Abstract

Reversed-phase HPLC is the most commonly applied peptide-separation technique in MS-based proteomics. Particle-packed capillary columns are predominantly used in nanoflow HPLC systems. Despite being the broadly applied standard for many years, capillary columns are still expensive and suffer from short lifetimes, particularly in combination with ultra-high-pressure chromatography systems. For this reason, and to achieve maximum performance, many laboratories produce their own in-house packed columns. This typically requires a considerable amount of time and trained personnel. Here, we present a new packing system for capillary columns enabling rapid, multiplexed column packing with pressures reaching up to 3000 bar. Requiring only a conventional gas pressure supply and methanol as the driving fluid, our system replaces the traditional setup of helium-pressured packing bombs. By using 10× multiplexing, we have reduced the production time to just under 2 min for several 50 cm columns with 1.9-µm particle size, speeding up the process of column production 40 to 800 times. We compare capillary columns with various inner diameters and lengths packed under different pressure conditions with our newly designed, broadly accessible high-pressure packing station.

Keywords: HPLC, LC-MS, capillary column, proteomics

Abbreviations: ES, electrospray; ID, inner diameter

Graphical Abstract

Highlights

-

•

We present a newly designed high-pressure packing station for capillary columns.

-

•

Detailed part lists and manufacturing instructions included.

-

•

40 to 800 times faster packing of capillary columns for high-performance proteomics.

-

•

Columns produced with the presented setup have state-of-the-art quality metrics.

In Brief

Capillary columns in nanoflow application are a basis of high-performance LC-MS–based proteomics but are difficult or expensive to procure. We present a new high-pressure packing station for capillary columns (1000–3000 bar) together with detailed instructions for reproducing our setup. Compared with previous publications, this produces capillary columns 40 to 800 times faster at undiminished chromatographic performance.

State-of-the-art MS-based proteomic pipelines typically consist of a sample preparation workflow to digest proteins and harvest pure peptides, an LC system for peptide separation, a mass spectrometer, and a sophisticated bioinformatics pipeline for raw data interpretation and subsequent statistical analysis (1, 2). The LC system plays a central role by partially separating the complex mixture of tens of thousands of peptides in a time-resolved manner according to their physicochemical properties, making them ultimately manageable for the MS system over the course of a gradient (3, 4). The most widely applied technique for high-performance applications is reversed-phase separation, originally introduced in the 1970s (5). In essence, chromatographic systems are made of programmable pumps with the ability to form a gradient of a mixture of different agents. In the case of reversed-phase LC, the stationary phase is nonpolar, separating analytes by hydrophobicity over the course of a gradient of an increasing nonpolar mobile phase. The LC system is coupled to the mass spectrometer by electrospray (ES) ionization via an emitter (6). Glass or steel needles are commonly connected to the column. Particle-packed capillaries for chromatography can also be used for ES without being coupled to an additional emitter (7, 8, 9). These basic attributes are shared by most LC-MS systems, and differences are mainly defined by operational flow. Nanoflow LC operates at flow rates of several hundred nanoliters per minute and is the standard in proteomics because of the high sensitivity obtainable.

High flow rates in the μl to ml range, applied to columns with large inner diameters (IDs), are typically used in high-throughput or industrial-scale analysis and analytical MS application areas. Although these microflow and analytical-flow systems limit sensitivity, recent work has demonstrated robust and reproducible performance (10, 11). Reproducibility and stability of those systems are high, but drawbacks are lowered sensitivity and a need for high sample amounts. Compared with developments in sample preparation, MS instrumentation, scan modes, and software, the LC apparatus has been largely unchanged in cutting-edge MS-based proteomics. Although identifications in proteomics experiments have doubled in single-shot experiments, this can mainly be traced to improvement on the MS instrumentation and software (12, 13, 14, 15, 16, 17). Current trends in LC developments aim rather toward systems for higher throughput and increasing robustness required for clinical applications (18), whereas the race for better separation in single-shot high performance runs with increasingly higher pump pressures has been comparatively abandoned. Consequently, a typically used setup for maximum sensitivity and performance for most experiments still consists of columns around 75-μm ID with a length of 20 to 50 cm, packed with sub-2-μm particles. Although, better performance could be reached by longer columns or smaller particles, both conditions would result in higher operational pressures that tend to make the LC systems unstable (4, 19). For example, very high pressures can lead to leaks in the LC flow paths, resulting in poor reproducibility and subsequently a loss of measurement time.

Commercially available capillary columns in the aforementioned dimensions are expensive, especially considering how frequently they must be replaced (e.g., in our laboratories, a 50 cm column with 75-μm ID has an average turnaround time from 10 to 14 days). Therefore, many high-throughput laboratories produce packed capillaries in-house. Empty glass capillaries, ready to be packed and used, can be either purchased or produced from cheap polyimide-coated capillaries using a laser puller. Typically, a gas pressure system is deployed to pack such columns with particles in the low μm range, and instructions on the manufacturing process can be found online with open access (https://proteomicsresource.washington.edu/docs/protocols05/Packing_Capillary_Columns.pdf). However, this process is inherently slow, and interesting methods have recently been established with the aim of speeding up the packing process with high pressure (20) or dense bead slurry, as in the FlashPack method (21).

