Abstract

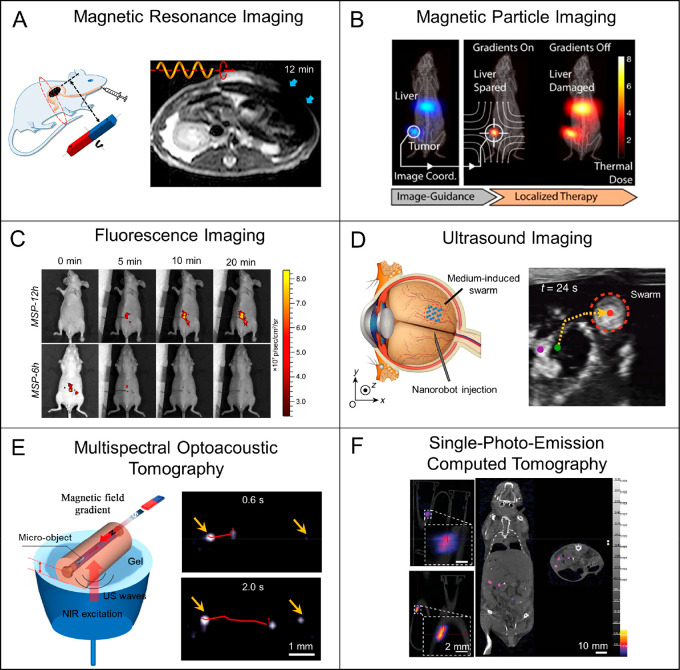

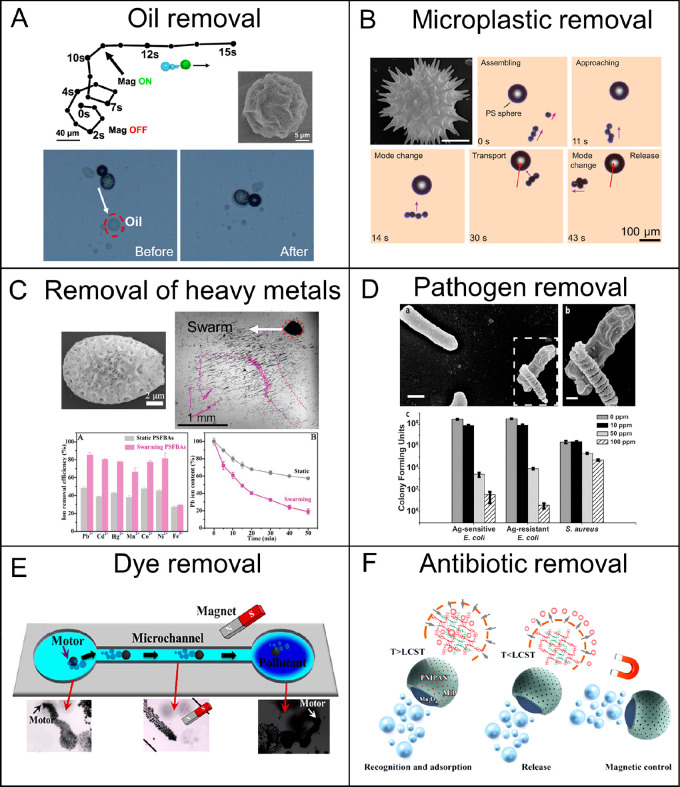

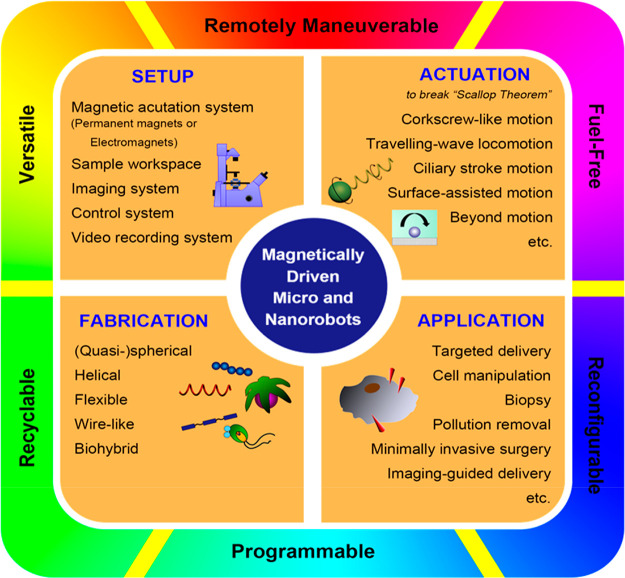

Manipulation and navigation of micro and nanoswimmers in different fluid environments can be achieved by chemicals, external fields, or even motile cells. Many researchers have selected magnetic fields as the active external actuation source based on the advantageous features of this actuation strategy such as remote and spatiotemporal control, fuel-free, high degree of reconfigurability, programmability, recyclability, and versatility. This review introduces fundamental concepts and advantages of magnetic micro/nanorobots (termed here as “MagRobots”) as well as basic knowledge of magnetic fields and magnetic materials, setups for magnetic manipulation, magnetic field configurations, and symmetry-breaking strategies for effective movement. These concepts are discussed to describe the interactions between micro/nanorobots and magnetic fields. Actuation mechanisms of flagella-inspired MagRobots (i.e., corkscrew-like motion and traveling-wave locomotion/ciliary stroke motion) and surface walkers (i.e., surface-assisted motion), applications of magnetic fields in other propulsion approaches, and magnetic stimulation of micro/nanorobots beyond motion are provided followed by fabrication techniques for (quasi-)spherical, helical, flexible, wire-like, and biohybrid MagRobots. Applications of MagRobots in targeted drug/gene delivery, cell manipulation, minimally invasive surgery, biopsy, biofilm disruption/eradication, imaging-guided delivery/therapy/surgery, pollution removal for environmental remediation, and (bio)sensing are also reviewed. Finally, current challenges and future perspectives for the development of magnetically powered miniaturized motors are discussed.

1. Introduction

Many species in nature, such as magnetotactic bacteria, birds, bats, butterflies, lobsters, and salmon, can fly or swim over a long distance by perceiving navigation cues from geomagnetic fields. Some species (e.g., Amitermes meridionalis) even have the ability to (re)orient their bodies or nests according to geomagnetic information. Similarly, the locomotion of nanoscale and microscale objects in a predefined path by the navigation of magnetic fields,1−4 which are mainly generated by moving charges (i.e., electric currents) and magnetic materials (such as permanent magnets), has drawn extensive attention owing to their tremendous potential for applications in biomedicine and environmental remediation. Such miniaturized objects are normally termed as “magnetically driven micro/nanorobots” (called “MagRobots” for short in this review), which is an important branch of micro and nanorobots.

Micro/nanorobots are locomotive artificial machines with size in the micro or nanoscale and rationally designed to execute tasks on command via self-propulsion or an externally controlled propulsion mechanism. Ideally, micro/nanorobots should have the ability to undertake tasks via encapsulation/functionalization with diagnostic or therapeutic agents, decoration with functional materials, or being fabricated into special micro/nano architectures; “delivery tasks” by moving toward targeted sites in a user-defined path or a theoretically and experimental optimized path; “execute tasks”, for example, killing diseased cells/tissues, removing environmental pollutants as required; and “exit tasks” after the task accomplishment via recycling or in situ degradation. During task implementation, locomotion behavior is of great importance for micro and nanorobots. The migration of micro and nanorobots can be powered by multiple strategies including chemical catalysis (e.g., O2 or H2 generation) or chemical gradients,5−11 external energy sources (e.g., magnetic field,12−14 light,15−21 acoustic wave,22−25 or electrical field26−28), and even motile cells (e.g., sperm cell, bacterial cell).29−37 According to the power source, micro/nanorobots can be classified as chemically driven (or fuel-driven), magnetically driven, light-driven, ultrasound-driven, electrically driven. The word “driven” can be replaced by “powered”, “actuated”, or “propelled”. According to their functionalities, micro/nanorobots can be named as micro/nanogrippers,38−40 micro/nanodrillers,41 micro/nanocleaners,42,43 micro/nanoscavengers,44 etc. Readers can refer to our latest review45 to obtain a more detailed classification of micro/nanorobots based on geometric shapes, motion modes, and functionalities.

Chemically propelled micro/nanorobots are faster than those with other propulsion methods, but their locomotion lacks directionality. Moreover, they require toxic fuels such as H2O2, N2H4, HCl, urea, and NaBH4.46,47 In comparison, those micro/nanorobots powered by external physical fields (such as magnetic, ultrasound, light, and electric fields) do not need toxic chemical fuels for propulsion, but their motion is relatively slow.48−52 Light-propelled micro/nanorobots can move in water; however, depending on their composition, they need H2O2 and a high-intensity light source, which could compromise their biocompatibility. On the other hand, micro/nanomotors propelled by ultrasound are biocompatible but lack directionality control, making it difficult for them to perform specific tasks. Finally, micro/nanomotors propelled by electric field are very promising for fuel-free locomotion; however, its biological application is still limited and not yet fully demonstrated. Magnetically driven micro/nanomotors address most disadvantages presented by others propulsion principles and, until now, have been the more explored and used in many biomedical applications as well as for environmental control and remediation. Furthermore, magnetic medical microrobots can be driven by magnetic resonance imaging (MRI) systems, thus utilizing existing clinical MRI equipment for dual purposes, namely the imaging and tracking of microrobots, and their propulsion and motion control.53,54 Likewise, clinical ultrasonography systems hold great potential to actuate ultrasonically driven microrobots.45

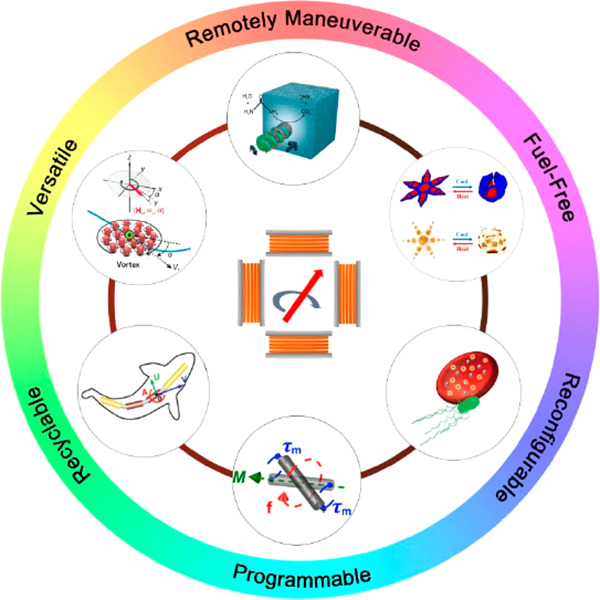

In addition, among all the actuation strategies, the utilization of a magnetic field for manipulating miniaturized robots has unparalleled advantages, which are summarized as follows. (i) Remote maneuverability: magnetic fields provide a noninvasive way to manipulate matter owing to the inherent contactless characteristics of magnetic forces. Such a wireless actuation method allows for micro and nano agents to move in an untethered manner while keeping their local chemical environment intact. (ii) Fuel-Free: using a magnetic field for propulsion is a clean process that does not consume liquid fuel (unlike for chemically and photochemically propelled swimmers). This feature eliminates the harmful effects of toxic chemicals (e.g., hydrogen peroxide) on cells and tissues during their biological application processes. In addition, magnetic fields exhibit insignificant dependence on features and properties of surrounding environments and cause negligible damage to cells at low frequencies. (iii) Reconfigurability and programmability of magnetic materials: reconfigurability refers to the rearrangement of the swimmer’s features such as the morphology, locomotion mode, or other motion parameters upon the application of magnetic fields or other external stimuli. Examples of reconfigurable structures are magnetically driven particulate swarms,55−57 stimuli-responsive magnetic materials (i.e., ferromagnetic shape-memory alloys), or composite structures (i.e., smart magneto-polymer composites58,59 or complex origami-like architectures60). This type of structure can readily change its shape by changing the conditions of the applied magnetic fields (i.e., frequency or magnitude). Programmability refers to the ability to manipulate the components of the MagRobots in terms of their shape, magnetic shape, magnetic anisotropy,61 and crystalline anisotropy to achieve a specific motion mode, position, or orientation when magnetic fields are applied.62,63 For example, the orientation of a magnetic composite-based structure can be programmed by suitably aligning the particles within the composite matrix.60 Specific shape-morphing small-scale systems can also be designed to exhibit both reconfigurability and programmability.64 (iv) Recyclability of magnetic materials: after micro/nanorobots have completed their tasks, the separation and recycling of introduced foreign matter from water, biological fluids, or even tissues might be necessary in terms of biosafety and biocompatibility. Magnetic nano/microrobots, as they are composed of magnetic building blocks (i.e., coating, segment, particulates), allow for a feasible and convenient magnetically assisted retrieval and recycling process. (v) Versatility: by combining a magnetic field with other actuation sources, the transport and delivery of functional cargos (e.g., drugs or a single cell at the nanosize level) can be achieved with high maneuverability and sensitivity.65 Currently, various hybrid power sources, such as magneto-acoustic,22,23,66 magneto-optical,67 and magneto-chemotaxis,68 have been reported, which provide dual propulsion modes in response to multiple stimuli.

