Abstract

There have been many studies on the microplastic pollution, influence and control mechanisms of different plastic products. The potential harm of microplastic pollution to the environment has been confirmed. With the outbreak and spread of the COVID-19 in the world, disposable surgical masks as effective and cheap protective medical equipment have been widely used by the public. Disposable masks have been a new social norm, but they must have a sense of environmental responsibilities. The random disposal of masks may result in new and greater microplastic pollution, because masks made of polymer materials would release microplastics after entering the environment. Current results showed that masks are a potential and easily overlooked source of environmental microplastics. The release amount of microplastics in the static water by one mask was 360 items, and with the increase of vibration rate, the release amount also increased. The addition of organic solvents (detergent and alcohol) in water would increase the release of microplastics from masks. When the mask became fragments, the ability to release microplastic fibers into the environment was greatly improved due to the increase of exposure area. After two months of natural weathering, the masks become very fragile pieces and microplastics. A fully weathered mask could release several billions of microplastic fibers into the aquatic environment once these fragile fragments enter the water without reservation. The rapid growth of mask production and consumption and improper disposable is worrying. It is urgent to understand the potential environmental risks and significance of masks.

Keywords: COVID-19, Disposable surgical masks, Microplastics, Plastic pollution, Natural aging, Potential source

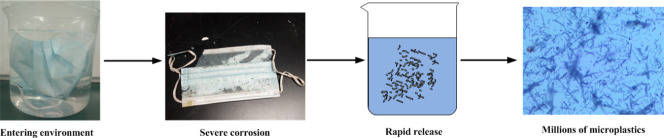

Graphical abstract

1. Introduction

The application of plastic products has brought great benefits to the society (Aragaw, 2020), however, microplastics and nanoplastics have also brought problems and environmental impacts with the plastic age (Wright and Kelly, 2017). The mismanagement of plastic waste and improvement of the production capacity of plastic polymers have aroused widespread concerns. The plastics can break down into smaller pieces overtime, and the more garbage in the environment, the more likely it is to decompose. Plastics can first decompose into macroplastics, and finally into microplastics and nanoplastics (Shen et al., 2019b; Shen et al., 2019c). Evidence showed that microplastics and nanoplastics have been widely penetrated into the environment (Kashiwada, 2006; Lusher et al., 2015; Oßmann et al., 2018; Wang et al., 2016; Xiong et al., 2018). Due to the release of a large number of plastic wastes in water, the uptake of microplastics and nanoplastics by aquatic organisms increases. These tiny particles and fibers are usually polymers that can accumulate in the food chain/web (Bouwmeester et al., 2015).

Microplastics in the aquatic systems can be derived from solid waste, and also come from urban sewage (Ziajahromi et al., 2017) and municipal waste runoff (Ziajahromi et al., 2020). Measures are being taken to curb the spread of plastic and microplastic pollution, such as restriction, prohibition and development of substitutes (Hu et al., 2019; Shen et al., 2019a). However, problematically, new applications of plastics are being introduced. At the end of 2019, COVID-19 was first detected began to ravage the world (Xu and Li, 2020). Since it was declared as a pandemic by the World Health Organization (WHO), countries have taken various methods to curb the virus and its further spread (Murray et al., 2020). With regard to the current pandemic, the researchers advocate that the public can use disposable surgical masks until understanding the transmission pattern of COVID-19 (Leung et al., 2020). It helps to reduce the number of times a person touching the face/mouth/nose with an unwashed hand, which can greatly reduce the chance of infection. As one of the preventive measures to slow the spread of COVID-19 from person to person, it has led to a global shortage of disposable surgical masks. The WHO estimates that 89 million medical masks are needed every month to cope with COVID-19 (World Health Organization, 2020). For example, China has increased its daily production of masks to 14.8 million by February 2020 (Xinhuanet, 2020), and more than 600 million mask orders per month have been secured as of April 2020 in Japan (METI, 2020). This demand has led to an unprecedented increase in global production of masks made from polymeric materials.

Disposable surgical masks can be made of different polymeric materials, such as polypropylene and polystyrene (Aragaw, 2020), and consist of four parts: inner layer (fiber material or nonwoven fabric), middle layer (melt-blown filter), outer layer (nonwoven fabric and colored), and ear band (fiber material). However, with the increase of mask production and consumption in the world, new challenges to the environment are put forward. COVID-19 has triggered another kind of emergency: disposable plastics are back on the rise around the world, and most of the non-recyclable personal protective equipment is pouring onto urban roads and blocking sewage pipes (Aragaw, 2020). The extensive use of masks in COVID-19 emergencies demonstrated environmental chaos in both aquatic and terrestrial environments, and the global epidemic has not reduced the challenges of increasing plastic and microplastic pollution in the environment. Evidence showed that disposable plastic products, such as plastic bag, box, bottle and containers, are considered to be an important source of environmental pollution caused by plastics and microplastics (Shen et al., 2020a; Shen et al., 2020b). These products will enter aquatic and terrestrial environments in different ways, including blowing, flooding, leaching and littering. Similarly, disposable surgical masks can also enter the environment. First of all, they are disposed in sanitary landfill, or discarded in public places, and then enter river, lakes and oceans, thereby becoming a new source of plastic and microplatics. Therefore, it is urgent to study the release ability of microplastics and influencing factors of the disposable surgical masks.

This paper aimed to evaluate the release ability of microplastics and nanoplastics and its influencing factors of disposable surgical masks in simulated environment. The effect of simulated use times and natural weathering on the ability of mask to release microplastic fiber was studied. The current research can not only lay a foundation for understanding the mechanism of microplastic fibers release from disposable surgical masks, but also provided a basis of the industry to formulate better mitigation strategies.

