Abstract

Dissolution of metals in organic solvents is relevant to various application fields, such as metal extraction from ores or secondary resources, surface etching or polishing of metals, direct synthesis of organometallic compounds, and separation of metals from other compounds. Organic solvents for dissolution of metals can offer a solution when aqueous systems fail, such as separation of metals from metal oxides, because both the metal and metal oxide could codissolve in aqueous acidic solutions. This review critically discusses organic media (conventional molecular organic solvents, ionic liquids, deep-eutectic solvents and supercritical carbon dioxide) for oxidative dissolution of metals in different application areas. The reaction mechanisms of dissolution processes are discussed for various lixiviant systems which generally consist of oxidizing agents, chelating agents, and solvents. Different oxidizing agents for dissolution of metals are reviewed such as halogens, halogenated organics, donor–acceptor electron-transfer systems, polyhalide ionic liquids, and others. Both chemical and electrochemical processes are included. The review can guide researchers to develop more efficient, economic, and environmentally friendly processes for dissolution of metals in their elemental state.

1. Introduction

In contrast to many metals salts, metals in their elemental state cannot be dissolved in conventional solvents. Their dissolution must necessarily involve simultaneously an oxidation step, so that the dissolution of metals can be described as oxidative dissolution. In case only part of the solid is dissolved, oxidative dissolution of metals can be described as a leaching process. The solution used for leaching is called a leaching system, leaching agent, or lixiviant. For oxidative dissolution of metals, the lixiviant must contain at least one oxidizing agent (to oxidize the metal), often a solvent (water or a nonaqueous solvent) to dissolve the oxidizing agent, and sometimes a complexing agent to adjust the redox potential of the metals and/or the solubility of the produced metal compounds. Oxidative dissolution of metallic elements happens in various applications such as extraction of gold from gold-bearing ores, separation of metals from other compounds, chemical etching in the microelectronics industry, surface polishing of metals or alloys, and direct synthesis of organometallic compounds from metals.1−4 Moreover, oxidative dissolution of metals could be relevant for recycling of valuable metals from secondary resources such as preconsumer production scrap and end-of-life products.5,6 Many metals and alloys are essential for the production of components in high-tech devices, such as neodymium–iron–boron (NdFeB) permanent magnets used in electric motors and wind turbines and platinum-group metals (PGMs) used in car exhaust catalysts. Rare-earth elements (REEs), together with PGMs, are on the lists of critical raw materials of the European Commission and the United States of America, because of their high economic importance and high supply risk.7,8 Recycling of metals is essential in a circular economy.

Conventional methods for dissolution of metals are water-based and the metals are oxidized in aqueous solutions by, for example, strong mineral acids such as hydrochloric acid and sulfuric acid with evolution of hydrogen gas. However, these nonoxidizing mineral acids are not able to dissolve noble metals such as gold, silver, and platinum. Current technologies for dissolution of noble metals involve the use of aqua regia or sodium cyanide (in the presence of oxygen gas), which cause serious safety and environmental concerns.9,10 Their use will probably be restricted in the near future. Therefore, the development of new efficient, economic, and environmentally benign leaching systems for metal dissolutions is a very relevant research activity.

Dissolution of metals by oxidizing agents in organic solvents is an alternative approach. The organic solvents can be conventional molecular organic solvents, ionic liquids (ILs), deep-eutectic solvents (DESs), or supercritical carbon dioxide (scCO2). Metal processing in organic solvents or mixed with small amounts of water (<50 vol %) is termed “solvometallurgy”, which is an emerging branch of extractive metallurgy and complementary to hydrometallurgy and pyrometallurgy.11 Examples of solvometallurgy are solvo-leaching, nonaqueous solvent extraction, nonaqueous precipitation and electrodeposition.12−16 When ionic solvents such as ionic liquids (ILs) or deep-eutectic solvents (DESs) are involved, the term “ionometallurgy” could be used.17 Dissolution of metals in organic solvents offer several advantages compared to aqueous solvents. Organic solvent systems usually generate smaller volumes of aqueous waste streams and are often more selective than aqueous systems. One of the earliest studies on the dissolution of metals in organic solvents dates from more than 70 years ago and is about the dissolution of uranium using elemental halogens as oxidizing agents.18 The number of papers published on the topic of oxidative dissolutions of metals in organic solvents grew very slowly in the beginning, but increased rapidly after the year 2000 (Figure 1), due to the search for new, efficient, and environmentally friendly processes for the extraction of metals from metal ores and secondary resources. At present, the total number of publications on oxidative dissolution of metals in their elemental state in organic solvents is still less than 200.

Figure 1.

Number of publications on dissolution of metals in organic solvents.

This review describes the different strategies for the oxidative dissolution of metals in organic solvents and possible applications of this approach. The review covers the literature from the 1950s until December 2020. Only research of oxidative dissolution of metals in their metallic state (oxidation state zero) is presented in this review, so that research on dissolution of other metal compounds such as metal oxides and sulfides has been omitted. Special attention has been paid to ionic liquids and deep-eutectic solvents, because their use for oxidative dissolution of metals is emerging. The various oxidizing systems show different mechanisms for the oxidative dissolution. To better understand the reaction mechanism in the different reaction media, this review is organized according to the different types of oxidizing agents. ILs and DESs are all combined in one section, irrespective of whether they have been used as oxidizing agent or as solvents, in order to highlight their application in oxidative dissolution of metals. The different types of organic leaching systems, together with the studied oxidative dissolution of metals in the corresponding systems, are summarized in Figure 2. The aim of this review is to give an overview of the emerging research field of oxidative dissolution of metals in organic solvents. By highlighting the oxidation reaction mechanisms, this review can be helpful for the development of new efficient, environmentally benign, and economic processes for dissolution of metals in their elemental state for various applications.

Figure 2.

Overview of the organic leaching systems and the metals that have been studied for oxidative dissolution in the corresponding leaching systems.

2. Solutions of Halogens in Polar Organic Solvents

Many studies on the oxidizing dissolution of metals in organic solvents use halogens, because they are strong oxidizing agents. Various metals can be dissolved directly in solutions of halogens in polar organic solvents, such as bromine in ethyl acetate (EtOAc) or methanol (MeOH) or chlorine in N,N-dimethylformamide (DMF). Addition of suitable ligands can enhance the dissolution of noble metals such as gold and platinum. These ligands can be simply halide compounds (e.g., tetraethylammonium iodide) or organic compounds such as dithio-oxamide. The subsections in section 2 are defined on the basis of the types of ligands in the leaching system. Subsection 2.1 describes halogen leaching systems without added ligands, and subsection 2.2 covers halogen leaching systems with halide anions as ligands, whereas subsection 2.3 is about organic compounds that can form adducts with halogens.

2.1. Halogens in Organic Solvents

The simplest organic lixiviants for the dissolution of elemental metals are solutions of halogens in an organic solvent. The halogens act as oxidizing agents to oxidize the metal from oxidation state zero to a higher oxidation state, which can be dissolved in the organic solvent. Examples of commonly used organic solvents are ethanol (EtOH), methyl acetate (MeOAc), butyl acetate (BuOAc), ethylene glycol (EG), acetonitrile (ACN), and tri-n-butylphosphate (TBP). A major application of organic solvent–halogen mixtures is the quantitative analysis of nonmetallic phase impurities in metals and alloys, because the metals in their elemental state are oxidatively dissolved, but metallic compounds (e.g., oxides and borides) and nonmetallic components (e.g., boron) are not soluble.19−23 Other applications are the dissolution of metals or metal alloys, the chlorination of metals, and the chemical etching and polishing of semiconductors.3,24−30 Leaching systems containing halogens and organic solvents used for dissolution of metals in various application fields are summarized in Table 1. Due to the large variety of combinations of halogens with organic solvents, this subsection is further divided into three subsections based on the type of halogens.

Table 1. Leaching Systems Using Halogens as Oxidizing Agents in Organic Solvents for Dissolution of Metals in Various Application Fields.

| Solvent system | Metals studied | Application | References |

|---|---|---|---|

| Br2-EtOAc | U, Nd, Sm, Ce, Pr, La, Y, Ga, Zr | Separation of metals and metal oxides | (2, 18, 31) |

| Br2-MeOH | Be, Zr, Th, U | Phase analysis (B content in metals) | (19) |

| GaAs, GaP | Polishing or etching of semiconductors | (3, 24, 25) | |

| Fe | Determination of iron content in rusted iron sponge | (32) | |

| Ni | Phase analysis (TiC-Ni cermets) | (33) | |

| X2 (Cl2, Br2, I2, ICl, Cl3–) -organic solvents (MeOH, MeOAc, BuOAc, ACN) | Al, Cr, Co, Cu, Fe, Pb, Mn, FeMo, Ni, FeNi, P, FeSi, S, Sn, Ti, FeW, V, | Phase analysis | (20−23) |

| Cl2-DMF | Mo | Chlorination | (26) |

| Cl2-DMF-H2O | Re, W, Mo | Chlorination | (27) |

| Cl2-DMF-HCl | Re, Pt | Chlorination | (28) |

| Cl2-DMF-FeCl3 | Zr | Chlorination | (29) |

| Cl2-tetrachloroethylene (TCE)-TBP | U | Chlorination | (30) |

| Br2-organic solvent (EtOH, DMF, EG, EtOAc, MeOAc) | Ni, Cu | Remove coatings from SmCo magnets | (34) |

| Br2-EtOH | Au, Ag, Pt | extracting noble metals from solid residues after mineral acid leaching of raw materials | (35) |

2.1.1. Bromine in Organic Solvents

Bromine is the most used halogen in organic solvents for oxidative dissolution of elemental metals, because of its moderate oxidizing power, which allows bromine to oxidize metals but not aggressively react with organic solvents. Various organic solvents (e.g., EtOAc, MeOAc, ACN, MeOH, EtOH) mixed with bromine have been studied for dissolution of metals in various applications. The reaction of bromine with metals can be described in eq 1:

| 1 |

where M represents a metallic element and x is the oxidation state of the metal. Solutions of bromine in ethyl acetate (Br2-EtOAc) have been investigated mostly for dissolution of uranium metal for nuclear applications. Elemental uranium is very reactive and can be dissolved rapidly in common mineral acids, such as nitric acid or hydrochloric acid. However, for the dissolution of uranium alloys with refractory alloying metals such as zirconium, aggressive reagents such as hydrofluoric acid, with or without extra added fluoride salts, have to be used to ensure complete dissolution of the uranium–zirconium alloy.18 Dissolution of such alloys in organic solvents is useful when fluoride ions must be absent for the subsequent analysis or for avoiding aggressive reagents. Bromine in ethyl acetate (Br2-EtOAc) reacts rapidly with both uranium and zirconium metal to form UBr4 and ZrBr4.18 Organic solvents other than ethyl acetate have been tested as solvents for bromine to dissolve uranium metal, but these solvents did not perform as well as ethyl acetate.18 Br2-EtOAc was successfully used for separation of metals from their oxides, including metallic uranium, magnesium, aluminum, and zinc. By using a solution of Br2-EtOAc to selectively separate uranium and rare-earth metals from their oxides, the yield of electrochemical reduction of the simulated oxide spent nuclear fuel in the molten salt mixture LiCl-Li2O was estimated.31 However, Br2-EtOAc is not reactive enough for dissolution of noble metals and their alloys.