Molecular machines are molecular components capable of implementing mechanical locomotion (as output) in response to particular external stimuli (as input).69−72 Stimuli can be various energy inputs such as chemical energy, electric energy, light, photochemical, electrochemical energy, or pH gradient.73−77 Although molecular machines can perform very complicated functions, most functions are limited to conformational movements.78−82 In terms of practical uses, particularly for biomedical applications, the operator’s real-time imaging and tracking of the tiny robots are required when they are carrying out specific tasks inside the human body.10,83 This requirement may limit the applicability of molecular machines due to their nanoscale (<10 nm) size being too small to be readily visualized using traditional imaging techniques. By contrast, larger micro- and nanorobots can provide greater feasibility for bioimaging for the applications in medical fields.53,84−86 To this end, swarms of micro/nanorobots can also be used for their imaging and positioning abilities.87−89

Recent reviews about micro and nanorobots that focus on fabrication techniques,51 geometric shapes (e.g., active particles,90 Janus,91 tubular,92 hybrid actuators81,93), actuation sources (e.g., light,48,49 magnetic field94), propulsion mechanisms,82 and potential applications (e.g., cancer therapy95) provide us with a basic understanding and up-to-date developments in this multidisciplinary and interdisciplinary area. A comprehensive understanding of how tiny machines behave under magnetic fields will inspire and trigger interdisciplinary and cross-disciplinary scientific and technological innovation for multiple applications. The goal of this review is to provide a general view of the locomotion behaviors of nano and microscale motors under the manipulation of a magnetic field and guidance for their rational design by describing the interaction of MagRobots and magnetic fields as well as actuation and movement mechanisms, and reporting state-of-the-art fabrication techniques. After demonstrating current applications in biological and environmental fields, a further outlook of this new and exciting field is presented.

2. Interations between Micro/Nanorobots and Magnetic Fields

2.1. Magnetic Fields and Magnetic Materials

Magnetic fields, as vector-valued functions of the position, originate from the movement of electric charge. Magnetic fields can be generated by two distinct sources: freely moving electric currents and magnetic materials. Typically, the former source is generated by the coil of an electromagnet that is externally controllable. The setups of a triaxial orthorhombic Helmholtz coil and eight electromagnetic coils (e.g., MiniMag, OctoMag) are representative and widely employed to generate magnetic fields for driving and steering MagRobots (see Section 2.2). The latter source is generated from the intrinsic magnetization of magnetic materials, specifically permanent ferromagnets, which can retain a large remnant magnetization. To manipulate micro- and nanomachines by magnetic fields, a conventional strategy consists of incorporating magnetic components into nano/microstructures. Magnetic materials can be classified as a function of the magnetic susceptibility (xm), a parameter that reflects how easy a magnetic material is magnetized. As such, magnetic materials are categorized as ferromagnetic (and ferrimagnetic) materials (xm ≫ 0), paramagnetic materials (xm > 0), and diamagnetic materials (xm < 0). Paramagnets and diamagnets are weakly attracted or repelled, respectively, to magnetic fields. Additionally, they cannot retain any magnetization once the magnetic field is removed. Ferro- and ferrimagnets are all strongly attracted to magnetic fields. Specifically, ferro- and ferrimagnets can retain magnetization, (i.e., exhibit remnant magnetization or remanence) after being subjected to a magnetic field. Usually, high remanence is a feature of hard-ferromagnetic materials, otherwise known as permanent magnets. Soft-ferromagnets, in contrast, exhibit low remanence. Both soft- and hard-magnets exhibit a hysteretic behavior, which means that to demagnetize these materials, a coercive magnetic field is necessary. This coercivity is large for hard-magnets and small for soft-magnets. Superparamagnets are a special class of materials in which features of both ferromagnets and paramagnets converge such as high susceptibility, no remanence, and no coercivity. While a few examples exist of micro/nanorobots constructed of paramagnets and diamagnets,96,97 the majority of magnetic small-scale robots have been made of ferromagnetic, ferrimagnetic, and superparamagnetic compounds. For extended details on types of magnetic materials, we suggest the reader to review the hereby indicated references.98−100

When placing a magnetic small-scale robot with a volume v in an external magnetic field B, the device will display a magnetization M. If the device is subject to a magnetic field gradient ΔB, it will experience an attractive force (or repulsive if it is a diamagnet) as expressed in eq 1. If the device is subjected to a magnetic field, to minimize its energy, it will experience a torque as expressed in eq 2, which will cause the magnetic robot to orient in such a way that its easy magnetization axis is parallel to the direction of the applied magnetic field. The easy magnetization axis is usually governed by the shape (shape anisotropy) but can also be ruled by specific crystal orientations of the materials (crystalline anisotropy). Additionally, the easy magnetization axis can be programmed, for instance, by orienting magnetic nanostructures with a matrix of a composite component or by premagnetizing a material in a specific direction:

| 1 |

| 2 |

Both magnetic forces generated in gradient fields and magnetic torque induced by spatially homogeneous or heterogeneous dynamic fields can function as “fuel” to actuate microscopic and nanoscopic motors in various environments. In terms of magnetic torque, weak homogeneous rotating or oscillating fields (see Section 2.3), which display higher efficiency in transforming magnetic energy into kinetic energy, are highly preferable. Magnetic fields offer a maximum of six degrees of freedom (DoFs) (i.e., three translational DoFs and three rotational DoFs) for absolute spatial manipulation of micro/nanorobots, depending on the setup of electromagnetic actuation systems (see Section 2.2). For instance, the widely used uniform rotating magnetic field with triaxial Helmholtz coil can supply three rotational DoFs, while MiniMag and OctoMag have five DoFs: two rotational and three translational DoFs.

2.2. Magnetic Manipulation Systems

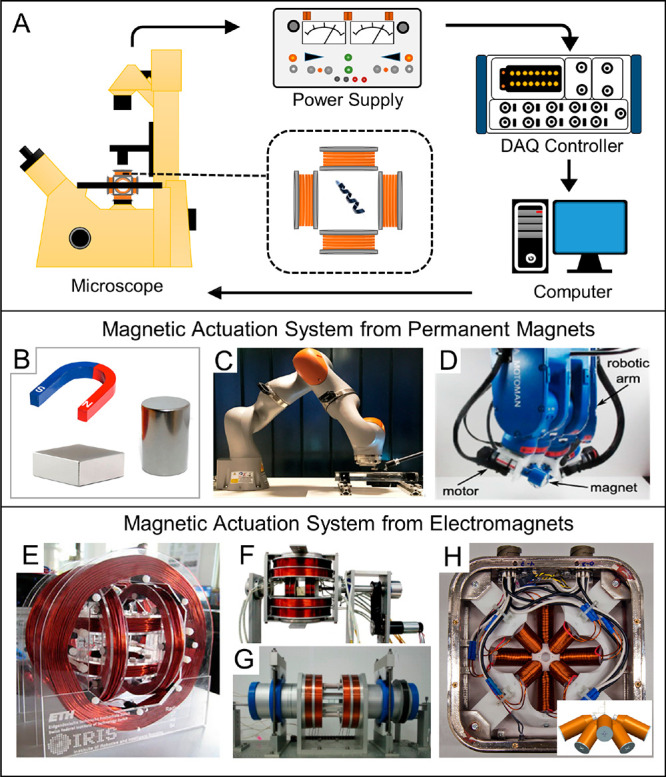

A typical setup platform for monitoring and actuating magnetically driven micro- and nanorobots consists of a sample stage, an optical microscope (eventually, coupled with a high-resolution camera), a magnetic manipulation system, and a computer system with video capture and analysis (Figure 1A). The magnetic manipulation system consists of a set of either permanent magnets or electromagnets107−110 as the source of the magnetic field. Recent contributions97,111,112 provide a systematic review of configurations of magnetic manipulation systems that can be applied to magnetic small-scale robots with sizes ranging from nanometers to millimeters. In this review, we will only focus on the commonly used magnetic systems employed for the manipulation of nanoscale and microscale robots.

Figure 1.

Experimental setup for magnetically driven micro/nanorobots and various magnetic actuation systems. (A) Diagram of the typical experimental workplace for actuating and visualizing MagRobots. (B) Magnetic actuation system consists of only a single permanent magnet. (C) Permanent magnet actuation system using cylindrical NdFeB permanent magnet fixed to its end-effector and a robotic arm. Reproduced with permission from ref (101). Copyright 2017 IEEE. (D) Rotating permanent magnet system consists of a magnet, a robotic arm, and a motor. Reproduced with permission from ref (102). Copyright 2013 IEEE. (E) Electromagnetic actuation system using triaxial circular Helmholtz coils. Reproduced with permission from ref (103). Copyright Springer Science + Business Media, LLC 2013. (F) Electromagnetic actuation system using a stationary Helmholtz–Maxwell coil and a rotational Helmholtz–Maxwell coil. Reproduced with permission from ref (104). Copyright 2009 Elsevier B.V. (G) Electromagnetic actuation system using multiply coils including a Helmholtz coil, Maxwell coil, uniform saddle coil, and gradient saddle coil. Reproduced with permission from ref (105). Copyright 2010 Elsevier B.V. (H) MiniMag electromagnetic system. Reproduced with permission from ref (106). Copyright 2014 Springer-Verlag GmbH Berlin Heidelberg.

One of the main differences between systems using permanent magnets and electromagnets is the fact that the magnetic field from a permanent magnet is persistent and its magnitude cannot be quickly changed. The distribution and strength of a magnet’s field depend on its geometrical shape and size. For a magnetized object with a given geometry shape and magnetization, large magnets can project their field further into space. However, large magnets produce smaller magnetic forces as demonstrated in eq 1 because the change of field in space (i.e., spatial derivatives in the field) is less pronounced. By manually or automatically adjusting the position or orientation of a magnet, a translatory or rotational movement of MagRobots can be triggered. Direct utilization of portable magnet provides an easy-to-operate way to drive the motion of MagRobots by simply adjusting the position and orientation of a magnet (Figure 1B). Although many researchers have reported the locomotion of magnetic micro/nanorobots by using single permanent magnets, the experimental reproducibility and accuracy are challenging aspects because the movement of magnets largely depends on their operator. Given the drawbacks of manual handling, many automatically operable magnet systems have been designed by integrating a magnet with a commercial robotic arm such as the LBR Med robotic arm from KUKA Robotics Corporation (Figure 1C) and MH5 robotic arm from Yaskawa Motoman. Such an integrated system is more reliable and precise. Besides magnetic field gradients, magnetic torque can also be exerted on small-scale devices when the magnet rotates (Figure 1D), which allows for rotational actuation mechanisms.

In magnetic actuation systems based on electromagnets, magnetic fields are generated from flowing currents through coils. A typical electromagnet is formed by wrapping insulated copper wires around a ferromagnetic core, which can concentrate and amplify the magnetic field and field gradient. An ideal soft magnetic material is often used as the core in order to avoid effects of hysteresis. On-demand setting of current in each coil can result in the required configuration of magnetic fields, such as rotating field, oscillating field, alternating fields, and conical fields, which will be discussed in Section 2.3. Different arrangements of coils constitute specialized electromagnet systems such as the Helmholtz coil, the Maxwell coil, the saddle coil, and the double-saddle Golay coil (detailed information can be found in ref (113)). Helmholtz coil, containing two circular and coaxial coils with equal radius and same handedness of flowing current, is the first and most important arrangement. Because the field generated from the Helmholtz coil is near-uniform at the center of the coils, such a magnetic actuation system is appropriate for magnetic torque control.114−117 Arbitrary uniform magnetic fields in a 2D plane or 3D space can be generated by two pairs of Helmholtz coils or triaxial Helmholtz coils, respectively. Triaxial circular Helmholtz coils are the most commonly used for actuating magnetic small-scale robots (Figure 1E). The combination of Helmholtz coils with other types of coils can engender systems with multi-DOF capabilities. Maxwell coil is also composed of two circular coaxial coils with equal radius, but the current flowing through different coils coil has the opposite handedness. Maxwell coils can create uniform magnetic field gradients, saddle coils can generate a uniform field or a gradient field, and double-saddle Golay coils can produce a transverse gradient. A magnetic manipulation system with a stationary Helmholtz–Maxwell coil and a rotational Helmholtz–Maxwell coil has the capacity of 3D locomotion of a magnetic small-scale robot through the control of both magnetic forces and torques (Figure 1F).104 Its upgraded system using four different coil pairs (i.e., a Helmholtz coil, a Maxwell coil, a rotatory uniform saddle coil, and a rotatory gradient saddle coil) occupies a smaller volume and consumes less driving energy (Figure 1G).105 Given the practical clinical application of biomedical micro/nanorobots, saddle coil and Golay coil with tubular construction are preferable because they have high space efficiency and, hence, are capable of accommodating the human body. For example, a widely used magnetic resonance imaging (MRI) scanner in clinical practice incorporates a Maxwell coil and two orthogonal Golay coils.118