2. Materials and methods

2.1. Materials

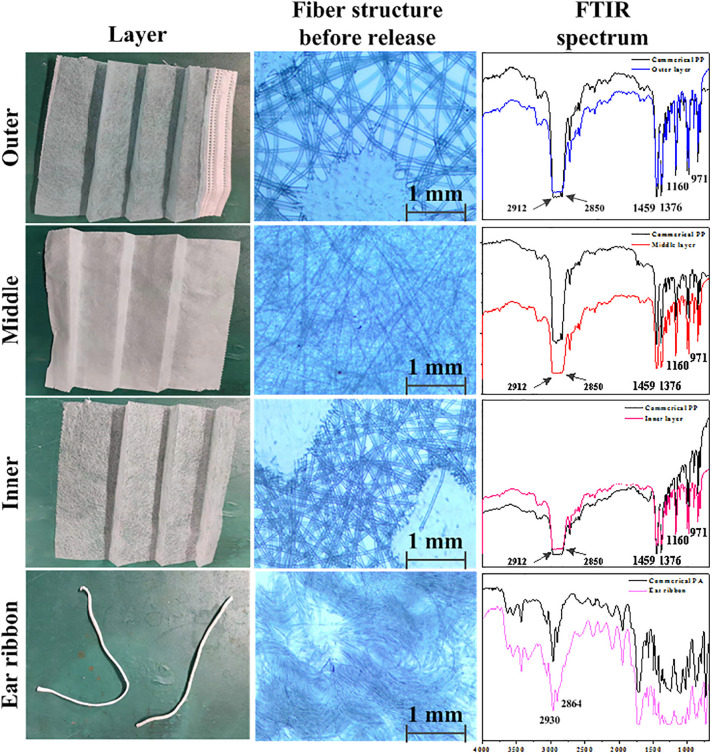

Masks used in this experiment were disposable surgical masks, which were purchased from the designated drug mask sales office. The disposable surgical mask is made of two layers of fiber nonwoven fabric (outer and inner) specially used for medical and health care, and a layer is added in the middle to filter and prevent more than 99% of the bacteria. The disposable surgical mask can be made of polypropylene, polyurethane, polyester, polyacrylonitrile, etc. (Fig. 1 ) (Aragaw, 2020). The polymer melt material is charged after being subjected to an electric field. In the electric field, the polymer material is removed and cut from the source to form a fine structure of nanofibers. Due to the relative risk of used masks, and the microplastic fibers intercepted by masks in the air may be re-released during the experiment, which will interfere with the experiment, so only new unused masks were used in this experiment.

Fig. 1.

Structure and chemical composition of disposable surgical mask before release. Electron microscopy resolution of 3.66 μm.

2.2. Release of microplastics from the mask

The whole new mask was put into a glass beaker, and 3 L of ultrapure water was added and stirred at room temperature for 24 h in a stirrer (120 rpm, thermostatic oscillator) (first release experiment). Since masks were not easily available during the COVID-19, the public chose to clean and reused the washed masks. Therefore, the mask was carefully washed using the ultrapure water to remove any debris and dried at room temperature (Fig. S1). Then, the release experiment of the washed mask after the first cleaning was performed and the parameters were the same as the first experiment (second release experiment). After the test, the washed mask was washed and dried again, and the release experiment was also carried out again (third release experiment). In order to systematically study the release of microplastics in masks, detergent solution and alcohol disinfectant solution were also used to determine the release of microplastics. The concentration of detergent (sodium dodecyl benzene sulfonate) was to be 10 mg L−1, and the concentration of alcohol disinfectant was of 75%. In addition, since the fibers in the mask were arranged in a certain direction, the mask was cut into horizontal and vertical shapes in order to understand the release mechanism. The horizontal and vertical shapes were also put into a beaker, and 3 L of water, detergent and alcohol solution were added respectively. The experimental conditions were the same as the first release experiment, and the fragments were also cleaned twice.

After each washing cycle, the mask sample was removed from the glass beaker with cleaned tweezers and dripped for 30 s to drain the excess liquid. The release solution was continuously stirred to maintain the uniformity of the suspension. The solution was then filtered by a filtration system consisting of a filter unit and a vacuum pump. The release water was filtered through nitrocellulose membrane with a pore size of 0.45 μm. In order to avoid too much fibers stacking on the membrane, a volume of the release water was selected with a target of 100 to 200 microplastic fibers per filter (Cai et al., 2020). The membrane was immediately put into a clean glass dish and dried at 40 °C for further study. All experiments were repeated three times, and all glass instruments were cleaned with ultrapure water and alcohol three times before use.

2.3. Effect of aging on microplastic released from the mask

The effect of aging on release of microplastic fibers from the mask was performed. The masks were placed at the roof of the laboratory building of Hunan University (112.95° E, 28.18° N), China for natural aged two months (July to September 2020). After two months of natural weathering, the materials were carefully recycled. Then the recycled materials were put into clean glass containers. The mask was very fragile due to natural corrosion. 0.1 g of fragment was used in the release experiment of microplastic fiber. The containers were sealed and stirred at 150 rpm at room temperature for 24 h, and all experiments were repeated three times.

2.4. Characterization

After each release experiment, the first step is to visually inspect the microplastic on the filter membrane (color and shapes). In order to judge the microplastics more clearly, the metallographic microscope (XD-202, Shanghai Precision Instrument Corporation, China) was also used to observe the microplastics on the filter membrane. The purpose of microscopic observation was to determine the number, size and length of microplastics. Different multiples (40× and 100×) were used to observe the characteristics of microplastics.