Combining these principles, we here present a high-pressure packing system for capillary columns using a high-concentration bead slurry that has previously been described as beneficial for column performance (22). These high slurry concentrations and packing pressures of 1000 to 2000 bar allow us to achieve packing times for 50 cm columns in the minute range with our system, compared with hours for traditional procedures. Deploying a manifold system and a pump capable of high flow rates further multiplexes packing to up to ten columns simultaneously and makes column production 40 to 800 times more time efficient than in previous systems. We observe consistently good column performance for packing pressures at over 1000 bar with no adverse effects on the column backpressure and lifetime, while packing times continued to decrease at higher pressures. We provide a detailed blueprint of the system so it can readily be set up in interested laboratories (supplemental Table S1).

Experimental Procedures

Preparation of Fused Silica

Fused silica from Polymicro (TSP075365 for 75-μm ID, TSP100365 for 100-μm ID, or TSP150365 for 150-μm ID) was cut to 140 cm. Polyimide coating was removed by a Bunsen burner and the silica surface was polished with an ethanol-soaked tissue in the middle of the cut capillary at a width of 2 cm. An ES emitter tip was pulled with a laser puller (Sutter P2000) at the polished part of the capillary resulting in two empty capillary columns ready to be packed.

Sample Preparation: Protein Digestion and in-StageTip Purification

HeLa cells were cultured in high-glucose Dulbecco's modified Eagle's medium with 10% fetal bovine serum and 1% penicillin/streptomycin (all from Life Technologies, Inc). Cells were counted using a countess cell counter (Invitrogen), and aliquots of 1 × 106 cells were washed twice with PBS (Life Technologies, Inc), snap-frozen, and stored at −80 °C. Sample preparation was carried out with the PreOmics iST kit (www.preomics.de). We used one HeLa pellet with one million cells per cartridge, determined the peptide concentration after peptide cleanup via NanoDrop, and adjusted the peptide concentration to 0.2 mg/ml.

Ultra-High-Pressure LC and MS

Samples were measured using LC-MS instrumentation consisting of an EASY-nLC 1200 ultra-high-pressure system (Thermo Fisher Scientific), coupled to an Orbitrap Exploris 480 instrument (Thermo Fisher Scientific) using a nano-ES ion source (Thermo Fisher Scientific). Purified peptides were separated on high-pressure packed columns as described in the Results and Discussion section. For each LC-MS/MS analysis with 75-μm ID columns, 500 ng peptides were used. For 100-μm ID columns, 888 ng peptides were used, and for 150-μm ID columns, 2000 ng peptides were used to adjust for the higher column volume. Peptides were loaded in buffer A∗ (2% acetonitrile (v/v), 0.1% trifluoroacetic acid (v/v)) and eluted with a linear 105 min gradient of 5 to 30% of buffer B (0.1% formic acid, 80% (v/v) acetonitrile), followed by a 10 min increase to 95% of buffer B and a 5 min wash of 95% buffer B. For the 75-μm ID columns, the flow rate was 300 nl/min, 535 nl/min for 100-μm ID columns, and 1200 nl/min for 150-μm ID columns to adjust for linear flow velocity. The column temperature was kept at 60 °C by an in-house developed oven containing a Peltier element, and parameters were monitored in real time by the SprayQC software. MS data were acquired with a Top15 data-dependent MS/MS scan method. MS1 automatic gain control target was set to 300% in the 300 to 1650 m/z range with a maximum injection time of 25 ms and a resolution of 60,000 at m/z 200. Fragmentation of precursor ions was performed by higher-energy C-trap dissociation with a normalized collision energy of 30 eV. MS/MS scans were performed at a resolution of 15,000 at m/z 200 with an automatic gain control target of 100% and a maximum injection time of 28 ms. Dynamic exclusion was set to 30 s to avoid repeated sequencing of identical peptides.

Each column was equilibrated with two 120 min HeLa runs before the representative run for column cross-comparison.

Data Analysis

MS raw files were analyzed by MaxQuant software, version 1.6.11.0, and peptide lists were searched against the human UniProt FASTA database (release 2019_01, 188441 entries). A contaminant database generated by the Andromeda search engine was configured with cysteine carbamidomethylation as a fixed modification and N-terminal acetylation and methionine oxidation as variable modifications. We set the false discovery rate to 0.01 for protein and peptide levels with a minimum length of seven amino acids for peptides, and the false discovery rate was determined by searching a reverse database. Enzyme specificity was set as C-terminal to arginine and lysine as expected using trypsin and LysC as proteases. A maximum of two missed cleavages were allowed. Peptide identification was performed with an initial precursor mass deviation up to 7 ppm and a fragment mass deviation of 20 ppm. All proteins and peptides matching to the reversed database were filtered out.

