal value of the flame is increased to a certain extent compared with the case without the cavity. As the cavity width increased from 500 to 800 mm, the decay rate of the maximum flame signal increased from 7.7 to 69.3%. Therefore, the maximum signal of the explosion flame is affected by the cavity width. When the width of the cavity is narrow, the cavity has an enhanced effect on the maximum signal of explosion flame. With the continuous increase in the width of the cavity, the maximum signal of explosion flame can be well suppressed after passing through the cavity.

Figure 4.

Flame signal at each measuring point under different conditions: (a) without a cavity, (b) with a cavity of 300 mm width, (c) with a cavity of 500 mm width, and (d) with a cavity of 800 mm width.

Table 2. Maximum Signal of Flame at Each Measurement Point under Different Test Conditions.

| in front of the cavity |

behind the cavity |

|||||

|---|---|---|---|---|---|---|

| no. | F1 (V) | F2 (V) | average value (V) | F3 (V) | F4 (V) | average value (V) |

| without chamber | 2.13 | 2.21 | 2.17 | 2.14 | 2.45 | 2.295 |

| chamber of 300 mm width | 2.34 | 2.63 | 2.485 | 2.81 | 2.64 | 2.725 |

| chamber of 500 mm width | 1.74 | 1.89 | 1.815 | 1.84 | 1.51 | 1.675 |

| chamber of 800 mm width | 1.64 | 1.71 | 1.675 | 0.56 | 0.47 | 0.515 |

The interval between two flame measuring points divides the time difference in which the flame signal reaches the two measuring points to get the average flame speed. When no cavity is attached, the average flame speed increases from 256.4 to 316.5 m/s. When the cavity with a width of 300 mm is attached, the average flame speed decreases from 275.1 to 200 m/s after passing through the cavity, and the decay rate of the average flame speed is 27.3%; when the cavity with a width of 500 mm is attached, the average flame speed decreases from 271.7 to 164.4 m/s after passing through the cavity, and the decay rate of the average flame speed is 39.5%. When the cavity with a width of 800 mm is attached, the average flame speed decreases from 299.4 to 121.7 m/s, and the decay rate of the average flame speed is 59.4%. Therefore, the propagation speed of flame can be reduced to a certain extent by all cavities within the size range of the test. The main reasons are as follows: on the one hand, when the flame propagates from the straight pipe with a small cross section to the cavity with a large cross section, the sudden change in cross-sectional area will produce an effect similar to pressure relief, which will lead to a deceleration of the flame propagation speed. On the other hand, after the flame wave propagates into the cavity, it will cause friction, reflection, diffraction, and other effects with the wall surface of the cavity, making the flame wave to lose a part of the kinetic energy and increasing the turbulence of the flame.35 However, excessive turbulence is not conducive to flame propagation,36 so the overall performance is that the flame propagation speed decreases after passing through the cavity. In addition, the suppression effect becomes more obvious as the cavity width increases.

3.1.2. Analysis of Explosion Overpressure

Figure 5 shows the time history curve of overpressure at each pressure measuring point under different conditions. It can be seen that the change in the shock wave intensity between the pressure measuring point is similar to that of the flame when a cavity is not attached, and both of them show a growth trend, while the shock wave can be attenuated to a certain extent after the cavity with different widths is laid in the pipe network. The enhancement of the shock wave between the measuring point M1 to M2 when a cavity is not laid can be explained as follows: the precursor shock wave breaks the diaphragm and carries part of the unburned gas, while the distance between the pressure measuring point and the sealing film is relatively short and the combustion reaction is violent, and the unburned gas is ignited by the immediately following flame front to generate the “exhausting and carrying effect”. The heat released by its continued reaction is greater than the heat lost from friction with the wall, heat conduction, and heat radiation, which timely replenishes the energy for the propagation of the shock wave and enhances the intensity of the explosion shock wave.

Figure 5.

Overpressure curve at each measuring point under different conditions: (a) without a cavity, (b) with a cavity of 300 mm width, (c) with a cavity of 500 mm width, and (d) with a cavity of 800 mm width.

Figure 6 presents the peak value of overpressure at each measuring point. When the cavity is not laid, the peak value of overpressure at M2 is 0.272 MPa. Compared with the overpressure at the M1 measuring point of 0.216 MPa, the decay rate of overpressure is −25.9%. However, the overpressure peak at M2 after a cavity is laid is less than that in the case of no cavity, and as the width of the cavity increases, the suppression effect of the explosion overpressure peak becomes more obvious. When laying the cavity with a width of 800 mm, the overpressure peak can be reduced to 0.134 MPa, and the decay rate of overpressure can reach 28.3%.

Figure 6.