A drawback of magnetic actuation systems consisting of paired coils lies in their restrictions on the shape and size of the workspace. In contrast, electromagnetic systems using several nonorthogonally distributed electromagnets, usually made of columnar coils with soft-iron cores, can break this limitation by arranging the electromagnets so that their generated dipoles keep their respective axes pointing to a common point in the given workspace. The first example of such configuration was the OctoMag, an electromagnet comprising a total of eight electromagnets. OctoMag is a system capable of generating magnetic forces and torques in three dimensions and allows for a 5-DOF magnetic control (3-DOF position and 2-DOF orientation).119 OctMag is composed of four evenly distributed electromagnets in a plane with the orientation of 90° from a central axis and four evenly distributed electromagnets with the orientation of 45° from a central axis. MiniMag is the scaled-down compact version of the OctoMag (Figure 1H). Utilization of OctMag and MiniMag has been reported to remotely manipulate micro- and nanorobots for targeted drug delivery,120 minimally invasive ophthalmic surgery,121 and stem cell transplantation in a rat brain.122 Other configurations of electromagnets, such as square antiprism, cubic, open asymmetric, and so on, were summarized in a recent review.113

2.3. Actuation Configurations for MagRobots

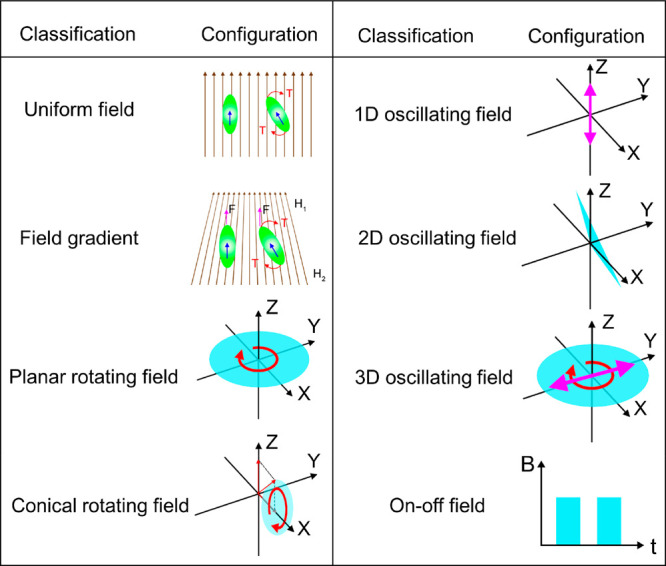

According to changes of the magnetic field vector with time, magnetic fields can be classified as static, dynamic (including a rotating magnetic field whose direction varies with time, an oscillating magnetic field whose strength varies with time), or on–off fields. Both static and dynamic magnetic fields can be homogeneous fields where the field vector modulus remains constant in space, or inhomogeneous magnetic fields where the field strength varies with position, that is, field gradient.123 Rotating magnetic fields are widely adopted to induce rotational motion. For some micro and nanomachines with specific shapes (e.g., helical structure), such temporal–periodic rotational motion can be converted into translational corkscrew motion (see Sections 3.1 and 4.2), which leads to a net spatial displacement. In contrast, oscillating magnetic fields can be utilized to activate traveling undulatory locomotion for some MagRobots such as those with soft tails (see Section 3.2) and those consisting of solid segments linked with soft hinges (see Section 4.4). Rotational magnetic fields can also induce thermophoretic motion for ferromagnetic materials by generating heat energy124 (see Section 3.4). Figure 2 summarizes different categories of magnetic fields and their corresponding field diagrams.125

Figure 2.

Classifications and configurations of magnetic fields in relation to the motion of MagRobots.

2.4. Effective Movements in MagRobots: “Symmetry-Breaking Strategies”

To begin this section, we would like to briefly introduce the hydrodynamic laws to understand how small-scale robots swim in a fluid. The Navier–Stokes equation, arising from Newton’s second law, describes the motion of a Newtonian fluid as follows (eq 3):

| 3 |

where vector ν and vector p (both of which are a function of position and time) are the flow velocity and pressure, respectively; ρ and η are the density and viscosity of the flow, respectively. The left-hand of the Navier–Stokes equation comprises the inertial forces, while the right-hand corresponds to the viscous forces. Here, we introduce an important dimensionless quantity called the Reynolds number (Re, expressed in eq 4), which is the ratio of inertial and viscous forces:

| 4 |

where L is the characteristic length of an object moving in a fluid.

For small-scale devices and organisms (i.e., motile cells, bacteria), L is very small (Re ≈ 10–4), which means that viscous forces rule their motion. A typical analogy of swimming at low Re is that a bacteria swimming in water is similar to a person swimming in honey. Considering that inertia forces are negligible in the low Re regimes, the Navier–Stokes equation can be simplified as an expression known as the Stokes equation:

| 5 |

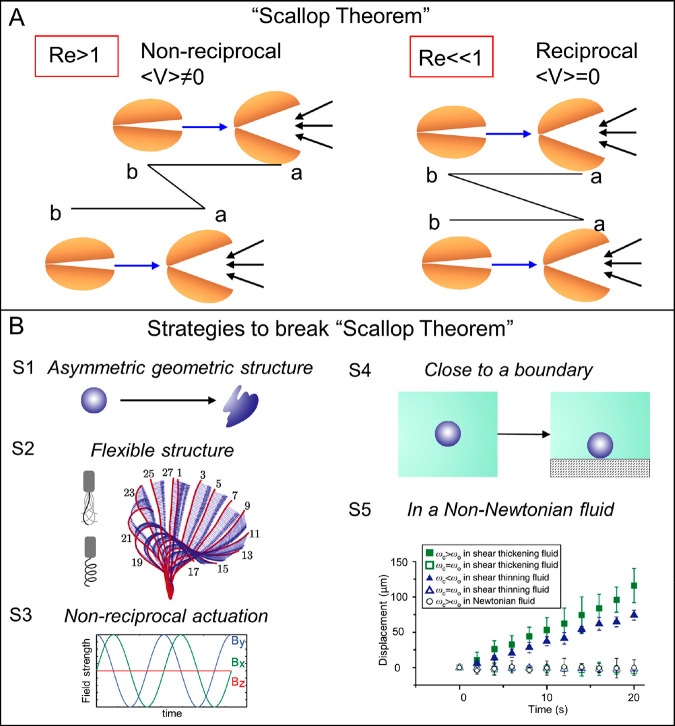

Note that this hydrodynamic equation is time-independent, meaning that no net displacement will occur after completing a cyclic process no matter if the speed of the swimmer is fast or slow. In other words, the resultant fluid flow exhibits instantaneous and time-reversible features. This is the so-called “Scallop Theorem,” as introduced by the Nobel laureate Purcell (Figure 3A). At low Reynolds number, a microscopic scallop can only perform back and forward movement (i.e., reciprocal motion). Once the actuation energy (such as a magnetic field) is removed, its motion is immediately halted due to the lack of inertial forces. Importantly, to generate a nonreciprocal translatory movement to execute tasks such as cargo delivery, Figure 3B summarizes some strategies employed to break Purcell’s Scallop Theorem. The first method involves fabricating a small-scale robot with an asymmetric shape such as a tubular,126 helical,60,127,128 fish-like,129 annelid-worm-like,130 tadpole-like,131 bullet-shaped,22 star-shaped,132 or even random-shaped133,134 structure. In addition, an asymmetric shape (e.g., carpet,135 ribbon56) can also be formed by self-assembling colloid particles with a symmetric shape based on collective behavior.90 A second approach consists of creating a micro- or nanostructure containing a flexible component, for example, a flexible tail, which can mimic the flagellum of a microorganism.81,136 Velocity distribution (indexed by frame number of a video sequence) of a single beating flagellum or cilium from a cell or a microorganism during one cycle137 indicated the generated traveling-wave motion (see Section 3.2) is nonreciprocal. Incorporating flexible components in between rigid structures to create multilink micro or nanoassemblies is also another possibility, which will be further discussed in Section 4.4. A recent strategy consists of integrating motile flagellated microorganisms and cells with magnetic micro and nanostructures to create biohybrid MagRobots (see Section 4.5). A third approach entails the use of a nonsymmetric actuation magnetic field. For example, a symmetric small structure can exhibit a translational motion by means of a traveling-wave138 or a cilia-beating motion mechanism139 under a nonsymmetric actuation field. The fourth approach is based on actuating magnetic small-scale devices in the proximity of a boundary (e.g., wall, interface) to break the spatial symmetry. The motion mechanism based on this method is called “surface-assisted propulsion”, which will be discussed in Section 3.3. All these symmetry-breaking strategies evade the constraints of the famous Scallop Theorem.100 Note that the Scallop Theorem only applies to Newtonian fluids. Time-reversible reciprocal locomotion can still generate an effective propulsion in non-Newtonian fluids (e.g., blood, saliva, mucus).140

Figure 3.

(A) Schematic image of Purcell’s scallop presenting a nonreciprocal motion in a high Reynolds number fluid and reciprocal motion in a low Reynolds number fluid with no net replacement (so-called “Scallop Theorem”141). (B) Summary of five strategies (S1–S6) to break the Scallop Theorem to produce an effective movement. S2 is reproduced with permission from refs (137 and 140). Copyright 2014, Brumley et al. This article is distributed under the terms of the Creative Commons Attribution License. S4 is reproduced with permission from ref (142). Copyright 2015 The authors. S5 is reproduced with permission from refs (137 and 140). Copyright 2014 Macmillan Publishers Limited. This is an open access article distributed under the terms of the Creative Commons CC BY license.

3. Actuation and Mechanisms of Magnetic Robots

Compared with macroscale motile robots, micro and nanoscale robots experience totally distinctive hydrodynamics. Hence, they exhibit distinctive assorted motion behaviors. A good understanding of various propulsion mechanisms is the basis for the design of propulsion microsystems including the shape and architecture of micro and nanorobots as well as the configuration of the magnetic field. The designed propulsion system must be able to overcome various resistive forces in the micro and nanodomains to realize the motion of small-scale robots effectively. The translational mechanisms of magnetic miniaturized machines could be broadly divided into three types: (a) corkscrew motion, (b) undulatory motion (i.e., traveling-wave motion), and (c) surface-assisted propulsion (i.e., surface walker).

3.1. Corkscrew-like Motion

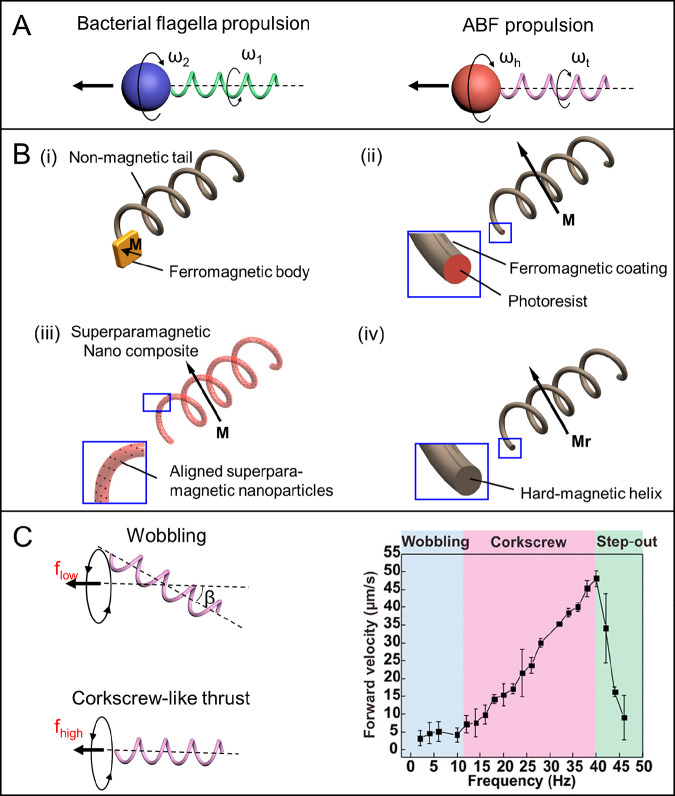

In nature, many microorganisms can coordinate their propulsion and orientation behaviors according to external stimuli with a motile appendage called a flagellum. Eukaryotic cells (e.g., spermatozoa) can produce a traveling-wave motion by making use of a flexible beating flagellum. In contrast, prokaryotic cells can perform a corkscrew-type motion by rotating their helical flagella. Bacteria (e.g., E. coli), as a representative of prokaryotic organisms, rely on the rotation of flagella for swimming. The flagellum, containing a basal body, a hook, and a filament, is the fundamental organelle for bacterial motion. There is a reversible motor inside the basal body controlling the rotation of the flagellum. The flagellum can not only trigger reorientation of the organism but also make them move forward and back. When the flagellum rotates in one direction with an action frequency ω1, the cell body counter-rotates with the reaction frequency ω2 (ω2 and ω1 are not equal) to balance the produced torque (Figure 4A). Inspired by the bacterial flagellum for efficient movement, man-made helical micronanomachines, known as artificial bacterial flagella (ABF),143−146 have been developed and investigated. Although there is no motor in the ABF system, external rotating magnetic fields provide a similar function for generating the rotation.