Electron microscopy was a method used to observe microplastics released from the mask because it can provide the possibility of observing small particles. The released microplastics from each experiment were analyzed three times. Scanning electron microscopy (SEM, Zeiss Sigma 300, Germany) images of the release solution were used to estimate the number and the size of release particles in the solution. The number and the particle size of released microplastic fibers of the mask were investigated by the Image J 2.0 analysis software. Due to the polydispersity of release solution of the mask, two average sizes were chosen: the first at 1000×, and the second at 10,000× (Hernandez et al., 2019). Additionally, fibers were randomly selected from the filter membrane to determine the mechanism of fiber breakage (Cai et al., 2020). All washing cycles on the filter were sampled, and ten fibers were randomly chosen and imaged with SEM. The experimental procedure was evaluated based on the degree of contamination and the reliability of the standardized workflow.

μ-Fourier transform infrared spectroscopy (μ-FTIR, The Nicolet iN10, USA) was chosen to characterize the chemical constituents of the released microplastic particles. The each release solution of the mask was filtered via a filter with pore size of 0.45 μm. The filtrate was dried on the aluminum foil in the dryer (40 °C) to produce a thin powder film. The spectral range was set to 4000–675 cm−1, and the spectral resolution was set to 6 cm−1. The number of scans was 16 times and the data interval was 0.482 cm−1 (Shen et al., 2021a; Shen et al., 2021b). Prior to μ-FTIR, samples were cleaned with absolute ethanol to remove any residue. The spectra obtained were compared with those of synthetic polymer spectral database. In addition, μ-FTIR analysis of commercial polypropylene was also performed to compare the chemical composition of mask and its release.

2.5. Quality assurance and quality control

Some quality assurance and quality control measures were used during the experiment. All the experimenters wore cotton clothes in the process of the experiment. All solvents were analytical grade (>95%), and all glassware were pre-cleaned with 30% ethanol solution, thoroughly rinsed with ultrapure water (pH 7.0), then heat treated at 400 °C to remove organic impurities. By avoiding the use of any plastic equipment and using only cleaned glassware and metal items, the potential sources of microplastic contamination were minimized. All filters have been cleaned with ultrapure water before use to reduce the external microplastic pollution and its own microplastic pollution. During the experiment, the number of people in the laboratory was controlled. The researcher also avoided contact with other products similar to the mask material (nonwoven fabric products).