Maximum overpressure and decay rate under different experimental conditions.

According to the overpressure–impulse principle (ΔP–I principle), the damage effect of the shock wave on a target is determined by overpressure (ΔP) and impulse (I). The target can ultimately be damaged when both of the variables reach or exceed a critical value.

The impulse before and after the shock wave passes through the cavity can be calculated using eq 1.29

| 1 |

where td is the duration of the positive phase, ta is the time of arrival of the blast wave, and P(t) is the overpressure as a function of time.

As shown in Figure 7, the impulse shows an increasing trend between the two pressure measuring points when a cavity is not attached. The impulse at the M2 measuring point is 0.03174 MPa·s, and the decay rate of impulse is −22.3%. While the shock wave impulse can be attenuated to varying degrees when cavities with different widths are attached to this section, the suppression effect of shock wave impulse is better as the cavity width increases. In the test range, the impulse of the shock wave can be attenuated from 0.01767 MPa·s in front of the cavity to 0.01329 MPa·s in back of the cavity after passing through the cavity with a width of 800 mm, and the decay rate of impulse is 24.8%.

Figure 7.

Impulse and decay rate under different experimental conditions.

3.1.3. Theoretical Analysis of Shock Wave Propagation Characteristics with Variable Section Width

When the cavity structure is attached to the gas extraction roadway and the transportation pipeline, considering that it is more feasible to change the width of the cavity than to change the height, the influence of the variable section width of cavity on the propagation characteristics of the shock wave is discussed. The propagation process of the one-dimensional positive shock wave along the pipeline direction is shown in Figure 8. D (m/s) is defined as the propagation velocity of the shock wave. The physical state parameters of the particles will change abruptly before and after the shock wavefront passes. The wavefront is an area that is not disturbed by the shock wavefront. The velocity, density, and pressure of the particle in this area are characterized by u0 (m/s), ρ0 (kg/m3), and P0 (kPa), respectively. Moreover, the cross-sectional area of the wavefront is S0 (m2). The postwave area is the side where the particle passes through the shock wavefront, and its related physical parameters are characterized by u1, ρ1, P1, and S1. Thus, the discontinuity formula of medium passing through the wavefront of constant cross-sectional AB in unit time is as follows

| 2 |

| 3 |

| 4 |

Figure 8.

Schematic diagram of shock wave propagation.

Introducing the gas-state equation

| 5 |

where e is the specific internal energy of shock wave (J/Kg) and γ is the adiabatic coefficient of gas.

As the shock wavefront propagates from the straight pipe to the cavity structure, as shown in Figure 9a, it will pass through the CC′ plane with a mutation in the section during the propagation process. The thickness of the shock wavefront is the distance from the AB plane to the HI plane, with only a few molecular spacing. In order to better display the change in the shock wavefront intensity when the shock wave passes through the CC′ plane, the detailed analysis, as shown in Figure 9b, is carried out. We assume that the intensity of the shock wavefront changes from Pa to Pb when the shock wave propagates from the CE plane to the FG plane in unit time. In fact, the CE plane and the FG plane coincide geometrically. Moreover, ignoring the mass force of the particle and its friction with the wall surface, for the ABHI control volume

| 6 |

| 7 |

where r is the diameter of the straight pipe (m), d is the width of the rectangular cavity (m), and h is the height of the rectangular cavity (m).

Figure 9.

Model of shock wave propagation at the section of variable width: (a) propagation diagram, (b) propagation equivalent diagram, and (c) propagation simplification diagram.

Introducing the Mach number M = D/c0, where c0 is the local sound velocity, the following can be obtained by combining 2

| 8 |

When the initial-state parameters (u0, ρ0, and P0) of the wavefront, the diameter of the straight pipe (r), and the height of the cavity (h) are given, the relation between the shock wavefront strength (Pa and Pb), the Mach number (M), and the width of the cavity (d) can be obtained from eq 8. Considering that the thickness of the wavefront is very thin, the internal condition of the shock wavefront is generally not analyzed. Moreover, the unknown number of shock wave propagation velocity D is included in eq 8. In order to further show the effect of cavity width on the intensity of shock waves, the propagation model is simplified, as shown in Figure 9c. It is assumed that the propagation velocity of shock waves is approximately equal before and after passing through a variable cross section. Moreover, the state of shock wave is characterized by the physical parameters which changed abruptly behind the shock wavefront.