Bioinformatics Analysis

Bioinformatics analyses were performed in Python (version 3.6.4.) using NumPy (1.19.2), Pandas (1.1.4), Matplotlib (3.3.2), Seaborn (0.11.0), and SciPy (1.5.2) packages.

Experimental Design and Statistical Rationale

The overall experimental design was focused on making different capillary columns for proteomics experiments as comparable as possible. To achieve this, statistical analysis was performed from triplicate experiments for the packing time and pressure performance experiments. Experimental conditions for column cross-comparisons were chosen to eliminate outer influences, including measurements on similar LC and MS systems and equilibration procedures.

Results and Discussion

A High-Pressure Packing Chamber for High-Density Bead Slurries

A central challenge of nano-flow chromatography in proteomics laboratories is the constant demand for new capillary columns. Owing to their costs, commercial columns cannot be treated as a disposable item. However, in our hands, we frequently observe peak performance only for a short life span for ultra-high-performance applications. Therefore, to reach the needed quantity and cost requirements, we and many other laboratories produce own capillary columns. However, the throughput of production is limited, especially for columns with a small ID and extended length such as the 50 cm 75-μm ID columns used in most applications in our laboratories. We produce pulled or fritted capillaries and pack them with solid phase material, typically sub-2-μm C18 beads. A skilled person can pull hundreds of empty columns within a day, and fritted columns are also easy to produce. However, the packing process is inherently low-throughput and error-prone, which makes high-performance columns prized items in MS laboratories. In particular, the use of longer column lengths is —in our experience— a precondition for ultra-high-performance.

We hypothesized that high-throughput packing of capillary columns could be achieved by highly concentrated bead slurries (21) in combination with very-high-pressure packing (>1000 bar) (20). However, an increased packing pressure and bead slurry concentration can lead to column blocking, slowing down and eventually halting the packing procedure. Chloroform as a bead solvent was reported as an approach to avoid this issue because it can solvate higher bead concentrations. However, in combination with our bead particles, we observed poor chromatographic performance during proteomic experiments. Instead, we combined elevated packing pressure with the FlashPack system (21), which prohibited bead aggregation at the column entrance via stirring.

To test our concept, we constructed a custom-made chamber for high-pressure packing, where the pressure derives from a conventional HPLC system (EASY-LC 1000 in our case). The device consists of a central chamber, containing the bead slurry and magnetic stirring bar, and has three openings. A large-bore access allows filling the chamber with the bead slurry, a microbore fitting holds the capillary entrance into the chamber, and a nanoviper connection is used as an inlet for the pressure from the HPLC system (supplemental Fig. S1). The slurry applied to pack columns in this system can be highly concentrated. To prepare the slurry, we mixed about 100-μl of bead particles with 500-μl of methanol. After brief vortexing and 1 minute of sonication in a sonication bath, we let the slurry settle for 5 min, whereupon we loaded 200-μl of slurry into the chamber with a 500-μl Hamilton pipette. The prototype packing chamber enabled us to fill single capillaries within minutes using the HPLC high-pressure pumps (950 bar). However, this system was not suited for high-throughput column production, and moreover, the low pump volume of the HPLC system resulted in noncontinuous packing as the pump had to be refilled several times until a column was filled with beads.

Encouraged by aspects of our newly devised packing system, we set out to further streamline column production. We replaced the small-volume HPLC pump with a Maximator HD-pump (Experimental Procedures). This high-flow continuous system converts driving gas from a standard laboratory gas supply line at a pressure ratio of 1:660 to a fluid outlet with a maximal pressure rating of 4000 bar and maximal flow capacity of 140 ml/min (Fig. 1). To use the FlashPack principle, we used methanol as the packing medium, which settles C18 beads at the chamber bottom (supplemental Fig. S2). The high flow capacity allowed us to implement multiple pump outlets for multiplex packing of up to ten columns with our station. We redesigned the original packing chamber to fit high-pressure connections (supplemental Fig. S3). For optimal stirring, we further created a rack system with magnets mounted on electric motors via 3D printed components to fit directly underneath the packing stations (detailed in Experimental Procedures and supplemental Fig. S4). Moreover, we connected a high-pressure range manometer to monitor packing pressure and added a pressure relief valve for efficient and controlled depressurization of the system, a notoriously time-consuming process. Although the system is typically running at 1500 bar in our laboratory, the relief of pressure takes only 60 s, without flowback from the running beads from the capillary. In addition, the system is secured from capacity exceeding driving gas pressure by a control valve, which prevents the pump to be exposed to a higher input than 6 bar. As with conventional packing systems, the weakest connection is the sealing of the capillary to the high-pressure chamber. We used a standard polyether-ether-ketone ferrule used in HPLC applications in combination with a newly designed, reinforced polyether-ether-ketone screw cap (supplemental Fig. S3D) to pin the column under very high pressure. Nevertheless, if the system pressure exceeds the durability of the material, the column is ejected. Owing to the low compression capabilities of methanol, this is dangerous if one has body parts directly above the fitting when a rupture occurs and hence this must be prevented. Compared with gas, which can compress much more than liquid, no explosion risk should arise from our new packing station. To pass health and safety standards, we set up the packing system in a chemical hood with air circulation to pump off any methanol or bead particle aerosols and minimize the possibility for physical contact.