3. Results

3.1. Microplastic fiber release from disposable surgical masks

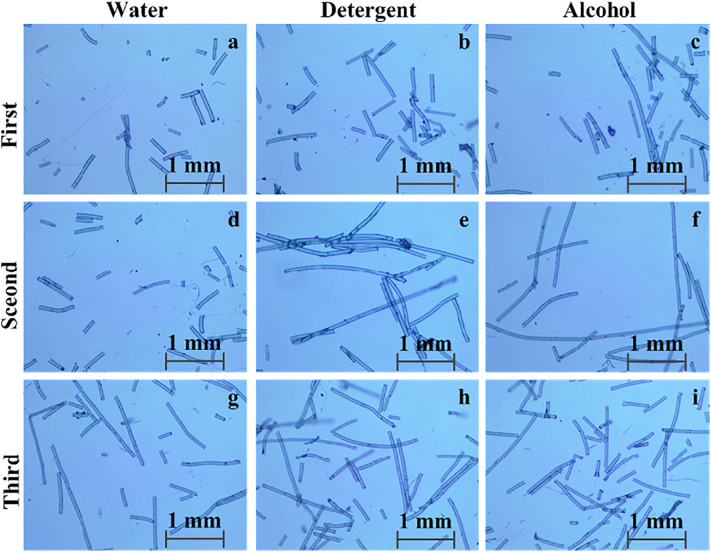

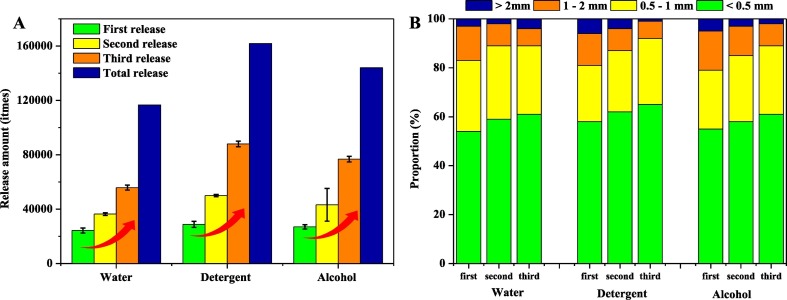

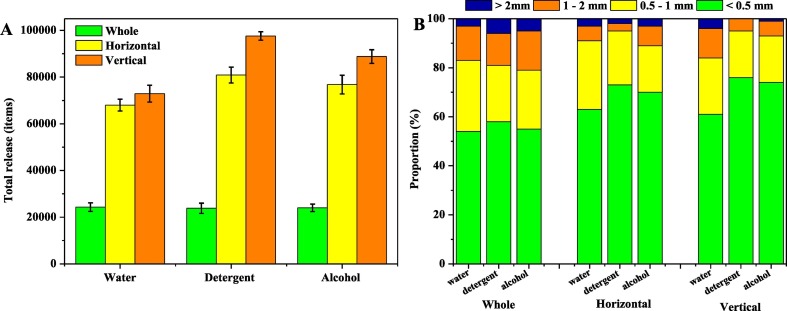

In order to estimate the number of microplastic fibers in each population, the average number were identified for each filter sample. The number of particles per unit area was calculated by using the number of particles in each image and the size of the area scanned by each magnification (Figs. 2 and S2). The number of microplastic fibers released from the disposable surgical mask under different conditions was shown in Fig. 3A . The current results showed that the mask can release microplastic fiber under all condition. Even when the mask was placed in a closed glass container for 24 h, the release of microplastics in water, detergent solution and alcohol solution was 3600, 5400 and 4400 items, respectively. With the increase of the number of mask cycles, the release of microplastics also increased. The release amount of microplastics by one mask increased from 24,300 items at first use to 36,400 items at the second use then to 55,900 items at the third use under water environment. When the mask was disinfected and cleaned with detergent or alcohol, the release of microplastics increased significantly. The results showed that the use of detergent or alcohol increased the release capacity of microplastics into water. The release amount of microplastics increased from 28,800 and 27,000 items at first use to 50,000 and 43,200 items at the second use, then to 88,000 and 76,800 items at the third use under detergent solution and alcohol solution. After washing for three times, the total amount of released microplastics were 116,600, 168,800 and 147,000 items by one mask in water, detergent solution and alcohol solution, respectively. In addition, to better evaluate the release of microplastics by the mask, the mass loss of the mask before and after the test was also measured (Table S1). The findings implied that the mass loss rate of the mask was measured to be 0.47%, 1.14% and 0.85%, respectively, for water, detergent solution and alcohol solution after three times of microplastic release test. After chemical analysis of the released microplastics, most of these microplastics came from the inner and outer layers. The morphology of different parts of the mask was given in Fig. 4 . The inner and outer layers of the mask are made of random plastic fiber, and there are many nodes in the mask to enhance the stability and strength of the mask. These plastic fibers are intertwined with each other and do not have a good fixation, which are easy to escape from the matrix under the action of external force.

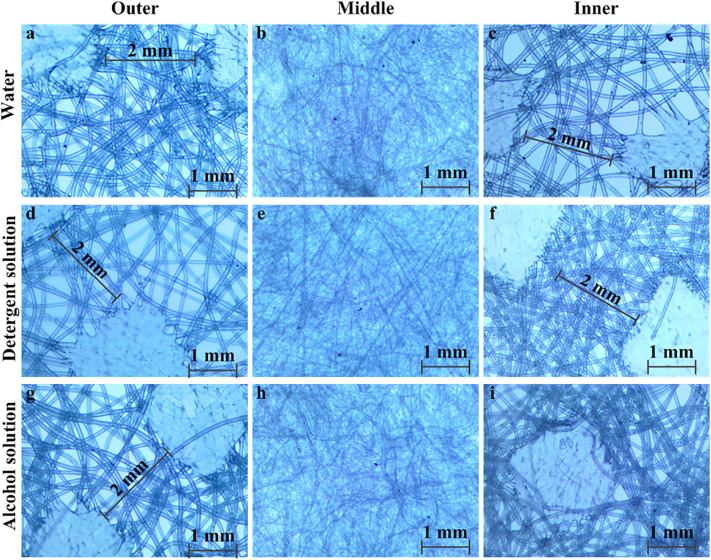

Fig. 2.

Release of microplastic fibers by disposable surgical masks. Masks were washed with water (figures a, b, c), detergent (figures d, e, f) and alcohol (figures g, h, i) for three experiments. Electron microscopy resolution of 3.66 μm.

Fig. 3.

Release of microplastic fibers by one mask under different conditions. (A) Showed the release amount of microplastic fibers by the mask per washing and the total release amount. (B) Illustrated the length distribution of released microplastic fibers.

Fig. 4.

Changes of distribution and morphology of plastic fibers under different experimental conditions. Masks were washed with water (figures a, b, c), detergent (figures d, e, f) and alcohol (figures g, h, i) for three experiments. Electron microscopy resolution of 3.66 μm.

After washing with detergent and alcohol solution, the distribution of plastic fibers in the inner and outer layers of the mask changed obviously (Fig. 4). On the one hand, the number of plastic fibers in the same area was significantly reduced (sparse arrangement), and there is obvious trace of plastic fiber fracture at the nodes. On the other hand, the size of binging force of the nodes became smaller (transparent), and plastic fibers were easy to escape from the matrix under the action of external force due to losing the binding force on the plastic fibers. Fig. 3B showed the length distribution of released microplastic fibers by the mask. The length of released microplastic fibers ranged from <0.5 mm to 3.8 mm, of which 50% were less than 0.5 mm and 80% were less than 1 mm (Fig. 2). The distance between the nodes in the mask was about 2 mm. Under the experimental conditions of aqueous solution, the length of released microplastic fibers was rarely more than 2 mm because the presence of nodes in the mask may limit the release of longer microplastic fibers. With the increase of washing times, the amount of microplastics released was increasing, and the proportion of the length less than 0.5 mm also increased. The addition of detergent and alcohol solution can increase the release of microplastic fibers and increase the proportion of fibers with smaller particle size. The reason for this phenomenon may be that the detergent can accelerate the fracture of the plastic fiber and dissolve some nodes, so that the plastic fiber can get rid of the bondage and enter the water.