Solutions of bromine in alcohols are one of the most studied leaching systems in the category of bromine in organic solvents. Bromine in EtOH can be used for extracting noble metals such as gold, silver, and platinum from raw materials.35 The raw materials containing noble metals were first leached in a mineral acid at temperatures 95–100 °C to leave the noble metals in a solid residue that was then treated with bromine in organic solvents twice. The recovery efficiency of noble metals could reach >95%. Recently, bromine in organic solvents has shown potential for removal of the metallic nickel–copper–nickel protective coatings of rare-earth permanent magnets (Nd–Fe–B and Sm–Co magnets), prior to recycling of the rare-earth elements.34 Among five solvents tested, namely 1 vol % of bromine in EtOH, DMF, EG, EtOAc, and MeOAc, the first two solutions could selectively dissolve nickel and copper without leaching the magnet alloy (Figure 3). Dissolution of metals in Br2-EG was slow due to the high viscosity of EG which is 1 order of magnitude higher than that of ethanol or DMF. The slow dissolution rate of metals in the MeOAc and EtOAc mixtures was attributed to the low solubility of the formed metal salts in these solvents. This solvometallurgical process performed better than an aqueous 2 M HNO3 solution, which could dissolve nickel but not copper.

Figure 3.

Screening dissolution test for the SmCo5 (top) and Sm2Co17 (bottom) permanent magnets at 20 min in 1 vol % Br2 in EG, DMF, EtOH, MeOAc, and EtOAc. The recovery yields, η (%), were the ratio of the concentration of a metal in solution after leaching for 20 min to the concentration of the same metal if all the content of the coating would be dissolved in solution. Reprinted from ref (34). Copyright 2019 Royal Society of Chemistry under [CC BY-NC 3.0] [https://creativecommons.org/licenses/by-nc/3.0/].

Bromine in methanol (Br2-MeOH) is another example of a bromine-alcohol mixture. It has been tested for the determination of boron in metals such as beryllium, zirconium, thorium, and uranium, by selective dissolution of the metal, followed by distillation of the formed boron methyl ester.19 With the anhydrous reaction mixture, traces of boron could be completely recovered by distillation. Another application of Br2-MeOH is for phase analysis, to quantify the composition of the titanium carbide-nickel cermets, more specifically to determine the amount of titanium present in a metallic nickel binder. Br2-MeOH was used as solvent at a low temperature (−20 °C) to dissolve the metallic phase without affecting the titanium carbide.33 Br2-MeOH has also been used for processing of semiconductors, for instance for chemical polishing of gallium arsenide and for etching of gallium phosphide.3,24,25 The etching behaviors of GaP in Br2-MeOH and in aqueous solutions of Br2 were similar, so that it seems preferable to use the aqueous solution for etching, considering the toxicity of Br2-MeOH. However, the advantages of Br2-MeOH solutions must be taken into account as well. For example, the reproducibility of the measurements in Br2-MeOH solutions was higher than that in the aqueous Br2 solutions. Moreover, Br2 has a higher solubility in methanol than in water. The metallic iron content in a rusted iron sponge was determined by using a solution of Br2-MeOH to selectively dissolve iron metal, leaving behind the iron oxides.32

Although Br2-MeOH can oxidatively dissolve metals, this system must be used with much caution. First, it must be stressed that it can be dangerous to prepare solutions of bromine in alcohol solvents, especially when the concentration of bromine is above 10 vol %. It was reported that by mixing a 50 vol % Br2-MeOH solution in a 250 mL volumetric flask, within seconds the solution was violently expelled from the flask.36 This is due to a strongly exothermic reaction between bromine and alcohol. Moreover, the vigorous reaction of bromine with methanol may generate gaseous products which could also eject the solution from the flask. Therefore, leaching of the metal with Br2-MeOH should be performed at room temperature, to avoid the rapid reaction between Br2 and MeOH at elevated temperatures. Second, the reaction of Br2 with MeOH could produce HBr and water. These products dissolve oxides so that the selectivity of metal dissolution decreases when metal oxides are present. Therefore, magnesium oxide is sometimes used to neutralize the formed acids to prevent the dissolution of oxides. Third, the reaction should be performed under anhydrous conditions, since water can react with Br2 forming HBr as well. For example, the use of a nonaqueous solution is mandatory in the application of quantification of titanium in titanium carbide-nickel cermets, because the HBr formed by hydrolysis of bromine can react with the carbide, resulting in errors in the phase analysis.33

2.1.2. Chlorine in Organic Solvents

Chlorination of refractive metals such as molybdenum, tungsten, uranium, zirconium, rhenium, and platinum has been studied by using chlorine in organic solvents, among which chlorine in DMF was the often used leaching system.26−29 It is known that halogens can react with organic solvents,18,36 but the influence of these side reactions on the dissolution of metals has been studied only occasionally. Drobot et al. studied the oxidative dissolution of molybdenum by chlorine gas dissolved in DMF.26 The IR and EPR spectra of the solutions obtained after chlorination of molybdenum suggested that the formed complexes are the diamagnetic Mo(VI) and paramagnetic Mo(V) complexes of composition R2[MoOCl5], where R is [(CH3)2NCOH2]+ and [(CH3)2NH2]+. Moreover, the complex [(CH3)2NH2][MoOCl5] is not stable upon prolonged storage and decomposes to form [(CH3)2NH2]Cl, indicating that the DMF solvent participates in the chlorination reaction. Therefore, DMF not only acts as solvent for chlorine but also enhances the chlorination reaction due to the formation and destruction of the formed molybdenum complex. The mechanism of chlorination of molybdenum could be described by the reactions given in Scheme 1.26

Scheme 1. Chlorination of Molybdenum by Chlorine in DMF.

Addition of water can enhance the oxidative dissolution of metals in chlorine-DMF.27 For example, when chlorine in DMF was used as a leaching system, only small amounts of rhenium and tungsten (<5%) could be oxidatively dissolved. However, an increase in the water content in the leaching system resulted in a higher amount of metals dissolved in the solution. Further increase in the water content resulted in a decrease of the dissolution of molybdenum and tungsten (Figure 4). Quantitative dissolution of rhenium was attained by adding 30 to 40% water with respect to the volume of DMF.

Figure 4.

Effect of water on dissolution of metals in solutions of chlorine in DMF. (Data were extracted from ref (27).)

Chlorination of refractory metals in DMF–H2O mixtures is much more efficient than that in the neat organic solvent. This is due to the fact that mixing of water and DMF can rupture some hydrogen bonds between water molecules and form new hydrogen bonds between the carbonyl oxygen atoms of DMF and water molecules. This new arrangement facilitates the molecular interaction between DMF and other molecules in the system. On the other hand, in the presence of chlorine gas, addition of water induces the formation of HCl and HClO. The new complex [(CH3)2N–CH=OH]+Cl– is formed with a hydrogen bond between the carbonyl oxygen atom of DMF and HCl (see Scheme 2). This protonated DMF molecule can further react with the chlorine-containing anion, e.g. [MOCl5]2–, to form an adduct, and this enhances the dissolution of metals.

Scheme 2. Complex Formed between DMF and HCl.

Similarly, addition of HCl in Cl2-DMF can enhance the oxidative dissolution of metals as well. Chlorine in DMF with addition of water or HCl solutions was applied to recover rhenium and platinum from end-of-life platinum–rhenium catalyst on an aluminum support.28 The influence of HCl on the dissolution efficiency was similar to that of water. One leaching step at 25–60 °C could dissolve 80 to 90% of rhenium, while less than 50% of platinum was dissolved, due to the modified (coked) state of platinum in the spent catalyst. After a decarbonization process (to burn off carbon at about 500 °C), a second chlorination leaching step was conducted, resulting in 70–94% of platinum recovery and 91–96% of rhenium recovery.28 No heating was required for the leaching step, and this is a cheap leaching system.