Figure 4.

Flagellar-based propulsion mechanisms. (A) Rotation of bacterial flagellum at frequency ω1 through rotary motor inside and a counter-rotation of the head at frequency ω2, while head and tail of ABF rotate in the same direction. (B) Typical types of magnetic ABFs. Reproduced with permission from ref (149). Copyright 2018 WILEY-VCH Verlag GmbH and Co. KGaA, Weinheim. (C) Field frequency-dependent ABF movement: ABF wobbles with a wobbling angle at low frequency; wobbling movement transforms into corkscrew-like swimming; then the wobbling decreases to zero at high rotational frequencies. Example of frequency-dependent propulsion of MOF-based helical swimmers. Reproduced with permission from ref (155). Copyright 2019 WILEY-VCH Verlag GmbH and Co. KGaA, Weinheim.

As discussed earlier, a MagRobot will align its easy magnetization axis parallel with the direction of a local homogeneous field upon experiencing a magnetic torque in that magnetic field. A continuously applied torque to a micro/nanoobject under an external rotating field gives rise to the rotational movement of the body. For artificial magnetic micromachines containing chiral helices, a steady rotation around their helical axis can be effectively converted into nonreciprocal translational motion, with the direction parallel with the rotating axis of a two-dimensional planar rotating field. At the same time, the tail and head (sometimes it has no head) of ABF perform the same (clockwise or counterclockwise) orientation. This is distinct from bacteria, whose head and tail rotate in the opposite orientation. If the ABF consists of a single rigid body, then the head and tail will rotate with the same frequency (ωh = ωt). Moreover, the progression direction (forward or backward) can be easily inverted by reversing the direction of rotation (i.e., clockwise or counterclockwise) of an applied magnetic field. In the magnetically actuated ABF system, similar to other magnetically controlled systems, magnetic materials are required in order to respond to the external field. Widely used ferromagnetic materials include Ni, Co, and Fe, while the frequently applied superparamagnetic materials include Fe2O3 and Fe3O4. Up to now, various types of ABF systems have been investigated.147,148 Some typical examples are shown in Figure 4B.149

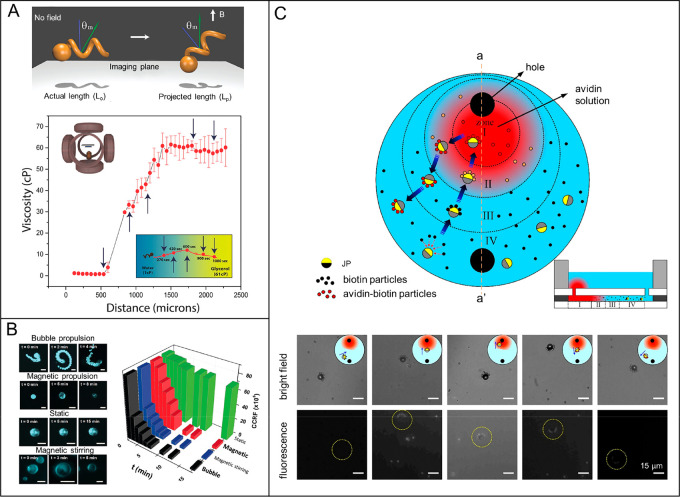

Many factors play a critical role in the movement of magnetic helical microswimmers such as solution properties (e.g., fluid viscosity, ion strength), geometrical parameters (e.g., helix pitch), surface characteristics (e.g., surface wettability,150,151 roughness), magnetic field properties (e.g., frequency, intensity, rotating, or oscillating field), magnetization properties of magnetic materials, head/tail shapes, mechanical properties (e.g., rigid or flexible), and boundary condition (e.g., wall). The simulation demonstrates that helical swimmers exhibit the highest propulsion efficiency when the pitch angle is about 45°.152 The optimal magnetization direction for helical microrobots is perpendicular to the helical axis in order to maximize the applicable magnetic torque around the axis. The motion mode and velocity of ABF are strongly associated with the applied field frequency. As shown in Figure 4C, at low frequency rotating magnetic fields (typically below several Hertz), a wobbling motion occurs when the axis of the helical MagRobot cannot align with the direction of the local field.153,154 As the rotating field frequency is enlarged, the wobbling angle decreases from 90° to zero, where a wobbling angle of zero corresponds to the rotation along the long axis with a direct corkscrew-like thrust. (Ratio of viscous to magnetic torque (i.e., Mason number), helix angle, and helical size can also bring about shrinkage of the wobbling angle of helical MagRobots under temporal–periodic torques.49 In the corkscrew-like motion region (also denoted as “synchronous” region), the translational velocity of helical MagRobots increases with the increased applied rotation frequency of an external magnetic field, performing a synchronous and linear relationship. Further increase with respect to a critical field frequency results in a decrease of the swimming velocity, which is attributed to the fact that the magnetic torque is not sufficient to maintain a synchronous relationship between the magnetic moment and the applied rotating magnetic field. The critical frequency is called the “step-out frequency”.155

Surface chemistry also influences the motion of helical MagRobots. Recently, it has been reported that magnetically driven helical microswimmers with hydrophobic surfaces possess larger step-out frequencies and higher maximum translatory velocities at low Reynolds numbers in comparison with those with hydrophilic surfaces.156 The increase in hydrophobicity of the swimmer surface causes an increase in both the step-out frequency and the maximum forward velocity in a nonlinear mode due to the interfacial slippage. Importantly, the forward velocity of ABF is independent of their surface wettability when MagRobots are manipulated below their critical frequency. A 3D oscillating magnetic field, created by the combination of DC magnetic field Bxy and oscillating Bz field, can only cause the reciprocal back-and-forth motion of a helical microswimmer. When symmetry is broken by placing the microswimmer near a surface, the rocking motion results in a net displacement. Moreover, the asymmetric helix (with polystyrene head and helical Co/SiO2 tail) exhibits much larger displacement than a nearly symmetric helix without a head under similar experimental conditions.157 The viscosity disturbance in different solutions results in the difference of precession angle (i.e., wobbling angle) of helical MagRobots when the applied frequency of the rotating field is smaller than the step-out frequency. Taking advantage of this feature, the detection of instantaneous orientations (i.e., wobbling angle) of MagRobots provides an innovative approach to evaluate the viscosity of the local medium with high spatial and temporal accuracy, which makes ABF a novel prototype for mobile viscometers.158

3.2. Traveling-Wave Locomotion/Ciliary Stroke Motion

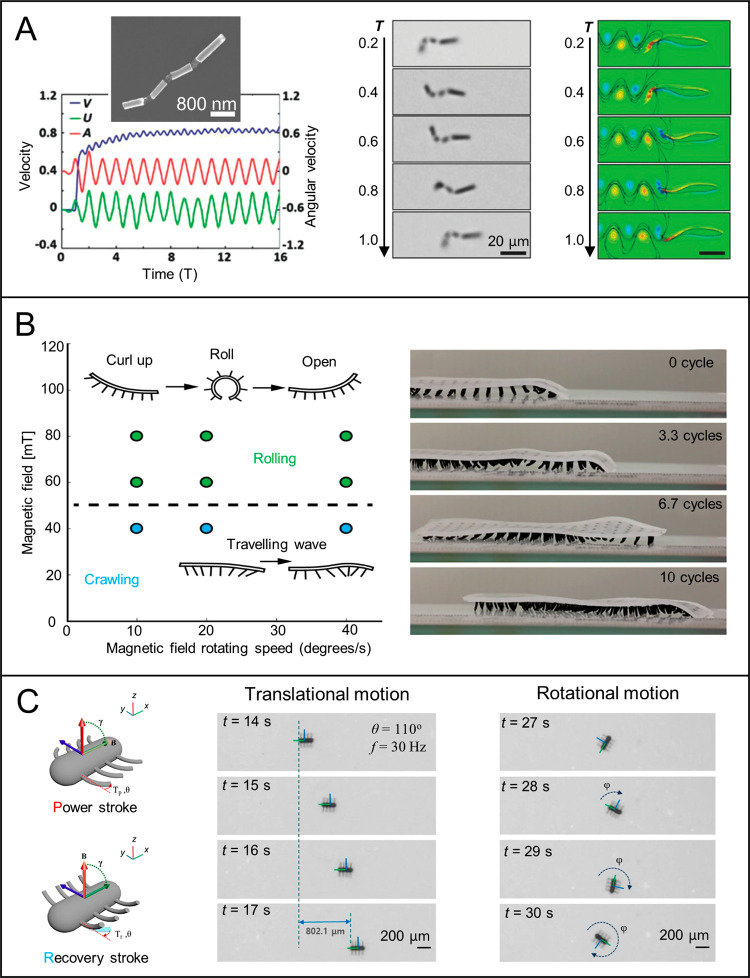

Both traveling-wave propulsion and metachronal-wave propulsion, inspired by the flagella and cilia of eukaryotic cells, respectively, are capable of breaking temporal symmetry to overcome the Scallop Theorem and generate an effective net displacement. Because short and rigid nano/microrobots can only generate very limited net propulsion due to the reciprocal nature of an oscillating movement, the presence of an elastic component is crucial for achieving traveling-wave propulsion. However, net displacement can also be hampered if the motor is too long and flexible due to the increase of drag force. Hence, the size and elasticity must be taken into consideration in terms of design. Traveling-wave propellers have been created either by incorporating elastic tails (e.g., a chain of paramagnetic beads using DNA as the soft hinge159) to a rigid head or by utilizing multilink nanowires connected by flexible segments (e.g., soft silver nanowire,3 elastic polymeric nanocylinders composed of multiple bilayers of polyallylamine chloride and polystyrenesulfonate97). The thrust from the backward-traveling wave generated by the undulatory motion of multilink artificial microswimmer, consisting of two magnetic nickel segments, two gold segments, and three soft silver, hinges upon the application of an oscillating magnetic field. Periodic mechanical deformation triggered fish-like locomotion at the microscopic level (Figure 5A).129 Other traveling-wave motion of wire-like MagRobots driven by an oscillating field can be found in Section 4.4.

Figure 5.

Flagellum-based locomotion of magnetically actuated robots. (A) Motion of Au–Ag–Ni–Ag–Ni–Ag–Au multilink nanowires with flexible silver hinges under a planar oscillating magnetic field. Reproduced with permission from ref (129). Copyright 2016 WILEY-VCH Verlag GmbH and Co. KGaA, Weinheim. (B) Multiple locomotion modes of millipede-like soft robots. Reproduced with permission from ref (160). Copyright 2020 The Authors. (C) Ciliary stroke motion of artificial micromotors. Reproduced with permission from ref (139). Copyright 2016 The Authors.

Although the metachronal wave, which is produced by the oscillatory locomotion of ciliated protozoa through hydrodynamic interactions, can also drive an effective nonreciprocal movement. Because of the complexity of manufacturing these structures at micro- and nanoscale, only millimeter-scale (not nanoscale or microscale) robot systems that mimic the metachronal-wave movement of cilia have been reported (Figure 5B).160 To date, one artificial cilia-like magnetic microarchitecture, as the exclusive example with regard to the simple ciliary stroke motion, has been fabricated by means of a 3D laser lithography method.139 The efficient movement of this microrobot in a fluid environment with a low Reynolds number was powered by the net propulsive force from the beating locomotion of cilia and its position and orientation can be precisely controlled by on–off fields with designated angle (Figure 5C).