Fig. 1.

High-pressure packing station. The scheme of the high-pressure packing station with detailed description of the crucial parts. The high-pressure pump is powered by a driving gas inlet and increases the pressure of a packing medium that is provided in a large volume flask by 660-fold. The compressed packing medium is channeled to ten packing chambers and placed on top of a magnetic stirring rack. A manometer is installed to monitor the system pressure and a pressure-release valve to facilitate time-efficient system depressurization. The inset depicts a packing chamber in detail, including high-pressure fittings, a stirring bar, and a capillary column.

Ultra-Fast Column Packing

The time required to fill a capillary column with beads depends on two variables, the bead concentration of the packing slurry and the flow rate through the capillary. Empty capillaries with a pulled ES emitter have high flow rates in the μl/min range even for conventional gas-based packing bombs with lower pressure (<100 bar). However, as the bead bed grows, the flow rate through the column decreases drastically. Hence, the high-density bead slurry of FlashPack enables short packing times especially for shorter columns (21). We anticipated that combining this principle with the potentially high flow rates of our extremely high-pressure system would significantly reduce packing times.

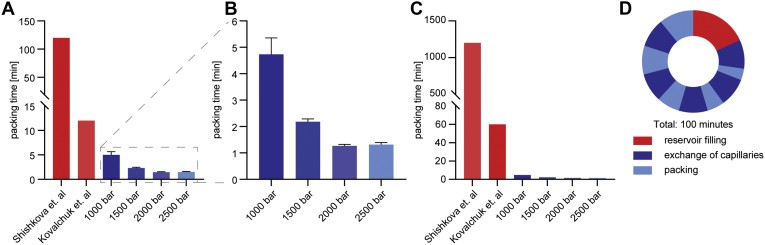

To quantify the production throughput of our system, we consecutively packed 50-cm capillaries with 75-μm ID at different pressures (1000–2500 bar) and measured the time required. With a freshly filled bead reservoir, packing at the lowest tested pressure took on average 4.7 min. Increasing pressure to 2000 bar results in packing times just over a minute. Even higher pressure did not result in faster packing. Overall, our system decreased the time for making a single column 10- to 100-fold compared with previous packing procedures (20, 21) (Fig. 2, A and B). Of note, the total production throughput is even higher due to multiplex packing and the option to quickly exchange capillaries and bead slurries. This results in a speed-up factor of 40 to 800 (Fig. 2, C). Once filled with bead slurry and mounted on the high-pressure system, the packing chambers can be used to pack several columns consecutively. This merely requires depressurizing the system via the pressure relief valve and exchanging the filled columns with empty capillaries. Consecutive packing of several columns from the same reservoir will decrease the packing speed because of the removal of beads from the reservoir. To fully restore packing speed, the bead chamber has to be opened and refilled, which takes about 10 min for all ten chambers together. Typically, we refilled the reservoir after five capillary exchanges. The average turn-around cycle for producing ten columns is thus 20 min, allowing the production of hundreds of columns in a working day (Fig. 2, D). An additional advantage of the high-throughput system is that it allows us to discard improperly packed columns, which occur in approximately 10% of cases.

Fig. 2.

Comparison of packing times.A, packing times of single columns as described in previous efforts and for different packing pressures (data collected in triplicates, displayed with SD) with a detailed view of the tested pressure conditions (B). C, production time for ten columns considering multiplexing (2× multiplexing for the system of Kovalchuk et al. and 10× for the system presented here) (20, 21). D, times of a packing cycle of 10 × 5 columns, taking a total of 100 min with filling of the reservoir and changing of capillaries between the actual packing steps.

The high-pressure system faces the same two main challenges as usual packing stations, which are particle clogging within the capillary and bead aggregation at the column entrance. Particle clogging can only be avoided by clean working conditions. This means dust-free storage and clean cutting of fused silica and the use of filtered fluids and dust-free particles for bead slurry preparation. Bead aggregation from dense slurry can be circumvented by optimized stirring conditions according to the FlashPack principle (21).