The presence of the Lewis acid FeCl3 in Cl2-DMF can influence the kinetics of dissolution of zirconium as well.29 The dissolution rate of zirconium metal increased appreciably relative to the FeCl3-free system. A maximum in the dissolution rate was observed at 1.5 g/L of FeCl3, and further increase of the FeCl3 content resulted in a rapid decrease of the dissolution rate. The dissolution of zirconium and the catalytic effect of FeCl3 could be described by eqs 2–5:

| 2 |

| 3 |

| 4 |

| 5 |

Besides DMF, tetrachloroethylene (TCE) was used as solvent, in combination with TBP (complexing agent) and chlorine as oxidizing agent for low-temperature chlorination of uranium metal.30 Uranium reacted with chlorine to form UCl4, which further complexed with TBP to form UCl4·2TBP (eq 6):

| 6 |

The dissolution rate increased with increasing concentrations of chlorine and TBP. Similar to the DMF-Cl2 leaching system, addition of water (0.2–0.6 vol%) did increase the dissolution rate significantly. The dissolution rate decreased with a further increase in water content. A maximum in dissolution rate was observed for a water content of 0.2–0.6 vol%. The function of TCE was not specifically mentioned in the paper, but it can be supposed to act as a diluent. The reason for the positive effect of water addition is probably the formation of HCl that can complex with TBP and enhance the metal dissolution.11

Chlorine can be used as a strong oxidizing agent for metals, but the fact that it can react with organic solvents as well makes the recycling of the organic solvent difficult. In some cases the strong reactivity of chlorine toward organic solvents with formation of chlorinated organic compounds has a negative effect on the dissolution of metals. For example, bromine in EtOAc was preferred over chlorine in EtOAc for dissolution of uranium metal.18

2.1.3. Other Halogens in Organic Solvents

One of the main applications of solutions of halogens in organic solvents is phase analysis of metals or alloys, to determine the concentration of impurities such as metallic compounds (e.g., oxides, sulfides) and nonmetallic compounds (e.g., boron, carbon) in metal alloys by selectively dissolution of metals. Pioneering work was performed by Beeghly, who used bromine-methyl acetate (Br2-MeOAc) solvent for the quantitative isolation of aluminum nitride from steel alloys.20 All nitrogen was recovered as insoluble aluminum nitride after dissolution of steel samples in the lixiviant. Inspired by this work, Headridge and co-workers investigated the feasibility of quantitative separation of carbide, nitride, oxide, and sulfide inclusions from metals by using solutions of halogens in organic solvents.21−23 For useful phase analysis, it is necessary that only the metals in their elemental state oxidatively dissolve in the leaching system, and other compounds such as oxides and nitrides that are present in metal alloys do not. Therefore, the reactivity of various metals in the elemental state and of metal compounds (oxides, nitrides, sulfides, carbides) with bromine in organic solvents MeOAc, BuOAc, and ACN was investigated. Additionally, the solubilities of the corresponding metal bromides formed by the reactions and of the metal compounds (oxides, nitrides, sulfides, carbides) in the leaching systems were reported. All the studied elements or alloys were found to react with bromine: aluminum, chromium, cobalt, copper, iron, lead, manganese, ferromolybdenum, nickel, ferroniobium, phosphorus, ferrosilicon, sulfur, tin, titanium, ferrotungsten, and vanadium. The study of the solubility showed that most of the metal bromides can dissolve in the organic solvent–bromine mixtures, but some metal bromides were poorly soluble, such as the bromides of lead, molybdenum, silicon, and tungsten.21 The poor solubility of metal bromides could limit the oxidative dissolution of these metals in the leaching systems. Most studied carbides, nitrides, and oxides of metals have low reactivity and solubility in Br2-ACN and Br2-MeOAc, whereas most sulfides have a significant solubility and some sulfides can react with the leaching agents violently. Therefore, organic solvent–bromine mixtures can be used for isolation of most carbides, nitrides, and oxides but not sulfides from metals.23

Subsequently, more organic solvent–halogen mixtures were used to study the solubilities of manganese silicon nitride, metals and their nitrides, carbides, oxides, and sulfides. The studied organic solvents were MeOH and MeOAc, and the halogens were Cl2, Br2, I2, ICl, and ICl3.22 Based on the reactivity and solubility of the metals and metal compounds in the leaching systems, a method was proposed to determine in steel the contents of total nitrogen, of mobile nitrogen, of nitrogen as manganese silicon nitride, and of nitrogen as aluminum nitride. A mixture of I2-MeOAc can be used in the first step to isolate manganese silicon nitride and aluminum nitrides while dissolving metals; subsequently, ICl3-MeOAc can be used to isolate aluminum nitride, while dissolving manganese silicon nitride.22 Therefore, organic solvent–halogen mixtures can be used to quantify nonmetallic phases in metals. Moreover, the organic solvent has a slight influence on the solubility of the metal bromide. For example, acetonitrile with its higher dielectric constant (ε = 36.5 at 25 °C) is a better coordinating solvent for ions and is thus a better solvent for divalent metal bromides than methyl acetate and butyl acetate with dielectric constants of ε = 6.7 (25 °C) and ε = 5.0 (20 °C), respectively.21

2.2. Halogens + Halide Ligands + Organic Solvents

The dissolution efficiency of metals largely depends on the solubility of the reaction products (metal halide salts) in the organic solvents. Increasing the solubility of the salts formed could suppress formation of a passivating layer and hence increase the dissolution efficiency. Moreover, addition of complexing agents to the organic solvent could change the redox potential of metals and hence the dissolution behavior of the metals. In the 1990s, Nakao and co-workers carried out a series of studies on the dissolution of metals with an organic lixiviant consisting of an elemental halogen, a halide salt, and a common organic solvent.4,37−43 They used the halogens chlorine, bromine, and iodine. Most of the used halide salts were quaternary ammonium halide, but metal halides such as KI, KBr, and NaI were tested as well. A variety of organic solvents including hydrocarbons, organic halides, alcohols, ketones, esters, and nitro compounds was investigated. Bromine–cetylpyridinium bromide (CPB)–benzene and iodine–cetylpyridinium iodide (CPI)–benzene were found to be effective for the dissolution of various metals, such as Fe, Ni, Cu, Zn, Au, Ag, Pd, Cr, Mn, Co, Ga, Ge, Se, Cd, In, Sb, Hg, and Pb.37 The metals were dissolved in the form of metal complex anions, such as [AgBr2]−, [AuBr4]−, [NiBr4]2–, [ZnBr4]2–, and [PdBr4]2–. In the dissolution process, the halogens acted as oxidizing agents and the halide compounds as complexing agents to allow the products to be soluble in the leaching systems. Besides tests on pure metal wires, gold and silver were efficiently extracted from quartzite ore (containing 13.1 ppm of gold and 389.2 ppm of silver) with the same lixiviant.41 Organic solvents can react with halogens, but in the presence of CPB or CPI, the reactivity of halogens is largely reduced, due to the formation of tribromide or triiodide anions by reaction between the halogens and the halide salts. These trihalide anions are still active to metals, but less active toward the organic solvents than elemental bromine and iodine. However, in most cases, elemental chlorine could not be used, because the trichloride anion is quite reactive toward organic solvents. On the other hand, it was observed that acetonitrile is very resistant toward chlorine at low temperatures. Thus a mixture of chlorine with chloride salts in acetonitrile can be used for oxidative dissolution of metals. Several lixiviants in acetonitrile comprising chlorine and different organic halide salts such as tetraethylammonium chloride, trimethylamine hydrogen chloride (Me3NHCl), and tetraethylammonium bromide were compared with lixiviants using inorganic halide salts such as I2–NaI–acetone, Br2–KBr–methanol, and I2–KI–methanol for dissolution of noble metals.38 All these systems could dissolve palladium, gold, and silver, except that silver could not be dissolved in the methanol systems, because of the formation of a passivating layer of silver halide on the silver metal surface. It was observed that chlorine reacted faster than bromine and iodine. Moreover, it was found that the system Cl2–Me3NHCl–acetonitrile did dissolve gold more rapidly than aqua regia at 30 °C.

An interesting phenomenon was observed in the I2–I– organic solvent system: when the molar ratio I2/I– was larger than 0.5, gold dissolved on heating as [AuI2]− and, upon cooling, part of the gold was deposited from the pregnant solution via formation of [AuI4]− and Au by a disproportionation reaction. When a new piece of gold was added to the resulting solution under reflux, an amount of gold equal to that deposited before was redissolved and upon cooling was redeposited. This process could be repeated several times. Such reversible dissolution/deposition behavior was not observed for any other metals, nor in Cl2–Cl–-organic solvent and Br2–Br–-organic solvent systems, in which gold dissolved exclusively in the form of very stable [AuX4]− complexes.40 However, upon addition of methanol, the reversible dissolution/deposition processes can be induced in all systems of X2-X––organic solvent (X = Cl, Br, and I).39

Organometallic complexes can be synthesized in one step by dissolving the corresponding metals in the above-mentioned organic solutions.4 This direct synthesis method can avoid the handling of hygroscopic metal halides as reagents. Lower valence metal compounds (for instance ferrous or cuprous compounds) can be obtained by selecting an appropriate molar ratio of X2/metal.

2.3. Dihalogen or Interhalogen Adducts

Halogen adducts are formed by the interaction between a σ-donor with a relatively high-lying HOMO and a dihalogen as an acceptor with a relatively low-energy LUMO (σ*). It has been found that these dihalogen adducts are capable of oxidizing elemental metals, including noble metals. The reactions between metals and diiodine and dibromine adducts with phosphine, arsine, and antimony donors have been studied.44−49 Examples of such adducts are diiodotrimethylarsine (Me3AsI2), diiodotriphenylantimony (Ph3SbI2), and dibromotrimethylphosphorus (Me3PBr2). These adducts can react with metals (e.g., Mn, Zn, Co, Ni, and Au) to form complexes with various structures. The nature of the formed metal complexes is strongly dependent on both the organic group and the halogen. Gold reacts with Me3AsI2 to form the square-planar complex [AuI3(AsMe3)], whereas the same metal reacts with Me3PI2 to form the trigonal-bipyramidal complex [AuI3(PMe3)2].49 Besides new perspectives in the field of inorganic chemistry, these results open the door to new applications of dihalogen adducts for recovery of noble metals from secondary resources or for metal refining. Unfortunately, the adducts with phosphine and arsine donors are very toxic and they require strictly anhydrous, anaerobic conditions and long reaction times.