3.3. Surface-Assisted Motion

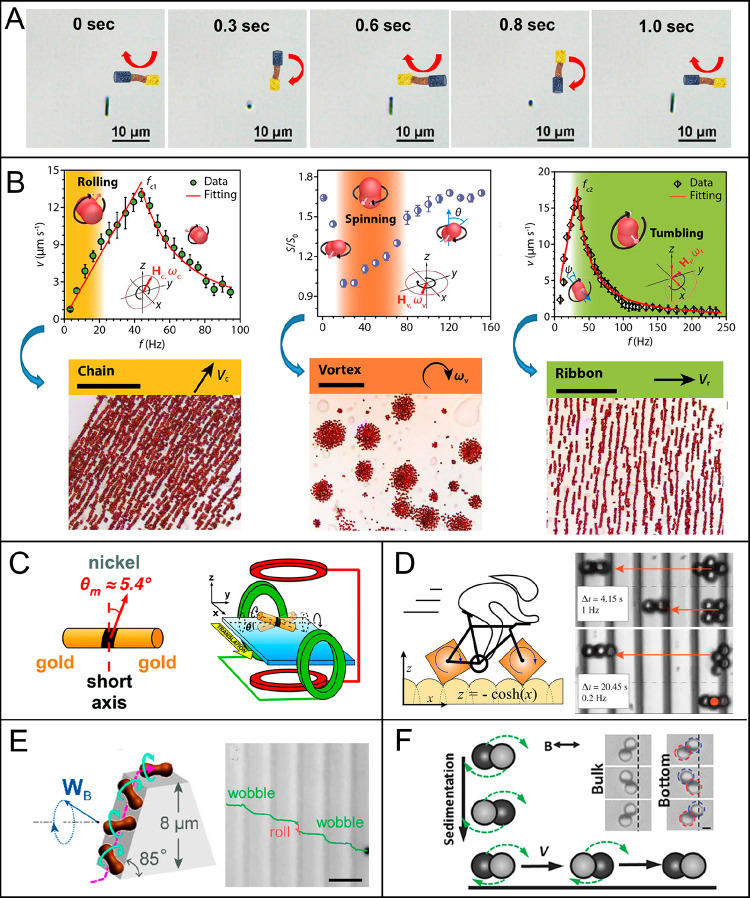

Apart from breaking the symmetry from the geometrical point of view, another strategy to overcome the Scallop Theorem and induce translational movement is to introduce a physical boundary to break the spatial symmetry. Such locomotion can be achieved by magnetically actuating a magnetic micro- or nanostructure when it lies in the proximity of a surface/interface161 or a wall in a liquid at low Reynolds number, or even a dry surface.162 The micro and nanorobots based on this “surface-assisted locomotion” mechanism are called “surface walkers” or “surface rollers.” Figure 6A exhibits a typical forward locomotion mode of a surface walker. Many magnetic micro and nanostructures have demonstrated such surface-assisted propulsion including (but not limited to) nanorods, dimers, assembled colloids, microtubes, and Janus particles. Simulations and experiments have confirmed that the dynamics and motion mechanism of surface walkers are governed by the boundary features (slip or nonslip), the degree of confinement (e.g., single or multiple confining boundaries, the distance of a MagRobot from the nearby boundary), fluid properties (e.g., finite inertia163), magnetic fields (e.g., configurations, frequency, strength), and others. The presence of a boundary modifies the hydrodynamic stresses on self-propelled nano/microrobots, resulting in a change in their orientation, velocity, trajectory, and even hydrodynamic bound states.164 Stronger frictional forces near a nonslip confining boundary (wall or surface) can drive microdevices to move forward, resulting in a larger net displacement compared with those in proximity to a smooth boundary. Hydrodynamic interactions can create stable finite clusters (“critters”) from an unstable front that is generated from the press of fingers.165

Figure 6.

Propulsion mechanisms for surface walkers. (A). Surface-assisted motion of an Au–Ag–Ni nanowire. Reproduced with permission from ref (173). Copyright 2020 American Chemical Society. (B) Motion mode transformation of hematite peanut-shaped microrobots among rolling mode under a yz-planar rotating field, spinning mode under an xy-planar rotating field, and tumbling mode under a conical rotating field; Swarming patterns of chain, vortex, and ribbon morphologies, respectively. Reproduced with permission from ref (56). Copyright 2019 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. (C) Magnetic coil arrangement and advection of Au/Ni/Au nanowire in kayak motion mode. Reproduced with permission from ref (168). Copyright 2017 The Royal Society of Chemistry. (D) Smooth translation motion of square-wheeled bicycles on bumpy roads and separation of diamond and square μwheels on the textured surface. Reproduced with permission from ref (169). Copyright 2019 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. (E) Schemes of a peanut-shaped motor climbing up a steep slope with the height of 8 μm via a wobbling mode and trajectory of the MagRobot climbing up and down a steep slope. Reproduced with permission from ref (170). Copyright 2018 American Chemical Society. (F) SEM image of a microdimer and its motion in bulk liquid and near a boundary. Reproduced with permission from ref (172). Copyright 2018 WILEY-VCH Verlag GmbH and Co. KGaA, Weinheim.

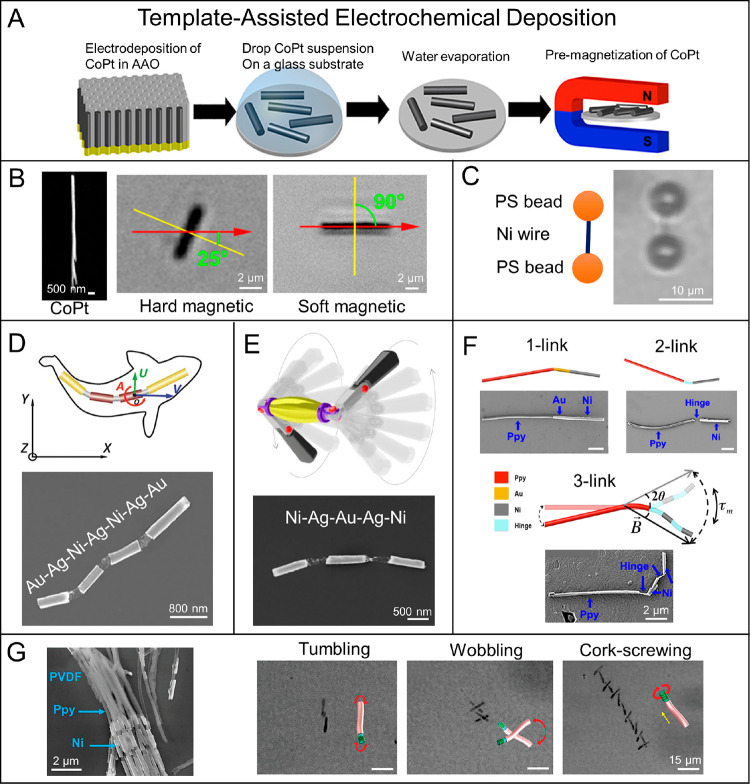

Motion modes of surface walkers are frequency- and field type-dependent. CoPt semihard magnetic nanowires experience the motion transformation from tumbling to precession and then to almost rolling near a surface boundary by raising the frequency of the applied planar rotating field. In the tumbling region, the y-axial translational velocity of nanowires synchronously increases with the field frequency regardless of the applied magnetic moment. In the procession region, the velocity still slowly increases and then decreases after reaching the maximum. The decrease of speed is ascribed to a decline of the precession angle, resulting from the change of motion configuration.166 Transformation of the motion mode can also occur in hematite peanut-shaped microrobots by using different magnetic fields, including a 1D oscillating magnetic fields (oscillating mode), yz-planar rotating magnetic field (rolling mode), xy-planar rotating magnetic field (spinning mode), and conical magnetic field (tumbling mode) corresponding to the collective configuration of liquid, chain, vortex, and ribbon, respectively (Figure 6B). A 2D vortex can be self-assembled by rotating magnetic colloids in a plane parallel to the interface; however, such a vortex cannot produce net displacement. On the contrary, net displacement occurs in rolling mode and tumbling mode once a boundary is present. Taking the chains with rolling mode as an example, net displacement along the x axis can be generated when the assembled magnetic chains are subjected to a yz-plane rotating field. In other words, the rotational motion of microrobots in a plane perpendicular to a nearby boundary can lead to nonreciprocal propulsion. Similar to the artificial bacterial flagella, the velocity of the individual peanut-shaped microrobots as well as that assembled chains (e.g., trimer and pentamer) linearly increases with applied frequency when the actuation frequency is below the step-out frequency. Above the step-out frequency, the increase of the rotating field’s frequency causes a decrease of the microrobots’ velocity owing to the considerable rise of liquid-induced viscous torque. In addition, the velocity of assembled chains is dependent on the number of microrobots composing the chains. Most importantly, collective formations and locomotion can be manipulated by a magnetic field in a programmable and reconfigurable fashion, providing versatile collective modes to meet multitasking requirements in complicated biological systems.56,125,167 Magnetic microkayaks demonstrate processing motion in a double-cone rotating way, similar to the movement of a paddle, when placed in proximity to a solid surface under the rotating fields with kilohertz frequency (Figure 6C).168

In comparison with flat surfaces, research of magnetic nano/microrobots on topographic surfaces is more challenging but more intriguing. Inspired by smooth-riding bicycles containing square-shaped wheels, utilization of a microroad with periodic bumps lead to 4-fold intensification in forward velocity of microwheels (μwheels) owing to the nonslip rotation of entire wheels. Because of the velocity difference between diamond μwheels and square μwheels on topographic surfaces, the separation of isomeric μwheels by symmetry can be fulfilled (Figure 6D).169 For surface walkers, climbing over a barrier is also possible by taking advantage of surface physics. A peanut-shaped hematite micromotor with its magnetic moment vertical-aligning with the long axis can achieve rolling movement under a rotating magnetic field and wobbling movement under a conical rotating field. The magnetically actuated MagRobot can climb up and down a steep slope with a height of 8 μm through the wobbling motion mode. By combining rolling motion mode and wobbling motion mode, the MagRobots can be utilized to deliver and release cells to an appointed place and form complex cell patterns under the control of a magnetic field in a contactless fashion (Figure 6E).170 Except for these artificial barriers, magnetic actuation of MagRobots on the uneven surface of biological tissue (i.e., ex vivo swine bladder) was investigated by Zhang’s group.171 In addition to a rotating field, an oscillating magnetic field can also be adopted to actuate the translational movement of a surface walker. Under an oscillating field, microdimers consisting of Ni-SiO2 magnetic Janus microspheres are able to roll on the solid surface after sedimentation treatment. In contrast, no net displacement can be produced when Janus microspheres are returned to the bulk of the liquid by acoustic levitation (Figure 6F).172

3.4. Application of Magnetic Fields in Other Propulsion Approaches

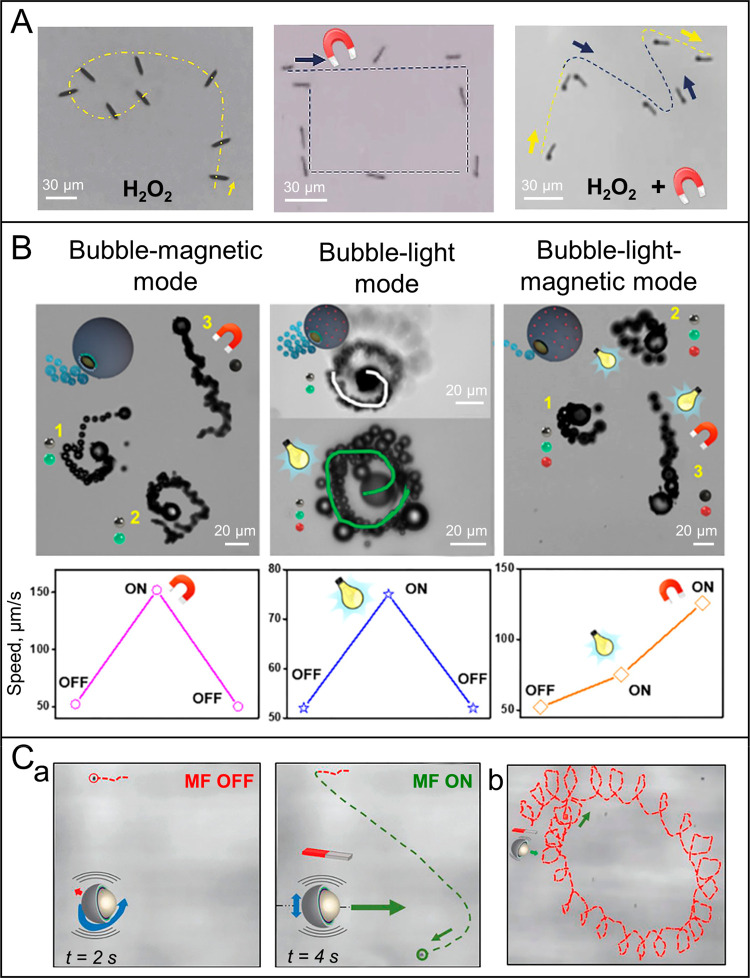

Approaches such as chemically or photochemically induced propulsion lack the level of control of magnetically driven micro and nanoswimmers, especially in terms of directionality, control over the speed, and ON/OFF motion features. However, chemically and photochemically driven swimmers are very useful for chemistry-on-the-fly applications such as water remediation applications. To provide better controllability on the motion aspects of these chemical and photochemical swimmers, the integration of magnetic components has been widely adopted. For example, a single TiO2–PtPd–Ni nanotube174 performed autonomous motion through the bubbles generated from the decomposition of hydrogen peroxide (Figure 7A). To control the directionality of bubble-propelled small-scale machines along any predetermined paths, the assistance of other power sources is necessary. After the application of a static magnetic field, the motion direction of those self-propelled nanodevices is controllable. A similar function of orientation control was found in fuel-free light-driven small-size robot systems,175 urease-powered nano/micromotors,176 cell-powered nanomicromachines,177 and acoustically actuated micronanoscale vehicles.97,178 Furthermore, the combination strategy can amplify the propulsive thrust by harvesting energies from different sources,179 resulting in more efficient task processing capabilities. A Janus microrobot, using three types of nanomaterials as engines, was capable of swimming by bubble propulsion, light-powered propulsion, and magnetic-actuated motion (Figure 7B).180 Compared with only bubble-propulsion, the bubble–magnetic dual propulsion mode boosted the velocity of microrobots up to 3 times, while the bubble–light dual mode could increase it up to 1.5 times. Because of the synergetic effect of the three energy sources (i.e., chemical energy, light, and magnetic field), the ternary bubble–light–magnetic mode exhibited a much higher speed than binary bubble-light mode.180 By switching on and off a magnetic field, the on-demand control of nanoand microscale robotic systems via braking or accelerating the propulsion process was demonstrated. Obvious growth of velocity was observed in an ultrasound-powered Janus micromotor when a static magnetic field switched from “OFF state” to “ON state” as shown in Figures 7C.181 Moreover, the use of external magnetic fields allowed for controlling the directionality to the acoustically driven microrobots.