Ignoring the diffraction, reflection, and energy loss of the shock wave during its propagation, the following equations can be obtained by applying 2 to the AB and HI wavefronts

| 9 |

| 10 |

| 11 |

For the ABHI control volume, the net external force acting on the control volume in unit time is equal to the momentum change of the fluid in the control volume.

| 12 |

According to eqs 7 and 9–12, it can be concluded that

|

13 |

In the abovementioned equation, the initial pressure in the cavity (P0), the diameter of the straight pipe (r), the cavity width (d), the cavity height (h), and the adiabatic coefficient of gas (γ) are all known; the shock wave overpressure (P1) can be measured. Therefore, the overpressure (P2) of the incident wave which enters the cavity after through the variable section can be calculated, and its value depends on the ratio of d/r2. When d/r2 ≥ π/h, it means P2 ≤ P1, the intensity of the shock wave decreases, and the higher the change rate of d/r2, the greater the attenuation amplitude of the shock wave. When d/r2 ≤ π/h, it means P2 ≥ P1, and the intensity of the shock wave is enhanced. Moreover, the greater the change rate of d/r2, the greater the increase in the intensity of the shock wave. When the shock wave enters the cavity from a straight pipe with a fixed diameter, the propagation section is suddenly enlarged, and its propagation form changes from the original plane wave to a spherical wave and continues to diffuse in the cavity. With the increase in the cavity width, it means that the larger the change rate of d/r2, the greater the expansion degree of the shock wave, the smaller the energy per unit area of the spherical wavefront, and the faster the attenuation of the shock wave strength. In addition, the larger the expansion degree of the spherical wavefront, the smaller the angle between the spherical wavefront and the wall of the cavity and the more likely the Mach reflection occurs, which consumes more energy along the shock wave path. When the shock wave exits the cavity and then enters the straight pipe, although the energy of the unit wavefront is increased, the area of the wavefront is reduced, and the energy is generally reduced. Moreover, with the increase in the cavity width, the greater the change rate of the cross section is, the stronger the turbulence effect is, and the more the energy of the shock wave consumed by the reflection and diffraction in the cavity and the friction with the wall of the cavity. Because the energy provided by the flame is less than the energy lost, the comprehensive performance is that the intensity of the shock wave decreases more obviously with the increase in the cavity width.

3.2. Explosion Suppression by Cavity-Combined Aluminum Hydroxide Powder

In order to further improve the explosion suppression effect of the cavity, based on the suppression by the cavity, combined with the mechanism on wave attenuation of the suppressant, experiments were carried out by filling the cavity with different qualities of aluminum hydroxide powder. The rectangular cavity with a size of 800 mm × 500 mm × 200 mm was selected, which has the best explosion suppression effect within the test range. Aluminum hydroxide powder, as an explosion suppressant, was suspended at the inlet of the cavity by a balloon composed mainly of polyisoprene. Figure 10 shows the particle size analysis of aluminum hydroxide powder. From the size distribution of aluminum hydroxide, the average particle size is 4.21 μm, and the statistical diameter d(0.9) is less than 13 μm.

Figure 10.

Particle size distributions of aluminum hydroxide.

3.2.1. Analysis of Explosion Flame

Table 3 displays the maximum value of the flame signal at each flame measuring point when the cavity is filled with aluminum hydroxide powder of different masses. It can be seen that the decay rates of the maximum value of the flame signal are more than 70% after the flame passes through the cavity with filling aluminum hydroxide powder of different masses in the test range. Moreover, with the increase in the mass of aluminum hydroxide powder, the better the suppression effect of the maximum value of flame signal is. When the filling amount of aluminum hydroxide powder increases to 120 g, the flame signal intensities detected by the flame sensors in the front and back of the cavity are shown in Figure 11. It can be seen that under this test condition, no flame signal can be received at the N3 and N4 measuring points, which indicates that the flame has been completely extinguished, and the decay rate of the maximum value of the flame signal is 100%.

Table 3. Maximum Signal of Flame at Each Measurement Point under Different Masses of Aluminum Hydroxide Powder.

| in front of the cavity |

behind the cavity |

||||||

|---|---|---|---|---|---|---|---|

| mass of powder (g) | F1 (V) | F2 (V) | average value (V) | F3 (V) | F4 (V) | average value (V) | decay rate (%) |

| 20 | 1.45 | 1.72 | 1.585 | 0.49 | 0.45 | 0.47 | 70.3 |

| 40 | 1.58 | 1.89 | 1.735 | 0.48 | 0.43 | 0.455 | 73.8 |

| 60 | 1.56 | 1.74 | 1.65 | 0.37 | 0.31 | 0.34 | 79.4 |

| 80 | 1.69 | 1.75 | 1.72 | 0.22 | 0.26 | 0.24 | 86 |

| 100 | 1.78 | 1.92 | 1.85 | 0.14 | 0.1 | 0.12 | 93.5 |

| 120 | 1.48 | 1.83 | 1.655 | 0 | 0 | 0 | 100 |

Figure 11.