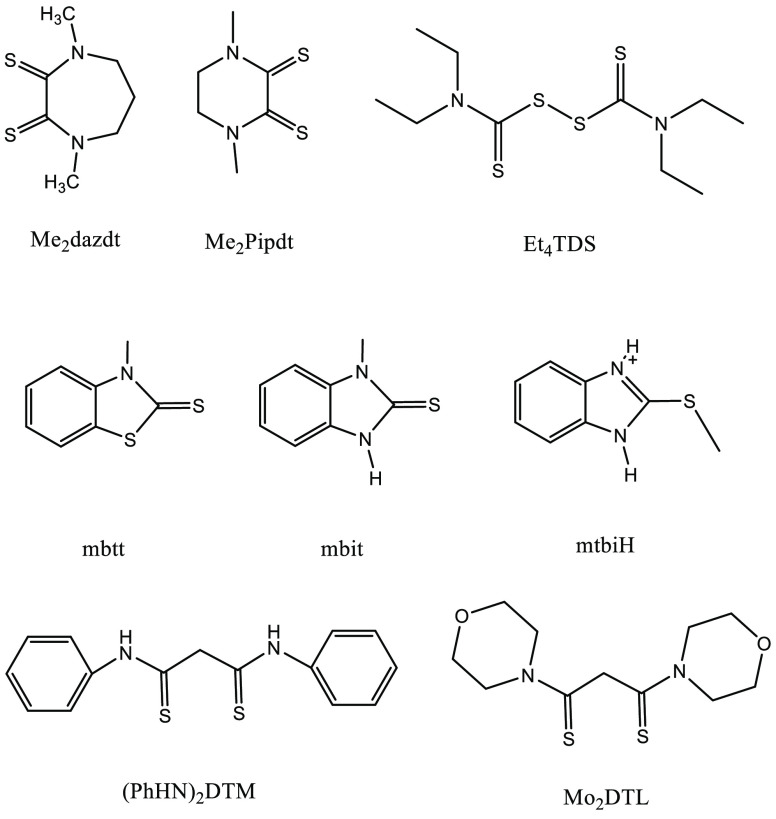

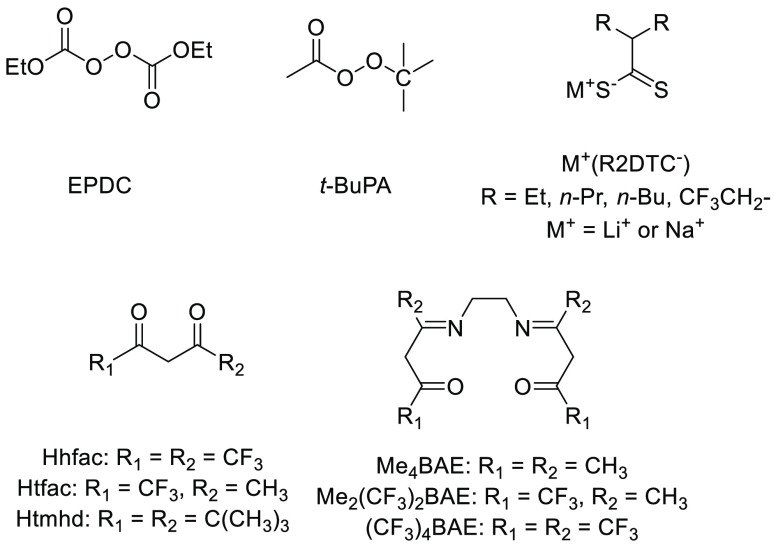

A series of new oxidation reagents of dihalogen adducts bearing S,S-donors or adducts on the basis of thioamide have been reported for dissolution of metals such as noble metals, cadmium, and mercury (Table 2 and Scheme 3).50−61 These adducts were prepared by simply mixing dihalogen or interhalogen with the donors in organic solvents such as CHCl3 or THF at room temperature. The resulting compounds have been claimed to be safe, inexpensive, easy to handle, and noncytotoxic. Proper choice of polyfunctional donors that favors the preferred geometry required by the metal undergoing oxidation is believed to enhance the oxidation reaction. Most of the synthesized adducts were applied for dissolution of noble metals such as gold, palladium, and platinum. The softness of the donor atoms, as well as the chelating properties of the two vicinal thiones stabilize the oxidized noble metals in the d8 configuration.

Table 2. Names and Abbreviations of Organic Ligands to Form Halogen Adducts.

| Name | Abbreviation |

|---|---|

| N,N’-dimethylperhydrodiazepine-2,3-dithione | Me2dazdt |

| N,N’-dimethylpiperazinium-2,3-dithione | Me2Pipdt |

| tetraethylthiuram disulfide | Et4TDS |

| 3-methyl-benzothiazole-2-thione | mbtt |

| 1-methyl-1H-benzimidazole-2(3H)-thione | mbit |

| N,N’-diphenyl dithiomalonamide | (PhHN)2DTM |

| dimorpholyldithiomalonamide | Mo2DTM |

Scheme 3. Structures and Abbreviations of the Reported Organic Ligands to Form Halogen Adducts.

The most extensively studied compound is the bis-diiodine adduct of N,N’-dimethylperhydrodiazepine-2,3-dithione (Me2dazdt·2I2) which can oxidatively dissolve gold and palladium under mild conditions in organic solvents.50,61 The oxidation reactions are shown in Scheme 4. The reaction product after dissolution of gold was identified as the square-planar [AuI2(Me2dazdt)]I3, where gold(III) is coordinated with two iodide ligands and one S,S-chelating ligand Me2dazdt. However, the reaction product after palladium dissolution was identified as [Pd(Me2dazdt)2](I3)2, wherein the first coordination sphere of palladium(II) comprises two bidentate Me2dazdt ligands. The reagent Me2dazdt·2I2 was tested for practical applications, for example the recovery of gold from waste inkjet printer cartridges and SIM cards.57 It was used for failure analysis on end-of-life microelectronic devices by selectively removing the upper layer of gold from the multilayer system such as Ti/Pt/Au in GaAs-based devices, without destroying the electrical contacts.52 The reagent allowed for quantitative recovery of palladium from a spent car exhaust catalyst (0.5–3.0 wt % Pd supported on Al2O3 and CeO2–ZrO2/Al2O3).61 The adduct Me2dazdt·2I2 cannot dissolve platinum or rhodium metal, either at room temperature or in refluxing THF or CH3CN. Therefore, palladium can be selectively recovered when platinum or rhodium is also present in the spent car catalyst. Moreover, it was found to be much more efficient than the aqueous lixiviant I2/I–, which could recover only 11% of the palladium from the same sample of spent car exhaust catalyst under the same conditions. Metallic palladium could easily be obtained by heating the formed complex [Pd(Me2dazdt)2](I3)2 at 600 °C for a few minutes. However, the ligand is destroyed during the thermal treatment of the complex to recover metallic palladium. This lowers the economic, environmental, and elemental sustainability of the recovery process. Therefore, the obtained complexes [Pd(Me2dazdt)2](I3)2 and [PdI2(Me2dazdt)] have been valorized themselves rather than recovering palladium metal from them, for instance as catalysts in the regio- and chemoselective C–H functionalization of benzo[h]quinoline to 10-alkoxybenzo[h]quinoline and 8-methylquinoline to 8-(methoxymethyl)quinoline in the presence of the oxidant PhI(OAc)2.59 Palladium powder can also be oxidized by a diiodine tellurium adduct (2-PyTe)2···I2 at room temperature with formation of a square planar geometry complex [PdI(TePy-2)(I2TePy-2)2] (Scheme 5).62

Scheme 4. Oxidative Dissolution of Gold and Palladium with Me2dazdt·2I2 in Organic Solvent at Room Temperature.

Scheme 5. Synthesis of a Palladium Complex from a Diiodine Tellurium Adduct.

Various dihalogens or interhalogens can form adducts with dithio-oxamide donors such as IBr, ICl, Br2, or I2.54 The oxidation power of the adducts can be tuned by varying the halogens. The adducts of Me2dazdt·2IBr have been tested for dissolution of gold. The square-planar complex [Au(Me2dazdt)Br2]IBr2, with a structure similar to that of the complex [AuI2(Me2dazdt)]I3, was formed by reaction between gold and Me2dazdt·2I2. The ligands act as an S,S-chelating ligand, and two halide ligands complete the first coordination sphere of gold(III). The effectiveness of these adducts in THF solutions for gold dissolution was compared with conventional I2/KI aqueous lixiviants, and the following trend was found: Me2dazdt·2I2 > Me2dazdt·2IBr > I2/KI. Besides a faster dissolution rate, the adducts also showed better etching behavior than I2/KI solutions. It was observed that gold etching by adducts was uniform, while the I2/KI-etched gold surface appeared porous and its color changed to red. This color was attributed to gold nanoparticles. A comparison of the cyclic voltammograms of the Me2dazdt·2IBr and Me2dazdt·I2 adducts with that of IBr and I2 in anhydrous CH2Cl2 suggests that the halogens are the only electroactive species in the oxidative dissolution process.

The adduct N,N’-dimethylpiperazinium-2,3-dithione triiodide, [Me2Pipdt]I3, is of interest because it can act as a powerful oxidation agent toward metallic platinum, with formation of the square-planar complex [Pt(Me2pipdt)2](I3)2 (Scheme 6).51 In contrast to the neutral adduct Me2dazdt·2I2, the adduct [Me2Pipdt]I3 is a salt, in which the cation is formed by the protonated ligand and the anion is a triiodide. Similarly to Me2dazdt·2I2, the adduct [Me2Pipdt]I3 can also react with other metals such as copper, silver, gold, and platinum. However, only [Me2Pipdt]I3 reacts with platinum, whereas Me2dazdt·2I2 does not. This difference in reactivity is most likely due to differences in the geometry of the ligand: Me2dazdt has a seven-ring structure, while Me2Pipdt has a six-ring structure. The six-ring structure probably favors the required geometry of the formed platinum complex. The adduct [Me2Pipdt]I3 can also quantitatively dissolve the hazardous elements cadmium and mercury in a one-step reaction.53 The formed complex [CdI(Me2pipdt)2]I3 has a coordination geometry intermediate between square-pyramidal and trigonal-bipyramidal, while the complex [HgI2(Me2pipdt)] shows a distorted tetrahedral geometry (Figure 5).