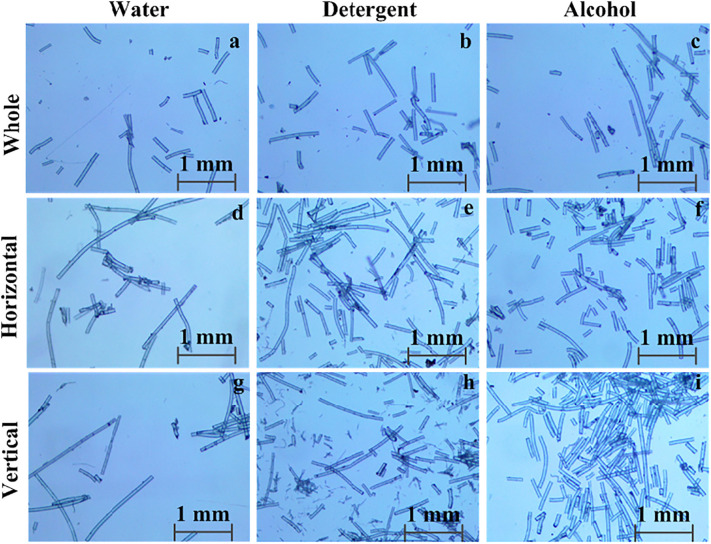

3.2. Effect of cutting modes on microplastic fiber release

The release of microplastic fibers by the mask under different cutting modes was shown in Fig. 5 . It can be clearly seen that after broken, the ability of the mask to release microplastic fibers into the water has been greatly improved. The total amount of released microplastic fibers by the mask and the length distribution were listed in Fig. 6 . The number of released microplastic fibers by whole mask, horizontal fragments and vertical fragments was, respectively, 24,300, 68,000, and 72,900 items under ultrapure water, and 23,800, 80,900 and 97,600 items under detergent solution, and 24,000, 76,800 and 88,800 items under alcohol solution. In addition, the mass loss rate of the mask during the test was also calculated and shown in Table S2. The mass loss rate of horizontal fragments was 0.27%, 0.55% and 0.45% under ultrapure water, detergent solution and alcohol solution, respectively, and 0.30%, 0.67% and 0.50% of vertical fragments under ultrapure water, detergent solution and alcohol solution. The results demonstrated that detergent and alcohol solution can accelerate the release of microplastic fibers in the mask. Fig. S3 showed the distribution of plastic fibers in the mask before and after being cut. Before being cut (before fragmented), the plastic fibers were fixed by many nodes in the mask. After being cut, the original fixed plastic fibers were exposed, part of the nodes was destroyed, and the control of the plastic fibers was lost. Some plastic fibers were also cut off, which made them easier to escape from the fragments. The finding suggested that the release capacity of microplastic fibers from the vertical mask fragments was greater than that from horizontal mask fragments. The main reason for this phenomenon was the increase of exposure area. The length of a new disposable surgical mask was about 16 cm and 10 cm in width (not expanded). The size of horizontal mask strip was 16 cm × 2 cm, and that of vertical strip was 2 cm × 10 cm, respectively. Consequently, the length of the new exposed part of horizontal strips was 104 cm (8 × 16 cm), while that of vertical strips was 140 cm (14 × 10 cm). The new exposure sites also led to a sharp increase in the release of microplastic fibers by the strips. The length distribution of released microplastic fibers was illustrated in Fig. 6B. When the mask was cut into strips (horizontal or vertical), the proportion of released microplastic fibers (>60%) less than 0.5 mm was increased. The microplastic fibers with length less than 0.5 mm released from vertical mask strips were significantly more than that from horizontal mask strips.

Fig. 5.

Release of microplastic fibers by cut disposable surgical mask. Figures a, b, c represent the release of microplastic fiber of whole mask; Figures d, e, f represent the release of microplastic fiber of horizontal mask; and Figures g, h, i represent the release of microplastic fiber of vertical mask. Electron microscopy resolution of 3.66 μm.

Fig. 6.

Effect of cutting modes on release of microplastic fibers by the mask. (A) Showed the amount of released microplastic fibers under different cutting methods, and (B) illustrated the length distribution of released microplastic fiber.