Flame signal information when the cavity is filled with 120 g of powder.

Figure 12 presents the change in the flame speed before and after passing through the cavity under different test conditions. It can be seen that when 20 g of aluminum hydroxide powder is filled in the cavity, the flame speed behind the cavity can be reduced to 115 m/s, which is lower than that of the pure cavity without any powder, but the effect is not obvious. With the increase in the powder mass in the cavity, the average flame propagation speed behind the cavity decreases continuously, and the corresponding decay rate of the flame propagation speed has shown an increasing trend. When the powder mass is increased to 100 g, the average flame speed behind the cavity can be reduced to 50.3 m/s, and the decay rate of the flame speed can reach 80.5%. The flame speed drops to 0 m/s as the mass of powder continues to increase to 120 g, and the flame is completely suppressed before leaving the cavity, which indicates that the cavity-combined explosion suppression powder of aluminum hydroxide can effectively improve the suppression effect on gas explosion flame.

Figure 12.

Flame speed under different experimental conditions.

3.2.2. Analysis of Explosion Overpressure

As an effective powder suppressor, aluminum hydroxide powder can greatly reduce the severity of explosion damage. Figure 13 shows the pressure peak change curve at the pressure measuring points in the front and behind the cavity when the cavity is filled with alumina hydroxide powder of different masses. It can be seen that when 20 g of aluminum hydroxide powder is filled, the peak overpressure behind the cavity decreases to 0.119 MPa, which is further reduced compared with 0.134 MPa when the powder is not filled in the cavity. With the increase in powder mass in the cavity, the peak overpressure of methane/air gas explosion tends to decrease first and then increase, and the corresponding decay rate of peak overpressure tends to increase first and then decrease. Among them, when the filling amount of aluminum hydroxide powder is 80 g in the cavity, the peak value of explosion overpressure decreases to the lowest, which decreased from 0.158 MPa in front of the cavity to 0.0799 MPa in back of the cavity, and the decay rate of peak overpressure under this condition also reaches the maximum value of 49.4%. Figure 14 presents the influence curves of different filling amounts of aluminum hydroxide powder in the cavity on the explosive impulse. It can be found that when the mass of the filled powder is 20 g, the explosive impulse behind the cavity is reduced to 0.01134 MPa·s, which is less than that in the cavity without any aluminum hydroxide powder. As the mass of powder continues to increase, the impulse of the shock wave behind the cavity presents a trend of first decreasing and then increasing. When the powder filling amount is 80 g in the test range, the impulse of the explosive shock wave after passing through the cavity decreases to the lowest value of 0.00892 MPa·s, and the corresponding decay rate of shock wave impulse reaches the maximum value of 39.4%. When the powder filling amount is increased further, the decay rate of shock wave impulse decreases. In summary, it is shown that there is an optimal explosion suppression filling degree for aluminum hydroxide powder to suppress the explosion shock wave in the limited space of the cavity, that is, an optimal explosion suppression concentration exists for aluminum hydroxide. Placing too much or too little powder in the cavity will reduce the effect of aluminum hydroxide powder on suppressing the shock wave strength.

Figure 13.

Maximum overpressure and decay rate under different experimental conditions.

Figure 14.

Impulse and decay rate under different experimental conditions.

The internal environment of the cavity filled with aluminum hydroxide powder after explosion is shown in Figure 15. It can be found that the white powder of aluminum hydroxide is approximately uniformly adhered to the inner wall of the cavity after the explosion, thus judging that the alumina hydroxide powder is dispersed in the whole cavity during the explosion process. On this basis, combined with the test results, that is, the explosion suppression effect is indeed improved after the cavity is filled with aluminum hydroxide powder, it can be considered that an effective explosion suppression cloud zone is formed in the limited space of the cavity. The combination of the cavity and alumina hydroxide powder is mainly reflected in the following aspects: on the one hand, the existence of the cavity (the cross-sectional area at the outlet of the cavity decreases sharply) provides sufficient physical space for the suspension of the powder, so that it can better form the explosion-suppression cloud zone under the action of the precursor shock wave. On the other hand, the existence of the cavity makes the shock wave constantly reflect and diffract with the cavity wall, so the existence time of the explosion-suppression cloud zone can be extended to a certain extent, which provides a longer reaction time for the contact between the powder and the explosion flame, so that the intensity of the explosion flame is suppressed. With the increase in the mass of powder filled in the cavity, the better the suppression effect on the explosion flame until it is quenched. In this case, the explosion flame cannot supplement the further energy for the propagation of the precursor shock wave, so the overall performance is that the explosion intensity is further attenuated when the cavity is filled with powder.