Figure 7.

Representative examples of applying magnetic fields to micro/nanorobots actuated by other propulsion sources. (A) Propulsion of a TiO2–PtPd–Ni tubular nanomotor by bubbles from the decomposition of chemical fuel, magnetic field, or both. Reproduced with permission from ref (174). Copyright 2016 WILEY-VCH Verlag GmbH and Co. KGaA, Weinheim. (B) Boost of propulsion velocity of a Janus micromotor propelled by dual mode or ternary mode. Reproduced with permission from ref (180). Copyright 2020 American Chemical Society. (C) ON–OFF feature and direction control capacity of the magnetic field for ultrasound-powered Janus micromotors: (a) Propulsion of a single microrobot without and with the application of a static magnetic field; (b) Magnetic navigation of a single acoustic-powered microrobot. Reproduced with permission from ref (181). Copyright 2020 WILEY-VCH GmbH and Co. KGaA, Weinheim.

3.5. Magnetic Stimulation of Micro/Nanorobots beyond Motion

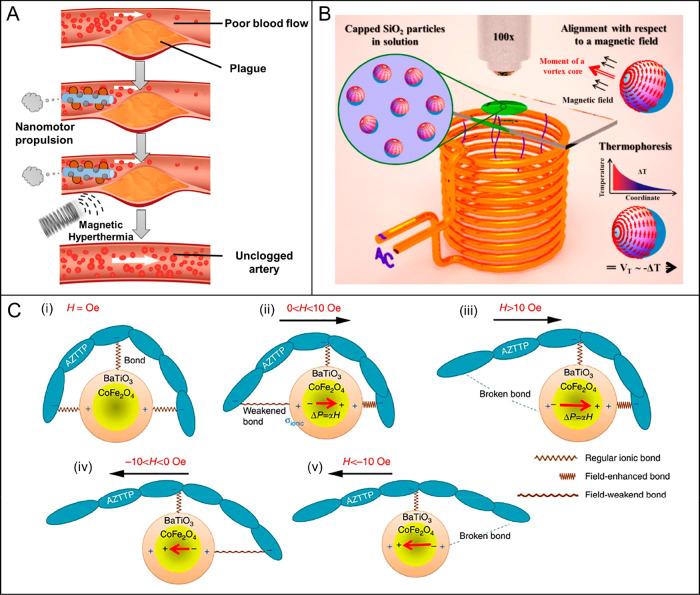

In addition to direct motion control, magnetic fields can be used as the energy source for triggering hyperthermia,182 thermophoresis, and magnetoelectricity. Magnetic hyperthermia refers to the heating of cells, tissues, tumors, or systems to temperatures up to 42 °C by converting magnetic energy into heat radiation.183,184 Such function is preferable for treating cancer cells while minimizing damage to surrounding healthy tissues as nanoscale and microscale robots can be externally delivered to the infection site with the assistance of real-time image guidance (e.g., clinical MRI scanner, magnetic particle imaging scanner185) and subsequent hyperthermia treatment is localized by only focusing on the tumor tissue. Recently, an approach that combined hyperthermia features with the propulsion force of nanoswimmers has been utilized to clear away plaques in a clogged blood artery. The nanorobots consisted of cellulose nanocrystals, Fe2O3 NPs, and Pd NPs.186 As demonstrated in Figure 8A, the flow of the bloodstream went back to its normal state after the blockage site from animal fat was fully melted and removed. Magnetically induced thermophoresis refers to a self-diffusive motion generated by the local temperature gradient induced by the nano/microrobot itself under an external field. An alternating (AC) magnetic field has been used to heat the spherical Janus robot half-capped with magnetic material (i.e., Fe19Ni81 alloy), giving rise to self-thermophoretic motion124 as shown in Figure 8B. Besides, the high heating power generated by the magnetic field was also reported to trigger a Fischer–Tropsch synthesis.187 In this process, the magnetic nanoparticles acted as magnetically induced heterogeneous catalysts.

Figure 8.

Magnetic stimulation of micro/nanorobots for hyperthermia, thermophoresis, and magnetoelectric applications. (A) Schematic process of removing cholesterol plaque in the blood artery via the magnetic hyperthermia of nanorobots. Reproduced with permission from ref (186). Copyright 2020 Elsevier B.V. (B) Experimental setup of Janus nanorobots for magnetically induced thermophoresis. Thermophoretic force, triggered by the temperature difference, causes the self-propulsion of a Janus particle. Reproduced with permission from ref (124). Copyright 2012 American Chemical Society. (C) Underlying physics of the magnetoelectrically triggered drug (i.e., AZTTP) release process. Reproduced with permission from ref (201). Copyright 2013 Macmillan Publishers Limited.

Magnetic fields can also be used to trigger electric polarization if magnetoelectric materials are incorporated in small-scale motile devices.188,189 Magnetoelectric materials are single-phase or composite materials, which become electrically polarized when subjected to an external magnetic field.188,190 To operate at room temperature, magnetoelectric materials are usually made by intimately coupling magnetostrictive and piezoelectric components, although certain single compounds, such as bismuth ferrite (BiFeO3), exhibit magnetoelectric features at room temperature. When a magnetic field is applied to these materials, the magnetostrictive part changes its dimensions. In turn, the magnetostrictive part stresses the piezoelectric part, which subsequently becomes electrically polarized. Magnetoelectric composites can be processed as bilayered or multilayered composite structures, core–shell architectures, or as particulate matrix composite films.191 Because of their ability to generate electric fields in a wireless fashion (i.e., external magnetic fields), magnetoelectric materials integrated into small-scale robots can serve at least two purposes: (a) magnetic navigation due to the responsiveness of the magnetostrictive component to magnetic fields and (b) application of an electric field to the surrounding environment (i.e., electrolytes, cells, tissues) due to the piezoelectric block. Switching between these two capabilities is managed by changing the conditions in which the magnetic fields are applied, for example, by changing the frequency of an oscillating magnetic field or by swapping between gradients (for motion) and oscillating magnetic fields (for triggering the magnetoelectric effect). The delivery of electric fields is interesting for a wealth of applications, especially in the biomedical domain such as cell electrostimulation and differentiation,192 electroendocytosis-mediated drug delivery,193 irreversible electroporation for cancer treatment,194 cell fusion,195 or even cell destruction.196,197 Magnetoelectric nanorobots or microrobots, despite being less investigated, have been utilized for targeted cell manipulation,198 neuronal-like cell differentiation,13 and targeted drug delivery.199 For instance, a helical microswimmer, incorporating core–shell magnetoelectric nanoparticles (i.e., CoFe2O4 as the core and BiFeO3 as the shell) into a hydrogel matrix was able to induce the differentiation of neuronal cells due to the generation of charges upon magnetic stimulation.13 On-demand drug release for killing cancer cells was demonstrated by FeGa@P(VDF-TrFE) core–shell nanowires upon the application of an AC magnetic field because of the magnetoelectric coupling effect.199 It is believed that magnetoelectrically induced drug release is caused by the rupture of drug–carrier bonds when the dipole moment triggered by a magnetic field goes beyond the threshold value (i.e., drug–carrier bond strength) and breaks the intrinsic charge distribution on atoms200,201 as suggested by Khizroev’s group (Figure 8C).

4. Magnetic Robots in the Making: Fabrication Approaches

4.1. (Quasi-)Spherical MagRobots

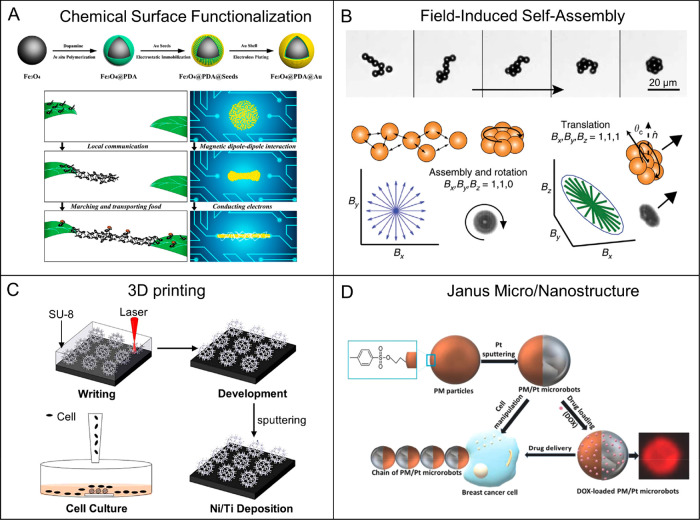

Colloidal magnetic particles have attracted scientists’ attention not only because of their individual properties but also due to an emergently investigated phenomenon called “swarm” or “collective behavior”,57,202−209 which is a term inspired by many phenomena in nature such as flocking of birds or team-work behaviors of insects. How to manipulate and actuate a large number of tiny robots with collective behaviors for potential in vivo applications, particularly in complex biological media and in a precisely controllable and programmable fashion, is the ultimate objective of scientists. The self-assembled MagRobots not only are capable of loading or unloading defined cargos on command but also transport them to a defined site (e.g., microfluidic system or biological environment), providing great potential for localized therapy and targeted drug delivery210 owing to their easy synthesis and versatile multifunctionalities by material design, structure optimization, and surface modification. The collective behavior via colloidal self-assembly presents a rapid, reversible, and programmable bottom-up approach to fabricate MagRobots by employing simple colloidal particles as building blocks. In the presence of a magnetic field, both commercially purchased paramagnetic materials (e.g., μm-sized Dynabeads135,211) and experimentally synthesized magnetic colloidal particles can be self-assembled into desired sizes and shapes (such as carpet,135 wire,212 lasso211). Yang et al.211 recently reported on superparamagnetic PVA-linked colloidal chains by applying a one-dimensional DC magnetic field with a strength of around 20 mT in the vertical direction to a diluted epoxy-functionalized Dynabeads solution. After the formation of linear chains, a circularly planar rotating magnetic field was operated to transform the chains into a lasso shape. By steering the magnetic field strength and phase lag, lassos can capture cargo through curling behavior and precisely transport it on the ground of a wheel-type mechanism at high velocities. Inspired by ants’ cooperative behavior to create a bridge with their bodies when encountering a vanished or nonexistent road (Figure 9A), Zhang’s group used a self-organized magnetic swarm robotic system as building blocks to form a microswitch to repair broken microcircuits. Each component of the system was made of a conductive gold-coated superparamagnetic Fe3O4 nanoparticle. Under a programmed oscillating field, these magnetic nanoparticles can self-reconfigure into a ribbon-like microswarm to act as a conductive bridge between two disconnected electrodes. The patterns and behaviors of the swarming MagRobots depend on the amplitude ratio and input oscillating frequency. Moreover, the elongation of the microswarm is reversible by altering the amplitude ratio.212,213 By applying an xy-plane rotating magnetic field with a few milli-Tesla (mT), microwheels of superparamagnetic beads can be self-assembled (Figure 9B).214 For microwheels lying on a surface, magnetic torque generated by a 2D rotating field can only induce a spinning movement of the micromachines without net displacement. After inputting a 3D oscillating field by adding a varied component vertical to the plane of the rotating field, that is, the microwheels were reoriented until they tilted to a surface, they began to translate with a velocity of around 100 μm s–1.214 Inspired by the rolling motion of neutrophiles on the vasculature walls, superparamagnetic beads can accumulate and roll on the surface of confined boundaries using a combination of magnetic and acoustic fields.66

Figure 9.