3.3. Effect of aging on microplastic fiber release

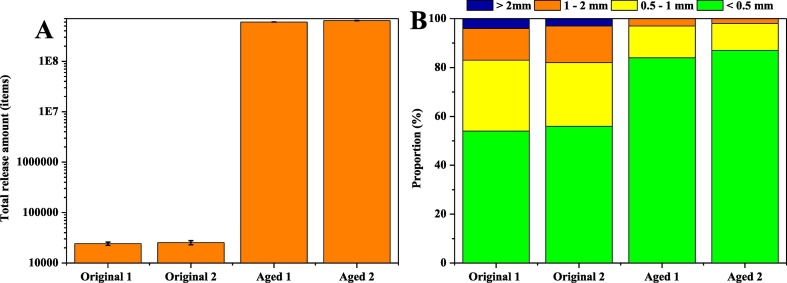

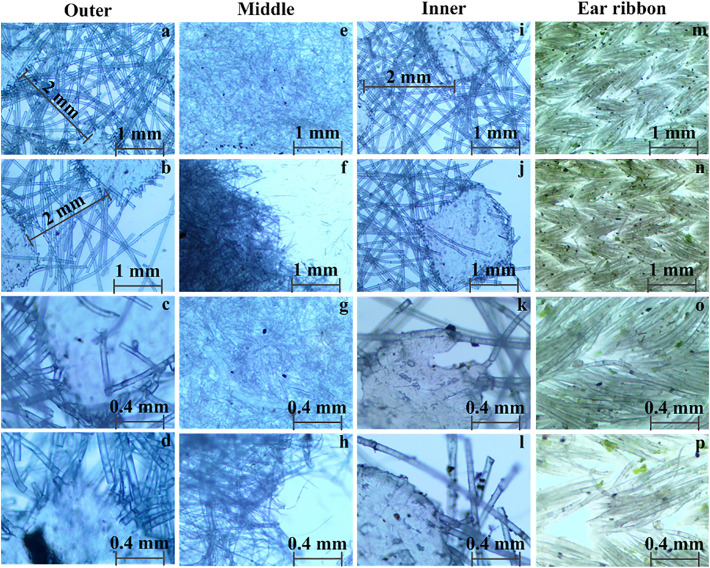

Fig. S4 showed the shape of the mask after two months of natural exposure. It can be clearly seen that the disposable surgical masks were seriously destroyed. After natural aging, the masks have become very fragile and irregular pieces and fragments. In order to avoid excessive release of microplastics, 0.1 g of broken mask fragments were used to carry out the release test. Fig. 7 revealed the total release amount of microplastics from the aged mask before and after two months natural weathering. Compared with the amount of microplastics released the aged mask, the amount of microplastic released by the mask before aging could be basically negligible. The total amount of released microplastic fibers by the mask have greatly increased from 24,300–25,400 items before aging to 6.0 × 108–6.4 × 108 items after aging, respectively, increased about 2.5 × 104 times (Fig. 7). Such a huge difference in the release behavior of microplastic fibers before and after the natural aging of masks exhibited that the natural environmental has a great influence on the mask and other similar nonwoven fabrics. This also showed that if the waste nonwovens enter the environment due to the improper treatment, it will have a significant impact on the local environment. The release of microplastic fibers by the aged disposable surgical mask was listed at Fig. 8 . The broken pieces of the aged mask completely turned into microplastic fibers entering the aquatic environment. This indicated that aging played a decisive role in the release of microplatics by the masks. The distribution of plastic fibers in the aged mask was illustrated in Fig. 9 . It can be clearly seen that after 2 months of natural aging, the plastic fibers in the three layers have obvious fracture marks, and the nodes of the inner and outer layers were also destroyed. At this time, this type of node is no longer enough to bind the plastic fibers. Once these fragile fragments entered the water body, a large number of microplastic fibers would be released in the aquatic environment without sufficient reservation. This is also an important reason for the release of billions microplastic fibers by the aged masks. The length distribution of released microplastic fibers by the aged mask was shown in Fig. 7B. Natural weathering reduced the length of microplastic fibers released from the mask. After natural aging, the plastic fibers have become more vulnerable. Under the action of external force, these fragile plastic fibers are easy to become microplastic fibers with smaller particle size.

Fig. 7.

Total release amount of microplastic fibers by the aged and original mask (A) and their length distribution (B).

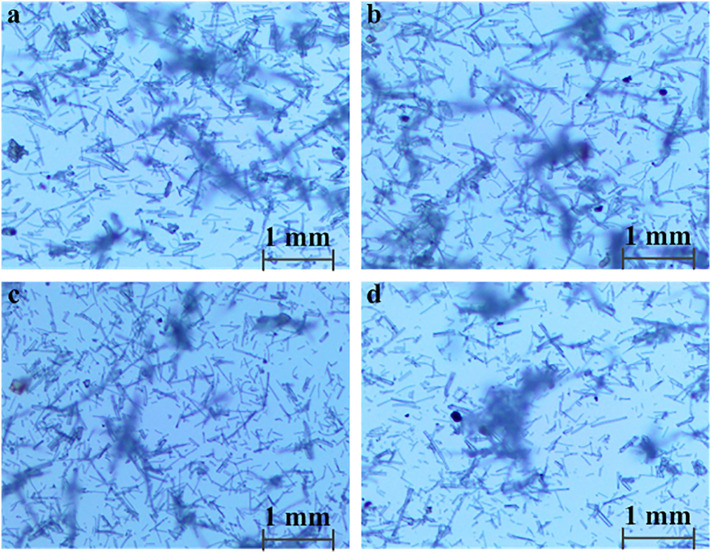

Fig. 8.

Release of microplastic fibers by the aged disposable surgical mask. Figures a-d represent the microplastic fibers released by naturally weathered mask fragments in this test. Electron microscopy resolution of 3.66 μm.

Fig. 9.

Effect of natural exposure on plastic fiber in the disposable surgical aged mask components (outer layer (figures a, b, c, d), middle layer (figures e, f, g, h), inner layer (figures i, j, k, l) and ear ribbon (figures m, n, o, p)). Electron microscopy resolution of 3.66 μm (1 mm) and 1.46 μm (0.4 mm).

4. Discussions

This study showed the disposable surgical masks can release a lot of microplastic fibers if they are discarded into the environment. The fragmentation of the mask will increase its exposure area and increase the release of microplastic fiber. With the gradual aging and decomposition of the masks in the environment, the whole mask would completely become microplastics into the environment. These billions of microplastics may have unexpected and serious consequences for the local ecology. The COVID-19 has swept the world and brought serious losses to the people and countries. The social epidemic prevention measures such as epidemic prevention and isolation can be coordinated with social epidemic prevention measures. The disposable surgical masks have dual functions of source control and primary prevention (Shetty et al., 2020). As one the preventive measures to slow down the spread the COVID-19 between the public, the consumption of the masks has led to a global short age of masks (Fadare and Okoffo, 2020). This demand has led to an unprecedented increase in global production of masks. The disposable surgical masks are a new social norm, but wearing them must have a sense of environmental responsibility, not thrown on the street or thrown away as daily waste (Fig. 10 ). According to a recent study by the plastic waste Innovation Center at University College London, the use of one mask a day in a year will produce 66,000 tons of contaminated plastic waste (Shetty et al., 2020). The influx of COVID-19 garbage worn by the public may limit the tracing of contacts and become a viable medium for the maintenance and prosperity of the COVID-19 virus. In addition, the masks can break down into tiny fragments and be swept into the aquatic environment, finally enter the ocean (Aragaw, 2020). COVID-19 protective equipment is overproduced, but may be improperly disposed, and may trigger another epidemic of global microplastics. The chaos caused by COVID-19 has brought substantial change, with strong infection control measures in the health care environment, and the trap is that the safety devices are easily available to the public and they are not aware of the safe disposable.