Scheme 6. Oxidative Dissolution Reaction of Platinum by [Me2Pipdt]I3 in Acetonitrile (Reflux for 4 days).

Figure 5.

Molecular structure of (a) [CdI(Me2pipdt)2]I3 and (b) [HgI2(Me2pipdt)], with thermal ellipsoids depicted at the 30% probability level. Symmetry code = −x; y; 1/2 – z. Reprinted with permission from ref (53). Copyright 2014 Elsevier B.V.

The donors of dihalogen adducts have been extended to other types, such as tetraethylthiuram disulfide (Et4TDS), 3-methyl-benzothiazole-2-thione (mbtt), and 1-methyl-1H-benzimidazole-2(3H)-thione (mbit).56,58 Their structures are shown in Scheme 3. The mixture of Et4TDS and I2 in acetone solutions can dissolve metallic gold powders and can etch a thin layer of gold from photonic devices with Si/SiO2/Ti/Au multilayer structures. By changing the molar ratio of Et4TDS to I2, a variety of gold complexes can be formed, such as [Au(Et2dtc)2][AuI2], [Au(Et2dtc)I2], [Au(Et2dtc)2]I, and [Au(Et2dtc)2]I3 (Et2dtc = N,N-diethyldithiocarbamate). The examples of formation of different complexes are shown in Scheme 7. The mixture of Et4TDS and I2 was also applied for gold recovery from real Waste Electrical and Electronic Equipment (WEEE) materials.60

Scheme 7. Oxidative Dissolution of Gold by Et4TDS/I2 in Acetone at Room Temperature with the Formation of Four Complexes by Varying the Molar Ratio of Et4TDS to I2.

Reprinted with permission from ref (58). Copyright 2013 WILEY-VCH Verlag GmbH & Co. KGaA.

Two thioamide donors 3-methyl-benzothiazole-2-thione (mbtt) and 1-methyl-1H-benzimidazole-2(3H)-thione (mbit) were exploited to form dihalogen adducts.56 Despite the similar structures of mbtt and mbit, their reactivities toward gold are totally different. The adduct mbtt·I2 quantitatively dissolved gold powder at a molar ratio of gold to mbtt·I2 of 1:2 at 25 °C within 3 days in anhydrous diethyl ether, whereas only 45% of gold was dissolved by mbit I2 under the same conditions. Moreover, gold was oxidized to the +1 oxidation state by mbtt I2 but to the +3 oxidation state by mbit I2. The cationic gold complex [Au(mbtt)2]I3 was formed with mbtt, whereas with mbit, the anionic gold complex [(mtbiH)2](AuI4)I3 was formed, which was not bound to any cationic 2-methylthiobenzimidazolium (mtbiH) unit but rather to iodides to form the square-planar [AuI4]− anion. The structures of mbtt, mbit, and mtbiH are shown in Scheme 3. The difference in reactivity of mbtt and mbit toward gold was attributed to the presence of the imido group that can form an intramolecular hydrogen bond with the S-bonded iodine atom (Ib) in the form of N–H···Ib. This new moiety might modify its reactivity with the gold surface.

The organic molecules dithiomalonamides (PhHN)2DTM and Mo2DTM (see Scheme 3) can react with iodine in organic solvent to form organic triiodides (OrgI3), namely 3,5-bis(phenylamino)-1,2-dithiolylium triiodide ([(PhHN)2DTL]I3) and 3,5-bis(morpholino)-1,2-dithiolylium triiodide [Mo2DTL]I3.55 These were applied for leaching of palladium from metal powders and model spent car exhaust catalysts at room temperature. Two more triiodides with tetrabutylammonium (N4444) and tetraphenylphosphonium (Ph4P) cations were formed directly from the corresponding iodide salt with iodine, and they were studied for leaching of palladium as well. Actually, these two triiodides are trihalide ionic liquids, but due to their high melting point, they are solid at room temperature, so that they can only be used when dissolved in organic solvents. Therefore, we include them in this section rather than in section 5. The crystals obtained after dissolution of palladium metal were characterized by single-crystal X-ray diffraction and showed that the formed complex had the formula Org2[Pd2I6] (Figure 6). The palladium recovery yields from spent car exhaust catalyst showed the trend following: [(PhHN)2)DTL]I3 > [Ph4P]I3 ≥ [N4444]I3 ≫ KI3. The aqueous KI3 solution gave the lowest recovery yield, due to the formation of a passivation layer of PdI2 on the palladium metal surface. The higher leaching yields of OrgI3 compounds than KI3 were ascribed to the formation of the Org2[Pd2I6] complex which prevents formation of a passivation layer and facilitates its extraction in organic solvent. Note that [(PhHN)2)DTL]I3 gave a similar leaching yield as the most often studied adduct Me2dazdt·2I2 under the same experimental conditions (98 vs 99%). Gold can be oxidized by [(PhHN)2)DTL]I3 and [Mo2DTL]I3 as well, and the formed complexes have the stoichiometry Org[AuI2]. Unlike for dissolution of palladium, the aqueous solutions of KI/I2 have comparable efficiency as OrgI3 solutions for dissolution of gold, because no occurrence of passivation was observed during the reaction.

Figure 6.

Leaching of palladium from spent catalyst by organic triiodides in methylethylketone (MEK) under reflux for 7 days. Reprinted with permission from ref (55). Copyright 2017 American Chemical Society.

Organic iodide salts which provide both oxidative power and a coordinating ligand could dissolve gold with formation of organo-gold compounds. The iodide salts were iodocarbenium iodides (N,N-dimethyliodomethyleneiminium iodide) and bis-donor-substituted iodocarbenium iodide (bis(N,N’-dimethylamino)iodomethylene iodide and 2-iodo-1,3-dimethylimidazolium iodide) (Scheme 8).63 Gold powder could be oxidized by iodocarbenium iodides in organic solvents (dichloromethane or acetonitrile) to form the gold(III)–carbene complex triiodo[(dimethylamino)methylene]gold(III) which was in equilibrium with gold(I) species iodo(dimethylamino)methylenegold(I) or [AuI2(CHNMe2)2]+[AuI2]− (Scheme 8). The yield of gold(III) complexes was low and could be increased by addition of iodine, whereas bis-donor-substituted iodocarbenium iodide could also react with gold to form complexes with no need of addition of iodine. The mono- and bis-carbene-gold(III) complexes were produced (Figure 7). These reactions provide the routes for preparation of carbene complexes directly from metals.

Scheme 8. Structures of Iodocarbene Iodide and Gold Complexes Formed by Reaction between Compound (a) and Gold.

The names of the compounds are (a) N,N-dimethyliodomethyleneiminium iodide; (b) bis(N,N’-dimethylamino)iodomethylene iodide; (c) 2-iodo-1,3-dimethylimidazolium iodide; (d) triiodo[(dimethylamino)methylene]gold(III); (e) iodo(dimethylamino)methylenegold(I); and (f) [AuI2(CHNMe2)2]+[AuI2]−.

Figure 7.

Crystal structures of carbene complexes: the urea-derived complexes 10-mono (top, left, dAu–C = 2.041(7) Å) and 10-bis (bottom, left, dAu–C = 2.085(4) Å) and the corresponding NHC-complexes 11-mono (top, right, dAu–C = 2.074(15) Å) and 11-bis (bottom, right, dAu–C = 2.021(7) Å). Thermal ellipsoids at 50% probability. Reprinted with permission from ref (63). Copyright 2017 Wiley-VCH Verlag GmbH & Co. KGaA.

It can be concluded from this subsection that dihalogen adducts bearing S,S-donors or adducts on the basis of thioamide in organic solvents can oxidatively dissolve metals such as noble metals, cadmium, and mercury. The structure and the chelating properties of the organic adducts play an important role in the oxidation reactions. The same adducts can form different crystal structures after oxidation reaction with different metals as shown in Figure 5. In addition, by slightly adjusting the structure of the organic adducts, their oxidizing capability could be changed. For example, [Me2Pipdt]I3 can oxidize platinum, whereas Me2dazdt·2I2 cannot. The dihalogen adducts also provide the possibility to form organo-gold compounds directly from metals as shown in Figure 7. Moreover, the organic lixiviants are sometimes more efficient than the aqueous lixiviant for oxidative dissolution of metals.55 Dihalogen adducts are claimed to be safe, cheap, easy to handle, and noncytotoxic. However, most of the organic compounds are destroyed in order to recover the metals after dissolution, so that these organic compounds cannot be reused. Therefore, economic analysis should be performed prior to large scale applications.

3. Halocarbons as Oxidizing Agent

Organic halides (halocarbons) can act as oxidizing agents in polar organic solvents and have been used for dissolution of metals with the aim of direct synthesis of metal complexes. Tezuka et al. studied the oxidative dissolution of copper by halocarbons in dimethyl sulfoxide (DSMO) with the formation of the complex CuCl2(DMSO).64

Both the halocarbon and the polar solvent played an important role in the dissolution process. The most studied halocarbon was carbon tetrachloride (CCl4), but other halocarbons could be used as oxidizing agents as well, such as diphenyldichloromethane, dichloroacetic acid, or trichloroacetic acid esters and bromoalkanes (e.g., carbon tetrabromide). DMSO could not be replaced by other polar organic solvents, such as methanol, tetrahydrofuran, benzene, chloroform, acetonitrile, or pyridine. The dissolution mechanism is described by eqs 7–9. First, copper is oxidized by CCl4-DMSO with the formation of CuCl2(DMSO)2 and dichlorocarbene (:CCl2). The dichlorocarbene instantaneously reacts with DMSO to produce dimethyl sulfide and phosgene. Phosgene directly reacts further with copper to form CuCl2(DMSO)2 and carbon monoxide.

| 7 |

| 8 |

| 9 |

Dimethylacetamide (DMAA) could replace DMSO for copper dissolution by CCl4 as oxidizing agent. The difference compared to the CCl4-DMSO system is that copper is oxidized to copper(I) by CCl4 in DMAA with the formation of C2Cl6. The formed copper(I) complexes are slowly oxidized by CCl4-DMAA or air to copper(II) complexes.65 Similar as in the CCl4-DMSO system, copper is dissolved in CCl4-DMAA via a radical mechanism, but the formed radical is CCl3 rather than :CCl2. The results showed that the oxidation of copper is a surface chemical reaction, with the interaction of the adsorbed organic compounds with the metal surface as the rate-limiting step.