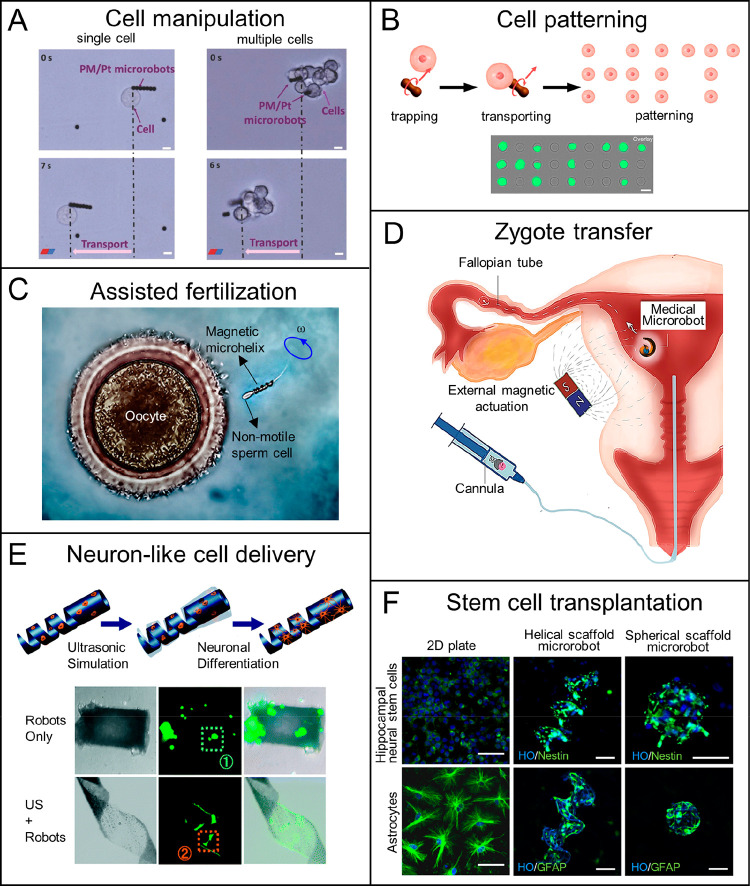

Schematic illustrations of the representative fabrication processes of (quasi-)spherical MagRobots. (A) Fabrication steps of Fe3O4@PDA@Au MagRobots and formation process of an ant bridge, corresponding to conceptual steps for a reconfigurable microswarm to repair an electrical circuit. Reproduced with permission from ref (212). Copyright 2019 American Chemical Society. (B) Microwheel prepared from the self-assembly of superparamagnetic Dynabeads M-450 Epoxy by rotating field and its field-dependent motion modes: planar rotating magnetic field makes colloids assemble and microwheels spin, whereas 3D oscillating magnetic field makes microwheels roll along the surface. Reproduced with permission from ref (214). Copyright 2019 The Authors. (C) Fabrication steps of the burr-like microrobots. Reproduced with permission from ref (215). Copyright 2018 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. (E) Fabricating process of PM/Pt Janus microrobots for cell manipulation, DOX drug loading, and delivery. Reproduced with permission from ref (210). Copyright 2018 WILEY-VCH Verlag GmbH and Co. KGaA, Weinheim.

3D laser lithography is among the most popular techniques used to fabricate small-scale robots with desired architecture. Burr-like spherical porous MagRobots were prepared by using a direct laser writing system followed by depositing Ni thin films for magnetic actuation and Ti thin films for biocompatibility via a sputtering system (Figure 9C).215 The fabricated microrobots can carry and deliver targeted cells to a predetermined location in vitro and in vivo under the control of a field gradient. In vitro experiments conducted in a microfluidic chip showed that cell-loaded microbots could be transferred along the blood vessel-like microchannel to a predefined area to release cells (i.e., MC3T3-E1 preosteoblasts). These free cells moved toward the tissue chamber through migration channels. In vivo experiments conducted on nude mice also confirmed that burr-like magnetic microrobots exhibited excellent cell loading, carrying, and release capabilities. In a similar fashion, Jeon et al. used 3D laser lithography and sputtering to fabricate cylindrical, hexahedral, helical, and spherical MagRobots.122 The use of a magnetic field gradient induced the pulling motion of cylindrical and hexahedral MagRobots, while the rotating field caused corkscrew motion for helical MagRobots and rolling motion for spherical microrobots.122

Spherical microrobots with Janus structure were fabricated by Martin Pumera’s group (Figure 9D).210 The Janus structure, formed by half-covering superparamagnetic polymer particles with catalytic Pt layer, can self-propel due to the catalytic decomposition of hydrogen peroxide and can be steered by an external magnetic field. Polymer particles with a tosyl group-rich surface provided the chance to bind anticancer drugs. In addition to drug loading and delivery, the microrobots could also manipulate cells when they assembled into a chain under magnetic guidance.

4.2. Helical MagRobots

Helical architectures, inspired by the flagella of bacteria, enable micronanomachines to convert rotational motion to a translational corkscrew motion by using a low-strength magnetic field in low Reynolds number liquids. Various micro- and nanofabrication techniques have been used to prepare helical micro/nanostructures, including template-assisted electrochemical deposition (TAED),216 laser ablation,217 direct laser writing and 3D printing,128,156,218−221 glancing angle deposition,127,222 coiled flow template,223,224 biotemplate,225,226 and origami-based self-scrolling technique.60,227

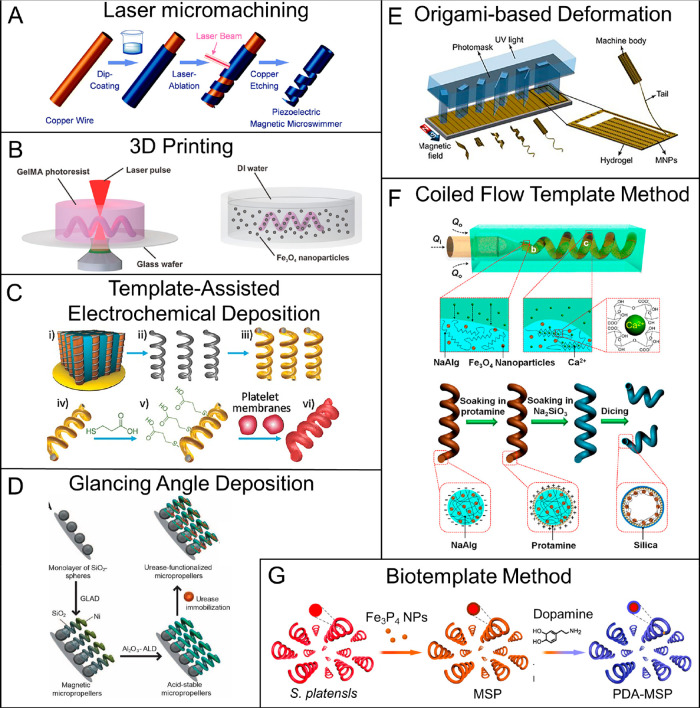

Laser micromachining allows the creation of arbitrary 3D structures. Piezoelectric soft MagRobots, which can deliver PC12 cells by employing a rotating magnetic field to induce neuronal differentiation under the stimulus of acoustic waves, were fabricated by Salvador Pané’s group.217 Helical MagRobots consisting of piezoelectric polymer matrix and CoFe2O4 magnetic component were formed by laser ablation of composite film coated on the surface of copper wire by dip-coating method, followed by etching copper wire with acidic ferric nitrate solution (Figure 10A). Steering of helical parameters such as pitch, pitch angle, and the ratio can be achieved by altering the laser spot size, laser motion speed, and rotating speed of copper wire. The helix microstructure can move in a corkscrew manner along its long axis by a rotating field.

Figure 10.

Schematic illustrations of representative synthetic methods for helical MagRobots. (A) Fabrication process of piezoelectric magnetic microswimmers by laser ablation. Reproduced with permission from ref (217). Copyright 2019 The Royal Society of Chemistry. (B) Fabrication of biodegradable helical MagRobots using two-photon polymerization. Reproduced with permission from ref (238). Copyright 2018 WILEY-VCH Verlag GmbH and Co. KGaA, Weinheim. (C) Preparation process of platelet-membrane-cloaked MagRobots by TAED method including (i) Pd/Cu coelectrodeposition, (ii) etching of Cu and collection of helical structures, (iii) deposition of Ni and Au layers, (iv) collection of helical nanostructures, (v) surface modification, and (vi) fusion of platelet-membrane-derived vesicles to the modified surface. Reproduced with permission from ref (216). Copyright 2017 WILEY-VCH Verlag GmbH and Co. KGaA, Weinheim. (D) Preparation steps of acid-stable enzyme-functionalized MagRobots by GLAD. Reproduced with permission from ref (222). Copyright 2015 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. (E) Origami-inspired approach to prepare microswimmers by one-step photolithography. Reproduced with permission from ref (245). Copyright 2019 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. (F) Fabrication of helical microrobots with hollow structures with the assistance of coiled flow template. Reproduced with permission from ref (223). Copyright 2018 American Chemical Society. (G) Fabrication process of biohybrid microswimmers based on Spirulina platensis. Reproduced with permission from ref (226). Copyright 2020 American Chemical Society.

3D/4D printing provides a feasible approach to fabricate soft micro/nanorobots with predesigned shapes.228−236 Recent reviews give a summary of functional soft robots created by 3D printing45 and 4D printing237 technique. 3D-printed enzymatically biodegradable soft helical microswimmers have been designed by Pané and co-workers.238 Two-photon polymerization (a type of 3D printing technique) was adopted to print photo-cross-linkable gelatin methacryloyl (GelMA) helical microswimmer. To decorate GelMA architecture with Fe3O4 nanoparticles for magnetic actuation, GelMA microstructures were immersed in a water suspension of PVP-coated Fe3O4 nanoparticles (Figure 10B). Another work about hydrogel-based biodegradable helical microswimmers with length of 20 μm and diameter of 6 μm was reported by Metin Sitti’s group.128 3D printing of double-helical architecture was realized by two-photon polymerization technique from a precursor mixture of GelMA, photoinitiator, and biofunctionalized superparamagnetic Fe3O4 nanoparticles. Such double-helical architecture allows these micromachines to host high therapeutic cargo loading and swimming abilities under a rotating magnetic field.

Although template-assisted electrochemical deposition (TAED) has been widely used to fabricate tubular micromotors, this method can also be employed to generate helical architectures.239−241 A representative example was demonstrated by fabricating platelet–membrane-cloaked magnetic helical nanomotors in Joseph Wang’s group.216 Pd helical microstructures with a length of 3–5 μm were synthesized by coelectrodepositing a Pd/Cu bilayer on an electrochemical platform using a polycarbonate template and followed by selectively etching the Cu with nitric acid. Afterward, Ni/Au thin films were deposited on the surface of the helical nanostructure via the electron beam evaporation method. To make the gold surface negatively charged, surface modification of the magnetic helical microstructures was carried out by overnight incubation of the microrobots with 3-mercaptopropionic acid. Then, platelet-membrane-derived vesicles were adsorbed, bound, and fused onto the negatively charged gold surface by ultrasonic mixing (Figure 10C).

Helical MagRobots can also be produced by glancing angle deposition (GLAD).242−244 In this approach, a seed layer, normally created by spreading a monolayer of silica beads on the substrate, is required to function as the nucleation site. Prior to deposition, the seed layer is fixed at a glancing angle with respect to the input vapor flux of a specific material. During the deposition process, a helical silica structure grows starting from an individual seed particle by continuously rotating the substrate. The pitch and chirality of asymmetric helical structures are changeable by adjusting the speed and direction of rotation. Finally, a layer of magnetic material is deposited in the resulting silica helical tail. While this method can batch-produce uniform helical nanostructures, this process is still limited in terms of material selection and shape. To make the magnetic section (i.e., Ni) of helical microstructure stable in acidic solution, helices were covered with an 8 nm Al2O3 thin film by atomic layer deposition. The stabilized helical micropropellers can be further functionalized with urease (Figure 10D).222

Inspired by origami designs, Huang et al.245 exploited thermoresponsive gel composites reinforced with magnetic nanoparticles to fabricate microswimmers with various 3D architectures by using a one-step photolithography technique and capitalizing on the self-folding of the hydrogel upon hydration (Figure 10E). During the gel polymerization process, a static uniform field was used to align the encapsulated magnetic nanoparticles. The folding axis direction of the MagRobots was consistent with the alignment direction of the magnetic particles as the swelling was constrained along the reinforcement direction. The produced microswimmers could change their shapes to adapt to local environmental variations in mechanical constraints and osmotic pressure.245

Hollow helical microstructures can be obtained by first synthesizing magnetic helical microfibers composed of calcium alginate hydrogel and Fe3O4 nanoparticles from coiled flow templates in glass-capillary microfluidic devices, followed by biosilicification and dicing process (Figure 10F). The produced microswimmer containing inflexible alginate/protamine/silica shell exhibited good mechanical performance for cargo transport.223 Utilization of bevel-tip capillary and syringe pump, heterogeneous core–shell hydrogel microsprings with calcium alginate hydrogel as shell components and functional materials (e.g., magnetic particles, agarose, cell-suspended collagen) as core components were produced.246

Because nature provides us with plenty of helical micro- and nanoarchitectures, preliminary attempts to extract the helical xylem vasculature of plants225 and Spirulina cyanobacterial green–blue microalgae247−249 as templates to fabricate biohybrid helical micro- and nanomachines open a new insight into strategic designs. The advantage of biohybrid small-scale robots is in the biocompatibility and biodegradability characteristics of the biotemplates. Cell-based helical microswimmers can be acquired from multicellular Spirulina via a single cost-effective dip-coating process in superparamagnetic Fe3O4 solution.249 Because of the intrinsic properties of microalgae, the prepared microswimmers allowed for in vivo fluorescence imaging without additional fluorescent markers. Moreover, large swarms of microswimmers can be accomplished inside the rat stomach by an external rotating magnetic field with the assistance of imaging.249 Model small molecules, as well as biomacromolecules, can be loaded into Spirulina cells by controlling their dehydration and rehydration.247 The micromachine loaded with molecular cargo can be magnetically driven in an intestinal tract phantom, thus providing the possibility of targeted molecular delivery for gastrointestinal diseases. By modifying their surface with polydopamine via dopamine self-polymerization (Figure 10G), Spirulina-based magnetic helical microswimmers exhibit an enhanced photoacoustic signal and photothermal effect.226 In addition to the above-mentioned helical MagRobots, many other helical architectures have been created.145,243,250−256

4.3. Flexible MagRobots

Flexible or soft small-sized robots refer to a nanoscale and microscale robotic system completely or partially comprising soft components or architectures that function as carriers, templates, hinges, joints, actuators, sensors, or reservoirs.257−262 The utilization of flexible microorganisms to create MagRobots will be discussed in Section 4.5. The advantages of flexible MagRobots are reflected in the following aspects: First, as described in Section 2.4, the integration of a soft segment as a hinge262 (see Section 4.4) or as a tail (see Section 3.2), into nano/microrobots can break spatial and temporal symmetries and generate a forward thrust. Second, flexible MagRobots are capable of transforming their configurations/architectures to execute special tasks under the magnetic actuation, such as grasp and release (similar to the function of a hand) of a small-scale object.263,264 Third, flexible and soft small-scale robots are more desirable for biomedical applications as these devices are more adaptive in complex biological scenarios, especially in confined, hard-to-reach tissues and vessels of the body when compared with swimmers made from rigid and hard parts.