Figure 15.

Internal environment of the cavity filled with aluminum hydroxide powder after explosion.

4. Discussion

4.1. Gas Explosion Suppression Mechanism

As a commonly used flame retardant, aluminum hydroxide has the advantages of good thermal stability, nonvolatile, nontoxicity, low smoke generation, and no secondary pollution.37 An STA449F3 thermal synchronous analyzer was applied to evaluate the thermal characteristics of aluminum hydroxide powder. The temperature increased from 30 to 1000 °C with a rate of 10 °C/min at atmospheric pressure. Nitrogen was used as the experimental atmosphere, and the flow rate was 20 mL/min. The thermogravimetry (TG), differential scanning calorimetry (DSC), and microcommercial thermogravimetry (DTG) curves of aluminum hydroxide are shown in Figure 16.

Figure 16.

Thermal analysis results of aluminum hydroxide.

Among them, the TG curve has a large gradient change at 217–366 and 366–565 °C. The corresponding DTG curve has two absorption peaks of 292 and 513 °C, indicating that the thermal decomposition of aluminum hydroxide is carried out in two processes. The weight loss rate of the first gradient is 27.71%, and that of the second gradient is 3.44%. Thus, the reaction formula of the two processes can be expressed as follows

| 14 |

| 15 |

According to the DSC curve, the heat absorption capacity of the alumina hydroxide powder sample during the whole pyrolysis process is 866.4 J/g, indicating that it has good heat absorption performance. The reason why the cavity-combined aluminum hydroxide powder can greatly inhibit the explosion intensity is mainly reflected in the following aspects: (1) the shock wave traveling in front of the explosion flame ruptures the balloon suspended at the inlet of the cavity first and part of energy carried by the shock wave is lost due to the momentum exchange with aluminum hydroxide powder in the balloon.38 Moreover, when the shock wave enters the large section of the cavity from the small section of the pipe, it will expand at the inlet end of the cavity, diffract at the corner of the cavity, and reflect with the wall at the exit of the cavity due to the sharp contraction of the section. The behaviors mentioned above will cancel out and consume a lot of shock wave energy. (2) The existence of the cavity structure increases the turbulence intensity of flame propagation, while an excessive turbulence structure will cause a large loss of momentum, and the energy consumption of friction between the flame and the wall will increase, which is not conducive to flame propagation.39,40 (3) Due to the small particle size and large surface area of the alumina hydroxide powder and the rapid shrinkage of the section structure at the exit of the cavity, most of the powder can be suspended in the cavity to form a powder cloud belt. When the flame passes through this section, aluminum hydroxide powder decomposes under the action of high temperature, absorbs a lot of heat to remove crystal water, and absorbs radiant energy from the flame, which reduces and slows down the heat transfer and inhibits the flame propagation. (4) The water vapor formed by dehydration of aluminum hydroxide powder can dilute the flammable gas and oxygen that are not completely reacted, preventing the combustion from proceeding further. (5) Aluminum hydroxide can be used as an electron donor to adsorb part of the HO• and H• free radicals formed in the combustion reaction41 and terminate the free radical reaction. In addition, it itself generates inorganic radicals with lower activity, which is not enough to initiate free radical reactions due to its low activity.

4.2. Advantages of Passive Explosion Suppression of the Cavity-Combined Powder

The traditional passive explosion suppression to mitigate the explosion hazards posed by methane/air is to spread rock dust or watershed in mine roadways. When explosion waves pass through the roadways, the rock dust or water mist is dispersed by the turbulent flow field and it acts as a thermal inhibitor; it absorbs heat from the flame front of an explosion and quenches its propagation.18 Compared with purely placing explosion suppressants such as rock dust and water in the roadway, the passive explosion suppression method of placing the explosion suppression powder in the rectangular cavity proposed in this paper has certain advantages. The main reason is that the cross-sectional area at the exit of the cavity decreases sharply, and the precursor shock wave generated by the explosion will reflect and diffract with the wall surface of the cavity, so that the explosion suppressant can better form an explosion suppression cloud zone in the cavity and prolong the existence time of the explosion suppression cloud zone. Moreover, the experimental results have proved that the cavity itself can also suppress the explosion intensity to a certain extent.

Compared with the passive explosion suppression method of the vacuum chamber28−30 attached to the side of the pipeline proposed in recent years, the installation and subsequent maintenance cost of the cavity designed by the authors is lower. Besides, the vacuum chamber no longer has the vacuum environment after the first explosion, so that it has no ability to suppress the secondary explosion. However, the cavity connected in the straight pipeline mainly uses the physical wave elimination mechanism of its spatial structure to suppress the intensity of gas explosion waves, and it can withstand the repeated impact of the explosion waves, so it still has a certain wave elimination effect for secondary explosions. In the next step, further explosion suppression research will be carried out based on the cavity, such as the combination of multiple cavities and the installation of active fine water mist explosion suppression device in the cavity.