A similar radical mechanism of oxidative dissolution of titanium was observed by Egorov et al. for the use of benzyl bromide as oxidizing agent in the presence of the polar solvent DMF.66 Analysis of the reaction products in the presence of radical scavengers dicyclohexyldeuterophosphine and in their absence suggested that the reaction occurs via the benzyl radical (·CH2–C6H5). Under oxygen-free conditions, the dissolution of titanium occurs by a one-electron transfer mechanism, with formation of 1,2-diphenylethane and titanium(IV) complexes. The complex [TiBr(DMF)2]Br2 is initially formed but slowly reacts further with benzyl bromide and DMF to yield the complex [TiBr(DMF)5]Br3. Note that titanium is not oxidized by benzyl bromide in DMF in the presence of oxygen, probably because of the formation of a passivating oxide film on the metal surface, which prevents contact between the metal surface and the oxidizing agent.

CCl4 in ammonia solutions can dissolve copper under very mild conditions with formation of [Cu(NH3)m]Cl2·nH2O.67 At the same time, CCl4 is decomposed to CH2Cl2. The reaction is believed to have the same radical mechanism as in DMSO, with the formation of intermediate :CCl2. Eight additional halogenated compounds were tested for copper dissolution in the presence of ammonia solution: CHCl3, CHBr2CHBr2, CH2Br2, CH3CCl3, CHCl2CHCl2, CH2ClCHCl2, CCl2CCl2, and CH2ClCH2Cl. More copper could be dissolved in ammonia solutions upon addition of the first four compounds and CCl4, whereas less was dissolved by adding the last four halogenated compounds. Among the nine halogenated compounds and NH3(aq), CCl4 is the best compound to solubilize copper. Although without CCl4, ammonium solution can dissolve copper as well, addition of CCl4 can speed up the reaction by a factor of 150. This system CCl4–NH3(aq) has different oxidizing power toward different metals. For example, zinc can be dissolved with an efficiency of 60% relative to copper. Less than 0.5% of silver and tin can be dissolved, but lead and iron do not react. This difference might be due to the different coordinating behaviors of metals with ammine ligands.

Halocarbons in organic solvents can even dissolve noble metals.68 The studied leaching systems contain halocarbon compounds used as oxidizing agents including CCl4, CBr4, CPh2Cl2, CPhCl3, and C(CN)2Cl2, and coordinating organic solvents including DMSO, DMF, and DMAA. The results for dissolution of various noble metals by different leaching systems are summarized in Table 3. Different combinations of oxidizing agents and solvents gave different behavior for metal dissolutions. It was proposed that the reaction proceeds through a carbene intermediate, similarly to the reaction between copper and CCl4–DMSO. Moreover, dissolution of the oxides, sulfides, tellurides, and selenides of noble metals (e.g., PdO, PtO2, PtS2, Ag2S, Ag2Se, and Ag2Te) was studied as well by this type of leaching system.68

Table 3. Dissolution of Noble Metals in Mixtures of Halocarbons with Organic Solvent68.

| Metal | Lixiviant | Temp (°C) | Reaction product |

|---|---|---|---|

| Ag | CCl4–DMSO | 80 | AgCl2– |

| CBr4–DMSO | 80 | AgBr2– | |

| CPh2Cl2–DMAA | 110 | AgCl2– | |

| Au | CBr4–DMSO | a | AuBr4– |

| Pd | CCl4–DMSO | a | PdCl2·2DMSO |

| CBr4–DMF | a | PdBr2·2DMF | |

| CPh2Cl2–DMAA | 110 | PdCl2·2DMAA | |

| CPh2Cl2–thiophene | a | PdCl2·2(C4H4S) | |

| Pt | CPh2Cl2–DMAA | 110 | PtCl2·2DMAA |

| C(CN)2Cl2–DMF | 100 | PtCl2·2DMF | |

| Rh | CPh2Cl2–DMAA | 110 | RhCl3·3DMAA |

| C(CN)2Cl2–DMF | 100 | RhCl3·3DMF | |

| Ru | No studied system could dissolve Ru | ||

Temperature was not reported.

An aqueous mixture of the halocarbon N-bromosuccinimide (NBS) and the coordinating solvent pyridine (Py) could dissolve gold.1 The leaching yield of gold with NBS/Py was higher than that with the classic cyanide method, with thiourea, and with solutions of KI/I2. NBS/Py also had good leaching selectivity for gold over other metals coexisting in the gold ore such as Fe, Al, Mg, Cu, and Zn (Figure 8). The oxidation by NBS involved mainly the release of a molecular bromine intermediate that oxidizes gold to form the anion complex [AuBr4]−, which subsequently reacted with a pyridine molecule to form PyAuBr3. The metal coordination with a pyridine-like unit decreased the redox potential for oxidation of metallic gold by NBS. Due to the exothermic reaction, the dissolution of gold proceeds better at lower temperatures, as indicated by the fact that the leaching yields of gold at 70 and 50 °C were much lower than the yield at 25 °C.

Figure 8.

Gold leaching from ores by N-bromosuccinimide/pyridine (NBS/Py). (a) Scanning electron microscopy (SEM) image of the gold ore; (b) corresponding metal contents in the raw gold ore; (c) effect of pH on the leaching yield of gold by different methods; (d) effect of pH on the leaching yields for the collective metals contained in the gold ores. The NBS and pyridine concentrations were 10 and 100 mm, respectively. Reprinted with permission from ref (1). Copyright 2017 Wiley-VCH Verlag GmbH & Co. KGaA.

Stabilized bromine compounds such as 1-chloro-3-bromo-5,5-dimethylhydrantoin (GEOBROM 3114) and 1,3-dibromo-5,5-dimethylhydantoin (GEOBROM 5500) (Scheme 9), which have lower vapor pressures than bromine, can dissolve gold as well.69 During the leaching of gold in GEOBROM 5500 media, gold is oxidized anodically to the auric state, while GEOBROM 5500 is cathodically reduced to the very effective oxidizing agent hypobromous acid. Subsequently, gold goes into solution as the tetrabromoaurate(III) complex, [AuBr4]−, which has a very high formation constant (1032) in aqueous solutions. Different metals and minerals can either decrease or increase the dissolution rate of gold in bromine media by galvanic interactions.69 For example, copper, iron, and galena decrease the dissolution rate of gold, due to the galvanic interaction between the two substances. Sphalerite can enhance the dissolution rate of gold significantly. This can probably be attributed to the action of dissolved Zn(II) ions on the surface of gold and the formation of a film (probably a zinc complex) on a gold surface which can increase its conductivity.

Scheme 9. Chemical Structures of GEOBROM 3114 (left) and GEOBROM 5500 (right).

It is shown in this section that various halocarbons could be used as solvent in leaching systems for dissolution of metals. However, most halocarbons are toxic, especially CCl4. Due to the suspected carcinogenicity of CCl4, the use of this solvent has been banned in many countries. Therefore, alternative green leaching systems should be developed for future use.

4. Donor–Acceptor Electron-Transfer Systems

In a donor–acceptor electron-transfer system, neither the donor nor the acceptor alone directly reacts with metals, but their mixtures do, because new species capable of oxidizing metals are generated by the interaction between the donor and the acceptor. Examples are mixtures of DMSO and ammonium halides (NH4X), DMSO and HX (X = Cl, Br, and I), and DMSO and SO2 and a mixture of thionyl chloride (SOCl2) and pyridine (organic aqua regia).

4.1. DMSO with Halide Acids or Salts

The DMSO–halide acids (HX, X = Cl, Br, I) in both aqueous and organic systems have been studied for oxidative dissolution of metals such as copper, silver, gold, palladium, and platinum.70−73 The final products of the reaction between DMSO and HX are mainly dimethyl sulfide (Me2S), dihalogens, and water, together with some byproducts such as CO and CS2. The intermediate products Me2S(OH)X, Me2S·X2, and X2 are most likely responsible for the oxidation of metals. The sequence of reactions between DMSO and HBr is presented in Scheme 10:

Scheme 10. Sequence of Reactions between DMSO and HBr.

Various metal complexes can be synthesized by dissolution of the corresponding metals in DMSO–HX solutions. For example, after adding palladium to the mixture of DMSO and HBr, the solid product Me2SPdBr2 was isolated. The liquid phase is most likely a mixture of several complexes, depending on the ratio of the components. By dissolving silver in the system of DMSO–HBr, several silver complexes, e.g. AgBr, [Me3S]AgBr2, and [Me3S]Ag2Br3, were formed. Whereas in the system of DMSO–HX–ketone (X = Br, I; ketone = acetone, acetylacetone, or acetophenone), the complexes formed were [Me2S+CH2COR]AgX2– (R = Me, Ph; X = Br, I). The composition of the complexes depended on various factors, including the DMSO-to-HX molar ratio, the nature of HX, and the methods used to isolate the solid products from the solution. It is noteworthy that silver does not dissolve in the DMSO–HF system and that it dissolves only very slowly in the DMSO–HCl system. This is probably due to the stronger reactivity of the formed complex with bounded molecular fluorine or chlorine toward organic molecules than to metals. The reactions between DMSO and HCl are shown in Scheme 11.