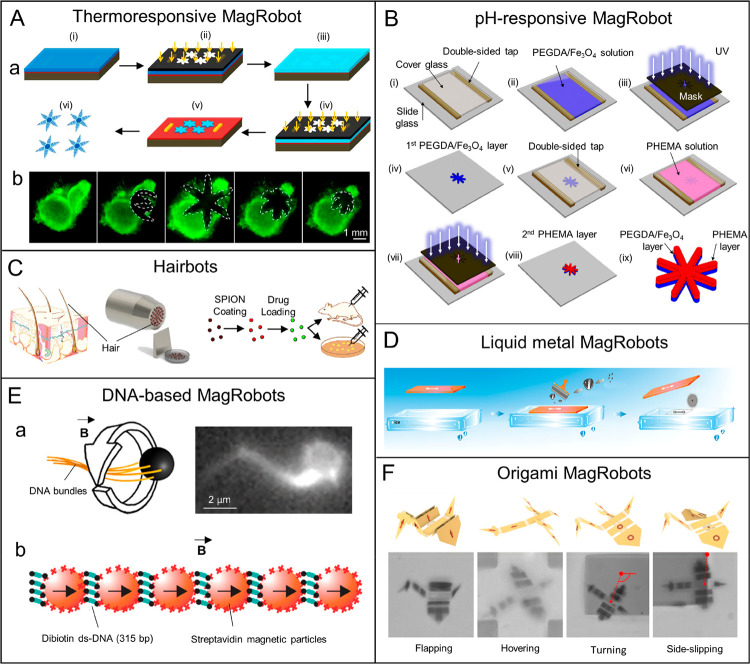

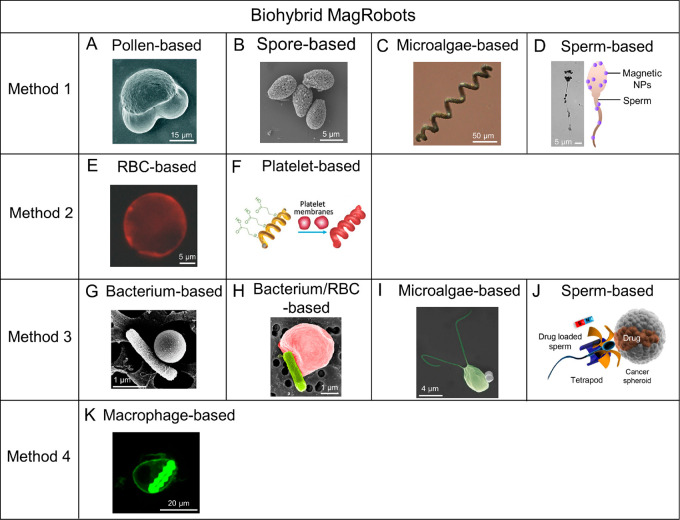

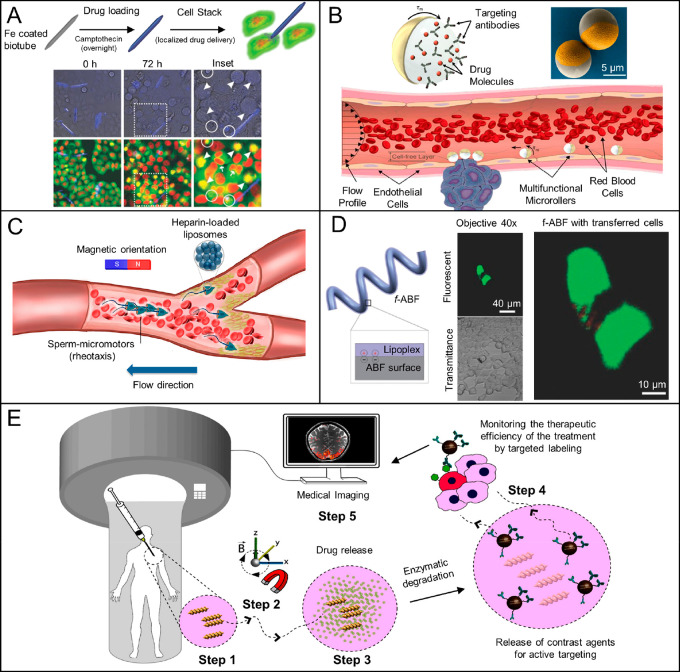

Soft robots can be constructed with stimuli-responsive polymer materials that enable shape transformations and the realization of other tasks depending on environmental changes (i.e., pH,265,266 temperature). For example, PPF/pNIPAM-AAc magnetic microgrippers with pNIPAM-AAc serving as a thermoresponsive swelling hydrogel segment, polypropylene fumarate (PPF) as a nonswellable stiff segment, and Fe3O4 nanoparticles for the magnetic actuation were prepared by serial photolithographic method (Figure 11A). The thermoresponsive soft self-folding microgrippers could be directed or retrieved to the desired location under the magnetic field to execute their tasks (e.g., to load or release therapeutics) in response to temperature stimulus at around physiological temperature without the need of wires, batteries, or other sources.39 Similarly, another thermoresponsive soft microrobot was manufactured and employed for pick-up/release applications due to the temperature-sensitive P(OEGMA-DSDMA) layer.267 Because of the pH-responsive property of 2-hydroxyethyl methacrylate (PHEMA), the PHEMA/PEGDA-Fe3O4 bilayer soft microrobot formed via photolithography (Figure 11B) performed the trapping of drug microbeads at about pH 9.58 by full folding motion and the release of drugs by unfolding motion at about pH 2.6.266

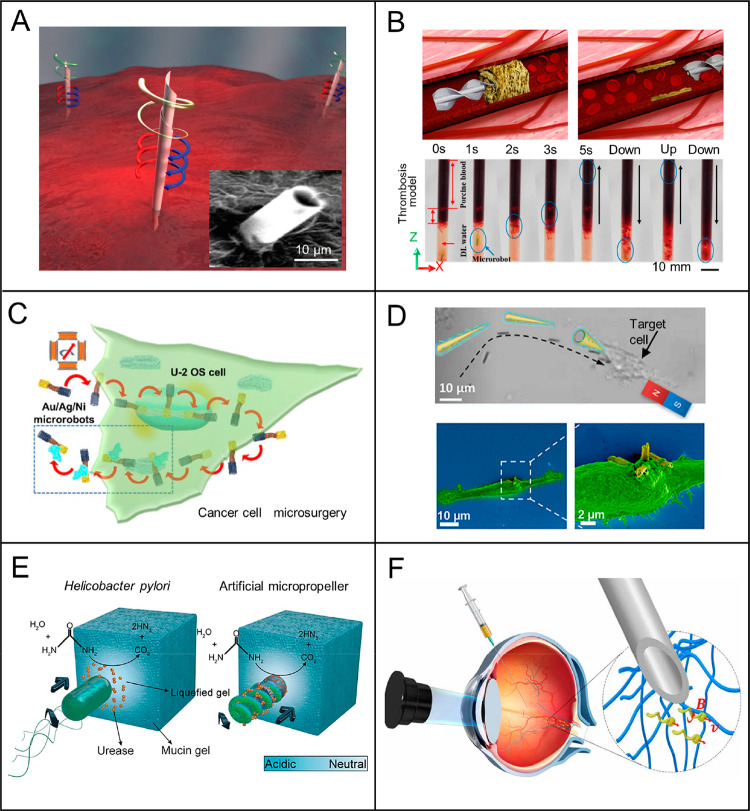

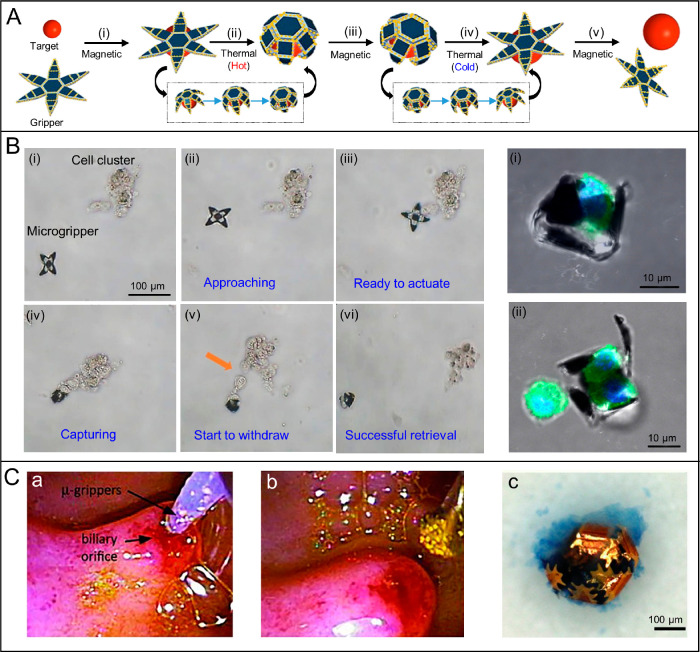

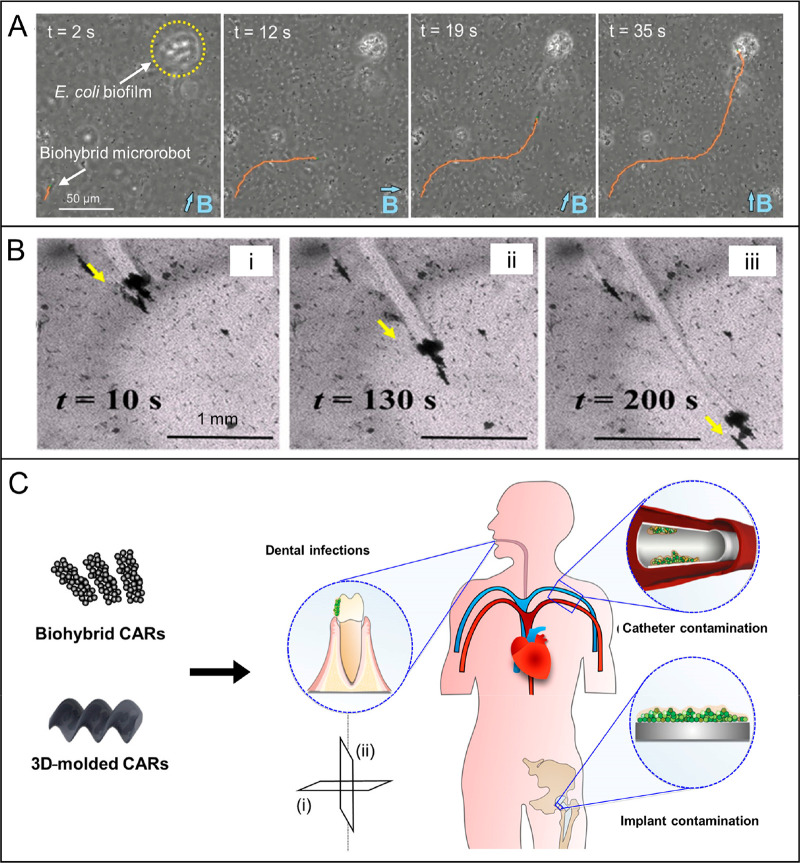

Figure 11.