5. Conclusions

-

(1)

With the increase in the cavity width, the suppression effect on the flame propagation speed becomes more and more obvious. Whether it can suppress the maximum signal of flame depends on the width of the cavity.

-

(2)

Combined with the ΔP–I principle to evaluate the explosion suppression performance of the cavity, it was found that both the overpressure peak and impulse of the shock wave could be effectively attenuated after passing through the cavity.

-

(3)

The mathematical model of shock wave propagation was established when the cavity with different widths was attached in the straight pipe. The theoretical analysis showed that the larger the width of the cavity, the faster the attenuation of the shock wave, and the experimental results were consistent with the theoretical analysis.

-

(4)

The cavity combined with aluminum hydroxide powder could effectively improve the explosion suppression effect, and the suppression effect on flame was better with the increase in the mass of powder filled in the cavity. However, in the limited space of the cavity, there was an optimal explosion suppression filling degree for aluminum hydroxide powder to suppress the shock wave. Too much or too little powder would reduce the explosion suppression effect.

Acknowledgments

The work is supported by the National Natural Science Foundation of China (grant nos. 11472007 and 51904010), the Natural Science Foundation of Anhui Province (grant no. 1808085QE149), and University Natural Science Research Project of Anhui Province (grant no. KJ2017A093). The financial contributions are gratefully acknowledged.

The authors declare no competing financial interest.

References

- Tutak M.; Brodny J.; Siwiec D.; Ulewicz R.; Bindzár P. Studying the Level of Sustainable Energy Development of the European Union Countries and Their Similarity Based on the Economic and Demographic Potential. Energies 2020, 13, 6643. 10.3390/en13246643. [DOI] [Google Scholar]

- Li G.; Wang X.; Xu H.; Liu Y.; Zhang H. Experimental study on explosion characteristics of ethanol gasoline-air mixture and its mitigation using heptafluoropropane. J. Hazard. Mater. 2019, 378, 120711. 10.1016/j.jhazmat.2019.05.104. [DOI] [PubMed] [Google Scholar]

- Wang K.; Liu Z.; Qian X.; Li M.; Huang P. Comparative study on blast wave propagation of natural gas vapor cloud explosions in open space based on a full-scale experiment and PHAST. Energy Fuels 2016, 30, 6143–6152. 10.1021/acs.energyfuels.6b01293. [DOI] [Google Scholar]

- Hu E.; Huang S.; Ku J.; Huang Z. Combustion characteristics of natural gas injected into a constant volume vessel. Fuel 2019, 235, 1146–1158. 10.1016/j.fuel.2018.08.101. [DOI] [Google Scholar]

- Tutak M.; Brodny J.; Szurgacz D.; Sobik L.; Zhironkin S. The Impact of the Ventilation System on the Methane Release Hazard and Spontaneous Combustion of Coal in the Area of Exploitation-A Case Study. Energies 2020, 13, 4891. 10.3390/en13184891. [DOI] [Google Scholar]

- Tutak M.; Brodny J. Forecasting Methane Emissions from Hard Coal Mines Including the Methane Drainage Process. Energies 2019, 12, 3840. 10.3390/en12203840. [DOI] [Google Scholar]

- Tutak M.; Brodny J. Predicting Methane Concentration in Longwall Regions Using Artificial Neural Networks. Int. J. Environ. Res. Public Health 2019, 16, 1406. 10.3390/ijerph16081406. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang C.; Han W.; Ning J.; Yang Y. High resolution numerical simulation of methane explosion in bend ducts. Saf. Sci. 2012, 50, 709–717. 10.1016/j.ssci.2011.08.047. [DOI] [Google Scholar]

- Mitu M.; Giurcan V.; Razus D.; Oancea D. Influence of Initial Pressure and Vessel’s Geometry on Deflagration of Stoichiometric Methane-Air Mixture in Small-Scale Closed Vessels. Energy Fuels 2020, 34, 3828. 10.1021/acs.energyfuels.9b04450. [DOI] [Google Scholar]

- Lv C.; Wu Z. Flame thickness and propagation characteristics of premixed methane-air explosion with a small filling ratio in an open-ended steel pipe. Appl. Therm. Eng. 2017, 119, 617–621. 10.1016/j.applthermaleng.2017.03.104. [DOI] [Google Scholar]

- Dounia O.; Vermorel O.; Poinsot T. Theoretical analysis and simulation of methane/air flame inhibition by sodium bicarbonate particles. Combust. Flame 2018, 193, 313–326. 10.1016/j.combustflame.2018.03.033. [DOI] [Google Scholar]