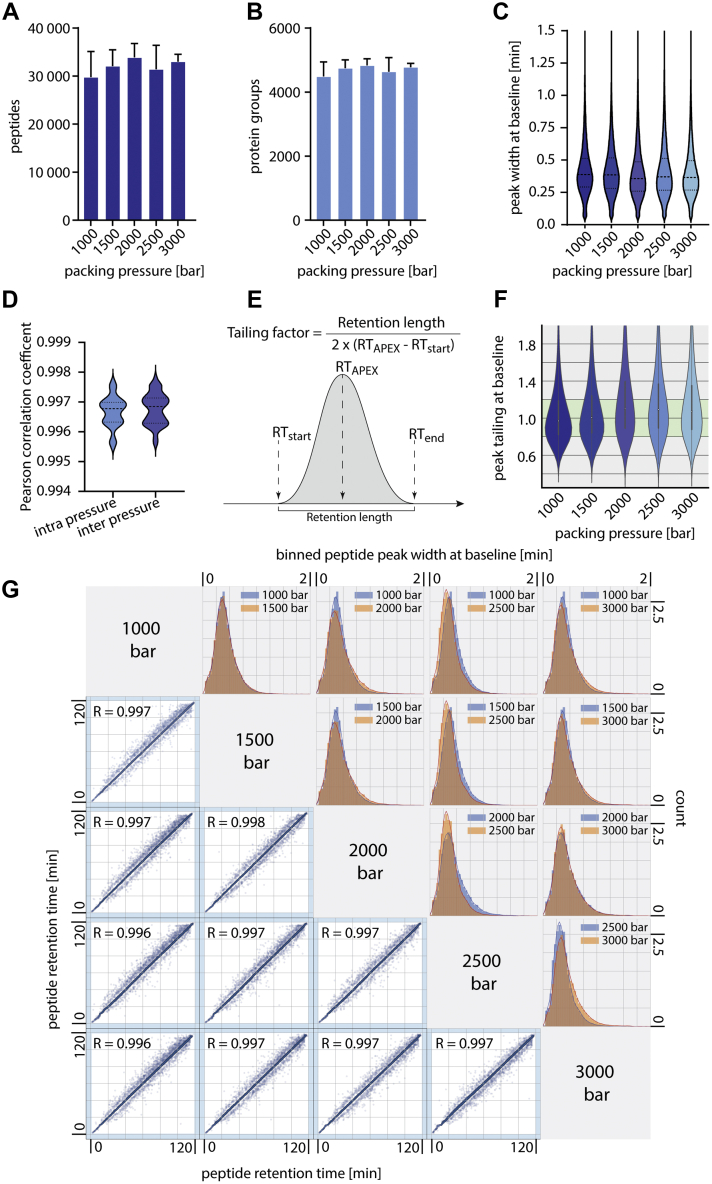

Influence of Packing Pressure on Column Performance

To evaluate the effect of packing pressure on column performance on realistic samples, we analyzed three of our laboratory standard HeLa digests on each column. Across all packing conditions, we observed no significant variation in the number of identified peptides and protein groups (Fig. 3, A/B). Moreover, the median peak widths of identified peptides were comparable for all conditions (Fig. 3, C). Correlation between the noncorrected retention times of peptides analyzed using columns produced at varying pressures was remarkably high (Pearson correlation coefficient >0.996) and not significantly altered from replicates packed with similar pressure conditions (Fig. 3, D).

Fig. 3.

Comparison of capillary columns packed at different pressures.A, numbers of identified peptides of triplicate measurements of 500 ng HeLa digests on columns filled at the indicated packing pressures. Peptides were separated on 50 cm and 75-μm ID columns packed with 1.9-μm Reprosil AQ Beads (Dr Maisch) with a 2 h gradient. B, numbers of identified protein groups of the same conditions as in panel A. Error bars indicate the standard deviation from triplicate measurements. C, median peak widths at baseline of identified peptides. D, distribution of Pearson correlation coefficients calculated on peptide retention times between columns packed at the same pressure and columns packed at different pressures (p-value of unpaired t-test for difference: 0.6). E, visualization of the tailing factor calculation, this is typically done at 5% peak height. F, Peak tailing at baseline for all identified peptides from runs with 75-μm ID columns and different packing pressures. G, correlation of peptide retention times across packing conditions. The density of peptides is color-coded. The histograms show the peak widths at baseline distribution of five representative runs. ID, inner diameter.