Fig. 10.

Abandoned disposable surgical masks found in the wild at Changsha, China.

With the increase concern of the public to the global microplastic pollution, their concern about the microplastic pollution caused by the disposable surgical masks is also increasing. This study has revealed the potential of disposable masks to release microplastic fibers in the environment, especially after natural weathering. Unfortunately, however, there is no reliable data to analyze the trend of terrestrial garbage pollution and marine garbage pollution because of the temporary suspension of field activities in the period of COVID-19, so it is impossible to estimate the impact on the environment (Shruti et al., 2020). The rapid growth in the production and consumption of masks is worrying as they already exist in water bodies on coastlines. These mask wastes will make the already serious marine micro plastic pollution worse. Although the mask can intercept part of the microplastic in the air, the microplastic released by the mask itself can also enter the human body directly through breathing. It is an urgent to understand the potential environmental risks and significance of masks to fill the knowledge gap during the global health crisis. Due to the prevalence of COVID-19, disposable surgical masks have become a standardized requirement, and the abundance of microplastics in the environment is to increase, thus having higher opportunities for interaction, ingestion, vectors, and harmful effects in the food chains/webs. Accordingly, with the increasing use of disposable surgical masks, they will continue to increase for a long time in the future until the COVID-19 is completely controlled in the world. It requires to carry out further research and rapid development in this field, for example, the environmental behavior, fate and potential toxicity of mask microplastic fiber. In addition, attention can be paid to how to minimize environmental risk/pollution by reusing masks without damaging them, and disinfection can be demonstrated as a means to achieve this goal (Bennet et al., 2021).

5. Conclusions

This study investigated the release mechanism of influencing factors of disposable surgical masks on microplastics in the aquatic environment. The findings demonstrated that disposable masks can be used as an important potential source of microplastic fibers in the environment, especially with the increase of global consumption. With the increase of using times, the release of microplastics was also increasing. The addition of detergent and alcohol solution improved the ability of the mask to release microplastics. When the masks became fragments, the exposure area increased due to the formation of pieces, and the release of microplastics was greatly increased. In addition, after two months of natural exposure, disposable masks became very fragile fragments. The broken pieces of aged mask completely turned into microplastics. A fully aged mask would release billions of microplastic fibers into the environment. Once these fragile fragments entered the water body, a large number of microplastic fibers would be released in the aquatic environment without sufficient reservation. The rapid growth of mask production and consumption is worrying, and the mask waste will make the serious microplastic pollution worse. It is urgent to understand the potential environmental risks and significance of masks, which needed further study. Additionally, more attention should be paid to how to minimize environmental risk/pollution by reusing masks without damaging them, such as disinfection.

CRediT authorship contribution statement

Maocai Shen: Writing – original draft, Methodology, Investigation, Formal analysis. Zhuotong Zeng: Methodology, Writing – review & editing. Biao Song: Investigation, Writing – review & editing. Huan Yi: Methodology, Writing – review & editing. Tong Hu: Investigation, Formal analysis, Writing – review & editing. Yaxin Zhang: Writing – review & editing. Guangming Zeng: Writing – review & editing, Methodology, Investigation. Rong Xiao: Methodology, Writing – review & editing.

Declaration of competing interest

The authors have no conflict of interest to declare regarding this article.

Acknowledgements

The study is financially supported by the Program for the National Natural Science Foundation of China (82003363, 82073449, U20A20323, 51521006).

Editor: Damia Barcelo

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.scitotenv.2021.148130.

Appendix A. Supplementary data

Supplementary material

References

- Aragaw T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020;159 doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bennet D., Harris A.F., Lacombe J., Brooks C., Bionda N., Strickland A.D., et al. Evaluation of supercritical CO2 sterilization efficacy for sanitizing personal protective equipment from the coronavirus SARS-CoV-2. Sci. Total Environ. 2021;780 doi: 10.1016/j.scitotenv.2021.146519. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bouwmeester H., Hollman P.C., Peters R.J. Potential health impact of environmentally released micro- and nanoplastics in the human food production chain: experiences from nanotoxicology. Environ. Sci. Technol. 2015;49:8932–8947. doi: 10.1021/acs.est.5b01090. [DOI] [PubMed] [Google Scholar]

- Cai Y., Yang T., Mitrano D.M., Heuberger M., Hufenus R., Nowack B. Systematic study of microplastic fiber release from 12 different polyester textiles during washing. Environ. Sci. Technol. 2020;54:4847–4855. doi: 10.1021/acs.est.9b07395. [DOI] [PubMed] [Google Scholar]

- Fadare O.O., Okoffo E.D. Covid-19 face masks: a potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hernandez L.M., Xu E.G., Larsson H.C.E., Tahara R., Maisuria V.B., Tufenkji N. Plastic teabags release billions of microparticles and nanoparticles into tea. Environ. Sci. Technol. 2019;53:12300. doi: 10.1021/acs.est.9b02540. [DOI] [PubMed] [Google Scholar]

- Hu D., Shen M., Zhang Y., Li H., Zeng G. Microplastics and nanoplastics: would they affect global biodiversity change? Environ. Sci. Pollut. Res. 2019;26:19997–20002. doi: 10.1007/s11356-019-05414-5. [DOI] [PubMed] [Google Scholar]