Scheme 11. Reactions between DMSO and HCl.

The dissolution of copper was investigated in the system of DMSO–HX (X = Br, Cl). HX was dissolved in water or organic solvents: acetonitrile (MeCN) and nitrobenzene (PhNO2).73 The dissolution rates of copper metal in nonaqueous media are 1 order of magnitude higher than in aqueous media, following the sequence: H2O < MeCN < PhNO2. This difference in reactivity was attributed to a change in the adsorbability of the reagents on the metal surface. The low reactivity of the aqueous system is caused by the strong adsorption of water on the metal surface, which competes with the oxidizing species for contacting with the metal surface. A distinctive feature of metal dissolution in the DMSO-HBraq system is the presence of two or three maxima in the plot of the metal dissolution rate as a function of the molar fraction of HBr, indicating that several species that can oxidize metals are formed upon the interaction of DMSO and HBr. Besides bromine-containing compounds, oxygen-containing compounds (H2O2, HXO) are formed as well, due to the interaction between DMSO and HX in aqueous solutions.72 DMSO-HXaq dissolves both transition metals (Cu) and noble metals (Au, Ag, and Pt), whereas gold is insoluble in the nonaqueous system DMSO–HClsolv. Therefore, the latter system can be used for selective dissolution of copper in the presence of gold.

The alternative system DMSO–NH4Xaq can dissolve copper as well.74 The mechanism for the formation of intermediates active for metal dissolution shown in Scheme 12 is similar to that for the system DMSO–-HX.

Scheme 12. Reactions between DMSO and NH4X.

Moreover, the dissolution rate of copper in air is faster than that in argon, indicating that molecular oxygen probably can react with the intermediate species to form a new species that can oxidize the metal. In the DMSO–HX system, nonaqueous solutions are more reactive toward metals than aqueous solutions. However, copper dissolves faster in NH4Iaq-O2 containing no DMSO than in DMSO–NH4Xaq. This was explained by the formation of the stronger oxidizing agent IO3– in the former system.

4.2. DMSO with SO2

The mixed nonaqueous system DMSO–SO2 has shown to have good potential for dissolution of metals.75−82 The metals Mg, Sr, Ba, V, Mn, Fe, Co, Ni, Cu, Zn, Al, In, Pb, and Yb dissolve in DMSO–SO2 to form metal disulfates (Mx(S2O7)y·zMe2SO), and the metals Sr, Ba, and Pb react as well with formation of metal sulfates which form a passive layer on the metal surface. Chromium is completely inert in the mixed solvent. Other metals, Na, Be, Ca, Ce, Pr, Eu, Dy, Ga, TI, Sn, Sb, Bi, I, and Cd, also react, but the reaction products have not been characterized yet. These metals dissolve neither in DMSO nor in SO2 separately, but they do dissolve in the mixture of DMSO and SO2. Adducts with compositions 2SO2·DMSO, SO2·DMSO, and SO2·2DMSO have been identified by Raman spectroscopy and phase study (i.e., by measuring the eutectic point for mixtures of SO2 with DMSO to obtain the structure of adducts).81,83 These adducts are considered as active intermediates for metal oxidation. Dimethyl sulfide is one of the reaction products, and the existence of the radical ion [SO2]•– and an ion pair containing a metal ion and [SO2]•– have been demonstrated.79 The adduct 2SO2·DMSO provides a starting point for the formation of a radical ion containing the S–O–S group, [DMSO·OS·O·SO2]•–. By stepwise reaction with DMSO, the disulfate anions are formed via a series of successive radical anions.

Besides DMSO, other solvents containing SO2 have been tested for dissolving metals such as Li, Na, Mg, Ca, Fe, and Zn. The solvents DMAA, DMF, formamide, ethanol, water, trimethyl phosphate, and tris(dimethylamino)phosphine oxide react with metals, whereas the solvents tetrahydrothiophen-1,1-dioxide, nitrobenzene, nitromethane, ethyl acetate, acetonitrile, diethyl ether, 1,4-dioxane, tetrahydrofuran, pyridine, and acetone do not. The solvent must have a high dielectric constant (ε > 20), as well as a high Gutmann donor number (DN > 20) for spontaneous dissolution of metals to occur. A solvent with a high dielectric constant is required for the formation of the sulfoxylate radical ion. A solvent with a high donor number is required for the solvation of metal ions with inhibition of recombination of metal ion and [SO2]•– to form metal and SO2. The reaction product after metal dissolution is a metal dithionite rather than a sulfate or disulfate.81 The dithionite anion is formed by direct dimerization of the radical ion [SO2]•–.

4.3. Organic Aqua Regia

“Organic aqua regia” was first reported by Lin and co-workers in 2010, and it can dissolve gold and palladium with a high dissolution rate at room temperature.84 It is a mixture of SOCl2 and a polar organic solvent such as pyridine (Py), DMF, or imidazole. It was named as “organic aqua regia”, because of its similarity to aqua regia: (1) it can dissolve noble metals; (2) noble metals cannot dissolve in either of the components, and only their mixtures are strongly oxidizing. The mixture SOCl2–Py can dissolve gold at a rate of 0.3 mol m–2 h–1 at room temperature, which is faster than the dissolution of gold in conventional cyanide leaching agents (<0.004 mol m–2 h–1) and iodide solutions (<0.16 mol m–2 h–1). The enhanced reactivity of organic aqua regia is ascribed to the formation of the adduct SOCl2·Py, resulting from the charge-transfer interaction between SOCl2 and Py. The sulfur atom in SOCl2 acts as an electron acceptor, and the nitrogen atom in pyridine acts as an electron donor. Gold dissolves in the solution in the form of [AuCl4]− rather than AuCl3 or its complex with pyridine.

Organic aqua regia can be formed not only with pyridine but also with other polar organic solvents.85 The following solvents or organic compounds have been found to be able to effectively dissolve gold in the presence of SOCl2: pyrrole, pyrrolidine, pyrrolidone, isoxazole, isothiazole, pyrazole, imidazole, thiazole, oxazole, pyrazolone, bipyrazole, pyridine, pyridazine, pyrimidine, pyrazine, triazine, indole, quinoline, purine, pteridine, phthalocyanine, N,N’-dicyclohexylcarbodiimide, DMF, N,N’-dimethylbenzylamine, dodecyltrimethylammonium bromide, trip-tolyl-phosphine, etc. However, effective dissolution of gold in a mixture of SOCl2 with any of the following chemicals has not been observed: maleimide, azobis(isobutyronitrile), aniline, polyaniline, phenanthroline, methylbenzyl cyanide, 2-acetyl-1-methylpyrrole, and benzyltriethylammonium tetrafluoroborate.

A qualitative study has shown that copper, iron, nickel, tin, indium, silver, and palladium dissolve in the SOCl2–Py mixture, whereas platinum, titanium, tungsten, tantalum, and chromium do not.85 The fact that some metals cannot be dissolved in SOCl2–Py is probably due to surface passivation.

By varying the composition of organic aqua regia, selective dissolution of noble metals can be achieved. For example, by replacing pyridine with DMF, the mixture SOCl2–DMF can dissolve gold but not palladium or platinum. A mixture of SOCl2–pyridine (3:1) can dissolve gold, silver, and palladium at room temperature, while platinum is completely inert, even at 70 °C (reflux) for 1 week. Therefore, selective dissolution of gold, palladium, and platinum on a silicon substrate could be achieved by first dissolving gold in SOCl2–DMF, followed by dissolution of palladium in the SOCl2–pyridine mixture (Figure 9). It is assumed that selective dissolution is caused by differences in interaction between SOCl2 and the organic solvent.

Figure 9.

Illustration of selective dissolution of gold, palladium, and platinum in organic aqua regia. A silicon substrate was metallized with a Pd/Au/Pt layer (250 nm thick each by electron-beam evaporation or direct current sputtering, with chromium used as the adhesion layer). The top row of images shows the photographs of the Pd/Au/Pt metallization layer on a silicon substrate during the process of selective dissolution. Reprinted with permission from ref (84). Copyright 2010 WILEY-VCH Verlag GmbH & Co. KGaA.

Besides the application in the recovery of noble metals, organic aqua regia can be applied in the microelectronic industry, for instance for “vapor” etching of gold metallization on a circuit board by vaporized organic aqua regia.84 Etching of copper from the fabrication of printed circuit boards has been studied by using the SOCl2–CH3CN solutions as etchant at room temperature. The etching rate was found to be much faster than any currently used etchant for copper.85 Subsequently, this solvent was successfully applied for the separation of platinum from a mixture of gold and platinum nanoparticles and from a Au/Pt core–shell nanoparticle catalyst, with the purity of the recovered platinum above 95%.86 This organic aqua regia was also applied in organic synthesis, for activation of gold/activated-carbon catalysts for hydrochlorination of acetylene.87 Activation of gold/activated-carbon catalyst in organic aqua regia improves the activity and stability of the catalyst compared to the activation procedure in conventional aqua regia.

Organic aqua regia can oxidize noble metals under mild conditions, but the employed reagents are hazardous, which makes this reagent less attractive from an environmental point of view, and this leads to a further search for safer alternatives for aqua regia.

5. Ionic Liquids and Deep Eutectic Solvents

5.1. Ionic Liquids

Ionic liquids (ILs) are solvents that are composed entirely of ions, and some of them can be considered as environmentally friendly solvents. They have been applied as alternatives for molecular organic solvents in various fields, due to their unique properties such as a negligible vapor pressure, a wide liquid range, high thermal and chemical stability, a wide electrochemical window, and poor flammability.88−93 The properties of ILs can be tuned by changing the structure of organic cations and inorganic or organic anions. For example, ILs with oxidizing power can be synthesized by adding molecular halogens to halide ILs so that tri- or polyhalide or interhalide ILs can be formed, such as [Cl3]−, [Br3]−, [I3]−, [ClBr2]−, [BrCl2]−, and [BrI2]−.94−98 The polyhalide ILs are most often used as reagents for halogenation of organic compounds, such as aromatics, alkenes, and alkynes,99−101 but they can be used for oxidative dissolution of metals or alloys as well.15,94,95,102,103 These polyhalide ILs can be used in pure form or as mixtures with halide ILs for dissolution of metals.