Another factor often used to characterize column performance is the tailing factor that can be calculated as depicted in Figure 3, E (23). Usually, the peak width at 5% peak height is used for peak width calculation but in proteomics experiments where tens of thousands of peaks are investigated, the base-to-base peak width is typically calculated, although full width at half maximum is also often given. We decided to calculate the peak tailing at baseline as a metric. In general, the distribution of peak shapes was wider than what would be expected from an analysis run of few analytes, but the median typically centered around the optimum of 1. The median of the peak tailing at baseline was below 1.0 for the lower and shifts above 1.0 for higher packing pressures up to a median of 1.2 (Fig. 3, F). In the literature, tailing factors in the range between 1 and 1.2 are often described (24). The shift towards this range with the higher packing pressures could result from denser compressed bead beds. As described above, the general performance was not altered for the proteomics metrics, which leads us to the conclusion that the minor change in peak tailing at baseline with higher packing pressures is not changing the LC-MS performance. This manifests in an only slightly altered distribution of peak widths between representative experiments of columns packed at different pressures (Fig. 3, G). From the correlation of peptide retention times, it is visible that for all representative comparisons, the peptides elute in a narrow and reproducible time window that is not influenced by the applied packing pressure. This retention time stability is accompanied by similar separation properties of the different columns, which can be visualized directly by the peak width at baseline of analyzed molecules. Figure 3, G shows bulk analysis of all identified peptides with nearly overlapping peak width at baseline distributions, whereas the minor differences do not constitute a significant trend toward a better performance for lower or higher packing pressures of capillary columns. We did not observe a significant change in column backpressure from the different packing conditions. Based on these results, it seems that the packing pressure has no or only minimal effect on the column performance.

LC-MS Performance of Columns With Different Lengths and IDs

The length and ID of capillary columns allow their adaptation to a plethora of sample materials and LC systems, specifically regarding separation power and backpressure. In MS-based proteomics, 75-μm ID columns in combination with flow rates in the range of 200 to 400 nl per minute are typical. Hence, we packed such capillary columns with different lengths (20, 30, 50 cm) with our high-pressure system and compared their performance. Packing time for the shorter columns was even faster and in the range of 30 s. The longest columns produced the smallest peak widths and subsequently resulted in the highest numbers of identified peptides and proteins (Fig. 4, A and B). Interestingly, the distribution of peptide intensities did not change significantly, and the peak tailing at baseline also remained unaffected (Fig. 4, C and D).

Fig. 4.

Length and inner diameter comparison. All columns were packed with 1000 bar packing pressure. A, peak width distribution from HeLa runs with different column length with the respective number of peptide and protein identifications (B), peptide intensity distribution (log10) (C), and peak tailing at baseline distribution (D). E, peak width distribution from HeLa runs with different column IDs with the respective number of peptide and protein identifications (F), peptide intensity distribution (log10) (G), and peak tailing at baseline distribution (H). ID, inner diameter.

Over the last years, the demand for high-throughput analysis has become apparent for the analysis of clinical samples, especially blood plasma as we have described before (25). This has been addressed by a novel HPLC principle with preformed gradients and slightly higher flow rates (18) and by higher-flow systems operating in the high microliter per minute range (10, 26). As these strategies require columns with a higher ID to maintain acceptable pressure during analysis, we produced columns with 75-μm, 100-μm, and 150-μm ID and tested their performance.

When comparing column IDs, the experimental setup has to be adapted to the conditions. To enable direct comparison of capillaries between different IDs, we scaled the flow rates to reach the same linear velocities and the amount of input material to the column volume (Experimental Procedures). For the 100-μm ID columns, this results in a flow rate of 535 nl/min and 888 ng of peptides for loading, whereas for the 150-μm ID column, 1200 nl/min and 2 μg of peptide material was loaded to be comparable to the 300 nl/min and 500 ng used for the 75-μm ID columns. This requirement of higher sample amount already limits the applicability of larger column diameters for samples with limited accessibility. The 1400 μl of pump volume from the Easy-LC 1200 used for the experiment was sufficient to run a 2 h gradient with the 150-μm ID column, but longer gradients or higher flow rates would exceed the capabilities of the LC system and require lower flow rates. The higher column IDs led to slightly broader peak widths, but peptide and protein identifications were not affected. Owing to the correction of the sample input amount, we did not see a difference in the peptide intensity distributions, and the peak tailing at baseline was also not affected by the column ID (Fig. 4, E–H).

Conclusion

Here, we aimed to increase the throughput and to streamline the production of capillary columns for MS-based proteomics. We provide a detailed list for the commercial parts and blueprints describing the construction of our high-pressure packing station. The setup can be built at relatively low costs (<$10,000), compared with the cumulative expenses for high-performing commercial columns. We designed this new station to fill multiple columns simultaneously within a few minutes, which accelerates the packing process of capillary columns more than a 100-fold compared with traditional gas pressure–driven stations. In this way, we hope our system helps researchers by streamlining the often work-intensive and fragile column production process. In addition, the extreme high pressures enable the packing of long, high-performing columns (>50 cm). The ability to produce high-performing columns at high-throughput allows for the possibility of only using capillary columns at the peak of their performance, replacing them as soon as peak broadening or decreased ionization is observed. Reassuring in terms of robustness of the packing process itself and the stability achieved at exceedingly high pressures, we have not observed variation in the performance characteristics over a wide range of packing pressure from 1000 to 3000 bar. We hope the technology described here will enable laboratories of any size to mass-produce high-performance long capillary columns.