- Cui C.; Shao H.; Jiang S.; Zhang X. Experimental study on gas explosion suppression by coupling CO2 to a vacuum chamber. Powder Technol. 2018, 335, 42–53. 10.1016/j.powtec.2018.04.070. [DOI] [Google Scholar]

- Luo Z.; Su Y.; Li R.; Chen X.; Wang T. Effect of Inert Gas CO2 on Deflagration Pressure of CH4/CO. ACS Omega 2020, 5, 23002–23008. 10.1021/acsomega.0c02686. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hu X.; Xie Q.; Yu Q.; Liu H.; Yan F. Effect of Carbon Dioxide on the Lower Flammability Limit of Propane in O2/CO2 Atmosphere. Energy Fuels 2020, 34, 4993–4998. 10.1021/acs.energyfuels.0c00601. [DOI] [Google Scholar]

- Battersby P. N.; Averill A. F.; Ingram J. M.; Holborn P. G.; Nolan P. F. Suppression of hydrogen-oxygen-nitrogen explosions by fine water mist: Part 2. Mitigation of vented deflagrations. Int. J. Hydrogen Energy 2012, 37, 19258–19267. 10.1016/j.ijhydene.2012.10.029. [DOI] [Google Scholar]

- Ingram J. M.; Averill A. F.; Battersby P.; Holborn P. G.; Nolan P. F. Suppression of hydrogen/oxygen/nitrogen explosions by fine water mist containing sodium hydroxide additive. Int. J. Hydrogen Energy 2013, 38, 8002–8010. 10.1016/j.ijhydene.2013.04.048. [DOI] [Google Scholar]

- Luo Z.; Su Y.; Chen X.; Zheng L. Effect of BC powder on hydrogen/methane/air premixed gas deflagration. Fuel 2019, 257, 116095. 10.1016/j.fuel.2019.116095. [DOI] [Google Scholar]

- Liu Q.; Hu Y.; Bai C.; Chen M. Methane/coal dust/air explosions and their suppression by solid particle suppressing agents in a large-scale experimental tube. J. Loss Prev. Process. 2013, 26, 310–316. 10.1016/j.jlp.2011.05.004. [DOI] [Google Scholar]

- Chen P.; Huang F.; Sun Y.; Chen X. Effects of metal foam meshes on premixed methane-air flame propagation in the closed duct. J. Loss Prev. Process. 2017, 47, 22–28. 10.1016/j.jlp.2017.02.015. [DOI] [Google Scholar]

- Nie B.; He X.; Zhang R.; Chen W.; Zhang J. The roles of foam ceramics in suppression of gas explosion overpressure and quenching of flame propagation. J. Hazard. Mater. 2011, 192, 741–747. 10.1016/j.jhazmat.2011.05.083. [DOI] [PubMed] [Google Scholar]

- Krasnyansky M. Prevention and suppression of explosions in gas-air and dust-air mixtures using powder aerosol-inhibitor. J. Loss Prev. Process 2006, 19, 729–735. 10.1016/j.jlp.2006.05.004. [DOI] [Google Scholar]

- Pei B.; Li J.; Wang Y.; Wen X.; Yu M.; Jing G. Synergistic inhibition effect on methane/air explosions by N2-twin-fluid water mist containing sodium chloride additive. Fuel 2019, 253, 361–368. 10.1016/j.fuel.2019.05.035. [DOI] [Google Scholar]

- Cui L.; Li X.; Yang G. Coupling Analysis of Chemiluminescence and Pressure Changes in CH4/Air Explosion Suppressed by NaHCO3 Powder. ACS Omega 2020, 5, 27133–27141. 10.1021/acsomega.0c02834. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kosinski P. Explosion suppression by a cloud of particles: Numerical analysis of the initial processes. Appl. Math. Comput. 2011, 217, 5087–5094. 10.1016/j.amc.2010.07.074. [DOI] [Google Scholar]

- Pei B.; Wei S.; Chen L.; Pan R.; Yu M.; Jing G. Synergistic inhibition effect on the self-acceleration characteristics in the initial stage of methane/air explosion by CO2 and ultrafine water mist. RSC Adv. 2019, 9, 13940–13948. 10.1039/c9ra01148j. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang Y.; Meng X.; Ji W.; Pei B.; Lin C.; Feng H.; Zheng L. The inhibition effect of gas-solid two-phase inhibitors on methane explosion. Energies 2019, 12, 398. 10.3390/en12030398. [DOI] [Google Scholar]