5.1.1. ILs as Oxidizing Agents

Trihalide ILs can be prepared by simply mixing equal molar amounts of halogens and halide ionic liquids. They can safely store halogens and in the meantime have oxidizing properties. Various metals can be dissolved in trihalide ionic liquids under mild conditions. The mixtures of trihalide and halide ILs work as well. In this case, halide ILs act as solvent and trihalide ILs as oxidizing agent. A series of trichloride ILs that are liquid form at room temperature was synthesized by Li et al.94 The cationic cores used were phosphonium, ammonium, pyridinium, pyrrolidinium, and imidazolium (Scheme 13), and the full names and abbreviations of the cations are shown in Table 4. It was confirmed by NMR spectroscopy that all the studied cations are stable in the presence of chlorine, except imidazolium cations. The trichloride ILs have a lower viscosity and melting point than the corresponding chloride ILs, due to the more extended charge delocalization in the trichloride anions compared to the chloride anion, and thus weaker electrostatic interactions between cations and anions. A total of 12 metals and two metal alloys have been tested for dissolution in the representative trichloride IL [P444,14][Cl3]: Fe, Cu, In, Zn, Ga, Sb, Au, Pt, Ge, Ta, Sm, Dy, GaAs, and InAs.94 All metals and alloys, except Sm (5 mm pieces), Dy (5 mm pieces), Ta (powder), and Pt (wires) could be dissolved in this trichloride IL at room temperature. Thus, trichloride ILs can selectively dissolve some metals and, for example, allow the separation of the highly valuable gold and platinum. The fact that samarium metal did not dissolve in the trichloride ILs was unexpected, because rare-earth metals are in general very reactive. In follow-up experiments using freshly milled samarium powder instead of samarium metal pieces, different results were obtained: samarium powder could indeed be oxidatively dissolved in trichloride ILs.15 This result showed that samarium metal pieces are difficult to dissolve in trichloride ILs because of the presence of a protective oxide layer on the samarium metal surface which prevents contact between the oxidizing trichloride anion and the metal.

Scheme 13. Structure of Cations of Trichloride ILs.

Reprinted from ref (94). Copyright 2018 Royal Society of Chemistry under [CC BY-NC 3.0] [https://creativecommons.org/licenses/by-nc/3.0/].

Table 4. Full Names and Abbreviations of the Cations of Trichloride ILs.

| Name of IL cation | Abbreviation |

|---|---|

| Trihexyl(tetradecyl)phosphonium | P666,14 |

| Tetrabutylphosphonium | P4444 |

| Tributyl(tetradecyl)phosphonium | P444,14 |

| 1-Butylpyridinium | BPy |

| Methyltrioctylammonium | N1888 |

| 1-Butyl-1-methylpyrrolidinium | BMPyrr |

| 1-Butyl-2-methylpyridinium | 2-MBPy |

| 1-Butyl-1-methylpiperidinium | BMPip |

| 1-Butyl-4-methylpyridinium | 4-MBPy |

| 1-Hexylpyridinium | HPy |

| 1-Butyl-3-methylimidazolium | Bmim |

| 1-Decyl-3-methylimidazolium | Dmim |

Metal recovery from spent samarium–cobalt (Sm–Co) magnets using a trichloride ionic liquid was studied by the same group.11 The results showed that Sm–Co magnets, containing Fe, Co, Cu, and Sm, can be quantitatively dissolved in trichloride ILs. Two processes are involved in oxidative dissolution: oxidation of the metals by trichloride ions and dissolution of the oxidation products in the ionic liquid. The oxidation process converts the metals to the corresponding metal chlorides, and simultaneously each trichloride anion is reduced to three chloride ions. The generated metal chlorides are subsequently dissolved in the IL by complex formation. Thus, the dissolution mechanism of Fe, Co, Cu, and Sm in the trichloride IL [P666,14][Cl3] in the presence of coordinating chloride ions can be expressed by the following equations:

| 10 |

| 11 |

| 12 |

| 13 |

More trihalide or tri-interhalide ionic liquids with a tributyldecylphosphonium cation ([P44410]) and various anions have been prepared, including trichloride ([Cl3]), bromidedichloride ([BrCl2]), chloridedibromide ([ClBr2]), tribromide ([Br3]), iodidedibromide ([IBr2]), bromidediiodide ([BrI2]), and triiodide ([I3]).95 One representative IL, [P44410][Br3], was selected for oxidative dissolution tests for metals. Several base metals and metalloids (iron, zinc, copper, cobalt, bismuth, indium, tin, gallium, antimony, and germanium) can be oxidatively dissolved in [P44410][Br3], as well as the noble metals palladium and gold. However, platinum and rhodium could not be dissolved, similarly to what was observed for the trichloride IL [P666,14][Cl3].94 Copper as a representative metal could be efficiently dissolved in all the synthesized trihalide ILs, suggesting that all these the trihalide ILs can oxidize metals. The same tribromide IL [P44410][Br3] could also efficiently leach gallium, indium, and arsenic from semiconductors (GaIn, GaAs) and light-emitting diodes that contained GaAs.103

May and co-workers studied the reaction of the interhalide IL 1-hexyl-3-methylimidazolium iodide dibromide ([Hmim][Br2I]) with copper, silver, and gold, investigated by using X-ray photoelectron spectroscopy, mass loss measurements, and gas-phase mass spectrometry.104 All the studied metals can be oxidized by the interhalide IL to form molecular iodine and metal ions in the +1 oxidation state, in the form of [Br–M–Br]− (M = Cu, Ag, and Au), which is different from dissolution of metals in trichloride ILs, where the metals are oxidized to their highest oxidation state.94 The reaction can be described as eq 14:

| 14 |

The dissolution behavior of gold in 1-hexyl-3-methylimidazolium dibromoiodide [Hmim][Br2I] and 1-butyl-2,3-dimethylimidazolium dibromoiodide [C4C1C1Im][Br2I] that was methylated at the 2-position of the imidazolium ring was compared, and this study rules out the formation of imidazole-carbene as a cause of the oxidation reaction. Moreover, the oxidation reaction is not sensitive to either water or air. The dissolution efficiency of gold in aqueous solutions of Na[Br2I] is at least ten times less than that in [Hmim][Br2I], indicating that the organic cation [Hmim]+ plays an important role in the dissolution of the formed metal complex.

Recently, ILs with a poly pseudohalide anion such as [Br(BrCN)]− and [Br(BrCN)3]− were synthesized and successfully used for dissolution of gold.105 The vapor pressures of the poly pseudohalogen salts bis(triphenylphosphoranylidene)iminium bromide [PNP]Br are reduced by at least a factor of 10 to 0.1 mbar (1 equiv BrCN) and 15.5 mbar (5 equiv BrCN) at ambient conditions, compared to the vapor pressure of toxic BrCN (160 mbar at 25 °C). Room temperature ILs can be obtained when more than 3 equiv of BrCN is added to bromide salts. Due to the significantly lower vapor pressures, the poly pseudohalide ILs can easily be handled and applied, for example, in metal recycling. A room temperature IL was formed by adding 4 equiv of BrCN to the IL butyldiethylmethylammonium bromide. This IL can dissolve gold with the formation of gold(I), as well as predominantly gold(III) cyanido and gold(III) bromidocyanido species.

Due to the involvement of halogens in ILs, the polyhalide ILs have oxidizing power and hence can be used as both oxidizing agent and solvent. However, ILs without oxidizing power can be applied as solvents for metals dissolutions together with some oxidizing agent, e.g. trihalide ILs in halide ILs as solvents.

5.1.2. ILs as Solvents

Whitehead and co-workers reported a series of studies where ILs were used as solvents for recovery of gold and silver from ores.106−108 Recovery efficiencies of metals were studied by varying solvent ILs and oxidizing and complexing agents. The IL [Bmim][HSO4] was extensively studied for metal extraction due to its acidity. The system of [Bmim][HSO4]/thiourea/Fe2(SO4)3 could effectively leach gold and silver with high selectivity over the base metals Cu, Zn, Pb, and Fe in a gold-bearing ore.106 Here the IL acts as solvent and Fe2(SO4)3 as oxidizing agent. Thiourea was selected as complexing agent because of its high selectivity for gold and silver. This IL system and the aqueous system of H2SO4/thiourea/Fe2(SO4)3 have similar capability for leaching of gold. However, this IL system has higher leaching efficiency of silver than the aqueous system, because in the aqueous system, insoluble silver species precipitate and form a passivation layer on the silver metal surface. An additional benefit was that the IL could be recycled. HSO4-based ILs with different 1-alkyl-3-methyl-imidazolium cations (alkyl = n-butyl, n-pentyl, n-hexyl, n-heptyl, and n-octyl) could also be used as solvents, but as the alkyl chain length was increased, the efficiency of gold recovery dropped, probably due to the higher viscosity of the ILs.108 Bmim-based ILs with varying anions (N(CN)2–, CH3SO3–, HSO4–, BF4–, and Cl–) were used as solvent for recovery of gold and silver, but among all five ILs investigated, only [Bmim][HSO4] showed high extraction efficiency and selectivity (Figure 10). The selectivity differences between different anions result from their differences in coordination ability with metal ions.

Figure 10.

Extraction of gold and silver (top) and base metals (bottom) from a complex sulfidic gold-bearing ore using thiourea leaching with ILs with the [Bmim]+ cation and different anions (50 °C, 48 h leaching). Reprinted with permission from ref (108). Copyright 2007 Elsevier B.V.