Data availability

The MS-based proteomics data have been deposited to the ProteomeXchange Consortium via the PRIDE partner repository and are available via ProteomeXchange with identifier PXD024296.

Supplemental data

This article contains supplemental data (21).

Conflict of interest

The authors declare no competing interests.

Acknowledgments

We thank all members of the Proteomics and Signal Transduction Group and the Clinical Proteomics Group for help and discussions and in particular Igor Paron and Christian Deiml for technical assistance and Mario Oroshi for help with the online resource. We thank the mechanical workshop and the educational workshop of the Max Planck Institute of Biochemistry especially Martin Wied, Andreas Kucher and Harry Spangenberg for the fabrication and iterative optimization of all self-constructed parts.

The work carried out in this project was partially supported by the Max Planck Society for the Advancement of Science.

Author contributions

J. B. M.-R. designed and assembled the packing station parts and carried out the bioinformatics analyses. J. B. M.-R., L. S., F. M. H., P. E. G., and P. V. T. designed the experiments, performed and interpreted the MS-based proteomic analyses, generated text and figures, and wrote the manuscript. M. M. supervised and guided the project, designed the experiments, and interpreted MS-based proteomics data.

Footnotes

Present address for Johannes B. Müller-Reif and Philipp E. Geyer: OmicEra Diagnostics GmbH, Planegg, Germany.

Supplemental Data

References

- 1.Aebersold R., Mann M. Mass spectrometry-based proteomics. Nature. 2003;422:198–207. doi: 10.1038/nature01511. [DOI] [PubMed] [Google Scholar]

- 2.Aebersold R., Mann M. Mass-spectrometric exploration of proteome structure and function. Nature. 2016;537:347–355. doi: 10.1038/nature19949. [DOI] [PubMed] [Google Scholar]

- 3.Michalski A., Cox J., Mann M. More than 100,000 detectable peptide species elute in single shotgun proteomics runs but the majority is inaccessible to data-dependent LC-MS/MS. J. Proteome Res. 2011;10:1785–1793. doi: 10.1021/pr101060v. [DOI] [PubMed] [Google Scholar]

- 4.Shishkova E., Hebert A.S., Coon J.J. Now, more than ever, proteomics needs better chromatography. Cell Syst. 2016;3:321–324. doi: 10.1016/j.cels.2016.10.007. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Horváth C., Melander W., Molnár I. Solvophobic interactions in liquid chromatography with nonpolar stationary phases. J. Chromatogr. A. 1976;125:129–156. [Google Scholar]

- 6.Fenn J.B., Mann M., Meng C.K., Wong S.F., Whitehouse C.M. Electrospray ionization for mass spectrometry of large biomolecules. Science. 1989;246:64–71. doi: 10.1126/science.2675315. [DOI] [PubMed] [Google Scholar]

- 7.Kennedy R.T., Jorgenson J.W. Preparation and evaluation of packed capillary liquid chromatography columns with inner diameters from 20 to 50 micrometers. Anal. Chem. 1989;61:1128–1135. [Google Scholar]

- 8.Emmett M.R., Caprioli R.M. Micro-electrospray mass spectrometry: Ultra-high-sensitivity analysis of peptides and proteins. J. Am. Soc. Mass Spectrom. 1994;5:605–613. doi: 10.1016/1044-0305(94)85001-1. [DOI] [PubMed] [Google Scholar]

- 9.Ishihama Y., Rappsilber J., Andersen J.S., Mann M. Microcolumns with self-assembled particle frits for proteomics. J. Chromatogr. A. 2002;979:233–239. doi: 10.1016/s0021-9673(02)01402-4. [DOI] [PubMed] [Google Scholar]

- 10.Bian Y., Zheng R., Bayer F.P., Wong C., Chang Y.C., Meng C., Zolg D.P., Reinecke M., Zecha J., Wiechmann S., Heinzlmeir S., Scherr J., Hemmer B., Baynham M., Gingras A.C. Robust, reproducible and quantitative analysis of thousands of proteomes by micro-flow LC–MS/MS. Nat. Commun. 2020;11:157. doi: 10.1038/s41467-019-13973-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Bian Y., Bayer F.P., Chang Y.C., Meng C., Hoefer S., Deng N., Zheng R., Boychenko O., Kuster B. Robust microflow LC-MS/MS for proteome analysis: 38 000 runs and counting. Anal. Chem. 2021;93:3686–3690. doi: 10.1021/acs.analchem.1c00257. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Bernhardt O., Selevsek N., Gillet L., Rinner O., Picotti P., Aebersold R., Reiter L. Spectronaut: a fast and efficient algorithm for MRM-like processing of data independent acquisition (SWATH-MS) data. F1000Res. 2014;5 [Google Scholar]