- AL-Zuraiji M. J. A.; Zanganeha J.; Moghtaderi B. Application of flame arrester in mitigation of explosion and flame deflagration of ventilation air methane. Fuel 2019, 257, 115985. 10.1016/j.fuel.2019.115985. [DOI] [Google Scholar]

- Jiang S.-g.; Wu Z.-y.; Li Q.-h.; He X.-j.; Shao H.; Qin J.-h.; Wang L.-y.; Hu L.-m.; Lin B.-q. Vacuum chamber suppression of gas-explosion propagation in a tunnel. Int. J. Min. Sci. Technol. 2008, 18, 337–341. 10.1016/s1006-1266(08)60071-1. [DOI] [Google Scholar]

- Shao H.; Jiang S.; Wu Z.; Zhang W.; Wang K. Influence of diaphragm thickness on gas explosion suppression by vacuum chamber. Powder Technol. 2016, 295, 245–253. 10.1016/j.powtec.2016.03.041. [DOI] [Google Scholar]

- Shao H.; Jiang S.; Zhang X.; Wu Z.; Wang K.; Zhang W. Influence of vacuum degree on the effect of gas explosion suppression by vacuum chamber. J. Loss Prev. Process. 2015, 38, 214–223. 10.1016/j.jlp.2015.09.013. [DOI] [Google Scholar]

- Catlin C. Passive explosion suppression by blast-induced atomisation from water containers. J. Hazard. Mater. 2002, 94, 103–132. 10.1016/s0304-3894(02)00119-x. [DOI] [PubMed] [Google Scholar]

- Nie B. S.; Zhang R. M.; He X. Q.; Li X. C.; Wang H.; Zhai S. R. Potential applications of foam ceramics in gas explosion prevention. Adv. Mater. Res. 2011, 284–286, 1330–1334. 10.4028/www.scientific.net/amr.284-286.1330. [DOI] [Google Scholar]

- Cui G.; Li Z.; Yang C.; Zhou Z.; Li J. Experimental Study of Minimum Ignition Energy of Methane-Air Mixtures at Low Temperatures and Elevated Pressures. Energy Fuels 2016, 30, 6738–6744. 10.1021/acs.energyfuels.6b00366. [DOI] [Google Scholar]

- Ma Q.; Zhang Q.; Li D.; Chen J.; Ren S.; Shen S. Effects of premixed methane concentration on distribution of flame region and hazard effects in a tube and a tunnel gas explosion. J. Loss Prev. Process. 2015, 34, 30–38. 10.1016/j.jlp.2015.01.018. [DOI] [Google Scholar]

- Tomita H.; Abdul Rahman M. R.; Miyamae S.; Yokomori T.; Ueda T. Flame dynamics of equivalence ratio oscillations in a laminar stagnating lean methane/air premixed flame. Proc. Combust. Inst. 2015, 35, 989–997. 10.1016/j.proci.2014.07.061. [DOI] [Google Scholar]

- Dorofeev S. B. Flame acceleration and explosion safety applications. Proc. Combust. Inst. 2011, 33, 2161–2175. 10.1016/j.proci.2010.09.008. [DOI] [Google Scholar]

- Xu Z.-s.; Yan L.; Chen L. Synergistic flame retardant effects between aluminum hydroxide and halogen-free flame retardants in high density polyethylene composites. Procedia Eng. 2016, 135, 631–636. 10.1016/j.proeng.2016.01.130. [DOI] [Google Scholar]

- Liu Y.; Liu X.; Li X. Numerical investigation of hydrogen detonation suppression with inert particle in pipelines. Int. J. Hydrogen Energy 2016, 41, 21548–21563. 10.1016/j.ijhydene.2016.09.170. [DOI] [Google Scholar]

- Kadam A. R.; Parida R. K.; Hindasageri V.; Kumar G. N. Heat transfer distribution of premixed methane-air laminar flame jets impinging on ribbed surfaces. Appl. Therm. Eng. 2019, 163, 114352. 10.1016/j.applthermaleng.2019.114352. [DOI] [Google Scholar]

- Yousefi-Asli V.; Houshfar E.; Beygi-Khosroshahi F.; Ashjaee M. Experimental investigation on temperature field and heat transfer distribution of a slot burner methane/air flame impinging on a curved surface. Appl. Therm. Eng. 2018, 129, 761–771. 10.1016/j.applthermaleng.2017.10.084. [DOI] [Google Scholar]

- Sun Y.; Yuan B.; Chen X.; Li K.; Wang L.; Yun Y.; Fan A. Suppression of methane/air explosion by kaolinite-based multi-component inhibitor. Powder Technol. 2019, 343, 279–286. 10.1016/j.powtec.2018.11.026. [DOI] [Google Scholar]