- Kashiwada S. Distribution of nanoparticles in the see-through sedaka (Oryzias latipes) Environ. Health Perspect. 2006;114:1697–1702. doi: 10.1289/ehp.9209. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Leung C.C., Lam T.H., Cheng K.K. Mass masking in the COVID-19 epidemic: people need guidance. Lancet. 2020;395:945. doi: 10.1016/S0140-6736(20)30520-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lusher A.L., Hernandez-Milian G., O’Brien J., Berrow S., O’Connor I., Officer R. Microplastic and macroplastic ingestion by a deep diving, oceanic cetacean: the True’s beaked whale Mesoplodon mirus. Environ. Pollut. 2015;199:185–191. doi: 10.1016/j.envpol.2015.01.023. [DOI] [PubMed] [Google Scholar]

- METI . 2020. Current Status of Production and Supply of Face Masks, Antiseptics and Toilet Paper. [Google Scholar]

- Murray O.M., Bisset J.M., Gilligan P.J., Hannan M.M., Murray J.G. Respirators and surgical facemasks for COVID-19: implications for MRI. Clin. Radiol. 2020;75:405–407. doi: 10.1016/j.crad.2020.03.029. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oßmann B.E., Sarau G., Holtmannspötter H., Pischetsrieder M., Christiansen S.H., Dicke W. Small-sized microplastics and pigmented particles in bottled mineral water. Water Res. 2018;141:307–316. doi: 10.1016/j.watres.2018.05.027. [DOI] [PubMed] [Google Scholar]

- Shen M., Zeng G., Zhang Y., Wen X., Song B., Tang W. Can biotechnology strategies effectively manage environmental (micro)plastics? Sci. Total Environ. 2019;697 doi: 10.1016/j.scitotenv.2019.134200. [DOI] [PubMed] [Google Scholar]

- Shen M., Zhang Y., Zhu Y., Song B., Zeng G., Hu D., et al. Recent advances in toxicological research of nanoplastics in the environment: a review. Environ. Pollut. 2019;252:511–521. doi: 10.1016/j.envpol.2019.05.102. [DOI] [PubMed] [Google Scholar]

- Shen M., Zhu Y., Zhang Y., Zeng G., Wen X., Yi H., et al. Micro(nano)plastics: unignorable vectors for organisms. Mar. Pollut. Bull. 2019;139:328–331. doi: 10.1016/j.marpolbul.2019.01.004. [DOI] [PubMed] [Google Scholar]

- Shen M., Huang W., Chen M., Song B., Zeng G., Zhang Y. (Micro)plastic crisis: un-ignorable contribution to global greenhouse gas emissions and climate change. J. Clean. Prod. 2020;254 [Google Scholar]

- Shen M., Song B., Zhu Y., Zeng G., Zhang Y., Yang Y., et al. Removal of microplastics via drinking water treatment: current knowledge and future directions. Chemosphere. 2020;251 doi: 10.1016/j.chemosphere.2020.126612. [DOI] [PubMed] [Google Scholar]

- Shen M., Hu T., Huang W., Song B., Qin M., Yi H., et al. Can incineration completely eliminate plastic wastes? An investigation of microplastics and heavy metals in the bottom ash and fly ash from an incineration plant. Sci. Total Environ. 2021;779 doi: 10.1016/j.scitotenv.2021.146528. [DOI] [PubMed] [Google Scholar]

- Shen M., Song B., Zeng G., Zhang Y., Teng F., Zhou C. Surfactant changes lead adsorption behaviors and mechanisms on microplastics. Chem. Eng. J. 2021;405 [Google Scholar]

- Shetty S.S., Wollenberg B., Merchant Y., Shabadi N. Discarded Covid 19 gear: a looming threat. Oral Oncol. 2020;107 doi: 10.1016/j.oraloncology.2020.104868. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shruti V.C., Perez-Guevara F., Elizalde-Martinez I., Kutralam-Muniasamy G. Reusable masks for COVID-19: a missing piece of the microplastic problem during the global health crisis. Mar. Pollut. Bull. 2020;161 doi: 10.1016/j.marpolbul.2020.111777. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang W., Ndungu A.W., Li Z., Wang J. Microplastics pollution in inland freshwaters of China: a case study in urban surface waters of Wuhan, China. Sci. Total Environ. 2016;575:1369–1374. doi: 10.1016/j.scitotenv.2016.09.213. [DOI] [PubMed] [Google Scholar]

- World Health Organization . 2020. Shortage of Personal Protective Equipment Endangering Health Workers Worldwide. [Google Scholar]

- Wright S.L., Kelly F.J. Plastic and human health: a micro issue? Environ. Sci. Technol. 2017;51:6634–6647. doi: 10.1021/acs.est.7b00423. [DOI] [PubMed] [Google Scholar]

- Xinhuanet . 2020. China Focus: Mask Makers Go All Out in Fight Against Novel Coronavirus. [Google Scholar]

- Xiong X., Zhang K., Chen X., Shi H., Luo Z., Wu C. Sources and distribution of microplastics in China's largest inland lake - Qinghai Lake. Environ. Pollut. 2018;235:899–906. doi: 10.1016/j.envpol.2017.12.081. [DOI] [PubMed] [Google Scholar]

- Xu S., Li Y. Beware of the second wave of COVID-19. Lancet. 2020;395:1321–1322. doi: 10.1016/S0140-6736(20)30845-X. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ziajahromi S., Neale P.A., Rintoul L., Leusch F.D. Wastewater treatment plants as a pathway for microplastics: development of a new approach to sample wastewater-based microplastics. Water Res. 2017;112:93–99. doi: 10.1016/j.watres.2017.01.042. [DOI] [PubMed] [Google Scholar]

- Ziajahromi S., Drapper D., Hornbuckle A., Rintoul L., Leusch F.D.L. Microplastic pollution in a stormwater floating treatment wetland: detection of tyre particles in sediment. Sci. Total Environ. 2020;713 doi: 10.1016/j.scitotenv.2019.136356. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material