- 13.Cox J., Mann M. MaxQuant enables high peptide identification rates, individualized p.p.b.-range mass accuracies and proteome-wide protein quantification. Nat. Biotechnol. 2008;26:1367–1372. doi: 10.1038/nbt.1511. [DOI] [PubMed] [Google Scholar]

- 14.Hu Q., Noll R.J., Li H., Makarov A., Hardman M., Graham Cooks R. The Orbitrap: A new mass spectrometer. J. Mass Spectrom. 2005;40:430–443. doi: 10.1002/jms.856. [DOI] [PubMed] [Google Scholar]

- 15.Kelstrup C.D., Bekker-Jensen D.B., Arrey T.N., Hogrebe A., Harder A., Olsen J.V. Performance evaluation of the Q Exactive HF-X for shotgun proteomics. J. Proteome Res. 2018;17:727–738. doi: 10.1021/acs.jproteome.7b00602. [DOI] [PubMed] [Google Scholar]

- 16.Meier F., Beck S., Grassl N., Lubeck M., Park M.A., Raether O., Mann M. Parallel accumulation-serial fragmentation (PASEF): Multiplying sequencing speed and sensitivity by synchronized scans in a trapped ion mobility device. J. Proteome Res. 2015;14:5378–5387. doi: 10.1021/acs.jproteome.5b00932. [DOI] [PubMed] [Google Scholar]

- 17.Meier F., Brunner A.D., Frank M., Ha A., Bludau I., Voytik E., Kaspar-Schoenefeld S., Lubeck M., Raether O., Bache N., Aebersold R., Collins B.C., Röst H.L., Mann M. diaPASEF: parallel accumulation–serial fragmentation combined with data-independent acquisition. Nat. Methods. 2020;17:1229–1236. doi: 10.1038/s41592-020-00998-0. [DOI] [PubMed] [Google Scholar]

- 18.Bache N., Geyer P.E., Bekker-Jensen D.B., Hoerning O., Falkenby L., Treit P.V., Doll S., Paron I., Müller J.B., Meier F., Olsen J.V., Vorm O., Mann M. A novel LC system embeds analytes in pre-formed gradients for rapid, ultra-robust proteomics. Mol. Cell Proteomics. 2018;17:2284–2296. doi: 10.1074/mcp.TIR118.000853. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Richards A.L., Merrill A.E., Coon J.J. Proteome sequencing goes deep. Curr. Opin. Chem. Biol. 2015;24:11–17. doi: 10.1016/j.cbpa.2014.10.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Shishkova E., Hebert A.S., Westphall M.S., Coon J.J. Ultra-high pressure (>30,000 psi) packing of capillary columns enhancing depth of shotgun proteomic analyses. Anal. Chem. 2018;90:11503–11508. doi: 10.1021/acs.analchem.8b02766. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Kovalchuk S.I., Jensen O.N., Rogowska-Wrzesinska A. FlashPack: Fast and simple preparation of ultrahigh-performance capillary columns for LC-MS. Mol. Cell Proteomics. 2019;18:383–390. doi: 10.1074/mcp.TIR118.000953. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Bruns S., Franklin E.G., Grinias J.P., Godinho J.M., Jorgenson J.W., Tallarek U. Slurry concentration effects on the bed morphology and separation efficiency of capillaries packed with sub-2 μm particles. J. Chromatogr. A. 2013;1318:189–197. doi: 10.1016/j.chroma.2013.10.017. [DOI] [PubMed] [Google Scholar]

- 23.Anderson J.L., Berthod A., Pino V., Stalcup A. Analytical Separation Science. Wiley-VCH Verlag GmbH & Co. KGaA; Weinheim, Germany: 2015. [Google Scholar]

- 24.Birdsall R.E., Kellett J., Yu Y.Q., Chen W. Application of mobile phase additives to reduce metal-ion mediated adsorption of non-phosphorylated peptides in RPLC/MS-based assays. J. Chromatogr. B Analyt. Technol. Biomed. Life Sci. 2019;1126-1127 doi: 10.1016/j.jchromb.2019.121773. [DOI] [PubMed] [Google Scholar]

- 25.Geyer P.E., Holdt L.M., Teupser D., Mann M. Revisiting biomarker discovery by plasma proteomics. Mol. Syst. Biol. 2017;13:942. doi: 10.15252/msb.20156297. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Messner C., Demichev V., Bloomfield N., Ivosev G., Wasim F., Zelezniak A., Lilley K., Tate S., Ralse M. ScanningSWATH enables ultra-fast proteomics using high-flow chromatography and minute-scale gradients. bioRxiv. 2019 doi: 10.1101/656793. [preprint] [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The MS-based proteomics data have been deposited to the ProteomeXchange Consortium via the PRIDE partner repository and are available via ProteomeXchange with identifier PXD024296.